Uniaxial cyclic loading deformation and fatigue life of ECC

-

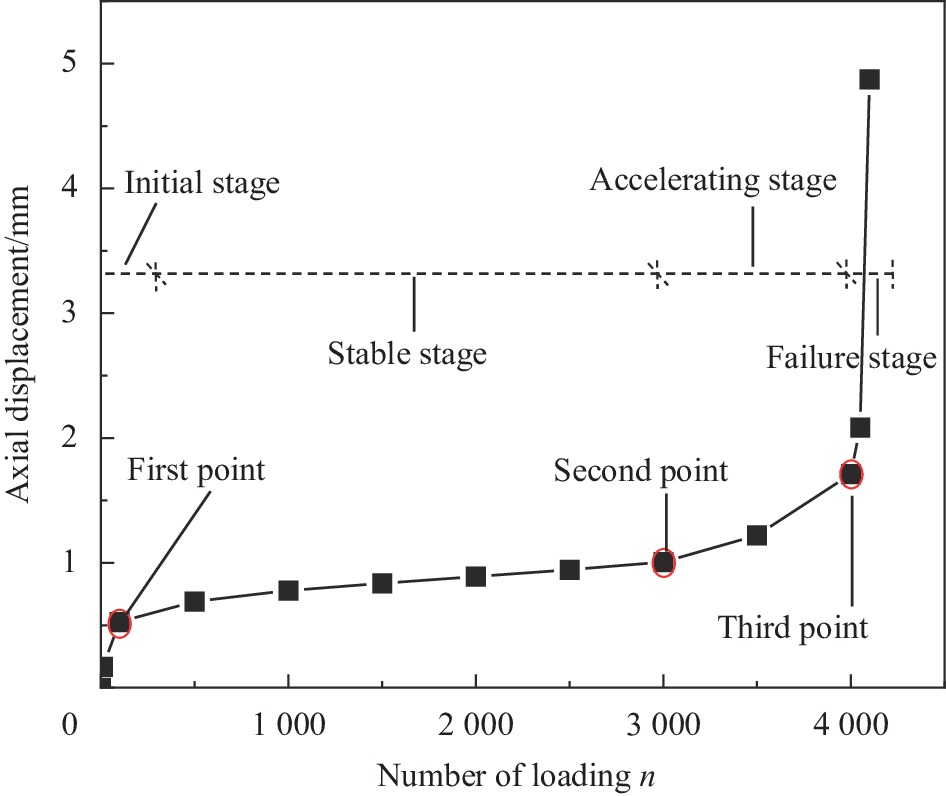

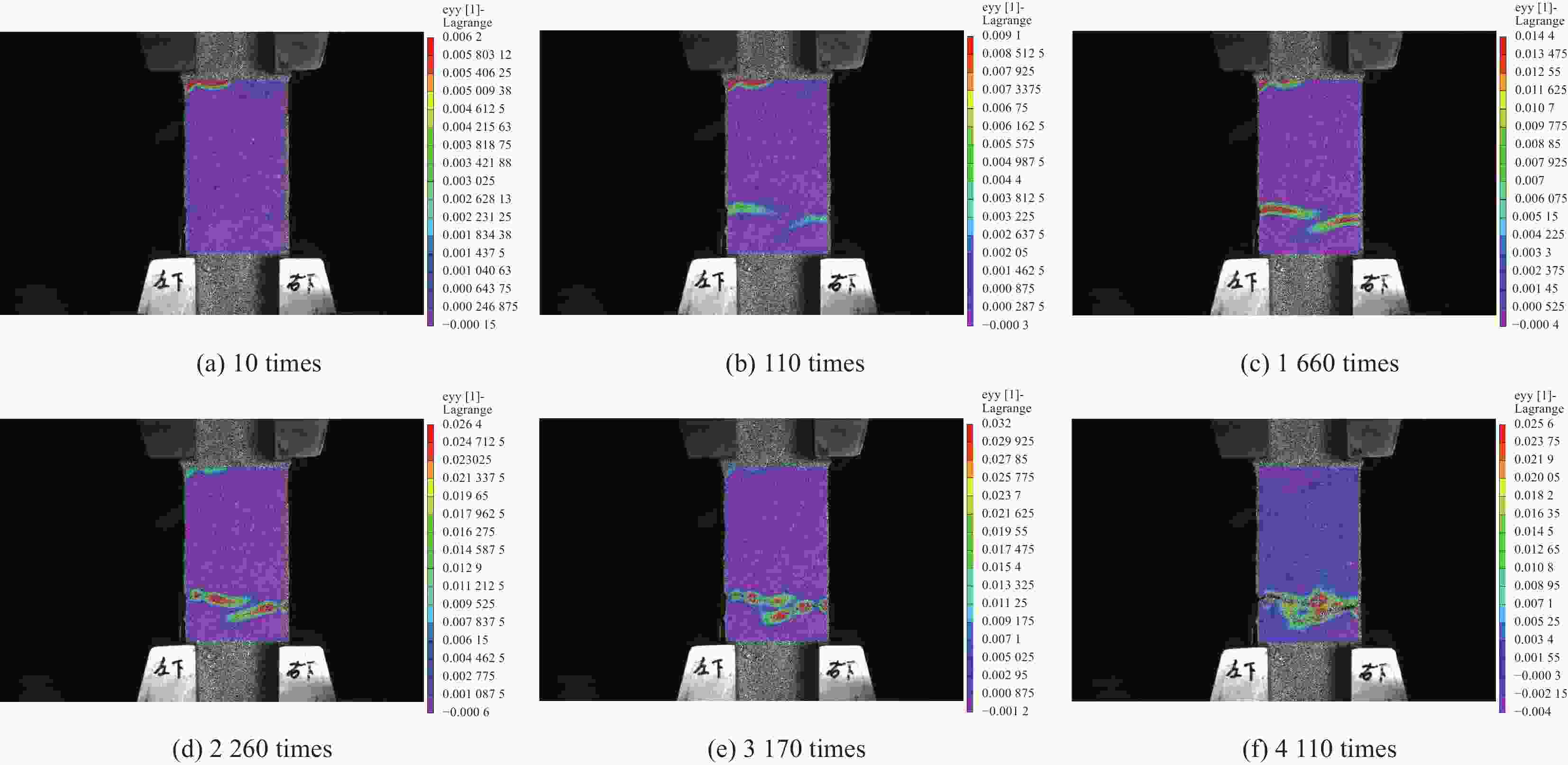

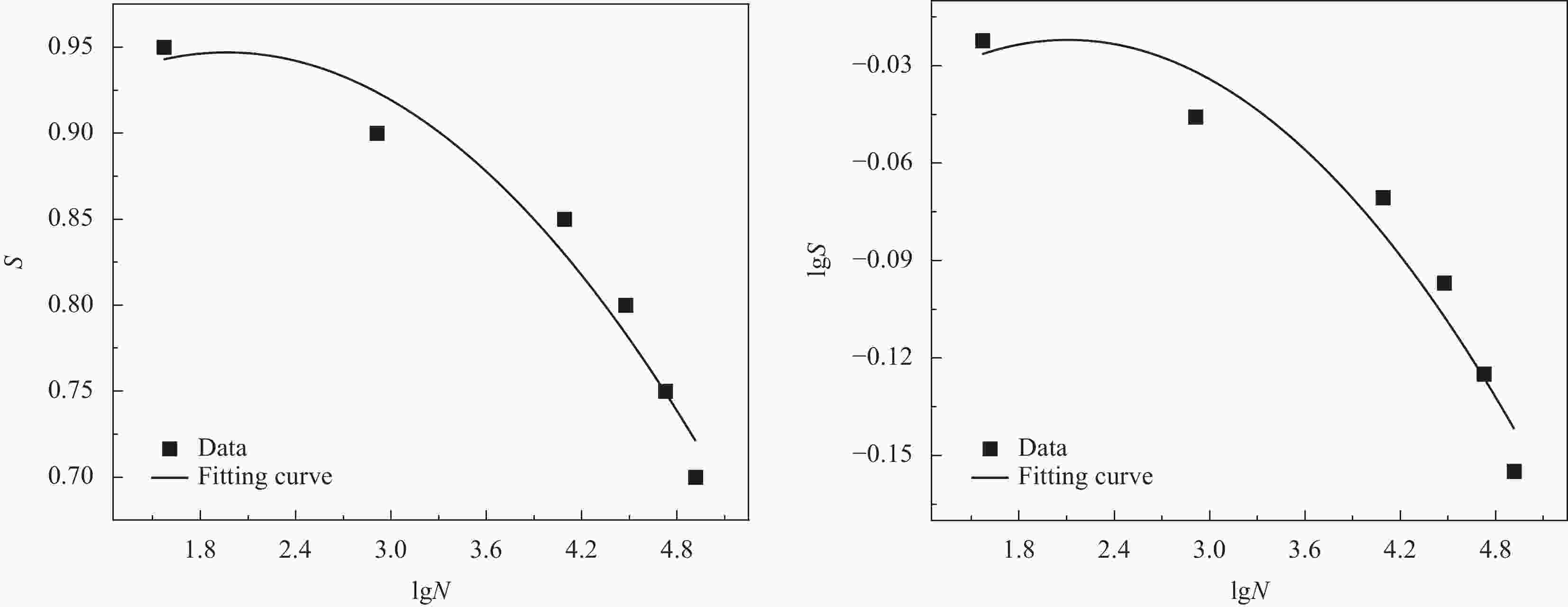

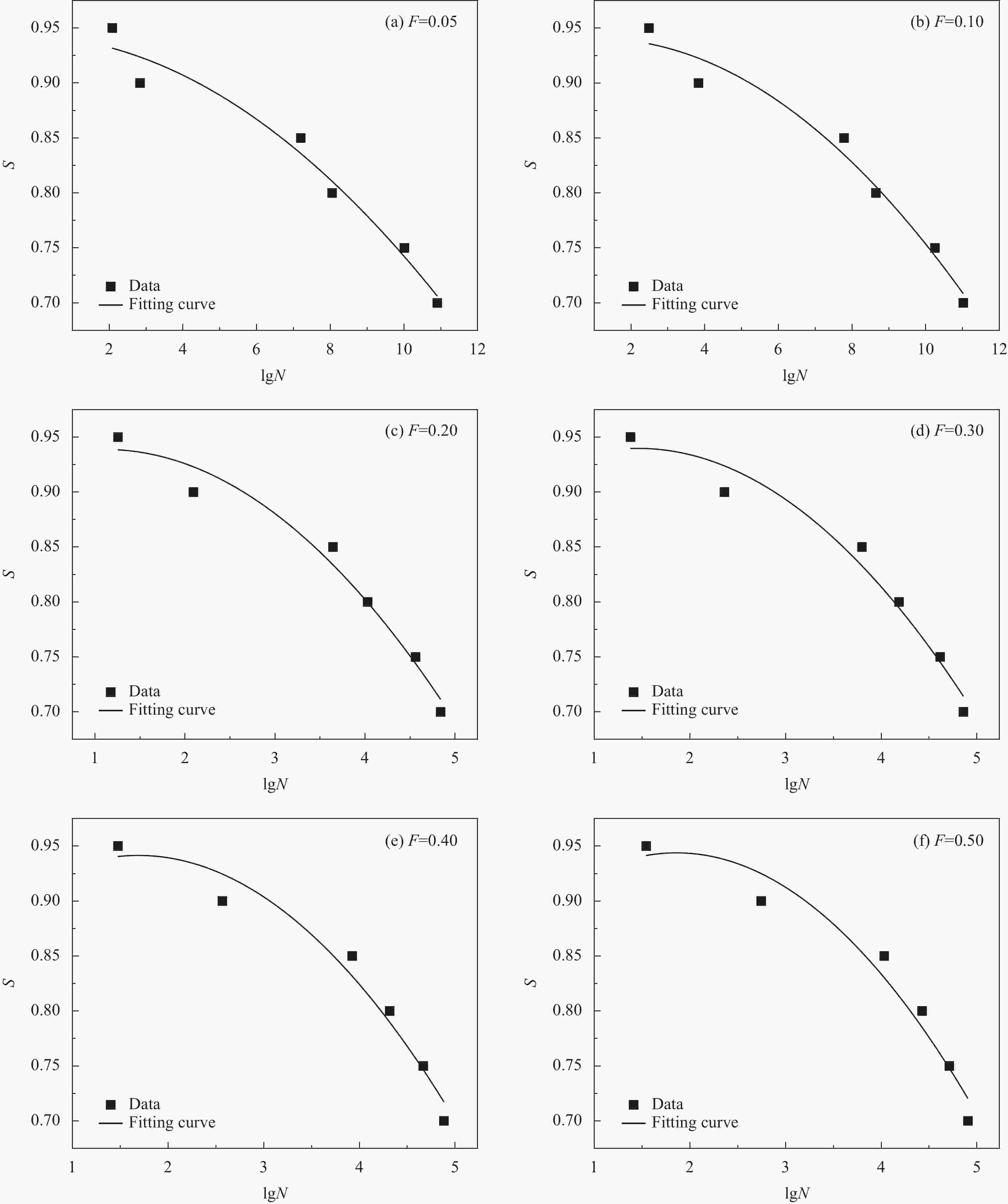

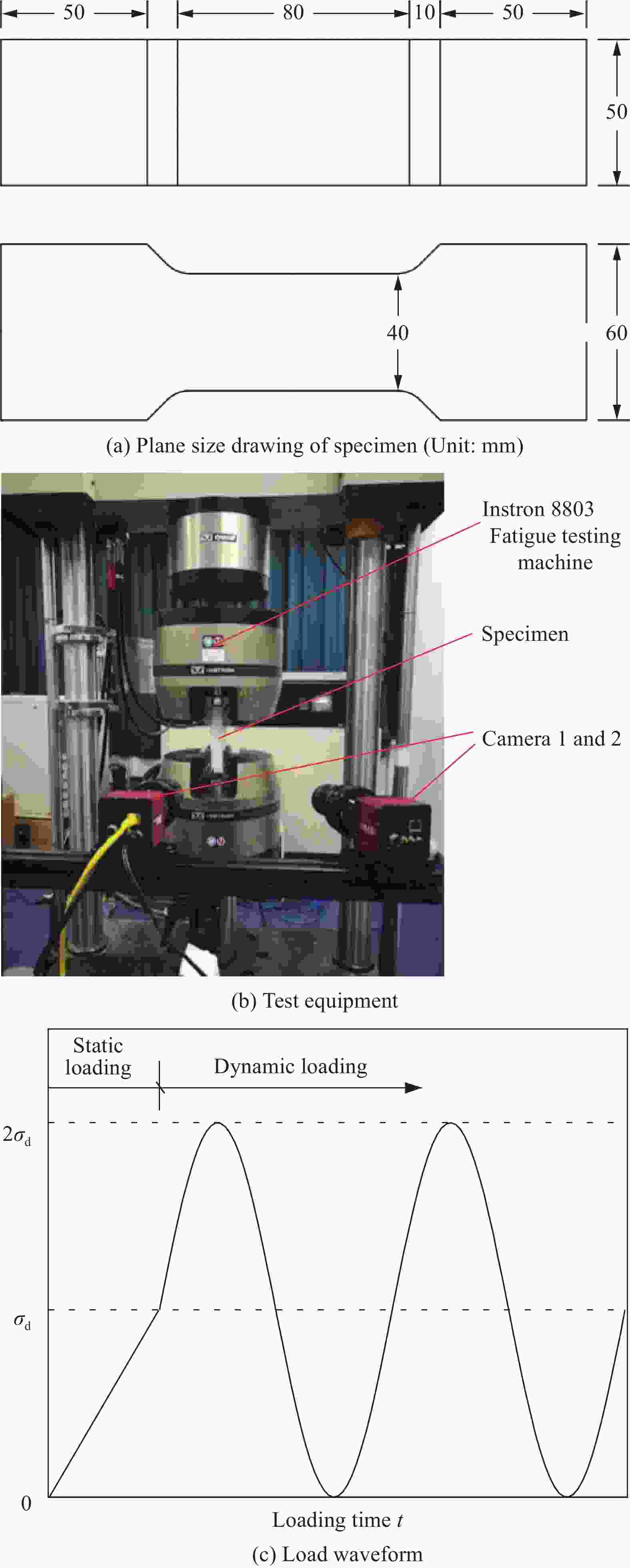

摘要: 高延性水泥基复合材料(ECC)多用于结构的抗震补强,其疲劳性能是工程中关注的重点。为研究其疲劳性能,通过疲劳试验机进行单轴拉伸循环加载试验,利用数字图像相关(DIC)技术实时监测位移发展与开裂行为。分析ECC试件的动力变形、疲劳规律并建立疲劳方程。结果表明:ECC试件的应变和轴向位移发展规律相似,分为初始阶段、稳定发展阶段、加速变形阶段和破坏阶段;动应力比越小,应变发展越快,破坏发生时的累积轴向应变越大;刚度比发展曲线分为三部分:快速下降阶段、稳定下降阶段和破坏阶段;其疲劳寿命可较好服从双参数Weibull分布;通过建立两种形式的疲劳方程:S-lgN和S-lgN-F疲劳方程,将极限疲劳寿命带入平均寿命疲劳方程,针对本文配合比得到疲劳极限应力水平为70.80%,对应的疲劳极限强度为2.69 MPa。Abstract: Engineered cementitious composites (ECC) are mostly used for seismic reinforcement of structures, and their fatigue performance is a major concern in engineering. In order to study the fatigue performance of ECC, the uniaxial tensile cyclic loading test was performed by fatigue testing machine, and the displacement development and cracking behavior in real time were monitored by using digital image correlation (DIC) technology to analyze the dynamic deformation and fatigue law of ECC specimens and establish the fatigue equation. The results show that the strain and axial displacement of ECC specimens develop similarly, which are divided into the initial stage, stable development stage, accelerated deformation stage and damage stage. The smaller the dynamic stress ratio, the faster the strain development and the larger the accumulated axial strain when damage occurs. The stiffness ratio development curve is divided into three parts: Rapid decline stage, stable decline stage and damage stage. The fatigue life of the ECC specimen obeys the two-parameter Weibull distribution well. By establishing two forms of fatigue equations: S-lgN and S-lgN-F fatigue equations, the ultimate fatigue life is brought into the average life fatigue equation, and the fatigue ultimate stress level is 70.80%. The corresponding fatigue ultimate strength is 2.69 MPa.

-

表 1 聚乙烯醇(PVA)纤维的各项性能指标

Table 1. Various performance indexes of polyvinyl alcohol (PVA) fiber

Length/mm Diameter/μm Length-diameter ratio/103 Tensile strength/MPa Elastic modulus

/GPaElongation/% Density/(g·cm−3) 12 39 0.31 1600 39 17 0.91 表 2 高延性水泥基复合材料(ECC)试件相对配合比 (kg/m3)

Table 2. Relative fit ratio of engineered cementitious composites (ECC) specimens (kg/m3)

Cement Water Sand PVA fiber Fly ash Water-reducing admixture 662.00 329.19 331.35 45.23 440.90 176.22 表 3 不同应力水平下的ECC疲劳寿命N的Weibull参数分布

Table 3. Weibull distribution test of fatigue life N of ECC under different stress levels

Stress

level SNumber of specimen i Cycles number

Ni$P = 1 - \dfrac{i}{{\left( {1 + K} \right)}}$ $\ln {N_i}$ $\ln \left[ {\ln \left( {1/P} \right)} \right]$ 0.95 1 16 0.83333 2.77259 −1.70198 2 26 0.66667 3.25810 −0.90272 3 38 0.50000 3.63759 −0.36651 4 42 0.33333 3.73767 0.09405 5 64 0.16667 4.15888 0.58320 0.90 1 106 0.83333 4.66344 −1.70198 2 305 0.66667 5.72031 −0.90272 3 405 0.50000 6.00389 −0.36651 4 1054 0.33333 6.96035 0.09405 5 2208 0.16667 7.69984 0.58320

0.851 4035 0.83333 8.30276 −1.70198 2 6524 0.66667 8.78324 −0.90272 3 12054 0.50000 9.39715 −0.36651 4 13518 0.33333 9.51178 0.09405 5 25478 0.16667 10.14557 0.58320

0.801 9225 0.83333 9.12967 −1.70198 2 15652 0.66667 9.65835 −0.90272 3 36584 0.50000 10.50737 −0.36651 4 42536 0.33333 10.65811 0.09405 5 45821 0.16667 10.73250 0.58320

0.751 36598 0.83333 10.50775 −1.70198 2 44750 0.66667 10.70885 −0.90272 3 46524 0.50000 10.74772 −0.36651 4 67546 0.33333 11.12056 0.09405 5 70451 0.16667 11.16267 0.58320

0.701 65894 0.83333 11.09580 −1.70198 2 76954 0.66667 11.25096 −0.90272 3 84572 0.50000 11.34536 −0.36651 4 88258 0.33333 11.38802 0.09405 5 95871 0.16667 11.47076 0.58320 Notes: P—Probability corresponding to the fatigue life NP; K—Total number of fatigue test data obtained at a given stress level. 表 4 ECC疲劳拉伸试验分析结果

Table 4. Analysis results of ECC fatigue tensile test

Stress

level $S$Regression coefficients $b$ $b\ln{N_{\text{a} } }$ Correlation coefficient R 0.95 1.6800 6.362 0.9852 0.90 0.7492 5.111 0.9663 0.85 1.2350 11.860 0.9643 0.80 1.1990 12.620 0.8920 0.75 2.9960 32.960 0.8793 0.70 6.1350 69.860 0.9886 Note: Na—Number of cycle loads. 表 5 不同应力比下ECC的拉伸疲劳寿命

Table 5. Tensile fatigue life of ECC under different stress ratios

Stress

level $S$Average fatigue

life $N$${\text{lg}}N$ ${\text{lg}}S$ 0.95 37.2 1.5705 –0.0223 0.90 815.6 2.9115 –0.0458 0.85 12321.8 4.0907 –0.0706 0.80 29963.6 4.4766 –0.0969 0.75 53173.8 4.7257 –0.1249 0.70 82309.8 4.9155 –0.1549 表 6 不同应力水平S及失效概率F下ECC的疲劳寿命

Table 6. Fatigue life of ECC under different failure probabilities F and stress levels S

Probability

of failure FStress level S 0.95 0.90 0.85 0.80 0.75 0.70 0.05 8 17 1337 3128 22247 54338 0.10 12 46 2395 5702 28289 61103 0.20 18 124 4397 10662 36340 69053 0.30 24 232 6428 15766 42499 74539 0.40 30 374 8598 21273 47912 79034 0.50 35 563 11009 27440 53051 83065 表 7 ECC的S-lgN-F疲劳方程的回归参数

Table 7. Regression parameters of S-lgN-F fatigue equation of ECC

Fatigue equation Failure probability F R2 ${{S}} = - 0.0098{({\rm{lg}}{{N}})^2} - 0.0037{\rm{lg}}{{N}} + 0.9430$ 0.05 0.9701 ${{S}} = - 0.0125{({\rm{lg}}{{N}})^2} + 0.0117{\rm{lg}}{{N}} + 0.9377$ 0.10 0.9749 ${{S}} = - 0.0164{({\rm{lg}}{{N}})^2} + 0.0364{\rm{lg}}{{N}} + 0.9185$ 0.20 0.9752 ${{S}} = - 0.0193{({\rm{lg}}{{N}})^2} + 0.0564{\rm{lg}}{{N}} + 0.8986$ 0.30 0.9721 ${{S}} = - 0.0218{({\rm{lg}}{{N}})^2} + 0.7039{\rm{lg}}{{N}} + 0.8790$ 0.40 0.9672 ${{S}} = - 0.0239{({\rm{lg}}{{N}})^2} + 0.0891{\rm{lg}}{{N}} + 0.8608$ 0.50 0.9605 -

[1] LI V C. Steady state and multiple cracking of short random fiber composites[J]. Journal of Engineering Mechanics, ASCE,1992,188(11):2246-2264. [2] LI V C. Engineered cementitious composites-Tailored composites through micromechanical modeling[J]. Journal of Advanced Concrete Technology,1998,1(3):1-38. [3] SUTHIWARAPIRA K P. Flexural fatigue failure characteristics of an engineered cementitious composites and polymer cement mortars[J]. Materials, Concrete Structural. Pavement, JSCE, 2002, 57: 121-134. [4] CACHIM P B, FIGUEIRAS J A, PEREIRA P A A. Fatigue behavior of fiber-reinforced concrete in compression[J]. Cement and Concrete Composites,2002,24(2):211-217. doi: 10.1016/S0958-9465(01)00019-1 [5] 邓明科, 杨铄, 梁兴文. 高延性混凝土单面加固构造柱约束砖砌体墙抗震性能试验研究[J]. 土木工程学报, 2018, 51(4):10-19.DENG Mingke, YANG Shuo, LIANG Xingwen. Experimental studies on seismic behavior of confined masonry walls strengthened with single ECC layer[J]. China Civil Engi-neering Journal,2018,51(4):10-19(in Chinese). [6] 邓明科, 张阳玺, 胡红波. 高延性混凝土加固钢筋混凝土柱抗剪承载力计算[J]. 工程力学, 2018, 35(3):159-166.DENG Mingke, ZHANG Yangxi, HU Hongbo. Experimental study and calculation of the shear capacity of RC columns strengthened with high ductile concrete[J]. Engineering Mechanics,2018,35(3):159-166(in Chinese). [7] 霍海峰, 刘汉磊, 杨雅静, 等. ECC单轴拉伸疲劳变形特性及寿命预测[J]. 复合材料学报, 2022, 39(7): 3404-3414 .HUO Haifeng, LIU Hanlei, YANG Yajing, et al. Fatigue deformation characteristics and life prediction of ECC under uniaxial tension[J]. Acta Materiae Compositae Sinica, 2022, 39(7): 3404-3414(in Chinese). [8] 余江滔, 许万里, 张远淼. ECC-混凝土黏结界面断裂试验研究[J]. 建筑材料学报, 2015, 18(6):958-963, 970. doi: 10.3969/j.issn.1007-9629.2015.06.008YU Jiangtao, XU Wanli, ZHANG Yuanmiao. Experiment study on fracture property of ECC-concrete interface[J]. Journal of Building Materials,2015,18(6):958-963, 970(in Chinese). doi: 10.3969/j.issn.1007-9629.2015.06.008 [9] 林建辉, 余江滔, LI Victor C. PVA纤维增强水泥基复合材料热处理后的力学性能[J]. 复合材料学报, 2016, 33(1):116-122.LIN Jianhui, YU Jiangtao, LI Victor C. Mechanical properties of PVA fiber reinforced engineered cementitious composite after thermal treatment[J]. Acta Materiae Compositae Sinica,2016,33(1):116-122(in Chinese). [10] 江佳斐, 隋凯. 纤维网格增强超高韧性水泥复合材料加固混凝土圆柱受压性能试验[J]. 复合材料学报, 2019, 36(8):1957-1967.JIANG Jiafei, SUI Kai. Experimental study of compression performance of concrete cylinder strengthened by textile reinforced engineering cement composites[J]. Acta Materiae Compositae Sinica,2019,36(8):1957-1967(in Chinese). [11] 韦选纯, 汤盛文, 何真, 等. 聚乙烯醇纤维增强钢渣粉-水泥复合材料基本力学性能及微观结构[J]. 复合材料学报, 2019, 36(8):1918-1925.WEI Xuanchun, TANG Shengwen, HE Zhen, et al. Mecha-nical and microstructural characteristics of polyvinyl alcohol fiber reinforced cementitious composites containing steel slag powder[J]. Acta Materiae Compositae Sinica,2019,36(8):1918-1925(in Chinese). [12] 曹明莉, 许玲, 张聪. 高延性纤维增强水泥基复合材料的微观力学设计、性能及发展趋势[J]. 硅酸盐学报, 2015, 43(5):632-642.CAO Mingli, XU Ling, ZHANG Cong. Review on micromechanical design, performance and development tendency of engineered cementitious composites[J]. Journal of the Chinese Ceramic Society,2015,43(5):632-642(in Chinese). [13] 周英武, 胡智恒, 胡彪. 受压区局部钢筋混凝土梁抗剪性能[J]. 深圳大学学报理工版, 2021, 38(5):479-488. doi: 10.3724/SP.J.1249.2021.05479ZHOU Yingwu, HU Zhiheng, HU Biao. Shear performance of local reinforced concrete beams in compression zone[J]. Journal of Shenzhen University Science and Technology Edition,2021,38(5):479-488(in Chinese). doi: 10.3724/SP.J.1249.2021.05479 [14] 金文. 超高性能混凝土弯曲疲劳性能及破坏中裂缝发展研究[D]. 广州: 华南理工大学, 2018.JIN Wen. Research on the flexural fatigue properties and fracture development of ultra-high-performance concrete[D]. Guangzhou: South China University of Technology, 2018(in Chinese). [15] DENG M, PAN J, SUN H. Bond behavior of deformed bar embedded in engineered cementitious composites under cyclic loading[J]. Construction and Building Materials,2019,197(9):164-174. [16] DENG M, DONG Z, MA P. Cyclic loading tests of flexural-failure dominant URM walls strengthened with engi-neered cementitious composite[J]. Engineering Structures,2019,194:173-182. doi: 10.1016/j.engstruct.2019.05.073 [17] DENG M, YANG S. Cyclic testing of unreinforced masonry walls retrofitted with engineered cementitious compo-sites[J]. Construction & Building Materials,2018,177:395-408. [18] AHMAD K E, ABD-ELRAHMAN A M. Updating a nonlinear discriminant function estimated from a mixture of two Weibull distributions[J]. Mathematical & Computer Modelling,1994,19(11):41-51. [19] 朱劲松. 混凝土双轴疲劳试验与破坏预测理论研究[D]. 大连: 大连理工大学, 2003.ZHU Jinsong. Research on concrete biaxial fatigue test and failure prediction theory[D]. Dalian: Dalian University of Technology, 2003(in Chinese). [20] 杨健辉. 侧压下混凝土静态受拉与受拉疲劳性能研究[D]. 大连: 大连理工大学, 2003.YANG Jianhui. Research on static tensile and tensile fatigue properties of concrete under lateral compression[D]. Dalian: Dalian University of Technology, 2003(in Chinese). [21] 易勇. 高韧性工程水泥基复合材料基本力学[D]. 北京: 北京工业大学, 2018.YI Yong. Basic mechanics of high toughness engineering cement-based composites[D]. Beijing: Beijing University of Technology, 2018(in Chinese). [22] 张小辉. 钢纤维混凝土弯曲疲劳及其损伤特性和细观强度研究[D]. 昆明: 昆明理工大学, 2001.ZHANG Xiaohui. Research on bending fatigue and damage characteristics and meso-strength of steel fiber concrete[D]. Kunming: Kunming University of Science and Technology, 2001(in Chinese). [23] 中国建筑材料联合会. 高延性纤维增强水泥基复合材料力学性能试验方法: JC/T 2461—2018[S]. 北京: 中国建材工业出版社, 2018.China Building Materials Federation. Standard test method for the mechanical properties of the ductile fiber reinforced cementitious composites: JC/T 2461—2018[S]. Beijing: China Building Materials Press, 2018(in Chinese). [24] 中国建筑科学研究院. 普通混凝土拌合物性能试验方法标准: GB/T 50081—2016[S]. 北京: 中国建筑工业出版社, 2016.China Academy of Building Research. Standard for test method of performance on ordinary fresh concrete: GB/T 50081-2016[S]. Beijing: China Architecture & Building Press, 2016(in Chinese). [25] 靳敏超, 沈健, 冯仲仁. 带预裂纹混凝土单双轴疲劳试验分析[J]. 施工技术, 2019, 48(S1):452-454.JIN Minchao, SHEN Jian, FENG Zhongren. Analysis of single and biaxial fatigue test of pre-cracked concrete[J]. Construction Technology,2019,48(S1):452-454(in Chinese). [26] JING L. Experimental and analytical study on uniaxial compressive fatigue behavior of self-compacting rubber lightweight aggregate concrete[J]. Construction and Building Materials,2020,237:1-13. [27] 白晓虹. 数字图像相关(DIC)测量方法在材料变形研究中的应用[D]. 沈阳: 东北大学, 2011.BAI Xiaohong. Application of digital image correlation method in study of material deformation[D]. Shenyang: Northeastern University, 2011(in Chinese). [28] YIN L H. Experimental study on the fatigue damage of high strength concrete under uniaxial compression[J]. Key Engineering Materials,2014(619):109-115. [29] CHEN X D, BU J W, FAN X Q, et al. Effect of loading frequency and stress level on low cycle fatigue behavior of plain concrete in direct tension[J]. Construction and Building Materials, 2017, 133(2): 367-375. -

下载:

下载: