Prediction of mode II fatigue delamination propagation in fibre reinforced composites: From strain energy release rate-life (G-N) curve to Paris' law

-

摘要: 疲劳分层是复合材料最常见、最危险的失效模式之一。本文建立了II型加载条件下复合材料疲劳分层扩展的模拟方法。基于对疲劳分层扩展提出的新的物理解释:疲劳分层扩展为一系列连续发生的疲劳分层起始扩展,将疲劳损伤累积描述为层间界面断裂韧性衰减,构建了新的疲劳内聚力单元模型。针对II型加载条件下的材料层间开裂变形场的特殊性,提出了用以描述II型加载条件的层间界面疲劳损伤累积的衰减法则,确立了依据应变能释放率-寿命(G-N)曲线的材料本构参数标定方法。引入疲劳内聚力单元模型,预测了复合材料II型疲劳分层扩展行为,与疲劳分层扩展实验所得Pairs' law能够很好地吻合。本文新提出的疲劳分层模拟方法相较于已有模型的优势在于:无需追踪裂纹扩展路径,降低了模型的应用难度,提高了计算效率;模型所需材料参数标定仅依赖于实验G-N曲线,无需实验Paris' law,参数标定所需的疲劳实验数量及时间大幅减少。

-

关键词:

- 疲劳 /

- 分层 /

- 内聚力单元模型 /

- 纤维增强树脂基复合材料 /

- 有限元模拟

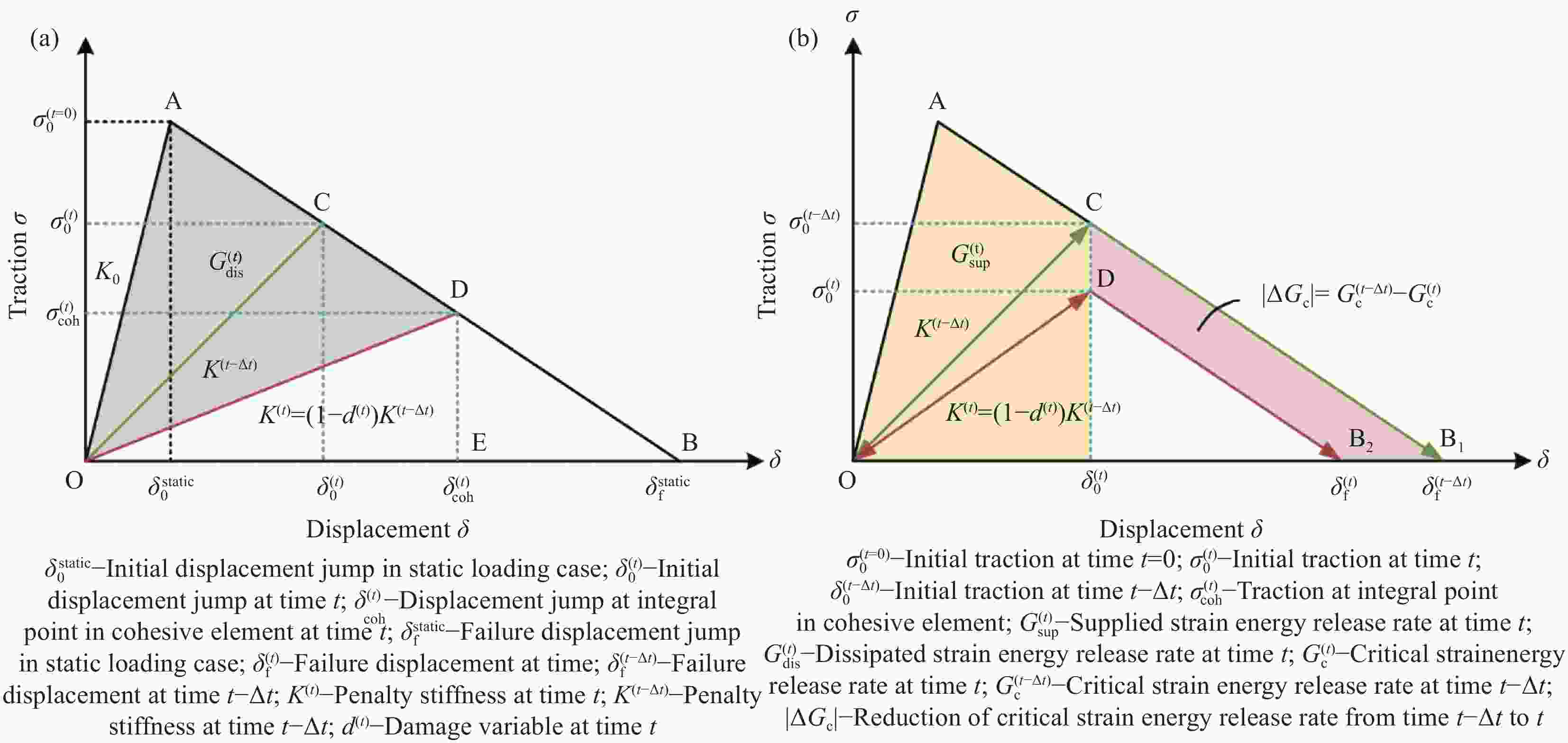

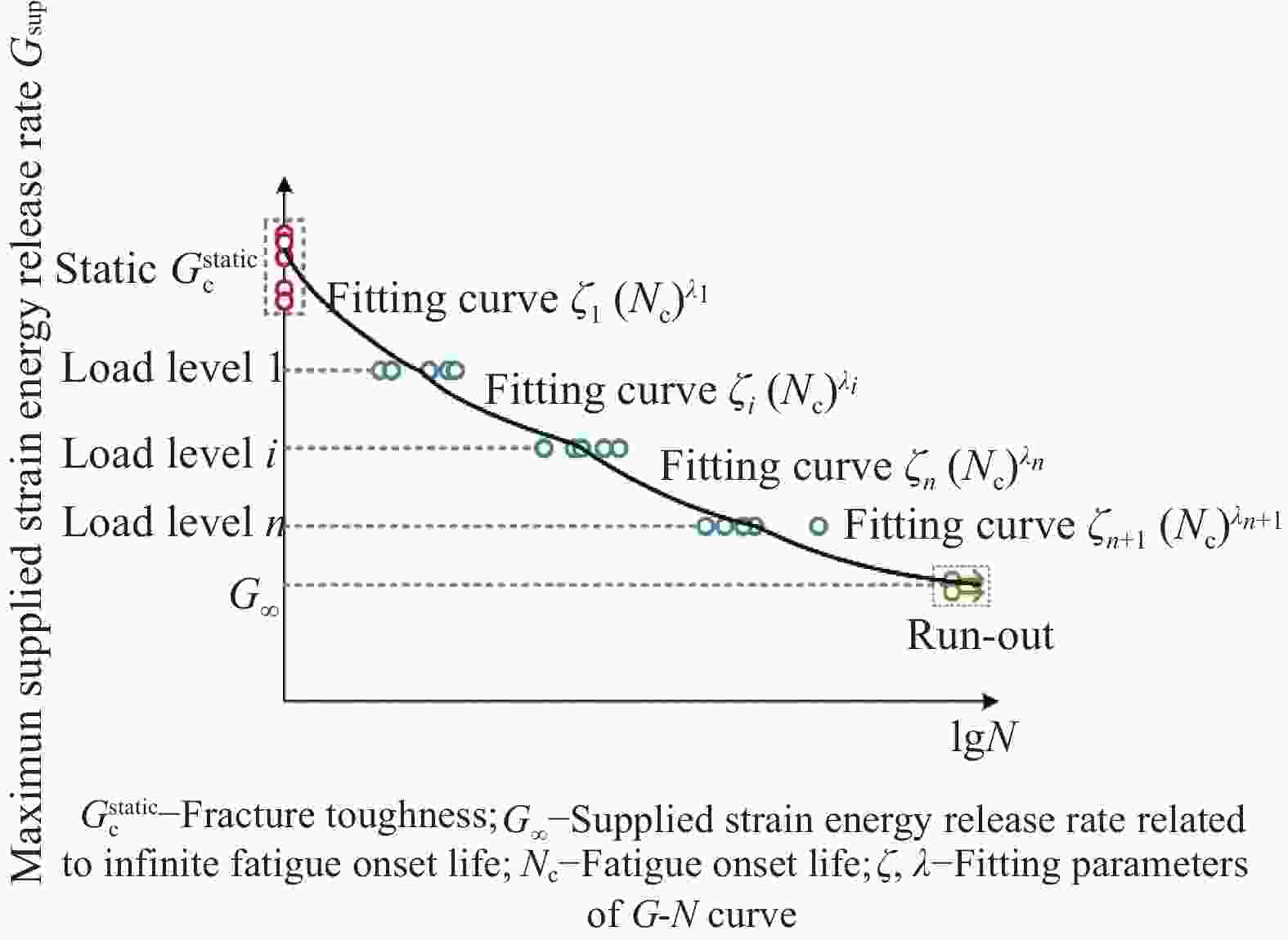

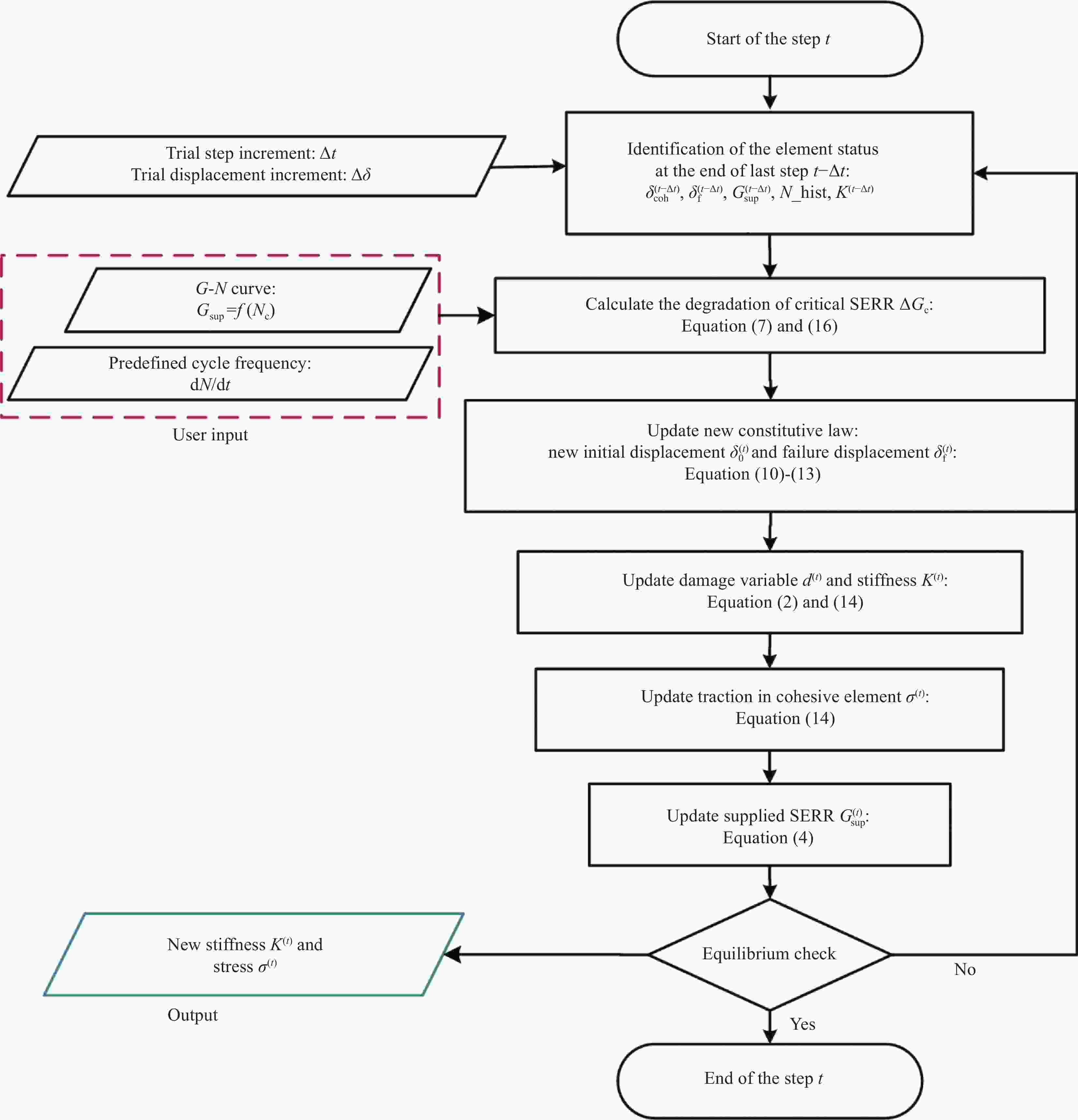

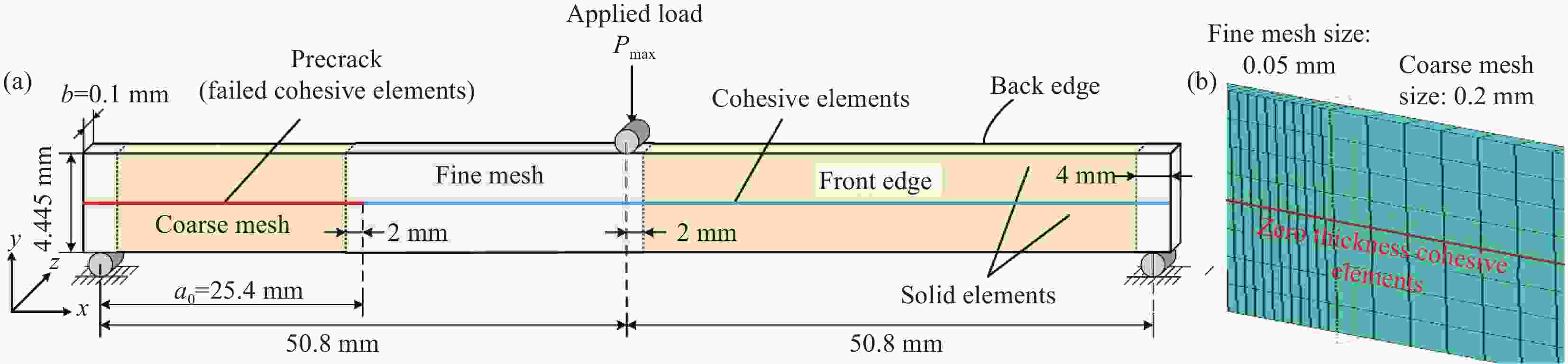

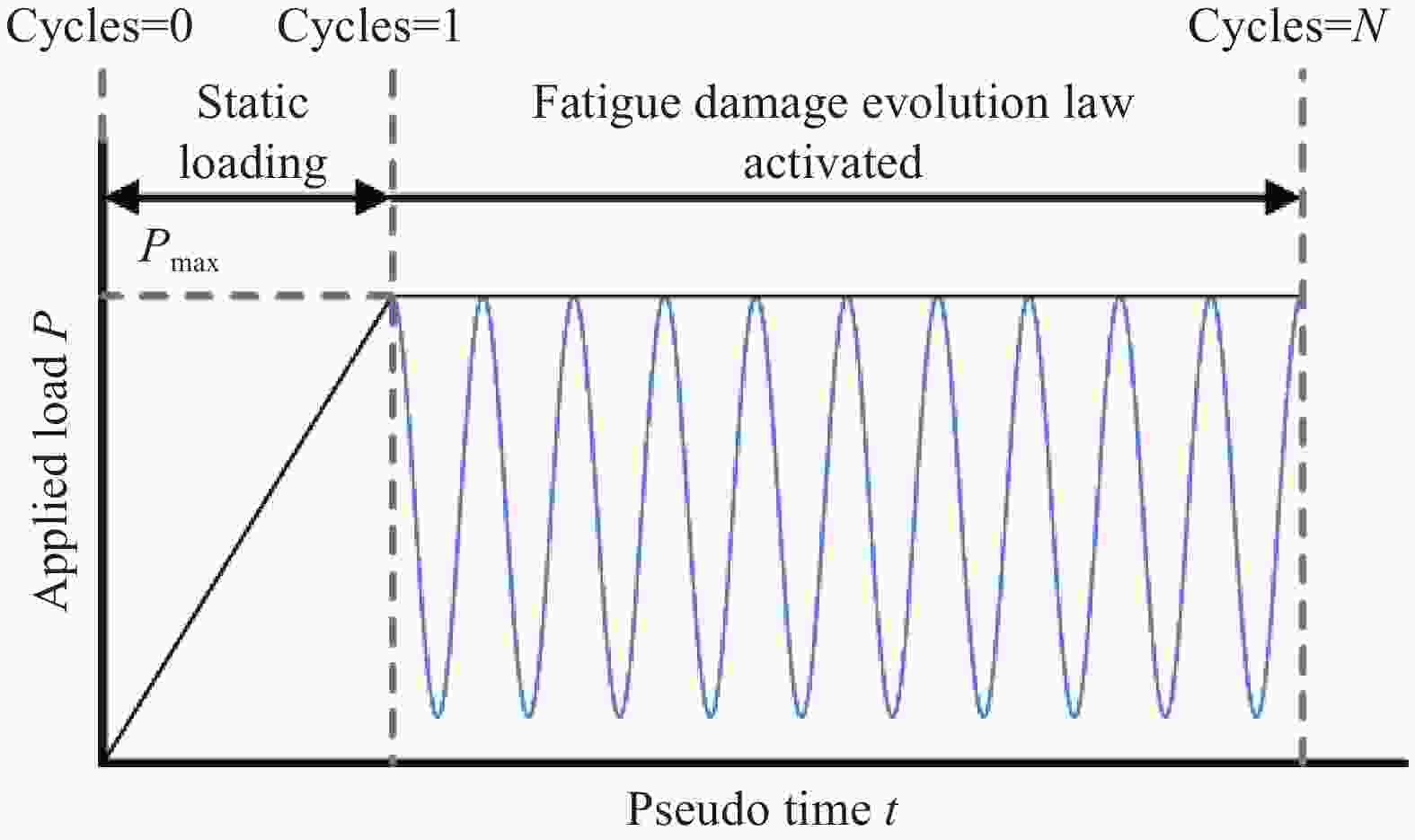

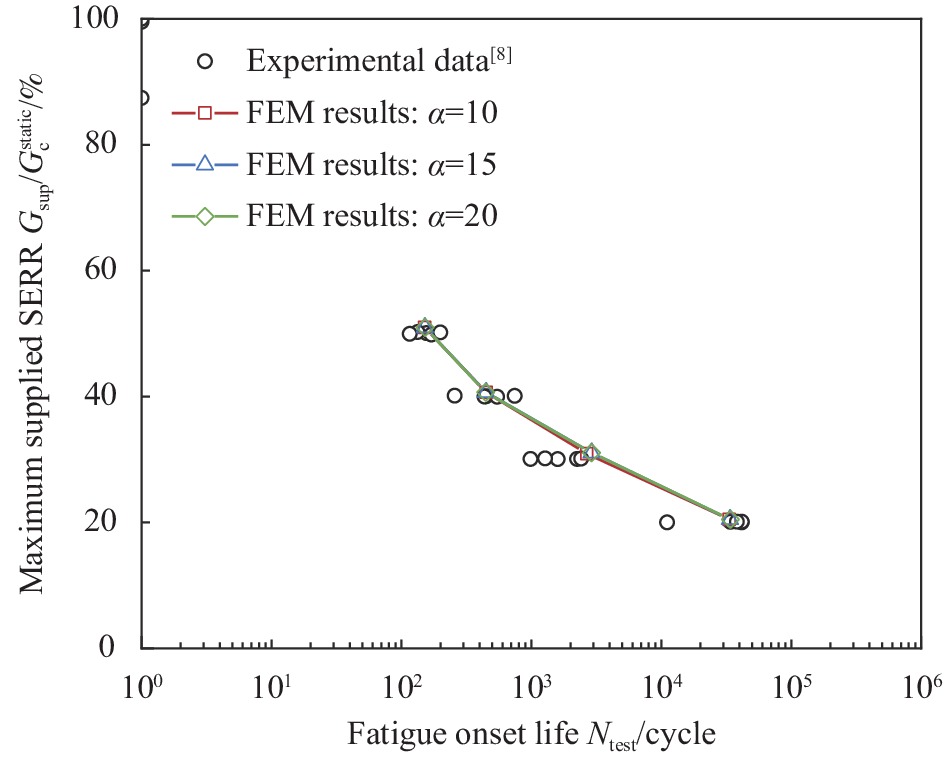

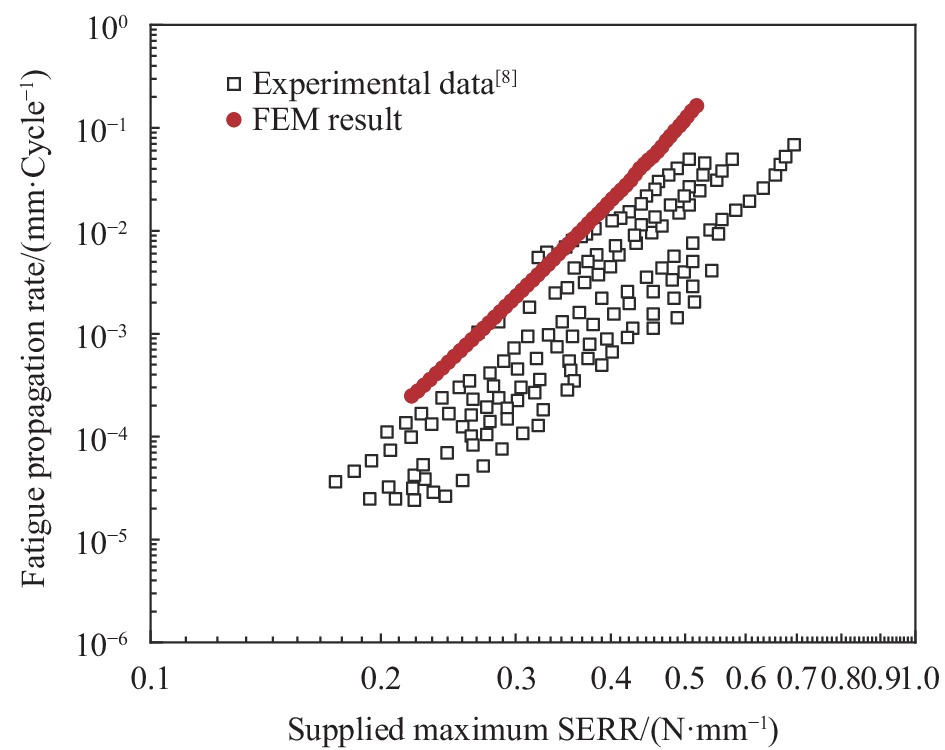

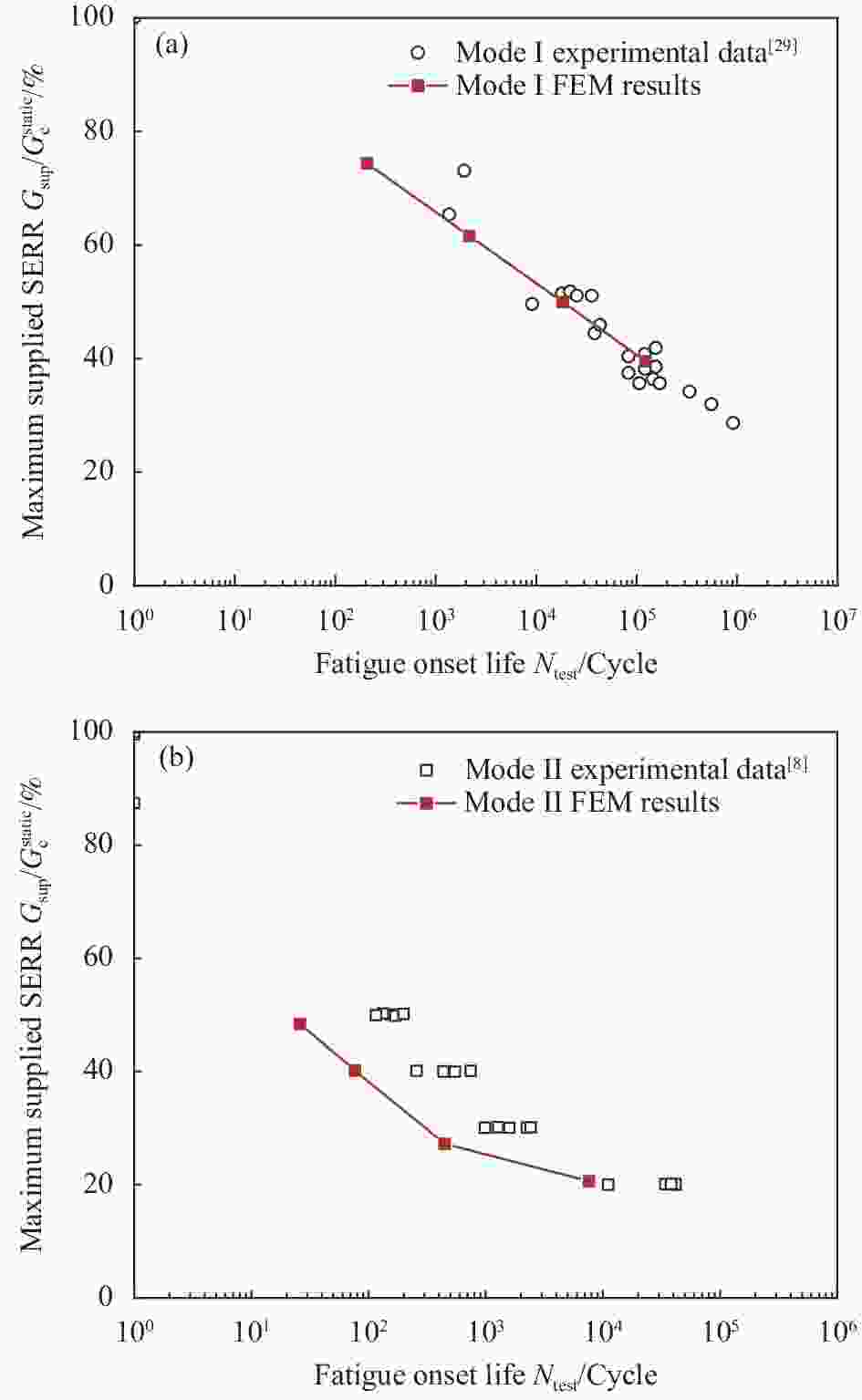

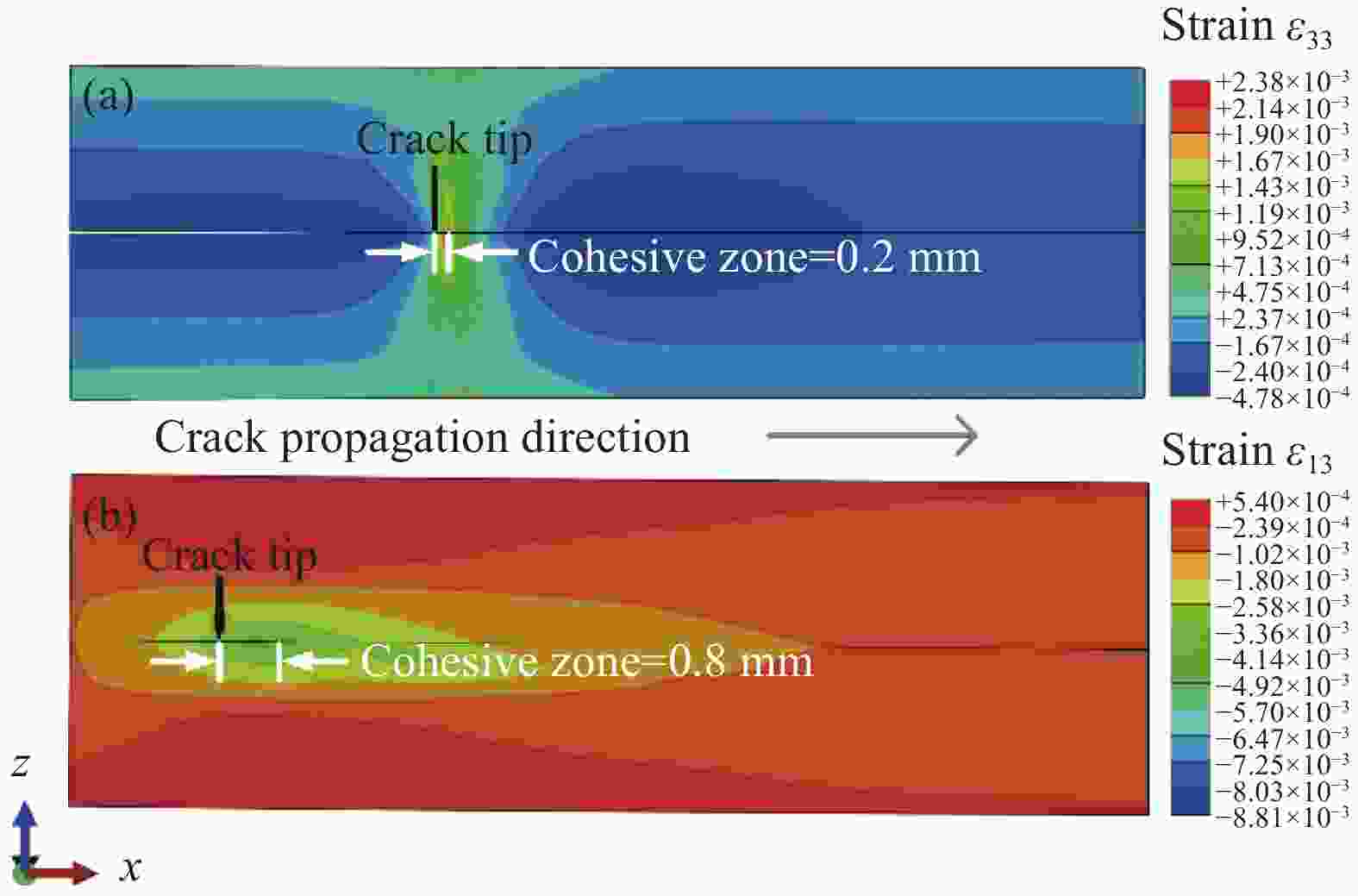

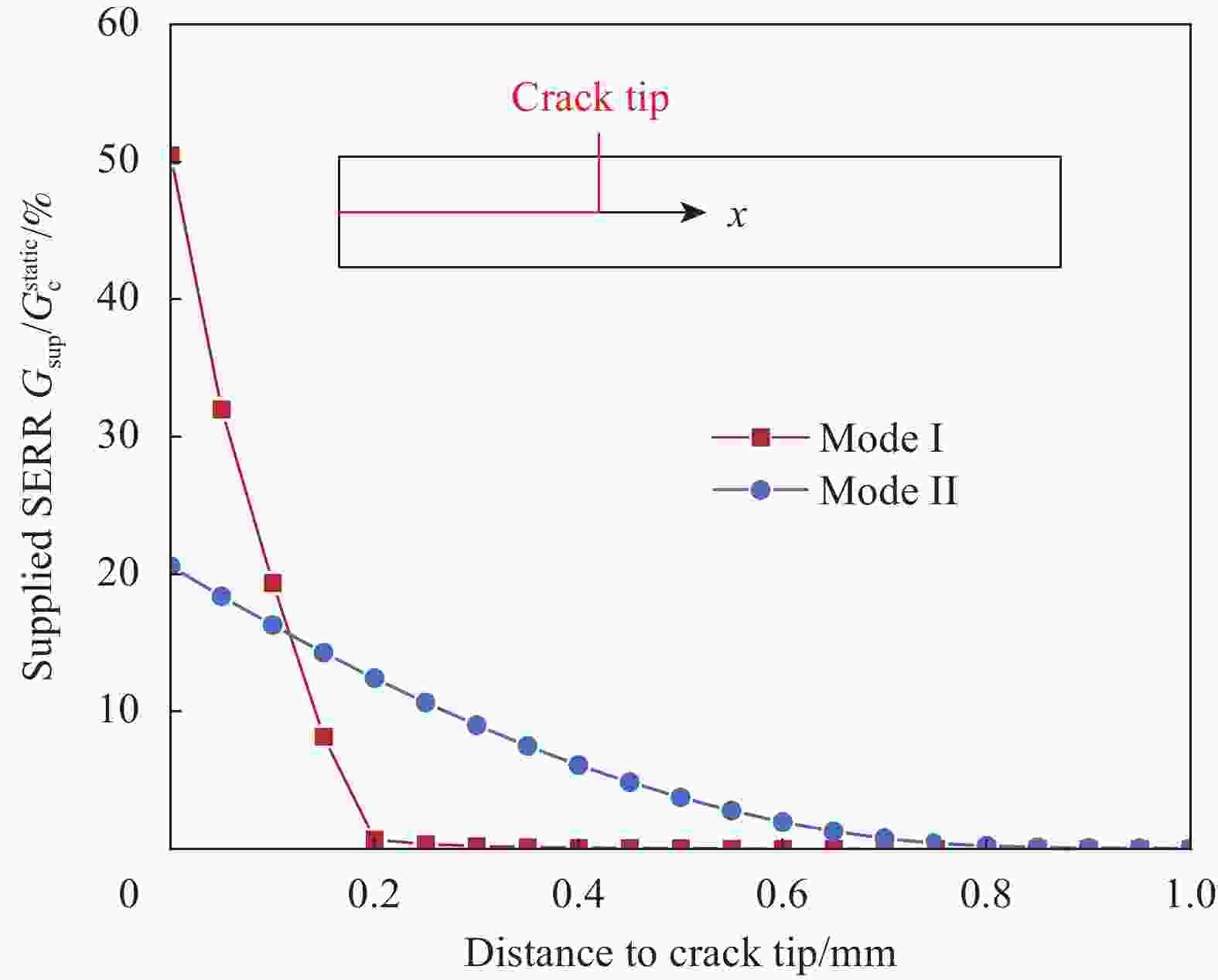

Abstract: Fatigue delamination is one of the most severe damage mode for laminated composites. A new cohesive zone model was adopted in this article for modeling fatigue delamination propagation in laminated composites, in which the strain energy release rate-lifetime (G-N) curve and Paris' law were linked. This model was developed based on a new interpretation of fatigue delamination propagation: Fatigue delamination propagation is a result of multiple onsets. A new fatigue cohesive constitutive law was constructed for describing fatigue damage accumulation in the inter-laminar interface of composites. All the parameters used in the constitutive law are with clear physical meaning and can be calibrated from the experimental G-N curve. Compared to the existing models for fatigue delamination in composites, the constitutive law developed in this model works independently in each element, without algorithms for getting the global crack information or tracking crack tip position. Considering the different deformation fields around the crack tip under mode II loading conditions, a new fatigue damage accumulation law was developed for mode II fatigue delamination propagation, and the predicted Paris' law for mode II was compared well with the experimental results. -

表 1 IM7/8552碳纤维/环氧树脂单向纤维复合材料层合板的相关材料参数[8]

Table 1. Material properties of IM7/8552 carbon fiber/epoxy unidirectional laminates[8]

Intra-ply properties E11/GPa E22=E33/GPa ν12=ν13 ν23 G12=G13/GPa G23/GPa $G_{\text{c}}^{{\text{static}}}$/

(N·mm−1)$\sigma _0^{{\text{static}}}$/MPa K0/

(N·mm−3)161 11.38 0.32 0.436 5.17 3.98 0.739 90 106 表 2 ENF实验测试IM7/8552碳纤维/环氧树脂复合材料起始扩展(FDO)寿命Ntest及柔度增加百分比[8]

Table 2. List of experimental fatigue delamination onset (FDO) life Ntest and percentage of compliance increase in ENF test of IM7/8552 carbon/epoxy composites[8]

$ {G_{\sup }}/G_{\text{c}}^{{\text{static}}} $ 50% 40% 30% 20% FDO life Ntest 156 257 1597 41642 133 449 987 11080 170 746 1275 34114 116 545 2246 41643 199 436 2420 38271 Average Ntest 155 487 1705 33350 Compliance increase/% 1.06 0.77 0.95 0.73 表 3 IM7/8552碳纤维/环氧树脂复合材料G-N曲线的拟合参数

Table 3. Fitting parameters of G-N curves for IM7/8552 carbon/epoxy composites

α 10 15 20 ξ1 0.739 0.739 0.739 λ1 −0.146 −0.148 −0.149 ξ2 1.048 1.042 1.040 λ2 −0.219 −0.221 −0.222 ξ3 0.371 0.361 0.355 λ3 −0.103 −0.101 −0.100 -

[1] TAKEDA N, OGIHARA S. Initiation and growth of delamination from the tips of transverse cracks in CFRP cross-ply laminates[J]. Composites Science and Technology,1994,52(3):309-318. doi: 10.1016/0266-3538(94)90166-X [2] OGIHARA S, TAKEDA N. Interaction between transverse cracks and delamination during damage progress in CFRP cross-ply laminates[J]. Composites Science and Technology,1995,54(4):395-404. doi: 10.1016/0266-3538(95)00084-4 [3] KASHTALYAN M, SOUTIS C. The effect of delaminations induced by transverse cracks and splits on stiffness properties of composite laminates[J]. Composites Part A: Applied Science and Manufacturing,2000,31(2):107-119. doi: 10.1016/S1359-835X(99)00066-4 [4] ASTM. Standard test method for determination of the mode II interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: ASTM D7905/D7905M-19e1[S]. West Conshohocken: ASTM International, 2019. [5] ISO. Fibre reinforced plastic composites—Determination of the mode II fracture resistance for unidirectionally reinforced materials using the calibrated end-loaded split (C-ELS) test and an effective crack length approach: ISO Standard 15114—2014[S]. Geneva: International Standards Organsiation, 2014. [6] ALLEGRI G, JONES M I, WISNOM M R, et al. A new semi-empirical model for stress ratio effect on mode II fatigue delamination growth[J]. Composites Part A: Applied Science and Manufacturing,2011,42(7):733-740. doi: 10.1016/j.compositesa.2011.02.013 [7] BRUNNER A J, STELZER S, PINTER G, et al. Mode II fatigue delamination resistance of advanced fiber-reinforced polymer-matrix laminates: Towards the development of a standardized test procedure[J]. International Journal of Fatigue,2013,50:57-62. doi: 10.1016/j.ijfatigue.2012.02.021 [8] O'BRIEN T K, JOHNSTON W M, TOLAND G J. Mode II interlaminar fracture toughness and fatigue characterization of a graphite epoxy composite material: NASA/TM-2010-216838[R]. Hampton: NASA Langley Research Center, 2010. [9] LIU C Q, GONG Y, GONG Y K, et al. Mode II fatigue delamination behaviour of composite multidirectional laminates and the stress ratio effect[J]. Engineering Fracture Mechanics,2022,264:108321. doi: 10.1016/j.engfracmech.2022.108321 [10] CHOWDHURY N M, HEALEY R, WANG J, et al. Using a residual strength model to predict mode II delamination failure of composite materials under block fatigue loading[J]. International Journal of Fatigue,2020,135:105563. doi: 10.1016/j.ijfatigue.2020.105563 [11] HEALEY R, WANG J, WALLBRINK C, et al. Predicting mode II delamination growth of composite materials to assist simplification of fatigue spectra by truncating non-damaging cycles validated with experiment[J]. International Journal of Fatigue,2021,145:106117. doi: 10.1016/j.ijfatigue.2020.106117 [12] BORG R, NILSSON L, SIMONSSON K. Simulating DCB, ENF and MMB experiments using shell elements and a cohesive zone model[J]. Composites Science and Technology,2004,64(2):269-278. doi: 10.1016/S0266-3538(03)00255-0 [13] TURON A, CAMANHO P P, COSTA J, et al. A damage model for the simulation of delamination in advanced composites under variable-mode loading[J]. Mechanics of Materials,2006,38(11):1072-1089. doi: 10.1016/j.mechmat.2005.10.003 [14] SØRENSEN B F, JACOBSEN T K. Characterizing delamination of fibre composites by mixed mode cohesive laws[J]. Composites Science and Technology,2009,69(3):445-456. [15] TURON A, COSTA J, CAMANHO P P, et al. Simulation of delamination in composites under high-cycle fatigue[J]. Composites Part A: Applied Science and Manufacturing,2007,38(11):2270-2282. doi: 10.1016/j.compositesa.2006.11.009 [16] HARPER P W, HALLETT S R. A fatigue degradation law for cohesive interface elements-development and application to composite materials[J]. International Journal of Fatigue,2010,32(11):1774-1787. doi: 10.1016/j.ijfatigue.2010.04.006 [17] BAK B L V, TURON A, LINDGAARD E, et al. A simulation method for high-cycle fatigue-driven delamination using a cohesive zone model[J]. International Journal for Numerical Methods in Engineering,2016,106(3):163-191. doi: 10.1002/nme.5117 [18] KAWASHITA L F, HALLETT S R. A crack tip tracking algorithm for cohesive interface element analysis of fatigue delamination propagation in composite materials[J]. International Journal of Solids and Structures,2012,49(21):2898-2913. doi: 10.1016/j.ijsolstr.2012.03.034 [19] TAO C C, QIU J H, YAO W X, et al. A novel method for fatigue delamination simulation in composite laminates[J]. Composites Science and Technology,2016,128:104-115. doi: 10.1016/j.compscitech.2016.03.016 [20] PIRONDI A, MORONI F. A progressive damage model for the prediction of fatigue crack growth in bonded joints[J]. The Journal of Adhesion,2010,86(5-6):501-521. doi: 10.1080/00218464.2010.484305 [21] MORONI F, PIRONDI A. A procedure for the simulation of fatigue crack growth in adhesively bonded joints based on the cohesive zone model and different mixed-mode propagation criteria[J]. Engineering Fracture Mechanics,2011,78(8):1808-1816. doi: 10.1016/j.engfracmech.2011.02.004 [22] NOJAVAN S, SCHESSER D, YANG Q D. A two-dimensional in situ fatigue cohesive zone model for crack propagation in composites under cyclic loading[J]. International Journal of Fatigue,2016,82:449-461. doi: 10.1016/j.ijfatigue.2015.08.029 [23] NOJAVAN S, SCHESSER D, YANG Q D. An in situ fatigue-CZM for unified crack initiation and propagation in composites under cyclic loading[J]. Composite Structures,2016,146:34-49. doi: 10.1016/j.compstruct.2016.02.060 [24] DAVILA C G. From SN to the Paris' law with a new mixed-mode cohesive fatigue model: NASA/TP-2018-219838[R]. Hampton: NASA Langley Research Center, 2018. [25] ZHU M, GORBATIKH L, LOMOV S V. An incremental-onset model for fatigue delamination propagation in composite laminates[J]. Composites Science and Technology,2020,200:108394. doi: 10.1016/j.compscitech.2020.108394 [26] ASTM. Standard test method for mode I fatigue delamination growth onset of unidirectional fiber-reinforced polymer matrix composites: ASTM D6115-97(2019)[S]. West Conshohocken: ASTM International, 2019. [27] BAK B L V, SARRADO C, TURON A, et al. Delamination under fatigue loads in composite laminates: a review on the observed phenomenology and computational methods[J]. Applied Mechanics Reviews,2014,66(6):060803. doi: 10.1115/1.4027647 [28] ZHU M, GORBATIKH L, LOMOV S V. An incremental cohesive law for delamination under a mixed mode loading[J]. Frontiers in Materials,2020,7:572995. [29] MURRI G B. Evaluation of delamination onset and growth characterization methods under mode I fatigue loading: NASA/TM-2013-217966[R]. Hampton: NASA Langley Research Center, 2013. -

下载:

下载: