Air-coupled ultrasonic testing and analysis on delamination defect of low-density thermal protection and insulation material

-

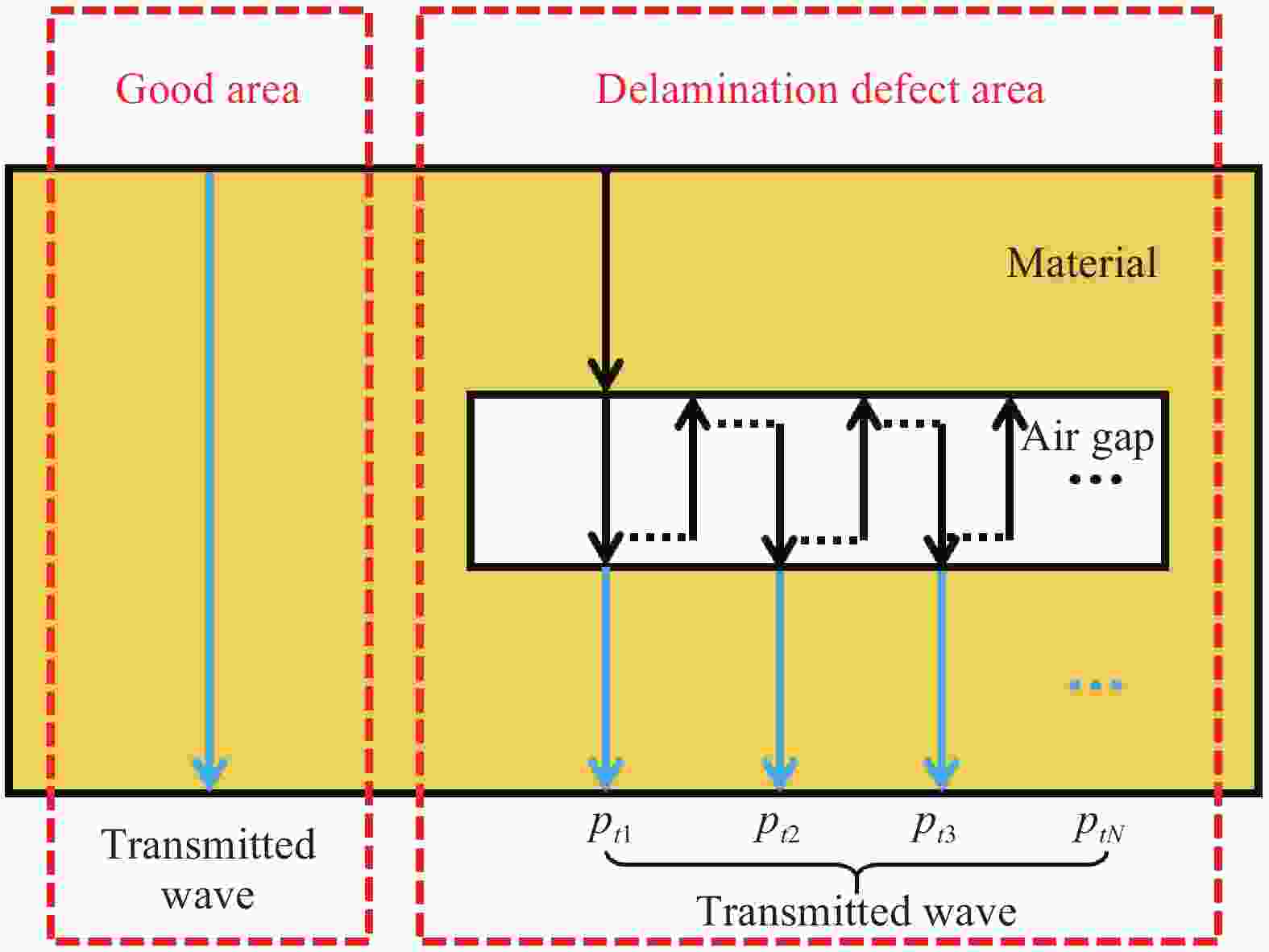

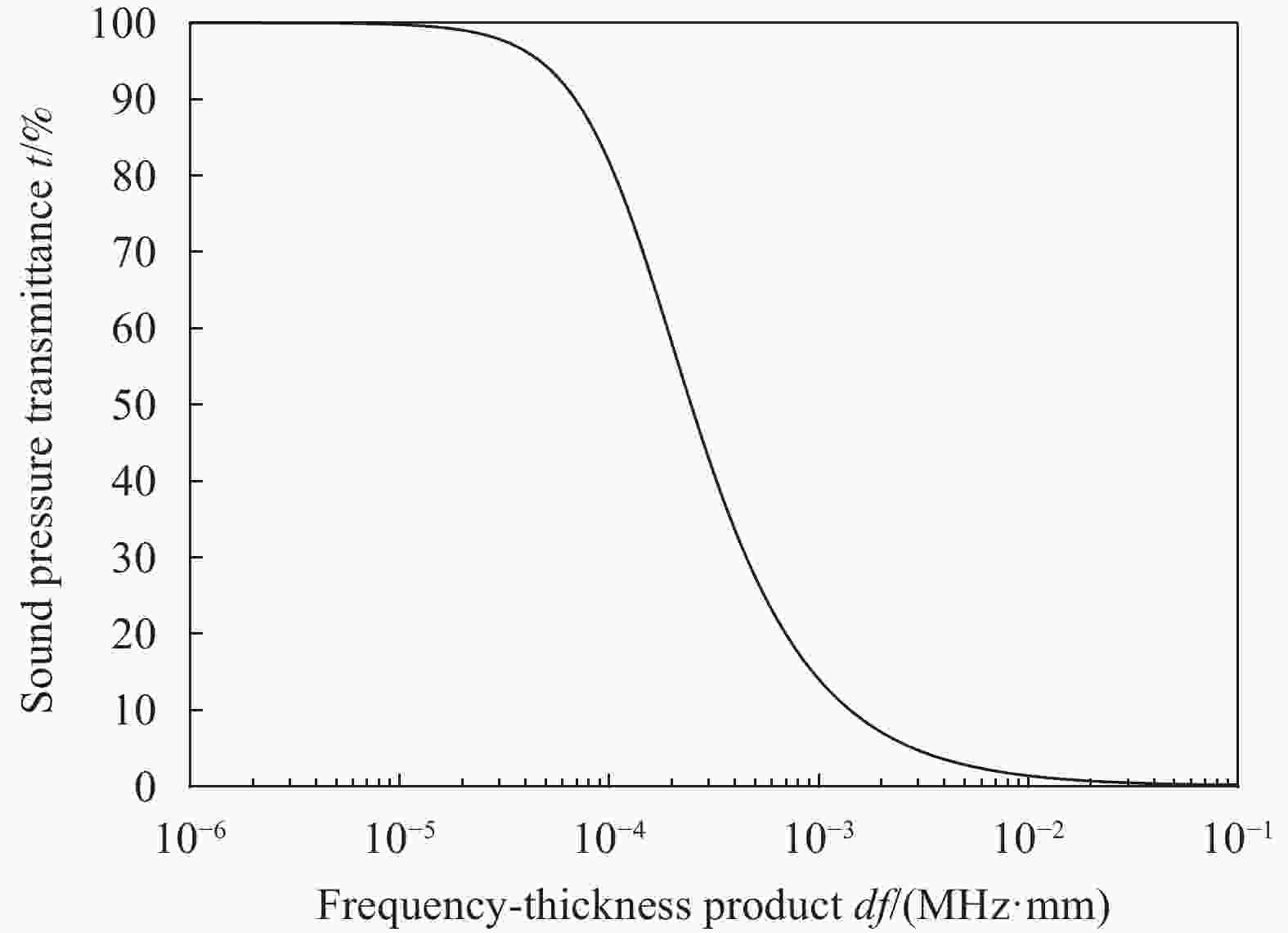

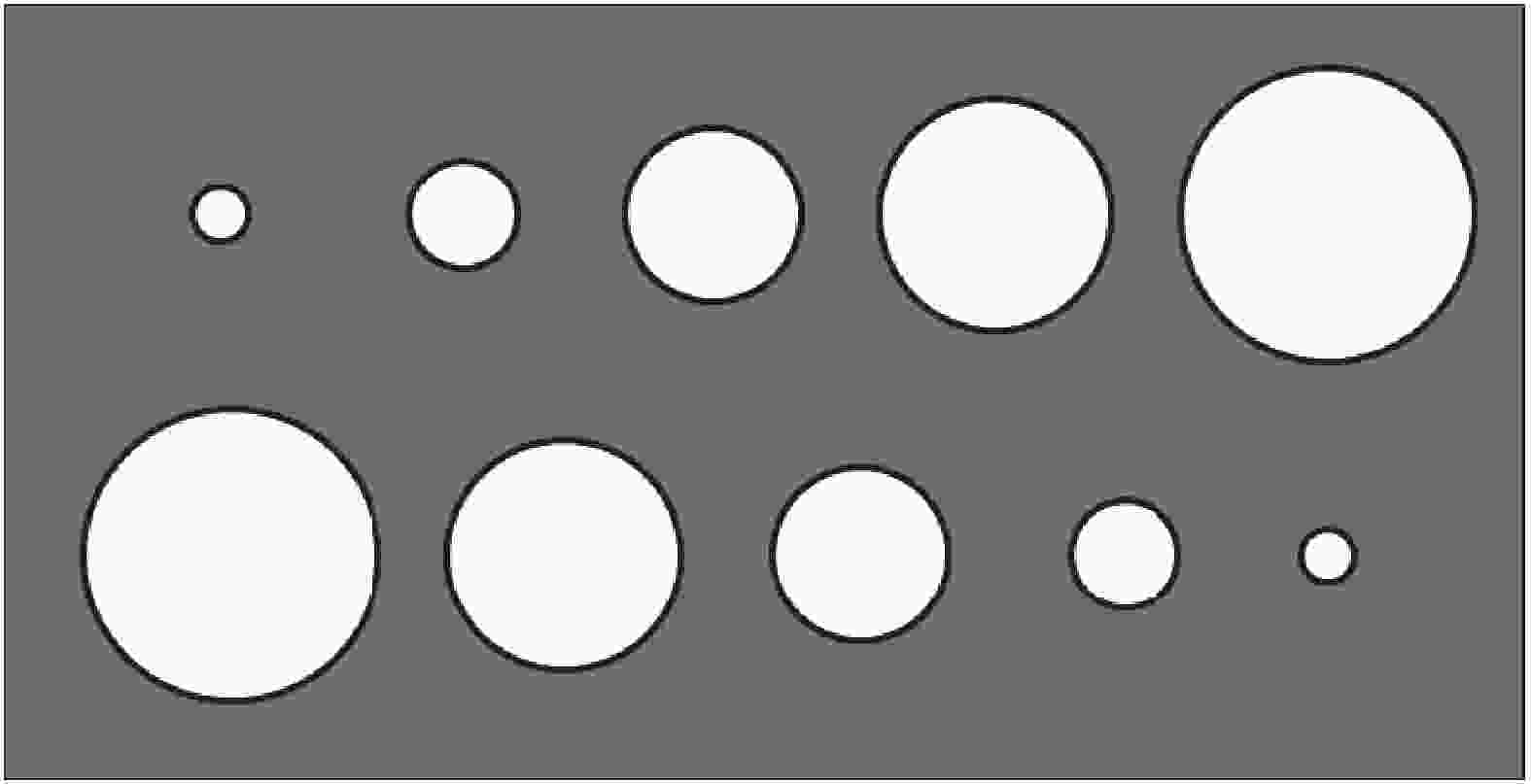

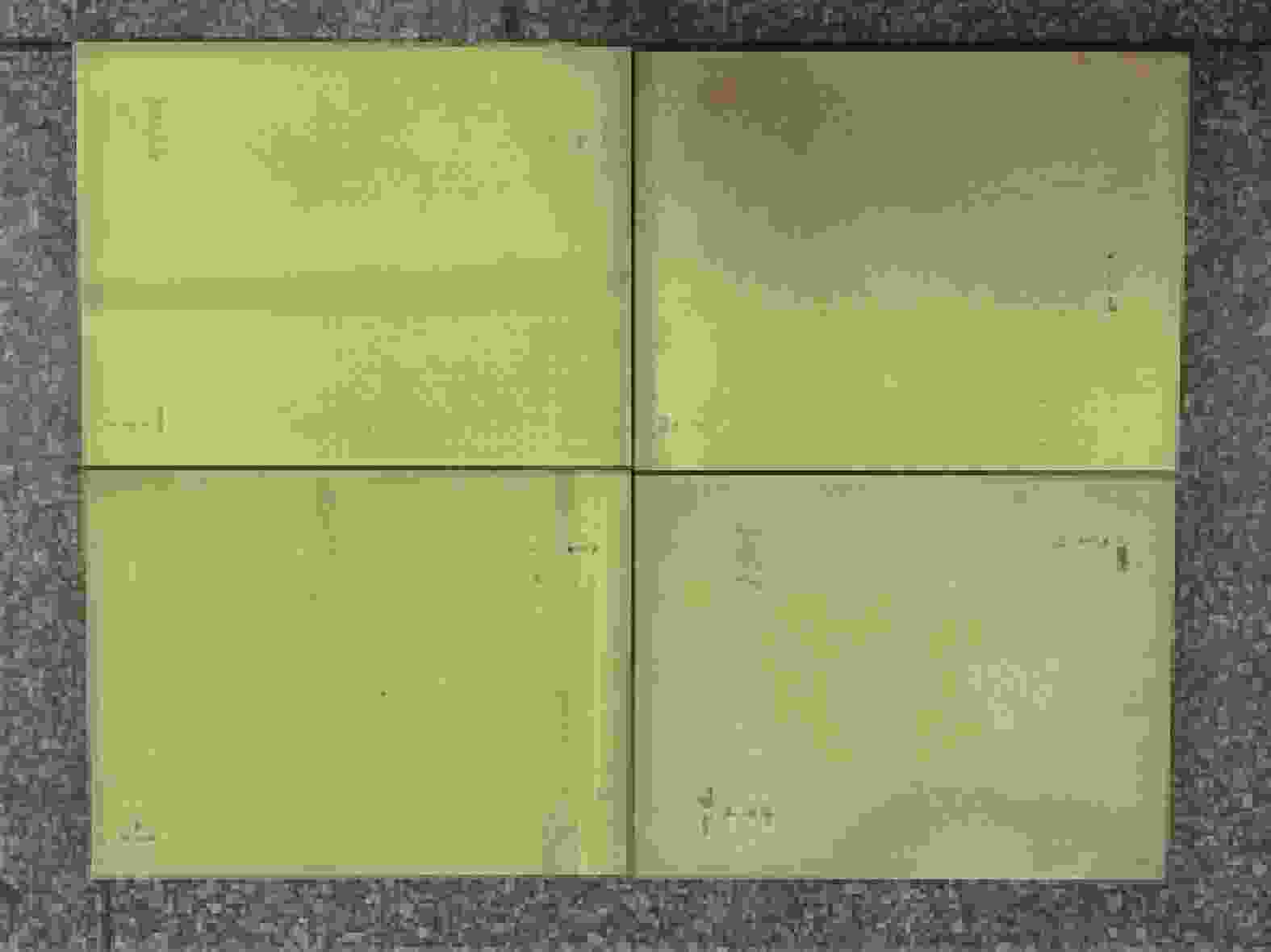

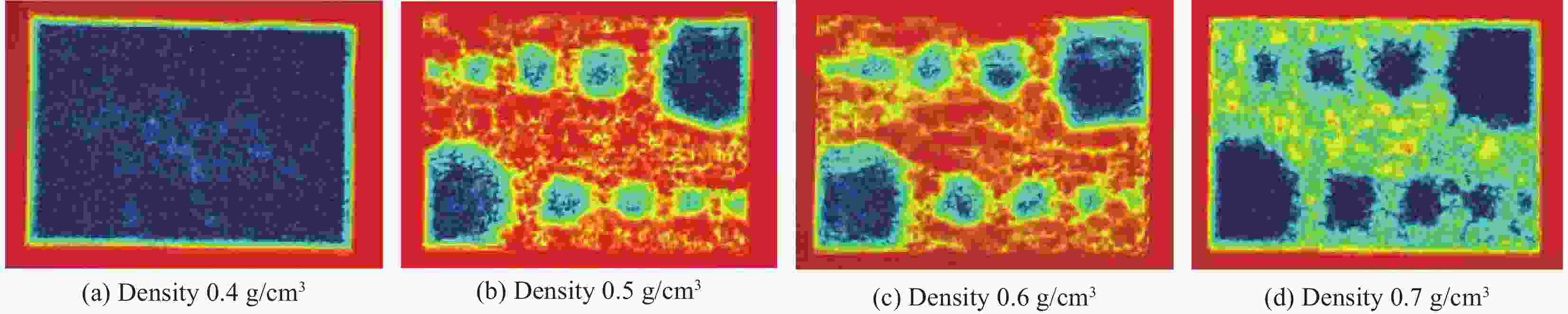

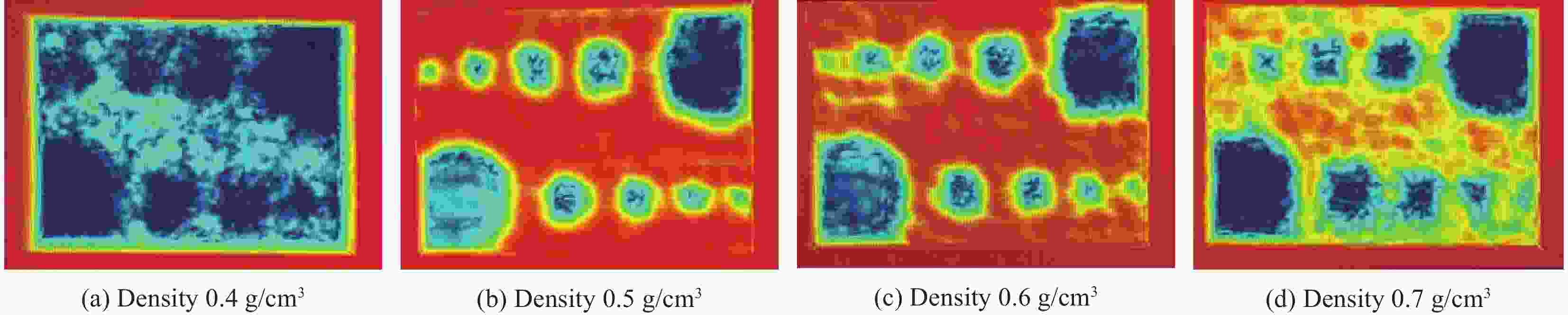

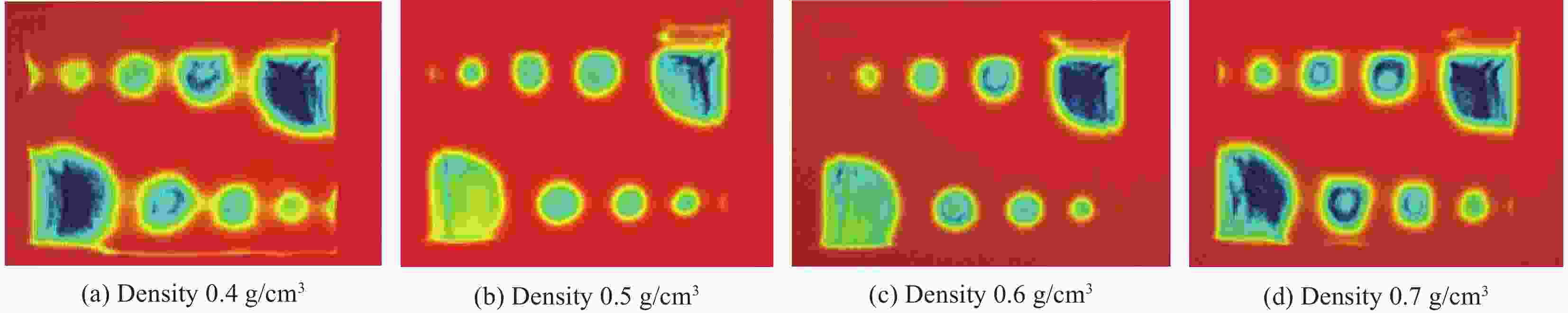

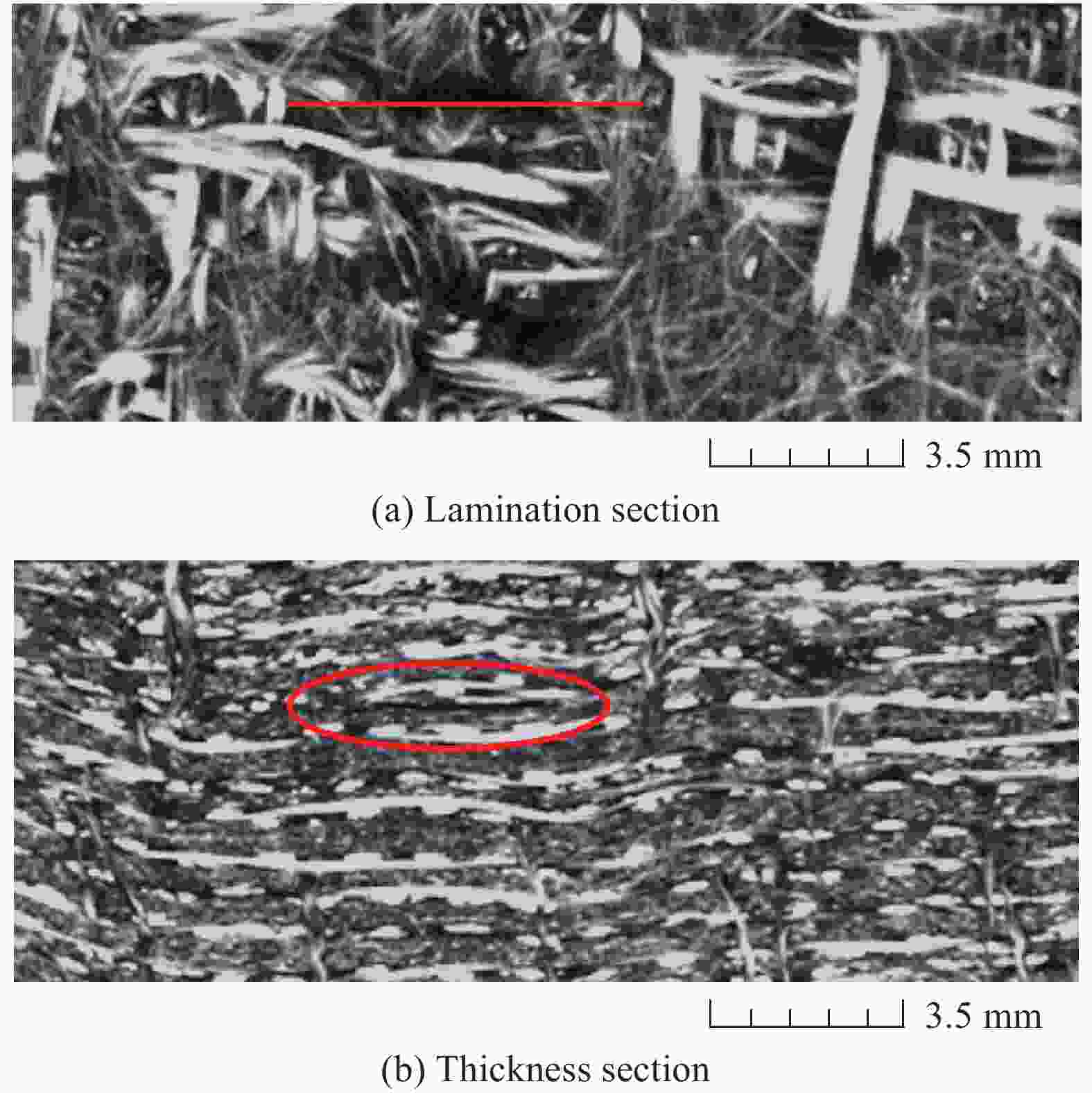

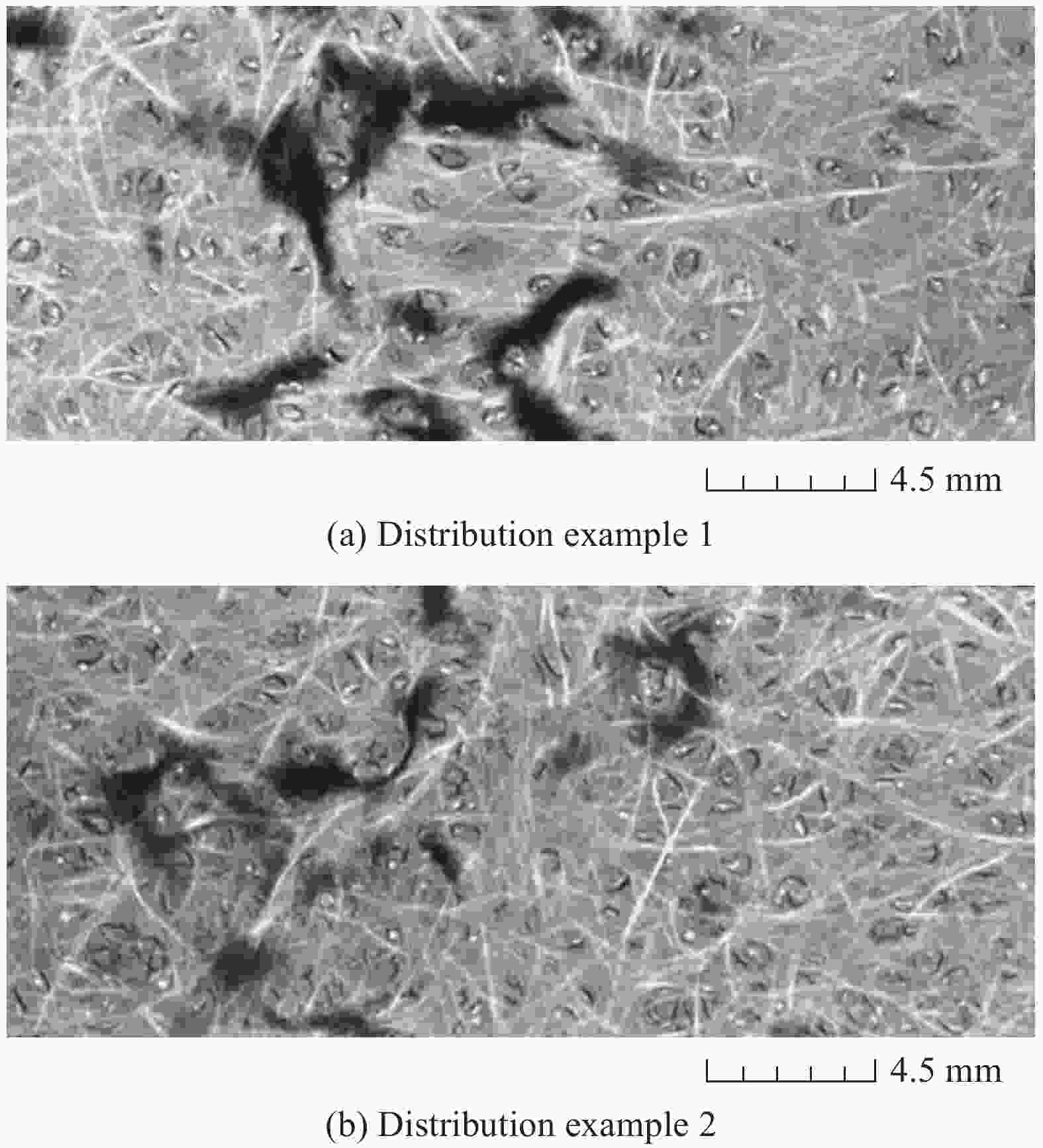

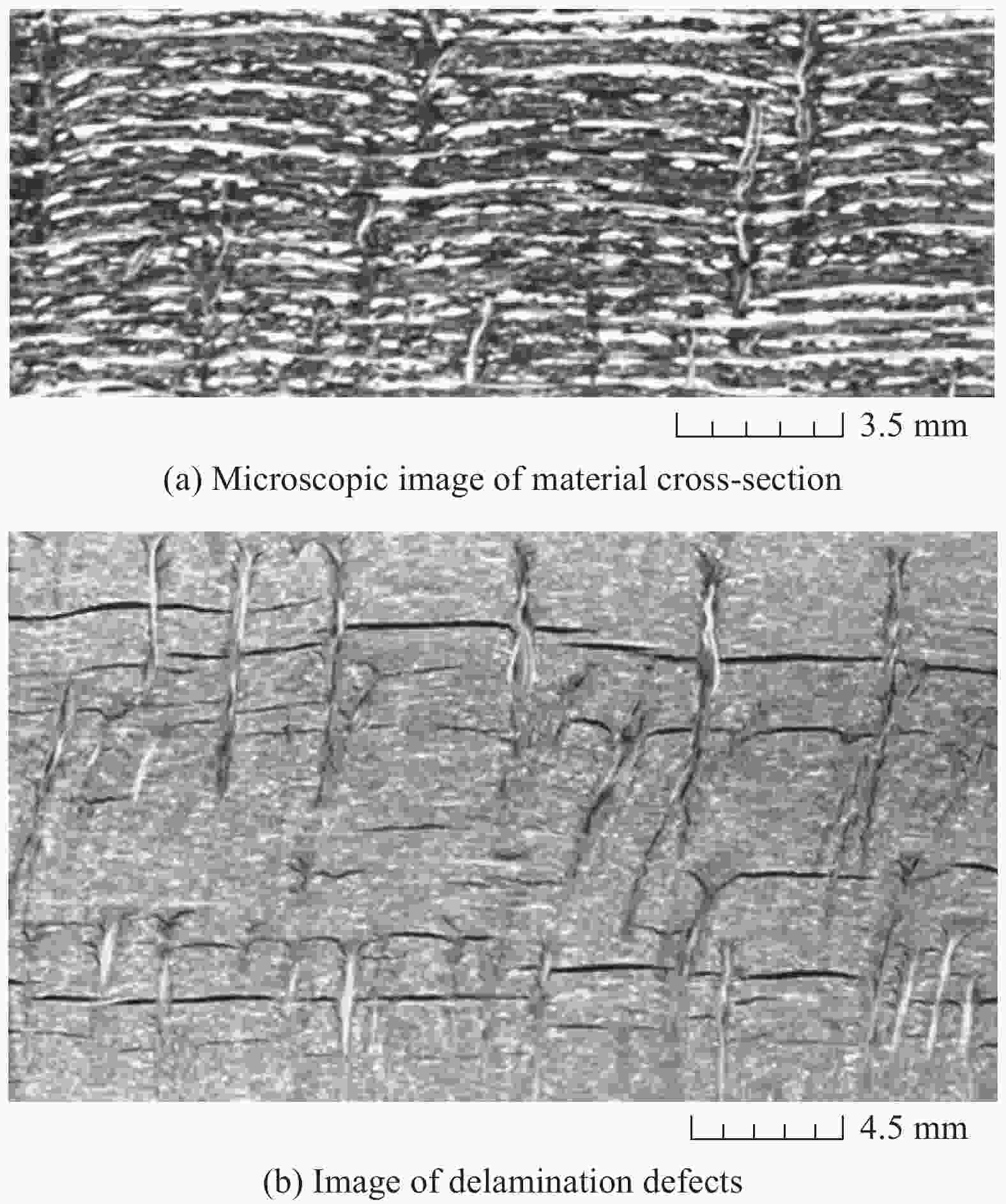

摘要: 低密度防隔热材料是航天飞行器热防护系统的重要组成材料,具有密度低、孔隙率高、热导率低等特点,在轻质的同时具备优异的防隔热性能。但是,该类型材料及其结构特点为材料内部缺陷的无损检测带来较大困难,常规超声喷水穿透法不适用,红外法效果较差。针对石英纤维针刺织物增强酚醛树脂基低密度防隔热材料内部分层缺陷的检测问题,开展了空气耦合超声检测研究。在研究中,通过X射线Micro-CT检测分析了材料的微观结构,估算了分层缺陷声压透射率与空气间隙厚度的关系,制作了密度分别为0.4、0.5、0.6、0.7 g/cm3材料的缺陷试样,并通过空气耦合超声检测搭配50、140、200 kHz频率探头对缺陷试样进行了检测研究。结果表明,空气耦合超声检测能有效发现低密度防隔热材料中的分层缺陷,检测适用频率和检测能力与材料密度和材料均匀性有关。在材料厚度30 mm,分层缺陷空气间隙厚度0.3 mm时,使用频率50 kHz的空气耦合超声探头,在密度0.4~0.7 g/cm3材料中均能发现直径30 mm及以上尺寸的缺陷。

-

关键词:

- 低密度防隔热材料 /

- 微观结构 /

- 分层缺陷 /

- 空气耦合超声检测 /

- Micro-CT检测

Abstract: The low-density thermal protection and insulation material is an important constituent material on aerospace craft thermal protection system. The material is low density, high porosity, and low thermal conductivity, with lightweight and excellent thermal protection and insulation performance. However, the material and its microscopic structure characteristics cause difficulties on non-destructive testing on the internal defects. The regular ultrasonic transmission testing is unsuitable, and the infrared testing is less effective. To detect the delamination defect of low-density thermal protection and insulation material, which is composed of quartz needled fabric and phenolic resin, the research on air-coupled ultrasonic testing is carried out. The microstructure of the material was analyzed by X-ray micro-CT detection. The relationship between delamination defect sound pressure transmittance and air gap thickness was estimated. The material specimens with densities of 0.4, 0.5, 0.6, 0.7 g/cm3 were made. The research of air-coupled ultrasonic testing on the specimens with probe frequencies of 50, 140, 200 kHz was performed. The result shows, the air-coupled ultrasonic testing is effective on delamination defect detection of low-density thermal protection and insulation material. The suitable detection frequency and detectability are both related to the material density and the material homogeneity. When the material thickness is 30 mm, the delamination defect air gap thickness is 0.3 mm, the probe frequency is 50 kHz, and the material density is within 0.4~0.7 g/cm3, the delamination defect with diameter greater than 30 mm can be detected. -

表 1 200 kHz频率探头在不同密度材料及不同尺寸缺陷处的穿透波分贝值(单位:dB)

Table 1. Transmission wave decibel values of 200 kHz frequency probe at different density materials and different defect sizes (unit: dB)

Defect diameter Density

0.4 g/cm3Density

0.5 g/cm3Density

0.6 g/cm3Density

0.7 g/cm3Good area Cannot

distinguish

−31.8~−28.4−13.1~−1.7 −15.3~−2.9 −22.2~−7.2 20 mm −22.7 −20.2 −21.6 30 mm −25.6 −21.0 −31.4 40 mm −27.0 −27.4 −31.4 50 mm −30.3 −30.2 −32.9 100 mm −31.3 −33.6 −32.7 表 2 140 kHz频率探头在不同密度材料及不同尺寸缺陷处的穿透波分贝值(单位:dB)

Table 2. Transmission wave decibel values of 140 kHz frequency probe at different density materials and different defect sizes (unit: dB)

Defect diameter Density

0.4 g/cm3Density

0.5 g/cm3Density

0.6 g/cm3Density

0.7 g/cm3Good area −30.1~−18.9 −6.9~−3.2 −17.3~−3.8 −22.9~−6.7 20 mm −35.6~−33.1 −24.7 −19.4 −23.1 30 mm −32.9 −28.4 −32.2 40 mm −35.5 −35.3 −38.5 50 mm −38.7 −37.6 −40.7 100 mm −41.3 −40.7 −44.3 表 3 50 kHz频率探头在不同密度材料及不同尺寸缺陷处的穿透波分贝值(单位:dB)

Table 3. Transmission wave decibel values of 50 kHz frequency probe at different density materials and different defect sizes (unit: dB)

Defect diameter Density

0.4 g/cm3Density

0.5 g/cm3Density

0.6 g/cm3Density

0.7 g/cm3Good area −8.0~−5.3 −6.5~−5.5 −6.5~−5.7 −6.9~−5.8 30 mm −17.2 −21.5 −17.4 −22.8 40 mm −20.9 −23.2 −22.1 −24.6 50 mm −30.1 −23.4 −23.7 −26.0 100 mm −35.9 −28.9 −30.4 −32.4 -

[1] 冯志海, 李俊宁, 田跃龙, 等. 航天先进复合材料研究进展[J]. 复合材料学报, 2022, 39(9): 4187-4195.FENG Zhihai, LI Junning, TIAN Yuelong, et al. Research progress of advanced composite materials for aerospace applications[J]. Acta Materiae Compositae Sinica, 2022, 39(9): 4187-4195(in Chinese). [2] 董彦芝, 刘峰, 杨昌昊, 等. 探月工程三期月地高速再入返回飞行器防热系统设计与验证[J]. 中国科学: 技术科学, 2015, 45(2): 151-159. doi: 10.1360/N092014-00468DONG Yanzhi, LIU Feng, YANG Changhao, et al. Design and verification of the TPS of the circumlunar free return and reentry flight vehicle for the 3rd phase of Chinese lunar exploration program[J]. Scientia Sinica (Technological), 2015, 45(2): 151-159(in Chinese). doi: 10.1360/N092014-00468 [3] QIAN Z, CAI H, CAO J, et al. 3D needle-punched carbon/quartz fabric reinforced nanoporous phenolic composites with co-optimized mechanics, insulation and ablation[J]. Composites Communication, 2022, 36: 101393. doi: 10.1016/j.coco.2022.101393 [4] 王国林, 金华, 孟松鹤, 等. 多相纤维增强酚醛树脂低密度烧蚀防热复合材料高温压缩性能及损伤机制[J]. 复合材料学报, 2019, 36(1): 133-138.WANG Guolin, JIN Hua, MENG Songhe, et al. High temperature compressive property and damage mechanism of low density multiphase fiber reinforced phenolic resin ablative thermal protective composite[J]. Acta Materiae Compositae Sinica, 2019, 36(1): 133-138(in Chinese). [5] 杨红娟, 杨正岩, 杨雷, 等. 碳纤维复合材料损伤的超声检测与成像方法研究进展[J]. 复合材料学报, 2023, 40(8): 4295-4317.YANG Hongjuan, YANG Zhengyan, YANG Lei, et al. Progress in ultrasonic testing and imaging method for damage of fiber composites[J]. Acta Materiae Compositae Sinica, 2023, 40(8): 4295-4317(in Chinese). [6] 赵建华, 罗明, 吴时红, 等. 超声波喷水穿透法在先进复合材料检测中的应用[J]. 宇航材料工艺, 2012, 42(4): 105-108.ZHAO Jianhua, LUO Ming, WU Shihong, et al. Application of ultrasonic squirter transmission method in detection of advanced composite materials[J]. Aerospace Materials & Technology, 2012, 42(4): 105-108(in Chinese). [7] 朱笑, 袁丽华. 基于红外热成像的CFRP复合材料低速冲击损伤表征[J]. 复合材料学报, 2022, 39(8): 4164-4171.ZHU Xiao, YUAN Lihua. Low-velocity impact damage characterization of CFRP composite based on infrared thermography[J]. Acta Materiae Compositae Sinica, 2022, 39(8): 4164-4171(in Chinese). [8] 刘哲军, 陈博, 金珂, 等. 航天复合材料智能健康监测技术研究进展[J]. 宇航材料工艺, 2022, 52(2): 109-115.LIU Zhejun, CHEN Bo, JIN Ke, et al. Progress of intelligent health monitoring for aerospace composite materials[J]. Aerospace Materials & Technology, 2022, 52(2): 109-115(in Chinese). [9] 林鑫, 刘哲军, 葛丽, 等. 复合材料粘接结构红外锁相热像法检测[J]. 无损检测, 2017, 39(1): 49-55.LIN Xin, LIU Zhejun, GE Li, et al. Lock-in infrared thermography in composite bonding structure[J]. Nondestructive Testing, 2017, 39(1): 49-55(in Chinese). [10] 钱震, 曹宇, 周耀忠, 等. 基于X射线原位拉伸的三维针刺预制体增强纳米孔酚醛复合材料的微观损伤演化[J]. 复合材料学报, 2023, 40(8): 4460-4470.QIAN Zhen, CAO Yu, ZHOU Yaozhong, et al. Micro-fracture behaviors of 3D needle punching fabric reinforced nanoporous phenolic composites based on in-situ X-ray[J]. Acta Materiae Compositae Sinica, 2023, 40(8): 4460-4470(in Chinese). [11] NIU B, ZHANG H Y, QIAN Z, et al. Micro-fracture behaviors of needled short-chopped fiber reinforced phenolic aerogel composites based on in-situ X-ray micro-CT[J]. Composites Communications, 2022, 33: 101224. doi: 10.1016/j.coco.2022.101224 [12] GE L, LI H, ZHONG J, et al. Micro-CT based trans-scale damage analysis of 3D braided composites with pore defects[J]. Composites Science and Technology, 2021, 21: 108830. [13] 陈嘉威, 沈宽. 低密度粉末材料的DR图像夹杂检测[J]. 光学学报, 2020, 40(11): 81-89.CHEN Jiawei, SHEN Kuan. Inclusion detection from DR images of low-density powder materials[J]. Acta Optica Sinica, 2020, 40(11): 81-89(in Chinese). [14] 杨存丰, 李敬明, 田勇, 等. 工业CT在增强硬质聚氨酯泡沫塑料无损检测中的应用[J]. CT理论与应用研究, 2009, 18(3): 66-71.YANG Cunfeng, LI Jingming, TIAN Yong, et al. Applications of industrial CT in reinforced rigid polyurethane foam non-destructive testing[J]. Computerized Tomopraphy Theory and Applications, 2009, 18(3): 66-71(in Chinese). [15] 万玉红, 董形影, 吴育衡, 等. 太赫兹时域光谱技术在涂层检测中的研究进展[J]. 测控技术, 2023, 42(6): 22-35.WAN Yuhong, DONG Xingying, WU Yuheng, et al. Research progress of terahertz time-domain spectroscopy technology in coating detection[J]. Journal Measurement & Control Technology, 2023, 42(6): 22-35(in Chinese). [16] POUDEL A, CHU J. Air-coupled ultrasonic testing of carbon-carbon composite aircraft brake disks[J]. Materials Evaluation, 2013, 71(8): 987-994 [17] LIVINGS R, DAVAL V, BARNARD D. Air-coupled ultrasonic resonance imaging of hexagonal SiC and alumina tiles[J]. Journal of Nondestructive Evaluation, 2017, 36: 15. doi: 10.1007/s10921-017-0399-3 [18] 陈正林, 肖任贤, 王兴国, 等. 氮化硅陶瓷的空气耦合超声纵波传播特性研究[J]. 陶瓷学报, 2015, 36(4): 405-409.CHEN Zhenglin, XIAO Renxian, WANG Xingguo et al. The propagation characteristics of Si3N4 ceramics based on the air-coupled ultrasonic testing[J]. Journal of Ceramics, 2015, 36(4): 405-409(in Chinese). [19] 吴君豪, 何双起, 罗明, 等. 空气耦合超声探头声场及其对检测的影响[J]. 宇航材料工艺, 2018, 48(2): 73-77.WU Junhao, HE Shuangqi, LUO Ming, et al. Acoustic field of air-coupled ultrasonic probe and its dffect on detection[J]. Aerospace Materials & Technology, 2018, 48(2): 73-77(in Chinese). [20] 肖轲迪, 高晨家, 陈博, 等. 铝管与泡沫层胶接结构脱黏缺陷的空气耦合超声检测[J]. 无损检测, 2024, 46(2): 6-9.XIAO Kedi, GAO Chenjia, CHEN Bo, et al. Air-coupled ultrasonic testing for debond defects of aluminum pipe and foam layer bonding material[J]. Nondestructive Testing, 2024, 46(2): 6-9. [21] CHIMENTI D. Review of air-coupled ultrasonic materials characterization[J]. Ultrasonics, 2014, 54(7): 1804-1816. doi: 10.1016/j.ultras.2014.02.006 [22] 刘旭, 吴俊伟, 何勇, 等. 基于空耦换能器的碳纤维增强环氧树脂编织复合材料激光超声检测技术[J]. 复合材料学报, 2021, 38(9): 2822-2831.LIU Xu, WU Junwei, HE Yong, et al. Laser ultrasonic testing technology for carbon fiber reinforced resin braided composites based on air-coupled transducer[J]. Acta Materiae Compositae Sinica, 2021, 38(9): 2822-2831(in Chinese). [23] 常俊杰, 曾雪峰, 万陶磊, 等. 空气耦合超声金属/非金属粘结缺陷检测[J]. 宇航材料工艺, 2020, 50(6): 91-97.CHANG Junjie, ZENG Xuefeng, WAN Taolei, et al. Air-coupled ultrasonic metal/non-metal bond defect detection[J]. Aerospace Materials & Technology, 2020, 50(6): 91-97(in Chinese). [24] 檀桢, 王明泉, 刘康驰, 等. 蜂窝夹芯结构脱粘的空气耦合超声检测技术研究[J]. 压电与声光, 2021, 43(6): 799-804.TAN Zhen, WANG Mingquan, LIU Kangchi, et al. Research on air-coupling ultrasonic testing technology for debonding of honeycomb sandwich structure[J]. Piezoelectrics & Acoustooptics, 2021, 43(6): 799-804(in Chinese). [25] 董方旭, 凡丽梅, 赵付宝, 等. 空气耦合超声检测技术在复合材料检测中的应用[J]. 无损探伤, 2022, 46(1): 10-13.DONG Fangxu, FAN Limei, ZHAO Fubao, et al. Application of air coupled ultrasonic testing technology in composite testing[J]. NDT, 2022, 46(1): 10-13(in Chinese). [26] 高铁成, 远桂民, 王昊. 电容式微机械超声换能器的设计与仿真[J]. 天津工业大学学报, 2021, 40(4): 84-88.GAO Tiecheng, YUAN Guimin, WANG Hao. Design and simulation of air-coupled CMUT[J]. Journal of Tiangong University, 2021, 40(4): 84-88(in Chinese). [27] 陈博, 袁生平, 金珂, 等. 显微CT技术在航天材料中的应用[J]. 宇航材料工艺, 2021, 51(2): 87-91.CHEN Bo, YUAN Shengping, JIN Ke, et al. Applications of micro-CT in aerospace material detection[J]. Aerospace Materials & Technology, 2021, 51(2): 87-91(in Chinese). [28] 国防科学技术工业委员会. 纤维增强复合材料无损检验方法 第1部分 超声波检验: GJB1038.1A-2004[S]. 北京: 国防科工委军标出版发行部, 2004.Commission of Science, Technology and Industry for National Defense. Non-destructive inspecting methods for fiber reinforced composite Part 1: Ultrasonic testing: GJB1038.1A-2004[S]. Beijing: National Defense Science and Industry Commission Military Standard Publication and Issuance Department, 2004(in Chinese). -

点击查看大图

点击查看大图

计量

- 文章访问数: 106

- HTML全文浏览量: 54

- 被引次数: 0

下载:

下载: