Effect of structural parameters on the low-velocity impact performance of aluminum honeycomb sandwich plate with CFRP face sheets

-

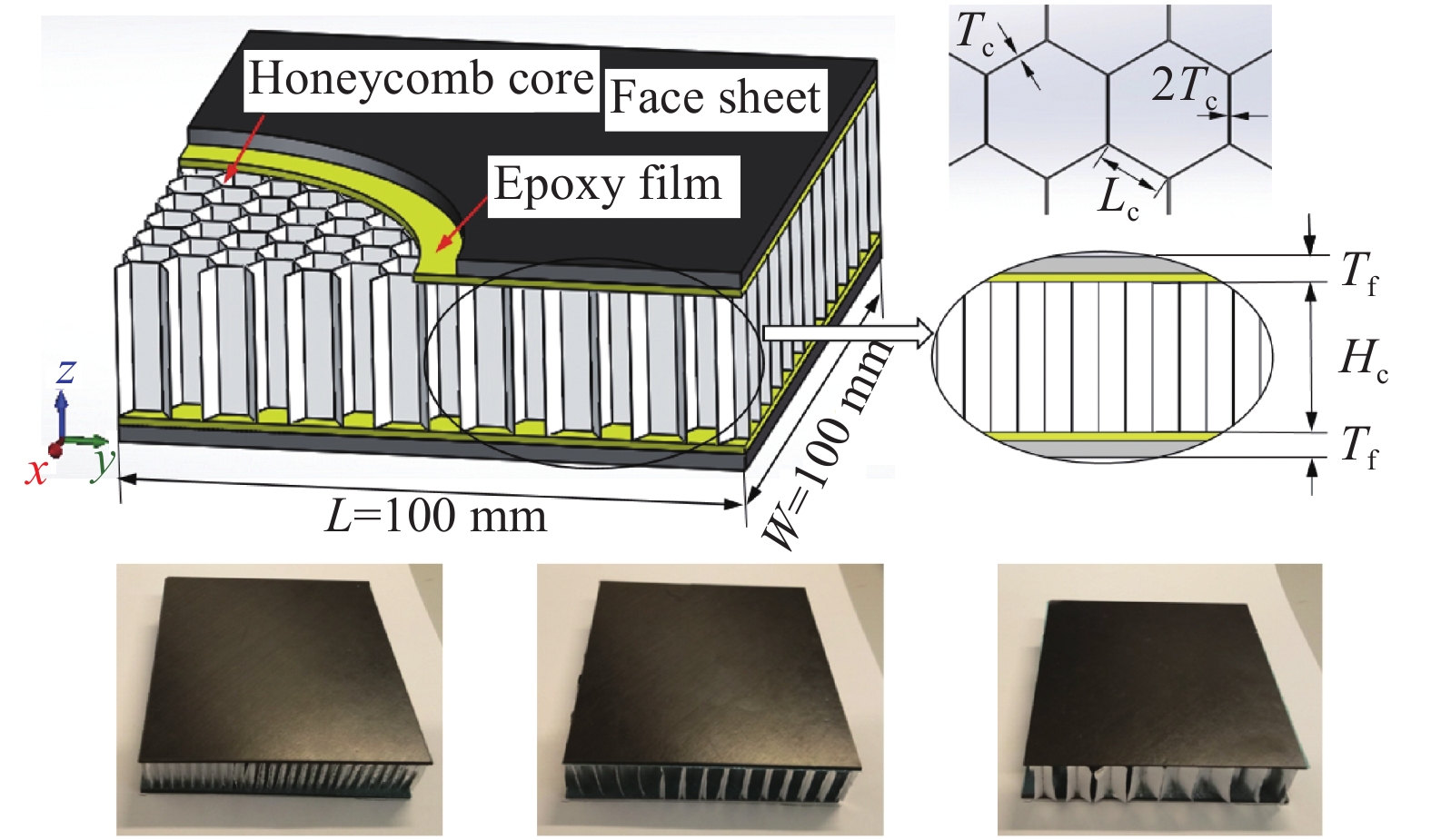

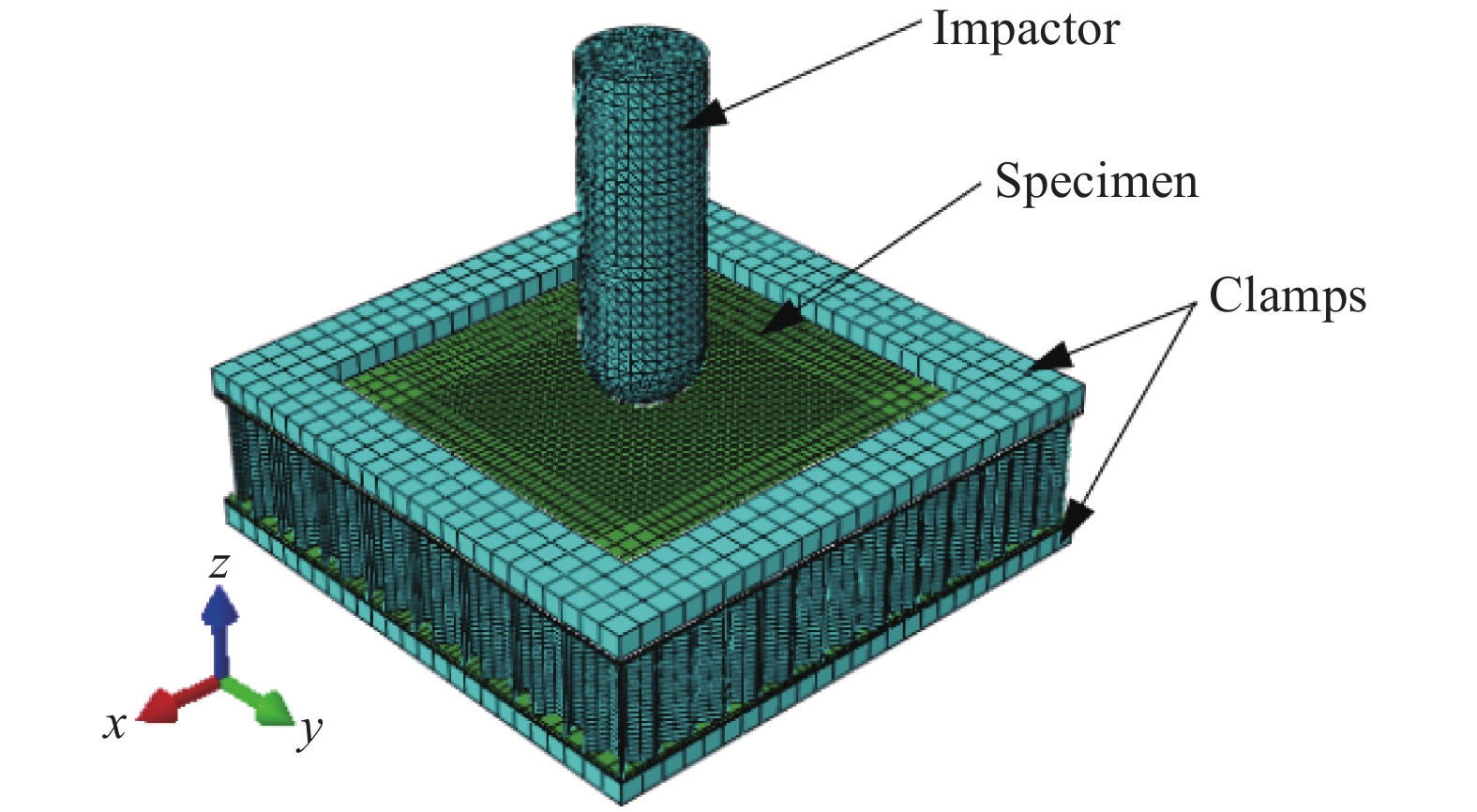

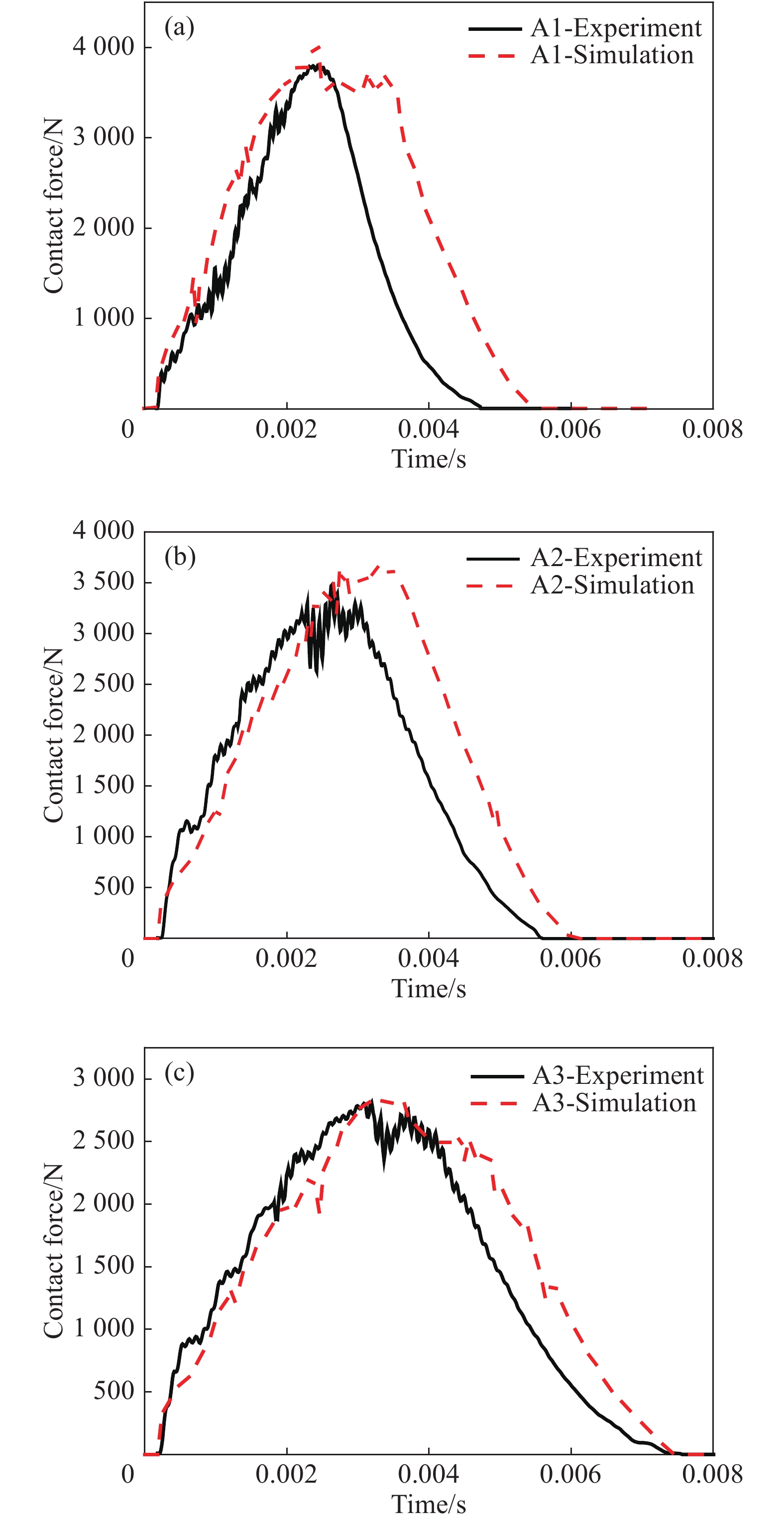

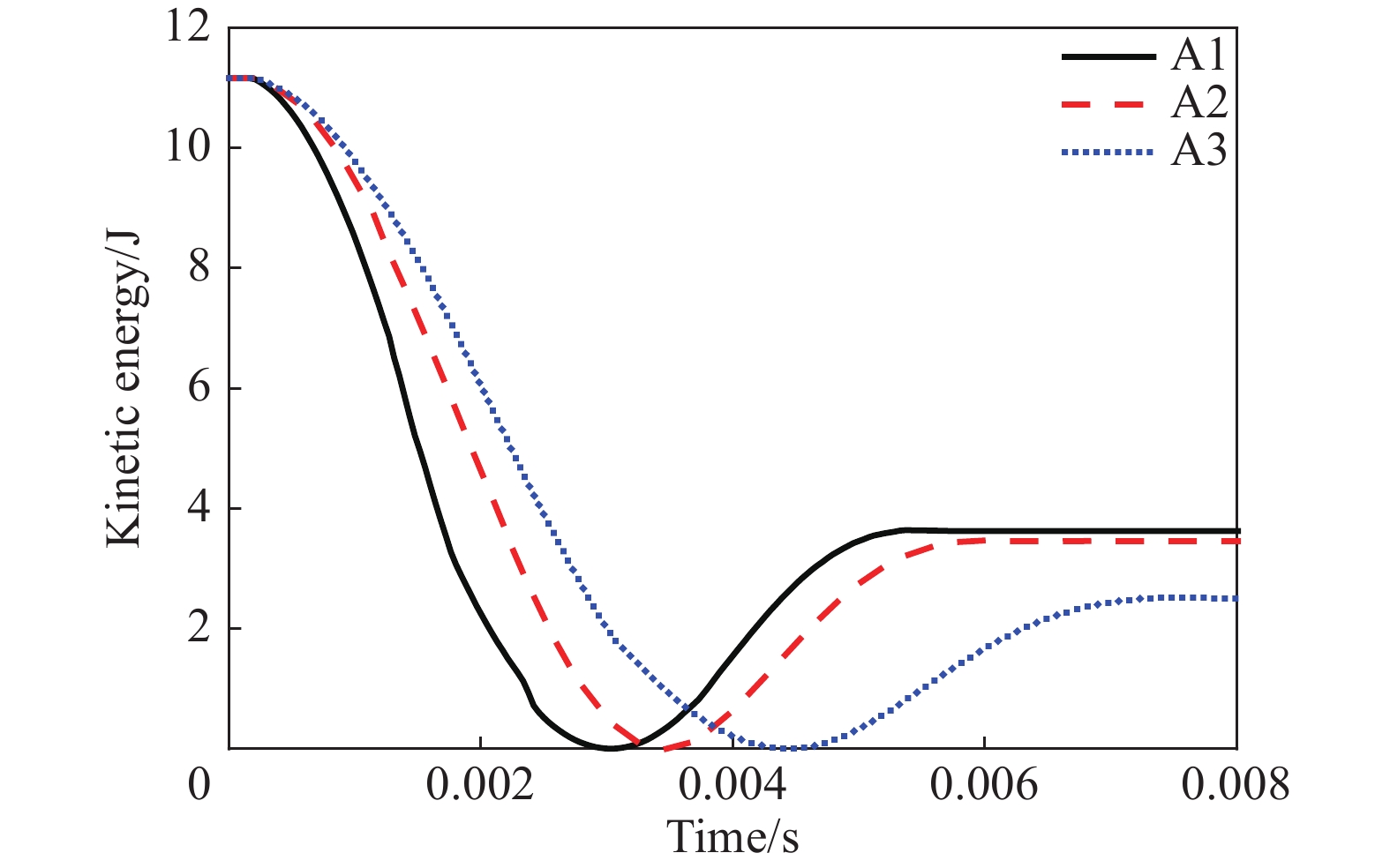

摘要: 针对碳纤维增强树脂复合材料(CFRP)蒙皮-铝蜂窝夹层结构,使用半球头式落锤冲击试验平台进行了低速冲击载荷下蜂窝芯单元尺寸对夹层板冲击性能影响的试验探究,并基于渐进损伤模型、内聚力模型和三维Hashin失效准则,在有限元仿真软件ABAQUS中建立了含蒙皮、蜂窝芯、胶层的CFRP蒙皮-铝蜂窝夹层板精细化低速冲击仿真模型,仿真结果与试验结果吻合较好。利用该数值模型进一步探究了蜂窝芯高度、蒙皮厚度和蜂窝芯壁厚等结构参数对于蜂窝夹层板低速冲击吸能效果的影响。结果表明:增大铝蜂窝芯的单元边长,会减小蜂窝夹层板的刚度,提升夹层板的吸能效果;芯层高度对夹层板的刚度及抗低速冲击性能影响较小;增大蜂窝夹层板的蒙皮厚度,可以提高夹层板的刚度,但会降低夹层板的吸能效果;增大蜂窝芯的壁厚,可以提高夹层板的刚度和抗低速冲击性能。Abstract: The effect of the size of honeycomb core unit on the resistance of sandwich plate of carbon fiber reinforced polymer (CFRP) under low-velocity impact load was investigated by using the impact test system of hemisphere-head drop hammer. Based on the continuous damage mechanics model, cohesive element model and 3D Hashin damage criteria, a refined low-velocity impact simulation model for honeycomb sandwich plate with CFRP face sheets, aluminum honeycomb core and cohesive films was established in finite element simulation software ABAQUS. The simulation results are in good agreement with the experimental results. The effects of structural parameters, such as the height of honeycomb core, the thickness of face sheets and the thickness of honeycomb cell wall, on the energy absorption of honeycomb sandwich plate were further investigated by using the numerical model. The results show that increasing the cell side length of aluminum honeycomb core can reduce the stiffness of honeycomb sandwich plate and improve the energy absorption effect of sandwich plate. The core height has little effect on the stiffness and low-velocity impact resistance of the sandwich plate. Increasing the skin thickness of honeycomb sandwich board can improve the stiffness of sandwich board, but reduce the energy absorption effect of sandwich board. Increasing the cell wall thickness can improve the stiffness and low-velocity impact resistance of sandwich board.

-

-

表 1 CFRP蒙皮的材料参数

Table 1 Mechanical properties of CFRP laminates

T300/7901 Value Adhesive Value E1/MPa 125 000 GCn/(N⋅mm−1) 0.52 E2,E3/MPa 11 300 GCs,GCt/(N⋅mm−1) 0.92 G12,G13/MPa 5 430 σn,max 50 {G_{23}}{\rm{/MPa}} 3 979 {\sigma _{{\rm{s}},\max }}{\rm{/MPa}} 94 ν12, ν23 0.3 {\sigma _{{\rm{t}},\max }}{\rm{/MPa}} 94 ν23 0.42 {K_{\rm{n}}}{\rm{/(N}} \cdot {\rm{m}}{{\rm{m}}^{ - {\rm{3}}}}{\rm{)}} 100 000 {X_{\rm{T}}}{\rm{/MPa}} 2 000 {K_{\rm{s} } },{K_{\rm{t} } }{\rm{/(N} } \cdot {\rm{m} }{ {\rm{m} }^{ - {\rm{3} } } }{\rm{)} } 100 000 {X_{\rm{C}}}{\rm{/MPa}} 1 100 {Y_{\rm{T}}},{Z_{\rm{T}}}{\rm{/MPa}} 80 {Y_{\rm{C}}},{Z_{\rm{T}}}{\rm{/MPa}} 280 S{\rm{/MPa}} 120 Notes: Ei(i=1,2,3) is Young’s modulus in i direction; Gij(i,j=1,2,3) is shear modulus in i-j plane; νij(i,j=1,2,3) is Poisson’s ratio in i-j plane; Xt/Xc and Yt/Yc are the tensile/compressive strengths in 1 and 2 directions, respectively; S is shear strength; G_{\rm{n}}^{\rm{C}} is toughness in tension; G_{\rm{s}}^{\rm{C}}and G_{\rm{t}}^{\rm{C}} are toughness components in shear; σn,max is maximum nominal stress of normal-only mode; σs,max and σt,max are maximum nominal stress in 1 and 2 directions, respectively; Kn is stiffness in tension; Ks and Kt are stiffness components in shear. 表 2 Al 3003-H19铝箔材料参数

Table 2 Material properties of Al3003-H19 aluminum alloy foil

Property Value Density/(kg·m−3) 2 730 Young’s modulus/GPa 70 Poisson’s ratio 0.3 Yield strength/MPa 183 表 3 CFRP蒙皮-铝蜂窝夹层板的结构参数

Table 3 Structural parameters of aluminum honeycomb sandwich plate with CFRP face sheets

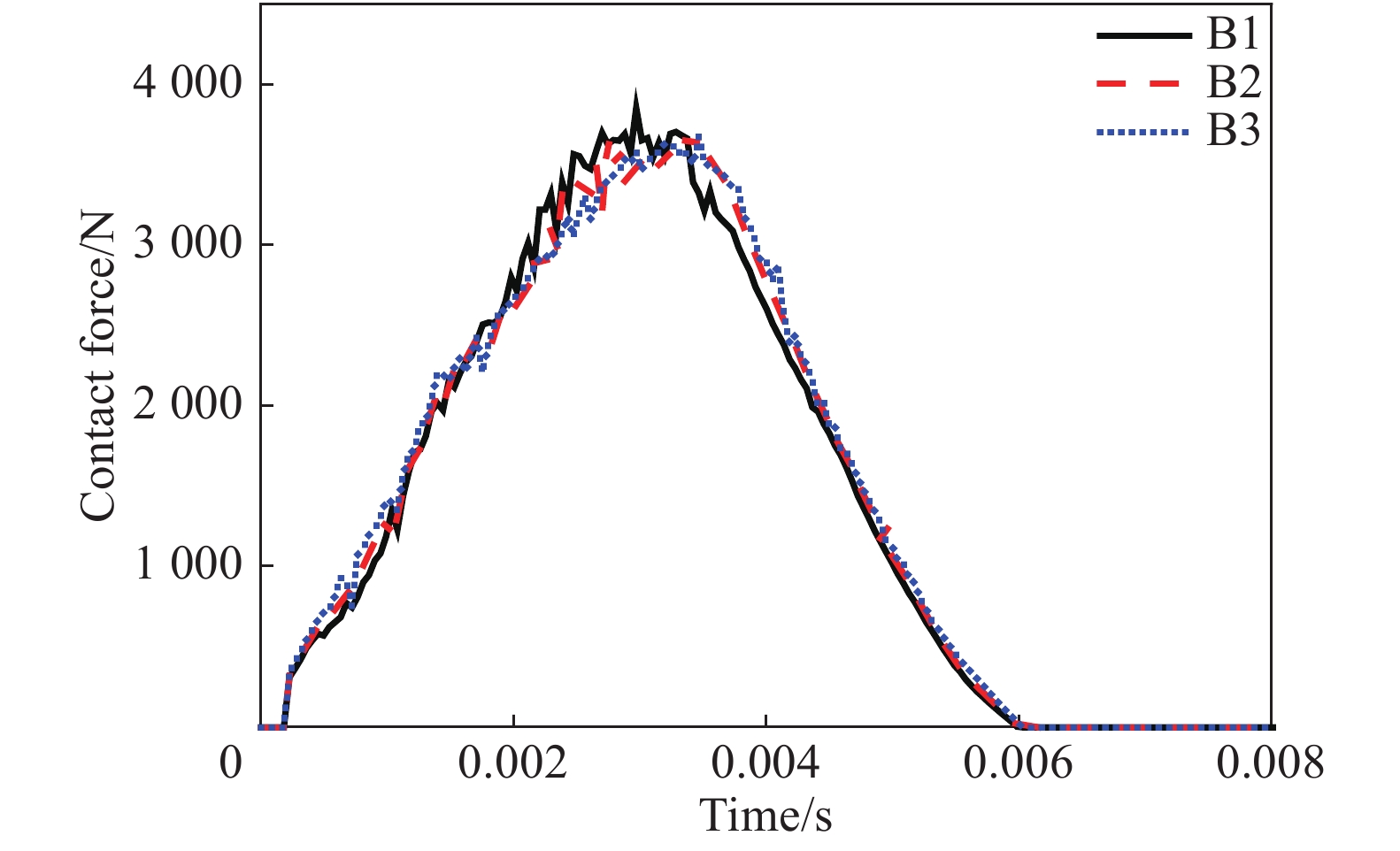

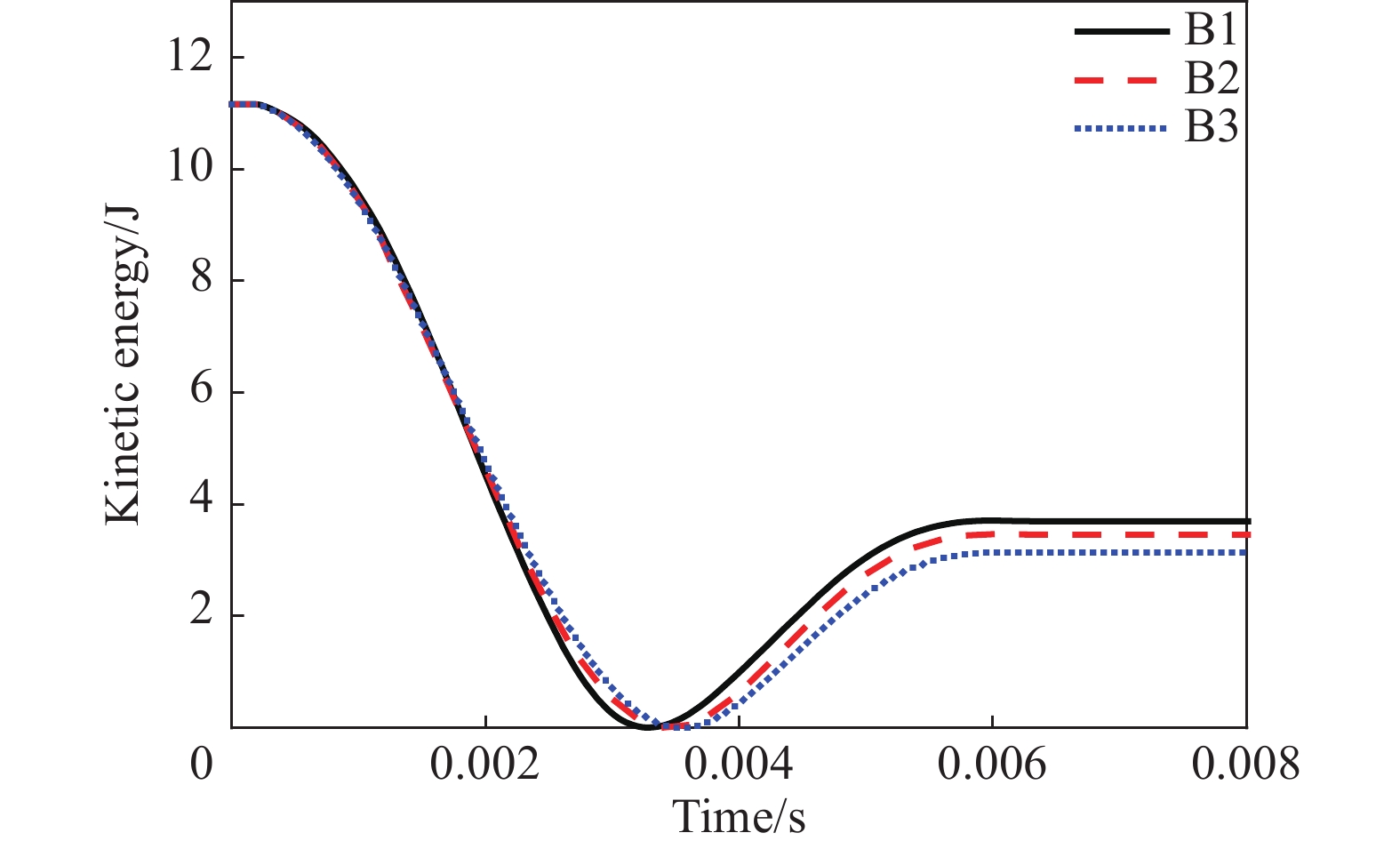

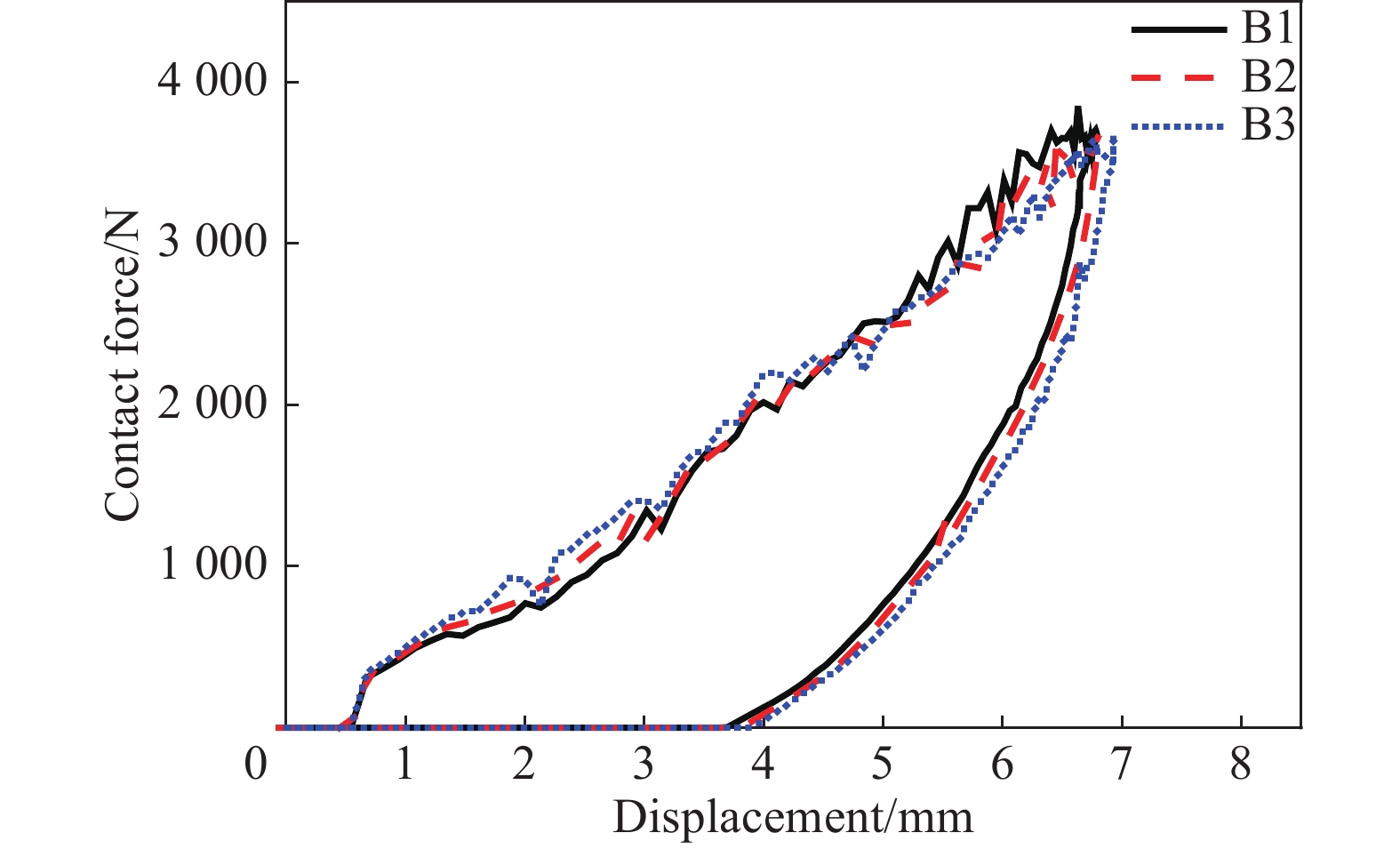

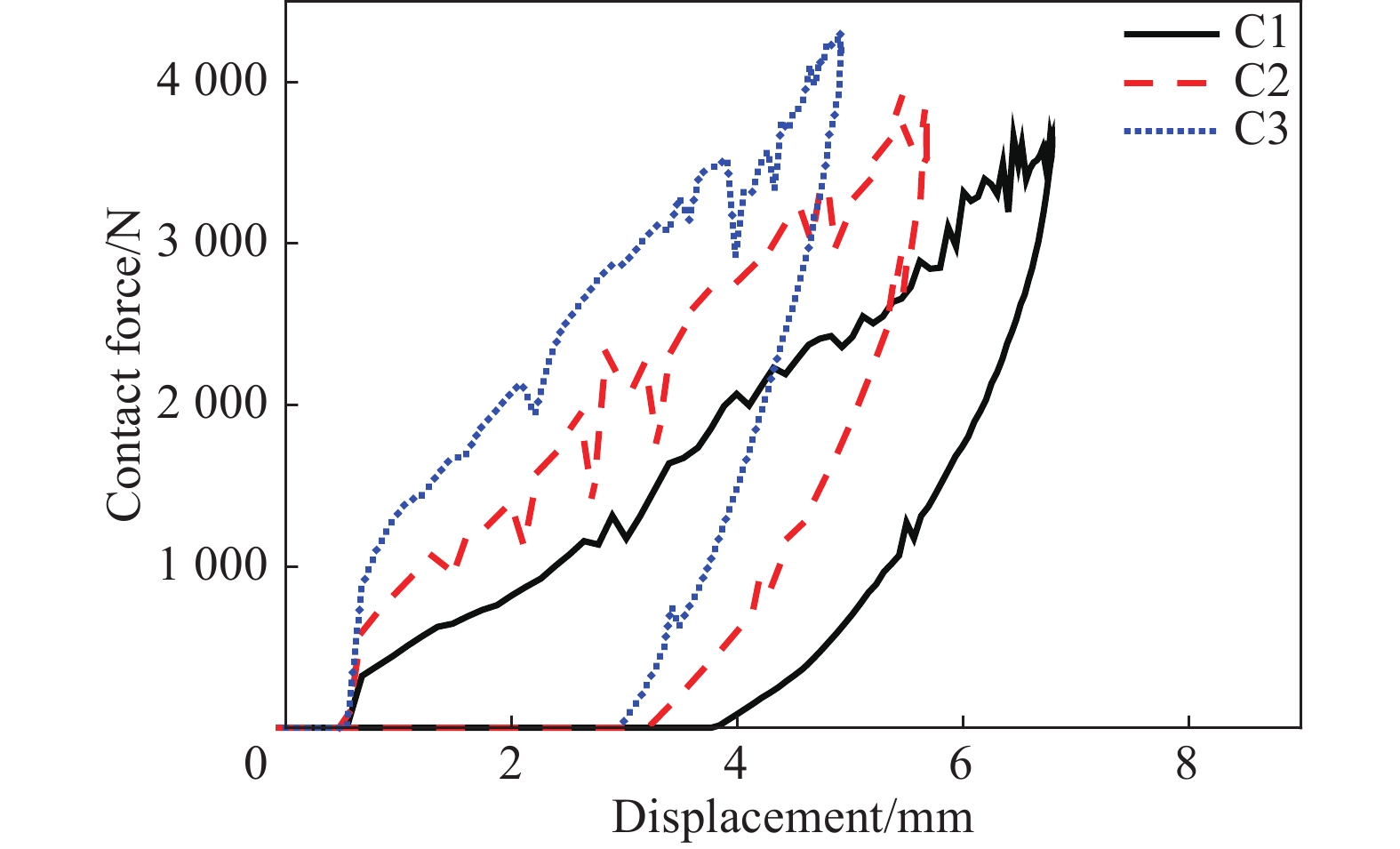

Label Cell side length {L_{\rm{c}}}/mm Core height {H_{\rm{c}}}/mm Facesheet thickness {T_{\rm{f}}}/mm Cell wall thickness {T_{\rm{c}}}/mm A1 2 20 1.2 0.06 A2 4 20 1.2 0.06 A3 6 20 1.2 0.06 B1 4 10 1.2 0.06 B2 4 20 1.2 0.06 B3 4 30 1.2 0.06 C1 4 20 1.2 0.06 C2 4 20 1.8 0.06 C3 4 20 2.4 0.06 D1 4 20 1.2 0.06 D2 4 20 1.2 0.10 D3 4 20 1.2 0.14 表 4 试验与仿真中蜂窝芯损伤深度δ的对比

Table 4 Comparison of experimental and numerical deformations δ of honeycomb cores

Label Top face sheet Cross-section Experiment Simulation-Honeycomb core A1

A2

A3

表 5 仿真预测的B组CFRP蒙皮-铝蜂窝夹层板冲击损伤

Table 5 Simulation predicted impact damage of group B aluminum honeycomb sandwich plate with CFRP face sheets

Label Cross-section Honeycomb sandwich plate Honeycomb core B1

B2

B3

表 6 仿真预测的C组CFRP蒙皮-铝蜂窝夹层板冲击损伤

Table 6 Simulation predicted impact damage of group C aluminum honeycomb sandwich plate with CFRP face sheets

Label Cross-section Honeycomb sandwich plate Honeycomb core C1

C2

C3

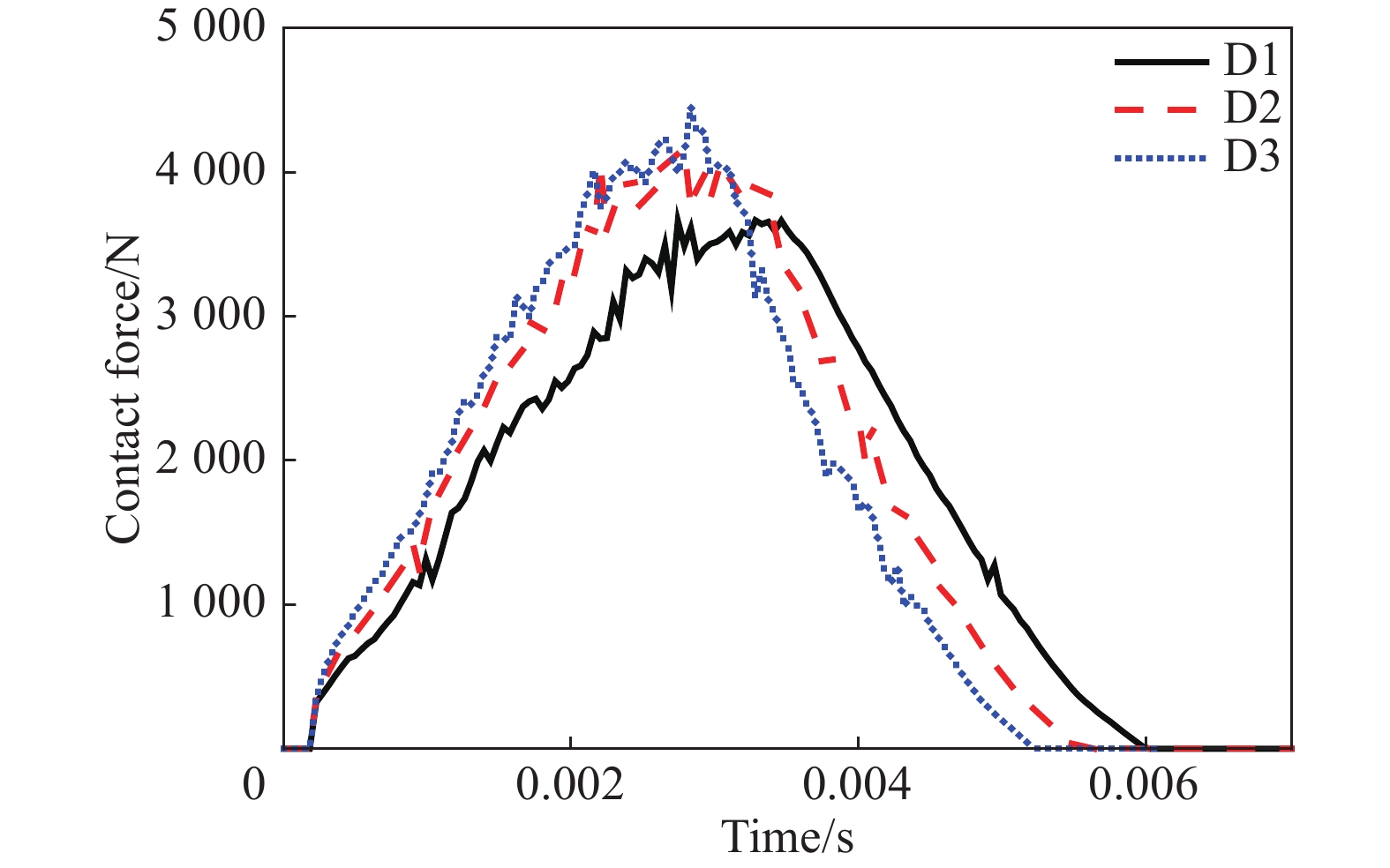

表 7 仿真预测的D组CFRP蒙皮-铝蜂窝夹层板冲击损伤

Table 7 Simulation predicted impact damage of group D aluminum honeycomb sandwich plate with CFRP face sheets

Label Cross-section Honeycomb sandwich plate Honeycomb core D1

D2

D3

表 8 不同结构参数的CFRP蒙皮-铝蜂窝夹层板组件吸能占比

Table 8 Absorbed energy rates by components of aluminum honeycomb sandwich plate with CFRP face sheets with different structural parameters

% Parameters Cell side length {L_{\rm{c}}} Core height {H_{\rm{c}}} Facesheet thickness {T_{\rm{f}}} Cell wall thickness {T_{\rm{c}}} A1 A2 A3 B1 B2 B3 C1 C2 C3 D1 D2 D3 Upper plate 20.43 17.29 16.49 19.53 17.29 16.04 17.29 26.97 31.72 17.29 20.88 30.02 Honeycomb 45.16 50.01 58.60 38.45 50.01 57.35 50.01 43.20 39.78 50.01 45.61 41.75 Lower plate 1.88 1.70 2.51 2.15 1.70 1.70 1.70 1.08 0.72 1.70 2.69 3.32 Impactor 32.53 31.00 22.40 39.87 31.00 24.91 31.00 28.05 27.78 31.00 30.82 24.91 Sandwich plate 67.37 69.00 77.60 60.13 69.00 75.09 69.00 71.95 72.22 69.00 69.18 75.09 -

[1] GUNES R, ARSLAN K. Development of numerical realistic model for predicting low-velocity impact response of aluminium honeycomb sandwich structures[J]. Journal of Sandwich Structures & Materials,2016,18(1):95-112.

[2] AMRAEI M, SHAHRAVI M, NOORI Z, et al. Application of aluminium honeycomb sandwich panel as an energy absorber of high-speed train nose[J]. Journal of Composite Materials,2014,48(9):1027-1037. DOI: 10.1177/0021998313482019

[3] BUITRAGO B L, SANTIUSTE C, SONIA S S, et al. Modelling of composite sandwich structures with honeycomb core subjected to high-velocity impact[J]. Composite Structures,2010,92(9):2090-2096. DOI: 10.1016/j.compstruct.2009.10.013

[4] 齐佳旗, 段玥晨, 李成, 等. 低速冲击下铝蜂窝夹层板的动态响应研究[J]. 玻璃钢/复合材料, 2019(05):5-11. DOI: 10.3969/j.issn.1003-0999.2019.05.001 QI Jiaqi, DUAN Yuechen, LI Cheng, et al. Dynamic response of aluminum honeycomb sandwich plate under low speed impact[J]. Fiber Reinforced Plastics/Composites,2019(05):5-11(in Chinese). DOI: 10.3969/j.issn.1003-0999.2019.05.001

[5] QIU Ang, FU Kunkun, LIN Wei, et al. Modelling low-speed drop-weight impact on composite laminates[J]. Materials and Design,2014,60:520-531.

[6] YAHAYA M A, RUAN D, LU G, et al. Response of aluminium honeycomb sandwich panels subjected to foam projectile impact—An experimental study[J]. International Journal of Impact Engineering,2015,75:100-109. DOI: 10.1016/j.ijimpeng.2014.07.019

[7] CRUPI V, EPASTO G, GUGLIELMINO E. Collapse modes in aluminium honeycomb sandwich panels under bending and impact loading[J]. International Journal of Impact Engineering,2012,43(5):6-15.

[8] GARAM K, RONALD S, WATERLOO T. Investigating the effects of fluid intrusion on Nomex-honeycomb sandwich structures with carbon fiber facesheets[J]. Composite Structures,2018,206:535-549.

[9] GIULIA P, GABRIELLA E, VINCENZO C, et al. Single and double-layer honeycomb sandwich panels under impact loading[J]. International Journal of Impact Engineering,2018,121:77-90. DOI: 10.1016/j.ijimpeng.2018.07.013

[10] CACCESE V, FERGUSON J R, EDGECOMB M A. Optimal design of honeycomb material used to mitigate head impact[J]. Composite Structures,2013,100:404-412.

[11] SUN Guangyong, CHEN Dongdong, HUO Xintao, et al. Experimental and numerical studies on indentation and perforation characteristics of honeycomb sandwich panels[J]. Composite Structures,2018,184:110-124.

[12] ZHANG Dahai, JIANG Dong, FEI Qingguo, et al. Experimental and numerical investigation on indentation and energy absorption of a honeycomb sandwich panel under low-velocity impact[J]. Finite Elements in Analysis & Design,2016,117-118:21-30.

[13] CHEN Yuan, HOU Shujuan, FU Kunkun, et al. Low-velocity impact response of composite sandwich structures: Modelling and experiment[J]. Composite Structures,2017,168:322-334.

[14] RICCIO A, RAIMONDO A, SAPUTO S, et al. A numerical study on the impact behaviour of natural fibres made honeycomb cores[J]. Composite Structures,2018,202:909-916.

[15] SUN M Q, WOWK D, MECHEFSKE C, et al. An analytical study of the plasticity of sandwich honeycomb panels subjected to low-velocity impact[J]. Composites Part B: Engineering,2019,168:121-128. DOI: 10.1016/j.compositesb.2018.12.071

[16] CRUPI V, KARA E, EPASTO G, et al. Theoretical and experimental analysis for the impact response of glass fibre reinforced aluminium honeycomb sandwiches[J]. Journal of Sandwich Structures & Materials,2018,20:42-69.

[17] IVAÑEZ I, SANCHEZ-SAEZ S. Numerical modelling of the low-velocity impact response of composite sandwich beams with honeycomb core[J]. Composite Structures,2013,106:716-723.

[18] MENNA C, ZINNO A, ASPRONE D, et al. Numerical assessment of the impact behavior of honeycomb sandwich structures[J]. Composite Structures,2013,106:326-339. DOI: 10.1016/j.compstruct.2013.06.010

[19] IVAÑEZ I, MOURE M M, GARCIA-CASTILLO S K, et al. The oblique impact response of composite sandwich plates[J]. Composite Structures,2015,133:1127-1136. DOI: 10.1016/j.compstruct.2015.08.035

[20] AUDIBERT C, ANDRÉANI A, LAINÉ É, et al. Discrete modelling of low-velocity impact on Nomex® honeycomb sandwich structures with CFRP skins[J]. Composite Structures,2019,207:108-118. DOI: 10.1016/j.compstruct.2018.09.047

[21] CRUPI V, EPASTO G, GUGLIELMINO E. Comparison of aluminium sandwiches for lightweight ship structures: Honeycomb vs. foam[J]. Marine Structures,2013,30:74-96.

[22] 张俊琪, 刘龙权, 汪海. 薄面板复合材料蜂窝夹层结构冲击试验[J]. 复合材料学报, 2014, 31(4):1063-1071. ZHANG Junqi, LIU Longquan, WANG Hai. Test of composite honeycomb sandwich structure with thin facesheet subject to impact load[J]. Acta Materiae Compositae Sinica,2014,31(4):1063-1071(in Chinese).

[23] ASTM International. Standard practice for damage resistance testing of sandwich constructions: ASTM D7766/D7766M—11[S]. USA: West Conshohocken, PA, 2011.

[24] 孙振辉, 铁瑛, 侯玉亮, 等. 相对冲击位置和补片层数对胶接修理CFRP复合材料层合板抗冲击性能的影响[J]. 复合材料学报, 2019, 36(5):1114-1123. SUN Zhenhui, TIE Ying, HOU Yuliang, et al. Effect of relative impact location and patch layer number on impact resistance of adhesive repaired CFRP laminates[J]. Acta Materiae Compositae Sinica,2019,36(5):1114-1123(in Chinese).

[25] TIE Ying, HOU Yuliang, LI Cheng, et al. An insight into the low-velocity impact behavior of patch-repaired CFRP laminates using numerical and experimental approaches[J]. Composite Structures,2018,190:179-188.

[26] ABAQUS Version 6.14 Documentation ABAQUS Analysis User’s Manual.

[27] 韩学群. 复合材料层合板分层损伤数值模拟[D]. 武汉: 武汉理工大学, 2010. HAN Xuequn. Numerical simulation of delamination damage for composite laminates[D]. Wuhan: Wuhan University of Technology, 2010(in Chinese).

[28] ABRATE S, FERRERO J F, NAVARRO P. Cohesive zone models and impact damage predictions for composite structures[J]. Meccanica,2015,50(10):2587-2620.

-

期刊类型引用(7)

1. 陈曦,代文彬,祁永峰,王书晓,陈学刚,王福明. 基于响应面法的矿用高铬磨球热处理参数优化设计. 中国矿山工程. 2023(04): 1-9+23 .  百度学术

百度学术

2. 贺雄飞,黄伟,张浩,唐刚. 基于响应面法的综合抗渗自愈性能水泥基渗透结晶防水材料制备方案优化. 化工矿物与加工. 2021(03): 31-35 .  百度学术

百度学术

3. 刘树龙,王发刚,李公成,刘国磊,王劼,齐兆军. 基于响应面法的复合充填料浆配比优化及微观结构影响机制. 复合材料学报. 2021(08): 2724-2736 .  本站查看

本站查看

4. 郑旭,袁丽婷. 复合调湿材料的研究现状及最新进展. 化工进展. 2020(04): 1378-1388 .  百度学术

百度学术

5. 张浩,朱大有. 基于综合热-湿性能的静电纺丝相变储湿纤维制备工艺的响应面法优化. 太阳能学报. 2020(04): 326-332 .  百度学术

百度学术

6. 张鑫林,蒋达华,廖绍璠,费华. 矿物基载体功能材料调温调湿性能研究进展. 应用化工. 2019(03): 662-667 .  百度学术

百度学术

7. 张磊,杨柳,桑国臣,翟永超. 基于响应面法的石灰-矿渣/生土复合材料热湿综合性能. 复合材料学报. 2017(05): 1095-1102 .  本站查看

本站查看

其他类型引用(6)

-

下载:

下载: