Experimental study on axial compressive damage performance of CFRP-reinforced wood columns

-

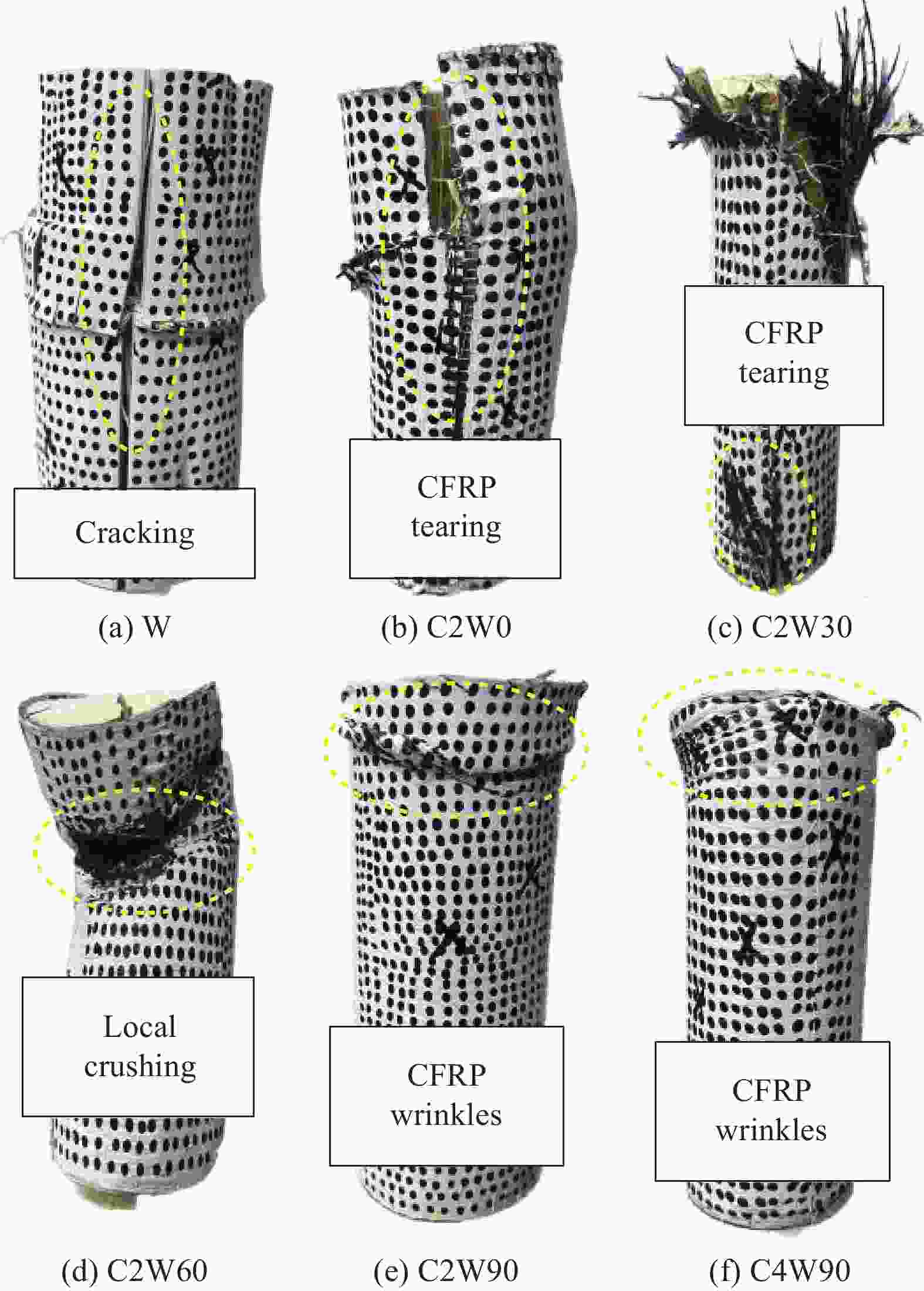

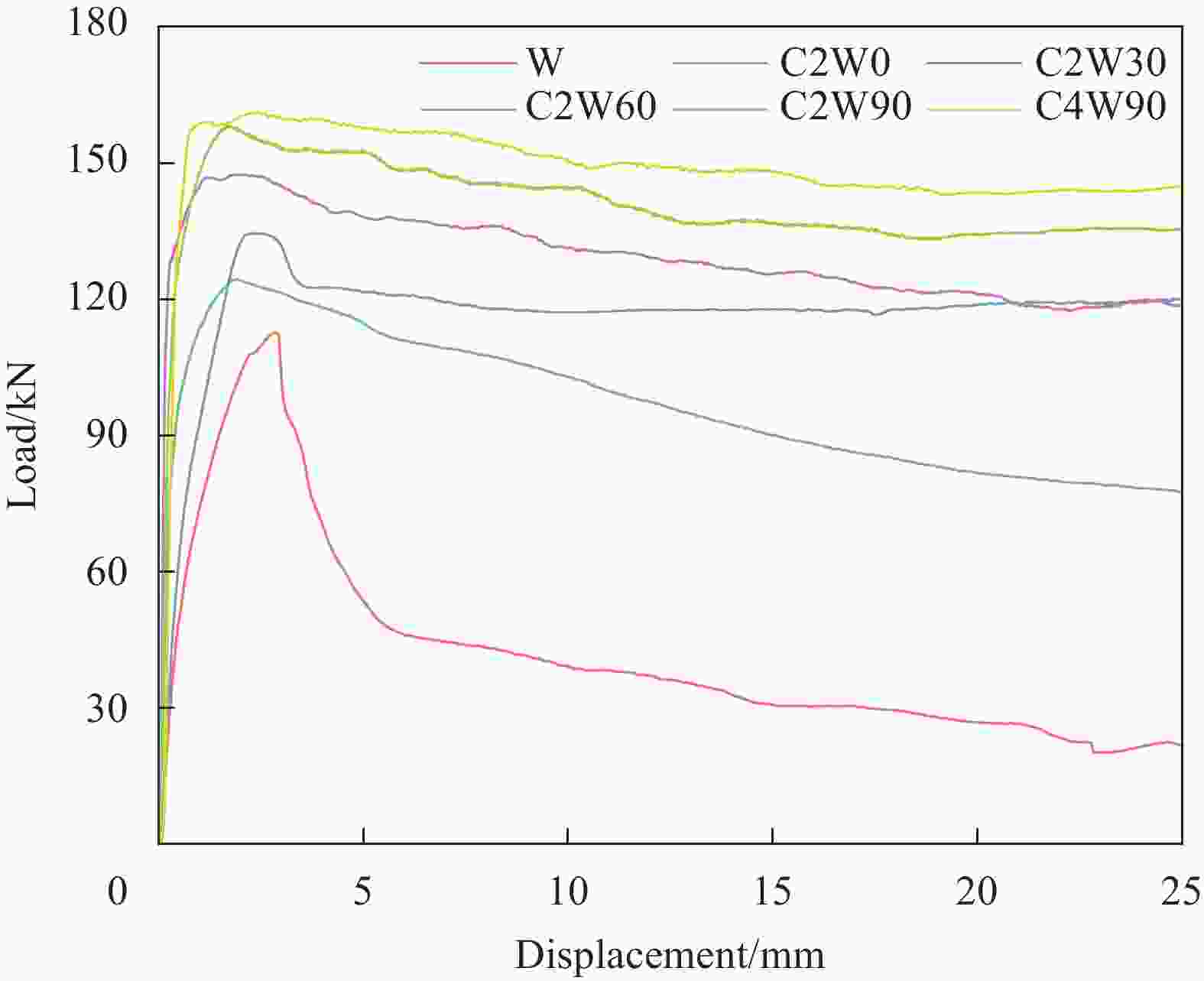

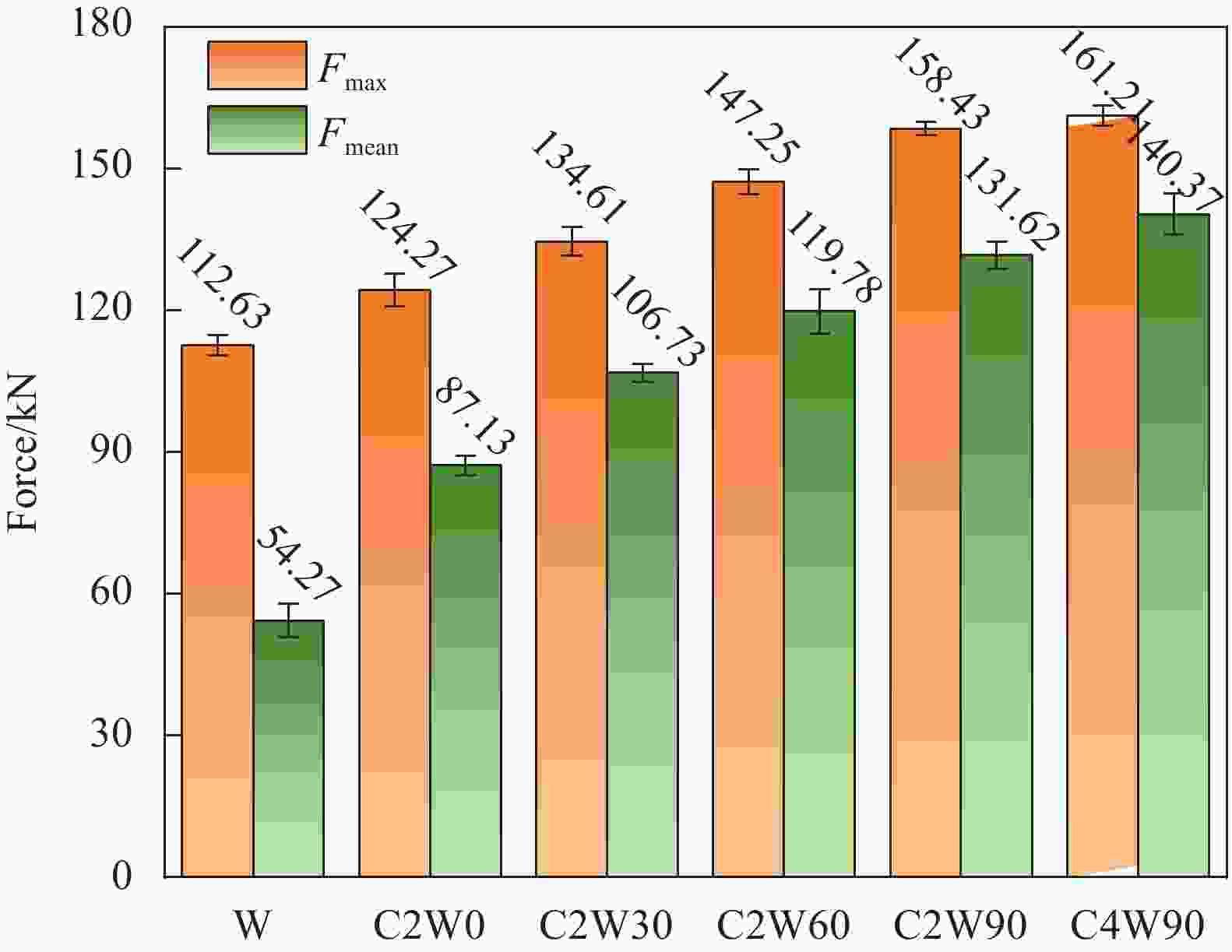

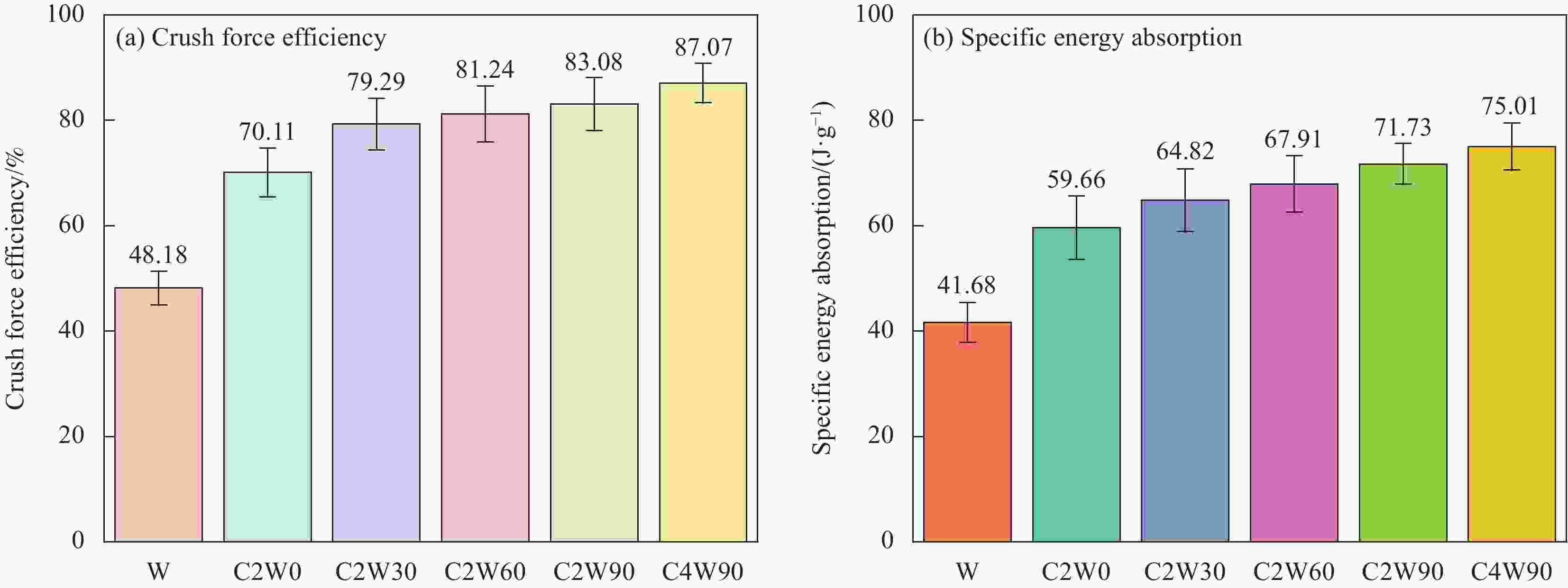

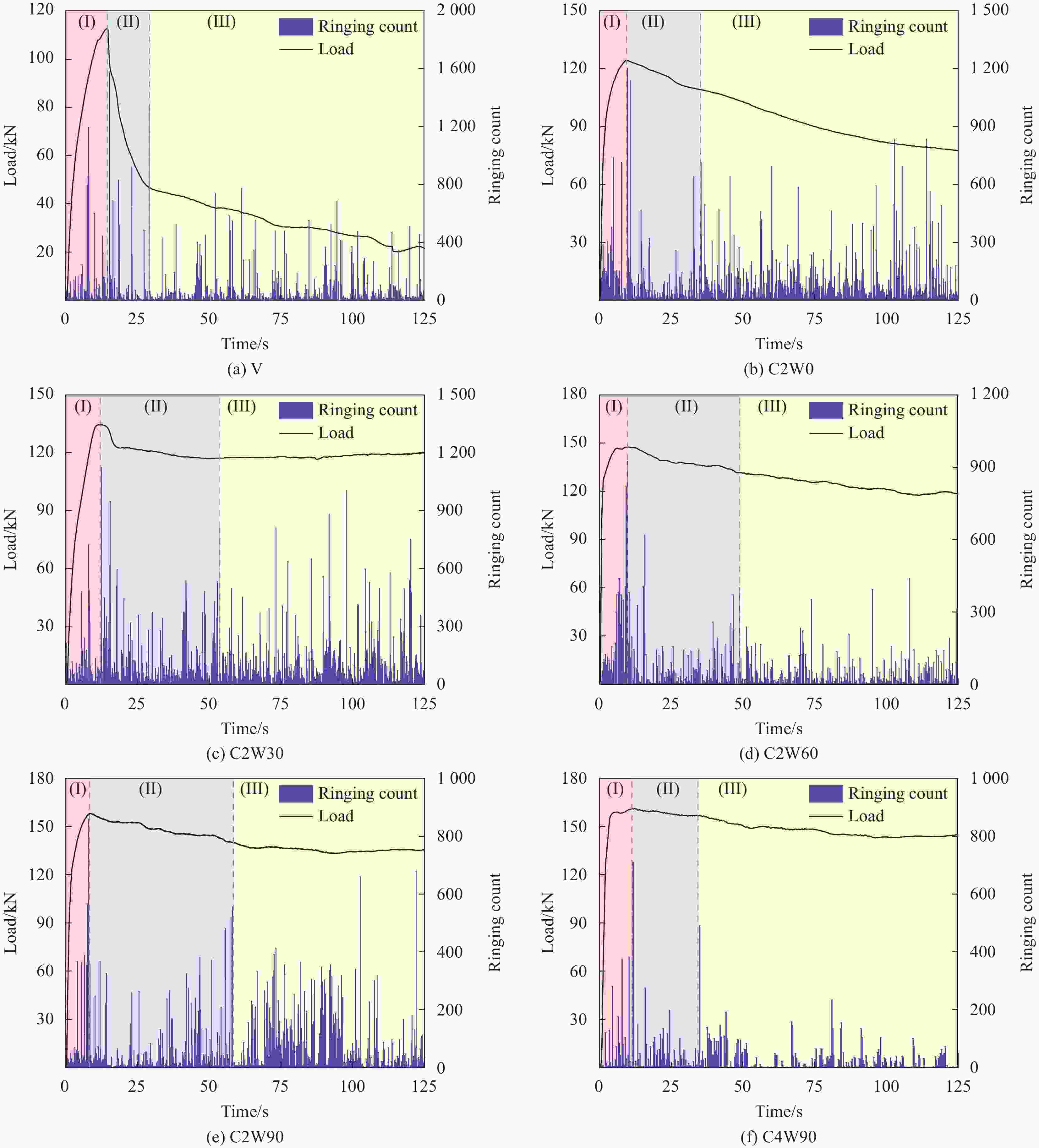

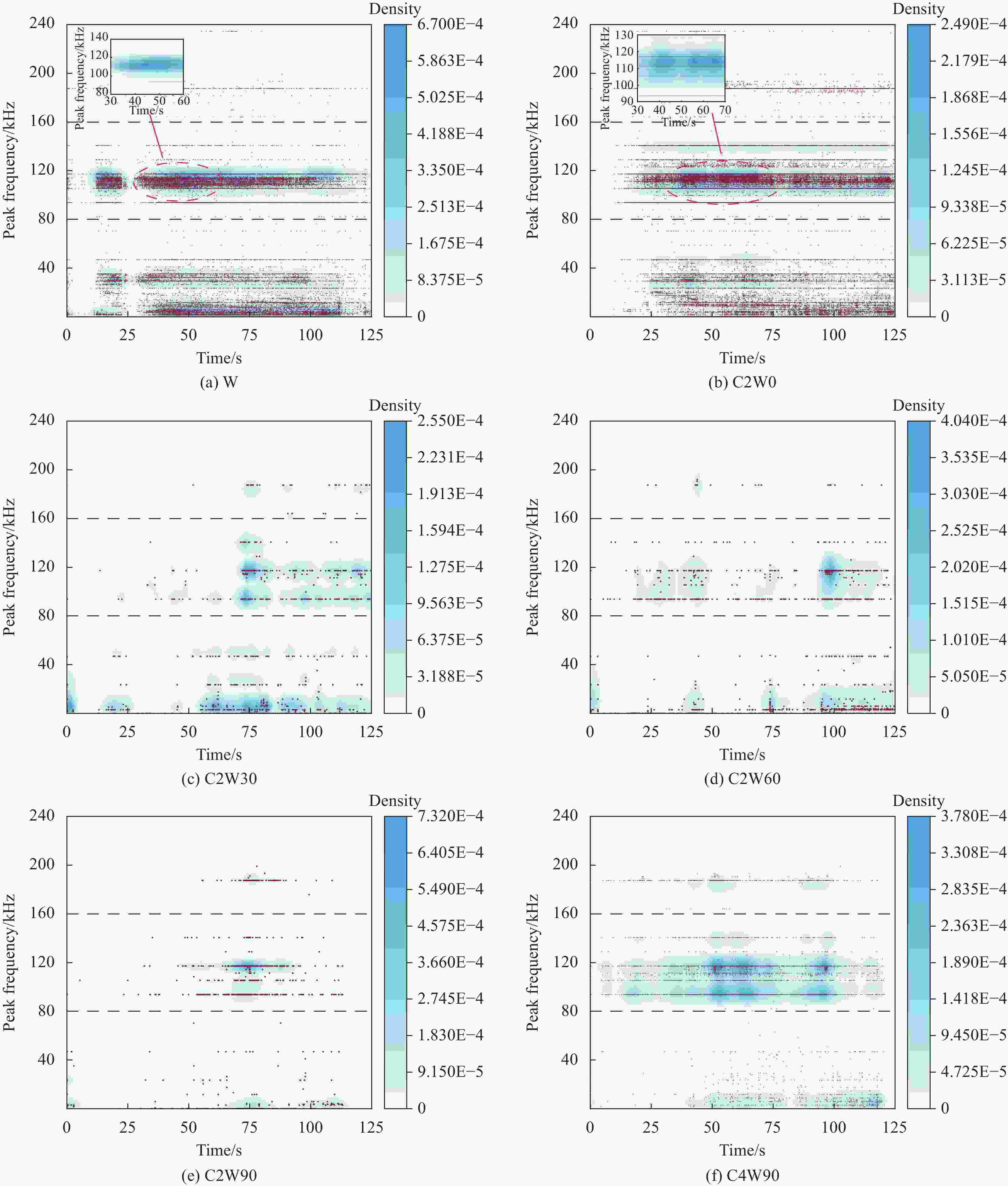

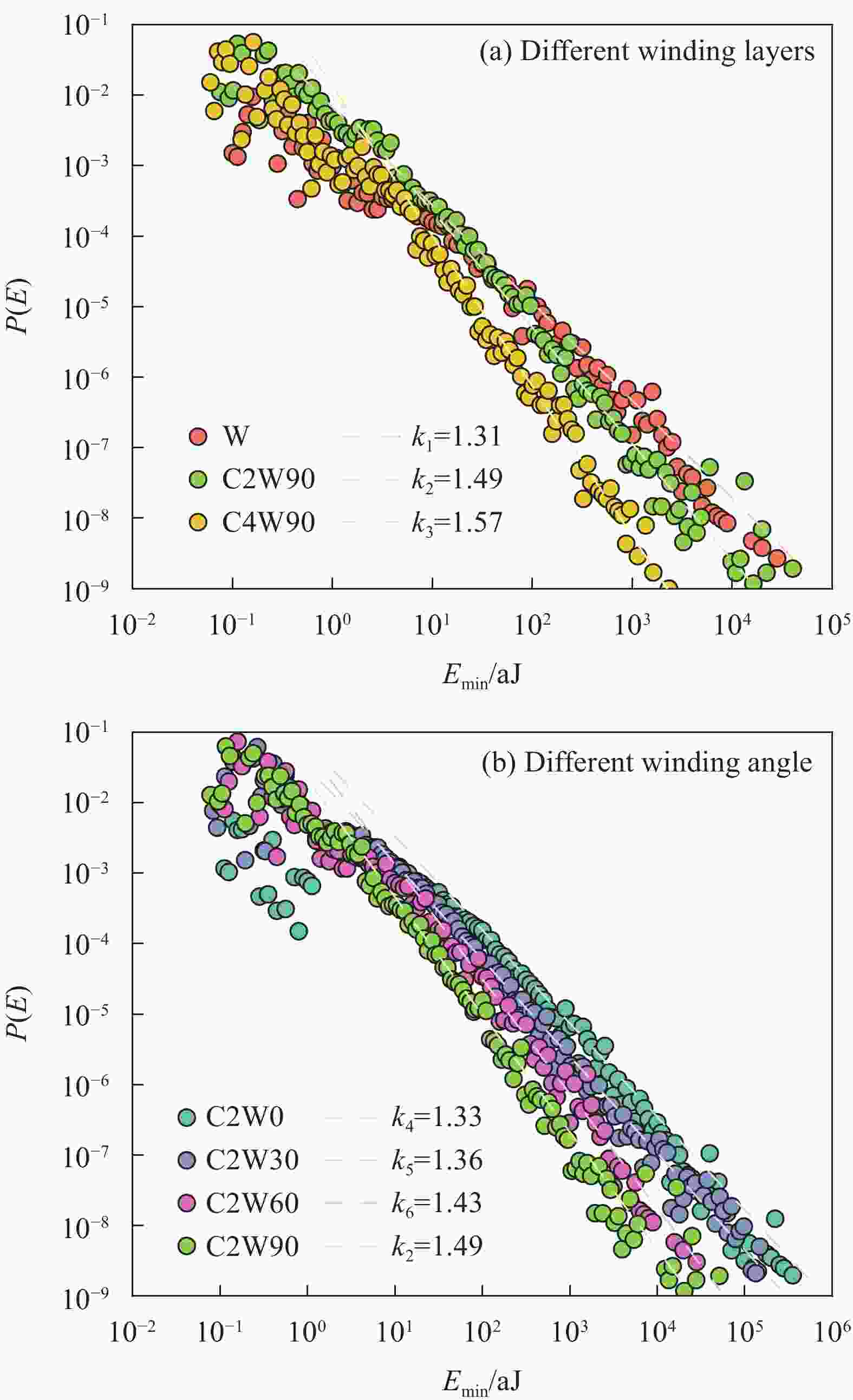

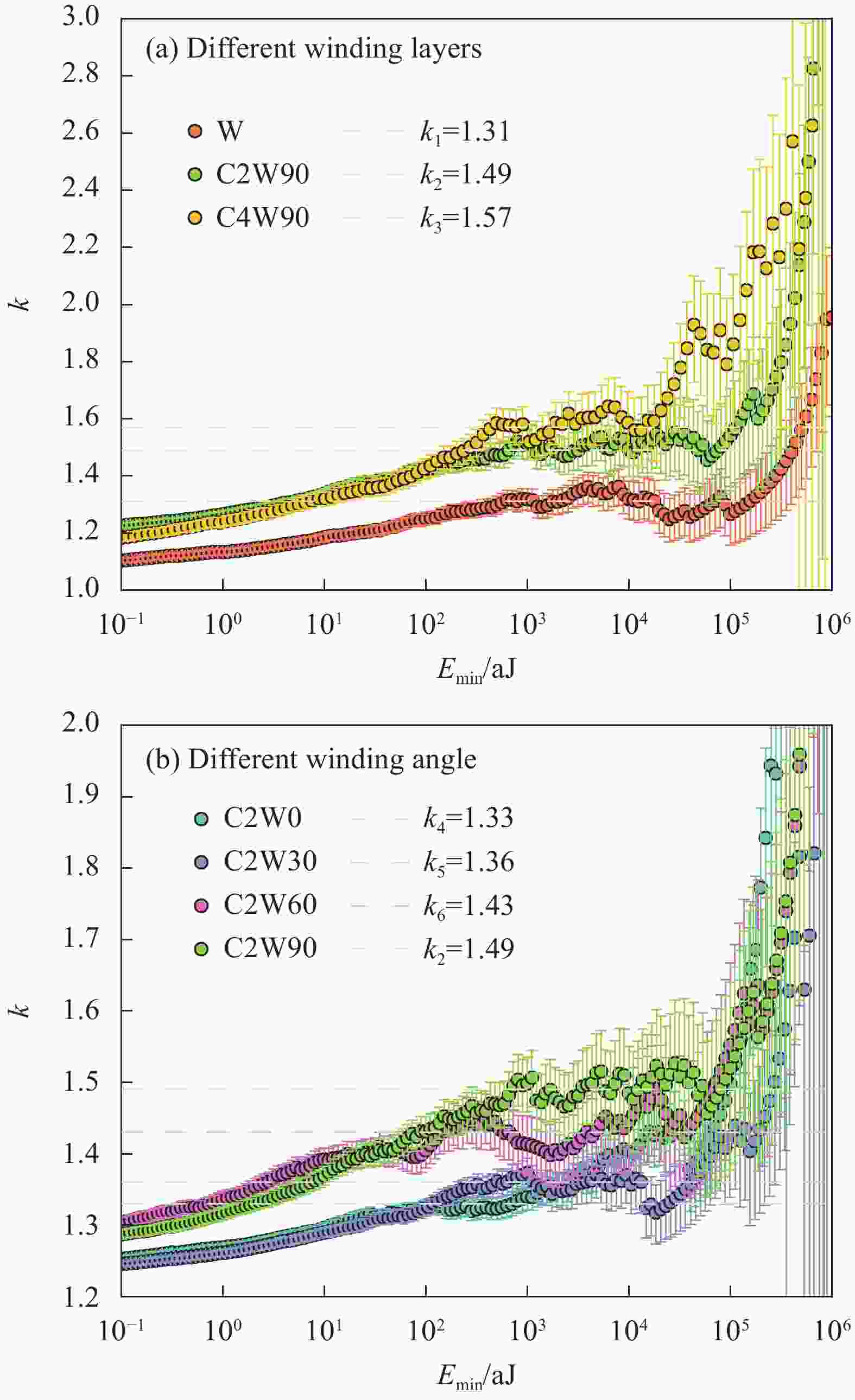

摘要: 为研究碳纤维增强树脂基复合材料(CFRP)加固木柱的轴压损伤性能及破坏机制,对6组不同CFRP缠绕方式的木柱开展了轴向压缩试验并进行了实时声发射(Acoustic emission, AE)监测。分析了不同缠绕层数和不同缠绕角度对CFRP加固木柱破坏形式、力学性能、吸能性能和声发射参数演化规律的影响。结果表明:CFRP的加固能明显改善木材的力学性能,抑制脆性破坏的发生;随着缠绕层数、角度的增大,木柱的极限承载力从112.63 kN提升至161.21 kN,位移延性系数也从1.44提升至1.72;CFRP缠绕层数、角度的增加能够显著提高CFRP加固木柱在轴压损伤过程中的稳定性和吸能能力;根据声发射的振铃计数演化特征可以将CFRP加固木柱的损伤过程分为弹性、压缩屈服和损伤破坏三个阶段;随着缠绕层数、角度的增加,声发射峰值频率逐渐从低频区间(0~80 kHz)向高频区间(160~240 kHz)过渡,损伤形式从大尺度损伤转变为小尺度损伤;不同缠绕方式的木柱声发射能量概率密度均遵循幂律无尺度分布,6种加固方式下,临界指数分别为1.31、1.33、1.36、1.43、1.49、1.57;临界指数随着缠绕层数、角度的增大而增大,CFRP的加固限制了木材内部裂纹的发展,减弱了内部结构的劣化。

-

关键词:

- 碳纤维增强树脂基复合材料 /

- 木柱 /

- 损伤性能 /

- 声发射 /

- 临界指数

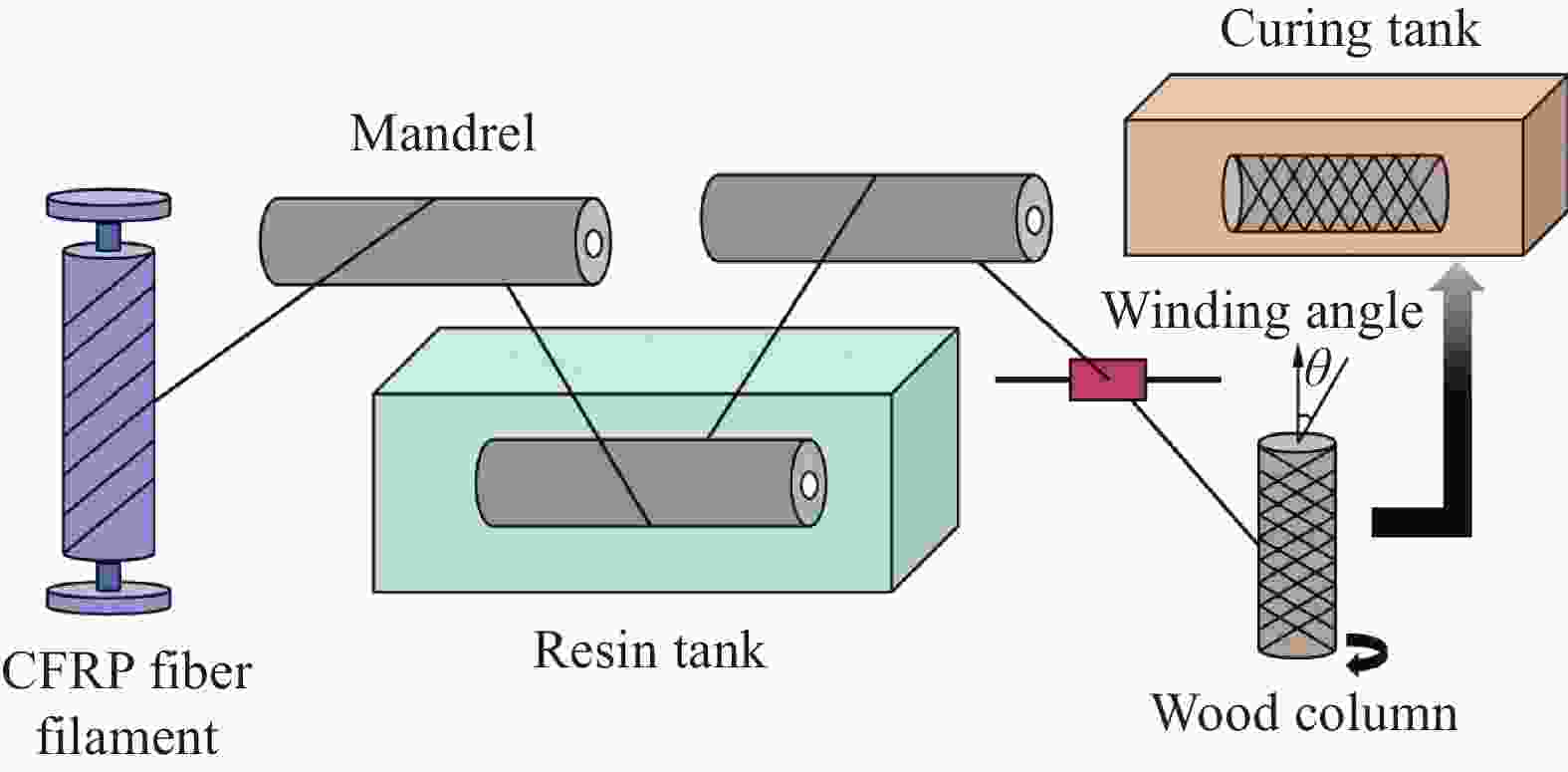

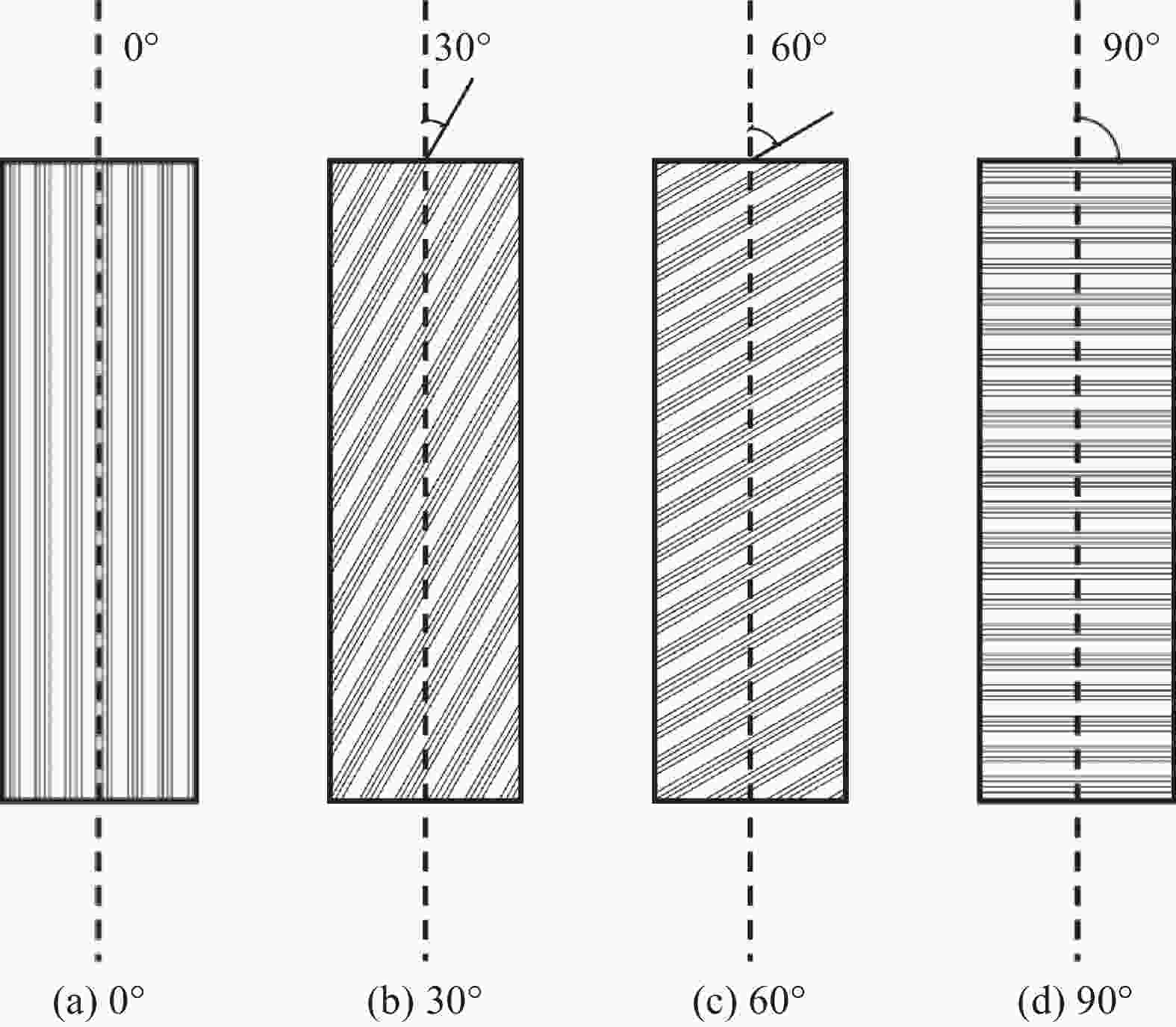

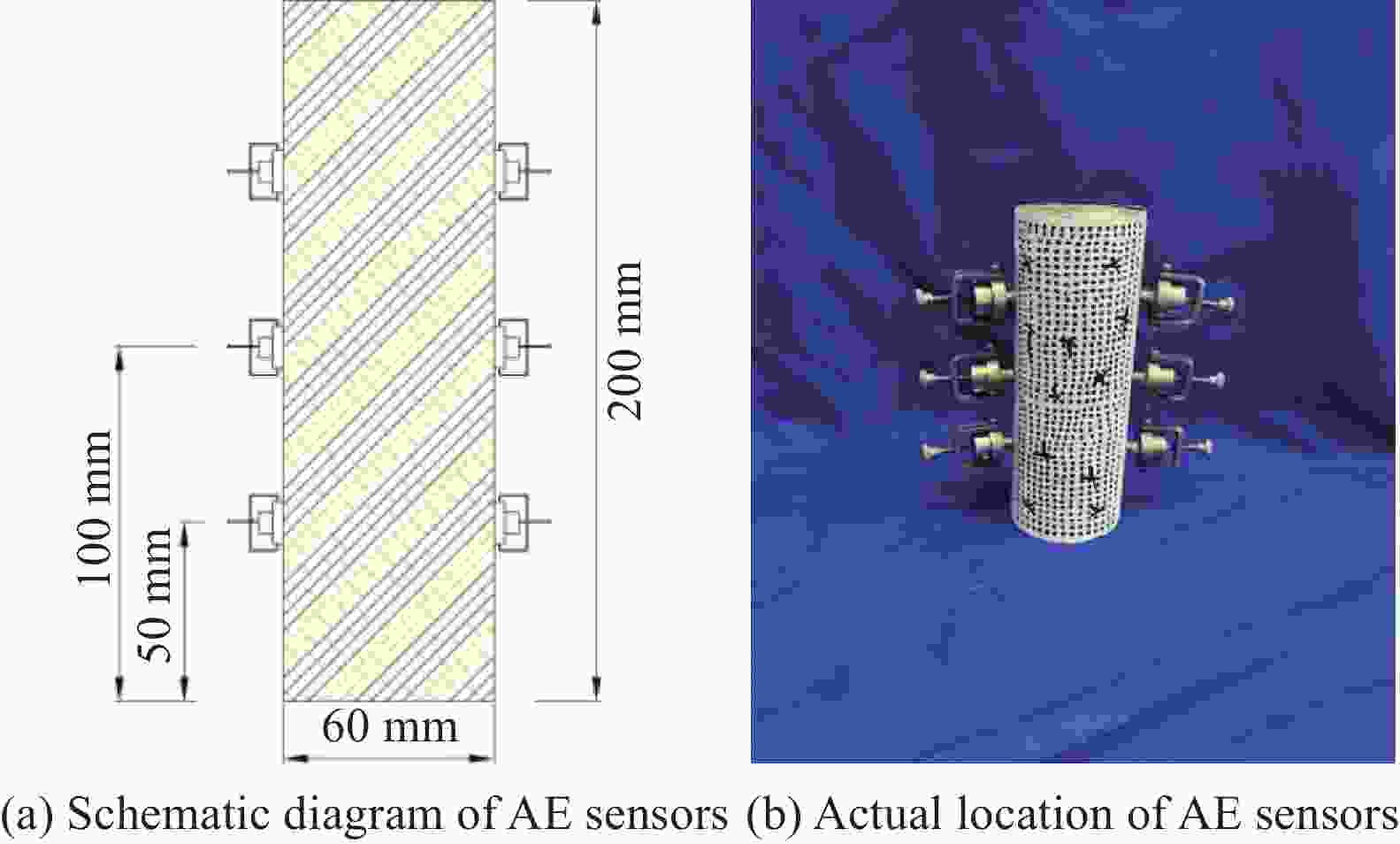

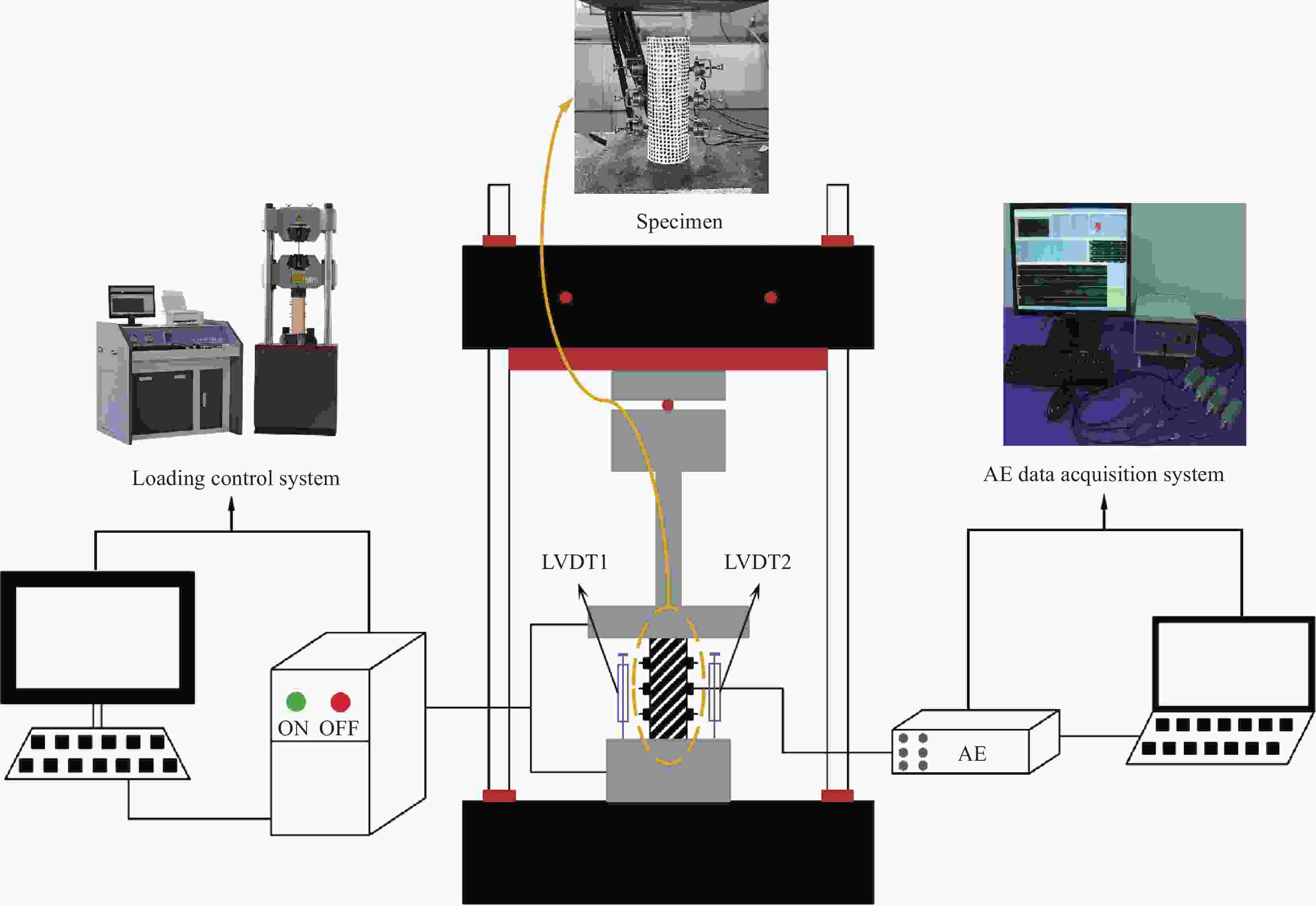

Abstract: To study the axial compression damage performance and failure mechanism of wood columns strengthened with carbon fiber reinforced polymer (CFRP), axial compression tests and real-time acoustic emission (AE) monitoring were carried out on six groups of wood columns with different CFRP winding methods. The effects of different winding layers and winding angle on the damage forms, mechanical properties, energy absorption properties and acoustic emission parameters of CFRP-reinforced wood columns were analyzed. The results show that: the reinforcement of CFRP can significantly improve the mechanical properties of wood, inhibit the occurrence of brittle damage; with the increase of the winding layers and angle, the ultimate bearing capacity of the wood columns increases from 112.63 kN to 161.21 kN, and the displacement ductility factor also increases from 1.44 to 1.72; the increase of CFRP winding layers and angle can significantly improve the stability and energy absorption capacity of CFRP-reinforced wood columns in the axial compression damage process; according to the evolution characteristics of acoustic emission ringing count, the damage process of CFRP-reinforced wood columns can be divided into three stages: elastic stage, compressive yield stage and damage failure stage; with the increase of the winding layers and angle, the peak frequency of acoustic emission gradually transitions from the low-frequency range (0~80 kHz) to the high-frequency range (160~240 kHz), and the damage form changes from large-scale damage to small-scale damage; the probability density of acoustic emission energy of wood columns with different winding methods follows a power-law scale-free distribution, the critical indices under six reinforcement methods are 1.31, 1.33, 1.36, 1.43, 1.49 and 1.57, respectively; the critical index increases with the increase of winding layers and angles, the reinforcement of CFRP limits the development of internal cracks and weakens the deterioration of the internal structure of the wood.-

Key words:

- carbon fiber reinforced polymer /

- wood columns /

- damage performance /

- acoustic emission /

- critical index

-

表 1 木材的主要力学性能指标

Table 1. Main mechanical properties of wood

Compressive strength parallel to grain/MPa Tensile strength parallel to grain/MPa Shear strength parallel to grain/MPa Bending strength/MPa 39.23 51.35 4.94 67.98 表 2 粘结剂和碳纤维的主要力学性能指标

Table 2. Main mechanical properties of impregnation adhesive and carbon fiber

Material Elastic modulus/GPa Tensile strength/MPa Elongation/% Carbon fiber 230 3700 1.8 Impregnation adhesive 2.5 40 1.5 表 3 试件基本参数

Table 3. Specimen basic parameters

Group No. Specimen No. CFRP winding layers CFRP winding angle/(°) m/g 1 W-1 — — 204.28 W-2 201.36 W-3 210.15 2 C2W0-1 2 0 218.21 C2W0-2 221.38 C2W0-3 215.63 3 C2W30-1 2 30 219.67 C2W30-2 226.14 C2W30-3 223.97 4 C2W60-1 2 60 229.36 C2W60-2 221.04 C2W60-3 230.43 5 C2W90-1 2 90 229.62 C2W90-2 224.18 C2W90-3 219.37 6 C4W90-1 4 90 239.42 C4W90-2 245.21 C4W90-3 236.81 Note: "W" stands for wood, "C" stands for CFRP: "W" means unreinforced wood column; "C2W30" means CFRP-reinforced wood column, with 2 winding layers and 30° winding angle; m is the mass of the specimen. 表 4 CFRP加固木柱的轴向压缩试验结果

Table 4. Axial compression test results of CFRP-reinforced wood columns

Specimen No. Ultimate bearing

capacity/kNΔmax/mm Δy/mm µ W 112.63 2.82 1.96 1.44 C2W0 124.27 2.91 1.95 1.49 C2W30 134.61 3.03 2.01 1.51 C2W60 147.25 2.97 1.88 1.58 C2W90 158.43 3.11 1.89 1.64 C4W90 161.21 3.34 1.94 1.72 Notes: Δmax—Ultimate displacement; Δy—Yield displacement; µ—Displacement ductility factor. -

[1] 谢启芳, 张保壮, 李胜英, 等. 残损木柱受力性能退化试验研究与有限元分析[J]. 建筑结构学报, 2021, 42(8): 117-125.XIE Qifang, ZHANG Baozhuang, LI Shengying, et al. Experimental study and finite element analysis on degradation of mechanical properties of damaged timber columns[J]. Journal of Building Structures, 2021, 42(8): 117-125(in Chinese). [2] 刘伟庆, 杨会峰. 现代木结构研究进展[J]. 建筑结构学报, 2019, 40(2): 16-43.LIU Weiqing, YANG Huifeng. Research progress on modern timber structures[J]. Journal of Building Structures, 2019, 40(2): 16-43(in Chinese). [3] 陈成, 程瑞香. 速生杨木改性研究进展[J]. 森林工程, 2014, 30(5): 27-29. doi: 10.3969/j.issn.1001-005X.2014.05.006CHEN Cheng, CHEN Ruixiang. Research progress in modified fast growing poplar wood[J]. Forest Engineering, 2014, 30(5): 27-29(in Chinese). doi: 10.3969/j.issn.1001-005X.2014.05.006 [4] 龚迎春, 蔡芸, 任海青. 我国木结构产业发展机遇与挑战[J]. 林产工业, 2016, 43(7): 6-10. doi: 10.3969/j.issn.1001-5299.2016.07.002GONG Yingchun, CAI Yun, REN Haiqing. Opportunity and challenge of wood structure development in China[J]. China Forest Puroducts Industry, 2016, 43(7): 6-10(in Chinese). doi: 10.3969/j.issn.1001-5299.2016.07.002 [5] Miao K T, Wei Y, Zhang S C, et al. Eccentric compression behavior of concrete-filled steel tube columns strengthened by CFRP/steel strip[J]. Engineering Structures, 2023, 287: 116191. doi: 10.1016/j.engstruct.2023.116191 [6] Wang G F, Wei Y, Shen C, et al. Compression performance of FRP-steel composite tube-confined ultrahigh-performance concrete (UHPC) columns[J]. Thin-Walled Structures, 2023, 192: 111152. doi: 10.1016/j.tws.2023.111152 [7] Wei Y, Chen S, Tang S F, et al. Mechanical Response of Timber Beams Strengthened with Variable Amounts of CFRP and Bamboo Scrimber Layers[J]. Journal of Composites for Construction, 2022, 26(4): 04022038. doi: 10.1061/(ASCE)CC.1943-5614.0001228 [8] 陈爱军, 贺国京, 蔡郭圣, 等. BFRP筋增强胶合木梁受力性能分析[J]. 中南林业科技大学学报, 2019, 39(3): 107-113.CHEN Aijun, HE Guojing, CAI Guosheng, et al. Experimental study on mechanical behaviour of glulam timber beams reinforced with BFRP[J]. Journal of Central South University of Forestry & Technology, 2019, 39(3): 107-113(in Chinese). [9] Zhou A, Qin R Y, Cheuk L C, et al. Bond integrity of aramid, basalt and carbon fiber reinforced polymer bonded wood composites at elevated temperature[J]. Composite Structures, 2020, 245: 112342. doi: 10.1016/j.compstruct.2020.112342 [10] 魏洋, 严少聪, 陈思, 等. FRP增强重组竹梁受弯性能数值模拟[J]. 复合材料学报, 2019, 36(4): 1036-1044.WEI Yang, YAN Shaocong, CHEN Si, et al. Numerical simulation of flexural properties of FRP reinforced recombinant bamboo beams[J]. Acta Materiae Compositae Sinica, 2019, 36(4): 1036-1044(in Chinese). [11] Cui W Q, Fernando D, Heitzmann M, et al. Manufacture and structural performance of modular hybrid FRP timber thin-walled columns[J]. Composite Structures, 2021, 260: 113506. doi: 10.1016/j.compstruct.2020.113506 [12] 左宏亮, 李昂, 贾茗睿. 外贴CFRP板对胶合木柱轴压性能的影响[J]. 森林工程, 2023, 39(3): 191-198. doi: 10.3969/j.issn.1006-8023.2023.03.022ZUO Hongliang, LI Ang, JIA Mingrui. Effect of CFRP board on axial compression performance reinforced glulam column[J]. Forest Engineering, 2023, 39(3): 191-198(in Chinese). doi: 10.3969/j.issn.1006-8023.2023.03.022 [13] 阿斯哈, 周长东, 杨礼赣. 复合加固木柱轴压特性试验研究[J]. 土木工程学报, 2021, 54(2): 1-9.A Siha, ZHOU Changdong, YANG Ligan. Experimental investigation on axial compression behavior of timber columns strengthened with composite reinforcement method[J]. China Civil Engineering Journal, 2021, 54(2): 1-9(in Chinese). [14] 徐杰, 姜绍飞. 纤维布加固墩接木柱轴压试验[J]. 哈尔滨工业大学学报, 2024, 56(2): 77-85.XU Jie, JIANG Shaofei. Experimental study on axial compression characteristics of spliced wood columns strengthened with FRP sheets[J]. Journal of Harbin Institute of Technology, 2024, 56(2): 77-85(in Chinese). [15] Vahedian A, Shrestha R, Crews K. Bond strength model for externally bonded FRP-to-timber interface[J]. Composite Structures, 2018, 200: 328. doi: 10.1016/j.compstruct.2018.05.152 [16] Biscaia H C, Cruz D, Chastre C. Analysis of the debonding process of CFRP-to-timber interfaces[J]. Construction and Building Materials, 2016, 113: 96. doi: 10.1016/j.conbuildmat.2016.03.033 [17] Vahedian A, Shrestha R, Crews K. Effective bond length and bond behaviour of FRP externally bonded to timber[J]. Construction and Building Materials, 2017, 151: 742. doi: 10.1016/j.conbuildmat.2017.06.149 [18] Raftery G M, Harte A M, Rodd P D. Bonding of FRP materials to wood using thin epoxy gluelines[J]. International Journal of Adhesion and Adhesives, 2009, 29(5): 580. doi: 10.1016/j.ijadhadh.2009.01.004 [19] Zhou A, Tam L H, Yu Z C, et al. Effect of moisture on the mechanical properties of CFRP-wood composite: An experimental and atomistic investigation[J]. COMPOS PART B-ENG, 2015, 2015,71: 63-73. [20] Niknejad A, Moradi A, Beheshti N. Indentation experiments on novel sandwich composite tubes[J]. Materials Letters, 2016, 179: 142-145. doi: 10.1016/j.matlet.2016.05.041 [21] Li H T, Li X L, Fu J H, et al. Experimental study on compressive behavior and failure characteristics of imitation steel fiber concrete under uniaxial load[J]. Construction and Building Materials, 2023, 399: 132599. doi: 10.1016/j.conbuildmat.2023.132599 [22] Li Z Q, Dong J, Chen H Y, et al. Mechanical behaviour and acoustic emission characteristics of basalt fibre mortar rubble under uniaxial cyclic compression[J]. Construction and Building Materials, 2023, 393: 132145. doi: 10.1016/j.conbuildmat.2023.132145 [23] Liu Z X, Han Z J, Qin L, et al. Identification of bending fracture characteristics of cement-stabilized coral aggregate in four-point bending tests based on acoustic emission[J]. Construction and Building Materials, 2023, 402: 132999. doi: 10.1016/j.conbuildmat.2023.132999 [24] Gao D Y, Ji D D, Gu Z Q, et al. Workability and mechanical properties analysis of hybrid fibers reinforced self-compacting concrete incorporating recycled aggregates based on acoustic emission technique[J]. Structures, 2023, 51: 1722-1741. doi: 10.1016/j.istruc.2023.03.139 [25] Ma G, Li H. Acoustic emission monitoring and damage assessment of FRP-strengthened reinforced concrete columns under cyclic loading[J]. Construction and Building Materials, 2017, 144: 86-98. doi: 10.1016/j.conbuildmat.2017.03.169 [26] Jiang X, Jiang D Y, Chen J, et al. Collapsing minerals: Crackling noise of sandstone and coal, and the predictability of mining accidents[J]. American Mineralogist, 2016, 101(12): 2751-2758. doi: 10.2138/am-2016-5809CCBY [27] Jiang X, Liu H, Main I G, et al. Predicting mining collapse: Superjerks and the appearance of record-breaking events in coal as collapse precursors[J]. Physical Review E, 2017, 96(2): 023004. doi: 10.1103/PhysRevE.96.023004 [28] 李猛, 佘艳华, 贺才豪, 等. 不同温度下的柏木构件顺纹压缩损伤规律研究[J]. 西南林业大学学报(自然科学), 2023, 43(5): 153-163.LI Meng, SHE Yanhua, HE Caihao, et al. Experimental study on compression damage law of cypress under different temperatures[J]. Journal of Southwest Forestry University (Natural science), 2023, 43(5): 153-163(in Chinese). [29] 李猛, 陈迪, 田康, 等. 不同含水率下木构件起裂荷载试验研究[J]. 森林工程, 2022, 38(4): 69-81. doi: 10.3969/j.issn.1006-8023.2022.04.009LI Meng, CHEN Di, TIAN Kang, et al. Experimental study on cracking load of wood members under different moisture content[J]. Forest Engineering, 2022, 38(4): 69-81(in Chinese). doi: 10.3969/j.issn.1006-8023.2022.04.009 [30] Guo Y, Zhu S L, Chen Y X, et al. Acoustic emission-based study to characterize the crack initiation point of wood fiber/HDPE composites[J]. Polymers, 2019, 11(4): 701. doi: 10.3390/polym11040701 [31] 中华人民共和国住房和城乡建设部. 木结构试验方法标准: GB/T 50329-2012 [S]. 北京: 建筑工业出版社, 2012.Ministry of Housing and Urban Rural Development of the People's Republic of China. Standard for Test Methods for Wood Structures: GB/T 50329-2012 [S]. Beijing: Building Industry Press, 2012(in Chinese). [32] 国家市场监督管理总局, 国家标准化管理委员会. 无疵小试样木材物理力学性质试验方法第9部分: 抗弯强度测定: GB/T 1927.9-2021 [S]. 北京: 中国标准出版社, 2021.State Administration for Market Regulation, National Standardization Administration. Test methods for physical and mechanical properties of flawless small specimens of wood-Part 9: Determination of flexural strength: GB/T 1927.9-2021 [S]. Beijing: China Standards Press, 2021(in Chinese). [33] 国家市场监督管理总局, 国家标准化管理委员会. 无疵小试样木材物理力学性质试验方法第11部分: 顺纹抗压强度测定: GB/T 1927.11-2022 [S]. 北京: 中国标准出版社, 2022.State Administration for Market Regulation, National Standardization Administration. Test methods for physical and mechanical properties of flawless small specimens of wood-Part 11: Determination of compressive strength along the grain: GB/T 1927.11-2022 [S]. Beijing: China Standards Press, 2022(in Chinese). [34] 国家市场监督管理总局, 国家标准化管理委员会. 无疵小试样木材物理力学性质试验方法第14部分: 顺纹抗拉强度测定: GB/T 1927.14-2022 [S]. 北京: 中国标准出版社, 2022.State Administration for Market Regulation, National Standardization Administration. Test methods for physical and mechanical properties of flawless small specimens of wood-Part 14: Determination of tensile strength along grain: GB/T 1927.14-2022 [S]. Beijing: China Standards Press, 2022(in Chinese). [35] 国家市场监督管理总局, 国家标准化管理委员会. 无疵小试样木材物理力学性质试验方法第16部分: 顺纹抗剪强度测定: GB/T 1927.16-2022 [S]. 北京: 中国标准出版社, 2022.State Administration for Market Regulation, National Standardization Administration Test methods for physical and mechanical properties of flawless small specimens of wood-Part 16: Determination of shear strength along the grain: GB/T 1927.16-2022 [S]. Beijing: China Standards Press, 2022(in Chinese). [36] 国家市场监督管理总局, 国家标准化管理委员会. 树脂浇铸体性能试验方法: GB/T 2567-2021 [S]. 北京: 中国标准出版社, 2022.State Administration for Market Regulation, National Standardization Administration. Test methods for properties of resin casting body: GB/T 2567-2021 [S]. Beijing: China Standards Press, 2022(in Chinese). [37] 骆雪, 赵栋梁, 薛振华, 等. 含水率对樟子松细胞壁弹性模量和硬度的影响规律[J]. 西北林学院学报, 2022, 37(5): 218-222.LUO Xue, ZHAO Dongliang, XUE Zhenhua, et al. Influence law of moisture content on elastic modulus and hardness of Pinus sylvestris var. mongolica cell wall[J]. Journal of Northwest Forestry University, 2022, 37(5): 218-222(in Chinese). [38] 何清慧. 木材干燥基准简易确定法-百度试验法[J]. 木材工业, 1998, (06): 38-40.HE Qinghui. Simple determination method for wood drying benchmark-100℃ test method[J]. Wood Industry, 1998, (06): 38(in Chinese). [39] Liang Q Q, Uy B, Liew J Y R. Nonlinear analysis of concrete-filled thin-walled steel box columns with local buckling effects[J]. Journal of Constructional Steel Research, 2006, 62(6): 581-591. doi: 10.1016/j.jcsr.2005.09.007 [40] Furtos G, Silaghi-Dumitrescu L, Pascuta P, et al. Mechanical properties of wood fiber reinforced geopolymer composites with sand addition[J]. Journal of Natural Fibers, 2021, 18(2): 285-296. doi: 10.1080/15440478.2019.1621792 [41] 万志敏, 桂良进, 谢志民, 等. 玻璃-环氧圆柱壳吸能特性的试验研究[J]. 复合材料学报, 1999, (2): 16-21. doi: 10.3321/j.issn:1000-3851.1999.02.004WAN Zhimin, GUI Liangjin, XIE Zhimin, et al. Experimental study on energy absorption characteristics of glass-epoxy cylindrical shells[J]. Acta Materiae Compositae Sinica, 1999, (2): 16-21(in Chinese). doi: 10.3321/j.issn:1000-3851.1999.02.004 [42] Farhidzadeh A, Mpalaskas A C, Matikas T E, et al. Fracture mode identification in cementitious materials using supervised pattern recognition of acoustic emission features[J]. Construction and building materials, 2014, 67: 129-138. doi: 10.1016/j.conbuildmat.2014.05.015 [43] Wildemann V E, Spaskova E V, Shilova A I. Research of the damage and failure processes of composite materials based on acoustic emission monitoring and method of digital image correlation[J]. Solid State Phenomena, 2016, 243: 163-170. [44] Gutenberg B, Richter C F. Frequency of earthquakes in California[J]. Bulletin of the Seismological society of America, 1944, 34(4): 185-188. doi: 10.1785/BSSA0340040185 [45] 王创业, 常新科, 杜晓娅. 不同尺寸砂岩破坏全过程声发射主频分析[J]. 矿冶工程, 2019, 39(6): 10-14. doi: 10.3969/j.issn.0253-6099.2019.06.003WANG Chuangye, CHANG Xinke, DU Xiaoya. Analysis of dominant frequency of acoustic emission through the whole failure process of different size of sandstone[J]. Mining and Metallurgical Engineering, 2019, 39(6): 10-14(in Chinese). doi: 10.3969/j.issn.0253-6099.2019.06.003 [46] 吴晓娲, 秦四清, 薛雷, 等. 基于震例探讨大地震的物理机制[J]. 地球物理学报, 2016, 59(10): 3696-3710. doi: 10.6038/cjg20161016WU Xiaowa, QIN Siqing, XUE Lei, et al. Physical mechanism of major erthquakes by erthquake cases[J]. Chinese Journal of Geophysics, 2016, 59(10): 3696-3710(in Chinese). doi: 10.6038/cjg20161016 [47] Girard L, Amitrano D, Weiss J. Failure as a critical phenomenon in a progressive damage model[J]. Journal of Statistical Mechanics:Theory and Experiment, 2010, 2010(1): P01013. [48] Clauset A, Shalizi C R, Newman M E J. Power-law distributions in empirical data[J]. SIAM review, 2009, 51(4): 661-703. doi: 10.1137/070710111 [49] Salje E K H, Planes A, Vives E. Analysis of crackling noise using the maximum-likelihood method: Power-law mixing and exponential damping[J]. Physical Review E, 2017, 96(4): 042122. doi: 10.1103/PhysRevE.96.042122 [50] 王磊, 蒋翔, 肖杨, 等. 钙质砂颗粒的尺寸效应及雪崩动力学特性试验研究[J]. 岩土工程学报, 2021, 43(6): 1029-1038. doi: 10.11779/CJGE202106006WANG Lei, JIANG Xiang, XIAO Yang, et al. Experimental research on the size effect and avalanche dynamics characteristics of calcareous sand particles[J]. Chinese Journal of Geotechnical Engineering, 2021, 43(6): 1029-1038(in Chinese). doi: 10.11779/CJGE202106006 [51] 何佳明, 佘艳华, 李猛. 不同含水率雪松木材损伤声发射参数特性[J]. 东北林业大学学报, 2024, 52(2): 91-96.HE Jiaming, SHE Yanhua, LI Meng. Characteristics of acoustic emission parameters of cedar wood damage with different moisture contents[J]. Journal of Northeast Foresrty University, 2024, 52(2): 91-96(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 157

- HTML全文浏览量: 79

- 被引次数: 0

下载:

下载: