Preparation technologies and advanced applications of transparent plant fiber-based composites

-

摘要:

植物纤维作为一种天然可再生和生物降解的绿色环保材料,来源广泛、储量丰富,如林业木竹和作物秸秆资源,广泛应用于制造纤维增强树脂/硅酸盐等复合材料,市场巨大、前景广阔。植物纤维基透明功能材料的研发,对于突破传统工程材料(如纤维板、木塑复合材料)光学不透明的技术瓶颈,拓宽农林木质制品应用范围具有科学意义与研究价值。本文详细梳理了纤维基透明材料的最新研究进展,系统归纳了纤维材料绿色漂白及透明化的制备机制及制备技术的优缺点和关键技术难点。论证了初步脱色透明化处理的透明材料可以优化工艺,在保留植物纤维特性的同时实现多功能化。重点从植物纤维基透明材料的力学、透明度、雾度、阻燃、隔热等方面进行阐述,探讨了纤维透明材料在节能建筑、光电子器件、储能材料领域的应用前景。植物纤维透明材料的开发,未来仍需大量系统化的基础理论研究。随着制备技术及改性方法的不断完善,其性能将得到进一步提升,推动在建筑、光电、储能等领域的应用。

Abstract:The plant fiber, as a natural renewable, biodegradable green and eco-friendly material, has a wide range of sources and abundant reserves, such as forestry wood, bamboo, and crop straw resources. It is widely used in the manufacturing of composite materials, such as fiber-reinforced resins/silicates, with a huge market and broad prospects. The development of transparent functional materials based on plant fibers has scientific significance and research value in breaking through the technical bottleneck of optical opacity for the traditional engineering materials (such as fiberboard and wood plastic composites) and expanding the application range of agricultural and forestry biomass products. The article provides a detailed overview of the latest research progress on fiber-based transparent materials. It systematically summarizes the mechanisms of green bleaching and transparency of plant fiber materials, as well as the characteristics and key difficulties of the preparation techniques. It has been demonstrated that transparent materials treated with preliminary decolorization and transparency can optimize the process, and achieve the multifunctionality while retaining the characteristics of plant fibers. This article focuses on the mechanics, transparency, haze, flame retardancy, and thermal insulation of plant fiber based transparent materials, and explores the application prospects of fiber transparent materials in energy-saving buildings, optoelectronic devices, and energy storage materials. There is still a lot of systematic research to be promoted in the utilization of plant fiber transparent materials. With the continuous improvement of preparation technology and modification methods, its performance will be further improved, promoting its application in fields such as architecture, optoelectronics, and energy storage.

-

自21世纪初以来,全球能源短缺和环境污染严峻一直是亟待解决的问题。相变材料(PCMs)作为一种便捷高效的热管理材料引起了大家的关注[1-5],能够在相变过程中可逆地吸收和释放大量热能,从而弥补了太阳能受时间和空间限制、不稳定性及效率低等问题。其中,有机固液PCMs(如石蜡(PW)和聚乙二醇(PEG)等)因具有高储能密度、固-液相变过程中体积变化小、热稳定性好、无毒无腐蚀性及成本低廉等优点,被广泛作为热存储材料[3-6]。然而,由于PCMs导热系数相对较小[7],导致其储热速率、太阳能热能转换能力及力学性能不足等问题,严重限制了其在实际应用中的推广[7-8]。为了解决这些问题,研究人员开始探究如何将导热填料、PCMs与高分子基体相结合来制备导热高分子基相变复合材料[9-10]。

在导热高分子基相变复合材料的制备过程中,填料的无序分布会导致大量的声子散射,从而影响复合材料的导热及力学性能[9, 11]。而通过控制导热填料的有序分布,使其结构发生取向,促使其内部具有定向导热骨架,已成为一种提高热导率的有效策略,在迫切需要具有定向传热需求的电子器件热管理等领域具有较大的应用前景。如以石墨烯泡沫(GF)为填料制备的GF/聚二甲基硅氧烷(PDMS)复合材料具有互联结构,在含量为0.7wt%时,其热导率(λ)达到基体的3倍[12]。此外,通过将石蜡(PW)浸渍到三维石墨烯纳米片(GNPs)泡沫中制备了一种GNPs/PW相变复合材料,λ由0.31 W·m−1·K−1 (PW)提高到0.62 W·m−1·K−1,并且实现了光-热转换和热存储的有效结合,保证了太阳能的持续利用[13]。

目前,在成型加工过程中通过外加电场、磁场或剪切力来控制填料在高分子材料中形成取向结构,可制备具有优良导热性能的复合材料[14-16]。Cho等[17]将电场开关与具有不同纵横比的填料相结合,构建出线性密集排列的具有取向结构的BN (LDPBNs),显著提高了复合材料的λ。当BN添加量为15vol%时,复合材料λ高达1.56 W·m−1·K−1,约为无LDPBNs结构的复合材料λ的4倍(0.4 W·m−1·K−1)。可见,取向结构的构筑对于提高导热高分子复合材料的性能至关重要,但已报道的方法大多存在过程复杂、成本高昂等缺点,限制了其在实际工业应用中的推广。因此,未来的研究将致力于开发简单、高效的制备方法,进一步探索填料与高分子基体之间的相互作用机制,推动导热高分子复合材料的发展和应用。

基于此,本文提出一种简单且高效的制备方法,充分利用聚乙烯辛烯共弹性体(POE)良好加工性能、柔韧性、力学性能优异等特点,旨在制备具有优异综合性能的PW-GNPs-BN/POE相变复合材料。该方法的关键在于充分利用开炼机双辊旋转产生的剪切力,使GNPs和氮化硼(BN)得以均匀分散并形成有序的取向结构,成功制备出了具有取向结构的相变复合材料,该材料不仅导热性能卓越,而且光热转换能力显著,为未来的应用提供了广阔的前景。

1. 实验材料及方法

1.1 原材料

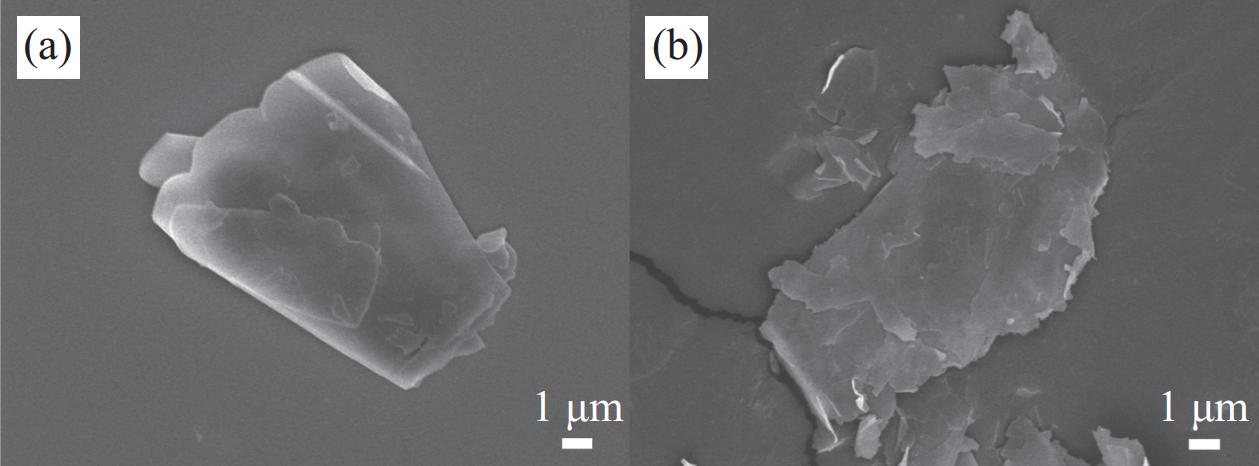

聚乙烯辛烯共弹性体(POE),商业上称为3980,由埃克森美孚化工有限公司提供,其密度为0.89 g·cm−3。切片石蜡(PW),表观密度为0.90 g·cm−3,熔点为52~54℃,储存温度为2~8℃,购自上海麦克林生化科技有限公司。石墨烯纳米片(GNPs)的厚度为4~20 nm,尺寸为5~10 µm,由成都有机化学研究所提供。氮化硼(BN)密度为2.25 g·cm−3,尺寸为5~15 μm,购于秦皇岛市伊诺先进材料有限公司。GNPs和BN微观形貌见图1。

1.2 PW-GNPs-BN/POE相变复合材料的制备

首先,在开炼机(SK-160B,中国上海橡胶机械厂)双辊温度为90℃的条件下,取一定比例的POE和PW通过双辊开炼机混合,随着辊筒的旋转,POE和PW被不断拉伸和折叠,同时,不断地重复三角打包法使复合材料剪断、均匀化,待复合材料开炼10 min混合均匀[14]。随后,根据前期的研究[18-20],加入固定的GNPs含量(2wt%)和不同含量的BN,继续混合开炼10 min以确保填料充分混合。最后,使用三辊压光机(LN-6,广东利拿实业有限公司)对样品进行冷却处理,得到厚度为0.2 mm的PW-GNPs-BN/POE相变复合材料,制备工艺见图2。详细配方见表1,为简化命名,将复合材料命名为PW-xGNPs-yBN/POE,其中x和y分别代表GNPs和BN占PW/POE总量的质量分数。

表 1 样品配方Table 1. Sample formulaSample POE/wt% PW/wt% Mass ratio of PW/POE GNPs/wt% BN/wt% PW/POE 70.0 30.0 7∶3 0 0 PW-2wt%GNPs/POE 68.6 29.4 7∶3 2 0 PW-2wt%GNPs-5wt%BN/POE 65.1 27.9 7∶3 2 5 PW-2wt%GNPs-10wt%BN/POE 61.6 26.4 7∶3 2 10 PW-2wt%GNPs-15wt%BN/POE 58.1 24.9 7∶3 2 15 PW-2wt%GNPs-25wt%BN/POE 51.1 21.9 7∶3 2 25 PW-25wt%BN/POE 52.5 22.5 7∶3 0 25 1.3 表征与测试

1.3.1 扫描电子显微镜(SEM)

使用捷克TESCAN公司VEGA3 LMH型钨灯丝扫描电子显微镜观察复合相变材料的形貌。测试前使用离子溅射仪对样品表面喷金处理。

1.3.2 X射线衍射分析(XRD)

使用日本Shimadzu公司XRD-7000s型多晶X射线衍射仪对所制备复合材料的结构进行表征。采用Cu Kα辐射(γ=0.1542 nm)扫描范围为10°~60°,扫描速度10°/min。

1.3.3 DSC测试

使用瑞士Mettlertoledo公司DSC1仪器测试复合相变材料的熔融和结晶行为,称取5~8 mg样品,在10℃·min−1下升温至100℃,随后在10℃· min−1下冷却至25℃,所有测试均在氮气氛围下进行。

1.3.4 力学性能测试

采用万能拉伸试验机(LDS 20KN,长春市智能设备有限公司)对样品进行拉伸性能和拉伸回复测试,拉伸速度分别为5 mm·min−1。

1.3.5 导热性能测试

使用美国TA公司Discovery DXF-900仪器通过激光闪射法测试复合相变材料的热扩散系数。复合相变材料的热导率(λ)采用下式进行计算[14]:

λ=αCpρ (1) 其中:α为热扩散系数;ρ为密度;Cp为比热容。复合相变材料的密度ρ通过将样品打磨成规则形状用天平称量质量后计算得到,比热容Cp利用DSC通过蓝宝石法测量得到。

1.3.6 光热及光电转换测试

使用中科微能(北京)科技有限公司CME-SL500型氙灯光源作为模拟太阳光源对复合相变材料表面施加不同强度光照,利用塞贝克热电设备实现热能到电能的转换,使用3000R型热电偶无纸记录仪记录样品表面温度变化,使用美国Keithley公司2400型数字源表实时采集输出的电压信号。实验前用北京中教金源科技有限公司CEL-NP2000型光功率计校正和调节光强。

1.3.7 热红外成像测试

将PW-GNPs-BN/POE相变复合材料样品放置在置物台上,使用中科微能(北京)科技有限公司CME-SL500型氙灯光源作为模拟太阳光源对复合相变材料表面施加不同强度光照,用热红外成像仪进行实时录制,记录在光照前后过程中样品的热红外温度变化情况。

2. 结果与讨论

2.1 PW-GNPs-BN/POE相变复合材料的形貌分析

为了研究GNPs和BN对PW/POE纳米复合材料结构的影响,对PW-GNPs-BN/POE相变复合材料平行于导热取向结构的方向进行了SEM测试,如图3所示。由图3(a)和图3(a1)对比发现,PW在POE基体中沿着取向方向主要呈短棒状均匀分布,经过高温热处理后,PW的分布状态消失。这是由于PW和POE互不相容,在开炼机的强剪切场下,PW在POE内部能够沿着剪切方向发生形变取向,并在较高的冷却速率下保留了取向结构,在60℃ (PW熔点为52~54℃)热水中去除截面的PW后,短棒状结构消失,这进一步证实了PW在POE基体中呈短棒状分布。随后,通过单独添加GNPs和BN,可以有效改善PW的短棒状堆积密度,如图3(b)和图3(c)所示。在向PW-2wt%GNPs/POE复合材料中加入5wt%的片状BN后,PW短棒状结构没有明显变化,如图3(d)所示。然而,随着BN含量的增加,不仅改善了PW的棒状化程度,促使棒状均匀分布在POE基体内,还观察到大量沿着剪切场方向取向分布的BN片状结构,如图3(e)~图3(g)所示。通过图3(g1)的局部分布图可以清晰地看出,短棒状PW和BN能够均匀地沿着剪切场的方向分布在POE基体内部。这是由于BN的加入提高了PW-2wt%GNPs/POE复合材料整体的黏度,改变了PW的流变性能,减弱了棒状结构的分布,并在GNPs固有导热性能优异的基础上充分利用了BN的高面内热导率,从而在取向方向上构建了高效的导热通道。

![]() 图 3 SEM图像:(a) PW/POE;(a1)高温处理的PW/POE;(b) PW-2wt%GNPs/POE;(c) PW-25wt%BN/POE;(d) PW-2wt%GNPs-5wt%BN/POE;(e) PW-2wt%GNPs-10wt%BN/POE;(f) PW-2wt%GNPs-15wt%BN/POE;PW-2wt%GNPs-25wt%BN/POE (g) 及其局部放大图(g1)Figure 3. SEM images: (a) PW/POE; (a1) Thermal heated PW/POE; (b) PW-2wt%GNPs/POE; (c) PW-25wt%BN/POE; (d) PW-2wt%GNPs-5wt%BN/POE; (e) PW-2wt%GNPs-10wt%BN/POE; (f) PW-2wt%GNPs-15wt%BN/POE; PW-2wt%GNPs-25wt%BN/POE (g) and local magnified image (g1)

图 3 SEM图像:(a) PW/POE;(a1)高温处理的PW/POE;(b) PW-2wt%GNPs/POE;(c) PW-25wt%BN/POE;(d) PW-2wt%GNPs-5wt%BN/POE;(e) PW-2wt%GNPs-10wt%BN/POE;(f) PW-2wt%GNPs-15wt%BN/POE;PW-2wt%GNPs-25wt%BN/POE (g) 及其局部放大图(g1)Figure 3. SEM images: (a) PW/POE; (a1) Thermal heated PW/POE; (b) PW-2wt%GNPs/POE; (c) PW-25wt%BN/POE; (d) PW-2wt%GNPs-5wt%BN/POE; (e) PW-2wt%GNPs-10wt%BN/POE; (f) PW-2wt%GNPs-15wt%BN/POE; PW-2wt%GNPs-25wt%BN/POE (g) and local magnified image (g1)2.2 PW-GNPs-BN/POE相变复合材料的结构分析

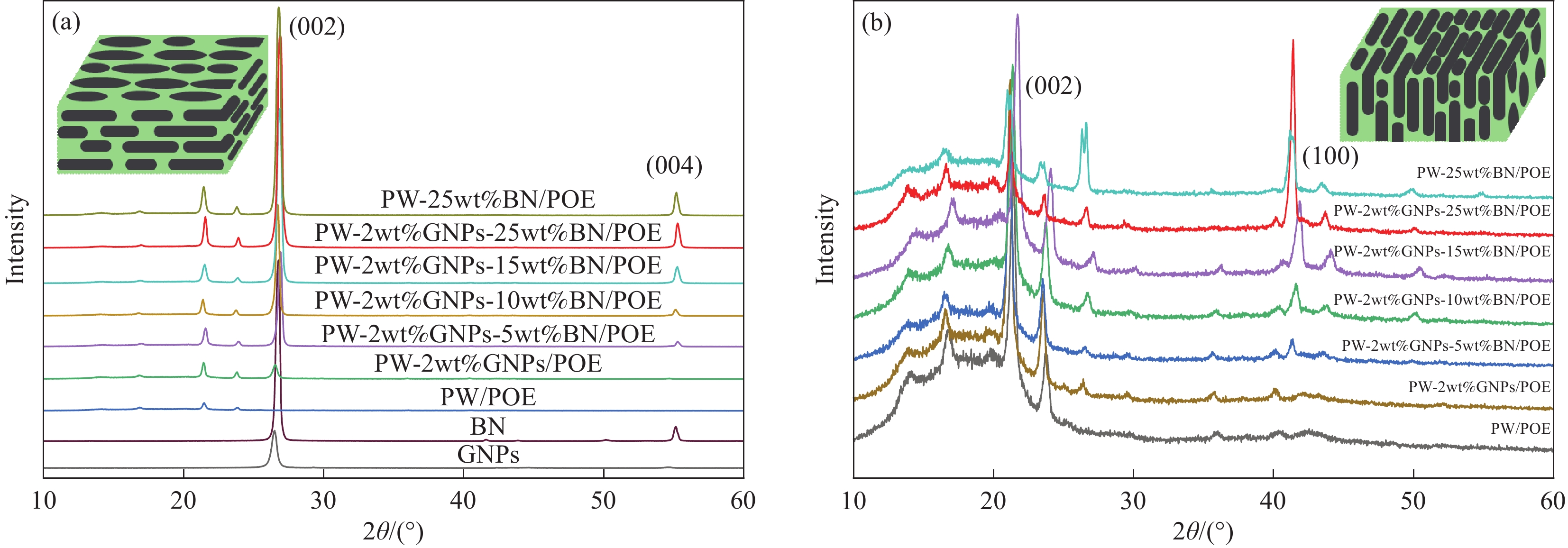

PW-GNPs-BN/POE相变复合材料平行于导热取向方向的表面和断面XRD图谱如图4所示。从图4(a)可见,PW/POE表现出3个明显的特征峰,其中POE的衍射峰位于16.8°,PW的特征衍射峰分别位于21.4°和23.8°[21],经过开炼机强剪切场共混,衍射峰角度均未发生偏移,这表明POE和PW之间是物理共混。在PW/POE复合材料中加入GNPs后,观察到PW-2wt%GNPs/POE在2θ=26.4°出现了新的特征峰,而在2θ=21.4°和23.8°处峰的位置和强度未发生明显变化,这表明PW在复合材料中仍保持其晶体形态,从而确保了潜热的有效释放。PW-GNPs-BN/POE相变复合材料在2θ=26.4°处观察到GNPs和BN的衍射峰[14, 20],并随着BN的加入,2θ=26.4°处的衍射峰强度大幅度提高。通过XRD数据进一步发现,PW-GNPs-BN/POE相变复合材料在2θ=55.1°处观察到新的BN衍射峰,同时,其余衍射峰的角度没有发生偏移,这进一步表明BN与POE基体是物理混合,没有发生化学反应;同时,随着BN含量的增加,在2θ=55.1°处衍射峰的强度也逐渐增加,说明了复合材料的结晶程度提高。而在PW-GNPs-BN/POE相变复合材料的XRD衍射峰中未观察到2θ=41.2°的衍射峰,这充分说明了BN经过强剪切场后没有沿着垂直流动场的方向排列。

在图4(b)中,PW-GNPs-BN/POE相变复合材料断面的XRD曲线衍射峰与表面的衍射峰基本相似,其中在2θ=41.2°处观察到了BN的(100)衍射峰,表明片层结构的BN沿着断面方向发生了取向分布,这与SEM对应,见图3(a)~图3(g)。为了进一步证明BN在复合材料内部的取向程度。采用公式I(100)/(I(100)+I(002))计算得到取向因子[22],其中I(100)、I(002)分别代表(100)和(002)衍射峰的强度,详见表2。从表2可以看出,复合材料的取向程度在0.49至0.83之间,并且随着BN含量的增加而增加,说明了BN在聚合物基体中的取向程度逐渐提高。而在XRD表面图中未观察到明显的(100)特征峰,这说明无法从表面图中观察到复合材料内部的取向结构。

表 2 PW-GNPs-BN/POE相变复合材料的取向度Table 2. Orientation degree of PW-GNPs-BN/POE phase change composite materialsSample Orientation factor PW-2wt%GNPs-5wt%BN/POE 0.49 PW-2wt%GNPs-10wt%BN/POE 0.51 PW-2wt%GNPs-15wt%BN/POE 0.57 PW-2wt%GNPs-25wt%BN/POE 0.83 PW-25wt%BN/POE 0.55 2.3 PW-GNPs-BN/POE相变复合材料的热储存性能

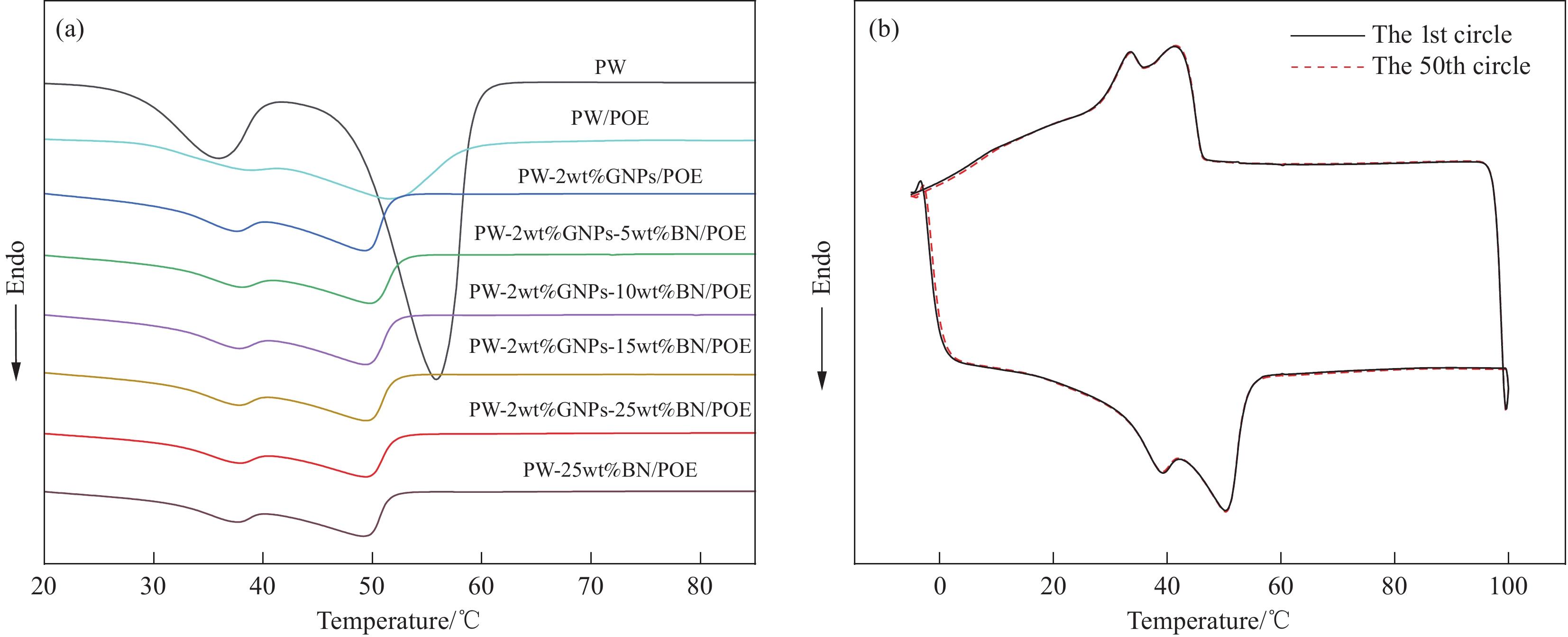

采用DSC对样品进行相变温度和相变潜热测试,结果如图5(a)所示。在升温过程中,所有样品均在37℃和50℃左右呈现出两个明显的吸热峰。根据相关研究[1, 3-4],37℃左右对应石蜡的固-固相变阶段,在固-固相变过程中,PW由晶体结构转变为非晶态结构;50℃左右对应石蜡固-液相变过程(融化),在这一阶段,石蜡能够以潜热的形式储存大量的热能。通过DSC曲线可以获取复合相变材料的熔点(表3),其中PW和PW/POE的熔点分别为56.2℃和52.3℃。加入GNPs后,PW-2wt%GNPs/POE的熔点下降至49.6℃,这主要归因于GNPs导热填料的加入为PW/POE复合材料提供了快速的导热路径,从而加速了复合材料的相变过程,导致复合材料的熔点降低[23]。随后添加不同含量的BN,可以观察到随着BN含量增加,复合相变材料的熔点基本保持不变。此外,通过对吸热过程的DSC曲线积分可以得到样品在熔融过程中的相变潜热。

表 3 融化过程中PW和PW-GNPs-BN/POE相变复合材料的相变参数Table 3. Phase transition parameters of PW and PW-GNPs-BN/POE phase change composite materials during the melting processSample TM/℃ HM/(J·g−1) PW 56.2 141.2 PW/POE 52.3 46.6 PW-2wt%GNPs/POE 49.6 56.6 PW-2wt%GNPs-5wt%BN/POE 50.16 51.9 PW-2wt%GNPs-10wt%BN/POE 49.8 51.9 PW-2wt%GNPs-15wt%BN/POE 49.8 47.5 PW-2wt%GNPs-25wt%BN/POE 49.8 44.1 PW-25wt%BN/POE 49.8 45.1 Notes:TM—Melting temperature; HM—Melting enthalpy. 从表3复合相变材料相变潜热可知,PW/POE的熔融焓为46.6 J·g−1,加入GNPs后,PW-2wt%GNPs/POE的焓值增加至56.6 J·g−1。这主要归因于加入的GNPs充当成核剂,提供了异相成核点,降低了成核壁垒,促进了PW的结晶,因此促进了焓值的提高[5, 9-10]。随后,随着BN含量的增加,PW-GNPs-BN/POE相变复合材料的焓值降低,由51.9 J·g−1 (PW-2wt%GNPs-5wt%BN/POE)降至44.1 J·g−1 (PW-2wt%GNPs-25wt%BN/POE)。这是由于在复合材料中加入BN时,石蜡在复合相变材料中的比例会相应减少,从而导致PW-GNPs-BN/POE相变复合材料的焓值降低。但PW-2wt%GNPs-25wt%BN/POE的焓值仍然保持在44.1 J·g−1左右,具备一定的储热性能,使该材料在热能储存领域仍具有实际应用价值。为了验证复合材料的相变稳定性,对PW-2wt%GNPs-25wt%BN/POE复合材料进行了50次熔融循环测试(图5(b)),结果显示在50次循环后,复合材料的结晶峰和熔融峰的位置均未发生变化,表明其熔融性能基本稳定,这证明了PW-2wt%GNPs-25wt%BN/POE复合材料具有优异的循环稳定性。

2.4 PW-GNPs-BN/POE相变复合材料的力学性能

PW-GNPs-BN/POE相变复合材料的力学性能表征如图6所示。图6(a)和图6(b)展示了PW-GNPs-BN/POE相变复合材料的应力-应变曲线。由图6(b)可知,在POE中掺入PW后,PW/POE的拉伸强度从POE的21.8 MPa增至26.3 MPa,断裂伸长率从POE的760%增至820%,这表明PW的添加改善了复合材料的强度和韧性。然而,当在PW/POE中加入GNPs和BN填料后,材料的拉伸强度和断裂伸长率略有下降。这是由于大量无机填料的加入在复合材料内部形成团聚体,造成应力缺陷,从而影响复合材料的力学性能。但PW-2wt%GNPs-25wt%BN/POE相变复合材料的拉伸强度和断裂伸长率仍保持在较高水平,其中,拉伸强度为21.1 MPa,断裂伸长率为719%。从图6(c)中可见,PW-2wt%GNPs-25wt%BN/POE复合材料在弯曲、卷曲或折叠成复杂的千纸鹤形状后,不会出现折损或破裂,说明其具有优异的柔韧性。随后,在图6(d)中对PW-2wt%GNPs-25wt%BN/POE复合材料施加不同应变(5%、10%、20%)进行了10次循环拉伸测试。结果显示,随着循环应变的增加,闭环的面积也随之增加。在相同应变下,经过多次循环拉伸后,闭环面积逐渐减小并趋于稳定,且闭环的形状未发生明显变化,表明复合材料具有出色的韧性和回弹性。这一现象可归因于应变软化效应(Mullins效应)引起的网络重组,导致更长且更少维持应力的大分子网络永久重组[24]。

![]() 图 6 PW-GNPs-BN/POE相变复合材料的力学性能曲线1#, 2#, 3#, 4#, 5#, 6#, 7#—PW/POE, PW-2wt%GNPs/POE, PW-2wt%GNPs-5wt%BN/POE, PW-2wt%GNPs-10wt%BN/POE, PW-2wt%GNPs-15wt%BN/POE, PW-2wt%GNPs-25wt%BN/POE, and PW-25wt%BN/POE, respectivelyFigure 6. Mechanical property curves of PW-GNPs-BN/POE phase change composite materials

图 6 PW-GNPs-BN/POE相变复合材料的力学性能曲线1#, 2#, 3#, 4#, 5#, 6#, 7#—PW/POE, PW-2wt%GNPs/POE, PW-2wt%GNPs-5wt%BN/POE, PW-2wt%GNPs-10wt%BN/POE, PW-2wt%GNPs-15wt%BN/POE, PW-2wt%GNPs-25wt%BN/POE, and PW-25wt%BN/POE, respectivelyFigure 6. Mechanical property curves of PW-GNPs-BN/POE phase change composite materials2.5 PW-GNPs-BN/POE相变复合材料的导热性能

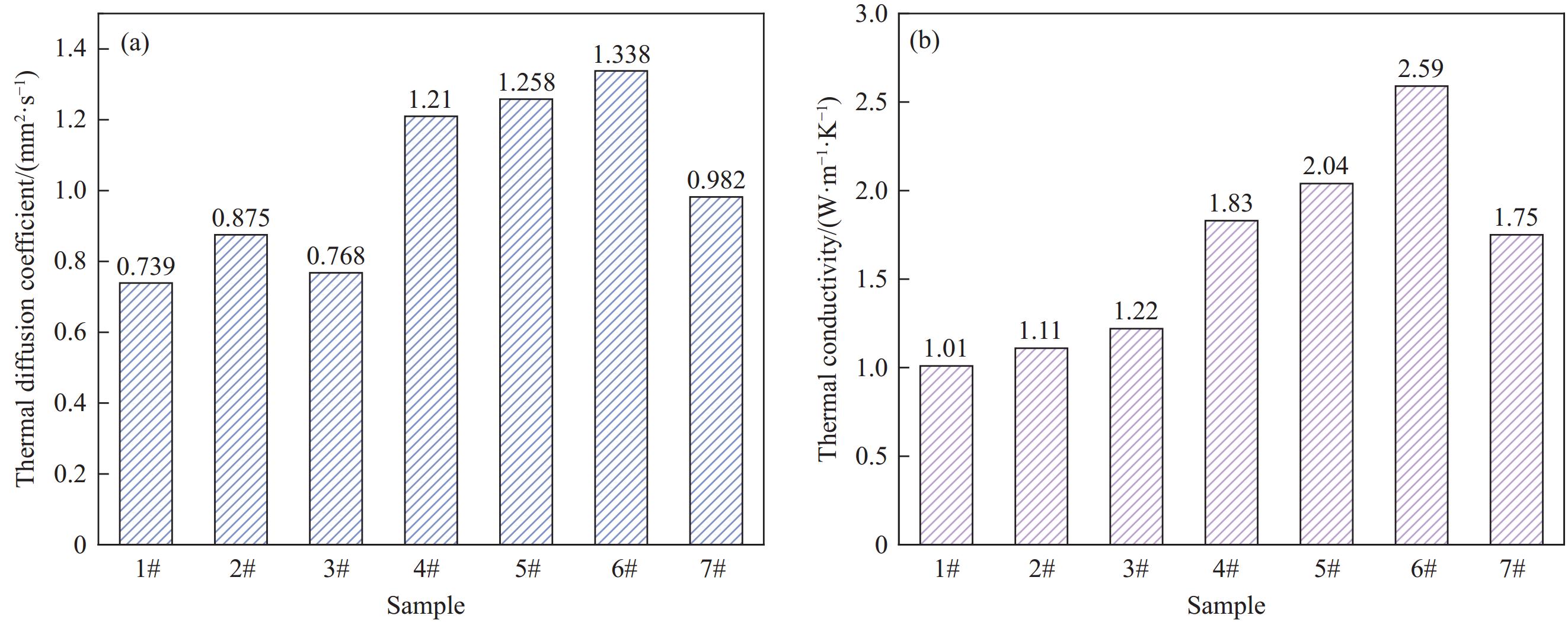

图7显示了PW-GNPs-BN/POE相变复合材料的热扩散系数和热导率(λ)。从图7(a)可见,在PW/POE中加入GNPs后,复合材料的热扩散系数从0.739 mm²·s−1提升至0.875 mm²·s−1。进一步添加5wt%的BN后,热扩散系数达到0.768 mm²·s−1,并且随着BN含量的增加,复合材料的热扩散系数呈现逐渐增加的趋势,从0.875 mm²·s−1增至1.338 mm²·s−1。热导率的变化趋势与热扩散系数基本一致,见图7(b)。从图7(b)中可以观察到,PW/POE、PW-2wt%GNPs/POE、PW-2wt%GNPs-5wt%BN/POE、PW-2wt%GNPs-10wt%BN/POE、PW-2wt%GNPs-15wt%BN/POE、PW-2wt%GNPs-25wt%BN/POE和PW-25wt%BN/POE复合材料的λ分别为1.01 W·m−1·K−1、1.11 W·m−1·K−1、1.22 W·m−1·K−1、1.83 W·m−1·K−1、2.04 W·m−1·K−1、2.59 W·m−1·K−1和1.75 W·m−1·K−1。其中,PW-2wt%GNPs-25wt%BN/POE复合材料的λ达到最优,是PW/POE复合材料的2.56倍。这是由于在GNPs固有导热性能优异的基础上,充分利用了BN片极高的面内λ及两种填料之间的正向协同效应,从而有效提高了λ。同时,随着BN含量的增加,促使复合材料内部取向程度更加完善,进一步改善了导热通路的构建,减少了传热过程中声子的散射现象,从而降低了界面热阻,提高了λ。

导热提高率(TCE)通过下式进行计算[25]:

TCE=λc−λPλP×100% (2) 式中,λP和λc分别代表POE及PW-GNPs-BN/POE相变复合材料的λ。

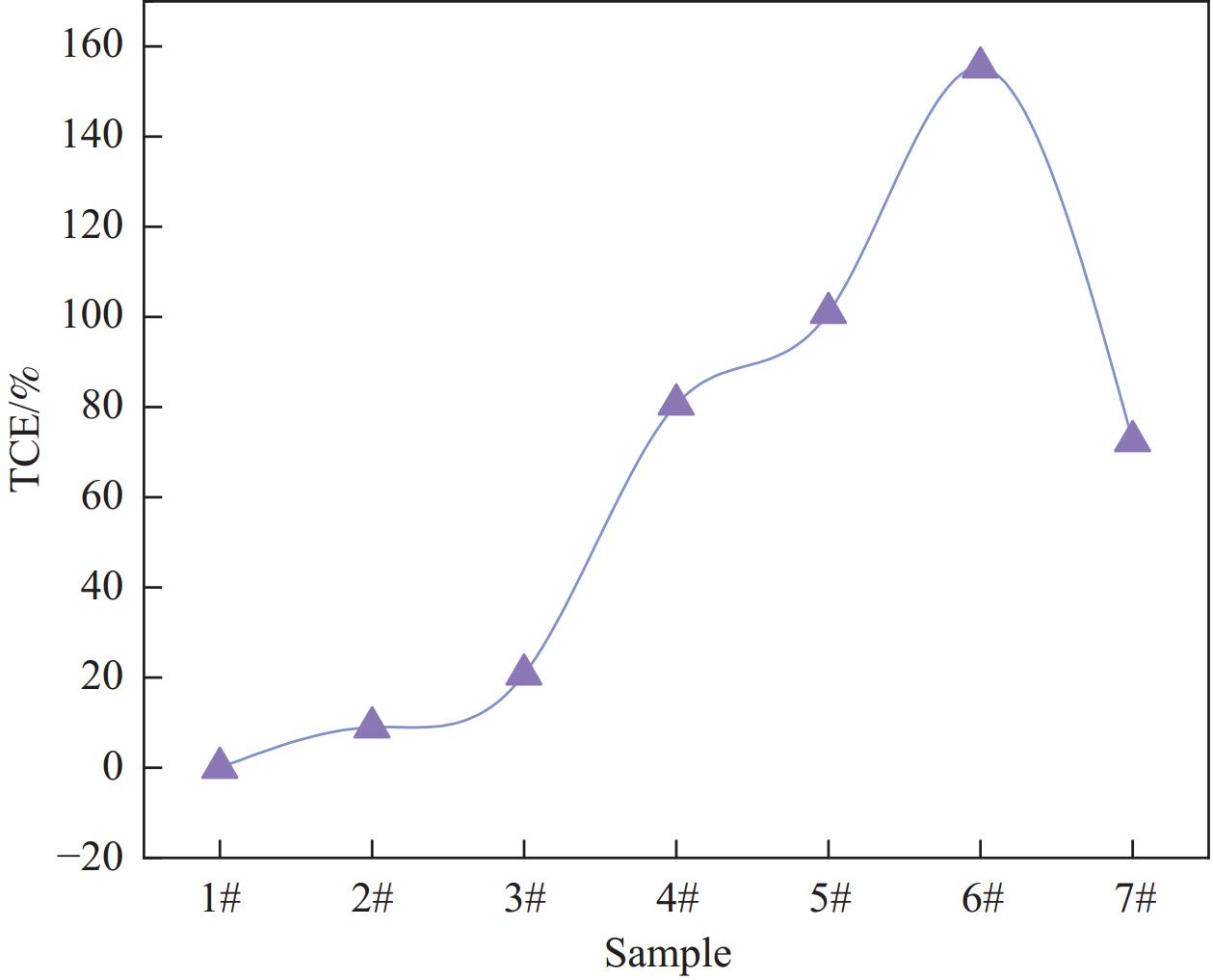

如图8所示,相比于PW/POE来说,加入BN与GNPs后,PW-GNPs-BN/POE相变复合材料的TCE呈现增高的趋势,其中PW-2wt%GNPs-25wt%BN/POE复合材料TCE达到最高,为156%,进一步说明取向程度的完善可大幅度提高复合材料的λ。

2.6 PW-GNPs-BN/POE相变复合材料的热管理应用

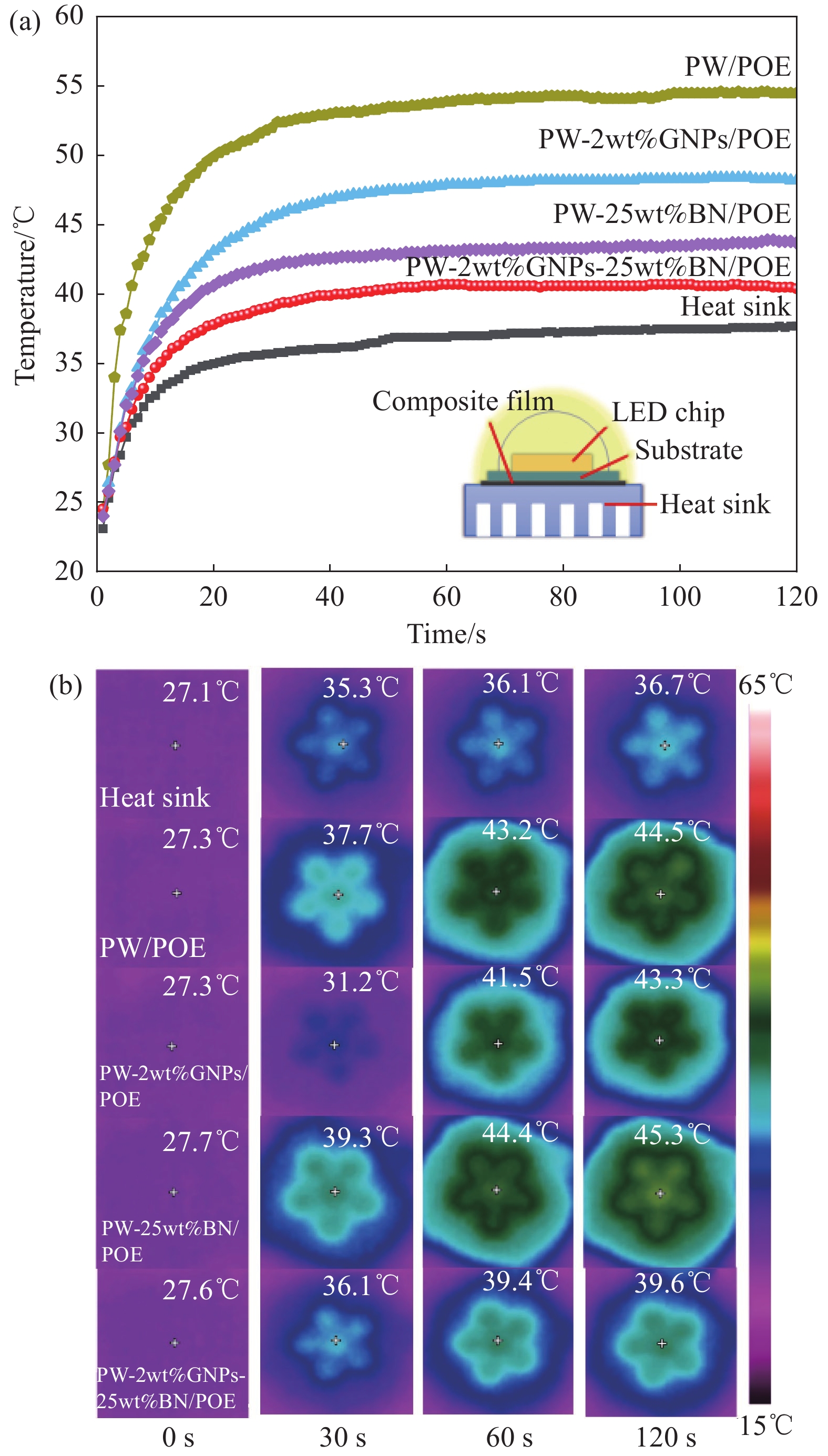

LED灯的使用寿命会随着工作温度的升高呈指数级递减,热量积累会引起波长偏移、输出功率降低等问题,因此,提高热管理材料的散热能力势在必行。为了验证热管理材料的散热能力,将2 mm厚的PW-GNPs-BN/POE相变复合材料分别放置于LED芯片和散热器之间,利用温度记录仪和热红外成像仪实时记录LED灯表面温度,如图9(a)、图9(b)所示。图9(a)为LED灯工作120 s内表面温度的变化过程。可以观察到,当将PW/POE样品用作热界面材料(TIM)时,随着工作时间的延长,LED表面温度逐渐升高并最终保持较高的稳态温度(44.5℃),LED表面轮廓明显,见图9(b)。这是由于PW/POE的热导率较低,不能及时将LED芯片产生的热量散发出去。然而,当使用PW-GNPs-BN/POE相变复合材料时,LED温度缓慢上升并最终保持相对较低的稳态温度,LED表面轮廓模糊,表明加入GNPs和BN会提高复合材料的散热能力。其中,当PW-2wt%GNPs-25wt%BN/POE被用作TIM时,LED灯的稳态温度为39.6℃,相比PW/POE、PW-2wt%GNPs/POE和PW-25wt%BN/POE作为TIM时LED灯的表面温度分别降低了4.9℃、3.7℃和5.7℃,与直接使用热扩散器时LED灯的表面温度接近,LED表面轮廓更加模糊,这表明了PW-2wt%GNPs-25wt%BN/POE具有最佳的散热效果、最优的热管理能力,与其高λ相符。

2.7 PW-GNPs-BN/POE相变复合材料的光热转换性能

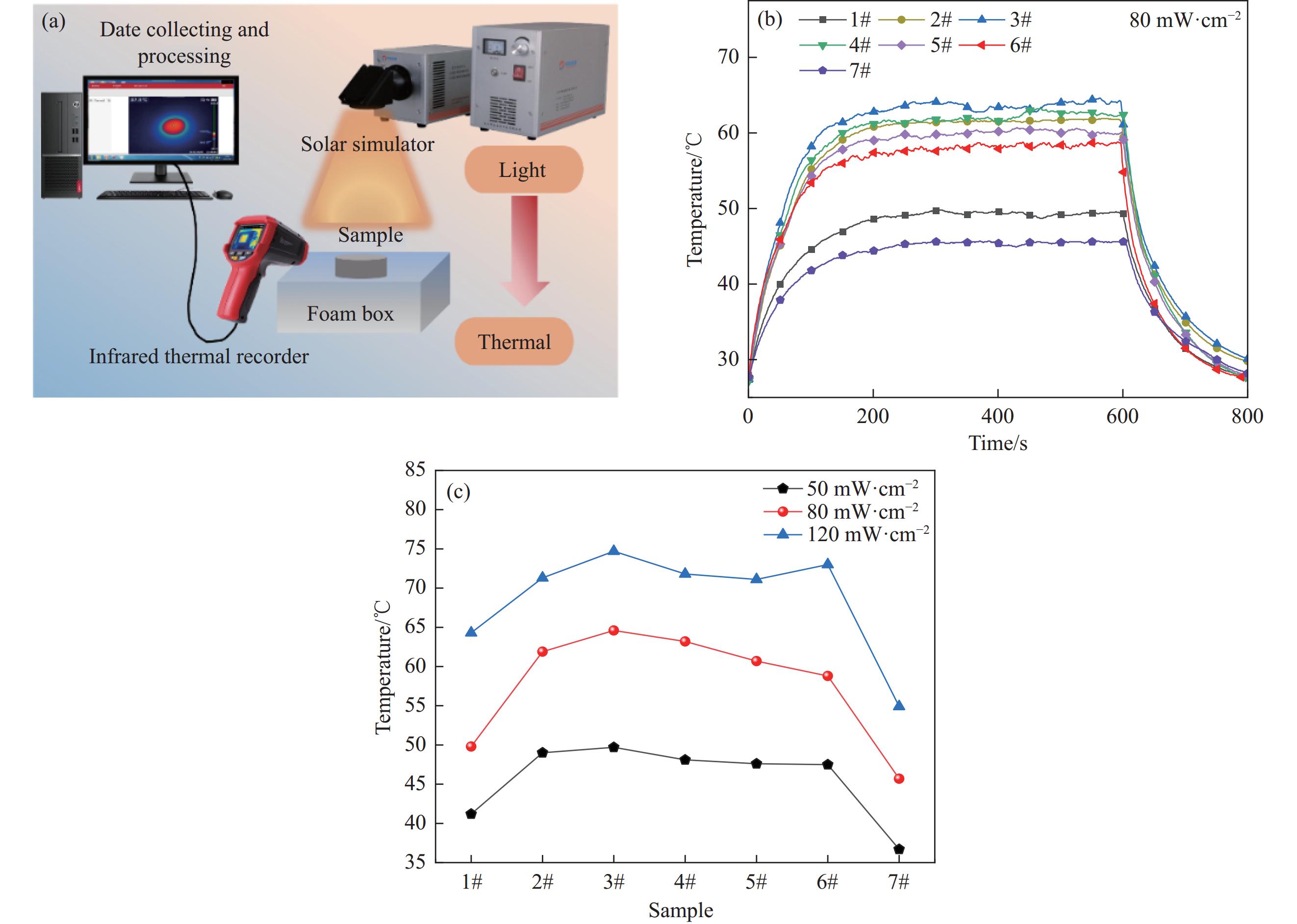

图10(a)利用自制的光热转换装置对PW-GNPs-BN/POE相变复合材料的光热转换能力进行了评估,通过施加不同强度光照,记录了工作800 s内复合薄膜表面温度的变化过程。如图10(b)所示,当光照强度为80 mW·cm−2时,PW/POE的温度可达49.8℃,加入GNPs后复合材料的表面温度迅速升高,达到61.9℃,且温度趋于稳定,结果表明GNPs的加入对复合材料的光热转换起到促进作用。

![]() 图 10 (a)光-热转换测量装置示意图;PW-GNPs-BN/POE相变复合材料分别在80 mW·cm−2 (b)和在不同光照强度下(c)的光热转换曲线Figure 10. (a) Schematic diagram of the light-to-heat conversion measurement device; Photothermal conversion curves of PW-GNPs-BN/POE phase change composite materials under 80 mW·cm−2 (b) and under different light intensities (c)

图 10 (a)光-热转换测量装置示意图;PW-GNPs-BN/POE相变复合材料分别在80 mW·cm−2 (b)和在不同光照强度下(c)的光热转换曲线Figure 10. (a) Schematic diagram of the light-to-heat conversion measurement device; Photothermal conversion curves of PW-GNPs-BN/POE phase change composite materials under 80 mW·cm−2 (b) and under different light intensities (c)这主要归因于GNPs对近红外光区域的强吸收性能和良好的光热转化性能,促使GNPs/聚合物基多功能光热纳米复合材料在近红外光的作用下实现温度的快速升高,从而提高复合材料的光热转换能力[26]。在PW-2wt%GNPs/POE复合材料中加入5wt% BN时,复合材料表面的最高温度基本没有影响;然而,随着BN含量的增加,温度有所降低。其中,在PW/POE中加入25wt% BN时,PW-2wt%GNPs-25wt%BN/POE复合材料的温度降至58.8℃,这是由于随着BN含量的增加,复合材料内部相对的GNPs含量减少,导致材料的光热转换能力逐渐下降。因此可以得出,GNPs对复合材料光热转换能力起主导作用。随后改变光照强度进行了对照试验,发现复合材料在光照强度为50和120 mW·cm−2时温度变化趋势(图10(c))与图10(b)趋势相同,随着光照强度的增加,复合材料的最高温度和温度平台也随之提高。综上所述,PW-2wt%GNPs-5wt%BN/POE表现出最优的光热转化能力。

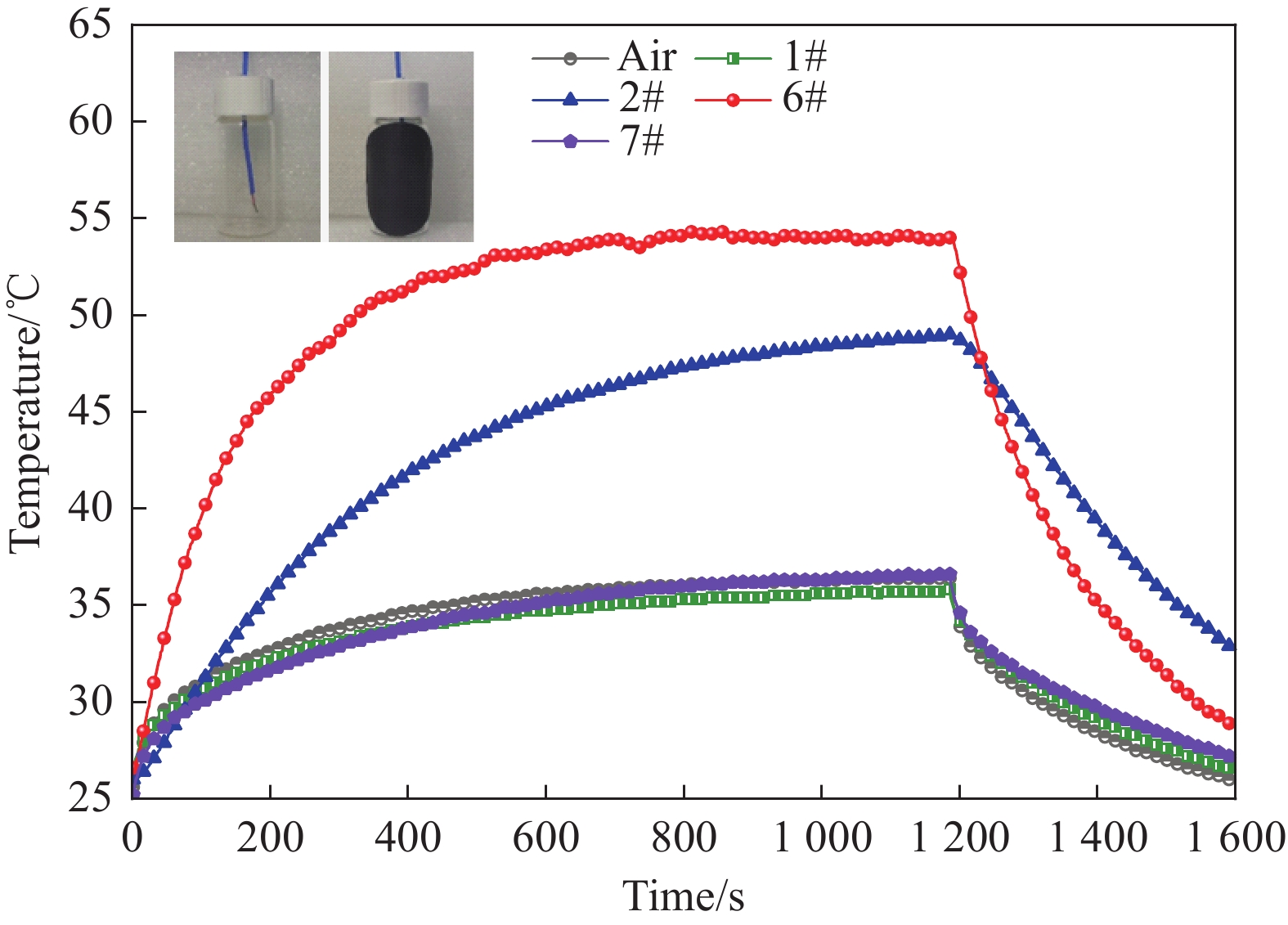

图11 进行光热转换应用模拟实验,将PW-GNPs-BN/POE相变复合材料包裹在装有热电偶的玻璃瓶表面,通过对玻璃瓶表面施加光照,并用温度记录仪记录内部温度。首先,在未包裹复合材料的瓶子表面施加80 mW·cm−2光照强度,温度可达36.4℃;其次将PW/POE与PW-25wt%BN/POE样品分别包裹在瓶子外侧,瓶内温度几乎保持不变,说明POE、PW及BN的存在对复合材料的光热转化几乎没有影响,这与图10(b)、图10(c)光热转换实验结果一致。最后将PW-2wt%GNPs/POE样品和PW-2wt%GNPs-25wt%BN/POE分别包裹在瓶子外侧,瓶内温度显著升高,分别升至49.0℃、54.3℃。这是由于GNPs对光热转换有促进作用及GNPs和BN之间的正向协同作用,促使PW-2wt%GNPs/POE和PW-2wt%GNPs-25wt%BN/POE复合材料表面温度显著升高。综上所述,PW-2wt%GNPs-25wt%BN/POE复合材料在光热转换的实际应用场景中展现出最佳的效果。

此外,在80 mW·cm−2的光照强度下,采用红外热像仪记录了复合材料表面温度的变化。根据图12可知,PW/POE在升温120 s后温度达到44.7℃,薄膜表面的轮廓模糊。当在PW/POE中添加GNPs后,PW-2wt%GNPs/POE温度显著上升,达到了68.1℃,薄膜表面轮廓清晰可见。另外,在PW-2wt%GNPs/POE中加入5wt%的BN后,温度略有下降(62.6℃),同时薄膜表面的轮廓也有所减小。当BN含量增至25wt%时,温度进一步下降(58.5℃),薄膜表面的轮廓也相应减小。然而,在PW/POE中仅添加25wt%的BN时,温度显著下降至42.5℃,薄膜表面的轮廓消失。以上观察结果表明,PW-2wt%GNPs/POE具有最佳的光热转换效率,与光热转换曲线的趋势相一致。

2.8 PW-GNPs-BN/POE相变复合材料的光驱动形状恢复能力

图13为测试在一定的光照条件下PW-GNPs-BN/POE相变复合材料的光驱动可恢复性图像。如图13(a)可以看出,将长方形的PW-2wt%GNPs-25wt%BN/POE复合材料在室温下折叠呈60°后,在80 mW·cm−2的光照强度下,10 s时复合材料恢复为90°,30 s恢复为初始时的状态。同样的,在室温下将正方形PW-2wt%GNPs-25wt%BN/POE复合材料4个角向内折叠至60°,在光照条件下,20 s时复合材料恢复为90°,60 s可恢复原始形状。然而,自然条件下(无光照)PW-2wt%GNPs-25wt%BN/POE复合材料在特定时间内形状没有得到恢复(图13(b))。以上现象的发生是由于PW-2wt%GNPs-25wt%BN/POE复合材料的光热特性导致PW晶区形态的可逆变化,从而形成了近红外光触发的形状记忆行为[2]。以上结果充分表明该复合材料具有优异的光驱动可恢复性能。

3. 结 论

(1)通过开炼机的强剪切场作用,成功构建了有序取向导热网络结构,显著提升了复合材料的导热性能。在聚乙烯辛烯共弹性体(POE)/石蜡(PW)中仅加入2wt%石墨烯纳米片(GNPs)和25wt%氮化硼(BN)时,PW-2wt%GNPs-25wt%BN/POE复合材料的热导率(2.59 W·m−1·K−1)较PW/POE复合材料提高156%,展现了出色的导热效果。同时,该复合材料还具备良好的机械性能,拉伸强度(21.1 MPa)和断裂伸长率(719%)均保持在较高水平,且经过多次循环拉伸后性能依然稳定。此外,PW-2wt%GNPs-25wt%BN/POE复合材料的储热性能(44.1 J·g−1)仍保持在一定水平,为实际应用提供了有力支撑。

(2) GNPs的加入不仅增强了复合材料的光热转换能力,还赋予了其光驱动可恢复性能。在模拟光热转换应用实验中,PW-2wt%GNPs-25wt%BN/POE复合材料展现出了显著的温度提升效果,较贴有未添加GNPs的PW/POE复合材料的瓶内温度提升超过20℃(光照强度80 mW·cm−2),表现出优异的光热转换应用能力。这一特性使该复合材料在光热转换领域具有广阔的应用前景,尤其是在需要高效热能转换的场合中,如太阳能利用、光热储能等领域。

-

图 2 透明纤维材料的分类及制备过程:透明木材照片(a)和SEM图像(b)[20];透明纤维板照片(c)和SEM图像(d)[24];纯生物质透明板照片(e)和SEM图像(f)[25]

FR-TWF—Flame retardant transparent wood film

Figure 2. Classification and preparation process of transparent fiber materials: Photograph (a) and SEM image (b) of transparent wood[20]; Photograph (c) and SEM image (d) of transparent fiberboard[24]; Photograph (e) and SEM image (f) of pure biomass transparent board[25]

图 3 不同界面改性的透明纤维材料:(a)多层透明木[40];(b)蒸汽爆破处理的竹纤维材料[41];(c)热处理亚麻纤维增强材料三维模型[44];(d) 分层和各向异性-聚乙烯醇(HA-PVA)水凝胶的冷冻辅助盐析处理[43];(e)碱溶胀处理水凝胶[45];(f)透明杨木贴面乙酰化改性[48];(g)琥珀酰化处理的透明木[49];(h)基于硫醇-烯体系聚合的透明木 [50]

AM—Acrylamide; UV—Ultraviolet; DMAP—4-dimethylaminopyridine; LIMA—Limonene acrylate

Figure 3. Transparent fiber materials in different interface modifications: (a) Multi-layer transparent wood[40]; (b) Bamboo fiber materials treated by steam explosion[41]; (c) Three dimensional model of flax fiber reinforced material by heat treatment[44]; (d) Freeze-assisted salting out treatment of hierarchical and anisotropic polyvinyl alcohol (HA-PVA) hydrogel[43]; (e) Alkali swelling treated hydrogel[45]; (f) Acetylation modification of transparent poplar veneer[48]; (g) Succinylation treatment of transparent wood[49]; (h) Transparent wood by thiol-ene system polymerization[50]

图 4 纤维基透明材料的不同复合方法:(a)溶液浸渍法制备透明木[57];(b)熔融浸渍法制备储能透明材料[58];(c)纤维混杂法制备秸秆纤维透明材料[24];(d)纤维混杂法制备木粉增强透明材料[59]

PW—Pristine balsa wood; LMW—Lignin modified wood; OTW—Optically transparent wood; PDMS—Polydimethylsiloxane; PEG—Polyethylene glycol; MMA—Methyl methacrylate; AIBN—2, 2'-azobis(2-methylpropionitrile); w/w—Mass ratio; TCWP—Powder-reinforced transparent wood; HTW—Hydrophobic transparent wood

Figure 4. Different composite methods of fiber based transparent materials: (a) Preparation of transparent wood by solution impregnation[57]; (b) Preparation of energy storage transparent materials by melt immersion method[58]; (c) Preparation of straw fiber transparent materials by fiber mixing method[24]; (d) Preparation of wood powder reinforced transparent materials by fiber mixing method[59]

图 5 纤维透明材料的光学性能比较:(a)木基透明材料的光线传输图;(b)不同纤维透明材料的透光率[27];(c)透明木材的透射图及其散射图[20];(d)天然木与透明木的透射率[20];(e)不同厚度纤维材料的透光率 [67];(f)锑掺杂透明木和玻璃的隔热实验温度-时间曲线[69];(g)玻璃及不同纤维透明材料的导热系数[66];(h)椴木、环氧树脂及其透明木材的热释放率[70];(i)不同透明木和聚乙烯醇(PVA)薄膜的储能模量[72];(j)原始竹材、脱木质素竹材和透明竹材的抗拉强度比较[73];(k)纤维板及其层压板的拉伸应力-应变曲线[75];(l)层压板、透明玻璃和树脂的弯曲应力-应变曲线[75]

HRR—Heat release rate; THR—Total heat release; R-wood—Radially cutpiece wood; L-wood—Longitudinal cutpiece wood; TW—Transparent wood; PMMA—Prepolymerized methyl methacrylate; LRW—Longitudinal and radially cutpiece wood; ATO—Antimony doped tin oxide; W—Wood; TFW—Transparent fiber wood; TFPW—Translucent fiber PMMA wood; DB—Delignified bamboo; OB—Original bamboo; TB—Transparent bamboo

Figure 5. Optical properties comparison of fiber transparent materials: (a) Light transmission of wood-based transparent materials; (b) Transmittance of different transparent materials[27]; (c) Transmission and scattering images of transparent wood[20]; (d) Transmittance of natural and transparent woods[20]; (e) Transmittance of fiber materials with different thicknesses[67]; (f) Temperature-time curves of insulation experiments for glass and antimony doped transparent wood[69]; (g) Thermal conductivities of glass and fiber transparent materials[66]; (h) Heat release rate of basswood, epoxy resin, and transparent wood[70]; (i) Storage modulus of transparent woods and polyvinyl alcohol (PVA) thin films[72]; (j) Comparison of tensile strength among raw, delignified and transparent bamboo[73]; (k) Tensile stress-strain curves of fiberboard and laminates[75]; (l) Bending stress-strain curves of laminated panels, transparent glass, and resin[75]

图 6 纤维透明材料的节能建筑应用:(a)木材填充通道结构中碳点、聚乙烯醇和纤维素之间的氢键相互作用[9];(b)发光透明材料对甲醛气体进行实时视觉检测[9];(c)冷态无色与热态彩色可逆变色透明竹材[76];(d)含二氧化钛纳米粒子的双功能透明木[77];(e)基于两层透明木材的玻璃系统的U因子和太阳热增益系数变化曲线[12];((f), (g))插入纤维素气凝胶薄膜的中空玻璃[78]

LTW—Luminescent transparent wood; CDs—Carbon dots; NW—Nature wood

Figure 6. Energy saving building applications of fiber transparent materials: (a) Hydrogen bonding interactions between carbon dots, polyvinyl alcohol, and cellulose in wood filled channel structures[9]; (b) Real time visual detection of formaldehyde gas using luminescent transparent materials[9]; (c) Cold colorless and hot colored reversible color changing transparent bamboo[76]; (d) Double functional transparent wood containing titanium dioxide nanoparticles[77]; (e) U-factor and solar thermal gain coefficient variation curves of a glass system based on two-layer transparent wood[12];((f), (g)) Hollow glass inserted with cellulose aerogel film[78]

图 7 纤维透明材料在光电子器件的应用:(a)透明纸铺覆砷化镓电池的电流密度与电压特性关系曲线[13];(b)砷化镓电池反射率与入射角和波长的函数等值线图[13];(c)入射到太阳能电池上的光分布示意图[16];柔性导电透明木材点亮LED灯泡照片(d)、电导率与温度的关系(e)和不同温度变化循环的电导率变化(f)[10];FeCl3/聚丙烯酸透明木材电导率随FeCl3浓度的变化关系(g)和人体动作电学响应((h), (i))[79];涂覆铟锡氧化物的透明木材模型图(j)和透射/反射功率的比较((k), (l))[80]

ARC—Anti-reflection coating; R—Resistance; PEC—Packaged electronic circuit; ITO—Indium tin oxide

Figure 7. Optoelectronic devices applications of fiber transparent materials: (a) Relationship curves between current density and voltage characteristics of transparent paper coated gallium arsenide batteries[13]; (b) Contour plot of reflectivity as a function of incident angle and wavelength for gallium arsenide batteries[13]; (c) Schematic diagram of light distribution incident on solar cells[16]; Photos of LED bulbs (d), relationship between conductivity and temperature (e) and conductivity changes under different temperature cycles (f) for flexible conductive transparent wood[10]; Relationship between conductivity and FeCl3 concentration (g), electrical response of human actions ((h), (i)) for FeCl3/polyacrylic acid transparent wood[79]; Model diagram (j), comparison of transmission/reflection power ((k), (l)) for transparent wood coated with indium tin oxide[80]

图 8 纤维透明材料的热能储存性能:透明储能木材的制备方法(a)及其加热(b)与冷却(c)的DSC图谱[49];透光储能木材界面结合机制(d)、光传输和热传导(e)及DSC曲线(f)[11];共聚柔性透明木材共聚物网络(g)、不同温度下的透明度(h)及热导率和热扩散率(i)[8]

TESW—Transmittance energy storage wood; PCM—Phase change materials; TW—Transparent wood; FDW—Flexible delignified wood; SBO—Copolymer of styrene (St)/butyl acrylate (BA)/1-octadecene (ODE), the subscript numbers indicate the ODE content

Figure 8. Thermal energy storage performance of fiber transparent materials: Preparation method of transparent energy storage wood (a), and its DSC spectra for heating (b) and cooling (c) process[49]; Interface binding mechanism (d), light transmission and thermal conductivity (e) and DSC curves for translucent energy storage wood (f)[11]; Copolymer network (g), transparency at different temperatures (h), and thermal conductivity and thermal diffusivity for flexible transparent wood (i)[8]

表 1 植物纤维材料脱色方法比较

Table 1 Comparison of decolorization methods for plant fiber materials

Method Mechanism Character Ref. Acid delignification Sodium chlorite solution decomposed into

chlorine gas and chlorine dioxide by reacting

with lignin as a widely used methodGood selectivity, moderate process conditions, intact fiber structure, release of harmful gases [28] Alkali delignification The ether bond broken by sodium hydroxide

and sodium sulfite reacting with ligninMost lignin and hemicelluloses removed,

little cellulose dissolved[29] Biological enzyme delignification The lignin degraded by enzyme to

achieve decolorizationEco-friendly, slow reaction speed,

no obvious effects[26] Delignification of ionic liquids Low vapor pressure, high solubility and

high stability, selectively dissolved ligninExpensive, high purity requirement, toxic [30-31] Lignin modification Instead of extracting lignin, change the

structure and remove the chromophoresStructural stability, simple process,

low requirement[27, 32] 表 2 木材的纤维素、木质素和常见树脂的折射率

Table 2 Refractive index of cellulose, lignin and common resins of wood

Matter Refractive index Basic property Ref. Air 1.00 — — Cellulose 1.53 The main component of plant fiber [52-53] Lignin 1.61 Contains special chromophores [52-53] Polymethyl methacrylate 1.49 Low density, high mechanical strength, unstable nature, explosive [54] Epoxy resin 1.50 Good compatible fiber, difficult to degrade [56] Polyvinylpyrrolidone 1.53 Environmentally friendly, biodegradable, hydrophilic,

good compatible fiberPolylimonene acrylate 1.50 Soluble in alcohol, ether and other organic solvents, insoluble in water [49] Mercaptan and ene monomer polymer 1.59 High yield, easy photoinduced polymerization, complex shrinkage

strain is low[50] Chitosan and cellulose nanofibers 1.52 Biodegradable, antioxidant, antibacterial, UV protection [55] Polyvinyl alcohol 1.51 Low cost, biodegradable, low viscosity, excellent film formation,

toughness, and transparency[18] -

[1] RAJ T, CHANDRASEKHAR K, KUMAR A N, et al. Lignocellulosic biomass as renewable feedstock for biodegradable and recyclable plastics production: A sustainable approach[J]. Renewable Sustainable Energy Reviews, 2022, 158: 112130. DOI: 10.1016/j.rser.2022.112130

[2] BELOUADAH Z, ATI A, ROKBI M, et al. Characterization of new natural cellulosic fiber from Lygeum spartum L[J]. Carbohydrate Polymers, 2015, 134: 429-437. DOI: 10.1016/j.carbpol.2015.08.024

[3] LU Y, XIAO J, LI Y, et al. 3D printing recycled concrete incorporating plant fibres: A comprehensive review[J]. Construction and Building Materials, 2024, 425: 135951. DOI: 10.1016/j.conbuildmat.2024.135951

[4] SONG J. Processing bulk natural wood into a high-performance structural material[J]. Nature, 2018, 554(7691): 224-228. DOI: 10.1038/nature25476

[5] CHEN X, GE-ZHANG S, HAN Y, et al. Ultraviolet-assisted modified delignified wood with high transparency[J]. Applied Sciences-Basel, 2022, 12(15): 7406. DOI: 10.3390/app12157406

[6] WANG Y, WU Y, YANG F, et al. A highly transparent compressed wood prepared by cell wall densification[J]. Wood Science and Technology, 2022, 56(2): 669-686. DOI: 10.1007/s00226-022-01372-3

[7] WANG X, SHAN S, SHI S, et al. Optically transparent bamboo with high strength and low thermal conductivity[J]. ACS Applied Materials & Interfaces, 2021, 13(1): 1662-1669.

[8] QIU Z, WANG S, WANG Y G, et al. Transparent wood with thermo-reversible optical properties based on phase-change material[J]. Composites Science and Technology, 2020, 200: 108407. DOI: 10.1016/j.compscitech.2020.108407

[9] LIU Y, YANG H, MA C, et al. Luminescent transparent wood based on lignin-D derived carbon dots as a building material for dual-channel, real-time, and visual detection of formaldehyde gas[J]. ACS Applied Materials & Interfaces, 2020, 12(32): 36628-36638.

[10] YANG L, WU Y, YANG F, et al. Study on the preparation process and performance of a conductive, flexible, and transparent wood[J]. Journal of Materials Research and Technology, 2021, 15: 5396-5404.

[11] XIA R, ZHANG W, YANG Y, et al. Transparent wood with phase change heat storage as novel green energy storage composites for building energy conservation[J]. Journal of Cleaner Production, 2021, 296: 126598. DOI: 10.1016/j.jclepro.2021.126598

[12] MI R Y, LI T, DALGO D, et al. A clear, strong, and thermally insulated transparent wood for energy efficient windows[J]. Advanced Functional Materials, 2020, 30(1): 1907511. DOI: 10.1002/adfm.201907511

[13] HA D, FANG Z, HU L, et al. Paper-based anti-reflection coatings for photovoltaics[J]. Advanced Energy Materials, 2014, 4(9): 1301804. DOI: 10.1002/aenm.201301804

[14] ZHOU T, ZHOU J, FENG Q, et al. Mechanically strong, hydrostable, and biodegradable all-biobased transparent wood films with UV-blocking performance[J]. International Journal of Biological Macromolecules, 2024, 255: 128188. DOI: 10.1016/j.ijbiomac.2023.128188

[15] YANG Y, LAI Y, ZHAO S, et al. Optically transparent and high-strength glass-fabric reinforced composite[J]. Composites Science and Technology, 2024, 245: 110338. DOI: 10.1016/j.compscitech.2023.110338

[16] ZHU M, LI T, DAVIS C, et al. Transparent and haze wood composites for highly efficient broadband light management in solar cells[J]. Nano Energy, 2016, 26: 332-339. DOI: 10.1016/j.nanoen.2016.05.020

[17] SIEGFRIED F. Transparent wood—A new approach in the functional study of wood structure[J]. Holzforschung, 1992, 46(5): 403-408. DOI: 10.1515/hfsg.1992.46.5.403

[18] RAO A, NAGARAJAPPA G, NAIR S, et al. Flexible transparent wood prepared from poplar veneer and polyvinyl alcohol[J]. Composites Science Technology, 2019, 182(29): 107719.

[19] 侯高远, 李冠辉, 胡招湘, 等. 高雾度透明纤维素薄膜制备、性能及其太阳能电池应用[J]. 复合材料学报, 2022, 39(5): 1907-1923. HOU Gaoyuan, LI Guanhui, HU Zhaoxiang, et al. Preparation, properties and application of high fog transparent cellulose film in solar cell[J]. Acta Materiae Compositae Sinica, 2022, 39(5): 1907-1923(in Chinese).

[20] ZHU M, SONG J, LI T, et al. Highly anisotropic, highly transparent wood composites[J]. Advanced Materials, 2016, 28(26): 5181-5187. DOI: 10.1002/adma.201600427

[21] LI X, ZHANG W, LI J, et al. Optically transparent bamboo: Preparation, properties, and applications [J]. Polymers, 2022, 14(16): 3234.

[22] ZHANG T, ZHENG M, LI H, et al. Photochromic transparent bamboo composite with excellent optical and thermal management for smart window applications[J]. Industrial Crops and Products, 2023, 205: 117532. DOI: 10.1016/j.indcrop.2023.117532

[23] El-KASSAS A, MOURAD A. Novel fibers preparation technique for manufacturing of rice straw based fiberboards and their characterization[J]. Materials & Design, 2013, 50: 757-765.

[24] TONG J, WANG X, KUAI B, et al. Development of transparent composites using wheat straw fibers for light-transmitting building applications[J]. Industrial Crops and Products, 2021, 170: 113685. DOI: 10.1016/j.indcrop.2021.113685

[25] ZHOU L, GUO W, ZHANG L, et al. A top-down strategy for the preparation of flame retardant, robust, and transparent wood-derived films[J]. Journal of Materials Research and Technology, 2022, 21: 3594-3603. DOI: 10.1016/j.jmrt.2022.10.151

[26] RAJESWARI G, JACOB S. Deciphering the aloe vera leaf rind as potent feedstock for bioethanol through enzymatic delignification and its enhanced saccharification[J]. Industrial Crops and Products, 2020, 143: 111876. DOI: 10.1016/j.indcrop.2019.111876

[27] WANG Y, GUO F, LI Y, et al. High overall performance transparent bamboo composite via a lignin-modification strategy[J]. Composites Part B: Engineering, 2022, 235: 109798. DOI: 10.1016/j.compositesb.2022.109798

[28] 吴燕, 韩岩, 黄楠, 等. 脱木质素工艺对透明木材性能的影响[J]. 林业工程学报, 2019, 4(6): 98-104. WU Yan, HAN Yan, HUANG Nan, et al. Effect of delignification process on properties of transparent wood[J]. Journal of Forestry Engineering, 2019, 4(6): 98-104(in Chinese).

[29] ZHU S, KUMAR B, QIU Z, et al. Transparent wood-based functional materials via a top-down approach[J]. Progress in Materials Science, 2023, 132: 101025. DOI: 10.1016/j.pmatsci.2022.101025

[30] 汪心娉, 余璟, 朱瑞琦, 等. 低共熔溶剂选择性溶解木质纤维原料的研究进展[J]. 中国造纸学报, 2021, 36(2): 79-86. WANG Xinping, YU Jing, ZHU Ruiqi, et al. Research progress on the selective dissolution of wood fiber raw materials with low eutectic solvents[J]. Chinese Paper Journal, 2021, 36(2): 79-86(in Chinese).

[31] KHAKALO A, TANAKA A, KORPELA A, et al. Delignification and ionic liquid treatment of wood toward multifunctional high-performance structural materials[J]. ACS Applied Materials & Interfaces, 2020, 12(20): 23532-23542.

[32] LI Y, FU Q, ROJAS R, et al. Lignin-retaining transparent wood[J]. Chemsuschem, 2017, 10(17): 3445-3451. DOI: 10.1002/cssc.201701089

[33] JIA C, LI T, CHEN C, et al. Scalable, anisotropic transparent paper directly from wood for light management in solar cells[J]. Nano Energy, 2017, 36: 366-373. DOI: 10.1016/j.nanoen.2017.04.059

[34] SHI R, SHENG X, JIA H, et al. Preparation of sustainable transparent wood with glucose and phenol derived resin[J]. Industrial Crops and Products, 2023, 193: 116234. DOI: 10.1016/j.indcrop.2022.116234

[35] SHARMA N, TTIPATHI S, BHARDWAJ N, et al. Utilization of sarkanda for making pulp and paper using elemental chlorine free and total chlorine free bleaching processes[J]. Industrial Crops and Products, 2020, 149: 112316.

[36] LU P, CHENG F, OU Y, et al. Rapid fabrication of transparent film directly from wood fibers with microwave-assisted ionic liquids technology[J]. Carbohydrate Polymers, 2017, 174: 330-336. DOI: 10.1016/j.carbpol.2017.06.057

[37] OH Y, PARK S, JUNG D, et al. Effect of hydrogen bond donor on the choline chloride-based deep eutectic solvent-mediated extraction of lignin from pine wood[J]. International Journal of Biological Macromolecules, 2020, 165(Pt A): 187-197.

[38] JING Y, LI F, LI Y, et al. Biohydrogen production by deep eutectic solvent delignification-driven enzymatic hydrolysis and photo-fermentation: Effect of liquid–solid ratio[J]. Bioresource Technology, 2022, 349: 126867. DOI: 10.1016/j.biortech.2022.126867

[39] ZHANG K, PEI Z, WANG D, et al. Organic solvent pretreatment of lignocellulosic biomass for biofuels and biochemicals: A review[J]. Bioresource Technology, 2016, 199: 21-33. DOI: 10.1016/j.biortech.2015.08.102

[40] QIN J, LI X, SHAO Y, et al. Optimization of delignification process for efficient preparation of transparent wood with high strength and high transmittance[J]. Vacuum, 2018, 158: 158-165. DOI: 10.1016/j.vacuum.2018.09.058

[41] ZHAO W, ZOU Y, ZHANG W, et al. Effect of fiber separation degree on the properties of bamboo fiber composites[J]. European Journal of Wood and Wood Products, 2023, 84: 1249-1259.

[42] ADAM P, HORVATH M, SINKO K. Sol-gel derived porous aluminum oxide cryogel—Fiber composite systems[J]. Journal of Molecular Liquids, 2023, 380: 121755. DOI: 10.1016/j.molliq.2023.121755

[43] HUA M, WU S, MA Y, et al. Strong tough hydrogels via the synergy of freeze-casting and salting out[J]. Nature, 2021, 590(7847): 594-599. DOI: 10.1038/s41586-021-03212-z

[44] PUCCI M, LIOTIER P J, SEVENO D, et al. Wetting and swelling property modifications of elementary flax fibres and their effects on the liquid composite molding process[J]. Composites Part A: Applied Science and Manufacturing, 2017, 97: 31-40. DOI: 10.1016/j.compositesa.2017.02.028

[45] CHEN C, WANG Y, ZHOU T, et al. Toward strong and tough wood-based hydrogels for sensors[J]. Biomacromolecules, 2021, 22(12): 5204-5213. DOI: 10.1021/acs.biomac.1c01141

[46] ZHOU J, XU W. Toward interface optimization of transparent wood with wood color and texture by silane coupling agent[J]. Journal of Materials Science, 2022, 57(10): 5825-5838. DOI: 10.1007/s10853-022-06974-7

[47] MA T, LI L, LIU Z, et al. A facile strategy to construct vegetable oil-based, fire-retardant, transparent and mussel adhesive intumescent coating for wood substrates[J]. Industrial Crops and Products, 2020, 154: 112628. DOI: 10.1016/j.indcrop.2020.112628

[48] HE W, WANG R, GUO F, et al. Preparation of transparent fast-growing poplar veneers with a superior optical performance, excellent mechanical properties, and thermal insulation by acetylation modification using a green catalyst[J]. Polymers, 2022, 14(2): 257. DOI: 10.3390/polym14020257

[49] MONTANARI C, OGAWA Y, OLSEN P, et al. High performance, fully bio-based, and optically transparent wood biocomposites[J]. Advanced Science, 2021, 8(12): 2100559. DOI: 10.1002/advs.202100559

[50] HOGLUND M, JOHANSSON M, SYCHUGOV I, et al. Transparent wood biocomposites by fast UV-curing for reduced light-scattering through wood/thiolene interface design[J]. ACS Applied Materials & Interfaces, 2020, 12(41): 46914-46922.

[51] ZHANG K, CHU C, LI M, et al. Transparent wood developed by impregnating poplar with epoxy resin assisted by silane coupling agent[J]. Bioresources, 2023, 18(2): 3598-3607. DOI: 10.15376/biores.18.2.3598-3607

[52] CHEN H, MONTANARI C, YAN M, et al. Refractive index of delignified wood for transparent biocomposites[J]. RSC Advances, 2020, 10(67): 40719-40724. DOI: 10.1039/D0RA07409H

[53] JIA C, CHEN C, MI R, et al. Clear wood toward high-performance building materials[J]. ACS Nano, 2019, 13(9): 9993-10001. DOI: 10.1021/acsnano.9b00089

[54] WU Y, ZHOU J, HUANG Q, et al. Study on the colorimetry properties of transparent wood prepared from six wood species[J]. ACS Omega, 2020, 5(4): 1782-1788. DOI: 10.1021/acsomega.9b02498

[55] HAI L, MUTHOKA R, PANICKER P, et al. All-biobased transparent-wood: A new approach and its environmental-friendly packaging application[J]. Carbohydrate Polymers, 2021, 264: 118012. DOI: 10.1016/j.carbpol.2021.118012

[56] HAN X, DING L, TIAN Z, et al. Potential new material for optical fiber: Preparation and characterization of transparent fiber based on natural cellulosic fiber and epoxy[J]. International Journal of Biological Macromolecules, 2023, 224: 1236-1243. DOI: 10.1016/j.ijbiomac.2022.10.209

[57] WANG H, YANG H, MU H. Preparation of hydrophobic optically transparent wood via an efficient UV-assisted route[J]. Forests, 2023, 14(4): 759. DOI: 10.3390/f14040759

[58] MONTANARI C, LI Y, CHEN H, et al. Transparent wood for thermal energy storage and reversible optical transmittance[J]. ACS Applied Materials & Interfaces, 2019, 11(22): 20465-20472.

[59] GAO J, WANG X, XU Q, et al. Efficient preparation and properties of wood fiber transparent materials with powdered wood[J]. Industrial Crops and Products, 2023, 193: 116291. DOI: 10.1016/j.indcrop.2023.116291

[60] WU Y, WANG Y, YANG F. Comparison of multilayer transparent wood and single layer transparent wood with the same thickness[J]. Frontiers in Materials, 2021, 8: 633345. DOI: 10.3389/fmats.2021.633345

[61] LIU Z, YANG S, WANG Z, et al. Preparation of bamboo-epoxy resin materials with microwave assistance[J]. Journal of Materials Research and Technology, 2022, 18: 3266-3272.

[62] 甘健, 杨乐晨, 吴新宇, 等. 基于碳量子点的荧光透明木的制备与性能[J]. 林业工程学报, 2022, 7(4): 31-37. GAN Jian, YANG Lechen, WU Xinyu, et al. Preparation and properties of fluorescent transparent wood based on carbon quantum dots[J]. Journal of Forestry Engineering, 2022, 7(4): 31-37(in Chinese).

[63] LIU X, LI H, ZHANG T, et al. Strong, tough, anisotropic, flexible, and transparent bamboo films[J]. Industrial Crops and Products, 2024, 207: 117757. DOI: 10.1016/j.indcrop.2023.117757

[64] ZHANG J, KOUBAA A, TAO Y, et al. The emerging development of transparent wood: Materials, characteristics, and applications[J]. Current Forestry Report, 2022, 8(4): 333-345. DOI: 10.1007/s40725-022-00172-z

[65] WANG S, LI L, ZHA L, et al. Wood xerogel for fabrication of high-performance transparent wood[J]. Nature Communications, 2023, 14(1): 2827. DOI: 10.1038/s41467-023-38481-x

[66] GAO J, WANG X, TONG J, et al. Large size translucent wood fiber reinforced PMMA porous composites with excellent thermal, acoustic and energy absorption properties[J]. Composites Communications, 2022, 30: 101059. DOI: 10.1016/j.coco.2022.101059

[67] LI Y, FU Q, YU S, et al. Optically transparent wood from a nanoporous cellulosic template: Combining functional and structural performance[J]. Biomacromolecules, 2016, 17(4): 1358-1364. DOI: 10.1021/acs.biomac.6b00145

[68] YUE D, FU G, JIN Z. Transparent wood prepared by polymer impregnation of rubber wood[J]. Bioresources, 2021, 16(2): 2491-2502. DOI: 10.15376/biores.16.2.2491-2502

[69] QIU Z, XIAO Z, GAO L, et al. Transparent wood bearing a shielding effect to infrared heat and ultraviolet via incorporation of modified antimony-doped tin oxide nanoparticles[J]. Composites Science and Technology, 2019, 172: 43-48. DOI: 10.1016/j.compscitech.2019.01.005

[70] MARTINKA J, MITTERPACH J, STEFKO T, et al. Fire hazard of epoxy-based transparent wood[J]. Journal of Thermal Analysis and Calorimetry, 2023, 148: 9893-9907. DOI: 10.1007/s10973-023-12360-5

[71] ALDALBAHI A, EL-NAGGAR M, KHATTAB T, et al. Preparation of flame-retardant, hydrophobic, ultraviolet protective, and luminescent transparent wood[J]. Luminescence, 2021, 36(8): 1922-1932. DOI: 10.1002/bio.4126

[72] ZHANG L, JIANG Y, ZHOU L, et al. Mechanical, thermal stability, and flame retardancy performance of transparent wood composite improved with delaminated Ti3C2T x (MXene) nanosheets[J]. Journal of Materials Science, 2022, 57(5): 3348-3359. DOI: 10.1007/s10853-021-06776-3

[73] WU Y, WANG J, WANG Y, et al. Properties of multilayer transparent bamboo materials[J]. ACS Omega, 2021, 6(49): 33747-33756. DOI: 10.1021/acsomega.1c05014

[74] WU J, LIANG Y, XIA C, et al. Laminated transparent woods with adjustable optical and enhanced mechanical properties[J]. Advanced Materials Technologies, 2023, 8(1): 2200704. DOI: 10.1002/admt.202200704

[75] ISHIOKA S, ISOBE N, HIRANO T, et al. Fully wood-based transparent plates with high strength, flame self-extinction, and anisotropic thermal conduction[J]. ACS Sustainable Chemistry & Engineering, 2023, 11(6): 2440-2448.

[76] JI Y, ZHANG Y, WANG X, et al. Reversible thermochromic transparent bamboo for dynamically adaptive smart windows[J]. Industrial Crops and Products, 2023, 197: 116593. DOI: 10.1016/j.indcrop.2023.116593

[77] WU T, XU Y, CUI Z, et al. Efficient heat shielding and ultraviolet isolating transparent wood via in situ generation of TiO2 nanoparticles[J]. ACS Sustainable Chemistry & Engineering, 2022, 10(47): 15380-15388.

[78] ABRAHAM E, CHERPAK V, SENYUK B, et al. Highly transparent silanized cellulose aerogels for boosting energy efficiency of glazing in buildings[J]. Nature Energy, 2023, 8(4): 381-396. DOI: 10.1038/s41560-023-01226-7

[79] YANG S, ZHANG Y, LI T, et al. Preparation and properties of FeCl3/polyacrylic acid transparent conductive wood[J]. Chemistry and Industry of Forest Products, 2022, 42(5): 107-112.

[80] CHO S, SONG S, HONG I. Analysis of the electromagnetic properties of eco-friendly transparent wood[J]. Microwave and Optical Technology Letters, 2021, 63(9): 2237-2241. DOI: 10.1002/mop.32385

[81] HUANG H, SHI T, HE R, et al. Phase-changing microcapsules incorporated with black phosphorus for efficient solar energy storage[J]. Advanced Science, 2020, 7(23): 2000602. DOI: 10.1002/advs.202000602

-

目的

从制备、功能、应用方面,详细综述透明植物纤维基复合材料的研究进展。梳理透明植物纤维基复合材料的发展历程,厘清透明植物纤维基复合材料的形成机理以及制备方法。阐述不同材质、不同制备方法得到的透明纤维材料的特点,探明光学、隔热阻燃、机械等性能方面的优化路径。总结透明植物纤维基复合材料近几年在建筑、光电子器件、储能材料等领域的应用进展,提出植物纤维基透明材料目前阶段存在的问题,展望未来的发展方向。

方法通过归纳整理近年来国内外透明植物纤维基复合材料的研究文献,先简述了植物纤维基复合材料的制备原理和制备方法,针对不同材质、不同制备方法得到的透明纤维材料的特点进行了分析。随后,重点阐述了植物纤维基复合材料的光学、阻热、力学等性能的优化方法。最后,根据其性能的优势介绍了其在不同领域的应用前景,并对植物纤维基透明材料目前阶段存在的问题和未来发展进行了剖析和展望。

结果透明植物纤维基复合材料大多通过脱除木质素和填充聚合物树脂实现透明化,主要分为透明木材、透明纤维板、纯生物质透明板三大类。其制备工艺包括纤维脱色、界面改性和树脂复合。透明度、雾度是评价光学性能的重要指标,脱色漂白可减少可见光的吸收,复合组分体积分数、聚合物性质是影响光学性能的关键因素。不同的纤维成分和各向异性微观结构决定了纤维透明材料的阻燃隔热性能。纤维透明材料在建筑、光电子器件、储能材料等领域的应用前景,凭借其优异的光学、隔热阻燃、力学性能,特别是在节能建筑、太阳能电池、相变材料,具有广阔的应用前景,并且符合国家绿色环保的战略要求。

结论以透明木竹为代表的透明纤维材料取得了丰硕的理论成果,但仍存在应用基础问题亟待解决。首先是大幅面制备技术的挑战,应增加小径木用于开发大幅面透明材的可行性。利用植物纤维为基材,采取自下而上的策略开发透明纤维材料,具成本优势和工业基础,但其瓶颈在于纤维本身及其成型材料存在的孔隙结构,造成光散射而影响透明。未来应着重解决植物纤维孔隙结构调控问题,明确纤维本身及其成型材料复杂孔隙与光学性能构效关系基础理论问题。植物纤维透明化复合改性同质化严重,应加强其他物质(如硅酸盐)等透明复合材料的研究,拓展其未来应用的领域。同时,复合物质与纤维的复合结构形态等对复合体宏观性能的影响机制尚不明确,还需要未来进一步研究解决。

下载:

下载: