Preparation and properties of graphene-supported copper reinforced copper matrix bulk composites

-

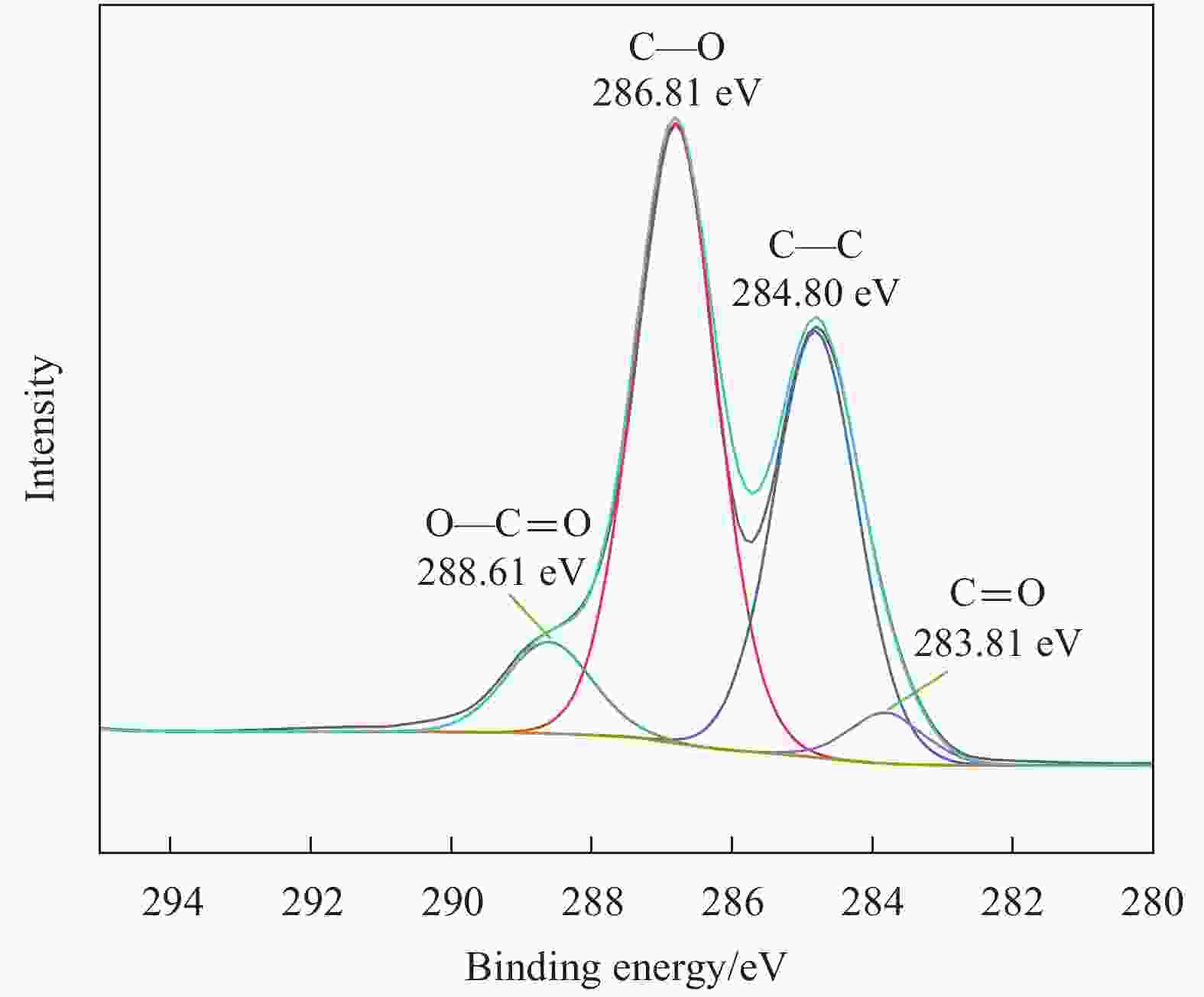

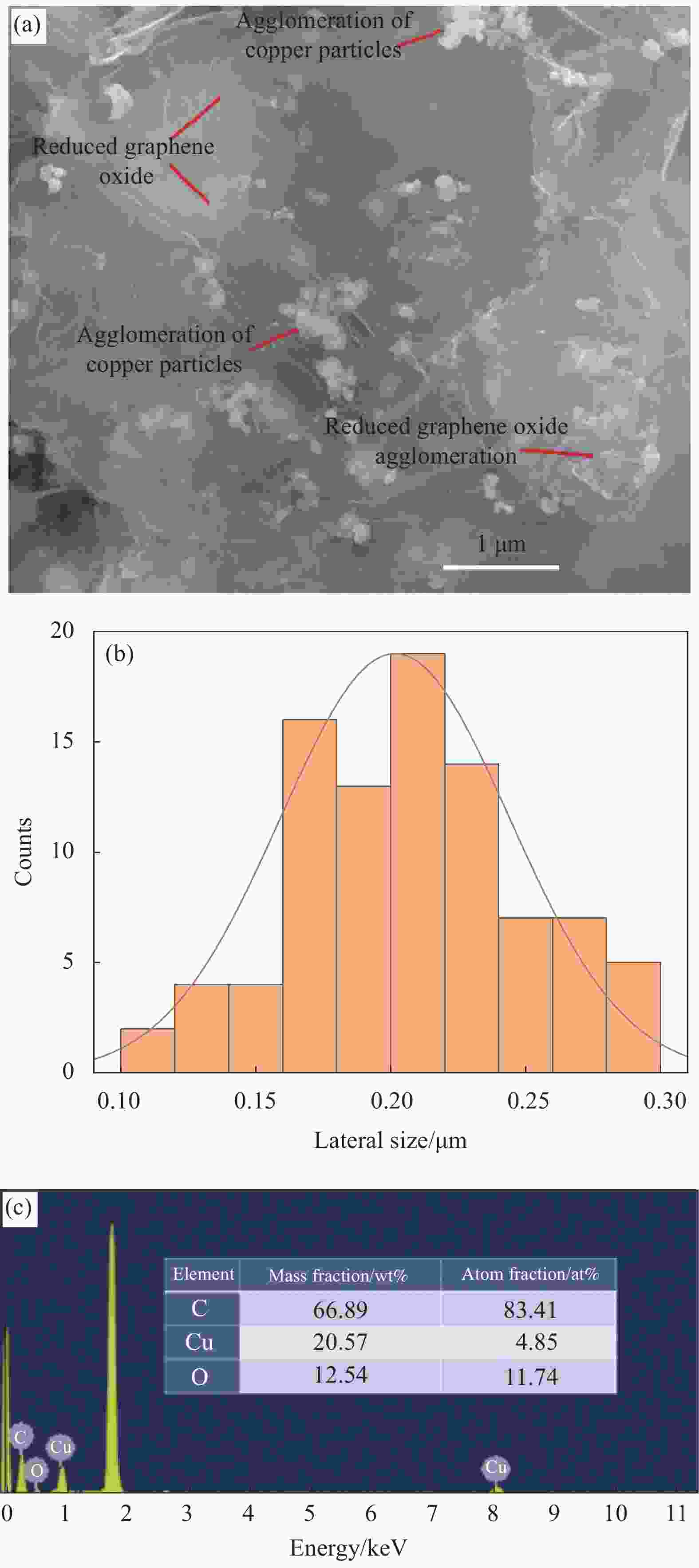

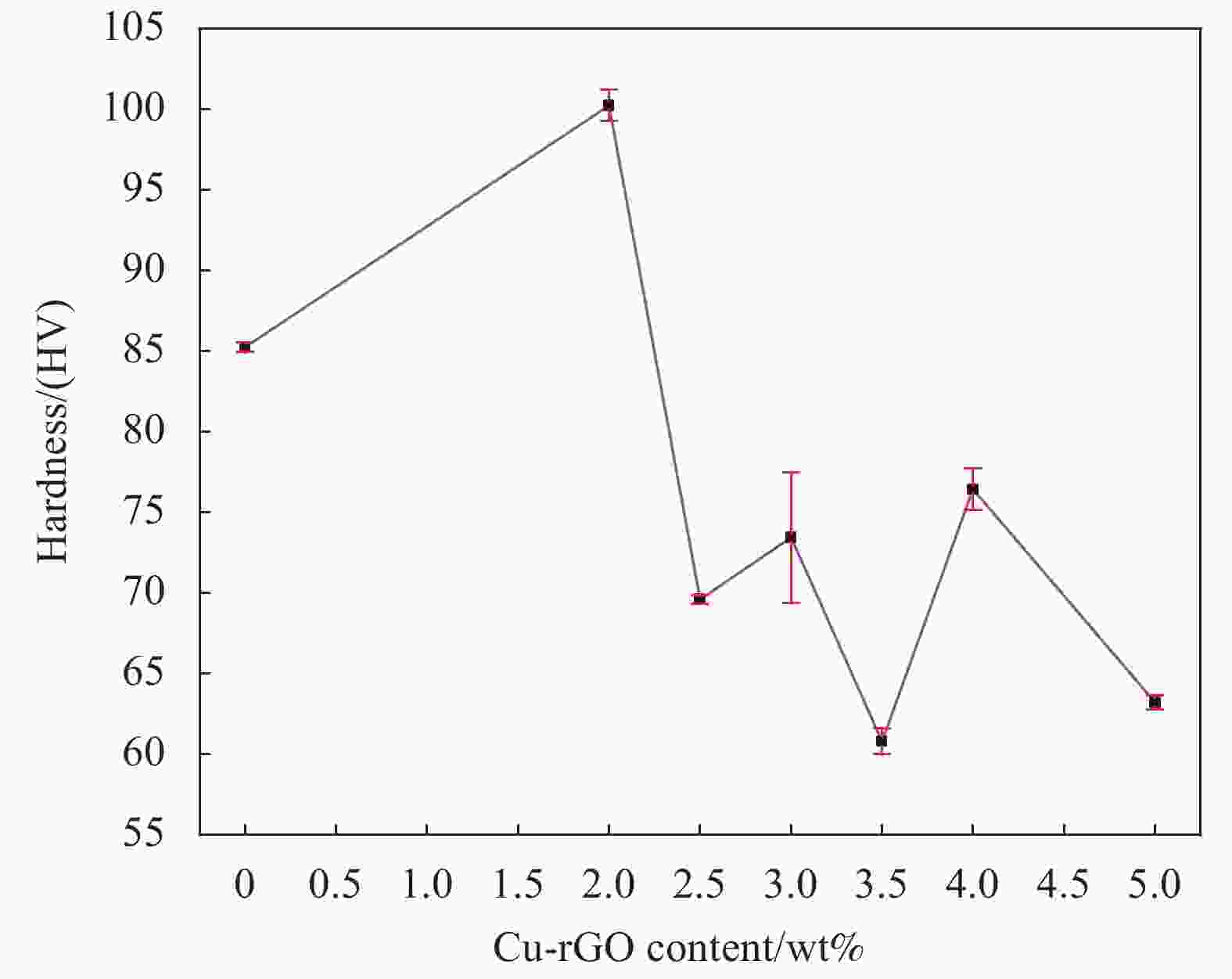

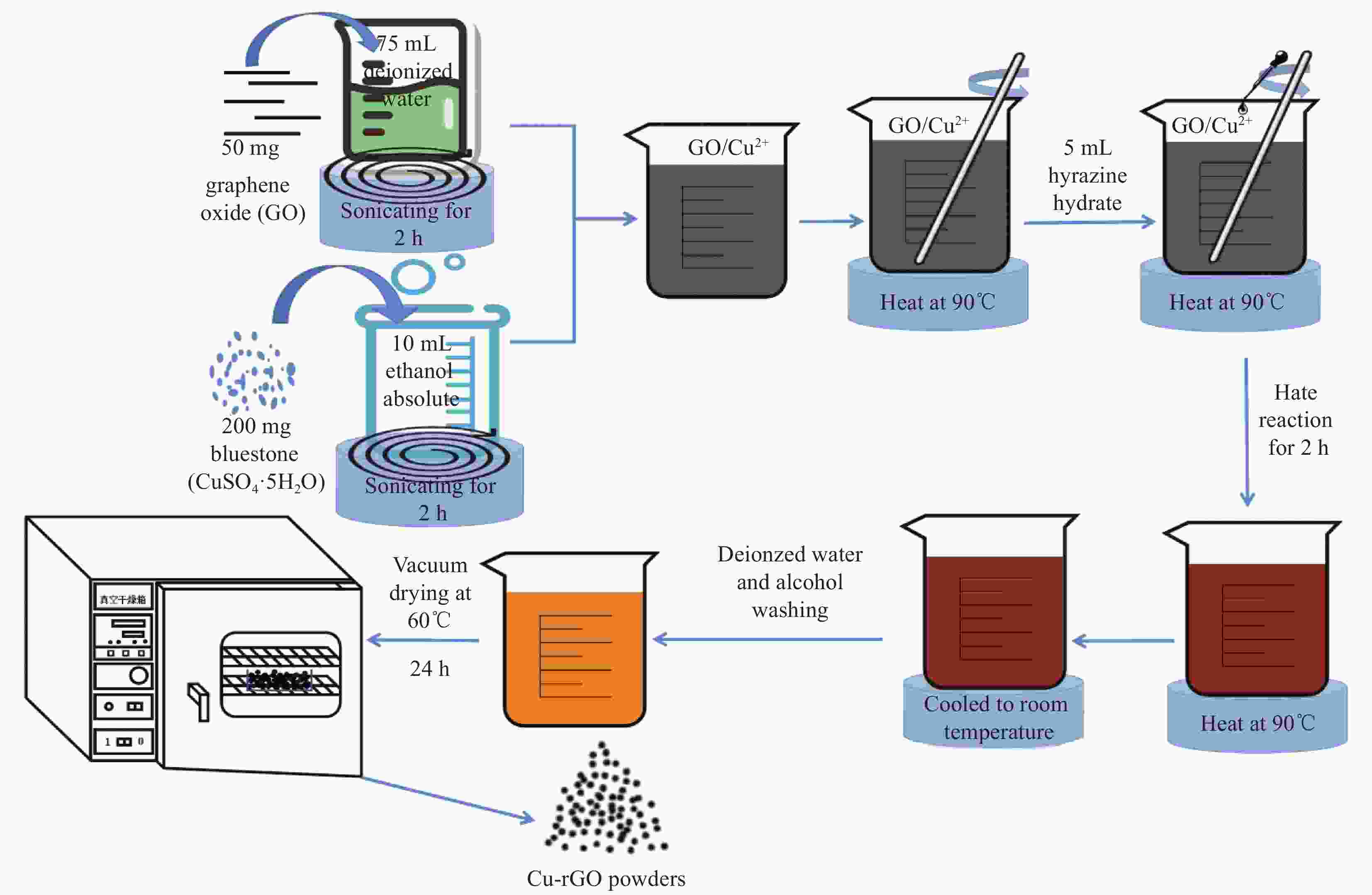

摘要: 石墨烯具有独特的二维结构及性能已成为金属基复合材料制备过程中理想的增强相备选材料之一。而铜因具有良好的导热性、导电性和化学稳定性已被广泛应用到电子产品中,但其存在机械强度低、硬度低等缺点成为其应用亟需解决的瓶颈问题。目前,将石墨烯和铜基材料进行结合,虽然在一定程度上可以改善铜基材料的的综合性能。但由于石墨烯易产生团聚,石墨烯与铜之间的润湿性差,使其两者难以形成良好的界面结合,进而导致复合材料的性能变差。因此,为了解决上述问题,本文通过化学还原法在石墨烯上负载铜粒子对石墨烯进行改性处理,成功制备了石墨烯负载铜复合粉体(Cu-rGO),并将其作为增强相,与纳米铜粉混合,运用放电等离子烧结(SPS)工艺制备了石墨烯负载铜增强铜基块体复合材料(Cu-rGO/Cu),研究Cu-rGO复合粉体含量对铜基体组织和性能的影响。研究发现,在50 mg氧化石墨烯(GO)和200 mg硫酸铜(CuSO4·5H2O)时,获得Cu-rGO复合粉体中还原氧化石墨烯较薄且分布均匀。同时结合TEM结构分析发现铜基体与增强相接触界面紧密,且增强相的引入可以有效地细化块体复合材料的晶粒。另外,随着增强相含量的递增,硬度呈现先增加后减小,尤其在含量为2wt%时,硬度提高17.6%。但其导电率和致密度呈现出下降趋势,可能是还原过程中,氧化石墨烯中含氧官能团没有彻底还原,同时也有可能是石墨烯因有缺陷的产生和团聚现象造成的。Abstract: Graphene has a unique two-dimensional structure and properties, which has become one of the ideal reinforcement phase candidates in the preparation of metal matrix composites. Copper has been widely used in electronic products because of its good thermal conductivity, electrical conductivity and chemical stability. But its shortcomings, such as low mechanical strength and low hardness have become a bottleneck problem that need to be solved urgently. At present, the combination of graphene and copper can improve the comprehensive properties of copper matrix materials to a certain extent. However, because graphene is easy to agglomerate and the wettability between graphene and copper is poor, it is difficult to form a good interface between graphene and copper, which leads to the deterioration of the properties of the composites. Therefore, in order to solve the above problem, by chemical reduction method, graphene was modified by reinforcing copper particles on graphene. Finally, the graphene-supported copper composite powder (Cu-rGO) was successfully prepared. Then it was selected the reinforcement phase and mixed with nano-copper powder, and the graphene-supported copper reinforced Cu matrix bulk composite materials (Cu-rGO/Cu) was prepared by the spark plasma sintering (SPS). The effect of the graphene-supported copper composite powder content on the microstructure and properties of copper matrix was studied. The results show that the reduced graphene oxide in the obtained graphene-supported copper composite powder is relatively thin and uniformly distributed with the mass of GO about 50 mg and CuSO4·5H2O about 200 mg. Meanwhile, combined with the TEM structure analysis, it is observed that the contact interface between the copper matrix and the reinforcing phase is close, and the introduction of the reinforcing phase can effectively refine the crystal grains of the bulk composite material. In addition, with the increase of the content of reinforced phase, the hardness first increases and then decreases. Especially, when the content is 2wt%, the hardness increases by 17.6%. However, its conductivity and density show a downward trend, which is due to that the oxygen-containing functional groups in the graphene oxide are not completely reduced during the reduction process, and it may be due to the occurrence of defects and agglomeration of the graphene.

-

图 9 纯铜和添加不同增强相含量铜基块体复合材料金相图像:(a) 纯铜;Cu-rGO含量2wt% (b)、2.5wt% (c)、3wt% (d)、3.5wt% (e)、4wt% (f)、5wt% (g) 的Cu-rGO/Cu块体复合材料

Figure 9. Metallographic images of pure copper and Cu matrix bulk composite materials with different the reinforcing phase contents: (a) Pure copper; Cu-rGO/Cu bulk composites with Cu-rGO containing 2wt% (b), 2.5wt% (c), 3wt% (d), 3.5wt% (e), 4wt% (f), 5wt% (g)

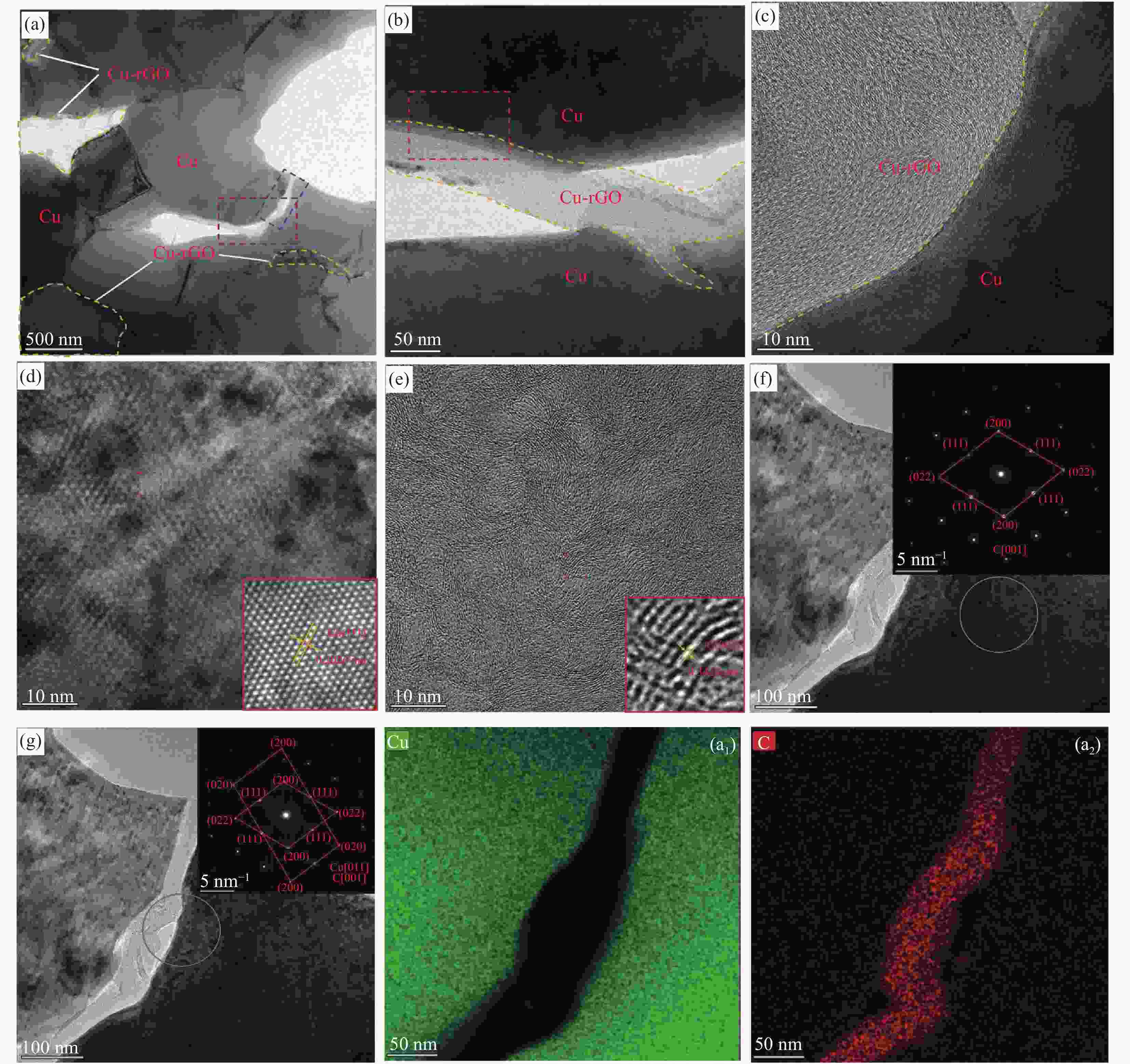

图 11 Cu-rGO含量2wt%的Cu-rGO/Cu块体复合材料TEM图像:(a) 微区全貌图;(b) 图11(a)中大方框放大图;(c) 图11(b)中方框区高分辨图;((d)、(e)) 图11(c)中选区高分辨图;((f)、(g)) 选区电子衍射图;((a1)、(a2))是图11(a)中小方框的EDS-mapping图

Figure 11. TEM images of Cu-rGO/Cu bulk composite materials with Cu-rGO content 2wt%: (a) Microgravity map; (b) Big box enlargement in Fig. 11(a); (c) High-resolution figure of the box in Fig. 11(b); ((d), (e)) High-resolution map of the constituency in Fig. 11(c); ((f), (g)) Electron diffraction map of the selection; ((a1), (a2)) EDS-mapping diagram of the small box in Fig. 11(a)

表 1 不同增强相Cu-rGO含量的铜基块体复合材料Cu(111)晶面测试或计算数据

Table 1. Cu(111) crystal surface test or calculated data of Cu-based bulk composites with different Cu-rGO contents in reinforcement phase

Cu-rGO content/

wt%d/nm 2θ/(°) B1/2/rad D/nm 0.0 0.210 43.2 3.92×10−3 38 2.0 0.209 43.3 4.01×10−3 37 2.5 0.209 43.3 3.92×10−3 38 3.0 0.210 43.2 3.91×10−3 38 3.5 0.207 43.7 4.30×10−3 34 4.0 0.208 43.4 4.23×10−3 35 5.0 0.210 43.2 3.95×10−3 37 Notes: d—Interplanar spacing; 2θ—Diffraction angle; B1/2—Half-height and width; D—Size of the grain. 表 2 Cu-rGO/Cu 块体复合材料能谱分析结果

Table 2. Energy spectrum analysis of Cu-rGO/Cu bulk composite materials

Element Mass fraction/wt% Atom fraction/at% C 24.06 62.63 Cu 75.94 37.37 Total 100.00 100.00 -

[1] DAVIS J R. ASM specialty handbook: Copper and copper alloys[M]. American: American Technical Publishers LTD., 2001. [2] TJONG S C. Novel nanoparticle-reinforced metal matrix composites with enhanced mechanical properties[J]. Advanced Engineering Materials,2007,9(8):639-652. doi: 10.1002/adem.200700106 [3] MORTENSEN A, LLORCA J. Metal matrix composites[J]. Annual Review of Materials Research,2010,40:243-270. doi: 10.1146/annurev-matsci-070909-104511 [4] MIRACLE D B. Metal matrix composites—From science to technological significance[J]. Composites Science and Technology,2005,65(15-16):2526-2540. doi: 10.1016/j.compscitech.2005.05.027 [5] ZHANG P, JIE J, GAO Y, et al. Preparation and properties of TiB2 particles reinforced Cu-Cr matrix composite[J]. Materials Science and Engineering: A,2015,642:398-405. doi: 10.1016/j.msea.2015.07.021 [6] MU X N, ZHANG H M, CAI H N, et al. Hot pressing titanium metal matrix compositesreinforced with graphene nanoplateletsthrough an in-situ reactive method[C]//AIP Conference Proceedings. American: AIP Publishing LLC, 2017, 1846(1): 020013. [7] SENTURK A E. Outstanding thermo-mechanical properties of graphene-like B3C3 and C3N3[J]. Applied Physics A,2020,126(8):1-15. doi: 10.1007/s00339-020-03764-3 [8] RAFIEE M A. Graphene-based composite materials[J]. Dissertations & Theses-Gradworks,2011,442(2):282-286. [9] HUANG X, QI X, BOEY F, et al. Graphene-based composites[J]. Chemical Society Reviews,2012,41(2):666-686. doi: 10.1039/C1CS15078B [10] 曾凡坤, 马洪兵, 江南, 等. 高定向石墨/铜复合材料的制备和热物理性能[J]. 复合材料学报, 2020, 37(8):1951-1959.ZENG Fankun, MA Hongbing, JIANG Nan, et al. Preparation and thermophysical properties of aligned graphite flake/Cu composites[J]. Acta Materiae Compositae Sinica,2020,37(8):1951-1959(in Chinese). [11] 陈俊, 徐海进, 杨蒙, 等. 石墨烯/星形聚丙烯酸酯纳米复合涂料的制备及性能[J]. 高分子材料科学与工程, 2017, 33(11):171-177.CHEN Jun, XU Haijin, YANG Meng, et al. Preparation and properties of graphene/star polyacylates nanocomposite coatings[J]. Polymer Materials Science & Engineering,2017,33(11):171-177(in Chinese). [12] MOHAN V B, LAU K, HUI D, et al. Enhanced strength in bulk graphene-copper composites[J]. Composites Part B: Engineering,2014,211(1):200-220. doi: 10.1016/j.compositesb.2018.01.013 [13] LI M, CHE H, LIU X, et al. Highly enhanced mechanical properties in Cu matrix composites reinforced with graphene decorated metallic nanoparticles[J]. Journal of Materials Science,2014,49(10):3725-3731. doi: 10.1007/s10853-014-8082-x [14] SAYYAD R, GHAMBARI M, EBADZADEH T, et al. Preparation of Ag/reduced grapheneoxide reinforced copper matrix composites through spark plasma sintering: An investigation of microstructure and mechanical properties[J]. Ceramics International,2020,46(9):13569-13579. doi: 10.1016/j.ceramint.2020.02.142 [15] HAN T, LI J, ZHAO N, et al. Fabricationof graphene nanoplates modified with nickelnanoparticles for reinforcing copper matrix composites[J]. Acta Metallurgica Sinica (English Letters),2020,33:643-648. doi: 10.1007/s40195-020-00999-0 [16] TANG Y, YANG X, WANG R, et al. Enhancement of the mechanical properties of graphene-copper composites with graphene-nickel hybrids[J]. Materials Science and Engineering: A,2014,599:247-254. doi: 10.1016/j.msea.2014.01.061 [17] LI X, YAN S, CHEN X, et al. Microstructure and mechanical properties of graphene-reinforced copper matrix composites prepared by in-situ CVD, ball-milling, and spark plasma sintering[J]. Journal of Alloys and Compounds,2020,834:155182. doi: 10.1016/j.jallcom.2020.155182 [18] 庄世豪, 顾吴瑜, 杜艾, 等. 基于微波分光计的谢乐公式验证实验[J]. 大学物理, 2016, 35(7):37-41. doi: 10.16854/j.cnki.1000-0712.2016.0106ZHUANG Shihao, GU Wuyu, DU Ai, et al. Microwave spectrometer verifying Scherrer equation[J]. College Physics,2016,35(7):37-41(in Chinese). doi: 10.16854/j.cnki.1000-0712.2016.0106 [19] XU C, WANG X. Fabrication of flexible metal-nanoparticle films using graphene oxidesheets as substrates[J]. Small,2009,5(19):2212-2217. doi: 10.1002/smll.200900548 [20] 胡建民, 王蕊, 王春婷, 等. 晶体X射线衍射模型和布拉格方程的一般推导[J]. 大学物理, 2015, 34(3):1-2. doi: 10.16854/j.cnki.1000-0712.2015.03.008HU Jianmin, WANG Rui, WANG Chunting, et al. X ray diffraction model of crystal and general derivation of Bragg equation[J]. College Physics,2015,34(3):1-2(in Chinese). doi: 10.16854/j.cnki.1000-0712.2015.03.008 [21] CHENG C, DENG J, LEI B, et al. Toward 3D graphene oxide gels based adsorbents for high-efficient water treatment via the promotion of biopolymers[J]. Journal of Hazardous Materials,2013,263(2):467-478. doi: 10.1016/j.jhazmat.2013.09.065 [22] GIESBERS M, MARCELIS A T M, ZUILHOF H. Simulation of XPS C1s spectra of organic monolayers by quantum chemical methods[J]. Langmuir,2013,29(15):4782-4788. doi: 10.1021/la400445s [23] IDRISS H. On the wrong assignment of the XPS O1s signal at 531-532 eV attributed to oxygen vacancies in photo-and electro-catalysts for water splitting and other materials applications[J]. Surface Science,2021,712:121894. doi: 10.1016/j.susc.2021.121894 [24] PINON-ESPITIA M, LARDI-GUTIERREZ D, CAMACHO-RIOS M L, et al. Electronic structure comparison of Cu2p and O1s X-ray photoelectron spectra for CuxO nanofibers (x=1, 2, i)[J]. Materials Chemistry and Physics,2021,272:124981. doi: 10.1016/j.matchemphys.2021.124981 [25] WANG L, YANG Z, CUI Y, et al. Graphene-copper composite with micro-layered grains and ultrahigh strength[J]. Scientific Reports,2017,7(1):1-10. doi: 10.1038/s41598-016-0028-x [26] SUN H, CHEN D, WU Y, et al. High quality graphene films with a clean surface prepared by an UV/ozone assisted transfer process[J]. Journal of Materials Chemistry C,2017,5(8):1880-1884. doi: 10.1039/C6TC05505B [27] SHI L, LIU M, YANG Y, et al. Achieving high strength and ductility in copper matrix composites with graphene network[J]. Materials Science and Engineering: A,2021,828:142107. doi: 10.1016/j.msea.2021.142107 [28] CHU K, JIA C. Enhanced strength in bulk graphene-copper composites[J]. Physica Status Solidi A,2014,211(1):184-190. doi: 10.1002/pssa.201330051 [29] CHOI J, OKIMURA N, YAMADA T, et al. Deposition of graphene-copper composite film by cold spray from particles with graphene grown on copper particles[J]. Diamond and Related Materials,2021,116:108384. doi: 10.1016/j.diamond.2021.108384 [30] WANG Z J, WEINBERG G, ZHANG Q, et al. Direct observation of graphene growth and associated copper substrate dynamics by in situ scanning electron microscopy[J]. ACS Nano,2015,9(2):1506-1519. doi: 10.1021/nn5059826 [31] LEE H C, JO S B, LEE E, et al. Facet-mediated growth of high-quality monolayer graphene on arbitrarily rough copper surfaces[J]. Advanced Materials,2016,28(10):2010-2017. doi: 10.1002/adma.201504190 [32] 廖燕平, 黄金英, 郜峰利, 等. 激光晶化多晶硅的制备与XRD谱[J]. 吉林大学学报: 理学版, 2004, 42(1):99-102.LIAO Yanping, HUANG Jinying, GAO Fengli, et al. Poly-silicon's preparation by excimer laser annealing and characterization by XRD[J]. Journal of Jinlin University (Science Edition),2004,42(1):99-102(in Chinese). [33] 胡林丽, 于艳丽, 黄琳莲, 等. RGO/Al基复合材料复压复烧制备工艺参数的优化[J]. 特种铸造及有色合金, 2018(10):1116-1120.HU Linli, YU Yanli, HUANG Linlian, et al. Repressing and re-sintering process parameters optimization for RGO/Al matrix composites[J]. Special-casting & Non-ferrous Alloys,2018(10):1116-1120(in Chinese). [34] ZHANG D, ZHAN Z. Strengthening effect of graphene derivatives in copper matrix composites[J]. Journal of Alloys and Compounds,2016,654:226-233. doi: 10.1016/j.jallcom.2015.09.013 [35] 魏邦争, 陈闻超, 朱曦, 等. 石墨烯化学镀铜及其对石墨烯/铜基复合材料组织性能的影响[J]. 粉末冶金技术, 2019, 36(5):363-369, 376.WEI Bangzheng, CHEN Wenchao, ZHU Xi, et al. Study of electroless plating Cu by reduced graphene oxide and the effects on the microstructures and properties of RGO/Cu composites[J]. Powder Metallurgy Technology,2019,36(5):363-369, 376(in Chinese). [36] WANG X, WANG X, LIU M, et al. Anisotropic thermal expansion coefficient of multilayer graphene reinforced copper matrix composites[J]. Journal of Alloys and Compounds,2018,755:114-122. doi: 10.1016/j.jallcom.2018.04.325 [37] FERRARI A C, MEYER J C, SCARDACI V, et al. Raman spectrum of graphene and graphene layers[J]. Physical Review Letters,2006,97(18):187401. doi: 10.1103/PhysRevLett.97.187401 [38] HWANG J, YOON T, JIN S H, et al. Enhanced mechanical properties of graphene/copper nanocomposites using a molecular-level mixing process[J]. Advanced Materials,2013,25(46):6724-6729. doi: 10.1002/adma.201302495 [39] HE C, ZHAO N, SHI C, et al. An approach to obtaining homogeneously dispersed carbon nanotubes in Al powders for preparing reinforced Al-matrix composites[J]. Advanced Materials,2007,19(8):1128-1132. doi: 10.1002/adma.200601381 [40] 黄焌晨, 缪国栋, 陈友明, 等. 石墨鳞片-碳纤维协同增强铜基复合材料的制备与热物理性能研究[J]. 复合材料学报, 2022, 39(2):759-768. doi: 10.13801/j.cnki.fhclxb.20210513.006HAUNG Junchen, MIAO Guodong, CHEN Youming, et al. Preparation and thermophysical properties of graphite flake-carbon fiber co-reinforced copper matrix composites[J]. Acta Materiae Compositae Sinica,2022,39(2):759-768(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210513.006 [41] 崔烨. 石墨烯/铜复合粉体的制备及其复合材料的组织与性能[D]. 哈尔滨: 哈尔滨工业大学, 2015.CUI Ye. Preparation of graphene/copper composite powders and structure and properties of composites[D]. Harbin: Harbin Institute of Technology, 2015(in Chinese). [42] 阮建明, 黄培云. 粉末冶金原理[M]. 北京: 机械工业出版社, 2012.RUAN Jianming, HUNAG Peiyun. Power metallurgy principle[M]. Beijing: China Machine Press, 2012(in Chinese). [43] 付华, 张光磊. 材料性能学[M]. 北京: 北京大学出版社, 2010.FU Hua, ZHANG Guanglei. Material properties[M]. Beijing: Peking University Press, 2010(in Chinese). [44] 王忠勇. 石墨烯增强铜基复合材料的组织与性能[D]. 长沙: 湖南大学, 2018.WANG Zhongyong. Microstructure and properties of graphene reinforced copper matrixcomposites[D]. Changsha: Hunan University of Technology, 2018(in Chinese). [45] 张丹丹. 石墨烯/铜复合材料的制备、组织及力学性能研究[D]. 秦皇岛: 燕山大学, 2016.ZHANG Dandan. Preparation, microstructure and mechanical properties of copper matrix composites reinforced by graphene materials[D]. Qinhuangdao: Yanshan University, 2016(in Chinese). [46] 王良子. 负载铜石墨烯增强的铜基块体复合材料组织及性能的研究[D]. 西安: 西安理工大学, 2017.WANG Liangzi. The invsetugation on microstructure and properties of Cu-doped RGO reinforced Cu matrix compo-sites[D]. Xi'an: Xi'an University of Technology, 2017(in Chinese). [47] 刘宇宁. 石墨烯增强铜基复合材料组织与性能研究[D]. 长沙: 湖南大学, 2018.LIU Yuning. Research on microstructure andcomposites of graphene reinforced copper matrix composites[D]. Changsha: Hunan University, 2018(in Chinese). [48] ZHANG D, ZHAN Z. Preparation of graphene nanoplatelets-copper composites by a modified semi-powder method and their mechanical properties[J]. Journal of Alloys and Compounds,2016,658:663-671. doi: 10.1016/j.jallcom.2015.10.252 [49] TJONG S C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets[J]. Materials Science and Engineering: R: Reports,2013,74(10):281-350. doi: 10.1016/j.mser.2013.08.001 [50] PAVITHRA C L P, SARADA B V, RAJULAPATI K V, et al. A new electrochemical approach for the synthesis of copper-graphene nanocomposite foils with high hardness[J]. Scientific Reports,2014,4:4049. doi: 10.1038/srep04049 -

下载:

下载: