Effect of thermo-oxidative aging on the mechanical properties of multi-layered biaxial weft knitted fabric reinforced composites

-

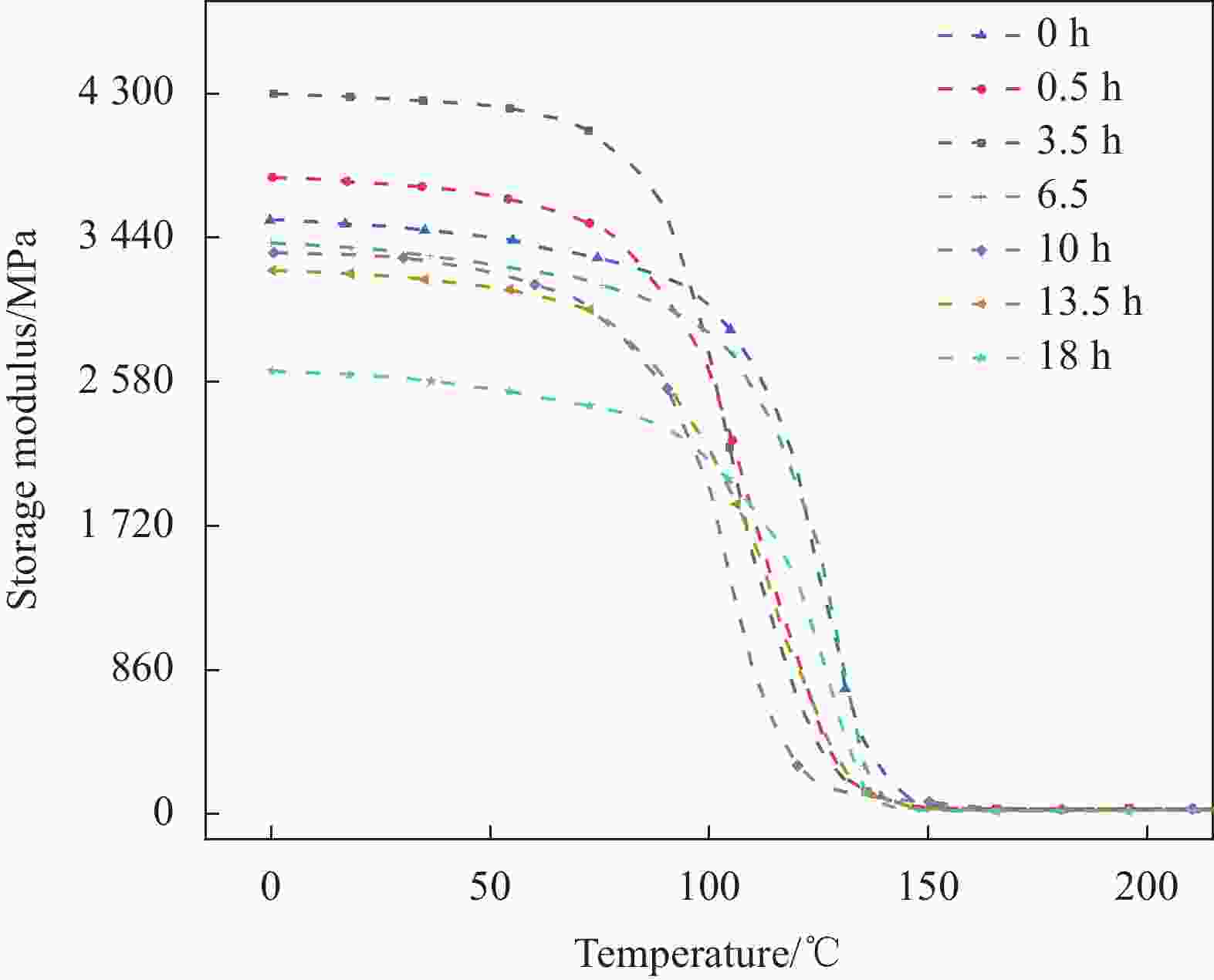

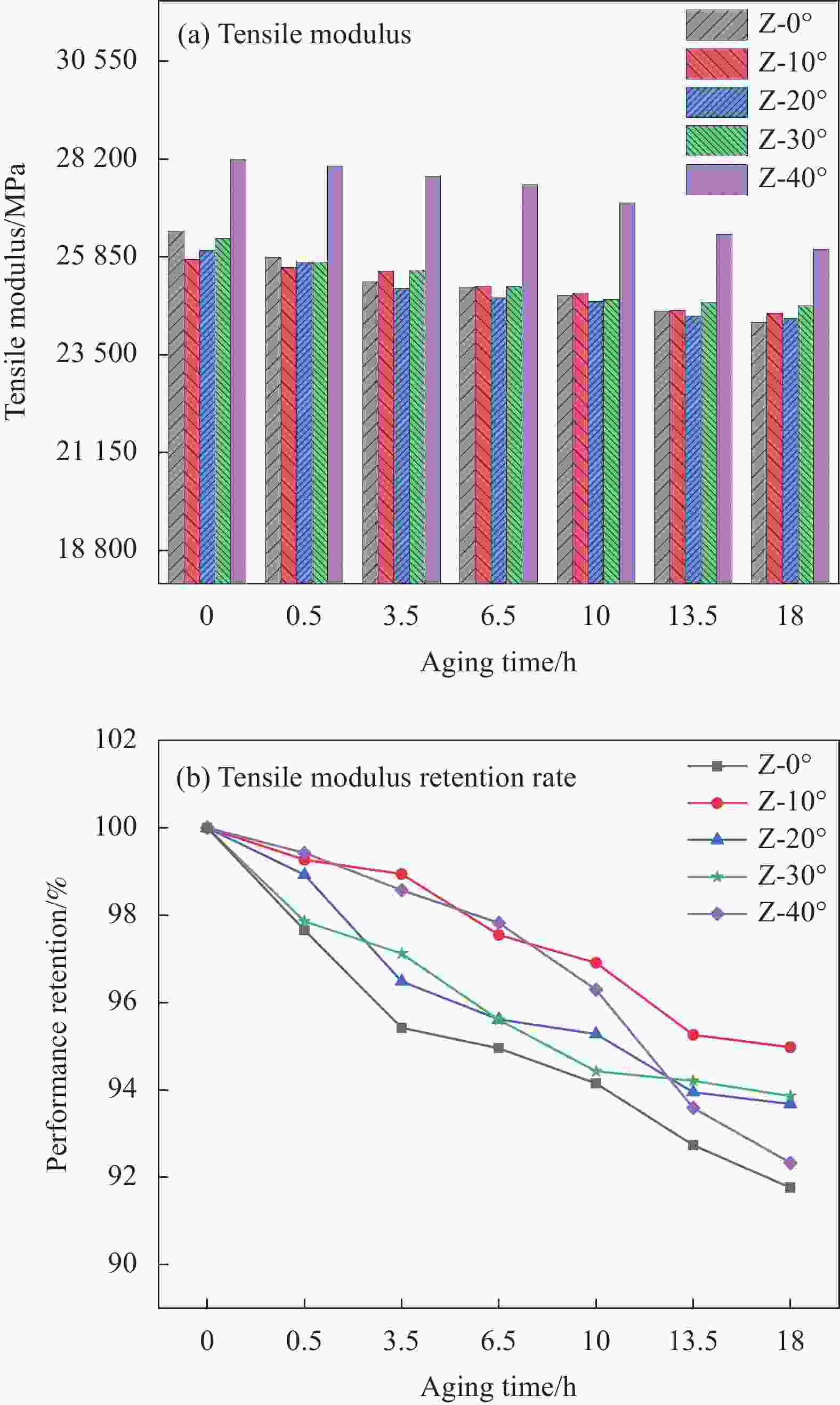

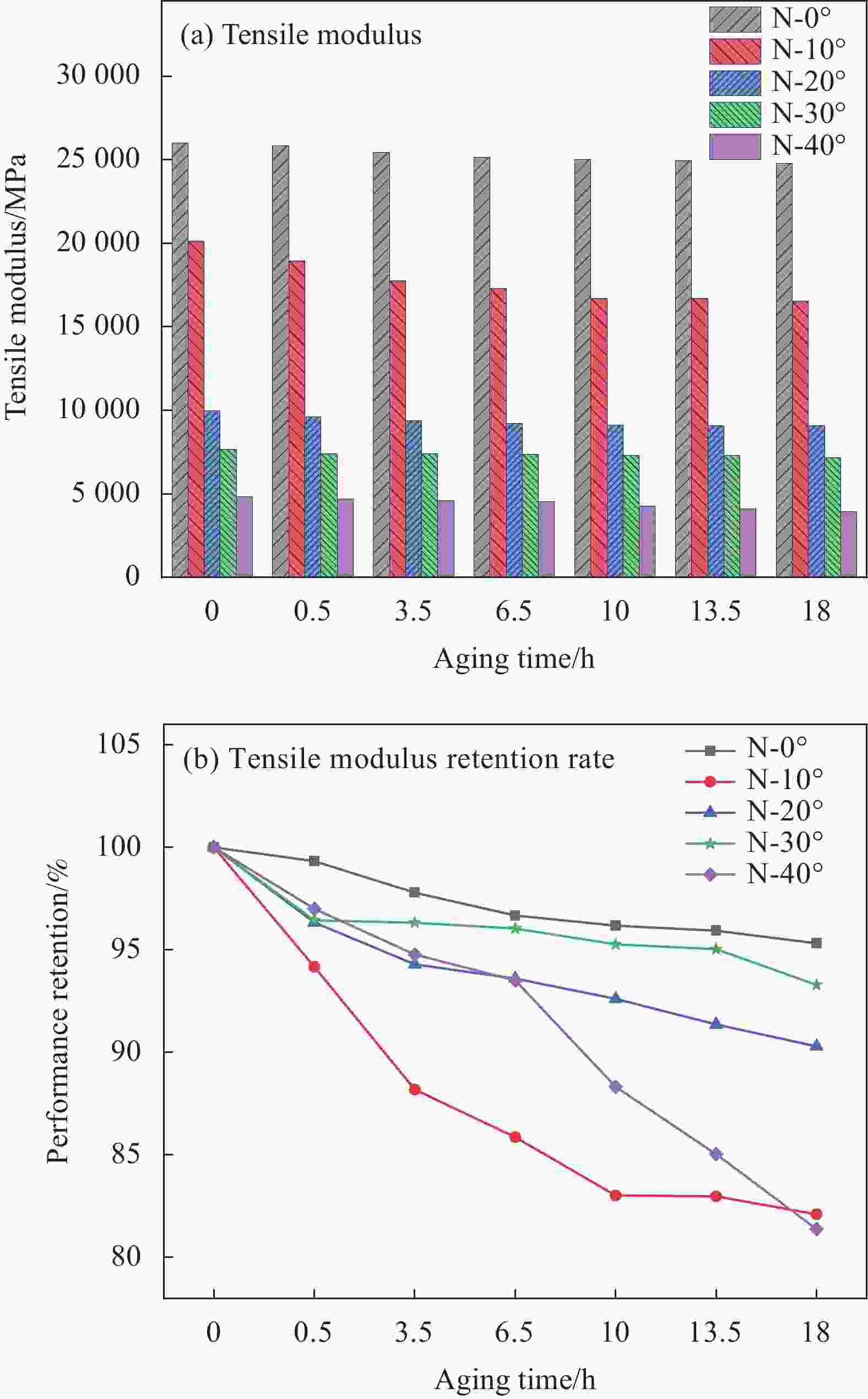

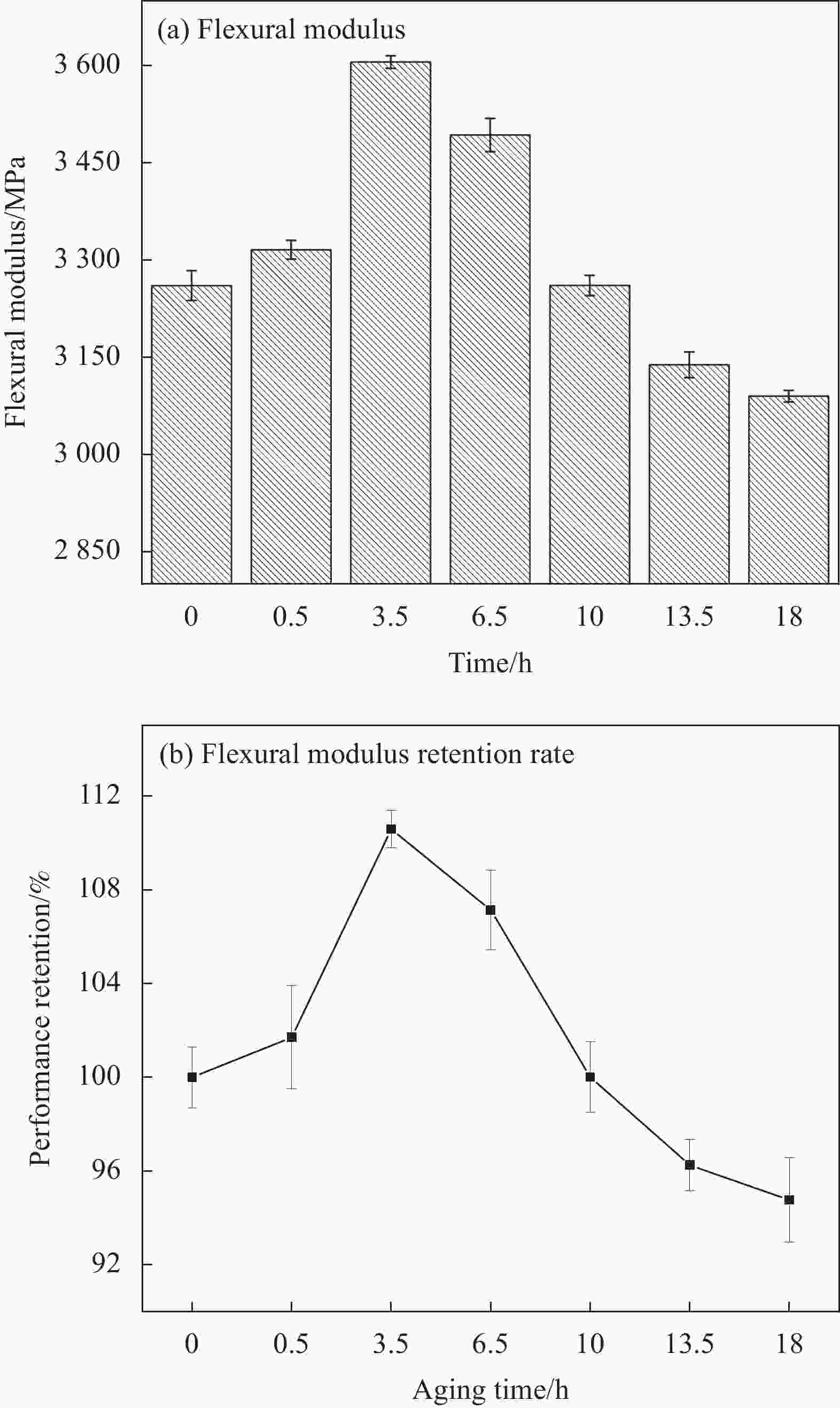

摘要: 通过改变预制体结构衬纱取向的方法制备了几种含不同剪切角的纬编双轴向多层衬纱(Multilayered biaxial weft knitted,MBWK)织物增强复合材料。基于Arrhenius模型和Ozawa法设计了热氧老化试验,采用力学性能测试、DSC、FTIR和DMA测试对老化前后的试样热-物理性能进行了表征。实验结果表明:预制体的纱线剪切角不同,其复合材料受热氧老化后力学性能的保留率也显著不同,由于乙烯基酯树脂在热氧老化环境中会发生后固化现象,因此复合材料的弯曲模量在老化过程中呈现先增加后下降的趋势,而拉伸性能则受到增强体结构的影响,纤维/基体界面的结合力退化使拉伸模量在老化过程中持续下降;随着老化时间的延长,树脂的固化度逐渐增加,玻璃化转变温度Tg逐渐升高,储能模量峰值在老化初期由于分子链交联上升,老化后期分子链断裂占据主导作用致使峰值逐渐下降。

-

关键词:

- 纬编双轴向多层衬纱织物增强复合材料 /

- 芳纶纤维 /

- 热氧老化 /

- 力学性能 /

- 剪切角

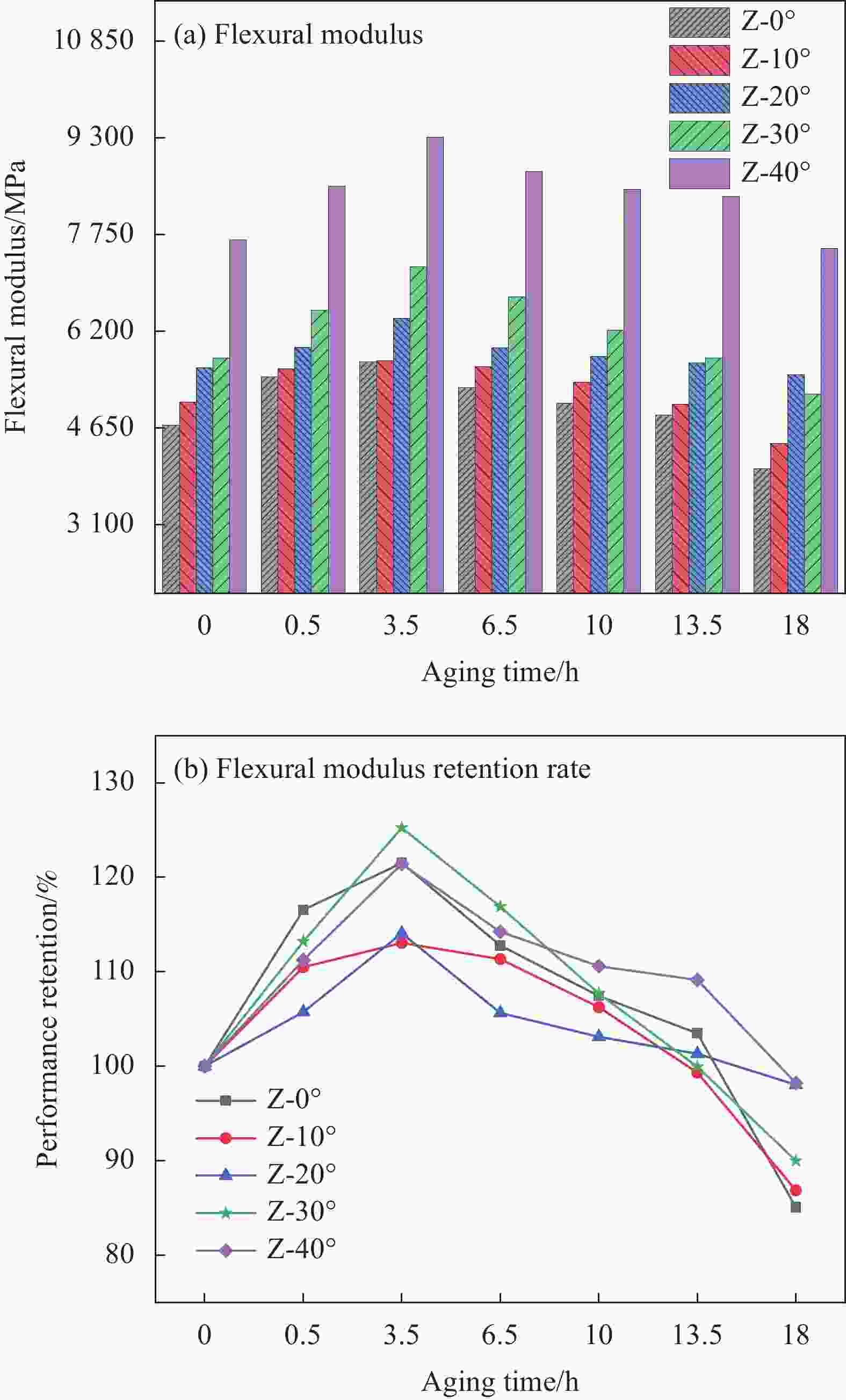

Abstract: Several multilayered biaxial weft knitted (MBWK) fabric reinforced composites with different shear angles were prepared by changing the orientation of preform inserting yarns. The thermo-oxidative aging test was designed based on Arrhenius model and Ozawa method. The thermal and physical properties of the samples before and after aging were characterized by mechanical properties, DSC, FTIR and DMA tests. The experimental results show that: With the change of yarns’ shearing angle, the composite mechanical properties retention rate after thermo-oxidative aging is also significantly different, because the post curing will occur for the vinyl ester resin in the thermo-oxidative aging environment. Therefore, the bending modulus of the composite materials in the aging process presents downward trend after increased first, and the tensile properties are affected by the reinforcement structure. The degradation of adhesion strength at fiber/matrix interface makes the tensile modulus decrease continuously during the aging process. With the aging time prolongation, the curing degree of resin increases gradually, and the glass transition temperature Tg increases gradually. The peak value of energy storage modulus increases at the initial stage of aging due to molecular chain crosslinking, while decreasing of the peak value is caused by molecular chain fracture at the later stage of aging. -

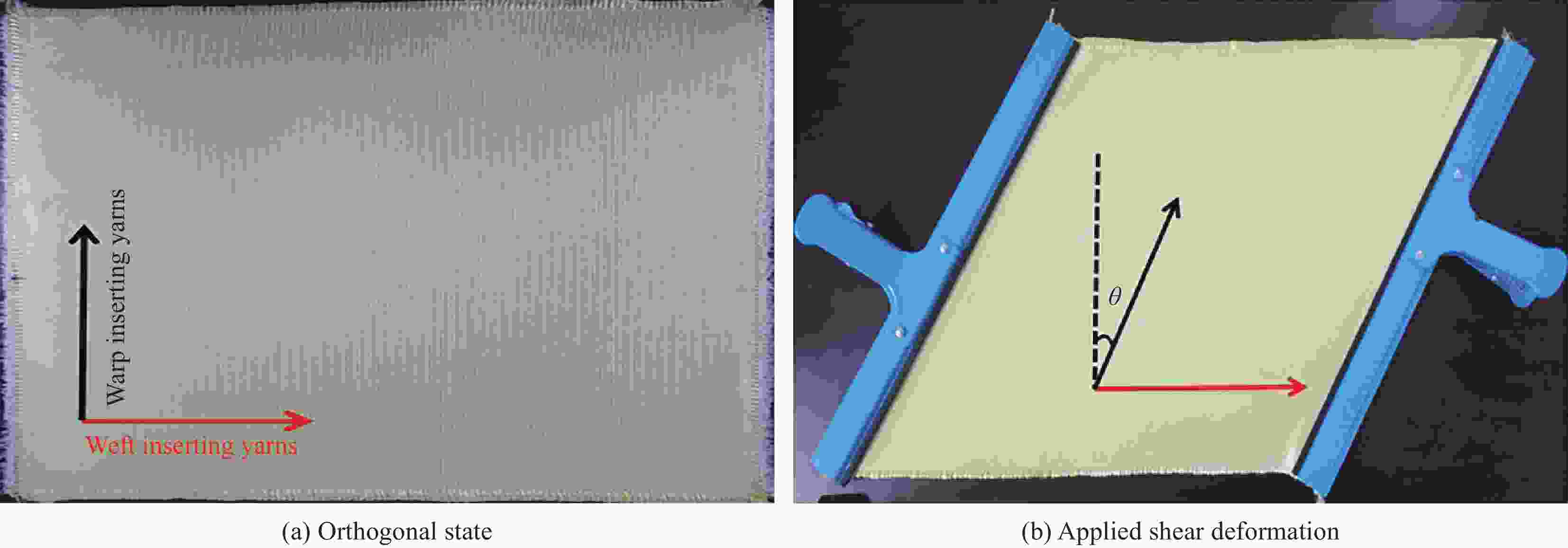

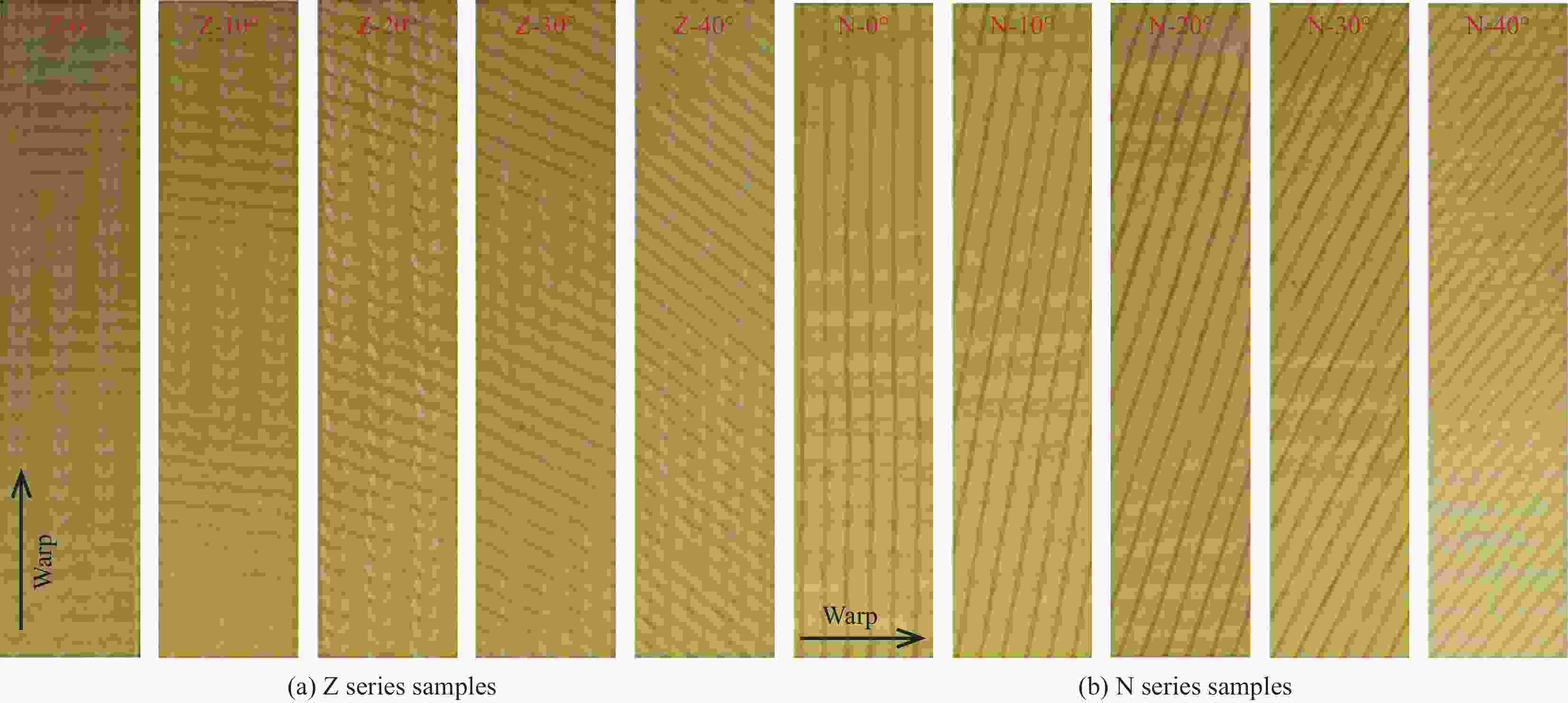

图 4 不同剪切角的MBWK复合材料试样

Figure 4. MBWK composite samples with different shear angles

Z-0°, Z-10°, Z-20°, Z-30°, Z-40°—Specimens with shear angles of 0°, 10°, 20°, 30°, 40° liner warp orientation in the same direction as the length of specimen; N-0°, N-10°, N-20°, N-30°, N-40°—Sample with shear angles of 0°, 10°, 20°, 30°, 40° liner warp orientation perpendicular to the sample length direction

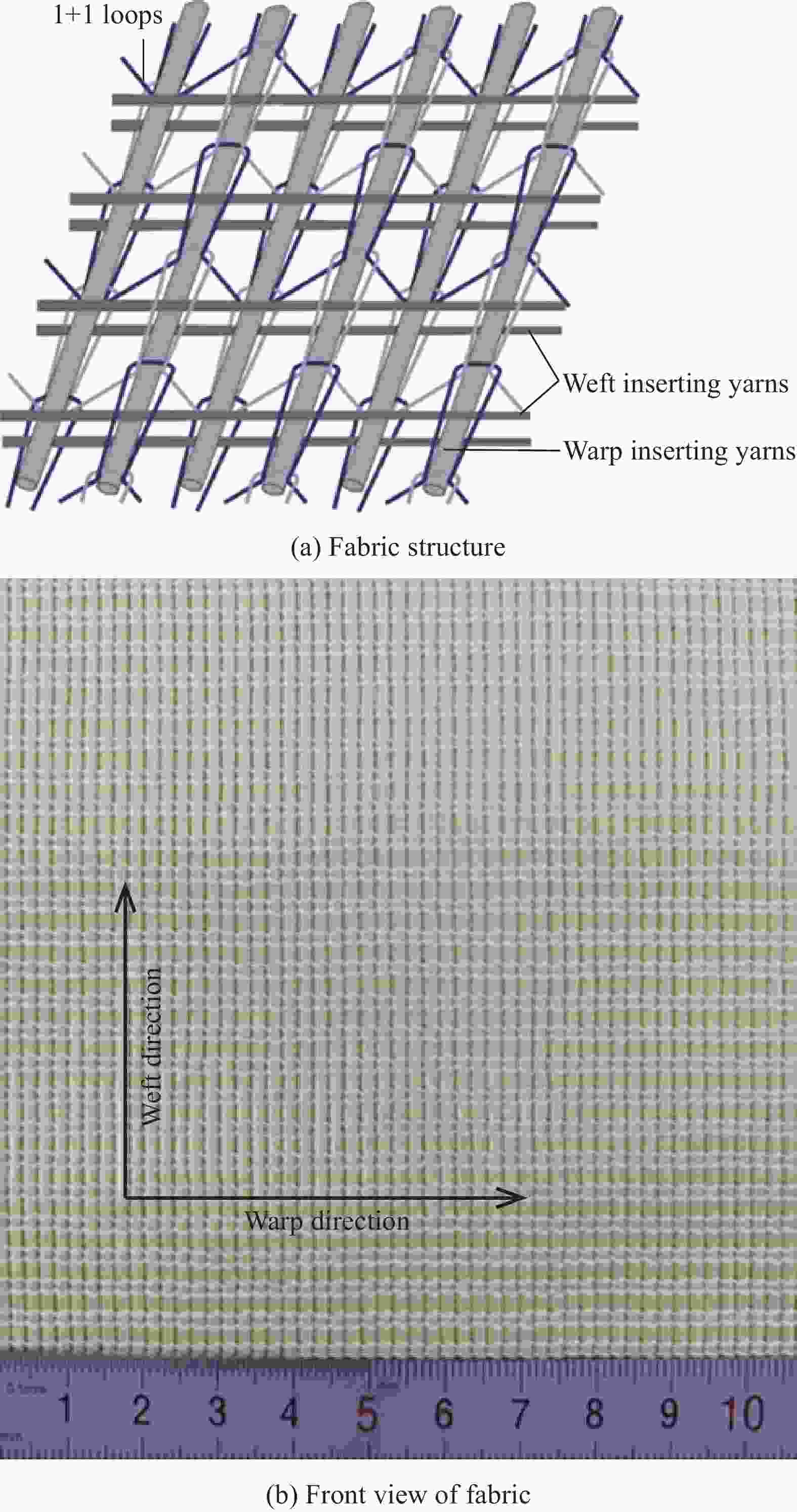

表 1 MBWK织物参数

Table 1. MBWK fabric parameters

Type Parameter Weft inserting yarns Kevlar-49 (474 g·km−1 (158×3)) Warp inserting yarns Kevlar-49 (948 g·km−1 (158×6)) Stitching yarns Polyester (16.7 g·km−1 (8.33×2)) Layer structure 90°/0°/90° Warp density/(tows·cm−1) 30 Weft density(tows·cm−1) 30 Thickness/mm 1.5 表 2 RIPOXY R-806 乙烯基酯树脂(VER)成品性能指标

Table 2. RIPOXY R-806 vinyl ester resin (VER) finished product performance indicators

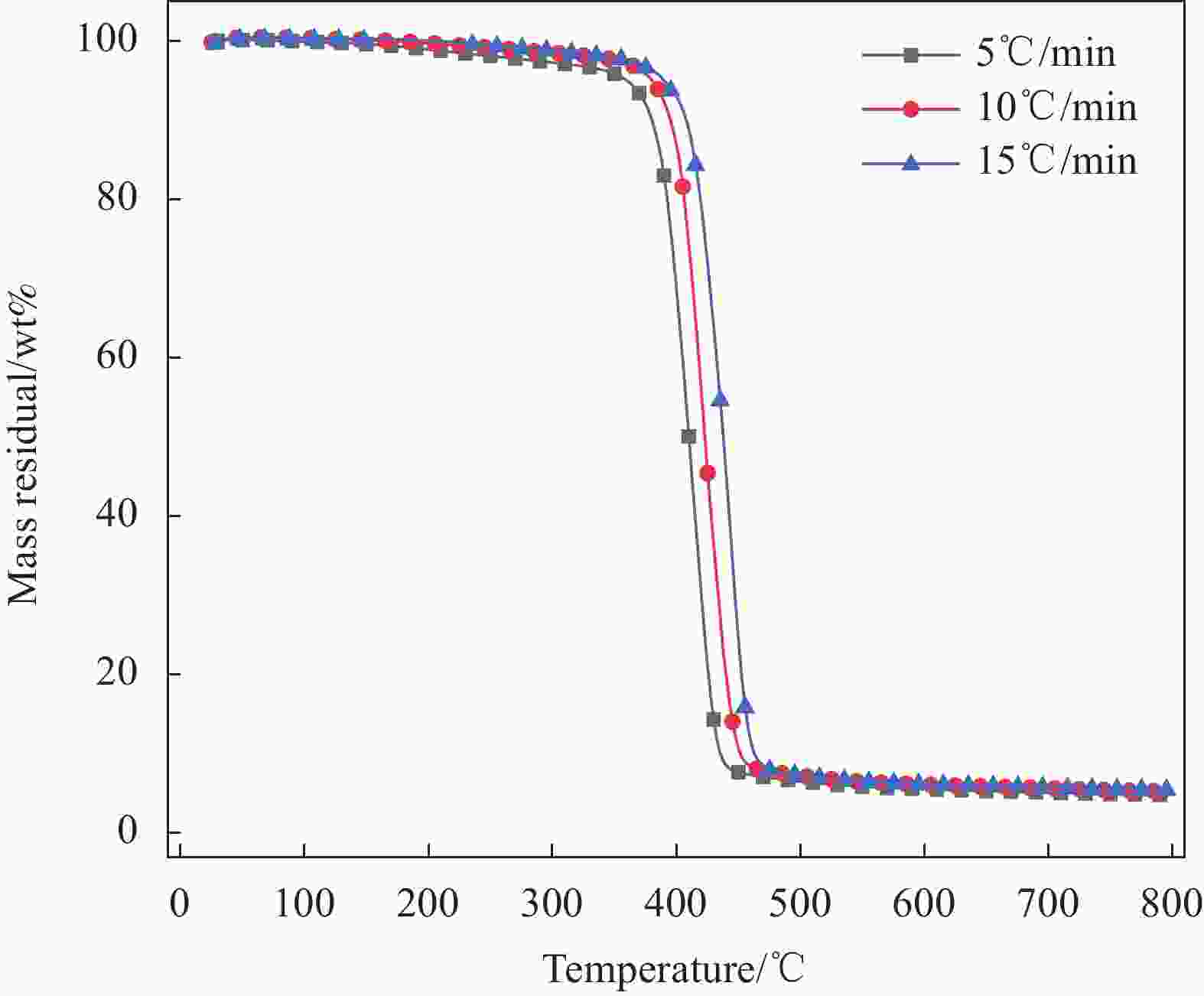

Parameter Value Tensile strength/MPa 69-89 Tensile modulus/GPa 2.9-3.3 Tensile elongation at break/% 3.2-4.0 Flexural strength/MPa 120-150 Flexural modulus/GPa 2.9-3.3 Distortion temperature/℃ 108-118 Barcol hardness 40 Volume shrinkage/% 7.5-8.5 表 3 VER浇铸体活化能计算数据

Table 3. Calculation data of activation energy of the VER casting body

Mass loss ratio Slope Activation energy/eV Average value/eV Deviation/% 0.90 −4315.24 0.8315 0.8029 3.56 0.85 −4238.74 0.7941 0.80 0.80 −4227.99 0.7832 1.97 表 4 MBWK复合材料和VER浇铸体的热氧老化实验时间与自然老化时间对应关系

Table 4. Relationship between the thermo-oxidative aging experimental time and the natural aging time of the MBWK composite and VER casting body

Temperature/

℃Thermo-oxidative

aging/hNatural aging

time/Month100 0.5 1 3.5 7 6.5 13 10 20 13.5 27 18 36 表 5 VER液态体系DSC测试结果

Table 5. DSC test results of VER liquid system

Heating rate/(℃·min−1) Initial temperature/℃ Peak temperature/℃ Final temperature/℃ Total enthalpy of reaction/(J·g−1) 2 83.6 88.9 93.0 266.1 5 89.3 98.6 113.6 235.1 10 125.1 138.4 155.5 279.5 12 149.9 164.1 173.9 249.9 15 155.5 172.8 185.3 256.6 表 6 VER浇铸体热氧老化后DSC测试结果

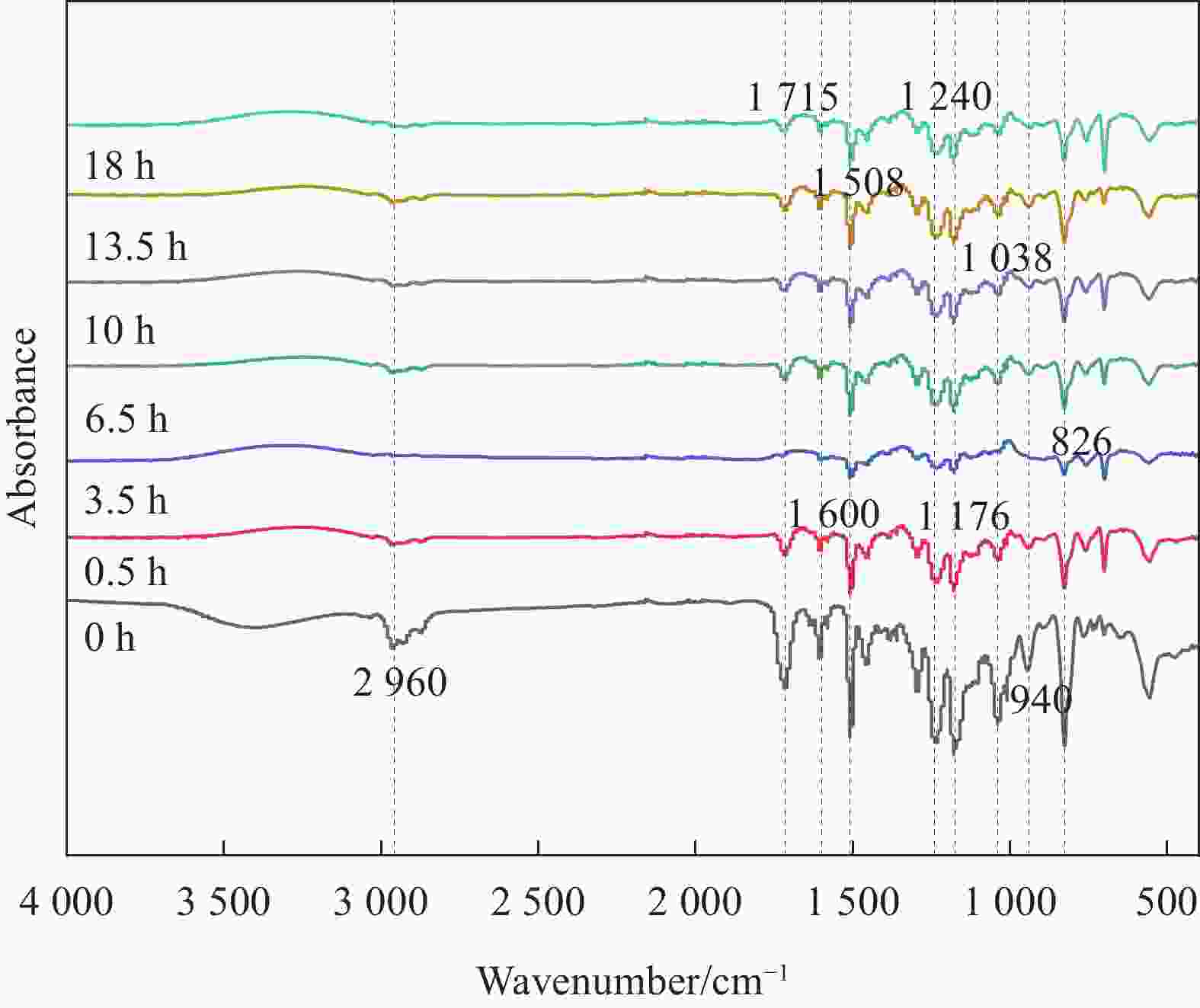

Table 6. DSC test results of the VER casting body after thermo-oxidative aging

Aging time/h Heating rate/

(℃·min−1)Initial

temperature/℃Peak

temperature/℃Final

temperature/℃Heat enthalpy/

(J·g−1)Degree of

cure/%0 5 61.4 80.5 132.6 73.270 71.54 0.5 5 76.5 93.9 131.3 37.770 85.33 3.5 5 128.9 135.3 148.7 11.460 95.55 6.5 5 129.7 137.1 150.8 11.400 95.57 10 5 111.4 120.3 134.9 11.310 95.60 13.5 5 119.4 137.6 146.4 4.078 98.42 18 5 123.1 136.1 150.3 3.635 98.60 -

[1] GUPTA K B N V, SEN B, HIREMATH M M, et al. Enhanced creep resistance of GFRP composites through interpenetrating polymer network[J]. International Journal of Mechanical Sciences,2021,212:106728. doi: 10.1016/j.ijmecsci.2021.106728 [2] QIWEN Q, DENVID L. Defect detection of FRP-bonded civil structures under vehicle-induced airborne noise[J]. Mechanical Systems and Signal Processing,2021,146:106992. doi: 10.1016/j.ymssp.2020.106992 [3] KARBHARI V M, XIAN G, HONG S. Effect of thermal exposure on carbon fiber reinforced composites used in civil infrastructure rehabilitation[J]. Composites Part A: Applied Science and Manufacturing,2021,149:106570. doi: 10.1016/j.compositesa.2021.106570 [4] MERSCHMAN E, SALMAN A M, BASTIDAS A E, et al. Assessment of the effectiveness of wood pole repair using FRP considering the impact of climate change on decay and hurricane risk[J]. Advances in Climate Change Research,2020,11(4):332-348. doi: 10.1016/j.accre.2020.10.001 [5] PRASHANTH S, SUBBAYA K M, NITHIN K, et al. Fiber reinforced composites—A review[J]. Journal of Material Sciences & Engineering,2017,6(3):2-6. [6] LI Z, LEPECH M D. Development of a multiphysics model of synergistic effects between environmental exposure and damage in woven glass fiber reinforced polymeric composites[J]. Composite Structures,2020,258:113230. [7] FRANCESCO M, ANTONIO N. Durability of FRP rods for concrete structures[J]. Construction and Building Materials,2004,18(7):491-507. doi: 10.1016/j.conbuildmat.2004.04.012 [8] 于洋, 樊威, 薛利利, 等. 热氧老化对三维编织碳纤维-玻璃纤维/双马来酰亚胺树脂复合材料力学性能的影响[J]. 复合材料学报, 2021, 38(12):4060-4072.YU Yang, FAN Wei, XUE Lili, et al. Influence of thermo-oxidative aging on the mechanical performance of three-dimensional braided carbon fiber-glass fiber/bismaleimide composites[J]. Acta Materiae Compositae Sinica,2021,38(12):4060-4072(in Chinese). [9] WEI F, JIA L L. Rapid evaluation of thermal aging of a carbon fiber laminated epoxy composite[J]. Polymer Composites,2014,35(5):975-984. doi: 10.1002/pc.22743 [10] MLYNIEC A, KORTA J, UHL T. Structurally based constitutive model of epoxy adhesives incorporating the influence of post-curing and thermolysis[J]. Composites Part B: Engineering,2016,86:160-167. doi: 10.1016/j.compositesb.2015.09.062 [11] LEVEQUE D, SCHIEFFER A, MAVEL A. Analysis of how thermal aging affects the long-term mechanical behavior and strength of polymer-matrix composites[J]. Composites Science and Technology,2005,65(3-4):395-401. doi: 10.1016/j.compscitech.2004.09.016 [12] AUDOUIN L, LANGLOIS V, VERDU J, et al. Role of oxygen diffusion in polymer ageing: Kinetic and mechanical aspects[J]. Journal of Materials Science,1994,29(3):569-583. doi: 10.1007/BF00445968 [13] BELLENGER V, VERDU J. Oxidative skeleton breaking in epoxy–amine networks[J]. Journal of Applied Polymer Science,1985,30(1):363-374. doi: 10.1002/app.1985.070300132 [14] POCHIRAJU K V, TANDON G P, SCHOEPPNER G A. Evolution of stress and deformations in high-temperature polymer matrix composites during thermo-oxidative aging[J]. Mechanics of Time-Dependent Materials,2008,12(1):45-68. doi: 10.1007/s11043-007-9042-5 [15] SCHOEPPNER G A, TANDON G P, RIPBERGER E R. Anisotropic oxidation and weight loss in PMR-15 composites[J]. Composites Part A: Applied Science and Manufacturing,2007,38(3):890-904. doi: 10.1016/j.compositesa.2006.07.006 [16] ROUQUIE S, LAFARIE-FRENOT M C, CINQUIN J, et al. Thermal cycling of carbon/epoxy laminates in neutral and oxidative environments[J]. Composites Science and Technology,2005,65(3-4):403-409. doi: 10.1016/j.compscitech.2004.09.007 [17] TANDON G P, POCHIRAJU K V. Heterogeneous thermo-oxidative behavior of multidirectional laminated composites[J]. Journal of Composite Materials,2011,45(4):415-435. doi: 10.1177/0021998310376109 [18] TANDON G P, RAGLAND W R. Influence of laminate lay-up on oxidation and damage growth: Isothermal aging[J]. Composites Part A: Applied Science and Manufacturing,2011,42(9):1127-1137. doi: 10.1016/j.compositesa.2011.04.018 [19] BOWLES K J, NOWAK G. Thermo-oxidative stability studies of Celion 6000/PMR-15 unidirectional composites, PMR-15, and Celion 6000 fiber[J]. Journal of Composite Materials,1988,22(10):966-985. doi: 10.1177/002199838802201005 [20] 顾杰斐, 陈普会, 孔斌, 等. 考虑制造因素的变刚度层合板的抗屈曲铺层优化设计[J]. 复合材料学报, 2018, 35(4):866-875.GU Jiefei, CHEN Puhui, KONG Bin, et al. Layup optimization for maximum buckling load of variable-stiffness laminates considering manufacturing factors[J]. Acta Materiae Compositae Sinica,2018,35(4):866-875(in Chinese). [21] 孔斌, 顾杰斐, 陈普会, 等. 变刚度复合材料结构的设计、制造与分析[J]. 复合材料学报, 2017, 34(10):2121-2133.KONG Bin, GU Jiefei, CHEN Puhui, et al. Design, manufacture and analysis of variable-stiffness composite structures[J]. Acta Materiae Compositae Sinica,2017,34(10):2121-2133(in Chinese). [22] LI X, BAI S. Sheet forming of the multi-layered biaxial weft knitted fabric reinforcement. Part I: On hemispherical surfaces[J]. Composites Part A: Applied Science and Manufacturing,2009,40(6-7):766-777. doi: 10.1016/j.compositesa.2009.03.007 [23] 项赫, 姜亚明, 齐业雄, 等. 纺织复合材料预制体成型过程无损检测技术研究进展[J]. 复合材料学报, 2021, 38(4):1029-1042.XIANG He, JIANG Yaming, QI Yexiong, et al. Research progress in nondestructive testing technologies for textile composite preform forming process[J]. Acta Materiae Compositae Sinica,2021,38(4):1029-1042(in Chinese). [24] MISHRA V, PEETERS D M J, ABDALLA M M. Stiffness and buckling analysis of variable stiffness laminates including the effect of automated fibre placement defects[J]. Composite Structures,2019,226:111233. doi: 10.1016/j.compstruct.2019.111233 [25] 中国国家标准化管理委员会. 树脂浇铸体性能试验方法: GB/T 2567—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People's Republic of China. Test methods for propertis of resin cating boby: GB/T 2567—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [26] 中国国家标准化管理委员会. 纤维增强塑料弯曲性能试验方法: GB/T 1449—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People's Republic of China. Fiber-reinforced pastic composites—Determination of flexural properties: GB/T 1449—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [27] 中国国家标准化管理委员会. 纤维增强塑料拉伸性能试验方法: GB/T 1447—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People's Republic of China. Fiber-reinforced plastics composites—Determination of tensile properties: GB/T 1447—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [28] BIANCHI O, OLIVEIRA R V B, FIORIO R, et al. Assessment of Avrami, Ozawa and Avrami-Ozawa equations for determination of EVA crosslinking kinetics from DSC measurements[J]. Polymer Testing,2008,27(6):722-729. doi: 10.1016/j.polymertesting.2008.05.003 [29] WANG S, DONG S, GAO Y, et al. Thermal ageing effects on mechanical properties and barely visible impact damage behavior of a carbon fiber reinforced bismaleimide composite[J]. Materials & Design,2017,115:213-223. doi: 10.1016/j.matdes.2016.11.062 [30] LI L, SUN X, LEE L J. Low temperature cure of vinyl ester resins[J]. Polymer Engineering & Science,1999,39(4):646-661. [31] PEREPELKIN K E, ANDREEVA I V, MESHCHERYAKOVA G P, et al. Change in the mechanical properties of para-aramid fibres in thermal aging[J]. Fibre Chemistry,2006,38(5):400-405. doi: 10.1007/s10692-006-0099-8 -

下载:

下载: