Effects of the adhesive layer and prestress on the flexural behavior of damaged steel beams strengthened with CFRP plates

-

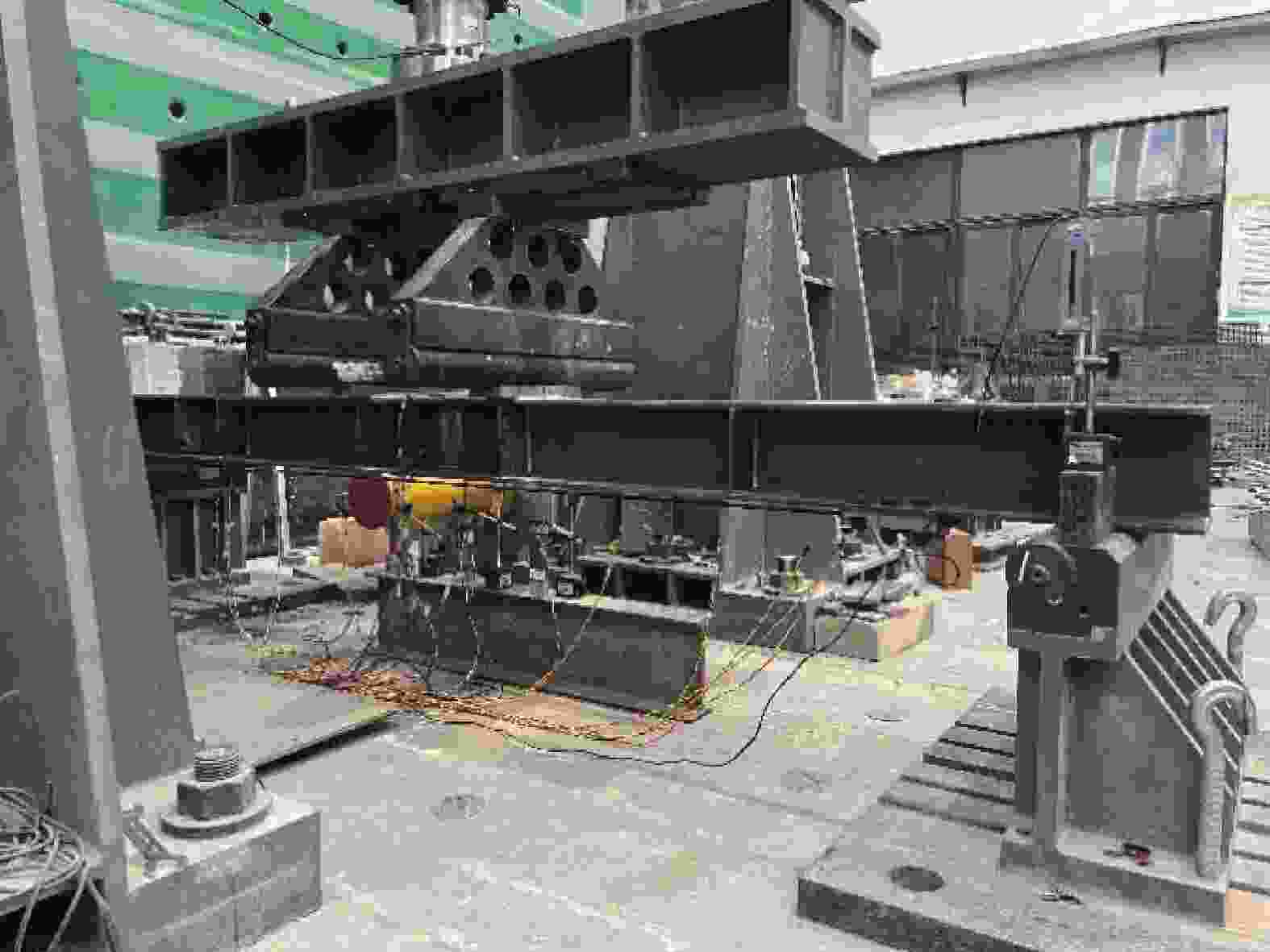

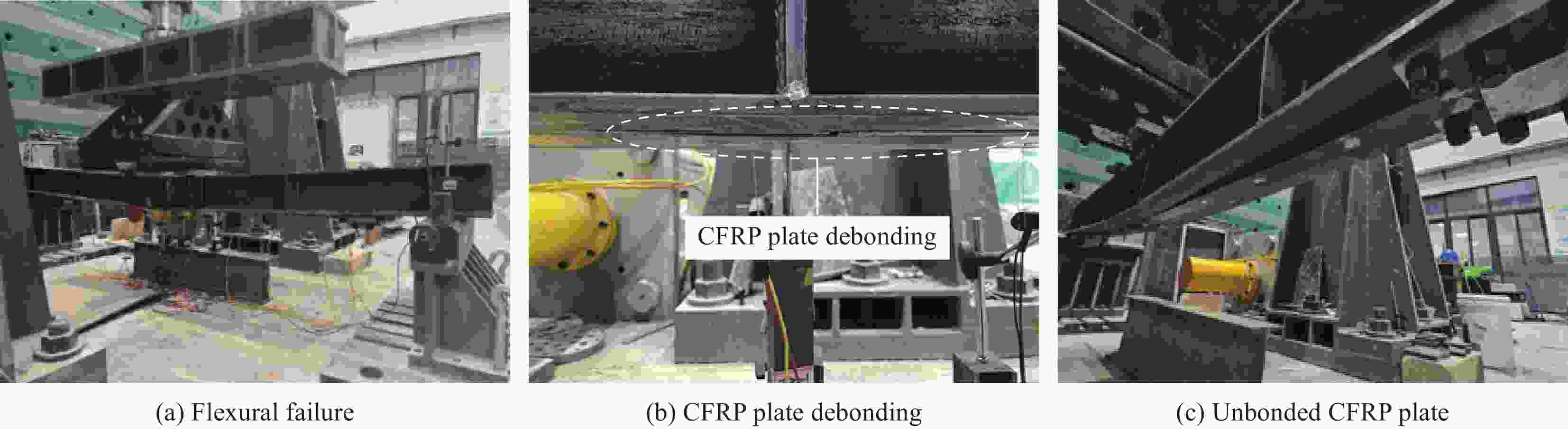

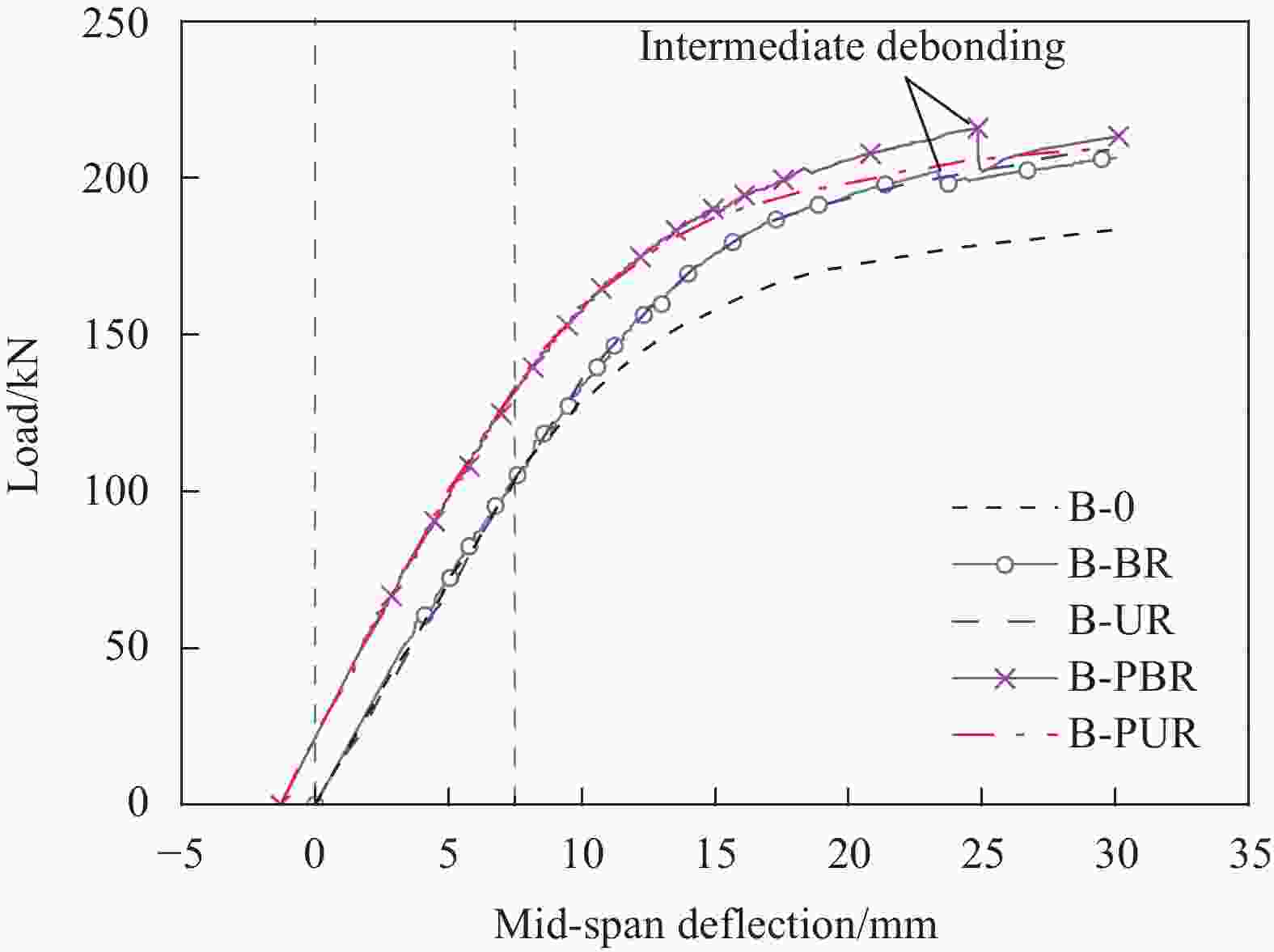

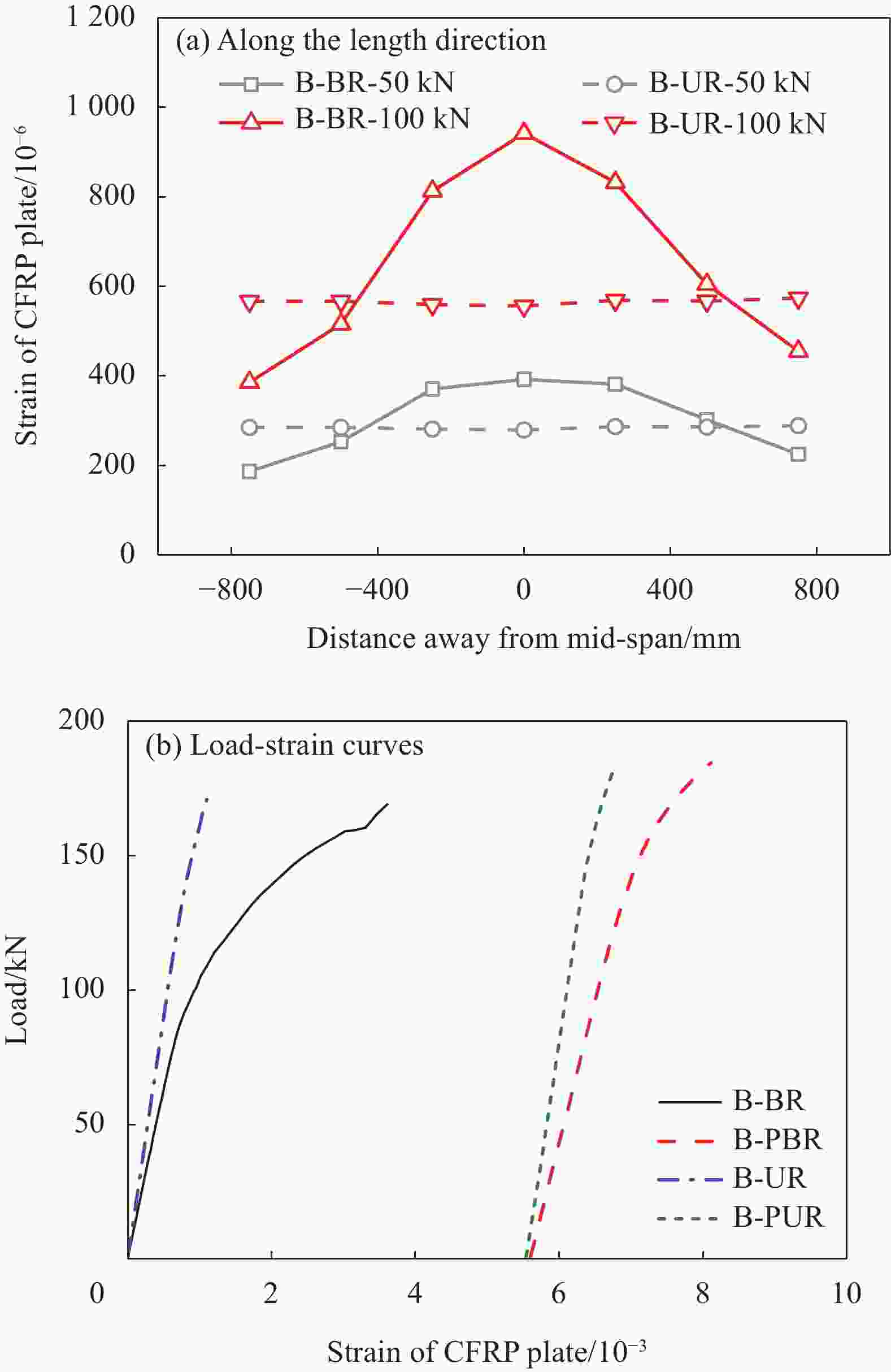

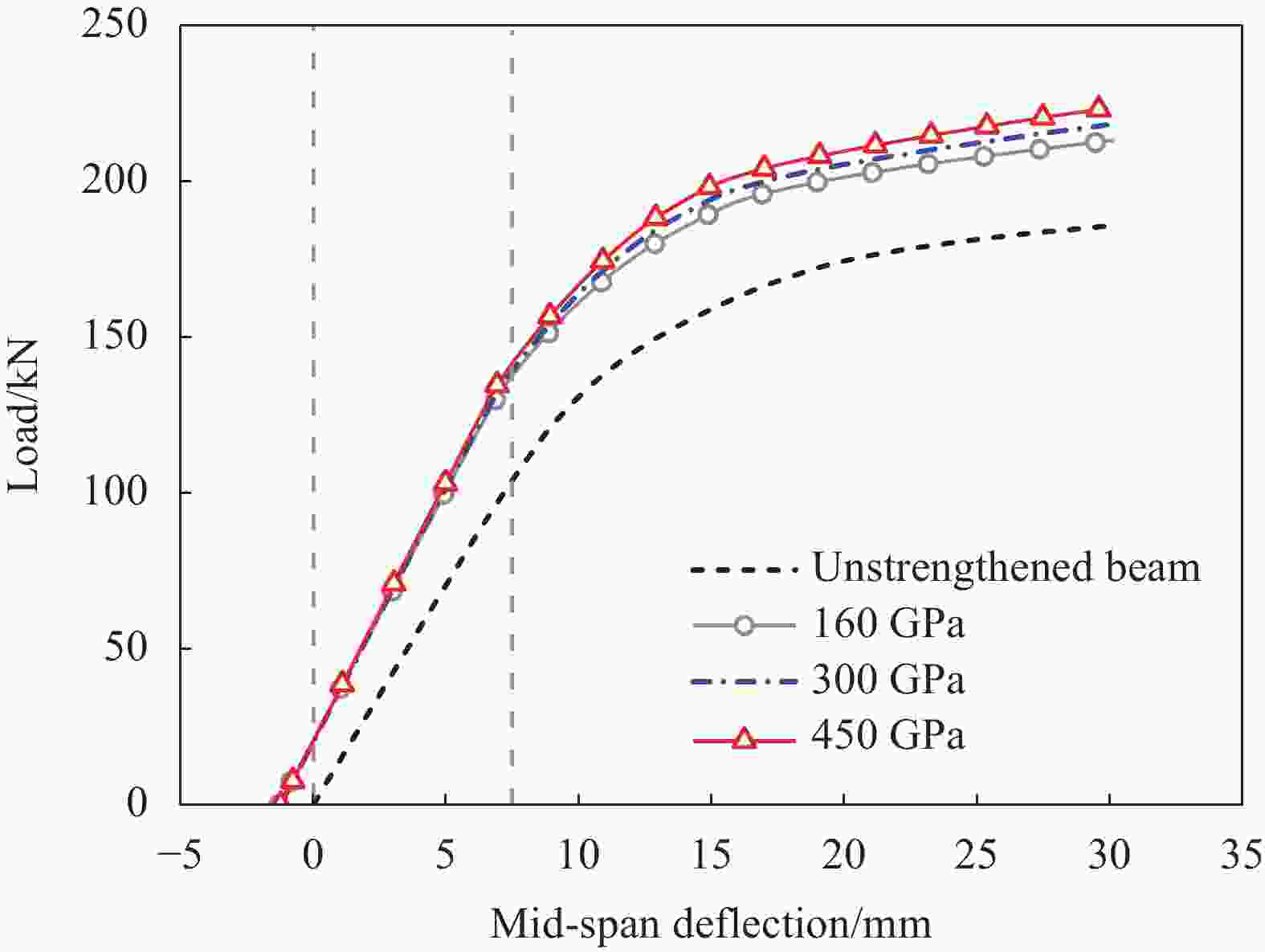

摘要: 为了对比粘结层和预应力对碳纤维增强聚合物复合材料(CFRP)板加固损伤钢梁抗弯性能的影响,进行了5根H型损伤钢梁的抗弯试验,分析了特征荷载、荷载-挠度曲线、CFRP板应变及其强度利用率的变化。试验结果表明:有粘结和无粘结CFRP板具有相近的加固效果,特征荷载差值小于2%;非预应力CFRP板在正常使用阶段的加固效果很小,而预应力CFRP板加固钢梁的特征荷载比非预应力CFRP板提高了近30%。平截面假定适用于有粘结CFRP板-钢梁复合截面,而不适用于无粘结CFRP板-钢梁复合截面。相比于非预应力CFRP板,对CFRP板施加预应力可以显著提高CFRP板的强度利用率。建立的有限元模型可以较好地预测试件的抗弯性能,增加CFRP板的预应力、厚度和弹性模量可以提高损伤钢梁的抗弯加固效果。Abstract: In order to investigate the effects of the adhesive layer and prestress on the flexural behavior of damaged steel beams strengthened with carbon fiber reinforced polymer (CFRP) plates, five damaged H-steel beams were tested under flexure. The characteristic load, load-deflection curve, CFRP plate strain and its strength utilization were analyzed. Test results show that the unbonded CFRP plate has a similar strengthening efficiency to the bonded CFRP plate, with a difference of less than 2% in the characteristic loads. The non-prestressed CFRP plate provides only a very small strengthening efficiency under the normal service state. However, the characteristic loads of steel beams strengthened with the prestressed CFRP plate can be significantly increased by about 30% compared with the non-prestressed CFRP plate. The plane section assumption is satisfied in the bonded CFRP plate-steel beam composite section while it is not satisfied in the unbonded CFRP plate-steel beam composite section. Compared with the non-prestressed CFRP plate, the strength utilization of the CFRP plate can be obviously increased when a prestress is applied in the CFRP plate. The developed finite element model can predict the flexural behavior of the specimens with good accuracy. The increase in the prestress, thickness and elastic modulus of the CFRP plate can increase the flexural strengthening efficiency of damaged steel beams.

-

Key words:

- CFRP plate /

- bonded strengthening /

- unbonded strengthening /

- prestressing /

- steel beam /

- flexural behavior

-

表 1 材料的主要力学性能

Table 1. Main mechanical properties of materials

Material type Elasticity modulus/GPa Yielding stress/MPa Tensile strength/MPa Elongation/% Q235 B steel 207.0 271 429.0 15.78 CFRP plate 163.0 - 2516.0 1.54 Adhesive 4.5 - 49.2 1.64 Note: CFRP—Carbon fiber reinforced polymer. 表 2 CFRP板加固损伤钢梁试件的加固参数

Table 2. Strengthening parameters of damaged steel beam strengthened with the CFRP plate specimens

Specimen Sectional area of CFRP plate/mm×mm Strengthening method Designed prestress/MPa B-0 - Unstrengthening - B-BR 50×2 Bonded strengthening 0 B-UR 50×2 Unbonded strengthening 0 B-PBR 50×2 Bonded strengthening 850 B-PUR 50×2 Unbonded strengthening 850 Notes: In the specimen, the first letter B represents the beam; The number 0 represents the unstrengthening, the letters BR, UR, PBR and PUR represent bonded CFRP plate strengthening, unbonded CFRP plate strengthening, prestressed bonded CFRP plate strengthening, and prestressed unbonded CFRP plate strengthening, respectively. 表 3 CFRP板加固损伤钢梁特征荷载比较

Table 3. Comparisons of characteristic loads of damaged steel beams strengthened with CFRP plates

Specimen P7.5/kN α7.5/% Py/kN αy/% B-0 102.5 - 105.8 - B-BR 104.6 2.0 124.6 17.8 B-UR 103.4 0.9 126.5 19.6 B-PBR 131.9 28.7 157.9 49.2 B-PUR 133.5 30.2 158.5 49.8 Notes: P7.5—Load when the mid-span deflection is 7.5 mm; Py—Yielding load; α7.5 and αy—Ratios between the P7.5 and Py of the strengthened beams and those of the unstrengthened beam, respectively. 表 4 CFRP板应变及强度利用率比较

Table 4. Comparisons of CFRP plate strain and strength utilization

Specimen ε0/10−6 εp7.5/10−6 εp7.5/εu/% εpy/10−6 εpy/εu/% B-BR 0 855 5.6 1287 8.4 B-UR 0 581 3.8 723 4.7 B-PBR 5605 6877 44.7 7276 47.2 B-PUR 5542 6300 40.9 6485 42.1 Notes: ε0—Initial tensioning strain of the CFRP plate; εp7.5—Strain of the CFRP plate at P7.5; εpy—Strain of the CFRP plate at Py; εu—Ultimate strain of the CFRP plate. 表 5 CFRP板加固损伤钢梁有限元与试验结果的对比

Table 5. Comparisons of finite element and test results of damaged steel beams strengthened with CFRP plates

Specimen P7.5 Py Test/kN Finite element/kN Ratio Test/kN Finite element/kN Ratio B-0 102.5 104.4 1.02 105.8 106.1 1.00 B-BR 104.6 107.4 1.03 124.6 131.1 1.05 B-UR 103.4 104.2 1.01 126.5 127.8 1.01 B-PBR 131.9 138.3 1.05 157.9 164.5 1.04 B-PUR 133.5 137.6 1.03 158.5 163.4 1.03 -

[1] 王海涛, 吴刚, 张磊. FRP修复开裂钢板的应力强度因子影响因素分析[J]. 河海大学学报(自然科学版), 2020, 48(5):440-445.WANG Haitao, WU Gang, ZHANG Lei. Influencing factor analysis of stress intensity factor for FRP-strengthened cracked steel plates[J]. Journal of Hohai University (Natural Sciences),2020,48(5):440-445(in Chinese). [2] 柏佳文, 魏洋, 张依睿, 等. 新型碳纤维增强复合材料-钢复合管海水海砂混凝土圆柱轴压试验[J]. 复合材料学报, 2021, 38(9):3076-3085.BAI Jiawen, WEI Yang, ZHANG Yirui, et al. Axial compression behavior of new seawater and sea sand concrete filled circular carbon fiber reinforced polymer-steel composite tube columns[J]. Acta Materiae Compositae Sinica,2021,38(9):3076-3085(in Chinese). [3] 陈卓异, 彭彦泽, 李传习, 等. 高温下双搭接钢-CFRP板胶粘界面力学性能试验[J]. 复合材料学报, 2021, 38(2):449-460.CHEN Zhuoyi, PENG Yanze, LI Chuanxi, et al. Experimental study for the adhesive interface mechanical properties of double lapped steel-CFRP plate at high temperature[J]. Acta Materiae Compositae Sinica,2021,38(2):449-460(in Chinese). [4] WANG H T, LIU S S, LIU Q L, et al. Influences of the joint and epoxy adhesive type on the CFRP-steel interfacial behavior[J]. Journal of Building Engineering,2021,43:103167. doi: 10.1016/j.jobe.2021.103167 [5] 王海涛, 吴刚, 吴智深. FRP布置方式对含裂纹钢板加固后的疲劳性能影响分析[J]. 土木工程学报, 2015, 48(1):56-63.WANG Haitao, WU Gang, WU Zhishen. Study on the effect of FRP configurations on the fatigue behavior of strengthened steel plate with an initial crack[J]. China Civil Engineering Journal,2015,48(1):56-63(in Chinese). [6] YOUSEFI O, NARMASHIRI K, GHAEMDOUST M R. Structural behaviors of notched steel beams strengthened using CFRP strips[J]. Steel and Composite Structures,2017,2(1):35-43. [7] SWEEDAN A M I, ALHADID M M A, EL-SAWY K M. Experimental study of the flexural response of steel beams strengthened with anchored hybrid composites[J]. Thin-Walled Structures,2016,99:1-11. doi: 10.1016/j.tws.2015.10.026 [8] TENG J G, YU T, FERNANDO D. Strengthening of steel structures with fiber-reinforced polymer composites[J]. Journal of Constructional Steel Research,2012,78:131-143. doi: 10.1016/j.jcsr.2012.06.011 [9] GALAL K, SEIF ELDIN H M, TIRCA L. Flexural perfor-mance of steel girders retrofitted using CFRP materials[J]. Journal of Composites for Construction,2011,16(3):265-276. [10] LI J, WANG Y, DENG J, et al. Experimental study on the flexural behaviour of notched steel beams strengthened by prestressed CFRP plate with an end plate anchorage system[J]. Engineering Structures,2018,171:29-39. doi: 10.1016/j.engstruct.2018.05.042 [11] SIWOWSKI T W, SIWOWSKA P. Experimental study on CFRP-strengthened steel beams[J]. Composites Part B: Engineering,2018,149:12-21. doi: 10.1016/j.compositesb.2018.04.060 [12] 卢亦焱, 张学朋, 吴涛, 等. 预应力碳纤维布加固钢梁的试验研究[J]. 应用基础与工程科学学报, 2009, 17(5):707-715.LU Yiyan, ZHANG Xuepeng, WU Tao, et al. Experimental research on steel beams strengthened by prestressed CFRP[J]. Journal of Basic Science and Engineering,2009,17(5):707-715(in Chinese). [13] GHAFOORI E, MOTAVALLI M. Flexural and interfacial behavior of metallic beams strengthened by prestressed bonded plates[J]. Composite Structures,2013,101:22-34. doi: 10.1016/j.compstruct.2013.01.021 [14] 万世成, 黄侨, 关健. 预应力CFRP板加固钢-混凝土组合梁受弯性能试验[J]. 哈尔滨工业大学学报, 2019, 51(3):86-93.WAN Shicheng, HUANG Qiao, GUAN Jian. Test on flexural behavior of steel-concrete composite beams strengthened with prestressed carbon fiber reinforced polymer plates[J]. Journal of Harbin Institute of Technology,2019,51(3):86-93(in Chinese). [15] GHAFOORI E, MOTAVALLI M. Innovative CFRP-prestressing system for strengthening metallic structures[J]. Jour-nal of Composites for Construction,2015,19(6):1-14. [16] HOSSEINI A, GHAFOORI E, MOTAVALLI M, et al. Flat prestressed unbonded retrofit system for strengthening of existing metallic I—Girders[J]. Composites Part B: Engi-neering,2018,155:156-172. doi: 10.1016/j.compositesb.2018.08.026 [17] 叶华文, 李新舜, 帅淳, 等. 无粘结预应力CFRP板加固受损钢梁疲劳试验研究[J]. 西南交通大学学报, 2019, 54(1):129-136.YE Huawen, LI Xinshun, SHUAI Chun, et al. Fatigue experimental analysis of damaged steel beams strengthened with prestressed unbonded CFRP plates[J]. Journal of South-west Jiaotong University,2019,54(1):129-136(in Chinese). [18] 中国国家标准化管理委员会. 金属材料拉伸试验: 第一部分: 室温试验方法: GB/T 228.1—2010[S]. 北京: 中国标准出版社, 2010.Standardization Administration of China. Tensile test of metallic materials: Part 1: Test method at room tempera-ture: GB/T 228.1—2010[S]. Beijing: Standards Press of China, 2010(in Chinese). [19] 中国国家标准化管理委员会. 定向纤维增强聚合物基复合材料拉伸性能试验方法: GB/T 3354—2014[S]. 北京: 中国标准出版社, 2014.Standardization Administration of China. Test method for tensile properties of directional fiber reinforced polymer matrix composites: GB/T 3354—2014[S]. Beijing: Standards Press of China, 2014(in Chinese). [20] 中华人民共和国工业和信息化部. 纤维增强复合材料加固修复钢结构技术规程: YB/T 4558—2016[S]. 北京: 冶金工业出版社, 2017.Ministry of Industry and Information Technology of the People’s Republic of China. Technical specificaition for strengthening steel structures with fiber reinforced polymer: YB/T 4558—2016[S]. Beijing: Metallurgical Industry Press, 2017(in Chinese). [21] WANG H T, WU G. Bond-slip models for CFRP plates externally bonded to steel substrates[J]. Composite Structures,2018,184:1204-1214. doi: 10.1016/j.compstruct.2017.10.033 [22] 中华人民共和国住房和城乡建设部. 钢结构设计标准: GB/T 50017—2017[S]. 北京: 中国建筑工业出版社, 2017.Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard for design of steel structures: GB 50017—2017[S]. Beijing: China Architecture & Building Press, 2017(in Chinese). [23] 庞育阳. 极端服役环境下CFRP-钢界面粘结性能研究[D]. 南京: 东南大学, 2019.PANG Yuyang. Study on the bond behavior of CFRP-steel interfaces under extreme service environment[D]. Nanjing: Southeast University, 2019(in Chinese). -

下载:

下载: