Polyphenylene ether type phthalonitrile resin and its composite materials

-

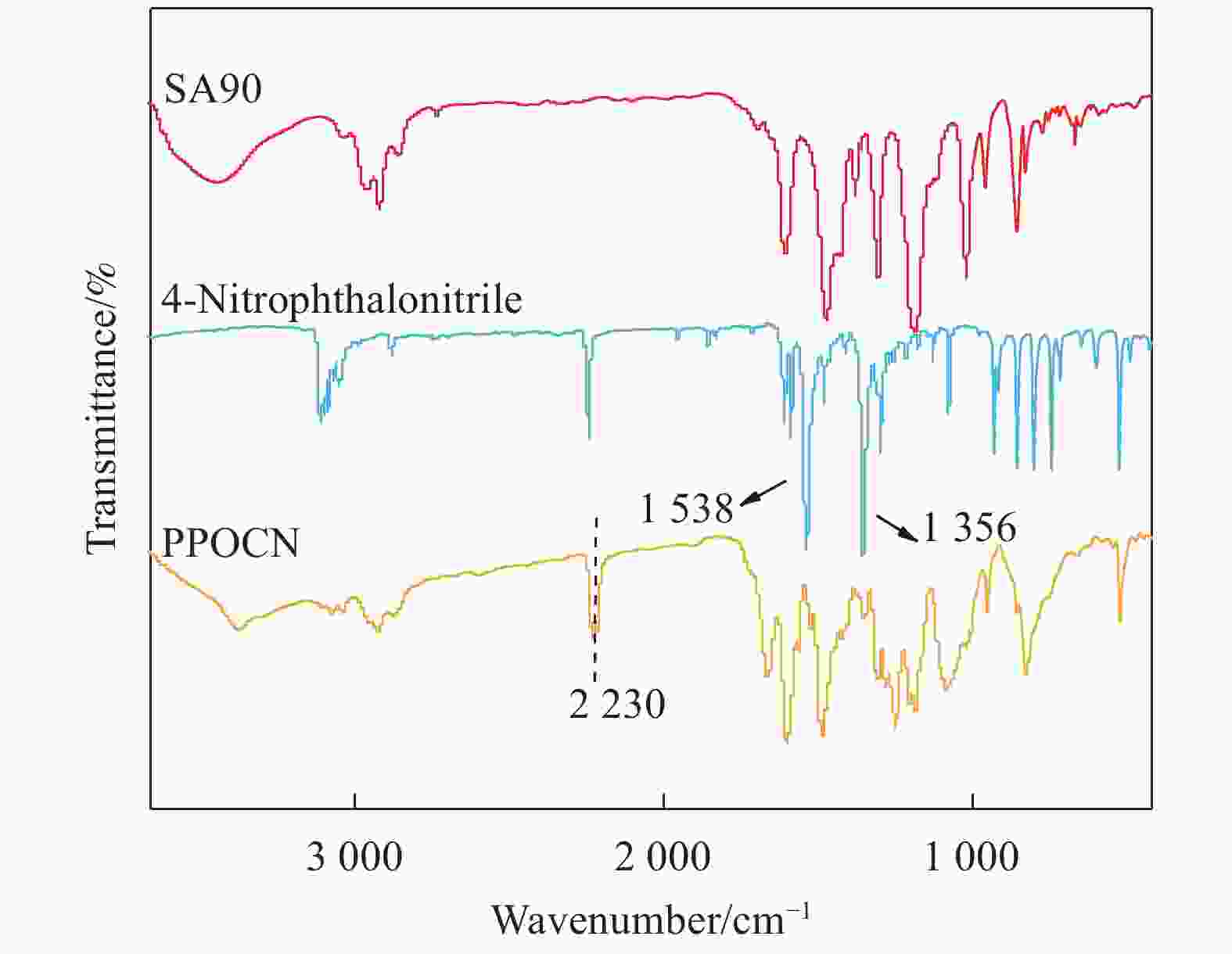

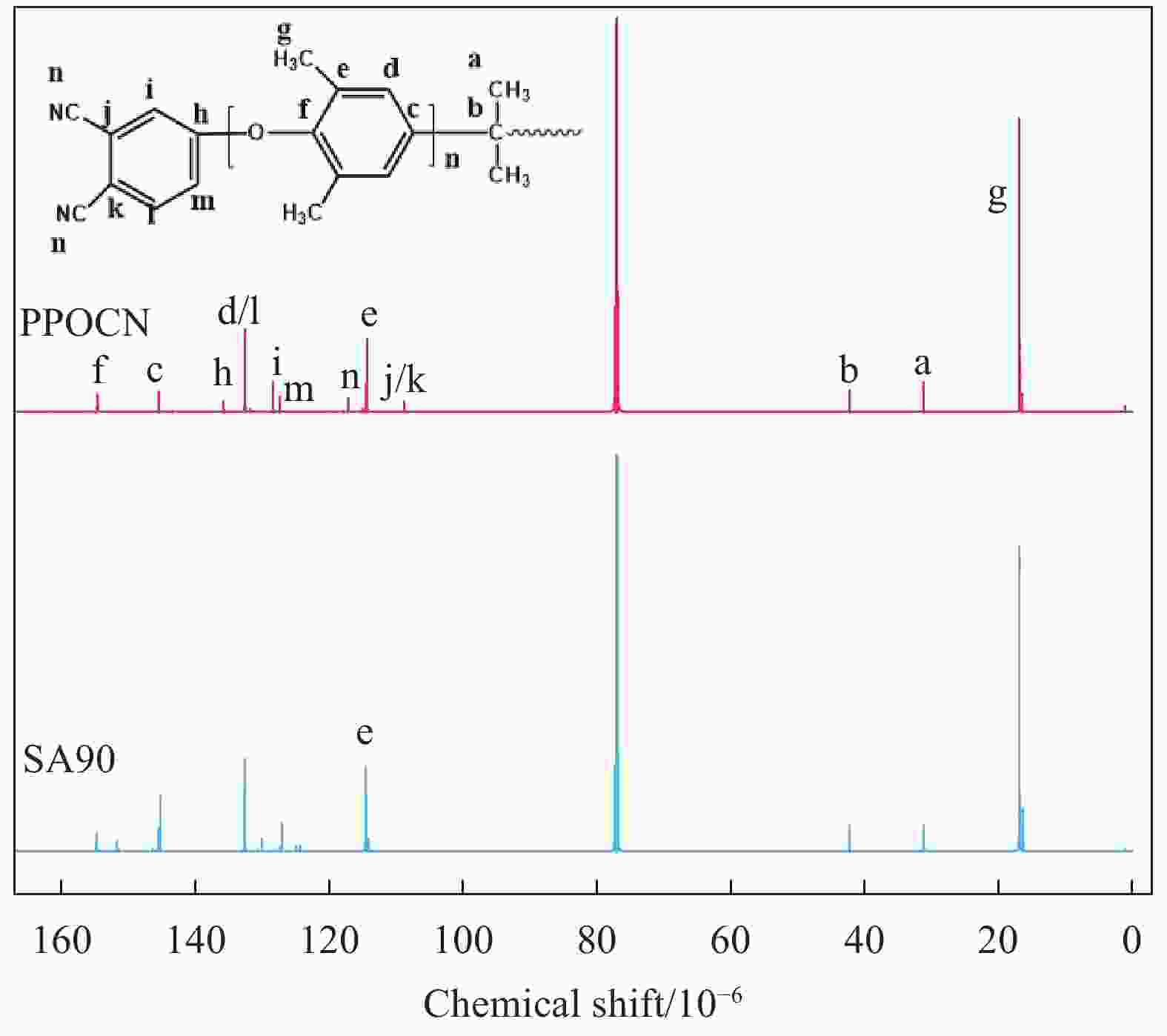

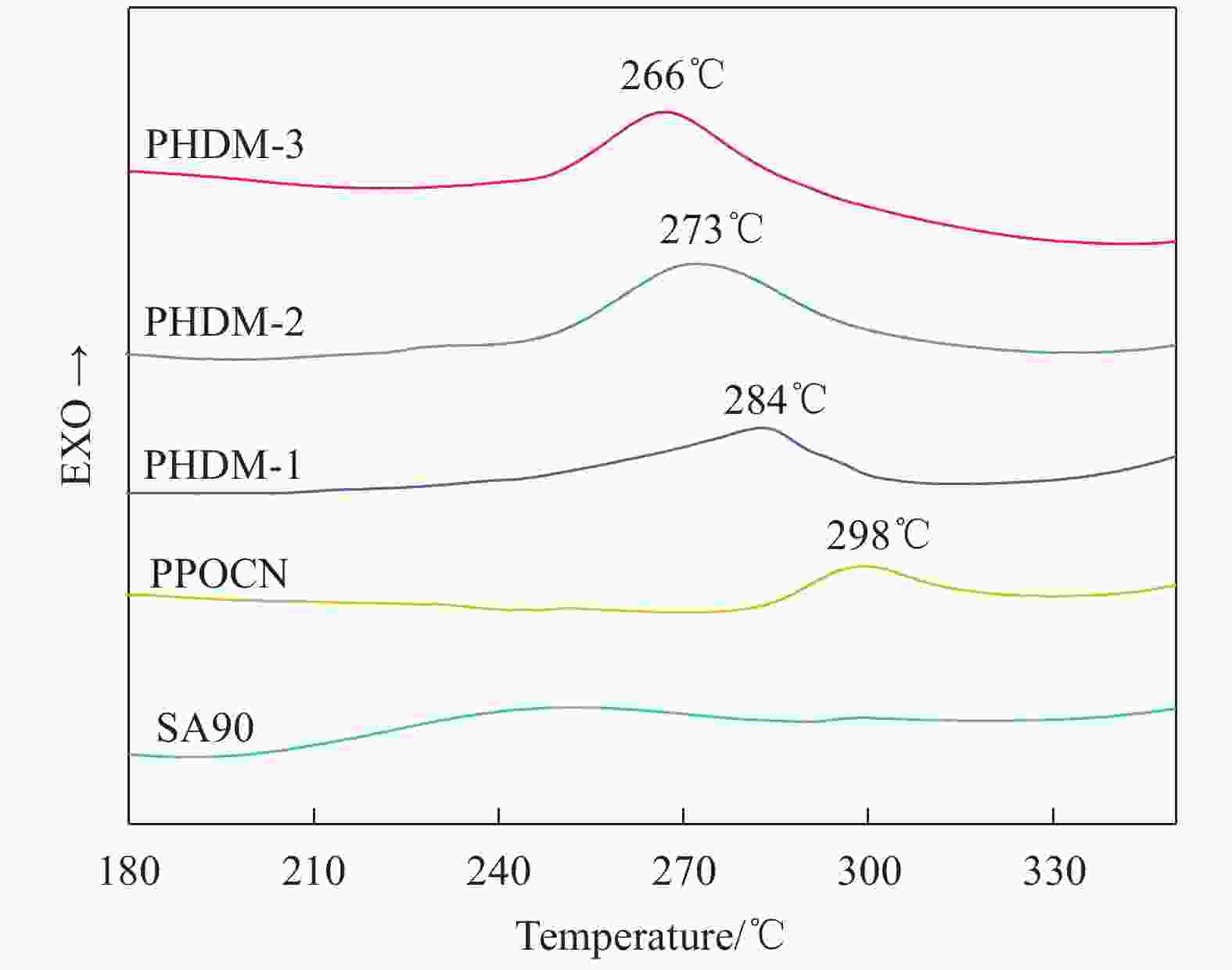

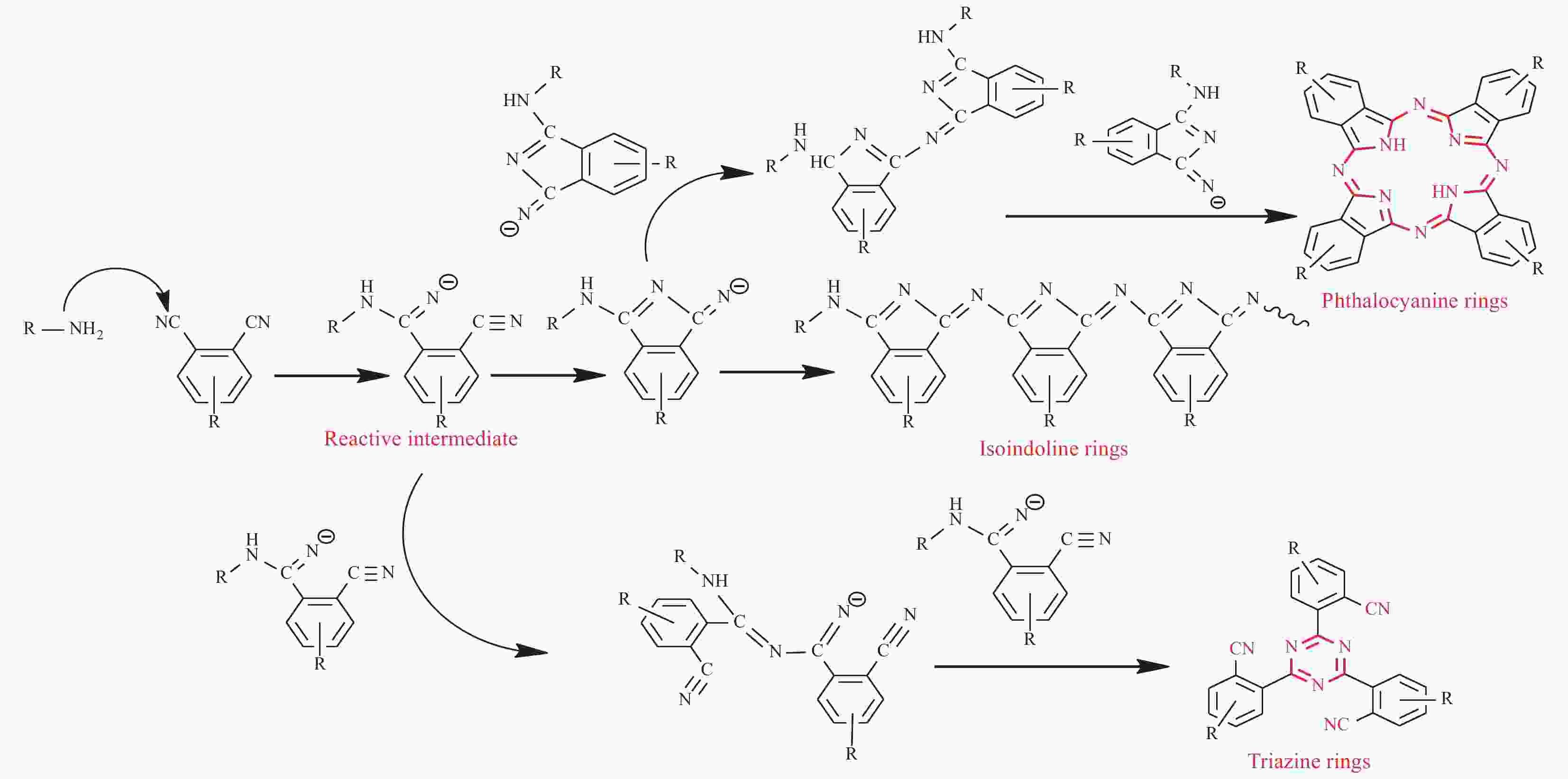

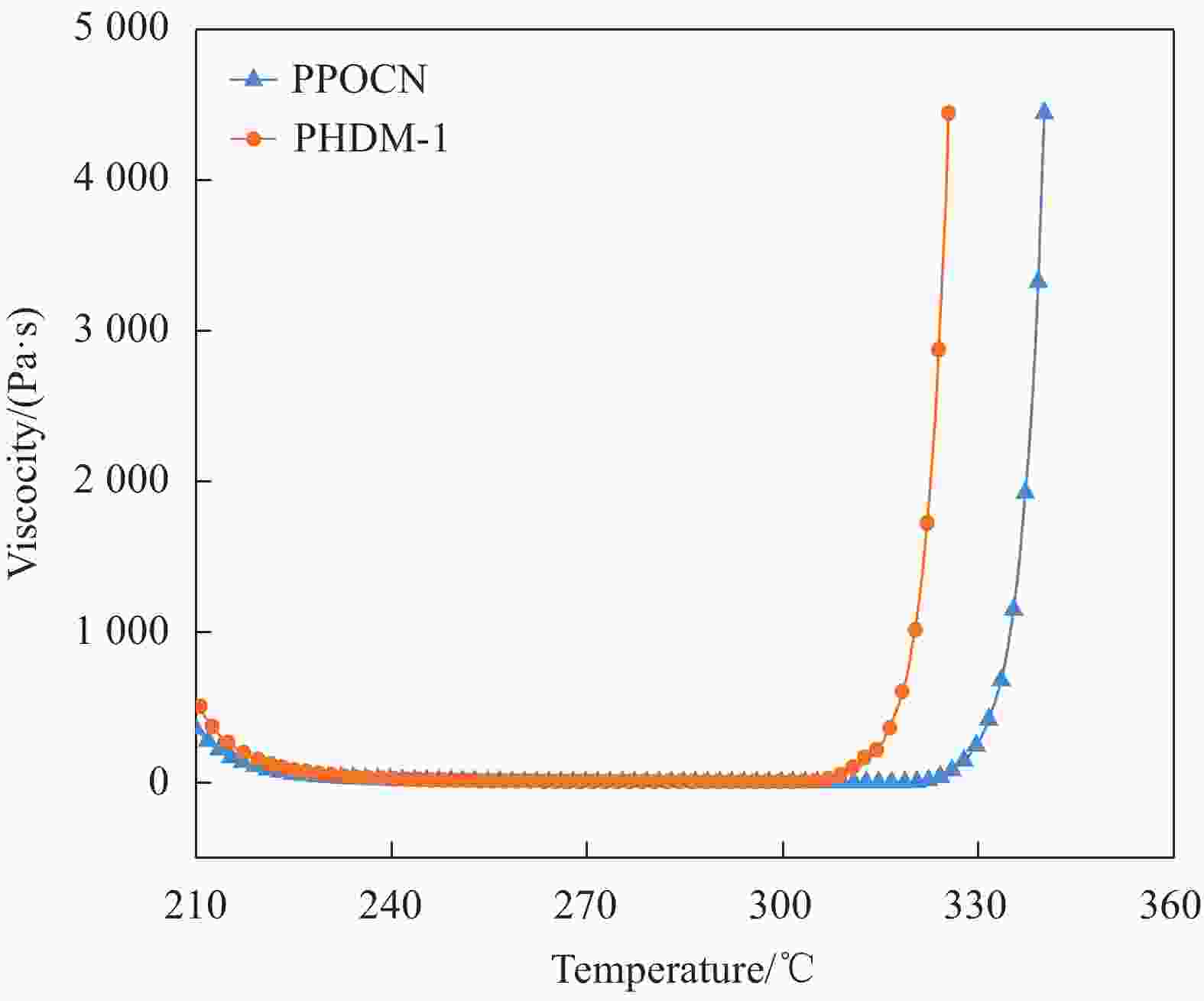

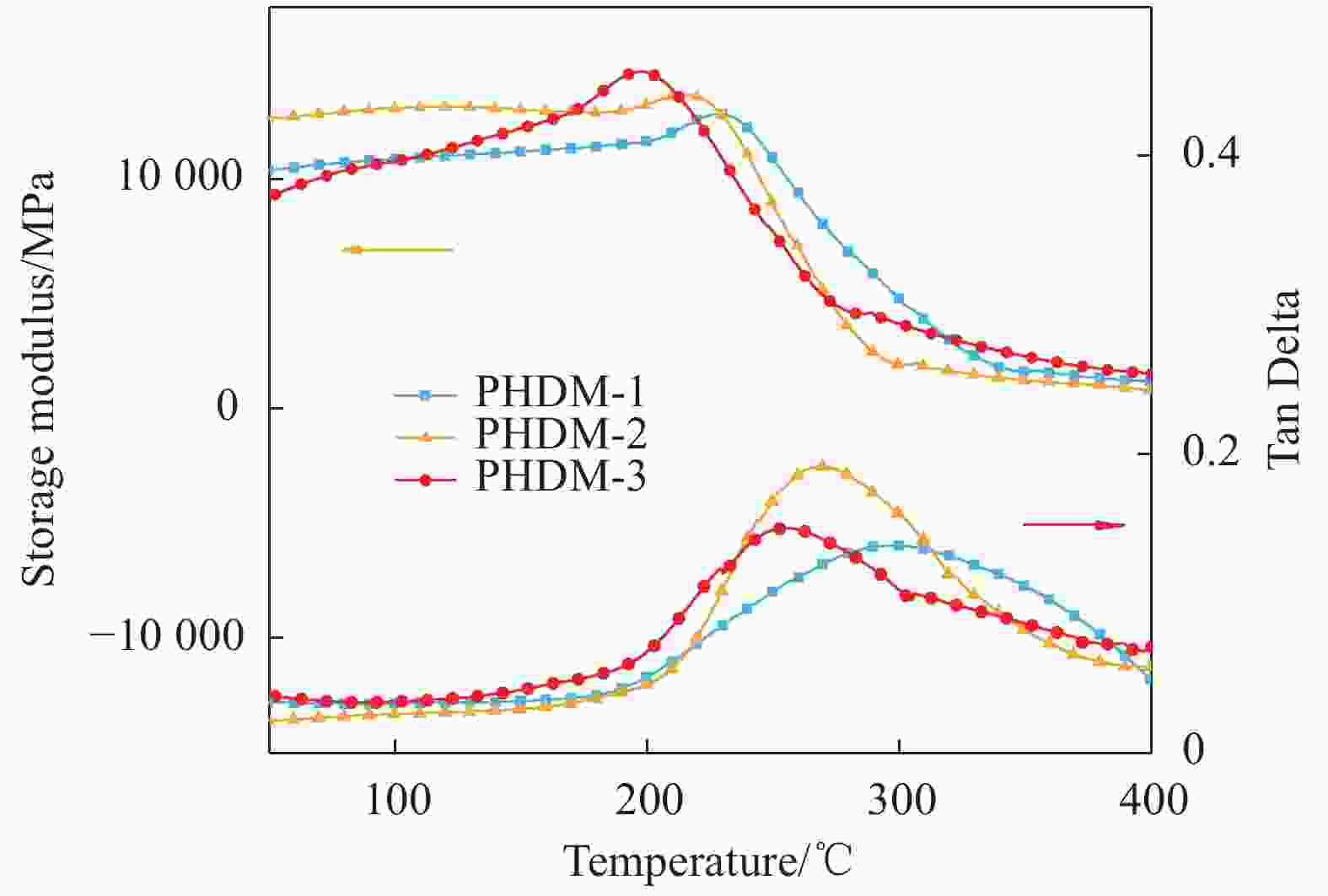

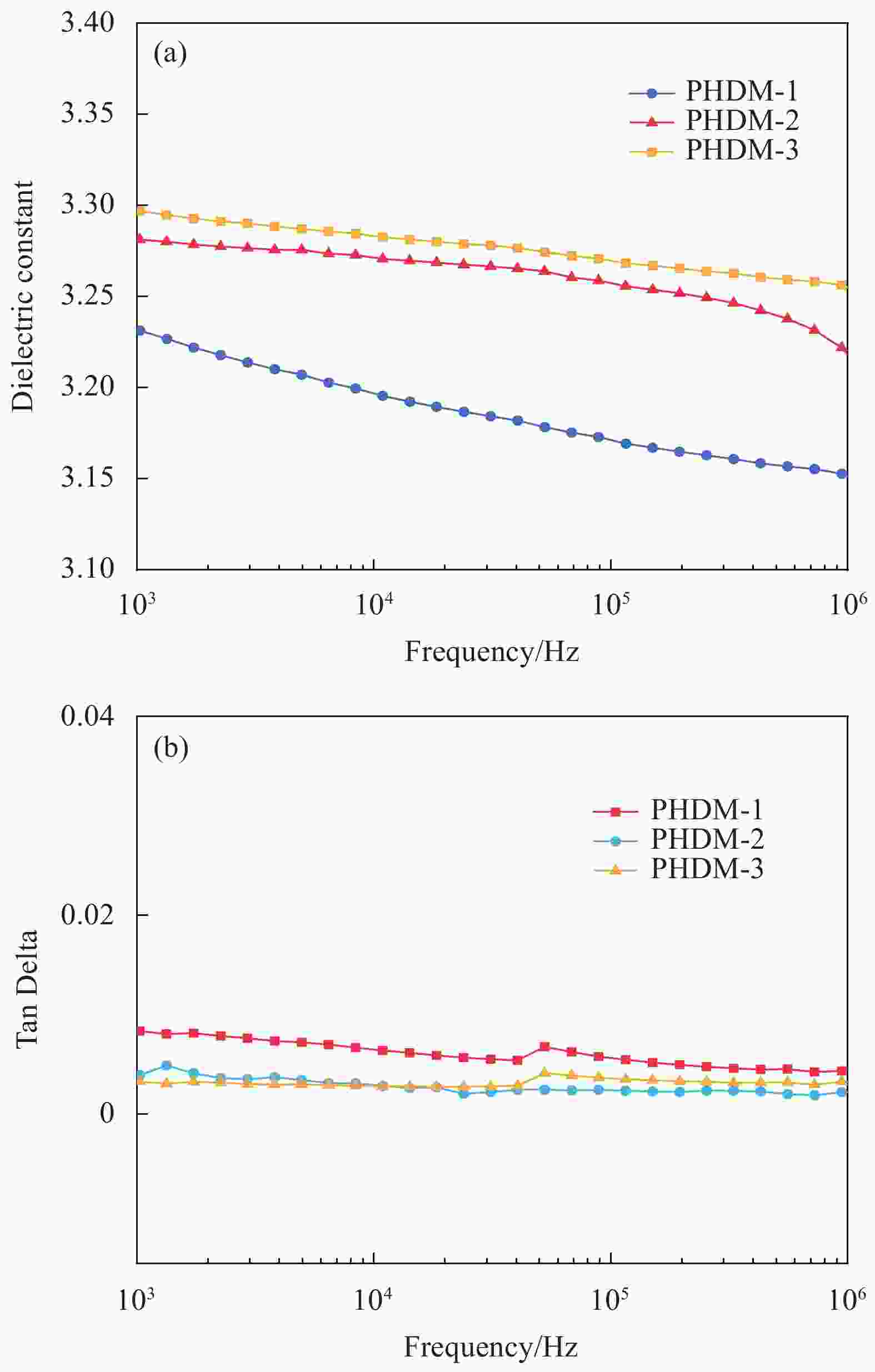

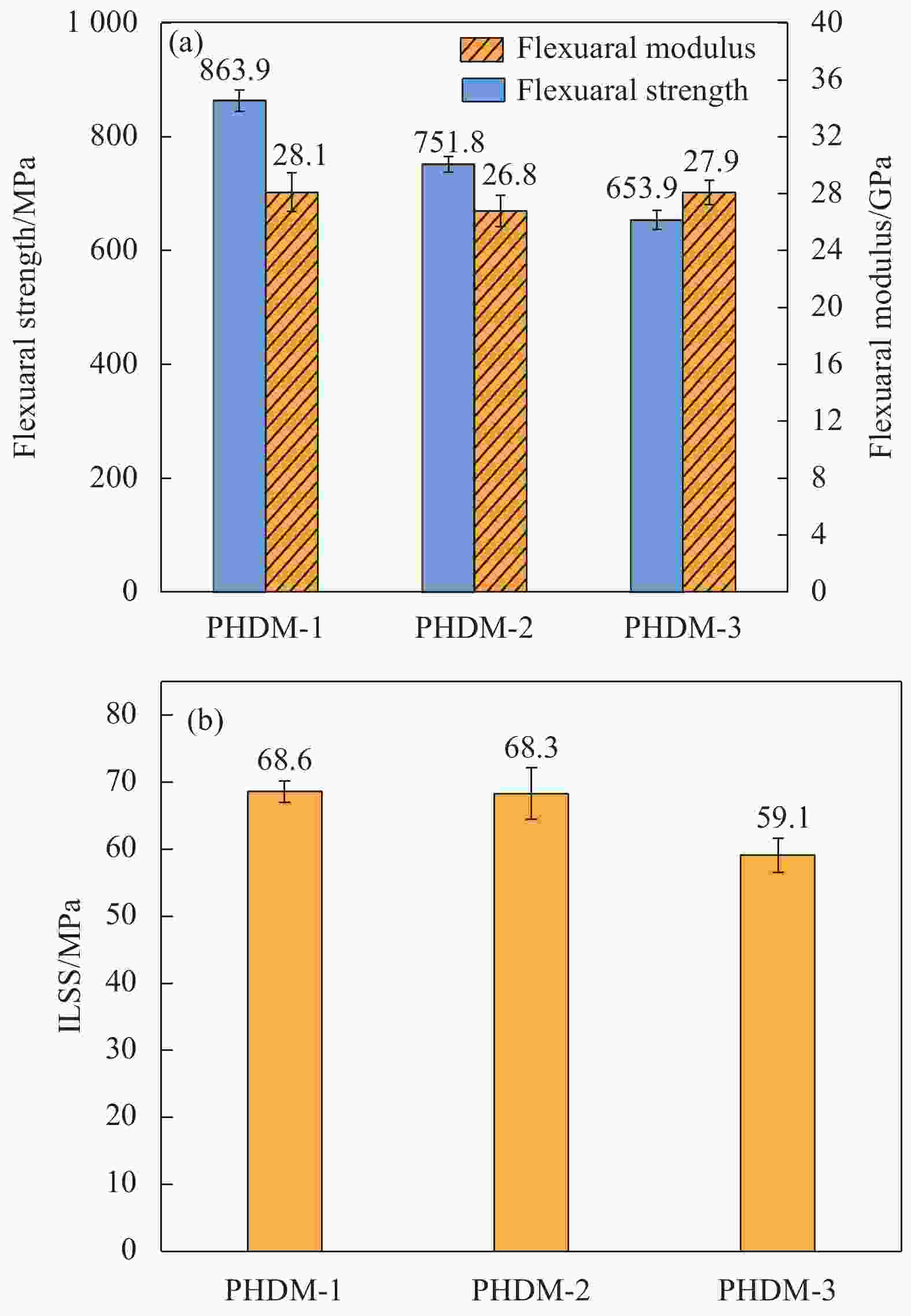

摘要: 为保留聚苯醚树脂优异介电性能的同时提升其耐溶剂性和热稳定性,拓宽其在高频高速覆铜板领域的应用,本文以K2CO3为缚酸剂,通过4-硝基邻苯二甲腈的亲核取代合成了一种聚苯醚型的邻苯二甲腈树脂(PPOCN)。通过FTIR、DSC、TGA、流变性分析对树脂的结构、固化行为、耐热性以及加工性能进行了综合分析,通过介电分析仪、动态热机械分析及力学性能测试评估了复合材料的各项性能。结果表明,PPOCN具备交联反应活性,固化物的玻璃化转变温度(Tg)为295 ℃,5%热失重温度(Td5%)为419.3 ℃,与聚苯醚原料相比热稳定性显著提高。以PPOCN为基体树脂,二氨基二苯甲烷(DDM)为固化剂制备的纤维增强复合材料具备优异的力学性能和介电性能,弯曲强度为863.9 MPa,层间剪切强度为68.6 MPa,1 GHz频率下的介电常数为3.15,损耗角正切为0.003。PPOCN在保留了聚苯醚树脂优异介电性能的同时,兼具优异的力学性能和优良的热性能。Abstract: In order to preserve the excellent dielectric properties of polyphenylene oxide resin while improving its solvent resistance and thermal stability, and expand its application in the field of high-frequency and high-speed copper clad laminates, this paper synthesized a polyphenylene oxide type phthalonitrile resin (PPOCN) through nucleophilic substitution of 4-nitrophthalonitrile using K2CO3 as a binding agent. A comprehensive analysis was conducted on the structure, curing behavior, heat resistance, and processing performance of the resin through FTIR, DSC, TGA, and rheological analysis. The various properties of the composite material were evaluated through dielectric analyzer, dynamic thermomechanical analysis, and mechanical performance testing. The results showed that PPOCN has crosslinking reaction activity, and the glass transition temperature (Tg) of the cured product is 295 ℃, and the 5% thermal weight loss temperature (Td5%) is 419.3 ℃. Compared with the raw material of polyphenylene oxide, the thermal stability of PPOCN is significantly improved. The fiber reinforced composite material prepared with PPOCN as the matrix resin and diaminodiphenylmethane (DDM) as the curing agent has excellent mechanical and dielectric properties, with a bending strength of 863.9 MPa, interlayer shear strength of 68.6 MPa, dielectric constant of 3.15 at 1 GHz frequency, and loss tangent of 0.003. PPOCN retains the excellent dielectric properties of polyphenylene oxide resin while also possessing excellent mechanical and thermal properties.

-

Key words:

- Thermosets /

- Polyphenylene ether /

- Phthalonitrile /

- Copper clad laminate /

- Dielectric properties

-

表 1 不同比例的PHDM树脂配方

Table 1. PHDM resin formula with different proportions

Sample Resin mass ratio PPOCN DDM PPOCN 100 0 PHDM-1 100 1 PHDM-2 100 2 PHDM-3 100 3 Notes: PPOCN−Polyphenylene ether type phthalonitrile resin; DDM—4,4'-diaminodiphenylmethane; PHDM−Blends of PPOCN and DDM 表 2 PPO树脂固化物的TGA数据

Table 2. TGA data of PPO resin cured products

Samples Td5% /℃ 800℃ Mass

retention/%N2 Air N2 Air SA90 357.3 349.5 21.4 0.49 PPOCN 417.6 409.9 55.46 0.529 PHDM-1 416.2 401.4 55.77 0.524 PHDM-2 418.5 406.0 54.22 0.536 PHDM-3 419.3 409.6 55.33 0.673 Notes:Td5%−5% weight loss temperature -

[1] 翁志焕, 宗立率, 刘程, 等. 邻苯二甲腈树脂分子结构及性能调控工作进展[J]. 高分子材料科学与工程, 2021, 37(01): 189-199.WENG Zhihuan, ZONG Lishuai, LIU Cheng, etc. Progress in molecular structure and performance control of phthalonitrile resin [J] Polymer Materials Science and Engineering, 2021, 37 (01): 189-199DOI: 10.16865/j.cnki.1000-755.2021.0016(in Chinese). [2] GU H, GAO C, DU A, et al. An overview of high-performance phthalonitrile resins: fabrication and electronic applications[J]. Journal of Materials Chemistry C, 2022, 10(8): 2925-2937. doi: 10.1039/D1TC05715D [3] LIU X, ZHANG S, YE J, et al. A highly-crosslinked phthalonitrile modified bismaleimide-triazine resin for PCB substrates: The synergistic effect on curing behavior and properties[J]. European Polymer Journal, 2023: 112243. [4] 刘孝波, 唐印, 刘朝慧, 等. 一种覆铜板用树脂基纤维增强复合材料及其制备方法, CN114506098BP/OL]. LIU Xiaobo, TANG Yin, LIU Chaohui, et al. A resin based fiber reinforced composite material and its preparation method for copper-clad laminates, CN114506098B [P/OL](in Chinese). [5] LU Y-F, WU S-H, WANG C, et al. Chemical and physical properties of low-molecular-weight poly (2, 6-dimethyl-1, 4-phenylene oxide)(LMW-PPO) synthesized by peroxydisulfate and metal/non-metal catalysts[J]. Polymer Chemistry, 2023, 14(16): 1933-1944. doi: 10.1039/D2PY01614A [6] HWANG H J, HSU S W, WANG C S. Synthesis and physical properties of low-molecular-weight redistributed poly (2, 6-dimethyl-1, 4-phenylene oxide) for epoxy resin[J]. Journal of applied polymer science, 2008, 110(3): 1880-1890. doi: 10.1002/app.28770 [7] ZHOU Y, PENG Z, JI J, et al. Fluorinated low molecular weight poly (phenylene oxide): Synthesis, characterization, and application in epoxy resin toward improved thermal and dielectric properties[J]. European Polymer Journal, 2021, 157: 110674. doi: 10.1016/j.eurpolymj.2021.110674 [8] 卢翔, 曾鸣, 谭登襦, 等. 面向超高频通信应用的低介电聚苯醚树脂的研究进展[J]. 绝缘材料, 2022, 55(05): 10-18.LU Xiang, ZENG Ming, TAN Dengru, et al. Research progress on low dielectric polyphenylene oxide resin for ultra-high frequency communication applications [J] Insulation materials, 2022, 55 (05): 10-18(in Chinese). [9] 步晓君, 许星烨, 贾宇翔, 等. DAP/聚苯醚改性氰酸酯树脂复合材料及其性能[J]. 复合材料科学与工程, 2023, (03): 108-11+19.BU Xiaojun, XU Xingye, JIA Yuxiang, et al. DAP/polyphenylene ether modified cyanate ester resin composite materials and theirproperties [J] Composite Materials Science and Engineering, 2023, (03): 108-11+19(in Chinese). [10] MA J-Z, CHENG K, LV J-B, et al. Phthalonitrile-PPO Blends: Cure Behavior and Properties[J]. Chinese Journal of Polymer Science, 2018, 36(4): 497-504. doi: 10.1007/s10118-018-2026-x [11] YE J, ZHANG S, WU M, et al. Thermal, mechanical and dielectric property enhancement of benzoxazine-containing phthalonitrile resin: The effect of functional oligomeric polyphenyl ether[J]. Polymer, 2023, 280: 126040. doi: 10.1016/j.polymer.2023.126040 [12] WENG L, ZHANG Y, ZHANG X, et al. Synthesis and properties of cured epoxy mixed resin systems modified by polyphenylene oxide for production of high-frequency copper clad laminates[J]. Polymer Composites, 2018, 39(S4): E2334-E45. [13] 黄晨飞, 粟俊华, 胡亚坤, 等. 马来酰亚胺封端聚苯醚的合成与表征[J]. 热固性树脂, 2021, 36(05): 21-24.HUANG Chenfei, SU Junhua, HU Yakun, et al. Synthesis and characterization of maleimide terminated polyphenylene ether [J] Thermosetting resin, 2021, 36 (05): 21-24(in Chinese). [14] WANG Y, CHENG S, LI W, et al. Synthesis and properties of thermosetting modified polyphenylene ether[J]. Polymer Bulletin, 2007, 59: 391-402. doi: 10.1007/s00289-007-0775-8 [15] WU X, XU C A, LU M, et al. Preparation and characterization of high temperature resistant thermosetting polyphenylene ether resin[J]. Journal of Applied Polymer Science, 2022, 139(39): e52858. doi: 10.1002/app.52858 [16] LIAO L Y, RUAN W H, ZHANG M Q, et al. Improving the Dimensional Stability of Polyphenylene Oxide without Reducing Its Dielectric Properties for High-Frequency Communication Applications[J]. Industrial & Engineering Chemistry Research, 2023, 62(18): 7007-7016. [17] YANG H, YUAN G, JIAO E, et al. Low dielectric constant and high thermal stability of liquid crystal epoxy polymers based on functionalized poly (phenylene oxide)[J]. European Polymer Journal, 2023, 198: 112378. doi: 10.1016/j.eurpolymj.2023.112378 [18] 吕敬坡, 粟俊华, 胡亚坤, 等. 侧基含马来酰亚胺基团聚苯醚的合成与表征[J]. 高分子材料科学与工程, 2022, 38(06): 140-144.LV Jingpo, SU Junhua, HU Yakun, et al. Synthesis and characterization of side groups containing maleimide groups in polyphenylene ether [J] Polymer Materials Science and Engineering, 2022, 38 (06): 140-144(in Chinese). [19] 吕满庚, 吴限坤, 徐长安, 等. 一种耐高温热固性聚苯醚树脂及其制备与应用, CN114891202AP/OL]. LV Mangeng, WU Jiekun, XU Chang'an, etc A high-temperature resistant thermosetting polyphenylene ether resin and its preparation and application, CN114891202A [P/OL] (in Chinese). [20] 盘文辉. 聚苯醚中羟基含量测定[J]. 分析测试技术与仪器, 2017, 23(03): 184-188.PAN Wenhui Determination of hydroxyl content in polyphenylene ether [J] Analysis and Testing Technology and Instruments, 2017, 23 (03): 184-188(in Chinese). [21] 中国国家标准化管理委员会. 纤维增强塑料弯曲性能试验方法: GB/T 1449-2005[S]. 北京: 中国标准出版社, 2005Standardization Administration of the People's Republic of China. Fiber-reinforced plastic composites: Determination of flexural properties: GB/T 1449-2005[S]. Beijing: C-hina Standards Press, 2005(in Chinese). [22] 中国国家标准化管理委员会. 聚合物基复合材料短梁剪切强度试验方法: GB/T 30969-2014[S]. 北京: 中国标准出版社, 2014Standardization Administration of the People's Republic of China. Test method for short-beam shear strength of polymer matrix composite materials: GB/T 30969-2014[S] Beijing: China Standards Press, 2014(in Chinese). [23] 中国国家标准化管理委员会. 玻璃纤维增强热固性塑料耐化学介质性能试验方法: GB/T 3587-2017[S]. 北京: 中国标准出版社, 2017Standardization Administration of the People's Republic of China. Test method for chemical resistance of glass fiber reinforced thermosetting plastics: GB/T 3587-2017[S]. Beijing: China Standards Press, 2017(in Chinese). [24] AUGUSTINE D, MATHEW D, NAIR C R. Phenol-containing phthalonitrile polymers–synthesis, cure characteristics and laminate properties[J]. Polymer international, 2013, 62(7): 1068-1076. doi: 10.1002/pi.4393 [25] 杨宋, 顾嫒娟, 梁国正, 等. 一种高频高速用覆铜板的制备及其性能研究[J]. 印制电路信息, 2017, 25(11): 44-48.YANG Song, GU Aijuan, LIANG Guozheng, et al. Preparation and performance study of a high-frequency and high-speed copper clad plate [J] Printed Circuit Information, 2017, 25 (11): 44-48(in Chinese). [26] 王耀先, 李伟, 李凡, 等. 烯丙化聚苯醚的合成及其性能研究[C]//第十六届玻璃钢/复合材料学术年会论文集, 安徽, 中国硅酸盐学, 2006.WANG Yaoxian, LI Wei, LI Fan, et al. Synthesis and Performance Study of Allylated Polyphenylene Ether [C]//Proceedings of the 16th Academic Annual Conference on Fiberglass/Composite Materials, Anhui, China, 2006(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 29

- HTML全文浏览量: 24

- 被引次数: 0

下载:

下载: