Barrier performance of Mo(N,O) thin films in CIGS solar cells based on stainless steel substrates

-

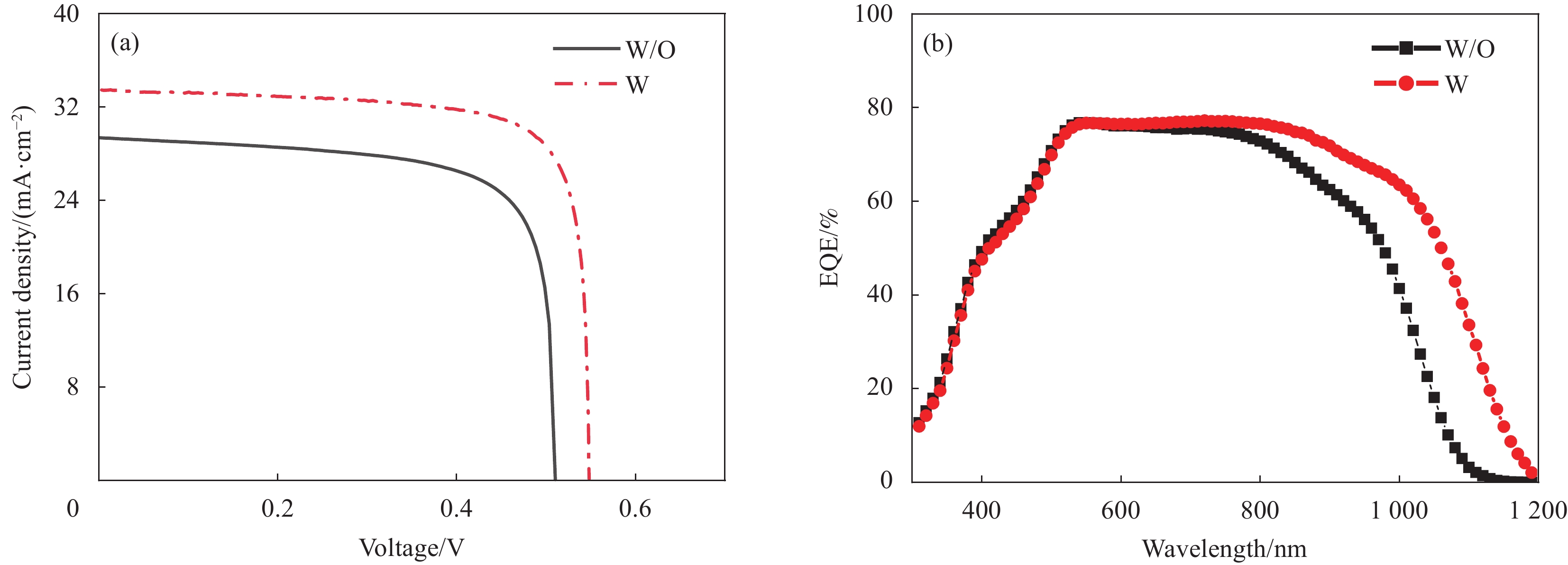

摘要: 不锈钢衬底铜铟镓硒(CIGS)太阳电池因其优异的光电转换效率和可弯曲特性而被广泛应用。但在制备CIGS薄膜过程中,衬底中的Fe元素会向CIGS薄膜扩散,导致电池性能下降。因此,需要在不锈钢衬底与Mo薄膜之间插入阻挡层来抑制Fe元素的扩散。采用反应磁控溅射方法制备了不同O2流量条件下的Mo(N,O)薄膜,通过XRD、SEM及XPS研究了O2流量对Mo(N,O)薄膜的晶体结构、微观形貌及元素组分的影响,二次离子质谱(SIMS)测试表明插入Mo(N,O)薄膜后,CIGS薄膜中Fe元素的相对强度由无阻挡层时的30 counts降至2 counts。通过优化选用O2流量0.25 mL/min制备Mo(N,O)阻挡层,并制备了CIGS太阳电池,电流密度-电压(J-V)特性测试表明插入Mo(N,O)阻挡层后,电池效率由11.07%提高到14.34%。Abstract: Copper indium gallium selenium (CIGS) solar cells on stainless steel substrate are widely used in the photovoltaics community due to their excellent photoelectric conversion efficiency and flexibility. However, the Fe element will diffuse into the CIGS thin film from the stainless-steel substrate during the process of the preparation of the CIGS thin films, which resulting deteriorated the performance of the devices. Therefore, it is necessary to insert a barrier layer between the stainless steel substrate and the Mo thin film to inhibit the diffusion of the Fe element. Mo(N,O) thin films were produced using reactive magnetron sputtering with varying O2 flow rates. The influence of the O2 flow rate on the crystal structure, microscopic morphology, and elemental composition of the Mo(N,O) thin films was analyzed using an XRD, SEM, and XPS. Base on secondary ion mass spectroscopy (SIMS) testing results, the addition of Mo(N,O) thin film to the fabrication process of CIGS solar cells results in a reduction of Fe element's relative intensity in the CIGS thin film from 30 counts to 2 counts. Moreover, current density-voltage (I-V) characteristic test demonstrated an increase in the photovoltaic conversion efficiency for the flexible CIGS solar cell on a stainless steel substrate, from 11.07% to 14.34%, upon the addition of the Mo(N,O) thin film.

-

Keywords:

- solar cells /

- barrier layer /

- Fe /

- Mo(N,O) thin film /

- O2 /

- CIGS /

- SIMS

-

果蔬、食品、乳酸菌、血液、疫苗等对环境温度敏感的物质,采用冷链物流耗能较大,而利用材料在相变过程中储存或释放能量调节周围环境的温度,可以改进并解决其保质运输与储存的问题。相变储能材料(PCMs)储能密度大、相变温度稳定、装置简单、设备灵活,能快速解决能源在时间及空间上不匹配的矛盾[1-2],在军工、航天、纺织、制冷设备、食品及农产品等领域有广泛的工程应用价值[3-9]。在冷链物流包装中,大多数果品贮藏温度为0~8℃,且具有相变温度稳定性好、相变潜热高等优点。相变储能材料按照材料类别可以分为无机相变储能材料、有机相变储能材料及共晶相变储能材料[10-11]。无机相变材料具有较高导热性和相变潜热,主要应用于中高温材料系统[12],但是普遍存在严重的过冷和相分离现象[13]。有机相变储能材料基本没有过冷度及相分离现象、化学性能稳定且成本低,但是储能密度相对较低,主要应用于中低温材料系统[14-15]。共晶相变储能材料是由两种或两种以上的成分组成的低共熔物,在一定程度上克服了有机相变储能材料与无机相储能材料的局限性,但在导热性能、循环稳定性和储热性能方面仍需改善[10]。

目前常用的有机相变储能材料主要包括石蜡、酯、脂肪酸、醇和烷烃等,固体成型性好、不易燃、不易发生过冷和相分离现象[16-18]。脂肪酸的过冷度小,有可逆的融化和凝固性能,是性能良好的有机相变储能材料。月桂酸、正癸酸、棕榈酸、肉豆蔻酸及它们的共混物是应用比较多的相变材料[19-22]。石蜡是一种固-液相变材料,具有相变潜热高、无过冷和相分离、熔点低、化学性质稳定、价格低廉等优点,通常用来改善正十二烷、正十四烷等烷烃的导热性能或熔点[23-24]。在0℃左右的有机相变储能材料中,正癸醇结构简单、相变潜热较高、性质稳定,是一种适合的相变材料,通常将其与其他材料复配得到可调节相变温度的材料[17]。

由于单一有机相变储能材料存在相变温度不可调、相变潜热较低等缺点,无法满足冷链物流用相变储能材料熔点为0~8℃、相变潜热高的要求,且部分有机相变储能材料价格昂贵,无法在生产生活中大量应用。因此,本文选用正癸酸、月桂酸甲酯、正癸醇、月桂酸及十四烷,通过物理共混法制备正癸酸-月桂酸甲酯、正癸酸-正癸醇、月桂酸-十四烷三种二元有机复配物,并针对二元有机复配物在相变过程中的泄漏问题利用凝胶对其进行吸附以期获得适用于果品保质包装与物流技术的有机相变储能材料。

1. 实验部分

1.1 原材料

正癸酸,99%,分析纯;正癸醇,98%;月桂酸,99%,优级纯;十四烷,98%;月桂酸甲酯,99%;N-异丙基丙烯酰胺,98%;N,N'-亚甲基双丙烯酰胺(MBA),99%;过硫酸铵,≥98%,分析纯;四甲基乙二胺,99%;聚乙二醇1000;聚乙二醇4000,化学纯;聚乙二醇8000,分析纯;聚乙二醇10000,上海阿拉丁生化科技股份有限公司。聚乙二醇200,化学纯,北京国药集团化学试剂有限公司。

1.2 样品制备

1.2.1 凝胶的制备方法

利用在氧化还原体系下引发单体进行原位自由基聚合的方法制备凝胶。首先,选择1 mol/L的N-异丙基丙烯酰胺(NIPAM)作为单体,MBA为交联剂,为单体总质量的0.5%,聚乙二醇1000(PEG1000)为致孔剂,为单体总质量的40%,将NIPAM、MBA、PEG1000共同溶解于去离子水中。其次,在过硫酸铵(APS)和四甲基乙二胺(TEMED)氧化还原体系中保持20℃引发聚合反应24 h,形成以PEG1000作致孔剂的聚N-异丙基丙烯酰胺(PNIPAM)凝胶,凝胶的命名规则为PNIPAM-y%PEGx,x代表聚乙二醇的分子量,y代表聚乙二醇占NIPAM质量的百分比(表1)。例如,PNIPAM-40%PEG1000为以PEG1000作为致孔剂的PNIPAM凝胶,且致孔剂含量为NIPAM质量的40%。制备过程如图1所示。APS广泛应用于水相自由基聚合,TEMED作为促进剂用于加快聚合反应的进行。第三步,将制备好的凝胶在去离子水中浸泡三天,每6 h换一次去离子水,以去除多余的单体及不参与反应的PEG1000,将浸泡处理之后的PNIPAM取出并放置于−25℃的冰箱中冷冻24 h,随后将冷冻好的PNIPAM凝胶放进冷冻干燥机(LGJ-10C 型,江苏金坛市环宇科学仪器厂)冷冻干燥72 h,冷肼温度为−55~−50℃,真空度为0.5~50 Pa。

表 1 聚N-异丙基丙烯酰胺(PNIPAM)-聚乙二醇(PEG)凝胶的命名Table 1. Naming of poly(N-isopropylacrylamide) (PNIPAM)-polyethylene glycol (PEG) gelSample Mass ratio of PEG∶NIPAM/% Molecular weight of PEG PNIPAM-y%PEGx y x Note: NIPAM—N-isopropylacrylamide. 1.2.2 二元有机复配物的制备方法

依据混合物凝固点下降原理,利用两种单一物质的物理共混加热法制备二元有机复配物,均匀的二元有机复配物体系的FTIR图谱如图2所示。首先,称取一定摩尔比的正癸酸、月桂酸甲酯于透明玻璃瓶中,将其置于60℃的恒温水浴锅中融化10 min,正癸酸融化完全。其次,用旋涡震荡仪(XW-80A型,佛山予华仪器科技有限公司)混合10 min,再用超声波震荡仪将混合物震荡2 min,正癸酸与月桂酸甲酯充分混合,得到正癸酸-月桂酸甲酯二元有机复配物体系,二元有机复配物体系没有分离现象,正癸酸-正癸醇及月桂酸-十四烷二元有机复配物体系采用相同的方法制备。

1.2.3 相变材料的制备方法

NIPAM的分子链上同时具有亲水性的酰胺基团和亲油性的异丙基团。当NIPAM通过自由基聚合形成PNIPAM-40%PEG1000凝胶,具有大分子网状结构,凝胶在液体中可显著溶胀。将冷冻干燥后的PNIPAM-40%PEG1000凝胶浸泡于二元有机复配物中进行溶胀。PNIPAM-40%PEG1000凝胶在二元有机复配物中的溶胀过程实际上是两种相反趋势的平衡过程,溶剂分子试图渗透到网络内部,使得凝胶体积溶胀从而导致三维分子网络的伸展平衡,交联点之间的分子链的伸展降低了它的构象熵值,分子网络的弹性收缩力使网络收缩。当两种相反的倾向互相抵消时,达到溶胀平衡,凝胶的溶胀程度用溶胀率(Swelling ratio,SR)表示。PNIPAM-40%PEG1000凝胶在三种二元有机复配物中溶胀(水浴60℃),得到PNIPAM-40%PEG1000/正癸酸-月桂酸甲酯、PNIPAM-40%PEG1000/正癸酸-正癸醇和PNIPAM-40%PEG1000/月桂酸-十四烷三种相变储能材料。

1.3 性能测试与结构表征

1.3.1 傅里叶红外测试

参考GB/T21186—2007[25]“傅里叶变换红外光谱仪”的实验方法,利用傅里叶红外扫描仪(Nicolet 6700型,赛默飞世尔Thermo-fisher科技(中国)有限公司)对正癸酸、月桂酸甲酯、正癸醇、月桂酸、十四烷、正癸酸-月桂酸甲酯、正癸酸-正癸醇及月桂酸-十四烷进行红外测试,将单一有机物的图谱与二元有机复配物的图谱进行对照,考察二元有机复配物是否有新的吸收峰生成,判断两种单一有机物的化学相容性。

1.3.2 差示扫描量热分析测试

参考GB/T 19466.3—2004[26]“塑料 差示扫描量热法(DSC)”的实验方法,利用差示扫描量热仪(TGA/DSC1型,梅特勒-托利多国际贸易(上海)有限公司(METTLER TOLEDO))对正癸酸、月桂酸甲酯、正癸醇、月桂酸、十四烷、正癸酸-月桂酸甲酯、正癸酸-正癸醇及月桂酸-十四烷进行DSC测试,测定其相变初始温度、相变终止温度及相变潜热。称取10 mg左右的样品放置于铝坩埚中,精确度为0.01 mg,用压样机进行压制,实验参比侧放置了一个标准的空铝坩埚。将温度从30℃降温至−30℃(速度:20℃/min),再升温至30℃(速度:20℃/min),这个升降温过程重复进行两次,去除材料的热历史,将物质在30℃恒温保持5 min,再降温至−30℃得到冷冻放热曲线(速度:5℃/min),然后再升温至30℃得到融化吸热曲线(速度:5℃/min)。月桂酸、正癸酸这两种物质的温度设置为0~80℃。DSC升降温速率是由N2作用控制的,其中N2作为反应气的速率为20 mL/min,N2作为保护气的速率为150 mL/min。月桂酸甲酯、正癸醇、十四烷、正癸酸-月桂酸甲酯及正癸酸-正癸醇的测试温度为−30~30℃,而正癸酸、月桂酸及月桂酸-十四烷的测试温度为−30~50℃。

参考GB/T 14797.3—2008[27]“浓缩天然胶乳 硫化胶乳 溶胀度的测定”的实验方法,对凝胶在二元有机复配物的溶胀性能进行测试。将冷冻干燥好的凝胶称重(万分之一天平,AR224CN型,奥豪斯仪器有限公司)W1

,将其浸入二元有机复配物中,在60℃的水浴环境下充分溶胀24 h,过程中每6 h测量一次凝胶的重量W2 ,并计算凝胶在二元有机复配物中的溶胀率Q: Q=W2−W1W1×100% (1) 其中:Q为凝胶在二元有机复配物中的溶胀率;W1、W2为凝胶溶胀前、后的质量。

2. 二元有机复配物热物性能估算

基于表2所示的正癸酸、月桂酸甲酯、正癸醇、月桂酸和十四烷的热物性数据,利用凝固点下降定律、热力学第二定律和相平衡关系,评估两种或多种物质共混时的相变温度。

表 2 有机物的热物性数据Table 2. Thermophysical data of organic matterSample Phase transition

temperature/℃Latent heats of

phase transition/

(J·g−1)Decanoic acid 31.39 153.72 Methyl laurate 4.74 179.25 1 decanol 6.13 200.31 Lauric acid 44.54 181.14 Tetradecane 5.68 215.85 利用Schroder Van Laar公式从理论上估算二元有机复配物体系的相变温度,即

{T=11TA−lnXARΔHAT=11TB−lnXBRΔHBXA+XB=1 (2) 其中:T为二元有机复配物的最低共熔点温度(K);XA、XB为组分A、组分B是摩尔分数(%);TA、TB为组分A、组分B的理论熔点(K);R为气体常数且取值为8.315 (J·mol−1·K−1));ΔHA、ΔHB为组分A、组分B的相变焓(J·mol−1)。

对于表2所列的单一有机物的热物性数据,由式(2)分别得到五种物质的Schroder Van Laar公式:

正癸酸-月桂酸甲酯:

{lnXA=10.46−3184.58/TlnXB=16.63−4620.83/TXA+XB=1 (3) 正癸酸-正癸醇:

{lnXA=10.46−3184.58/TlnXB=13.64−3809.57/TXA+XB=1 (4) 月桂酸-十四烷:

{lnXA=13.47−4369.92/TlnXB=18.47−5150.03/TXA+XB=1 (5) 通过MATLAB软件分别计算上述方程组(3)~(5),获得正癸酸-月桂酸甲酯、正癸酸-正癸醇和月桂酸-十四烷二元复合物体系的理论共熔点及对应的摩尔比,如表3所示。显然,这三种二元有机复配物的理论最低共熔点在−1~4℃的范围内,接近于目标相变温度0~8℃,故可进一步通过实验分析来探究它们的热物性能。

表 3 二元有机复配物最低共熔点Table 3. The lowest common melting point of binary organic compoundSample The lowest common

melting point/℃Molar

ratioDecanoic acid-methyl laurate −0.86 29∶71 Decanoic acid-1 decanol −0.74 29∶71 Lauric acid-tetradecane 3.58 13∶87 3. 实验结果与讨论

3.1 二元有机复配物的热物性能

图2为正癸酸、月桂酸甲酯、正癸醇、月桂酸、十四烷及二元有机复配物(正癸酸-月桂酸甲酯、正癸酸-正癸醇、月桂酸-十四烷)的FTIR图谱,由单一有机材料物理共混加热得到二元有机复配物,其FTIR图谱中并没有新的官能团生成,这说明二元有机复配物各组分之间能够共存,即共混过程不发生化学反应。

图3和图4分别描述了不同二元有机复配物的差示扫描量热曲线及热物性数据,“↑exo”表示放热方向,

T0 、T1 、ΔH分别表示起始温度、终止温度和相变焓。通过对比分析这两幅图,可获得二元有机复配物的热物性能。对于正癸酸-月桂酸甲酯二元有机复配物,当组分摩尔比在3∶97~30∶70范围内,月桂酸甲酯能够溶解正癸酸,差示扫描量热曲线光滑且只有一个吸热峰。当组分摩尔比在33∶67~66∶34范围内,月桂酸甲酯饱和,无法溶解过量的正癸酸,在室温下有不溶物质,正癸酸-月桂酸甲酯的差示扫描量热曲线出现第二个吸热峰,如图3(a)、图3(b)和图3(c)所示。当组分摩尔比在3∶97~66∶34范围内,二元有机复配物相变初始温度在1.62~3.48℃的范围内变化,波动比较小,相变潜热处于165.35~193.40 J/g之间。当正癸酸与月桂酸甲酯的摩尔比为30∶70,相变初始温度为1.62℃、相变终止温度为8.15℃、相变焓为193.40 J/g,如图4(a)所示,此时相变潜热最高,性价比最高,相变初始温度和相变终止温度合适,适用于果品保质包装与物流技术。

对于正癸酸-正癸醇二元有机复配物,当组分摩尔比在3∶97~36∶64范围内,正癸醇能够溶解正癸酸,差示扫描量热曲线光滑且只有一个吸热峰。当组分摩尔比在39∶61~66∶64范围内,正癸醇饱和,无法溶解过量的正癸酸,在室温下有不溶物质,正癸酸-正癸醇的差示扫描量热曲线出现第二个吸热峰,如图3(d)和图3(e)所示。当组分摩尔比在3∶97~66∶34范围内,二元有机复配物的相变初始温度在−2~8℃范围内变化,相变潜热处于154.97~198.27 J/g之间。相变初始温度先从4.6℃降低到−2℃,当正癸酸摩尔比达到24%时,相变初始温度开始上升到0℃以上,最后稳定到4℃左右,波动较大。正癸酸-正癸醇二元复配物的相变初始温度范围广、相变潜热较高、规律性较明显。当正癸酸与正癸醇的摩尔比为36∶64,相变初始温度为3.80℃、相变终止温度为11.72℃、相变焓为180.94 J/g,如图4(b)所示,此时相变潜热较高,性价比最高,相变初始温度和相变终止温度合适,亦适用于果品包装。

对于月桂酸-十四烷二元有机复配物,当组分摩尔比在3∶97~21∶79范围内,十四烷能够溶解月桂酸,差示扫描量热曲线光滑且只有一个吸热峰。当组分摩尔比在24∶76~30∶70,十四烷饱和,无法溶解过量的月桂酸,在室温下有不溶物质,月桂酸-十四烷的差示扫描量热曲线出现第二个吸热峰,如图3(f)所示。二元有机复配物的相变初始温度为5~6℃且波动最小,相变潜热为205.80~217.94 J/g。十四烷成本较高,它与月桂酸的复配有利于大幅度降低成本。当月桂酸与十四烷的摩尔比为21∶79,相变初始温度为5.51℃、相变终止温度为26.74℃、相变焓为216.46 J/g,如图4(c)所示,此时相变潜热较高,性价比最高,也适用于果品包装。

3.2 相变储能材料的热物性能

3.2.1 MBA交联剂含量对溶胀程度的影响

PNIPAM凝胶在二元有机复配物的溶胀程度取决于pH值、温度以及凝胶的交联强度等,选用单体浓度分别为0.5 mol/L、1 mol/L、1.5 mol/L和2 mol/L的PNIPAM凝胶进行溶胀,以探究单体浓度对溶胀程度的影响。由于NIPAM浓度为0.5 mol/L的凝胶成胶性弱,无法得到成型性好的凝胶,故无法进行溶胀实验。如图5(a)所示,单体浓度为1 mol/L的PNIPAM凝胶具有最高的溶胀度,在其他条件不变时,单体浓度越小,越有利于凝胶对二元有机复配物的吸附。选用交联剂含量分别为NIPAM质量的0.25%、0.5%、0.75%和1%的PNIPAM凝胶进行溶胀,进一步探究MBA交联剂含量对溶胀程度的影响。图5(b)所示的实验结果表明,交联剂含量为NIPAM质量的0.25%的PNIPAM凝胶具有最高的溶胀度,在其他条件不变时,交联剂越少,越有利于凝胶对二元有机复配物的吸附,但是交联剂含量为NIPAM质量的0.25%的PNIPAM凝胶在溶胀之后过于柔软,形状稳定性不好。因此制备PNIPAM凝胶的单体浓度为1 mol/L,交联剂含量为NIPAM质量的0.5%。

3.2.2 PEG作致孔剂对PNIPAM-y%PEGx凝胶物化性能的影响

在PNIPAM凝胶的制备过程中加入致孔剂PEG,得到PNIPAM-y%PEGx凝胶,可以有效增加凝胶中胞元的尺寸。致孔剂聚乙二醇在PNIPAM-y%PEGx凝胶形成的过程中并不参与反应,只是占据一定的空间,在凝胶形成之后,可以通过去离子水浸泡法去除致孔剂聚乙二醇。图6为PNIPAM、PNIPAM-40%PEG1000两种凝胶的FTIR图谱,显然两种凝胶的FTIR图谱相同。其中3300 cm−1为NH的伸缩振动,2945 cm−1为聚合物主链上饱和CH3的振动吸收,1650 cm−1属于C=O的双键伸缩振动(酰胺I带),1540 cm−1属于CNH的摇摆振动(酰胺II带),1387 cm−1和1459 cm−1为CH3的吸收峰,在PN100040凝胶的FTIR图谱中1150~1050 cm−1处没有观察到典型的COC吸收,说明PNIPAM-40%PEG1000凝胶中没有PEG1000,PEG1000分子仅在凝胶聚合过程中充当致孔剂,没有参与PNIPAM-40%PEG1000凝胶的形成反应,在反应完成后通过在去离子水中浸泡除去。

3.2.3 PEG分子量及含量对溶胀程度的影响

凝胶PNIPAM与凝胶PNIPAM-y%PEGx内部含有丰富的微胞结构,如图7所示,从凝胶PNIPAM及PNIPAM-y%PEGx的SEM图像(S4800场发射扫描电镜冷场,S4800型,日立Hitachi公司)可以看出,PEG分子量越大,形成胞元的尺寸越大,但是溶胀度不会随着其一直增大,溶胀结果见图8所示。实验结果表明,PNIPAM-40%PEG1000凝胶在二元有机复配物中具有最高的溶胀率:在正癸酸-月桂酸甲酯中,PNIPAM-40%PEG1000凝胶的溶胀度可以达到53.31%;在正癸酸-正癸醇中,PNIPAM-40%PEG1000凝胶的溶胀度可以达到53.70%;在月桂酸-十四烷中,PNIPAM-40%PEG1000凝胶的溶胀度可以达到52.47%。这主要是由于当PEG的分子量为4000、8000和10000时,由于微胞尺寸较大且毛细管力较弱,造成微胞之间导热性能较低且凝胶吸附能力差;当不含PEG或PEG分子量为200时,凝胶为微胞单元较小,吸附二元有机复配物的能力较差,相应所得的有机相变储能材料的相变潜热也较小。凝胶完全浸没在二元有机复配物中成为一个整体,整个微胞呈现出有些透明凝胶状态,这表明此时二元有机复配物的质量超过了凝胶的饱和吸附量。用自封袋分别装入100 g的PNIPAM-40%PEG1000/正癸酸-月桂酸甲酯、PNIPAM-40%PEG1000/正癸酸-正癸醇及PNIPAM-40%PEG1000/月桂酸-十四烷,并进行冷冻处理,随后将其放置于30℃的恒温恒湿箱中8 h(模拟夏季高温情况),最后从自封袋中取出相变储能材料并进行称重,质量损失率分别为2.8%、5.7%和5.1%,说明PNIPAM-40%PEG1000凝胶能够有效减少二元有机复配物的泄露量。

3.2.4 相变温度和相变潜热

相变温度和相变潜热是决定相变储能材料能否应适用于冷链物流的重要条件。通过PNIPAM-y%PEGx凝胶对二元有机复配物进行吸附得到相变储能材料,添加致孔剂PEG可以提高凝胶内部微胞的尺寸,提高凝胶的溶胀率,但是胞元越大,凝胶的毛细管作用力就越小,因此凝胶的溶胀率不会随着致孔剂分子量及含量的增加而一直增加,如图8所示。PNIPAM-40%PEG1000凝胶在三种二元有机复配物中的溶胀效果最好,相变潜热最高,如图9所示。这三种相变储能材料的热物性能为:(1) 正癸酸-月桂酸甲酯(摩尔比30∶70)对应的相变储能材料为PNIPAM-40%PEG1000/正癸酸-月桂酸甲酯,其相变初始温度为3.2℃、相变焓为188.10 J/g;(2) 正癸酸-正癸醇(摩尔比36∶64)对应的相变储能材料为PNIPAM-40%PEG1000/正癸酸-正癸醇相变储能材料,其相变初始温度为1.2℃、相变焓为177.74 J/g;(3) 月桂酸-十四烷(摩尔比21∶79)对应的相变储能材料为PNIPAM-40%PEG1000/月桂酸-十四烷相变储能材料,其相变初始温度为4.2℃、相变焓为206.17 J/g。

4. 结 论

(1) 通过物理共混法得到三种相变温度适当、相变潜热较高的二元有机复配物:正癸酸-月桂酸甲酯、正癸酸-正癸醇和月桂酸-十四烷,这三种二元有机复配物无过冷和相分离现象、相变温度范围是0~5℃,且具有可逆的熔化和凝固性能,满足果品保鲜包装的要求。

(2) 由于二元有机复配物在相变过程中会有液相生成,不可避免地会发生泄漏,利用聚N-异丙基丙烯酰胺(PNIPAM)凝胶的吸油性可以对三种二元有机复配物进行吸附,可以减少其在应用过程中的泄漏量。

(3) 当在PNIPAM凝胶的制备过程中加入致孔剂聚乙二醇1000(PEG1000),凝胶在二元有机复配物的溶胀度提高,制备出三种适用于果品保质包装与物流技术的有机相变储能材料:PNIPAM-40%PEG1000/正癸酸-月桂酸甲酯、PNIPAM-40%PEG1000/正癸酸-正癸醇及PNIPAM-40%PEG1000/月桂酸-十四烷相变储能材料。

-

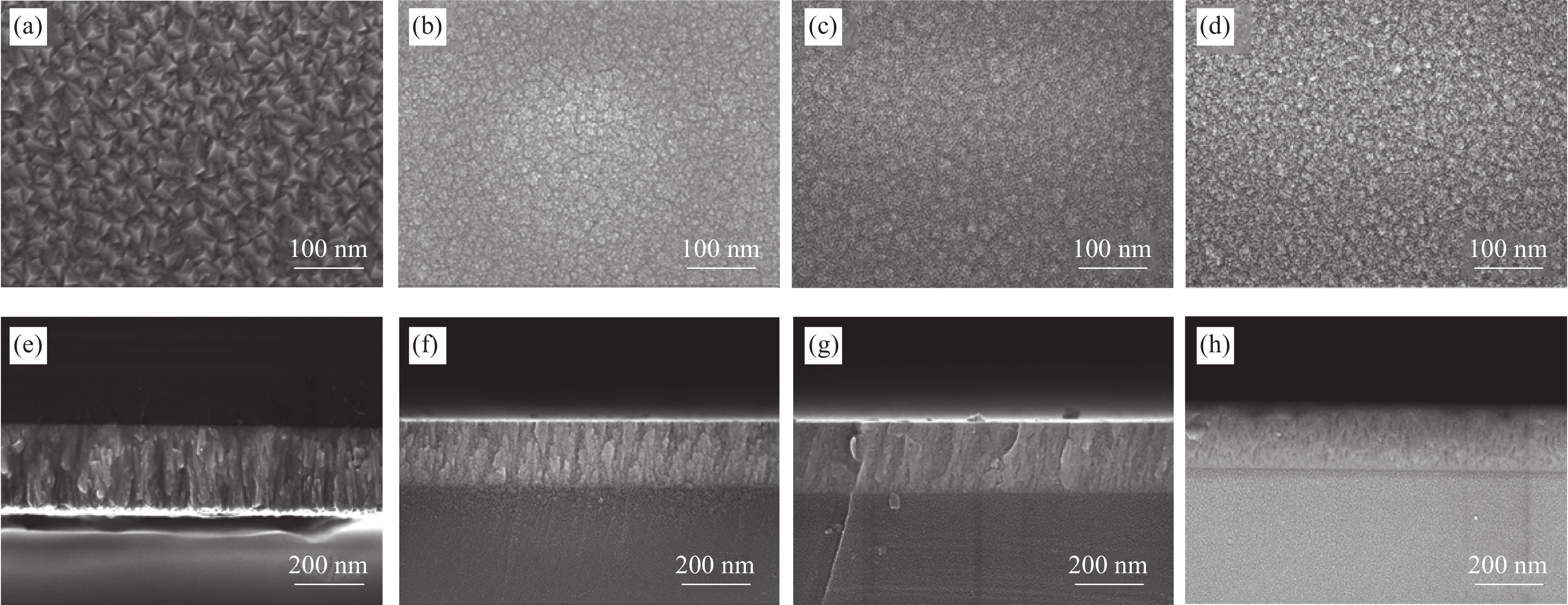

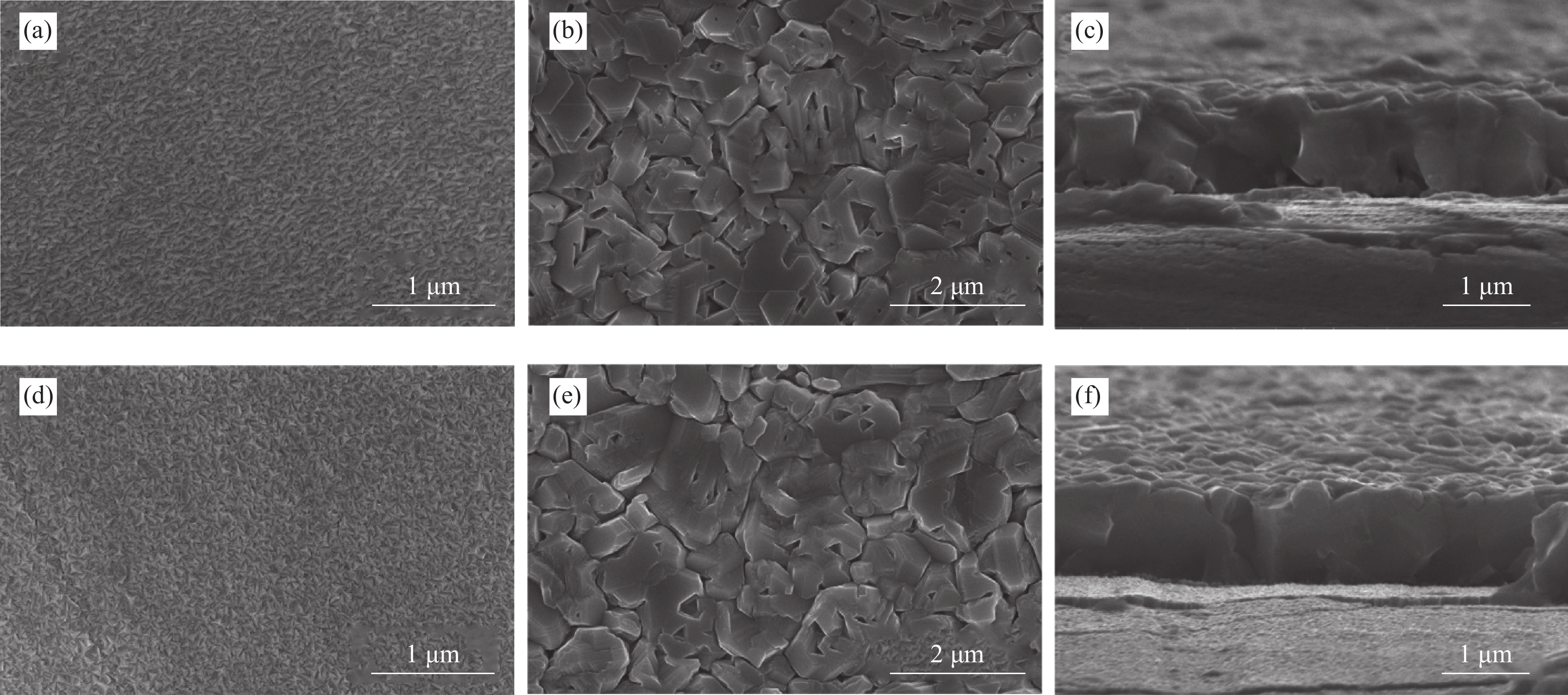

图 2 不同O2流量条件下Mo(N,O)薄膜的SEM图像:表面形貌:(a) 0 mL/min;(b) 0.15 mL/min;(c) 0.20 mL/min;(d) 0.25 mL/min;截面形貌:(e) 0 mL/min;(f) 0.15 mL/min;(g) 0.20 mL/min;(h) 0.25 mL/min

Figure 2. SEM images of Mo(N,O) thin films at different O2 flow rates: Surface: (a) 0 mL/min; (b) 0.15 mL/min; (c) 0.20 mL/min; (d) 0.25 mL/min; Section: (e) 0 mL/min; (f) 0.15 mL/min; (g) 0.20 mL/min; (h) 0.25 mL/min

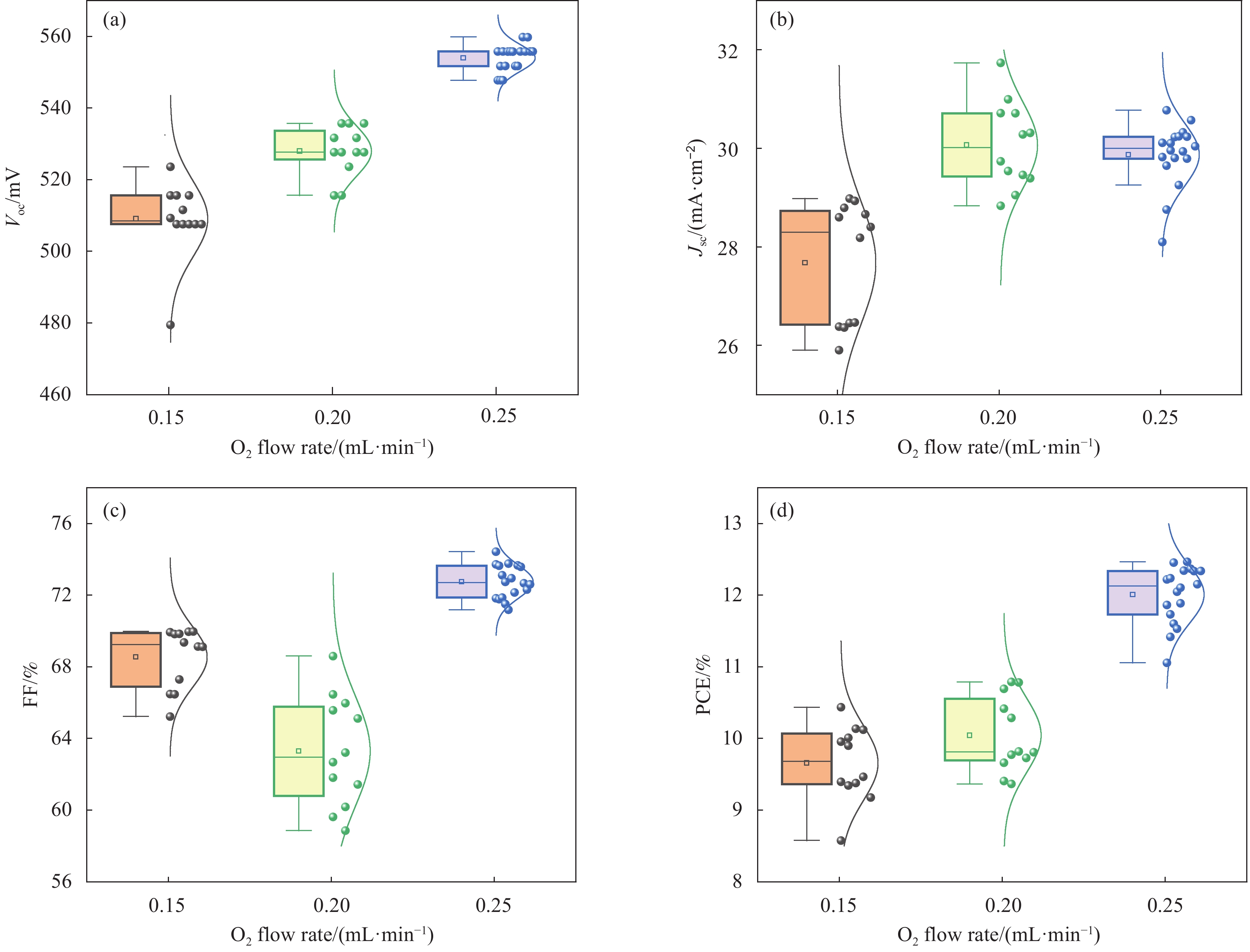

图 5 不同O2流量下制备的Mo(N,O)薄膜的CIGS太阳电池特性参数:(a)开路电压Voc;(b)短路电流密度Jsc;(c)填充因子(FF);(d)光电转换效率(PCE)

Figure 5. Parameters of CIGS thin-film solar cells with Mo(N,O) thin films deposited at different O2 flow rates: (a) Open circuit voltage Voc; (b) Short circuit current density Jsc; (c) Fill factor (FF); (d) Photoelectric conversion efficiency (PCE)

图 7 有无阻挡层所制备的Mo薄膜和CIGS薄膜的SEM图像:(a) SS/Mo表面形貌;(b) SS/Mo/CIGS表面形貌;(c) SS/Mo/CIGS截面形貌;(d) SS/Mo(N,O)/Mo表面形貌;(e) SS/Mo(N,O)Mo/CIGS表面形貌;(f ) SS/Mo(N,O)Mo/CIGS截面形貌

Figure 7. SEM images of Mo thin film and CIGS thin film prepared with and without barrier layer: (a) SS/Mo surface image; (b) SS/Mo/CIGS surface image; (c) SS/Mo/CIGS section image; (d) SS/Mo(N,O)/Mo surface image; (e) SS/Mo(N,O)Mo/CIGS surface image; (f) SS/Mo(N,O)Mo/CIGS section image

表 1 Mo(N,O)薄膜制备工艺参数

Table 1 Process parameters of Mo(N,O) thin film

Ar:N2:O2/

(mL·min−1)Sputtering

pressure/PaSputtering

power/WSubstrate

temperature/

℃Thickness/

nm30:20:0 1 150 100 300 30:20:0.15

30:20:0.20

30:20:0.251

1

1150

150

150100

100

100300

300

300表 2 不同O2流量下制备Mo(N,O)薄膜的CIGS太阳电池特性参数

Table 2 Parameters of CIGS solar cells with Mo(N,O) thin films deposited at different O2 flow rates

O2 flow rate/

(mL·min−1)Voc/mV Jsc/(mA·cm-2) FF/% PCE/% 0.15 509.1±10.6 27.7±1.2 68.6±1.7 9.7±0.5 0.20

0.25528.0±6.9

554.0±3.730.1±0.9

29.9±0.663.3±3.1

72.8±0.910.1±0.5

12.1±0.4表 3 有无阻挡层CIGS太阳电池特性参数

Table 3 Characteristic parameters of CIGS solar cells with or without barrier layer

R/(Ω·cm2) G/(mS·cm−2) A J0/(mA·cm−2) W/O

W1.70

1.273.07

1.291.74

1.512.16×10−4

7.59×10−5Notes: R—Series resistance; G—Reciprocal of the shunt resistance; A—Diode ideality factor; J0—Reverse saturation current. -

[1] BARMAN B, KALITA P. Influence of back surface field layer on enhancing the efficiency of CIGS solar cell[J]. Solar Energy, 2021, 216: 329-337. DOI: 10.1016/j.solener.2021.01.032

[2] FEURER T, REINHARD P, AVANCINI E, et al. Progress in thin film CIGS photovoltaics—Research and development, manufacturing, and applications[J]. Progress in Photovoltaics: Research and Applications, 2017, 25(7): 645-667. DOI: 10.1002/pip.2811

[3] HU D, MA B, LI X, et al. Innovative and sustainable separation and recovery of valuable metals in spent CIGS materials[J]. Journal of Cleaner Production, 2022, 350: 131426.

[4] NAKAMURA M, YAMAGUCHI K, KIMOTO Y, et al. Cd-free Cu(In,Ga)(Se,S)2 thin-film solar cell with record efficiency of 23.35%[J]. IEEE Journal of Photovoltaics, 2019, 9(6): 1863-1867. DOI: 10.1109/JPHOTOV.2019.2937218

[5] 赵彦民, 李威, 闫礼, 等. 卷对卷技术制备大面积柔性CIGS薄膜太阳电池吸收层[J]. 人工晶体学报, 2011, 40(2): 379-382. ZHAO Yanmin, LI Wei, YAN Li, et al. Deposition for scale-up absorption layer of CIGS thin-film solar cell on flexible substrate using roll-to-roll technology[J]. Journal of Synthetic Crystals, 2011, 40(2): 379-382(in Chinese).

[6] CHIRILA A, BUECHELER S, PLANEZZI F, et al. Highly efficient Cu(In,Ga)Se2 solar cells grown on flexible polymer films[J]. Nature Materials, 2011, 10(11): 857-861. DOI: 10.1038/nmat3122

[7] PIANEZZI F, CHIRILA A, BLOSCH P, et al. Electronic properties of Cu(In,Ga)Se2 solar cells on stainless steel foils without diffusion barrier[J]. Progress in Photovoltaics: Research and Applications, 2012, 20(3): 253-259. DOI: 10.1002/pip.1247

[8] OTTE K, MAKHOVA L, BRAUN A, et al. Flexible Cu(In,Ga)Se2 thin-film solar cells for space application[J]. Thin Solid Films, 2006, 511: 613-622.

[9] BREMAUD D, RUDMANN D, KAELIN M, et al. Flexible Cu(In,Ga)Se2 on Al foils and the effects of Al during chemical bath deposition[J]. Thin Solid Films, 2007, 515(15): 5857-5861. DOI: 10.1016/j.tsf.2006.12.152

[10] JACKSON P, GRABITA P, STROHM A, et al. Contamination of Cu(In,Ga)Se2 by metallic substrates[C]//Proceedings of the 19th European Photovoltaic Solar Energy Conference and Exhibition. Munich: WIP Renewable Energies, 2004: 1936-1938.

[11] HERZ K, EICKE A, KESSLER F, et al. Diffusion barriers for CIGS solar cells on metallic substrates[J]. Thin Solid Films, 2003, 431-432: 392-397.

[12] WUERZ R, EICKE A, FRANKENFELD M, et al. CIGS thin-film solar cells on steel substrates[J]. Thin Solid Films, 2009, 571(7): 2415-2418.

[13] SHI C Y, SUN Y, HE Q, et al. Cu(In,Ga)Se2 solar cells on stainless-steel substrates covered with ZnO diffusion barriers[J]. Solar Energy Materials and Solar Cells, 2009, 93(5): 654-656. DOI: 10.1016/j.solmat.2008.12.004

[14] PARK H, KIM S C, BAE H C, et al. ALD-grown Al2O3 as a diffusion barrier for stainless steel substrates for flexible Cu(In,Ga)Se2 solar cells[J]. Molecular Crystals and Liquid Crystals, 2011, 551(1): 147-153. DOI: 10.1080/15421406.2011.600634

[15] KIM K B, KIM M, BAEK J, et al. Influence of Cr thin films on the properties of flexible CIGS solar cells on steel substrates[J]. Electronic Materials Letters, 2014, 10: 247-251. DOI: 10.1007/s13391-013-3158-3

[16] HERZ K, KESSLER F, WACHTER R, et al. Dielectric barriers for flexible CIGS solar modules[J]. Thin Solid Films, 2002, 403: 384-389.

[17] 陈海波, 周继承, 李幼真. Ta基纳米薄膜扩散阻挡特性的比较研究[J]. 功能材料, 2007, 4(38): 655-658. DOI: 10.3321/j.issn:1001-9731.2007.04.043 CHEN Haibo, ZHOU Jicheng, LI Youzhen. Comparison of diffusion barrier properties of nanoscale Ta-based thin- films[J]. Journal of Functional Materials, 2007, 4(38): 655-658(in Chinese). DOI: 10.3321/j.issn:1001-9731.2007.04.043

[18] 韩胜男, 常宣, 陈静伟, 等. MoNx薄膜制备及其在柔性不锈钢CIGS太阳电池中的应用[J]. 太阳能学报, 2023, 44(7): 122-128. HAN Shengnan, CHANG Xuan, CHEN Jingwei, et al. Fabrication of MoNx thin films and its applications in flexible stainless steel CIGS solar cells[J]. Acta Energiae Solaris Sinica, 2023, 44(7): 122-128(in Chinese).

[19] XU C K, ZHANG H W, PARRY J, et al. A single source three-stage evaporation approach to CIGS absorber layer for thin film solar cells[J]. Solar Energy Materials and Solar Cells, 2013, 117: 357-362. DOI: 10.1016/j.solmat.2013.06.006

[20] ULICNA S, ARNOU P, ABBAS A, et al. Deposition and application of a Mo-N back contact diffusion barrier yielding a 12.0% efficiency solution-processed CIGS solar cell using an amine-thiol solvent system[J]. Journal of Materials Chemistry A, 2019, 7(12): 7042-7052. DOI: 10.1039/C8TA12089G

[21] KIM G T, PARK T K, CHUNG H, et al. Growth and characterization of chloronitroaniline crystals for optical parametric oscillators: I. XPS study of Mo-based compounds[J]. Applied Surface Science, 1999, 152(1-2): 35-43. DOI: 10.1016/S0169-4332(99)00293-7

[22] LI B Y, ZHANG Y, WANG H, et al. Preferred orientation of Cu(In,Ga)Se2 thin film deposited on stainless steel substrate[J]. Progress in Photovoltaics: Research and Applications, 2013, 21(5): 838-848. DOI: 10.1002/pip.2164

[23] 陈永翀, 黎振华, 其鲁, 等. 固体中的扩散应力研究[J]. 金属学报, 2006, 42(3): 225-233. CHEN Yongchong, LI Zhenhua, QI Lu, et al. Diffusion-induced stresses in solids[J]. Acta Metallurgica Sinica, 2006, 42(3): 225-233(in Chinese).

[24] OKADA K. Activation energy of mullitization from various starting materials[J]. Journal of the European Ceramic Society, 2008, 28(2): 377-382.

[25] WANG C, ZHUANG D M, ZHAO M, et al. The effects of preheating temperature on CuInGaSe2/CdS interface and the device performance[J]. Solar Energy, 2019, 194: 11-17. DOI: 10.1016/j.solener.2019.10.054

[26] WEI Y W, ZHUANG D M, ZHAO M, et al. Pre-deposition of CdS layer to improve the diode quality of CZTSSe solar cells[J]. Materials Letters, 2018, 229: 372-374. DOI: 10.1016/j.matlet.2018.07.066

-

目的

不锈钢衬底铜铟镓硒太阳电池因其优异的光电转换效率和可弯曲特性而被广泛应用。但在制备铜铟镓硒(CIGS)薄膜过程中,衬底中的Fe元素会向CIGS薄膜扩散,形成Fe、Fe深能级缺陷,降低电池的开路电压、短路电流导致电池性能下降。因此,需要在不锈钢衬底与Mo薄膜之间插入阻挡层来抑制Fe元素的扩散。按照阻挡能力排名,单晶、纳米晶和非晶材料居前;其次是填充结构和巨大晶粒材料;多晶材料阻挡能力相对较弱。本文采用反应磁控溅射方法制备非晶Mo(N,O)薄膜作为不锈钢衬底CIGS太阳电池的阻挡层。

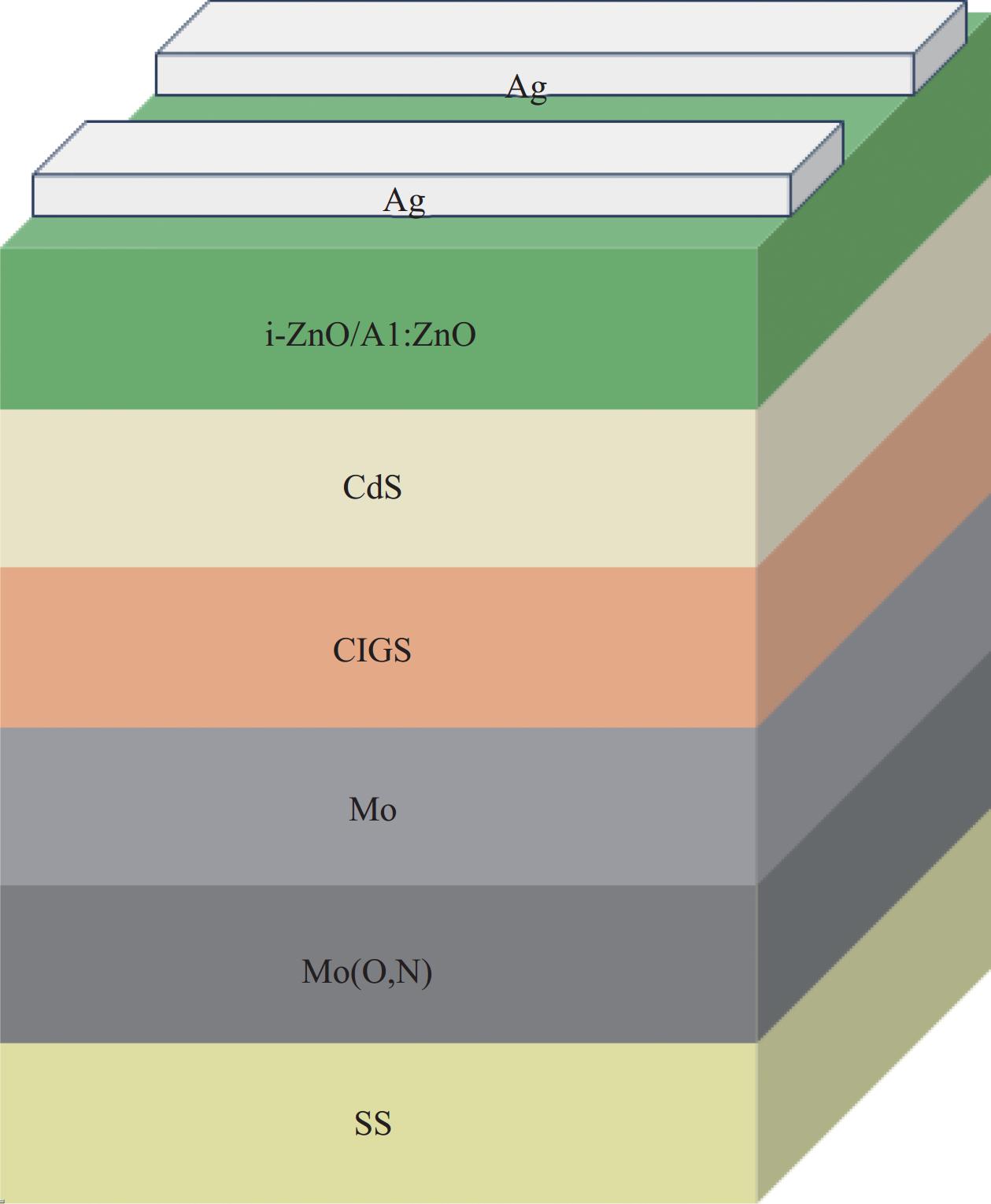

方法采用反应磁控溅射制备Mo(N,O)薄膜,通过扫描电子显微镜(SEM)和X射线衍射仪(XRD)研究了O流量对Mo(N,O)薄膜特性的影响,同时通过SEM、XRD和二次离子质谱(SIMS)研究了阻挡层对Mo、CIGS薄膜特性影响,并制备了结构为SS/Mo(N,O)/Mo/CIGS/CdS/i-ZnO/Al:ZnO/Ag的CIGS太阳电池,通过I-V和EQE分析阻挡层对电池器件的影响。

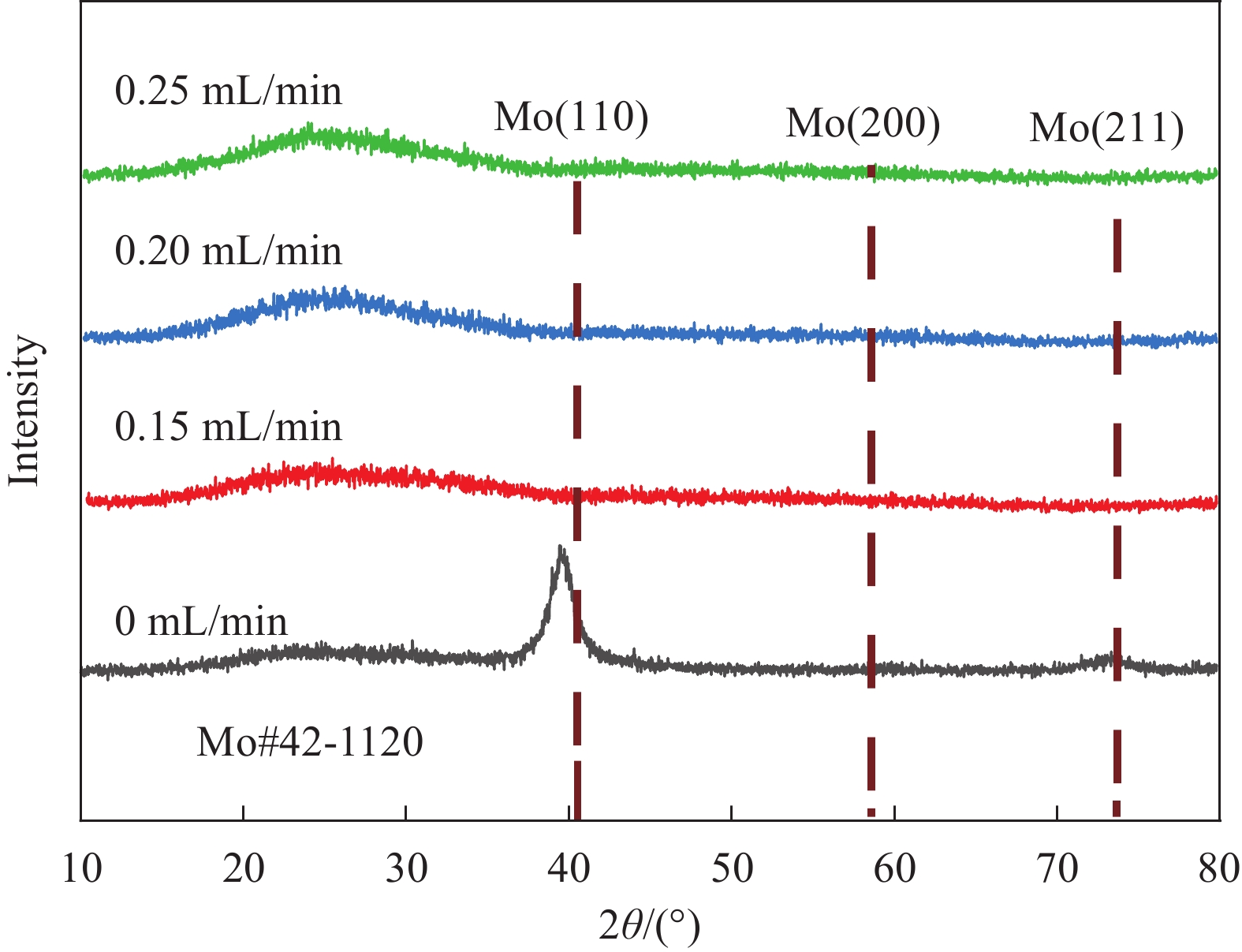

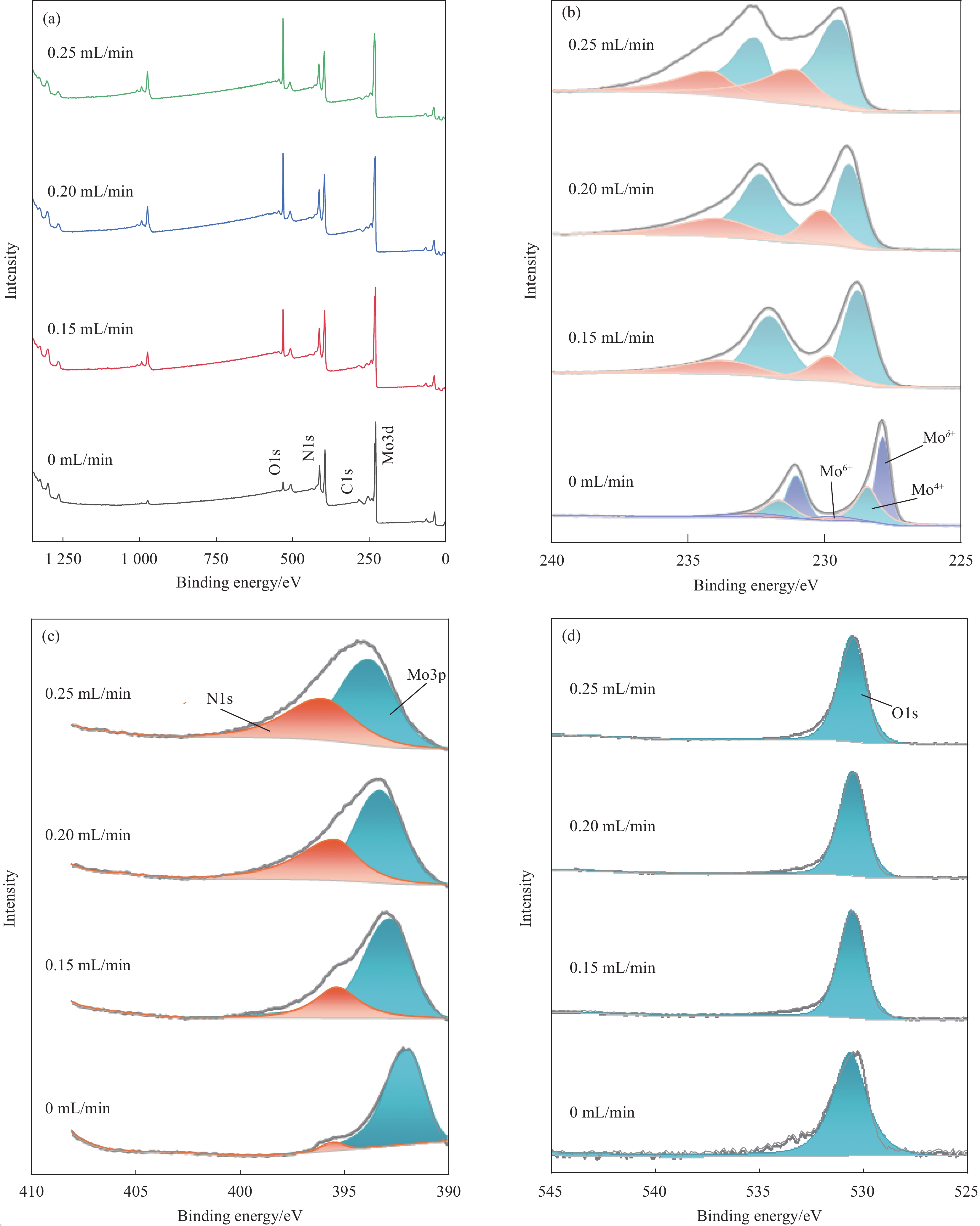

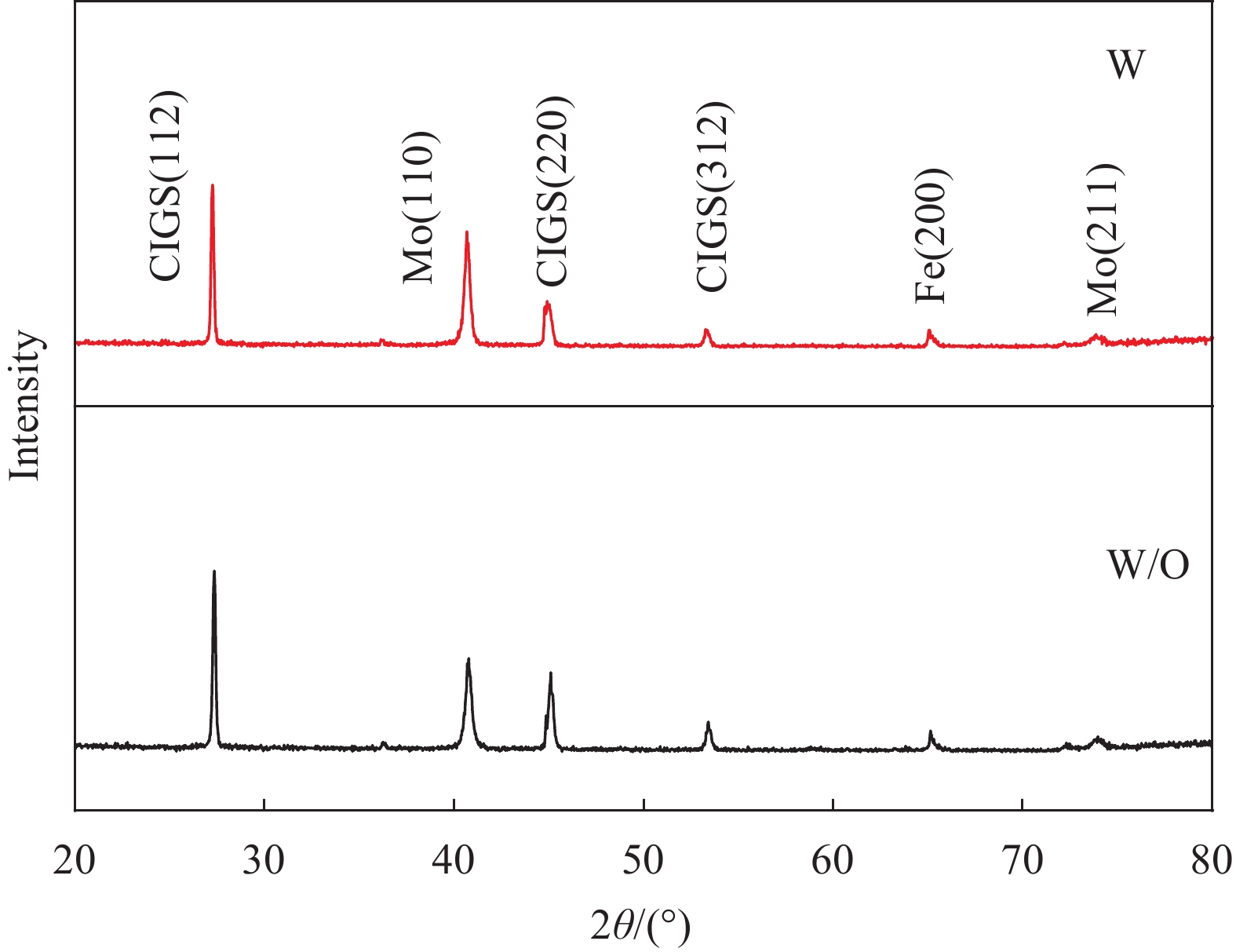

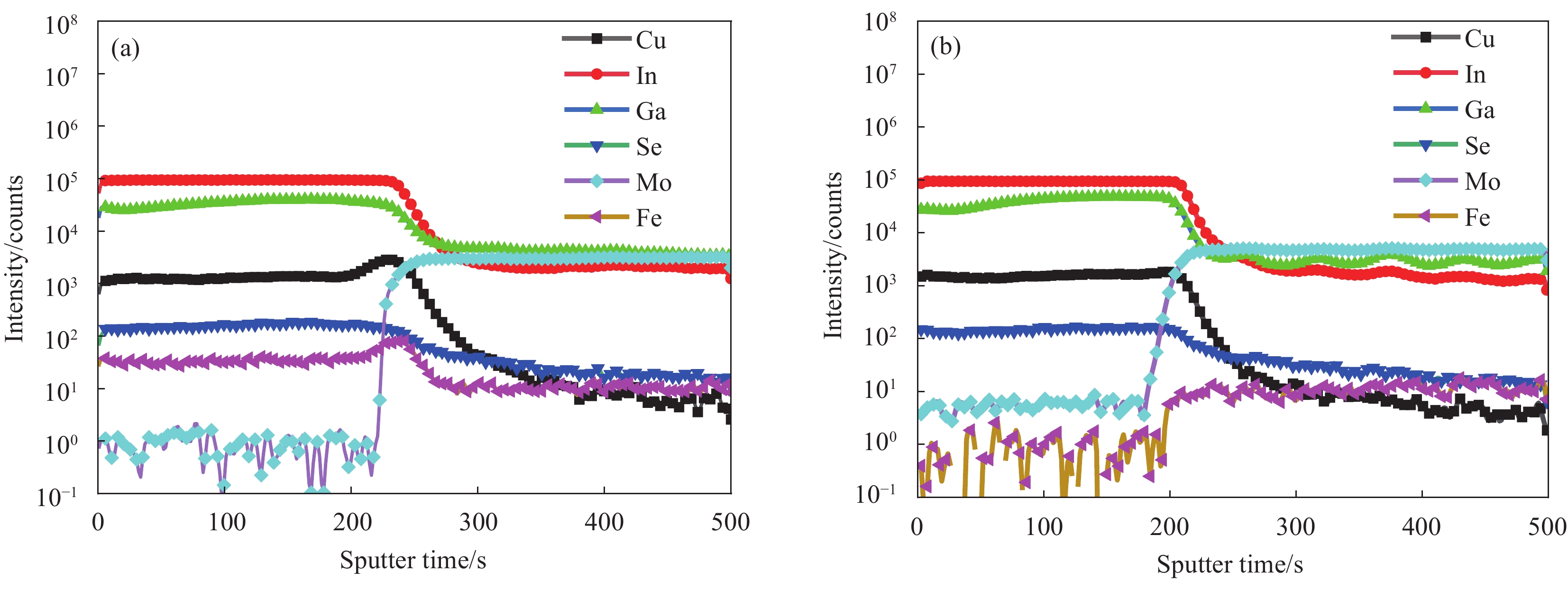

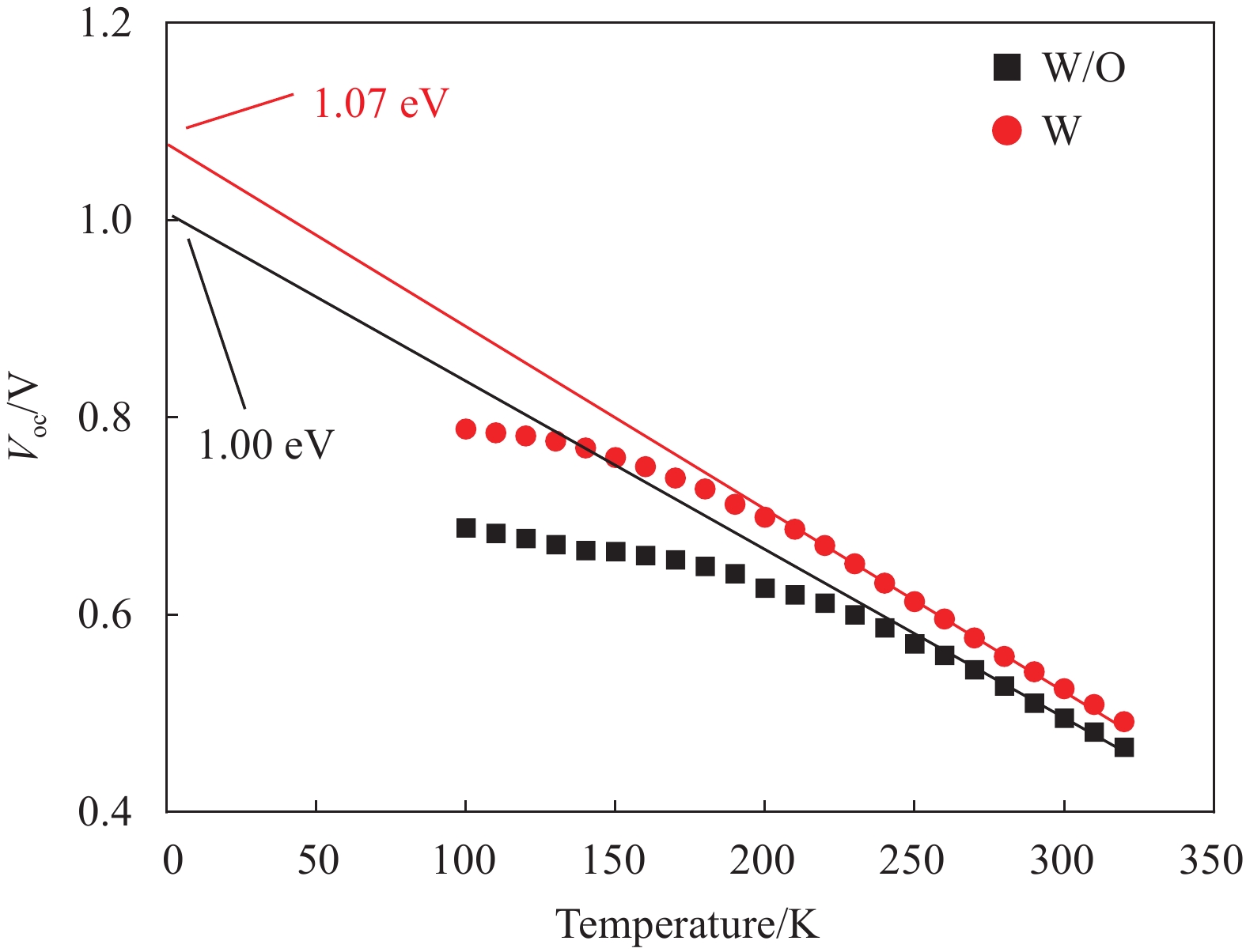

结果1.根据Mo(N,O)薄膜的表征结果可以看出:未通O时,薄膜表面呈现形状为金字塔结构的晶粒,通入0.15 mL/min O后,薄膜表面形貌发生改变,原来的金字塔结构的晶粒消失,转变为团簇的菜花状的晶粒,随着O流量的增加,薄膜的晶粒尺寸变小,晶界越来越不明显;XRD结果表明未通入O时,薄膜在39°左右出现明显的衍射峰,通入0.15 mL/min O后,薄膜的衍射峰消失,随着O流量的增加,没有衍射峰的出现;说明通入O后改变了薄膜的生长方式且形成非晶Mo(N,O)薄膜。2.把不同O流量条件下制备的Mo(N,O)薄膜作为阻挡层并完成太阳电池的制备,O流量为0.25 mL/min时,对应的太阳电池光电转换效率最佳。3. 选用0.25 mL/min O条件下制备的Mo(N,O)薄膜为阻挡层,通过XRD、SEM和SIMS测试观察阻挡层对Mo薄膜以及CIGS薄膜特性影响,结果表明有无阻挡层对Mo薄膜和CIGS薄膜的微观结构影响不大,Mo薄膜均呈现(110)择优生长,表面形貌呈现为三角形状的晶粒;CIGS薄膜均呈现(112)择优生长和连续且致密的大晶粒,但插入Mo(N,O)阻挡层使CIGS(220)/(112)的比值明显下降;SIMS结果表明插入Mo(N,O)阻挡层后,CIGS薄膜中Fe元素的相对信号强度由30 counts降至2 counts。4.通过优化工艺,并前掺NaF作为碱金属源,制备有无Mo(N,O)阻挡层的CIGS电池器件,I-V测试结果表明插入Mo(N,O)阻挡层后,器件的V由508 mV提高到了548 mV,J从29.5 mA·cm提高到33.1 mA·cm,FF从74%提高到78%,最终光电转换效率从11.07%提高到14.34%。EQE测试结果表明插入Mo(N,O)阻挡层明显提高了波长在800 nm至1100 nm的光谱响应。

结论本文通过反应磁控溅射制备了不同O流量的Mo(N,O)薄膜并应用于CIGS太阳电池,发现通入O使晶粒形状为金字塔结构的多晶MoN薄膜转变为团簇菜花状的非晶Mo(N,O)薄膜,O流量为0.25 mL/min时,电池器件性能最佳;Mo(N,O)薄膜不会影响Mo薄膜及CIGS薄膜的晶体结构和微观形貌,但可以有效阻挡衬底中Fe元素的扩散,使CIGS薄膜中Fe元素的相对信号强度由30 counts降至2 counts;引入Mo(N,O)阻挡层后,CIGS太阳电池光电转换效率由11.07%提高到14.34%。

下载:

下载: