Research progress on inter-ply slipping in prepreg stacking preforming

-

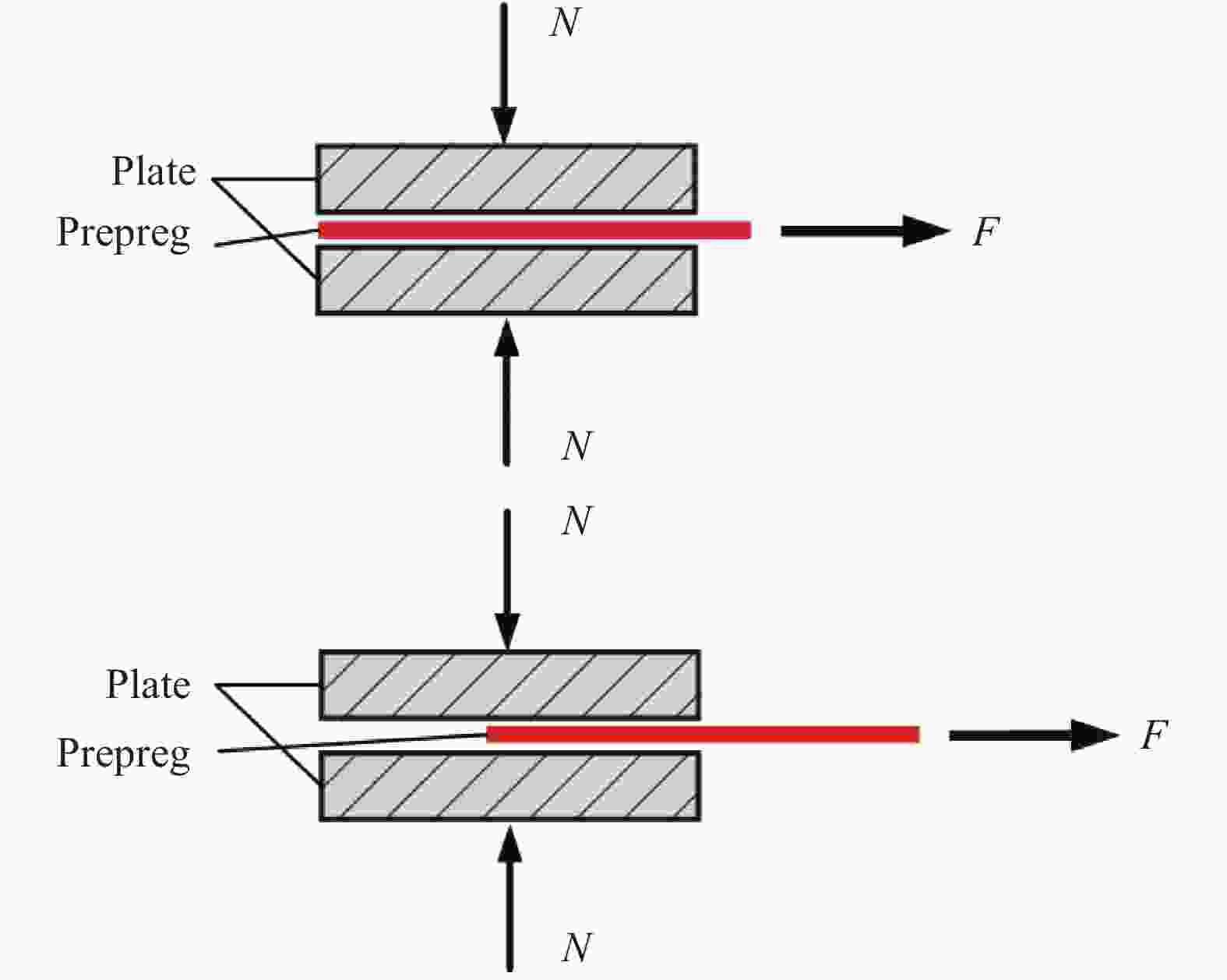

摘要: 层间滑移是预浸料叠层预成型中重要成型机制之一,层间滑移机制的研究可以对起皱和撕裂等缺陷进行有效预测和控制,对提高复合材料的力学性能和使用寿命具有重要的理论意义。目前,层间滑移机制的研究主要通过层间滑移测试和层间滑移模型构建的方式进行,其中最常用的测试方法是通过自主搭建层间滑移装置进行不同预浸料铺层和工艺条件下的性能测试;在模型构建方面,根据层间滑移模型的构成特点,可将模型分为三类:早期混合模型、基于Stribeck理论的唯象模型和经验模型。本文首先对层间滑移装置进行分类综述,剖析了每种类型装置的优缺点,然后详细介绍了层间滑移性能的表征及模型的构建等研究成果,最后对树脂基复合材料成型中的层间滑移发展方向进行了展望。Abstract: Inter-ply slipping is one of the important mechanisms in prepreg stacking preforming, and the research of inter-ply slipping mechanism can effectively predict and control the defects such as wrinkling and tearing, which is of great theoretical significance to improve the mechanical properties and service life of composites. At present, the research on inter-ply slipping mechanism mainly involves inter-ply slipping tests and the construction of inter-ply slipping models. The most commonly used test method is to conduct inter-ply slipping test using the homemade measuring device under different prepreg layups and process conditions. In terms of model construction, according to the characteristics of the inter-ply slipping model, the model can be classified into three categories: early mixed models, phenomenological models based on Stribeck theory and empirical models. In this paper, firstly, the classification of inter-ply slipping devices is reviewed, and the advantages and disadvantages of each type of device are dissected. And then the research results such as the characterization of inter-ply slipping performance and the construction of models are introduced in detail. Finally, the development direction of inter-ply slipping in the resin-matrix composite forming is looked forward to.

-

表 1 不同学者建立的层间滑移装置简介

Table 1. Introduction to inter-ply slipping device established by different scholars

Sholar Experimental principle Heating method Loading method Specificities Murtagh et al.[45](1995) pull-out Heating plate Hydraulic press/Weight Two test methods were used and were among the earlier scholars to conduct pull-out tests. Martin et al.[44](1996) pull-out Heating plate Pneumatic cylinder Use locating pins to lock the platens together to prevent misalignment. Lebrun et al.[47](2004) pull-out Cartridge heaters Springs It is possible to perform prepreg-prepreg and tool-prepreg slip experiments. Ersoy et al.[46](2005) pull-out Heating plate Springs A rubber mat is used under the prepreg to ensure even pressure distribution. Kaushik and Raghavan[65](2010) pull-through Heating plate Pneumatic cylinder Inter-ply slip test system for autoclave environments. Larberg and Åkermo[53](2011) pull-through Temperature chamber Pneumatic cylinder The stability of this part must be ensured when pulling the hinge mechanism consisting of cylinders. Joven[48](2013) pull-out Heating plate Pneumatic cylinder Flexible bushings are fitted to the test stand base to increase the sensitivity of the system, but only for temperature testing. Sun et al.[49](2014) pull-out Heating film Springs Aluminum plates and rubber pads were used between the heating films and the specimen to ensure that the temperature and pressure were uniformly distributed over the testing areas. Erland et al.[41](2015) pull-through Temperature chamber Pneumatic cylinder Similar to the device designed by Larberg[40]. Yu et al.[66,67](2021) pull-through Non-heating device Weight Simple structure, but lacks a heating device. Kim et al.[62](2021) pull-through Resistance wire Pneumatic cylinder The pressure between the pressure plate and the mounting surface should not be excessive. Rashidi et al.[54,68](2021) pull-through Heating plate Hydraulic cylinder Uniform normal pressure distribution must be ensured, and the device can also achieve the same parameters as in a hot press tank. Liu et al.[69](2021) pull-through Temperature chamber Rotating shaft Pressure is adjusted by rotating the Rotating shaft. Li et al.[61](2023) pull-through Heating plate Pneumatic cylinder The cylinder applying pressure part is similar to the device of Zhao[47]. Dutta et al.[70](2023) pull-through Cartridge heaters Pneumatic cylinder Similar to the device designed by Larberg[40]. Liu et al.[64](2023) pull-through Temperature chamber Springs The structure is simple and can only be used for inter-ply slipping experiments between the tool and the prepreg. Aveiga et al.[52](2023) pull-out Cartridge heaters Pneumatic cylinder It can be tested between prepregs and prepregs, as well as between prepregs and tools. 表 2 Stribeck理论相关模型

Table 2. Related model of Stribeck theory

Model contributor Time Model expression Parameter meaning Chow[93] 2002 $ {\mu }_{\mathrm{e}\mathrm{f}\mathrm{f}}=\dfrac{{\mu }_{c}\cdot \left(a\cdot {N}_{\mathrm{T}}\right)+\left(m\cdot {\dot{\gamma }}^{n-1}\right)\cdot \dot{\gamma }\cdot {A}_{\mathrm{r}}}{{N}_{\mathrm{T}}} $ Where $ {\mu }_{\mathrm{e}\mathrm{f}\mathrm{f}} $ is the effective coefficient of friction; $ {\mu }_{c} $ the Coulomb friction coefficient; $ {N}_{\mathrm{T}} $ the normal load; $ {A}_{\mathrm{r}} $ the contact area of the fluid film;

$ a $ portion of Coulomb friction; $ m $ the consistency, $ n $ the Power-Law index; and $ \dot{\gamma } $ the shear rate.Gorczyca-Cole et al.[89] 2007 $ {\mu }_{\mathrm{e}\mathrm{f}\mathrm{f}}={C}_{1}\cdot {H}+{C}_{2}-{S}_{\mathrm{t}\mathrm{t}} $ Where $ {C}_{1} $ and $ {C}_{2} $ is the model coefficient; $ {S}_{\mathrm{t}\mathrm{t}} $ the linear shift term; and H the Hersey number. Liu et al.[69] 2021 $ {\mu }_{\mathrm{k}}=0.22\cdot {{\mathrm{e}}}^{27.25\tfrac{\eta \nu }{N}}-7.42\times {10}^{-4}\cdot \mathrm{\Delta }T-0.03 $ Where $ {\mu }_{\mathrm{s}} $ is the static friction coefficient; $ v $ the sliding velocity; $ N $ the normal force; and $ \mathrm{\Delta }T $ the temperature difference. $ {\mu }_{\mathrm{s}}=5.02\cdot \left({\dfrac{v}{N}}\right)^{0.12}-6.35\times {10}^{-3}\cdot \mathrm{\Delta }T $ 表 3 经验模型

Table 3. Empirical Model

Model contributor Time Model expression Parameter meaning Lin et al.[42] 2006 $ \tau =\text{565}\cdot {10}^{-6}\sqrt[3]{\dfrac{{U}^{1.37}\cdot P}{4.0\cdot {10}^{-6}{a}_{\mathrm{T}}}} $

$ {a}_{\mathrm{T}}={10}^{-282.85\left(\tfrac{1}{T}-\tfrac{1}{180}\right)} $where $ \tau $ is the shear stress in MPa, U the velocity in mm/s, P the normal pressure in MPa and T the temperature in℃. Wang et al.[21] 2019 $ \tau ={k}_{1}d\left(d < dy\right) $

$ \tau ={p}_{1}+{p}_{2}/d\left({d}_{y}\leqslant d\leqslant {d}_{h}\right) $

$ \tau ={\tau }_{\mathrm{h}}+{k}_{3}\left(d-{d}_{h}\right)\left(d > {d}_{h}\right) $where $ \tau $ is the tangential stress; $ d $ the relative slipping displacement; $ {d}_{y} $ the displacement at yield point; $ {d}_{h} $ the displacement at harding point; and $ {k}_{1} $, $ {p}_{1} $, $ {p}_{2} $, $ {k}_{3} $ the model parameters. Sourki et al.[94] 2021 $ {\widehat{\mu }}_{{m}_{i}}\left(\alpha \right)={a}_{0}+\displaystyle\sum\nolimits _{n=1}^{N}\left[{a}_{n}\cos\alpha \omega +{b}_{n}\sin\alpha \omega \right] $

$ {P}^{\text{'}}=P\left[H\left(P-{P}_{p}\right)-H\left(P-{P}_{p+1}\right)\right] $

$ {\mu }_{\mathrm{i}}={\widehat{\mu }}_{\mathrm{p}\mathrm{i}}\left(\alpha \right)+\dfrac{{\widehat{\mu }}_{\mathrm{p}\mathrm{i}}\left(\alpha \right)-{\widehat{\mu }}_{\mathrm{p}\mathrm{i}}\left(\alpha \right)}{{P}_{\mathrm{p}+1}-{P}_{\mathrm{p}}}\left({P}^{\text{'}}-{P}_{\mathrm{p}+1}\right) $Where $ {\widehat{\mu }}_{{\mathrm{m}}_{\mathrm{i}}}\left(\alpha \right) $ is the static (when $ i=s $), or dynamic (when $ i=k $) coefficient of friction at the given pressure level m, as a function of the ply orientation $ \alpha $; $ H $(.) the Heaviside step function; $ {a}_{0} $, $ {a}_{\mathrm{n}} $, $ {b}_{\mathrm{n}} $ and $ \omega $ are the coefficients and period of the Fourier series. Here $ M=\text{3} $ for the given three pressure levels, and $ N=\text{8} $ for the number of Fourier terms used for the fit. Li et al.[61] 2023 $ {\tau }_{\mathrm{l}}=Es $

$ {\tau }_{\mathrm{y}}=A+B*{s}^{C} $

$ {\tau }_{\mathrm{H}}={H}_{\mathrm{s}}+{\tau }_{0} $where $ \tau $ is the tangential stress; $ s $ the sliding distance; $ E $ the elastic parameters; $ A $, $ B $ and $ C $ yield model parameters; and $ {\tau }_{0} $ the Y-axis intercept of the hardening curve. -

[1] 李成良, 杨超, 倪爱清, 等. 复合材料在大型风电叶片上的应用与发展[J]. 复合材料学报, 2023, 40(3): 1274-1284.LI Chengliang, YANG Chao, NI Aiqing, et al. Application and development of composite materials in large-scale wind turbine blade[J]. Acta Materiae Compositae Sinica, 2023, 40(3): 1274-1284(in Chinese). [2] 肇研, 孙铭辰, 张思益, 等. 连续碳纤维增强高性能热塑性复合材料的研究进展[J]. 复合材料学报, 2022, 39(9): 4274-4285.ZHAO Yan, SUN Mingchen, ZHANG Siyi, et al. Advance in continuous carbon fiber reinforced high performance thermoplastic composites[J]. Acta Materiae Compositae Sinica, 2022, 39(9): 4274-4285(in Chinese). [3] 曹建凡, 白树林, 秦文贞, 等. 碳纤维增强热塑性复合材料的制备与性能研究进展[J]. 复合材料学报, 2023, 40(3): 1229-1247.CAO Jianfan, BAI Shulin, QIN Wenzhen, et al. Research progress on preparation and properties of carbon fiber reinforced thermoplastic composites[J]. Acta Materiae Compositae Sinica, 2023, 40(3): 1229-1247(in Chinese). [4] 邢丽英, 冯志海, 包建文, 等. 碳纤维及树脂基复合材料产业发展面临的机遇与挑战[J]. 复合材料学报, 2020, 37(11): 2700-2706.XING Liying, FENG Zhihai, BAO Jianwen, et al. Facing opportunity and challenge of carbon fiber and polymer matrix composites industry development[J]. Acta Materiae Compositae Sinica, 2020, 37(11): 2700-2706(in Chinese). [5] LEE J M, LEE C J, KIM B M, et al. Design of Prepreg Compression Molding for Manufacturing of CFRTP B-pillar Reinforcement with Equivalent Mechanical Properties to Existing Steel Part[J]. International Journal of Precision Engineering and Manufacturing, 2020, 21: 545-556. doi: 10.1007/s12541-019-00265-z [6] 王立冬. 碳纤维预浸料层间滑移性能研究及在热隔膜成型中的应用[D]. 上海交通大学, 2020.WANG Lidong. Investigation on Inter-ply slipping behavior of carbon fiber prepreg and its application in hot diaphragm forming[D]. Shanghai Jiao Tong University, 2020(in Chinese). [7] 陈吉平, 李岩, 刘卫平, 等. 连续纤维增强热塑性树脂基复合材料自动铺放原位成型技术的航空发展现状[J]. 复合材料学报, 2019, 36(4): 784-794.CHEN Jiping, LI Yan, LIU Weiping, et al. Development of AFP in-situ consolidation technology on continuous fiber reinforced thermoplastic matrix composites in aviation[J]. Acta Materiae Compositae Sinica, 2019, 36(4): 784-794 (in Chinese). [8] 邢丽英, 李亚锋, 陈祥宝. 先进复合材料在航空装备发展中的地位与作用[J]. 复合材料学报, 2022, 39(9): 4179-4186.XING Liying, LI Yafeng, CHEN Xiangbao. Status and role of the advanced composite materials in the development of aviation equipment[J]. Acta Materiae Compositae Sinica, 2022, 39(9): 4179-4186(in Chinese). [9] 梁宪珠, 谢向莉, 韩立军, 等. 叠层成型用吸胶材料吸树脂量分析[J]. 玻璃钢/复合材料, 1997, (4): 15-16+20.LIANG Xianzhu, XIE Xiangli, HAN Lijun, et al. Analysis of bleeder’s bleeding content in ply process[J]. Fiber Reinforced Plastics/Composites, 1997, (4): 15-16+20(in Chinese). [10] 薛向晨, 胡江波, 王犇, 等. 叠层滑移工艺制造大型机身帽型长桁[J]. 航空制造技术, 2020, 63(4): 62-67.XUE Xiangchen, HU Jiangbo, WANG Ben, et al. Laminated Slip Manufacture Method for Large Fuselage Hat-Section Stringer[J]. Aeronautical manufacturing technology, 2020, 63(4): 62-67(in Chinese). [11] 薛向晨, 胡江波, 王犇, 等. 基于叠层滑移工艺的复合材料J形和C形梁成形技术[J]. 航空科学技术, 2020, 31(6): 27-34.XUE Xiangchen, HU Jiangbo, WANG Ben, et al. Manufacture technology of composite J-section and C-section beam based on laminated sliding process[J]. Aeronautical Science & Technology, 2020, 31(6): 27-34(in Chinese). [12] LONG A C. Composites forming technologies[M]. Composites forming technologies, 2014. [13] MOHAN R P, ALSHAHRANI H, HOJJATI M. Investigation of intra-ply shear behavior of out-of-autoclave carbon/epoxy prepreg[J]. Journal of Composite Materials, 2016, 50(30): 4251-4268. doi: 10.1177/0021998316635238 [14] ALSHAHRANI H, HOJJATI M. Experimental and numerical investigations on formability of out-of-autoclave thermoset prepreg using a double diaphragm process[J]. Composites Part A: Applied Science and Manufacturing, 2017, 101: 199-214. doi: 10.1016/j.compositesa.2017.06.021 [15] ALSHAHRANI H, HOJJATI M. Bending behavior of multilayered textile composite prepregs: Experiment and finite element modeling[J]. Materials & Design, 2017, 124: 211-224. [16] ALSHAHRANI H, HOJJATI M. A new test method for the characterization of the bending behavior of textile prepregs[J]. Composites Part A: Applied Science and Manufacturing, 2017, 97: 128-140. doi: 10.1016/j.compositesa.2017.02.027 [17] LIGHTFOOT J S, WISNOM M R, POTTER K. A new mechanism for the formation of ply wrinkles due to shear between plies[J]. Composites Part A: Applied Science and Manufacturing, 2013, 49: 139-147. doi: 10.1016/j.compositesa.2013.03.002 [18] HALLANDER P, AKERMO M, MATTEI C, et al. An experimental study of mechanisms behind wrinkle development during forming of composite laminates[J]. Composites Part A: Applied Science and Manufacturing, 2013, 50: 54-64. doi: 10.1016/j.compositesa.2013.03.013 [19] DODWELL T J, BUTLER R, HUNT G W. Out-of-plane ply wrinkling defects during consolidation over an external radius[J]. Composites Science and Technology, 2014, 105: 151-159. doi: 10.1016/j.compscitech.2014.10.007 [20] DODWELL T J. Internal wrinkling instabilities in layered media[J]. Philosophical Magazine, 2015, 95(28-30): 3225-3243. doi: 10.1080/14786435.2015.1034221 [21] WANG L D, XU P, PENG X Q, et al. Characterization of inter-ply slipping behaviors in hot diaphragm preforming: Experiments and modelling[J]. Composites Part A: Applied Science and Manufacturing, 2019, 121: 28-35. doi: 10.1016/j.compositesa.2019.03.012 [22] GREWAL H S. Characterization of interply shear behaviour of out-of-autoclave thermosetting prepreg composites[D]. Concordia University, 2015. [23] ERSOY N, GARSTKA T, POTTER K, et al. Modelling of the spring-in phenomenon in curved parts made of a thermosetting composite[J]. Composites Part A: Applied Science and Manufacturing, 2010, 41(3): 410-418. doi: 10.1016/j.compositesa.2009.11.008 [24] ARAFATH A R A, VAZIRI R, POURSARTIP A. Closed-form solution for process-induced stresses and deformation of a composite part cured on a solid tool: Part I - Flat geometries[J]. Composites Part A: Applied Science and Manufacturing, 2008, 39(7): 1106-1117. doi: 10.1016/j.compositesa.2008.04.009 [25] FLETCHER T A, BUTLER R, DODWELL T J. Anti-symmetric laminates for improved consolidation and reduced warp of tapered C-sections[J]. Advanced Manufacturing: Polymer & Composites Science, 2015, 1(2): 105-111. [26] MUKHOPADHYAY S, JONES M I, HALLETT S R. Compressive failure of laminates containing an embedded wrinkle; experimental and numerical study[J]. Composites Part A: Applied Science and Manufacturing, 2015, 73: 132-142. doi: 10.1016/j.compositesa.2015.03.012 [27] HÖRRMANN S, ADUMITROAIE A, VIECHTBAUER C, et al. The effect of fiber waviness on the fatigue life of CFRP materials[J]. International Journal of Fatigue, 2016, 90: 139-147. doi: 10.1016/j.ijfatigue.2016.04.029 [28] BIAN X X, GU Y Z, SUN J, et al. Effects of processing parameters on the forming quality of C-shaped thermosetting composite laminates in hot diaphragm forming process[J]. Applied Composite Materials, 2013, 20: 927-945. doi: 10.1007/s10443-012-9310-7 [29] HALLANDER P, AKERMO M, MATTEI C, et al. An experimental study of mechanisms behind wrinkle development during forming of composite laminates[J]. Composites Part A: Applied Science and Manufacturing, 2013, 50: 54-64. doi: 10.1016/j.compositesa.2013.03.013 [30] FARNAND K, ZOBEIRY N, POURSARTIP A, et al. Micro-level mechanisms of fiber waviness and wrinkling during hot drape forming of unidirectional prepreg composites[J]. Composites Part A: Applied Science and Manufacturing, 2017, 103: 168-177. doi: 10.1016/j.compositesa.2017.10.008 [31] HALLANDER P, SJÖLANDER J, PETERSSON M, et al. Interface manipulation towards wrinkle-free forming of stacked UD prepreg layers[J]. Composites Part A: Applied Science and Manufacturing, 2016, 90: 340-348. doi: 10.1016/j.compositesa.2016.07.013 [32] FRIEDRICH K, HOU M, KREBS J. Thermoforming of continuous fibre/thermoplastic composite sheets[M]. Composite materials Series. 1997, 11: 91-162Elsevier, 1997: 91-162. [33] HAANAPPEL S P, TEN THIJE R H, SACHS U, et al. Formability analyses of uni-directional and textile reinforced thermoplastics[J]. Composites Part A: Applied science and Manufacturing, 2014, 56: 80-92. doi: 10.1016/j.compositesa.2013.09.009 [34] NEZAMI F N, GEREKE T, CHERIF C. Analyses of interaction mechanisms during forming of multilayer carbon woven fabrics for composite applications[J]. Composites Part A: Applied Science and Manufacturing, 2016, 84: 406-416. doi: 10.1016/j.compositesa.2016.02.023 [35] ALLAOUI S, BOISSE P, CHATEL S, et al. Experimental and numerical analyses of textile reinforcement forming of a tetrahedral shape[J]. Composites Part A: Applied Science and Manufacturing, 2011, 42(6): 612-622. doi: 10.1016/j.compositesa.2011.02.001 [36] LIN H, WANG J, LONG A, et al. Textile wrinkling in composite forming [C]. Proceedings of the AUTEX World Textile Conference, 2006. [37] LEE J S, HONG S J, YU W-R, et al. The effect of blank holder force on the stamp forming behavior of non-crimp fabric with a chain stitch[J]. Composites science and Technology, 2007, 67(3-4): 357-366. doi: 10.1016/j.compscitech.2006.09.009 [38] 孔令国, 王继辉, 陈宏达, 等. 压边力对非平衡平纹机织物预制体成型作用规律[J]. 复合材料学报, 2022, 39(4): 1798-1812.KONG Lingguo, WANG Jihui, CHEN Hongda, et al. Influence of blank-holder force on the draping process of unbalanced plain woven fabric preform[J]. Acta Materiae Compositae Sinica, 2022, 39(4): 1798-1812(in Chinese). [39] ZHANG Y, HAN X, LIU R, et al. Effect of temperature aging of thermoset UD prepregs on inter-ply friction behavior and formability in prepreg compression molding process[J]. Polymer Composites, 2024. 1-18. [40] ZHANG W, ZHOU H, HUANG B, et al. Characterization of tool-ply friction behavior for treated jute/PLA biocomposite prepregs in thermoforming[J]. Composites Part A: Applied Science and Manufacturing, 2024, 177: 107875. doi: 10.1016/j.compositesa.2023.107875 [41] ERLAND S, DODWELL T J, BUTLER R. Characterisation of inter-ply shear in uncured carbon fibre prepreg[J]. Composites Part A: Applied Science and Manufacturing, 2015, 77: 210-218. doi: 10.1016/j.compositesa.2015.07.008 [42] LIN H, HARRISON P, VAN DE HAAR K, et al. Investigation of tool-ply friction of viscous textile composites[C]. Proceedings of the 8th International Conference on Textile Composites, 2006. [43] GROVES D J. A characterization of shear flow in continuous fibre thermoplastic laminates[J]. Composites, 1989, 20(1): 28-32. doi: 10.1016/0010-4361(89)90678-2 [44] MARTIN C J, SEFERIS J C, WILHELM M A. Frictional resistance of thermoset prepregs and its influence on honeycomb composite processing[J]. Composites Part A: Applied Science and Manufacturing, 1996, 27(10): 943-951. doi: 10.1016/1359-835X(96)00037-1 [45] MURTAGH A M, LENNON J J, MALLON P J. Surface friction effects related to press forming of continuous fibre thermoplastic composites[J]. Composites Manufacturing, 1995, 6(3-4): 169-175. doi: 10.1016/0956-7143(95)95008-M [46] ERSOY N, POTTER K, WISNOM M R, et al. An experimental method to study the frictional processes during composites manufacturing[J]. Composites Part A: Applied Science and Manufacturing, 2005, 36(11): 1536-1544. doi: 10.1016/j.compositesa.2005.02.010 [47] LEBRUN G, BUREAU M N, DENAULT J. Thermoforming-stamping of continuous glass fiber/polypropylene composites: interlaminar and tool-laminate shear properties[J]. Journal of Thermoplastic Composite Materials, 2004, 17(2): 137-165. doi: 10.1177/0892705704035411 [48] JOVEN R. Characterization and modeling of shear stress during manufacturing and thermal properties of structural composite materials[D]. Wichita State University, 2013. [49] SUN J, LI M, GU Y, et al. Interply friction of carbon fiber/epoxy prepreg stacks under different processing conditions[J]. Journal of Composite Materials, 2014, 48(5): 515-526. doi: 10.1177/0021998313476320 [50] SCHERER R, FRIEDRICH K. Inter-and intraply-slip flow processes during thermoforming of CF/PP-laminates[J]. Composites Manufacturing, 1991, 2(2): 92-96. doi: 10.1016/0956-7143(91)90185-J [51] MORRIS S R, SUN C T. An investigation of interply slip behaviour in AS4/PEEK at forming temperatures[J]. Composites Manufacturing, 1994, 5(4): 217-224. doi: 10.1016/0956-7143(94)90136-8 [52] AVEIGA D, GÓMEZ D G, MOCERINO D, et al. Friction resistance of uncured carbon/epoxy prepregs under thermoforming process conditions: experiments and modelling[J]. Journal of Manufacturing and Materials Processing, 2023, 7(1): 14. doi: 10.3390/jmmp7010014 [53] LARBERG Y R, ÅKERMO M. On the interply friction of different generations of carbon/epoxy prepreg systems[J]. Composites Part A: Applied Science and Manufacturing, 2011, 42(9): 1067-1074. doi: 10.1016/j.compositesa.2011.04.010 [54] RASHIDI A, KEEGAN C, MILANI A S. Analysis of inter-ply friction in consolidation process of thermoset woven prepregs[C]. AIP Conference Proceedings, 2019. [55] 李林秀, 岳广全, 杨洋, 等. 连续碳纤维增强聚苯硫醚预浸料层间滑移行为研究[J]. 复合材料科学与工程, 2021, (2): 24-31. doi: 10.3969/j.issn.1003-0999.2021.02.004LI Linxiu, YUE Guangquan, YANG Yang et al. Research on interlayer slip behavior of continuous carbon fiber reinforced polyphenylene sulfide prepreg[J]. Composite materials science and engineering, 2021, (2): 24-31(in Chinese). doi: 10.3969/j.issn.1003-0999.2021.02.004 [56] LIEBL M, ENGELFRIED M, CAROSELLA S, et al. Investigation of the friction behaviour of spread carbon fibre tows with reactive binder[C]. SAMPE Europe Conference. 2021. [57] LAWRENCE G D, CHEN S, WARRIOR N A, et al. The influence of inter-ply friction during double-diaphragm forming of biaxial NCFs[J]. Composites Part A: Applied Science and Manufacturing, 2023, 167: 107426. doi: 10.1016/j.compositesa.2023.107426 [58] PIERIK R, GROUVE W, WIJSKAMP S, et al. On the origin of start-up effects in ply-ply friction for UD fiber-reinforced thermoplastics in melt[C]. 24th International Conference on Material Forming, , 2021. [59] PIERIK E R, GROUVE W J B, WIJSKAMP S, et al. Prediction of the peak and steady-state ply-ply friction response for UD C/PAEK tapes[J]. Composites Part A: Applied Science and Manufacturing, 2022, 163: 107185. doi: 10.1016/j.compositesa.2022.107185 [60] ZHAO Y Q, ZHANG T, LI H, et al. Characterization of prepreg-prepreg and prepreg-tool friction for unidirectional carbon fiber/epoxy prepreg during hot diaphragm forming process[J]. Polymer Testing, 2020, 84: 106440. doi: 10.1016/j.polymertesting.2020.106440 [61] LI Z, ZHAO D, SUN B, et al. Experimental characterization and modeling of the inter-ply sliding behavior of unidirectional prepreg in the preforming process[J]. Materials Research Express, 2023, 10(3): 035602. doi: 10.1088/2053-1591/acbf0d [62] KIM J Y, HWANG Y T, BAEK J H, et al. Study on inter-ply friction between woven and unidirectional prepregs and its effect on the composite forming process[J]. Composite Structures, 2021, 267: 113888. doi: 10.1016/j.compstruct.2021.113888 [63] 陈洁, 顾轶卓, 李敏, 等. 碳纤维/环氧预浸料摩擦滑移特性测试及其变化规律[J]. 复合材料学报, 2014, 31(1): 101-106.CHEN Jie, GU Yizhuo, LI Min et al. Measurement and evolution of frictional slipping behavior of carbon fiber/epoxy prepreg[J]. Acta Materiae Compositae Sinica, 2014, 31(1): 101-106(in Chinese). [64] LIU Z, SIMONETTO E, GHIOTTI A, et al. Investigation on the inter-ply friction when deforming magnesium-based fibre metal laminates at elevated temperature[J]. Materials Research Proceedings, 2023, 25: 463-470. [65] KAUSHIK V, RAGHAVAN J. Experimental study of tool-part interaction during autoclave processing of thermoset polymer composite structures[J]. Composites Part A: Applied Science and Manufacturing, 2010, 41(9): 1210-1218. doi: 10.1016/j.compositesa.2010.05.003 [66] YU F, CHEN S, HARPER L T, et al. Investigation into the effects of inter-ply sliding during double diaphragm forming for multi-layered biaxial non-crimp fabrics[J]. Composites Part A: Applied Science and Manufacturing, 2021, 150: 106611. doi: 10.1016/j.compositesa.2021.106611 [67] YU F, CHEN S, LAWRENCE G D, et al. A global-to-local sub modelling approach to investigate the effect of lubrication during double diaphragm forming of multi-ply biaxial non-crimp fabric preforms[J]. Composites Part B: Engineering, 2023, 254: 110590. doi: 10.1016/j.compositesb.2023.110590 [68] RASHIDI A, CRAWFORD B, OLFATBAKHSH T, et al. A mixed lubrication model for inter-ply friction behaviour of uncured fabric prepregs[J]. Composites Part A: Applied Science and Manufacturing, 2021, 149: 106571. doi: 10.1016/j.compositesa.2021.106571 [69] LIU S, SINKE J, DRANSFELD C. An inter-ply friction model for thermoset based fibre metal laminate in a hot-pressing process[J]. Composites Part B: Engineering, 2021, 227: 109400. doi: 10.1016/j.compositesb.2021.109400 [70] DUTTA A, HAGNELL M K, ÅKERMO M. Interply friction between unidirectional carbon/epoxy prepreg plies: Influence of fibre orientation[J]. Composites Part A: Applied Science and Manufacturing, 2023, 166: 107375. doi: 10.1016/j.compositesa.2022.107375 [71] RASHIDI A, MONTAZERIAN H, YESILCIMEN K, et al. Experimental characterization of the inter-ply shear behavior of dry and prepreg woven fabrics: Significance of mixed lubrication mode during thermoset composites processing[J]. Composites Part A: Applied Science and Manufacturing, 2020, 129: 105725. doi: 10.1016/j.compositesa.2019.105725 [72] PASCO C, KHAN M, GUPTA J, et al. Experimental investigation on interply friction properties of thermoset prepreg systems[J]. Journal of Composite Materials, 2019, 53(2): 227-243. doi: 10.1177/0021998318781706 [73] HENNING F, KÄRGER L, DÖRR D, et al. Fast processing and continuous simulation of automotive structural composite components[J]. Composites Science and Technology, 2019, 171: 261-279. doi: 10.1016/j.compscitech.2018.12.007 [74] GORCZYCA J L. A study of the frictional behavior of a plain-weave fabric during the thermo-stamping process[D]. University of Massachusetts Lowell, 2004. [75] TEN THIJE R H W, AKKERMAN R, UBBINK M, et al. A lubrication approach to friction in thermoplastic composites forming processes[J]. Composites Part A: Applied Science and Manufacturing, 2011, 42(8): 950-960. doi: 10.1016/j.compositesa.2011.03.023 [76] GONG Y, SONG Z, NING H, et al. A comprehensive review of characterization and simulation methods for thermo-stamping of 2D woven fabric reinforced thermoplastics[J]. Composites Part B: Engineering, 2020, 203: 108462. doi: 10.1016/j.compositesb.2020.108462 [77] HARRISON P, THIJE R T, AKKERMAN R, et al. Characterising and modelling tool-ply friction of viscous textile composites[J]. World Journal of Engineering, 2010, 7(1): 5-22. [78] HEYER P, LÄUGER J, CO A, et al. A Flexible Platform for Tribological Measurements on a Rheometer[J]. AIP Conference Proceedings. 2008, 1027, (1): 1168-1170. [79] DAS A, CHOONG G Y H, DILLARD D A, et al. Characterizing friction for fiber reinforced composites manufacturing: Method development and effect of process parameters[J]. Composites Part B: Engineering, 2022, 236: 109777. doi: 10.1016/j.compositesb.2022.109777 [80] LIU Z, SIMONETTO E, GHIOTTI A, et al. Inter-ply friction behaviour in the temperature assisted forming of magnesium/glass fibre reinforced thermoplastic polymer laminates[J]. Composites Part A: Applied Science and Manufacturing, 2023, 173: 107635. doi: 10.1016/j.compositesa.2023.107635 [81] SACHS U, AKKERMAN R, FETFATSIDIS K, et al. Characterization of the dynamic friction of woven fabrics: Experimental methods and benchmark results[J]. Composites Part A: Applied Science and Manufacturing, 2014, 67: 289-298. doi: 10.1016/j.compositesa.2014.08.026 [82] MURTAGH A M, MALLON P J. Characterisation of shearing and frictional behaviour during sheet forming[M]. Composite materials Series. 1997, 11: 163-216. [83] NOSRAT F N, GEREKE T, CHERIF C. Active forming manipulation of composite reinforcements for the suppression of forming defects[J]. Composites Part A: Applied Science and Manufacturing, 2017, 99: 94-101. doi: 10.1016/j.compositesa.2017.04.011 [84] WANG W T, YU H N, POTTER K, et al. Improvement of composite drape forming quality by enhancing interply slip[C]. ECCM17-17th European Conference on Composite Materials, 2016. [85] STACHOWIAK G W, BATCHELOR A W. Engineering tribology[M]. Butterworth-heinemann, 2013. [86] WILKS C E. Characterization of the Tool/Ply interface during forming[D]. University of Nottingham, 1999. [87] CLIFFORD M J, LONG A C, DELUCA P. Forming of engineering prepregs and reinforced thermoplastics[C]. TMS annual meeting and exhibition, second global symposium on innovations in materials, processing and manufacturing: sheet materials: composite processing. 2001. [88] GREWAL H S, HOJJATI M. Inter-ply Friction of Unidirectional Tape and Woven Fabric Out-of-autoclave Prepregs[J]. International Journal of Composite Materials, 2017, 7(6): 161-170. [89] GORCZYCA-COLE J L, SHERWOOD J A, CHEN J. A friction model for thermostamping commingled glass-polypropylene woven fabrics[J]. Composites Part A: Applied Science and Manufacturing, 2007, 38(2): 393-406. doi: 10.1016/j.compositesa.2006.03.006 [90] GORCZYCA-COLE J L, SHERWOOD J A, LIU L, et al. Modeling of Friction and Shear in Thermo-stamping of Composites-Part I[J]. Journal of Composite Materials, 2004, 38(21): 1911-1929. doi: 10.1177/0021998304048416 [91] LEE J M, KIM B M, LEE C J, et al. A characterisation of tool-ply friction behaviors in thermoplastic composite[J]. Procedia Engineering, 2017, 207: 90-94. doi: 10.1016/j.proeng.2017.10.743 [92] FETFATSIDIS K A, JAUFFRÈS D, SHERWOOD J A, et al. Characterization of the tool/fabric and fabric/fabric friction for woven-fabric composites during the thermostamping process[J]. International Journal of Material Forming, 2013, 6(2): 209-221. doi: 10.1007/s12289-011-1072-5 [93] CHOW S. Frictional interaction between blank holder and fabric in stamping of woven thermoplastic composites[D]. University of Massachusetts Lowell, 2002. [94] SOURKI R, CRAWFORD B, VAZIRI R, et al. Orientation dependency and hysteresis nature of inter-ply friction in woven fabrics[J]. Applied Composite Materials, 2021, 28(1): 113-127. doi: 10.1007/s10443-020-09846-y -

点击查看大图

点击查看大图

计量

- 文章访问数: 83

- HTML全文浏览量: 50

- 被引次数: 0

下载:

下载: