Current status of interface modification of carbon fiber cement-based composite materials

-

摘要: 碳纤维增强水泥基复合材料(Carbon fiber reinforced cement composite,CFRCC)以其高强度质量比、耐腐蚀性和耐久性而通常用于建筑、基础设施和土木工程等领域。对CFRCC而言,界面是联系基体与增强相的桥梁,界面性能、结构直接关系到复合材料粘结强度,从而直接影响到复合材料的各项宏观性能。然而,碳纤维的疏水性及其与水性悬浮液之间不充分的结合行为,限制了碳纤维在水泥和其他矿物建筑材料中的应用。为了解决这一问题,学者们研究了物理和化学改性方法,以加强从矿物基质到碳纤维的负载转移。本文介绍了碳纤维、CFRCC及CFRCC界面的性能及存在的问题。总结了近些年国内外学者对CFRCC及其界面改性方法,例如氧化、电泳沉积、等离子体和接枝处理等表面改性方法,并讨论了相关机制分析。还介绍了碳纤维本身的特性及其与水泥基质的结合行为的表征方法。Abstract: Carbon fiber reinforced cement composite (CFRCC) is widely used in the fields of construction, infrastructure, and civil engineering due to its high strength-to-weight ratio, corrosion resistance, and durability. In the context of CFRCC, the interface plays a crucial role as it acts as a bridge connecting the matrix and the reinforcing phase. The performance and structure of the interface directly impact the bond strength of the composite material, thereby influencing its overall macroscopic properties. However, the inherent hydrophobic nature of carbon fibers and their inadequate bonding with aqueous suspensions limit their application in cement and other mineral building materials. To address this issue, researchers have explored physical and chemical modification methods to enhance the transfer of load from the mineral matrix to the carbon fibers. This paper provides an overview of the properties of carbon fibers, CFRCC, and CFRCC interfaces, while also summarizing recent studies by domestic and foreign scholars on CFRCC and its interface modification methods, such as oxidation, electrophoretic deposition, plasma, and grafting treatments, along with discussions on relevant mechanistic analyses. Additionally, it presents characterization methods for studying the properties of carbon fibers themselves and their bonding behavior with cementitious matrices.

-

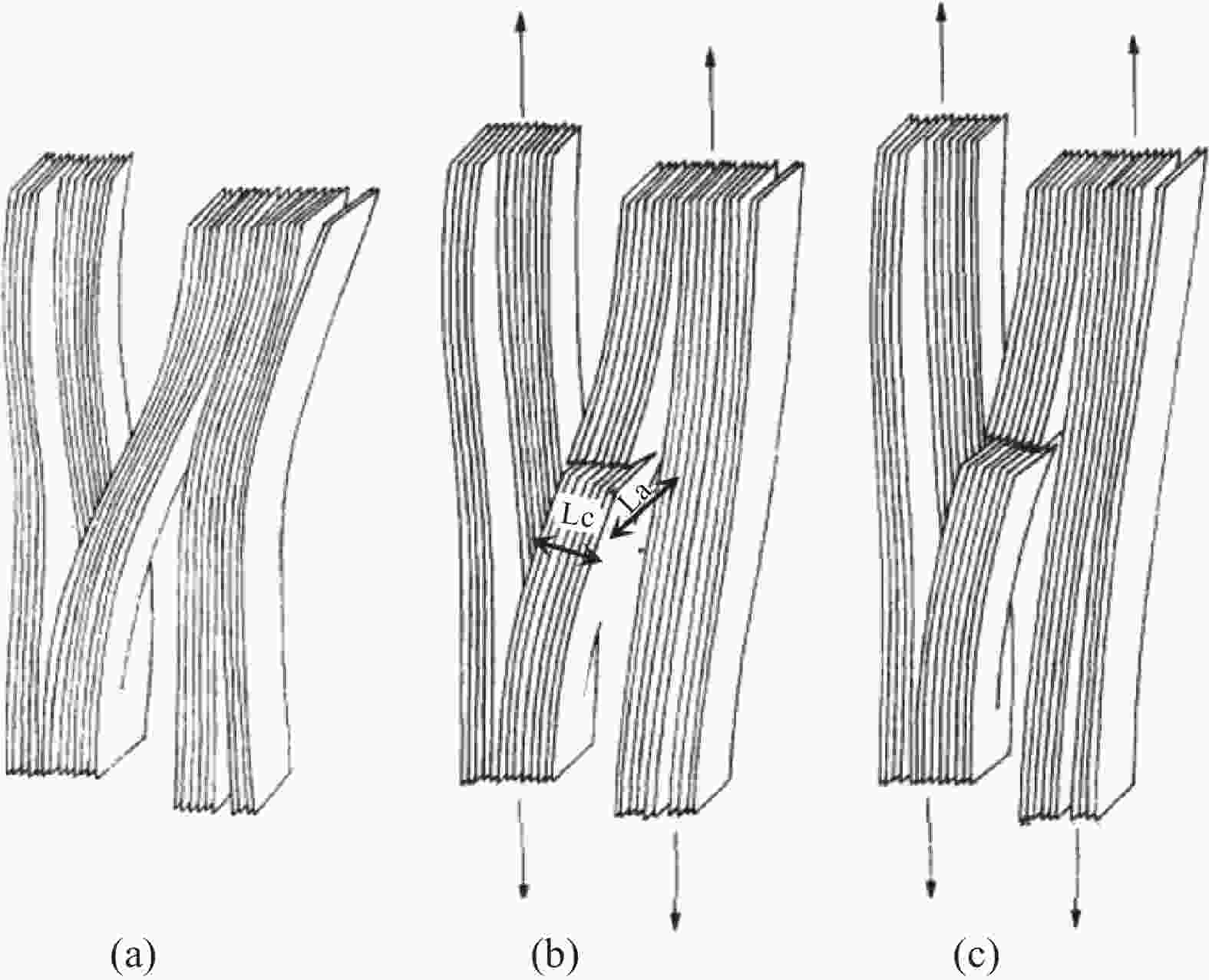

图 1 拉伸破坏机制:(a) 连接平行于纤维轴的两个晶粒的取向错误的晶粒;(b) 平行于纤维轴施加的拉伸应力导致基面在La方向上断裂,裂纹沿着La和Lc发展;(c) 应力的进一步施加导致取向不良的微晶完全失效[58]

Figure 1. Mechanism of tensile failure: (a) Misoriented crystallite linking two crystallites parallel to fibre axis; (b) Tensile stress exerted parallel to fibre axis causes basal plane rupture in direction La, crack develops along La and Lc; (c) Further exertion of stress causes complete failure of misoriented crytallite[58]

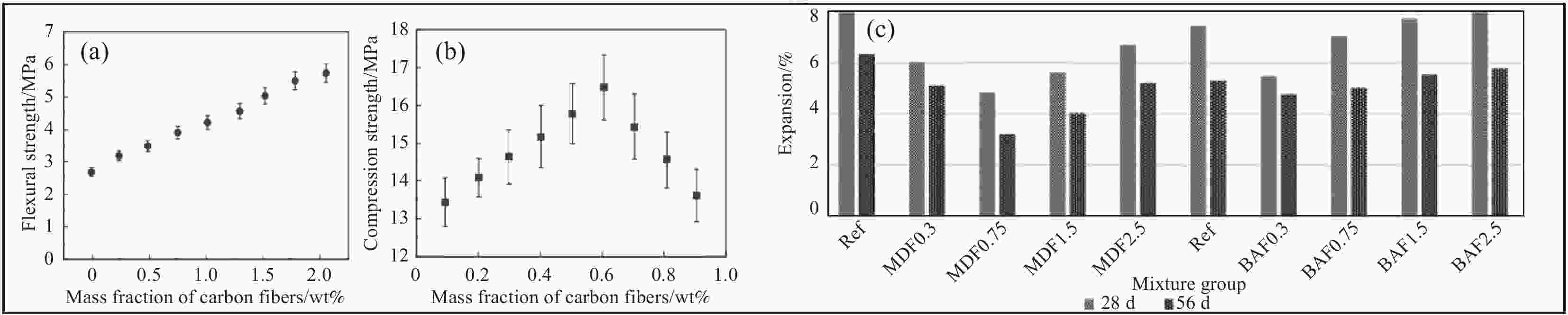

图 2 碳纤维增强水泥基复合材料(CFRCC)的力学性能:(a) CFRCC弯曲强度与碳纤维质量分数之间的关系[65];(b) CFRCC抗压强度与碳纤维质量分数之间的关系[65];(c) 碳纤维对大理石灰和底灰混合料固化28天和56天抗硫酸盐性能的影响[66]

Figure 2. Mechanical properties of carbon fiber reinforced cement composite (CFRCC): (a) Relationship between CFRCC flexural strength and carbon fiber mass fraction[65]; (b) Relationship between CFRCC compressive strength and carbon fiber mass fraction[65]; (c) Effect of carbon fiber on sulfate resistance for marble dust and bottom ash mixture groups at 28 days and 56 days of curing[66]

MD—Marble dust; BA—Bottom ash; F—Carbon fibers

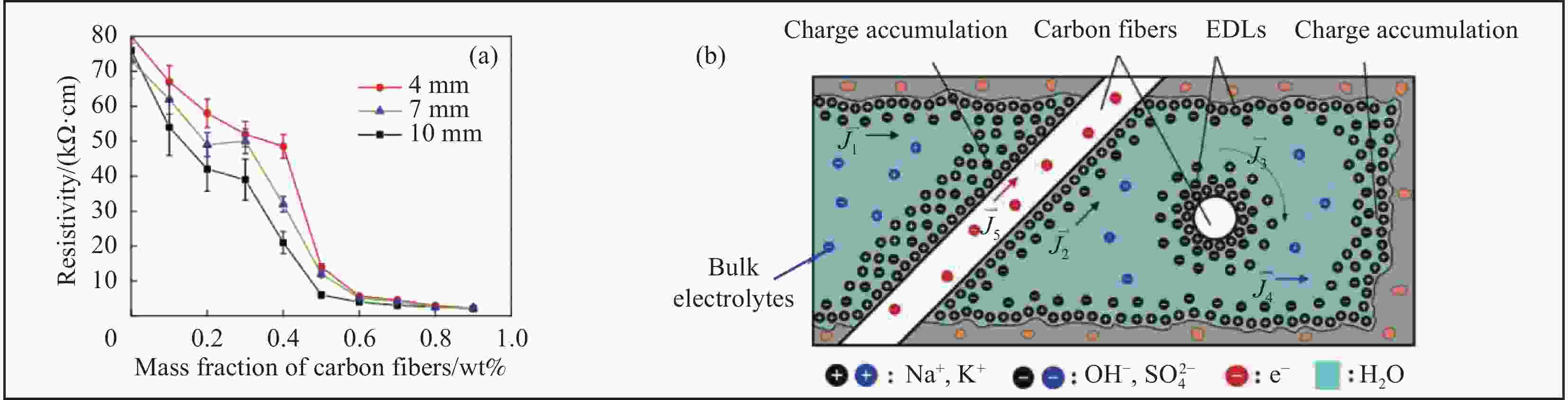

图 3 CFRCC的功能性:(a) 碳纤维混凝土的电阻率随碳纤维长度和含量的变化[65];(b) 水泥基传感器中理论传导路径的示意图[3]

Figure 3. Functionality of CFRCC: (a) Electrical resistivity of CFRCC varies with carbon fiber length and content[65]; (b) Schematic presentation of theoretical conduction pathways in a cement-based sensor[3]

EDLs—Electrical double layers; Schematic presentation of theoretical conduction pathways in a cement-based sensor. The insulative cement matrix and aggregates are represented by grey and orange areas, respectively: ${\overrightarrow J _1} $—Current density in the EDLs of cement-electrolyte interface; ${\overrightarrow J _2} $ and ${\overrightarrow J _3} $—Current densities in the EDLs of fibre-electrolyte interface; ${\overrightarrow J _4} $—Current density in bulk electrolyte; ${\overrightarrow J _5} $—Current density in or between fibre bodies. For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.

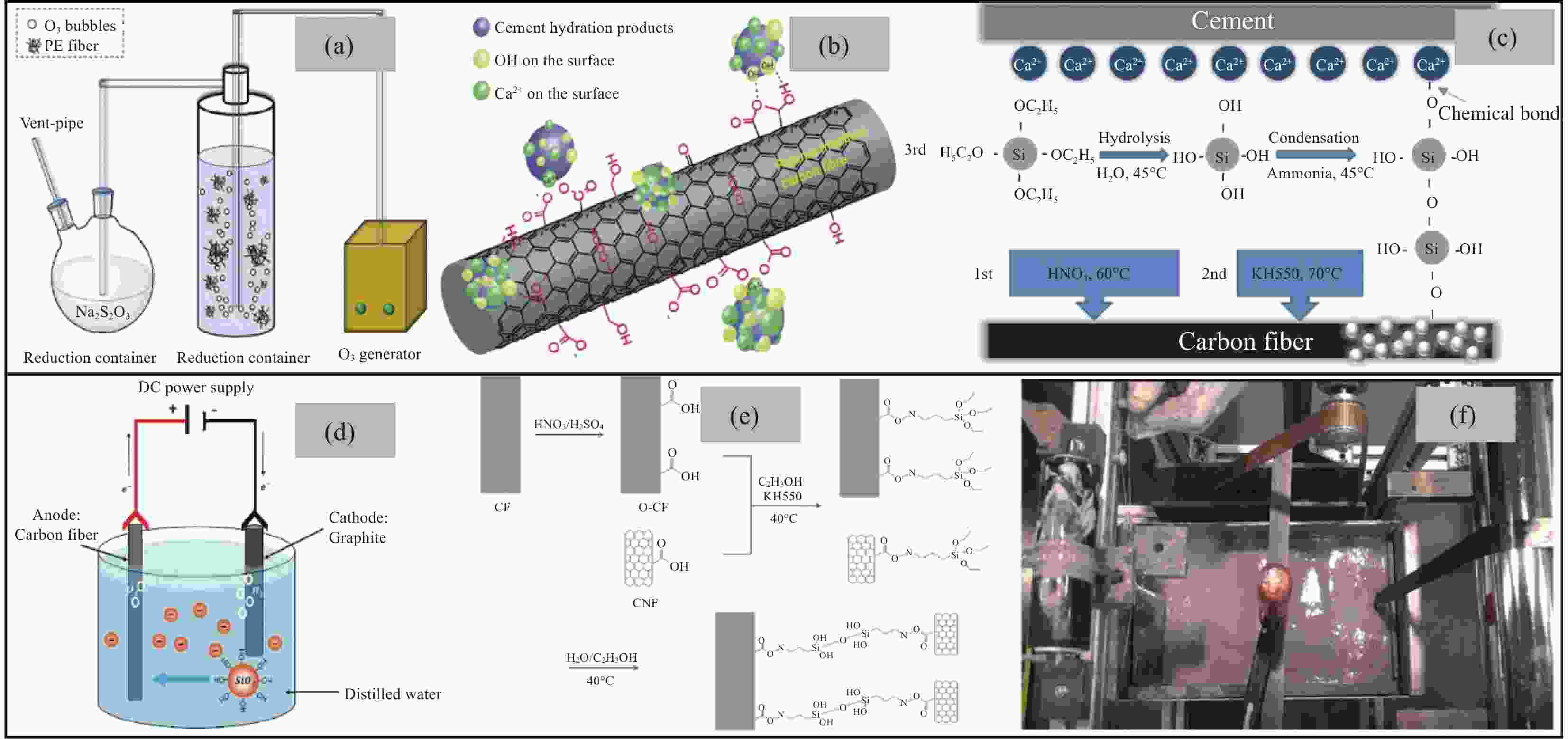

图 5 (a) 臭氧改性聚乙烯(PE)纤维示意图[86];(b) 等离子体氧化碳纤维的成键原理[87];(c) 涂层法改性碳纤维原理示意图[91];(d) 电化学沉积法改性碳纤维装置示意图[33];(e) 接枝法改性碳纤维原理示意图[81];(f) 浸渍碳纤维装置图[103]

Figure 5. (a) Ozone modified polyethylene (PE) fiber[86]; (b) Bonding principle of plasma oxidation of CF[87]; (c) Schematic diagram of the principle of coating method modified CF [91]; (d) Electrochemical deposition method modified CF device[33]; (e) Schematic diagram of grafting method for modifying CF[81];(f) Impregnation CF device[103]

DC—Direct current; O-CF—Oxidized carbon fiber; CNF—Carbon nanotube; KH550—γ-aminopropyltriethoxysilane (silane coupling agent KH550)

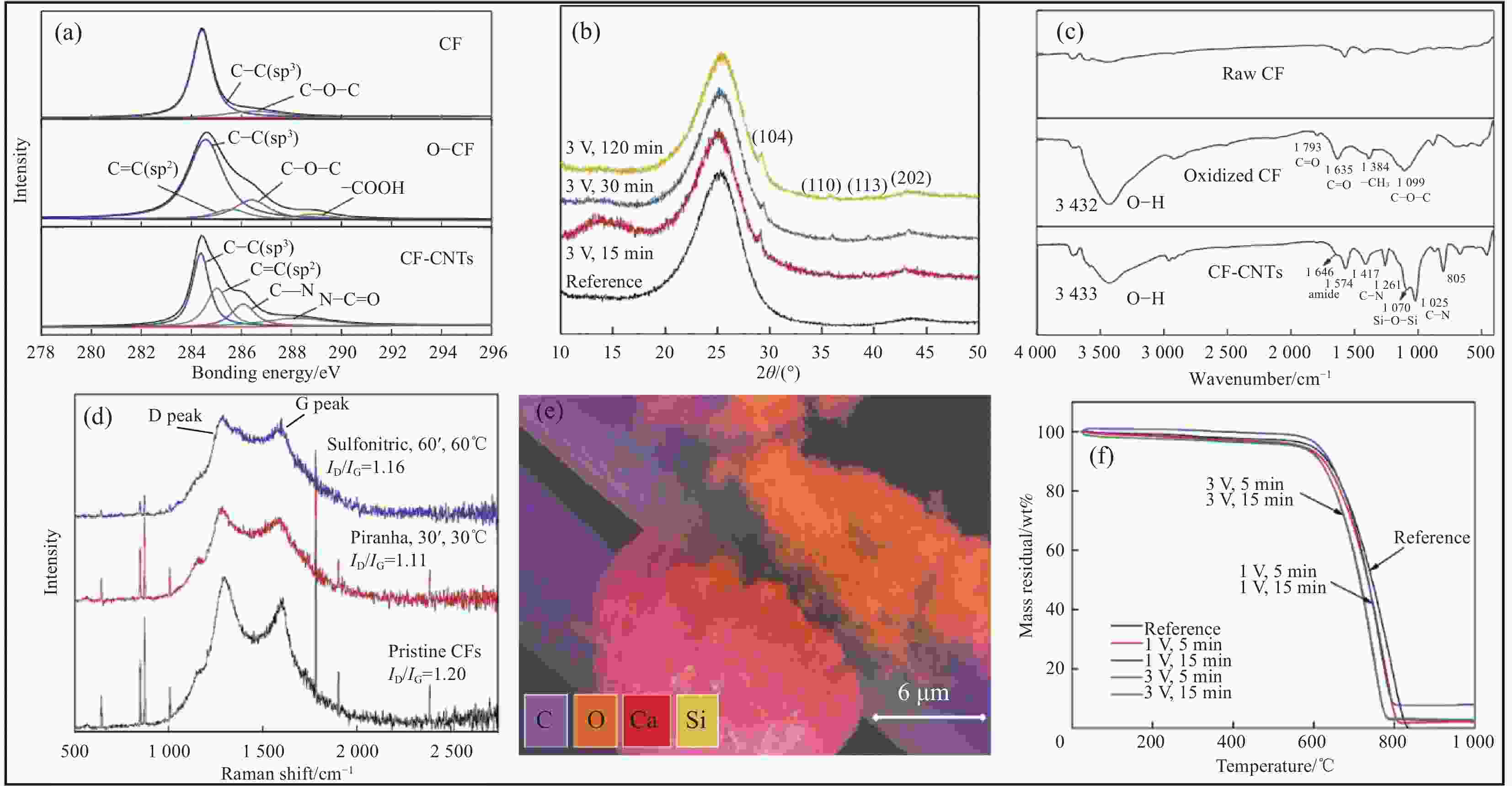

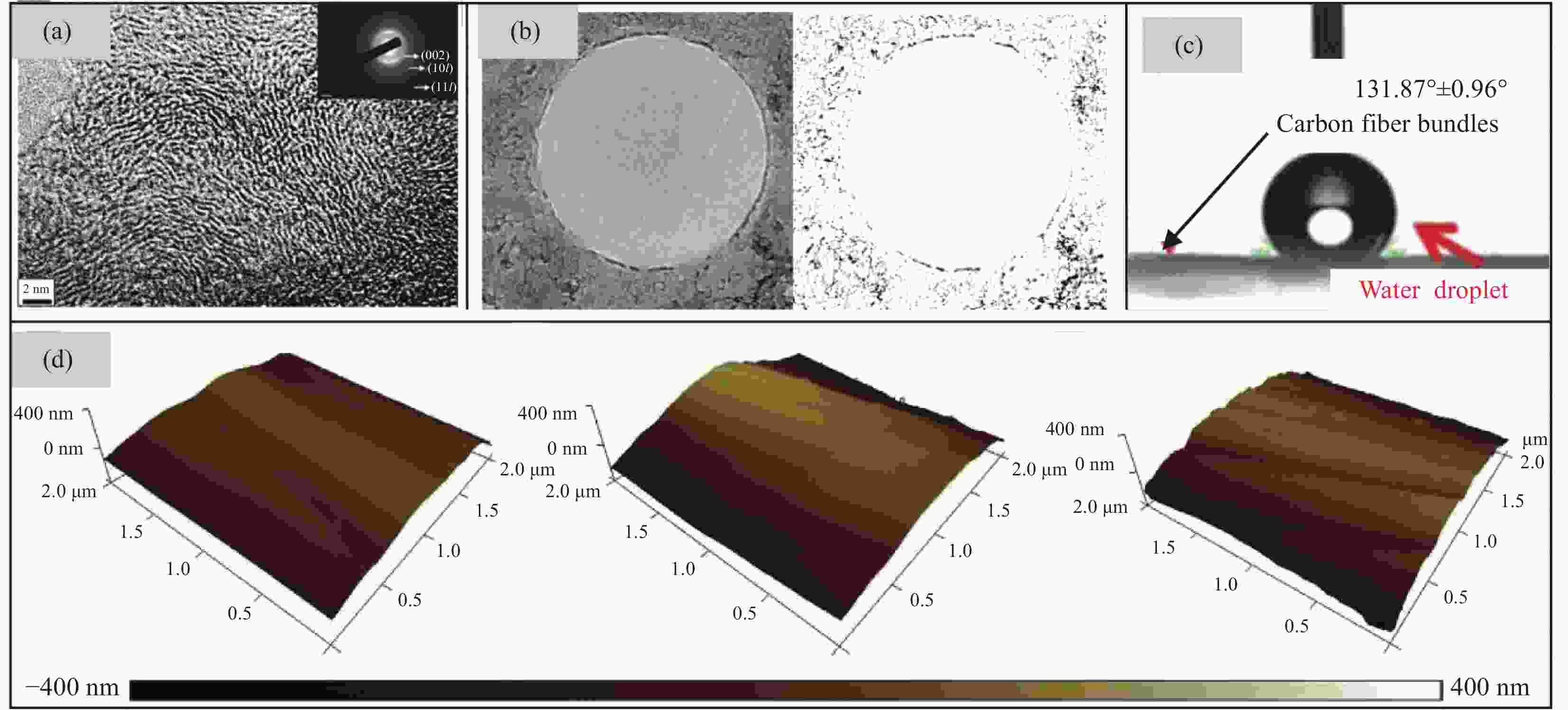

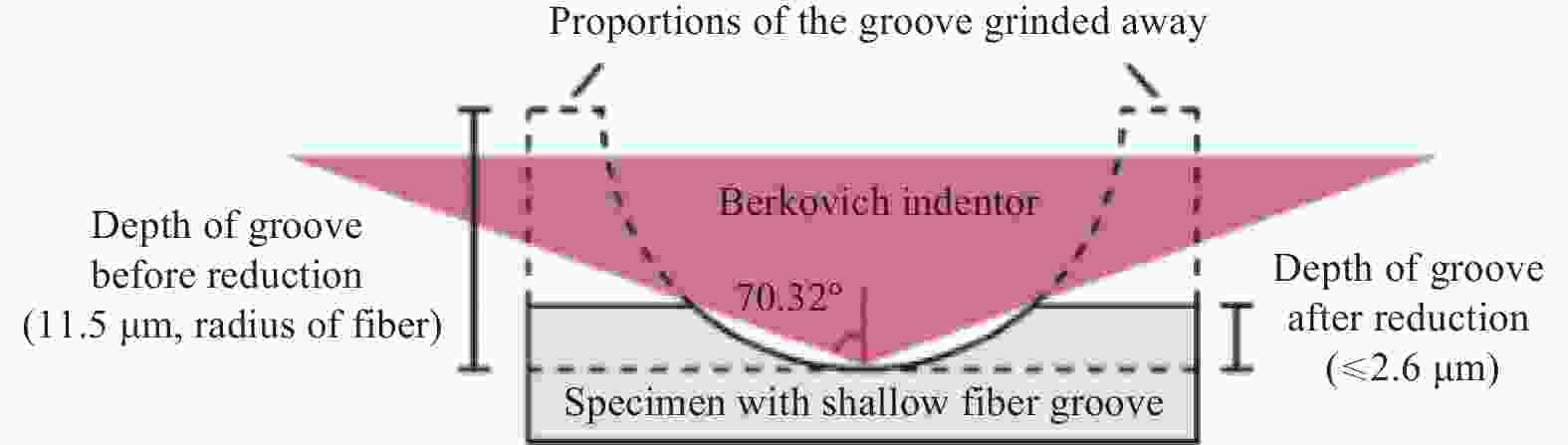

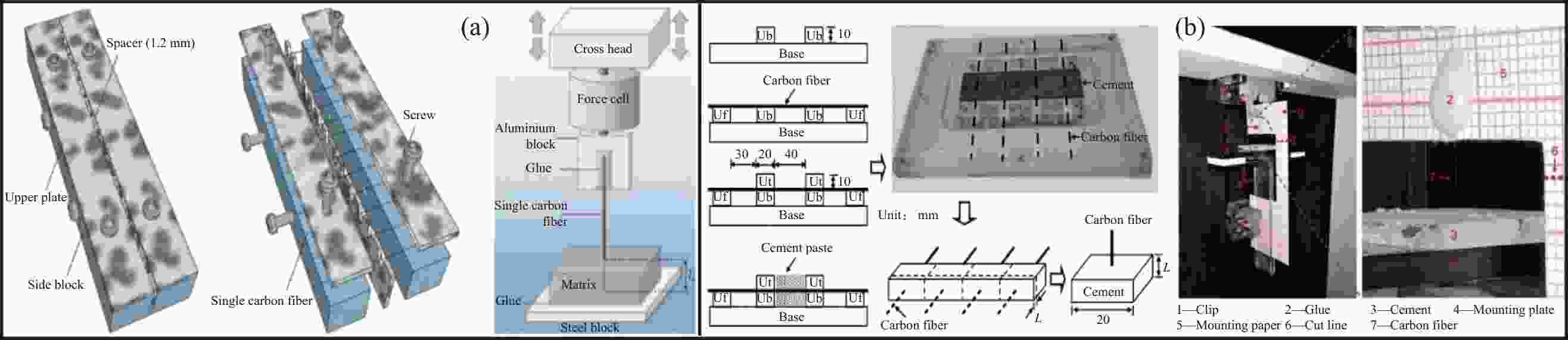

图 6 化学元素表征方法:(a) XPS[81];(b) XRD[114];(c) FTIR[81];(d) Raman[119];(e) EDX[33];(f) TGA[33]

Figure 6. Characterization method of chemical elements: (a) XPS[81]; (b) XRD[114]; (c) FTIR[81]; (d) Raman[119]; (e) EDX[33]; (f) TGA[33]

CNTs—Carbon nanotubes; ID/IG—Ratio of the intensities of the D and G peaks in Raman spectra, where the D peak represents defects in carbon atom crystals and the G peak represents the in-plane stretching vibrations of sp² hybridized carbon atoms; I refers to intensity.

表 1 碳纤维表面改性常用方法

Table 1. Common methods for surface modification of carbon fibers

Surface modification of carbon fiber Principle Characteristic Oxidation method Electrochemical

oxidationThe carbon fiber was electrified by electrochemical method, so that its surface was oxidized and functional groups were introduced to increase the surface active sites of the fiber Increase fiber surface active sites, but the equipment is complex and the cost is high Ozonation Ozone gas oxidizer was used to oxidize the fiber surface to increase the reactive groups on the fiber surface Oxidation time is short, reaction conditions are mild and easy to control, but ozone has certain toxicity Plasma oxidation Oxygen dissociates into oxygen atoms or ions to produce oxygen-containing free radicals, which etch the surface of the fiber and generate oxygen-containing functional groups at the fiber defects It is easy to expand, eco-friendly and efficient, but the equipment is complex and the cost is high Coating method Coating on carbon fiber surface by physical or chemical methods Protect the strength of fiber body, simple process, but limited durability Deposition method Under the chemical or electric drive, the groups in the electrolyte will move towards the electrode with opposite charge, so that the desired product is deposited on the surface of carbon fiber Less damage to the fiber body, functional groups can be deposited, but the preparation efficiency is low, and the process parameters need to be optimized Grafting method The introduction of polymer chains or active functional groups such as hydroxyl, carboxyl and amino groups on the surface of carbon fibers through chemical reactions It has strong controllability and can realize multifunctional modification, but the process is complex and some organic solvents used are not friendly to the environment Impregnation method By immersing the fiber in a solution containing mineral components, the mineral components penetrate into the fiber, thereby improving the performance of the fiber The mineral composition usually used is environment-friendly, low cost and relatively simple process, but it may damage the fiber 表 2 界面性能表征常用方法

Table 2. Common methods for evaluating interface performance

Characterization methods Method type Advantage Disadvantage XPS Elemental

characterizationProvides chemical composition and chemical state information of material surfaces Requires analysis under vacuum conditions and high surface requirements for samples XRD Elemental

characterizationProvides crystal structure information, beneficial for the analysis of crystalline materials Unable to provide material chemical composition information, weak in analyzing amorphous materials FTIR Elemental

characterizationProvides molecular structure and chemical bond information of materials, suitable for organic and polymer analysis Weak in analyzing inorganic crystalline materials Raman spectroscopy Elemental

characterizationProvides molecular structure and crystal structure information of materials, suitable for non-destructive analysis Weak signal intensity, weak in surface analysis of materials EDX Elemental

characterizationProvides material element composition and distribution information, suitable for micro-area analysis Relatively low resolution, weak in analyzing light elements TGA Elemental

characterizationProvides material thermal stability and thermal decomposition information Unable to provide material structural information, weak in analyzing non-thermally decomposing materials SEM Surface morphology characterization Provides material surface morphology and microstructure information Unable to provide material chemical composition and crystal structure information TEM Surface morphology characterization Provides material microstructure and crystal structure information, particularly suitable for nano-scale material analysis Requires complex sample preparation and operation techniques, high sample requirements Electron backscatter diffraction (EBSD) Surface morphology characterization Provides material crystal structure and grain orientation information Requires complex sample preparation and operation techniques, high sample requirements AFM Surface morphology characterization Provides material surface morphology, roughness, and other surface property information Only provides surface property information, weak in analyzing other properties Contact angle measurement Polarity characterization Provides material surface hydrophilicity and hydrophobicity information Only provides polarity performance information, weak in analyzing other properties Nanoindentation (NI) Mechanical testing Provides material hardness and elastic modulus information Requires complex sample preparation and operation techniques, high sample requirements Micro-droplet detachment test Mechanical testing Mechanical testing provides material surface adhesion information Requires complex sample preparation and operation techniques, high sample requirements Fiber tensile

testingMechanical testing Provides material tensile mechanical properties High variability, requires a large number of repeated tests Fiber pullout testing Mechanical testing Mechanical testing provides material interfacial mechanical properties Requires complex sample preparation and operation techniques, high requirements for samples and testing equipment -

[1] LIU X, WANG G, YU J, et al. Stress-sensitivity of carbon nanotube-grafted-carbon fiber incorporated cement-based composites[J]. Journal of Building Engineering, 2023, 64: 105589. doi: 10.1016/j.jobe.2022.105589 [2] KANG Z, ASLANI F, HAN B. Prediction of mechanical and electrical properties of carbon fibre-reinforced self-sensing cementitious composites[J]. Case Studies in Construction Materials, 2024, 20: e02716. [3] ZHANG J, HEATH A, ABDALGADIR H M T, et al. Electrical impedance behaviour of carbon fibre reinforced cement-based sensors at different moisture contents[J]. Construction and Building Materials, 2022, 353: 129049. doi: 10.1016/j.conbuildmat.2022.129049 [4] TAFESSE M, ALEMU A S, LEE H K, et al. Effect of chloride penetration on electrical resistivity of CNT-CF/cement composites and its application as chloride sensor for reinforced mortar[J]. Cement and Concrete Composites, 2022, 133: 104662. doi: 10.1016/j.cemconcomp.2022.104662 [5] GALAO O, BANON L, BAEZA F, et al. Highly conductive carbon fiber reinforced concrete for icing prevention and curing[J]. Materials, 2016, 9(4): 281. doi: 10.3390/ma9040281 [6] MUTHUSAMY S, CHUNG D D L. Carbon-fiber cement-based materials for electromagnetic shielding[J]. ACI Materials Journal, 2010, 107(6): 602-610. [7] NASER M Z, HAWILEH R A, ABDALLA J A. Fiber-reinforced polymer composites in strengthening reinforced concrete structures: A critical review[J]. Engineering Structures, 2019, 198: 109542. doi: 10.1016/j.engstruct.2019.109542 [8] LI H, LIEBSCHER M, ZHAO D, et al. A review of carbon fiber surface modification methods for tailor-made bond behavior with cementitious matrices[J]. Progress in Materials Science, 2023, 132: 101040. doi: 10.1016/j.pmatsci.2022.101040 [9] YANG E H, WANG S, YANG Y, et al. Fiber-bridging constitutive law of engineered cementitious composites[J]. Journal of Advanced Concrete Technology, 2008, 6(1): 181-193. doi: 10.3151/jact.6.181 [10] LIN C, KANSTAD T, JACOBSEN S, et al. Bonding property between fiber and cementitious matrix: A critical review[J]. Construction and Building Materials, 2023, 378: 131169. doi: 10.1016/j.conbuildmat.2023.131169 [11] HAN B, ZHANG L, ZHANG C, et al. Reinforcement effect and mechanism of carbon fibers to mechanical and electrically conductive properties of cement-based materials[J]. Construction and Building Materials, 2016, 125: 479-489. doi: 10.1016/j.conbuildmat.2016.08.063 [12] PELED A, ZAGURI E, MAROM G. Bonding characteristics of multifilament polymer yarns and cement matrices[J]. Composites Part A: Applied Science and Manufacturing, 2008, 39(6): 930-939. doi: 10.1016/j.compositesa.2008.03.012 [13] REN G, WANG J, WEN X, et al. Using sol-gel deposition of nanosilica to enhance interface bonding between sisal fiber and ultra-high performance concrete[J]. Cement and Concrete Composites, 2022, 133: 104705. doi: 10.1016/j.cemconcomp.2022.104705 [14] 张旺玺. 聚丙烯腈基碳纤维[M]. 上海: 东华大学出版社, 2005: 163.ZHANG Wangxi. Polyacrylonitrile based carbon fiber[M]. Shanghai: Donghua University Press, 2005: 163(in Chinese). [15] 谭婷婷. 高性能PAN基碳纤维微观结构与力学性能相关性研究[D]. 济南: 山东大学, 2013.TAN Tingting. Relationship between microstructure and mechanical properties of high-performance PAN based carbon fibers[D]. Jinan: Shandong University, 2013(in Chinese). [16] BENNETT S, JOHNSON D. Structural heterogeneity in carbon fibers[C]//Proceedings of the Fifth London International Carbon and Graphite Conference. London: Society of Chemical Industry, 1978: 377. [17] 徐樑华, 曹维宇, 胡良全. 聚丙烯腈基碳纤维[M]. 北京: 国防工业出版社, 2018: 1.XU Lianghua, CAO Weiyu, HU Liangquan. Polyacrylonitrile based carbon fiber[M]. Beijing: National Defense Industry Press, 2018: 1(in Chinese). [18] 李伟伟, 康宏亮, 徐坚, 等. 高强高模型碳纤维与高模型碳纤维微观结构分析[J]. 高分子学报, 2018(3): 380-388.LI Weiwei, KANG Hongliang, XU Jian, et al. Microstructure analysis of high-strength and high model carbon fibers and high model carbon fibers[J]. Acta Polymerica Sinica, 2018(3): 380-388(in Chinese). [19] 张婧, 陈虹, 于今, 等. PAN基碳纤维原丝纺丝技术及其发展现状[J]. 高科技纤维与应用, 2013, 38(6): 46-48, 54.ZHANG Jing, CHEN Hong, YU Jin, et al. PAN based carbon fiber precursor spinning technology and its development status[J]. Hi-Tech Fiber and Application, 2013, 38(6): 46-48, 54(in Chinese). [20] FU X L, LU W M, CHUNG D D L. Improving the tensile properties of carbon fiber reinforced cement by ozone treatment of the fiber[J]. Cement and Concrete Research, 1996, 26(10): 1485-1488. doi: 10.1016/0008-8846(96)00141-X [21] XU X F, HU Y Y. The properties of oxidated carbon fibers reinforced cement[J]. Advanced Materials Research, 2011, 163-167: 1203-1206. [22] LI J. Interfacial studies on the O3 modified carbon fiber-reinforced polyamide 6 composites[J]. Applied Surface Science, 2008, 255(5): 2822-2824. doi: 10.1016/j.apsusc.2008.08.013 [23] FINEGAN I C, TIBBETTS G G, GLASGOW D G, et al. Surface treatments for improving the mechanical properties of carbon nanofiber/thermoplastic composites[J]. Journal of Materials Science, 2003, 38: 3485-3490. doi: 10.1023/A:1025109103511 [24] 张承双. 氧气等离子体改性对PBO纤维表面及PBO/PPESK复合材料界面的影响[D]. 大连: 大连理工大学, 2009.ZHANG Chengshuang. Effect of oxygen plasma modification on surface properties of PBO fibers and interface of PBO/PPESK composites[D]. Dalian: Dalian University of Technology, 2009(in Chinese). [25] 刘哲. 等离子体处理对PBO纤维、碳纤维表面性能及其复合材料界面性能的影响[D]. 大连: 大连理工大学, 2014.LIU Zhe. Effect of plasma treatment on surface properties of PBO fibers, carbon fibers, and interface properties of composite materials[D]. Dalian: Dalian University of Technology, 2014(in Chinese). [26] 韩德滨. 常压空气DBD等离子体对PBO纤维及PBO/PPESK复合材料界面性能的影响[D]. 大连: 大连理工大学, 2023.HAN Debin. Effect of atmospheric air DBD plasma on the interfacial properties of PBO fibers and PBO/PPESK composites[D]. Dalian: Dalian University of Technology, 2023(in Chinese). [27] CHEN J H, WEI G, MAEKAWA Y, et al. Grafting of poly (ethylene-block-ethylene oxide) onto a vapor grown carbon fiber surface by γ-ray radiation grafting[J]. Polymer, 2003, 44(11): 3201-3207. doi: 10.1016/S0032-3861(03)00274-X [28] LI J Q, HUANG Y D, FU S Y, et al. Study on the surface performance of carbon fibres irradiatedby γ-ray under different irradiation dose[J]. Applied Surface Science, 2010, 256(7): 2000-2004. doi: 10.1016/j.apsusc.2009.09.035 [29] TIWARI S, BIJWE J, PANIER S. Gamma radiation treatment of carbon fabric to improve the fiber-matrix adhesion and tribo-performance of composites[J]. Wear, 2011, 271(9-10): 2184-2192. doi: 10.1016/j.wear.2010.11.032 [30] LEE H S, KIM S Y, NOH Y J, et al. Design of microwave plasma and enhanced mechanical properties of thermoplastic composites reinforced with microwave plasma-treated carbon fiber fabric[J]. Composites Part B: Engineering, 2014, 60: 621-626. doi: 10.1016/j.compositesb.2013.12.064 [31] DILSIZ N, ERINC N K, BAYRAMLI E. Surface energy and mechanical properties of plasma modified carbon fibers[J]. Carbon, 1995, 33(6): 853-858. doi: 10.1016/0008-6223(94)00181-X [32] WANG S, WANG X, HE J, et al. Mechanical behavior and microstructure of graphene oxide electrodeposited carbon fiber reinforced cement-based materials[J]. Crystals, 2022, 12(7): 964. doi: 10.3390/cryst12070964 [33] LI H, LIEBSCHER M, CUROSU I, et al. Electrophoretic deposition of nano-silica onto carbon fiber surfaces for an improved bond strength with cementitious matrices[J]. Cement and Concrete Composites, 2020, 114: 103777. doi: 10.1016/j.cemconcomp.2020.103777 [34] LU Z, HANIF A, SUN G, et al. Highly dispersed graphene oxide electrodeposited carbon fiber reinforced cement-based materials with enhanced mechanical properties[J]. Cement and Concrete Composites, 2018, 87: 220-228. doi: 10.1016/j.cemconcomp.2018.01.006 [35] IROH J O, YUAN W. Surface properties of carbon fibres modified by electrodeposition of polyamic acid[J]. Polymer, 1996, 37(18): 4197-4203. doi: 10.1016/0032-3861(96)00266-2 [36] 李启金, 李国忠. 聚丙烯纤维化学接枝改性增强水泥基复合材料的界面结合[J]. 复合材料学报, 2013, 30(4): 238-244.LI Qijin, LI Guozhong. Surface modification of polypropylene fibers chemical grafted methods to reinforce the interfacial bonding of cement-based composites[J]. Acta Materiae Compositae Sinica, 2013, 30(4): 238-244(in Chinese). [37] 林国良, 郑玉婴. 碳纤维化学接枝甲基丙烯酸甲酯的研究[J]. 表面技术, 2015, 44(2): 83-86, 104.LIN Guoliang, ZHENG Yuying. Study on chemical grafting of methyl methacrylate on carbon fiber[J]. Surface Technology, 2015, 44(2): 83-86, 104(in Chinese). [38] ZHANG T, XU Y, LI H, et al. Interfacial adhesion between carbon fibers and nylon 6: Effect of fiber surface chemistry and grafting of nano-SiO2[J]. Composites Part A: Applied Science and Manufacturing, 2019, 121: 157-168. doi: 10.1016/j.compositesa.2019.03.029 [39] LUO L, FEI J, DUAN X, et al. Chemically grafting APS onto MnO2 nanosheets as a new interphase for improving interfacial properties in carbon fiber composites[J]. Tribology International, 2019, 134: 145-153. doi: 10.1016/j.triboint.2019.01.044 [40] LAVAGNA L, MASSELLA D, PAVESE M. Preparation of hierarchical material by chemical grafting of carbon nanotubes onto carbon fibers[J]. Diamond and Related Materials, 2017, 80: 118-124. doi: 10.1016/j.diamond.2017.10.013 [41] GAO B, ZHANG J, HAO Z, et al. In-situ modification of carbon fibers with hyperbranched polyglycerol via anionic ring-opening polymerization for use in high-performance composites[J]. Carbon, 2017, 123: 548-557. doi: 10.1016/j.carbon.2017.08.008 [42] GERZESKI H R, SPRAGUE A, HU J J, et al. Growth of contiguous graphite fins from thermally conductive graphite fibers[J]. Carbon, 2014, 69: 424-436. doi: 10.1016/j.carbon.2013.12.045 [43] LYU P, FENG Y Y, ZHANG P, et al. Increasing the interfacial strength in carbon fiber/epoxy composites by controlling the orientation and length of carbon nanotubes grown on the fibers[J]. Carbon, 2011, 49: 4665-4673. doi: 10.1016/j.carbon.2011.06.064 [44] 关蓉波, 杨永岗, 郑经堂, 等. 上浆剂对 CF/EP 界面粘结的影响[J]. 纤维复合材料, 2002, 23(1): 23-26.GUAN Rongbo, YANG Yonggang, ZHENG Jingtang, et al. The effect of sizing agents on CF/EP interface bonding[J]. Fiber Composites, 2002, 23(1): 23-26(in Chinese). [45] LI S X, YANG C L, YAO L L, et al. Use a polyurethane sizing agent to improve the interfacial properties of carbon fiber-reinforced polyurethane composites[J]. New Carbon Materials, 2023, 38(2): 385-390. doi: 10.1016/S1872-5805(23)60705-X [46] MECHTCHERINE V, MICHEL A, LIEBSCHER M, et al. Mineral-impregnated carbon fiber composites as novel reinforcement for concrete construction: Material and automation perspectives[J]. Automation in Construction, 2020, 110: 103002. [47] HOMORO O, MICHEL M, BARANGER T N. Pull-out response of glass yarn from ettringite matrix: Effect of pre-impregnation and embedded length[J]. Composites Science and Technology, 2019, 170: 174-182. doi: 10.1016/j.compscitech.2018.11.045 [48] SCHNEIDER K, MICHEL A, LIEBSCHER M, et al. Mineral-impregnated carbon fibre reinforcement for high temperature resistance of thin-walled concrete structures[J]. Cement and Concrete Composites, 2019, 97: 68-77. [49] DONNINI J, LANCIONI G, CORINALDESI V. Failure modes in FRCM systems with dry and pre-impregnated carbon yarns: Experiments and modeling[J]. Composites Part B: Engineering, 2018, 140: 57-67. doi: 10.1016/j.compositesb.2017.12.024 [50] DONNINI J, CORINALDESI V. Mechanical characterization of different FRCM systems for structural reinforcement[J]. Construction and Building Materials, 2017, 145: 565-575. doi: 10.1016/j.conbuildmat.2017.04.051 [51] NADIV R, PELED A, MECHTCHERINE V, et al. Micro- and nanoparticle mineral coating for enhanced properties of carbon multifilament yarn cement-based composites[J]. Composites Part B: Engineering, 2017, 111: 179-189. doi: 10.1016/j.compositesb.2016.12.005 [52] LI D, LU C, WANG L, et al. A reconsideration of the relationship between structural features and mechanical properties of carbon fibers[J]. Materials Science and Engineering, 2017, 685: 65-70. [53] LI Z R, WANG J B, TONG Y J, et al. Anodic oxidation on structural evolution and tensile properties of polyacrylonitrile based carbon fibers with different surface morphology[J]. Journal of Materials Science & Technology, 2012, 28(12): 1123-1129. [54] QIN X Y, LU Y G, XIAO H, et al. A comparison of the effect of graphitization on microstructure and properties of polyacrylonitrile and mesophase pitch-based carbon fiber[J]. Carbon, 2012, 50: 4459-4469. doi: 10.1016/j.carbon.2012.05.024 [55] YAO L B, YANG W M, LI S Y, et al. Graphitization of PAN-based carbon fibers by CO2 laser irradiation[J]. Carbon Letters, 2017, 24(1): 97-102. [56] BALDAN A. Adhesively-bonded joints and repairs in metallic alloys, polymers and composite materials: Adhesives, adhesion theories and surface pretreatment[J]. Journal of Maters Science, 2004, 39(1): 1-49. doi: 10.1023/B:JMSC.0000007726.58758.e4 [57] GRIFFITH A A. The phenomena of rupture and flow in solids[J]. Philosophical Transactions of the Royal Society of London. Series A, Containing Papers of a Mathematical or Physical Character, 1921, 221: 163-198. [58] BENNETT S, JOHNSON D, JOHNSON W. Strength-structure relationships in PAN-based carbon fibres[J]. Journal of Materials Science, 1983, 18: 3337-3347. [59] BENNETT S, JOHNSON D. Electron-microscope studies of structural heterogeneity in PAN-based carbon fibres[J]. Carbon, 1979, 17: 25-39. [60] JOHNSON D. Structure-property relationships in carbon fibres[J]. Journal of Physics D: Applied Physics, 1987, 20: 286. [61] CHEN M, GAO P, GENG F, et al. Mechanical and smart properties of carbon fiber and graphite conductive concrete for internal damage monitoring of structure[J]. Construction & Building Materials, 2017, 142: 320-327. [62] 陈宇良, 李堂, 姜锐, 等. 碳纤维再生混凝土复合受剪力学性能试验[J]. 复合材料学报, 2023, 40(7): 4107-4116.CHEN Yuliang, LI Tang, JIANG Rui, et al. Composite shear mechanical properties of carbon fiber recycled aggregate concrete[J]. Acta Materiae Compositae Sinica, 2023, 40(7): 4107-4116(in Chinese). [63] 曹雅娴, 侯慧芳, 刘曙光, 等. PVA纤维混凝土力学性能增长规律研究[J]. 混凝土与水泥制品, 2021(5): 56-59.CAO Yaxian, HOU Huifang, LIU Shuguang, et al. Study on the growth law of mechanical properties of PVA fiber concrete[J]. China Concrete and Cement Products, 2021(5): 56-59(in Chinese). [64] 肖良丽, 陈宇标, 刘彦, 等. 玻璃纤维增强塑料筋混杂纤维混凝土梁抗弯性能研究[J]. 武汉科技大学学报, 2021, 44(4): 295-303.XIAO Liangli, CHEN Yubiao, LIU Yan, et al. Flexural performance of concrete beams reinforced with GFRP bars and hybrid fibers[J]. Journal of Wuhan University of Science and Technology, 2021, 44(4): 295-303(in Chinese). [65] WANG C, JIAO G S, LI B L, et al. Dispersion of carbon fibers and conductivity of carbon fiber-reinforced cement-based composites[J]. Ceramics International, 2017, 43(17): 15122-15132. doi: 10.1016/j.ceramint.2017.08.041 [66] ATIYEH M, AYDIN E. Carbon-fiber enriched cement-based composites for better sustainability[J]. Materials, 2020, 13(8): 1899. doi: 10.3390/ma13081899 [67] BELLI A, MOBILI A, BELLEZZE T, et al. Commercial and recycled carbon-based fillers and fibers for self-sensing cement-based composites: Comparison of mechanical strength, durability, and piezoresistive behavior[J]. Journal of Building Engineering, 2023, 73: 106836. doi: 10.1016/j.jobe.2023.106836 [68] 尚国秀. 碳纤维水泥基复合材料纤维分散性及导电性能试验研究[D]. 郑州: 郑州大学, 2015.SHANG Guoxiu. Experimental study on fiber dispersion and conductivity of carbon fiber cement-based composite materials[D]. Zhengzhou: Zhengzhou University, 2015(in Chinese). [69] GAO J, SHA A, WANG Z, et al. Characterization of carbon fiber distribution in cement-based composites by computed tomography[J]. Construction and Building Materials, 2018, 177: 134-147. doi: 10.1016/j.conbuildmat.2018.05.114 [70] 韩朝锋, 薛有松, 张东生, 等. 碳纤维复合材料电导特性和力电耦合行为研究进展[J]. 复合材料学报, 2023, 40(6): 3136-3152.HAN Chaofeng, XUE Yousong, ZHANG Dongsheng, et al. Research progress on electrical property and electromechanical coupling behaviors of carbon fiber composites[J]. Acta Materiae Compositae Sinica, 2023, 40(6): 3136-3152(in Chinese). [71] 黄世峰, 徐东宇, 徐荣华, 等. 碳纤维/ 水泥基复合材料微观结构及机敏特性[J]. 复合材料学报, 2006, 23(4): 95-99.HUANG Shifeng, XU Dongyu, XU Ronghua, et al. Microcosmic and smart properties of carbon fiber cement-based composites[J]. Acta Materiae Compositae Sinica, 2006, 23(4): 95-99(in Chinese). [72] 赵晓华, 李国宝, 王玉林, 等. 碳纤维增强水泥基复合材料的压阻效应[J]. 复合材料学报, 2011, 28(5): 214-219.ZHAO Xiaohua, LI Guobao, WANG Yulin, et al. Piezoresistivity of carbon fiber reinforced cement-matrix composites[J]. Acta Materiae Compositae Sinica, 2011, 28(5): 214-219(in Chinese). [73] 陶冶王之, 张大伟, 陈冠浩. 碳纤维织物增强水泥基复合材料拉拔过程力阻响应和等效分层破坏模型[J]. 复合材料学报, 2022, 39(11): 5170-5180.TAOYE Wangzhi, ZHANG Dawei, CHEN Guanhao. Piezoresistive response of carbon fibric reinforced cementitious matrix during pull-out test and the establishment of equivalent delamination failure model[J]. Acta Materiae Compositae Sinica, 2022, 39(11): 5170-5180(in Chinese). [74] WEI J, ZHANG Q, ZHAO L, et al. Enhanced thermoelectric properties of carbon fiber reinforced cement composites[J]. Ceramics International, 2016, 42(10): 11568-11573. doi: 10.1016/j.ceramint.2016.04.014 [75] LIU K, LU L, WANG F, et al. Theoretical and experimental study on multi-phase model of thermal conductivity for fiber reinforced concrete[J]. Construction and Building Materials, 2017, 148: 465-475. [76] 黄平, 郭丹. 界面力学(精)[M]. 北京: 清华大学出版社, 2013: І.HUANG Ping, GUO Dan. Interface mechanics (Precision)[M]. Beijing: Tsinghua University Press, 2013: І(in Chinese). [77] 沈荣熹, 崔琪, 李清海. 新型纤维增强水泥基复合材料[M]. 北京: 中国建材工业出版社, 2004: 55.SHEN Rongxi, CUI Qi, LI Qinghai. New fiber-reinforced cement-based composite materials[M]. Beijing: China Building Materials Industry Press, 2004: 55(in Chinese). [78] ZHANG W, DENG X, SUI G, et al. Improving interfacial and mechanical properties of carbon nanotube-sized carbon fiber/epoxy composites[J]. Carbon, 2019, 145: 629-639. doi: 10.1016/j.carbon.2019.01.063 [79] LEE Y, KANG S T, KIM J K. Pullout behavior of inclined steel fiber in an ultra-high strength cementitious matrix[J]. Construction and Building Materials, 2010, 24(10): 2030-2041. doi: 10.1016/j.conbuildmat.2010.03.009 [80] WANG Y, HU S, SUN X. Experimental investigation on the elastic modulus and fracture properties of basalt fiber-reinforced fly ash geopolymer concrete[J]. Construction and Building Materials, 2022, 338: 127570. doi: 10.1016/j.conbuildmat.2022.127570 [81] CUI H, JIN Z, ZHENG D, et al. Effect of carbon fibers grafted with carbon nanotubes on mechanical properties of cement-based composites[J]. Construction and Building Materials, 2018, 181: 713-720. doi: 10.1016/j.conbuildmat.2018.06.049 [82] STYNOSKI P, MONDAL P, MARSH C. Effects of silica additives on fracture properties of carbon nanotube and carbon fiber reinforced Portland cement mortar[J]. Cement & Concrete Composites, 2015, 55: 232-240. [83] WEI J, ZHANG Q, ZHAO L, et al. Enhanced thermoelectric properties of carbon fiber reinforced cement composites[J]. Ceramics International, 2016, 42(10): 11568-11573. [84] HAN W, CHOI W K, AN K H, et al. Effects of crack resistance properties of ozone-treated carbon fibers-reinforced nylon-6 matrix composites[J]. Journal of the Korean Industrial & Engineering Chemistry, 2013, 24(4): 363-369. [85] PARK O K, KIM W Y, KIM S M, et al. Effect of oxygen plasma treatment on he mechanical properties of carbon nanotube fibers[J]. Materials Letters, 2015, 156: 17-20. doi: 10.1016/j.matlet.2015.04.141 [86] LU Z, YIN R, YAO J, et al. Surface modification of polyethylene fiber by ozonation and its influence on the mechanical properties of strain-hardening cementitious composites[J]. Composites Part B: Engineering, 2019, 177: 107446. doi: 10.1016/j.compositesb.2019.107446 [87] HUANG S, CHENG X, GUO X, et al. Ethanol plasma-induced polymerization of carbon fiber surface for improving mechanical properties of carbon fiber-reinforced lightweight oil well cement[J]. Applied Surface Science, 2019, 497: 143765. doi: 10.1016/j.apsusc.2019.143765 [88] DENG C, JIANG J J, LIU L, et al. Influence of carbon nanotubes coatings onto carbon fiber by oxidative treatments combined with electrophoretic deposition on interfacial properties of carbon fiber composite[J]. Applied Surface Science, 2015, 357: 1274-1280. doi: 10.1016/j.apsusc.2015.09.178 [89] WANG C F, LI J, SUN S F, et al. Electrophoretic deposition of graphene oxide on continuous carbon fibers for reinforcement of both tensile and interfacial strength[J]. Composites Science & Technology, 2016, 135: 46-53. [90] LU M, XIAO H, LIU M, et al. Improved interfacial strength of SiO2 coated carbon fiber in cement matrix[J]. Cement and Concrete Composites, 2018, 91: 21-28. [91] LU M, XIAO H, LIU M, et al. Carbon fiber surface nano-modification and enhanced mechanical properties of fiber reinforced cementitious composites[J]. Construction and Building Materials, 2023, 370: 130701. doi: 10.1016/j.conbuildmat.2023.130701 [92] OZTURK M, CHUNG D D L. Enhancing the electromagnetic interference shielding effectiveness of carbon-fiber reinforced cement paste by coating the carbon fiber with nickel[J]. Journal of Building Engineering, 2021, 41: 102757. doi: 10.1016/j.jobe.2021.102757 [93] DEHGHANPOUR H. Electrical and microstructural characterization of carbon nanotube-carbon fiber added cementitious conductive surface coating[J]. Construction and Building Materials, 2023, 406: 133449. doi: 10.1016/j.conbuildmat.2023.133449 [94] YANG T, HAN E, WANG X D, et al. Surface decoration of polyimide fiber with carbon nanotubes and its application for mechanical enhancement of phosphoric acid-based geopolymers[J]. Applied Surface Science, 2017, 416: 200-212. doi: 10.1016/j.apsusc.2017.04.166 [95] 袁玉环, 左进霞, 彭聪, 等. 聚氨酯/纳米SiO2改性碳纤维增强环氧树脂复合材料界面性能[J]. 复合材料学报, 2023, 40(11): 6073-6086.YUAN Yuhuan, ZUO Jinxia, PENG Cong, et al. Interfacial properties of polyurethane/nano-SiO2 modified carbon fiber epoxy resin composites[J]. Acta Materiae Compositae Sinica, 2023, 40(11): 6073-6086(in Chinese). [96] COHEN Z, PELED A. Controlled telescopic reinforcement system of fabric-cement composites—Durability concerns[J]. Cement & Concrete Research, 2010, 40(10): 1495-1506. [97] IVANIC A, LUBEJ S, RUDOLF R, et al. Bond behavior of carbon-fiber yarn embedded in cement mortar[J]. Science & Engineering of Composite Materials, 2011, 18(3): 181-186. [98] ZHU M C. Bond behavior and degradation mechanisms of multi-functional fabric reinforced cementitious matrix (MFRCM) composites used for ICCP-SS[D]. Sapporo: Hokkaido University, 2020. [99] DONNINI J, CORINALDESI V, NANNI A. Mechanical properties of FRCM using carbon fabrics with different coating treatments[J]. Composites Part B: Engineering, 2016, 88: 220-228. [100] DVORKIN D, POURSAEE A, PELED A, et al. Influence of bundle coating on the tensile behavior, bonding, cracking and fluid transport of fabric cement-based composites[J]. Cement and Concrete Composites, 2013, 42: 9-19. doi: 10.1016/j.cemconcomp.2013.05.005 [101] SCHEFFLER C, GAO S L, PLONKA R, et al. Interphase modification of alkali-resistant glass fibres and carbon fibres for textile reinforced concrete I: Fibre properties and durability[J]. Composites Science and Technology, 2009, 69(3-4): 531-538. doi: 10.1016/j.compscitech.2008.11.027 [102] SCHEFFLER C, FORSTER T, MADER E, et al. Aging of alkali-resistant glass and basalt fibers in alkaline solutions: Evaluation of the failure stress by Weibull distribution function[J]. Journal of Non-Crystalline Solids, 2009, 355(52-54): 2588-2595. doi: 10.1016/j.jnoncrysol.2009.09.018 [103] MECHTCHERINE V, MICHEL A, LIEBSCHER M, et al. Mineral-impregnated carbon fiber composites as novel reinforcement for concrete construction: Material and automation perspectives[J]. Automation in Construction, 2020, 110: 103002. doi: 10.1016/j.autcon.2019.103002 [104] ERNEST B M, LLUIS G, LUIS M, et al. Mechanical properties of pre-stressed fabric-reinforced cementitious matrix composite (PFRCM)[J]. Construction and Building Materials, 2018, 191: 228-241. doi: 10.1016/j.conbuildmat.2018.09.210 [105] ISLA F, RUANO G, LUCCIONI B. Analysis of steel fibers pull-out. Experimental study[J]. Construction and Building Materials, 2015, 100: 183-193. doi: 10.1016/j.conbuildmat.2015.09.034 [106] BADANOIU A, JONAS H. Cementitious composites reinforced with continuous carbon fibres for strengthening of concrete structures[J]. Cement and Concrete Composites, 2003, 25(3): 387-394. doi: 10.1016/S0958-9465(02)00054-9 [107] 袁晓敏. 碳纤维表面处理技术对CFRP界面特性影响研究[D]. 济南: 山东大学, 2019.YUAN Xiaomin. Surface treatment research of carbon fiber and its effect on the interfacial propertiess of CFRP[D]. Jinan: Shandong University, 2019(in Chinese). [108] 刘浏. 碳纤维表面处理及其复合材料性能研究[D]. 长春: 长春工业大学, 2019.LIU Liu. Research on carbon fiber surface treatment and composite material properties[D]. Changchun: Changchun University of Technology, 2019(in Chinese). [109] 徐志明. 碳纤维表面负载GO/CNTs体系构建及其界面性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2018.XU Zhiming. Construction of GO/CNTs system loaded on carbon fiber surface and study of its interfacial properties[D]. Harbin: Harbin Institute of Technology, 2018(in Chinese). [110] 赵广东. 碳纤维表面化学修饰及其与SiBCN陶瓷基体的界面结合特性[D]. 哈尔滨: 哈尔滨工业大学, 2017.ZHAO Guangdong. Chemical modification of carbon fiber surface and its interface bonding characteristics with SiBCN ceramic matrix[D] Harbin: Harbin Institute of Technology, 2017(in Chinese). [111] 王彩凤. 碳纤维表面多尺度组元构筑及其复合材料界面性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2017.WANG Caifeng. Multiscale component construction on carbon fiber surface and study on interface properties of composite materials[D]. Harbin: Harbin Institute of Technology, 2017(in Chinese). [112] LI H, LIEBSCHER M, MICHEL A, et al. Oxygen plasma modification of carbon fiber rovings for enhanced interaction toward mineral-based impregnation materials and concrete matrices[J]. Construction and Building Materials, 2021, 273: 121950. doi: 10.1016/j.conbuildmat.2020.121950 [113] SCHNEIDER K, LIEBOLDT M, LIEBSCHER M, et al. Mineral-based coating of plasma-treated carbon fibre rovings for carbon concrete composites with enhanced mechanical performance[J]. Materials, 2017, 10: 360. [114] LI H, LIEBSCHER M, RANJBARIAN M, et al. Electrochemical modification of carbon fiber yarns in cementitious pore solution for an enhanced interaction towards concrete matrices[J]. Applied Surface Science, 2019, 487: 52-58. doi: 10.1016/j.apsusc.2019.04.246 [115] SHARD A G. Practical guides for X-ray photoelectron spectroscopy: Quantitative XPS[J]. Journal of Vacuum Science & Technology A, 2020, 38: 041201. [116] SELLITTI C, KOENIG J, ISHIDA H. Surface characterization of graphitized carbon fibers by attenuated total reflection Fourier transform infrared spectroscopy[J]. Carbon, 1990, 28: 221-228. [117] BARHOUM A, GARCIA-BETANCOURT M L, RAJIER H, et al. Physicochemical characterization of nanomaterials: Polymorph, composition, wettability, and thermal stability[M]. Emerging Applications of Nanoparticles and Architecture Nanostructures: Micro and Nano Technologies. Netherlands: Elsevier Science, 2018: 255-278. [118] HEO G H, PARK J G, SONG K C, et al. Mechanical properties of SiO2-coated carbon fiber-reinforced mortar composites with different fiber lengths and fiber volume fractions[J]. Advances in Civil Engineering, 2020, 2: 1-12. [119] LAVAGNA L, MUSSO S, FERRO G, et al. Cement-based composites containing functionalized carbon fibers[J]. Cement and Concrete Composites, 2018, 88: 165-171. doi: 10.1016/j.cemconcomp.2018.02.007 [120] ZENG J, ZHAO G, LIU J, et al. Interaction between thermal stabilization temperature program, oxidation reaction, and mechanical properties of polyacrylonitrile (PAN) based carbon fibers[J]. Diamond and Related Materials, 2024, 141: 110588. [121] NEWBURY D E, RITCHIE N W M. Performing elemental microanalysis with high accuracy and high precision by scanning electron microscopy/silicon drift detector energy-dispersive X-ray spectrometry (SEM/SDD-EDS)[J]. Journal of Materials Science, 2015, 50(2): 493-518. [122] LI H, YANG J, WANG L, et al. Multiscale assessment of performance of limestone calcined clay cement (LC3) reinforced with virgin and recycled carbon fibers[J]. Construction and Building Materials, 2023, 406: 133228. doi: 10.1016/j.conbuildmat.2023.133228 [123] LI H, LIEBSCHER M, MICUSIK M, et al. Role of pH value on electrophoretic deposition of nano-silica onto carbon fibers for a tailored bond behavior with cementitious matrices[J]. Applied Surface Science, 2022, 600: 154000. doi: 10.1016/j.apsusc.2022.154000 [124] LEE S H, LEE S M, ROH J S. Microstructure of milled polyacrylonitrile-based carbon fiber analyzed by micro-Raman spectroscopy and TEM[J]. Materials, 2021, 14(16): 4711. doi: 10.3390/ma14164711 [125] LI D, LU C, WU G, et al. Heat-induced internal strain relaxation and its effect on the microstructure of polyacrylonitrile-based carbon fiber[J]. Journal of Materials Science & Technology, 2014, 30(10): 1051-1058. [126] 吕梦圆. 纳米二氧化硅与纤维改性水泥基复合材料的强韧化研究[D]. 哈尔滨: 哈尔滨工业大学, 2021.LYU Mengyuan. Research on the strengthening and toughening of nano-SiO2 and fiber modified cement-based composites[D]. Harbin: Harbin Institute of Technology, 2021(in Chinese). [127] PI Z, XIAO H, LIU R, et al. Effects of brass coating and nano-SiO2 coating on steel fiber-matrix interfacial properties of cement-based composite[J]. Composites Part B: Engineering, 2020, 189: 107904. doi: 10.1016/j.compositesb.2020.107904 [128] WANG C, LI J, SUN S, et al. Controlled growth of silver nanoparticles on carbon fibers for reinforcement of both tensile and interfacial strength[J]. RSC Advances, 2016, 6(17): 14016-14026. doi: 10.1039/C5RA22032G [129] SPEIGHT J G. 4-thermodynamics of water[M]. Natural Water Remediation: Chemistry and Technology. Oxford: Butterworth-Heinemann, 2020: 131-163. [130] MA J, JIANG L, DAN Y, et al. Study on the inter-laminar shear properties of carbon fiber reinforced epoxy composite materials with different interface structures[J]. Materials & Design, 2022, 214: 110417. [131] YING J W, XIE Z M, JIANG Z J, et al. Microscale fracture and creep analysis of 3D porous graphene-based cementitious material by nanoindentation test and energy-based method[J]. Construction and Building Materials, 2023, 409: 133992. [132] GAUTHAM S, SASMAL S. Constitutive relations of nanoscale hydration products present in engineered cementitious composites from machine learning assisted experimental nanoindentation[J]. Journal of Building Engineering, 2023, 75: 106912. [133] XU W, TANG Z, XIE Y, et al. Recent advances and insights in nanoindentation technique in the characterization of cement-based materials[J]. Journal of Building Engineering, 2023, 80: 108022. doi: 10.1016/j.jobe.2023.108022 [134] PEREZ-MARTIN H, MACKENZIE P, BAIDAK A, et al. Microstructural and micromechanical property characterisation of CF/PEKK composites using nanoindentation[J]. Materials & Design, 2023, 234: 112359. [135] YU L, BAI S, GUAN X. Effect of graphene oxide on microstructure and micromechanical property of ultra-high performance concrete[J]. Cement and Concrete Composites, 2023, 138: 104964. [136] HE S, LI Z, YANG E H. Quantitative characterization of anisotropic properties of the interfacial transition zone (ITZ) between microfiber and cement paste[J]. Cement and Concrete Research, 2019, 122: 136-146. doi: 10.1016/j.cemconres.2019.05.007 [137] 陈丕钰. 碳纤维增强复合材料的电化学回收方法研究[D]. 深圳: 深圳大学, 2017.CHEN Piyu. Research on electrochemical recovery methods of carbon fiber reinforced composite materials[D]. Shenzhen: Shenzhen University, 2017(in Chinese). [138] HUGHES J D H. The carbon fibre/epoxy interface—A review[J]. Composites Science & Technology, 1991, 41(1): 13-45. [139] ASTM International. Standard test method for tensile strength and Young's modulus for high-modulus single-filament materials (Withdrawn 1998): ASTM D3379-75(1989)e1[S]. West Conshohocken: ASTM, 1989. [140] YANG L, CHEN Y, XU Z, et al. Ni, effect of surface modification of carbon fiber based on magnetron sputtering technology on tensile properties[J]. Carbon, 2023, 204: 377-386. [141] REDON C, LI V C, WU C, et al. Measuring and modifying interface properties of PVA fibers in ECC matrix[J]. Journal of Materials in Civil Engineering, 2001, 13(6): 399-406. doi: 10.1061/(ASCE)0899-1561(2001)13:6(399) [142] LI H Y, ZHAO D, LIEBSCHER M, et al. An experimental and numerical study on the age depended bond-slip behavior between nano-silica modified carbon fibers and cementitious matrices[J]. Cement and Concrete Composites, 2022, 128: 104416. doi: 10.1016/j.cemconcomp.2022.104416 [143] 李晓娇. 纳米材料改性水泥基复合材料及其界面性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2015.LI Xiaojiao. Research on nanomaterial modified cementitious composite materials and their interface properties[D]. Harbin: Harbin Institute of Technology, 2015(in Chinese). [144] 杨浩楠. 膨胀剂—碳纤维水泥基材料力学特性研究[D]. 哈尔滨: 哈尔滨工业大学, 2017.YANG Haonan. Effects of expansive agent and carbon fiber on the mechanical properties of carbon fiber cement-based composites[D]. Harbin: Harbin Institute of Technology, 2017(in Chinese). [145] KANAKUBO T, SHI H, WANG J. Influence of matrix strength on bridging performance of fiber-reinforced cementitious composite with bundled aramid fiber[J]. Journal of Composites Science, 2022, 6: 131. [146] 彭楚汗. 碳纤维/超高性能混凝土基体界面粘结性能及机制研究[D]. 广州: 华南理工大学, 2022.PENG Chuhan. Interface bonding between carbon fiber/ultra-high performance concrete matrix: Properties and mechanism[D]. Guangzhou: South China University of Technology, 2022(in Chinese). [147] HEMMATIAN A, JALALI M, NADERPOUR H, et al. Machine learning prediction of fiber pull-out and bond-slip in fiber-reinforced cementitious composites[J]. Journal of Building Engineering, 2023, 63: 105474. -

下载:

下载: