Effect of red mud substitution rate on the properties of ternary solid waste geopolymers

-

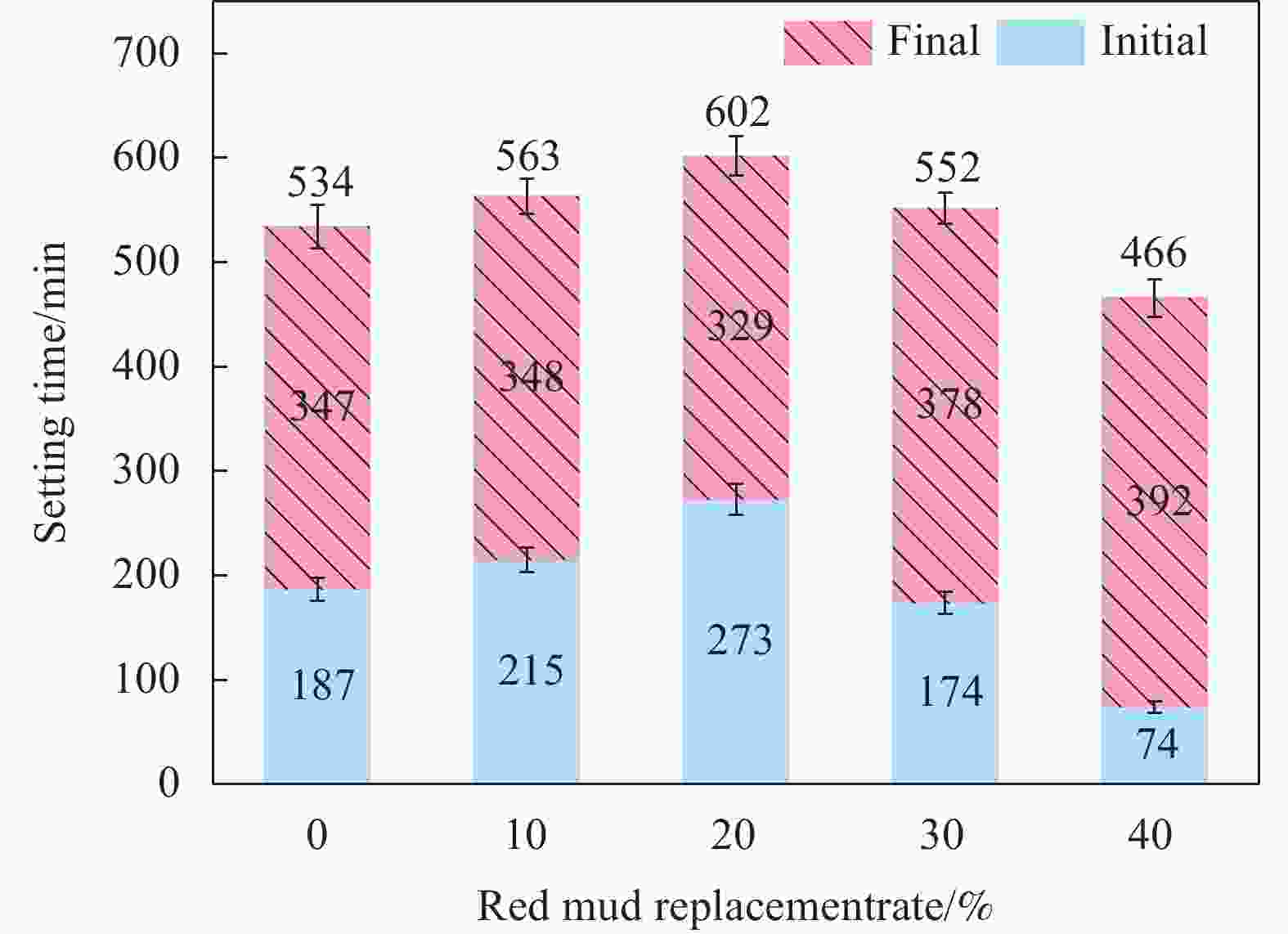

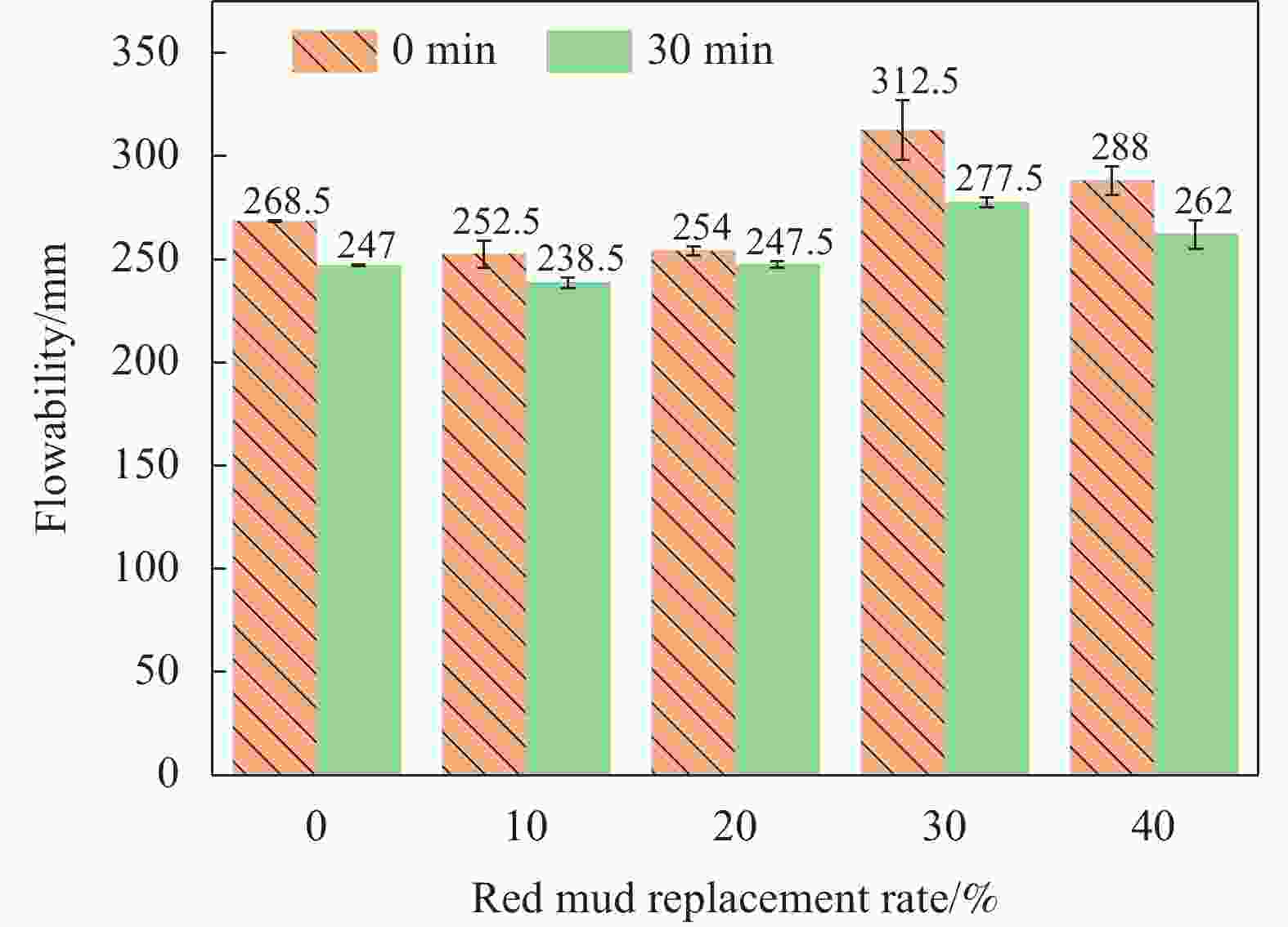

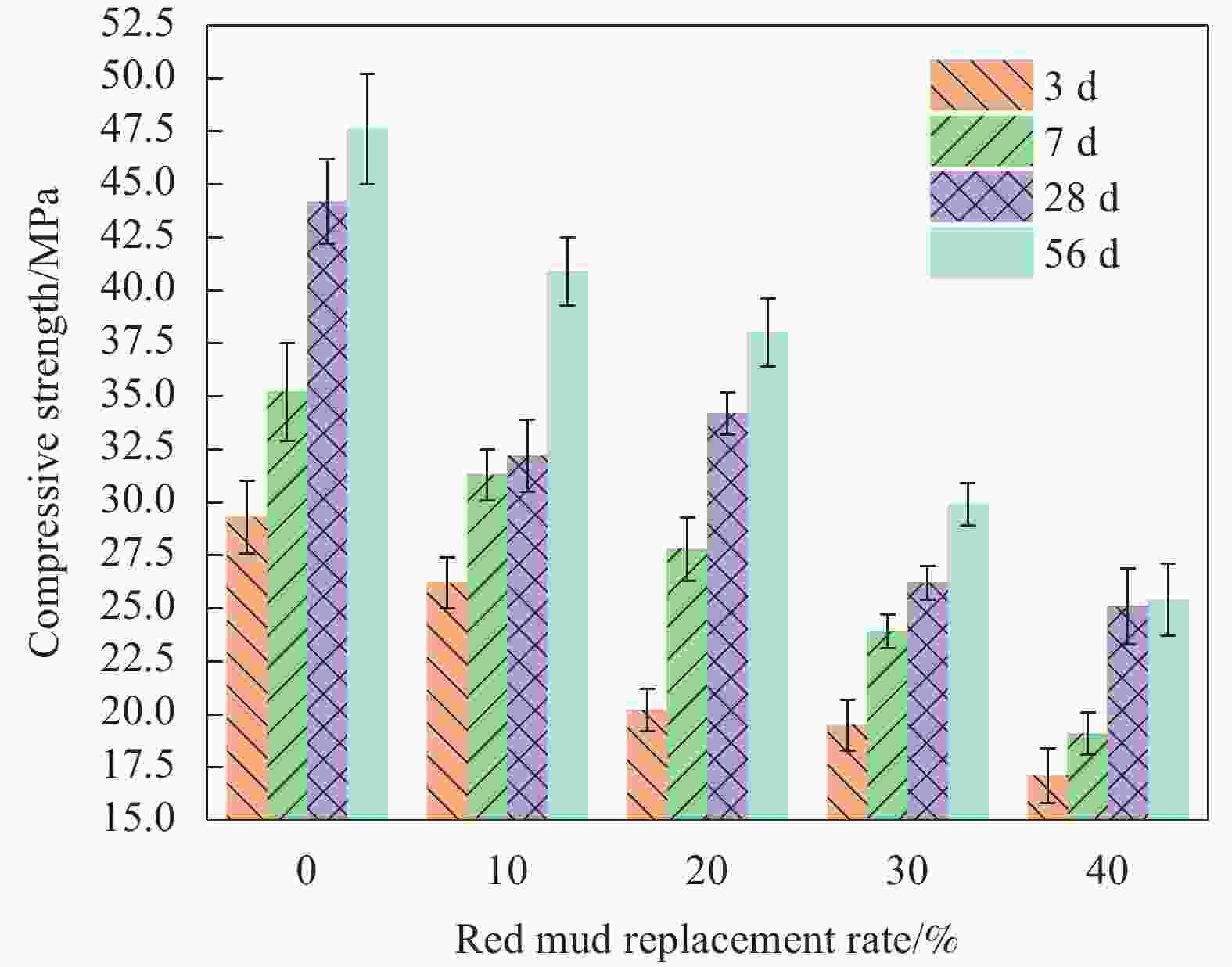

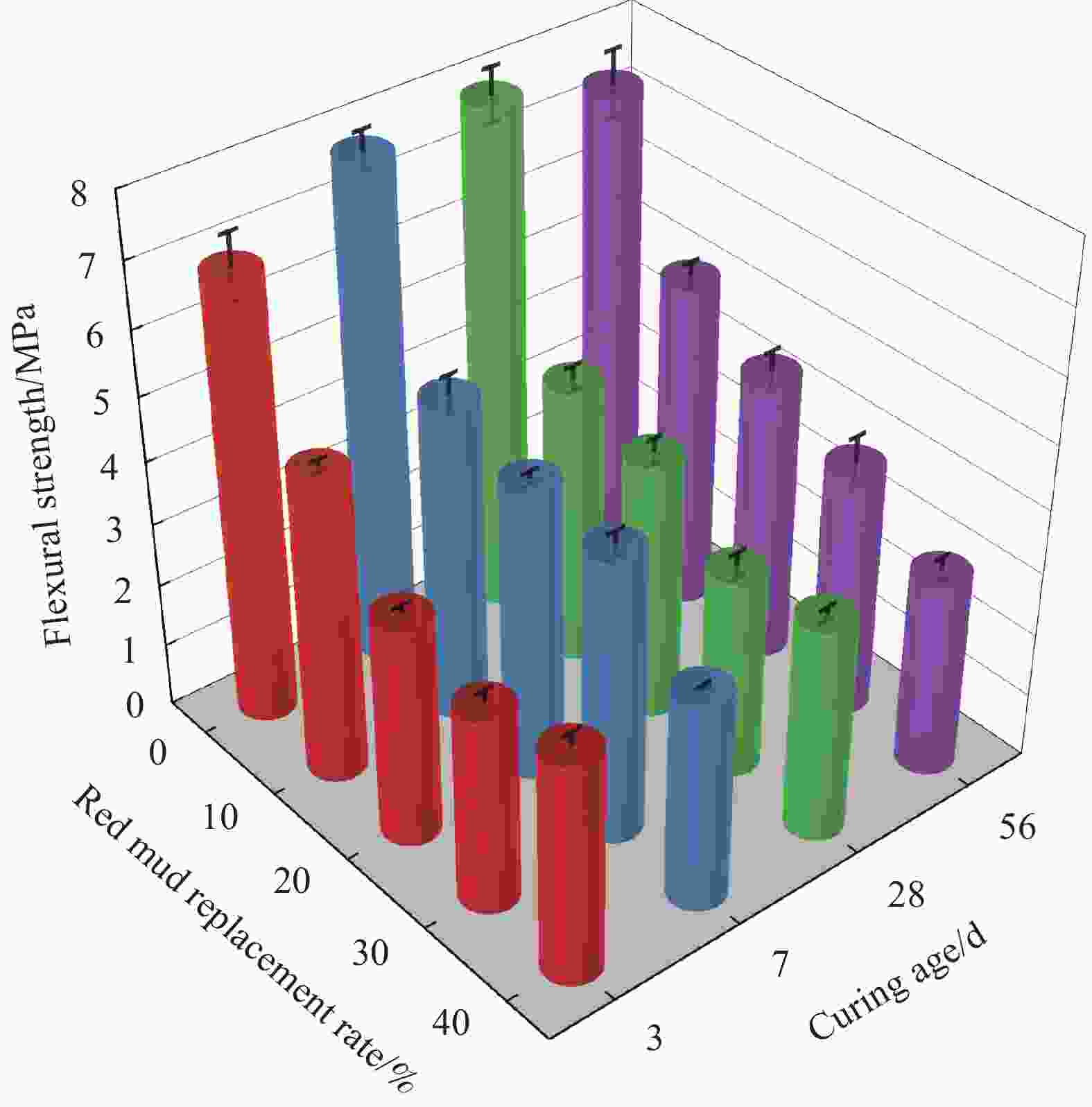

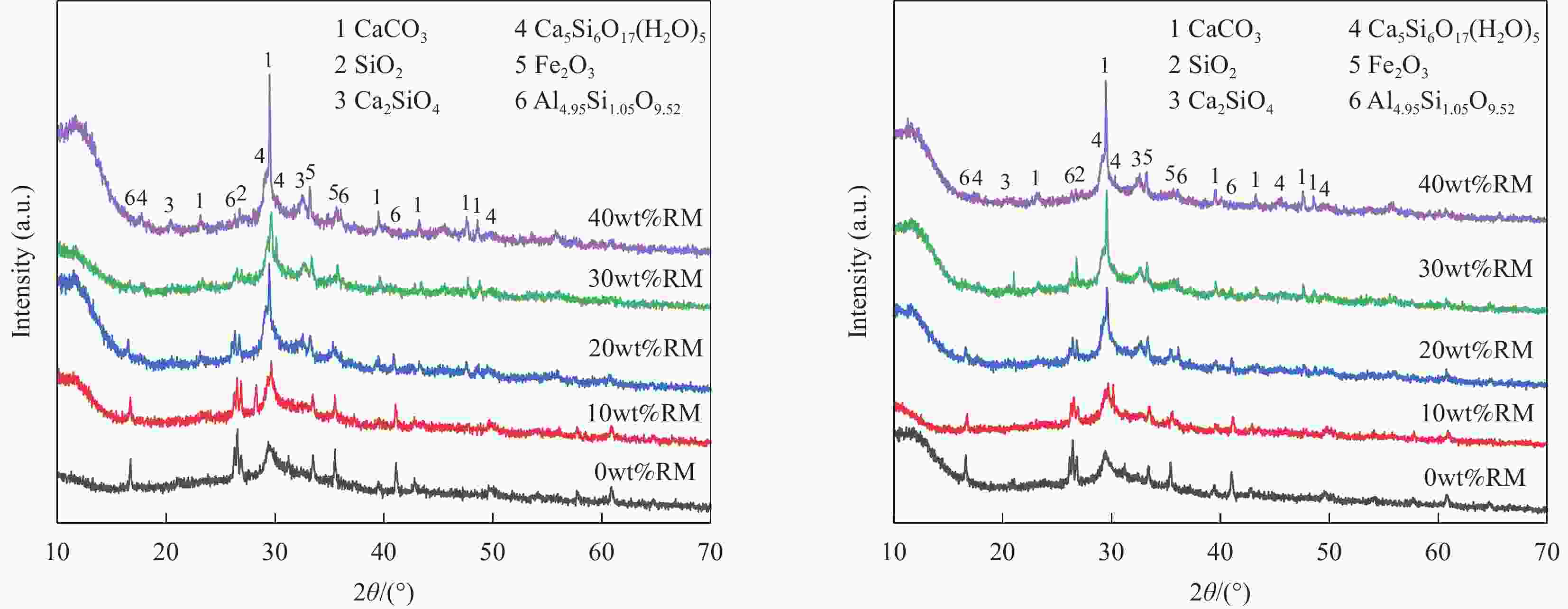

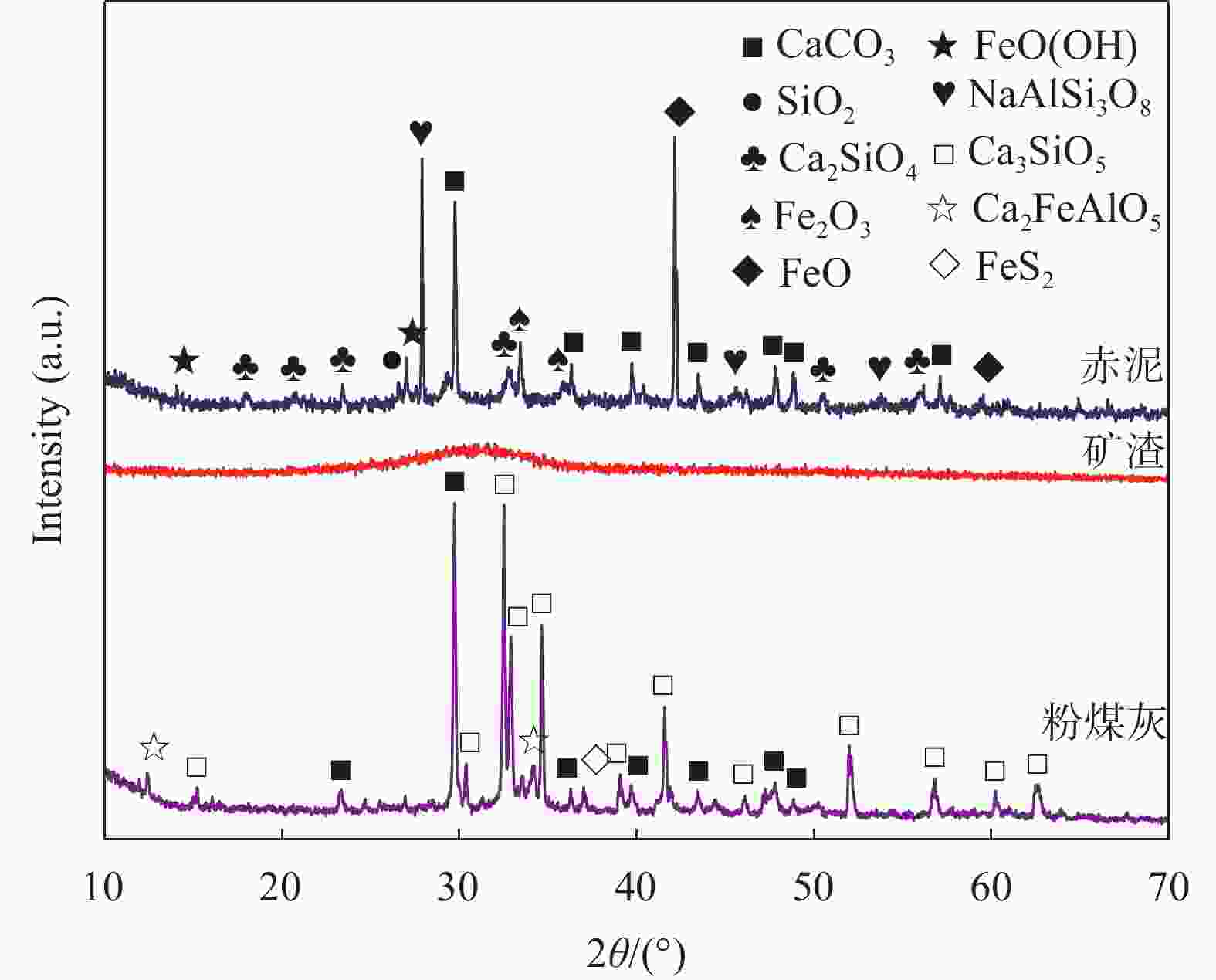

摘要: 为进一步提升赤泥(Red mud,RM)综合利用率,本文将赤泥掺入矿渣-粉煤灰基地聚物中制备了三元全固废地聚物(Ternary solid waste geopolymer,TSWG)材料,研究了不同赤泥取代率对TSWG的力学性能及和易性的影响,结合X射线衍射(XRD)和扫描电子显微镜(SEM)测试,重点探讨了不同取代率赤泥对TSWG性能影响机制,并对TSWG砂浆的成本效益和环境影响进行了评估。结果表明,高掺量的赤泥能够促进铝硅酸盐材料的解聚过程,与基准组(赤泥掺量为0wt%)相比,40wt%赤泥掺量的TSWG的初凝时间缩短了113 min;随着赤泥取代率的增加,提高了地聚物的聚合反应程度,体系中出现了越来越多的硅酸二钙、石英等晶体,破坏地聚物材料的原有结构,导致抗压强度逐渐下降;20wt%赤泥取代率下TSWG28 d抗压强度达34.2 MPa,浆液初始流动度为254 mm,与普通波特兰水泥砂浆相比,具有更好的经济效益和环境效益,以及更方便的制备方法。Abstract: In order to further enhance the comprehensive utilization rate of red mud (RM), ternary solid waste geopolymer (TSWG) materials were prepared by incorporating red mud into slag-fly ash-based polymers. The effects of varying red mud substitution rates on the mechanical properties and workability of these TSWG materials were investigated. Combining X-ray diffraction (XRD) and scanning electron microscopy (SEM) tests, the influence mechanism of red mud with different substitution rates on the properties of TSWG was discussed. Furthermore, the cost-effectiveness and environmental impact of TSWG mortars were evaluated. The results indicate that a high content of red mud can stimulate the depolymerization process of aluminosilicate materials. Compared to the reference group (with 0wt% red mud content), the initial setting time of the TSWG containing 40wt% red mud is shortened by 113 minutes. As the red mud substitution rate increases, the degree of polymerization reaction in the geopolymer is improved, but an increasing number of crystals, such as dicalcium silicate and quartz, emerge in the system, disrupting the original structure of the geopolymer material and resulting in a gradual decrease in compressive strength. At a 20wt% red mud replacement rate, the compressive strength of the TSWG after 28 days reaches 34.2 MPa, and the initial fluidity of the slurry is 254 mm. Compared to ordinary Portland cement mortar, this TSWG exhibits superior economic and environmental benefits, as well as a more convenient preparation method.

-

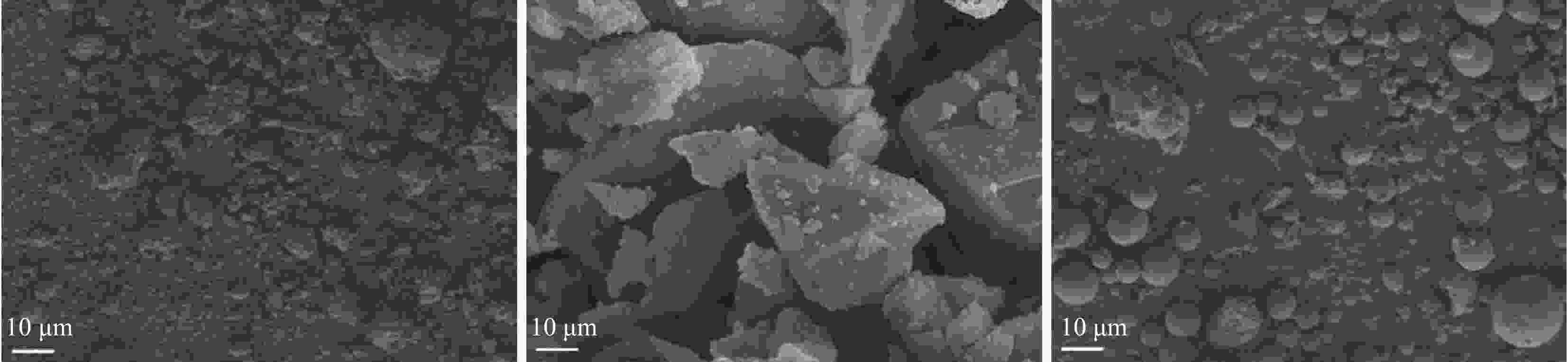

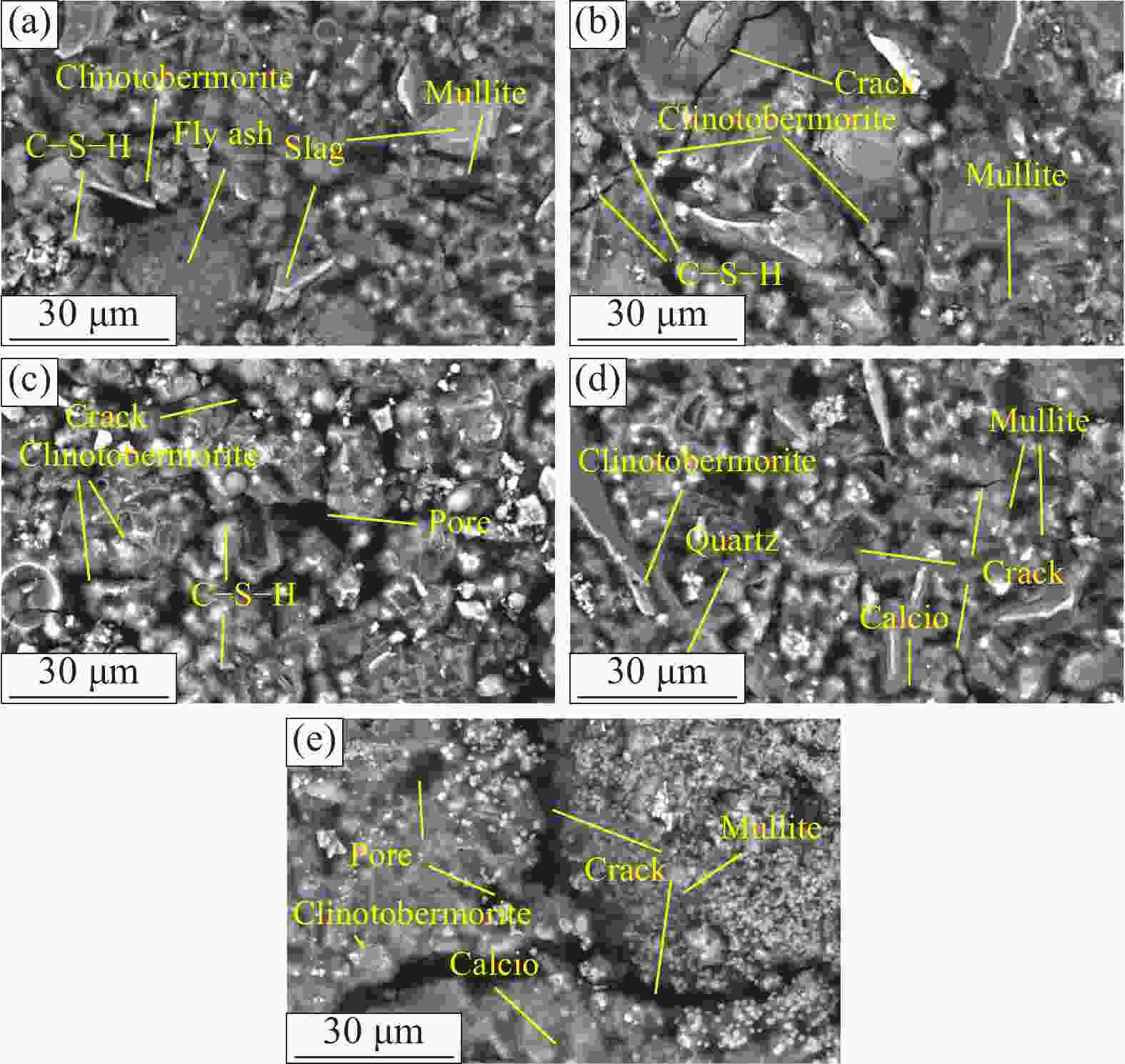

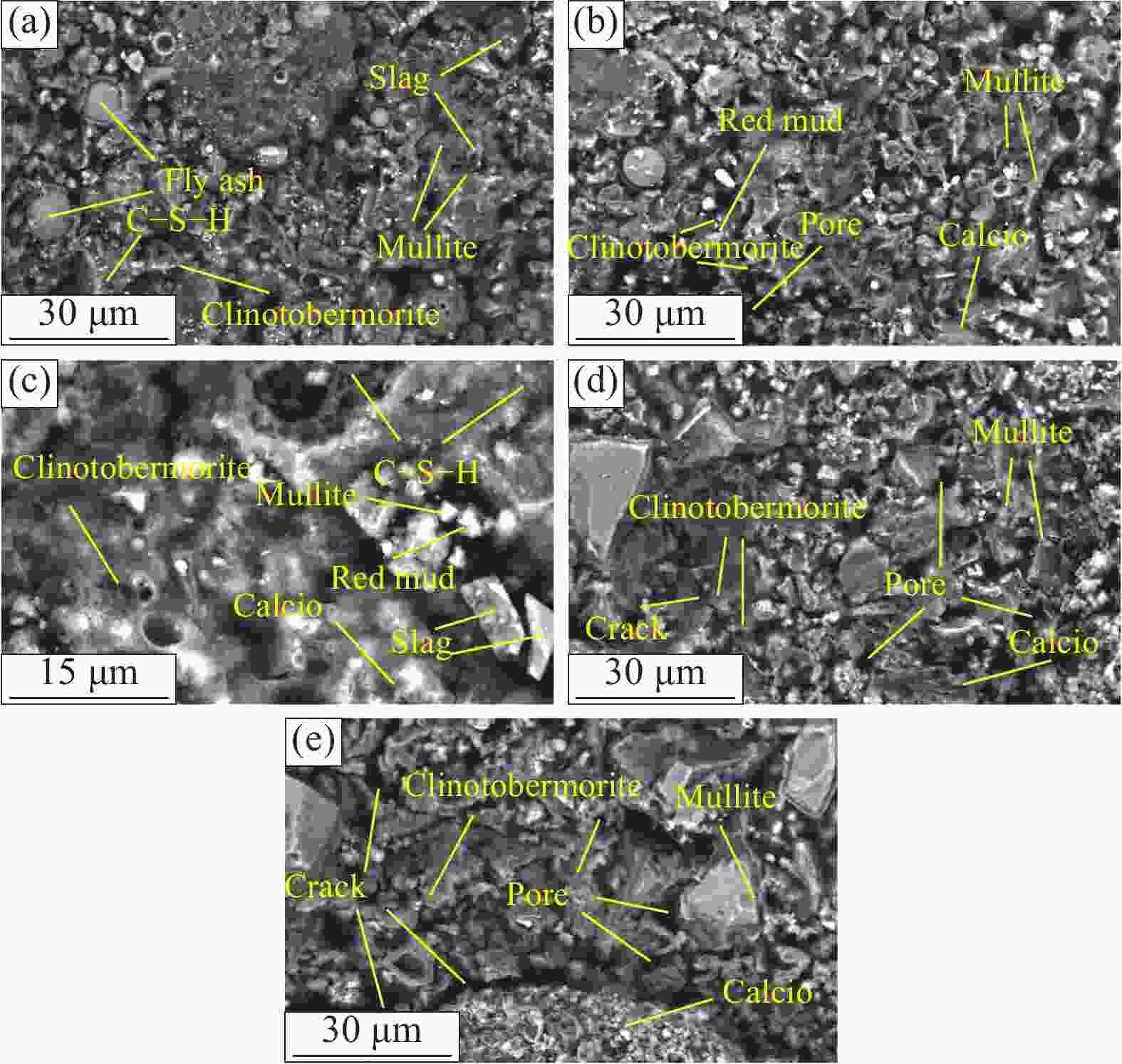

图 10 养护3 d时TSWG的SEM图像:(a) 0 wt%RM,养护3 d;(b) 10 wt%RM,养护3 d;(c) 20 wt%RM,养护3 d;(d) 30 wt%RM,养护3 d;(e) 40 wt%RM,养护3 d

Figure 10. SEM images of TSWG curing for 3 d: (a) 0 wt%RM,curing for 3 d; (b) 10 wt%RM,curing for 3 d; (c) 20 wt%RM,curing for 3 d; (d) 30 wt%RM,curing for 3 d; (e) 40 wt%RM,curing for 3 d

图 11 养护7 d时TSWG的SEM图像:(a) 0 wt%RM,养护7 d;(b) 10 wt%RM,养护7 d;(c) 20 wt%RM,养护7 d;(d) 30 wt%RM,养护7 d;(e) 40 wt%RM,养护7 d

Figure 11. SEM images of TSWG curing for 7 d: (a) 0 wt%RM,curing for 7 d; (b) 10 wt%RM,curing for 7 d; (c) 20 wt%RM,curing for 7 d;(d) 30 wt%RM,curing for 7 d; (e) 40 wt%RM,curing for 7 d

表 1 赤泥、矿渣和粉煤灰的化学成分(wt%)

Table 1. Chemical composition of red mud, slag, and fly ash (wt%)

Material Na2O MgO Al2O3 SiO2 P2O5 SO3 K2O CaO TiO2 MnO Fe2O3 ZrO2 Slag 0.47 8.58 15.24 30.54 0.01 2.08 0.45 40.75 0.73 0.58 0.31 0.04 Red mud 2.02 1.46 9.39 22.12 0.23 1.84 0.51 45.43 3.46 0.06 12.79 0.16 Fly ash 0.50 0.48 38.26 48.72 0.41 1.68 1.20 2.99 1.51 0.04 3.76 0.09 表 2 三元全固废地聚物(TSWG)浆液配合比

Table 2. Mix ratio of ternary solid waste geopolymer(TSWG) slurry

Group Slag content/wt% Fly ash content/wt% Red mud dosage/wt% Sodium silicate content

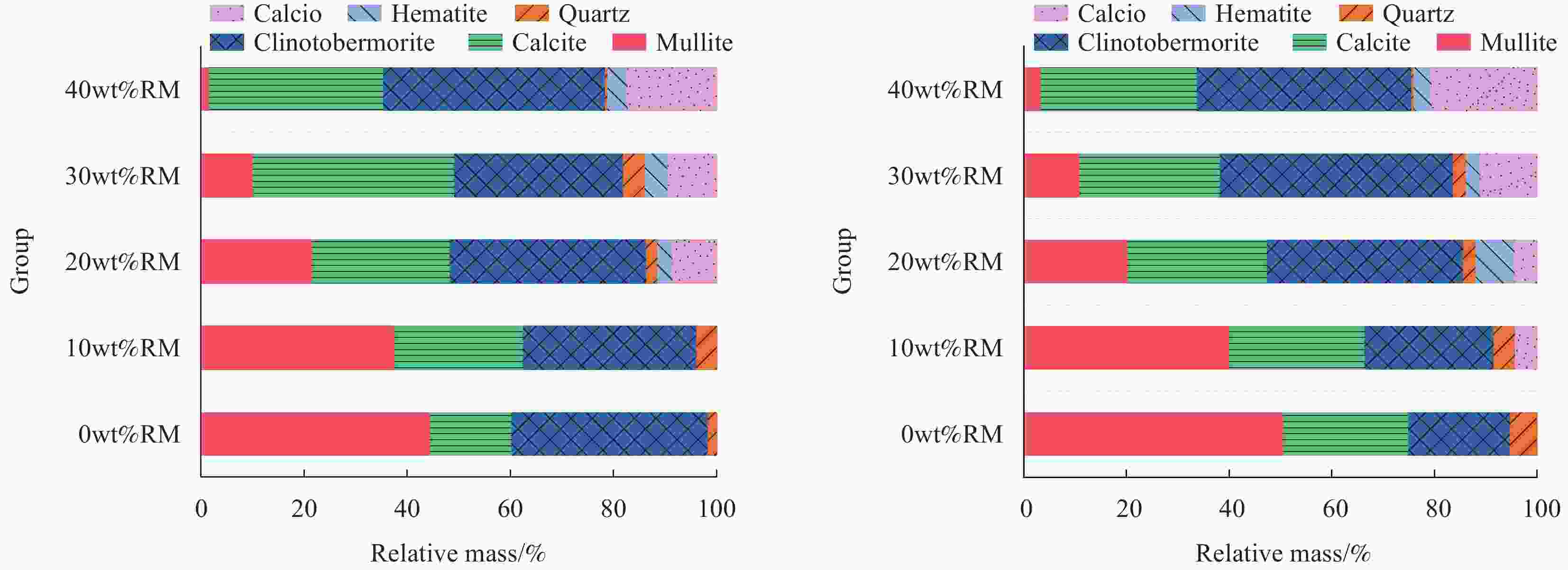

(relative to cementitious materials)/wt%Water-glue ratio 0 wt%RM 60 40 0 8.54 0.5 10 wt%RM 60 30 10 20 wt%RM 60 20 20 30 wt%RM 60 10 30 40 wt%RM 60 0 40 表 3 3 d不同赤泥取代率下TSWG中各种矿物相含量(wt%)

Table 3. Content of various mineral phases in TSWG under different red mud replacement rates for three days (wt%)

Group Mullite Calcite Clinotobermorite Quartz Hematite Calcio 0 wt%RM 44.4 15.8 38 1.8 — — 10 wt%RM 37.5 24.9 33.6 4 — — 20 wt%RM 21.5 26.7 38.1 2.1 3 8.6 30 wt%RM 10.1 39 32.7 4.2 4.4 9.6 40 wt%RM 1.6 33.7 43 0.5 3.9 17.3 表 4 7 d不同赤泥取代率下TSWG中各种矿物相含量(wt%)

Table 4. Content of various mineral phases in TSWG under different red mud replacement rates for seven days (wt%)

Group Mullite Calcite Clinotobermorite Quartz Hematite Calcio 0 wt%RM 50.5 24.4 19.8 5.3 — — 10 wt%RM 40 26.4 25.1 4.2 — 4.3 20 wt%RM 20.2 27.2 38.2 2.4 7.6 4.4 30 wt%RM 10.9 27.3 45.4 2.5 2.8 11.1 40 wt%RM 3.3 30.4 41.8 0.4 3.6 20.5 表 5 原材料的成本和二氧化碳当量E

Table 5. Cost of raw materials and E

Materials Cost/(CNY·kg−1) E/(kgCO2·kg−1) Fly ash 0.25 0.027 Instant Na2SiO3 powder 2.50 1.530 Water 0.002 0.0006 Red mud 0.01 0.00518 Slag 0.09 0.143 表 6 TSWG成本效益和环境影响

Table 6. Cost effectiveness and environmental impact of TSWG

Group Compressive strength/MPa ${C}_{\mathrm{p}} $/(CNY·

MPa−1·m−3)$ {E}_{\mathrm{p}} $/(kgCO2·

MPa−1·m−3)0 wt%RM 44.2 11.72 7.24 10 wt%RM 32.2 15.05 9.84 20 wt%RM 34.2 13.18 9.18 30 wt%RM 26.2 15.91 11.86 40 wt%RM 25.1 15.27 12.26 Control group 30 16.29 13.54 Notes: Control group refers to ordinary Portland cement mortar. -

[1] LI J, DANG X T, ZHANG J W, et al. Mechanical properties of fly ash-slag based geopolymer for repair of road subgrade diseases[J]. Polymers, 2023, 15(2): 309. doi: 10.3390/polym15020309 [2] WANG Y L, TANG H Y, SU J X, et al. Effect of sodium sulfate and gypsum on performances of expansive grouting material with aluminum as expansion agent[J]. Construction and Building Materials, 2023, 394: 132212. doi: 10.1016/j.conbuildmat.2023.132212 [3] WANG J J, WANG Y L, YU J, et al. Effects of sodium sulfate and potassium sulfate on the properties of calcium sulfoaluminate (CSA) cement based grouting materials[J]. Construction and Building Materials, 2022, 353: 129045. doi: 10.1016/j.conbuildmat.2022.129045 [4] WANG Y L, YU J, WANG J J, et al. Effects of sodium aluminate and quicklime on the properties of CSA grouting materials[J]. Journal of Building Engineering, 2022, 58: 105060. doi: 10.1016/j.jobe.2022.105060 [5] LIU H B, TANG W Q, MA W Z, et al. Research progress of cement-based grouting materials[J]. Concrete, 2016, 3(3): 71. [6] ZHANG L, WEN P, WANG C, et al. Advances in non-excavation grouting reinforcement materials in the road engineering[J]. Mater. Rep, 2017, 31: 98-105. [7] 李召峰, 陈经棚, 杨磊, 等. 石粉对赤泥基注浆材料的影响机制[J]. 工程科学学报, 2021, 43(6): 768-777.LI ZHAOFENG, CHEN JINGPENG, YANG LEI, et al. Influence mechanism of limestone powder on red mud-based grouting material[J]. Chinese Journal of Engineering, 2021, 43(6): 768-777(in Chinese). [8] AZAD NM, SAMARAKOON SMSMK. Utilization of industrial by-products/waste to manufacture geopolymer cement/concrete[J]. Sustainability, 2021, 13(2): 873. doi: 10.3390/su13020873 [9] REN B, ZHAO Y, BAI H, et al. Eco-friendly geopolymer prepared from solid wastes: A critical review[J]. Chemosphere, 2021, 267: 128900. doi: 10.1016/j.chemosphere.2020.128900 [10] 田中男, 张争奇, 何勇海, 等. 全固废地聚物稳定钢渣基层的性能及微观特性分析[J]. 中国公路学报, 2023, 36(12): 131.TIAN ZHONGNAN, ZHANG ZHENGQI, HE YONGHAI, et al. Performance and Microscopic Characteristics of Geopolymer Stabilized Steel Slag Roadbase with Full Solid-waste Reusing[J]. China Journal of Highway and Transport, 2023, 36(12): 131(in Chinese). [11] XIE J H, CHEN W, WANG J J, et al. Coupling effects of recycled aggregate and GGBS/metakaolin on physicochemical properties of geopolymer concrete[J]. Construction and Building Materials, 2019, 226: 345-359. doi: 10.1016/j.conbuildmat.2019.07.311 [12] XIE J H, WANG J J, ZHANG B X, et al. Physicochemical properties of alkali activated GGBS and fly ash geopolymeric recycled concrete[J]. Construction and Building Materials, 2019, 204: 384-398. doi: 10.1016/j.conbuildmat.2019.01.191 [13] MUTHADHI A, SUGANYA B. Effect of activator on strength and microstructure of alkali activated concrete with class C fly ash[J]. Iranian Journal of Science and Technology, Transactions of Civil Engineering, 2021, 46: 261-269. [14] YURT. High performance cementless composites from alkali activated GGBFS[J]. Construction and Building Materials, 2020, 264: 120222. doi: 10.1016/j.conbuildmat.2020.120222 [15] TCHAKOUTE H K, RUESCHER C H, KAMSEU E, et al. Influence of the molar concentration of phosphoric acid solution on the properties of metakaolin-phosphate-based geopolymer cements[J]. Applied Clay Science, 2017, 147: 184-194. doi: 10.1016/j.clay.2017.07.036 [16] GAO L, ZHENG Y X, TANG Y, et al. Effect of phosphoric acid content on the microstructure and compressive strength of phosphoric acid-based metakaolin geopolymers[J]. Heliyon, 2020, 6: 4. [17] ZHANG B F, GUO H Z, YUAN P, et al. Novel acid-based geopolymer synthesized from nanosized tubular halloysite: The role of precalcination temperature and phosphoric acid concentration[J]. Cement and Concrete Composites, 2020, 110: 103601. doi: 10.1016/j.cemconcomp.2020.103601 [18] NIKOLOV A, NUGTEREN H, ROSTOVSKY I. Optimization of geopolymers based on natural zeolite clinoptilolite by calcination and use of aluminate activators[J]. Construction and Building Materials, 2020, 243: 118257. doi: 10.1016/j.conbuildmat.2020.118257 [19] 张博. 2023赤泥绿色利用国际论坛在郑州召开[J]. 中国有色金属, 2023, (24): 10-11. doi: 10.3969/j.issn.1673-3894.2023.24.002ZHANG BO. The 2023 International Forum on Green Utilization of Red Mud was held in Zhengzhou[J]. China Nonferrous Metals, 2023, (24): 10-11(in Chinese). doi: 10.3969/j.issn.1673-3894.2023.24.002 [20] 李召峰, 刘超, 王川, 等. 赤泥–高炉矿渣–钢渣三元体系注浆材料试验研究[J]. 工程科学与技术, 2021, 53(1): 203-211.LI ZHAOFENG, LIU CHAO, WANG CHUAN, et al. Experimental Study on Grouting Material of Red Mud-blast Furnace Slag-steel Slag Ternary System[J]. Advanced Engineering Sciences, 2021, 53(1): 203-211(in Chinese). [21] 张健. 赤泥协同多源固废制备注浆材料组成设计、水化机理与性能调控 [D]. 济南: 山东大学, 2021.ZHANG JIAN. Composition design, hydraton mechanism and performance control of grouting material prepared by red mud and multi-source solid waste [D]. Jinan: Shandong University, 2021(in Chinese). [22] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 水泥标准稠度用水量、凝结时间、安定性检验方法: GB/T 1346—2011[S]. 北京: 中国标准出版社, 2011.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People’s Republic of China. Test methods for water requirement of normal consistency, setting time and soundness of the portland cement: GB/T 1346—2011[S]. Beijing: China Standards Press, 2011(in Chinese). [23] 中华人民共和国住房和城乡建设部, 中华人民共和国国家质量监督检验检疫总局. 水泥基灌浆材料应用技术规范: GB/T 50448—2015[S]. 北京: 中国建筑工业出版社, 2015.Ministy of Housing and Urban-Rural Development of the People's Republic of China, Inspection and Quarantine of the People's Republic of China, General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Technical code for application of cementitious grout: GB/T 50448—2015[S]. Beijing: China Architecture & Building Press, 2015(in Chinese). [24] 国家市场监督管理总局, 国家标准化管理委员会. 水泥胶砂强度检验方法(ISO法): GB/T 17671—2021[S]. 北京: 中国标准出版社, 2021.State Administration for Market Regulation, Standardization Administration of the People’s Republic of China. Test method of cement mortar strength(ISO method): GB/T 17671—2021[S]. Beijing: China Standards Press, 2021(in Chinese). [25] 徐勍, 徐霁, 周琼, 等. 碱含量对水泥性能影响的研究[J]. 建筑工程技术与设计, 2017, 16: 2013-2013. doi: 10.3969/j.issn.2095-6630.2017.06.950XU QING, XU JI, ZHOU QIONG, et al. Study on the effect of alkali content on cement properties[J]. Architectural Engineering Technology and Design, 2017, 16: 2013-2013(in Chinese). doi: 10.3969/j.issn.2095-6630.2017.06.950 [26] 钟卿瑜, 粟淼, 彭晖. 偏高岭土-矿渣地聚物宏观性能试验及Lasso回归模型[J]. 复合材料学报, 2022, 39(11): 5474-5485.ZHONG QINGYU, SU MIAO, PENG HUI. Experiment and Lasso regression model of the macroscopic performance of metakaolin-slag geopolymer paste[J]. Acta Materiae Compositae Sinica, 2022, 39(11): 5474-5485(in Chinese). [27] 张健, 王川, 李召峰, 等. 赤泥基绿色高性能注浆材料工程特性试验研究[J]. 岩石力学与工程学报, 2022, 41(S2): 3339-3352.ZHANG JIAN, WANG CHUAN, LI ZHAOFENG, et al. Experimental study on the engineering charateristics of red mud-based green high-performance grouting material[J]. Chinese Journal of Rock Mechanics and Engineering, 2022, 41(S2): 3339-3352(in Chinese). [28] 杨进波, 赵钲洋, 尹航. 基于分子动力学的C-S-H凝胶性能研究进展[J]. 材料导报, 2021, 35(5): 5095-5101+5121. doi: 10.11896/cldb.19120140YANG JINBO, ZHAO ZHENGYANG, YING HANG. Research Development on Molecular Dynamics of C-S-H Gels[J]. Materials Reports, 2021, 35(5): 5095-5101+5121(in Chinese). doi: 10.11896/cldb.19120140 [29] ZHANG J, LI S, LI Z, et al. Feasibility study of red mud for geopolymer preparation: effect of particle size fraction[J]. Journal of Material Cycles and Waste Management, 2020, 22(5): 1328-1338. doi: 10.1007/s10163-020-01023-4 [30] 刘树龙, 王贻明, 吴爱祥, 等. 赤泥复合充填材料浸出行为及固化机制[J]. 复合材料学报, 2023, 40(12): 6729-6739.LIU SHULONG, WANG YIMING, WU AIXIANG, et al. Leaching behavior and solidification mechanism of red mud composite filling material[J]. Acta Materiae Compositae Sinica, 2023, 40(12): 6729-6739(in Chinese). [31] 高英力, 祝张煌, 孟浩, 等. 电石渣-脱硫石膏-钢渣改性粉煤灰地聚物协同增强机理[J]. 建筑材料学报, 2023, 26(8): 870-878. doi: 10.3969/j.issn.1007-9629.2023.08.007GAO YINGLI, ZHU ZHANGHUANG, MENG HAO, et al. Synergistic Enhancement Mechanism of Calcium Carbide ResidueDesulfurization Gypsum-Steel Slag Modified Fly Ash Geopolymer[J]. Journal of Building Materials, 2023, 26(8): 870-878(in Chinese). doi: 10.3969/j.issn.1007-9629.2023.08.007 [32] 夏冬桃, 吴晨, 崔凯, 等. 粉煤灰和硅灰取代率对碱矿渣混凝土力学性能影响研究 [J/OL]. (2023-09-28) [2024-10.17]. http://kns.cnki.n-et/kcms/detail/51.1277.u.20230927.1938.004.html.XIA DONGTAO, WU CHEN, CUI KAI, et al. Effect of Fly Ash and Silica Fume Con-tents on the Mechanical Properties of Alkali-activated Slag-based Concrete [J/OL]. (2023-09-28) [2024-10.17]. http://kns.cnki.net/kcm-s/detail/51.1277.u.20230927.1938.004.html (in Chinese). [33] 刘刚, 丁明巍, 刘金军, 等. 碱激发矿粉-粉煤灰-偏高岭土地聚物水化行为和力学性能[J]. 硅酸盐通报, 2023, 42(6): 2106-2114.LIU GANG, DING MINGWEI, LIU JINJUN, et al. Hydration Behavior and Mechanical Properties of Alkaline Excited Slag-Fly Ash-Metakaolin Geopolymer[J]. Bulletin of the Chinese Ceramic Society, 2023, 42(6): 2106-2114(in Chinese). [34] 张佳丽, 庞来学, 王文超, 等. 铁尾矿粉基CLSM的制备及水化产物的Rietveld结构精修[J]. 材料导报, 2023, 37(S2): 305-310.ZHANG JIALI, PANG LAIXUE, WANG WENCHAO, et al. Preparation of Iron Tailing Powder Based CLSM and the Structure Finishing of Hydration Product by Rietveld[J]. Materials Reports, 2023, 37(S2): 305-310(in Chinese). [35] 黄华, 郭梦雪, 张伟, 等. 粉煤灰-矿渣基地聚物混凝土力学性能与微观结构[J]. 哈尔滨工业大学学报, 2022, 54(3): 74-84. doi: 10.11918/202104058HUANG HUA, GUO MENGXUE, ZHANG WEI, et al. Mechanical property and microstructure of geopolymer concrete based on fly ash and slag[J]. Journal of Harbin Institute of Technology, 2022, 54(3): 74-84(in Chinese). doi: 10.11918/202104058 [36] MO K H, ALENGARAM U J, JUMAAT M Z. Utilization of ground granulated blast furnace slag as partial cement replacement in lightweight oil palm shell concrete[J]. Materials and structures, 2015, 48: 2545-2556. doi: 10.1617/s11527-014-0336-1 [37] ZHAO J B, XIE J H, WU J W, et al. Workability, compressive strength, and microstructures of one-part rubberized geopolymer mortar[J]. Journal of Building Engineering, 2023, 68: 106088. doi: 10.1016/j.jobe.2023.106088 [38] 杨超超. 赤泥微粉对水泥混凝土路面性能影响的研究 [D]. 贵阳: 贵州大学, 2022.YANG CHAOCHAO. Research on the influence of red mud micro powder on the performance of cement concrete pavement [D]. Guiyang: Guizhou University, 2022(in Chinese). [39] TOUFIGH V, GHASSEMI P, AZIZMOHAMMADI M, et al. Mechanical properties and environmental impact of rubberized fly ash-and red mud-based geopolymer concrete[J]. European Journal of Environmental and Civil Engineering, 2022, 26(16): 8091-8114. doi: 10.1080/19648189.2021.2018358 -

点击查看大图

点击查看大图

计量

- 文章访问数: 34

- HTML全文浏览量: 25

- 被引次数: 0

下载:

下载: