Research progress of preparation and tribological application of two-dimensional layered Ti3C2Tx

-

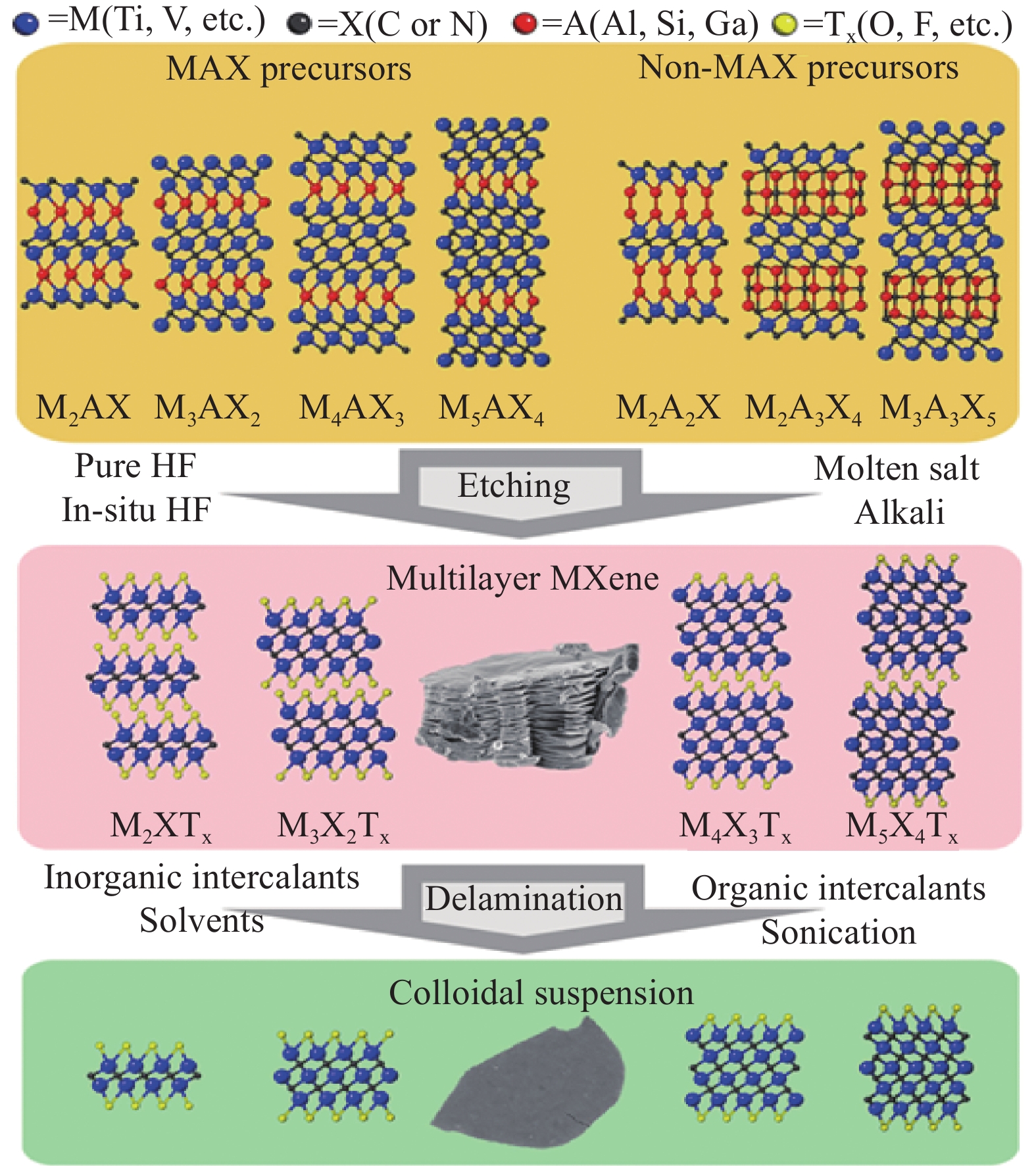

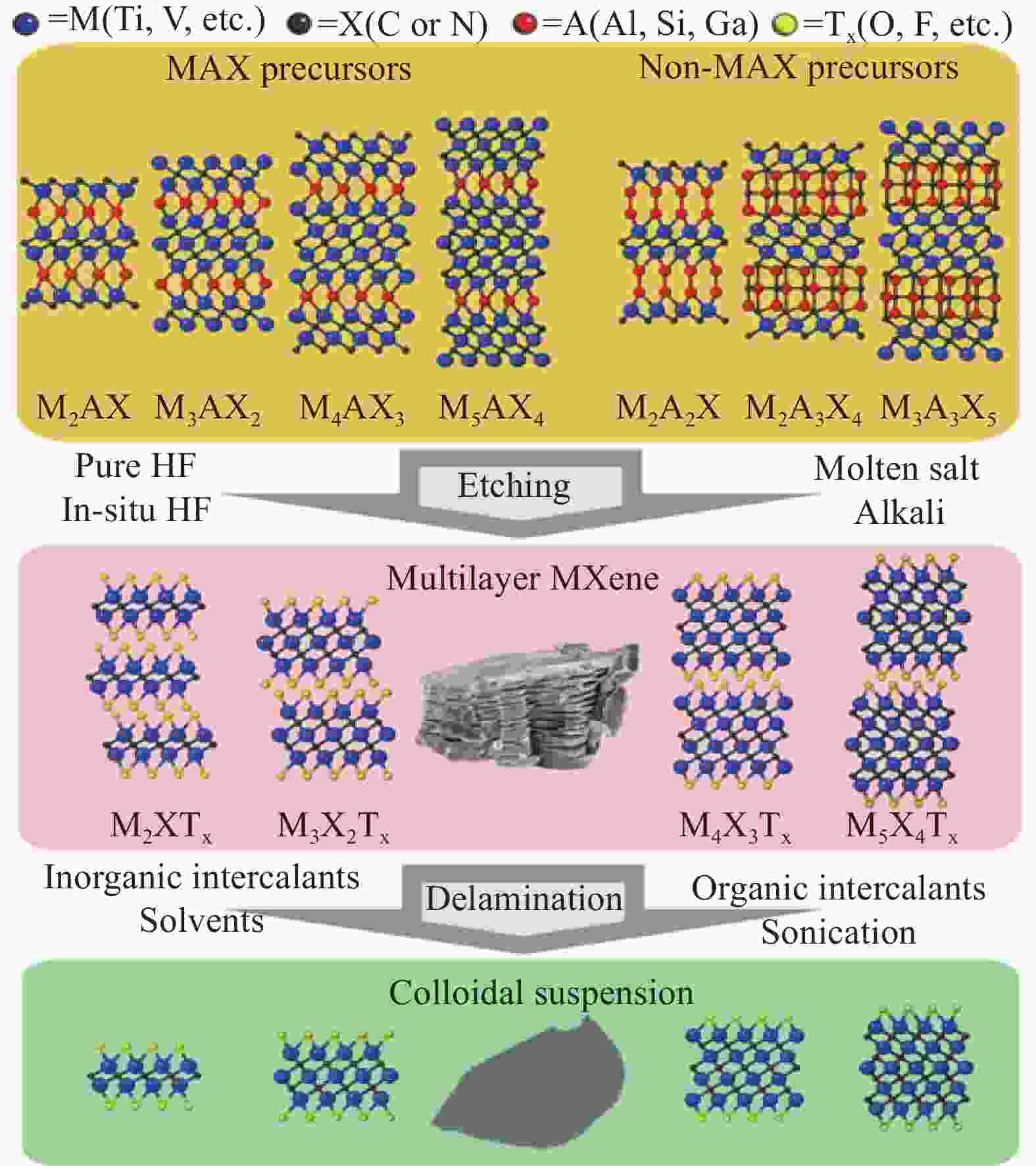

摘要: 二维层状材料不仅具有极高的承载能力,并且凭借其超薄的厚度在摩擦过程能较容易地进入摩擦接触区。因此,它们在减少摩擦和磨损方面具有巨大的研究和应用潜力。Mxenes作为一种类似于石墨烯的二维层状材料,具有独特的结构和丰富的官能团,其中Ti3C2Tx Mxenes因低层间剪切阻力、高比表面积、良好的分散性等优点而被广泛用作润滑添加剂。本文主要介绍了二维层状Ti3C2Tx的主要制备方法,包括“自上而下”和“自下而上”两种制备路线。同时对二维Ti3C2Tx作为液体润滑剂添加剂、固体润滑涂层添加剂、复合材料增强相的摩擦学应用及效果进行综述,并对其润滑机制进行了探讨。进一步对二维Ti3C2Tx的制备技术的发展和其作为新型润滑材料的应用前景作出展望。Abstract: The two-dimensional layered material not only has a very high load bearing capacity, but also can easily enter the friction contact zone during the friction process by virtue of its ultra-thin thickness. Therefore, they have great research and application potential in reducing friction and wear. As a two-dimensional layered material similar to graphene, Mxenes has a unique structure and rich functional groups. Among them, Ti3C2Tx Mxenes is widely used as a lubricating additive because of its advantages such as shear resistance between low layers, high specific surface area and good dispersion. This paper mainly introduces the main preparation methods of two-dimensional layered Ti3C2Tx, including "top-down" and "bottom-up" preparation routes. The tribological applications and effects of 2D Ti3C2Tx as liquid lubricant additive, solid lubricant coating additive and composite reinforcement phase are reviewed, and the lubrication mechanism of Ti3C2Tx is discussed. Further, the development of 2D Ti3C2Tx preparation technology and its application as a new lubrication material are prospected.

-

Key words:

- MXenes /

- two-dimensional Ti3C2Tx /

- lubricating additive /

- tribological property /

- lubrication mechanism

-

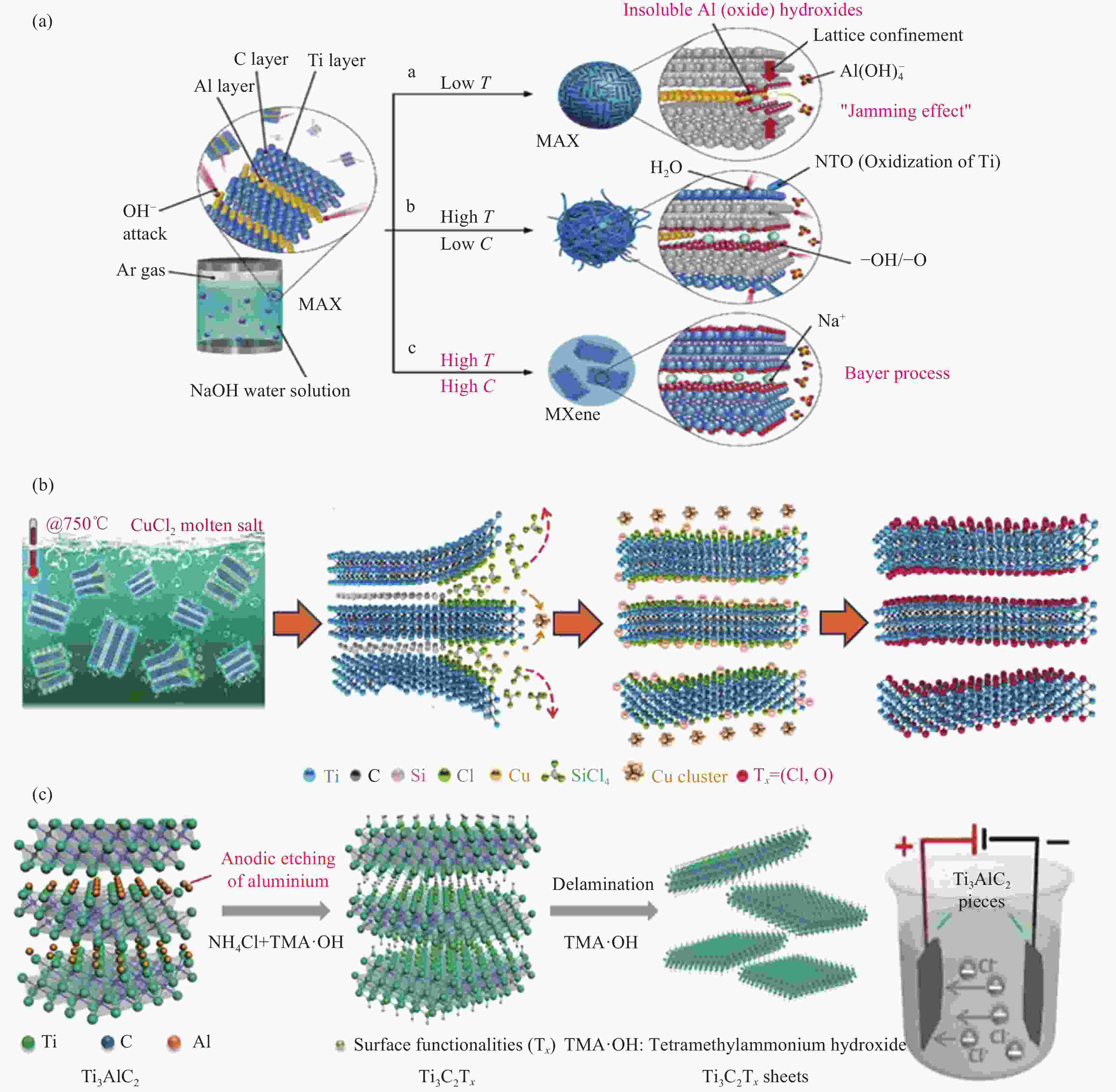

图 2 (a) Ti3C2Tx的氢氟酸刻蚀法[22];(b) 手风琴状多层Ti3C2Tx的SEM图像[22];(c) 多层Ti3C2Tx的插层与剥离[24] ;(d) 四甲基氢氧化铵插层-剥离的Ti3C2Tx纳米片的SEM图像[25]

Figure 2. (a) Hydrofluoric acid etching of Ti3C2Tx[22]; (b) SEM image of accordion-like multilayer Ti3C2Tx[22]; (c) Intercalation and stripping of multilayer Ti3C2Tx[24]; (d) SEM image of Ti3C2Tx nanosheets obtained by efficient intercalation and stripping with tetramethylammonium hydroxide[25]

图 6 (a) TDPA-Ti3C2合成路线;(b) 纯蓖麻油、添加0.1wt%未改性Ti3C2Tx 和TDPA改性Ti3C2Tx的蓖麻油润滑下的摩擦系数随时间变化规律;(c) 各实验组对应的磨损率[42]

Figure 6. (a) Synthesis route of TDPA-Ti3C2; (b) Time variation of friction coefficient of lubrication with pure castor oil, castor oil with 0.1wt% unmodified Ti3C2Tx and castor oil with TDPA modified Ti3C2Tx; (c) Wear rate of each experimental group[42]

TDPA—Tetradecyl phosphonic acid

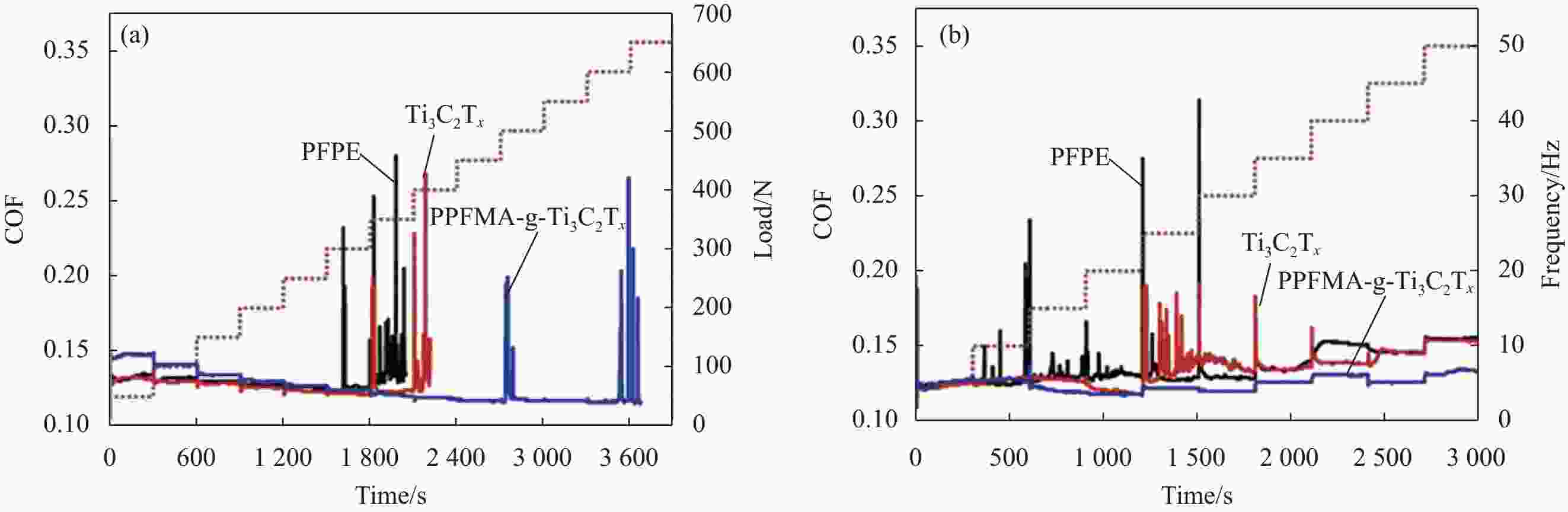

图 7 (a) 斜坡载荷作用下纯全氟聚醚(PFPE)、添加未改性Ti3C2Tx的PFPE和添加聚[2-(全氟辛基)甲基丙烯酸乙酯] (PPFMA)-g-Ti3C2Tx的PFPE润滑下的摩擦系数随时间变化规律;(b) 斜坡频率作用下各对应实验组的摩擦系数随时间变化规律[43]

Figure 7. (a) Time variation of friction coefficient of lubrication with pure PFPE, PFPE with unmodified Ti3C2Tx and PFPE with PPFMA-g-Ti3C2Tx under slope load; (b) Time variation of friction coefficient of each experimental group under slope frequency[43]

PPFMA—Poly[2-(perfluorooctyl)ethyl methacrylate)]; PFPE—Perfluoropolyether; COF—Coefficient of friction

图 9 (a) Si3N4与蓝宝石超润滑系统示意图;(b) 在Ti3C2Tx-甘油溶液润滑下Si3N4和蓝宝石表面的接触区示意图;((c)~(e)) 边界润滑接触区;(f) 弹性流体动力润滑示意图[48]

Figure 9. (a) Si3N4 and sapphire super lubrication system; (b) Diagram of contact zone between Si3N4 and sapphire surface lubricated by Ti3C2Tx-glycerin solution; ((c)-(e)) Boundary lubrication contact area; (f) Diagram of elastic hydrodynamic lubrication[48]

图 12 (a) MoS2/Ti3C2Tx复合涂层制备及摩擦试验示意图;(b) MoS2/Ti3C2Tx复合涂层与钢对钢、MoS2涂层对钢和Ti3C2Tx涂层对钢稳态摩擦系数;(c) MoS2/Ti3C2Tx复合涂层在不同载荷下的磨损率[62]

Figure 12. (a) MoS2/Ti3C2Tx composite coating preparation and friction test; (b) Steady state friction coefficient of MoS2/Ti3C2Tx composite coating and steel-to-steel, MoS2 coating on steel and Ti3C2Tx coating on steel; (c) Wear rate of MoS2/Ti3C2Tx composite coating under different loads[62]

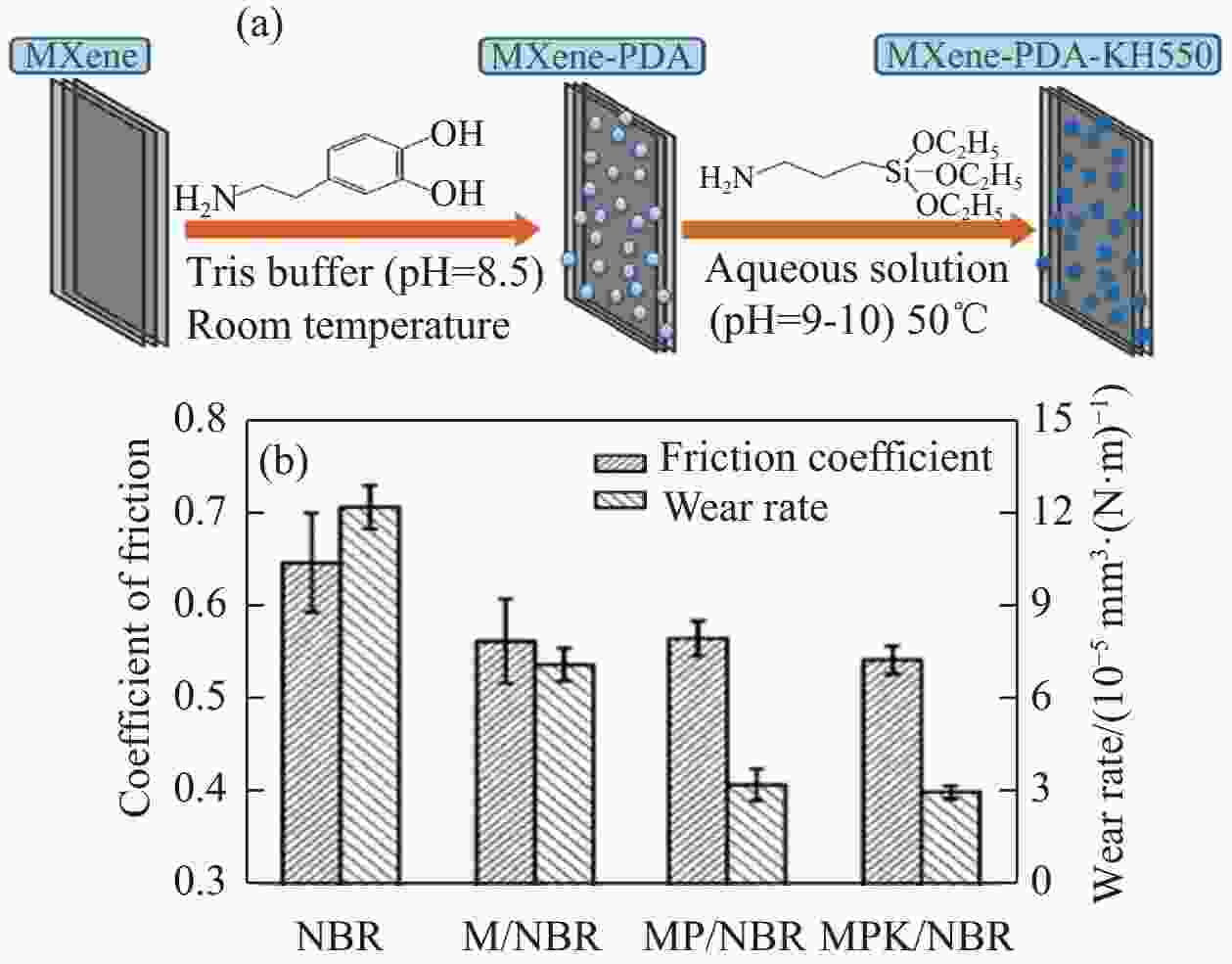

图 13 (a) 聚多巴胺(PDA)-3-氨基丙基三乙氧基硅烷(KH550)-Ti3C2Tx填料制备流程;(b) 纯丁腈橡胶(NBR)、Ti3C2Tx/NBR、PDA-Ti3C2Tx/NBR和PDA-KH550-Ti3C2Tx/NBR平均摩擦系数与磨损率[68]

Figure 13. (a) Preparation process of PDA-KH550-Ti3C2Tx filler; (b) Average coefficient of friction and wear rate of pure NBR, Ti3C2Tx/NBR, PDA-Ti3C2Tx/NBR and PDA-KH550-Ti3C2Tx/NBR[68]

PDA—Polydopamine; KH550—3-aminopropyl trie-thoxysilane; NBR—Nitrile butadiene rubber; M—MXene; MP—MXene-PDA; MPK—MXene-PDA-KH550

图 14 (a) 电解质中Ti3C2Tx的浓度分别为0、26、40 mg/mL时制备的Ti3C2Tx/Cu 复合材料摩擦系数随循环次数的变化规律;(b) 各实验组的磨损率及磨损区域SEM图像[73]

Figure 14. (a) Friction coefficient with the number of cycles of Ti3C2Tx/Cu composites prepared when the concentration of Ti3C2Tx in electrolyte is 0, 26, 40 mg/mL, respectively; (b) Wear rate and SEM images of wear area of each experimental group[73]

表 1 Ti3C2Tx作为液体润滑剂添加剂的润滑机制

Table 1. Lubrication mechanism of Ti3C2Tx as liquid lubricant additives

Base lubricant Friction pair Lubrication effects Lubrication mechanism Ref. Paraffin oil Ball 440-C-disk 45# COF: 50% decrease Ti3C2Tx nanosheets enter the friction surface to promote the formation of a continuous uniform lubrication film, micro-polishing and self-healing of the wear area. [38] 100SN base oil Ball 440-C-disk 45# COF: 10%-25%

decreaseTi3C2Tx nanosheets promote the formation of low shear stress lubrication film on the friction surface. [39] PAO8 base oil Ball 32100 steel-

disk 32100 steelCOF: 9% decrease;

Wear volume: 92.3%

decreaseTi3C2Tx nanosheets promote the formation of low shear stress lubrication film on the friction surface. [40] PAO8 base oil Ball 32100 steel-

disk 32100 steelCOF: 31% decrease Enhance the bearing capacity of the lubrication film. [54] Castor oil Ball steel-disk steel COF: 27.9% decrease;

Wear rate: 55.1%

decreaseThe phosphoric acid group of TDPA binds to the hydroxyl group on the surface of Ti3C2Tx, while the long chain alkyl group penetrates into the oil molecules, allowing Ti3C2Tx to be stably dispersed in the oil. Ti3C2Tx promotes the formation of a lubrication film with low shear stress. [42] PFPE Ball GCr15 steel-

disk GCr15 steelCOF: 7% decrease;

Wear rate: 75.3%

decreaseTi3C2Tx nanosheets grafted with fluoropolymer have good dispersion and stability in lubricant. The physical adsorption film of Ti3C2Tx and the tribochemical reaction film together form a continuous and stable lubrication film to separate the contact surface and reduce friction. Ti3C2Tx reduces the decomposition of PFPE at high temperatures. [43] PAO base oil Ball AISI 52100 steel-

disk AISI 52100 steelCOF: 74.6% decrease;

Wear volume: 88.1%

decreaseThe Ti3C2Tx nanosheets loaded with Cu nanoparticles are easier to slide between layers. The physical adsorption film and friction oxide film together form a continuous and stable lubricating film. Cu nanoparticles repair interfacial wear areas. Ti3C2Tx nanosheets were used as growth carriers to avoid agglomeration of Cu nanoparticles. [45] Water Ball AISI 440 C steel-

disk AISI 440 C steelCOF: 20% decrease;

Wear volume: 48%

decreaseTi3C2Tx adsorbs friction surfaces to form a lubrication film with low shear stress, filling in worn areas. [46] Water Ball SiC-

disk 316 steelCOF: 34.74% decrease;

Wear volume: 45.58% decreaseTi3C2Tx adsorbs the friction surface to form a lubrication film with low shear stress, while improving the wettability of water to the steel pan. [47] Water/

glycerolBall Si3N4-

disk sapphireSuperlubrication

(COF: 0.002)

Wear volume: 97.87% decreaseTi3C2Tx forms a physical adsorption film and a friction oxide film composed of titanium and silicon oxide colloids and constitutes a continuous and uniform lubrication film. A large number of hydroxyl groups present in glycerol and water are attached to the Ti3C2Tx nanosheet through hydrogen bond interaction, and a hydrated layer is generated on the nanosheet, which further reduces the shear stress of the liquid film and achieves super-lubrication. As shown in Fig.9. [48] Notes: PFPE—Perfluoropolyether; TDPA—Tetradecylphosphonic acid. 表 2 Ti3C2Tx作为固体润滑涂层的润滑机制

Table 2. Lubrication mechanism of Ti3C2Tx as solid lubricating coating

Base lubricant Friction pair Lubrication effects Lubrication mechanism Ref. Ti3C2Tx Ball AISI 52100 steel-

disk Cu

(Ti3C2Tx coating)COF: 75.1% decrease;

Wear volume: 94.9% decreaseTi3C2Tx nanocoatings promote the formation of carbon transfer film to with friction pairs. [57] Ti3C2Tx Ball 100Cr6 steel-

disk 100Cr6 steel

(Ti3C2Tx coating)COF: 35.9% decrease;

Wear volume: 53.8% decreaseDense Ti3C2Tx forms a low shear stress lubrication film, reducing friction and wear. [58] Ti3C2Tx/EP Ball GCr15 steel-

disk Ti-6Al-V

(Ti3C2Tx/EP coating)COF: 34% decrease Ti3C2Tx nanosheets and EP form a stable transfer lubrication film with good adhesion and lubrication properties. [63] Ti3C2Tx/nano-

diamondBall PTFE-silicon chip (Ti3C2Tx/nano-

diamond coating)COF: 50% decrease;

Nearly zero wearThe protective and self-lubricating effect of PTFE, the rolling of nano-diamond, the shear slip of Ti3C2Tx nanosheets and the synergistic effect of various mechanisms achieve low friction and ultra-wear-resistant lubrication. [60] Graphene/

Ti3C2TxBall stainless steel

(DLC coating)-

Silicon chip

(Graphene/Ti3C2Tx

coating)Superlubrication

COF: 0.0042;

Wear rate: 95.5%

decreaseTi3C2Tx nanosheets work collaboratively with graphene to form a lubrication film with low shear stress, while the graphene coating protects the DLC coating of the steel ball. [61] MoS2/Ti3C2Tx Ball AISI 52100 steel-

disk AISI 52100 steel

(MoS2/Ti3C2Tx coating)Superlubrication

COF: 0.0034;

Wear rate: 95.5%

decreaseA strong friction film is formed under high contact pressure. Ti eliminates the harmful effects of oxygen on the lubrication performance of MoS2. [62] Notes: EP—Epoxy resin; PTFE—Polytetrafluoroethylene; DLC—Diamond like carbon. 表 3 Ti3C2Tx作为复合材料增强相的润滑机制

Table 3. Lubrication mechanism of Ti3C2Tx as composite reinforcement phase

Base lubricant Friction pair Lubrication effects Lubrication mechanism Ref. Ti3C2Tx/UHMWPE Pin steel-disk

Ti3C2Tx/UHMWPECOF: 31.2% decrease Ti3C2Tx spalling during the friction process to form a lubricating film. The addition of Ti3C2Tx improves the hardness and crystallinity of the matrix, and improves the mechanical properties and wear resistance. [67] PDA-KH550-

Ti3C2Tx/NBRBall GCr15 steel-

disk PDA-KH550-

Ti3C2Tx/NBRCOF: 16% decrease;

Wear volume: 76% decreaseThe Ti3C2Tx nanoparticle forms a lubricating film on the wear surface. The surface modification of Ti3C2Tx improves the interface bonding strength and hardness between Ti3C2Tx and matrix, and inhibits abrasive wear and adhesive wear.

[68]Ti3C2/EP Ball GCr15 steel-

disk Ti3C2/EPCOF: 76.3% decrease;

Wear volume: 67.3% decreaseThe addition of Ti3C2Tx nanosheet improves the hardness and thermal conductivity of the material, reduces the deformation and damage during friction, and reduces the defects caused by heat accumulation. [69] Al2O3@Ti3C2Tx/EP Ring GCr15 steel-plate Al2O3@Ti3C2Tx/EP Superlubrication;

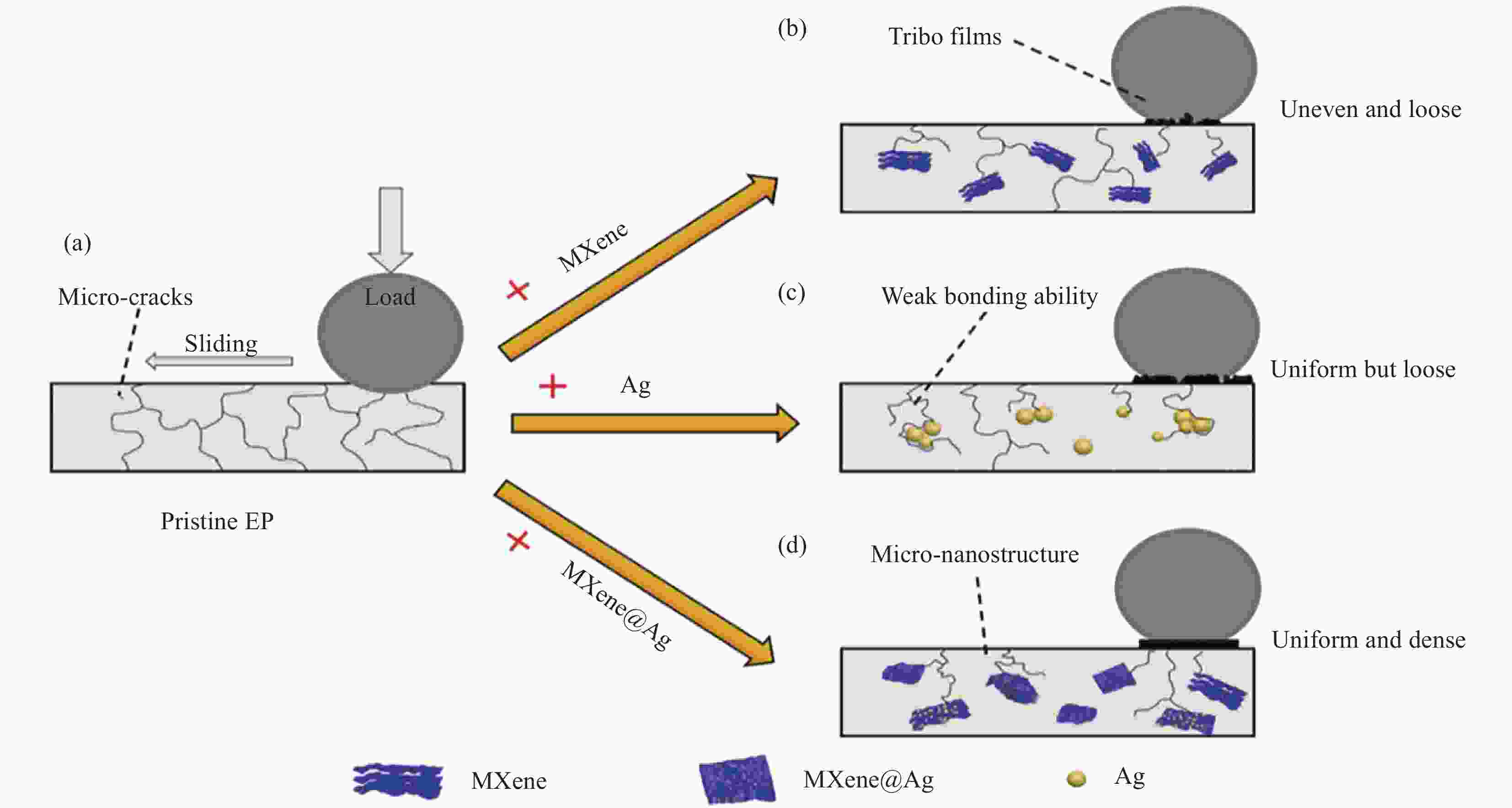

Wear volume: 97% decreaseThe sliding interface of Ti3C2Tx, EP and Al2O3 adhere to the metal surface to form a strong lubricating film, which inhibits the oxidation of the steel surface. Al2O3 in friction film induces carbon element to transform into carbon film. [70] Ag@Ti3C2Tx/EP Ball 304 steel-disk Ag@Ti3C2Tx/EP COF: 14.3% decrease;

Wear volume: 87.5% decreaseTi3C2Tx and Ag nanoparticles promote the formation of a continuous and stable friction film, as shown in Fig.15. [78] Ti3C2Tx/Al Ball GCr15 steel-

disk Ti3C2Tx/AlCOF: 59.2% decrease Ti3C2Tx forms a lubricating film on the friction surface and reduces the friction coefficient. Ti3C2Tx improves the hardness of the composite and inhibits abrasive wear. [72] Ti3C2Tx/Cu Ball GCr15 steel-

disk Ti3C2Tx/CuCOF: 46% decrease;

Wear volume: 95% decreaseThe worn surface forms a dense lubricating film rich in Ti3C2Tx. [73] Note: UHMWPE—Ultrahigh molecular weight polyethylene. -

[1] HOLMBERG K, ERDEMIR A. Influence of tribology on global energy consumption, costs and emissions[J]. Friction, 2017, 5(3): 263-284. doi: 10.1007/s40544-017-0183-5 [2] NOVOSELOV K S, GEIM A K, MOROZOV S V, et al. Electric field effect in atomically thin carbon films[J]. Science, 2004, 306(5696): 666-669. [3] SHENEVE Z B, SHAWNA M H, CAO L Y, et al. Progress, challenges, and opportunities in two-dimensional materials beyond graphene[J]. ACS Nano, 2013, 7(4): 2898-2926. doi: 10.1021/nn400280c [4] FIORI G, BONACCORSO F, IANNACCONE G, et al. Electronics based on two-dimensional materials[J]. Nature Nanotechnology, 2014, 9: 1063. doi: 10.1038/nnano.2014.283 [5] FELICE T, TIAN C G. Related two-dimensional crystals and hybrid systems for printed and wearable electronics[J]. Nano Today, 2018, 23: 73-96. [6] LIN J Y, CHAN C Y, CHOU S W. Electrophoretic deposition of transparent MoS2-graphene nanosheet composite films as counter electrodes in dye-sensitized solar cells[J]. Chemical Communications, 2013, 49: 1440-1442. doi: 10.1039/c2cc38658e [7] HU S, LOZADA H M, WANG F, et al. Proton transport through one-atom-thick crystals[J]. Nature, 2014, 516: 227-230. doi: 10.1038/nature14015 [8] TAO Y, XIE X, LYU W, et al. Towards ultrahigh volumetric capacitance: Graphene derived highly dense but porous carbons for supercapacitors[J]. Scientific Reports, 2013, 3: 2975. doi: 10.1038/srep02975 [9] CHIA X, PUMERA M. Characteristics and performance of two-dimensional materials for electrocatalysis[J]. Nature Catalysis, 2018, 1: 909-921. doi: 10.1038/s41929-018-0181-7 [10] ZHANG S, MA T B, ERDEMIR A, et al. Tribology of two-dimensional materials: From mechanisms to modulating strategies[J]. Materials Today, 2019, 26: 67-86. doi: 10.1016/j.mattod.2018.12.002 [11] NAGUIB M, KURTOGLU M, PRESSER V, et al. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2[J]. Advanced Materials, 2011, 23(37): 4248-4253. [12] NAGUIB M, BARSOUM M W, YURY G. Ten years of progress in the synthesis and development of MXenes[J]. Advanced Materials, 2021, 33: 2103393. doi: 10.1002/adma.202103393 [13] LI X, HUANG Z, SHUCK C E, et al. MXene chemistry, electrochemistry and energy storage applications[J]. Nature Reviews Chemistry, 2022, 6: 389-404. doi: 10.1038/s41570-022-00384-8 [14] WANG H, WANG H, WANG Z W, et al. Covalent organic framework photocatalysts: Structures and applications[J]. Chemical Society Reviews, 2020, 49(12): 4135-4165. doi: 10.1039/D0CS00278J [15] HAN M K, SHUCK C E, ROMAN R, et al. Beyond Ti3C2T x: MXenes for electromagnetic interference shielding[J]. ACS Nano, 2020, 14(4): 5008-5016. doi: 10.1021/acsnano.0c01312 [16] XIE Z J, PENG Y P, YU L, et al. Solar-inspired water purification based on emerging 2D materials: Status and challenges[J]. Solar RRL, 2020, 4(3): 1900400. [17] BHARDWA J, RADH A, HAZRA A. MXene-based gas sensors[J]. Journal of Materials Chemistry C, 2021, 9(44): 15735-15754. doi: 10.1039/D1TC04085E [18] SOLEYMANIHA M, SHAHBAZI M A, RAFIEERAD A R, et al. Promoting role of MXene nanosheets in biomedical sciences: Therapeutic and biosensing innovations[J]. Advanced Healthcare Materials, 2019, 8(1): 1801137. [19] MIKHAIL S, CHRISTOPHER C E, SARYCHEVA A, et al. Characterization of MXenes at every step, from their precursors to single flakes and assembled films[J]. Progress in Materials Science, 2021, 120: 100757. doi: 10.1016/j.pmatsci.2020.100757 [20] XU C, WANG L, LIU Z, et al. Large-area high-quality 2D ultrathin Mo2C superconducting crystals[J]. Nature Materials, 2015, 14: 1135-1141. doi: 10.1038/nmat4374 [21] ZAHARIN H A, GHAZALI M J, THACHNATHAREN N, et al. Progress in 2D materials based nanolubricants: A review[J]. Flatchem, 2023, 38: 100485. [22] NAGUIB M, MOCHALIN V N, BARSOUM M W, et al. MXenes: A new family of two-dimensional materials[J]. Advanced Materials, 2014, 26(7): 992-1005. [23] XU M S, LIANG T, SHI M M, et al. Graphene-like two-dimensional materials[J]. Chemical Reviews, 2013, 113(5): 3766-3798. doi: 10.1021/cr300263a [24] WU S M, WANG H, LI L, et al. Intercalated MXene-based layered composites: Preparation and application[J]. Chinese Chemical Letters, 2020, 31(4): 961-968. doi: 10.1016/j.cclet.2020.02.046 [25] ALHABEB M, MALESKI K, ANASORI B, et al. Guidelines for synthesis and processing of two-dimensional [2D] titanium carbide (Ti3C2T x MXene)[J]. Chemistry of Materials, 2017, 29(18): 7633-7644. doi: 10.1021/acs.chemmater.7b02847 [26] ALHABEB M, MALESKI K, MATHIS T S, et al. Selective etching of silicon from Ti3SiC2 (MAX) to obtain 2D titanium carbide (MXene)[J]. Angewandte Chemie International Edition, 2018, 57(19): 5444-5448. doi: 10.1002/anie.201802232 [27] LI T F, YAO L L, LIU Q L, et al. Fluorine-free synthesis of high-purity Ti3C2Tx (T=OH, O) via alkali treatment[J]. Angewandte Chemie International Edition, 2018, 57(21): 6115-6119. [28] LI Y, SHAO H, LIN Z, et al. A general Lewis acidic etching route for preparing MXenes with enhanced electrochemical performance in non-aqueous electrolyte[J]. Nature Materials, 2020, 19: 894-899. doi: 10.1038/s41563-020-0657-0 [29] JIANG L, ZHOU D, YANG J, et al. 2D single- and few-layered MXenes: Synthesis, applications and perspectives[J]. Journal of Materials Chemistry A, 2022, 10(26): 13651-13672. doi: 10.1039/D2TA01572B [30] YANG S, ZHANG P, WANG F, et al. Fluoride-free synthesis of two-dimensional titanium carbide (MXene) using a binary aqueous system[J]. Angewandte Chemie International Edition, 2018, 57(47): 15491-15495. doi: 10.1002/anie.201809662 [31] SANG X, XIE Y, YILMAZ D E, et al. In situ atomistic insight into the growth mechanisms of single layer 2D transition metal carbides[J]. Nature Communications, 2018, 9: 2266. doi: 10.1038/s41467-018-04610-0 [32] WANG D, ZHOU C K, FILATOV A S, et al. Direct synthesis and chemical vapor deposition of 2D carbide and nitride MXenes[J]. Science, 2023, 379(6638): 1242-1247. doi: 10.1126/science.add9204 [33] SEYEDEH Al K, WANG Y. Super strong 2D titanium carbide MXene-based materials: A theoretical prediction[J]. Journal of Physics: Condensed Matter, 2019, 32(11): 11LT01. [34] LU X Y, GU X L, SHI Y J. A review on the synthesis of MXenes and their lubrication performance and mechanisms[J]. Tribology International, 2023, 179: 108170. doi: 10.1016/j.triboint.2022.108170 [35] DAWCZYK J, MORGAN N, RUSSO J, et al. Film thickness and friction of ZDDP tribofilms[J]. Tribology Letters, 2019, 67: 34. doi: 10.1007/s11249-019-1148-9 [36] ROKOSZ M J, CHEN A E, LOWE-MA C K, et al. Characterization of phosphorus-poisoned automotive exhaust catalysts[J]. Applied Catalysis B: Environmental, 2001, 33(3): 205-215. doi: 10.1016/S0926-3373(01)00165-5 [37] CHOUHAN A, MUNGSE H P, KHATRI O P. Surface chemistry of graphene and graphene oxide: A versatile route for their dispersion and tribological applications[J]. Advances in Colloid and Interface Science, 2020, 283: 102215. doi: 10.1016/j.cis.2020.102215 [38] YANG J, CHEN B B, SONG H J, et al. Synthesis, characterization, and tribological properties of two-dimensional Ti3C2[J]. Crystal Research and Technology, 2014, 49(11): 926-932. [39] ZHANG X H, XUE M Q, YANG X H, et al. Preparation and tribological properties of Ti3C2(OH)2 nanosheets as additives in base oil[J]. RSC Advances, 2015, 5(4): 2762-2767. doi: 10.1039/C4RA13800G [40] LIU Y, ZHANG X, DONG S, et al. Synthesis and tribological property of Ti3C2T x nanosheets[J]. Materials Science, 2017, 52: 2200-2209. doi: 10.1007/s10853-016-0509-0 [41] WYATT B C, ROSENKRANZ A, ANASORI B. 2D MXenes: Tunable mechanical and tribological properties[J]. Advanced Materials, 2021, 33(17): 2007973. doi: 10.1002/adma.202007973 [42] FENG Q, DENG F K, LI K C, et al. Enhancing the tribological performance of Ti3C2 MXene modified with tetradecylphosphonic acid[J]. Colloids and Surfaces A, 2021, 625: 126903. doi: 10.1016/j.colsurfa.2021.126903 [43] GUO J L, WU P X, ZENG C, et al. Fluoropolymer grafted Ti3C2T x MXene as an efficient lubricant additive for fluorine-containing lubricating oil[J]. Tribology International, 2022, 170: 107500. doi: 10.1016/j.triboint.2022.107500 [44] JIAO S L, LIU L. Friction-induced enhancements for photocatalytic degradation of MoS2@Ti3C2 nanohybrid[J]. Industrial and Engineering Chemistry Research, 2019, 58(39): 18141-18148. doi: 10.1021/acs.iecr.9b03680 [45] CUI Y H, XUE S H, CHEN X, et al. Fabrication of two-dimensional MXene nanosheets loading Cu nanoparticles as lubricant additives for friction and wear reduction[J]. Tribology International, 2022, 176: 107934. doi: 10.1016/j.triboint.2022.107934 [46] NGUYEN H T, CHUNG K H. Assessment of tribological properties of Ti3C2 as a water-based lubricant additive[J]. Materials, 2020, 13(23): 5545. doi: 10.3390/ma13235545 [47] CHEN J F, ZHAO W J. Simple method for preparing nanometer thick Ti3C2T x sheets towards highly efficient lubrication and wear resistance[J]. Tribology International, 2021, 153: 106598. doi: 10.1016/j.triboint.2020.106598 [48] YI S, LI J J, LIU Y F, et al. In-situ formation of tribofilm with Ti3C2T x MXene nanoflakes triggers macroscale superlubricity[J]. Tribology International, 2021, 154: 106695. doi: 10.1016/j.triboint.2020.106695 [49] PARRA-MINOZ N, SOLER M, ROSENKRANZ A. Covalent functionalization of MXenes for tribological purposes: A critical review[J]. Advances in Colloid and Interface Science, 2022, 309: 102792. doi: 10.1016/j.cis.2022.102792 [50] DU C F, ZHAO X Y, WANG Z J, et al. Recent advanced on the MXene-organic hybrids: Design, synthesis, and their applications[J]. Nanomaterials, 2021, 11(1): 166. doi: 10.3390/nano11010166 [51] MAHMUD S T, HASAN M M, BAIN S, et al. Multilayer MXene heterostructures and nanohybrids for multifunctional applications: A review[J]. ACS Materials Letters, 2022, 4(6): 1174-1206. doi: 10.1021/acsmaterialslett.2c00175 [52] JIAO D, ZHENG S H, WANG Y Z, et al. The tribology properties of alumina/silica composite nanoparticles as lubricant additives[J]. Applied Surface Science, 2011, 257(13): 5720-5725. doi: 10.1016/j.apsusc.2011.01.084 [53] LUO T, WEI X W, ZHAO H Y, et al. Tribology properties of Al2O3/TiO2 nanocomposites as lubricant additives[J]. Ceramics International, 2014, 40(7): 10103-10109. doi: 10.1016/j.ceramint.2014.03.181 [54] ZHANG X F, GUO Y, LI Y J, et al. Preparation and tribological properties of potassium titanate-Ti3C2T x nanocomposites as additives in base oil[J]. Chinese Chemical Letters, 2019, 30(2): 502-504. doi: 10.1016/j.cclet.2018.07.007 [55] UZOMA P C, HU H, KHADEM M, et al. Tribology of 2D nanomaterials: A review[J]. Coatings, 2020, 10(9): 897. doi: 10.3390/coatings10090897 [56] 王汝霖. 润滑剂摩擦化学[M]. 北京: 中国石化出版社, 1994: 318-387.WANG Rulin. Tribochemistry of lubricant[M]. Beijing: China Petrochemical Press, 1994: 318-387(in Chinese). [57] LIAN W Q, MAI Y J, LIU C S, et al. Two-dimensional Ti3C2 coating as an emerging protective solid-lubricant for tribology[J]. Ceramics International, 2018, 44(16): 20154-20162. doi: 10.1016/j.ceramint.2018.07.309 [58] MARIAN M, SONG G C, WANG B, et al. Effective usage of 2D MXene nanosheets as solid lubricant—Influence of contact pressure and relative humidity[J]. Applied Surface Science, 2020, 531: 147311. doi: 10.1016/j.apsusc.2020.147311 [59] MARIAN M, STEPHAN T, SANDRO W, et al. Mxene nanosheets as an emerging solid lubricant for machine elements-Towards increased energy efficiency and service life[J]. Applied Surface Science, 2020, 523: 146503. doi: 10.1016/j.apsusc.2020.146503 [60] YIN X, JIN J, CHEN X C, et al. Ultra-wear-resistant MXene-based composite coating via in situ formed nanostructured tribofilm[J]. ACS Applied Materials and Interfaces, 2019, 11(35): 32569-32576. doi: 10.1021/acsami.9b11449 [61] HUANG S, MUTYALA K C, SUMANT A V, et al. Achieving superlubricity with 2D transition metal carbides (MXenes) and MXene/graphene coatings[J]. Materials Today Advances, 2021, 9: 100133. doi: 10.1016/j.mtadv.2021.100133 [62] MACKNOJIA A, AYYAGARI A, ZAMBRANO D, et al. Macroscale superlubricity induced by MXene/MoS2 nanocomposites on rough steel surfaces under high contact stresses[J]. ACS Nano, 2023, 17(3): 2421-2430. doi: 10.1021/acsnano.2c09640 [63] DU C F, WANG Z J, WANG X M, et al. Probing the lubricative behaviors of a high MXene-content epoxy-based composite under dry sliding[J]. Tribology International, 2022, 165: 107314. doi: 10.1016/j.triboint.2021.107314 [64] MALAKI M, VARMA R S. Mechanotribological aspects of MXene-reinforced nanocomposites[J]. Advanced Materials, 2020, 32(38): 2003154. doi: 10.1002/adma.202003154 [65] FAKHAR A, RAZZAGHI-KASHANI M, MEHRANPOUR M. Improvements in tribological properties of polyoxymethylene by aramid short fiber and polytetrafluoroethylene[J]. Iranian Polymer Journal, 2013, 22: 53-59. doi: 10.1007/s13726-012-0102-6 [66] SLIOZBERG Y, ANDZELM J, HATTER C B, et al. Interface binding and mechanical properties of MXene-epoxy nanocomposites[J]. Composites Science and Technology, 2020, 192: 108124. doi: 10.1016/j.compscitech.2020.108124 [67] ZHANG H, WANG L B, CHEN Q, et al. Preparation, mechanical and anti-friction performance of MXene/polymer composites[J]. Materials and Design, 2016, 92: 682-689. doi: 10.1016/j.matdes.2015.12.084 [68] QU C H, LI S, ZHANG Y M, et al. Surface modification of Ti3C2-MXene with polydopamine and amino silane for high performance nitrile butadiene rubber composites[J]. Tribology International, 2021, 163: 107150. doi: 10.1016/j.triboint.2021.107150 [69] MENG F N, ZHANG Z Y, GAO P L, et al. Excellent tribological properties of epoxy-Ti3C2 with three-dimensional nanosheets composites[J]. Friction, 2021, 9: 734-746. doi: 10.1007/s40544-020-0368-1 [70] GUO L H, ZHANG Y M, ZHANG G, et al. MXene-Al2O3 synergize to reduce friction and wear on epoxy-steel contacts lubricated with ultra-low sulfur diesel[J]. Tribology International, 2021, 153: 106588. doi: 10.1016/j.triboint.2020.106588 [71] WYATT B C, NEMANI S K, ANASORI B. 2D transition metal carbides (MXenes) in metal and ceramic matrix composites[J]. Nano Convergence, 2021, 8(16):1-8. doi: 10.1186/s40580-021-00266-7 [72] HU J, LI S B, ZHANG J, et al. Mechanical properties and frictional resistance of Al composites reinforced with Ti3C2T x MXene[J]. Chinese Chemical Letters, 2020, 31(4): 996-999. doi: 10.1016/j.cclet.2019.09.004 [73] MAI Y J, LI Y G, LI S L, et al. Self-lubricating Ti3C2 nanosheets/copper composite coatings[J]. Journal of Alloys and Compounds, 2019, 770: 1-5. doi: 10.1016/j.jallcom.2018.08.100 [74] 司晓阳, 陈凡燕, 邓启煌, 等. MXene/铜合金复合材料的制备与性能研究[J]. 无机材料学报, 2018, 33(6): 603-608. doi: 10.15541/jim20170297SI Xiaoyang, CHEN Fanyan, DENG Qihuang, et al. Preparation and property of MXene/copper alloy composites[J]. Journal of Inorganic Materials, 2018, 33(6): 603-608(in Chinese). doi: 10.15541/jim20170297 [75] ZHOU W W, ZHOU Z X, FAN Y C, et al. Significant strengthening effect in few-layered MXene-reinforced Al matrix composites[J]. Materials Research Letters, 2021, 9(3): 148-154. doi: 10.1080/21663831.2020.1861120 [76] 王守坤. 二维MXene增强铜基复合材料的制备与性能研究[D]. 北京: 北京交通大学, 2020.WANG Shoukun. Preparation and properties of 2D-MXene reinforced copper matrix composites[D]. Beijing: Beijing Jiaotong University, 2020(in Chinese). [77] ZHOU Y J, LIU M, WANG Y L, et al. Significance of constructed MXene@Ag hybrids for enhancing the mechanical and tribological performance of epoxy composites[J]. Tribology International, 2022, 165: 107328. doi: 10.1016/j.triboint.2021.107328 [78] WU H, GU J X, LI Z C, et al. Characterization of phonon thermal transport of Ti3C2T x MXene thin film[J]. Journal of Physics: Condensed Matter, 2022, 34: 155704. doi: 10.1088/1361-648X/ac4f1c [79] CAO Y, DENG Q H, LIU Z D, et al. Enhanced thermal properties of poly(vinylidene fluoride) composites with ultrathin nanosheets of MXene[J]. RSC Advances, 2017, 7(33): 20494-20501. doi: 10.1039/C7RA00184C [80] MAO M Y, LOU D, WANG D L, et al. Ti3C2T x MXene nanofluids with enhanced thermal conductivity[J]. Chemical Thermodynamics and Thermal Analysis , 2022, 8: 100077. doi: 10.1016/j.ctta.2022.100077 -

下载:

下载: