Influence of carbon/glass hybrid fiber layup structure on the bending-twisting coupling behavior of wind turbine blades

-

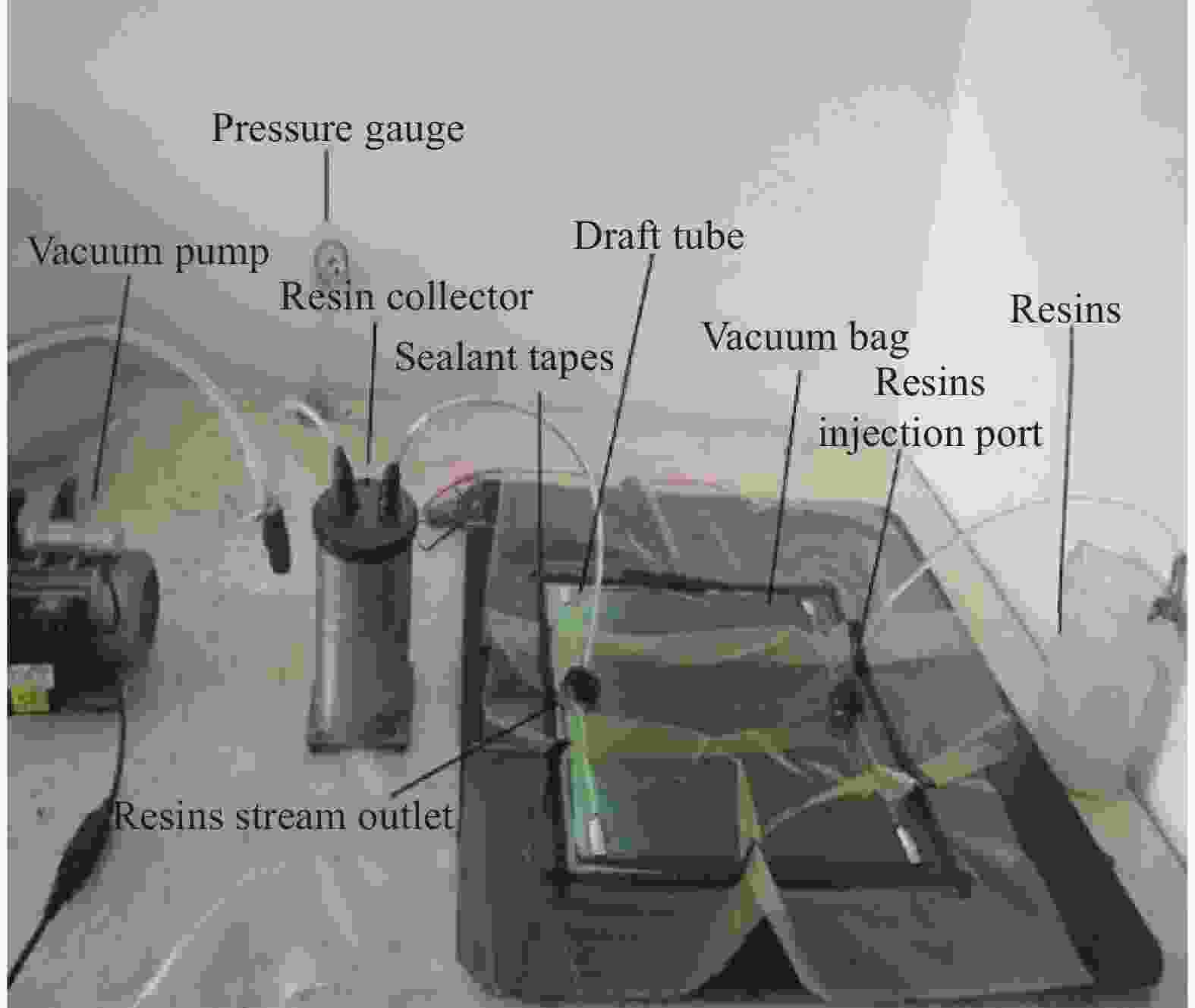

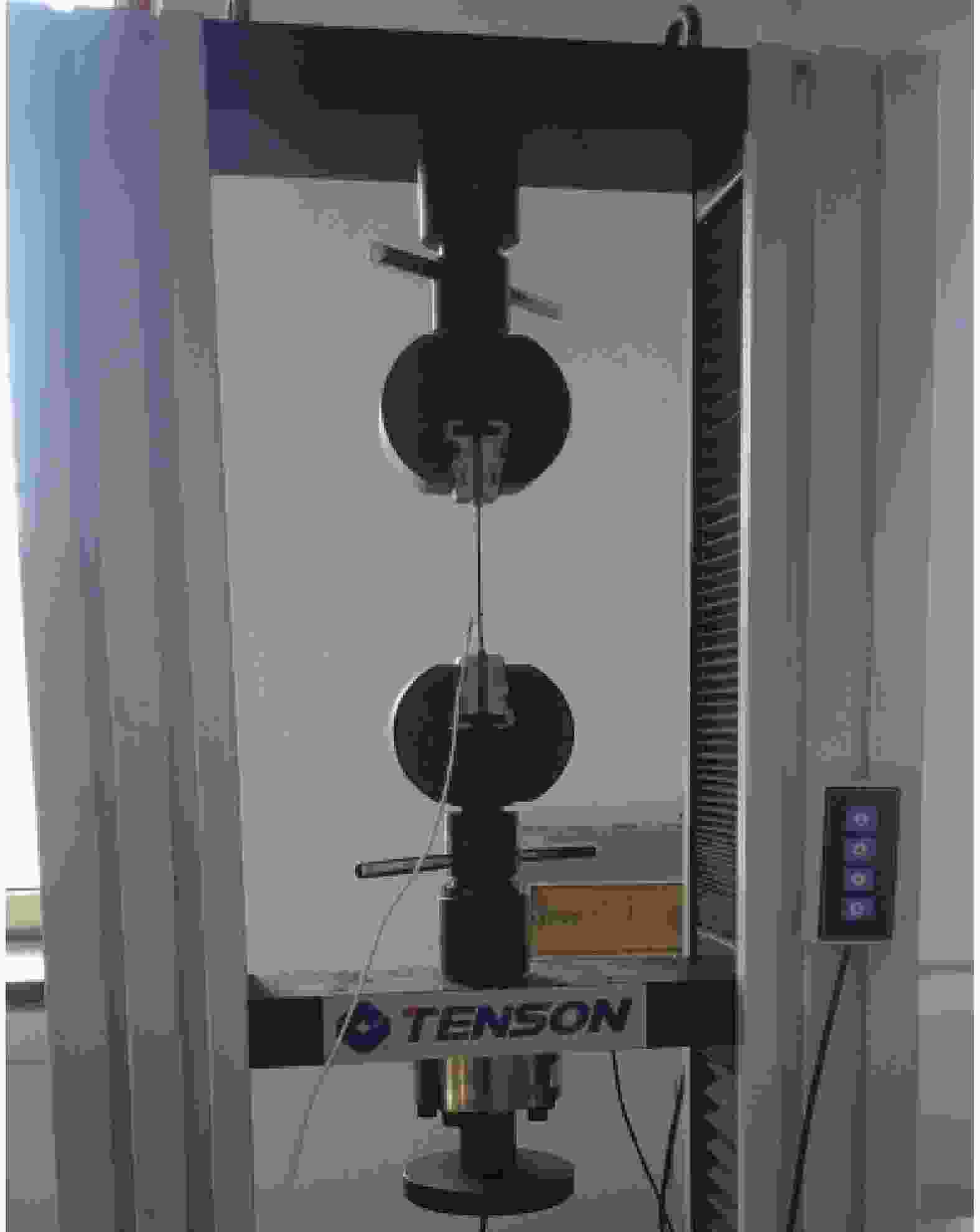

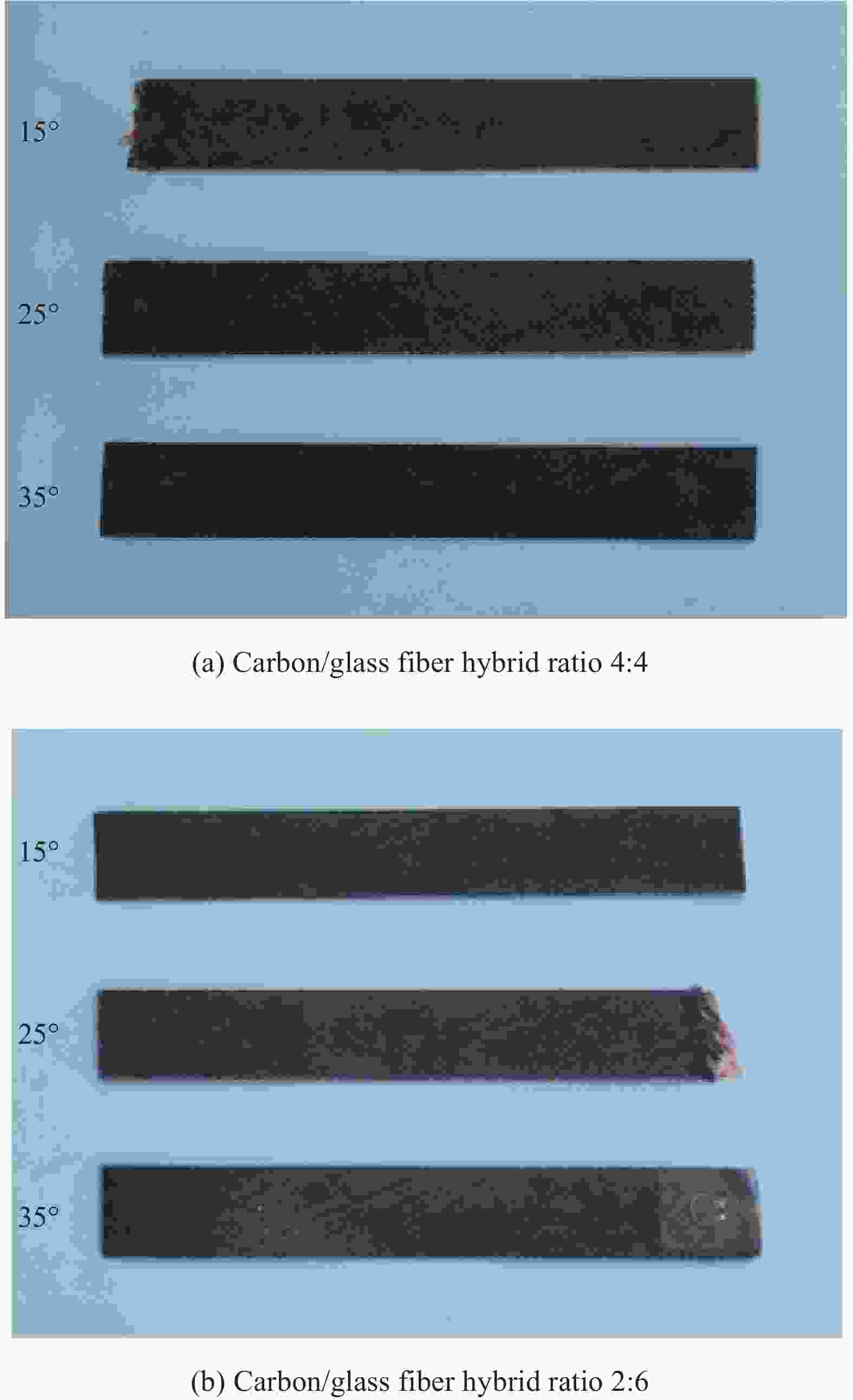

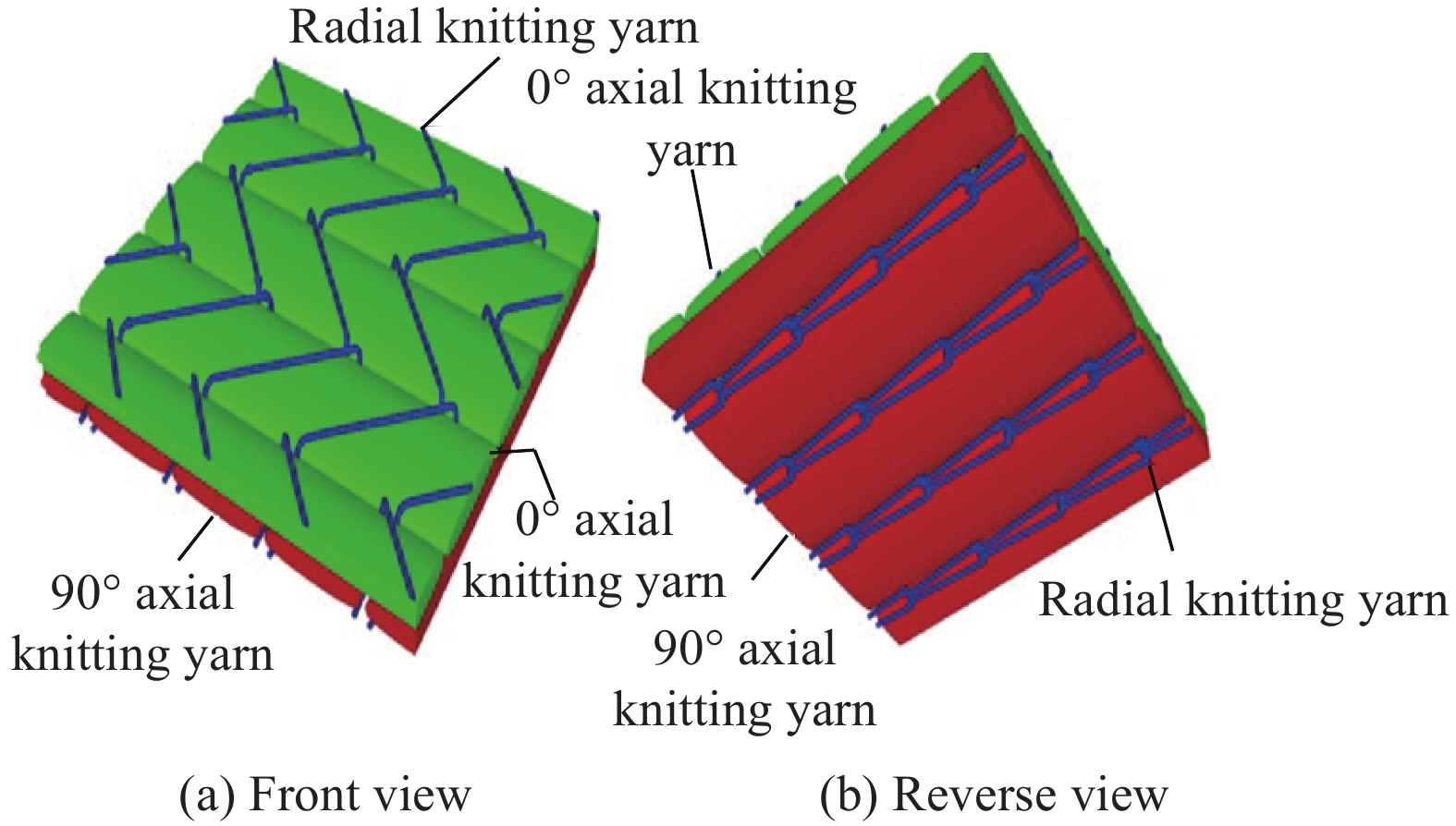

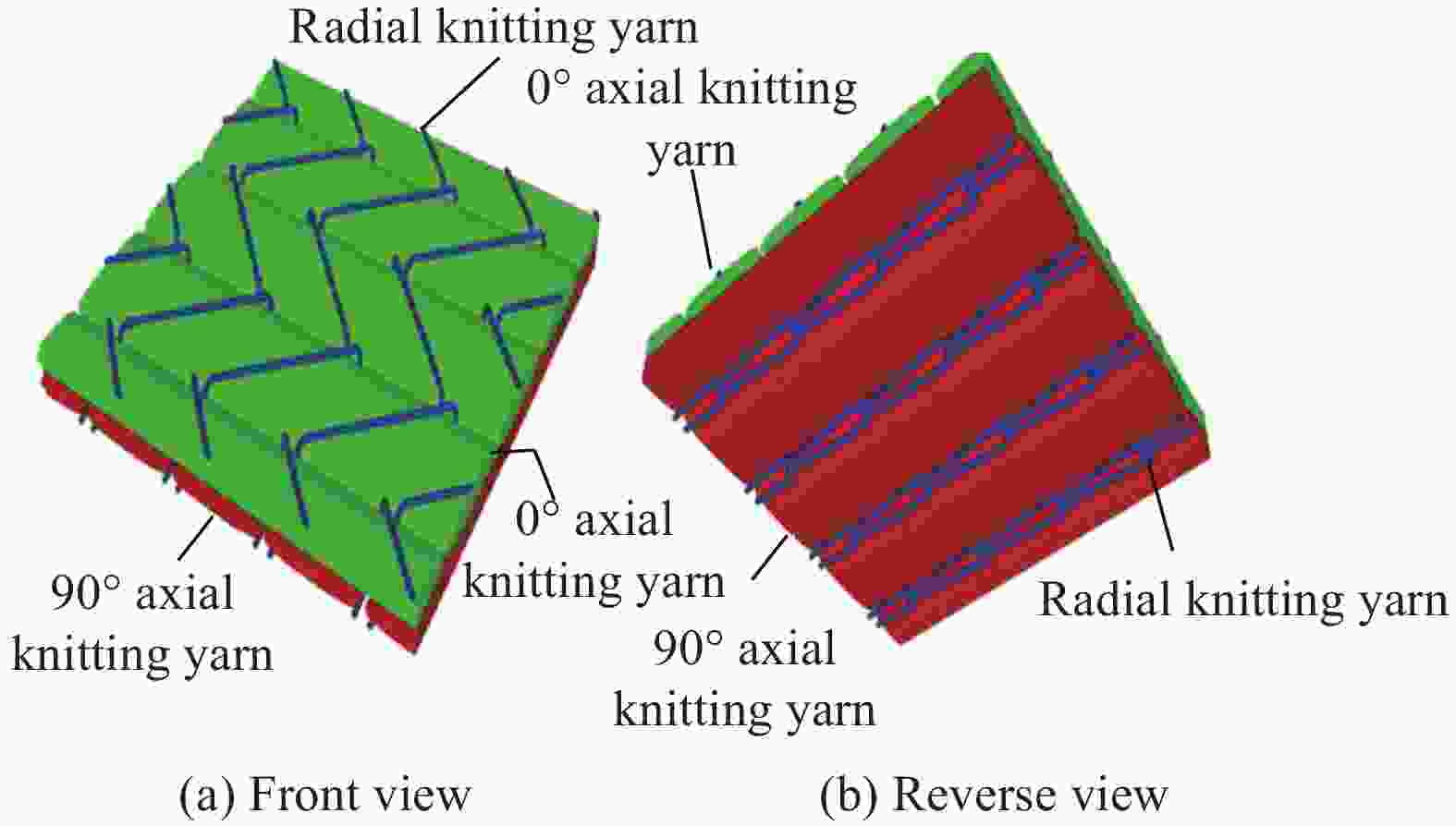

摘要: 为研究复合材料铺层结构对叶片弯扭耦合特性的影响。以功率2 kW的风力机叶片试样为研究对象,选用碳/玻纤维不同混杂比(4∶4和2∶6)双轴向经编织物。基于经典层合板理论及联合节点位移法,实验研究集中载荷作用下,铺层结构叶片试样形变特性,分析叶片试样弯扭耦合特性。结果表明:同种碳/玻纤维混杂时,纤维排列角度为25°时,叶片试样等效弯扭耦合系数最佳为0.186,而同种纤维排列角度,碳/玻纤维混杂比4∶4的叶片试样等效弯扭耦合系数大于碳/玻纤维混杂比2∶6的叶片试样。应变测试实验发现沿叶片试样展向,叶片试样主应变逐渐减小,弯扭耦合特性可有效改善叶根处主应变。Abstract: In order to analyze the influence of layer structure of composite material on bending-twisting coupling behavior of wind turbine blade, the carbon/glass biaxial warp knitting fabric with hybrid layer ratio 4∶4 and 2∶6 were selected as reinforcement to fabricate blade. A 2 kW wind turbine blade samples model was established and the strain deform behavior of blade samples was experimental studied by combining classical laminate theory and nodal displacement method. The bending-twisting coupling behavior was also analyzed. The results show that when the carbon/glass hybrid ratio is same and the fiber off-axis angle is 25°, the optimal value of equivalent bending-twisting coupling coefficient of blade samples is 0.186. With same fiber off-axis angle, carbon/glass hybrid ratio 4∶4 blade samples has higher equivalent bending-twisting coupling coefficient than carbon/glass hybrid ratio 2∶6 blade samples. The strain measurement experiment shows that the principal strains decreases gradually along with blade length, and bending-twisting coupling behavior have a good effect on perfecting the principal strain at the blade root.

-

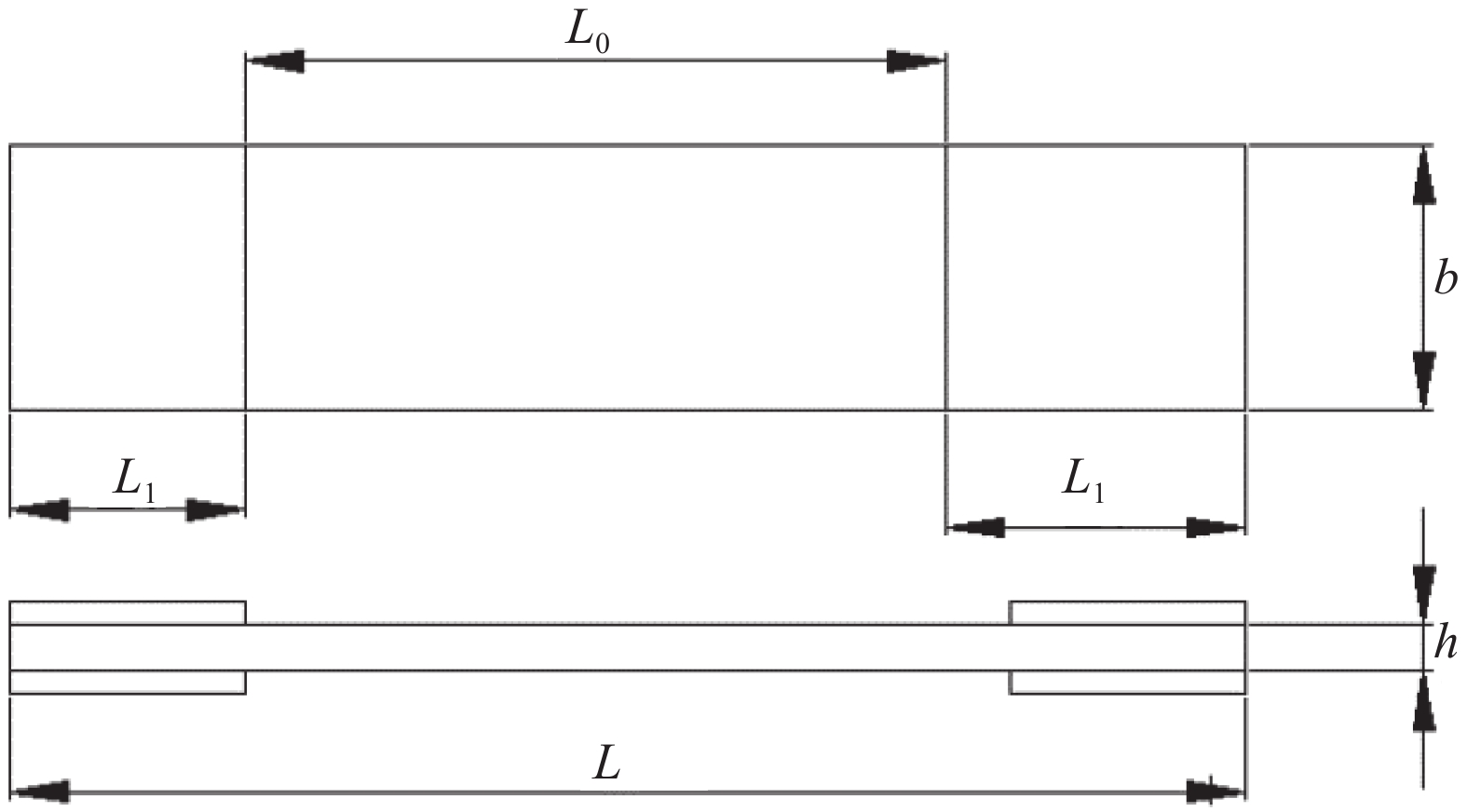

图 3 碳/玻混杂材料试样示意图

Figure 3. Schematic diagram of carbon/glass hybrid material samples

L—Total length of composite material samples; L0—Test length of composite material sample; L1—Length of reinforcing piece of composite material sample; b—Width of composite material sample; h—Thickness of composite material sample

表 1 碳/玻混杂叶片材料试样尺寸

Table 1. Samples size of carbon/glass hybrid blade material

Title Size/mm Length L 250 Width b 25 Thickness h 2-3 Test section L0 150 Strengthening section L1 50 表 2 碳/玻混杂叶片试样性能

Table 2. Properties of carbon/glass hybrid blade samples

Carbon/glass

hybrid ratioTest

direction/(°)Density/(g·cm−3) E/GPa G/GPa ν 4∶4 0 1.73 8.15 3.17 0.284 90 7.56 2.94 2∶6 0 1.77 5.15 2.02 0.275 90 4.64 1.82 Notes: E—Modulus of elasticity; G—Shear modulus; ν—Poisson's ratio. 表 3 碳/玻混杂叶片试样编号及含义

Table 3. Carbon/glass hybrid blade samples number and meaning

Number Implication A0 Ratio (carbon/glass) 4∶4,angle 0° A15 Ratio (carbon/glass) 4∶4,angle 15° A25 Ratio (carbon/glass) 4∶4,angle 25° A35 Ratio (carbon/glass) 4∶4,angle 35° A45 Ratio (carbon/glass) 4∶4,angle 45° A55 Ratio (carbon/glass) 4∶4,angle 55° B0 Ratio (carbon/glass) 2∶6,angle 0° B15 Ratio (carbon/glass) 2∶6,angle 15° B25 Ratio (carbon/glass) 2∶6,angle 25° B35 Ratio (carbon/glass) 2∶6,angle 35° B45 Ratio (carbon/glass) 2∶6,angle 45° B55 Ratio (carbon/glass) 2∶6,angle 55° 表 4 碳/玻混杂叶片试样各截面加权系数

Table 4. Weighting factors for measured cross sections of carbon/glass hybrid blades samples

Measurement cross-section Weighting factor 1-1 0.0018 2-2 0.0054 3-3 0.0090 4-4 0.0126 5-5 0.0162 6-6 0.0198 7-7 0.0234 8-8 0.0270 9-9 0.0306 10-10 0.0342 表 5 碳/玻混杂叶片试样的等效弯扭耦合系数

Table 5. Equivalent bend-twist coupling coefficient of carbon/glass hybrid blades samples

Blade Coefficient A15 0.133 A25 0.186 A35 0.154 A45 0.133 A55 0.128 B15 0.130 B25 0.150 B35 0.117 B45 0.053 B55 0.104 -

[1] 王同光. 风力机叶片结构设计[M]. 北京: 科学出版社, 2015: 12-22.WANG Tongguang. Wind turbine blade structure design[M]. Beijing: Science Press, 2015: 12-22(in Chinese) . [2] 邓富泉, 张丽, 刘少祯,等. 单向连续碳纤维-玻璃纤维层间混杂增强环氧树脂基复合材料的力学性能[J]. 复合材料学报, 2018, 35(7):1857-1863. doi: 10.13801/j.cnki.fhclxb.20180402.003DENG Fuquan, ZHANG Li, LIU Shaozhen, et al. Mechanical properties of unidirectional continuous carbon fiber-glass fiber interlayer hybrid reinforced epoxy resin matrix composites[J]. Acta Materiae Compositae Sinica,2018,35(7):1857-1863(in Chinese). doi: 10.13801/j.cnki.fhclxb.20180402.003 [3] CHEN J G, SHEN X, ZHU X C, et al. Study on composite bend-twist coupled wind turbine blade for passive load mitigation[J]. Composite Structures,2019,213:173-189. doi: 10.1016/j.compstruct.2019.01.086 [4] PRAVEEN S, MOHAMMED R S, DIPAK K M. A parametric study of flutter behavior of a composite wind turbine blade with bend-twist coupling[J]. Composite Structures,2019,207:764-775. doi: 10.1016/j.compstruct.2018.09.064 [5] 周邢银. 大型风力机复合材料叶片弯扭耦合特性研究[D]. 北京: 华北电力大学(北京), 2016.ZHOU Xingyin. Study on the bending and twisting coupling characteristics of large wind turbine composite blades[D]. Beijing: North China Electric Power University (Beijing), 2016(in Chinese). [6] 张龙, 贾普荣, 王波, 等. 考虑弯扭耦合效应的复合材料叶片铺层优化方法[J]. 西北工业大学学报, 2018, 36(6):1093-1101. doi: 10.3969/j.issn.1000-2758.2018.06.009ZHANG Long, JIA Purong, WANG Bo, et al. Optimization method of composite blade layup considering bending-torsion coupling effect[J]. Journal of Northwestern Polytechnic University,2018,36(6):1093-1101(in Chinese). doi: 10.3969/j.issn.1000-2758.2018.06.009 [7] ZHANG Z, WU J, LIANG B, et al. Investigation to the torsion generation of spatial tubes in bending-twisting process[J]. International Journal of Advanced Manufacturing Technology,2020,107(3/4):1191-1203. doi: 10.1007/s00170-020-05101-7 [8] JING Z, CHEN J. An investigation on design of signs in composite laminates to control bending-twisting coupling effects using sign optimization algorithm[J]. Structural and Multidisciplinary Optimization,2019,60(5):2131-2156. doi: 10.1007/s00158-019-02315-6 [9] GU H, SHAW A D, AMOOZGAR M, et al. Twist morphing of a composite rotor blade using a novel metamaterial[J]. Composite Structures,2020,254:112855. doi: 10.1016/j.compstruct.2020.112855 [10] 刘瑞杰. 智能风力机的气弹特性仿真研究[D]. 北京: 华北电力大学(北京), 2019.LIU Ruijie. Simulation study of air-elastic characteristics of intelligent wind turbine[D]. Beijing: North China Electric Power University (Beijing), 2019(in Chinese). [11] KHAZAR H, ALVARO G M L, CARLOS D M, et al. Flutter performance of bend-twist coupled large-scale wind turbine blades[J]. Journal of Sound and Vibration,2016,370:149-162. doi: 10.1016/j.jsv.2016.01.032 [12] STABLEIN A R, HANSEN M H, PIRRUNG G. Fundamental aeroelastic properties of a bend-twist coupled blade section[J]. Journal of Fluids & Structures,2017,68:72-89. doi: 10.1016/j.jfluidstructs.2016.10.010 [13] FARSADI T, KAYRAN A. Flutter study of flapwise bend-twist coupled composite wind turbine blades[J]. Wind and Structures An International Journal,2021,32(3):267-281. doi: 10.12989/was.2021.32.3.267 [14] 周邢银, 安利强, 王璋奇. 对称非匀层合板梁的弯扭耦合效应[J]. 复合材料学报, 2017, 34(7):1462-1468. doi: 10.13801/j.cnki.fhclxb.20170121.001ZHOU Xingyin, AN Liqiang, WANG Zhangqi. Bend-twist coupling effect of symmetric un-uniform laminate plate beam[J]. Acta Materiae Compositae Sinica,2017,34(7):1462-1468(in Chinese). doi: 10.13801/j.cnki.fhclxb.20170121.001 [15] 王庆涛. 碳/玻层内混杂单向经编织物渗透性能及混杂复合材料力学性能研究[D]. 上海: 东华大学, 2018.WANG Qingtao. Study on the permeability properties of unidirectional warp-knitted fabrics blended within carbon/glass layers and the mechanical properties of blended composites[D]. Shanghai: Donghua University, 2018(in Chinese). [16] KIM S H, SHIN H, BANG H J. Bend-twist coupling behavior of 10 MW composite wind blade[J]. Composites Research,2016,29(6):369-374. doi: 10.7234/composres.2016.29.6.369 [17] 杨庆生. 复合材料力学[M]. 北京: 科学出版社, 2020: 134-158.YANG Qingsheng. Mechanics of composite materials[M]. Beijing: Science Press, 2020: 134-158(in Chinese). [18] 马腾, 李炜. 单向碳/玻璃纤维层内-层间混杂复合材料拉伸破坏模式研究[J]. 复合材料科学与工程, 2015, 262(12):87-93.MA Teng, LI Wei. Study on tensile damage mode of unidirectional carbon/glass fiber intra-layer-interlayer hybrid composites[J]. Composites Science and Engineering,2015,262(12):87-93(in Chinese). [19] International Organization for Standardization. Plastics— Determination of tensile properties—Part 5: Test conditions for fibre-reinforced plastic composites: ISO 527-5: 2009[S]. Genève: ISO, 2009-06-26. [20] 刘旺玉, 龚佳兴, 刘希凤, 等. 基于弯扭耦合的自适应风力机叶片设计[J]. 太阳能学报, 2011, 32(7):1014-1019.LIU Wangyu, GONG Jiaxing, LIU Xifeng, et al. Adaptive wind turbine blade design based on bending-torsion coupling[J]. Journal of Solar Energy,2011,32(7):1014-1019(in Chinese). [21] 庞程燕. 水平轴水轮机叶片的弯扭耦合设计及流固耦合计算[D]. 哈尔滨: 哈尔滨工程大学, 2014.PANG Chengyan. Bending-torsional coupling design and fluid-structure coupling calculation of horizontal axis hydraulic turbine blades[D]. Harbin: Harbin Engineering University, 2014(in Chinese). [22] WIENS M, MEYER T, WENSKE J. Exploiting bend-twist coupling in wind turbine control for load reduction[J]. IFAC-Papers On Line,2020,53(2):12139-12144. doi: 10.1016/j.ifacol.2020.12.781 -

下载:

下载: