Effect of mineral microcapsules on self-healing properties of cement mortar

-

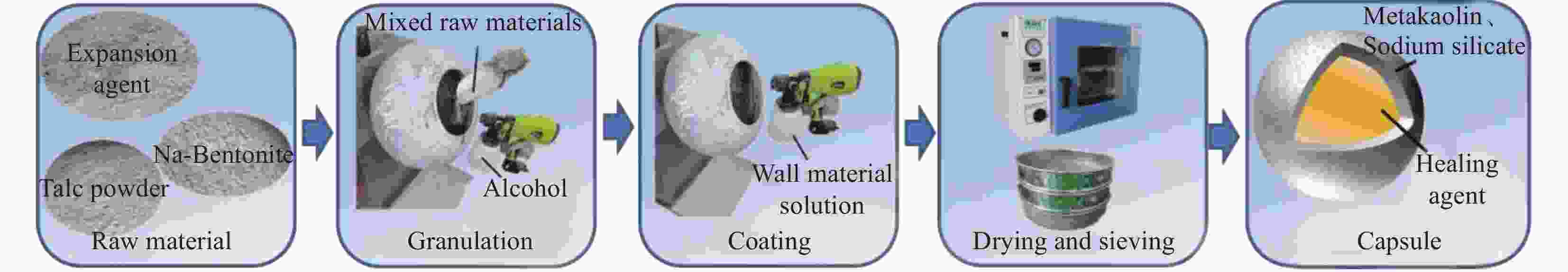

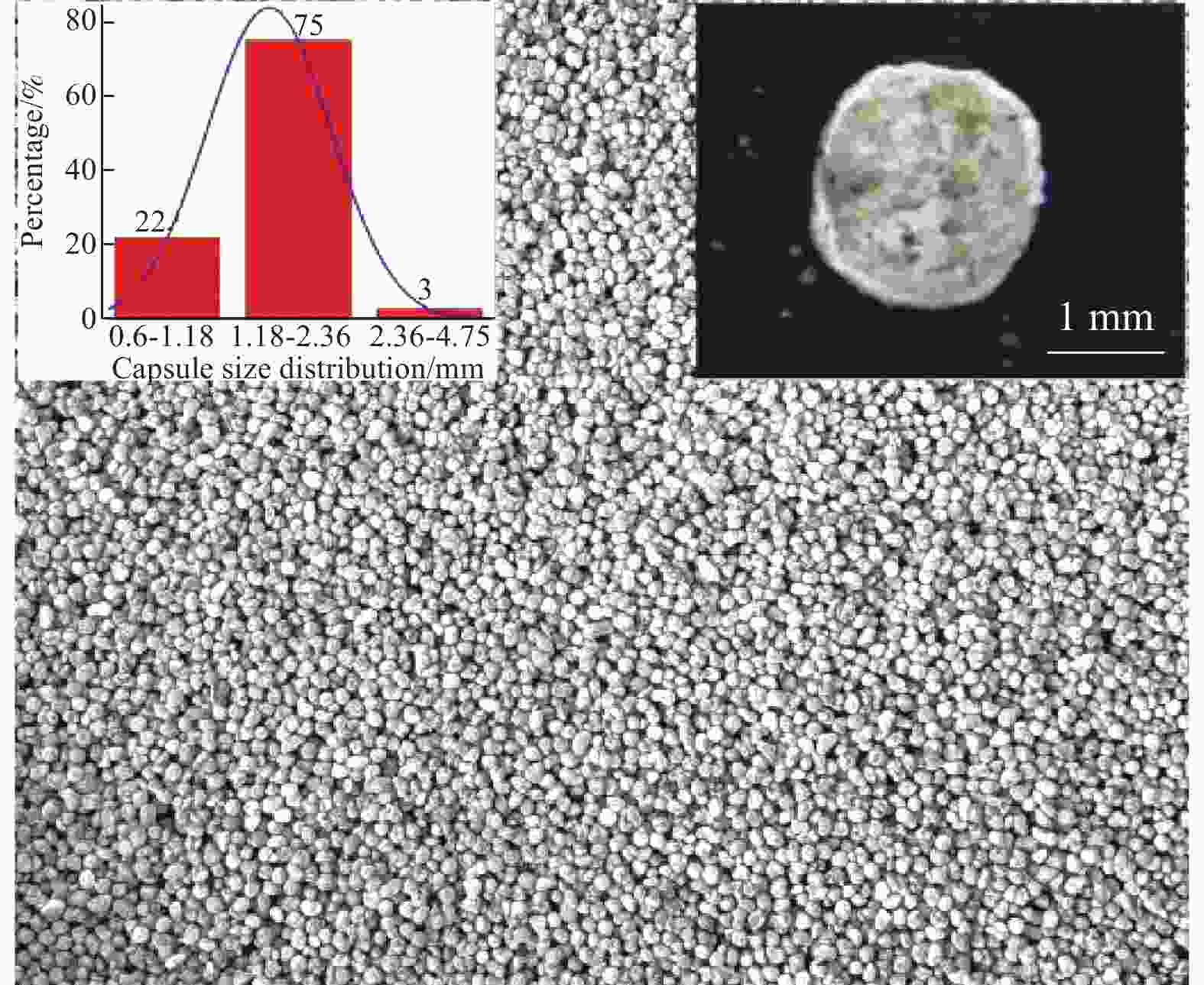

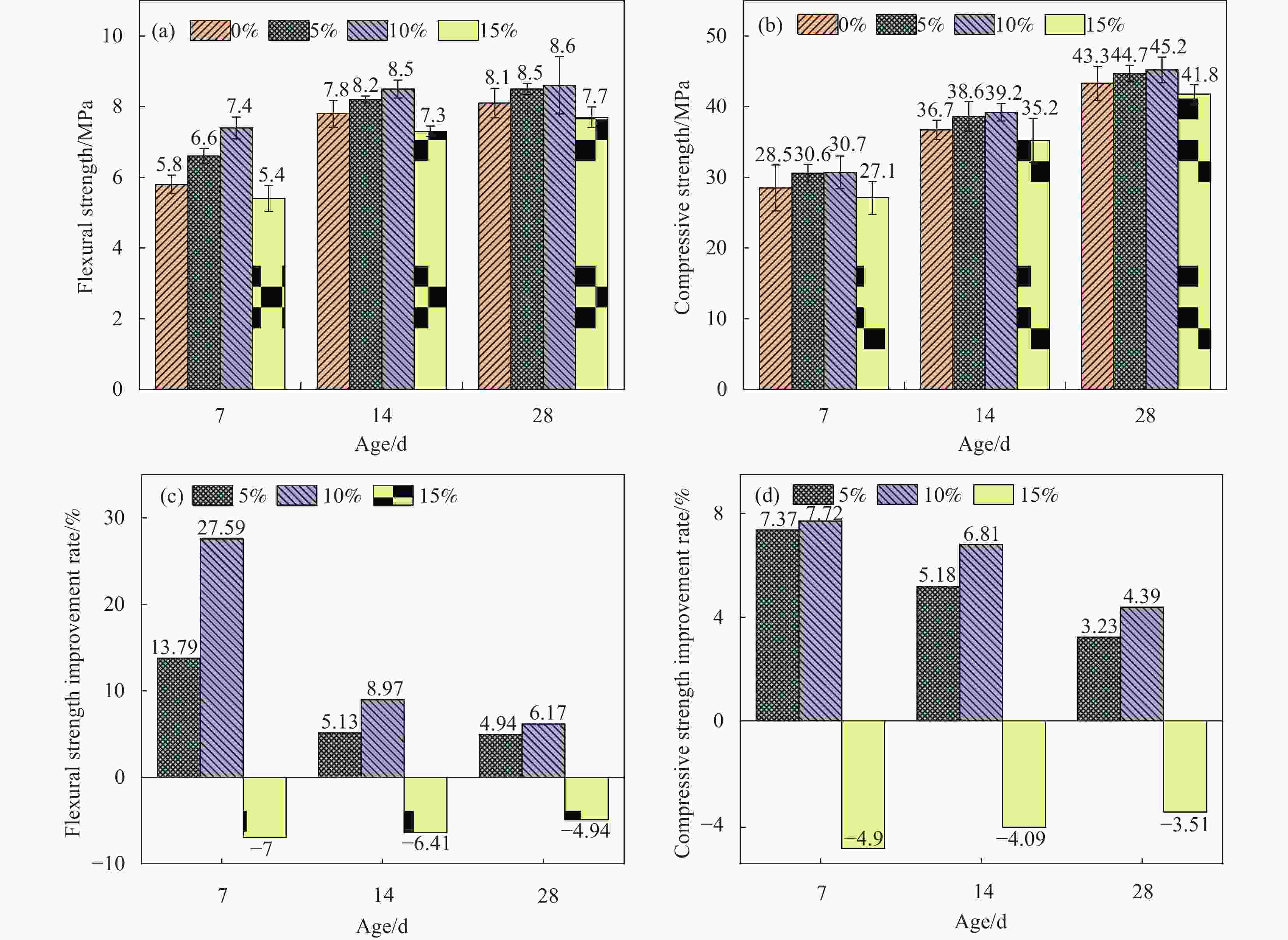

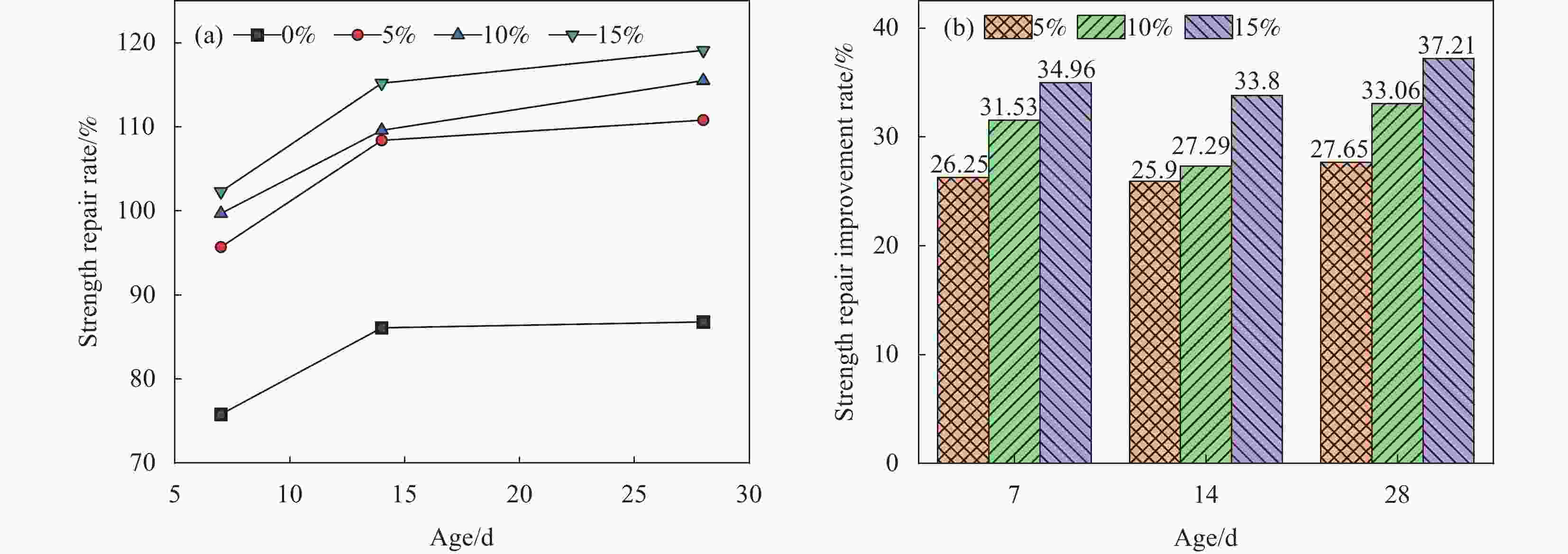

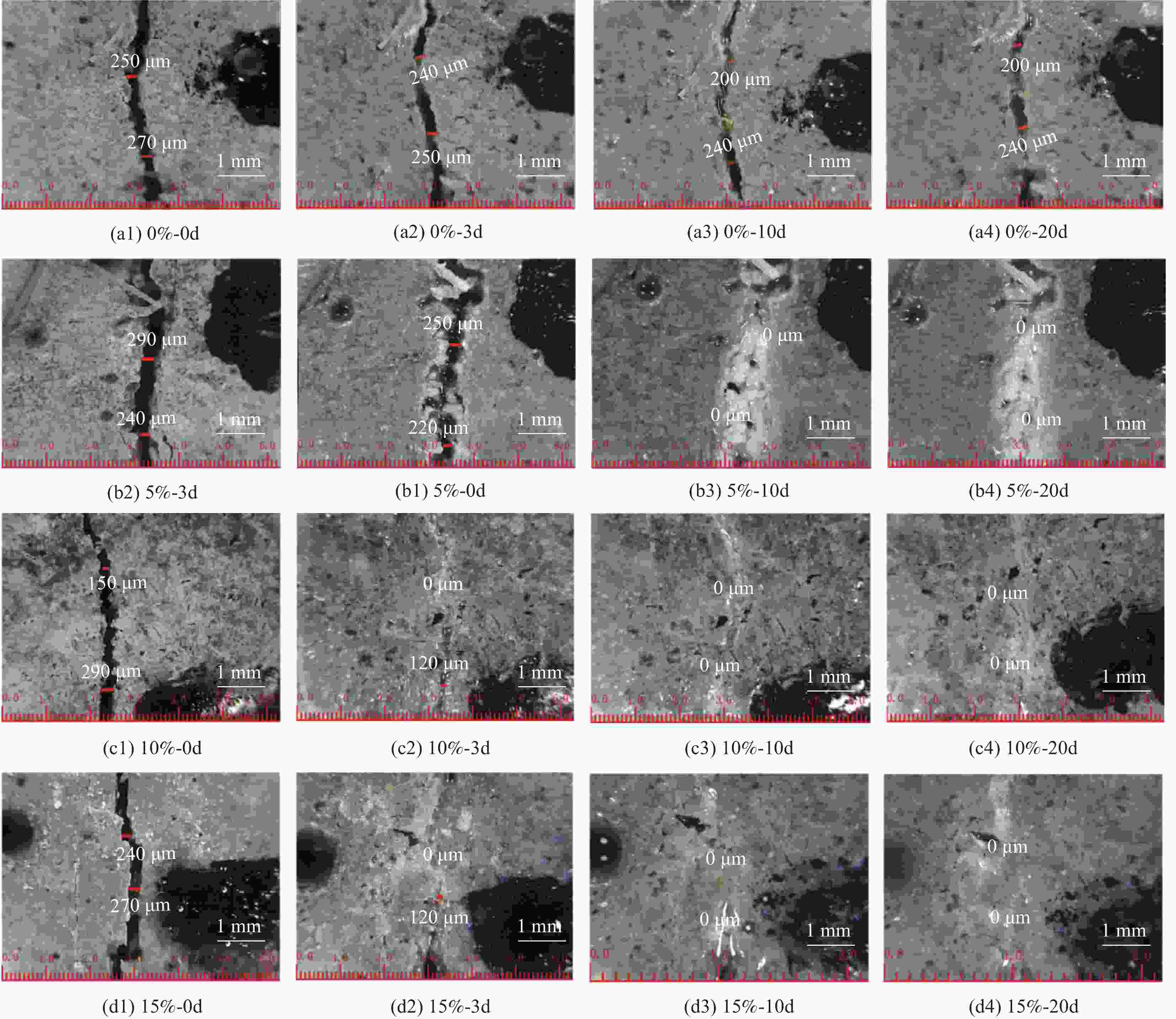

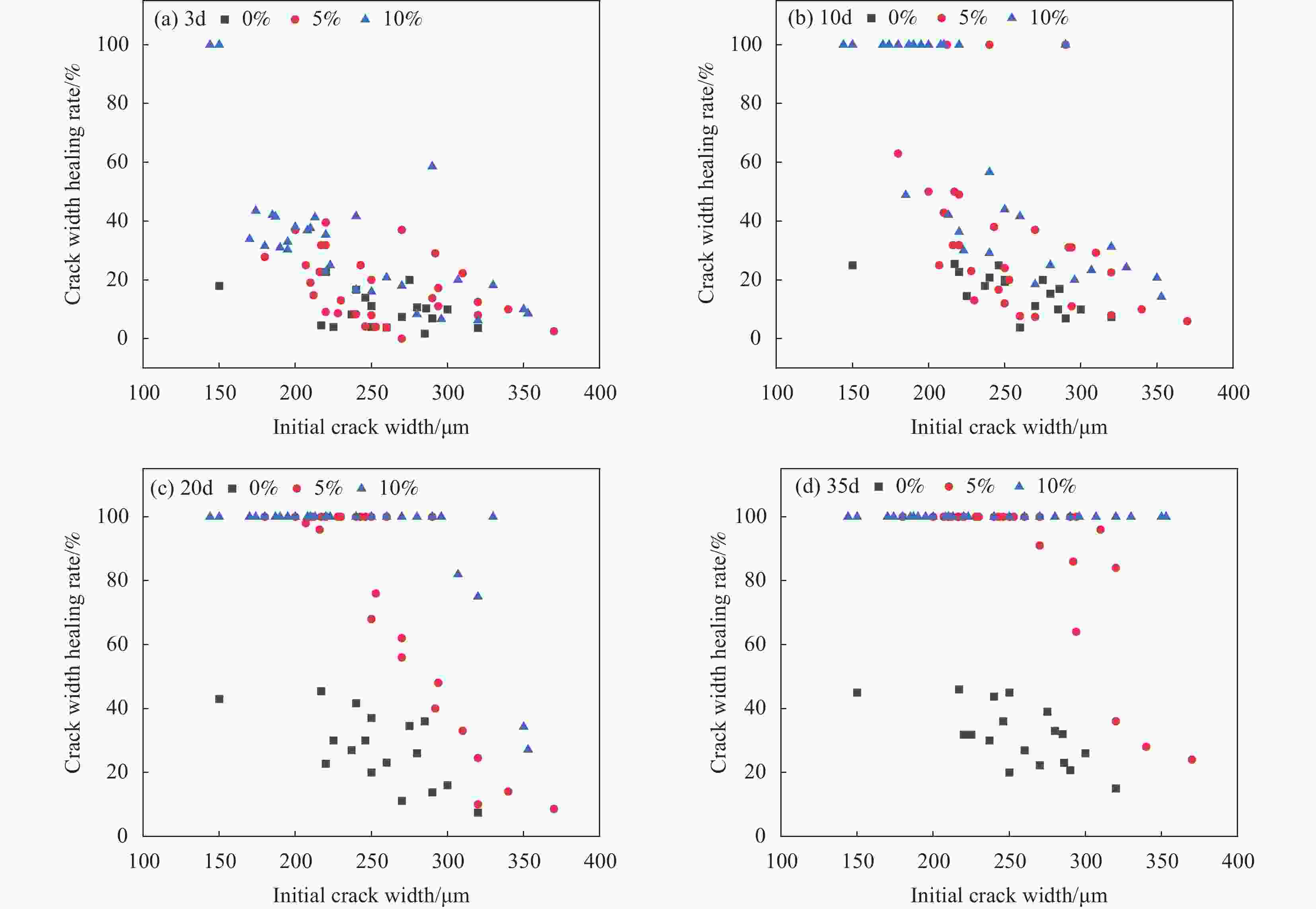

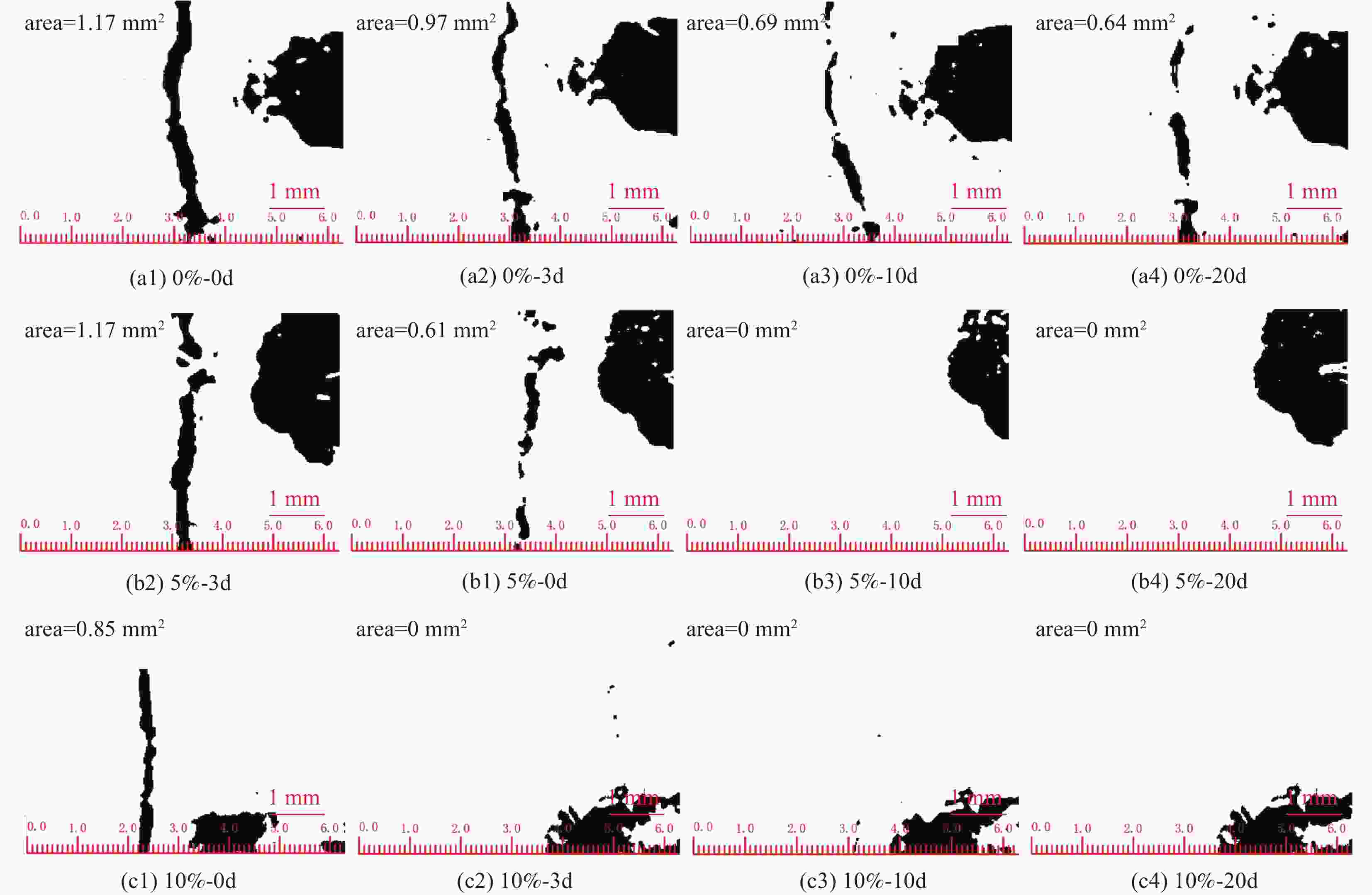

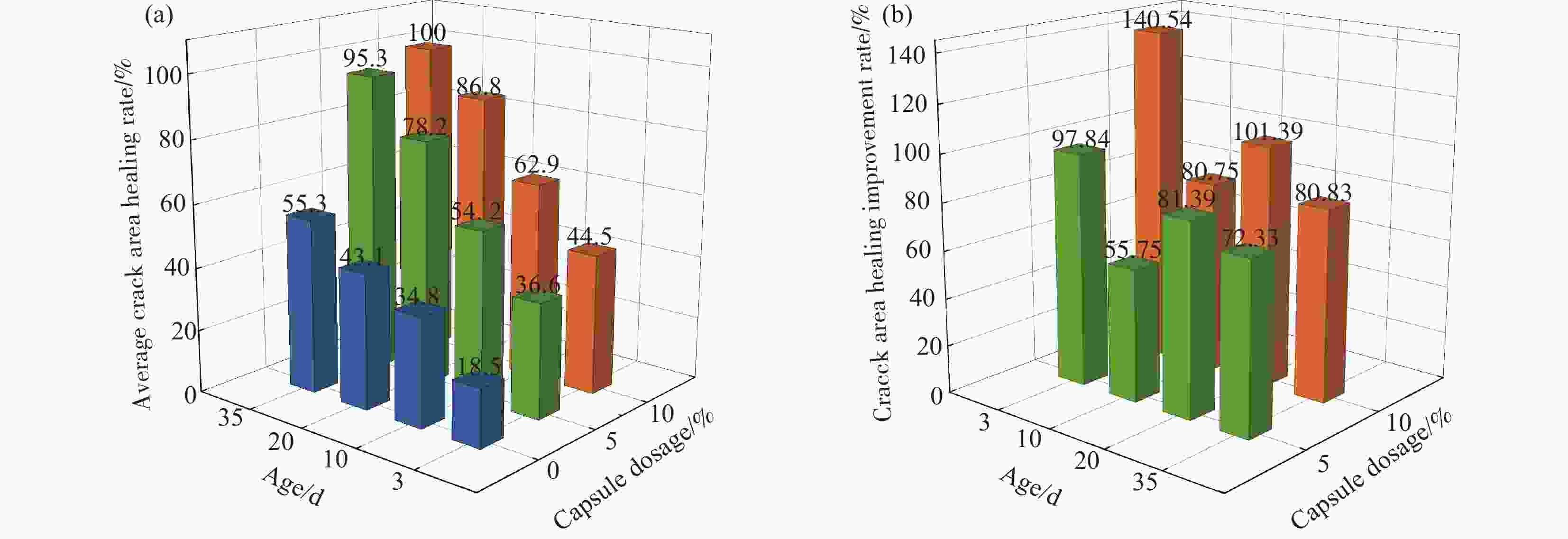

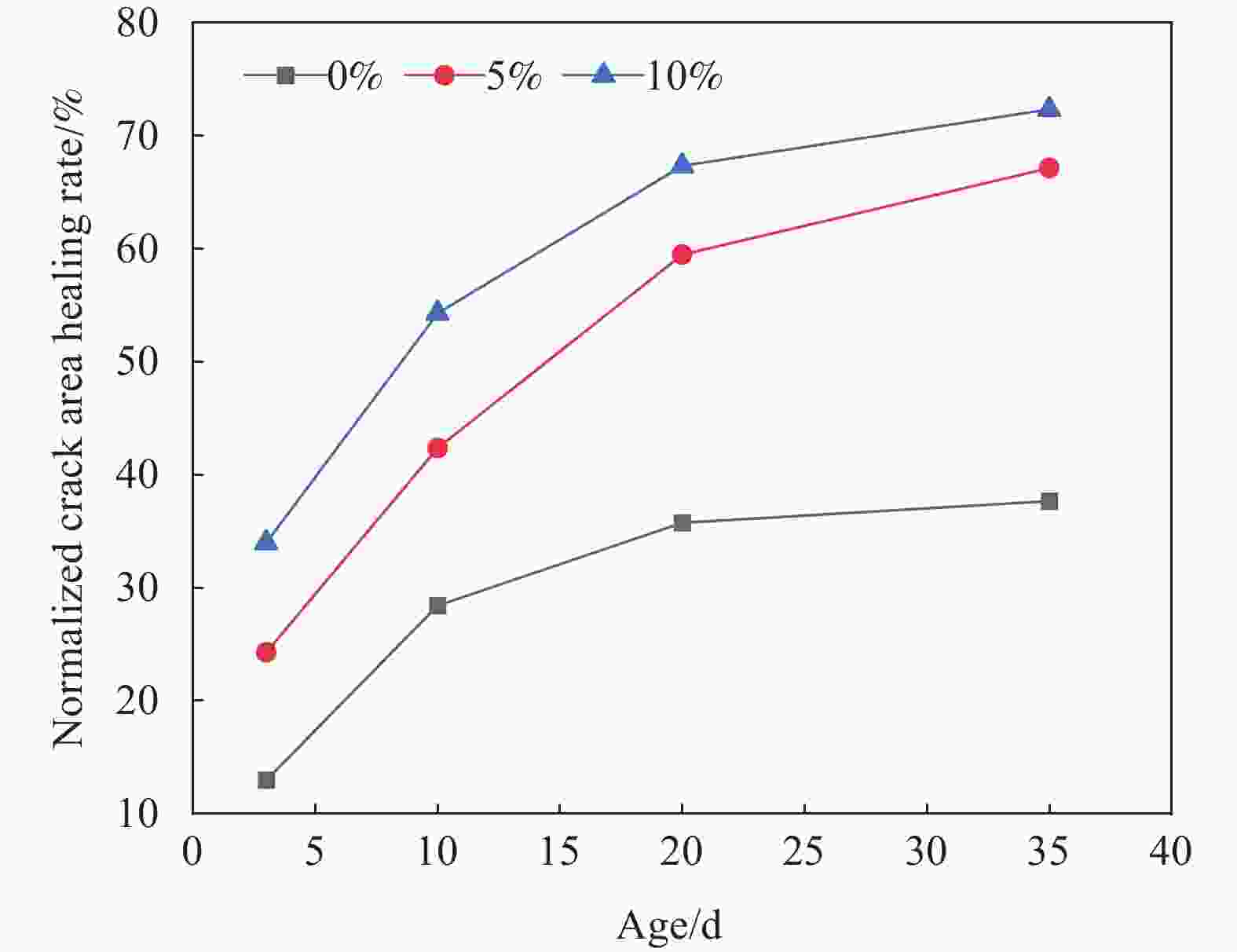

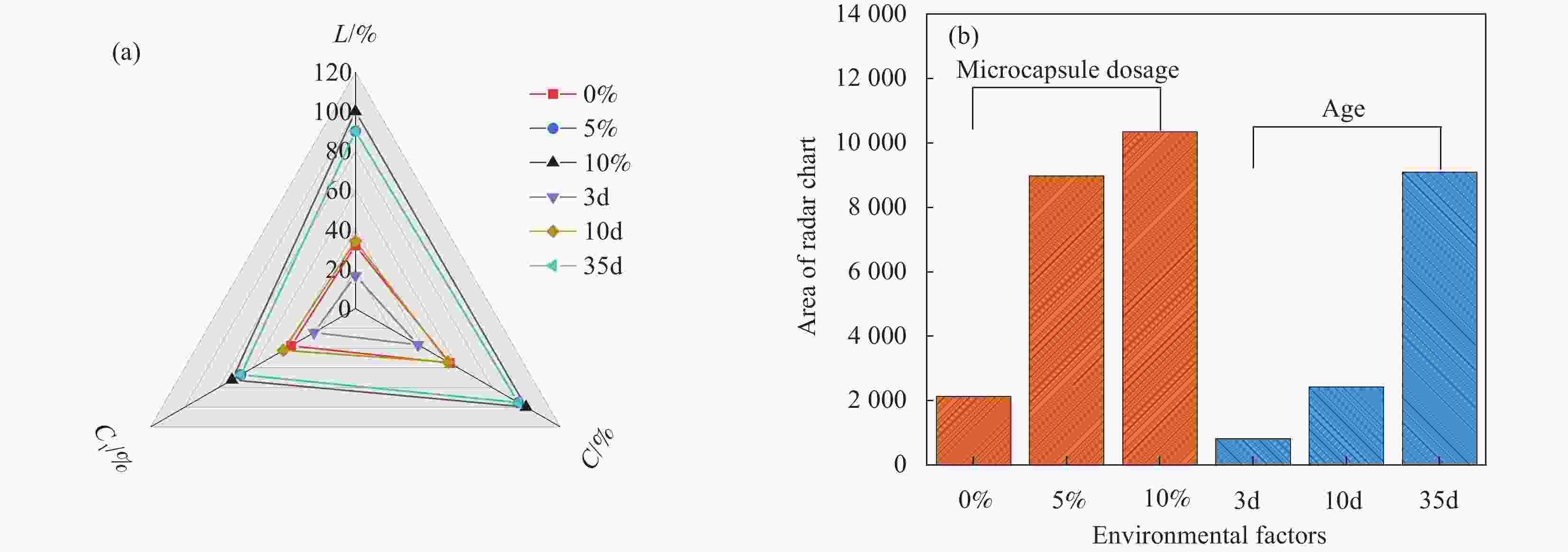

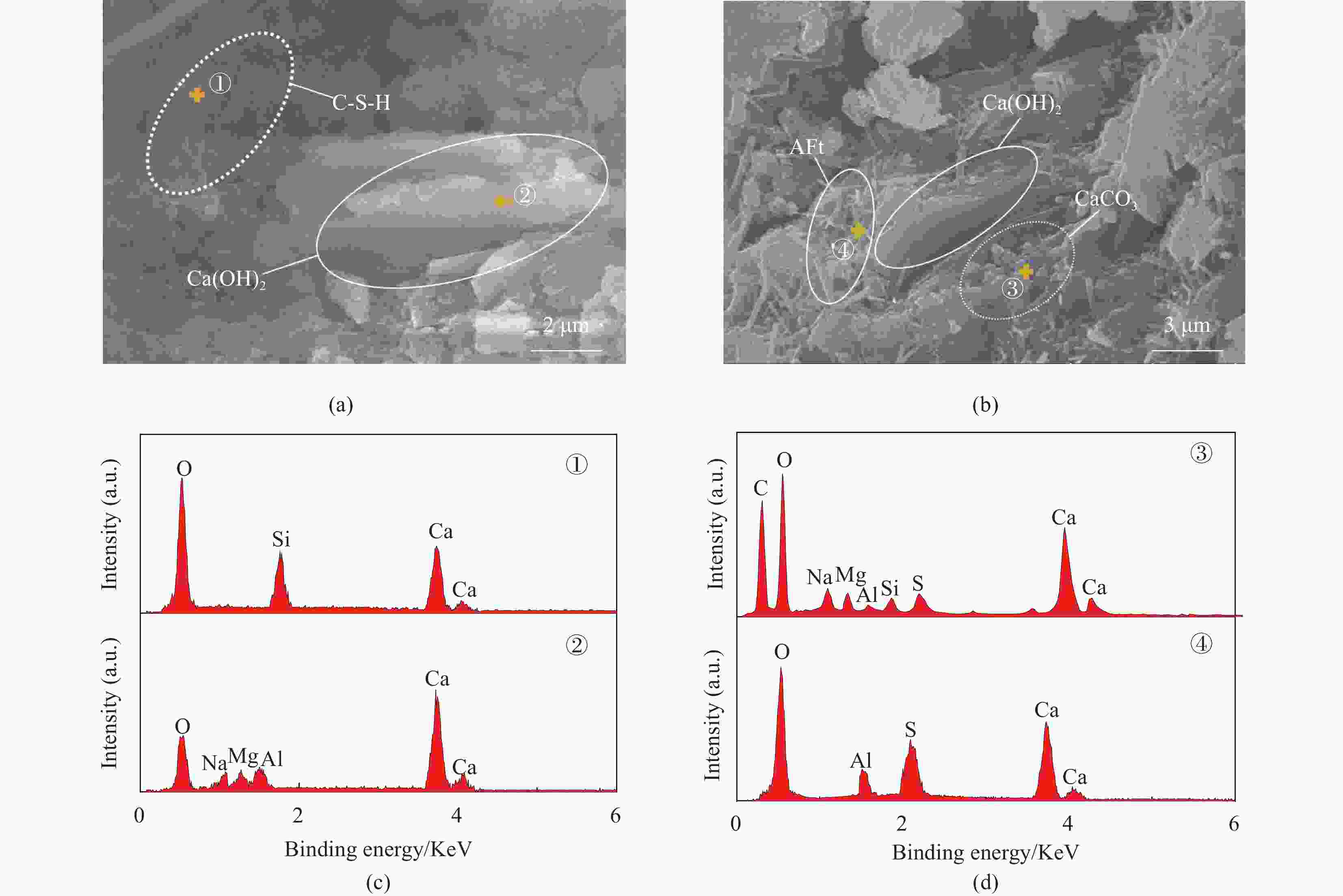

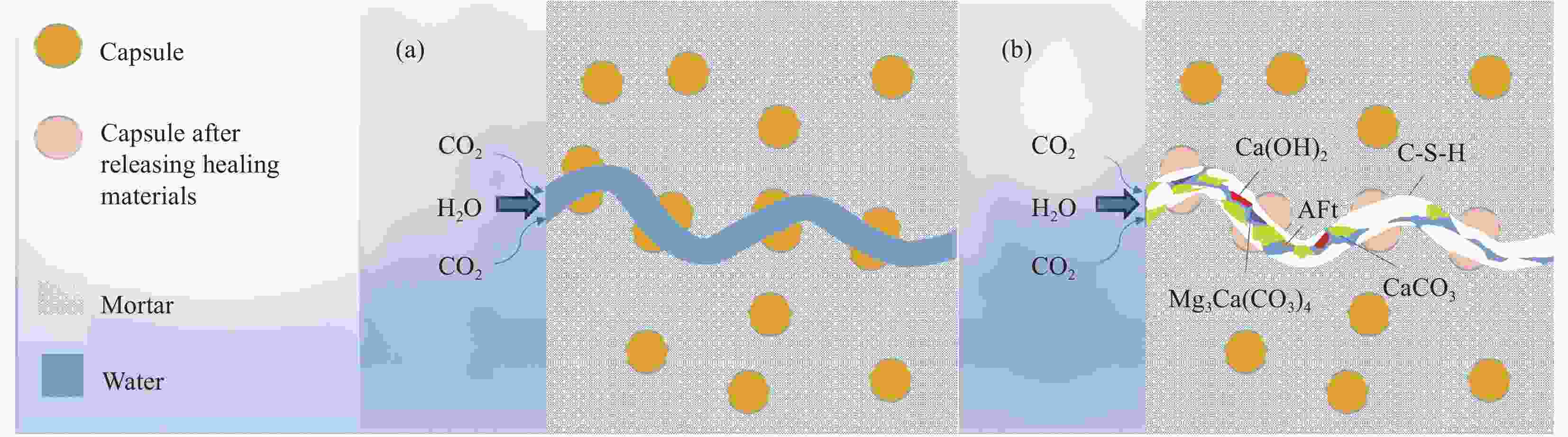

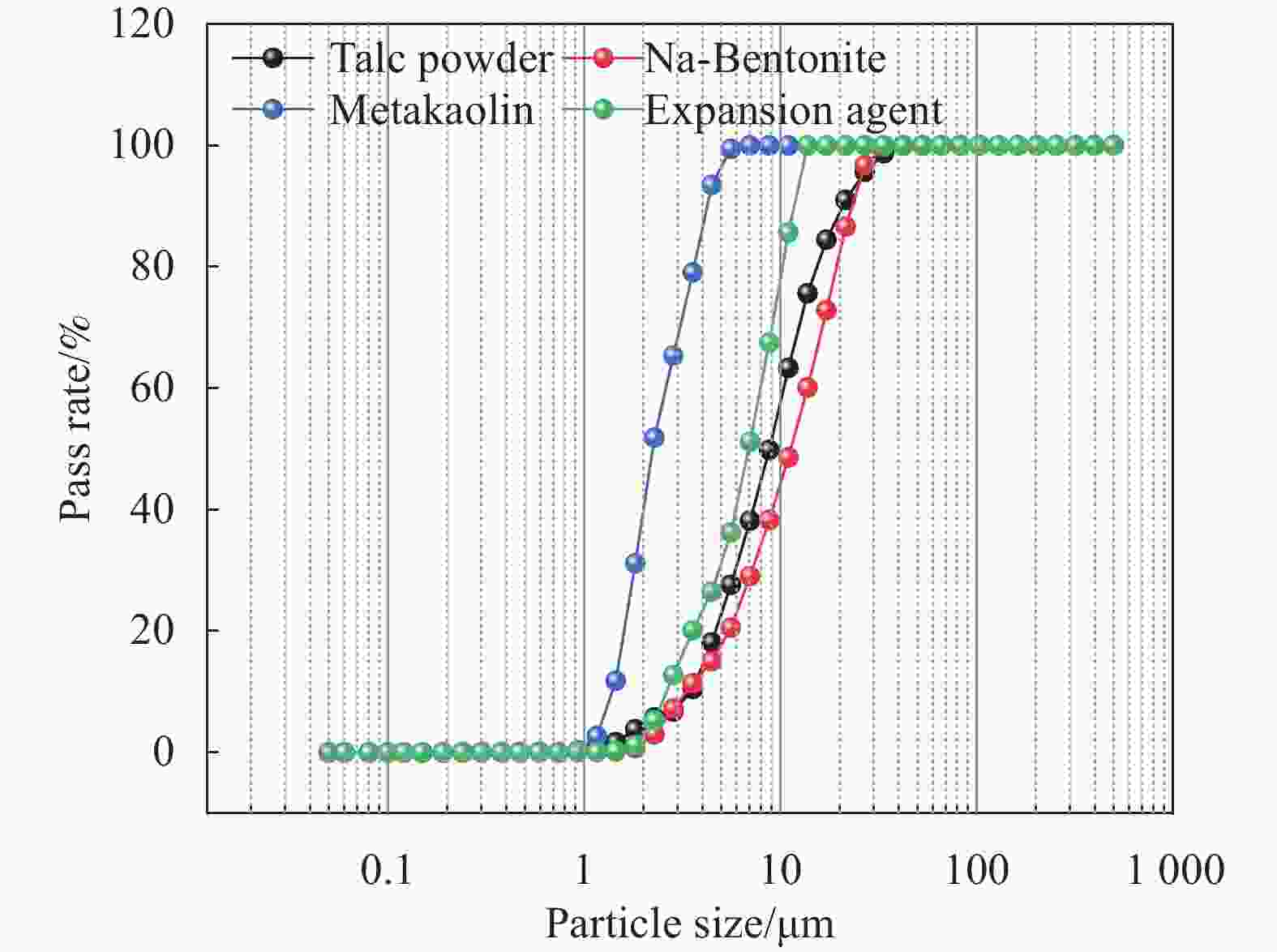

摘要: 水泥基复合材料受多种物化因素的影响易开裂,从而影响其耐久性能。提升水泥基复合材料的裂缝自修复性能,是提高其耐久性和降低整个生命周期维护成本的关键。因此,基于结晶膨胀、储水释水、助剂补强三种功能特性,本文以复合膨胀剂、Na-膨润土和滑石粉三种矿物为芯材,碱激发材料(水玻璃激发偏高岭土)为壁材,研发了一种集修复补强一体的全无机微胶囊型水泥基裂缝自修复材料。基于本征力学性能研究,以强度恢复率、裂缝宽度愈合率、裂缝面积修复率为评价指标,探究了微胶囊对水泥砂浆试件裂缝自修复效果的影响规律,通过微观测试分析了修复机理。结果表明,随着微胶囊掺量的增加,砂浆强度呈现先增加后减小的趋势;当其掺量为10%时,砂浆28d抗折和抗压强度最高,较空白组分别提高了6.17%和4.39%。同掺量下,二次养护28d强度恢复率达到了115.5%,35d时30条裂缝的平均面积修复率和归一化裂缝面积修复率分别为100%和72.3%,远高于空白组的55.3%和37.7%。XRD和SEM分析表明,二次养护条件下裂缝处生成了大量的Ca(OH)2、AFt、CaCO3、Mg3Ca(CO3)4以及C-S-H凝胶等微膨胀、高强、胶凝性好的水化产物,从而实现快速填充、修复裂缝和补强。Abstract: Cement-based composites are prone to cracking under the influence of many physical and chemical factors, which affects their durability. Improving the crack self-healing performance of cement-based composites is the key to improve their durability and reduce the maintenance cost throughout their life cycle. Therefore, based on the three functional characteristics of crystal expansion, water storage and release, and auxiliary reinforcement, this paper developed an all-inorganic microcapsule cement-based crack self-healing material integrating repair and reinforcement, with three minerals, namely composite expansion agent, Na-bentonite and talc powder, as the core material, and alkali exciting material (water glass stimulated metakaolin) as the wall material. Based on the study of intrinsic mechanical properties, with strength recovery rate, crack width healing rate and crack area healing rate as evaluation indexes, the influence of microcapsule on the crack self-healing effect of cement mortar specimens was explored, and the self-healing mechanisms were analyzed through microscopic testing. The results show that the strength of mortar increases first and then decreases with the increase of microcapsule content. When the dosage is 10%, the 28d flexural and compressive strengths of mortar are the highest, which are 6.17% and 4.39% higher than that of blank group, respectively. With the same dosage, the strength recovery rate reaches 115.5% after secondary cured in water for 28 days, and both the average and normalized crack area healing rates are 100% and 72.3%, respectively, at 35d, which are much higher than 55.3% and 37.7% of the blank group. The XRD and SEM analysis show that under the condition of secondary curing, a large number of hydration products such as Ca(OH)2, AFt, CaCO3, Mg3Ca(CO3)4 and C-S-H gel with micro-expansion, high strength and good cementitious properties are generated at the crack, so as to realize rapid filling, repairing and reinforcing of cracks.

-

图 15 微胶囊掺量10%的胶砂试件裂缝处生成物的SEM图像和EDS图谱

(图(a) ①、②的EDS对应图(c) ①、②,图(b) ③、④的EDS图对应图(d) ③、④)

Figure 15. SEM photos and EDS spectrum of the product at the crack of the mortar sample with 10% microcapsule content

(The EDS in Figure (a) ① and ② correspond to the EDS in Figure (c) ① and ②, and the EDS in Figure (b) ③、④ correspond to the EDS in Figure (d) ③、④)

表 1 各原材料的化学组成(wt%)

Table 1. Chemical composition of each raw material (wt%)

Material CaO SiO2 Al2O3 Fe2O3 MgO SO3 K2O Na2O TiO2 Loss Cement 61.56 20.56 5.65 3.45 2.36 2.26 0.75 0.18 — 2.22 Metakaolin 0.38 55.50 40.90 0.56 0.21 — 0.24 0.35 1.34 — Compound expansion agent 69.90 2.74 1.62 0.68 2.63 21.60 0.33 0.11 0.12 — Talc powder 3.60 42.30 — 0.27 53.60 — — — — — Na-Bentonite 5.91 73.00 12.00 0.89 3.62 — 2.44 1.85 0.10 — 表 2 膨胀剂性能指标

Table 2. Performance index of expansion agent

Test item Standard value Test value Fineness Specific surface area/(m2·kg−1) ≥200 235 Setting time Initial setting/(hour: minute) ≥0:45 1:35 Final setting/(hour: min) ≤6:00 2:52 Limited expansion rate 7 d in water/% ≥0.035 0.156 Compressive strength 7 d/MPa ≥22.5 23.6 表 3 测试力学性能的砂浆试件原材料配比

Table 3. Raw material ratio of mortar specimens for testing mechanical properties

Microcapsule content/% Sand/g Cement/g Water/g Self-healing material/g 0 1350 450 225 0 5 1282.5 450 225 67.5 10 1215 450 225 135 15 1 012.5 450 225 202.5 表 4 需要压制裂缝的砂浆试件原材料配比

Table 4. Raw material ratio of mortar specimen to suppress cracks

Microcapsule content/% Sand/g Cement/g Water/g Self-healing material/g Polypropylene fibre/g 0 1350 450 225 0 2.25 5 1282.5 450 225 67.5 2.25 10 1215 450 225 135 2.25 15 1012.5 450 225 202.5 2.25 -

[1] QIAN C X, YU X N, ZHENG T W, et al. Review on bacteria fixing CO2 and biomineralization to enhance the performance of construction materials[J]. CO2 Util, 2022, 55: 101849. doi: 10.1016/j.jcou.2021.101849 [2] YU X N, HUI R. Seawater based MICP cements two-phase/one-phase cemented sand blocks[J]. Applied Ocean Research, 2022, 118: 102972. doi: 10.1016/j.apor.2021.102972 [3] QURESHI T, KANELLOPOULOS A, AL-TABBAA. A. Autogenous self-healing of cement with expansive minerals-I: impact in early age crack healing[J]. Construction and Building Materials, 2018, 192: 768. doi: 10.1016/j.conbuildmat.2018.10.143 [4] JIANG Z W, LI J, LI W T. Preparation and autolytic behavior of autolytic mineral microsphere for self-healing cementitious materials[J]. Cement and Concrete Composites, 2019, 103: 112. doi: 10.1016/j.cemconcomp.2019.04.004 [5] WU M Y, HU X M, ZHANG Q, et al. Application of bacterial spores coated by a green inorganic cementitious material for the self-healing of concrete cracks[J]. Cement and Concrete Composites, 2020, 113: 103718. doi: 10.1016/j.cemconcomp.2020.103718 [6] SUN D Q, LI B, YE F Y, et al. Fatigue behavior of microcapsule-induced self-healing asphalt concrete[J]. Cleaner Production, 2018, 188: 466. doi: 10.1016/j.jclepro.2018.03.281 [7] PAPANIKOLAOU I, ARENA N, AL-TABBAA A. Graphene nanoplatelet reinforced concrete for self-sensing structures-a lifecycle assessment perspective[J]. Cleaner Production, 2019, 240: 118202. doi: 10.1016/j.jclepro.2019.118202 [8] 张猛, 王永海, 冷发光, 等. 水泥基材料裂缝自修复技术的研究与进展[J]. 混凝土, 2023, (4): 149-154. doi: 10.3969/j.issn.1002-3550.2023.04.031ZHANG Meng, WANG Yonghai, LENG Faguang, et al. Research and progress of crack self-repairing technology for cement-based materials[J]. Concrete, 2023, (4): 149-154 (in Chinese). doi: 10.3969/j.issn.1002-3550.2023.04.031 [9] 房国豪, 陈锦妹, 王琰帅, 等. 微胶囊自修 复混凝土研究进展[J]. 硅酸盐学报, 2023, 51(9): 2423-2432.FANG Guohao, CHEN Jinmei, WANG Yanshuai, et al. Research Development on Microencapsulated Self-Healing Concrete[J]. Journal of the Chinese Ceramic Society, 2023, 51(9): 2423-2432(in Chinese). [10] 张立卿, 余家乐, 王云洋, 等. 渗透结晶水泥基复合材料研究综述[J]. 材料导报, 2024, 38(13): 22100014.ZHANG Liqing, YU Jiale, WANG Yunyang, et al. Study on Cementitious Composites with Permeable Crystalline Agent: A Review[J]. Materials Reports, 2024, 38(13): 22100014(in Chinese). [11] 申薛靖, 刘科海, 高东岳, 等. 微胶囊型自愈 合聚合物基复合材料研究进展[J]. 复合材料 学报, 2018, 35(9): 2303-2320.SHEN Xuejing, LIU Kehai, GAO Dongyue, et al. Research progress in microencapsulated self-healing polymer matrix composites[J]. Acta Materiae Compositae Sinica, 2018, 35(9): 2303-2320 (in Chinese). [12] GAO J, JIN P, ZHANG Y Z, et al. Fast-responsive capsule based on two soluble components for self-healing concrete[J]. Cement and Concrete Composites, 2022, 133: 104711. doi: 10.1016/j.cemconcomp.2022.104711 [13] LI J L, BAI S, GUAN X C. Development optimization and performance evaluation of mineral capsules based on magnesium oxide expansive agent[J]. Journal of Building Engineering, 2024, 86: 108825. doi: 10.1016/j.jobe.2024.108825 [14] QURESHI T, KANELLOPOULOS A, AL-TABBAA A. Autogenous self-healing of cement with expansive minerals-II: impact of age and the role of optimised expansive minerals in healing performance[J]. Construction and Building Materials, 2019, 194: 266-275. doi: 10.1016/j.conbuildmat.2018.11.027 [15] TAE-HO A, TOSHIHARU K. Crack Self-healing behavior of cementitious composites incorporating various mineral admixtures[J]. Journal of Advanced Concrete Technology, 2010, 8(2): 171-186. doi: 10.3151/jact.8.171 [16] 金海东. 微胶囊自修复水泥基材料渗透性修 复效果及其评定[D]. 杭州: 浙江工业大学, 2018.JIN Haidong. Study and evaluation of the self-healing efficiency on permeability of microcapsule self-healing cement-based material [D]. Hangzhou: Zhejiang University of Technology, China, 2018 (in Chinese). [17] WU M Y, HU X M, ZHANG Q, et al. Synergistic effect of OH-rich fibers and mineral capsules on the self-healing properties of cement mortar[J]. Cement and Concrete Composites, 2023, 137: 104913. doi: 10.1016/j.cemconcomp.2022.104913 [18] 刘路明. 微膨胀超高性能混凝土的配制和性 能及工程应用[D]. 长沙: 湖南大学, 2022.LIU Luming. Investigation on preparation, properties, and application of expansive UHPC[D]. Changsha: Hunan University, China, 2022 (in Chinese). [19] 黄锐新. 掺滑石粉自密实混凝土工作性能及 力学性能研究[D]. 佛山: 佛山科学技术学院, 2020.HUANG Ruixin. Workability and MechanicalProperties of Talcum PowderSelf-compacting Concrete[D]. Foshan: Foshan University, China, 2020 (in Chinese). [20] CHANG H L, GUO Z K, CHEN C, et al. Mechanical properties, durability and self-healing performance of mortar containing double-layers capsules[J]. Materials Today Communications, 2024, 38: 107880. doi: 10.1016/j.mtcomm.2023.107880 [21] LV L Y, ZHANG X Y, ŠAVIJA B, et al. Self-healing of cementitious materials using sustainable cenosphere-based manufactured aggregate[J]. Construction and Building Materials, 2024, 419(10): 135361. [22] 全国水泥标准化技术委员会. 水泥胶砂强度检验方法(ISO法): GB/T17671-2021[S]. 北京: 中国标准出版社, 2021.National cement Standardization Technical Committee. Test method of cement mortar strength(ISO method): GB/T17671-2021[S]. Beijing: China Standards Press, 2021(in Chinese). [23] JIANG Z W, LI J, LI W T. Preparation and characterization of autolytic mineral microsphere for self-healing cementitious materials[J]. Cement and Concrete Composites, 2019, 103: 112-120. doi: 10.1016/j.cemconcomp.2019.04.004 [24] 马衍轩, 吴睿, 葛亚杰, 等. 粘土固化型微胶囊复合水泥基材料的设计与力学损伤自修复行为[J]. 复合 材料学报, 2023, 40(9): 5288-5301.MA Yanxuan, WU Rui, GE Yajie, et al. Design and self-repair behavior of clay-cured microcapsule composite cementitious materials[J]. Acta Materiae Compositae Sinica, 2023, 40(9): 5288-5301(in Chinese). [25] ZHENG Q M, XIE Z C, LI J, et al. Autogenously self-healable cementitious composite incorporating autolytic mineral microspheres: hydration regulation and structural alteration[J]. Composites Part B: Engineering, 2023, 259: 110724 doi: 10.1016/j.compositesb.2023.110724 [26] 余泳江. 外掺丙烯酸镁水泥基材料自修复性能研究[D]. 成都: 西南交通大学, 2020.YU Yongjiang. Study on self-healing properties of cement-based materials with magnesium acrylate[D]. Chengdu: Southwest Jiaotong University, China, 2020 (in Chinese). [27] 张立卿, 边明强, 王云洋, 等. 自修复混凝土修复性能评估中的若干关键技术与方法研究综述[J]. 材料 导报, 2024, 38(9): 22100028.ZHANG Liqing, BIAN Mingqiang, WANG Yunyang, et al. A Review of Some Key Technologies and Methods Used for Evaluating the Healing Performance of Self-healing Concrete[J]. Materials Reports, 2024, 38(9): 22100028(in Chinese). [28] XIANG J C, QIU J P, WU P Q, et al. Autolytic capsules incorporating alkali-activated slag system for self-healing cementitious composites[J]. Cement and Concrete Composites, 2024, 147: 105439. doi: 10.1016/j.cemconcomp.2024.105439 [29] WANG X F, CHEN S C, YANG Z H, et al. Self-healing concrete incorporating mineral additives and encapsulated lightweight aggregates: preparation and application[J]. Construction and Building Materials, 2021, 301: 124119. doi: 10.1016/j.conbuildmat.2021.124119 [30] 张盼盼, 贾冠华, 姜晨等. 初始裂缝宽度对混凝土自修复效果的影响[J]. 中国科技论文, 2022, 17(7): 795-800. doi: 10.3969/j.issn.2095-2783.2022.07.014ZHANG Panpan, JIA Guanhua, JIANG Chen, et al. Influence of initial crack width on self-healing effect of concrete[J]. China Science Paper, 2022, 17(7): 795-800 (in Chinese). doi: 10.3969/j.issn.2095-2783.2022.07.014 [31] FAN L, ZHENG J H, PENG S Q, et al. Experimental investigation on the influence of crack width of asphalt concrete on the repair effect of microbially induced calcite precipitation[J]. Materials, 2023, 16(9): 3576. doi: 10.3390/ma16093576 [32] MENG W N, KHAYAT K. Effects of saturated lightweight sand content on key characteristics of ultra-high-performance concrete[J]. Cement and Concrete Research, 2017, 101: 46-54. doi: 10.1016/j.cemconres.2017.08.018 [33] 张立卿, 占小静, 韩宝国, 等. 静电自组装碳 纳米管/二氧化钛水泥基复合材料的自感知性 能[J]. 复合材 料学报, 2023, 40(9): 5225-5240.ZHANG Liqing, ZHAN Xiaojing, HAN Baoguo, et al. Self-sensing performance of cementitious composites with electrostatic self-assembly carbon nanotube/titanium dioxide[J]. Acta Materiae Compositae Sinica, 2023, 40(9): 5225-5240(in Chinese). [34] QURESHI T, KANELLOPOULOS A, AL-TABBAA A, Glass encapsulated minerals for self-healing in cement based composites[J]. Construction and Building Materials, 2015, 98: 780-791. [35] 耿薇薇, 贾艳征, 王强强, 等. 浅谈常见的涂层硬度测试方法及测试要点[J]. 中国建材科技, 2023, 32(4): 103. doi: 10.12164/j.issn.1003-8965.2023.04.026GENG Weiwei, JIA Yanzheng, WANG Qiangqiang, et al. Discussion on common testing methods and key points for coating hardness[J]. China Building Materials Science & Technology, 2023, 32(4): 103(in Chinese). doi: 10.12164/j.issn.1003-8965.2023.04.026 [36] GÜL Y A, BERFIN M, EMRE S, et al. Improving mechanical properties of huntite hydromagnesite reinforced flame retardant polymer composites with calcite and zeolite minerals[J]. Vietnam Journal of Chemistry, 2024, 62(1): 114-121. doi: 10.1002/vjch.202300157 [37] CABRERA-LUNA K, PEREZ-CORTES P, ESCALANTE-Garcia J I. Pumice-based supersulfated cements in mortars: effects of pumice fineness and activator ratio on physical and environmental characteristics[J]. Construction and Building Materials, 2022, 342: 127947. doi: 10.1016/j.conbuildmat.2022.127947 -

点击查看大图

点击查看大图

计量

- 文章访问数: 55

- HTML全文浏览量: 38

- 被引次数: 0

下载:

下载: