Advance in the continuous preparation methods and applications of metallized carbon fiber

-

摘要:

金属化处理的碳纤维(CF)能兼备原始纤维轻质高强和金属高导电/导热等多重性能,在电磁屏蔽、防雷击、除冰/防冰、电能传输、超级电容、信号传感、复合材料结构功能一体化等领域,可一定程度替代传统金属材料使用,是跨越材料属性限制的创新,市场应用潜力突出。本文综述了研究学者在CF表面金属化方面取得的进展。具体从金属化工艺入手,分析了近年来主要CF金属化工艺路线,包括喷涂、磁控溅射(PVD)、化学气相沉积(CVD)、电镀、化学镀等,从商业化工程应用角度重点分析了具有大长度连续金属化潜力的电镀和化学镀的核心环节和工艺特点。总结了金属化碳纤维(MCF)的应用现状,展望了CF表面金属化将面临的挑战及未来发展趋势。

Abstract:Metallized carbon fiber (CF) possesses multiple properties, such as the original fiber's lightweight and high strength, as well as the metal's high electrical/thermal conductivity. It has the potential to partially replace traditional metal materials in various fields, including electromagnetic interference, pro-lightning, de-icing/anti-icing, power transmission, super-capacitors, signal sensing, and structure-function integration of composites. This innovative approach surpasses material limitations and exhibits remarkable market application potential. This papper reviewed the development made by researchers on the metallized CF. The main carbon fiber metallization process routes in recent years were analyzed, including spraying, magnetron sputtering (PVD), chemical vapor deposition (CVD), electroplating, electroless plating, etc. From the perspective of commercial engineering application, the core links and process characteristics of electroplating and electroless plating were analyzed, possessing the capability for continuous metallization of extensive lengths. The application status of metallized CF is summarized, and the challenges and future development trend of carbon fiber surface metallization are prospected.

-

可再生能源的间隙性和波动性为能量的安全、高效利用带来较大挑战,已经成为经济可持续发展面临的重要议题[1]。钒液流电池(Vanadium liquid flow battery,VRB)可将电能高效储存,具有本征安全、响应速度快和运行寿命长等特点,相对于其他类型储能技术,钒电池技术在大规模、长时储能领域显示出优越的发展前景[1-3]。

作为钒电池的关键部件,质子交换膜(Proton exchange membrane,PEM)需具有如下特性[4-5]:(1)高离子选择性,即高质子传导率和低钒离子渗透率;(2)高拉伸强度和穿刺强度;(3)良好的理化稳定性;(4)较好的经济性。目前,基于全氟磺酸树脂的PEM在VRB中的应用最为广泛,如杜邦公司Nafion系列膜,但其溶胀性和离子选择性等与VRB的严格要求仍存在差距,优化膜的离子渗透性是本领域的研究热点[6-8]。实验表明,向膜中引入具有适宜孔道结构和表面性质的功能材料是改善其离子选择性的有效手段[5],如金属-有机框架(Metal-organic frameworks,MOFs)材料[9-11]。

在MOFs材料中,UIO-66 (Zr-MOF)由六核氧化锆簇作为二级构建单元和1, 4-苯二甲酸接头构建[12],具有刚性结构和较强的耐酸性,同时拥有介于水和离子(<0.3 nm)和钒离子(>0.6 nm)的孔道尺寸[13]。UIO-66主要通过水热合成法制备,但在合成过程中,烘箱加热较难提供均匀的受热环境,存在合成时间长、材料结构均一性差等问题[14]。微波加热可促进反应物中分子或离子直接耦合,实现能量的快速传导,具有反应速率快和产率高等优点,已被广泛用于多种纳米材料的合成[14-16]。Zhai等[6]通过在磺化聚醚醚酮(SPEEK)中掺入15wt% 的传统水热法UIO-66-NH2来改善复合膜的质子传导率,在120 mA·cm−2电流密度下,电池的能量效率(Energy efficiency,EE)为77.3%。Lu等[17]制备高质子选择性的聚多巴胺(PDA)@MOF-808,并将其掺入SPEEK中以优化复合膜的性能,在120 mA·cm−2电流密度下,该膜的EE为83.9%。贾儒等[13]和Wan等[14]也分别对UIO-66的合成和应用展开研究,均采用耗时较长的传统水热法。

鉴于此,本文采用不同加热方式制备氨基官能化的UIO-66 (UIO-66-NH2),验证微波加热在UIO-66-NH2材料的合成效率、结构优化方面的优势,并将其与Nafion 掺杂,通过溶液浇筑法制备复合膜,对膜的理化性质和电池性能进行表征,探讨新型膜材料对钒电池性能的影响。

1. 实验部分

1.1 原材料

氯化锆(ZrCl4,98%)、2-氨基对苯二甲酸(BDC-NH2,99%),上海麦克林生化科技有限公司;Nafion溶液(固含量5%),美国杜邦公司;无水乙醇,沈阳试剂二厂;N, N-二甲基甲酰胺(DMF)、MgSO4、硫酸氧钒(VOSO4·5H2O)、浓硫酸(98%)、乙酸(99%),国药集团化学试剂有限公司。

1.2 UIO-66-NH2的制备

UIO-66-NH2合成原料摩尔比:ZrCl4∶BDC-NH2 = 1∶1。首先,将二者分别溶于20 mL DMF,再在配体溶液中加入2.3 mL乙酸,超声波辅助下混合20 min后得均匀的合成液。随后,将适量上述合成液倒入微波合成罐中,在不同温度下合成15 min,离心后获得棕黄色粉末。将上述粉末分散在无水乙醇中,多次更新乙醇下保持48 h,完成产物清洗。最后,在60℃下干燥12 h,获得产物UIO-66-NH2,记为M-U66-NH2。作为对比,采用同样的合成液,利用传统烘箱加热,在120℃条件下反应24 h制备UIO-66-NH2,经过相同的清洗、干燥处理,获得产物UIO-66-NH2,记为T-U66-NH2。具体操作流程和样品编号见图1和表1。

1.3 复合质子交换膜的制备

以溶液浇筑法制备复合膜[18]:称取一定质量的M-U66-NH2,在超声辅助下分散在Nafion树脂溶液(固含量5%)中,在450 r/min下搅拌10 h后获得铸膜液。将适量铸膜液倒入带有凹槽的玻璃板上,在140℃真空烘箱中处理4 h,除去溶剂后得到复合膜,在恒温、恒湿条件下保存、备用。将掺杂M-U66-NH2的复合膜记作M/N-X,X=1、2、3、6和9,X表示Nafion树脂中M-U66-NH2的质量分数。将掺杂T-U66-NH2的复合膜记作T/N-X,X=3。同时,采用相似工艺制备无M-U66-NH2掺杂的纯树脂膜,记作P-N。具体操作流程和样品编号见图1和表1。

![]() 图 1 微波合成氨基官能化的UIO-66 (UIO-66-NH2)及Nafion复合膜的制备过程示意图Figure 1. Schematic diagram of the preparation process of UIO-66-NH2 and Nafion composite membraneM-U66-NH2—UIO-66-NH2 prepared by microwave assisted method; UIO-66-NH2—Zr-MOF when the preparation method does not need to be distinguished; BDC-NH2—2-aminoterephthalic Acid; DMF—N, N-dimethylformamide; HAc—Acetic acid表 1 复合质子交换膜的命名Table 1. Naming of composite proton exchange membranes

图 1 微波合成氨基官能化的UIO-66 (UIO-66-NH2)及Nafion复合膜的制备过程示意图Figure 1. Schematic diagram of the preparation process of UIO-66-NH2 and Nafion composite membraneM-U66-NH2—UIO-66-NH2 prepared by microwave assisted method; UIO-66-NH2—Zr-MOF when the preparation method does not need to be distinguished; BDC-NH2—2-aminoterephthalic Acid; DMF—N, N-dimethylformamide; HAc—Acetic acid表 1 复合质子交换膜的命名Table 1. Naming of composite proton exchange membranesSample name Instruction M-U66-NH2 "M" represents microwave heating; "U66" refers to the metal-organic framework material UIO-66; Overall, it indicates the UIO-66-NH2 sample prepared by microwave heating. T-U66-NH2 "T" represents traditional oven heating; Overall, it indicates the UIO-66-NH2 sample prepared by oven heating. M/N-X "M/N" represents the composite membrane with M-U66-NH2 and Nafion resin; "X" represents the percentage content of M-U66-NH2 in the membrane. T/N-X "T/N" represents the composite membrane with T-U66-NH2 and Nafion resin; "X" represents the percentage content of T-U66-NH2 added to the membrane. P-N A pure, unmodified Nafion membrane N212 Commercial Nafion 212 membrane from DuPont (USA) 1.4 形貌、结构表征和性能测试

采用X射线衍射仪(XRD,Bruker D8)和傅里叶红外光谱(FTIR,Nicolet 380,扫描范围:

4000 ~750 cm−1)评价粉末结构;扫描电子显微镜(SEM,SU8010,Hitachi)和扫描电子能谱(EDS)表征样品的微观形貌和元素分布;万能拉伸试验机(Instron 1186,加载速度为10 mm/min)检测膜的力学性能。膜面积溶胀率的计算公式如下:

SR = (Swet−Sdry)Sdry×100% (1) 式中:Swet为湿膜面积(cm2);Sdry为干膜面积(cm2)。

吸水率的计算公式如下:

WU = (Wwet−Wdry)Wdry×100% (2) 式中:Wwet为湿膜质量(g);Wdry为干膜质量(g)。

应用紫外分光光度计(TU-1810,Beijing Purcell General Instrument Co., Ltd.)测试膜的VO2+渗透性[7],取样间隔12 h,钒离子渗透率计算公式如下:

VBd(CB(t))dt=APL(CA−CB(t)) (3) 式中:CA为VOSO4溶液侧VO2+浓度;CB(t)为t时刻MgSO4溶液侧VO2+浓度;VB为MgSO4溶液体积;P为钒离子渗透率;L为膜厚度;A为膜的有效面积(1.77 cm2)。

应用电化学工作站(CHI660E,上海辰华)测试膜的离子电导率(σ),计算公式如下:

σ=DRb (4) 式中:Rb为膜的面电阻;D为膜厚度。

采用新威电池测试系统表征VRB的电池性能,电流密度范围为100~200 mA·cm−2。循环测试的电流密度为150 mA·cm−2,循环200次。测试膜的放电容量衰减率,计算公式如下:

容量衰减率=Qdis200Qdis1×100% (5) 式中:Qdis200为循环200次后的放电容量;Qdis1为第一次循环前放电容量。

单次衰减=容量衰减率循环次数 (6) 2. 结果分析与讨论

2.1 UIO-66-NH2的形貌与结构

为了优化UIO-66-NH2的合成参数,考察微波合成温度对材料结构的影响。如图2(a)所示,合成时间为15 min,当温度较低时(60℃),晶体结构较规则,颗粒尺寸约为1 μm,但产率仅为60%。随着合成温度的升高,晶体结构特征逐渐增强。如图2(c)所示,100℃下所合成样品具有明显的近八面体的晶体形貌[18]。当温度升至120℃时,晶体结构更加完整,此时粒径约为200 nm (图2(d)),分散性较好,且产率接近90%。由图2(e)可见,通过普通水热法也可以制备出形貌规则的UIO-66-NH2材料,只是所需的合成时间更长[19]。

XRD图谱反映样品的结晶度,如图2(f)所示,样品在2θ=7.40°和8.66°处出现了较明显的衍射峰,对应UIO-66-NH2的(111)和(002)晶面,在2θ=26.22°和31.86°等处出现强度略低的衍射峰,以上峰位置和强度与文献报道结果基本一致[20],证明本实验成功合成出UIO-66-NH2晶体。而且,随着合成温度的升高,晶体的衍射峰强度逐渐增加,即使在60℃下仍能合成出晶体。主要原因在于微波作用下反应釜内晶体前驱体溶液能够快速、均匀受热,微波的折射和反射诱导晶体快速成核、生长[21],合成效率得到显著提高。

2.2 质子交换膜的形貌与结构

为了更清晰地观察复合膜的微观形貌以及膜厚度,本实验对膜样品进行SEM表征。如图3(a)~3(c)所示,不同膜样品均呈现出较均匀、致密的形貌特征,M-U66-NH2的掺杂量对膜形貌的影响较小。图3(d)~3(f)中,不同膜的厚度相近,约为40 μm。P-N膜的截面更加平滑,随着M-U66-NH2掺杂量的增加,复合膜截面的粗糙度逐渐增加,但晶体的掺入未明显改变复合膜的结构。图3(g)~3(j)清晰地展现出M-U66-NH2在M/N-3膜表面的元素分布情况,与M-U66-NH2相关的Zr、N元素及与Nafion树脂相关的F、S元素在膜表面均匀分布,说明复合膜中M-U66-NH2的分散性良好,未发生明显的团聚现象,这为功能材料充分发挥其表面性质和孔道尺寸等优势提供了条件。

![]() 图 3 P-N (a)、M/N-1 (b)、M/N-3 (c) 膜的表面SEM图像;P-N (d)、M/N-1 (e)、M/N-3 (f)膜的截面SEM图像;M/N-3膜的表面EDS元素分布图((g) N;(h) Zr;(i) F;(j) S)Figure 3. Surface SEM images of P-N (a), M/N-1 (b) and M/N-3 (c); Cross-section SEM images of P-N (d), M/N-1 (e) and M/N-3 (f); EDS element images of M/N-3 ((g) N; (h) Zr; (i) F; (j) S)

图 3 P-N (a)、M/N-1 (b)、M/N-3 (c) 膜的表面SEM图像;P-N (d)、M/N-1 (e)、M/N-3 (f)膜的截面SEM图像;M/N-3膜的表面EDS元素分布图((g) N;(h) Zr;(i) F;(j) S)Figure 3. Surface SEM images of P-N (a), M/N-1 (b) and M/N-3 (c); Cross-section SEM images of P-N (d), M/N-1 (e) and M/N-3 (f); EDS element images of M/N-3 ((g) N; (h) Zr; (i) F; (j) S)为了探究高M-U66-NH2含量对复合膜结构的影响,本实验制备了M/N-6和M/N-9膜。如图4(a)所示,当掺杂量为6wt%时,复合膜截面出现较多尺寸约为2~3 μm的孔洞,这是由于较高掺杂量下,强相互作用促使M-U66-NH2粒子团聚,导致膜内出现缺陷。当掺杂量增至9wt%时,复合膜截面呈现出非对称结构,膜层中可以观察到大尺寸的M-U66-NH2团聚体。产生该现象的原因在于成膜过程中随着溶剂的缓慢挥发,较大尺寸的团聚体会逐渐下沉,并在玻璃板侧富集,形成高M-U66-NH2含量的多孔、疏松区域,此结构不利于UIO-66-NH2功能的充分发挥。同时,产生的缺陷会加速钒离子的跨膜渗透,降低质子交换膜的离子选择性和力学性能[14]。

通过FTIR分析M-U66-NH2、P-N、M/N-3膜样品的结构特征,如图5所示。M-U66-NH2在

3458 、3356 和1436 cm−1处具有明显的特征峰,分别对应N—H的对称和非对称伸缩振动及N—H的剪切伸缩振动,与文献报道一致[22]。P-N膜在1207 、1151 cm−1处为C—F伸缩振动峰,1053 cm−1处为O=S=O振动峰及980 cm−1处为C—F特征峰,此结果与文献中Nafion树脂的特征峰一致[18]。M/N-3膜的FTIR图谱可以近似为M-U66-NH2和P-N图谱的叠加,表明UIO-66-NH2材料在膜中稳定存在,制膜过程并未破坏其微观结构。2.3 复合质子交换膜的理化性质

吸水率和溶胀率是质子交换膜的重要性能指标。如图6(a)所示,基于M-U66-NH2的亲水性和丰富孔道,复合膜的吸水率和溶胀率均随掺入量的提高而增大[23]。同时,M-U66-NH2的刚性结构赋予膜较低的溶胀率(<4%)[24]。膜的吸水率和溶胀率直接影响其离子传导性能,由图6(b)可见,随着UIO-66-NH2掺杂量的提高,膜的质子传导率逐渐增大,而面电阻逐渐变小,如M/N-3的质子传导率达到122.18 mS·cm−1,此改善效果得益于膜中—NH2和—SO3H形成的酸/碱对及存在的氢键网络[25]。当掺杂量超过6wt%时,M-U66-NH2在膜内团聚而缺陷产生,膜的质子传导率较低。比较可见,M/N-3膜的吸水率、溶胀率和质子传导率均高于T/N-3膜,这与UIO-66-NH2的尺寸均一性和完整结构相关。

通过拉伸测试评价膜的机械强度。如图6(c)和图6(d)所示,M-U66-NH2掺杂量低于3wt%时,复合膜的拉伸强度均高于P-N膜,如M/N-3膜的强度达到27 MPa,也高于T/N-3膜(22.3 MPa)。主要原因是UIO-66-NH2具有刚性结构,且—NH2基团与Nafion的—SO3H基团可形成共轭酸碱对,其强相互作用促使Nafion的分子链与UIO-66-NH2发生物理交联,从而提高了复合膜的力学性能[26]。同时,尺寸更小、更规则的M-U66-NH2与Nafion树脂间的分散更充分、交联程度更高,表现出更优的强化作用[1]。当UIO-66-NH2掺杂量超过6wt%时,膜中的孔洞缺陷导致其机械强度显著降低。

2.4 复合膜的钒离子渗透性和离子选择性

本实验选取的UIO-66-NH2的有效孔径为0.52 nm,介于水分子(<0.3 nm)和钒离子(>0.6 nm)之间[14],可通过筛分效应提高膜的离子选择性。如图7(a)所示,M/N-X系列复合膜的阻钒性更好,如M/N-3膜的钒离子渗透浓度最低,仅为P-N膜的23%左右,而M/N-9膜的阻钒性能最差。当测试时间大于48 h,T/N-3膜的表现略差于M/N-3膜,主要原因是传统水热法所制备UIO-66-NH2的晶体结构不够完善。

高钒离子渗透性不利于钒电池长期稳定运行,如图7(b)所示,优化条件下所制备的M/N-3膜的钒离子渗透率最低,仅为8.3×10−8 cm2·min−1,且该膜的离子选择性达到15.6×105 S·min·cm−3,约为P-N膜的30倍。当UIO-66-NH2掺入量过低或过高时,膜的离子选择性均较低。另外,与M/N-3膜相比,掺杂T-U66-NH2的复合膜具有接近的离子选择性,这说明两种方法所制备UIO-66-NH2对复合膜离子选择性的影响较小。有研究结果指出增加厚度会提高膜的钒离子渗透率,进而降低膜的离子选择性[7, 27-29]。因此,本实验在充分参考文献数据的基础上,为了平衡氢离子、钒离子的渗透情况,确定膜厚度为40 μm左右。

2.5 复合膜的电池性能

分别将P-N、M/N-X和T/N-3膜组装成模拟电池进行测试,评价不同电池的电压效率(Voltage efficiency,VE)、库伦效率(Coulombic efficiency,CE)和能量效率(EE)。由图8(a)可知,在相同电流密度下,随着M-U66-NH2掺杂量的增加,电池的CE逐渐增大,在100 mA·cm−2电流密度下,M/N-3膜电池的库伦效率达到97.66%,高于P-N膜(95.8%)。因膜内粒子团聚造成了结构缺陷,M/N-6和M/N-9膜电池的CE低于M/N-3膜。图8(b)显示M/N-X复合膜的VE高于P-N膜,且随着电流密度的增加,复合膜所装配电池的VE逐渐减小,该趋势与文献报道相似[5]。能量效率是电池性能的综合体现,由图8(c)可见,在电流密度为100~200 mA·cm−2的范围内,M/N-3膜的电池能量效率均高于P-N膜和N212膜(美国杜邦公司Nafion212商品膜),最高达到83.8%,说明M-U66-NH2的掺入有效提升了Nafion膜的电池性能。图8(d)~8(f)更清晰地显示了P-N膜、M/N-3膜和T/N-3膜的性能。在测试电流密度范围内,M/N-3膜的库伦效率与T/N-3膜相当,而其电压效率和能量效率均高于其他两种类型膜样品。可见,适宜比例M-U66-NH2的引入有利于改善膜性能,进而提升钒电池的充放电效率。

在150 mA·cm−2电流密度下,对不同膜所装配电池充放电200次,比较其循环稳定性。如图9(a)所示,在200次的充放电测试过程中,M/N-3和T/N-3膜的电池CE、VE和EE相对较稳定,无明显降低,说明UIO-66-NH2的引入有效阻碍了钒离子在膜内的渗透,保证了质子在膜中快速、稳定传输。此外,在测试周期内,M/N-3和T/N-3膜的能量效率分别稳定在77.8%和76.5%,无明显衰减,说明复合膜的理化稳定性可以满足钒电池工作环境的需求。但是,测试周期内不同电池的容量衰减情况差异较大。由图9(b)可见,P-N膜的电池容量衰减了81%,而经过同样测试后,掺杂UIO-66-NH2膜的电池容量衰减率仅为45%左右,其中基于M-U66-NH2的复合膜显示出更低的容量衰减率,单次衰减率仅为0.19%,较T/N-3膜(0.24%)提高0.05%,较P-N膜(0.41%)提高0.22%,同时,图9(c)证明了掺杂M-U66-NH2的确会优化VRBs所用质子交换膜的电池性能。

![]() 图 9 150 mA·cm−2电流密度下复合膜所装配电池的循环效率(a)、容量保持率(b)以及与报道性能的对比(c)Figure 9. Cycle efficiency (a) and capacity retention (b) of composite membranes at 150 mA·cm−2, and comparisons with reported performance (c)PBI—Polybenzimidazole; PS—Polystyrene; GO—Graphene oxide; SPEEK—Sulfonated poly(ether ether ketone); 2D-ZMs—Two-dimensional zeolite

图 9 150 mA·cm−2电流密度下复合膜所装配电池的循环效率(a)、容量保持率(b)以及与报道性能的对比(c)Figure 9. Cycle efficiency (a) and capacity retention (b) of composite membranes at 150 mA·cm−2, and comparisons with reported performance (c)PBI—Polybenzimidazole; PS—Polystyrene; GO—Graphene oxide; SPEEK—Sulfonated poly(ether ether ketone); 2D-ZMs—Two-dimensional zeolite3. 结 论

(1)与传统水热法相比,微波加热合成UIO-66-NH2的效率更高,耗时仅为前者的1/96,且所制备晶体的结构更完整、更均匀,粒径约为200 nm,在Nafion溶液中分散性良好。

(2) UIO-66-NH2可改善复合膜的理化稳定性,且可提高膜的质子传导性和离子选择性,优化条件下复合膜的质子传导率可达122.18 mS·cm−1,离子选择性可达15.6×105 S·min·cm−3。

(3)优化条件下复合膜体现出良好的电池性能。在150 mA·cm−2电流密度下,电池的能量效率大于77%,200次循环周期内单次容量衰减率为0.19%,较纯树脂膜提高0.22%。

(4)基于微波法的UIO-66-NH2与Nafion形成的复合膜具有良好的理化性质和电池性能,为全钒液流电池用高性能质子交换膜的设计和制备提供了新的策略,具有良好的发展前景。

-

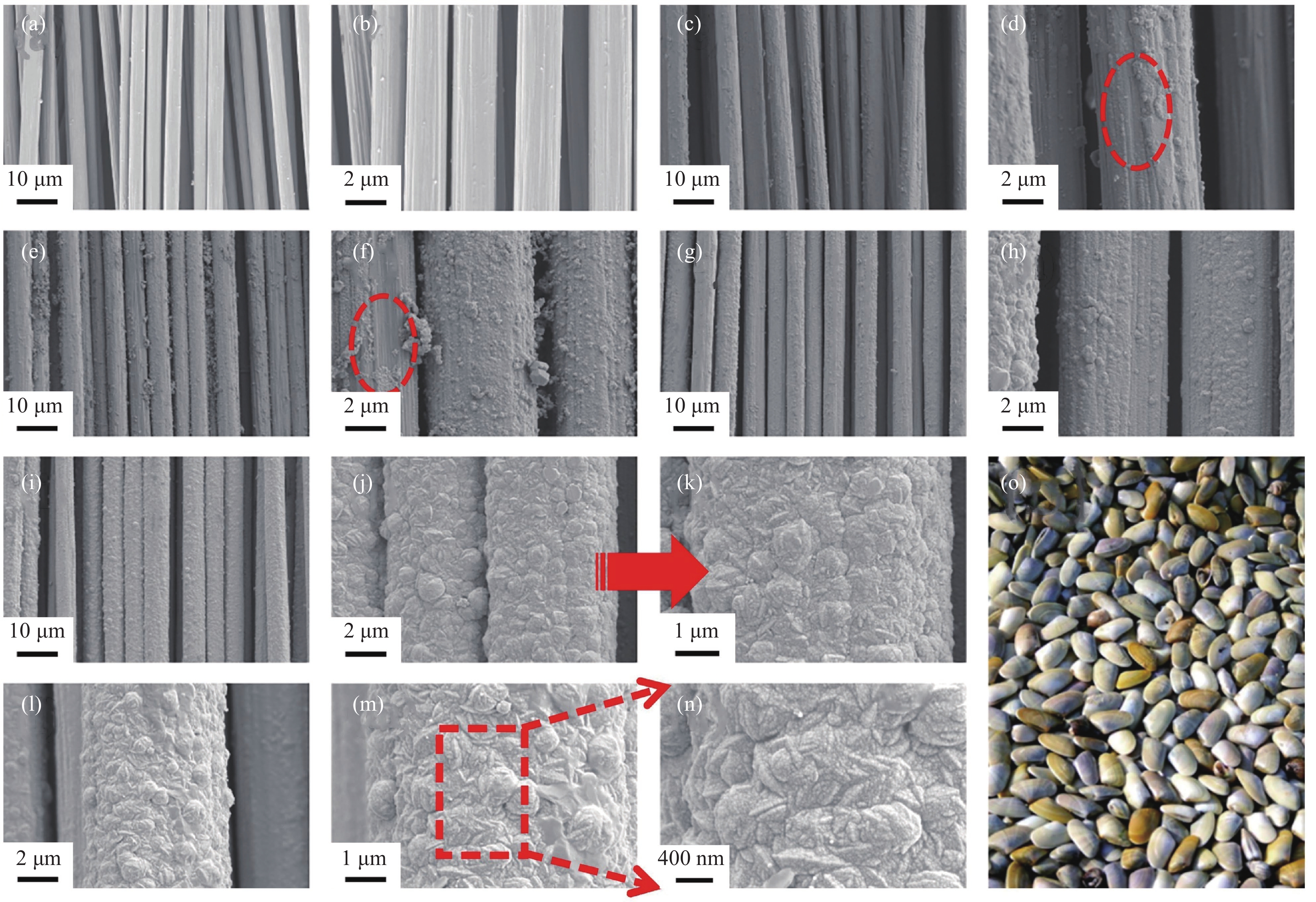

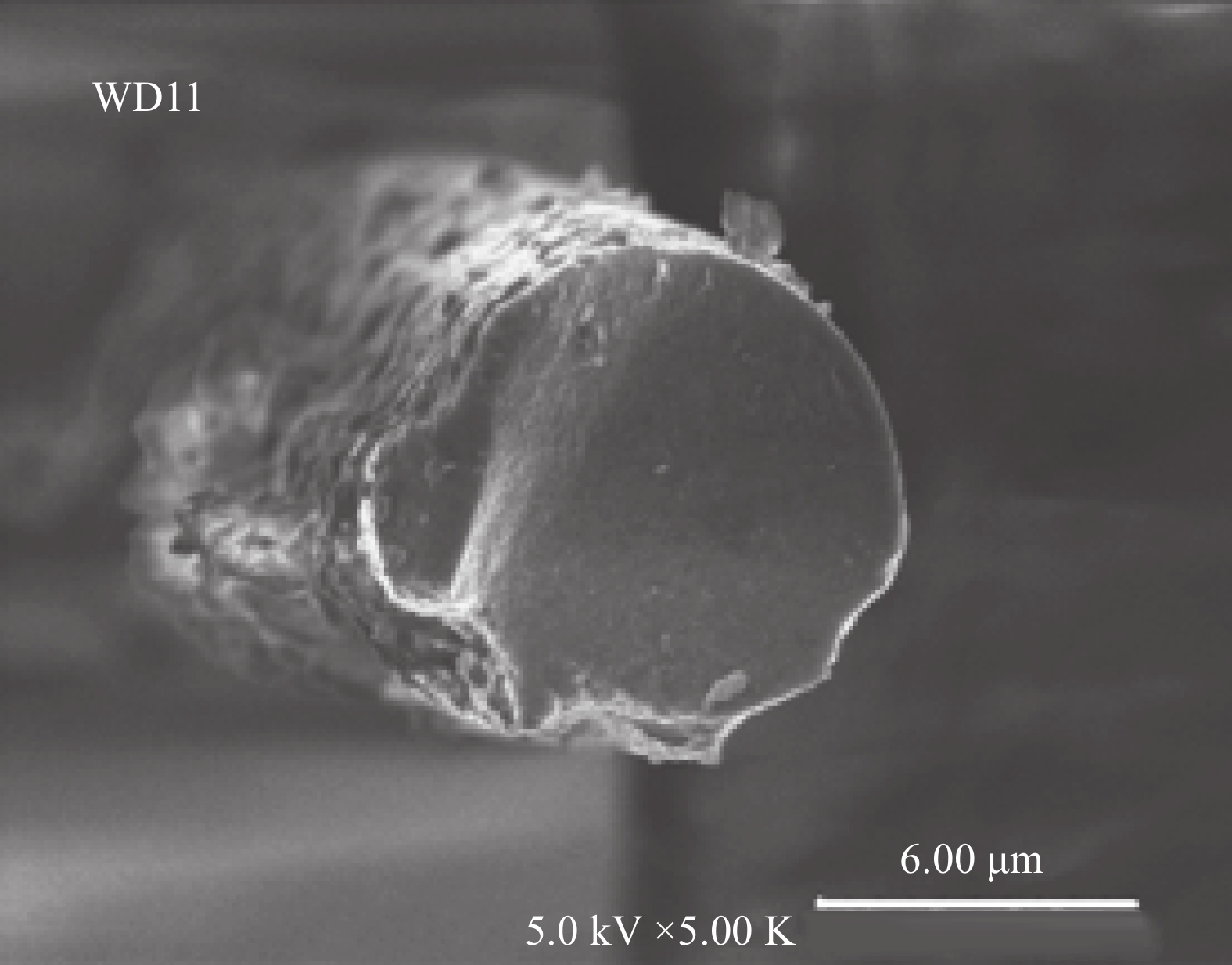

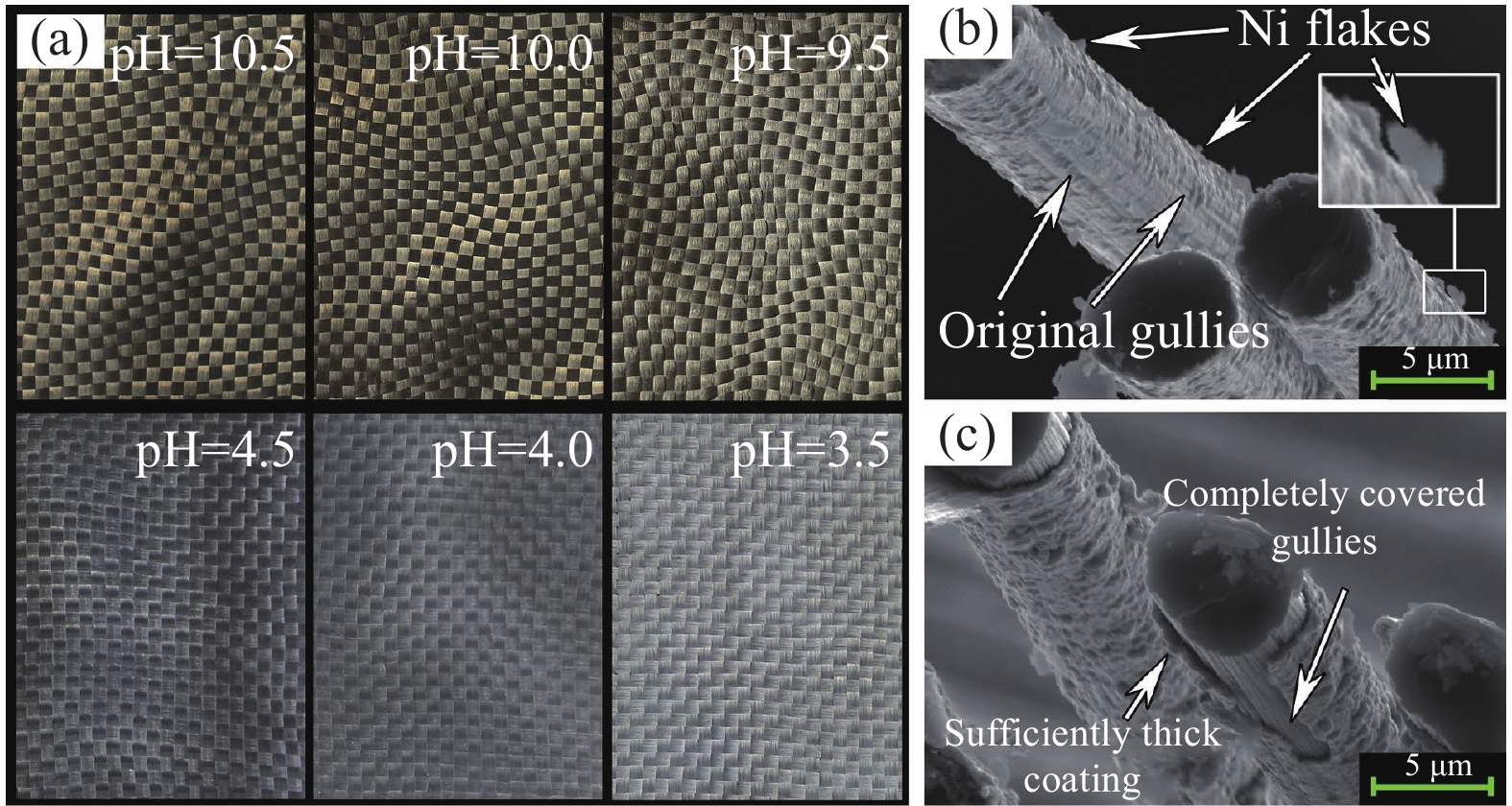

图 1 不同喷涂次数下碳纤维织物(CFFs)@Ag的SEM图像[5]:((a), (b))原始CFFs;((c), (d))喷10 次;((e), (f))喷30 次;((g), (h))喷50 次;((i)~(k))喷70 次;((l)~(n))喷100 次;(o)壳状结构

Figure 1. SEM images of carbon fiber fabrics (CFFs)@Ag with different spraying times[5]: ((a), (b)) Pristine CFFs; ((c), (d)) 10 times; ((e), (f)) 30 times; ((g), (h)) 50 times; ((i)-(k)) 70 times; ((l)-(n)) 100 times; (o) Picture of shells

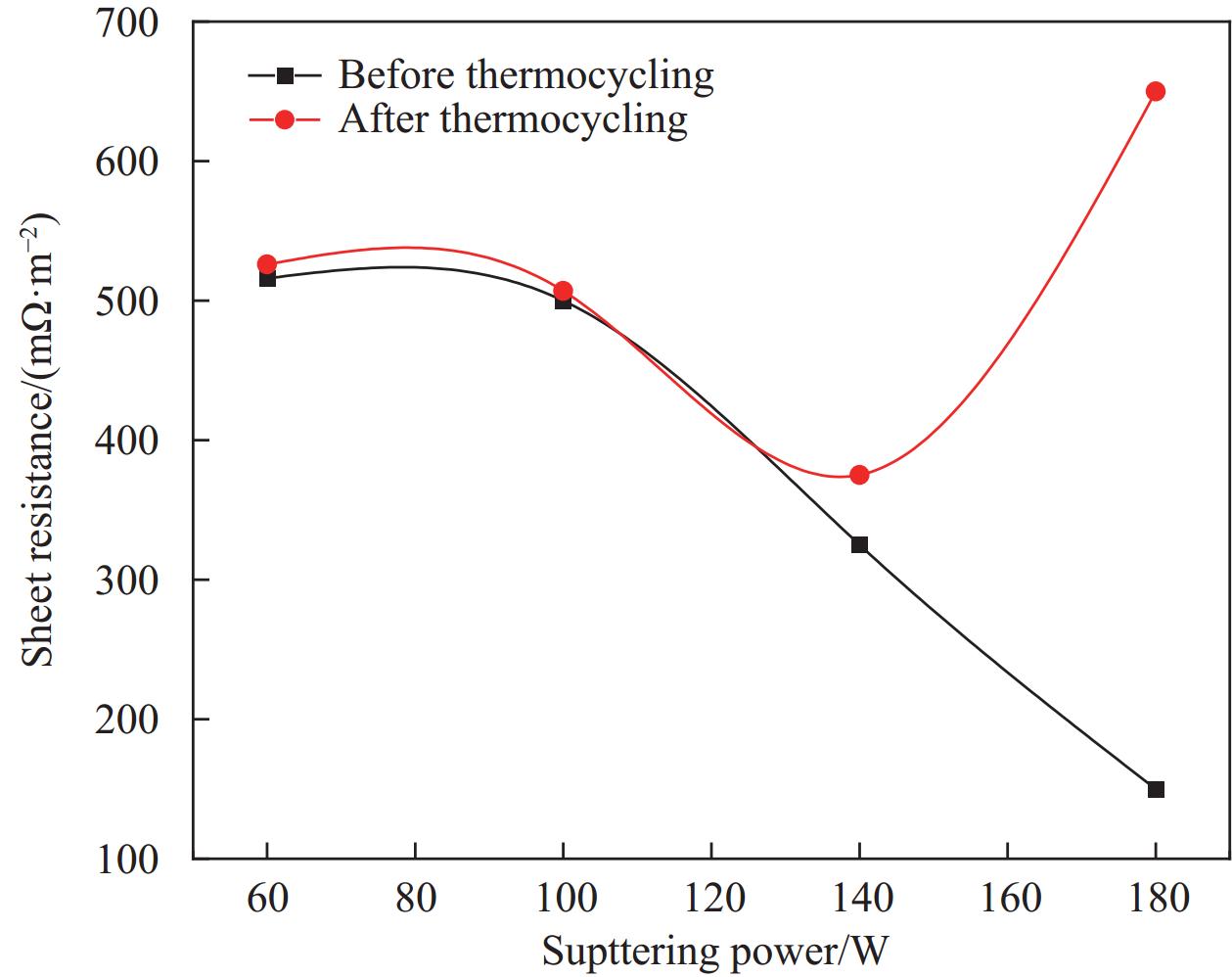

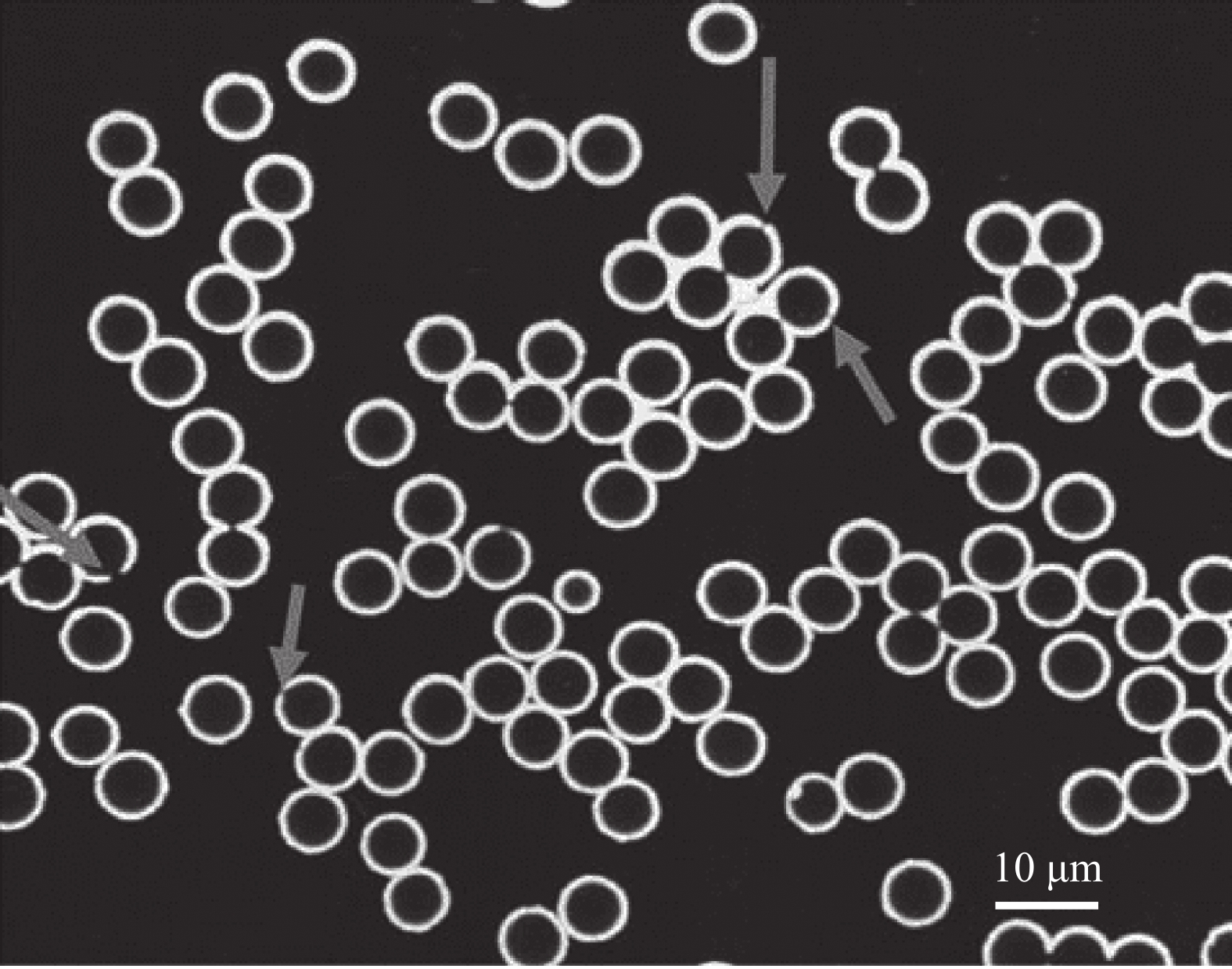

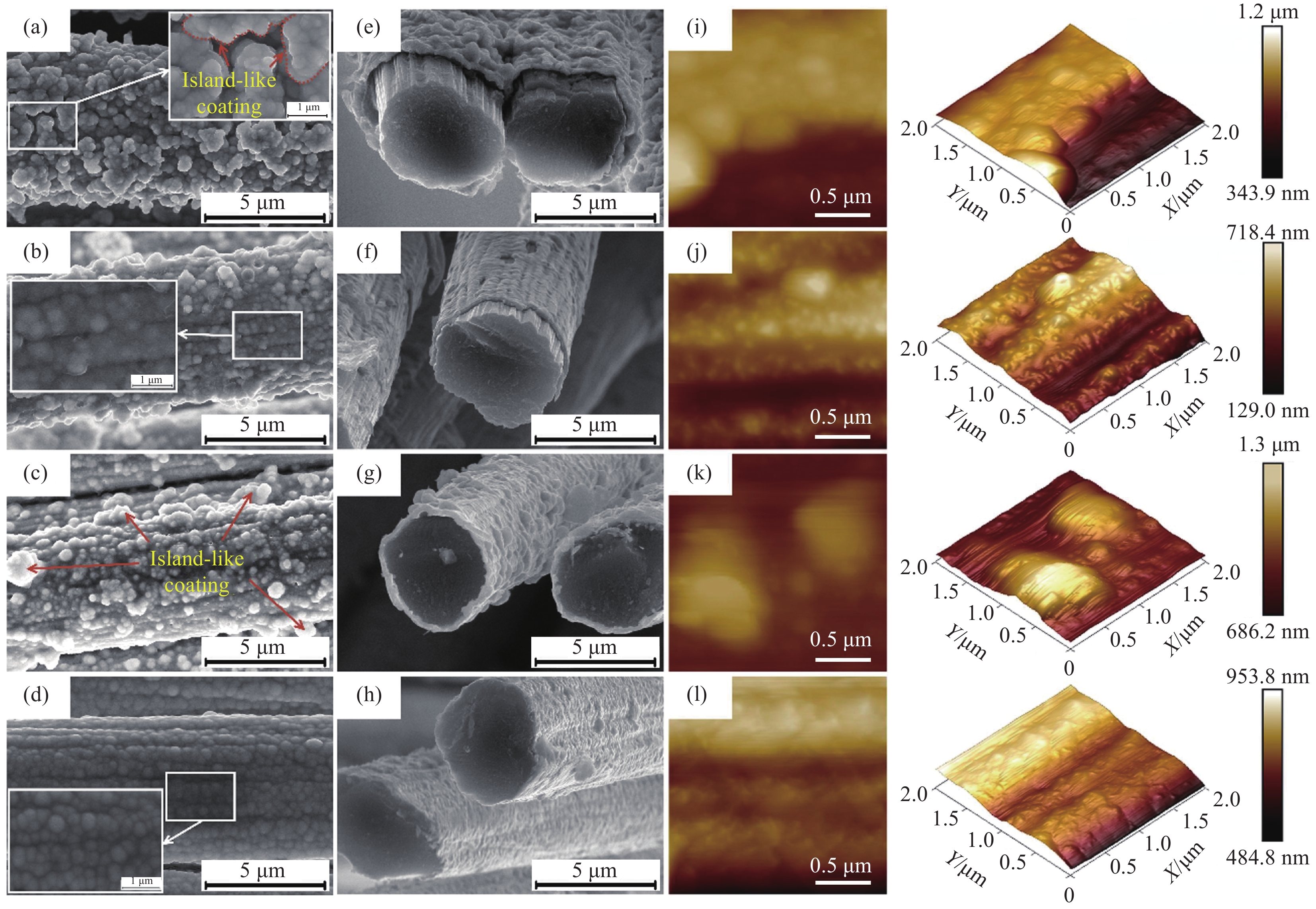

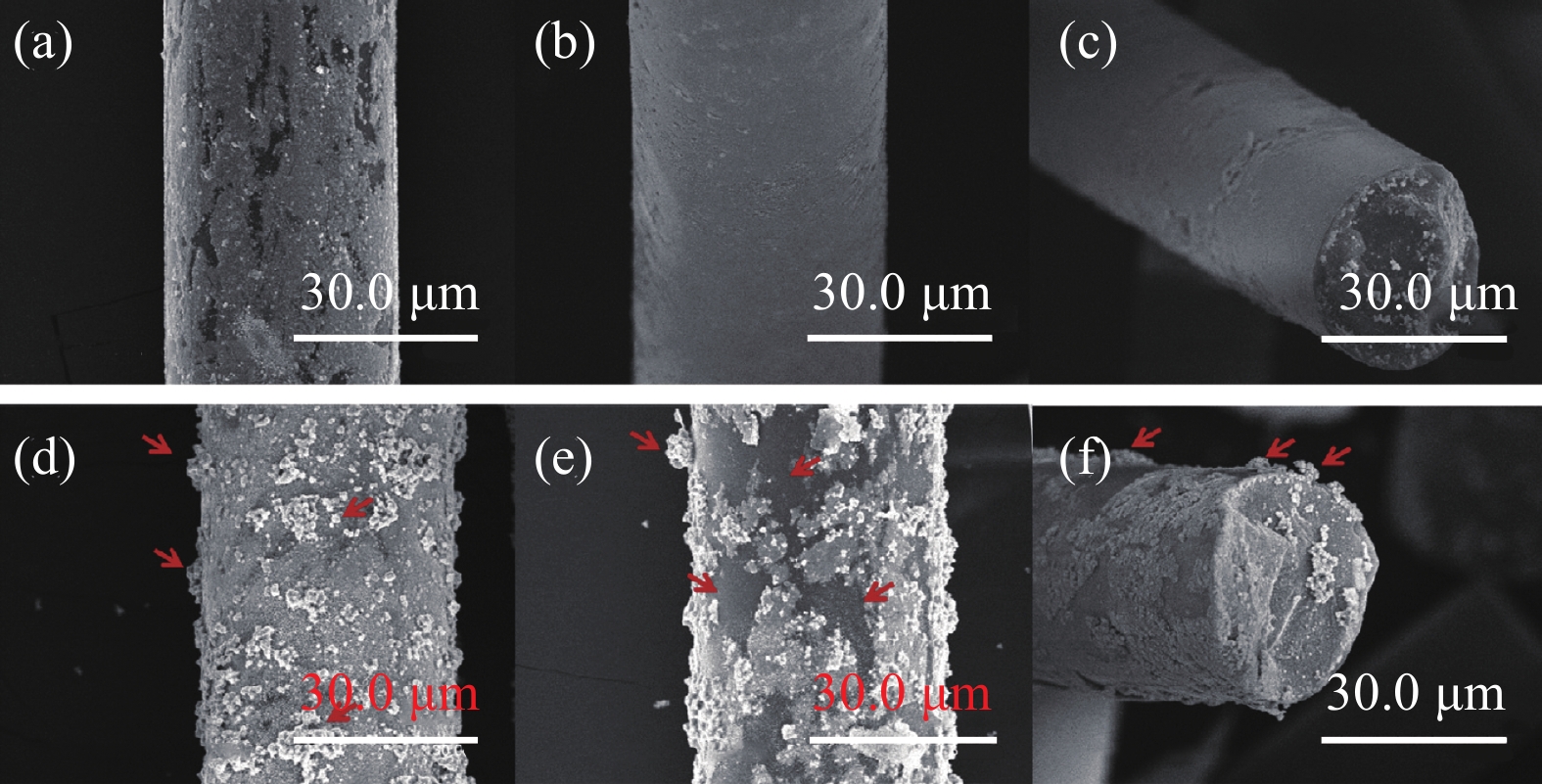

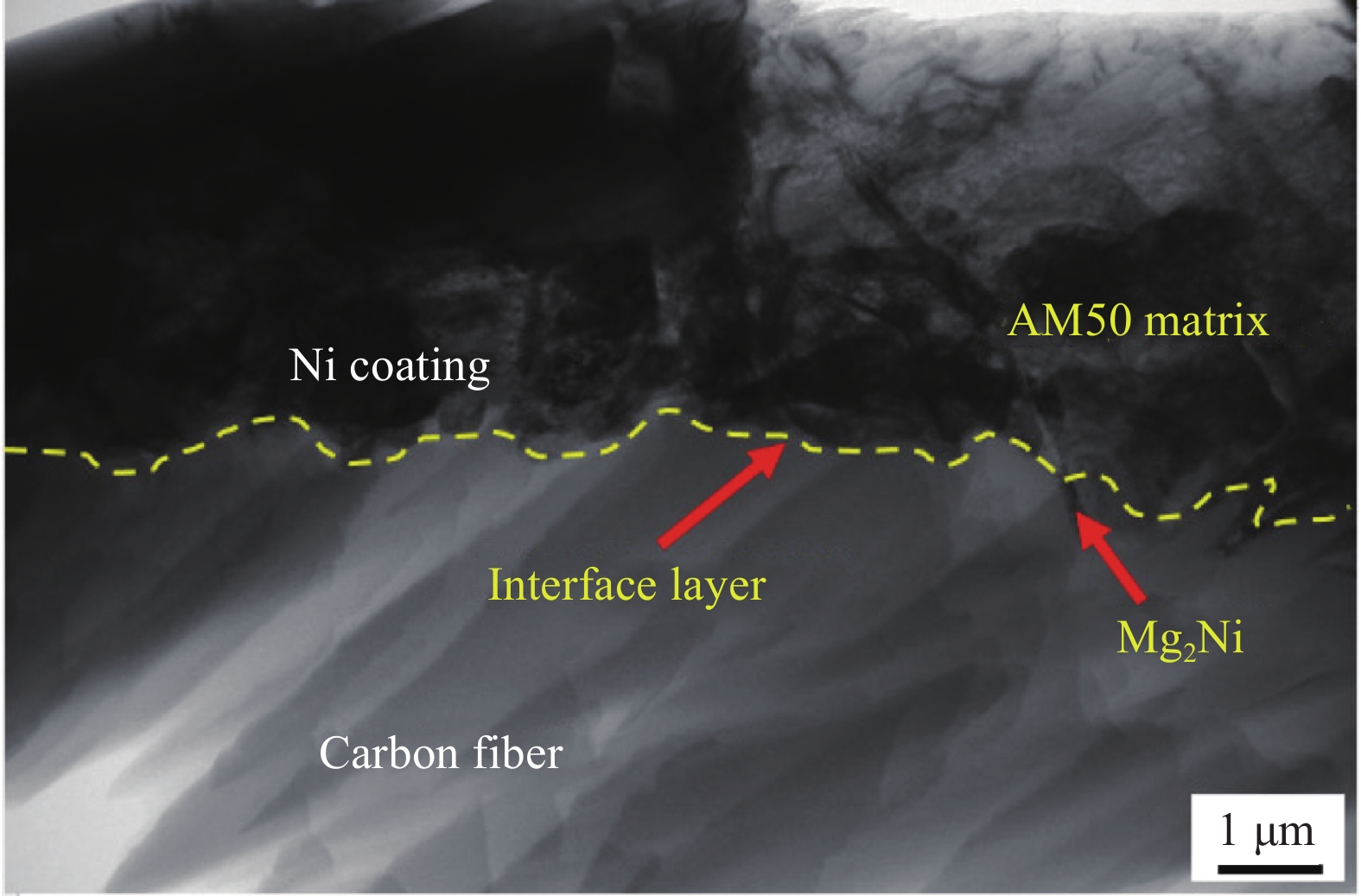

图 8 PVD工艺下不同活化法CF@Ni的SEM和AFM图像[22]:((a), (e), (i))二步Pd活化;((b), (f), (j))一步Pd胶体活化;((c), (g), (k))强氧化混合酸(SMA)刻蚀;((d), (h), (i))一步Pd与SMA刻蚀组合活化

Figure 8. SEM and AFM images of CF@Ni with different activation methods by the PVD process[22]: ((a), (e), (i)) Two-step Pd activation; ((b), (f), (j)) One-step Pd-colloid activation; ((c), (g), (k)) Strong oxidizing mixed acid (SMA) etching; ((d), (h), (i)) With the combination of SMA etching and one-step Pd-colloid activation

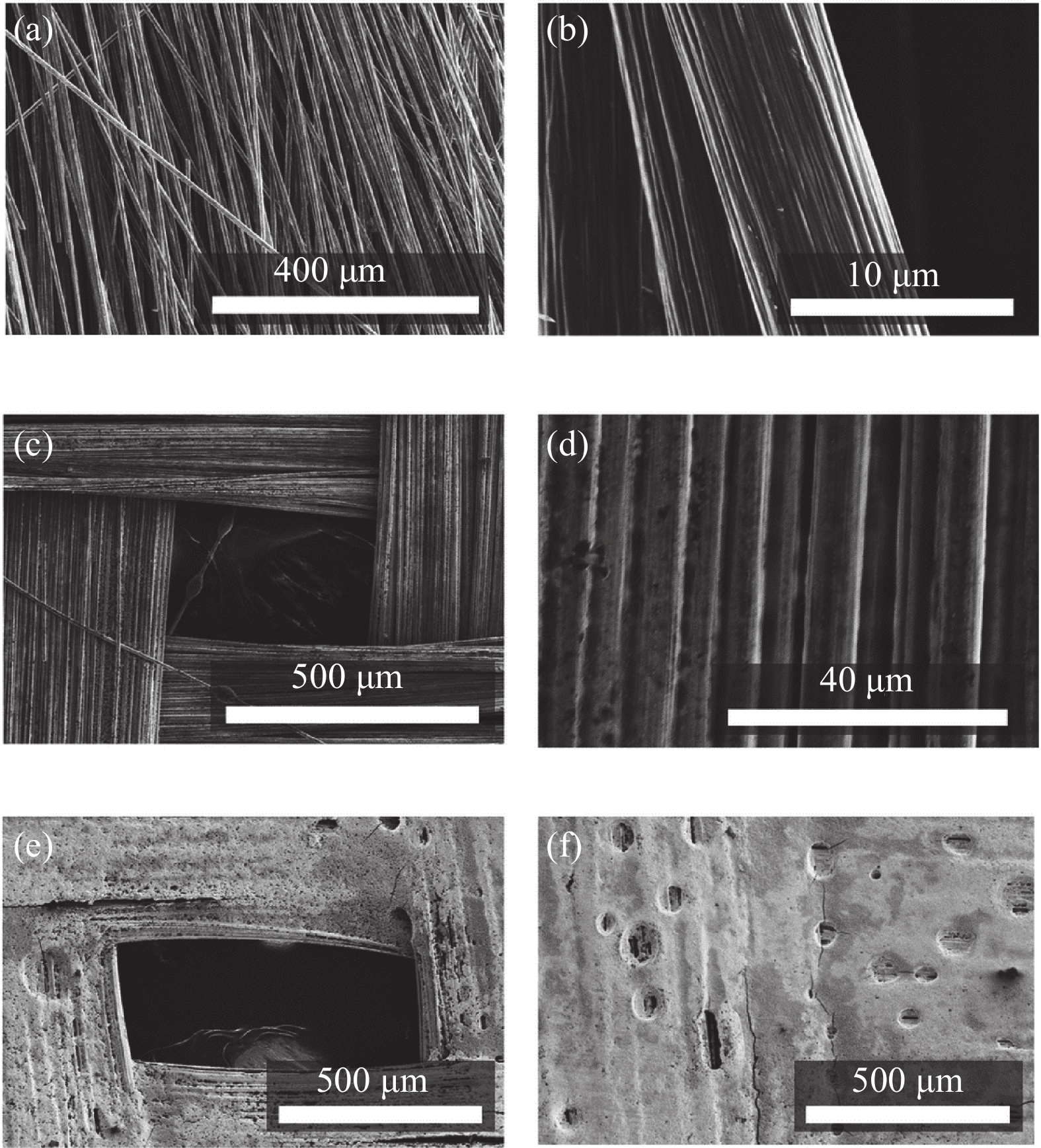

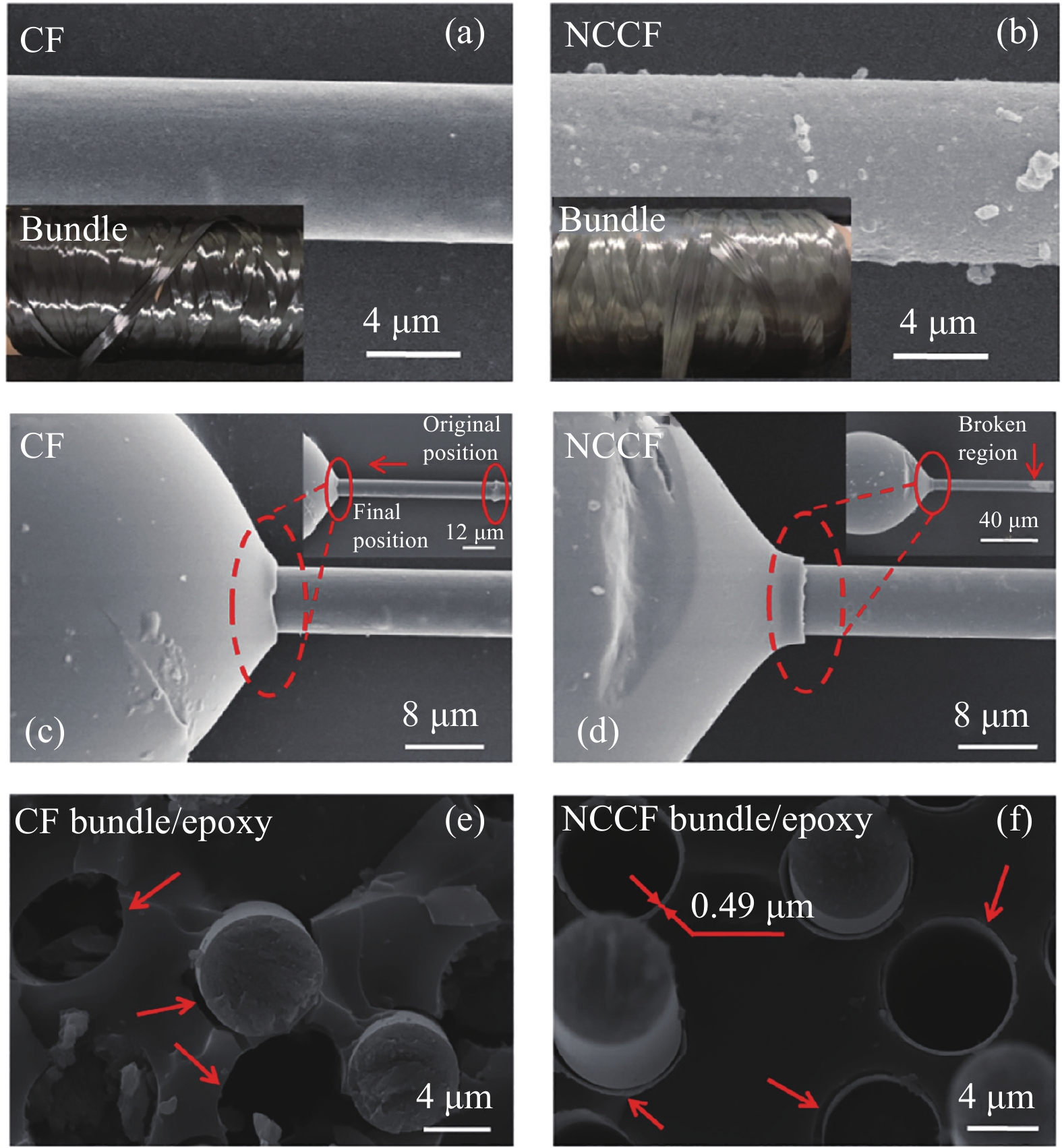

图 9 ((a), (b)) CF和CF@Ni的SEM图像;((c), (d)) CF IFSS和CF@Ni IFSS的SEM图;((e), (f)) CF/EP和CF@Ni/EP拉伸断面SEM图像[23]

Figure 9. ((a), (b)) SEM images of CF and CF@Ni; ((c), (d)) SEM images of CF IFSS and CF@Ni IFSS; ((e), (f)) SEM images of CF/EP and CF@Ni/EP tensile fracture cross section[23]

NCCF—Nickel coated carbon fiber

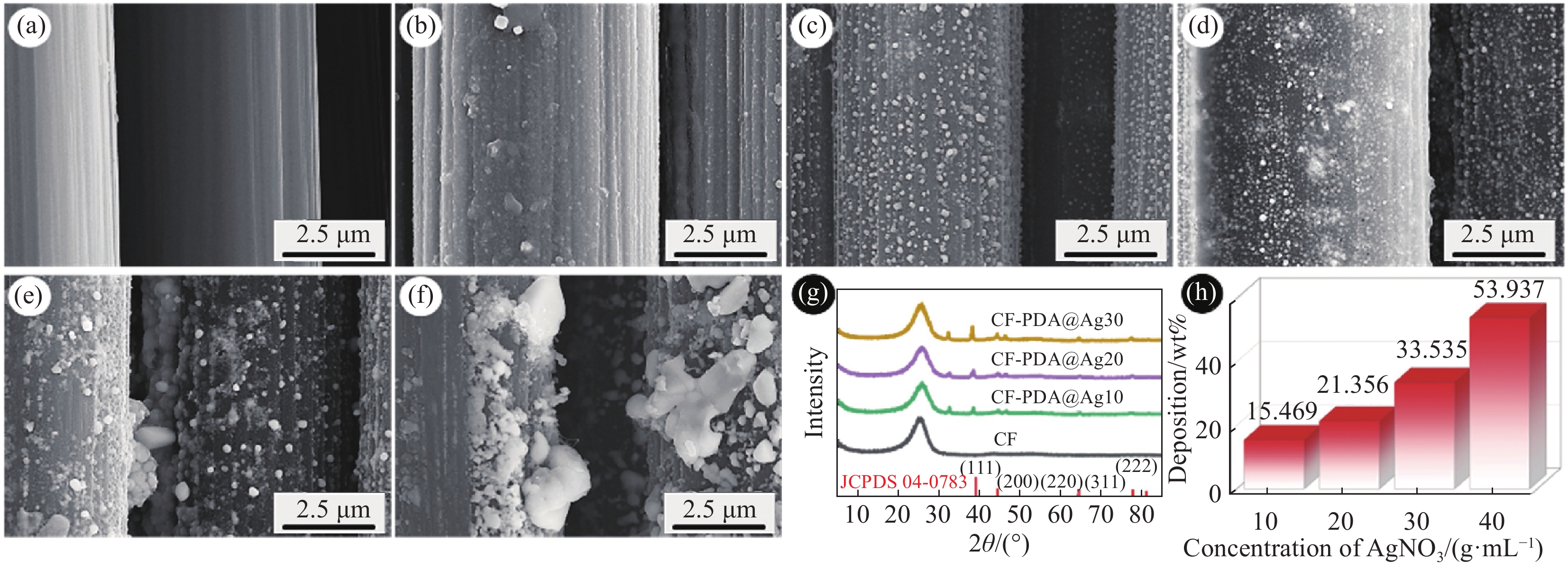

图 11 化学镀工艺下不同阶段CF的SEM图像[30]:(a)原始CF;(b)聚多巴胺(PDA)涂层CF;((c)~(f)) AgNO3浓度分别为10、20、30、40 g/mL的CF-PDA@Ag;(g) CF和CF-PDA@Ag的XED图谱;(h)不同AgNO3浓度下Ag增加量

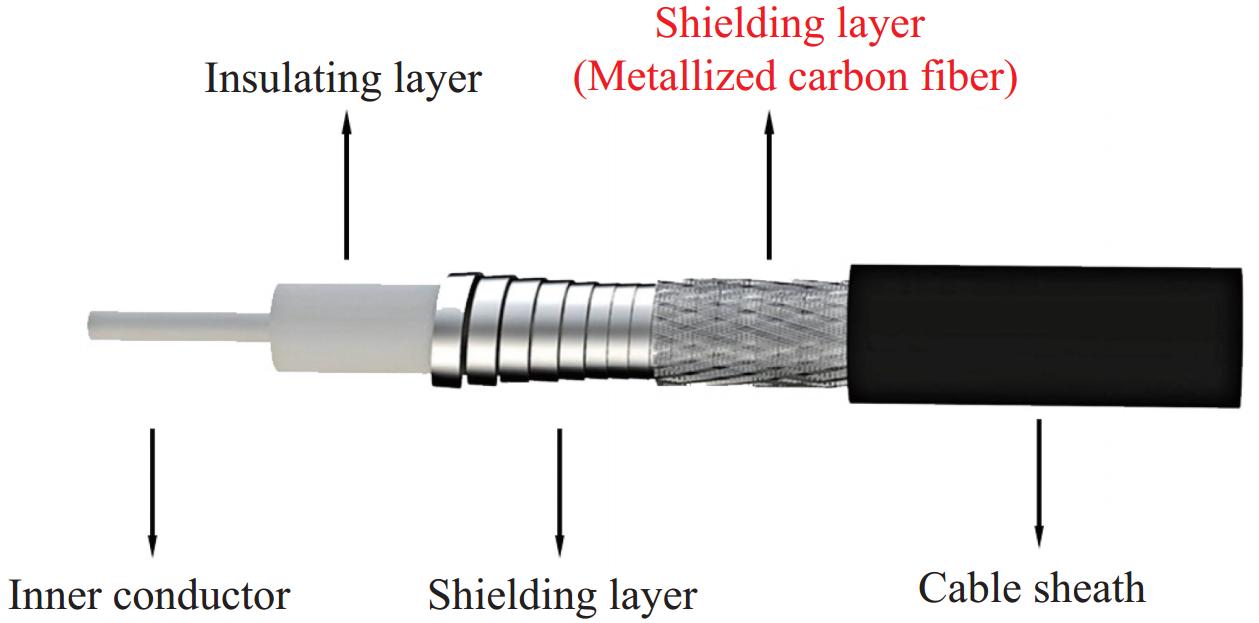

Figure 11. SEM images of CF with different stage by electroless plating process[30]: (a) Pristine CF; (b) CF coated polydopamine (PDA); ((c)-(f)) CF-PDA@Ag with AgNO3 concentrations 10, 20, 30, 40 g/mL; (g) XED patterns of CF and CF-PDA@Ag; (h) Loading of CF-PDA@Ag with different AgNO3 concentrations

表 1 不同预处理方法下金属化纤维复合材料的IFSS

Table 1 Metallized fiber composites IFSS with different pretreatment methods

-

[1] 曹维宇, 杨学萍, 张藕生. 我国高性能高分子复合材料发展现状与展望[J]. 中国工程科学, 2020, 22(5): 112-120. DOI: 10.15302/J-SSCAE-2020.05.010 CAO Weiyu, YANG Xueping, ZHANG Ousheng. Development and prospect of high performance polymer composites in China[J]. Strategic Study of CAE, 2020, 22(5): 112-120(in Chinese). DOI: 10.15302/J-SSCAE-2020.05.010

[2] 高家诚, 谭尊, 任富忠. 碳纤维表面化学镀镍工艺及机理研究[J]. 功能材料, 2011, 42(8): 1360-1363. GAO Jiacheng, TAN Zun, REN Fuzhong. Study on the process and mechanism of chemical nickel coating on carbon fiber surface[J]. Journal of Functional Materials, 2011, 42(8): 1360-1363(in Chinese).

[3] 叶伟, 徐刘碗, 严仁杰, 等. 碳纤维金属化镀镍的研究进展[J]. 科技视界, 2015(13): 8-10. DOI: 10.3969/j.issn.2095-2457.2015.13.003 YE Wei, XU Liuwan, YAN Renjie, et al. Research progress in nickel coating on carbon fiber[J]. Science & Technology Vision, 2015(13): 8-10(in Chinese). DOI: 10.3969/j.issn.2095-2457.2015.13.003

[4] 董晓阳, 郭金海. 纤维增强树脂基复合材料表面金属化研究进展[J]. 玻璃钢/复合材料, 2017(2): 93-99. DONG Xiaoyang, GUO Jinhai. Research progress on surface metallization of fiber reinforced resin matrix composite materials[J]. Composites Science and Engineering, 2017(2): 93-99(in Chinese).

[5] LIU C Y, KANG Z X. Facile fabrication of conductive silver films on carbon fiber fabrics via two components spray deposition technique for electromagnetic interference shielding[J]. Applied Surface Science, 2019, 487: 1245-1252. DOI: 10.1016/j.apsusc.2019.04.186

[6] PARK J, HU X, TORFEH M, et al. Exceptional electromagnetic shielding efficiency of silver coated carbon fiber fabrics via a roll-to-roll spray coating process[J]. Journal of Materials Chemistry C, 2020, 8(32): 11070-11078. DOI: 10.1039/D0TC02048F

[7] 胡隆. 织物表面银基复合涂层的制备及电磁屏蔽性能研究[D]. 广州: 华南理工大学, 2022. HU Long. Preparation and electromagnetic interference shielding performance of silver-based composite coatings on fabric surfaces[D]. Guangzhou: South China University of Technology, 2022(in Chinese).

[8] 王孝锋. 基于磁控溅射C/C膜界面复合材料的制备[D]. 芜湖: 安徽工程大学, 2019. WANG Xiaofeng. Preparation of C/C film interface composite based on magnetron sputtering[D]. Wuhu: Anhui Polytechnic University, 2019(in Chinese).

[9] 岳光辉. 低维纳米功能材料制备及研究[D]. 兰州: 兰州大学, 2007. YUE Guanghui. Preparation and study of low-dimensional functional nanomaterials[D]. Lanzhou: Lanzhou University, 2007(in Chinese).

[10] NELYUB V A, FEDOROV S Y, MALYSHEVA G V, et al. Properties of carbon fibers after applying metal coatings on them by magnetron sputtering technology[J]. Fibre Chemistry, 2021, 53(4): 252-257. DOI: 10.1007/s10692-022-10279-5

[11] 李颖, 王鸿博, 高卫东. 碳纤维表面磁控溅射镀铜研究[J]. 化工新型材料, 2011, 39(12): 62-63, 86. DOI: 10.3969/j.issn.1006-3536.2011.12.020 LI Ying, WANG Hongbo, GAO Weidong. The study of carbon fibers with magnetron sputtered copper coating[J]. New Chemical Materials, 2011, 39(12): 62-63, 86(in Chinese). DOI: 10.3969/j.issn.1006-3536.2011.12.020

[12] 陈缘, 徐珍珍, 杨莉, 等. 基于磁控溅射技术的碳基电磁屏蔽材料[J]. 工程塑料应用, 2022, 50(3): 25-31, 37. DOI: 10.3969/j.issn.1001-3539.2022.03.005 CHEN Yuan, XU Zhenzhen, YANG Li, et al. Carbon-based electromagnetic shielding materials based on magnetron sputtering technology[J]. Engineering Plastics Application, 2022, 50(3): 25-31, 37(in Chinese). DOI: 10.3969/j.issn.1001-3539.2022.03.005

[13] ANDRÉANI A S, POULON-QUINTIN A, REBILLAT F. Oxidation of refractory metallic coatings on carbon fibers heated up to

1850 ℃[J]. Surface and Coatings Technology, 2010, 205(5): 1262-1267. DOI: 10.1016/j.surfcoat.2010.10.037[14] 宋季. 碳纤维表面改性、界面粘合及金属化的研究[D]. 北京: 北京化工大学, 2020. SONG Ji. Surface modification, interfacial adhesion and metallization of carbon fiber[D]. Beijing: Beijing University of Chemical Technology, 2020(in Chinese).

[15] ROHATGI P K, TIWARI V, GUPTA N. Squeeze infiltration processing of nickel coated carbon fiber reinforced Al-2014 composite[J]. Journal of Materials Science, 2006, 41(21): 7232-7239. DOI: 10.1007/s10853-006-0915-9

[16] 李一, 聂俊辉, 李楠, 等. 镍覆膜碳纤维的制备与性能研究[J]. 功能材料, 2012, 43(13): 1688-1691, 1695. DOI: 10.3969/j.issn.1001-9731.2012.13.007 LI Yi, NIE Junhui, LI Nan, et al. Preparation and performance study of nickel coated carbon fiber[J]. Journal of Functional Materials, 2012, 43(13): 1688-1691, 1695(in Chinese). DOI: 10.3969/j.issn.1001-9731.2012.13.007

[17] OGAWA F, MASUDA C, FUJII H. In situ chemical vapor deposition of metals on vapor-grown carbon fibers and fabrication of aluminum-matrix composites reinforced by coated fibers[J]. Journal of Materials Science, 2017, 53(7): 5036-5050.

[18] GUO H W, CHEN Z Q, LI J J, et al. Study of Fe/Ni alloy coated carbon fibres prepared by electroplating[J]. Surface Engineering, 2018, 35(10): 841-847.

[19] 吕钊钊, 沙建军, 祖宇飞, 等. 碳纤维表面超声振荡辅助电镀镍涂层工艺及其参数的影响规律[J]. 中国有色金属学报, 2020, 30(3): 571-579. DOI: 10.11817/j.ysxb.1004.0609.2020-37513 LYU Zhaozhao, SHA Jianjun, ZU Yufei, et al. Ultrasonic oscillation assisted electroplating of nickel coating on carbon fiber surface and the influence of its parameters[J]. The Chinese Journal of Nonferrous Metals, 2020, 30(3): 571-579(in Chinese). DOI: 10.11817/j.ysxb.1004.0609.2020-37513

[20] ZHANG G D, YU J W, SU C, et al. The effect of annealing on the properties of copper-coated carbon fiber[J]. Surfaces and Interfaces, 2023, 37: 102630. DOI: 10.1016/j.surfin.2023.102630

[21] ZHENG X R, KIM S, PARK C W. Enhancement of thermal conductivity of carbon fiber-reinforced polymer composite with copper and boron nitride particles[J]. Composites Part A: Applied Science and Manufacturing, 2019, 121: 449-456. DOI: 10.1016/j.compositesa.2019.03.030

[22] LIU J M, ZHANG Y B, GUO Z K, et al. Enhancement of fiber-matrix adhesion in carbon fiber reinforced Al-matrix composites with an optimized electroless plating process[J]. Composites Part A: Applied Science and Manufacturing, 2021, 142: 106258. DOI: 10.1016/j.compositesa.2020.106258

[23] CAO Y H, FARHA F I, GE D S, et al. Highly effective E-heating performance of nickel coated carbon fiber and its composites for de-icing application[J]. Composite Structures, 2019, 229: 111397. DOI: 10.1016/j.compstruct.2019.111397

[24] KURKOWSKA M, AWIETJAN S, KOZERA R, et al. Application of electroless deposition for surface modification of the multiwall carbon nanotubes[J]. Chemical Physics Letters, 2018, 702: 38-43. DOI: 10.1016/j.cplett.2018.04.056

[25] VITRY V, BONIN L. Formation and characterization of multilayers borohydride and hypophosphite reduced electroless nickel deposits[J]. Electrochimica Acta, 2017, 243: 7-17. DOI: 10.1016/j.electacta.2017.04.152

[26] BALARAJU J N, RADHAKRISHNAN P, EZHILSELVI V, et al. Studies on electroless nickel polyalloy coatings over carbon fibers/CFRP composites[J]. Surface & Coatings Technology, 2016, 302: 389-397.

[27] CHOI B K, CHOI W K, RHEE K Y, et al. Influence of heat treatment temperature on structure and exothermic properties of electroless Ni-P plating carbon fiber heating elements[J]. Composites Part B: Engineering, 2019, 167: 676-682. DOI: 10.1016/j.compositesb.2019.03.057

[28] JIAO Y X, LI J, DU F, et al. A study of the wear resistance of carbon fiber composites deposited using an alkaline-based palladium-free electroless plating method[J]. Materials Today Communications, 2023, 37: 106931. DOI: 10.1016/j.mtcomm.2023.106931

[29] YIM Y J, RHEE K Y, PARK S J. Influence of electroless nickel-plating on fracture toughness of pitch-based carbon fibre reinforced composites[J]. Composites Part B: Engineering, 2015, 76: 286-291. DOI: 10.1016/j.compositesb.2015.01.052

[30] REN X, HAO R X, YANG Y Q, et al. A facile and green strategy to achieve metallized woven carbon fiber through the triple roles of dopamine in in-situ thermal reduction of Ag[J]. Composites Communications, 2023, 40: 101585. DOI: 10.1016/j.coco.2023.101585

[31] KISS P, GLINZ J, STADLBAUER W, et al. The effect of thermally desized carbon fibre reinforcement on the flexural and impact properties of PA6, PPS and PEEK composite laminates: A comparative study[J]. Composites Part B: Engineering, 2021, 215: 108844. DOI: 10.1016/j.compositesb.2021.108844

[32] 肇研, 孙铭辰, 张思益, 等. 连续碳纤维增强高性能热塑性复合材料的研究进展[J]. 复合材料学报, 2022, 39(9): 4274-4285. ZHAO Yan, SUN Mingchen, ZHANG Siyi, et al. Advance in continuous carbon fiber reinforced high performance thermoplastic composites[J]. Acta Materiae Compositae Sinica, 2022, 39(9): 4274-4285(in Chinese).

[33] 梁晶晶. 导电芳纶纤维的制备与性能研究[D]. 上海: 上海大学, 2013. LIANG Jingjing. Preparation and performance of conductive aramid fibers[D]. Shanghai: Shanghai University, 2013(in Chinese).

[34] 王丽雪, 王春艳, 于久灏, 等. 碳纤维表面化学镀预处理工艺研究[J]. 黑龙江工程学院学报, 2017, 31(2): 49-52. WANG Lixue, WANG Chunyan, YU Jiuhao, et al. Research on pretreatment process of carbon fibers before electroless[J]. Journal of Heilongjiang Institute of Technology, 2017, 31(2): 49-52(in Chinese).

[35] 贾志刚, 孔德龙, 王洺浩, 等. 尼龙无铬粗化与无钯活化的金属化过程[J]. 哈尔滨工业大学学报, 2017, 49(5): 42-48. DOI: 10.11918/j.issn.0367-6234.201611017 JIA Zhigang, KONG Delong, WANG Minghao, et al. Metallization process of PA10T with chrome-free roughening and palladium-free activation[J]. Journal of Harbin Institute of Technology, 2017, 49(5): 42-48(in Chinese). DOI: 10.11918/j.issn.0367-6234.201611017

[36] NELYUB V A. Plasma processing of fibrous carbon materials prior to their metallization[J]. Polymer Science, Series D, 2020, 13(4): 429-434. DOI: 10.1134/S1995421220040140

[37] 李颖, 王鸿博, 高卫东. 磁控溅射碳纤维基纳米铜薄膜的结构及其性能[J]. 纺织学报, 2012, 33(9): 10-14. DOI: 10.3969/j.issn.0253-9721.2012.09.003 LI Ying, WANG Hongbo, GAO Weidong. Structure and properties of nano-copper thin films deposited on carbon fiber fabric by magnetron sputtering[J]. Journal of Textile Research, 2012, 33(9): 10-14(in Chinese). DOI: 10.3969/j.issn.0253-9721.2012.09.003

[38] 蔡超迁, 韩乾翰, 黄壮, 等. 基于常压协同射流等离子体改性国产高强中模碳纤维表面的研究[J]. 纺织科学与工程学报, 2021, 38(2): 29-34. DOI: 10.3969/j.issn.2096-5184.2021.02.007 CAI Chaoqian, HAN Qianhan, HUANG Zhuang. Research on the surface modification of domestic high strength and medium modulus carbon fiber based on atmospheric pressure collaborative jet plasma[J]. Journal of Textile Science and Engineering, 2021, 38(2): 29-34(in Chinese). DOI: 10.3969/j.issn.2096-5184.2021.02.007

[39] 林雅. 新型碳纤维表面活化方法研究[D]. 西安: 西安建筑科技大学, 2016. LIN Ya. New surface activation method of carbon fiber[D]. Xi'an: Xi'an University of Architecture and Technology, 2016(in Chinese).

[40] 杜颖. 碳复合材料表面处理和镀铜的工艺研究[D]. 长沙: 湖南大学, 2021. DU Ying. Investigation on surface treatment and copper plating of carbon composite materials[D]. Changsha: Hunan University, 2021(in Chinese).

[41] SUN Z P, HUANG J J. Fabrication of nickel coating on polyethylene terephthalate substrate modified with primer: Effect of surface roughness on structural properties of plated coating[J]. Journal of Electronic Materials, 2019, 48(10): 6298-6305. DOI: 10.1007/s11664-019-07291-7

[42] CHU H Q, QIN Z Q, ZHANG Y Z, et al. Magnetic field enhancing preferred orientation of nickel-cobalt plated carbon fibers in cement paste, with relevance to compression self-sensing[J]. Measurement, 2023, 220: 113396. DOI: 10.1016/j.measurement.2023.113396

[43] ZHANG J J, LIU S C, LIU J M, et al. Electroless nickel plating and spontaneous infiltration behavior of woven carbon fibers[J]. Materials & Design, 2020, 186: 108301.

[44] 朱雁风, 张君艺, 高培凯. 碳纤维无钯化学镀银工艺研究[J]. 化学工程, 2023, 51(4): 18-21, 33. ZHU Yanfeng, ZHANG Junyi, GAO Peikai. Palladium-free electroless silver plating on carbon fiber[J]. Chemical Engineering (China), 2023, 51(4): 18-21, 33(in Chinese).

[45] WANG Q H, LI X S. Study on new process of electroless copper plating pretreatment on carbon fiber surface[J]. Materials Research Express, 2023, 10(2): 025604. DOI: 10.1088/2053-1591/acac02

[46] LI M L, SONG B Z, SU L F, et al. Electroless nickel metallization on palladium-free activated polyamide fabric for electromagnetic interference shielding[J]. Fibers and Polymers, 2021, 22(9): 2433-2439. DOI: 10.1007/s12221-021-0992-z

[47] HUANG M M, LI W W, LIU X J, et al. Study on structure and performance of surface-metallized carbon fibers reinforced rigid polyurethane composites[J]. Polymers for Advanced Technologies, 2020, 31(8): 1805-1813. DOI: 10.1002/pat.4907

[48] DARVISHZADEH A, NASOURI K. Manufacturing, modeling, and optimization of nickel-coated carbon fabric for highly efficient EMI shielding[J]. Surface and Coatings Technology, 2021, 409: 126957. DOI: 10.1016/j.surfcoat.2021.126957

[49] 熊海洋. 碳纤维连续金属化改性及其复合材料电磁屏蔽性能的研究[D]. 上海: 东华大学, 2023. XIONG Haiyang. Research on continuous metallization modification of carbon fiber and the performance of electromagnetic shielding of composite materials[D]. Shanghai: Donghua University, 2023(in Chinese).

[50] 田庆, 韩庆军, 刘艳, 等. 镀镍碳纤维功能一体化复合材料的工艺及性能研究[J] 材料科学, 2018, 8(4): 374-381. TIAN Qing, HAN Qingjun, LIU Yan, et al. Study on the process and properties of nickel coated carbon fiber functional integrated composites subtitle as needed[J]. Material Sciences, 2018, 8(4): 374-381(in Chinese).

[51] ZHOU Q W, LI G L, ZHOU Z P, et al. Effect of Ni2+ concentration on microstructure and bonding capacity of electroless copper plating on carbon fibers[J]. Journal of Alloys and Compounds, 2021, 863: 158467. DOI: 10.1016/j.jallcom.2020.158467

[52] 乔英铭, 甘春雷, 曲迎东, 等. 工艺参数对连续碳纤维表面电磁搅拌化学镀镍的影响[J]. 表面技术, 2020, 49(5): 325-334. QIAO Yingming, GAN Chunlei, QU Yingdong, et al. EMI shielding effectiveness of electroless nickel-plated carbon fibres/epoxy resin composites[J]. Surface Technology, 2020, 49(5): 325-334(in Chinese).

[53] 陈娜. 碳纤维表面金属化及其在铜基复合材料中的应用[D]. 南昌: 南昌大学, 2023. CHEN Na. Surface metallization of carbon fiber and its application in copper matrix composites[D]. Nanchang: Nanchang University, 2023(in Chinese).

[54] KANG S S, JI H J, GUL H Z, et al. Metal-coated carbon fiber for lighter electrical metal wires[J]. Synthetic Metals, 2016, 222: 180-185. DOI: 10.1016/j.synthmet.2016.10.015

[55] WANG Y, WANG W, DING X D, et al. Multilayer-structured Ni-Co-Fe-P/polyaniline/polyimide composite fabric for robust electromagnetic shielding with low reflection characteristic[J]. Chemical Engineering Journal, 2020, 380: 122553. DOI: 10.1016/j.cej.2019.122553

[56] 陈春亮. 高效涂层改性碳纤维的表界面结构及电热性能研究[D]. 武汉: 武汉纺织大学, 2022. CHEN Chunliang. Study on surface interface structure and electrothermal properties of carbon fiber modified by high efficiency coating[D]. Wuhan: Wuhan Textile University, 2022(in Chinese).

[57] 赵中杰. 结构-导电复合材料的制备及其导电性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2019. ZHAO Zhongjie. Study on preparation of structural-conductive composites and their conducting properties[D]. Harbin: Harbin Institute of Technology, 2019(in Chinese).

[58] LYU G F, WANG F, DU X D, et al. Microstructure, mechanical and wear properties of short carbon fiber-reinforced AM50 magnesium matrix composite[J]. International Journal Metalcasting, 2024, 18: 3028-3046.

[59] GAO C Q, LIANG A, MA Q. Tensile properties and fracture mechanism of copper matrix composites reinforced by carbon fibres with Ni-Co-P alloy coating[J]. Rare Metal Materials and Engineering, 2022, 51(11): 3949-3955.

[60] ZHOU X, GAO Y M, WANG Y R. Effect of Cu/Ni coating on the interface and mechanical properties of Cf/2024Al composites[J]. Diamond and Related Materials, 2023, 140(B): 110439.

[61] AL-SALEH M H, SUNDARARAJ U. Electrically conductive carbon nanofiber/polyethylene composite: Effect of melt mixing conditions[J]. Polymers for Advanced Technologies, 2011, 22(2): 246-253. DOI: 10.1002/pat.1526

[62] 闫丽丽, 乔妙杰, 雷忆三, 等. 化学镀镍碳纤维/环氧树脂复合材料电磁屏蔽性能[J]. 复合材料学报, 2013, 30(2): 44-49. YAN Lili, QIAO Miaojie, LEI Yisan, et al. EMI shielding effectiveness of electroless nickel-plated carbon fibres/epoxy resin composites[J]. Acta Materiae Compositae Sinica, 2013, 30(2): 44-49 (in Chinese).

[63] 吴骅, 朱忠仁, 卓越, 等. 一种超轻低损稳相同轴电缆: CN, ZL201721325765.8[P]. 2017-10-16. WU Hua, ZHU Zhongren, ZHUO Yue, et al. An ultra-light and low-loss stable coaxial cable: CN, ZL201721325765.8[P]. 2017-10-16(in Chinese).

[64] WANG H, LIU M Y, LI S N, et al. A self-healing and flexible Ag@carbon fiber/polyurethane composite based on disulfide bonds and application in electromagnetic interference shielding[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2022, 646: 128956. DOI: 10.1016/j.colsurfa.2022.128956

[65] LI J P, QI S H, ZHANG M Y, et al. Thermal conductivity and electromagnetic shielding effectiveness of composites based on Ag-plating carbon fiber and epoxy[J]. Journal of Applied Polymer Science, 2015, 132(33): 42306. DOI: 10.1002/app.42306

[66] YANG J, LI W W, ZHOU Y L, et al. Spirally Ag-coated short carbon fiber as a reinforcing filler for rigid poly-urethane[J]. Materials Chemistry and Physics, 2022, 291: 126747. DOI: 10.1016/j.matchemphys.2022.126747

[67] 游文涛. 民机复合材料含镍涂层涡流加热效应及其除冰研究[D]. 德阳: 中国民用航空飞行学院, 2019. YOU Wentao. Study on eddy current heating effect and deicing of nickel-coated coatings in civil aircraft composites[D]. Deyang: Civil Aviation Flight University of China, 2019(in Chinese).

[68] SUN Y L, ZHANG M, ZHANG Y H, et al. Fabrication of high thermal and electrical conductivity composites via electroplating Cu network on 3D PEEK/CF felt skeletons[J]. Composites Communications, 2021, 28: 100909. DOI: 10.1016/j.coco.2021.100909

[69] ZHANG R, BIN Y Z, DONG E Y, et al. Considerable different frequency dependence of dynamic tensile modulus between self-heating (Joule heat) and external heating for polymer-nickel-coated carbon fiber composites[J]. The Journal of Physical Chemistry B, 2014, 118(25): 7047-7058. DOI: 10.1021/jp5031202

[70] WAN Y Z, XIAO J, LI C Z, et al. Microwave absorption properties of FeCo-coated carbon fibers with varying morphologies[J]. Journal of Magnetism and Magnetic Materials, 2016, 399: 252-259. DOI: 10.1016/j.jmmm.2015.10.006

[71] BARD S, SCHÖNL F, DEMLEITNER M, et al. Copper and nickel coating of carbon fiber for thermally and electrically conductive fiber reinforced composites[J]. Polymers, 2019, 11(5): 823. DOI: 10.3390/polym11050823

[72] MING Y K, XIN Z B, ZHU Y S, et al. 3D printed nickel-plated carbon fiber mesh for lightning strike protection[J]. Materials Letters, 2021, 294: 129809. DOI: 10.1016/j.matlet.2021.129809

[73] GAO L B, SURJADI J U, CAO K, et al. Flexible fiber-shaped supercapacitor based on nickel-cobalt double hydroxide and pen ink electrodes on metallized carbon fiber[J]. ACS Applied Materials & Interfaces, 2017, 9(6): 5409-5418.

[74] STEINBILD P J, WIEJA N, CONDÉ-WOLTER J, et al. Changes in electric resistance of cracked copper-coated, pitch-based carbon fibers for structural health monitoring in a glider wing[J]. Journal of Physics: Conference Series, 2023, 2526: 012066. DOI: 10.1088/1742-6596/2526/1/012066

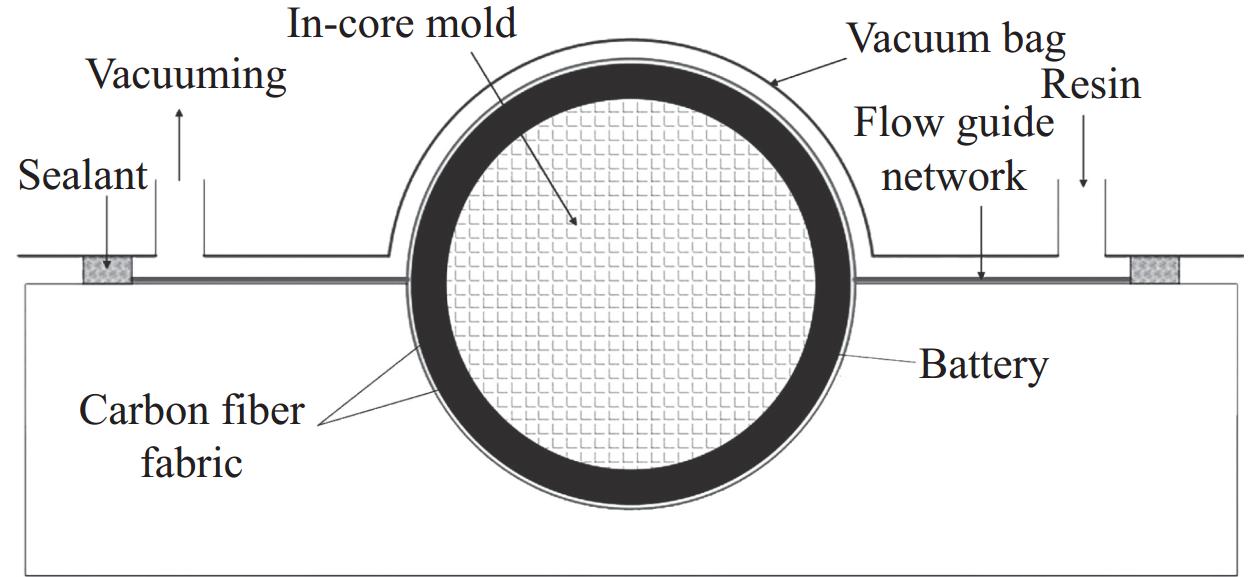

[75] 王亚震, 张峻滔, 李晖, 等. 超薄镀镍碳纤维管状结构电池的制备及性能研究[J]. 复合材料科学与工程, 2023(5): 12-18. WANG Yazhen, ZHANG Junhui, LI Hui, et al. Preparation and performance study on ultra-thin nickel-plated carbon fiber tubular structure battery[J]. Composites Science and Engineering, 2023(5): 12-18(in Chinese).

-

目的

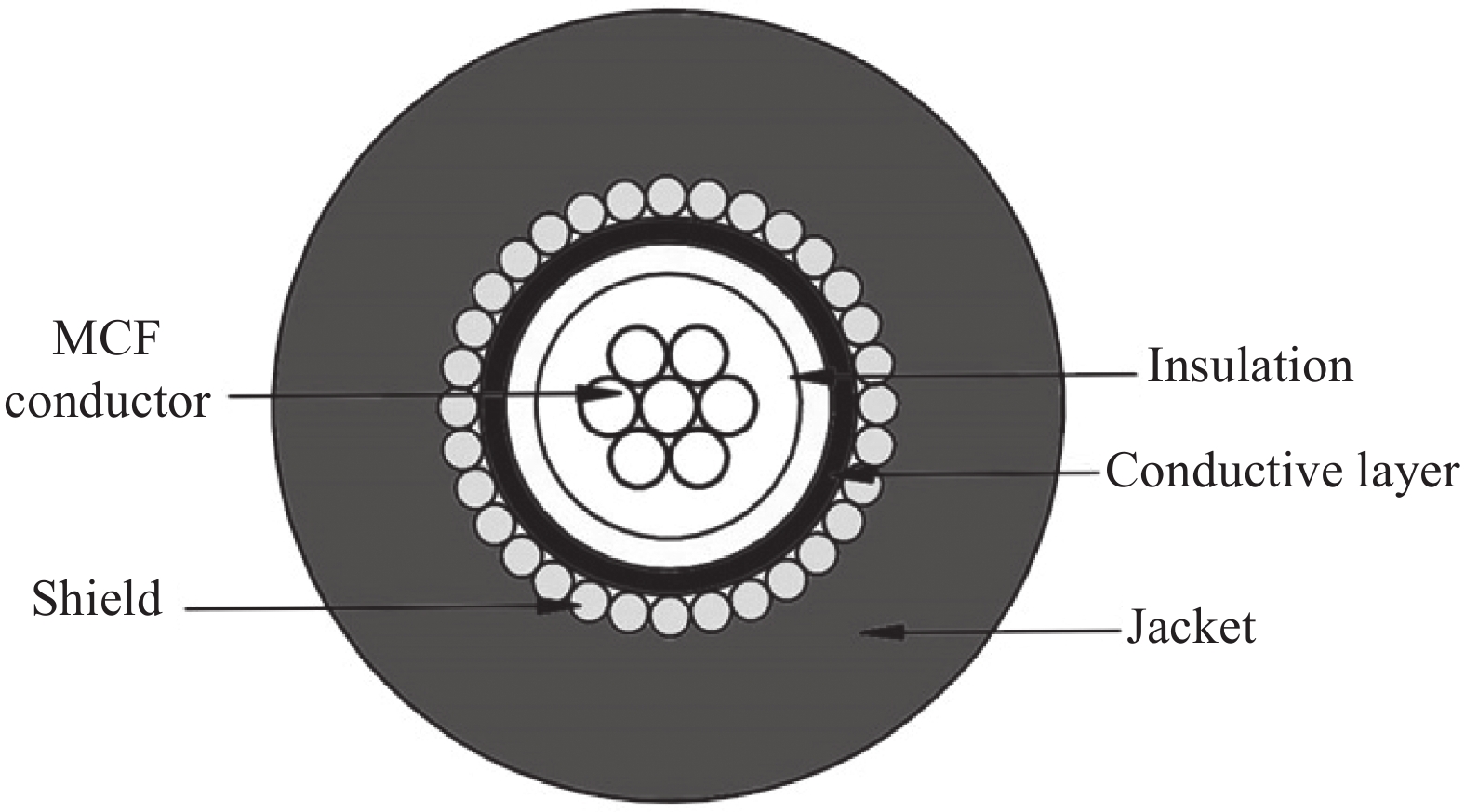

在碳纤维(CF)表面进行金属化处理可以使碳CF兼备原始纤维轻质高强和金属高导电/导热等多重性能,并可一定程度改善其可编织性,是丰富CF功能、提高纤维界面结合能力和赋能复合材料结构与功能一体化的有效手段之一,在电磁屏蔽、防雷击、除冰/防冰、电能传输、超级电容、信号传感、复合材料结构功能一体化等领域,可一定程度替代传统金属材料使用。

方法本文综述了研究学者在CF表面金属化方面取得的进展。具体从金属化工艺入手,分析了近年来主要CF金属化工艺路线,包括喷涂、磁控溅射(PVD)、化学气相沉积(CVD)、电镀、化学镀等,从商业化工程应用角度重点分析了具有大长度连续金属化潜力的电镀和化学镀的核心环节和工艺特点。总结了金属化碳纤维(MCF)的应用现状,展望了CF表面金属化将面临的挑战及未来发展趋势。

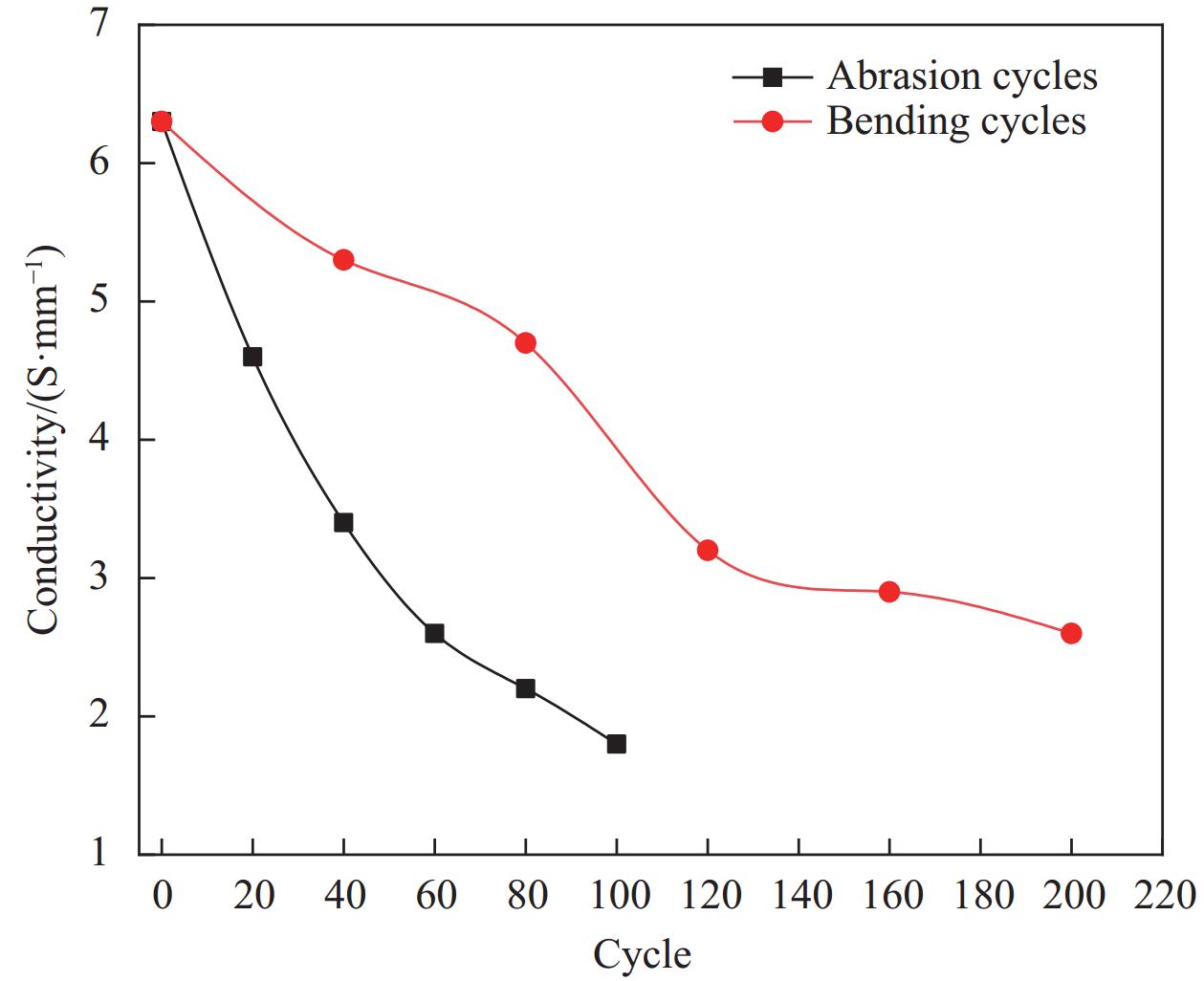

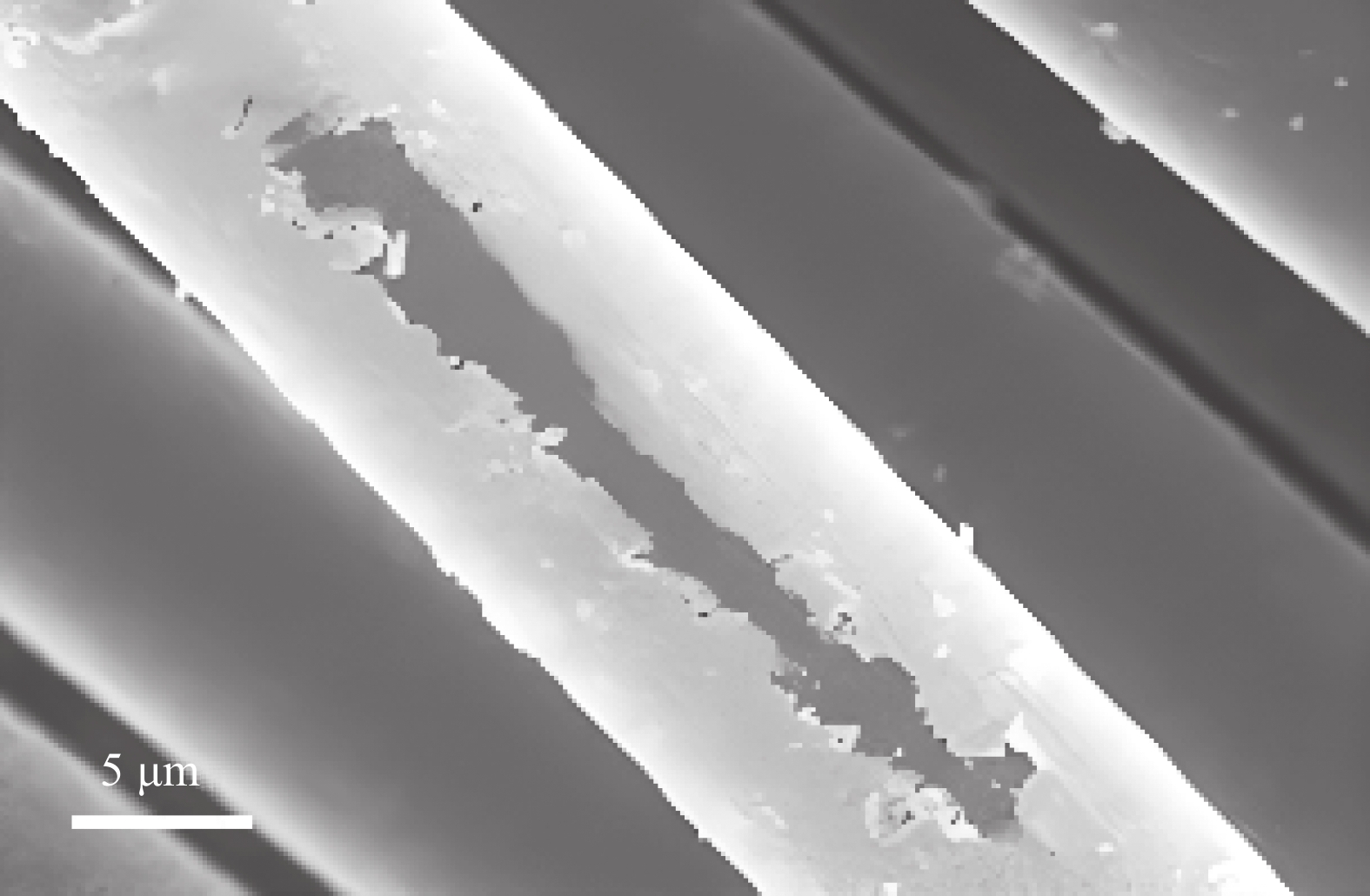

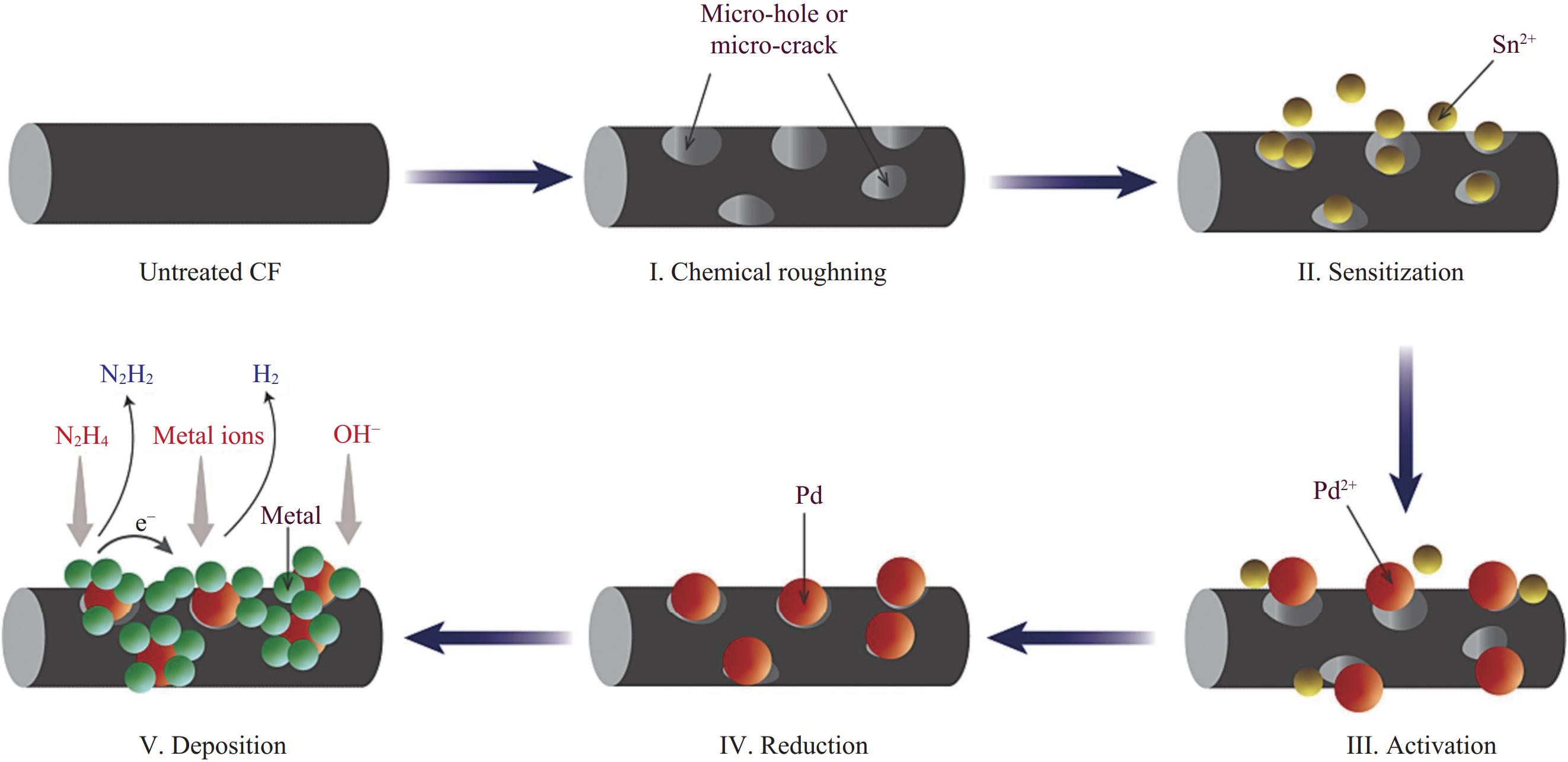

结果目前CF的表面金属化处理方法主要有喷涂、磁控溅射(PVD)、化学气相沉积(CVD)、电镀、化学镀,此外还包括溶胶-凝胶法、原子层沉积、金属熔敷等新概念技术。各种CF金属化处理方法均有其优势和弊端,鉴于目前技术水平,用作电磁屏蔽填料的场景多使用MCF短纤,在CF短纤金属化层面,多种金属化方法共存,主要以满足实验和部分应用验证需求;从商业规模化应用角度看,大长度连续MCF更能满足如柔性电磁屏蔽材料、防雷除冰、信号传感器、电气线路传输、超级电容、结构电池等工程领域的复杂应用需求。电镀和化学镀作为众多金属化方法中兼备大长度连续金属化潜力和较高性价比的技术,二者工艺路线基本相似,仅在施镀条件上有所差异,其核心环节会直接影响到镀层质量与材料性能。无论电镀或化学镀,CF金属化处理之前均需对其表面进行去胶、粗化、活化(敏化)等预处理,其目的为增强纤维与金属层间的界面结合力。CF表面除胶方法主要有高温灼烧法、酸蚀法及丙酮浸泡法。高温热处理和有机溶剂清洗是除胶的主要手段,其中有机溶剂可能还要增加超声震荡分散、索氏提取器来辅助达到理想除胶效果,在连续金属化应用上二者各有利弊。现有粗化方法多为强氧化试剂处理法,对纤维本体会造成不可逆损伤,大大加重了金属化纤维在长期服役中分解失效、力学性能和导电性能损失的风险。而等离子体处理对界面能的改善效果突出,由等离子体处理的MCF所制备复合材料的IFSS增幅比经化学处理的复合材料IFSS增幅高出了约27%,比经涂覆聚多巴胺处理的复合材料IFSS增幅高出了约90.5%。电流密度、镀覆时间、主盐浓度和温度是电镀工艺的关键参数。在面对连续MCF制备时,为了最大化保留CF力学性能和柔韧可织的优势,同时发挥出金属层的高导电特性,适中厚度(0.5-1.0μm)、低电流密度、少施镀时间、光滑镀层的电镀条件可能更适合连续金属化。化学镀配方体系繁多,各因素条件对镀层成型的影响程度会略有不同。当面向连续MCF制备时,为了最大化保留CF力学性能和柔韧可织的优势,同时发挥出金属层的高导电特性,选择碱性镀液配方可能更适合在连续CF表面快速沉积微薄金属层,以实现CF与金属的性能兼备。特别指出的是,在施镀过程中增加对镀液内离子的均匀分散处理,如镀液搅拌,可以有效提高镀层质量,减少漏镀现象发生。在应用方面,将CF表面金属化可以有效改善CF表面能,有利于制造性能更佳的复合材料;且其低密度、高比强度、耐高温、耐腐蚀、导电性好等优异性能使其在电磁屏蔽材料、电热材料以及其他结构-功能一体化材料领域具有广阔的应用前景。其中在MCF产业中,工艺最成熟、应用最广泛的是CF@Ni,其主要用于屏蔽和传导。

结论当前金属化工艺中,电镀和化学镀可能更适合连续金属化工程制备。在纤维表面预处理的环节中,无Pd活化处理可进一步研究,其中等离子体处理方法对CF损伤程度可控,一次处理可同时获得机械铆合点位和附着活性基团,为CF连续金属化的高效、高质量、低成本工艺路线提供了有力支撑。CF本身具有战略意义,表面金属化更为其锦上添花,所以在制备与应用方面仍具有较大的提升空间,可在以下方面寻求进一步发展:(1)协同升级CF表面改性处理以及金属化工艺或探索新工艺,提升金属化CF力学与导电性能稳定性;(2)对MCF连续化制备工艺加大投入,加快学术研究成果的产业生产转化;(3)积极探索MCF的应用场景,发掘潜在的应用领域,以需求牵引国产化自循环,加速MCF的国产化进程,扩大国际市场份额。

下载:

下载: