Finite element modelling considering the bending behavior of uncured unidirectional prepregs

-

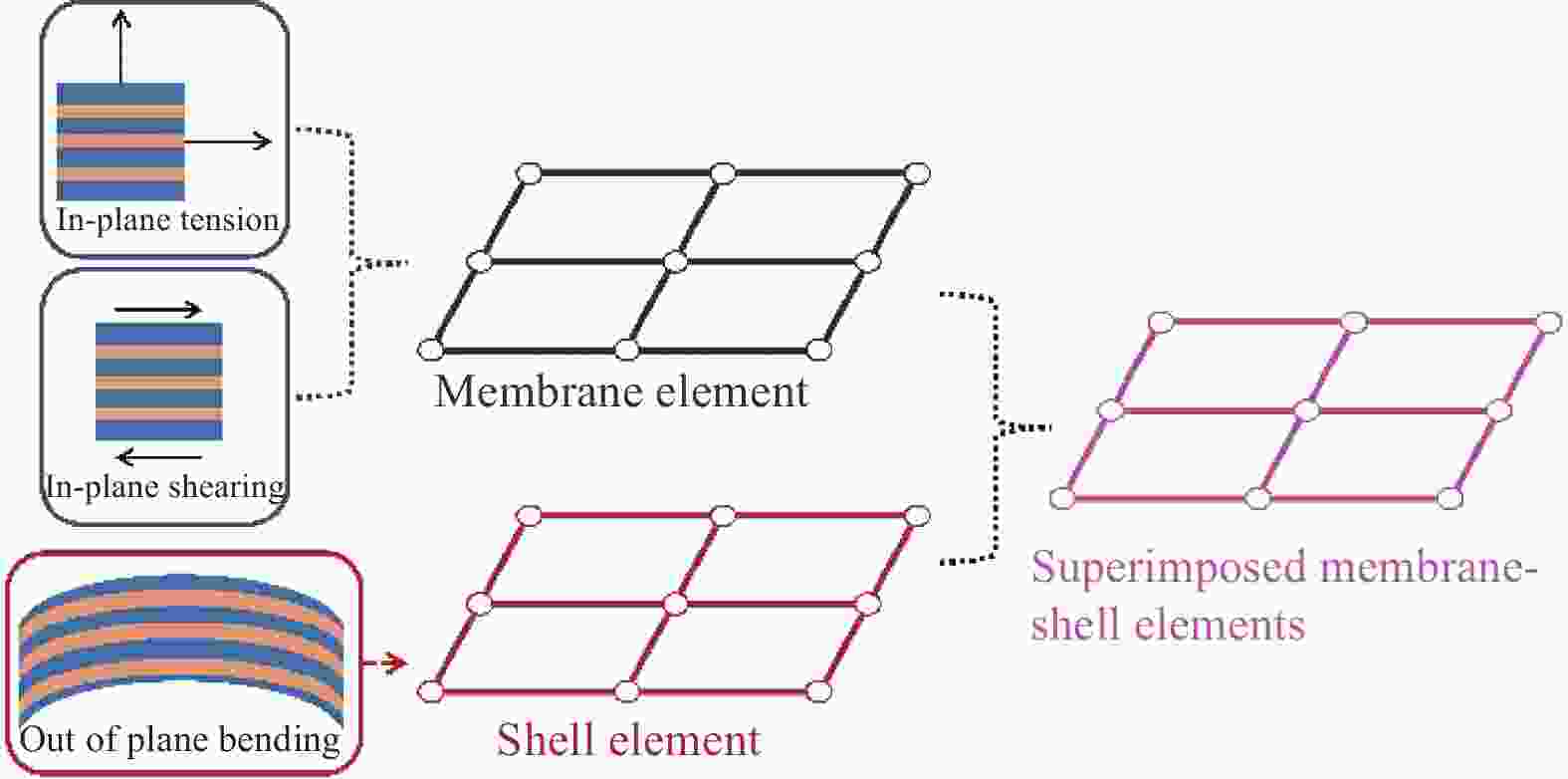

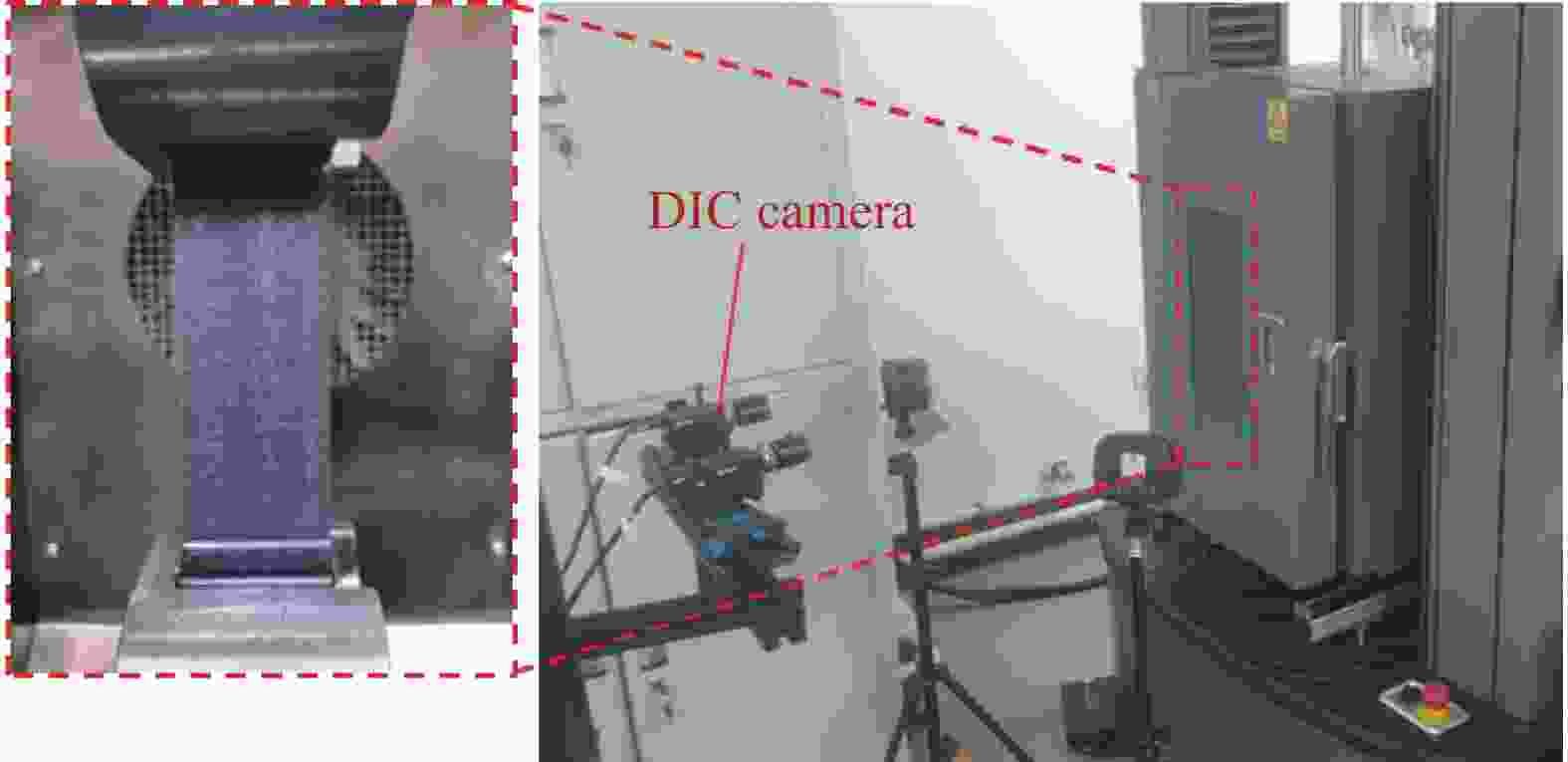

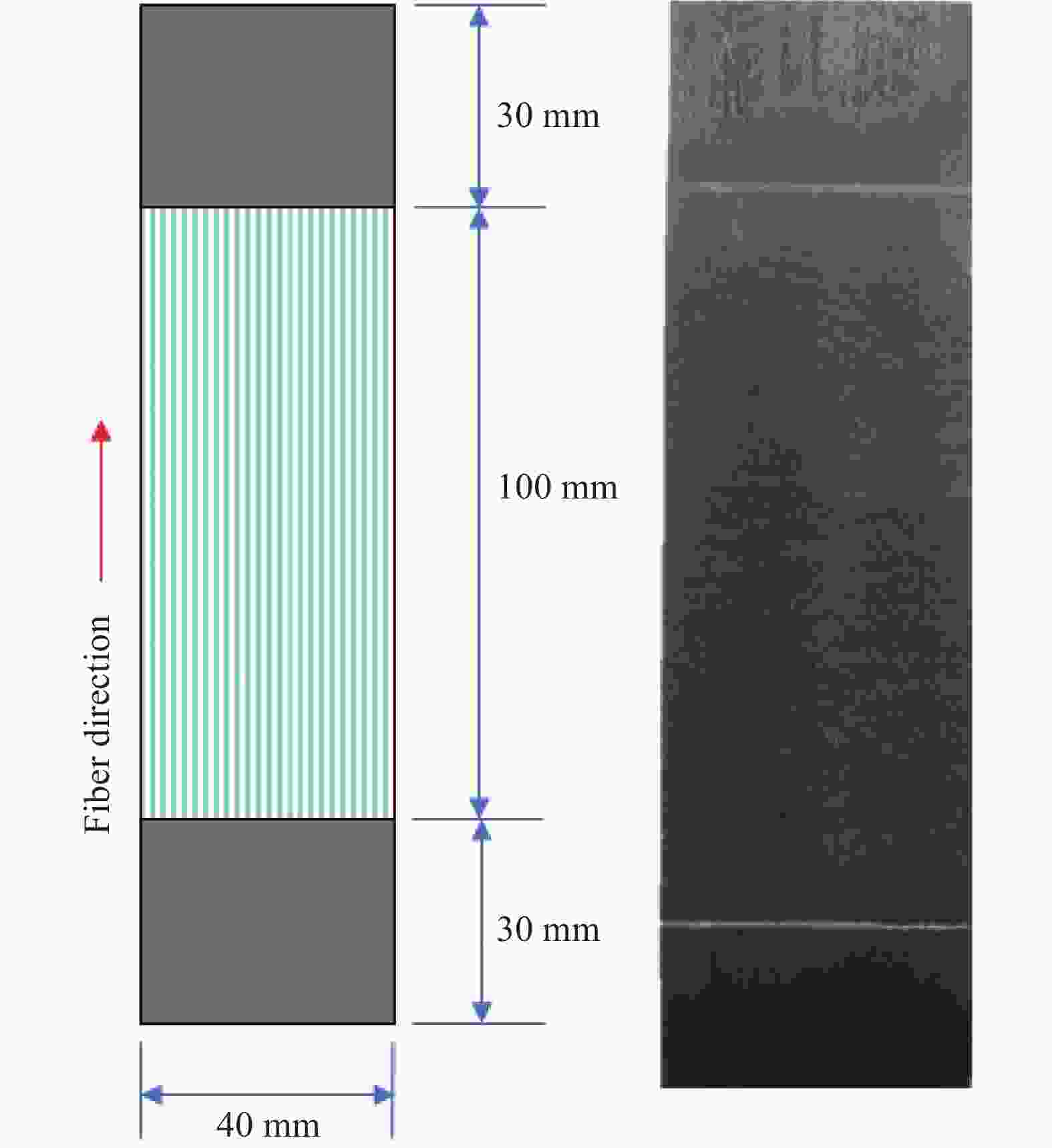

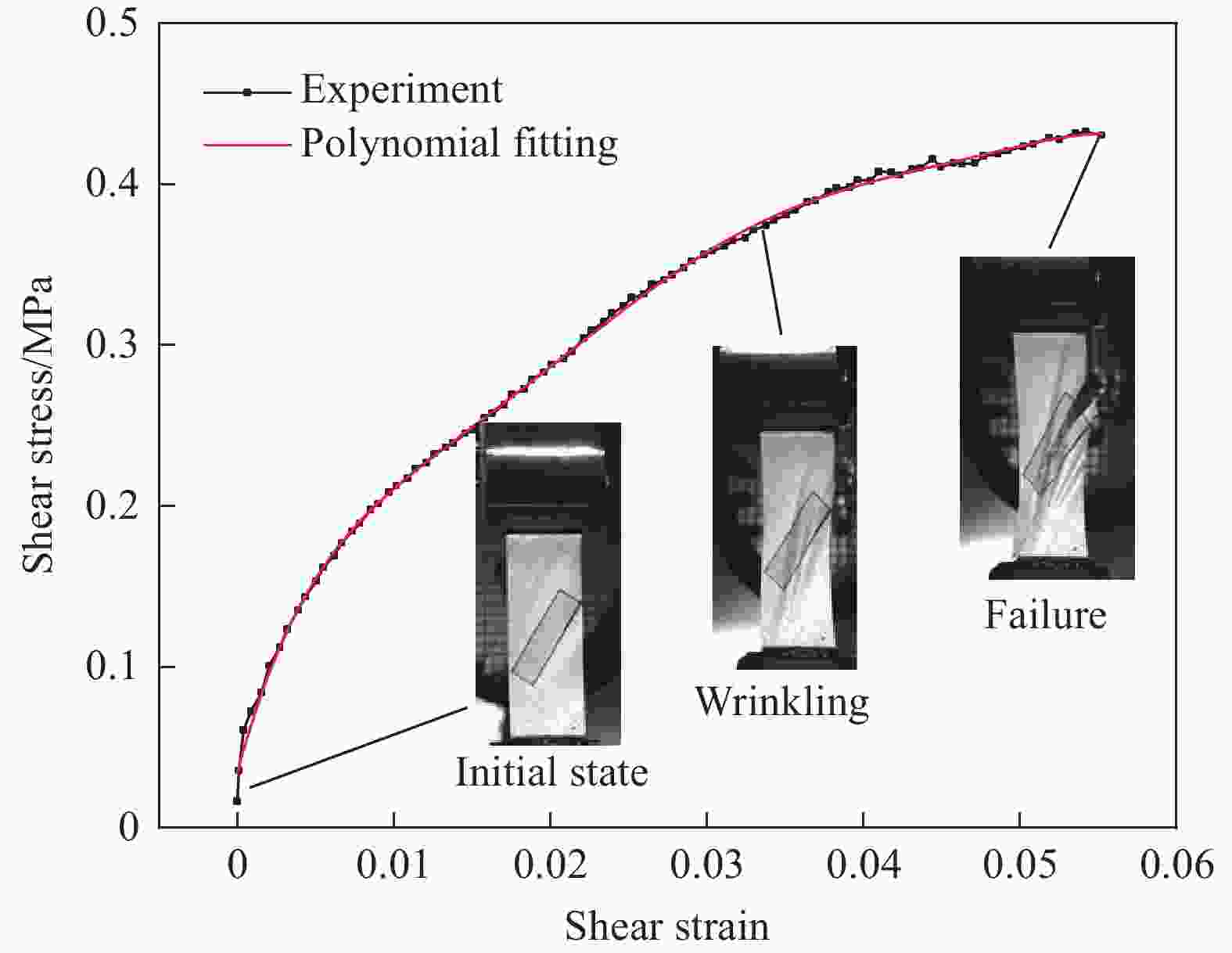

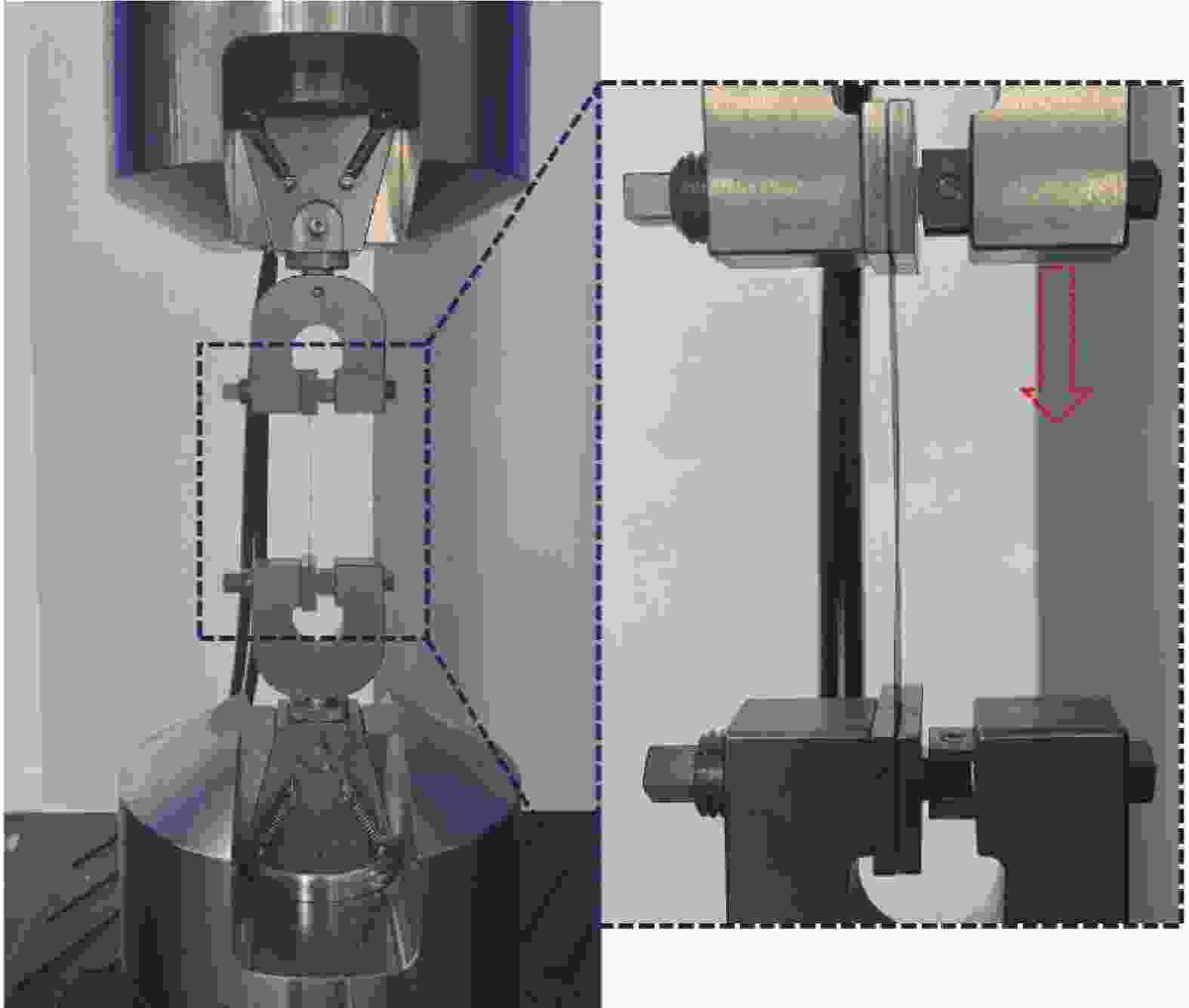

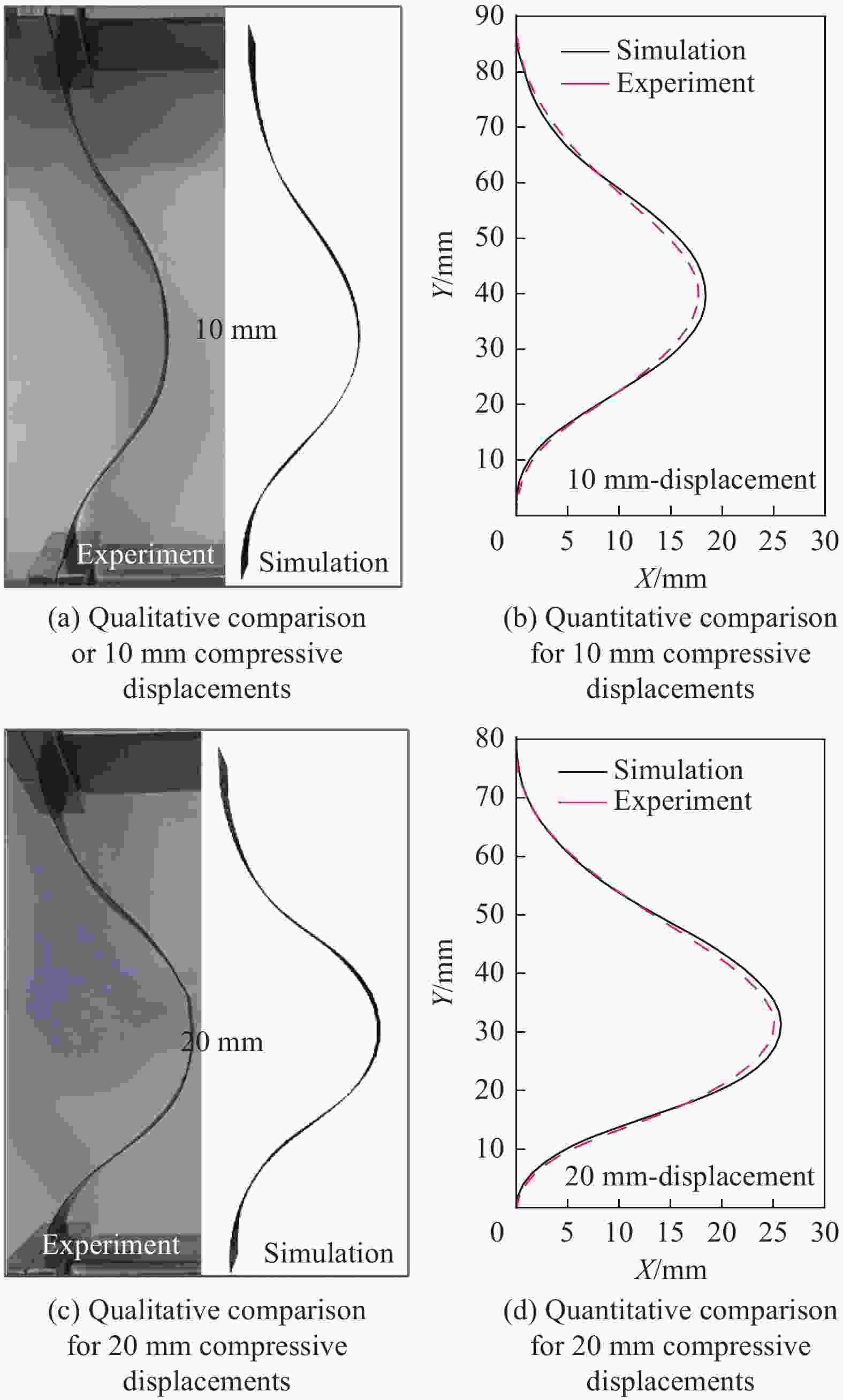

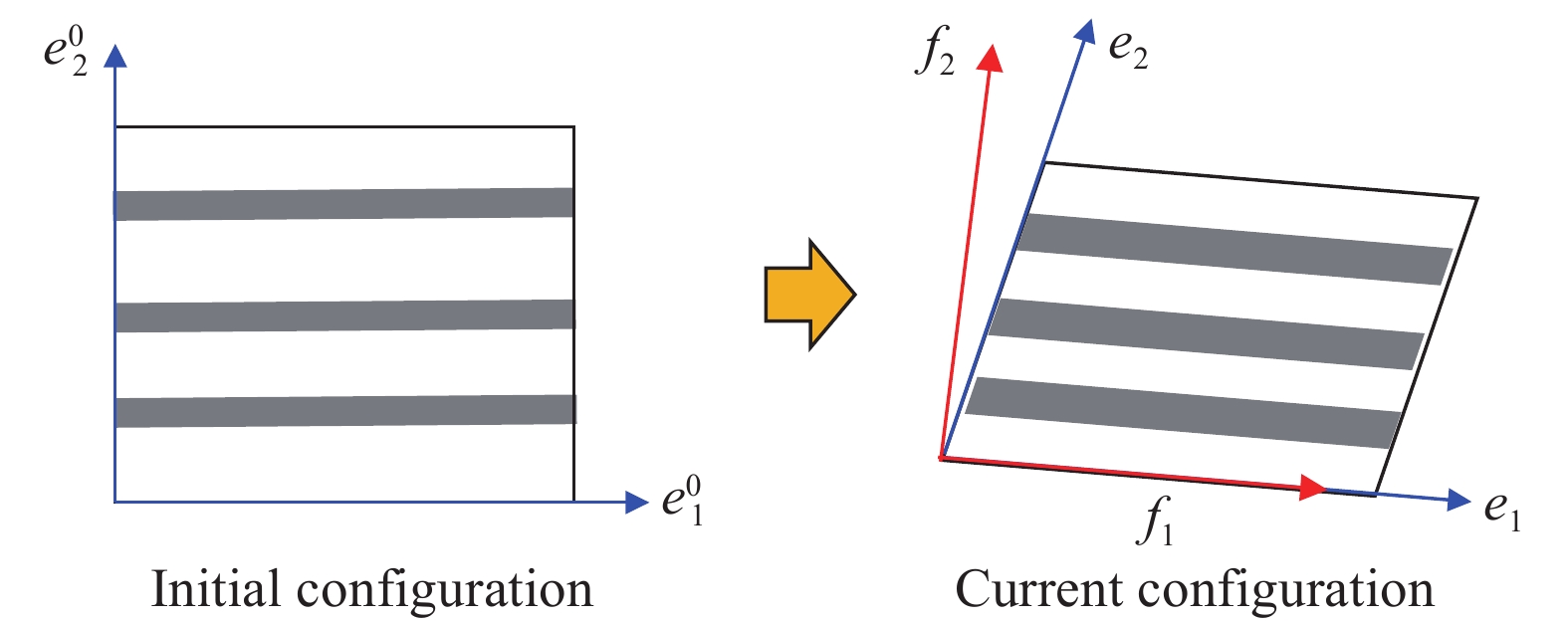

摘要: 热固性树脂基预浸料沿纤维方向具有极高的拉伸模量和较小的弯曲刚度,准确描述预浸料的这种力学特性对于成型过程中褶皱等缺陷的预测与抑制、提升成型过程的有限元仿真精度具有重要意义。本文建立了基于纤维方向准确跟踪并考虑非线性剪切行为的单向预浸料本构模型,并通过共节点壳膜混合单元实现了预浸料高拉伸模量和低弯曲刚度的解耦。同时,以国产AC531/CCF800H单向预浸料为对象,系统测量了未固化预浸料的拉伸模量、剪切模量和弯曲刚度。最后,通过单向预浸料的偏轴拉伸试验和轴向压缩试验分别验证了本文所建立的有限元模型在膜单元和壳单元主导的受力条件下的有效性。Abstract: Thermoset resin based prepregs exhibit very high tensile modulus and relatively low bending stiffness, and the accurate characterization of such special properties of prepregs is critical to predict and avoid the wrinkle defect during forming process, and improve the accuracy of finite element simulation of composite forming process. In the present paper, a finite element model that accurately tracks the fiber directions was built considering the nonlinear in-plane shear behavior of unidirectional prepregs, and the high tensile stiffness and significantly lower bending stiffness of the prepreg were decoupled using superimposed membrane-shell elements. Besides, the tensile stiffness, no-linear shear stiffness, and bending stiffness of the domestic prepreg system AC531/CCF800H were characterized experimentally. Finally, the 30° off-axis tensile test and axial compression test were used to prove the validity of the proposed model, respectively.

-

表 1 仿真模型中壳膜混合单元属性

Table 1. Properties of membrane-shell elements used in FEM

Element

typeThickness/

mmE1/

MPaE2/

MPaG12/MPa Membrane 0.16 73017 31.1 37400000γ4−

4440000γ3+181635γ2−

3140γ+26.76Shell 0.16 32 0.008 0 Notes: E1 and E2—Longitudinal and transverse elastic moduli; G12 —In-plane shear modulus; γ—In-plane shear strain. -

[1] 何靓, 朱攀星, 俆小伟, 等. 复合材料残余应力与固化变形机理及控制研究进展[J]. 复合材料科学与工程, 2022(7): 121-128.HE Liang, ZHU Panxing, XU Xiaowei, et al. A review on mechanism and control methods of residual stress and cured deformation of composite materials[J]. Composites Science and Engineering, 2022(7): 121-128(in Chinese). [2] POTTER K, KHAN B, WISNOM M, et al. Variability, fibre waviness and misalignment in the determination of the properties of composite materials and structures[J]. Composites Part A: Applied Science and Manufacturing, 2008, 39(9): 1343-1354. doi: 10.1016/j.compositesa.2008.04.016 [3] LIANG B, BOISSE P. A review of numerical analyses and experimental characterization methods for forming of textile reinforcements[J]. Chinese Journal of Aeronautics, 2021, 34(8): 143-163. doi: 10.1016/j.cja.2020.09.027 [4] LIANG B, HAMILA N, PEILLON M L, et al. Analysis of thermoplastic prepreg bending stiffness during manufacturing and of its influence on wrinkling simulations[J]. Composites Part A: Applied Science and Manufacturing, 2014, 67: 111-122. [5] BOISSE P, COLMARS J, HAMILA N, et al. Bending and wrinkling of composite fiber preforms and prepregs. A review and new developments in the draping simulations[J]. Composites Part B: Engineering, 2018, 141: 234-249. [6] HU H, CAO D, CAO Z, et al. Experimental and numerical investigations of wrinkle effect on failure behavior of curved composite laminates[J]. Composite Structures, 2021, 261: 113541. doi: 10.1016/j.compstruct.2021.113541 [7] LONG A C, RUDD C D. Simulation of reinforcement deformation during the production of preforms for liquid moulding processes[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 1994, 208(42): 269-278. [8] SKORDOS A A, MONROY ACEVES C, SUTCLIFFE M P F. A simplified rate dependent model of forming and wrinkling of pre-impregnated woven composites[J]. Composites Part A: Applied Science and Manufacturing, 2007, 38(5): 1318-1330. [9] CHEROUAT A, BILLOËT J L. Mechanical and numerical modelling of composite manufacturing processes deep-drawing and laying-up of thin pre-impregnated woven fabrics[J]. Journal of Materials Processing Technology, 2001, 118(1): 460-471. [10] OROMIEHIE E, PRUSTY B G, COMPSTON P, et al. Automated fibre placement based composite structures: Review on the defects, impacts and inspections techniques[J]. Composite Structures, 2019, 224(15): 110987. [11] HAN M G, CHANG S H. Draping simulations of carbon/epoxy fabric prepregs using a non-orthogonal constitutive model considering bending behavior[J]. Composites Part A: Applied Science and Manufacturing, 2021, 148: 106483. doi: 10.1016/j.compositesa.2021.106483 [12] YU F, CHEN S, VIISAINEN J V, et al. A macroscale finite element approach for simulating the bending behaviour of biaxial fabrics[J]. Composites Science and Technology, 2020, 191: 108078. doi: 10.1016/j.compscitech.2020.108078 [13] THOMPSON A J, BELNOUE J P H, HALLETT S R. Modelling defect formation in textiles during the double diaphragm forming process[J]. Composites Part B: Engineering, 2020, 202: 108357. doi: 10.1016/j.compositesb.2020.108357 [14] DÖRR D, SCHIRMAIER F J, HENNING F, et al. A viscoelastic approach for modeling bending behavior in finite element forming simulation of continuously fiber reinforced composites[J]. Composites Part A: Applied Science and Manufacturing, 2017, 94: 113-123. doi: 10.1016/j.compositesa.2016.11.027 [15] SREEHARI R, MICHAEL A S, SUBRAMANI S, et al. Simulations and experiments for automated fiber placement of prepreg slit tape: Wrinkle formation and fundamental observations[J]. Composites Part B: Engineering, 2020, 201: 108287. [16] ROPERS S, SACHS U, KARDOS M, et al. A thermo-viscoelastic approach for the characterization and modeling of the bending behavior of thermoplastic composites—Part II[J]. Composites Part A: Applied Science and Manufacturing, 2017, 96: 67-76. doi: 10.1016/j.compositesa.2017.02.007 [17] 邢丽英, 冯志海, 包建文, 等. 碳纤维及树脂基复合材料产业发展面临的机遇与挑战[J]. 复合材料学报, 2020, 37(11): 2700-2706.XING Liying, FENG Zhihai, BAO Jianwen, et al. Facing opportunity and challenge of carbon fiber and polymer matrix composites industry development[J]. Acta Materiae Compositae Sinica, 2020, 37(11): 2700-2706(in Chinese). [18] SASA G, ZHENG T Q, ZHANG Y, et al. An efficient hyper-elastic model for the preforming simulation of carbon-Kevlar hybrid woven reinforcement[J]. Chinese Journal of Aeronautics, 2022, 35(12): 321-335. doi: 10.1016/j.cja.2022.05.007 [19] ZHAO Z, ZHANG K, CHENG H, et al. Experimental characterization and numerical modelling of bending behavior of carbon fiber unidirectional thermoset prepregs[J]. Journal of Reinforced Plastics and Composites, 2024, 43(5-6): 277-292. [20] 何靓, 俆小伟, 胡大豹, 等. 国产T800级高韧性环氧树脂基预浸料的TTT图绘制[J]. 复合材料科学与工程, 2023(5): 25-31.HE Liang, XU Xiaowei, HU Dabao, et al. Time-temperature-transformation (TTT) diagram of a domestic T800 carbon fiber epoxy prepreg[J]. Composites Science and Engineering, 2023(5): 25-31(in Chinese). [21] NIMA B, MEHDI H. An experimental and simulative study on the defects appeared during tow steering in automated fiber placement[J]. Composites Part A: Applied Science and Manufacturing, 2018, 113: 122-131. doi: 10.1016/j.compositesa.2018.07.031 [22] American Society for Testing and Materials. Standard test method for stiffness of fabrics: ASTM D1388—23[S]. West Conshohocken: ASTM International, 2023. [23] DÖBRICH O, GEREKE T, DIESTEL O, et al. Decoupling the bending behavior and the membrane properties of finite shell elements for a correct description of the mechanical behavior of textiles with a laminate formulation[J]. Journal of Industrial Textiles, 2013, 44(1): 70-84. [24] BELHAJ M, HOJJATI M. Wrinkle formation during steering in automated fiber placement: Modeling and experimental verification[J]. Journal of Reinforced Plastics and Composites, 2018, 37(6): 396-409. doi: 10.1177/0731684417752872 [25] DODWELL T J, BUTLER R, HUNT G W. Out-of-plane ply wrinkling defects during consolidation over an external radius[J]. Composites Science & Technology, 2014, 105: 151-159. -

下载:

下载: