Progress in grinding mechanical modeling of fiber reinforced SiC ceramic matrix composites

-

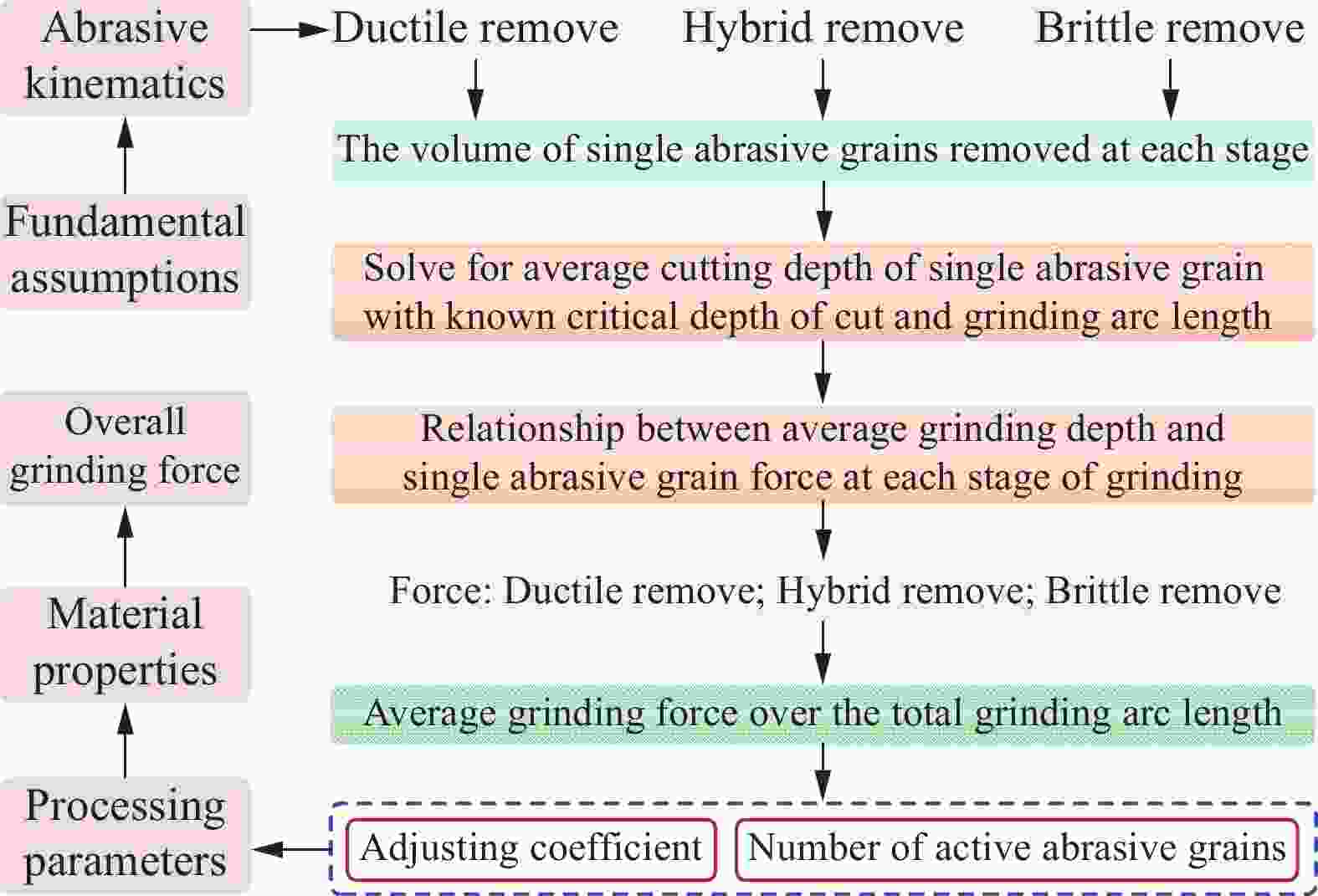

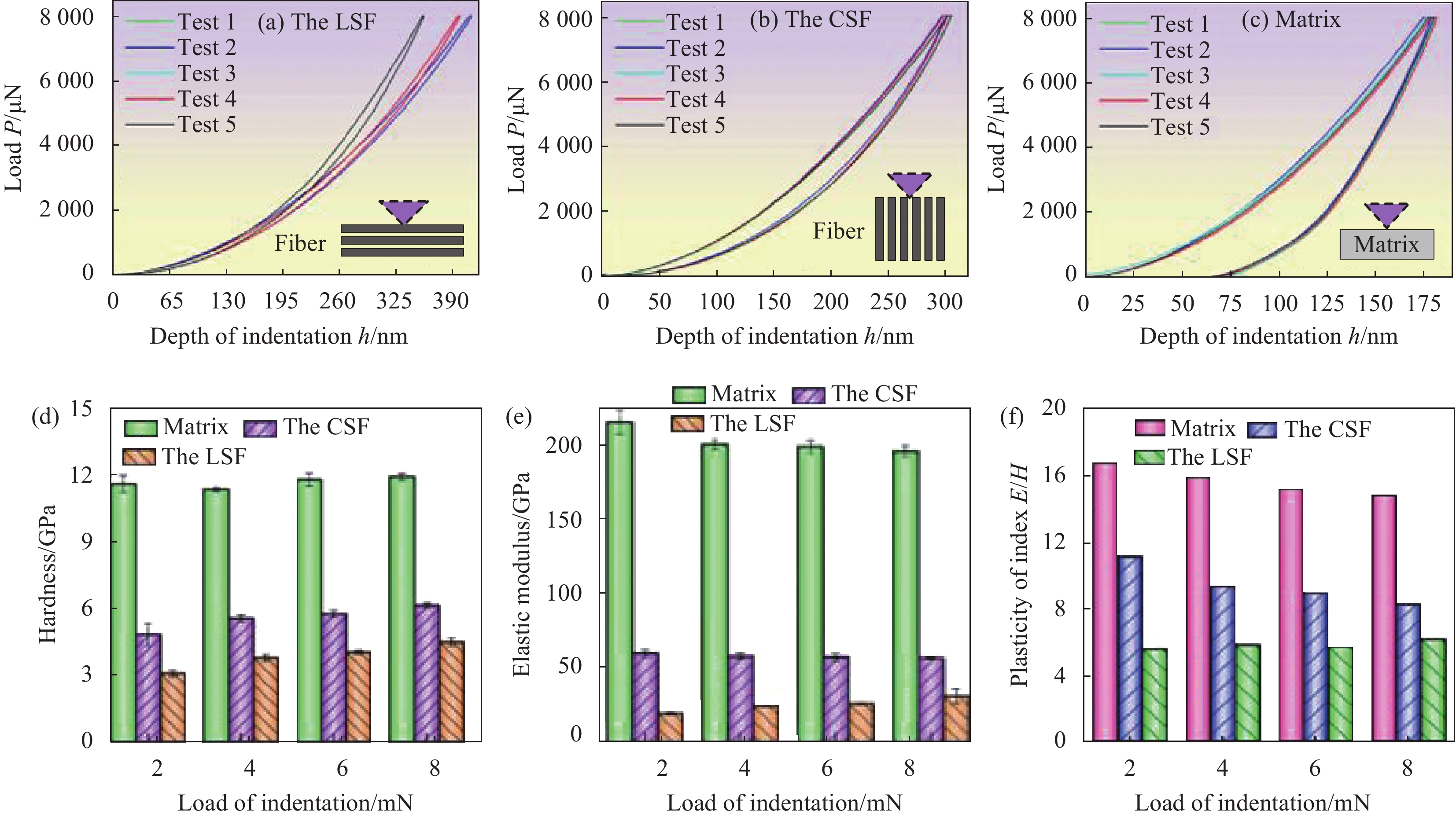

摘要: 纤维增强碳化硅陶瓷基复合材料(FRCMC)因其高比强度和比模量、以及优异的耐高温、耐腐蚀等性能已成为航空航天、轨道交通以及核能工业等领域的优选材料。尽管FRCMC是由成型技术制备,但一些加工工艺,例如磨削对于提升尺寸精度和表面完整性是必要的,在FRCMC结构件的高性能制造中不可或缺。然而,高硬度和脆性的材料属性及其结构上的不均质性和力学性能上的各向异性等特点是高效低损伤磨削加工的技术难点。磨削力作为反馈和控制生产过程质量和精度的关键信号,受磨削过程砂轮与工件几何学与运动学等多参数协同作用的影响,解析磨粒与工件的微观力学行为并建立磨削力预测模型,对深度理解材料去除机制、指导高性能制造至关重要。基于此,首先分析了磨削过程中材料特性及磨削参数对磨粒与FRCMC相互作用的影响规律,揭示了FRCMC磨削过程的材料去除机制。其次,系统回顾了FRCMC磨削力预测模型的研究现状,从单颗磨粒磨削力、磨粒几何学、纤维随机分布几何特性以及材料去除阶段判定准则分析推导了磨削力的建模过程。进一步的,从磨屑的成形机制、未变形切屑厚度、磨粒运动学等角度,分析了超声振动辅助磨削FRCMC的材料去除机制及磨削力力学行为的特殊性。最后,针对FRCMC材料去除机制和磨削力模型,分析了当前研究的潜在问题与研究热点。目标是为FRCMC制定可行的低损伤磨削准则,并建立溯源递进的理论框架以推动FRCMC磨削力模型的发展。Abstract: Fiber reinforced SiC ceramic matrix composites (FRCMC) have emerged as preferred materials in aerospace, nuclear energy, and other cutting-edge scientific and technological fields owing to their exceptional specific strength and modulus, as well as superior resistance to high temperatures and chemicals. Although FRCMC are prepared by molding techniques, some machining processes, such as grinding, are necessary to enhance dimensional accuracy and surface integrity, and are indispensable in the high-performance fabrication of FRCMC structural components. However, the innate material properties of high hardness and brittleness, coupled with structural characteristics such as anisotropy and non-homogeneity, pose challenges for efficient and low-damage grinding. The grinding force, serving as a crucial indicator for feedback and control in the production process, is influenced by synergistic effect of multiple parameters of the grinding process, such as wheel and workpiece geometry and kinematics. Therefore, elucidating the mechanical behavior of abrasive grains and work-pieces, and modeling the grinding force, are imperative for comprehending the processing mechanism and guiding efficient production practices. Based on this, the paper firstly analyzed the influence of material properties and grinding parameters on the interaction mechanism between abrasive grains and FRCMC during the grinding process. Secondly, the current research status of FRCMC grinding force prediction modeling was systematically reviewed. The modeling process of grinding force was analytically deduced from the grinding force of a single grain, the geometry of the grain, the geometric properties of the random distribution of fibers, and the criteria for determining the stage of material removal. Furthermore, it discussed the unique aspects of material removal mechanisms and grinding force modeling for ultrasonic vibration-assisted grinding of FRCMC from the viewpoints of the chips shaping mechanism, the thickness of the undeformed chips, and the kinematics of the abrasive grains. Finally, the paper discussed current research gap, and identifies potential research hotspots. The objective is to formulate practical guidelines for low-damage grinding of FRCMC and establish a robust theoretical framework to advance grinding force modeling not only for FRCMC but also for other materials.

-

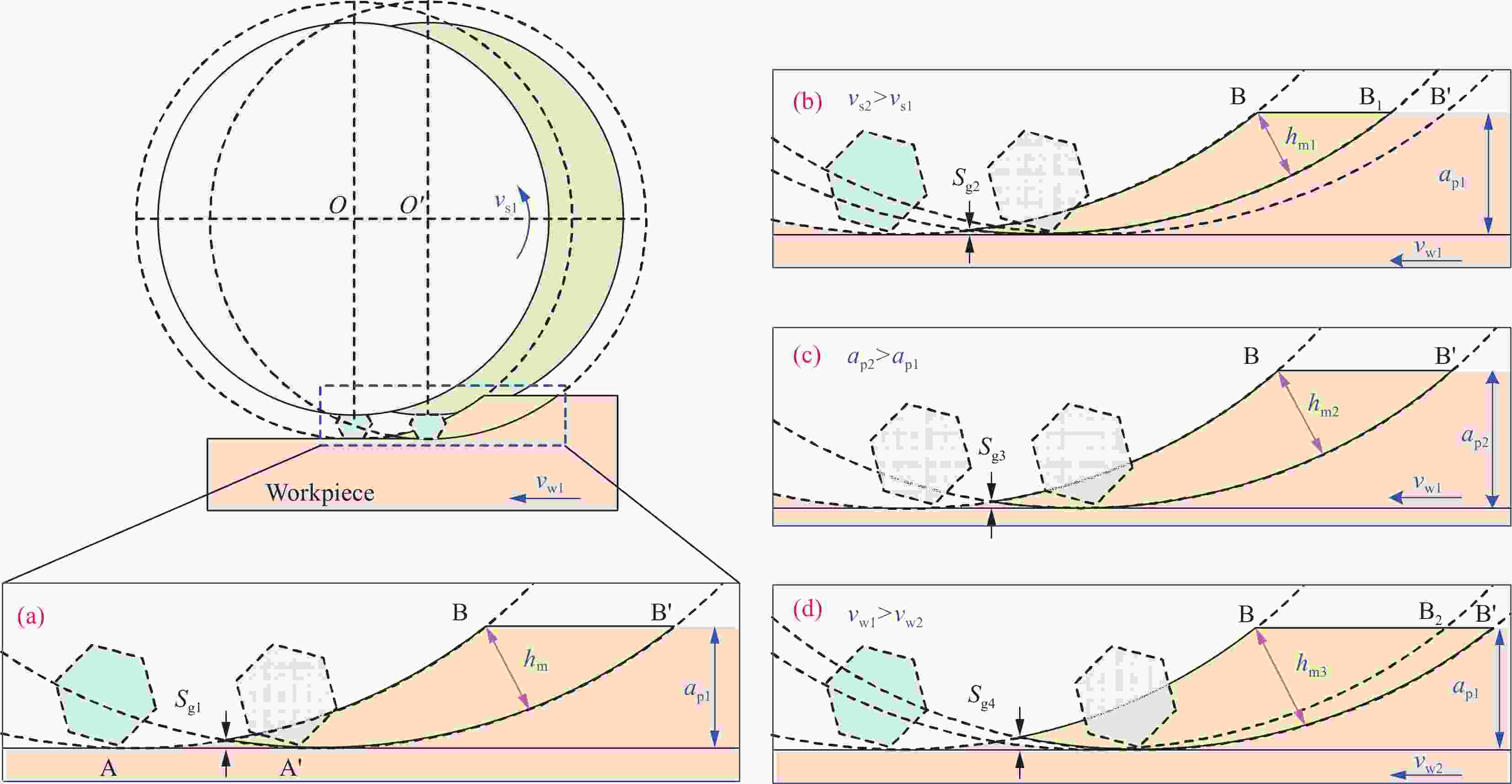

图 7 磨削参数对未变形切屑厚度及残余轮廓高度的影响

Figure 7. Effect of grinding parameters on thickness of undeformed chips and scallop height

Sg—Scallop height of workpiece; ap—Grinding depth; vw—Feed speed of workpiece; vs—Linear velocity of grinding wheel; hm—Maximum undeformed chip thickness; The numerical subscripts only represent different working conditions and have no special meaning

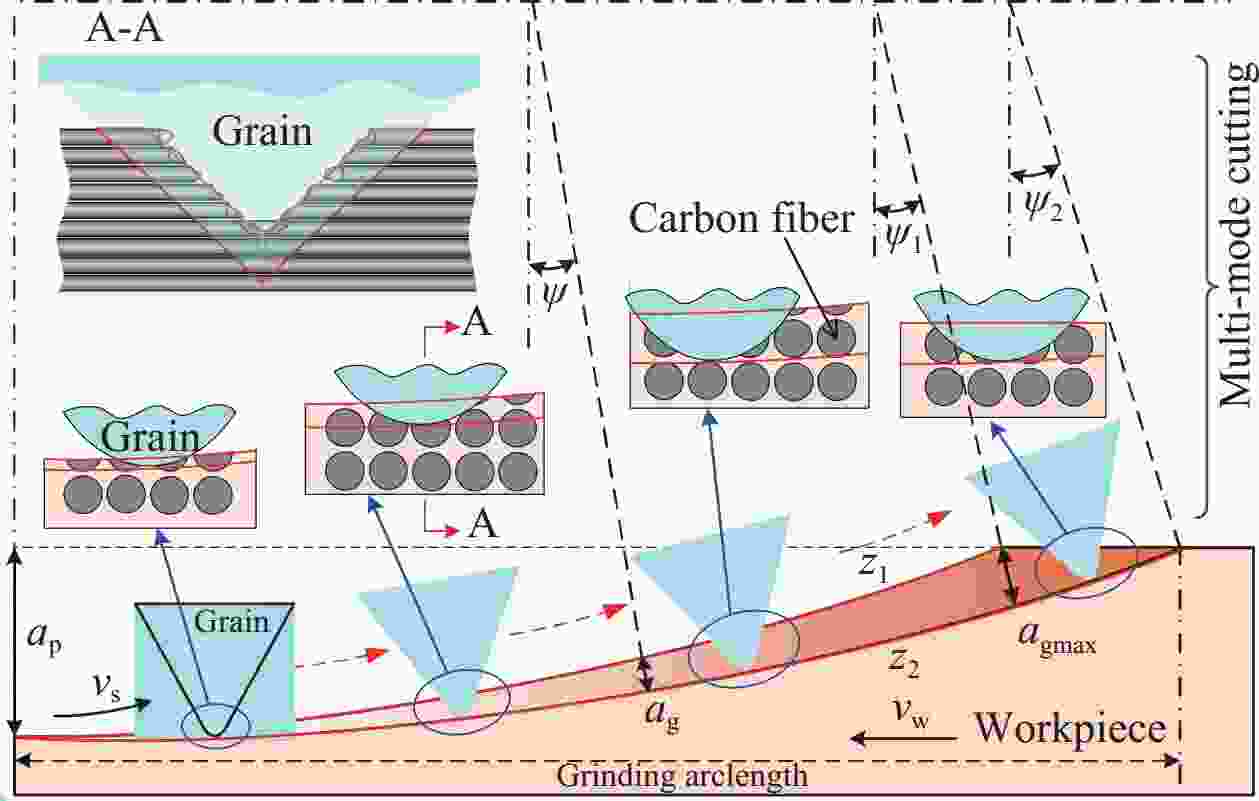

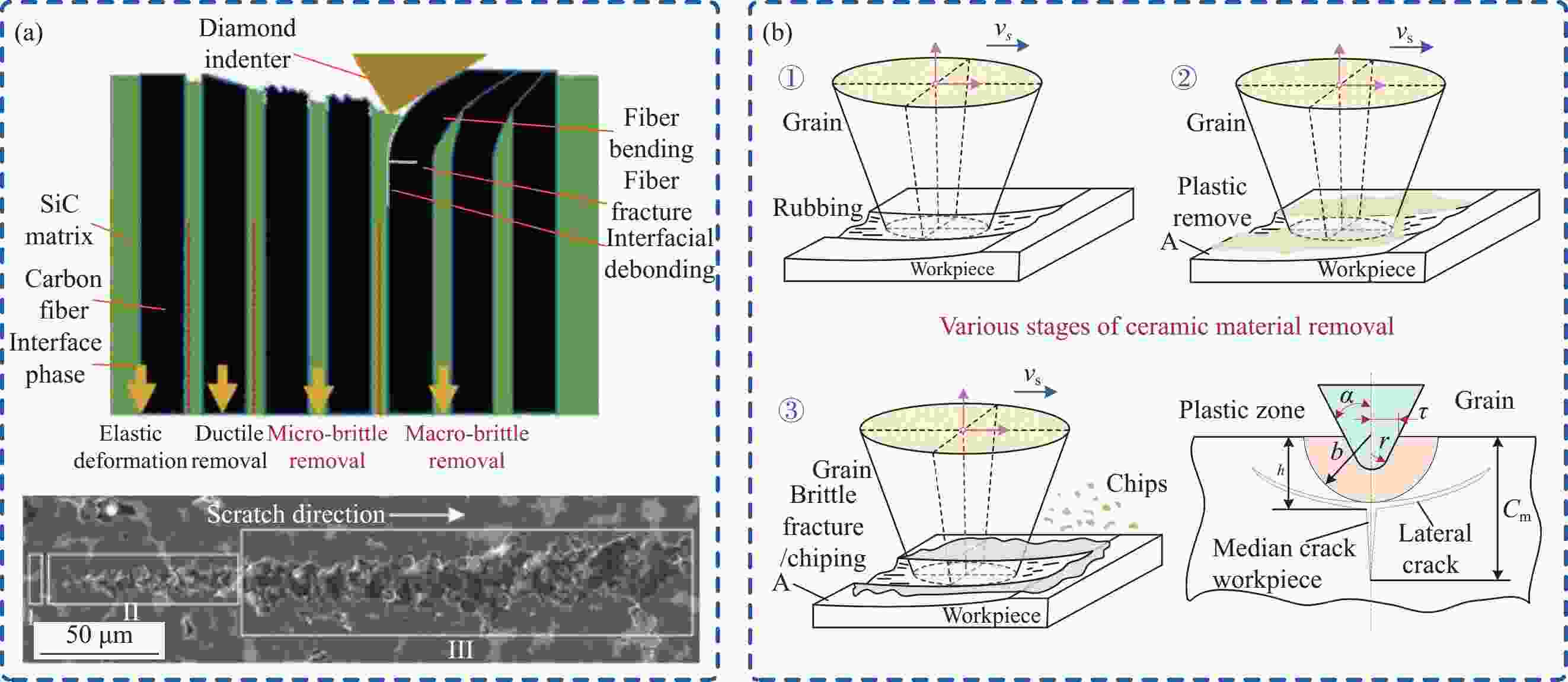

图 12 磨削弧区磨粒-FRCMC接触行为

Figure 12. Abrasive grain-FRCMC contact behavior in the grinding arc region

ψ, ψ1, ψ2—Grinding angle of the abrasive grains at different moments; ag—Penetration depth of abrasive grains; agmax—Maximum undeformed chip thickness; z1—Previous grit grinding trajectory; z2—Trajectory of the next grit

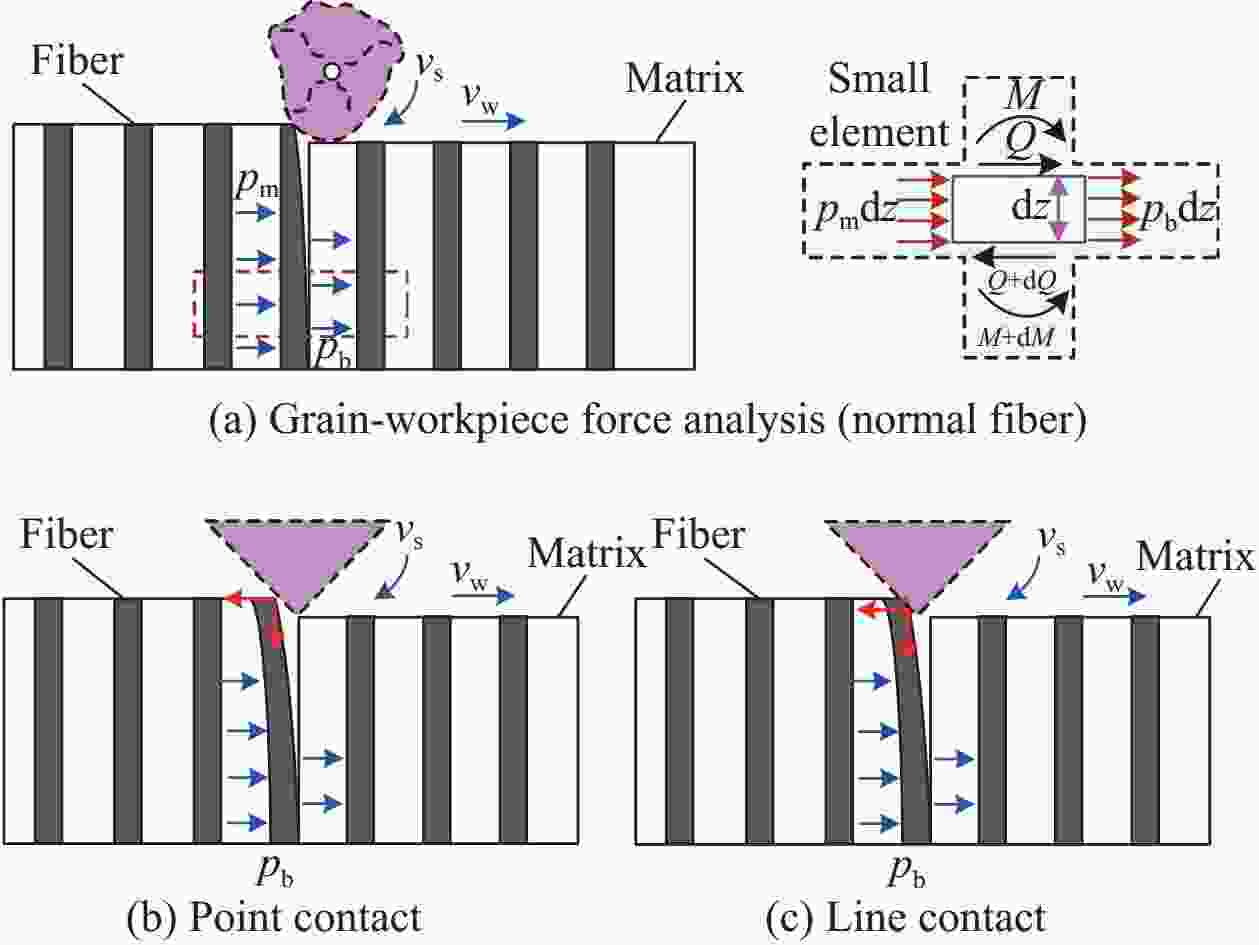

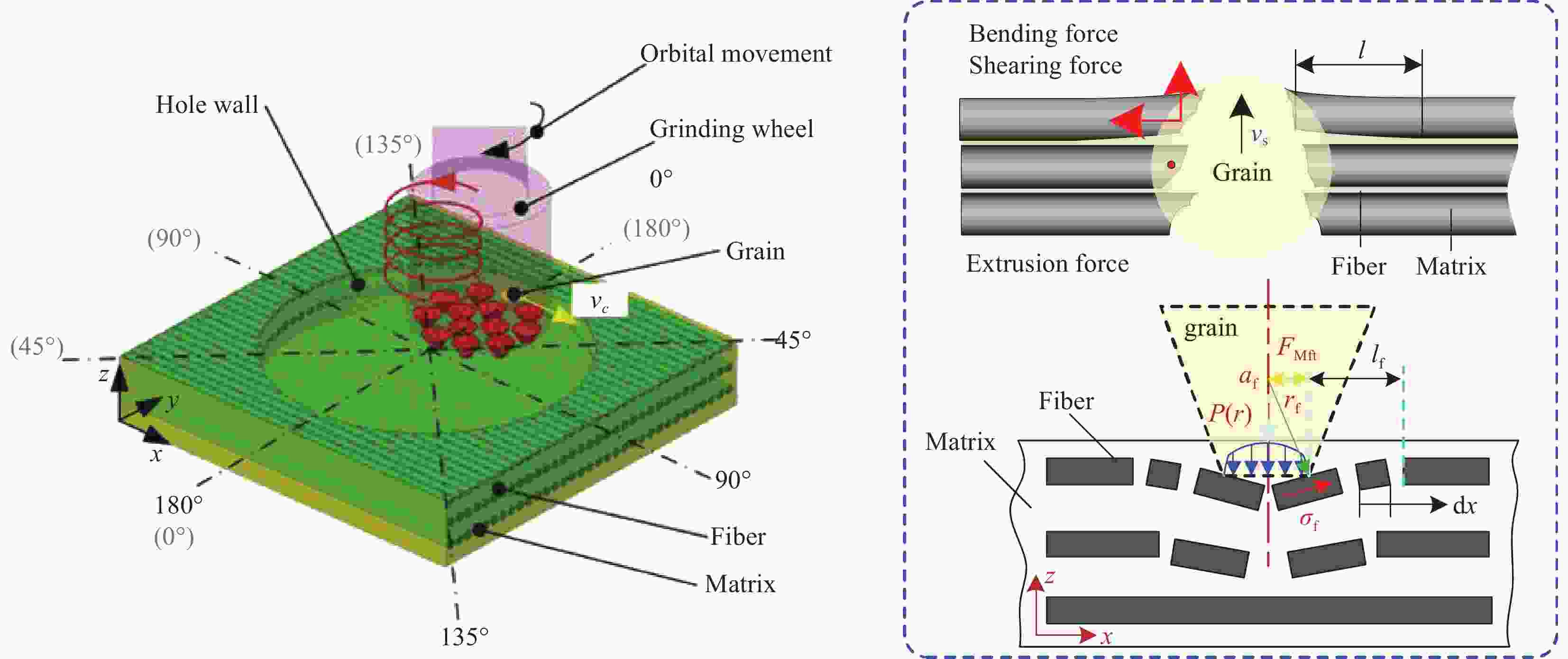

图 14 磨粒-纤维螺旋制孔接触力学行为

Figure 14. Contact mechanical behavior of abrasive grain-fiber in helical grinding

FMft—Axial component of fiber removal force; σf—Stress along the axis; P(r)—Normal pressure distribution on the contact surface; lf—Length of fractured fiber under contact area; af—Half of the contact length of the abrasive grain; rf—Radius of abrasive grain

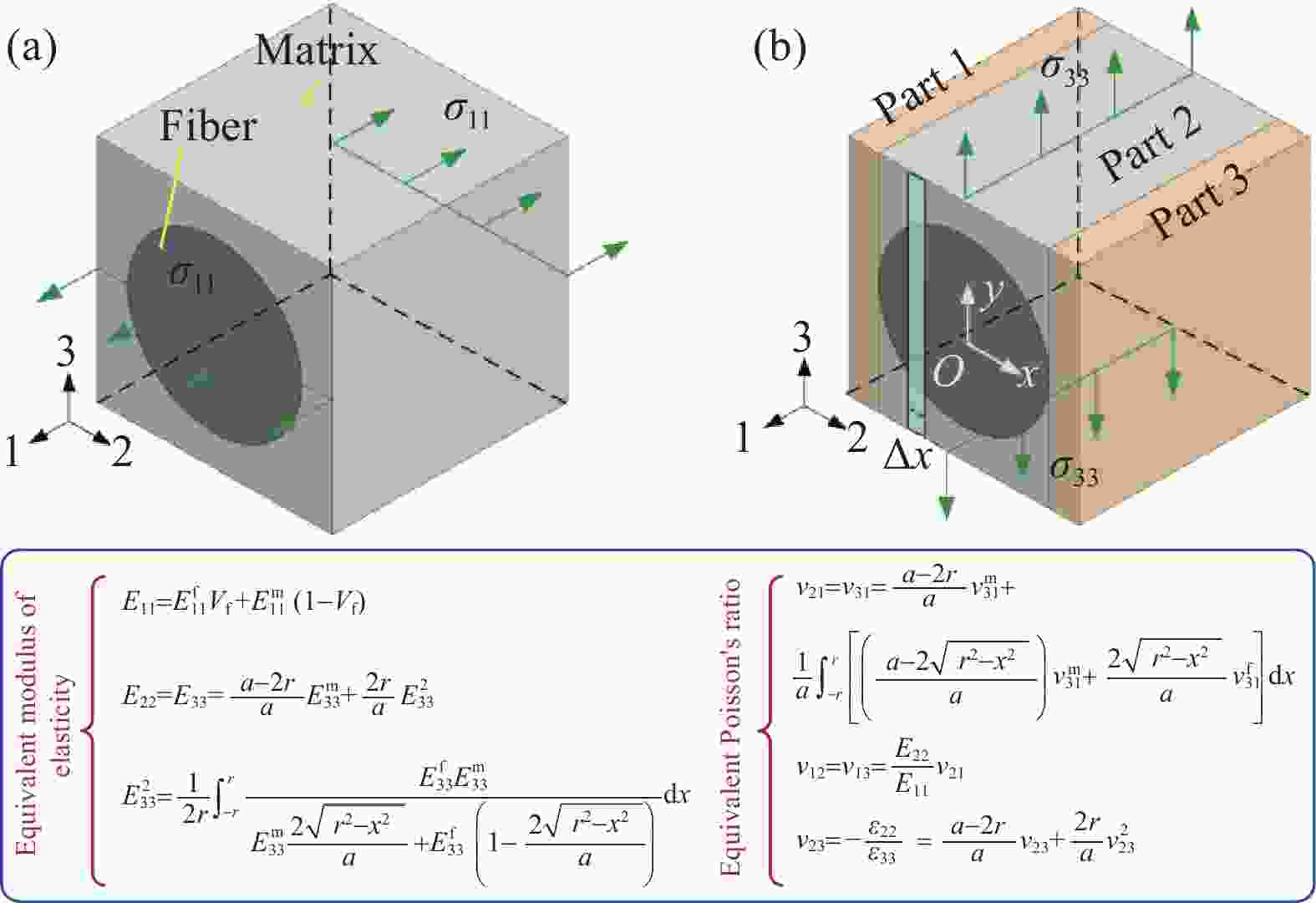

图 15 SiCf/SiC复合材料在不同方向上代表性体积单元(RVE)的荷载[77]

Figure 15. Load schematic of representative volume element (RVE) of SiCf/SiC composite in different directions[77]

σ11—Stress in direction 1; σ33—Stress in direction 3; Δx—Differential unit; E11—Equivalent elastic modulus of the composite in direction 1; $ E_{11}^{\mathrm{f }}$ and $ E_{11}^{\mathrm{m}} $—Elastic modulus of the fiber and matrix in direction 1, respectively; E22 and E33—Equivalent elastic modulus of the composite in directions 2 and 3, respectively; $ E_{33}^{\mathrm{m}} $—Equivalent elastic modulus of the matrix in direction 3; $ E_{33}^2 $—Equivalent elastic modulus of part 2 in direction 3; a—Edge length of the RVE; r—Radius of the fibers; Vf—Volume of fiber fraction; v—Equivalent Poisson's ratio in each direction

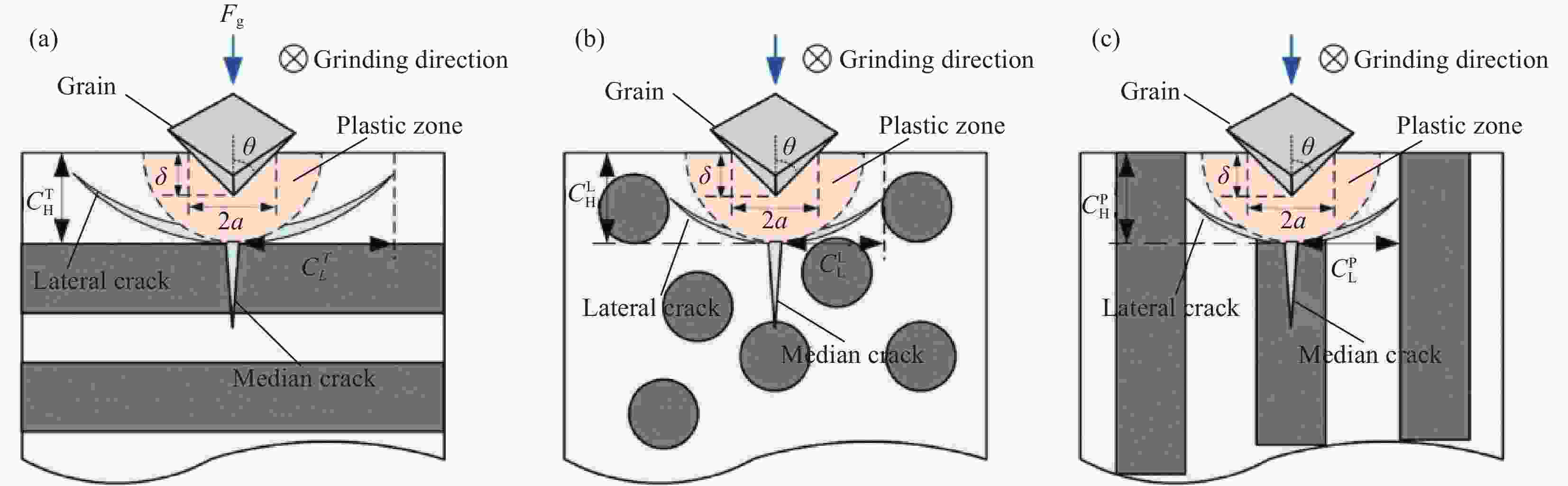

图 16 磨粒与不同取向纤维接触产生的裂纹系统[77]

Figure 16. Cracking systems produced by contact of abrasive grains with different fiber orientations[77]

$ C_{\mathrm{H}}^{\mathrm{T}},C_{\mathrm{L}}^{\mathrm{T}} $—Width and depth of the lateral crack when grinding along transverse fiber; $ C_{\mathrm{H}}^{\mathrm{L}},C_{\mathrm{L}}^{\mathrm{L}} $—Width and depth of the lateral crack when grinding along longitudinal fiber; $ C_{\mathrm{H}}^{\mathrm{P}},C_{\mathrm{L}}^{\mathrm{P}} $—Width and depth of the lateral crack when grinding along perpendicular fiber

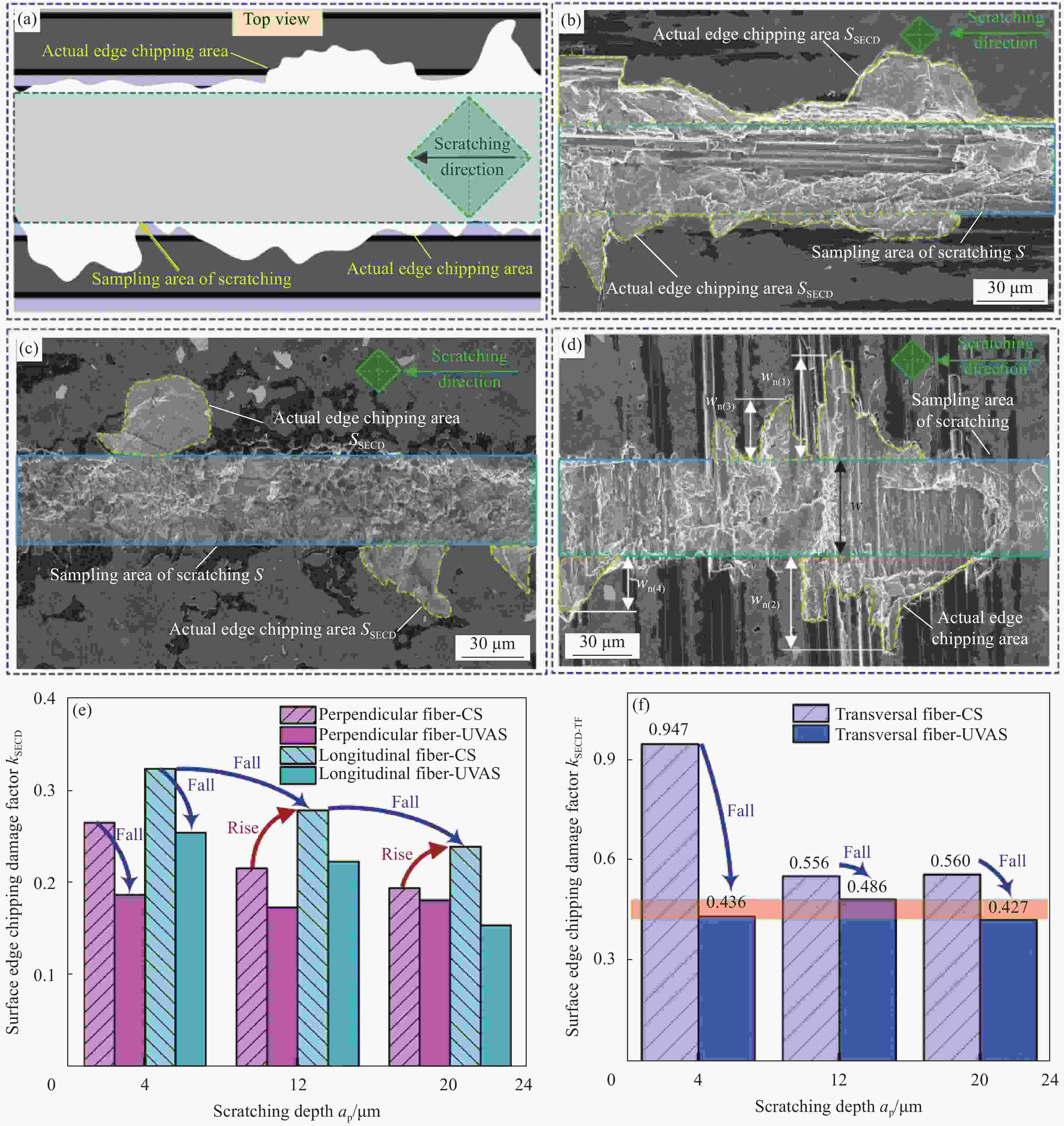

图 20 旋转超声振动划擦表面损伤评价[112]

Figure 20. Evaluation of surface damage by rotational ultrasonic vibration scratching[112]

wn(i) is the width of surface edge chipping damage (SECD) at place i perpendicular to the direction of scratch, and w is actual width of the scratch in the sampled view; CS—Conventional conventional scratching; UVAS—Ultrasonic vibration-assisted scratching

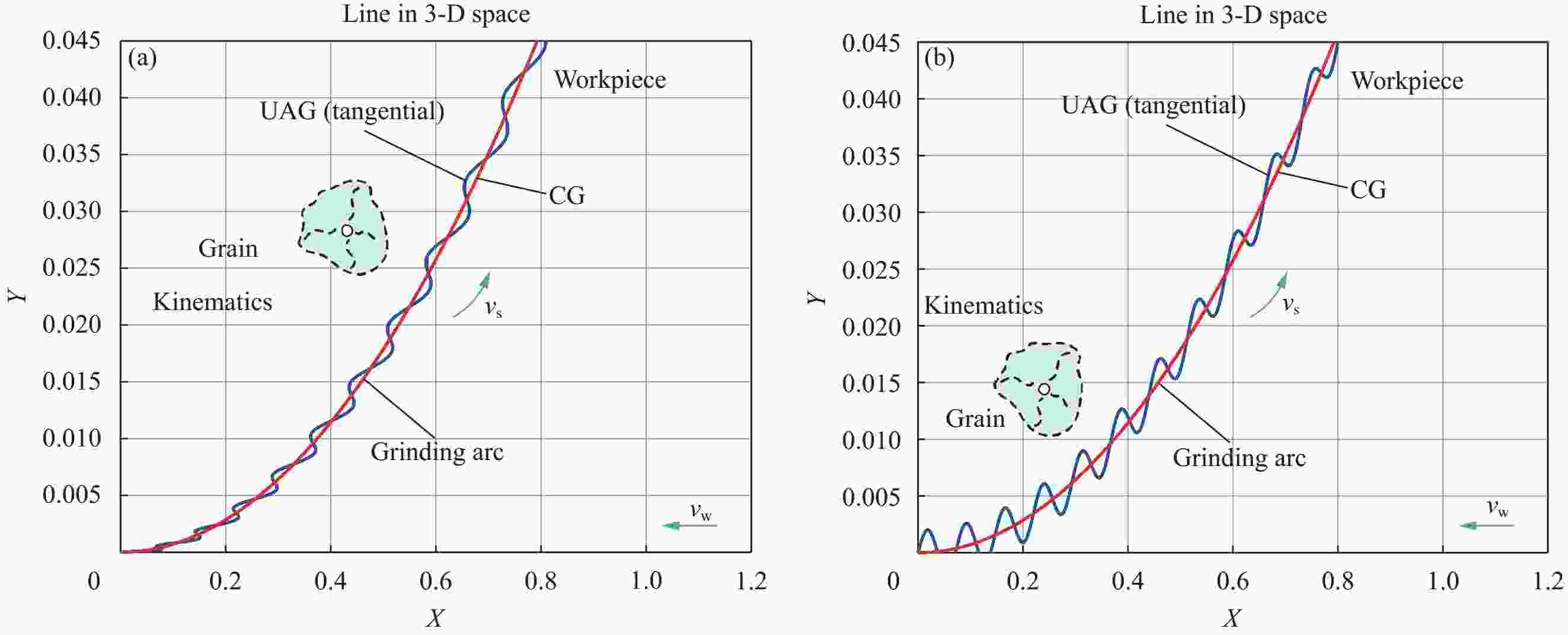

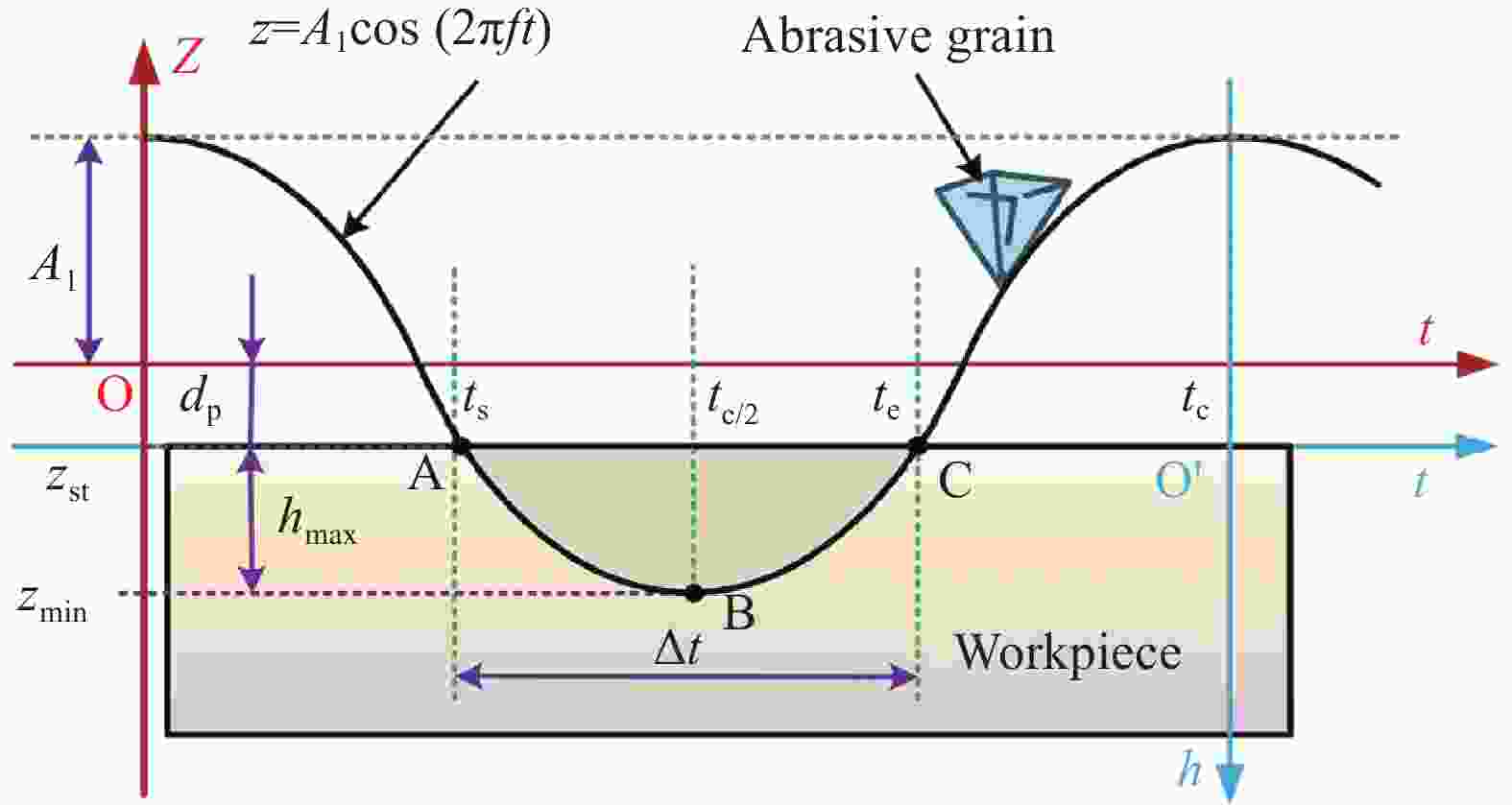

图 24 磨粒-工件周期性的接触行为

Figure 24. Cyclic abrasive-workpiece contact behaviour

A1—Amplitude of ultrasonic vibration; dp—Distance between the workpiece and the center of vibration of the abrasive grain; zst—The initial contact height between the abrasive grain and the workpiece; zmin—Minimum contact height between the abrasive and the workpiece; hmax—Maximum undeformed cutting chip thickness; t—The moments at different stages of contact; Δt—One contact time of the abrasive grain with the workpiece

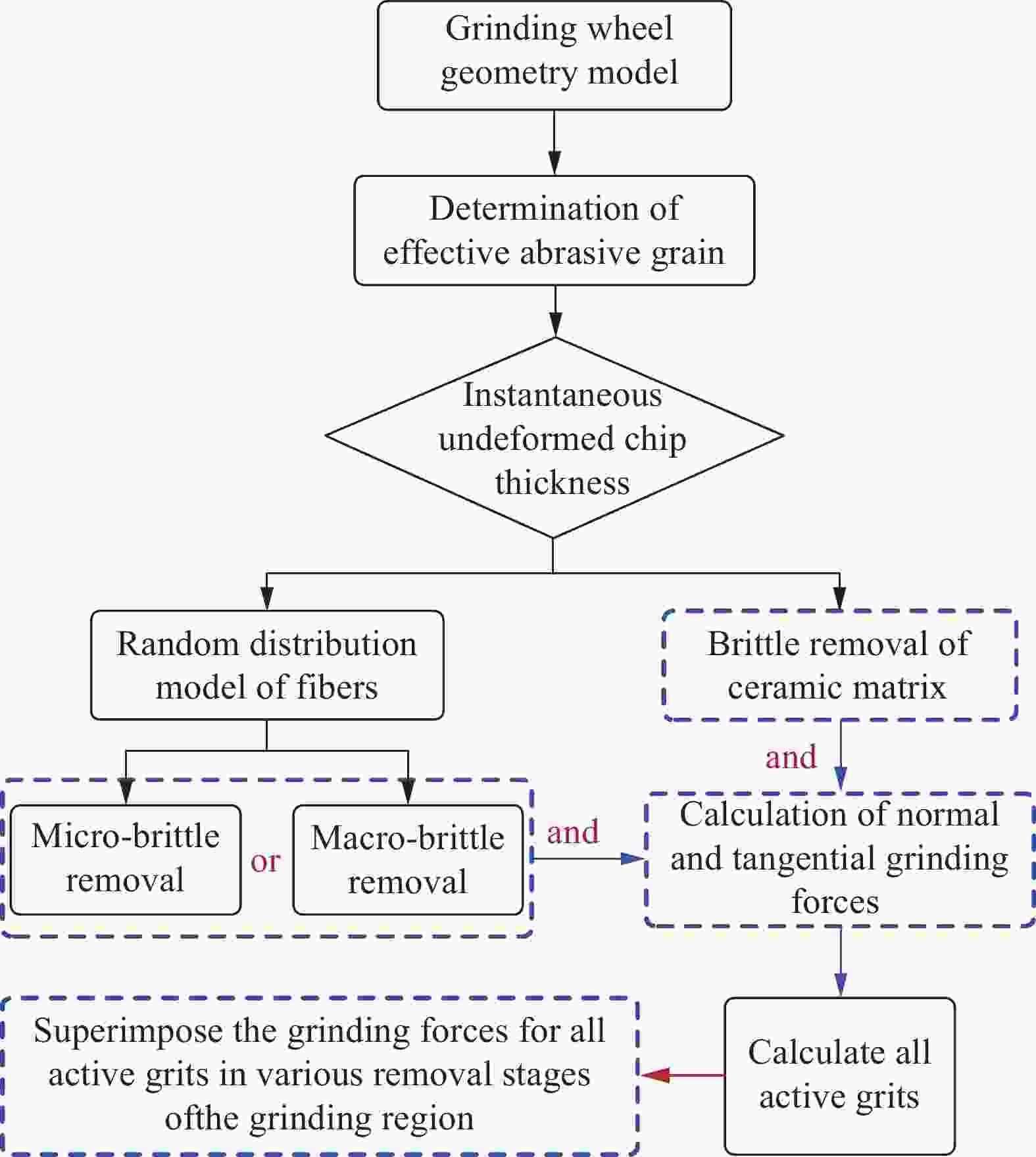

表 1 FRCMC传统磨削的磨削力预测模型

Table 1. Grinding force prediction model of FRCMC in conventional grinding

Working condition Grinding force model Key findings and numbers Ref. Grinding Cf/SiC

(along fiber normal)$ \begin{gathered}F_{\mathrm{t\mathit{x}}}=\delta l_{\mathrm{c}}C\beta'\left(\frac{K_{1\mathrm{C}}^{1/2}H^{9/10}}{E_{\mathrm{w}}^{2/5}}\right)\left(\frac{v_{\mathrm{w}}}{v_{\mathrm{s}}}\right)^{3/4}d_{\mathrm{s}}^{1/12}a_{\mathrm{p}}^{11/12}+ \\ 0.38Cl_{\mathrm{c}}Kd_{\mathrm{a}}\frac{1}{d_{\mathrm{f}}}\left(\int_0^{a_{\mathrm{p}}+h}k_{\mathrm{m}}x_1\mathrm{d}\mathrm{\mathit{z}}+\int_{a_{\mathrm{p}}+h}^{\infty}\left(k_{\mathrm{m}}+k_{\mathrm{b}}\right)x_2\mathrm{d}\mathit{z}\right) \\ \end{gathered} $ Significant increase in grinding force with increasing grinding depth. (2-1) [75] Grinding Cf/SiC

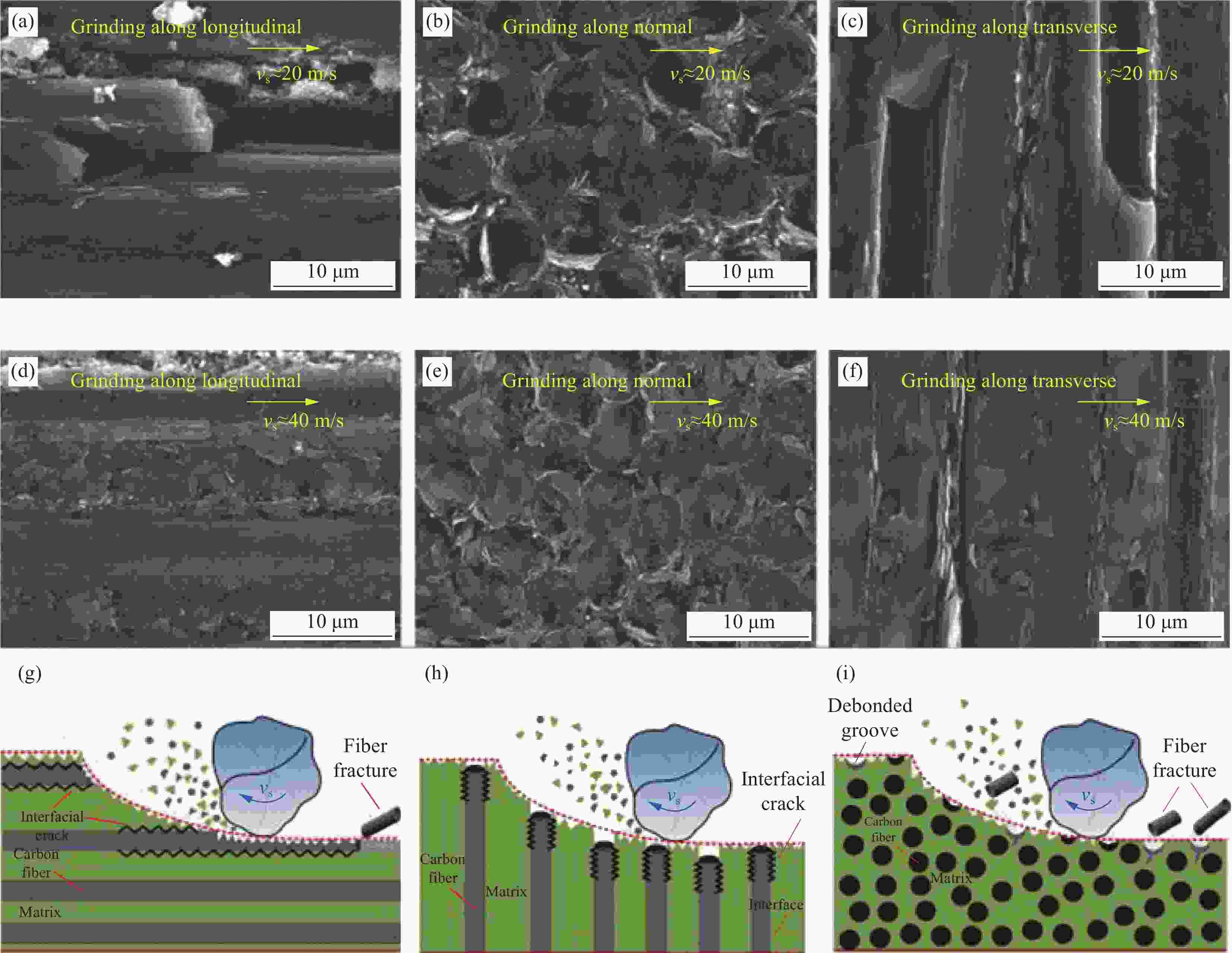

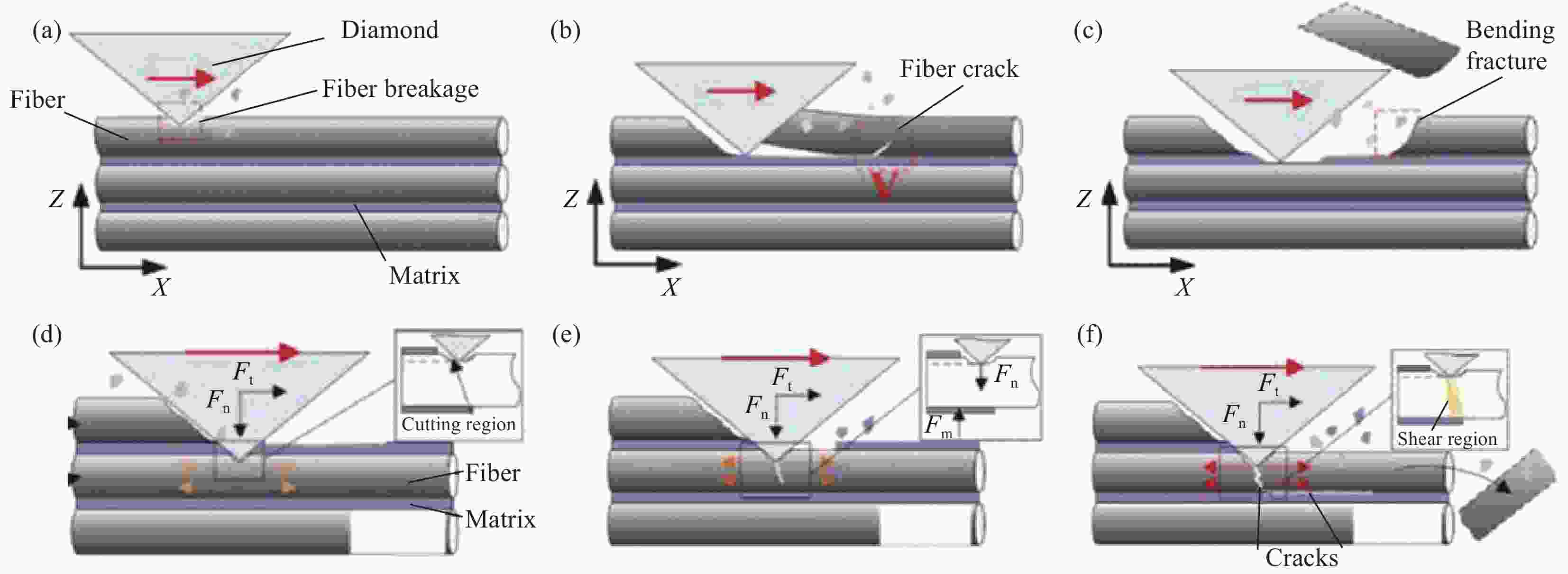

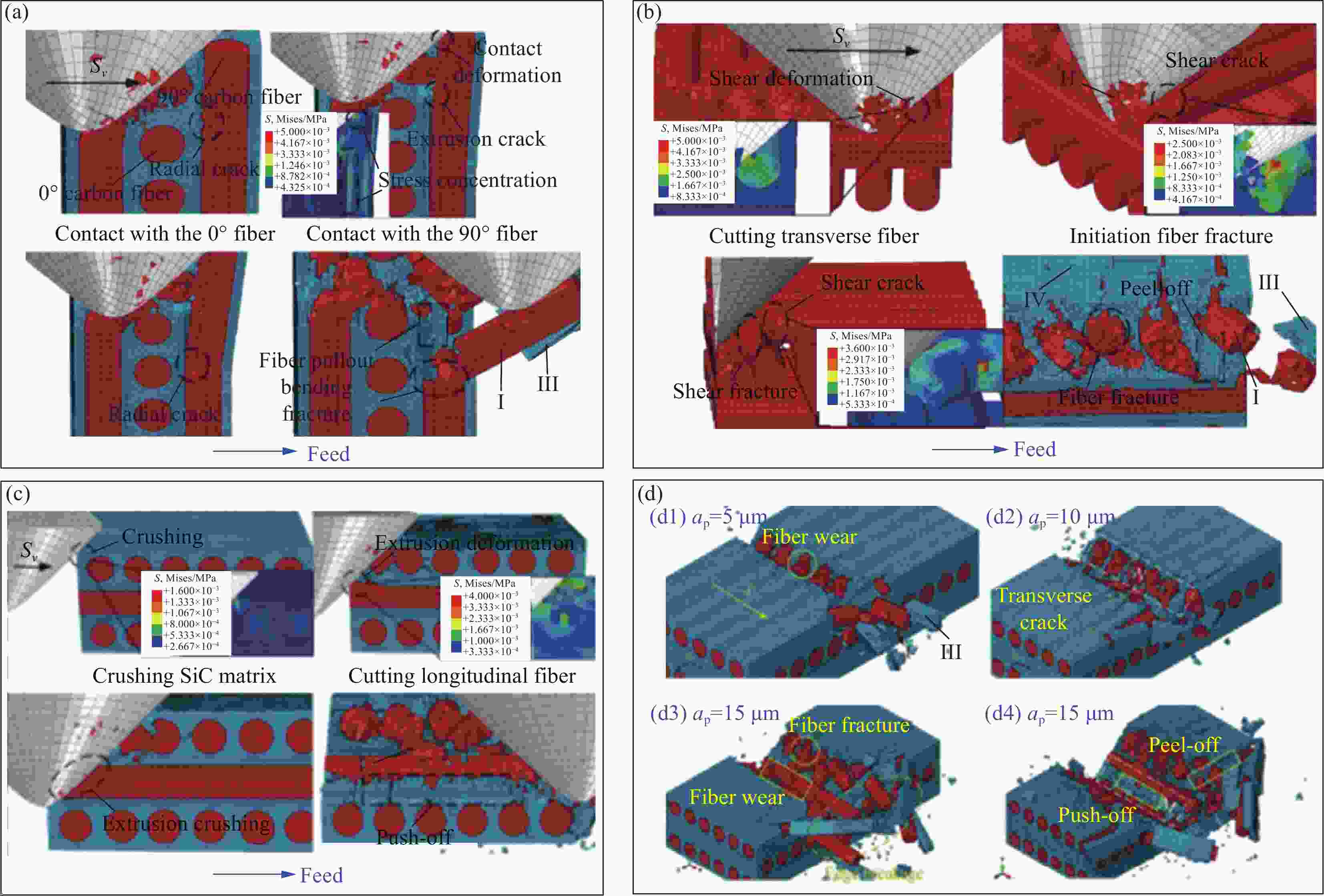

(along fiber normal)$ F = \displaystyle\sum\limits_i^n {\left( {{F_{{\mathrm{est}}}} + {F_{{\mathrm{bst}}}} + {F_{{\mathrm{mst}}}}} \right)} $ The model more accurately predicts the fluctuation amplitude and distribution pattern of the grinding force signal, with a prediction error of less than 10%. (2-2) [72] Grinding SiCf/SiC

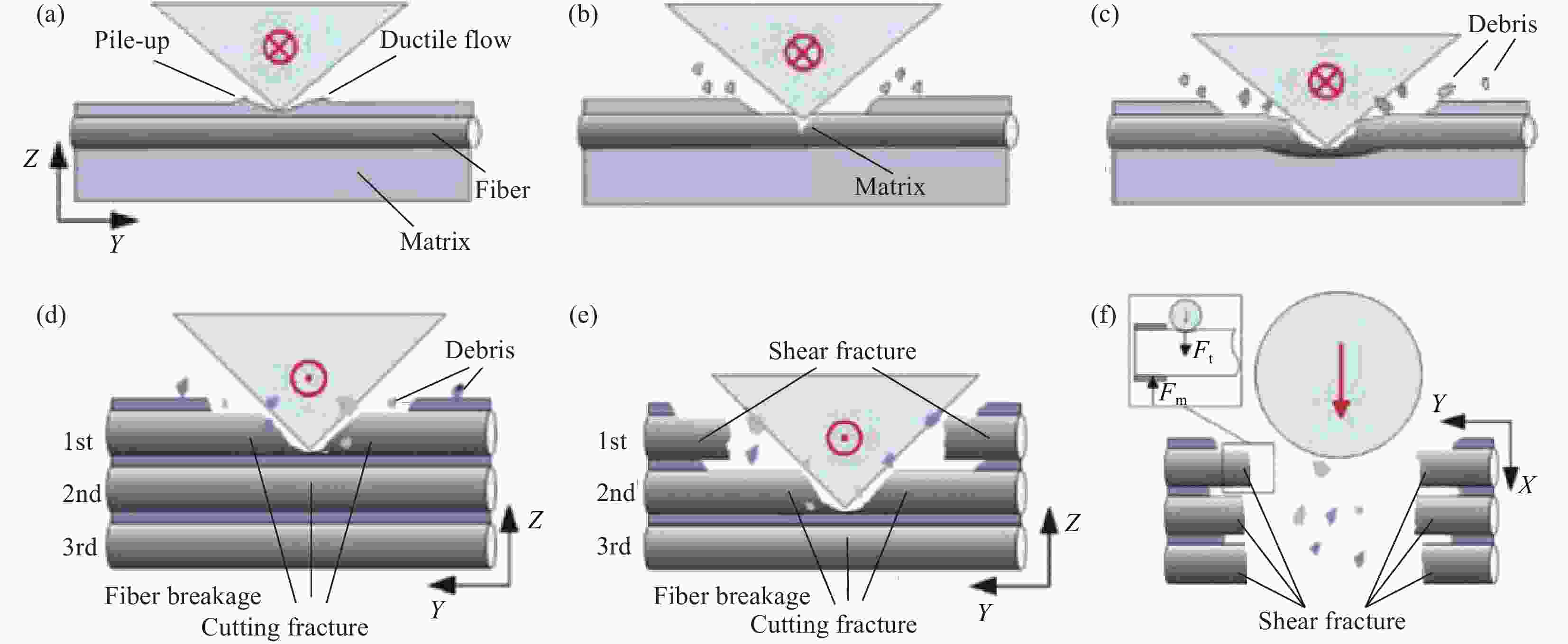

(along fiber normal and longitudinal)$ \begin{gathered} {F_{\mathrm{p}}} = \lambda {h_{\mathrm{m}}}{h_{{\mathrm{gm}}}}H\frac{{\left[ {0.333 h_{{\mathrm{gc}}}^2{l_1}{C_{\mathrm{h}}} + 0.298 h_{{\mathrm{gc}}}^2{l_2}{C_{\mathrm{h}}}} \right]}}{{{C_{\mathrm{h}}}\left[ {\sqrt 3 h_{{\mathrm{gc}}}^2\left( {{l_1} + {l_2}} \right) + 6{C_{\mathrm{h}}}{C_{\mathrm{l}}}{l_3}} \right]}} + \\ \lambda {h_{\mathrm{m}}}{h_{{\mathrm{gm}}}}H\frac{{0.684\sqrt {C_{\mathrm{h}}^2 + C_{\mathrm{l}}^2} \left[ {h_{{\mathrm{gm}}}^2{l_{\mathrm{c}}} - h_{{\mathrm{gc}}}^2\left( {{l_1} + {l_2}} \right)} \right]}}{{{C_{\mathrm{h}}}\left[ {\sqrt 3 h_{{\mathrm{gc}}}^2\left( {{l_1} + {l_2}} \right) + 6{C_{\mathrm{h}}}{C_l}{l_3}} \right]}} \\ \end{gathered} $ The average error between predicted and experimental values is 7.43%. (2-3) [101] Notes: In Eq. (2-2), Fest is the grinding force at the elastic scratch stage, Fbst is the grinding force at the brittle removal stage, and Fmst is the grinding force at the matrix removal stage. In Eq. (2-3), hm is the thickness of the workpiece, hgm is the maximum undeformed chip thickness, hgc is the critical depth of cut for brittle removal, lc is the grinding tool/workpiece arc length of contact, l1 is the contact length at the stage of ductile removal, l2 is the contact length at the stage of delayed brittle removal, l3 is the contact length at the stage of brittle removal, H is the Vickers hardness of the workpiece in, and λ is the correction coefficient. 表 2 FRCMC超声振动辅助磨削的磨削力预测模型

Table 2. Grinding force prediction model of FRCMC in ultrasonic vibration-assisted grinding

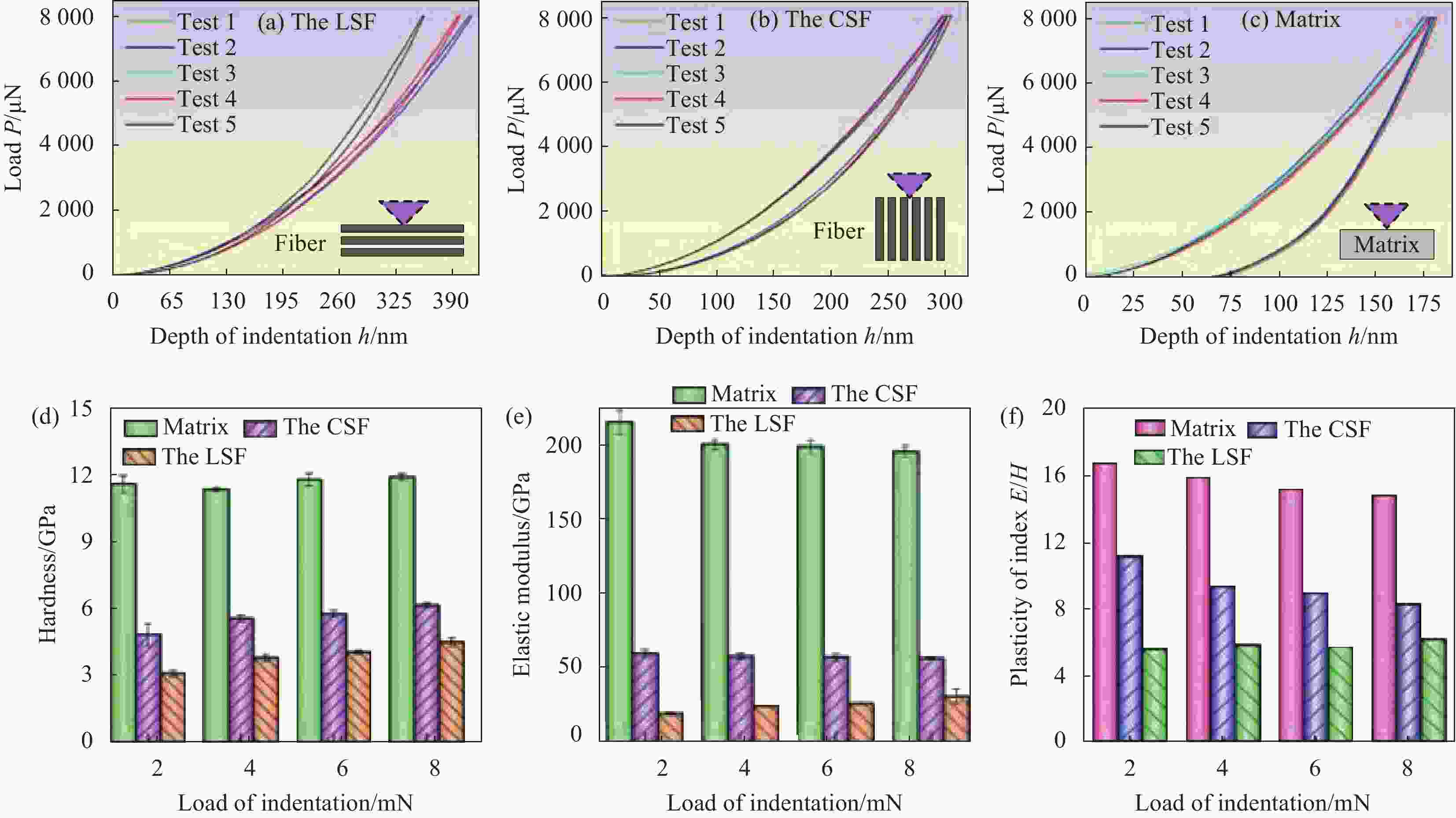

Working condition Grinding force model Key findings and numbers Ref. Rotary ultrasonic vibratory grinding 2D-Cf/SiC $ {F_{{\mathrm{gdn}}}} = \dfrac{8}{3}{s^2}{{\text{π}} ^2}n_{\mathrm{s}}^2 t_1^2\tan \theta \sqrt {{{\tan }^2}\theta + 2} {H_{\mathrm{v}}} $

$ \begin{gathered} {F_{{\mathrm{gbn}}}} = \left[ {\dfrac{{{a_{\mathrm{p}}}{v_{\mathrm{w}}}}}{{C{v_{\mathrm{s}}}}} - \int_0^{{t_1}} {\tan \theta {h^2}\left( t \right)\sqrt {v_x^2\left( t \right) + v_y^2\left( t \right) + v_{\textit{z}}^2\left( t \right)} {\mathrm{d}}t} } \right]/ \\ 2 C_1^2{\left( {\cot \theta } \right)^{\tfrac{3}{4}}}{\left[ {\dfrac{{{E^{7/4}}}}{{H_{\mathrm{v}}^3{K_{{\mathrm{IC}}}}{{\left( {1 - {v^2}} \right)}^{1/2}}}}} \right]^{1/2}}\int_{{t_1}}^{{t_2}} {\sqrt {v_x^2\left( t \right) + v_y^2\left( t \right) + v_{\textit{z}}^2\left( t \right)} {\mathrm{d}}t} \\ \end{gathered} $The relative average errors in the normal and tangential grinding forces were 11.45% and 20.83%, respectively. (3-1) [119] Two-dimensional ultrasonic vibration grinding 2.5D-Cf/SiC $ F_{\mathrm{n}}=\dfrac{2}{3}a_{\mathrm{gc}}^2\tan\theta\sqrt{\tan^2\theta+2}H_{\mathrm{v}}N_{\mathrm{d}}+N_{\mathrm{b}}\left(\dfrac{a_{\mathrm{p}}^{3/2}bv_{\mathrm{w}}R^{1/2}K_{\mathrm{ID}}^{3/4}H_{\mathrm{v}}^{1/2}}{\sqrt{2}Kl_{\mathrm{u}}v_{\mathrm{s}}N_{\mathrm{a}}}\right) $

$ F_{\mathrm{n}}=\dfrac{2}{3}a_{\max}^2\tan\theta\sqrt{\tan^2\theta+2}H_{\mathrm{v}}N_{\mathrm{a}} $The mean relative errors for the normal and tangential grinding forces were 8.49% and 13.59%, respectively. (3-2) [120] Rotary ultrasonic vibration grinding

in 1D-SiCf/SiC$ F_{\mathrm{n}}=\left[\dfrac{60(H)^{3/2}\left(K_{\rm{IC}}\right)^{1/2}\left(1-v_1^2\right)^{1/4}a_{\rm{p}}v_{\rm{f}}}{\begin{array}{l}2k_1k_{\rm{h}}\text{π}dN_{\rm{d}}n_{\rm{s}}(\tan\theta)^{-3/4}E^{7/8} \\ \int_0^{t_1}\sqrt{\left[\dfrac{\text{π}n_{\mathrm{s}}}{30}R\cos\left(\dfrac{\text{π}n_{\mathrm{s}}}{30}t\right)+v_{\mathrm{f}}\right]^2+\left[-\dfrac{\text{π}n_{\rm{s}}}{30}R\sin\left(\dfrac{\text{π}n_{\rm{s}}}{30}t\right)\right]^2+(2\text{π}fA\cos2\text{π}ft)^2\rm{d}t}\end{array}}\right]^{8/9} $ The mean relative errors for the normal and tangential grinding forces were 9.29% and 6.16%, respectively. (3-3) [77] Longitudinal-torsional ultrasonic vibration end grinding SiCf/SiC $ F_{\mathrm{n}}=\left[\dfrac{\begin{gathered}\text{π}\left(R_0+R_i\right)a_{\mathrm{p}}v_{\mathrm{w}}-N_{\mathrm{z}}fL_1\left(r_{\mathrm{g}}^2\arccos\left(1-\dfrac{\delta_{\mathrm{da}}}{r_{\mathrm{g}}}\right)-\left(r_{\mathrm{g}}-\delta_{\mathrm{da}}\right)\sqrt{2r_{\mathrm{g}}\delta_{\mathrm{da}}-\delta_{\mathrm{da}}^2}\right)- \\ N_{\mathrm{\mathrm{z}}}fL_2\left(r_{\mathrm{g}}^2\arccos\left(1-\dfrac{\delta_{\mathrm{ba}}}{r_{\mathrm{g}}}\right)-\left(r_{\mathrm{g}}-\delta_{\mathrm{ba}}\right)\sqrt{2r_{\mathrm{g}}\delta_{\mathrm{ba}}-\delta_{\mathrm{ba}}^2}\right) \\ \end{gathered}}{\dfrac{\text{π}}{2}N_{\mathrm{\mathrm{z}}}fC_2^2\left(1/\tan\varphi\right)^{3/4}\dfrac{E_{\mathrm{e}}^{7/8}}{H_{\mathrm{V}}^{3/2}K_{\mathrm{IC}}^{1/2}\left(1-\nu^2\right)^{1/4}}L_3}\right]^{8/9} $ The maximum relative errors for the normal and tangential grinding forces were 8.51% and 10.19%, respectively. The ultrasonically assisted grinding force exhibited a non-linear decrease compared to conventional grinding. (3-4) [118] Rotary ultrasonic vibratory spiral grinding holes SiCf/SiC $ F\mathrm{_t}=\dfrac{n_{\mathrm{M}}}{4}c_4h_{\mathrm{M}}^2\tan^22\theta_{\mathrm{M}}H_{\mathrm{M}}\arccos\left(1-\dfrac{h_{\mathrm{M}}}{A}\right) $ Higher ultrasonic amplitudes reduced the grinding forces.

(3-5)[76] Notes: In Eq. (3-1), Fgdn is the ductile removal grinding force, Fgbn is brittle removal grinding force, s the feed per cutting point in a cutting cycle, ns is the spindle speed, t1 is the start time of brittle removal, t2 is the maximum undeformed chip thickness forming time, vx(t), vy(t), vz(t) are the velocity for the single abrasive grain, KIC is fracture toughness, and θ is conical abrasive grain half top angle. In Eq. (3-2), agc is the critical cutting depth of brittle removal, b is the width of the grinding area, R is the radius of the grinding tool, KID is the dynamic fracture toughness of the workpiece, K is the correction factor, lu is the contact length between the abrasive grain and the workpiece, and amax is the maximum undeformed chip thickness. In Eq. (3-3), vf is feed rate, f is frequency of ultrasonic vibration, A is amplitude of ultrasonic vibration, R is radius of wheel, and kl, kh are dimensionless coefficients. In Eq. (3-4), R0 is Tool's average radius, Nz is numbers of abrasive grains on the tool periphery end face, L1, L2, and L3 are a single abrasive grain's path length in ductile, ductile-to-brittle transition and brittle regions, and rg is abrasive grain radius. In Eq. (3-5), Ft is grinding force with ultrasonic vibration, nM is number of grains on end face, c4 is coefficient of force of ultrasonic vibration, hM is theoretical grinding thickness, and HM is hardness of matrix. -

[1] 沙建军, 代吉祥, 张兆甫. 纤维增韧高温陶瓷基复合材料(Cf, SiCf/SiC)应用研究进展[J]. 航空制造技术, 2017(19): 16-32.SHA Jianjun, DAI Jixiang, ZHANG Zhaofu. Research and application progress of fiber-reinforced high temperature ceramic matrix composites: Cf/SiC and SiCf/SiC[J]. Aeronautical Manufacturing Technology, 2017(19): 16-32(in Chinese). [2] 方国东, 王章文, 李赛, 等. 碳纤维增韧陶瓷基复合材料高温氧化性能研究进展: 氧化机制、氧化损伤实验与模型[J]. 复合材料学报, 2024, 41(9): 4518-4534.FANG Guodong, WANG Zhangwen, LI Sai, et al. Review of high-temperature oxidation properties for carbon fiber toughened ceramic matrix composites: Oxidation mechanisms, oxidation damage experiments and models[J]. Acta Materiae Compositae Sinica, 2024, 41(9): 4518-4534(in Chinese). [3] 李龙彪. 陶瓷基复合材料在航空发动机应用与适航符合性验证研究进展[J/OL]. 复合材料学报. 2024: 1-35[2024-07-10]. https://fhclxb.buaa.edu.cn/article/id/7b0a338e-7577-472d-a2aa-4cc1b0505b91LI Longbiao. Research progress on application and airworthiness compliance validation of ceramic matrix composites in aeroengines[J/OL]. Acta Materiae Compositae Sinica, 2024: 1-35[2024-07-10]. https://fhclxb.buaa.edu.cn/article/id/7b0a338e-7577-472d-a2aa-4cc1b0505b91 (in Chinese). [4] 王鸣, 董志国, 张晓越, 等. 连续纤维增强碳化硅陶瓷基复合材料在航空发动机上的应用[J]. 航空制造技术, 2014(6): 10-13.WANG Ming, DONG Zhiguo, ZHANG Xiaoyue, et al. Application of continuous fiber reinforced ceramic matrix composites in application of continuous fiber reinforced ceramic matrix composites in aeroengine[J]. Aeronautical Manufacturing Technology, 2014(6): 10-13(in Chinese). [5] AN Q L, CHEN J, MING W W, et al. Machining of SiC ceramic matrix composites: A review[J]. Chinese Journal of Aeronautics, 2021, 34(4): 540-567. doi: 10.1016/j.cja.2020.08.001 [6] ZHANG H Y, ZHAO Z G, LI J J, et al. Review on abrasive machining technology of SiC ceramic composites[J]. Micromachines, 2024, 15(1): 106. [7] 董志刚, 王中旺, 冉乙川, 等. 碳纤维增强陶瓷基复合材料超声振动辅助铣削加工技术的研究进展[J]. 机械工程学报, 2024, 59: 1-31.DONG Zhigang, WANG Zhongwang, RAN Yichuan, et al. Advances in ultrasonic vibration-assisted milling of carbon fiber reinforced ceramic matrix composites[J]. Journal of Mechanical Engineering, 2024, 59: 1-31(in Chinese). [8] SHIH A J, DENKENA B, GROVE T, et al. Fixed abrasive machining of non-metallic materials[J]. Cirp Annals-Manufacturing Technology. 2018, 67(2): 767-790. [9] 王晶, 成来飞, 刘永胜, 等. 碳化硅陶瓷基复合材料加工技术研究进展[J]. 航空制造技术, 2016(15): 50-56.WANG Jing, CHENG Laifei, LIU Yongsheng, et al. Research development on processing technology of silicon carbide ceramic matrix composites[J]. Aeronautical Manufacturing Technology, 2016(15): 50-56(in Chinese). [10] DIAZ O G, LUNA G G, LIAO Z R, et al. The new challenges of machining ceramic matrix composites (CMCs): Review of surface integrity[J]. International Journal of Machine Tools and Manufacture, 2019, 139: 24-36. [11] GONG Y D, QU S S, YANG Y Y, et al. Some observations in grinding SiC and silicon carbide ceramic matrix composite material[J]. International Journal of Advanced Manufacturing Technology, 2019, 103(5-8): 3175-3186. doi: 10.1007/s00170-019-03735-w [12] QU S S, GONG Y D, YANG Y Y, et al. Surface topography and roughness of silicon carbide ceramic matrix composites[J]. Ceramics International, 2018, 44(12): 14742-14753. doi: 10.1016/j.ceramint.2018.05.104 [13] AGARWAL S, RAO P V. Predictive modeling of undeformed chip thickness in ceramic grinding[J]. International Journal of Machine Tools and Manufacture, 2012, 56: 59-68. [14] AGARWAL S, RAO P V. Predictive modeling of force and power based on a new analytical undeformed chip thickness model in ceramic grinding[J]. International Journal of Machine Tools and Manufacture, 2013, 65: 68-78. [15] ZHANG B, LU S X, RABIEY M, et al. Grinding of composite materials[J]. Cirp Annals-Manufacturing Technology, 2023, 72(2): 645-671. doi: 10.1016/j.cirp.2023.05.001 [16] DAMBATTA Y S, SAYUTI M, SARHAN A A D, et al. Comparative study on the performance of the MQL nanolubricant and conventional flood lubrication techniques during grinding of Si3N4 ceramic[J]. International Journal of Advanced Manufacturing Technology, 2018, 96(9-12): 3959-3976. doi: 10.1007/s00170-018-1689-3 [17] DAMBATTA Y S, SAYUTI M, SARHAN A A D, et al. Tribological performance of SiO2-based nanofluids in minimum quantity lubrication grinding of Si3N4 ceramic[J]. Journal of Manufacturing Processes, 2019, 41: 135-147. doi: 10.1016/j.jmapro.2019.03.024 [18] GAITONDE V N, KARNIK S R, FIGUEIRA L, et al. Performance comparison of conventional and wiper ceramic inserts in hard turning through artificial neural network modeling[J]. International Journal of Advanced Manufacturing Technology, 2011, 52(1-4): 101-114. doi: 10.1007/s00170-010-2714-3 [19] FENG J, CHEN P, NI J. Prediction of grinding force in microgrinding of ceramic materials by cohesive zone-based finite element method[J]. International Journal of Advanced Manufacturing Technology, 2013, 68(5-8): 1039-1053. doi: 10.1007/s00170-013-4895-z [20] ZHANG X L, CHEN P, ZHANG J, et al. Study on grinding force of Si3N4 ceramics in random rotation grinding with truncated polyhedral grains[J]. International Journal of Advanced Manufacturing Technology, 2021, 115(9-10): 3139-3148. doi: 10.1007/s00170-021-07372-0 [21] 傅玉灿, 田霖, 徐九华, 等. 磨削过程建模与仿真研究现状[J]. 机械工程学报, 2015, 51(7): 197-205. doi: 10.3901/JME.2015.07.197FU Yuchan, TIAN Lin, XU Jiuhua, et al. Development and application on the grinding process modeling and simulation[J]. Journal of Mechanical Engineering, 2015, 51(7): 197-205(in Chinese). doi: 10.3901/JME.2015.07.197 [22] DU J G, ZHANG H Z, GENG Y M, et al. A review on machining of carbon fiber reinforced ceramic matrix composites[J]. Ceramics International, 2019, 45(15): 18155-18166. doi: 10.1016/j.ceramint.2019.06.112 [23] LU Y, SUN P Y, YANG X H, et al. Review of research progress in nontraditional machining of ultrahigh-temperature ceramic matrix composites[J]. Coatings, 2023, 13(1): 187. [24] 张修峰, 邵国栋, 刘传成, 等. 碳化硅陶瓷基复合材料常用的特种加工技术: 综述[J]. 机械工程学报, 2023, 59(1): 199-218. doi: 10.3901/JME.2023.01.199ZHANG Xiufeng, SHAO Guodong, LIU Chuancheng, et al. Special processing techniques commonly used for silicon carbide ceramic-based composites: Review[J]. Journal of Mechanical Engineering, 2023, 59(1): 199-218(in Chinese). doi: 10.3901/JME.2023.01.199 [25] 王晓博, 李璐璐, 赵波, 等. 陶瓷基复合材料加工技术及其表面亚表面损伤机制研究进展[J]. 表面技术, 2021, 50(12): 17-34.WANG Xiaobo, LI Lulu, ZHAO Bo, et al. Research progress on processing technology and surface and subsurface damage mechanism of ceramic matrix composites[J]. Surface Technology, 2021, 50(12): 17-34(in Chinese). [26] LI Y C, GE X, WANG H, et al. Study of material removal mechanisms in grinding of C/SiC composites via single-abrasive scratch tests[J]. Ceramics International, 2019, 45(4): 4729-4738. doi: 10.1016/j.ceramint.2018.11.165 [27] AZARHOUSHANG B. Wear of non-segmented and segmented diamond wheels in high-speed deep grinding of carbon fibre-reinforced ceramics[J]. International Journal of Advanced Manufacturing Technology, 2014, 74(9-12): 1293-1302. doi: 10.1007/s00170-014-6082-2 [28] LI W, LONG G, SHI F, et al. Influence of the fiber orientation on 3D C/C-SiC composite material and its formation mechanism of the machining surface[J]. International Journal of Advanced Manufacturing Technology, 2022, 118(7-8): 2725-2743. doi: 10.1007/s00170-021-08149-1 [29] LIU Q, HUANG G Q, FANG C F, et al. Experimental investigations on grinding characteristics and removal mechanisms of 2D-Cf/C-SiC composites based on reinforced fiber orientations[J]. Ceramics International, 2017, 43(17): 15266-15274. doi: 10.1016/j.ceramint.2017.08.064 [30] LIU Y, QUAN Y, WU C J, et al. Single diamond scribing of SiCf/SiC composite: Force and material removal mechanism study[J]. Ceramics International, 2021, 47(19): 27702-27709. doi: 10.1016/j.ceramint.2021.06.195 [31] 殷景飞, 徐九华, 丁文锋, 等. SiCf/SiC陶瓷基复合材料单颗磨粒磨削试验研究[J]. 中国机械工程, 2022, 33(15): 1765-1771.YIN Jingfei, XU Jiuhua, DING Wenfeng, et al. Experimental study of single grain grinding for SiCf/SiC ceramic matrix composites[J]. China Mechanical Engineering, 2022, 33(15): 1765-1771(in Chinese). [32] WANG Z W, DONG Z G, RAN Y C, et al. On understanding the mechanical properties and damage behavior of Cf/SiC composites by indentation method[J]. Journal of Materials Research and Technology, 2023, 26: 3784-3802. [33] ZHANG L F, REN C Z, JI C H, et al. Effect of fiber orientations on surface grinding process of unidirectional C/SiC composites[J]. Applied Surface Science, 2016, 366: 424-431. doi: 10.1016/j.apsusc.2016.01.142 [34] QU S S, GONG Y D, YANG Y Y, et al. Grinding characteristics and removal mechanism of 2.5D-needled Cf/SiC composites[J]. Ceramics International, 2019, 45(17): 21608-21617. doi: 10.1016/j.ceramint.2019.07.156 [35] QU S S, GONG Y D, YANG Y Y, et al. Grinding characteristics and removal mechanisms of unidirectional carbon fibre reinforced silicon carbide ceramic matrix composites[J]. Ceramics International, 2019, 45(3): 3059-3071. doi: 10.1016/j.ceramint.2018.10.178 [36] LIU Q, HUANG G Q, XU X P, et al. Influence of grinding fiber angles on grinding of the 2D-Cf/C-SiC composites[J]. Ceramics International, 2018, 44(11): 12774-12782. doi: 10.1016/j.ceramint.2018.04.083 [37] ZHANG Z K, YUAN S M, XU W W, et al. Damage behavior and removal mechanism of different yarn orientations 2.5D SiCf/SiC composites under single-abrasive scratch test[J]. Ceramics International, 2022, 48(20): 30868-30883. doi: 10.1016/j.ceramint.2022.07.041 [38] CAO X Y, LIN B, ZHANG X F. Investigations on grinding process of woven ceramic matrix composite based on reinforced fiber orientations[J]. Composites Part B: Engineering, 2015, 71: 184-192. [39] DIAZ O G, AXINTE D A, BUTLER-SMITH P, et al. On understanding the microstructure of SiC/SiC ceramic matrix composites (CMCs) after a material removal process[J]. Materials Science and Engineering: A, 2019, 743: 1-11. doi: 10.1016/j.msea.2018.11.037 [40] CHEN G J, XU J K, WANG J D, et al. Numerical and experimental study on the amplitude effect of ultrasonic vibration-assisted milling of 3D needle-punched Cf/SiC composite[J]. Ceramics International, 2022, 48(12): 17893-17914. doi: 10.1016/j.ceramint.2022.03.061 [41] CAO C, SONG Q H, FU H, et al. Fiber orientation effects on grinding characteristics and removal mechanism of 2.5D Cf/SiC composites[J]. Chinese Journal of Aeronautics, 2023, 36(12): 425-441. doi: 10.1016/j.cja.2023.02.023 [42] YANG H T, ZHAO G L, XIA H J, et al. Effect of fiber orientation on material removal mechanisms in the machining of 3D Cf/SiC composite with a brazed diamond grinding rod: Experiment and simulation[J]. Journal of Manufacturing Processes, 2024, 114: 18-38. doi: 10.1016/j.jmapro.2024.01.066 [43] GUO M X, TAO J B, WU C J, et al. High-speed grinding fracture mechanism of Cf/SiC composite considering interfacial strength and anisotropy[J]. Ceramics International, 2023, 49(2): 2600-2612. doi: 10.1016/j.ceramint.2022.09.240 [44] YIN J F, XU J H, DING W F, et al. Effects of grinding speed on the material removal mechanism in single grain grinding of SiCf/SiC ceramic matrix composite[J]. Ceramics International, 2021, 47(9): 12795-12802. [45] YIN J F, LI M, XU J H, et al. Edge chipping characteristics in grinding SiCf/SiC composite[J]. Ceramics International, 2022, 48(5): 7126-7135. doi: 10.1016/j.ceramint.2021.11.272 [46] YANG Y Y, QU S S, GONG Y D. Investigating the grinding performance of unidirectional and 2.5D-C/SiCs[J]. Ceramics International, 2021, 47(4): 5123-5132. doi: 10.1016/j.ceramint.2020.10.090 [47] ZHANG K, YIN Z, DAI C W, et al. Material removal mechanism of SiC ceramics by elliptic ultrasonic vibration-assisted grinding (EUVAG) using single grain[J]. Ceramics International, 2023, 49(6): 10041-10055. doi: 10.1016/j.ceramint.2022.11.184 [48] YANG M, HAO J C, WU W T, et al. Critical cutting thickness model considering subsurface damage of zirconia grinding and friction-wear performance evaluation applied in simulated oral environment[J]. Tribology International, 2024, 198: 109881. [49] BIFANO T G, DOW T A, SCATTERGOOD R O. Ductile-regime grinding: A new technology for machining brittle materials[J]. Journal of Engineering for Industry, 1991, 113(2): 184-189. doi: 10.1115/1.2899676 [50] WANG Y G, WANG H J, WEI J H, et al. Finite element analysis of grinding process of long fiber reinforced ceramic matrix woven composites: Modeling, experimental verification and material removal mechanism[J]. Ceramics International, 2019, 45(13): 15920-15927. doi: 10.1016/j.ceramint.2019.05.100 [51] ZHOU Y G, ZOU J, ZHANG C X, et al. Study on grinding removal mechanism and subsurface damage of bionic layered graphene ceramic matrix composites[J]. International Journal of Advanced Manufacturing Technology, 2024, 130(7-8): 3837-3849. doi: 10.1007/s00170-023-12897-7 [52] CHEN J, AN Q L, CHEN M. Transformation of fracture mechanism and damage behavior of ceramic-matrix composites during nano-scratching[J]. Composites Part A: Applied Science and Manufacturing, 2020, 130: 105756. [53] LUNA G G, AXINTE D, NOVOVIC D. Influence of grit geometry and fibre orientation on the abrasive material removal mechanisms of SiC/SiC Ceramic Matrix Composites (CMCs)[J]. International Journal of Machine Tools and Manufacture, 2020, 157: 103580. [54] LUNA G G, AXINTE D, NOVOVIC D. Engineered grinding tools reimplemented by precise sharpening: A case study on an ultrahard ceramic matrix composite (CMC)[J]. Cirp Annals, 2022, 71(1): 289-292. doi: 10.1016/j.cirp.2022.04.011 [55] XU W H, LI C H, CUI X, et al. Atomization mechanism and machinability evaluation with electrically charged nanolubricant grinding of GH4169[J]. Journal of Manufacturing Processes, 2023, 106: 480-493. doi: 10.1016/j.jmapro.2023.10.037 [56] XU W H, LI C H, ZHANG Y B, et al. Electrostatic atomization minimum quantity lubrication machining: From mechanism to application[J]. International Journal of Extreme Manufacturing, 2022, 4(4): 042003. [57] ZHANG Q, WANG B, SONG C, et al. Processing strategy of SiCf/SiC composites during single grain scratching under minimum quantity lubrication[J]. International Journal of Advanced Manufacturing Technology, 2024, 131(5-6): 2477-2495. doi: 10.1007/s00170-023-11843-x [58] ADIBI H, ESMAEILI H, REZAEI S M. Study on minimum quantity lubrication (MQL) in grinding of carbon fiber-reinforced SiC matrix composites (CMCs)[J]. International Journal of Advanced Manufacturing Technology, 2018, 95(9-12): 3753-3767. doi: 10.1007/s00170-017-1464-x [59] QU S S, GONG Y D, YANG Y Y, et al. Investigating minimum quantity lubrication in unidirectional Cf/SiC composite grinding[J]. Ceramics International, 2020, 46(3): 3582-3591. doi: 10.1016/j.ceramint.2019.10.076 [60] QU S S, GONG Y D, YANG Y Y, et al. An investigation of carbon nanofluid minimum quantity lubrication for grinding unidirectional carbon fibre-reinforced ceramic matrix composites[J]. Journal of Cleaner Production, 2020, 249: 119353. [61] QU S S, YAO P, GONG Y D, et al. Environmentally friendly grinding of C/SiCs using carbon nanofluid minimum quantity lubrication technology[J]. Journal of Cleaner Production, 2022, 366: 132898. [62] YANG M, LI C H, ZHANG Y B, et al. Predictive model for minimum chip thickness and size effect in single diamond grain grinding of zirconia ceramics under different lubricating conditions[J]. Ceramics International, 2019, 45(12): 14908-14920. doi: 10.1016/j.ceramint.2019.04.226 [63] YANG M, LI C H, ZHANG Y B, et al. Maximum undeformed equivalent chip thickness for ductile-brittle transition of zirconia ceramics under different lubrication conditions[J]. International Journal of Machine Tools and Manufacture, 2017, 122: 55-65. [64] GAO T, XU P M, WANG W, et al. Force model of ultrasonic empowered minimum quantity lubrication grinding CFRP[J]. International Journal of Mechanical Sciences, 2024, 280: 109522. [65] GAO T, LI C H, YANG M, et al. Mechanics analysis and predictive force models for the single-diamond grain grinding of carbon fiber reinforced polymers using CNT nano-lubricant[J]. Journal of Materials Processing Technology, 2021, 290: 116976. [66] HUANG H, LI X L, MU D K, et al. Science and art of ductile grinding of brittle solids[J]. International Journal of Machine Tools and Manufacture, 2021, 161: 103675. [67] GUO Y, LIU M H, LI C L. Modeling and experimental investigation on grinding force for advanced ceramics with different removal modes[J]. International Journal of Advanced Manufacturing Technology, 2020, 106(11-12): 5483-5495. doi: 10.1007/s00170-020-05013-6 [68] LI C, LI X L, WU Y Q, et al. Deformation mechanism and force modelling of the grinding of YAG single crystals[J]. International Journal of Machine Tools and Manufacture, 2019, 143: 23-37. [69] LI H N, YU T B, WANG Z X, et al. Detailed modeling of cutting forces in grinding process considering variable stages of grain-workpiece micro interactions[J]. International Journal of Mechanical Sciences, 2017, 126: 319-339. doi: 10.1016/j.ijmecsci.2016.11.016 [70] MA L J, GONG Y D, CHEN X H, et al. Surface roughness model in experiment of grinding engineering glass-ceramics[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2014, 228(12): 1563-1569. doi: 10.1177/0954405414521403 [71] SUN Y, SU Z P, GONG Y D, et al. An experimental and numerical study of micro-grinding force and performance of sapphire using novel structured micro abrasive tool[J]. International Journal of Mechanical Sciences, 2020, 181: 105741. [72] ZHANG M H, SHAN C W, XIA Z W, et al. Dynamic mechanical model in grinding C/SiC composites[J]. International Journal of Mechanical Sciences, 2024, 268: 109042. [73] LAWN B R, EVANS A G, MARSHALL D B. Elastic/plastic indentation damage in ceramics: The median/radial crack system[J]. Journal of the American Ceramic Society, 1980, 65(11): 561-566. [74] ZHENG Z D, HUANG K, LIN C T, et al. An analytical force and energy model for ductile-brittle transition in ultra-precision grinding of brittle materials[J]. International Journal of Mechanical Sciences, 2022, 220: 107107. [75] QU S S, GONG Y D, YANG Y Y, et al. Mechanical model and removal mechanism of unidirectional carbon fibre-reinforced ceramic composites[J]. International Journal of Mechanical Sciences, 2020, 173: 105465. [76] DONG Z G, ZHANG H T, KANG R K, et al. Mechanical modeling of ultrasonic vibration helical grinding of SiCf/SiC composites[J]. International Journal of Mechanical Sciences, 2022, 234: 107701. [77] RAN Y C, KANG R K, DONG Z G, et al. Ultrasonic assisted grinding force model considering anisotropy of SiCf/SiC composites[J]. International Journal of Mechanical Sciences, 2023, 250: 108311. [78] LIU Y M, WARKENTIN A, BAUER R, et al. Investigation of different grain shapes and dressing to predict surface roughness in grinding using kinematic simulations[J]. Precision Engineering, 2013, 37(3): 758-764. [79] ZHANG T, JIANG F, HUANG H, et al. Towards understanding the brittle-ductile transition in the extreme manufacturing[J]. International Journal of Extreme Manufacturing, 2021, 3(2): 022001. [80] SUN J A, LI C H, ZHOU Z M, et al. Material removal mechanism and force modeling in ultrasonic vibration-assisted micro-grinding biological bone[J]. Chinese Journal of Mechanical Engineering, 2023, 36(1): 129. doi: 10.1186/s10033-023-00842-4 [81] 崔歆, 李长河, 张彦彬, 等. 磁力牵引纳米润滑剂微量润滑磨削力模型与验证[J]. 机械工程学报, 2023, 60(9): 323-337.CUI Xin, LI Changhe, ZHANG Yanbin, et al. Force model and verification of magnetic traction nanolubricant grinding[J]. Journal of Mechanical Engineering, 2023, 60(9): 323-337(in Chinese). [82] 高腾, 李长河, 张彦彬, 等. 纳米增强生物润滑剂CFRP材料去除力学行为与磨削力预测模型[J]. 机械工程学报, 2023, 59(13): 325-342. doi: 10.3901/JME.2023.13.325GAO Teng, LI Changhe, ZHANG Yanbin, et al. Mechanical behavior of material removal and predictive force model for CFRP grinding using nano reinforced biological lubricant[J]. Journal of Mechanical Engineering, 2023, 59(13): 325-342(in Chinese). doi: 10.3901/JME.2023.13.325 [83] ZHANG Y B, LI C H, JI H J, et al. Analysis of grinding mechanics and improved predictive force model based on material-removal and plastic-stacking mechanisms[J]. International Journal of Machine Tools and Manufacture, 2017, 122: 81-97. [84] CHEN H, YU T B, DONG J L, et al. Kinematic simulation of surface grinding process with random cBN grain model[J]. International Journal of Advanced Manufacturing Technology, 2019, 100(9-12): 2725-2739. doi: 10.1007/s00170-018-2840-x [85] MA Z L, WANG Q H, CHEN H, et al. A grinding force predictive model and experimental validation for the laser-assisted grinding (LAG) process of zirconia ceramic[J]. Journal of Materials Processing Technology, 2022, 302: 117492. [86] MENG Q Y, GUO B, WU G C, et al. Dynamic force modeling and mechanics analysis of precision grinding with microstructured wheels[J]. Journal of Materials Processing Technology, 2023, 314: 117900. [87] SUN Y, SU Z P, JIN L Y, et al. Modelling and analysis of micro-grinding surface generation of hard brittle material machined by micro abrasive tools with helical chip pocket[J]. Journal of Materials Processing Technology, 2021, 297: 117242. [88] QIN S Q, ZHU L D, HAO Y P, et al. Theoretical and experimental investigations of surface generation induced by ultrasonic assisted grinding[J]. Tribology International, 2023, 179: 108120. [89] 刘明政, 李长河, 张彦彬, 等. 低温冷风微量润滑磨削钛合金换热机制与对流换热系数模型[J]. 机械工程学报, 2023, 59(23): 343-357. doi: 10.3901/JME.2023.23.343LIU Mingzheng, LI Changhe, ZHANG Yanbin, et al. Heat transfer mechanism and convective heat transfer coefficient model of cryogenic air minimum quantity lubrication grinding titanium alloy[J]. Journal of Mechanical Engineering, 2023, 59(23): 343-357(in Chinese). doi: 10.3901/JME.2023.23.343 [90] JIANG J L, GE P Q, HONG J. Study on micro-interacting mechanism modeling in grinding process and ground surface roughness prediction[J]. International Journal of Advanced Manufacturing Technology, 2013, 67(5-8): 1035-1052. doi: 10.1007/s00170-012-4546-9 [91] XIAO H P, YIN S X, WANG H R, et al. Models of grinding-induced surface and subsurface damages in fused silica considering strain rate and micro shape/geometry of abrasive[J]. Ceramics International, 2021, 47(17): 24924-24941. doi: 10.1016/j.ceramint.2021.05.220 [92] LIU M Z, LI C H, ZHANG Y B, et al. Analysis of grain tribology and improved grinding temperature model based on discrete heat source[J]. Tribology International, 2023, 180: 108196. [93] LIU M Z, LI C H, ZHANG Y B, et al. Analysis of grinding mechanics and improved grinding force model based on randomized grain geometric characteristics[J]. Chinese Journal of Aeronautics, 2023, 36(7): 160-193. doi: 10.1016/j.cja.2022.11.005 [94] DING W F, DAI C W, YU T Y, et al. Grinding performance of textured monolayer CBN wheels: Undeformed chip thickness nonuniformity modeling and ground surface topography prediction[J]. International Journal of Machine Tools and Manufacture, 2017, 122: 66-80. [95] LI H, ZOU L, WANG W X, et al. Introducing abrasive wear into undeformed chip thickness modeling with improved grain kinematics in belt grinding[J]. Journal of Manufacturing Processes, 2023, 108: 903-915. doi: 10.1016/j.jmapro.2023.11.039 [96] WANG Y, FU Z Q, DONG Y H, et al. Research on surface generating model in ultrasonic vibration-assisted grinding[J]. International Journal of Advanced Manufacturing Technology, 2018, 96(9-12): 3429-3436. doi: 10.1007/s00170-018-1744-0 [97] XU H H K, JAHANMIR S, IVES L K. Effect of grinding on strength of tetragonal zirconia and zirconia-toughened alumina[J]. Machining Science and Technology, 1997, 1(1): 49-66. doi: 10.1080/10940349708945637 [98] ZHANG M H, SHAN C W, XIA Z W, et al. Scratch-induced surface formation mechanism in C/SiC composites[J]. International Journal of Mechanical Sciences, 2024, 265: 108885. [99] LI L Y, ZHANG Y B, CUI X, et al. Mechanical behavior and modeling of grinding force: A comparative analysis[J]. Journal of Manufacturing Processes, 2023, 102: 921-954. doi: 10.1016/j.jmapro.2023.07.074 [100] MENG Q Y, GUO B, ZHAO Q L, et al. Modelling of grinding mechanics: A review[J]. Chinese Journal of Aeronautics, 2023, 36(7): 25-39. doi: 10.1016/j.cja.2022.10.006 [101] ZHANG Z K, YUAN S M, GAO X X, et al. Analytical modelling of side grinding of orthogonal laminated SiCf/SiC composites based on effective elastic properties[J]. International Journal of Advanced Manufacturing Technology, 2022, 120(9-10): 6419-6434. doi: 10.1007/s00170-022-09170-8 [102] 罗潇, 刘小冲, 曾雨琪, 等. 陶瓷基复合材料构件内嵌孔加工工艺研究进展[J]. 复合材料学报, 2024, 41(8): 3987-4003.LUO Xiao, LIU Xiaochong, ZENG Yuqi, et al. Research progress on machining process of embedded holes in hot-section ceramic-matrix composite components[J]. Acta Materiae Compositae Sinica, 2024, 41(8): 3987-4003(in Chinese). [103] YANG Z C, ZHU L D, ZHANG G X, et al. Review of ultrasonic vibration-assisted machining in advanced materials[J]. International Journal of Machine Tools and Manufacture, 2020, 156: 103594. [104] DAMBATTA Y S, LI C H, SAYUTI M, et al. Grindability evaluation of ultrasonic assisted grinding of silicon nitride ceramic using minimum quantity lubrication based SiO2 nanofluid[J]. Chinese Journal of Mechanical Engineering, 2024, 37(1): 25. doi: 10.1186/s10033-024-01011-x [105] 丁文锋, 曹洋, 赵彪, 等. 超声振动辅助磨削加工技术及装备研究的现状与展望[J]. 机械工程学报, 2022, 58(9): 244-269. doi: 10.3901/JME.2022.09.244DING Wenfeng, CAO Yang, ZHAO Biao, et al. Research status and future prospects of ultrasonic vibration-assisted grinding technology and equipment[J]. Journal of Mechanical Engineering, 2022, 58(9): 244-269(in Chinese). doi: 10.3901/JME.2022.09.244 [106] AZARHOUSHANG B, TAWAKOLI T. Development of a novel ultrasonic unit for grinding of ceramic matrix composites[J]. International Journal of Advanced Manufacturing Technology, 2011, 57(9-12): 945-955. doi: 10.1007/s00170-011-3347-x [107] DING K, FU Y C, SU H H, et al. Experimental studies on drilling tool load and machining quality of C/SiC composites in rotary ultrasonic machining[J]. Journal of Materials Processing Technology, 2014, 214(12): 2900-2907. doi: 10.1016/j.jmatprotec.2014.06.015 [108] DING K, FU Y C, SU H H, et al. Study on surface/subsurface breakage in ultrasonic assisted grinding of C/SiC composites[J]. International Journal of Advanced Manufacturing Technology, 2017, 91(9-12): 3095-3105. doi: 10.1007/s00170-017-0012-z [109] HUANG B, WANG W H, JIANG R S, et al. Experimental study on ultrasonic vibration-assisted drilling micro-hole of SiCf/SiC ceramic matrix composites[J]. International Journal of Advanced Manufacturing Technology, 2022, 120(11-12): 8031-8044. doi: 10.1007/s00170-022-09186-0 [110] WANG X B, WU M Q, SONG C S, et al. Experimental and mechanism study of Cf/SiC undergoing longitudinal-torsional ultrasonic vibration-assisted grinding[J]. International Journal of Advanced Manufacturing Technology, 2023, 127(11-12): 5791-5802. doi: 10.1007/s00170-023-11982-1 [111] JIN J W, WANG X B, BIE W B, et al. Machinability of SiCf/SiC ceramic matrix composites using longitudinal-torsional coupled rotary ultrasonic machining[J]. International Journal of Advanced Manufacturing Technology, 2024, 131(5-6): 2465-2476. doi: 10.1007/s00170-023-11792-5 [112] WANG Z W, BAO Y, FENG K, et al. Characterization, quantitative evaluation, and formation mechanism of surface damage in ultrasonic vibration assisted scratching of Cf/SiC composites[J]. Journal of the European Ceramic Society, 2024, 44(7): 4502-4523. doi: 10.1016/j.jeurceramsoc.2024.01.087 [113] CHEN J, AN Q L, MING W W, et al. Investigation on machined surface quality in ultrasonic-assisted grinding of Cf/SiC composites based on fracture mechanism of carbon fibers[J]. International Journal of Advanced Manufacturing Technology, 2020, 109(5-6): 1583-1599. doi: 10.1007/s00170-020-05739-3 [114] ZHANG Z K, YUAN S M, LI Q L, et al. Investigation on the machined surface quality and removal mechanism of SiCf/SiC composites in ultrasonic-assisted grinding[J]. International Journal of Advanced Manufacturing Technology, 2022, 123(11-12): 4427-4445. doi: 10.1007/s00170-022-10469-9 [115] YAO L X, LIU Z Q, SONG Q H, et al. Numerical prediction of surface morphology and roughness in rotary ultrasonic face grinding SiO2/SiO2 composite[J]. Journal of Materials Research and Technology, 2023, 25: 5917-5937. [116] ZHANG M H, PANG Z X, JIA Y X, et al. Understanding the machining characteristic of plain weave ceramic matrix composite in ultrasonic-assisted grinding[J]. Ceramics International, 2022, 48(4): 5557-5573. doi: 10.1016/j.ceramint.2021.11.100 [117] XIONG Y F, WANG W H, JIANG R S, et al. Feasibility and tool performance of ultrasonic vibration-assisted milling-grinding SiCf/SiC ceramic matrix composite[J]. Journal of Materials Research and Technology, 2022, 19: 3018-3033. [118] BIE W B, CHEN F, WANG X B, et al. Longitudinal-torsional coupled rotary ultrasonic machining end surface grinding of SiCf/SiC composites: A mechanical model of cutting force[J]. International Journal of Advanced Manufacturing Technology, 2023, 129(3-4): 1227-1248. doi: 10.1007/s00170-023-12360-7 [119] ZHANG M H, XIA Z W, SHAN C W, et al. Analytical model of grinding force for ultrasonic-assisted grinding of Cf/SiC composites[J]. International Journal of Advanced Manufacturing Technology, 2023, 126(5-6): 2037-2052. doi: 10.1007/s00170-023-11257-9 [120] ZHOU Y G, TIAN C C, JIA S Q, et al. Study on grinding force of two-dimensional ultrasonic vibration grinding 2.5D-C/SiC composite material[J]. Crystals, 2023, 13(1): 151. [121] GONG P, ZHANG Y B, WANG C J, et al. Residual stress generation in grinding: Mechanism and modeling[J]. Journal of Materials Processing Technology, 2024, 324: 118262. [122] XIAO G J, YANG Z Y, ZHOU K, et al. Significant improvement of machinability of Cf/SiC composites through matching laser scanning spacing and abrasive belt grain size[J/OL]. Chinese Journal of Aeronautics, 2024: 1-16[2024-07-10]. https://www.sciencedirect.com/science/article/pii/S1000936124001286. [123] XIAO G J, YANG Z Y, ZHOU K, et al. Subsurface damage inhibiting and synchronous removal behavior of Cf/SiC composites with laser-induced controllable ablation during abrasive belt grinding[J]. Applied Surface Science, 2023, 639: 158283. [124] ZHOU K, XIAO G J, HUANG Y. Understanding machinability improvements and removal mechanism of ceramic matrix composites during laser-ablating assisted grinding[J]. Wear, 2024, 538-539: 205199. [125] ZHOU K, XU J Y, XIAO G J, et al. A novel low-damage and low-abrasive wear processing method of Cf/SiC ceramic matrix composites: Laser-induced ablation-assisted grinding[J]. Journal of Materials Processing Technology, 2022, 302: 117503. -

下载:

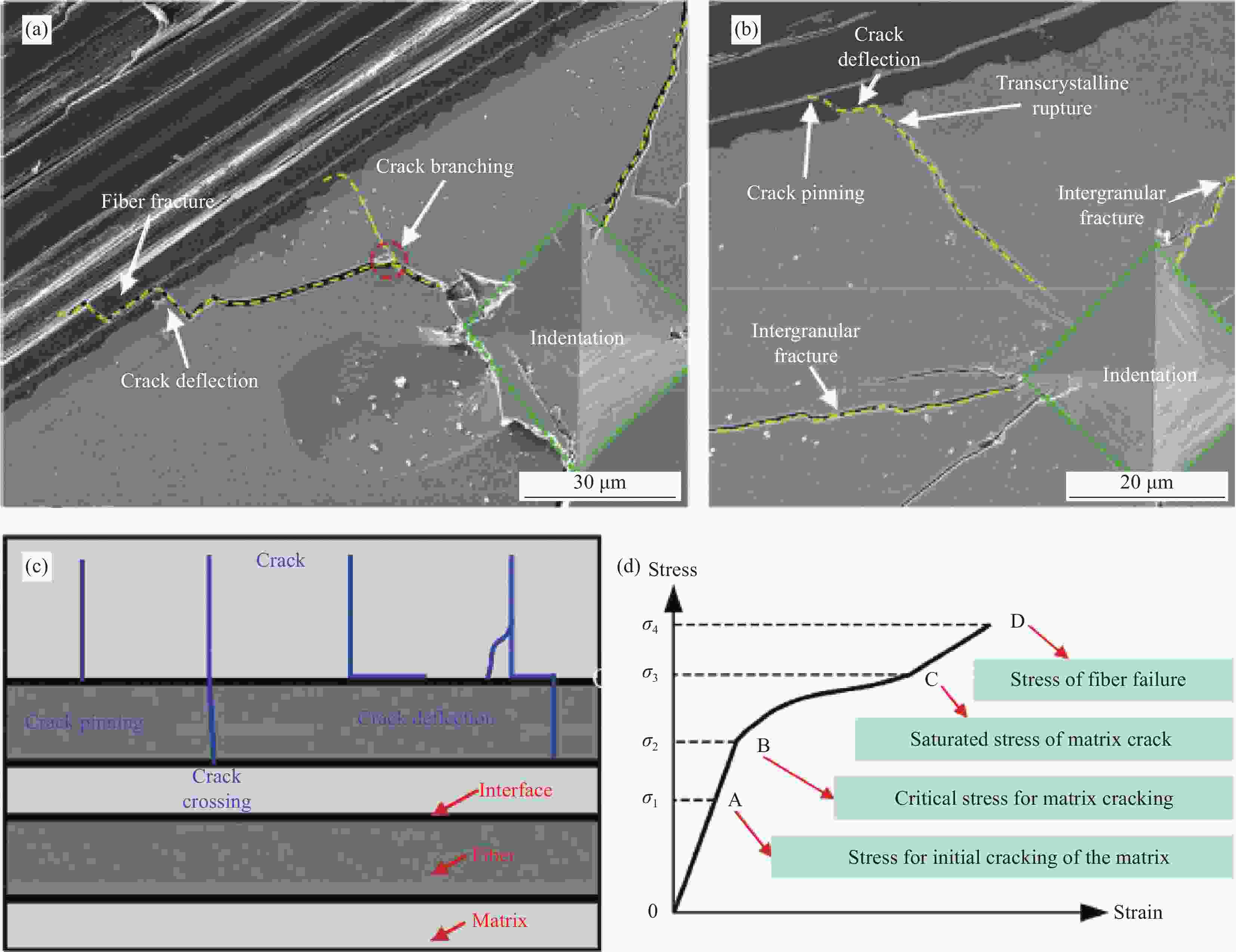

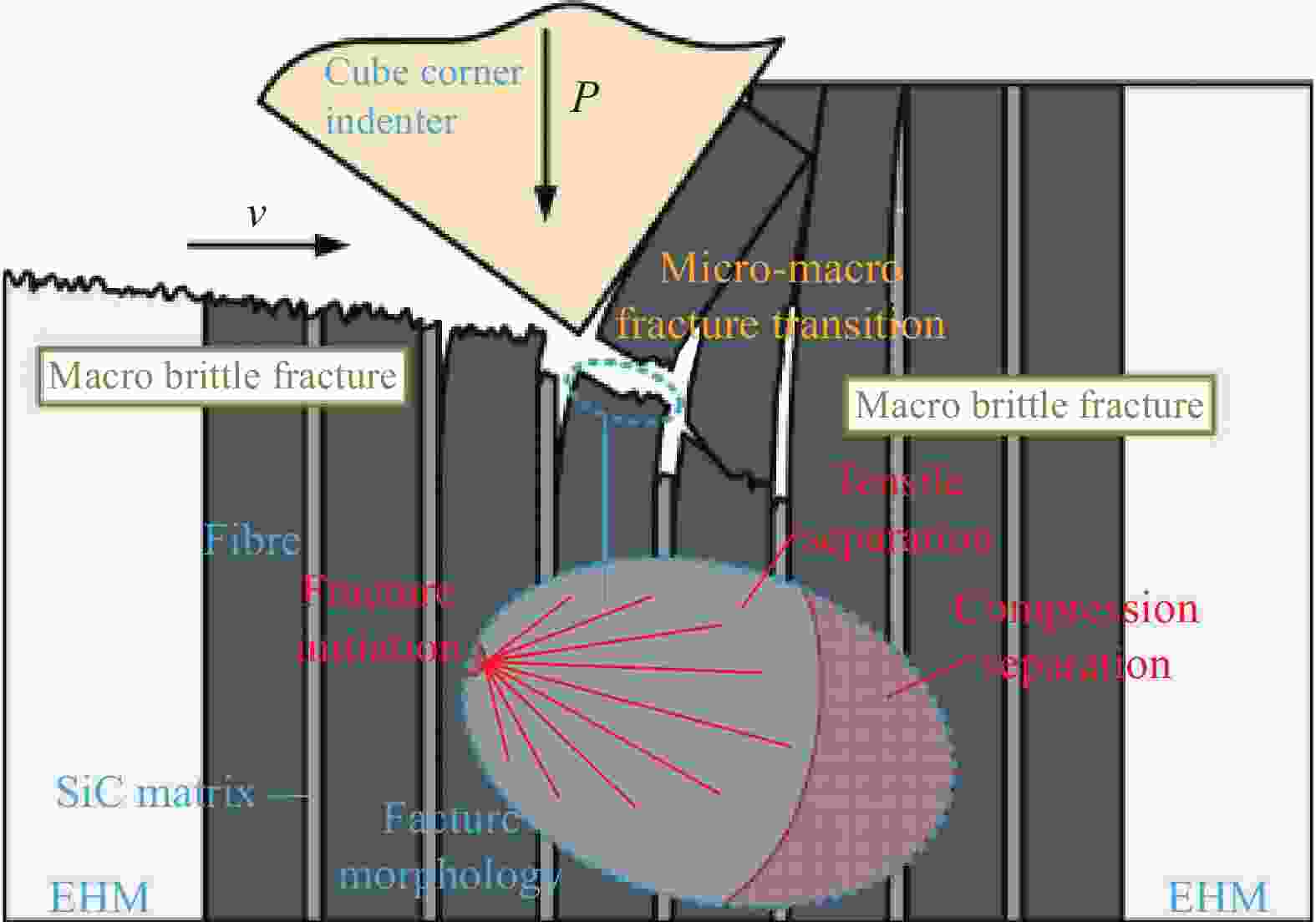

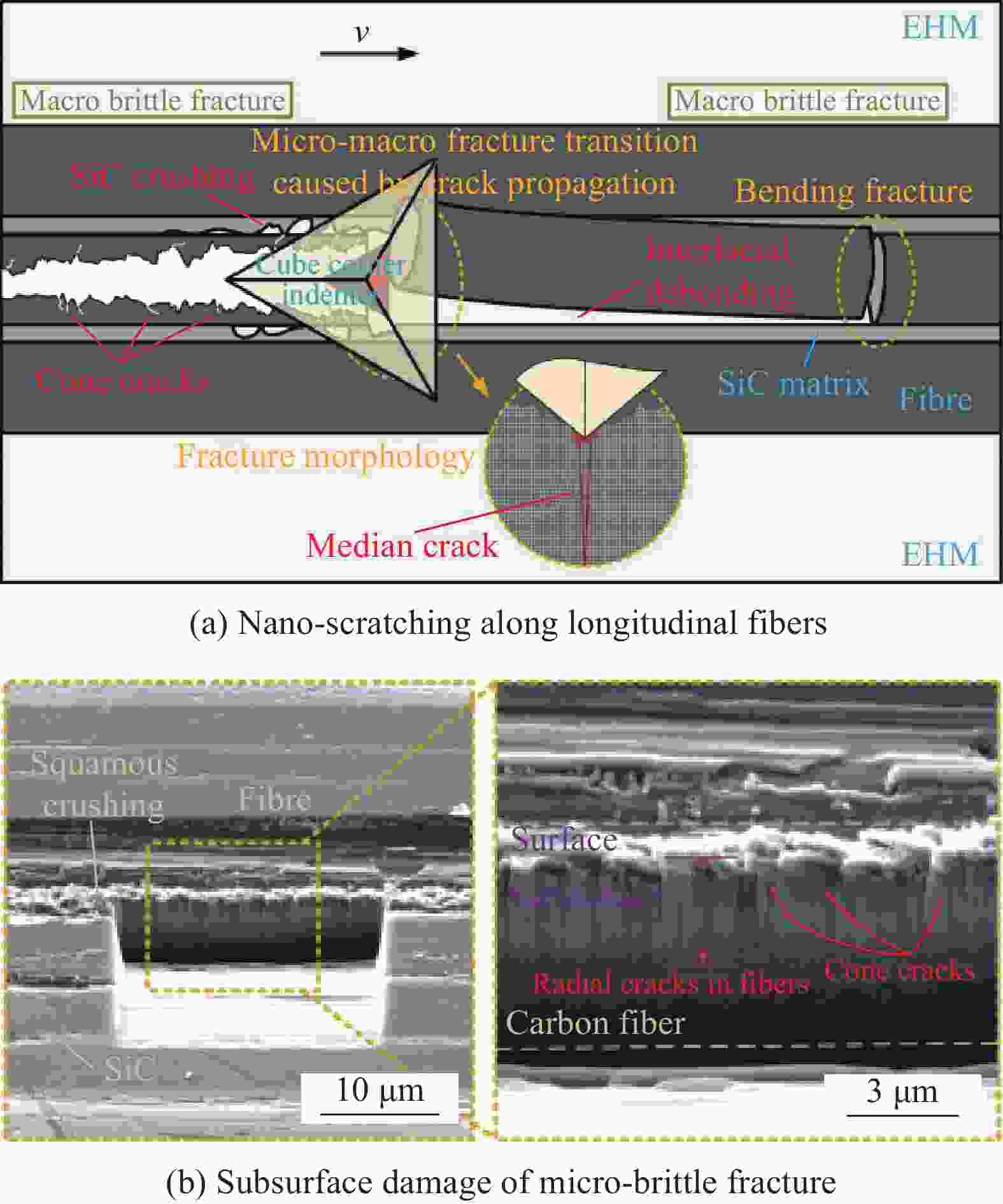

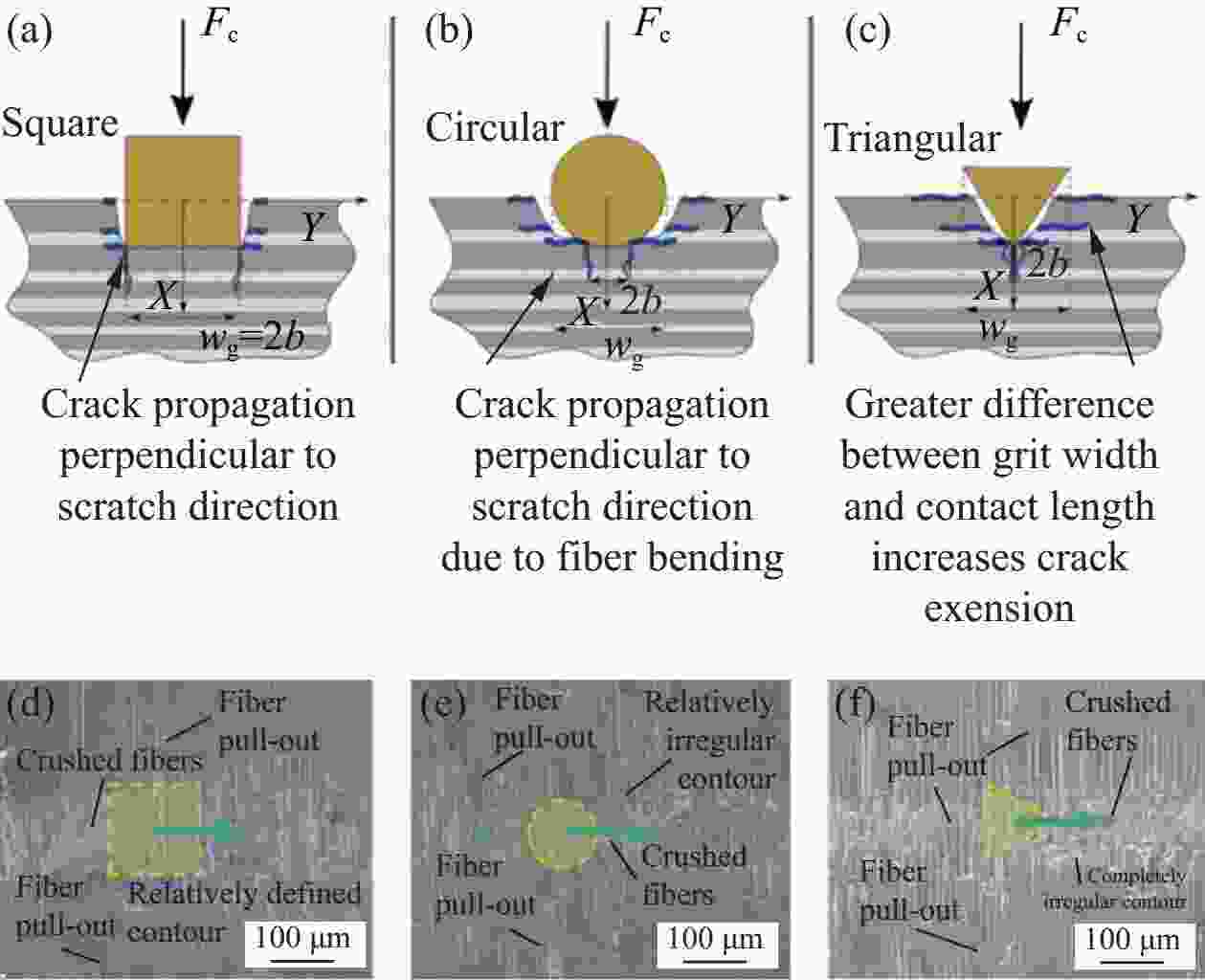

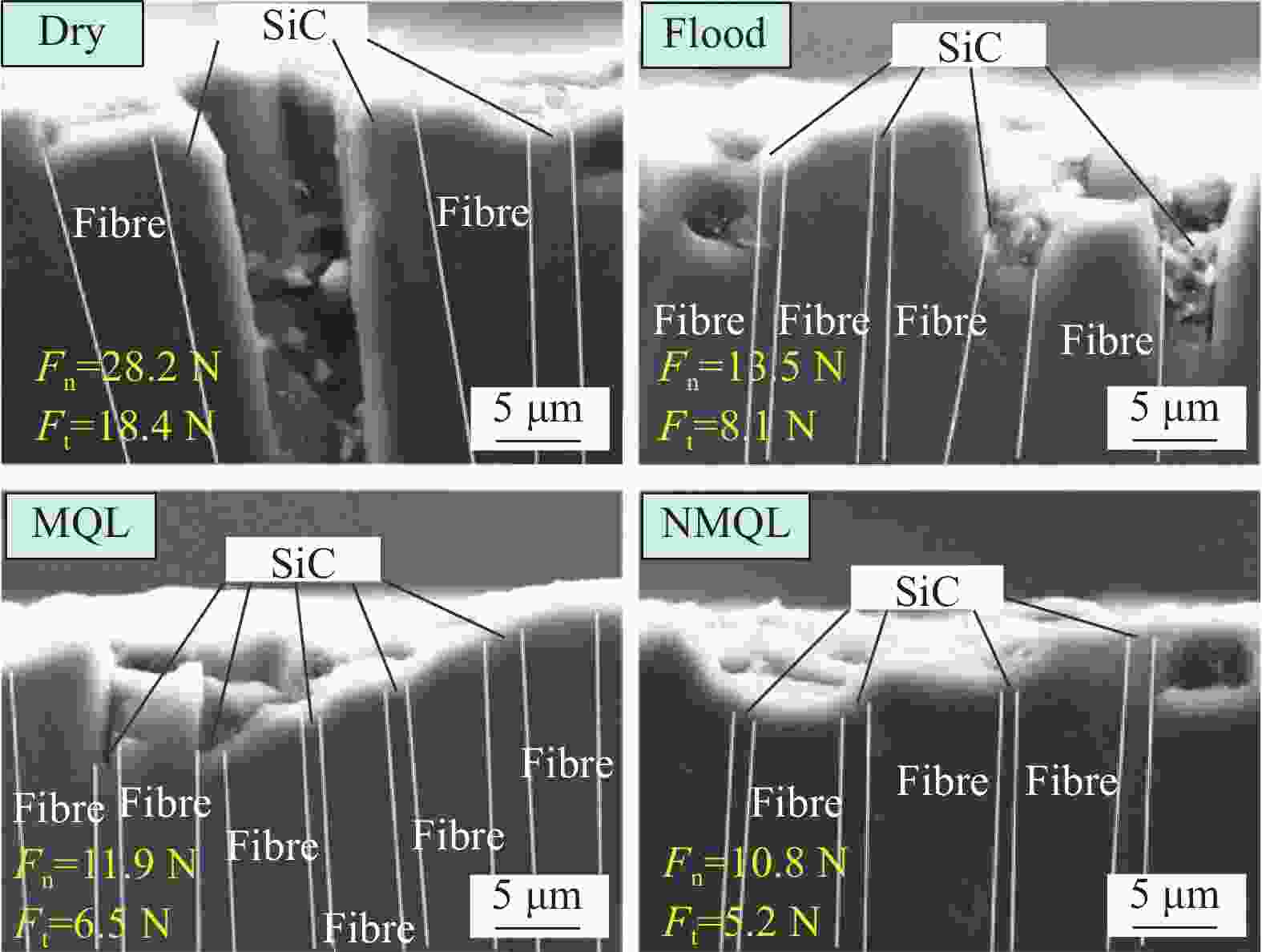

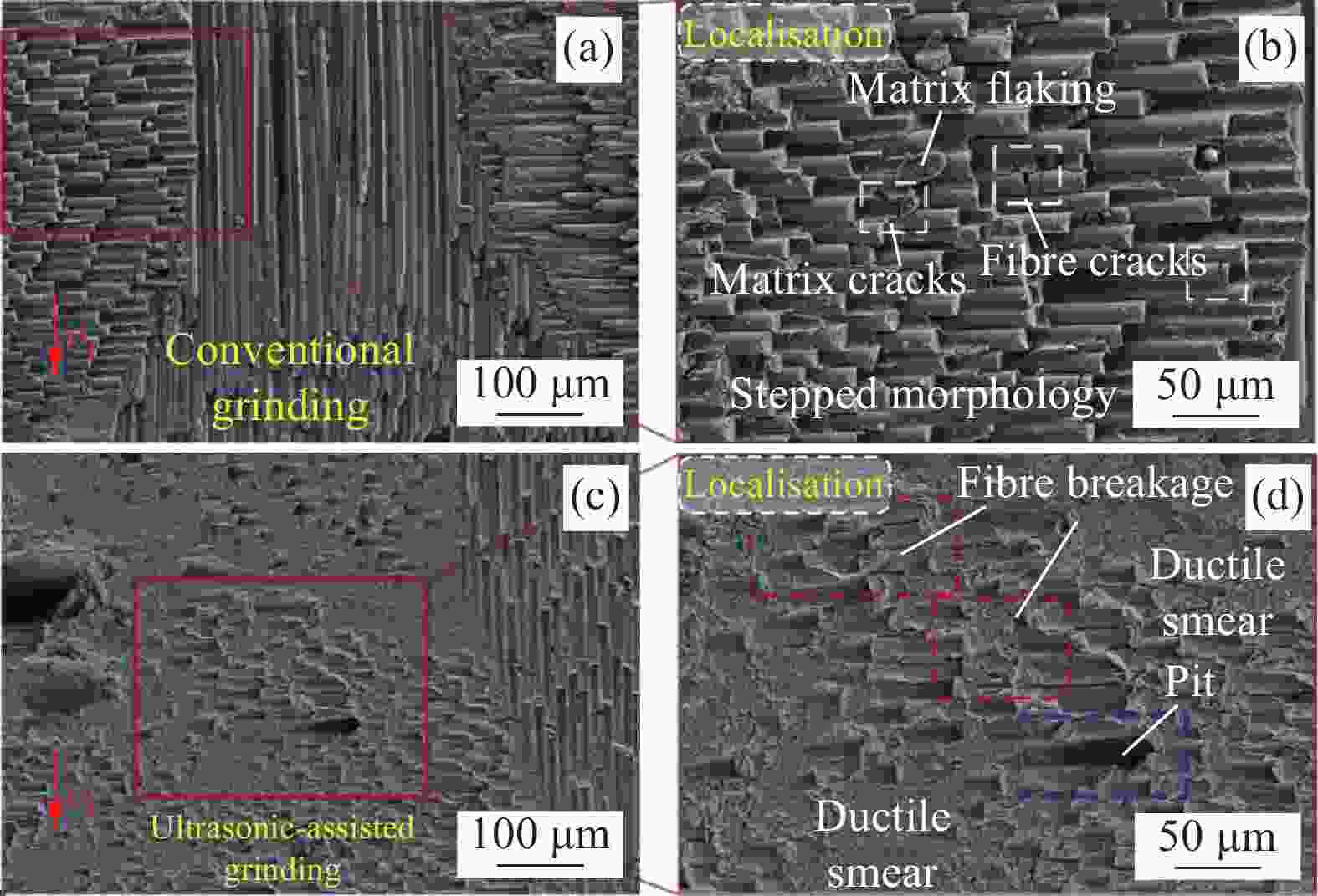

下载: