Research progress on polyphenols modified fiber reinforced polymer composites

-

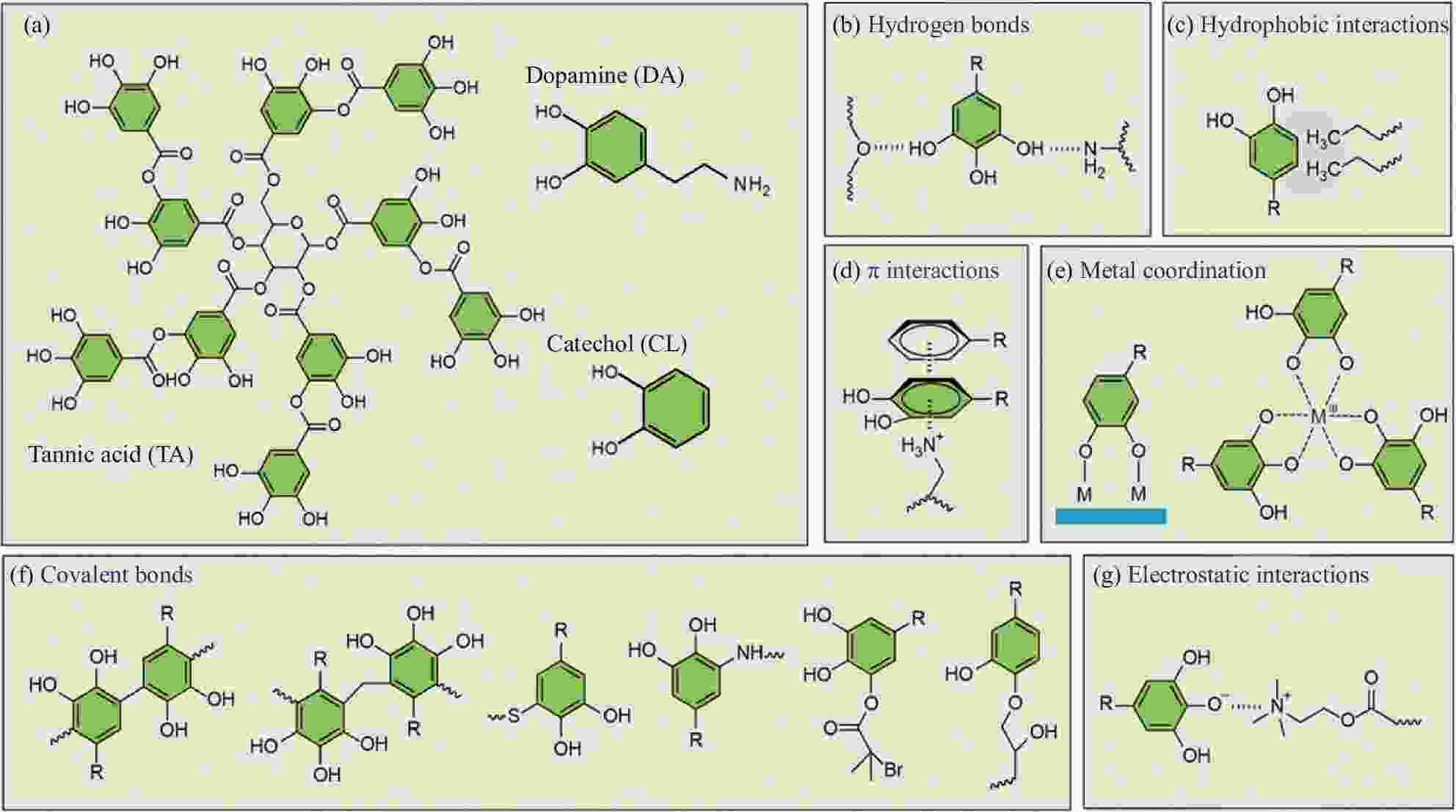

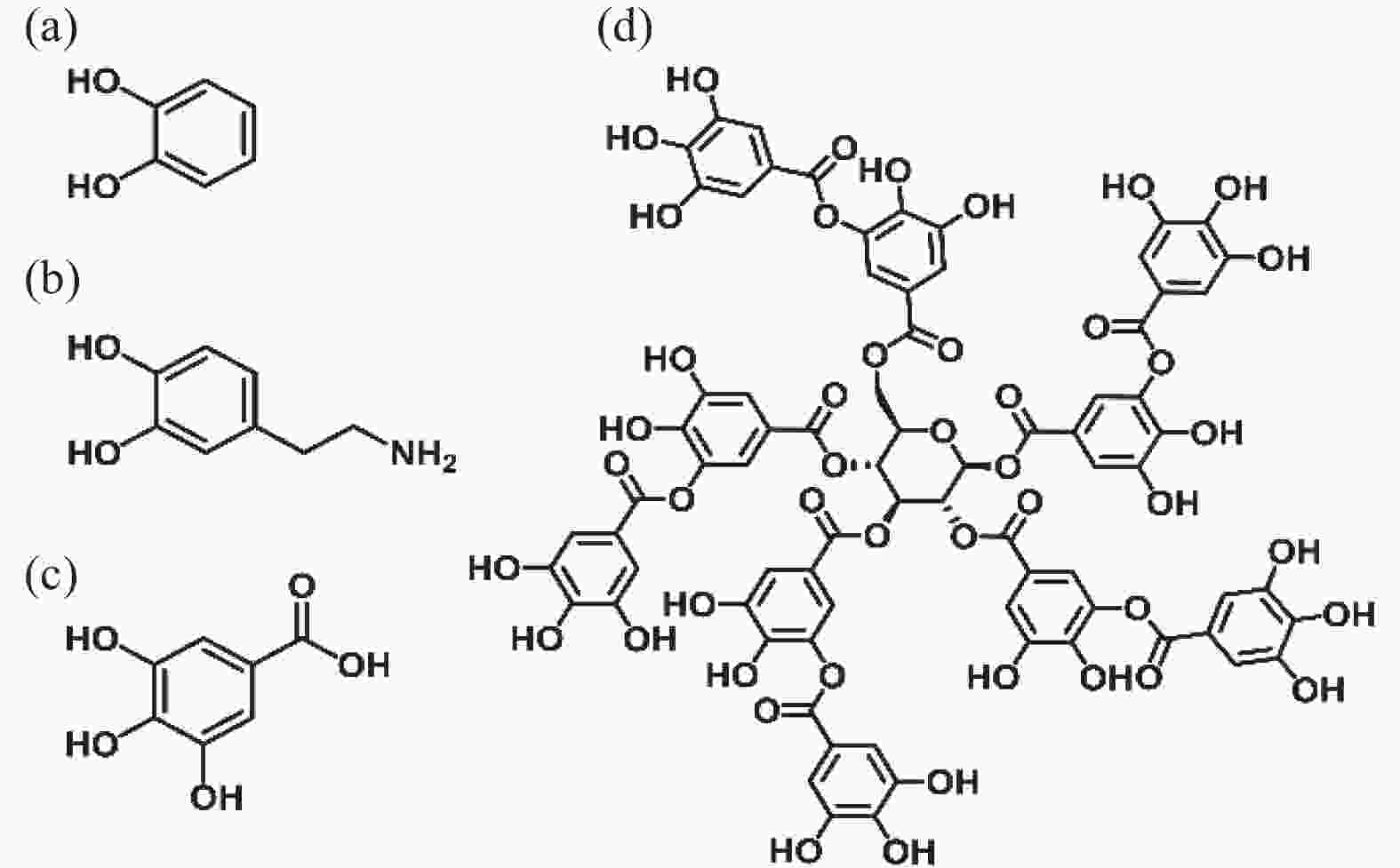

摘要: 多酚是一种含有多个酚羟基的化合物,广泛存在于天然植物中。多酚中含有大量疏水芳香环和酚羟基,与材料之间能够实现氢键、金属配位和π-π相互作用等多种类型的相互作用,被广泛应用于材料功能化改性中。本文综述了多巴胺、邻苯二酚、没食子酸及单宁酸4种多酚在纤维增强聚合物基复合材料改性方面的研究进展,其中主要包括不同多酚的结构及特性、对纤维表面的改性方法及在纤维增强聚合物基复合材料中的应用;最后,结合目前多酚的应用和限制,对多酚改性研究的未来研究方向和研究重点进行了展望。Abstract: Polyphenols are compounds with abundant phenolic hydroxyl groups which can be widely found in natural plants. Polyphenols can interact with the various materials to form hydrogen bonds, metal coordination and π-π interactions. Over the past few years, polyphenols have been widely applied in material functional modifications. In this paper, the structures and properties of polyphenols, including dopamine, catechol, gallic acid and tannic acid were reviewed. Meanwhile, the modification methods of fiber surface and the applications of fiber reinforced polymer composites were introduced. Finally, a prospective analysis on the future research direction and focus of polyphenol modification studies were provided.

-

Key words:

- fiber reinforced polymer composites /

- method of modification /

- dopamine /

- catechol /

- gallic acid /

- tannic acid

-

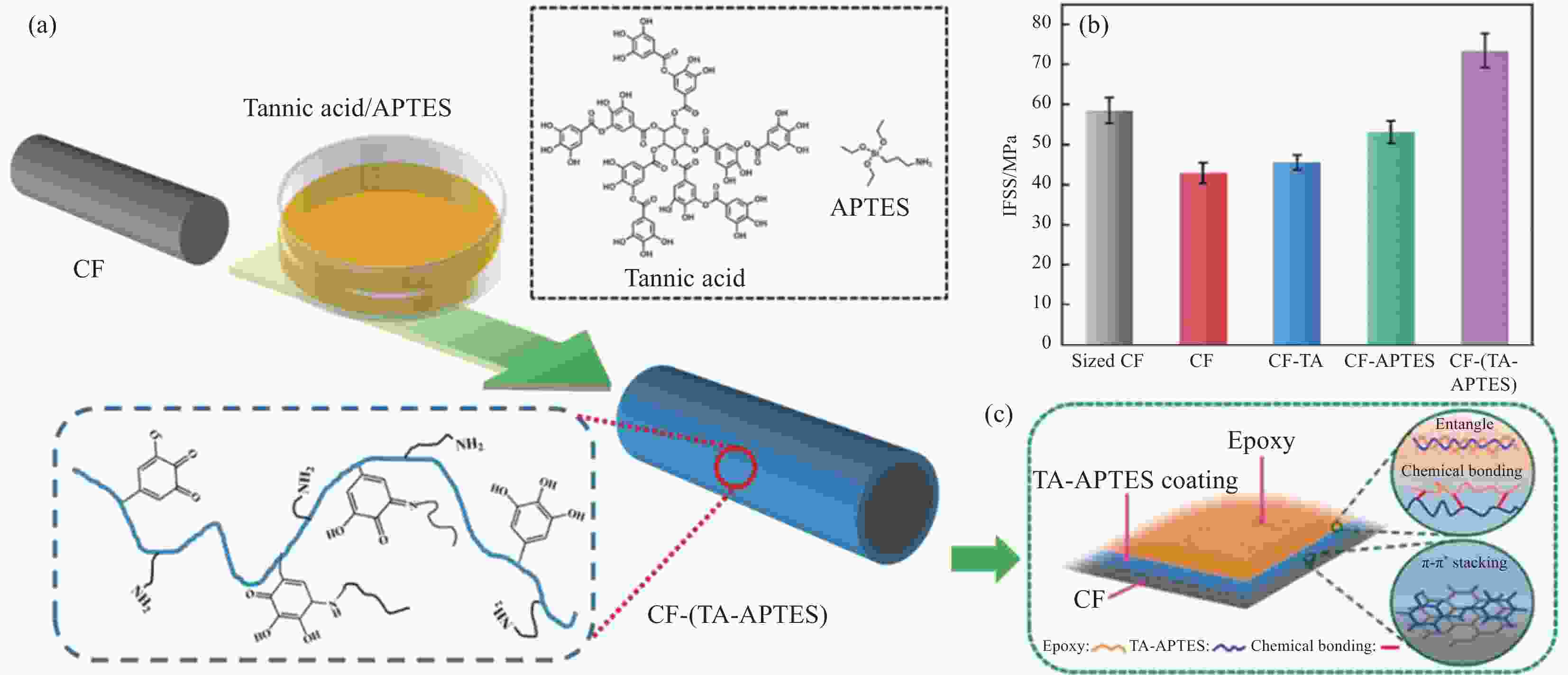

图 4 (a) CF共沉积处理工艺示意图;(b) 不同复合材料的界面剪切强度(IFSS);(c) CF复合材料的界面增强机制 [57]

Figure 4. (a) Schematic illustration of co-deposition treatment procedure of CF; (b) Interfacial shear strength (IFSS) of different composites; (c) Interfacial enhancement mechanism of CF composites[57]

APTES—Aminopropyltriethoxysilane

图 6 碳纤维增强复合材料(CFRP)断口表面的SEM图像:(a) 原始 CF/RPU 复合材料;(b) (CF-Ni)/RPU 复合材料;((c), (d)) (CF-TA-Ni)/RPU 复合材料[67]

Figure 6. SEM images of the carbon fibre reinforced polymer (CFRP) fractured surface: (a) Pristine CF/RPU composites; (b) (CF-Ni)/RPU composites; ((c), (d)) (CF-TA-Ni)/RPU composites[67]

RPU—Rigid polyurethane

表 1 多酚对纤维改性处理

Table 1. Fiber modification by polyphenols

Fiber Matrix Main compositions of coating Performance Ref. Carbon fiber Epoxy GA, gelatin IFSS: 85.6 MPa; Surface energy of the substrate (γP): 75.41 mN/m [34] Polyester fiber None GA, EDA Water contact angle reduced by 57.2°; The tensile strength of the modified fiber paper (2.022 kN/m) were increased by 35.2% [35] Carbon fiber PI PDA, Fe3+ minerali-

zation (β-FeOOH)Tensile strength: 202.5 MPa; Tensile modulus: 7.445 GPa; Low wear rates under different sliding speed (5 N, 200-500 r/min, 60 min) [36] Carbon fiber Nanosilica epoxy PDA After the 3-week salt spray test, the ILSS value of the PDA-SiO2 CFRP laminate is still 11% higher than that of the unmodified CFRP [37] Glass fiber None PDA, Ag NPs Conductivity: 2.49×106 S/m; Great flexibility (Could easily operate as a conductive wire for a LED light even under various bending angles) [38] UHMWPE fiber Rubber CL, TEPA, ZnO NPs Water contact angle: 36.2°; Surface energy: 37.8 mJ/m2; Pull-out force: 32.3 N [39] PET fiber Epoxy CL, PEI Water contact angle: 58.9°; The fabric melting temperature and decomposition temperature increased from 253.78℃ and

394.08℃ to 255.01℃ and 398.21℃, respectively[40] Polyamides fiber None TA/Thiophene Conductivity: 45 kΩ/cm; Electrothermal performance (Within 75 s, the temperature rises from 26.8 to 29.1℃ and basically reaches a robust level) [41] Wood fiber None TA, Fe(II) ions Surface area is increased 66.8% by TA; The complexes promote the pyrolysis of wood fibers at lower temperature (162℃) and generate more residual char (110%) [42] Notes: UHMWPE—Ultra high molecular weight polyethylene; PET—Polyethylene glycol terephthalate; EDA—Ethylenediamine; PI—Polyimide; PDA—Polydopamine; GA—Gallic acid; CL—Catechol; TEPA—Tetraethylenepentamine; PEI—Polyethyleneimine; TA—Tannic acid; IFSS—Interfacial shear strength; NPs—Nanoparticles; ILSS—Interlaminar shear strength; CFRP—Carbon fibre reinforced polymer. -

[1] 张孟华, 庞梓玄, 贾云祥, 等. 纤维增强陶瓷基复合材料的加工研究进展与发展趋势[J]. 航空材料学报, 2021, 41(5):14-27. doi: 10.11868/j.issn.1005-5053.2021.000033ZHANG Menghua, PANG Zixuan, JIA Yunxiang, et al. Research progress and development trend of fiber-reinforced ceramic matrix composites[J]. Journal of Aeronautical Materials,2021,41(5):14-27(in Chinese). doi: 10.11868/j.issn.1005-5053.2021.000033 [2] 吴利华, 袁宇慧. 先进纤维增强复合材料在大型客机上的应用现状[J]. 兵器材料科学与工程, 2018, 41(3):100-103. doi: 10.14024/j.cnki.1004-244x.20180509.002WU Lihua, YUAN Yuhui. Applications of advanced fiber-reinforced composite materials in large commercial aircraft[J]. Ordnance Material Science and Engineering,2018,41(3):100-103(in Chinese). doi: 10.14024/j.cnki.1004-244x.20180509.002 [3] 孙少杰. 碳纤维复合材料(CFRP)在汽车轻量化中的应用[J]. 粘接, 2022, 49(7):76-79. doi: 10.3969/j.issn.1001-5922.2022.07.018SUN Shaojie. Application of carbon fiber reinforced polymer (CFRP) in automotive lightweight[J]. Adhesion,2022,49(7):76-79(in Chinese). doi: 10.3969/j.issn.1001-5922.2022.07.018 [4] 邢丽英, 冯志海, 包建文, 等. 碳纤维及树脂基复合材料产业发展面临的机遇与挑战[J]. 复合材料学报, 2020, 37(11):2700-2706. doi: 10.13801/j.cnki.fhclxb.20200824.005XING Liying, FENG Zhihai, BAO Jianwen, et al. Facing opportunity and challenge of carbon fiber and polymer matrix composites industry development[J]. Acta Materiae Compositae Sinica,2020,37(11):2700-2706(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200824.005 [5] 吴超, 吴瑞东, 蒋金桥, 等. 土木工程应用中碳纤维/环氧树脂界面在环境影响下退化的分子模拟研究进展[J]. 复合材料学报, 2020, 37(12):2941-2952. doi: 10.13801/j.cnki.fhclxb.20200831.003WU Chao, WU Ruidong, JIANG Jinqiao, et al. Recent advances in understanding environmental effects on degradation of carbon fiber/epoxy matrix interface in civil engineering applications via molecular simulation[J]. Acta Materiae Compositae Sinica,2020,37(12):2941-2952(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200831.003 [6] 刘树博, 王子君, 张宏娜, 等. 聚四氟乙烯/芳纶纤维复合材料的制备工艺研究[J]. 化工新型材料, 2020, 48(12):48-51, 56.LIU Shubo, WANG Zijun, ZHANG Hongna, et al. Study on the preparation technology of PTFE/AF composite[J]. New Chemical Materials,2020,48(12):48-51, 56(in Chinese). [7] ZHOU Y, JIANG L, JIANG Z, et al. Surface hydrophilizing modification of polytetrafluoroethylene/glass fiber fabric through oxidant-induced polydopamine deposition[J]. Journal of Industrial Textiles,2019,50(3):364-379. [8] ALARA O R, ABDURAHMAN N H, UKAEGBU C I. Extraction of phenolic compounds: A review[J]. Current Research in Food Science,2021,4:200-214. doi: 10.1016/j.crfs.2021.03.011 [9] EJIMA H, RICHARDSON J J, LIANG K, et al. One-step assembly of coordination complexes for versatile film and particle engineering[J]. Science,2013,341(6142):154-157. doi: 10.1126/science.1237265 [10] 周青青. 酚类化合物/金属离子对纺织品的超疏水改性及应用研究[D]. 苏州: 苏州大学, 2020.ZHOU Qingqing. Study on superhydrophobic modifacation of textiles by phenolic compounds and metal ions and its application[D]. Soochow: Soochow University, 2020(in Chinese). [11] WANG Y, ZHANG J, ZHAO Y, et al. Innovations and challenges of polyphenol-based smart drug delivery systems[J]. Nano Research,2022,15(9):8156-8184. doi: 10.1007/s12274-022-4430-3 [12] SAMEC D, KARALIJA E, SOLA I, et al. The role of polyphenols in abiotic stress response: The influence of molecular structure[J]. Plants (Basel),2021,10(1):118. [13] LEE H, DELLATORE S M, MILLER W M, et al. Mussel-inspired surface chemistry for multifunctional coatings[J]. Science,2007,318(5849):426-430. doi: 10.1126/science.1147241 [14] DALSIN J L, MESSERSMITH P B. Bioinspired antifouling polymers[J]. Materials Today,2005,8(9):38-46. doi: 10.1016/S1369-7021(05)71079-8 [15] WAITE J H, QIN X X. Polyphosphoprotein from the adhesive pads of Mytilus edulis[J]. Biochemistry,2001,40(9):2887-2893. doi: 10.1021/bi002718x [16] WANG H, WU J, CAI C, et al. Mussel inspired modification of polypropylene separators by catechol/polyamine for Li-ion batteries[J]. ACS Applied Materials & Interfaces,2014,6(8):5602-5608. doi: 10.1021/am406052u [17] HONG S, WANG Y, PARK S Y, et al. Progressive fuzzy cation-π assembly of biological catecholamines[J]. Science Advances,2018,4(9):7457. doi: 10.1126/sciadv.aat7457 [18] ZHANG C, XIANG L, ZHANG J, et al. Revisiting the adhesion mechanism of mussel-inspired chemistry[J]. Chemical Science,2022,13:1698-1705. doi: 10.1039/D1SC05512G [19] 郑秀霞, 祝冬, 贯东艳, 等. 没食子酸检测方法的研究进展[J]. 中国食物与营养, 2022, 28(7):26-29.ZHENG Xiuxia, ZHU Dong, GUAN Dongyan, et al. Research progress of gallic acid detection method[J]. Food and Nutrition in China,2022,28(7):26-29(in Chinese). [20] KHALIL A, GERARDIN-CHARBONNIER C, CHAPUIS H, et al. Original bio-based antioxidant poly(meth)acrylate from gallic acid-based monomers[J]. ACS Sustainable Che-mistry & Engineering,2021,9(34):11458-11468. [21] ZHAN K, KIM C, SUNG K, et al. Tunicate-inspired gallol polymers for underwater adhesive: A comparative study of catechol and gallol[J]. Biomacromolecules,2017,18(9):2959-2966. doi: 10.1021/acs.biomac.7b00921 [22] FERRAZ DA COSTA D C, PEREIRA RANGEL L, QUARTI J, et al. Bioactive compounds and metabolites from grapes and red wine in breast cancer chemoprevention and therapy[J]. Molecules,2020,25(15):3531. doi: 10.3390/molecules25153531 [23] 石闪闪, 何国庆. 单宁酸及其应用研究进展[J]. 食品工业科技, 2012, 33(4):410-412. doi: 10.13386/j.issn1002-0306.2012.04.073SHI Shanshan, HE Guoqing. Tannic acid and the progress of its application[J]. Science and Technology of Food Industry,2012,33(4):410-412(in Chinese). doi: 10.13386/j.issn1002-0306.2012.04.073 [24] BELMARES R, CONTRERAS-ESQUIVEL J C, RODRÍGUEZ-HERRERA R, et al. Microbial production of tannase: An enzyme with potential use in food industry[J]. LWT-Food Science and Technology,2004,37(8):857-864. doi: 10.1016/j.lwt.2004.04.002 [25] 李冬冬, 蔡超, 杨萌, 等. 基于单宁酸的功能材料研究进展[J]. 高分子通报, 2017, 221(9):10-20. doi: 10.14028/j.cnki.1003-3726.2017.09.002LI Dongdong, CAI Chao, YANG Meng, et al. Progress in the application of tannic acid to the functional materials[J]. Polymer Bulletin,2017,221(9):10-20(in Chinese). doi: 10.14028/j.cnki.1003-3726.2017.09.002 [26] WU D, LIU X, SHENG Y, et al. Polyhedral oligomeric silsesquioxane encountering tannic acid: A mild and efficient strategy for interface modification on carbon fiber composites[J]. Langmuir,2022,38(27):8334-8341. doi: 10.1021/acs.langmuir.2c00866 [27] SALEH M N, TOMIĆ N Z, MARINKOVIĆ A, et al. The effect of modified tannic acid (TA) eco-epoxy adhesives on mode I fracture toughness of bonded joints[J]. Polymer Testing,2021,96:107122. doi: 10.1016/j.polymertesting.2021.107122 [28] 汪维海, 陈宏, 黄志超, 等. 多酚-氨基硅烷改性超高分子量聚乙烯纤维的制备及其界面性能[J]. 现代纺织技术, 2022, 30(6):63-72.WANG Weihai, CHEN Hong, HUANG Zhichao, et al. Preparation and interfacial properties of UHMWPE fibers modified by polyphenol & amino silane[J]. Advanced Textile Technology,2022,30(6):63-72(in Chinese). [29] 高佳鑫, 马金阳, 王世成, 等. 单宁酸仿生修饰及多元胺可控接枝表面改性超高分子量聚乙烯纤维[J]. 高分子材料科学与工程, 2021, 37(8):131-137. doi: 10.16865/j.cnki.1000-7555.2021.0201GAO Jiaxin, MA Jinyang, WANG Shicheng, et al. Tannic acid bionic modification and polyamine controllable grafting surface modification of ultra-high molecular weight polyethylene fiber[J]. Polymer Materials Science & Engineering,2021,37(8):131-137(in Chinese). doi: 10.16865/j.cnki.1000-7555.2021.0201 [30] BARRETT D G, SILEIKA T S, MESSERSMITH P B. Molecular diversity in phenolic and polyphenolic precursors of tannin-inspired nanocoatings[J]. Chem Commun (Camb),2014,50(55):7265-7268. doi: 10.1039/C4CC02961E [31] 王磊. 橡胶基复合材料用高性能纤维的表面修饰及其粘合性能研究[D]. 北京: 北京化工大学, 2017.WANG Lei. Surface modifacation of high performance fibers used in rubber-based composites and their interfacial adhension properties[D]. Beijing: Beijing University of Chemical Technology, 2017(in Chinese). [32] GUO Y, SUN Q, WU F G, et al. Polyphenol-containing nanoparticles: Synthesis, properties, and therapeutic delivery[J]. Advanced Materials,2021,33(22):2007356. doi: 10.1002/adma.202007356 [33] ZHOU J, LIN Z, JU Y, et al. Polyphenol-mediated assembly for particle engineering[J]. Accounts of Chemical Research,2020,53(7):1269-1278. doi: 10.1021/acs.accounts.0c00150 [34] ZHANG M, JIN L, ZHAI Y, et al. Bio-inspired gallic acid-gelatin coating: A novel strategy for eco-friendly interfacial modification of carbon fiber composites[J]. Composites Communications,2021,26:100790. doi: 10.1016/j.coco.2021.100790 [35] 庄思杰, 张静贤, 龙柱, 等. 没食子酸/乙二胺共沉积聚酯纤维的制备及其成纸性能[J]. 精细化工, 2021, 38(4):846-852.ZHUANG Sijie, ZHANG Jingxian, LONG Zhu, et al. Preparation of gallic acid/ethylenediamine co-deposited polyester fiber and its paper-forming properties[J]. Fine Chemicals,2021,38(4):846-852(in Chinese). [36] LIN Z, YANG J, JIA X, et al. Polydopamine/FeOOH-modified interface in carbon cloth/polyimide composites for improved mechanical/tribological properties[J]. Materials Chemistry and Physics,2020,243:122677. doi: 10.1016/j.matchemphys.2020.122677 [37] HAN W, ZHANG H P, XU X, et al. Hybrid enhancements by polydopamine and nanosilica on carbon fibre reinforced polymer laminates under marine environment[J]. Composites Part A: Applied Science and Manufacturing,2018,112:283-289. doi: 10.1016/j.compositesa.2018.06.019 [38] LIU G, ZHOU N, XIONG Q. Preparation of highly conductive and flexible Ag-coated single fiberglass via dopamine functionalization and electroless depositing[J]. Journal of Materials Science: Materials in Electronics,2021,32(3):3661-3672. doi: 10.1007/s10854-020-05112-w [39] FANG Z, TU Q, CHEN Z, et al. Study on catechol/tetraethylenepentamine and nano zinc oxide co-modifying ultrahigh molecular weight polyethylene fiber surface to improve interfacial adhesion[J]. Polymers for Advanced Technologies,2022,33(12):4072-4083. doi: 10.1002/pat.5838 [40] CHEN Y, WU X, WEI J, et al. Characterization and application to fiber reinforced composite of catechol/polyethyleneimine modified polyester fabrics by mussel-inspiration[J]. Fibers and Polymers,2020,21(11):2625-2634. doi: 10.1007/s12221-020-1161-5 [41] AI X, XIE A, CHENG J, et al. Fabrication of robust and high resilient polythiophene conductive polyamides fibers based on tannic acid modification[J]. Industrial & Engineering Chemistry Research,2022,61(30):11025-11033. [42] HUANG Y, LIN Q, YU Y, et al. Functionalization of wood fibers based on immobilization of tannic acid and in situ complexation of Fe(II) ions[J]. Applied Surface Science,2020,510:145436. doi: 10.1016/j.apsusc.2020.145436 [43] JIN L, ZHANG M, SHANG L, et al. A nature-inspired interface design strategy of carbon fiber composites by growing brick-and-mortar structure on carbon fiber[J]. Composites Science and Technology,2020,200:108382. doi: 10.1016/j.compscitech.2020.108382 [44] WU D, YAO Z, SUN X, et al. Mussel-tailored carbon fiber/carbon nanotubes interface for elevated interfacial properties of carbon fiber/epoxy composites[J]. Chemical Engineering Journal,2022,429:132449. doi: 10.1016/j.cej.2021.132449 [45] AI X, CHENG J, HOU X, et al. Fabrication of robust silver plated conductive polyamide fibres based on tannic acid modification[J]. RSC Advances,2022,12(29):18585-18593. doi: 10.1039/D2RA03116G [46] YANG L W, HAN L L, REN J, et al. Coating process and stability of metal-polyphenol film[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2015,484:197-205. [47] WANG Z, XIE Y J, LI Y W, et al. Tunable, metal-loaded polydopamine nanoparticles analyzed by magnetometry[J]. Chemistry of Materials,2017,29(19):8195-8201. doi: 10.1021/acs.chemmater.7b02262 [48] LIU Y, FANG Y, LIU X, et al. Mussel-inspired modification of carbon fiber via polyethyleneimine/polydopamine co-deposition for the improved interfacial adhesion[J]. Composites Science and Technology,2017,151:164-173. doi: 10.1016/j.compscitech.2017.08.008 [49] ZHANG M, LIU L, JIN L, et al. Catechol-based co-deposited carbon fiber surfaces for enhancement of fiber/epoxy composites[J]. Polymer Composites,2020,41(9):3817-3829. doi: 10.1002/pc.25679 [50] 赵晗, 尚晴, 杨萌, 等. 邻苯二酚-四乙烯五胺改性超高分子量聚乙烯纤维[J]. 高分子学报, 2020, 51(3):287-294.ZHAO Han, SHANG Qing, YANG Meng, et al. Surface modification of ultra-high molecular weight polyethylene fiber by catechol-tetraethylenepentamine[J]. Acta Polymerica Sinica,2020,51(3):287-294(in Chinese). [51] 王世成, 高佳鑫, 冯霞. 单宁酸协同改性超高分子量聚乙烯纤维与环氧树脂复合材料[J]. 高分子材料科学与工程, 2021, 37(4):92-98. doi: 10.16865/j.cnki.1000-7555.2021.0113WANG Shicheng, GAO Jiaxin, FENG Xia. Tannic acid synergistically modified ultra-high molecular weight polyethylene fiber and epoxy resin composite[J]. Polymer Materials Science & Engineering,2021,37(4):92-98(in Chinese). doi: 10.16865/j.cnki.1000-7555.2021.0113 [52] XUE S K, LI C C, LI J M, et al. A catechol-based biomimetic strategy combined with surface mineralization to enhance hydrophilicity and anti-fouling property of PTFE flat membrane[J]. Journal of Membrane Science,2017,524:409-418. doi: 10.1016/j.memsci.2016.11.075 [53] GREWAL M S, YABU H. Biomimetic catechol-based adhesive polymers for dispersion of polytetrafluoroethylene (PTFE) nanoparticles in an aqueous medium[J]. RSC Advances,2020,10(7):4058-4063. doi: 10.1039/C9RA10606E [54] XU H, NISHIDA J, MA W, et al. Competition between oxidation and coordination in cross-linking of polystyrene copolymer containing catechol groups[J]. ACS Macro Letters,2012,1(4):457-460. doi: 10.1021/mz200217d [55] WANG Z X, LAU C H, ZHANG N Q, et al. Mussel-inspired tailoring of membrane wettability for harsh water treatment[J]. Journal of Materials Chemistry A,2015,3(6):2650-2657. doi: 10.1039/C4TA05970K [56] CHEN L, ZHANG G, WU G, et al. Facile and environment-friendly mussel-inspired surface modification of PBO fibers via dopamine/3-aminopropyltrimethoxysilane co-deposition for advanced composite[J]. Polymer,2021,229:123999. doi: 10.1016/j.polymer.2021.123999 [57] ZHANG M, CHENG C, GUO C, et al. Co-depositing bio-inspired tannic acid-aminopropyltriethoxysilane coating onto carbon fiber for excellent interfacial adhesion of epoxy composites[J]. Composites Science and Technology,2021,204:108639. doi: 10.1016/j.compscitech.2020.108639 [58] EJIMA H, RICHARDSON J J, CARUSO F. Metal-phenolic networks as a versatile platform to engineer nanomaterials and biointerfaces[J]. Nano Today,2017,12:136-148. doi: 10.1016/j.nantod.2016.12.012 [59] 陈丽娟, 汪君, 闫叶寒, 等. 聚多巴胺涂层的研究与应用进展[J]. 高分子通报, 2018(7):42-49. doi: 10.14028/j.cnki.1003-3726.2018.07.005CHEN Lijuan, WANG Jun, YAN Yehan, et al. The progress of research and application of polydopamine coatings[J]. Polymer Bulletin,2018(7):42-49(in Chinese). doi: 10.14028/j.cnki.1003-3726.2018.07.005 [60] WANG L, ZHANG B, LI X, et al. Enhanced adhesion property of aramid fibers by polyphenol-metal iron complexation and silane grafting[J]. The Journal of Adhesion,2019,97(4):346-360. [61] WANG S, MA J, FENG X, et al. An effective surface modification of UHMWPE fiber for improving the interfacial adhesion of epoxy resin composites[J]. Polymer Composites,2020,41(4):1614-1623. doi: 10.1002/pc.25483 [62] SUN Z, GUO F L, LI Y Q, et al. Effects of carbon nanotube-polydopamine hybridization on the mechanical properties of short carbon fiber/polyetherimide composites[J]. Composites Part B: Engineering,2022,236:109848. doi: 10.1016/j.compositesb.2022.109848 [63] SHANMUGAM L, FENG X, YANG J. Enhanced interphase between thermoplastic matrix and UHMWPE fiber sized with CNT-modified polydopamine coating[J]. Composites Science and Technology,2019,174:212-220. doi: 10.1016/j.compscitech.2019.03.001 [64] WU Q, YANG X, YE Z, et al. Dopamine-dependent graphene oxide modification and its effects on interfacial adhesion of carbon fiber composites[J]. Surfaces and Interfaces,2022,31:102086. doi: 10.1016/j.surfin.2022.102086 [65] ZENG L, LIU X, CHEN X, et al. π-π interaction between carbon fibre and epoxy resin for interface improvement in composites[J]. Composites Part B: Engineering,2021,220:108983. doi: 10.1016/j.compositesb.2021.108983 [66] HAN W, ZHANG H P, TAVAKOLI J, et al. Polydopamine as sizing on carbon fiber surfaces for enhancement of epoxy laminated composites[J]. Composites Part A: Applied Science and Manufacturing,2018,107:626-632. doi: 10.1016/j.compositesa.2018.02.003 [67] LIU X, LI W, FENG M, et al. Strength and toughness of carbon fibers reinforced rigid polyurethane composites by adsorbing tannic acid and refining Ni grains on carbon fibers surface[J]. Polymers for Advanced Technologies,2020,32(1):326-334. [68] WOO R S C, ZHU H, LEUNG C K Y, et al. Environmental degradation of epoxy-organoclay nanocomposites due to UV exposure: Part II residual mechanical properties[J]. Composites Science and Technology,2008,68(9):2149-2155. doi: 10.1016/j.compscitech.2008.03.020 [69] 乔琨, 朱波, 高学平, 等. 紫外老化对碳纤维增强环氧树脂复合材料性能的影响[J]. 功能材料, 2012, 43(21):2989-2992. doi: 10.3969/j.issn.1001-9731.2012.21.026QIAO Kun, ZHU Bo, GAO Xueping, et al. Influence of artificial accelerating UV aging on carbon fiber reinforced epoxy composite[J]. Journal of Functional Materials,2012,43(21):2989-2992(in Chinese). doi: 10.3969/j.issn.1001-9731.2012.21.026 [70] 付晨阳, 倪爱清, 王继辉, 等. 紫外老化对玻璃纤维增强环氧树脂基复合材料疲劳性能的影响[J]. 复合材料科学与工程, 2020(7):74-80. doi: 10.3969/j.issn.1003-0999.2020.07.011FU Chenyang, NI Aiqing, WANG Jihui, et al. Effects of UV aging on fatigue properties of glass fiber reinforced epoxy resin composites[J]. Composites Science and Engineering,2020(7):74-80(in Chinese). doi: 10.3969/j.issn.1003-0999.2020.07.011 [71] 刘杰, 贾伯岩, 田霖, 等. 紫外老化对双酚A型环氧树脂综合性能影响[J]. 科学技术与工程, 2022, 22(20):8701-8707.LIU Jie, JIA Boyan, TIAN Lin, et al. Effect of UV aging on comprehensive properties of bisphenol a epoxy resin[J]. Science Technology and Engineering,2022,22(20):8701-8707(in Chinese). [72] YANG X, DUAN L, RAN X Q. Effect of polydopamine coating on improving photostability of polyphenylene sulfide fiber[J]. Polymer Bulletin,2017,74(3):641-656. doi: 10.1007/s00289-016-1735-y [73] CHEN L, LI Z, WU G, et al. In situ growth of TiO2 nanoparticles onto PBO fibers via a mussel-inspired strategy for enhancing interfacial properties and ultraviolet resistance[J]. Polymer Composites,2021,42(10):5065-5074. doi: 10.1002/pc.26205 [74] JIANG J, WANG S X, ZHANG S H, et al. Nano titanium dioxide/PAoQ-coated polybenzoxazol fibers for enhancing anti-ultraviolet performance[J]. Textile Research Journal,2018,88(19):2267-2275. doi: 10.1177/0040517517720501 [75] GE W, CAO S, SHEN F, et al. Rapid self-healing, stretchable, moldable, antioxidant and antibacterial tannic acid-cellulose nanofibril composite hydrogels[J]. Carbohydrate Polymers,2019,224:115147. doi: 10.1016/j.carbpol.2019.115147 [76] QIU S, SUN J, LI H, et al. A green way to simultaneously enhance the mechanical, flame retardant and anti-ultraviolet aging properties of polylactide composites by the incorporation of tannic acid derivatives[J]. Polymer Degradation and Stability,2022,196:109831. doi: 10.1016/j.polymdegradstab.2022.109831 [77] ZHANG L, LI Z, WANG D Y. Polydopamine-assisted strategies for preparation of fire-safe polymeric materials: A review[J]. European Polymer Journal,2020,138:109973. doi: 10.1016/j.eurpolymj.2020.109973 [78] YANG W, WU S, YANG W, et al. Nanoparticles of polydopamine for improving mechanical and flame-retardant properties of an epoxy resin[J]. Composites Part B: Engineering,2020,186:107828. doi: 10.1016/j.compositesb.2020.107828 [79] KIM Y O, CHO J, YEO H, et al. Flame retardant epoxy derived from tannic acid as biobased hardener[J]. ACS Sustainable Chemistry & Engineering,2019,7(4):3858-3865. [80] KIM Y O, CHO J, KIM Y N, et al. Recyclable, flame-retardant and smoke-suppressing tannic acid-based carbon-fiber-reinforced plastic[J]. Composites Part B: Engineering,2020,197:108173. doi: 10.1016/j.compositesb.2020.108173 [81] ZHENG Y, WANG X, WU G. Facile strategy of improving interfacial strength of silicone resin composites through self-polymerized polydopamine followed via the sol-gel growing of silica nanoparticles onto carbon fiber[J]. Polymers (Basel),2019,11(10):1639. doi: 10.3390/polym11101639 [82] CUI X, MA L, WU G. Mussel-inspired co-deposition of polydopamine/silica nanoparticles onto carbon fiber for improved interfacial strength and hydrothermal aging resistance of composites[J]. Polymers (Basel),2020,12(3):712. doi: 10.3390/polym12030712 [83] CUI X, LIU J, MA L, et al. Grafting of the hierarchical natural tannic acid and polyethyleneimine onto carbon fiber for significantly improved surface/interface properties[J]. Polymers for Advanced Technologies,2020,31(12):3126-3133. doi: 10.1002/pat.5037 -

下载:

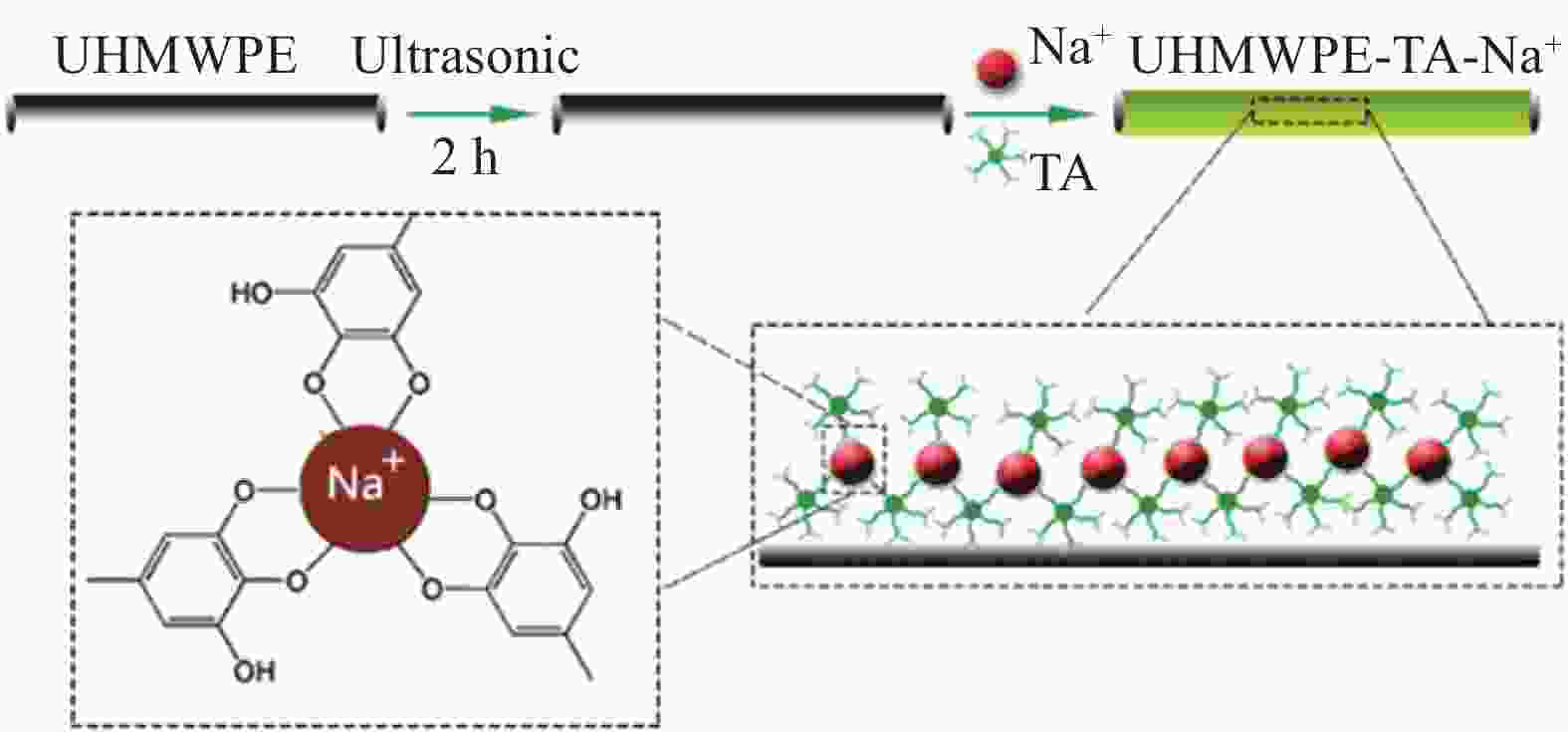

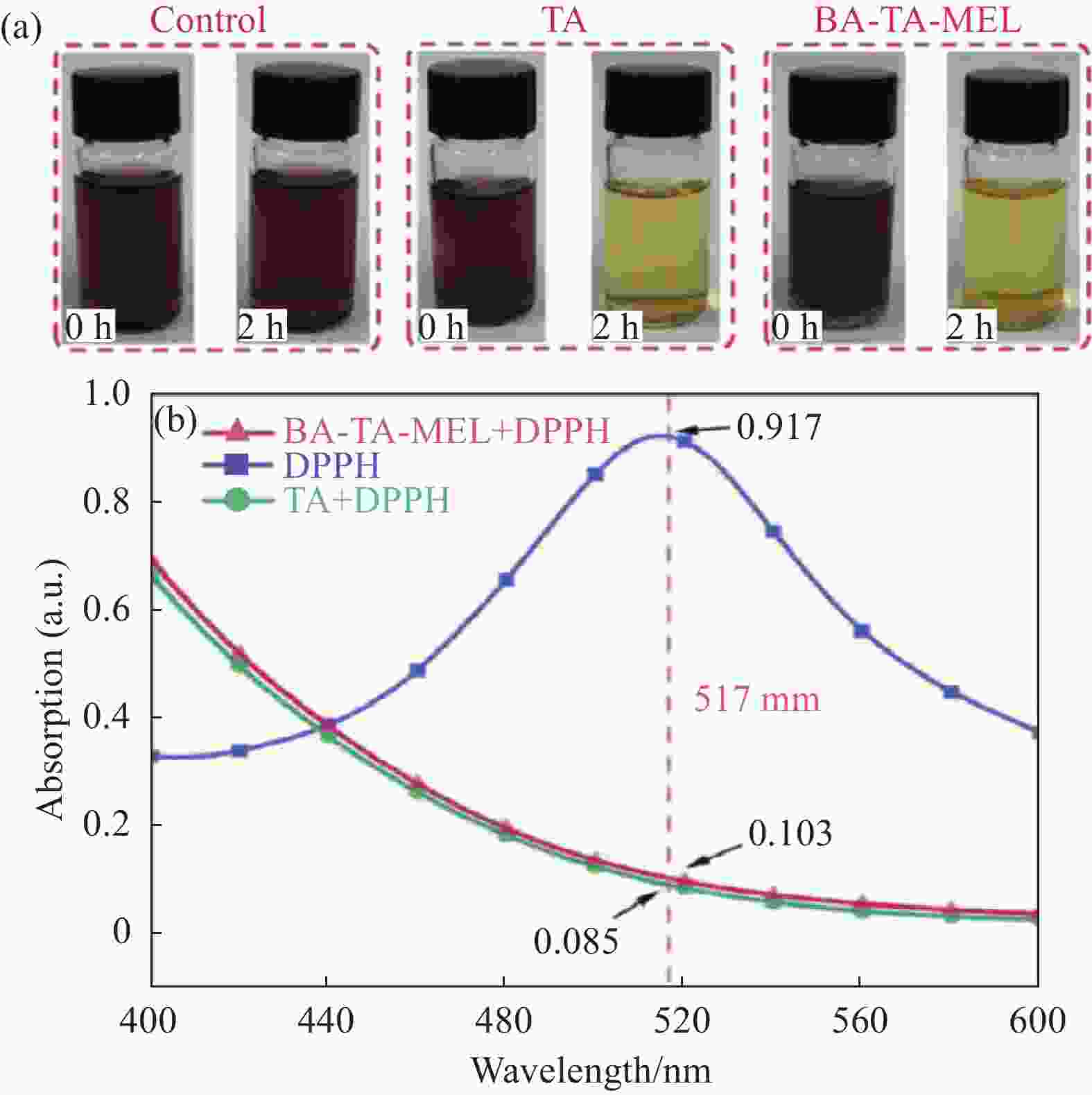

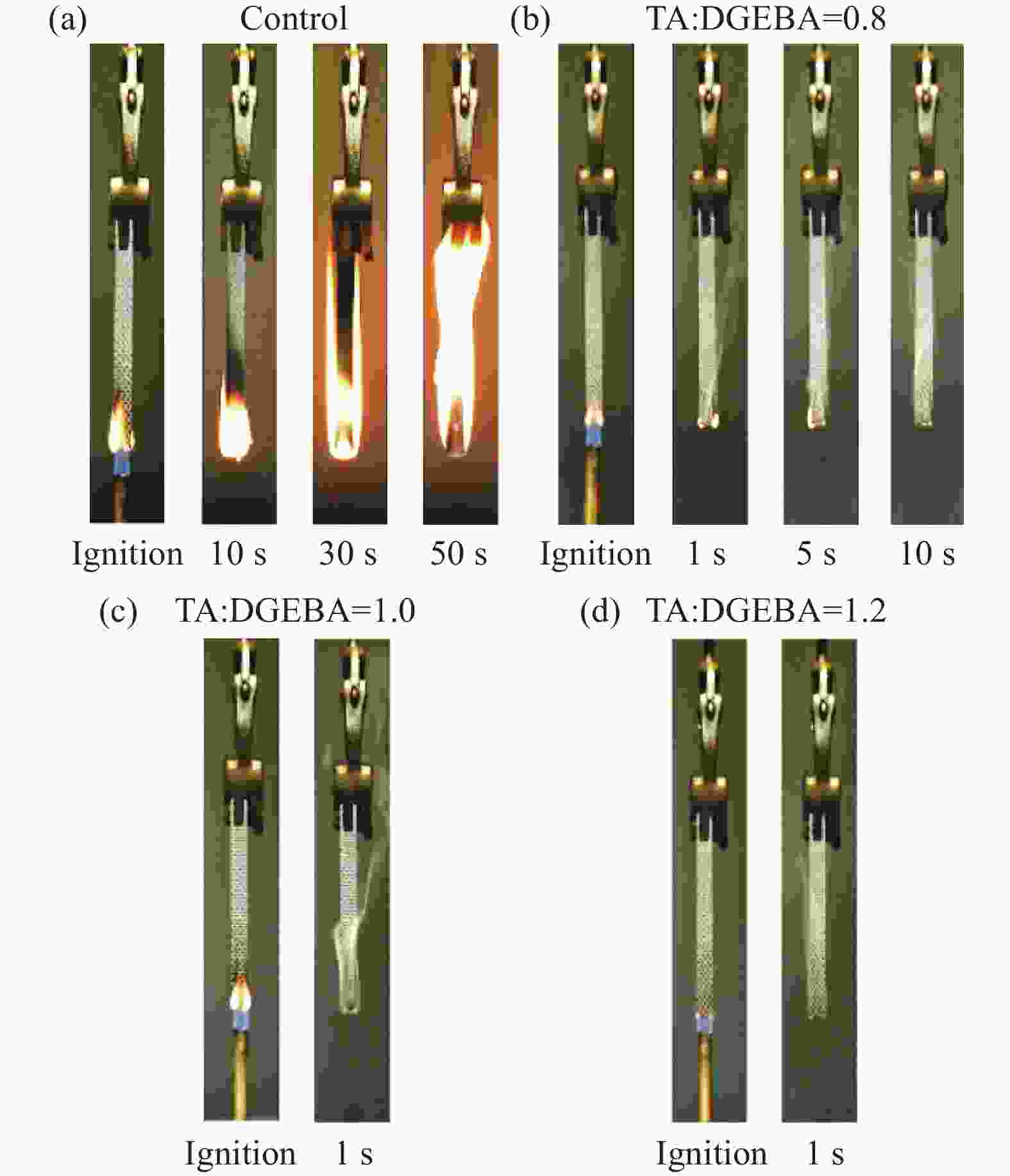

下载: