Research progress in the design, manufacturing, characterization, and evaluation of tailorable thermal expansion mechanical metamaterials

-

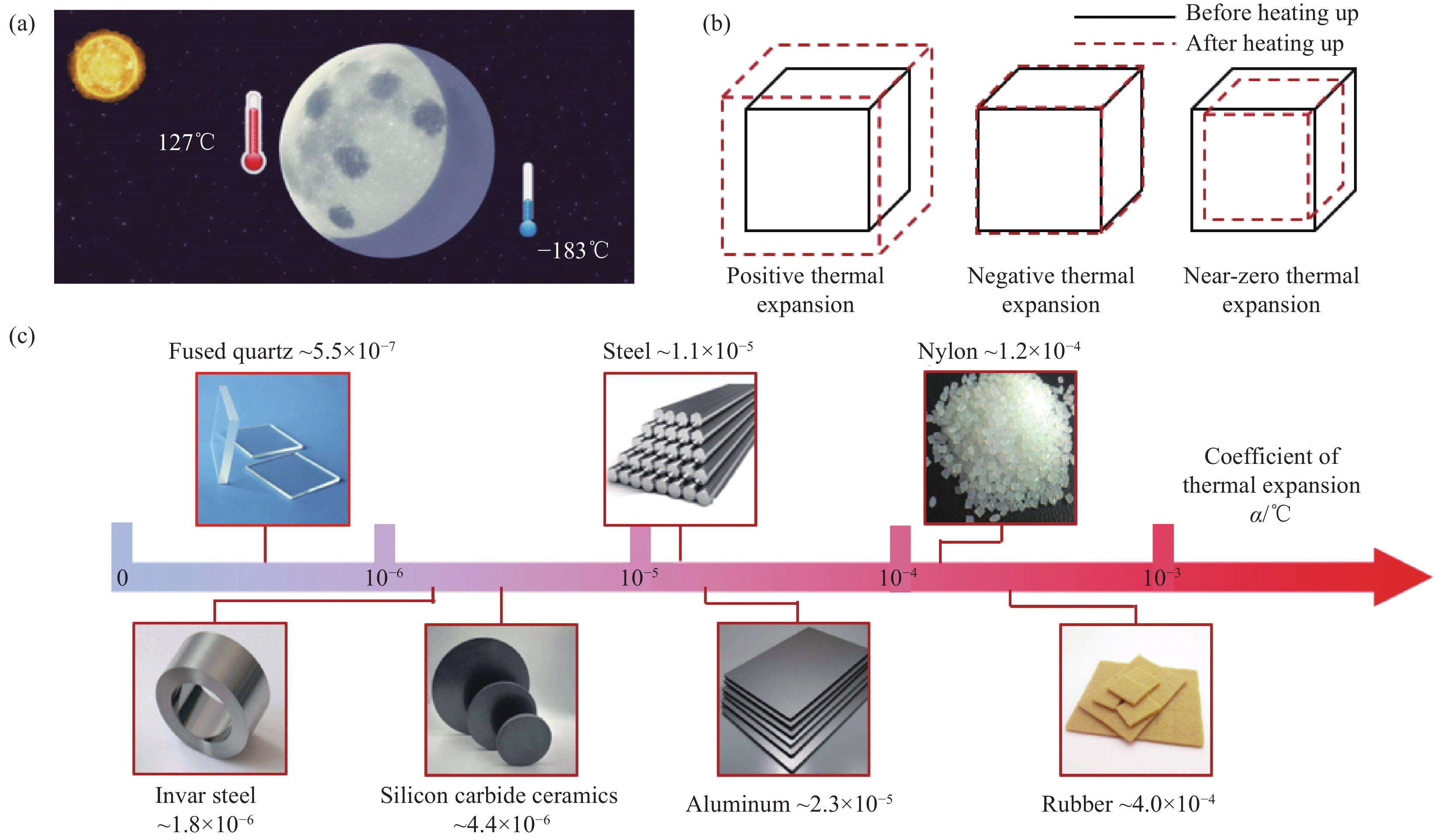

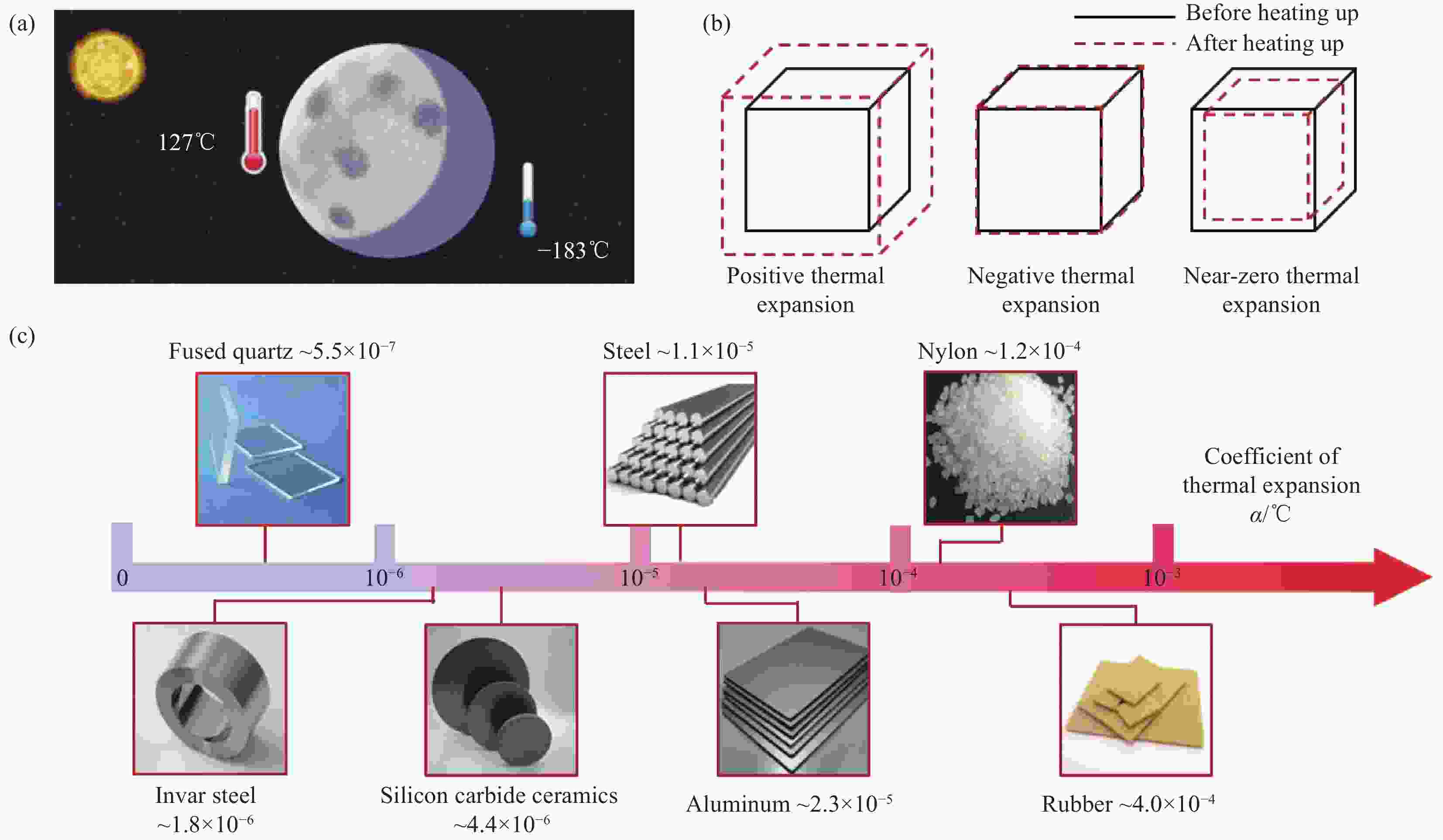

摘要: 我国太空探测事业的蓬勃发展对航天装备的可靠性提出了诸多挑战。在温度急剧变化的环境下,精确控制大型空间结构、精密探测设备和微电子封装等材料与结构的热变形成为亟待突破的瓶颈问题。因此,发展具有可调控热膨胀系数的力学超材料具有重要意义。本文针对可调控热膨胀力学超材料设计制备与表征评测等方面的研究现状与进展进行了概述,系统整理了可调控热膨胀力学超材料的设计方法,总结了热膨胀与刚度、泊松比等力学参数的协同调控策略,探讨了可调控热膨胀力学超材料拓扑优化方法,介绍了热膨胀可调力学超材料制备工艺与性能评测方法。本文还对可调控热膨胀力学超材料的发展趋势进行了展望,为其在航天装备中的深入应用提供指导与借鉴。Abstract: The vigorous development of China's space exploration industry has posed numerous challenges to the reliability of aerospace equipment. In environments with drastic temperature changes, precise control of thermal deformation in materials and structures such as large-scale space structures, precision detection equipment, and microelectronic packaging has become a bottleneck issue that urgently needs to be broken through. Therefore, it is of great significance to develop mechanical metamaterials with tailorable thermal expansion coefficients. This article provides an overview of the current status and progress of research on the design, preparation, and characterization of tailorable thermal expansion mechanical metamaterials. It systematically sorts out the design methods of tailorable thermal expansion mechanical metamaterials, summarizes the collaborative control strategies of thermal expansion, stiffness, Poisson's ratio, and other mechanical parameters, explores the topological optimization methods of tailorable thermal expansion mechanical metamaterials, and introduces the preparation techniques and performance evaluation methods of thermally tailorable mechanical metamaterials. This article also looks into the development trends of tailorable thermal expansion mechanical metamaterials, providing guidance and reference for their in-depth application in aerospace equipment.

-

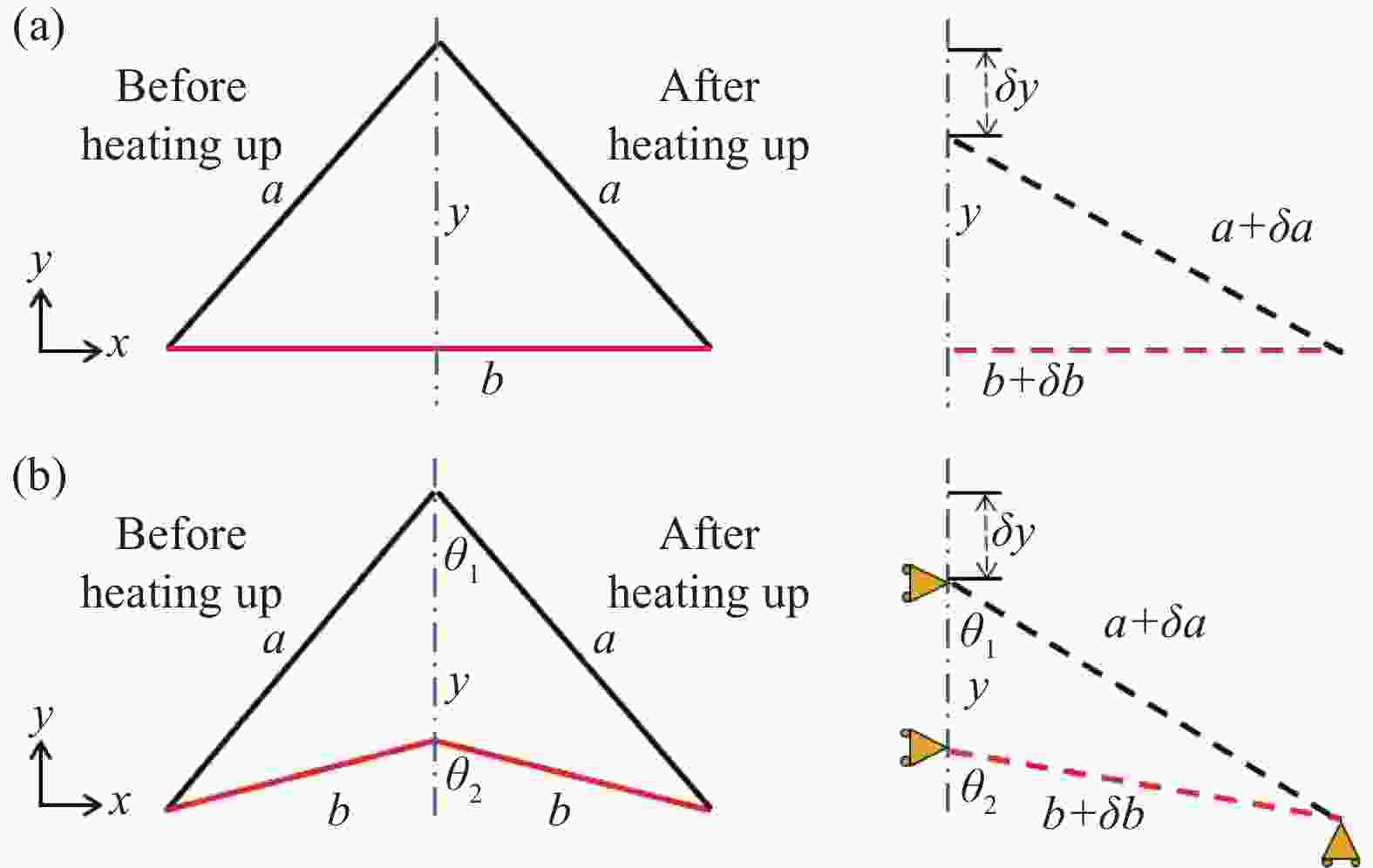

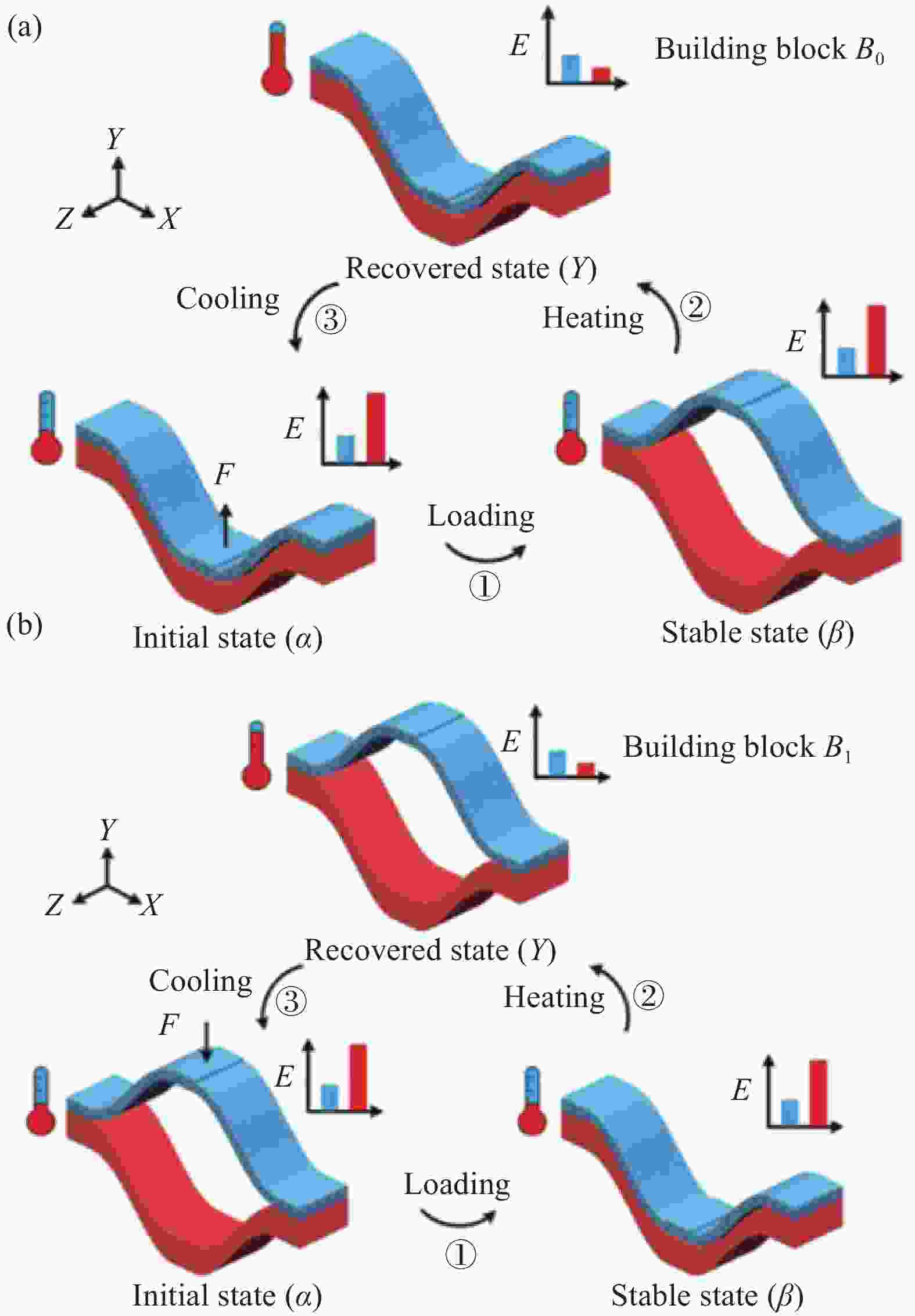

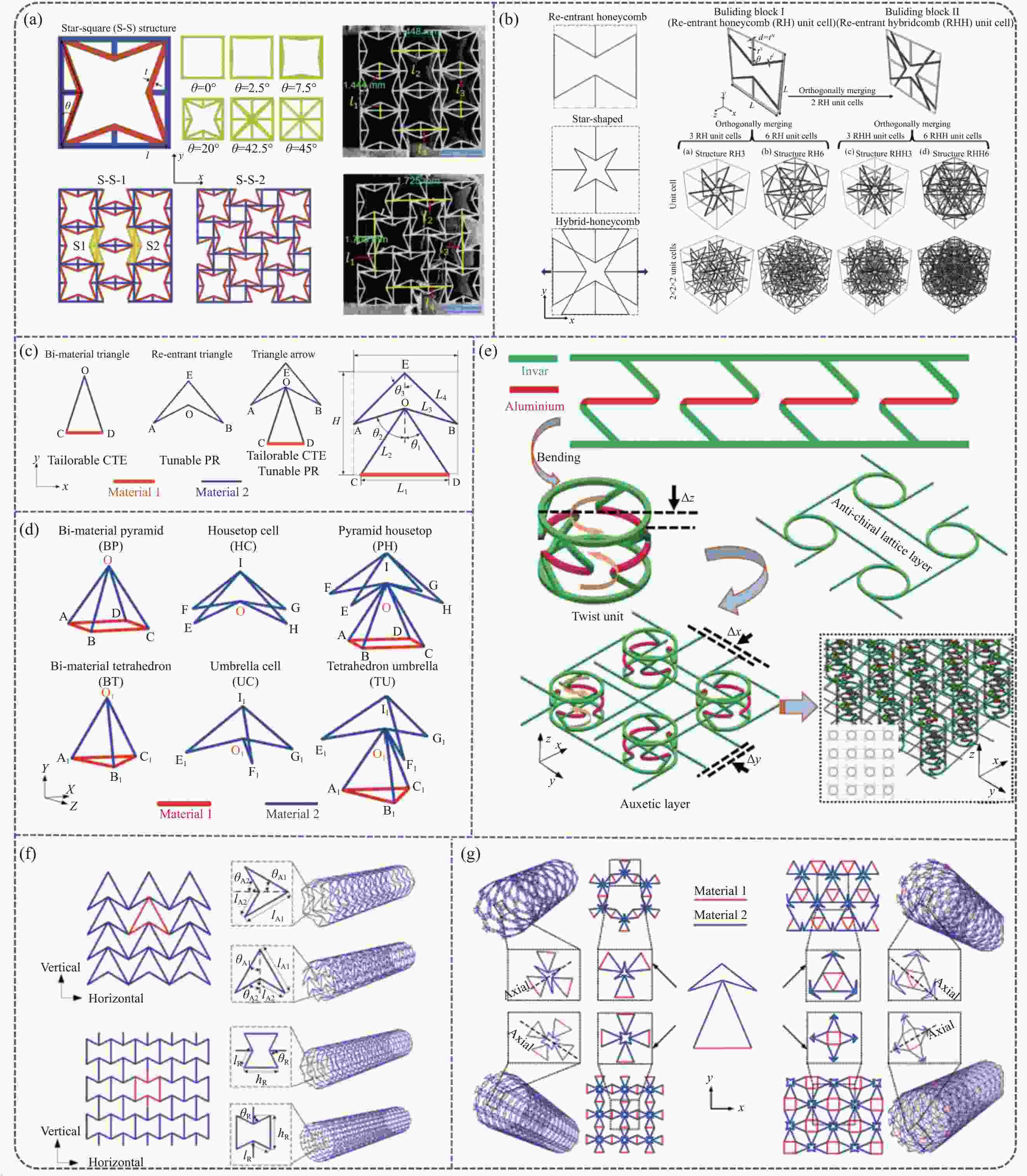

图 2 拉伸机制主导的可调控热膨胀力学超材料:(a)三角结构[10];(b)凹角结构[11]

Figure 2. Sretching mechanism-dominated tailorable thermal expansion mechanical metamaterials: (a) Triangular structure[10]; (b) Re-entrant structure[11]

a, b—Length of cell edge; δa, δb and δy—Deformation of cell along a, b edges and y direction after temperature changes; θ1, θ2—Structural angle

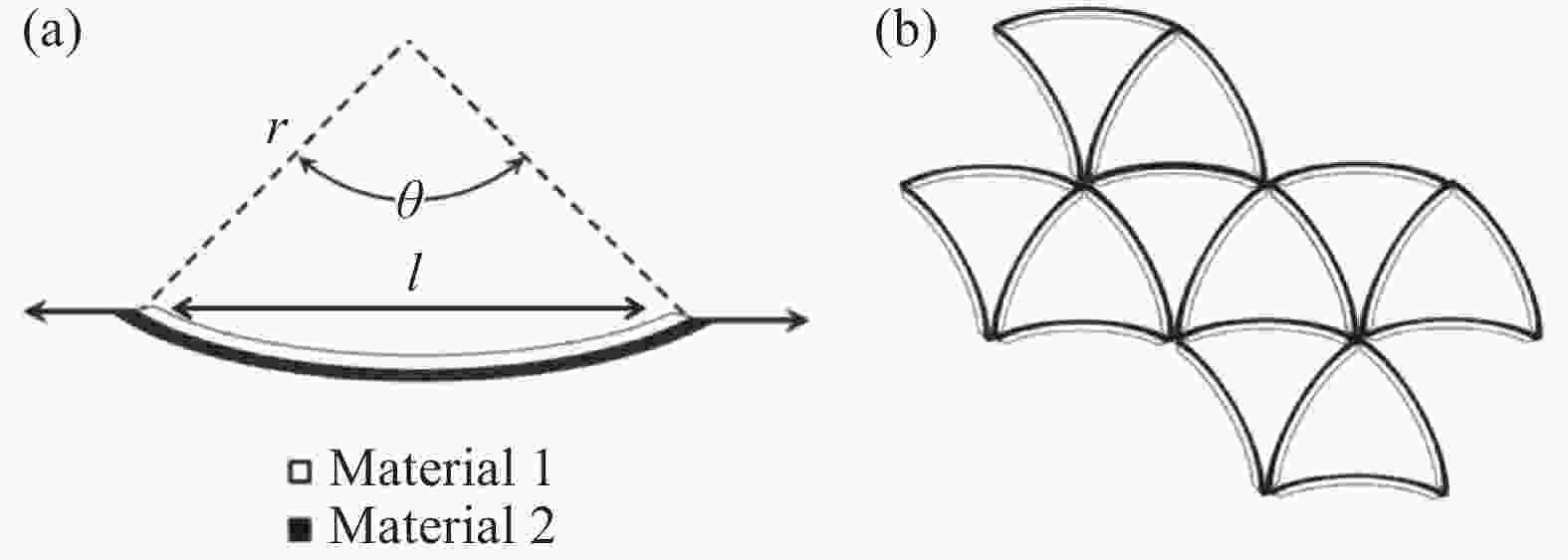

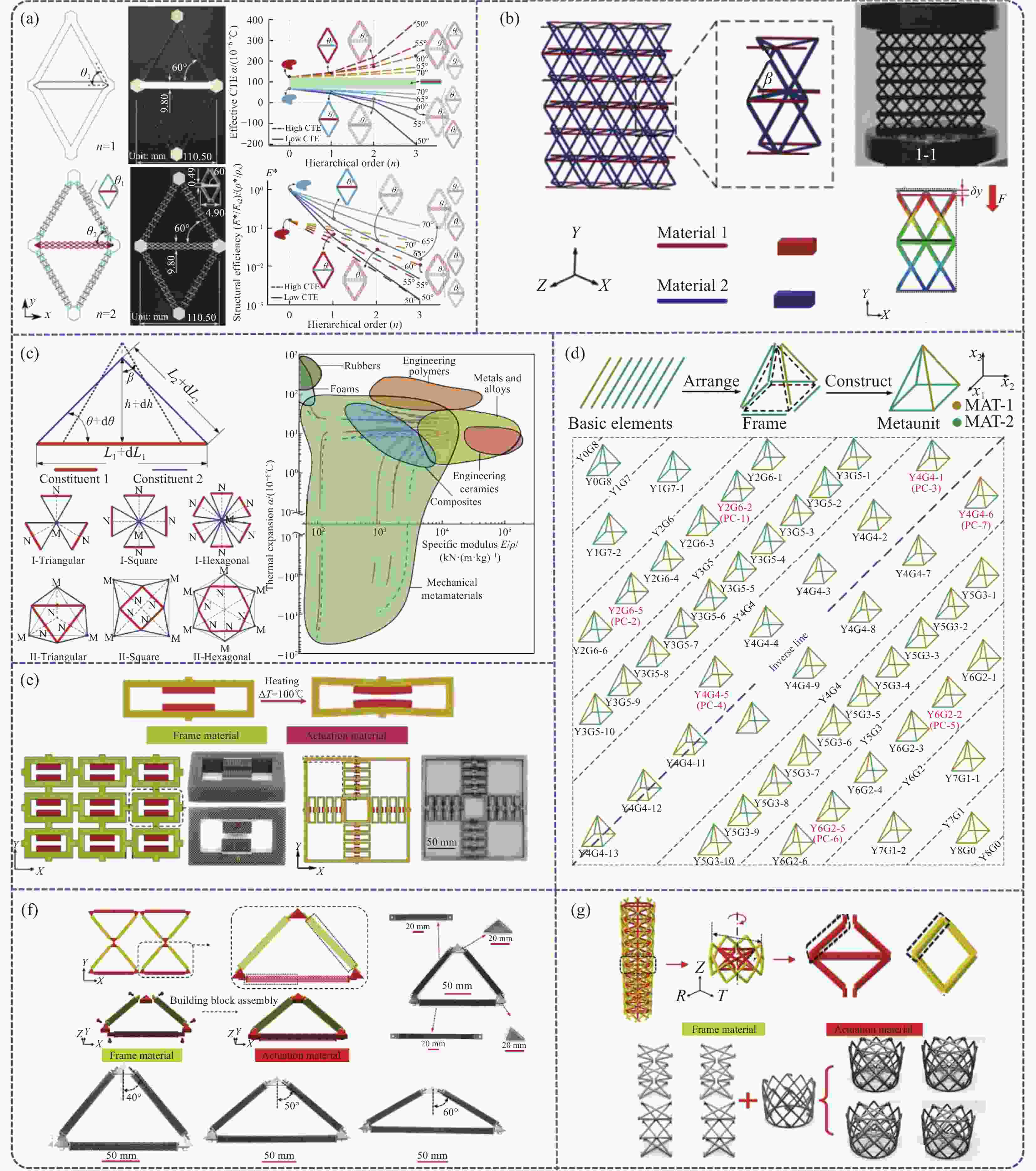

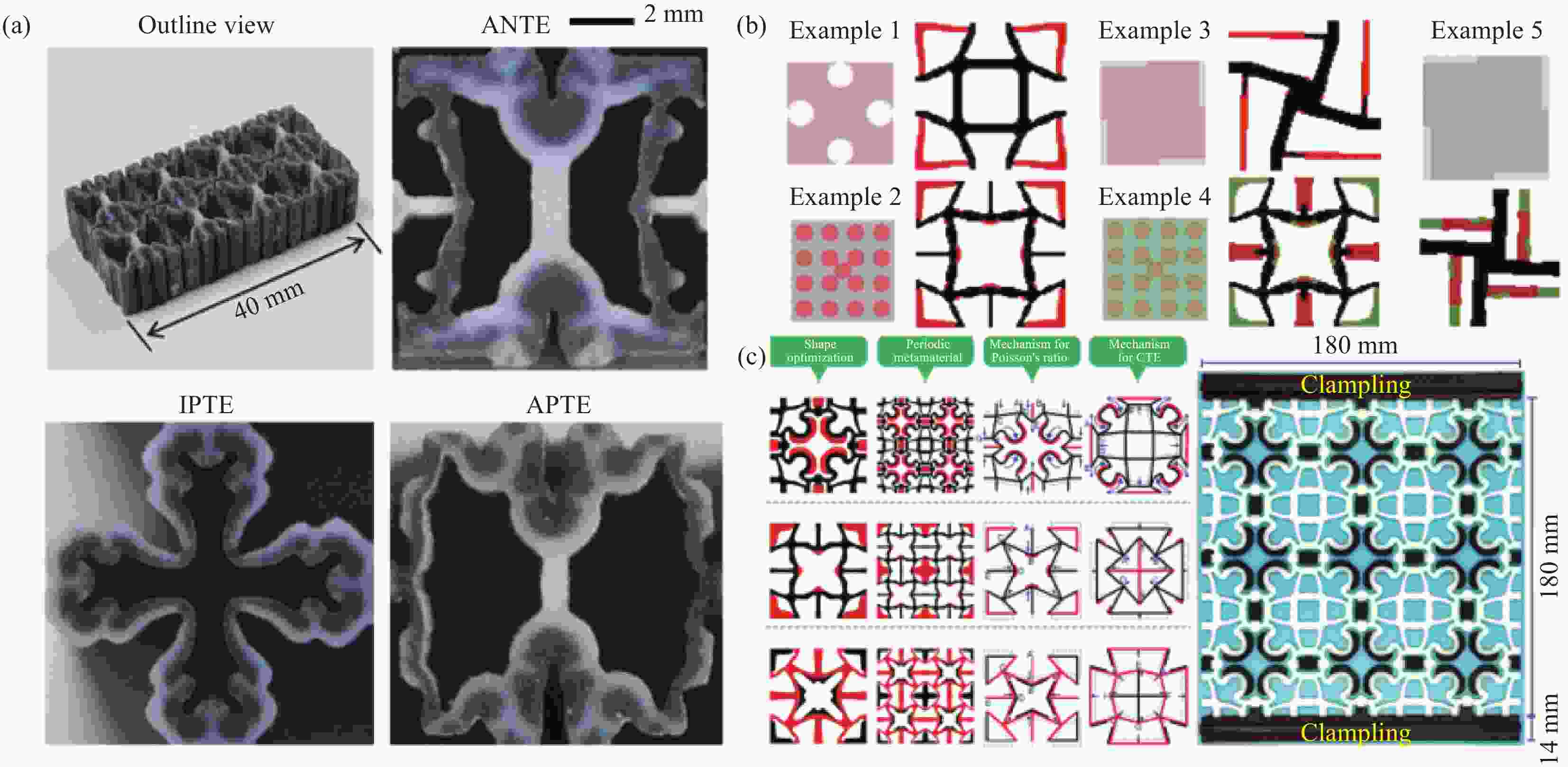

图 8 刚度-热膨胀双调控力学超材料

Figure 8. Dual-tailorable mechanical metamaterial with stiffness and thermal expansion coefficient

CTE—Coefficient of thermal expansion; Δy—Deformation of cell along y direction after temperature changes; β—Structural angle; L—Length of cell edge; dL—Deformation of cell edge after temperature changes; h—Height of cell; dh—Change of height after temperature changes; θ—Structural angle; dθ—Change of structural angle after temperature changes; ΔT—Change of temperature

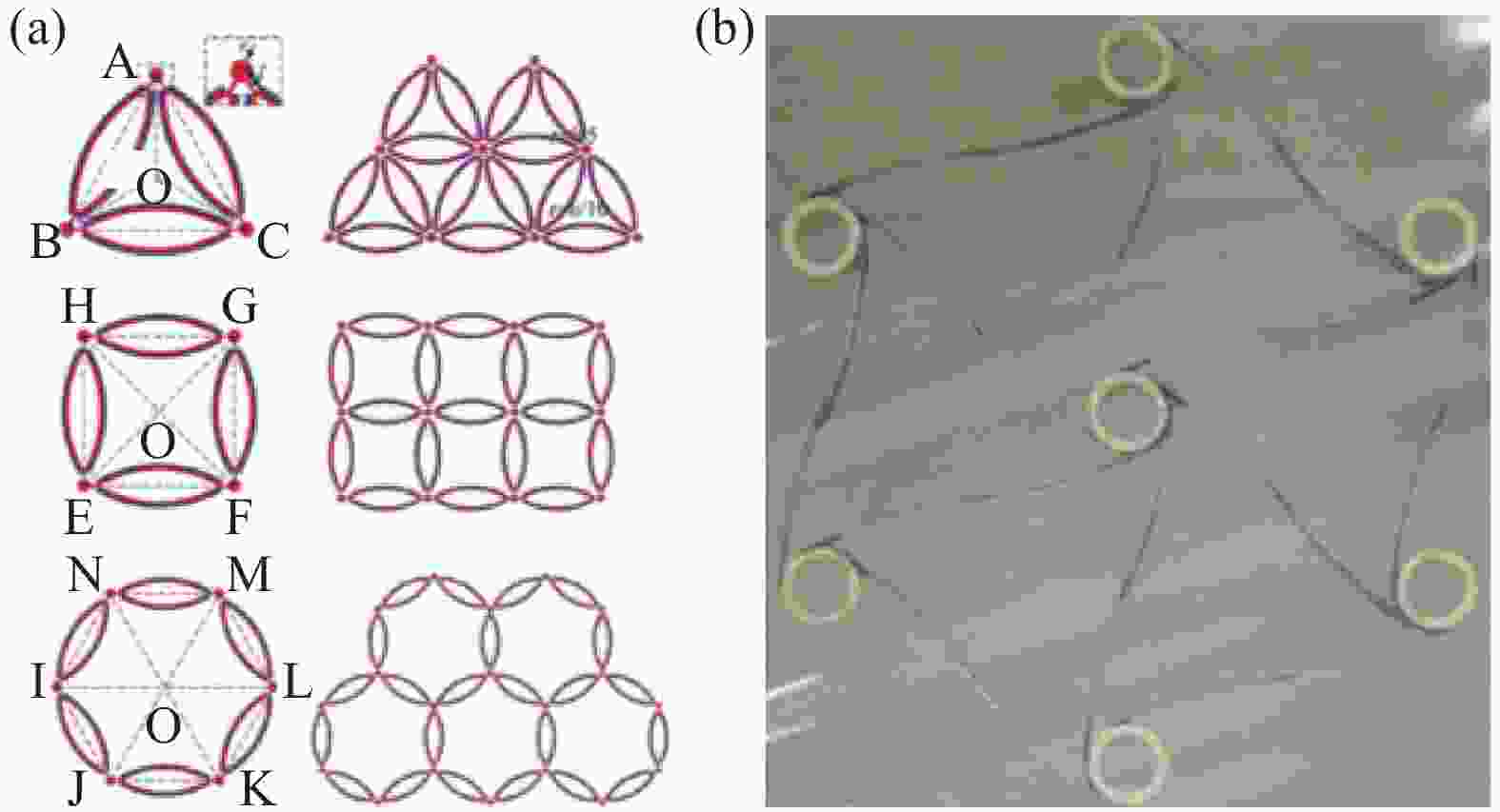

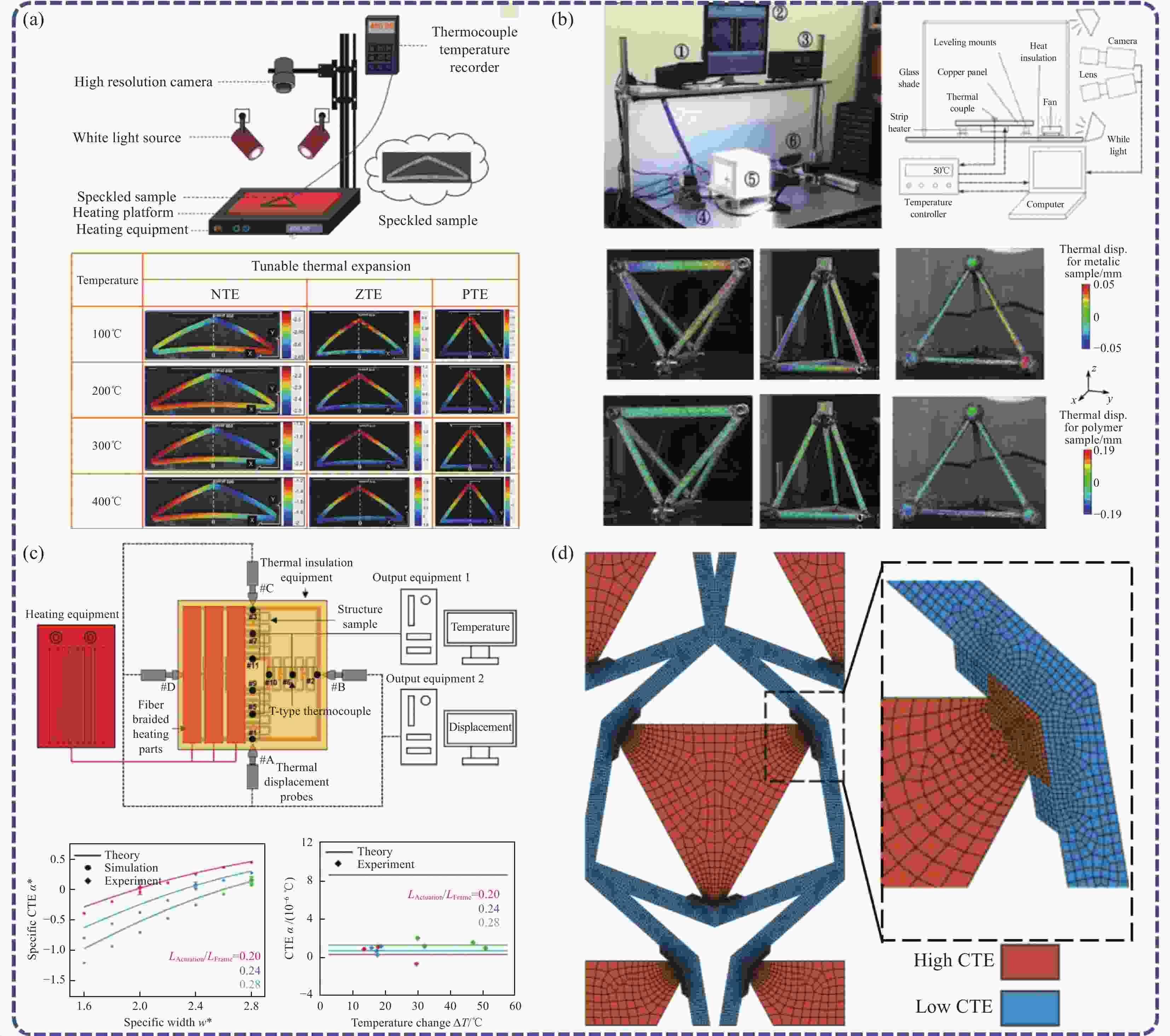

图 13 可调控热膨胀力学超材料的性能测试方法

Figure 13. Testing methods for the performance of tailorable thermal expansion mechanical metamaterials

LActuation—Length of actuation material; LFrame—Length of frame material; NTE—Negative thermal expansion; ZTE—Zero thermal expansion; PTE—Positive thermal expansion; Disp.—Displacement

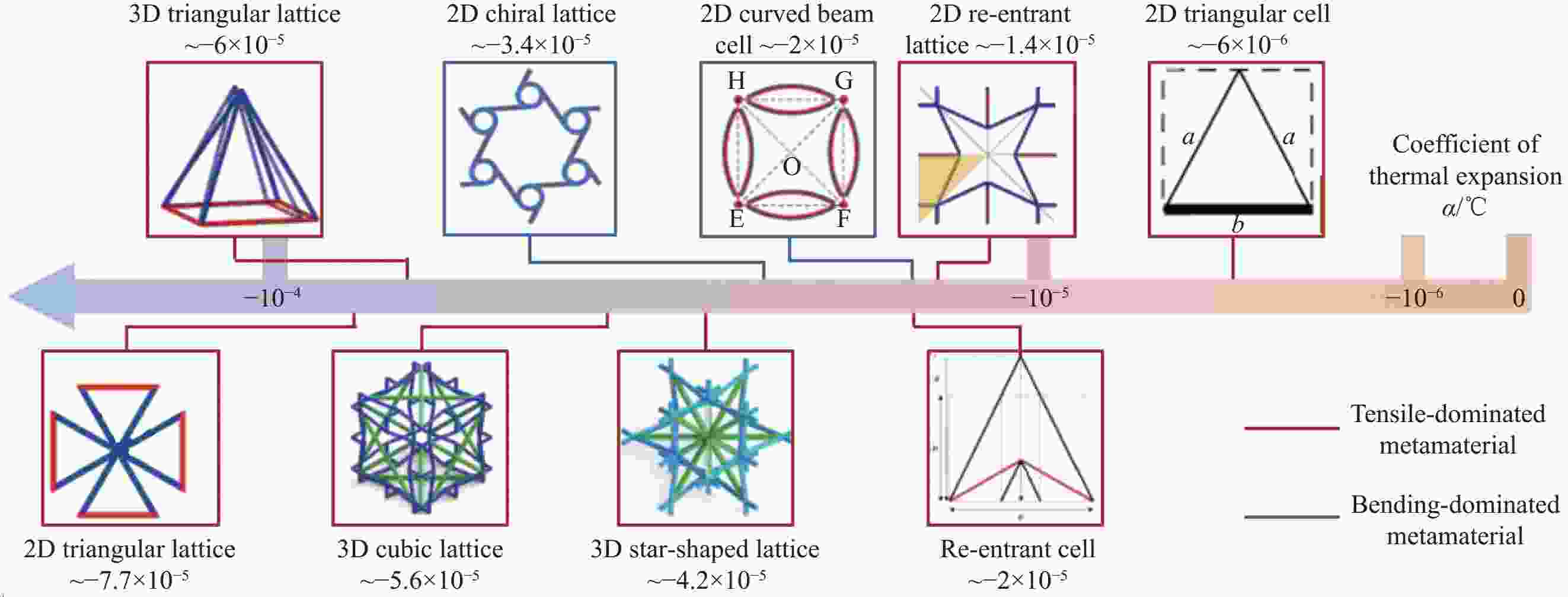

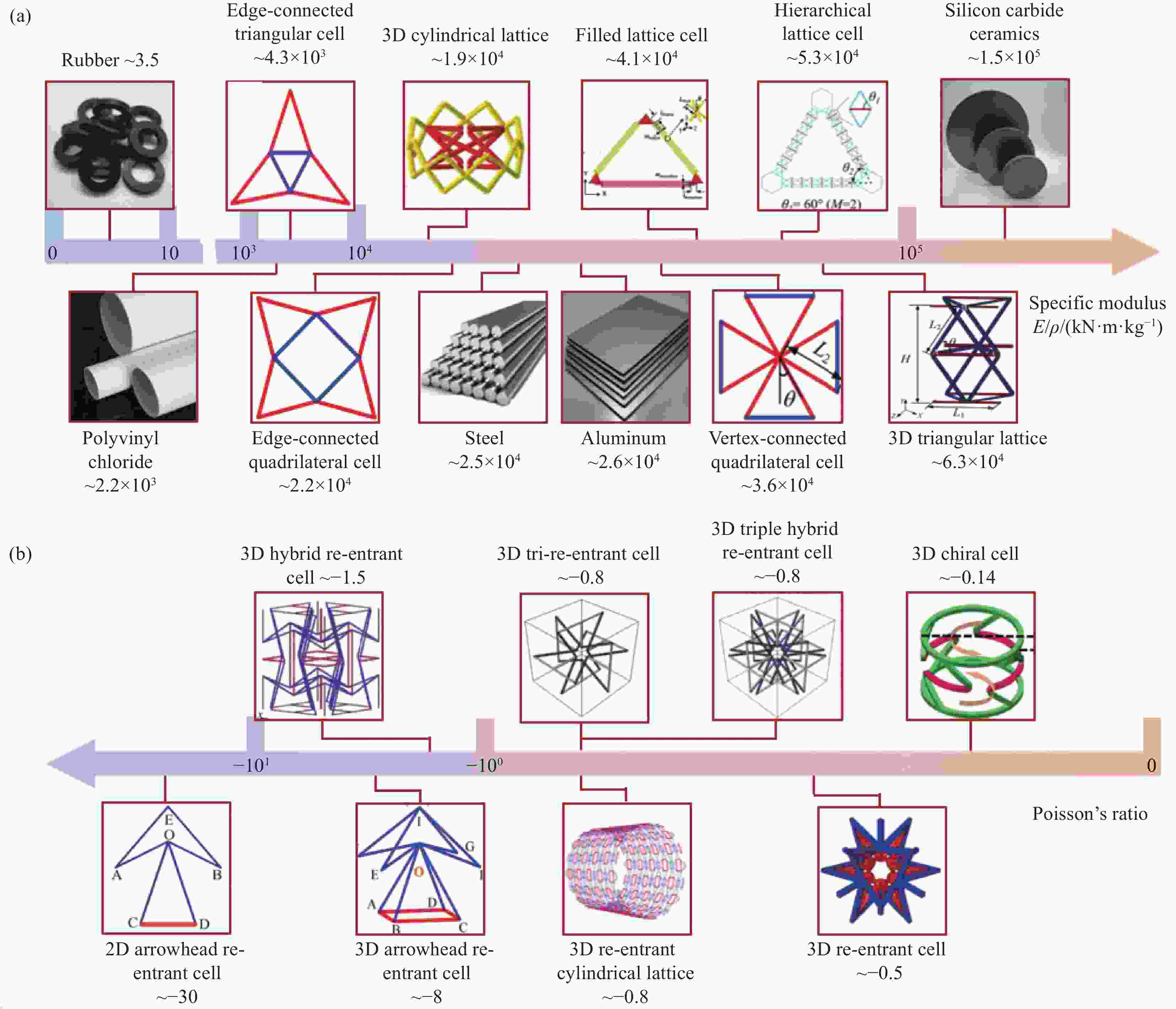

表 1 几种典型可调控热膨胀力学超材料及其最大负热膨胀系数

Table 1. Several typical tailorable thermal expansion mechanical metamaterials and their maximum negative thermal expansion coefficients

Metamaterial structure Maximum negative thermal

expansion coefficient α/°CDesign mechanism Research method Ref. 2D triangular cell −6.0×10−6 Tensile-dominated Theoretical calculation [10] 2D re-entrant lattice −1.4×10−5 Tensile-dominated Simulation [25] 2D curved beam cell −2.0×10−5 Bending-dominated Theoretical calculation + Simulation [21] 2D re-entrant cell −2.0×10−5 Tensile-dominated Theoretical calculation + Simulation [11] 2D chiral lattice −3.4×10−5 Bending-dominated Simulation [22] 3D star-shaped lattice −4.2×10−5 Tensile-dominated Simulation [19] 3D cubic lattice −5.6×10−5 Tensile-dominated Simulation [19] 3D triangular lattice −6.0×10−5 Tensile-dominated Theoretical calculation [16] 2D triangular lattice −7.7×10−5 Tensile-dominated Theoretical calculation + Simulation [18] -

[1] 刘宇峰, 张中伟, 许正辉, 等. 空间高稳定碳/碳蜂窝夹层结构制备及性能[J]. 宇航学报, 2020, 41(8): 1067-1075. doi: 10.3873/j.issn.1000-1328.2020.08.010LIU Yufeng, ZHANG Zhongwei, XU Zhenghui, et al. Preparation and properties of carbon/carbon honeycomb sandwich panels for space ultra-stable structures[J]. Journal of Astronautics, 2020, 41(8): 1067-1075(in Chinese). doi: 10.3873/j.issn.1000-1328.2020.08.010 [2] 丁勇, 薛明德, 王新堂. 大型空间结构热弹性非线性有限元分析[J]. 宇航学报, 2006, 27(6): 1162-1167. doi: 10.3321/j.issn:1000-1328.2006.06.008DING Yong, XUE Mingde, WANG Xintang. Thermal structural finite element analysis of large space structure considering geometric non-linearity[J]. Journal of Astronautics, 2006, 27(6): 1162-1167(in Chinese). doi: 10.3321/j.issn:1000-1328.2006.06.008 [3] 邓启文, 韦庆, 李泽湘. 大时延力反馈遥操作系统的PID控制[J]. 宇航学报, 2006, 27(2): 153-156, 200. doi: 10.3321/j.issn:1000-1328.2006.02.001DENG Qiwen, WEI Qing, LI Zexiang. PID control of force-reflecting teleoperation system with large time-delay[J]. Journal of Astronautics, 2006, 27(2): 153-156, 200(in Chinese). doi: 10.3321/j.issn:1000-1328.2006.02.001 [4] 崔铎. 负热膨胀材料及其增强铝基复合材料的制备与性能研究[D]. 上海: 上海交通大学, 2020.CUI Duo. Preparation and properties of negative thermal expansion materials and reinforced aluminum matrix composites[D]. Shanghai: Shanghai Jiao Tong University, 2020(in Chinese). [5] 孔祥鲲, 孔令奇, 姜顺流, 等. 电磁超材料在超宽带雷达隐身微小卫星设计中的应用[J]. 宇航学报, 2021, 42(6): 775-782. doi: 10.3873/j.issn.1000-1328.2021.06.011KONG Xiangkun, KONG Lingqi, JIANG Shunliu, et al. Application of electromagnetic metamaterials in design of ultra-wideband radar stealth microsatellite[J]. Journal of Astronautics, 2021, 42(6): 775-782(in Chinese). doi: 10.3873/j.issn.1000-1328.2021.06.011 [6] 樊会涛, 段鹏飞, 袁成. 航空颠覆性技术初探[J]. 航空学报, 2024, 45(5): 16-32.FAN Huitao, DUAN Pengfei, YUAN Cheng. A preliminary study on disruptive technologies in aviation[J]. Acta Aeronautica et Astronautica Sinica, 2023, 42(5): 1-16(in Chinese). [7] 于相龙, 周济. 力学超材料的构筑及其超常新功能[J]. 中国材料进展, 2019, 38(1): 14-21, 41. doi: 10.7502/j.issn.1674-3962.2019.01.02YU Xianglong, ZHOU Ji. Mechanical metamaterials: Architected materials and unexplored properties[J]. Materials China, 2019, 38(1): 14-21, 41(in Chinese). doi: 10.7502/j.issn.1674-3962.2019.01.02 [8] 任鑫, 张相玉, 谢亿民. 负泊松比材料和结构的研究进展[J]. 力学学报, 2019, 51(3): 656-687. doi: 10.6052/0459-1879-18-381REN Xin, ZHANG Xiangyu, XIE Yimin. Research progress in auxetic materials and structures[J]. Chinese Journal of Theoretical and Applied Mechanics, 2019, 51(3): 656-687(in Chinese). doi: 10.6052/0459-1879-18-381 [9] 武亚卓. 热膨胀可调控多孔超材料制备及实验表征[D]. 长沙: 湖南大学, 2020.WU Yazhuo. The fabrication and characterization of porous metamaterials with adjustable thermal expansion[D]. Changsha: Hunan University, 2020(in Chinese). [10] MILLER W, MACKENZIE D S, SMITH C W, et al. A generalised scale-independent mechanism for tailoring of thermal expansivity: Positive and negative[J]. Mechanics of Materials, 2008, 40(4-5): 351-361. doi: 10.1016/j.mechmat.2007.09.004 [11] NG C K, SAXENA K K, DAS R, et al. On the anisotropic and negative thermal expansion from dual-material re-entrant-type cellular metamaterials[J]. Journal of Materials Science, 2017, 52: 899-912. doi: 10.1007/s10853-016-0385-7 [12] BERGER J B, MCMEEKING R M. Mechanical characterization of a bonded tailorable coefficient of thermal expansion lattice with near optimal performance[J]. Journal of Materials Research, 2018, 33(20): 3383-3397. doi: 10.1557/jmr.2018.327 [13] LI X, GAO L, ZHOU W, et al. Novel 2D metamaterials with negative Poisson’s ratio and negative thermal expansion[J]. Extreme Mechanics Letters, 2019, 30: 100498. doi: 10.1016/j.eml.2019.100498 [14] AI L, GAO X L. Three-dimensional metamaterials with a negative Poisson's ratio and a non-positive coefficient of thermal expansion[J]. International Journal of Mechanical Sciences, 2018, 135: 101-113. doi: 10.1016/j.ijmecsci.2017.10.042 [15] WANG K, LIN F, CHEN J, et al. Three-dimensional hierarchical metamaterials incorporating multi-directional programmable thermal expansion[J]. Mechanics of Materials, 2021, 163: 104095. doi: 10.1016/j.mechmat.2021.104095 [16] WEI K, PENG Y, WANG K, et al. Three dimensional lightweight lattice structures with large positive, zero and negative thermal expansion[J]. Composite Structures, 2018, 188: 287-296. doi: 10.1016/j.compstruct.2018.01.030 [17] XU H, PASINI D. Structurally efficient three-dimensional metamaterials with controllable thermal expansion[J]. Scientific Reports, 2016, 6(1): 34924. doi: 10.1038/srep34924 [18] WEI K, XIAO X, XU W, et al. Large programmable coefficient of thermal expansion in additively manufactured bi-material mechanical metamaterial[J]. Virtual and Physical Prototyping, 2021, 16(sup1): S53-S65. doi: 10.1080/17452759.2021.1917295 [19] SARVESTANI H Y, AKBARZADEH A H, THERRIAULT D, et al. Engineered bi-material lattices with thermo-mechanical programmability[J]. Composite Structures, 2021, 263: 113705. doi: 10.1016/j.compstruct.2021.113705 [20] LAKES R. Cellular solid structures with unbounded thermal expansion[J]. Journal of Materials Science Letters, 1996, 15: 475-477. doi: 10.1007/BF00275406 [21] XU W, XIAO X, CHEN J, et al. Program multi-directional thermal expansion in a series of bending dominated mechanical metamaterials[J]. Thin-Walled Structures, 2022, 174: 109147. doi: 10.1016/j.tws.2022.109147 [22] YU H, WU W, ZHANG J, et al. Drastic tailorable thermal expansion chiral planar and cylindrical shell structures explored with finite element simulation[J]. Composite Structures, 2019, 210: 327-338. doi: 10.1016/j.compstruct.2018.11.043 [23] WU L, LI B, ZHOU J. Isotropic negative thermal expansion metamaterials[J]. Applied Materials & Interfaces, 2016, 8: 17721-17727. [24] HA C S, HESTEKIN E, LI J, et al. Controllable thermal expansion of large magnitude in chiral negative Poisson's ratio lattices[J]. Physica Status Solidi (B), 2015, 252(7): 1431-1434. doi: 10.1002/pssb.201552158 [25] AI L, GAO X L. Metamaterials with negative Poisson’s ratio and non-positive thermal expansion[J]. Composite Structures, 2017, 162: 70-84. doi: 10.1016/j.compstruct.2016.11.056 [26] YANG H, D'AMBROSIO N, LIU P, et al. Shape memory mechanical metamaterials[J]. Materials Today, 2023, 66: 36-49. doi: 10.1016/j.mattod.2023.04.003 [27] STEEVES C A, DOS SANTOS E LUCATO S L, HE M, et al. Concepts for structurally robust materials that combine low thermal expansion with high stiffness[J]. Journal of the Mechanics and Physics of Solids, 2007, 55(9): 1803-1822. doi: 10.1016/j.jmps.2007.02.009 [28] LEHMAN J, LAKES R S. Stiff, strong, zero thermal expansion lattices via material hierarchy[J]. Composite Structures, 2014, 107: 654-663. doi: 10.1016/j.compstruct.2013.08.028 [29] XU H, FARAG A, PASINI D. Multilevel hierarchy in bi-material lattices with high specific stiffness and unbounded thermal expansion[J]. Acta Materialia, 2017, 134: 155-166. doi: 10.1016/j.actamat.2017.05.059 [30] LI J, LIU H T, ZHANG Z Y. Stiffness characteristics for bi-directional tunable thermal expansion metamaterial based on bi-material triangular unit[J]. International Journal of Mechanical Sciences, 2023, 241: 107983. doi: 10.1016/j.ijmecsci.2022.107983 [31] WEI K, CHEN H, PEI Y, et al. Planar lattices with tailorable coefficient of thermal expansion and high stiffness based on dual-material triangle unit[J]. Journal of the Mechanics and Physics of Solids, 2016, 86: 173-191. doi: 10.1016/j.jmps.2015.10.004 [32] WEI K, PENG Y, WEN W, et al. Tailorable thermal expansion of lightweight and robust dual-constituent triangular lattice material[J]. Journal of Applied Mechanics, 2017, 84(10): 101006. doi: 10.1115/1.4037589 [33] CHEN J, WANG H, WANG K, et al. Mechanical performances and coupling design for the mechanical metamaterials with tailorable thermal expansion[J]. Mechanics of Materials, 2022, 165: 104176. doi: 10.1016/j.mechmat.2021.104176 [34] CHEN J, XU W, WEI Z, et al. Stiffness characteristics for a series of lightweight mechanical metamaterials with programmable thermal expansion[J]. International Journal of Mechanical Sciences, 2021, 202-203: 106527. doi: 10.1016/j.ijmecsci.2021.106527 [35] WANG K, CHEN J, HAN Z, et al. Synergistically program thermal expansional and mechanical performances in 3D metamaterials: Design-Architecture-Performance[J]. Journal of the Mechanics and Physics of Solids, 2022, 169: 105064. doi: 10.1016/j.jmps.2022.105064 [36] YU H, LIANG B, ZHAO Z, et al. Metamaterials with a controllable thermal-mechanical stability: Mechanical designs, theoretical predictions and experimental demonstrations[J]. Composites Science and Technology, 2021, 207: 108694. doi: 10.1016/j.compscitech.2021.108694 [37] YU H, WANG H, LIANG B, et al. Metamaterials with remarkable thermal–mechanical stability and high specific modulus: Mechanical designs, theoretical predictions and experimental demonstrations[J]. Extreme Mechanics Letters, 2021, 49: 101436. doi: 10.1016/j.eml.2021.101436 [38] YU H, WANG H, GUO X, et al. Building block design for composite metamaterial with an ultra-low thermal expansion and high-level specific modulus[J]. Composite Structures, 2022, 300: 116131. doi: 10.1016/j.compstruct.2022.116131 [39] YU H, WANG H, WANG X, et al. The cylindrical mechanical metamaterial with high-level thermal-mechanical stabilities and high dynamic stiffness[J]. Mechanics of Materials, 2023, 186: 104799. doi: 10.1016/j.mechmat.2023.104799 [40] RAMINHOS J S, BORGES J P, VELHINHO A. Development of polymeric anepectic meshes auxetic metamaterials with negative thermal expansion[J]. Smart Materials and Structures, 2019, 28: 045010. doi: 10.1088/1361-665X/ab034b [41] XU N, LIU H T. A novel 3D structure with tunable Poisson's ratio and adjustable thermal expansion[J]. Composites Communications, 2020, 22: 100431. doi: 10.1016/j.coco.2020.100431 [42] PENG X L, BARGMANN S. A novel hybrid-honeycomb structure: Enhanced stiffness, tunable auxeticity and negative thermal expansion[J]. International Journal of Mechanical Sciences, 2021, 190: 106021. doi: 10.1016/j.ijmecsci.2020.106021 [43] PENG X L, BARGMANN S. Tunable auxeticity and isotropic negative thermal expansion in three-dimensional lattice structures of cubic symmetry[J]. Extreme Mechanics Letters, 2021, 43: 101201. doi: 10.1016/j.eml.2021.101201 [44] LI J, YANG Q, WEI Y, et al. A synergistic design of composite metamaterial with drastically tailorable thermal expansion and Poisson's ratio[J]. Composite Structures, 2021, 275: 114446. doi: 10.1016/j.compstruct.2021.114446 [45] WEI K, PENG Y, QU Z, et al. A cellular metastructure incorporating coupled negative thermal expansion and negative Poisson's ratio[J]. International Journal of Solids and Structures, 2018, 150: 255-267. doi: 10.1016/j.ijsolstr.2018.06.018 [46] PENG Y, WEI K, MEI M, et al. Simultaneously program thermal expansion and Poisson’s ratio in three dimensional mechanical metamaterial[J]. Composite Structures, 2021, 262: 113365. doi: 10.1016/j.compstruct.2020.113365 [47] 王雪松, 刘卫东, 刘典. 新型反四手性蜂窝结构的面内拉伸弹性[J]. 复合材料学报, 2023, 40(8): 4849-4861.WANG Xuesong, LIU Weidong, LIU Dian. In-plane tensile elasticity of a novel anti-tetrachiral cellular structure[J]. Acta Materiae Compositae Sinica, 2023, 40(8): 4849-4861(in Chinese). [48] 刘旭畅, 李爽, 杨金水. 一种新型手性负泊松比结构的减振性能[J]. 复合材料学报, 2024, 41(1): 477-484.LIU Xuchang, LI Shuang, YANG Jinshui. Damping performance of a new chiral negative Poisson's ratio structure[J]. Acta Materiae Compositae Sinica, 2024, 41(1): 477-484(in Chinese). [49] LI J, YANG Q, HUANG N, et al. A novel mechanical metamaterial with tailorable Poisson’s ratio and thermal expansion based on a chiral torsion unit[J]. Smart Materials and Structures, 2021, 30(11): 115004. doi: 10.1088/1361-665X/ac25c9 [50] LING B, WEI K, WANG Z, et al. Experimentally program large magnitude of Poisson's ratio in additively manufactured mechanical metamaterials[J]. International Journal of Mechanical Sciences, 2020, 173: 105466. doi: 10.1016/j.ijmecsci.2020.105466 [51] LING B, WEI K, QU Z, et al. Design and analysis for large magnitudes of programmable Poisson's ratio in a series of lightweight cylindrical metastructures[J]. International Journal of Mechanical Sciences, 2021, 195: 106220. doi: 10.1016/j.ijmecsci.2020.106220 [52] WEI K, XU W, LING B, et al. Multi-functional cylindrical metastructures to simultaneously program both thermal expansion and Poisson’s ratio[J]. Extreme Mechanics Letters, 2021, 43: 101177. doi: 10.1016/j.eml.2021.101177 [53] TAKEZAWA A, KOBASHI M. Design methodology for porous composites with tunable thermal expansion produced by multi-material topology optimization and additive manufacturing[J]. Composites Part B: Engineering, 2017, 131: 21-29. doi: 10.1016/j.compositesb.2017.07.054 [54] ZHANG X, YE H, WEI N, et al. Design optimization of multifunctional metamaterials with tunable thermal expansion and phononic bandgap[J]. Materials & Design, 2021, 209: 109990. [55] HAN Z, WANG Z, WEI K. Shape morphing structures inspired by multi-material topology optimized bi-functional metamaterials[J]. Composite Structures, 2022, 300: 116135. doi: 10.1016/j.compstruct.2022.116135 [56] HAN Z, WEI K. Multi-material topology optimization and additive manufacturing for metamaterials incorporating double negative indexes of Poisson’s ratio and thermal expansion[J]. Additive Manufacturing, 2022, 54: 102742. doi: 10.1016/j.addma.2022.102742 [57] HAN Z, XIAO X, CHEN J, et al. Bifunctional metamaterials incorporating unusual geminations of Poisson’s ratio and coefficient of thermal expansion[J]. ACS Applied Materials & Interfaces, 2022, 14(44): 50068-50078. [58] PARSONS E M. Lightweight cellular metal composites with zero and tunable thermal expansion enabled by ultrasonic additive manufacturing: Modeling, manufacturing, and testing[J]. Composite Structures, 2019, 223: 110656. doi: 10.1016/j.compstruct.2019.02.031 [59] TOROPOVA M M, STEEVES C A. Robust lightweight multifunctional thermally tailored lattices[J]. Smart Materials and Structures, 2020, 29(3): 035011. doi: 10.1088/1361-665X/ab6694 [60] PALUMBO N M A, SMITH C W, MILLER W, et al. Near-zero thermal expansivity 2D lattice structures: Performance in terms of mass and mechanical properties[J]. Acta Materialia, 2011, 59(6): 2392-2403. doi: 10.1016/j.actamat.2010.12.037 [61] ZHANG K, WANG K, CHEN J, et al. Design and additive manufacturing of 3D-architected ceramic metamaterials with programmable thermal expansion[J]. Additive Manufacturing, 2021, 47: 102338. doi: 10.1016/j.addma.2021.102338 [62] ZHANG K, WEI K, CHEN J, et al. Stereolithography additive manufacturing of multi-ceramic triangle structures with tunable thermal expansion[J]. Journal of the European Ceramic Society, 2021, 41(4): 2796-2806. doi: 10.1016/j.jeurceramsoc.2020.11.033 [63] HOPKINS J B, SONG Y, LEE H, et al. Polytope sector-based synthesis and analysis of microstructural architectures with tunable thermal conductivity and expansion[J]. Journal of Mechanical Design, 2016, 138(5): 051401. doi: 10.1115/1.4032809 [64] YANG Q, WEI K, YANG X, et al. Microstructures and unique low thermal expansion of Invar 36 alloy fabricated by selective laser melting[J]. Materials Characterization, 2020, 166: 110409. doi: 10.1016/j.matchar.2020.110409 [65] WEI K, YANG Q, LING B, et al. Mechanical properties of Invar 36 alloy additively manufactured by selective laser melting[J]. Materials Science & Engineering: A, 2020, 772: 138799. [66] YANG Q, WEI K, QU Z, et al. In-situ X-ray computed tomography of high-temperature tensile behavior for laser powder bed fused Invar 36 alloy[J]. Additive Manufacturing, 2024, 83: 104072. [67] BERGER J, MERCER C, MCMEEKING R M, et al. The design of bonded bimaterial lattices that combine low thermal expansion with high stiffness[J]. Journal of the American Ceramic Society, 2011, 94: s42-s54. doi: 10.1111/j.1551-2916.2010.04019.x [68] STEEVES C A, MERCER C, ANTINUCCI E, et al. Experimental investigation of the thermal properties of tailored expansion lattices[J]. International Journal of Mechanics and Materials in Design, 2009, 5(2): 195-202. doi: 10.1007/s10999-009-9094-6 [69] XU H, FARAG A, PASINI D. Routes to program thermal expansion in three-dimensional lattice metamaterials built from tetrahedral building blocks[J]. Journal of the Mechanics and Physics of Solids, 2018, 117: 54-87. doi: 10.1016/j.jmps.2018.04.012 [70] WEI K, XIAO X, CHEN J, et al. Additively manufactured bi-material metamaterial to program a wide range of thermal expansion[J]. Materials & Design, 2021, 198: 109343. -

下载:

下载: