Research progress on improving the gas barrier of biodegradable films using nanomaterials

-

摘要: 传统塑料的大量使用及其废弃后无法降解给生态环境造成了严重污染,同时也给日益严峻的石化能源造成了巨大压力。薄膜材料是塑料的主要制品之一,其中生物降解薄膜因具有绿色环保、实现碳循环目标等优点,且能够在很大程度上改善全球环境污染和能源短缺的困境,被认为是当前薄膜发展的重要趋势。然而,生物降解薄膜也存在性能不理想、成本较高等问题,其较差的阻隔性更是限制了它在包装方面的应用。本文综述了纳米材料用于生物降解薄膜气体阻隔性的研究现状,主要从纳米材料的种类、组合方式以及生产纳米复合薄膜的加工方式三部分展开介绍,并对生物降解薄膜未来的研究发展做了展望。Abstract: The extensive use of traditional plastics and their non-degradable nature after disposal have led to severe pollution in the ecological environment and exerted enormous pressure on the increasingly critical petrochemical energy resources. Thin film material is one of the primary plastic products currently in application. The biodegradable films, known for their environmental friendliness and contribution to achieving carbon cycling goals, hold the potential to make substantial strides in mitigating global environmental pollution and addressing energy shortages. However, biodegradable films face challenges such as suboptimal performance and higher costs, with their poor barrier properties particularly limiting their application in packaging films. This article reviews the current research status of nanomaterials for enhancing the gas barrier properties of biodegradable films. The discussion is divided into three main parts: The types of nanomaterials, their combinations, and the processing methods for producing nanocomposite films. The article also provides insights into the future research and development of biodegradable films.

-

Key words:

- biodegradable /

- composite films /

- nanomaterials /

- carbon recycling /

- barrier properties

-

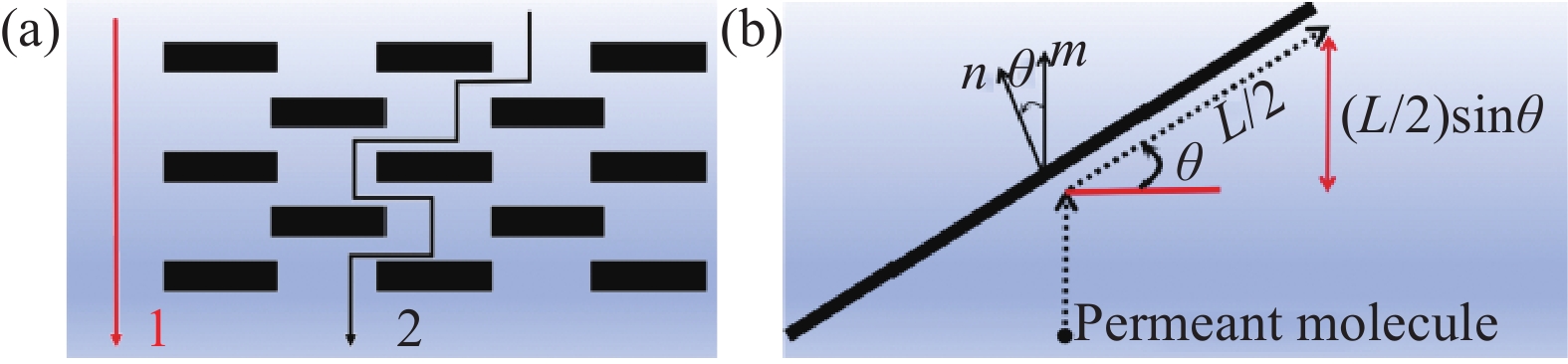

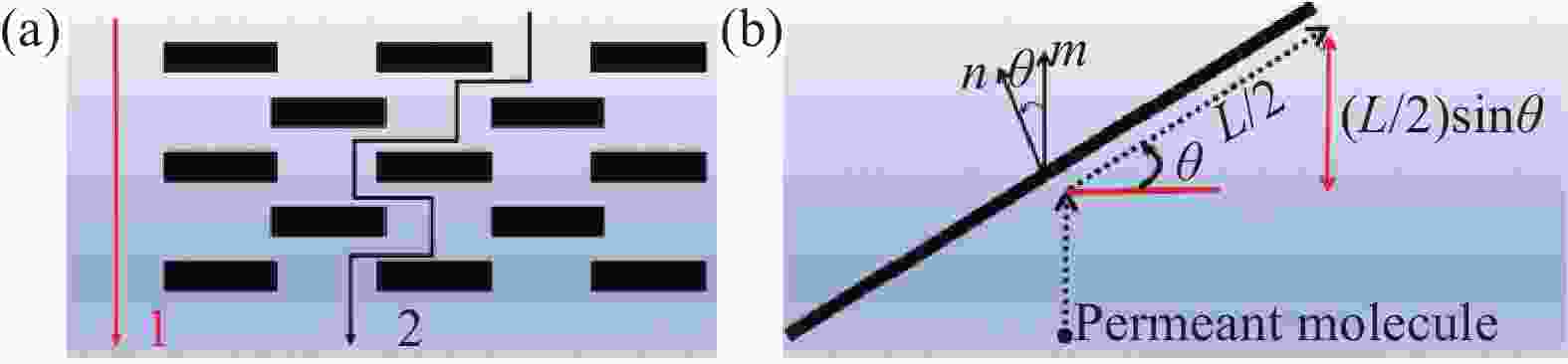

图 1 (a)气体在聚合物中的渗透路径图解(路径1:纯聚合物的气体透过路径;路径2:纳米聚合物复合材料的气体透过路径);(b)气体渗透弯曲度计算示意图

Figure 1. (a) Diagram of the permeation path of a gas in a polymer (Path 1: Permeation path of a pure polymer; Path 2: Gas permeability path of nanopolymer composites); (b) Schematic diagram of gas permeability bending calculation

n—Nanoplatelet normal unit vector; m—Permeation direction; θ—Orientation angle; L—Length

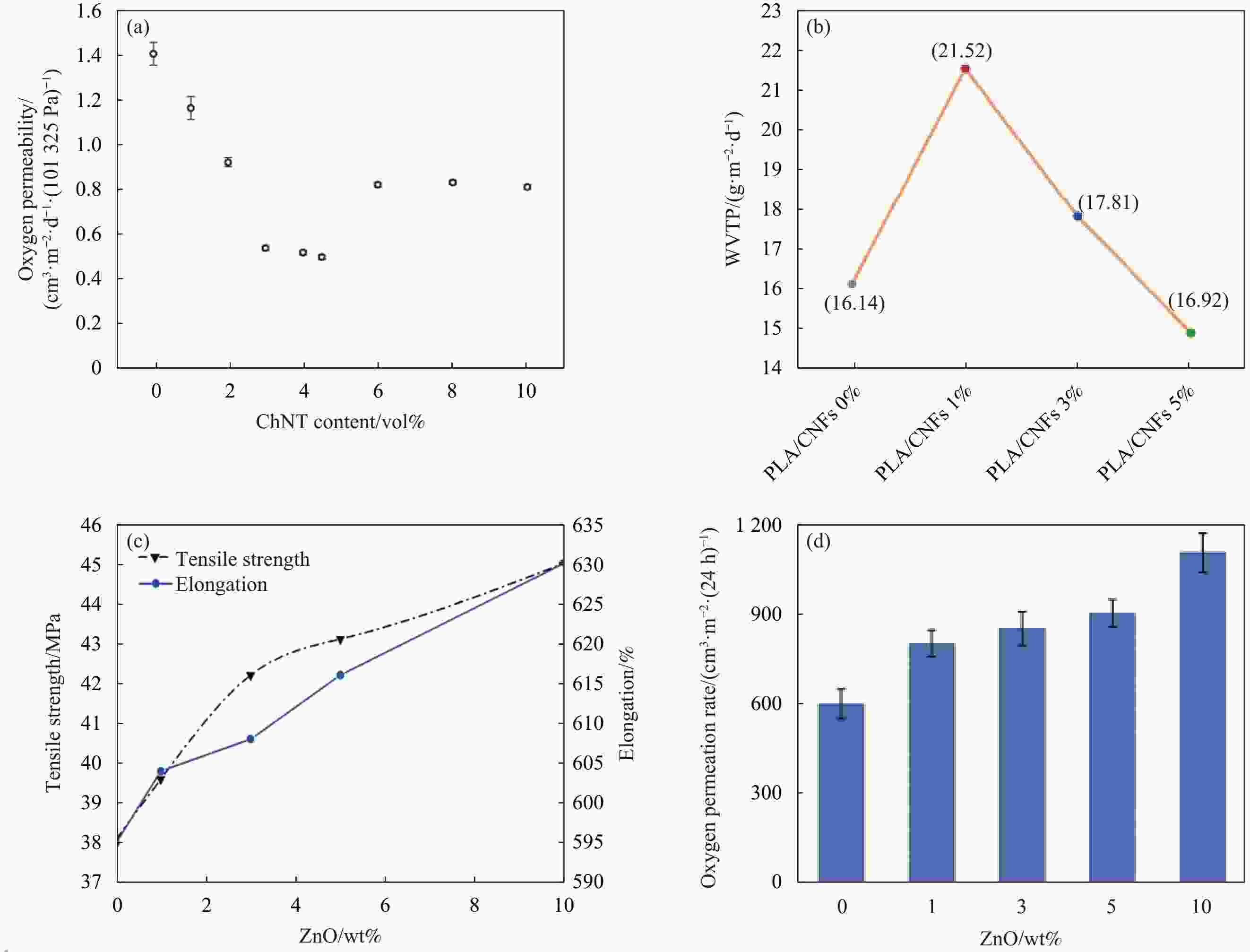

图 2 (a)氧渗透性与碳纳米管(ChNT)体积含量的关系[37];(b)不同浓度纤维素纳米纤维(CNFs)对CNFs负载纳米复合材料的水蒸气透过率(WVTR)的研究[38];(c)聚己二酸/对苯二甲酸丁二酯(PBAT)/ZnO纳米复合薄膜的力学性能[39];(d) PBAT和PBAT/ZnO纳米复合薄膜在25℃时的氧渗透速率[39]

Figure 2. (a) Relationship between oxygen permeability and the volume content of carbon nanotubes (ChNT)[37]; (b) Study of water vapor transmission rate (WVTR) of different concentrations of cellulose nanofiber (CNFs) on CNFs-supported nanocomposites[38]; (c) Mechanical properties of poly(butylene adipate-co-terephthalate) (PBAT)/ZnO nanocomposite films[39]; (d) Oxygen permeation rate of PBAT and PBAT/ZnO nanocomposite films at 25℃[39]

PLA—Polylactic acid

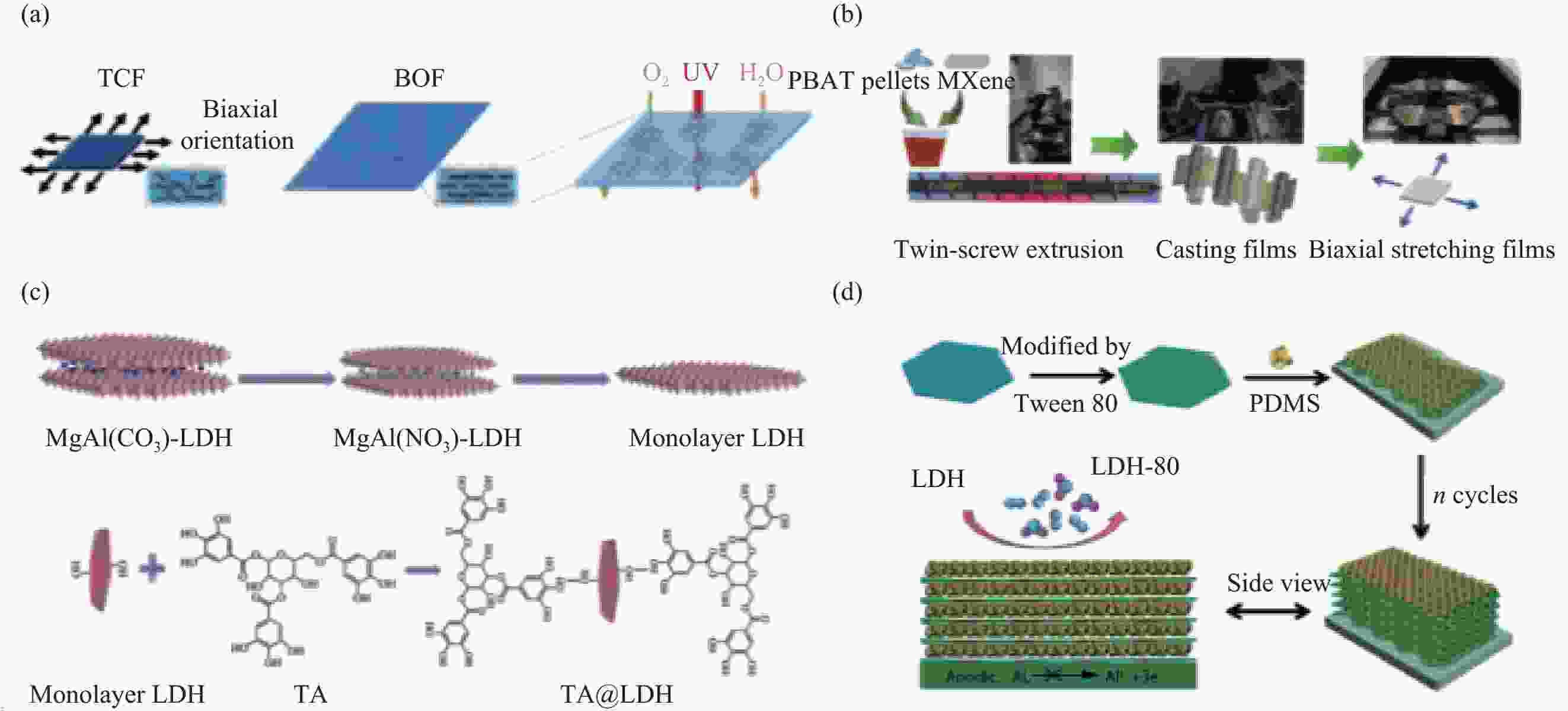

图 3 (a)蒙脱土(MMT)纳米复合薄膜的双轴拉伸过程示意图[47];(b) PBAT/碳化钛(Ti3C2TX)纳米复合双轴拉伸膜的制备示意图[48];(c)单层层状双氢氧化物(LDH)纳米片制备工艺示意图[49];(d)用于防腐保护的两亲表面活性剂修饰的水滑石纳米片/聚二甲基硅氧烷(LDH-80/PDMS)n薄膜在铝箔衬底上的组装工艺示意图[52]

Figure 3. (a) Schematic diagram of the biaxial stretching process of montmorillonite (MMT) nanocomposite films[47]; (b) Schematic diagram of the preparation of PBAT/titanium carbide (Ti3C2TX) nanocomposite biaxial stretch films[48]; (c) Schematic diagram of the preparation process of single-layer layered double hydroxide (LDH) nanosheets[49]; (d) Schematic diagram of the assembly process of hydrotalcite nanosheets/polydimethyloxysilicone (LDH-80/PDMS)n films modified by amphiphilic surfactants for anti-corrosion protection on aluminum foil substrates[52]

TCF—Thermo-compressed films; BOF—Biaxially oriented film; TA—Tannic acid

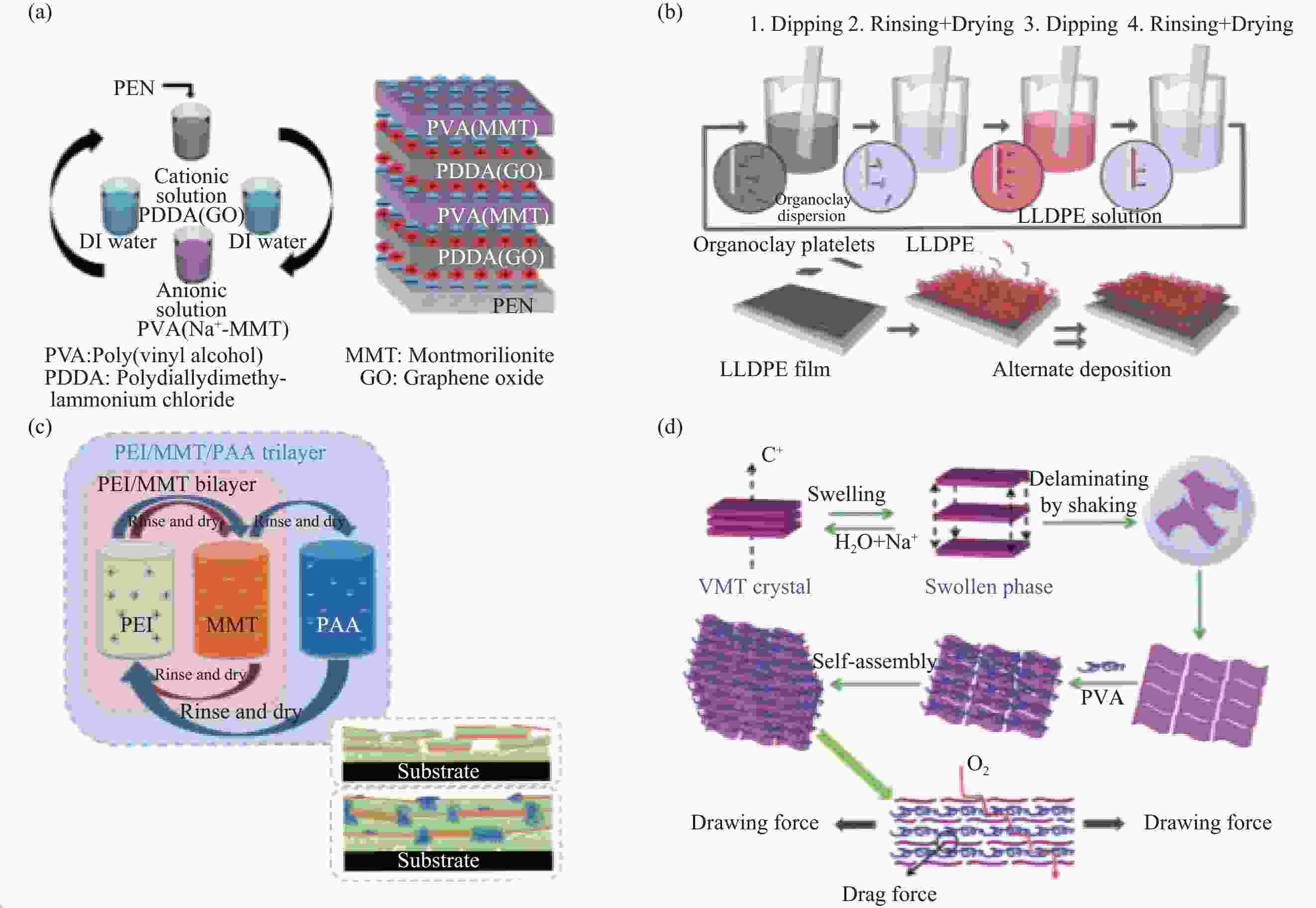

图 4 (a)层层自组装(LBL)法制备聚二烯丙基二甲基氯化铵(氧化石墨烯)和聚乙烯醇(钠离子蒙脱土)(PDDA(GO)/PVA(Na+-MMT))薄膜的顺序和电键合制备的PDDA(GO)/PVA(Na+-MMT)薄膜的结构[53];(b)自组装沉积技术方案及得到的多层纳米结构的三维横截面图[60];(c)阳离子聚乙烯亚胺(PEI)、阴离子蒙脱土(MMT)和阴离子聚丙烯酸(PAA)组成的三层(TL)体系示意图[61];(d)具有机械和气体阻隔性能的二维层状蛭石(VMT)-PVA复合膜的形成过程示意图[62]

Figure 4. (a) Structure of polydiallyl dimethylammonium chloride (graphene oxide) and polyvinyl alcohol (sodium ion montmorillonite) (PDDA(GO)/PVA(Na+-MMT)) films prepared by sequential and electrical bonding of PDDA(GO)/PVA(Na+-MMT) films prepared by layer self-assembly (LBL) method[53]; (b) Self-assembly deposition technology scheme and three-dimensional cross-sectional diagram of the obtained multilayer nanostructures[60]; (c) Schematic diagram of a three-layer (TL) system composed of cationic polyethylenimine (PEI), anionic montmorillonite (MMT) and anionic polyacrylic acid (PAA)[61]; (d) Schematic diagram of the formation process of a vermiculite (VMT)-PVA composite film with mechanical and gas barrier properties[62]

PEN—Polyethylene naphthalate; DI—Deionized DI; LLDPE—Linear low density polyethylene pellets

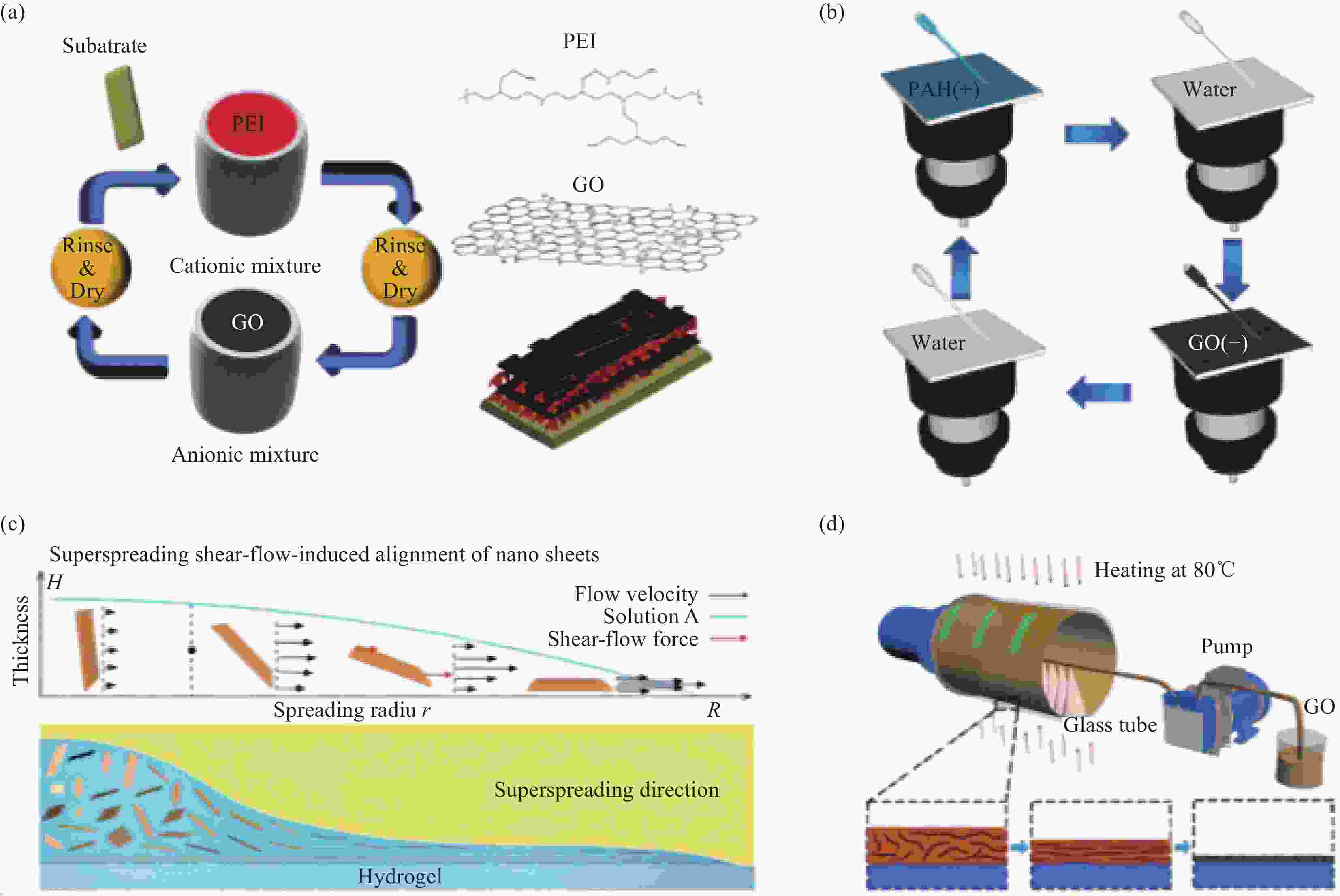

图 5 (a)逐层沉积工艺示意图[11];(b)使用GO片作为带负电荷的材料和聚丙烯胺盐酸盐(PAH)作为带正电荷的聚电解质的旋转逐层组装过程示意图[68];(c)理论研究(上)和原理图(下)的剪切流诱导纳米薄片在超铺展过程中的对准机制示意图[69];(d)连续离心铸造(CCC)示意图[70]

Figure 5. (a) Schematic diagram of layer-by-layer deposition process[11]; (b) Schematic diagram of rotational layer-by-layer assembly process using GO sheet as negatively charged material and polyacrylamine hydrochloride (PAH) as positively charged polyelectrolyte[68]; (c) Schematic diagram of the alignment mechanism of shear-flow-induced nanosheets during superspreading for theoretical study (top) and schematic diagram (bottom)[69]; (d) Schematic diagram of continuous centrifugal casting (CCC)[70]

H—Height of the droplet; R—Radius of the droplet

-

[1] 徐玲. 可生物降解塑料薄膜[J]. 塑料通讯, 1997(3): 15-16, 45.XU Ling. Biodegradable plastic film[J]. Plastics Communications, 1997(3): 15-16, 45(in Chinese). [2] 师岩, 李凤红, 姜天赐, 等. 可生物降解膜材料的研究进展[J]. 化工新型材料, 2020, 48(5): 16-19, 25.SHI Yan, LI Fenghong, JIANG Tianci, et al. Research progress on biodegradable membrane materials[J]. New Chemical Materials, 2020, 48(5): 16-19, 25(in Chinese). [3] COSQUER R, PRUVOST S, GOUANVÉ F. Improvement of barrier properties of biodegradable polybutylene succinate/graphene nanoplatelets nanocomposites prepared by melt process[J]. Membranes, 2021, 11(2): 151. doi: 10.3390/membranes11020151 [4] 常玲菲. 可生物降解材料在不同环境中降解机理的研究[D]. 镇江: 江苏科技大学, 2021.CHANG Lingfei. Study on the degradation mechanism of biodegradable materials in different environments[D]. Zhenjiang: Jiangsu University of Science and Technology, 2021(in Chinese). [5] 韩国程, 郭蕊, 俞朝晖. 淀粉基生物降解薄膜材料的研究进展[J]. 生物加工过程, 2019, 17(5): 460-465.HAN Guocheng, GUO Rui, YU Zhaohui. Research progress of starch-based biodegradable film materials[J]. Bioprocessing, 2019, 17(5): 460-465(in Chinese). [6] 杨小龙, 李永青, 闫晓堃, 等. 聚合物/石墨烯阻气型复合材料的研究进展[J]. 中国塑料, 2021, 35(12): 145-153.YANG Xiaolong, LI Yongqing, YAN Xiaokun, et al. Research progress of polymer/graphene gas barrier composites[J]. China Plastics, 2021, 35(12): 145-153(in Chinese). [7] 许鑫, 王斌, 崔波. 可生物降解改性淀粉基薄膜的特性及应用研究进展[J]. 食品工业科技, 2023, 44(15): 474-481.XU Xin, WANG Bin, CUI Bo. Research progress on characteristics and application of biodegradable modified starch-based films[J]. Science and Technology of Food Industry, 2023, 44(15): 474-481(in Chinese). [8] LIU P, JIN Z, KATSUKIS G, et al. Layered and scrolled nanocomposites with aligned semi-infinite graphene inclusions at the platelet limit[J]. Science, 2016, 353(6297): 364-367. doi: 10.1126/science.aaf4362 [9] 张玉德, 刘钦甫, 张乾, 等. 填料在聚合物中的气体阻隔贡献模型研究[J]. 中国非金属矿工业导刊, 2010(4): 21-25.ZHANG Yude, LIU Qinfu, ZHANG Qian, et al. Study on gas barrier contribution model of fillers in polymers[J]. China Non-metallic Minerals Industry Guide, 2010(4): 21-25(in Chinese). [10] DING F, LIU J, ZENG S, et al. Biomimetic nanocoatings with exceptional mechanical, barrier, and flame-retardant properties from large-scale one-step coassembly[J]. Science Advances, 2017, 3(7): e1701212. doi: 10.1126/sciadv.1701212 [11] YANG Y H, BOLLING L, PRIOLO M A, et al. Super gas barrier and selectivity of graphene oxide-polymer multilayer thin films[J]. Advanced Materials, 2013, 25(4): 503-508. doi: 10.1002/adma.201202951 [12] LI C, WANG B, SHANG Z, et al. High-barrier poly(butylene succinate-co-terephthalate) blend with poly(lactic acid) as biodegradable food packaging films[J]. Industrial & Engineering Chemistry Research, 2023, 62(18): 7250-7261. [13] 张振伟. 纳米技术在高分子材料改性中的应用及研究进展[J]. 中国石油和化工标准与质量, 2021, 41(18): 156-157. doi: 10.3969/j.issn.1673-4076.2021.18.076ZHANG Zhenwei. Application and research progress of nanotechnology in polymer material modification[J]. China Petroleum and Chemical Industry Standards and Quality, 2021, 41(18): 156-157(in Chinese). doi: 10.3969/j.issn.1673-4076.2021.18.076 [14] BARRER R M, KELSEY K E. Thermodynamics of interlamellar complexes. Part 1. Hydrocarbons in methylammonium montmorillonites[J]. Transactions of the Faraday Society, 1961, 57: 452-462. doi: 10.1039/TF9615700452 [15] KIM H, ABDALA A A, MACOSKO C W. Graphene/polymer nanocomposites[J]. Macromolecules, 2010, 43(16): 6515-6530. doi: 10.1021/ma100572e [16] CHOUDALAKIS G, GOTSIS A. Free volume and mass transport in polymer nanocomposites[J]. Current Opinion in Colloid & Interface Science, 2012, 17(3): 132-140. doi: 10.1016/J.COCIS.2012.01.004 [17] CUI Y, KUMAR S, RAO KONA B, et al. Gas barrier properties of polymer/clay nanocomposites[J]. RSC Advances, 2015, 5(78): 63669-63690. doi: 10.1039/c5ra10333a [18] CUI Y, KUNDALWAL S I, KUMAR S. Gas barrier performance of graphene/polymer nanocomposites[J]. Carbon, 2016, 98: 313-333. doi: 10.1016/j.carbon.2015.11.018 [19] JALALI DIL E, BEN DHIEB F, AJJI A. Modeling the effect of nanoplatelets orientation on gas permeability of polymer nanocomposites[J]. Polymer, 2019, 168: 126-130. doi: 10.1016/j.polymer.2019.02.024 [20] FALLA W R, MULSKI M, CUSSLER E L. Estimating diffusion through flake-filled membranes[J]. Journal of Membrane Science, 1996, 119(1): 129-138. doi: 10.1016/0376-7388(96)00106-8 [21] BRYDGES W T, GULATI S T, BAUM G. Permeability of glass ribbon-reinforced composites[J]. Journal of Materials Science, 1975, 10: 2044-2049. doi: 10.1016/0010-4361(76)90261-5 [22] FEREYDOON M, TABATABAEI S H, AJJI A. Properties of co-extruded nanoclay-filled aliphatic nylon (PA6)/linear low-density polyethylene and aromatic nylon (MXD6)/linear low-density polyethylene multilayer films[J]. Journal of Plastic Film & Sheeting, 2014, 31(1): 45-77. [23] RAJEEV R S, HARKIN-JONES E, SOON K, et al. A method to study the dispersion and orientation of nanoclay tactoids in PET matrix-focused ion beam milling combined with electron microscopy[J]. Materials Letters, 2008, 62(25): 4118-4120. doi: 10.1016/j.matlet.2008.06.012 [24] DUNKERLEY E, SCHMIDT D. Effects of composition, orientation and temperature on the O2 permeability of model polymer/clay nanocomposites[J]. Macromolecules, 2010, 43(24): 10536-10544. [25] IKHMAYIES S J. Characterization of nanomaterials[J]. JOM, 2013, 66: 28-29. [26] CHAVAN P, SINHMAR A, SHARMA S, et al. Nanocomposite starch films: A new approach for biodegradable packaging materials[J]. Starch, 2022, 74: 2100302. [27] KOH S J. Low-dimensional nanomaterials: Synthesis and application of zero- and one-dimensional nanomaterials[J]. JOM, 2010, 62(4): 34. doi: 10.1007/s11837-010-0056-0 [28] VAN OSS C J, GIESE R F. The hydrophilicity and hydrophobicity of clay minerals[J]. Clays and Clay Minerals, 1995, 43(4): 474-477. doi: 10.1346/CCMN.1995.0430411 [29] KHODAMANDN E, BARZEGAR H, JOKAR A, et al. Production and evaluation of physicochemical, mechanical and antimicrobial properties of Chia (Salvia hispanica L.) mucilage-gelatin based edible films incorporated with chitosan nanoparticles[J]. Journal of Food Measurement and Characterization, 2022, 16: 3547-3556. doi: 10.1007/s11694-022-01470-7 [30] SHANKAR S, WANG L F, RHIM J W. Incorporation of zinc oxide nanoparticles improved the mechanical, water vapor barrier, UV-light barrier, and antibacterial properties of PLA-based nanocomposite films[J]. Biomaterials Advances, 2018, 93: 289-298. [31] 潘静, 卞立春, 高明. 团聚参数对纳米复合材料性能的影响分析[C]//中国力学大会-2017暨庆祝中国力学学会成立60周年大会. 北京: 中国力学学会, 2017: 1-7.PAN Jing, BIAN Lichun, GAO Ming. Analysis of the influence of agglomeration parameters on the properties of nanocomposites[C]//Proceedings of the Chinese Mechanics Conference-2017 and the 60th Anniversary Celebration of the Chinese Society of Mechanics. Beijing: Chinese Society of Mechanics, 2017: 1-7(in Chinese). [32] AFRAMEHR W M, MOLKI B, HEIDARIAN P, et al. Effect of calcium carbonate nanoparticles on barrier properties and biodegradability of polylactic acid[J]. Fibers and Polymers, 2017, 18: 2041-2048. doi: 10.1007/s12221-017-6853-0 [33] GARNETT E, MAI L, YANG P. Introduction: 1D nanomaterials/nanowires[J]. Chemical Reviews, 2019, 119(15): 8955-9360. doi: 10.1021/acs.chemrev.9b00423 [34] TAGMATARCHIS N. Emerging trends in one- and two-dimensional nanomaterials[J]. Royal Society Open Science, 2020, 7(10): 201786. doi: 10.1098/rsos.201786 [35] 刑天豪. PET/埃洛石复合薄膜的阻隔性能研究[D]. 绵阳: 西南科技大学, 2015.XING Tianhao. Research on barrier properties of PET/halloysite composite film[D]. Mianyang: Southwest University of Science and Technology, 2015(in Chinese). [36] CHI H, LI W, FAN C, et al. Effect of high pressure treatment on poly(lactic acid)/nano-TiO2 composite films[J]. Molecules, 2018, 23(10): 2621. doi: 10.3390/molecules23102621 [37] WU Y, YUDIN V E, OTAIGBE J U, et al. Gas barrier behavior of polyimide films filled with synthetic chrysotile nanotubes[J]. Journal of Polymer Science, 2013, 51(15): 1184-1193. [38] KUMAR R, KUMARI S, RAI B, et al. Effect of nano-cellulosic fiber on mechanical and barrier properties of polylactic acid (PLA) green nanocomposite film[J]. Materials Research Express, 2019, 6(12): 125108. doi: 10.1088/2053-1591/ab5755 [39] GE F F, TSOU C H, YUAN S, et al. Barrier performance and biodegradability of antibacterial poly(butylene adipate-co-terephthalate) nanocomposites reinforced with a new MWCNT-ZnO nanomaterial[J]. Nanotechnology, 2021, 32(48): 485706. doi: 10.1088/1361-6528/ac1b52 [40] CHI H, XUE J, ZHANG C, et al. High pressure treatment for improving water vapour barrier properties of poly(lactic acid)/Ag nanocomposite films[J]. Polymers, 2019, 10(9): 1011. [41] BEN SHALOM T, BELSEY S, CHASNITSKY M, et al. Cellulose nanocrystals and corn zein oxygen and water vapor barrier biocomposite films[J]. Nanomaterials, 2021, 11(1): 245. doi: 10.3390/nano11010245 [42] SAMYKANO M. Progress in one-dimensional nanostructures[J]. Materials Characterization, 2021, 179: 111373. doi: 10.1016/j.matchar.2021.111373 [43] GUO Y T, YI S S. Recent advances in the preparation and application of two-dimensional nanomaterials[J]. Materials, 2023, 16(17): 5798. doi: 10.3390/ma16175798 [44] YING W, KHAN A, PENG X. Gas transport through two-dimensional nanoslits[J]. Materials Today Nano, 2020, 10: 100074. doi: 10.1016/j.mtnano.2020.100074 [45] ZHANG J, LEI W, SCHUTZ J, et al. Improving the gas barrier, mechanical and thermal properties of poly(vinyl alcohol) with molybdenum disulfide nanosheets[J]. Journal of Polymer Science, 2019, 57(7): 406-414. [46] AZEEM M, JAN R, FARRUKH S, et al. Improving gas barrier properties with boron nitride nanosheets in polymer-composites[J]. Results in Physics, 2019, 12: 1535-1541. doi: 10.1016/j.rinp.2019.01.057 [47] LI J, WANG S, LAI L, et al. Synergistic enhancement of gas barrier and aging resistance for biodegradable films with aligned graphene nanosheets[J]. Carbon, 2021, 12: 1535-1541. [48] LI Y, ZHANG L, LI F, et al. Fabrication and the barrier characterization of the cellulose nanofibers/organic montmorillonite/poly lactic acid nanocomposites[J]. Journal of Applied Polymer Science, 2021, 139(12): 51827. [49] SHI K, XU X, DONG S, et al. Stretchable gas barrier films achieved by hydrogen-bond self-assembly of nano-brick multilayers[J]. AIChE Journal, 2021, 67(10): e17373 doi: 10.1002/aic.17373 [50] MA Y T, YANG J N, WANG X L, et al. Preparation of high-density polyethylene/montmorillonite nanocomposites with high gas barrier by micro-nano torsional laminated extrusion[J]. Polymer Composites, 2023, 44(10): 6747-6757. doi: 10.1002/pc.27594 [51] GAO Y, PICOT O T, TU W, et al. Multilayer coextrusion of graphene polymer nanocomposites with enhanced structural organization and properties[J]. Journal of Applied Polymer Science, 2017, 15(13): 46041. [52] WANG J, PAN T, ZHANG J, et al. Hybrid films with excellent oxygen and water vapor barrier properties as efficient anticorrosive coatings[J]. RSC Advances, 2018, 8(38): 21651-21657. doi: 10.1039/C8RA03819H [53] KIM S J, KIM T Y, KANG B H, et al. Fabrication of graphene oxide/montmorillonite nanocomposite flexible thin films with improved gas-barrier properties[J]. RSC Advances, 2018, 8(68): 39083-39089. doi: 10.1039/C8RA08232D [54] MERRITT S M J, WEMYSS A M, FARRIS S, et al. Gas barrier polymer nanocomposite films prepared by graphene oxide encapsulated polystyrene microparticles[J]. ACS Applied Polymer Materials, 2020, 2(2): 725-731. doi: 10.1021/acsapm.9b01041 [55] SHI Z, GE Y, YUN Q, et al. Two-dimensional nanomaterial-templated composites[J]. Accounts of Chemical Research, 2022, 55(24): 3581-3593. doi: 10.1021/acs.accounts.2c00579 [56] 郭坤, 李伟杰, 王晓玲. 层层自组装聚合物材料的制备及应用[J]. 西南民族大学学报(自然科学版), 2020, 46(4): 341-348.GUO Kun, LI Weijie, WANG Xiaoling. Preparation and application of layer-by-layer self-assembled polymer materials[J]. Journal of Southwest Minzu University (Natural Science Edition), 2020, 46(4): 341-348(in Chinese). [57] 郭雪. 层层自组装复合膜的制备及其渗透汽化性能研究 [D]. 天津: 天津工业大学, 2019.GUO Xue. Preparation of layer-layer self-assembled composite membranes and their permeation vaporization properties[D]. Tianjin: Tianjin Polytechnic University, 2019(in Chinese). [58] 代学玉, 于娇娇, 汪永丽. 层层自组装法制备超疏水表面的研究进展[J]. 山东化工, 2020, 49(12): 44-45. doi: 10.3969/j.issn.1008-021X.2020.12.018DAI Xueyu, YU Jiaojiao, WANG Yongli. Research progress on preparation of superhydrophobic surfaces by layer-by-layer self-assembly[J]. Shandong Chemical Industry, 2020, 49(12): 44-45(in Chinese). doi: 10.3969/j.issn.1008-021X.2020.12.018 [59] XU X, LI Y, MA X, et al. Synergistic reinforcing effect of nano-montmorillonite and cellulose nanocrystals on poly (3-hydroxybutyrate-co-3-hydroxyhexanoate)[J]. Cellulose, 2020, 2(12): 1959. [60] MOTEDAYEN A A, REZAEIGOLESTANI M, GUILLAUME C, et al. Gas barrier enhancement of uncharged apolar polymeric films by self-assembling stratified nano-composite films[J]. RSC Advances, 2019, 9(19): 10938-10947. doi: 10.1039/C9RA01109A [61] HAGEN D A, BOX C, GREENLEE S, et al. High gas barrier imparted by similarly charged multilayers in nanobrick wall thin films†[J]. RSC Advances, 2014, 4(35): 18354-18359. doi: 10.1039/C4RA01621A [62] TIAN W, LI Z, GE Z, et al. Self-assembly of vermiculite-polymer composite films with improved mechanical and gas barrier properties[J]. Applied Clay Science, 2019, 180: 105198. doi: 10.1016/j.clay.2019.105198 [63] WANG L, DOU Y, WANG J, et al. Layer-by-layer assembly of layered double hydroxide/rubber multilayer films with excellent gas barrier property[J]. Composites Part A: Applied Science and Manufacturing, 2017, 102: 314-321. doi: 10.1016/j.compositesa.2017.07.014 [64] KANAI T, EGOSHI K, OHNO S, et al. The evaluation of stretchability and its applications for biaxially oriented polypropylene film[J]. Advances in Polymer Technology, 2017, 37(6): 2253-2260. [65] 刘文彬, 于敬海, 吴健生. 薄膜材料双轴拉伸试验[J]. 工程力学, 1998(2): 138-144.LIU Wenbin, YU Jinghai, WU Jiansheng. Biaxial tensile test of thin film materials[J]. Engineering Mechanics, 1998(2): 138-144(in Chinese). [66] WANG X, LI X, CUI L, et al. Improvement of gas barrier properties for biodegradable poly(butylene adipate-co-terephthalate) nanocomposites with MXene nanosheets via biaxial stretching[J]. Polymers, 2022, 14(3): 480. doi: 10.3390/polym14030480 [67] YAGER K G. Spontaneous assembly of hierarchical phases[J]. Nature Nanotechnology, 2023, 18: 223-224. doi: 10.1038/s41565-022-01294-y [68] LEE K H, HONG J, KWAK S J, et al. Spin self-assembly of highly ordered multilayers of graphene-oxide sheets for improving oxygen barrier performance of polyolefin films[J]. Carbon, 2015, 83: 40-47. doi: 10.1016/j.carbon.2014.11.025 [69] ZHAO C, ZHANG P, ZHOU J, et al. Layered nanocomposites by shear-flow-induced alignment of nanosheets[J]. Nature, 2020, 580: 210-215. doi: 10.1038/s41586-020-2161-8 [70] LUDWICZAK J, FRĄCKOWIAK S, LELUK K. Study of thermal, mechanical and barrier properties of biodegradable PLA/PBAT films with highly oriented MMT[J]. Materials, 2021, 14(23): 7189. doi: 10.3390/ma14237189 [71] ZHAO Y, LAI J Q, HUANG Y, et al. Effect of molding on the structure and properties of poly(butylene adipate-co-terephthalate)/poly(propylene carbonate)/organically modified montmorillonite nanocomposites[J]. Applied Clay Science, 2023, 234: 106854. doi: 10.1016/j.clay.2023.106854 [72] 步真松. PBAT基高阻隔仿生纳米复合全生物降解薄膜专用改性料[M]. 杭州: 杭州明日新材料科技有限公司, 2022: 11.BU Zhensong. Special modifier for PBAT-based high-barrier biomimetic nanocomposite fully biodegradable film[M]. Hangzhou: Hangzhou Tomorrow New Material Technology Co., Ltd., 2022: 11(in Chinese). -

下载:

下载: