Preparation of amidinourea phytate and its flame retardant effect on wood

-

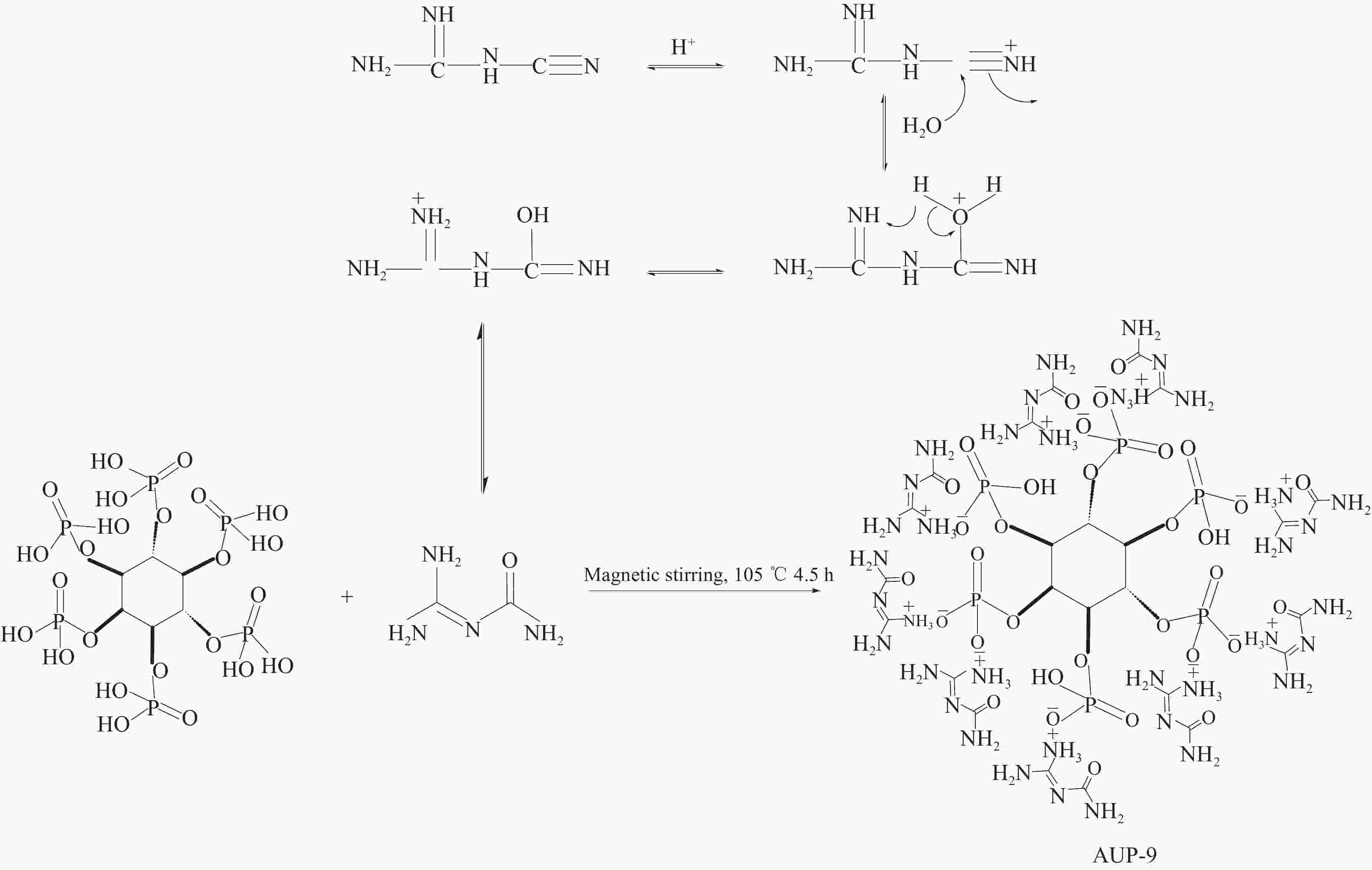

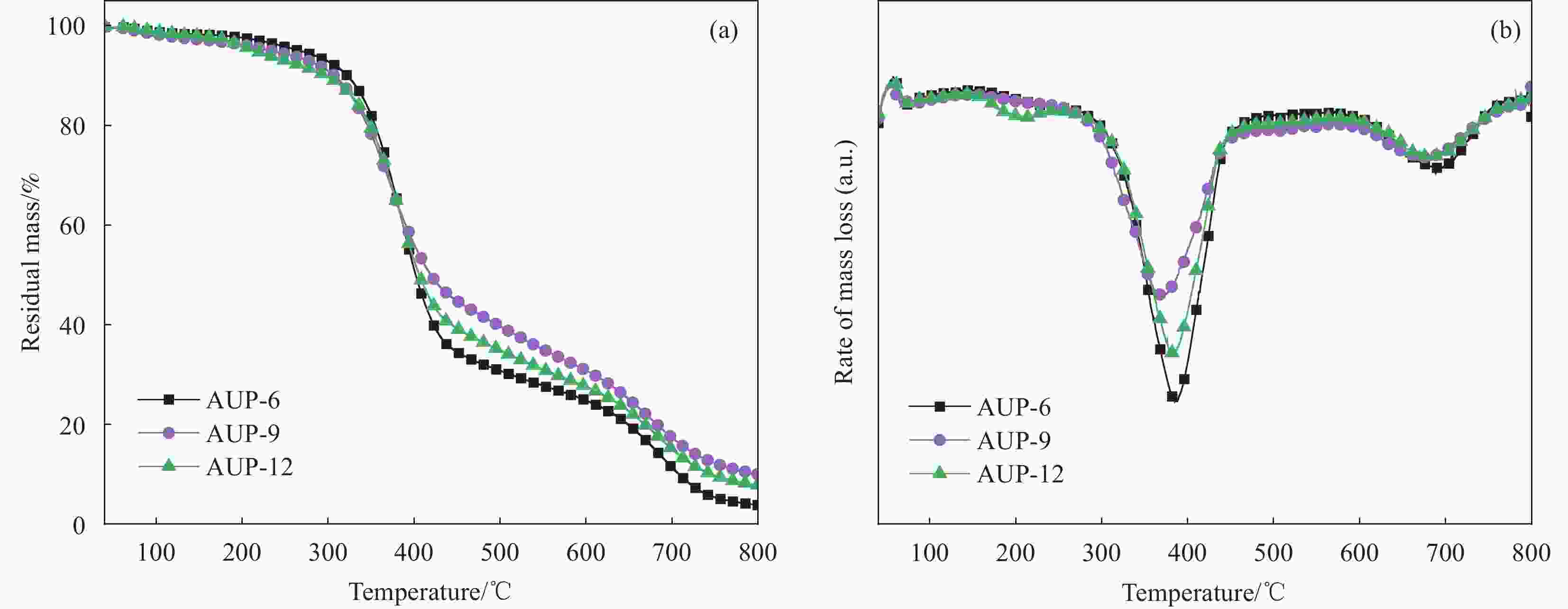

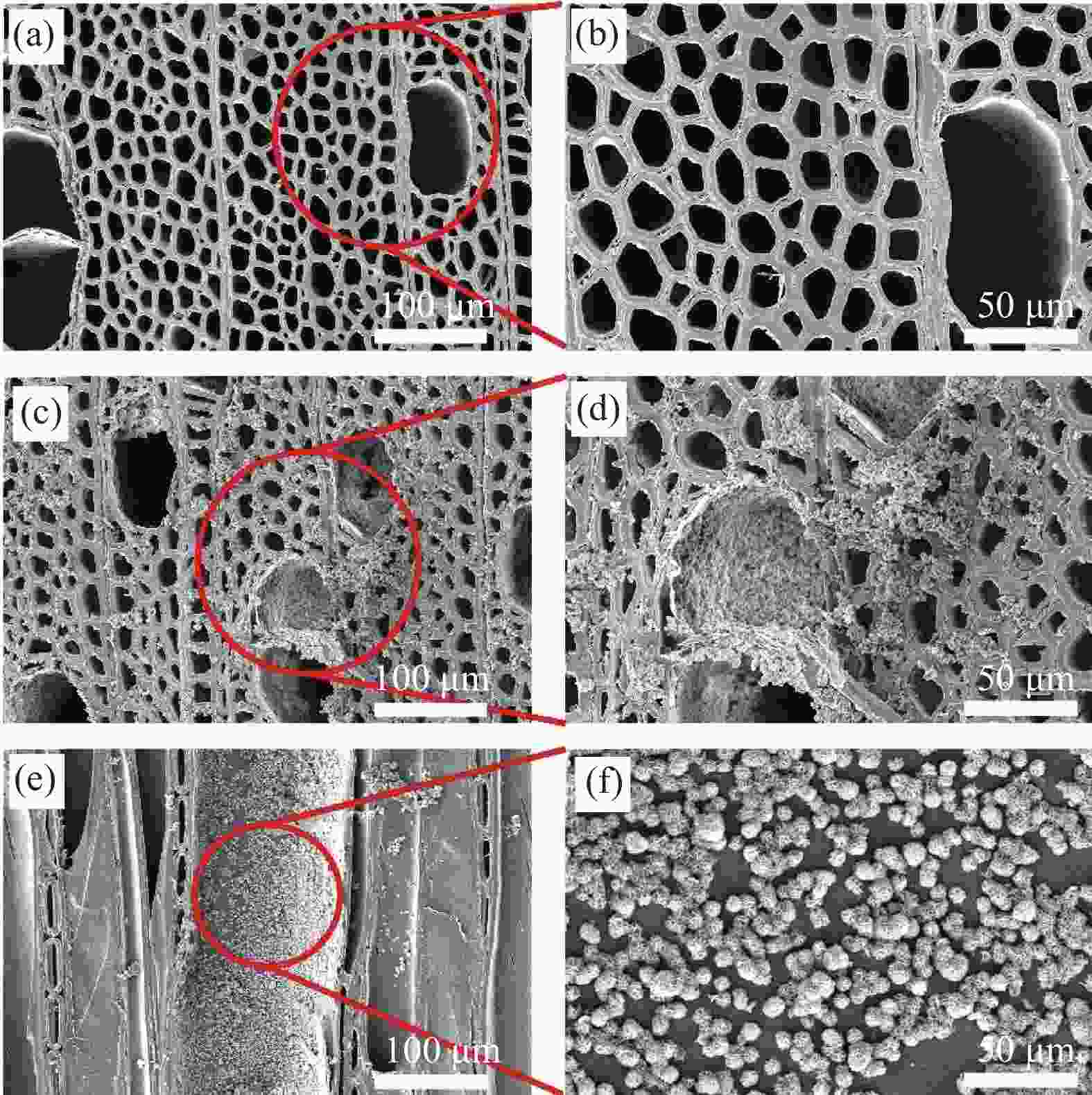

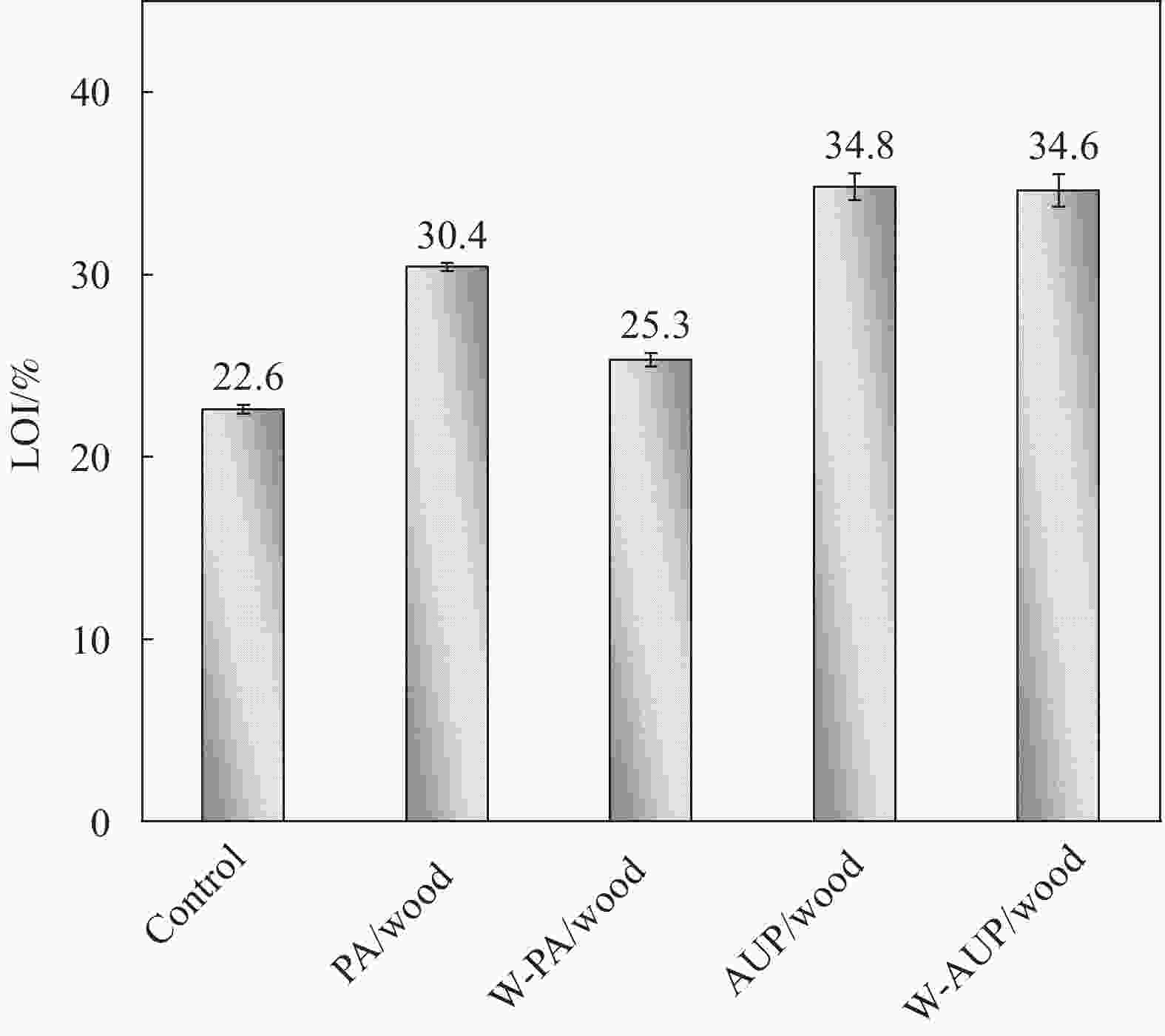

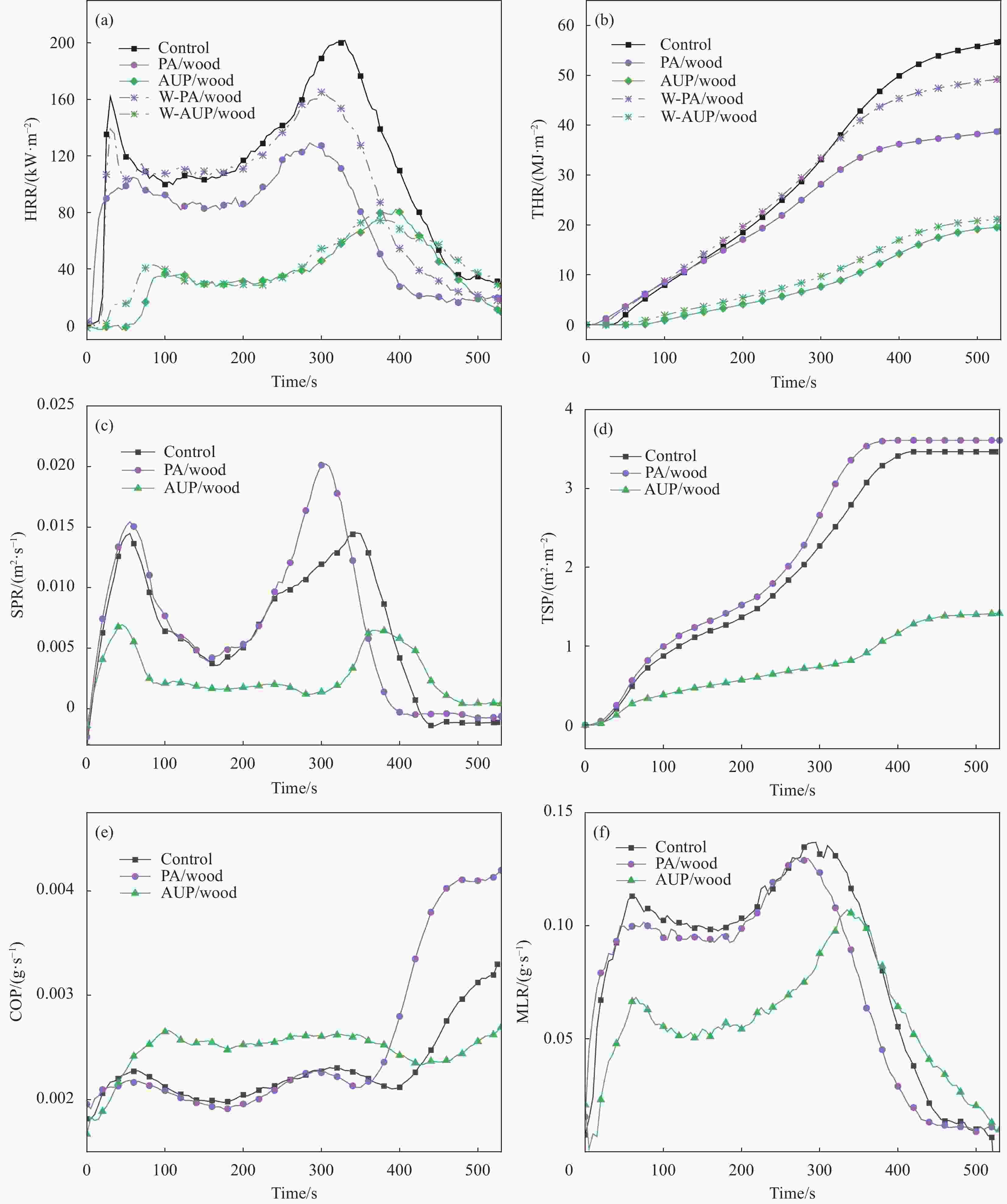

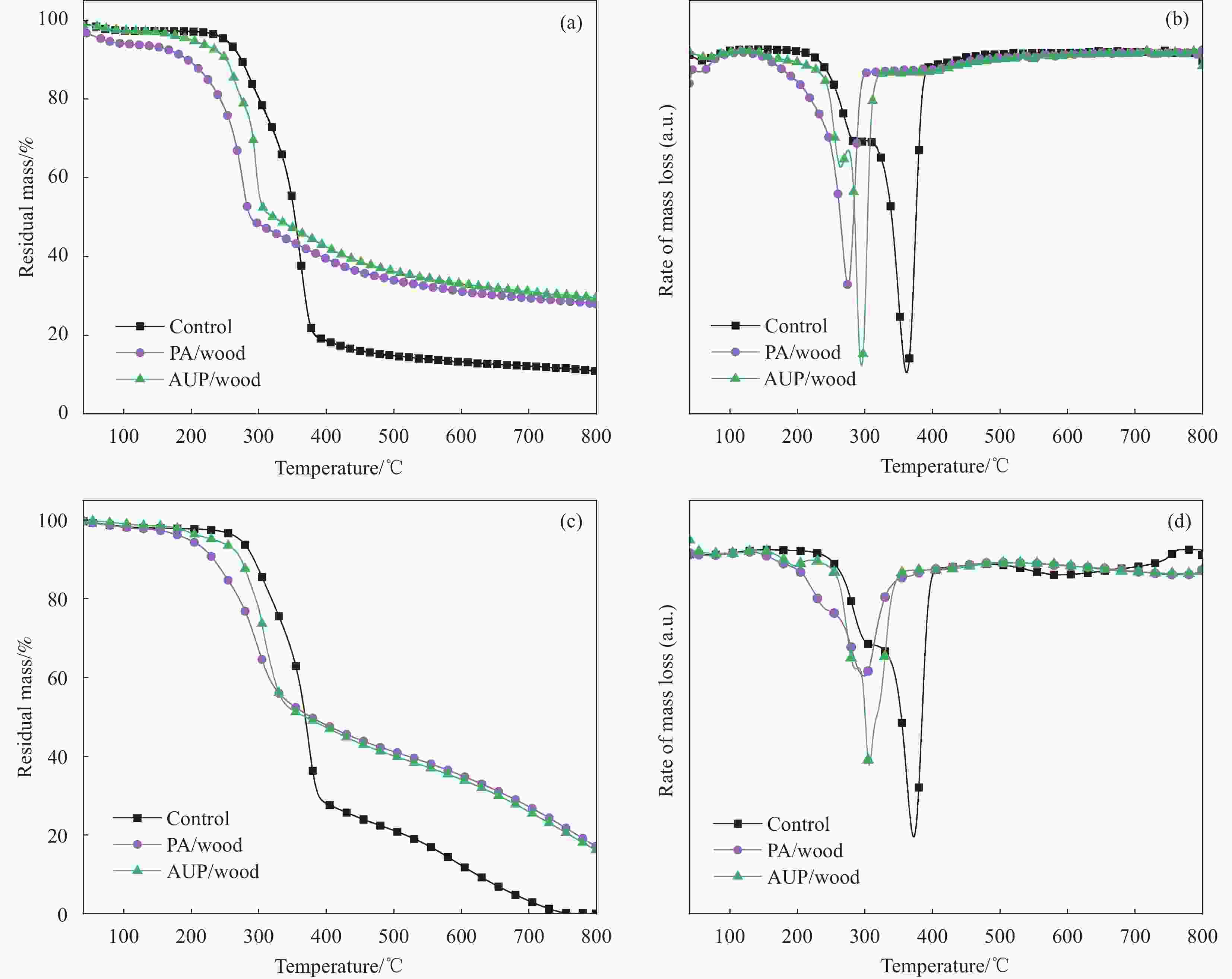

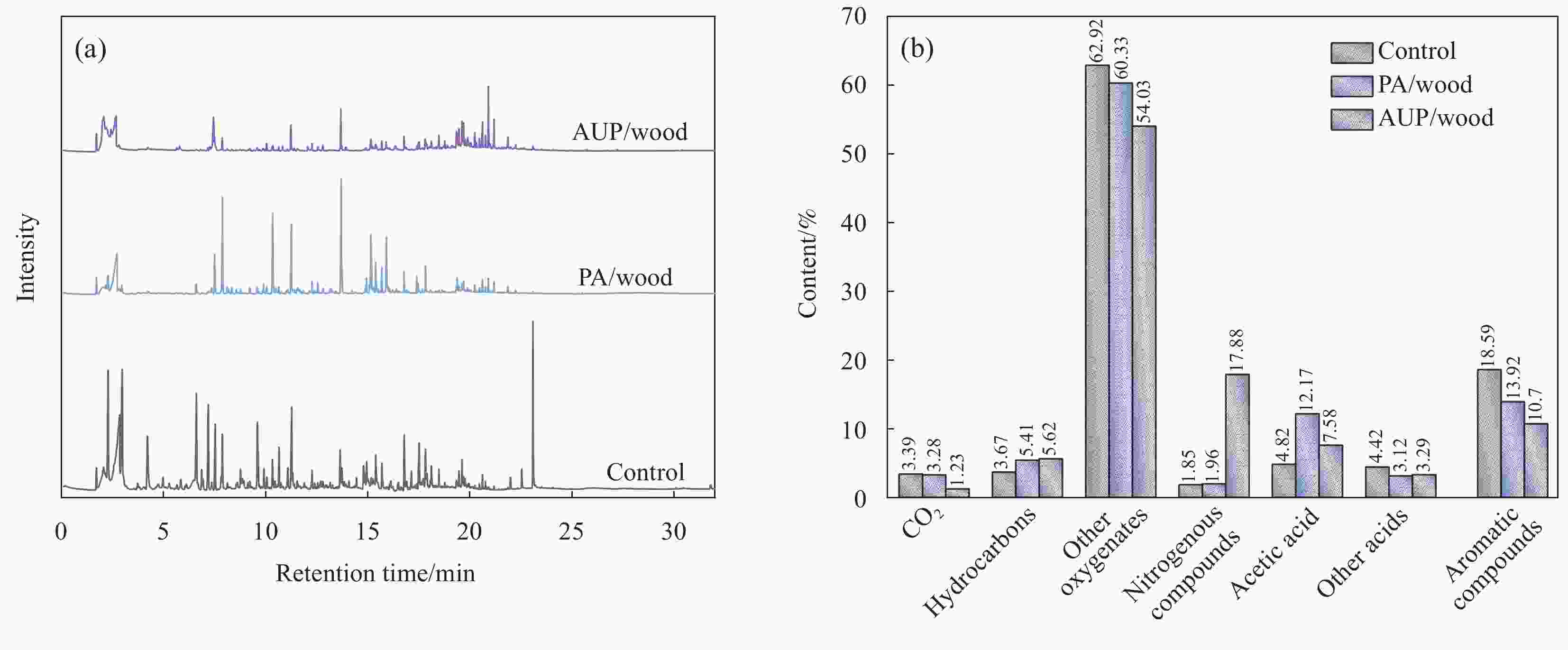

摘要: 植酸(Phytic acid, PA)是一种极具潜力的磷系水性生物基阻燃剂,但其单独处理木材存在PA易流失,燃烧烟释放量大等问题,通过与其他氮、硼系阻燃剂复配,可在一定程度上缓减上述问题。然而,由于PA酸性较强,PA及其复配阻燃剂处理木材时会造成木材降解,进而影响其力学强度。以PA和双氰胺为原料合成了一类新型磷氮阻燃剂——植酸脒基脲(Amidinourea phytate,AUP)。利用FTIR、XRD、XPS及TG等手段对AUP阻燃剂理化特性进行了表征。采用TG、Py-GC/MS、氧指数测定仪、CONE等研究了AUP对杨木的热解及燃烧行为的影响,探究了其阻燃机制。结果表明:AUP阻燃材在较低的增重率(8.73%)下表现出优异的阻燃及抑烟性能,优于增重率为14.8%的PA阻燃材,且抗流失性较好;AUP阻燃材的LOI值为34.8%,较未处理材提高了54.0%;总释热量和总生烟量分别降低了57.7%、65.7%,成炭率提高了148%,残炭结构更为密实,具有凝聚相与气相协效阻燃效果。此外,AUP阻燃材冲击强度比未处理材提高了58.5%,而PA阻燃材则下降了29.2%。Abstract: Phytic acid (PA) is a very promising phosphorus-based aqueous bio-based flame retardant, but its treatment of wood alone has problems such as easy loss of PA and high release of combustion smoke. This challenge can be mitigated to some extent by compounding with other nitrogen and boron flame retardants. However, due to the strong acidity of PA, PA and its complex flame retardants used in wood fire-retardant treatment may cause wood degradation, which in turn affects its mechanical strength. In this study, a new type of phosphorus-nitrogen flame retardant, amidinourea phytate (AUP), was synthesised from PA and dicyandiamide. The physicochemical properties of AUP was characterised using FTIR, XRD, XPS and TG. The effects of AUP on the pyrolysis and combustion behaviours of poplar wood were investigated by TG, Py-GC/MS, limiting oxygen index tester and CONE, and the flame retardant mechanism was explored. The results showed that the AUP flame retardant wood showed excellent flame retardant and smoke suppression properties at a lower weight gain rate (8.73%) than the PA flame retardant wood with a weight gain rate of 14.8%, and the loss resistance was better; the LOI value of the AUP flame retardant wood was 34.8%, which was 54.0% higher than that of the untreated wood; the total heat release and the total amount of smoke production were reduced by 57.7% and 65.7%, respectively, and the charcoal rate was increased by 148%, and the residual charcoal structure was more compact. The total heat release and total smoke production were reduced by 57.7% and 65.7% respectively, and the char formation rate was increased by 148%, and the residual char structure was denser, with the effect of cohesive phase and gas phase. In addition, the impact strength of AUP flame retardant wood increased by 58.5% compared with that of untreated wood, while that of PA flame retardant wood decreased by 29.2%.

-

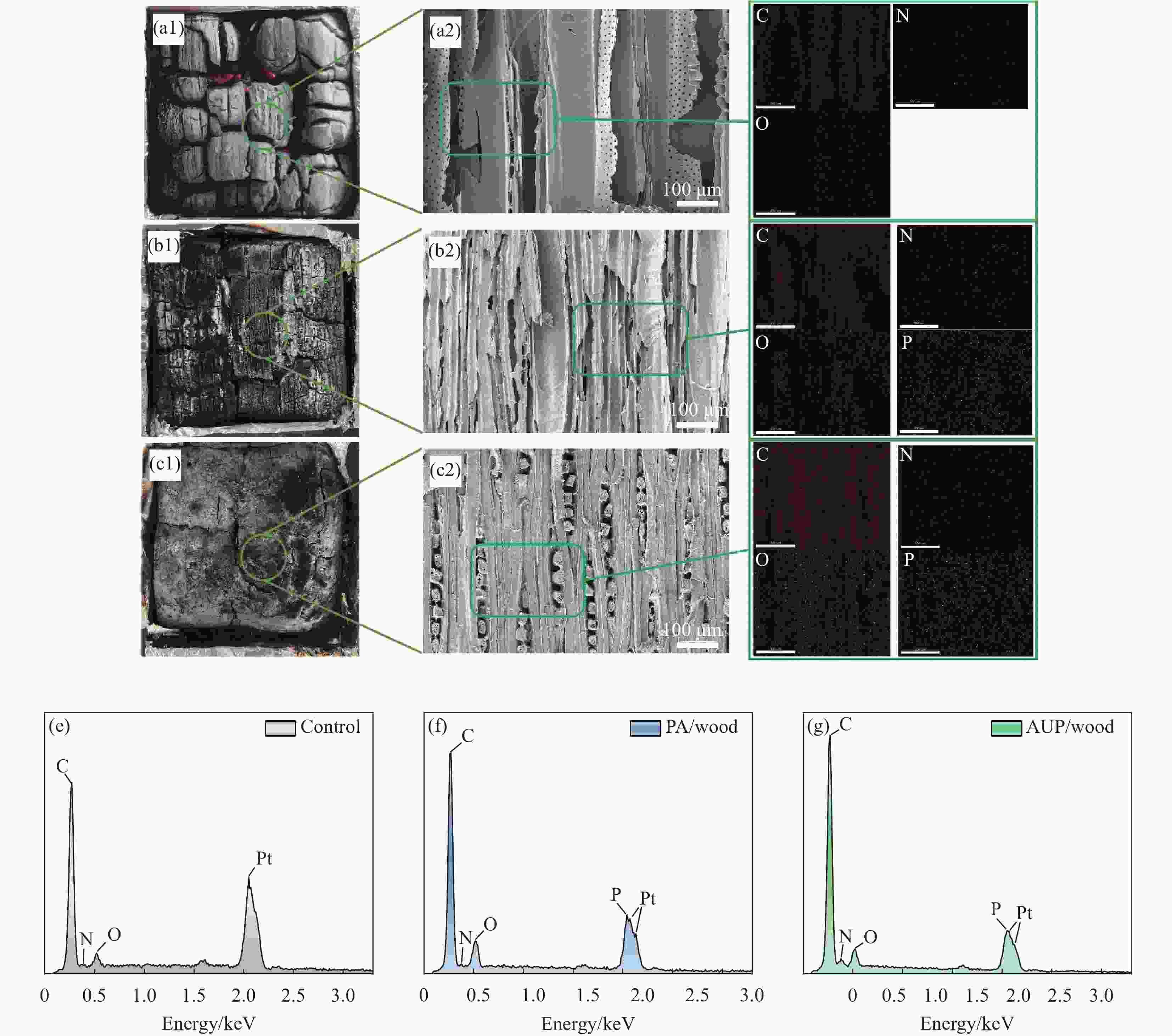

图 5 未处理材及AUP阻燃处理材的SEM图像:(a)、(b)为未处理材的横截面;(c)、(d)为AUP处理材的横截面;(e)为AUP处理材的纵切面;(f)为附着在木材内部的AUP阻燃剂分子形貌

Figure 5. SEM images of untreated wood and AUP flame retardant treated wood: (a), (b) are cross section of untreated wood; (c), (d) are cross section of AUP treated wood; (e) are longitudinal section of AUP treated wood; (f) are molecular morphology of AUP flame retardant attached to wood.

表 1 AUP-x的合成配方

Table 1. Formulation of AUP-x

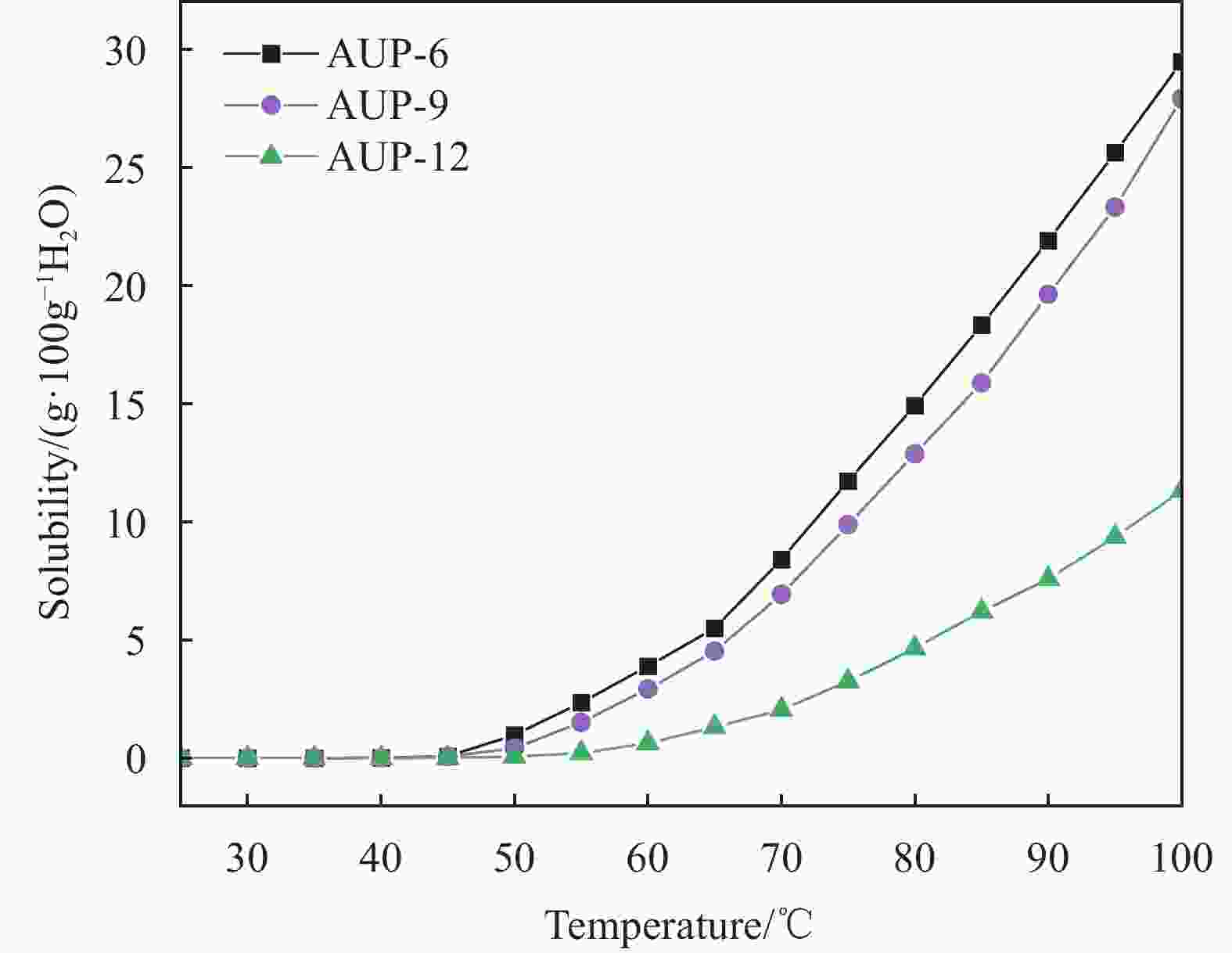

Ingre-dients DCD/g 60%PA/mL Molar ratio (PA to DCD) H2O/mL apH AUP-6 12.6 27.6 1∶6 10.4 3.52 AUP-9 18.9 27.6 1∶9 21.4 4.34 AUP-12 25.2 27.6 1∶12 32.1 5.39 Notes: apH value is tested after reaction at 25℃; AUP—Amidinourea phytate; PA—Phytic acid; DCD—Dicyandia-mide. 表 2 AUP-x的元素原子比

Table 2. XPS patterns of AUP-x

Sample AUP-6 AUP-9 AUP-12 C /atom% 23.91 25.17 25.34 O /atom% 38.65 37.02 30.78 N /atom% 30.36 32.48 38.41 P /atom% 7.08 5.33 5.47 表 3 抗流失试验相关参数

Table 3. Parameters related to erosion resistance test

Sample ε/% y1 y2 I/% PA/wood −53.94 68.53±3.49 15.73±1.65 22.89±1.35 AUP/wood −1.36 41.65±0.67 35.55±0.52 85.36±1.09 Notes: ε indicates the moisture absorption rate of the flame retardant material; y1, y2 indicates the amount of drug load before and after the anti-erosion test; I indicates the loss resistance of the flame retardant. 表 4 未处理材、PA阻燃材、AUP阻燃材的力学性能

Table 4. Mechanical properties of Control, PA/wood and AUP/wood

Sample Flexural strength/MPa Flexural modulus/GPa Impact strength/(kJ·m−2) Control 122.68±0.16 11.31±0.08 19.92±0.29 PA/wood 91.65±0.21 10.69±0.11 14.10±0.12 AUP/wood 113.18±0.07 10.81±0.07 31.58±0.25 表 5 未处理材、PA阻燃材、AUP阻燃材的锥形量热测试参数

Table 5. Cone calorimetric test parameters of control, PA/wood and AUP/wood

Sample Pk1-HRR/

(kW·m−2)Pk2-HRR/

(kW·m−2)THR/

(MJ·m−2)Av-EHC/

(MJ·kg−1)TSP/

(m2·m−2)Av-COY/

(MJ·kg−1)TTI/s FPI/

(s·m2·k−1)Char yield/

(%)B-W A-W B-W A-W B-W A-W Control 161.9 201.7 58.2 12.4 3.5 0.026 31 0.154 13.5 PA/wood 104.9 139.1 129.2 165.1 39.0 49.9 9.8 3.6 0.035 19 0.147 19.4 AUP/wood 36.3 42.9 82.1 77.1 20.0 21.4 5.7 1.2 0.041 55 0.670 33.5 Notes: B-W refers to before the loss resistance test; A-W refers to after the loss resistance test; Pk-HRR was the peak values of HRR with time; THR was the total heat release; Av-EHC was the average effective heat of combustion; TSP was the total smoke release; Av-COY was the average CO production; TTI was the was the time from when the cone shutter opened, exposing the sample to the set heat flux, to the moment flaming was established; FPI indicates fire performance index; Char yield was the carbon residue ratio. 表 6 未处理材、PA阻燃材和AUP阻燃材的热重特征参数

Table 6. Thermogravimetric parameters of control, PA/wood and AUP/wood

Sample Atmosphere T5wt%/℃ T10wt%/℃ T50wt%/℃ Tmax/℃ W800℃/% Control N2 240 300 353 362 10.9 Air 264 293 369 372 0.1 PA/wood N2 72 194 288 264 27.9 Air 183 233 377 298 17.2 AUP/wood N2 200 252 322 294 29.5 Air 213 274 369 306 16.8 Notes: The data in the table are obtained under nitrogen and air atmosphere. T5wt% refers to the temperature at 5% weight loss; T10wt% refers to the temperature at 10% weight loss; T50wt% refers to the temperature at 50% weight loss; Tmax refers to the temperature at which the rate of heat loss is maximized; W800℃ refers to the residual rate of the sample at 800℃. -

[1] 徐有明. 木材学(第2版)[M]. 北京: 中国林业出版社, 2019: 2-10.XU Youming. Wood Science (Second edition) [M]. Beijing: China forestry press, 2001: 4-10(in Chinese). [2] 侯方淼, 李浩爽. 全球价值链下中国木材产业参与国际分工及其影响因素[J]. 林业经济, 2020, 42(5): 3-18.HOU Fangmiao, LI Haoshuang. Factors influencing China’ s timber industry’s participation into the division of global value chain[J]. Forestry Economics, 2020, 42(5): 3-18(in Chinese). [3] 吴天博, 田刚. “丝绸之路经济带”视域下中国与沿线国家木质林产品贸易——基于引力模型的实证研究[J]. 国际贸易问题, 2019, (11): 77-87.WU Tianbo, TIAN Gang. The trade of woody forest products between China and the countries along the Silk Road Economic Belt——an empirical study based on gravity model[J]. Journal of International Trade, 2019, (11): 77-87(in Chinese). [4] 张其, 肖泽芳, 龚宸, 等. 磷酸脒基脲和季戊四醇磷酸酯复合改性MUF木材涂料的阻燃性能研究[J]. 林业工程学报, 2018, 3(6): 48-55(in Chinese).ZHANG Qi, XIAO Zefang, GONG Chen, et al. Wood amino-resin coatings using synergistic fire-retardant modification of pentaerythritol phosphate and guanylurea phosphate[J]. Journal of Forestry Engineering, 2018, 3(6): 48-55(in Chinese). [5] 班大明, 徐春萍. 国内磷系阻燃剂在环氧树脂中的应用及研究进展[J]. 贵州师范大学学报(自然科学版), 2023, 41(3): 95-102.BAN Daming, XU Chunping. Application and development of phosphorus based flame retardant on epoxy resins in China[J]. Journal of Guizhou Normal University(Natural Sciences), 2023, 41(3): 95-102(in Chinese). [6] 胡泊, 朱继伟, 武保林, 等. HPCTP/MMT复配阻燃环氧树脂阻燃及力学性能研究[J]. 塑料科技, 2019, 47(1): 125-128.HU Bo, ZHU Jiwei, WU Baolin, et al. Study on flame retardancy and mechanical properties of epoxy resin flame-retarded by HPCTP/MMT compound[J]. Plastics Science and Technology, 2019, 47(1): 125-128(in Chinese). [7] 胡泊, 赵腾龙, 武保林, 等. 含磷阻燃剂阻燃环氧树脂的阻燃特性研究[J]. 工业安全与环保, 2019, 45(7): 5-9. doi: 10.3969/j.issn.1001-425X.2019.07.002HU Bo, ZHAO Tenglong, WU Baolin, et al. Study on flame retardant properties of epoxy resin with phosphorous-containing flame retardant[J]. Industrial Safety and Environmental Protection, 2019, 45(7): 5-9(in Chinese). doi: 10.3969/j.issn.1001-425X.2019.07.002 [8] 王会娅, 程哲, 卢林刚等. 新型环磷腈阻燃剂合成及其在环氧树脂中的应用[J]. 塑料, 2019, 48(5): 57-62.WANG Huiya, CHENG Zhe, LU Lingang, et al. Synthesis and performance in epoxy resins of novel cyclotriphosphazene flame retardants[J]. Plastics, 2019, 48(5): 57-62(in Chinese). [9] 李霈, 付海, 赵欧等. 聚磷酸酯阻燃剂复配聚磷酸铵对环氧树脂阻燃性能的影响[J]. 高等学校化学学报, 2017, 38(2): 294-302. doi: 10.7503/cjcu20160599LI Pei, FU Hai, ZHAO Ou, et al. Influence of Polyphosphate Flame Retardant Couple with Ammonium Polyphosphate on Epoxy Resin[J]. Chemical Journal of Chinese Universities, 2017, 38(2): 294-302(in Chinese). doi: 10.7503/cjcu20160599 [10] 秦维, 闵样, 陈超等. 聚磷酸酯膨胀阻燃剂复配有机蒙脱土阻燃改性环氧树脂[J]. 中国塑料, 2018, 32(12): 112-117.QIN Wei, MIN Yang, CHEN Chao, et al. Ammonium Polyphosphate/Organic Montmorillonite Compounds Flame-retardant Epoxy Resin[J]. China Plastics, 2018, 32(12): 112-117(in Chinese). [11] XUE Y, ZUO X, WANG L, et al. Enhanced flame retardancy of poly(lactic acid) with ultra-low loading of ammonium polyphosphate[J]. Composites Part B Engineering, 2020, : 108124. [12] CHENG X W, GUAN J P, TANG R C, et al. Phytic acid as a bio-based phosphorus flame retardant for poly(lactic acid) nonwoven fabric[J]. Journal of Cleaner Production, 2016, 124(15): 114-119. [13] CHENG X W, LIANG C X. GUAN J P, et al. Flame retardant and hydrophobic properties of novel sol-gel derived phytic acid/silica hybrid organic-inorganic coatings for silk fabric[J]. Applied Surface Science, 2018, 427: 69-80. doi: 10.1016/j.apsusc.2017.08.021 [14] Costes L, Laoutid F, Brohez S, et al. Phytic acid–lignin combination: A simple and efficient route for enhancing thermal and flame retardant properties of polylactide[J]. European Polymer Journal, 2017, 94: 270-285. doi: 10.1016/j.eurpolymj.2017.07.018 [15] 王冬. 植酸基阻燃剂的制备及其阻燃机制研究[D]. 江南大学, 2023.WANG Dong. Preparation of Phytate Based Flame Retardants and Study on the Flame-retardant Mechansims[D]. Jiangnan University, 2023(in Chinese). [16] LI L M, CHEN Z, LU J, et al. Combustion Behavior and Thermal Degradation Properties of Wood Impregnated with Intumescent Biomass Flame Retardants: Phytic Acid, Hydrolyzed Collagen, and Glycerol[J]. ACS Omega, 2021, 6(5): 3921-3930 doi: 10.1021/acsomega.0c05778 [17] 吴宇晖, 张少迪, 任自忠, 等. 植酸-三聚氰胺处理木材阻燃性能研究[J]. 北京林业大学学报, 2020, (4): 7.WU Yuhui, ZHANG Shaodi, REN Zizhong, et al. Flame retardant properties of phytic acid and melamine treated wood[J]. Journal of Beijing Forestry University, 2020, (4): 7(in Chinese). [18] 王海军, 陈立新, 缪桦. 氮系阻燃剂的研究及应用概况[J]. 热固性树脂, 2005, 20(4): 36-41. doi: 10.3969/j.issn.1002-7432.2005.04.011WANG Haijun, CHEN Lixin, MIAO Hua. The study on nitrogen-Containing flame retardants and its application in plastics[J]. Thermosetting Resin, 2005, 20(4): 36-41(in Chinese). doi: 10.3969/j.issn.1002-7432.2005.04.011 [19] 刘勤, 柴生勇, 李岩, 等. 双氰胺氰尿酸盐在聚丙烯中的阻燃应用[J]. 塑料工业, 2021, 49(4): 163-168. doi: 10.3969/j.issn.1005-5770.2021.04.031LIU Qin, CHAI Shengyong, LI Yan, et al. The Application of Dicyanodiamide Cyanurate in Polypropylene as Flame Retardant[J]. China Plastics Industry, 2021, 49(4): 163-168(in Chinese). doi: 10.3969/j.issn.1005-5770.2021.04.031 [20] 全国木材标准化技术委员会. 改性木材尺寸稳定性测试方法: LY/T 2490-2015[S]. 北京: 中国标准出版社, 2015.National Wood Standardization Technical Committee. Test method for dimensional stability of modified wood: LY/T 2490-2015[S]. Beijing: China Standard Press, 2015(in Chinese). [21] American Wood Protection Association. AWPA E11-06 Standard methods for accelerated evaluation of preservative[S]. American: American Wood Protection Association, 2016. [22] 中国国家标准化管理委员会. 塑料 用氧指数法测定燃烧行为 第2部分: 室温试验: GB/T 2406.2-2009[S]. 北京: 中国标准出版社, 2009.Standardization Administration of China. Deter-mination of burning behavior of plastics by oxygen index method Part 2: Room temperature test: GB/T 2406.2-2009 [S]. Beijing: China Standard Press, 2009(in Chinese). [23] 中国国家标准化管理委员会. 塑料简支梁冲击性能的测定 第1部分: 非仪器化冲击试验: GB/T 1043.1-2008 [S]. 北京: 中国标准出版社, 2008.Standardization Administration of China. Deter-mination of impact properties of simply supported beams of plastics Part 1: Non-instrumented impact test: GB/T 1043.1-2008 [S]. Beijing: China Standard Press, 2008(in Chinese). [24] American Society for Testing and Materials. ASTM D790-03 Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials[S]. American: American Society for Testing and Materials, 2003. [25] ISO. ISO 5660-1 Reaction-to-fire tests—Heat release, smoke production and mass loss rate—Part 1: Heat release rate (cone calorimeter method) and smoke production rate (dynamic measurement)[S]. Geneva: ISO, 2015. [26] Rayée Q, Nguyen PT, Segato T, et al. Electrochemical synthesis of copper(I) dicyanamide thin films[J]. Electroanal Chem, 2018, 819: 331-337. doi: 10.1016/j.jelechem.2017.11.001 [27] YUAN X H, LUO K, WU Y J, et al. Investigation on the stability of derivative melam from melamine pyrolysis under high pressure[J]. Nanomaterials, 2018, 8(3): 172. doi: 10.3390/nano8030172 [28] ZHANG F X, GAO W W, JIA Y L, et al. A concise water-solvent synthesis of highly effective, durable, and eco-friendly flame-retardant coating on cotton fabrics[J]. Carbohydrate Polymers, 2018, 199: 256-265. doi: 10.1016/j.carbpol.2018.05.085 [29] PAN Y, LIU L X, WANG X, et al. Hypophosphorous acid cross-linked layer-by-layer assembly of green polyelectrolytes on polyester-cotton blend fabrics for durable flame-retardant treatment[J]. Carbohydrate Polymers, 2018, 201: 1-8. doi: 10.1016/j.carbpol.2018.08.044 [30] ROSACE G, CASTELLANO A, TROAVTO V, et al. Thermal and flame retardant behaviour of cotton fabrics treated with a novel nitrogen-containing carboxyl-functionalized organo-phosphorus system[J]. Carbohydrate Polymers, 2018, 196: 348-358. doi: 10.1016/j.carbpol.2018.05.012 [31] LIU L, PAN Y, ZHAO Y, et al. Self-assembly of phosphonate-metal complex for super-hydrophobic and durable flame-retardant polyester–cotton fabrics[J]. Cellulose, 2020, 27(10): 6011-6025. doi: 10.1007/s10570-020-03148-z [32] XU F, ZHANG G X, WANG P, et al. A novel ε-polylysine-derived durable phosphorus-nitrogen-based flame retardant for cotton fabrics[J]. Cellulose, 2021, 28(6): 3807-3822. doi: 10.1007/s10570-021-03714-z [33] LIN C, KARLSSON O, MARTINKA J, et al. Approaching Highly Leaching-Resistant Fire-Retardant Wood by In Situ Polymerization with Melamine Formaldehyde Resin[J]. ACS Omega 2021, 6: 12733–12745. [34] HONG J, HUANG S Z, WU H Q, et al. Effects of eutrophic water with ammonium chloride, urea, potassium dihydrogen phosphate and sodium-β-glycerophosphate on Myriophyllum verticillatum and epiphytic bacteria[J]. The Science of the total environment, 2023, 891: 164507. doi: 10.1016/j.scitotenv.2023.164507 [35] YAMADA Y, TANAKA H, KUBO S, et al. Unveiling bonding states and roles of edges in nitrogen-dopedgraphene nanoribbon by X-ray photoelectron spectroscopy[J]. Carbon, 2021, 185: 342-367 doi: 10.1016/j.carbon.2021.08.085 [36] SALMEIA A K, GAAN S, MALUCELLI G, et al. Recent Advances for Flame Retardancy of Textiles Based on Phosphorus Chemistry[J]. Polymers, 2016, 8(9): 319. doi: 10.3390/polym8090319 [37] André L M D, Jivaldo do R M. Study of thermal behavior of phytic acid[J]. Brazilian Journal of Pharmaceutical Sciences, 2013, 49(2): 277-282. [38] 郝畅, 郭垂根. 复配阻燃剂对木材阻燃与力学性能的影响[J]. 消防科学与技术, 2016, 35(5): 663-667 doi: 10.3969/j.issn.1009-0029.2016.05.022HAO Chang, GUO Chuigen. Effect of compound flame retardant on flame retardant and mechanical properties of pinus sylvestris[J]. Fire Science and Technology, 2016, 35(5): 663-667(in Chinese). doi: 10.3969/j.issn.1009-0029.2016.05.022 [39] SHANG S, YUAN B, SUN Y. et al. Facile preparation of layered melamine-phytate flame retardant via supramolecular self-assembly technology[J]. ColloidInterface Sci, 2019, 553: 364-371. [40] YUAN L, CHEN X, HU Y. Combination effect of 4-picolinic acid with 5A zeolite on ammonium polyphosphate flame-retarded sawdust board. Journal of Fire Sciences. 2014, 32 (3): 230-240. [41] ANNA A, STEC T, RICHARD H. Fire toxicity and its assessment. In Fire Retardancy of Polymeric Materials; Taylor & Francis Group: Oxfordshire, 2009; 453–477. [42] YAN D, CHEN D, TAN J, et al. Synergistic flame retardant effect of a new N-P flame retardant on wood wood density board[J]. Polymer Degradation and Stability, 2023, 211: 110331. doi: 10.1016/j.polymdegradstab.2023.110331 [43] 王清文. 新型木材阻燃剂FRW[D]. 东北林业大学, 2007.WANG Qingwen. FRW Fire Retardant for Wood[D]. Northeast Forestry University, 2007(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 104

- HTML全文浏览量: 77

- 被引次数: 0

下载:

下载: