Research progress of integrated materials for heat conduction and electromagnetic wave absorption

-

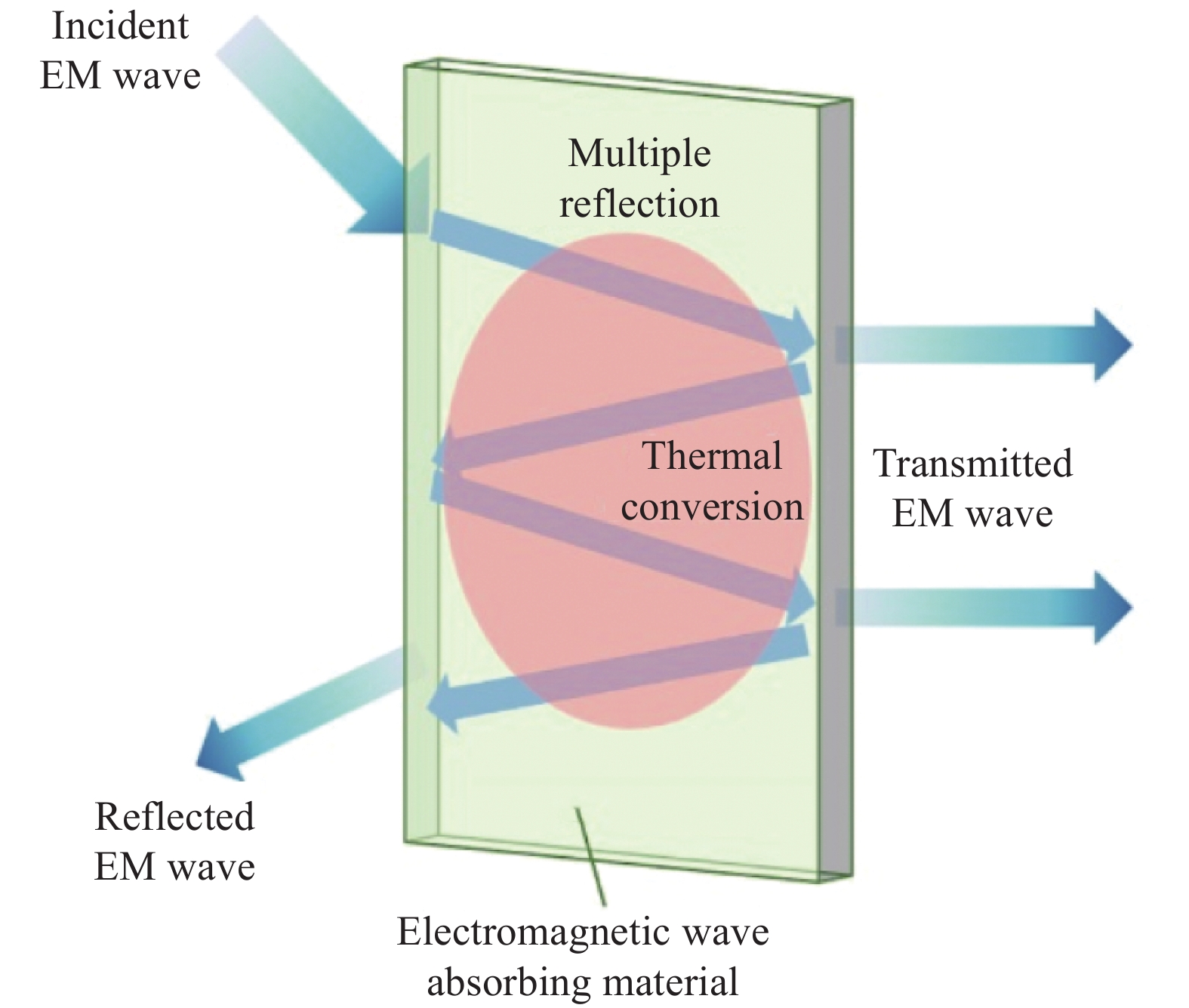

摘要: 5G通信中电磁污染尤为严重,吸波材料可有效的吸收和衰减电磁波,将电磁能转换为热能的形式散失掉,已被广泛应用于航天航空、军事设施及电子通信等领域。然而,电子设备的小型化、集成化与高频化使电子设备无法及时将其产生的热能耗散掉,从而影响设备的正常运行。因此,如何将导热材料高效的应用于电磁波吸收成为了当前吸波领域研究的重点和热点。基于此,本文综述了不同种类的导热材料在电磁波吸收中的应用及研究进展,首先按照组成成分介绍了导热材料的种类,并详细阐述了金属材料、陶瓷材料、碳材料及其复合物和导热高分子材料及其复合物的导热机制及不同导热材料在电磁波吸收中的作用机制与应用。最后对导热吸波一体化材料未来的研究方向及推广应用提出了见解。Abstract: Electromagnetic pollution is a significant concern in 5G communication. Electromagnetic wave absorbing materials can efficiently soak up and decrease the intensity of electromagnetic waves, whereby they dissipate the energy as heat. These materials have extensive applications in aerospace, military equipment and electronic communications. However, the miniaturization, integration and high frequency of electronic equipment make it impossible for electronic equipment to dissipate the heat energy generated by it in time, thus affecting the normal operation of the equipment. Therefore, how to efficiently apply thermally conductive materials to electromagnetic wave absorption has become the focus and hotspot of current research in the field of wave absorption. This paper reviews the application and research progress of different kinds of thermal conductive materials in electromagnetic wave absorption. Firstly, the types of thermal conductive materials are introduced according to the composition, and the thermal conduction mechanism of metal materials, ceramic materials, carbon materials and their composites, thermal conductive polymer materials and their composites, as well as the mechanism and application of different thermal conductive materials in electromagnetic wave absorption are described in detail. Finally, the future research direction and application of integrated materials for thermal conductivity and electromagnetic wave absorption are put forward.

-

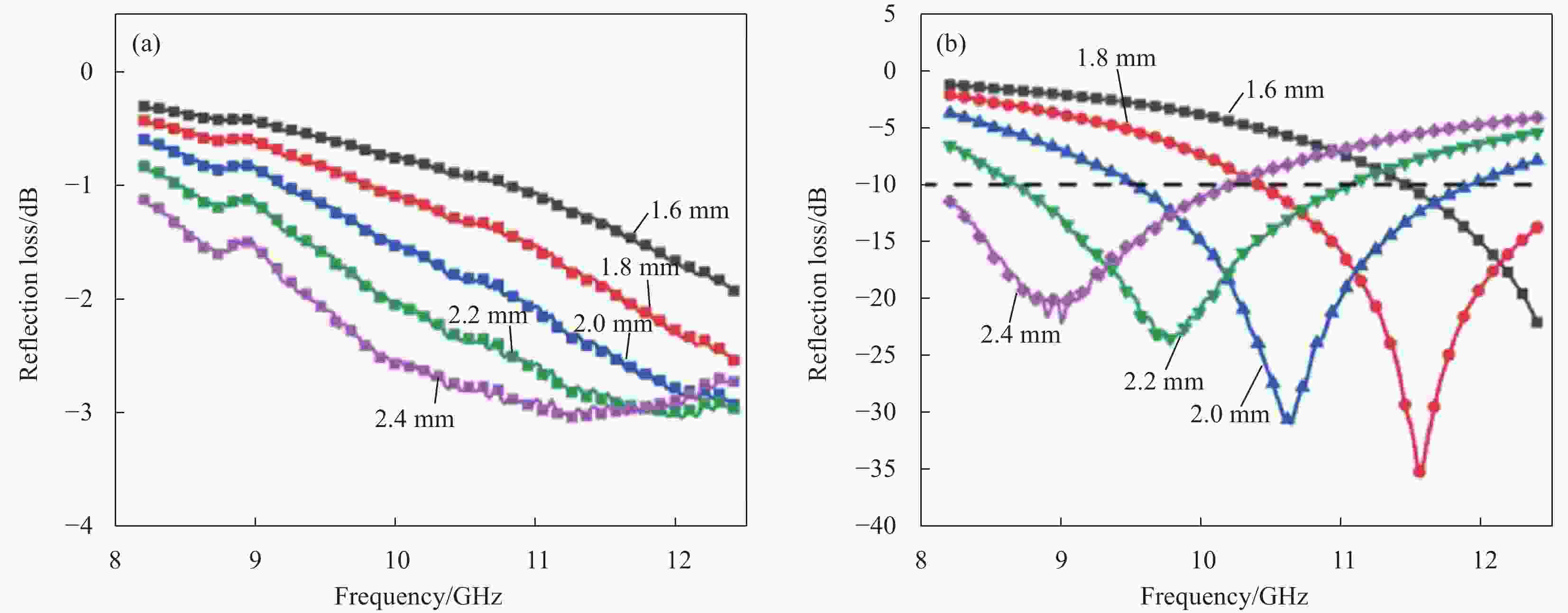

图 4 Al2O3/ZnO/Fe(CO)5/硅橡胶(SR)复合材料热导率(a)和吸波性能:(b)反射损耗;(c)有效损耗带宽[47]

AM—Fe(CO)5; TC—Al2O3 and ZnO (Mass ratio of 1∶1); TA-1, TA-2, TA-3—Al2O3, ZnO and Fe(CO)5 with mass ratios of 1∶2, 1∶1 and 2∶1, respectively

Figure 4. Thermal conductivity (a) and absorbing properties of Al2O3/ZnO/Fe(CO)5/silicone rubber (SR) composite materials: (b) Reflection loss;(c) Effective loss bandwidth[47]

图 9 样品的α值(a)和Z值(d) ;PCF7-CFO (1.5和2.0 mm)的反射损耗(RL) (b) 、α值和Z值(e);PCF7-CFO的RL值(c)和1/4波长厚度(f)[69]

Figure 9. Values of α (a) and Z (d) of the samples; Values of reflection loss (RL) (b) and α and Z (e) for PCF7-CFO (1.5 and 2.0 mm); RL values (c) and the quarter wavelength thickness of PCF7-CFO (f)[69]

PCF—Phragmites-derived hollow carbon fiber; CF—Carbon fiber; CFO—CoFe2O4; α—Constant; Zin—Input impedance; Z0—Air impedance; λ—Wavelength

图 10 有机高分子材料导热机制图:(a)纯高分子材料;(b)有改善链取向的高分子材料;(c)填充有具有热导性填料的高分子材料[84]

Figure 10. Thermal conductivity mechanism diagram of organic polymer materials: (a) Pure polymer materials; (b) Polymer materials with improved chain orientation; (c) Polymer materials filled with fillers with thermal conductivity[84]

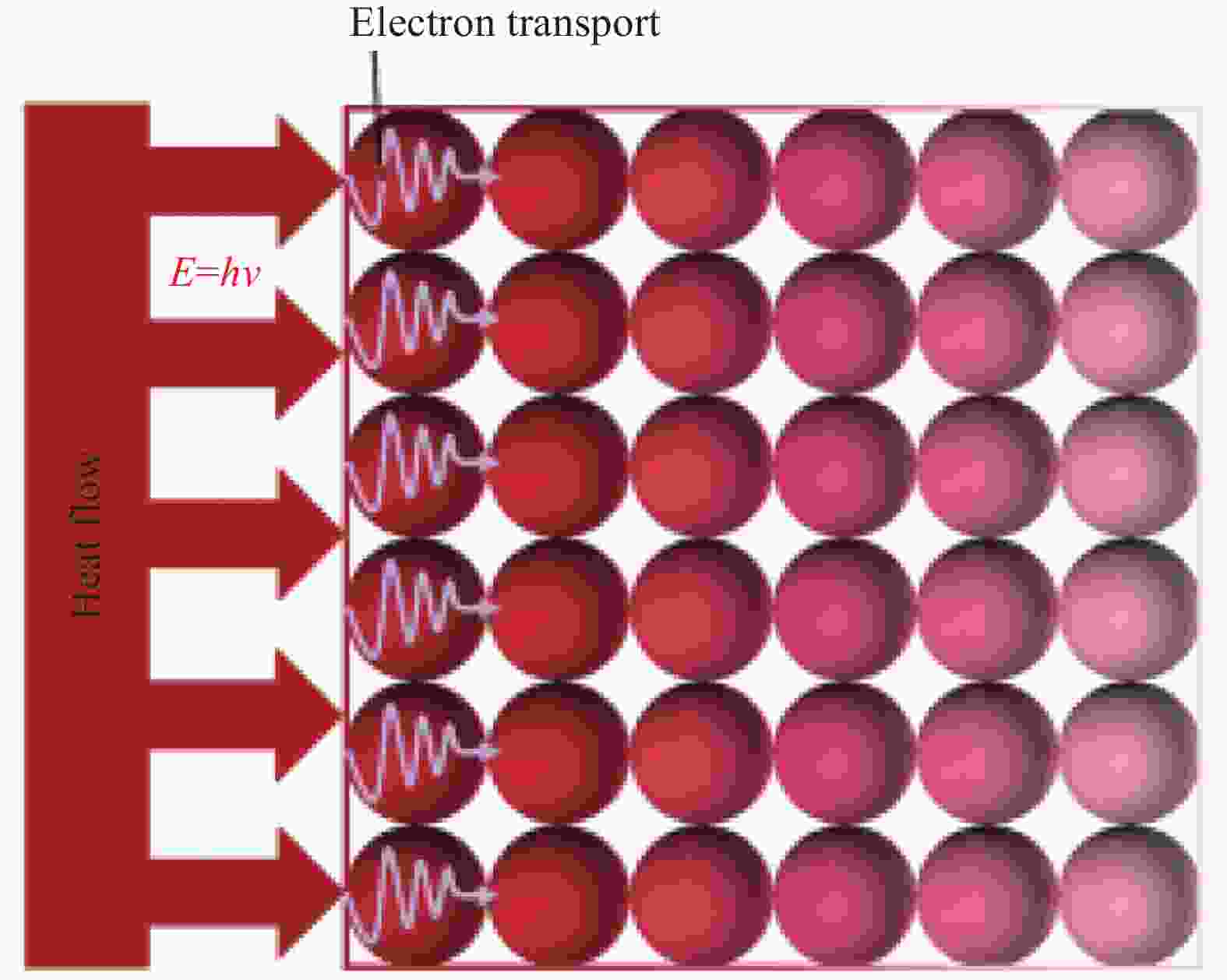

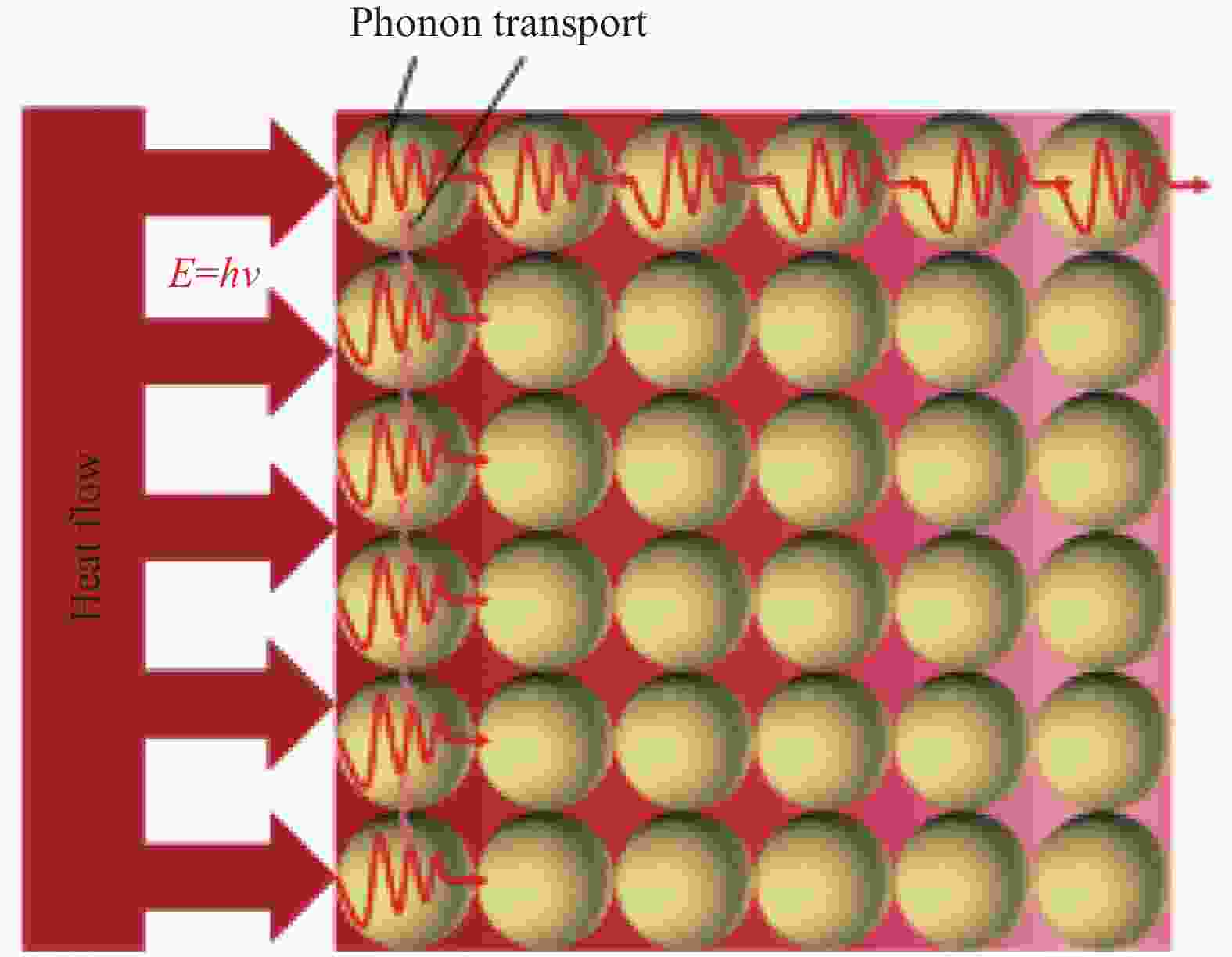

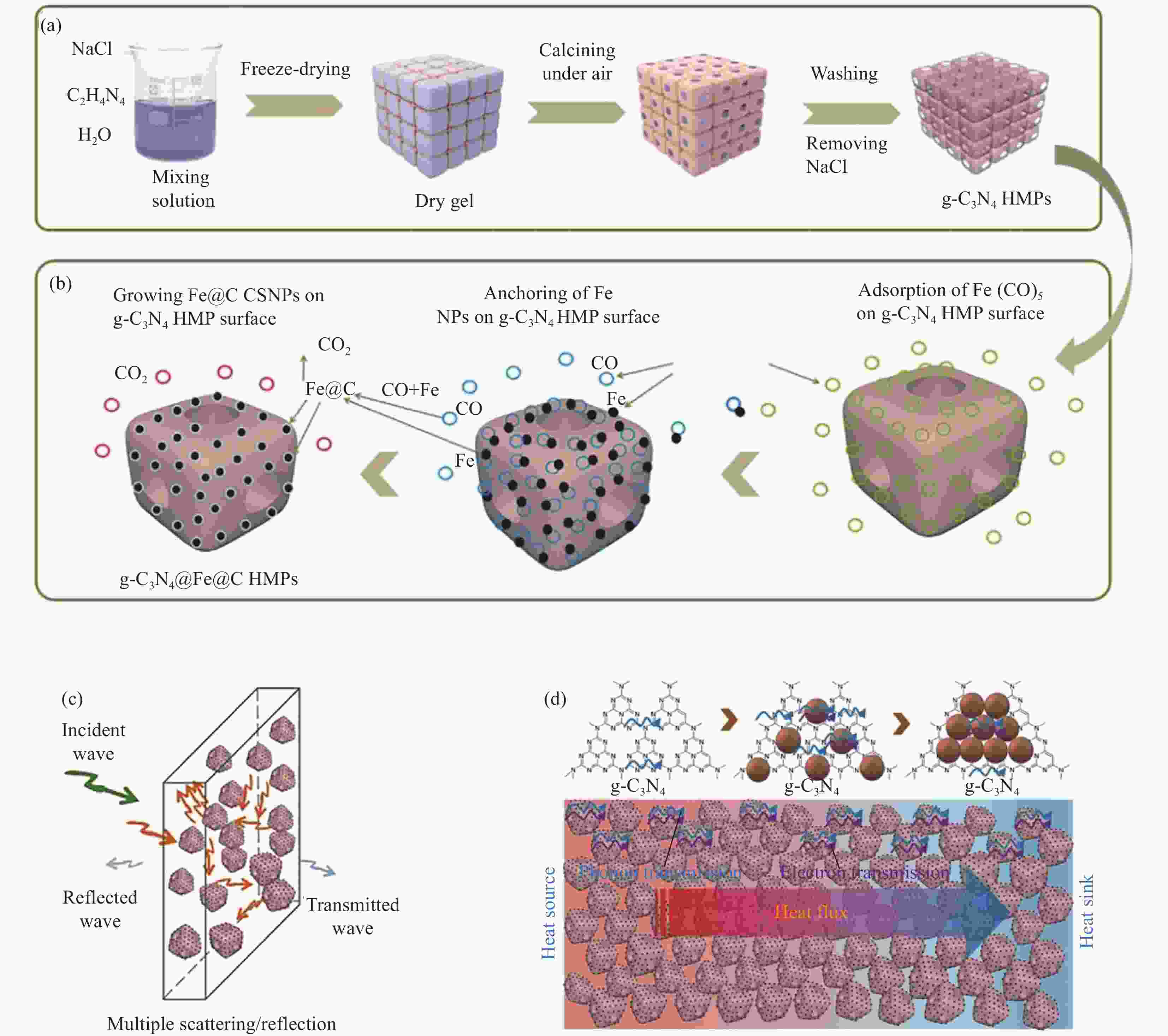

图 11 通过盐模板法合成g-C3N4 HMPs (a)和通过Fe(CO)5热解合成g-C3N4@Fe@C HMPs (b);g-C3N4@Fe@C HMPs复合材料的导热(c)与吸波机制示意图(d)[94]

Figure 11. Synthesis of g-C3N4 HMPs via a salt-template route (a) and g-C3N4@Fe@C HMPs via the pyrolysis of Fe(CO)5 (b); Schematic diagram of thermal conduction (c) and electromagnetic wave absorption principles (d) in the g-C3N4@Fe@C HMPs composite[94]

HMPs—Hollow micro-polyhedra; CSNPs—Core–shell nanoparticles; NPs—Nanoparticles

表 1 常见导热材料的热导率(λ)

Table 1. Thermal conductivity (λ) of common thermal conductive materials

表 2 金属氧化物/磁性材料/碳材料复合材料的吸波性能和导热性能

Table 2. Microwave absorbing properties and thermal conductivity of metal oxide/magnetic material/carbon material

Sample RLmin/dB D/mm EAB/GHz λ/(W·(m·K)−1) Ref. TiO2-Fe-C nanocomposites –42.59 1.2-2.1 5.60 2.69-2.93 [75] Al2O3-Ni-C composites –42.43 1.7 4.24 2.84 [76] MgO-Co-C foams –59.42 2.1 5.44 3.40-4.09 [77] Notes: RLmin—Reflection loss; D—Thickness; EAB—Effective absorption bandwidth; λ—Thermal conductivity. 表 3 不同种类的导热材料在电磁波吸收应用中的优缺点

Table 3. Advantages and disadvantages of different types of thermal conductive materials in electromagnetic wave absorption applications

Heat conductor Advantage Disadvantage

Metallic materialsConductive metal Excellent thermal and electrical conductivity The electromagnetic wave has a low absorbing capacity, resulting in most of the wave being reflected or transmitted Magnetic metal High permeability can promote the absorption of electromagnetic wave High density, poor electrical and thermal conductivity Ceramic materials High melting point, strong corrosion resistance, high hardness; Excellent insulation properties, chemical stability and high temperature stability Relatively low thermal conductivity, high fragility, susceptibility to cracking, and difficulty in processing Carbon materials Low-density, lightweight, complex and varied struc-tures, excellent thermal and electrical conductivity Higher cost, single electromagnetic wave loss mechanism, poorer impedance matching Thermally conductive polymer materials Light weight, easy to process, low cost, corrosion resistant; The ordered topology can promote the thermal conductivity and wave absorption properties of other materials Thermal decomposition and aging at high temperatures, poor thermal conductivity, lower efficiency of electromagnetic wave absorption -

[1] WU N, HU Q, WEI R, et al. Review on the electromagnetic interference shielding properties of carbon based materials and their novel composites: Recent progress, challenges and prospects[J]. Carbon, 2021, 176: 88-105. doi: 10.1016/j.carbon.2021.01.124 [2] ZHAO Y, HAO L, ZHANG X, et al. A novel strategy in electromagnetic wave absorbing and shielding materials design: Multi-responsive field effect[J]. Small Science, 2022, 2(2): 2100077. doi: 10.1002/smsc.202100077 [3] JI E, XIE G Z, XIE N Y, et al. Microwave absorbing properties of flaky carbonyl iron powder prepared by rod milling method[J]. Journal of Electronic Materials, 2019, 48: 2495-2500. doi: 10.1007/s11664-019-06986-1 [4] WANG S S, ZHU H H, JIAO Q Z, et al. Controllable synthesis of multi-shelled SiO2@C@NiCo2O4 yolk-shell composites for enhancing microwave absorbing properties[J]. New Journal of Chemistry, 2021, 45(44): 20928-20936. [5] 王杰, 白雪, 吉聪, 等. 高性能软磁吸波材料的研究进展[J]. 电子元件与材料, 2021, 40(10): 975-982. doi: 10.14106/j.cnki.1001-2028.2021.0275WANG Jie, BAI Xue, JI Cong, et al. Research progress of high performance soft magnetic absorbing materials[J]. Electronic Components and Materials, 2021, 40(10): 975-982(in Chinese). doi: 10.14106/j.cnki.1001-2028.2021.0275 [6] PRADHAN S S, UUNNIKRISHNAN L, MOHANTY S, et al. Thermally conducting polymer composites with EMI shielding: A review[J]. Journal of Electronic Materials, 2020, 49: 1749-1764. doi: 10.1007/s11664-019-07908-x [7] JIJI L M. Heat convection [M]. Berlin: Springer, 2006: 1-20. [8] QIAN X, ZHOU J, CHEN G. Phonon-engineered extreme thermal conductivity materials[J]. Nature Materials, 2021, 20(9): 1188-1202. doi: 10.1038/s41563-021-00918-3 [9] 贾琨, 王喆, 王蓬, 等. 导热吸波材料的研究进展及未来发展方向[J]. 材料导报, 2021, 35(9): 9133-9139, 9149. doi: 10.11896/cldb.20020002JIA Kun, WANG Zhe, WANG Peng, et al. Progress and future developments of thermal microwave absorbing materials[J]. Materials Reports, 2021, 35(9): 9133-9139, 9149(in Chinese). doi: 10.11896/cldb.20020002 [10] SHEN Z, FENG J. Highly thermally conductive composite films based on nanofibrillated cellulose in situ coated with a small amount of silver nanoparticles[J]. ACS Applied Materials & Interfaces, 2018, 10(28): 24193-24200. [11] CHEN T F, SIOW K S. Comparing the mechanical and thermal electrical properties of sintered copper (Cu) and sintered silver (Ag) joints[J]. Journal of Alloys and Compounds, 2021, 866: 158783. doi: 10.1016/j.jallcom.2021.158783 [12] CHO H J, WANG S, ZHOU Y, et al. Thermal conductivity of bulk electrodeposited nanocrystalline nickel[J]. International Journal of Heat and Mass Transfer, 2016, 100: 490-496. doi: 10.1016/j.ijheatmasstransfer.2016.04.068 [13] 陈庆军, 王健, 沈军, 等. 铁钴基块体非晶合金的热膨胀特性和热导率[J]. 稀有金属材料与工程, 2016, 45(3): 765-770.CHEN Qingjun, WANG Jian, SHEN Jun, et al. Thermal expansion characteristics and thermal conductivity of FeCo-based bulk amorphous alloys[J]. Rare Metal Materials and Engineering, 2016, 45(3): 765-770(in Chinese). [14] CHO T Y, KIM Y W. Effect of grain growth on the thermal conductivity of liquid-phase sintered silicon carbide ceramics[J]. Journal of the European Ceramic Society, 2017, 37(11): 3475-3481. doi: 10.1016/j.jeurceramsoc.2017.04.050 [15] DAI W, MA T, YAN Q, et al. Metal-level thermally conductive yet soft graphene thermal interface materials[J]. ACS Nano, 2019, 13(10): 11561-11571. doi: 10.1021/acsnano.9b05163 [16] CHOI S, KIM J. Thermal conductivity of epoxy composites with a binary-particle system of aluminum oxide and aluminum nitride fillers[J]. Composites Part B: Engineering, 2013, 51: 140-147. doi: 10.1016/j.compositesb.2013.03.002 [17] WU X, LEE J, VARSHNEY V, et al. Thermal conductivity of wurtzite zinc-oxide from first-principles lattice dynamics-A comparative study with gallium nitride[J]. Scientific Reports, 2016, 6(1): 22504. doi: 10.1038/srep22504 [18] KUMANEK B, JANAS D. Thermal conductivity of carbon nanotube networks: A review[J]. Journal of Materials Science, 2019, 54(10): 7397-7427. doi: 10.1007/s10853-019-03368-0 [19] BALANDIN A A, GHOSH S, BAO W, et al. Superior thermal conductivity of single-layer graphene[J]. Nano Letters, 2008, 8(3): 902-907. doi: 10.1021/nl0731872 [20] DAI S, LI J, LU N. Research progress of diamond/copper composites with high thermal conductivity[J]. Diamond and Related Materials, 2020, 108: 107993. doi: 10.1016/j.diamond.2020.107993 [21] MIRANDA A T, BOLZONI L, BAREKAR N, et al. Processing, structure and thermal conductivity correlation in carbon fibre reinforced aluminium metal matrix composites[J]. Materials & Design, 2018, 156: 329-339. [22] EZEKOYE O A. Conduction of heat in solids[M]. New York: SFPE Handbook of Fire Protection Engineering, 2016: 25-52. [23] 袁家伟. 高导热Mg-Zn-Mn合金及其性能研究[D]. 北京: 北京有色金属研究总院, 2013.YUAN Jiawei. High thermal conductivity Mg-Zn-Mn alloy and its performance research [D]. Beijing: Beijing Nonferrous Metal Research Institute, 2013(in Chinese). [24] XU C, ZHANG H, FANG G. Review on thermal conductivity improvement of phase change materials with enhanced additives for thermal energy storage[J]. Journal of Energy Storage, 2022, 51: 104568. doi: 10.1016/j.est.2022.104568 [25] ZHANG P, MENG Z N, ZHU H, et al. Melting heat transfer characteristics of a composite phase change material fabricated by paraffin and metal foam[J]. Applied Energy, 2017, 185: 1971-1983. doi: 10.1016/j.apenergy.2015.10.075 [26] MAKINSON R E B. The thermal conductivity of metals[C]//Mathematical Proceedings of the Cambridge Philosophical Society. Cambridge: Cambridge University Press, 1938, 34(3): 474-497. [27] KLEMENS P G. Thermal conductivity and lattice vibrational modes [J]. Solid State Physics, 1958, 7: 1-98. [28] LIU Y, JI C, LU L, et al. Facile synthesis and electromagnetic wave absorption properties of silver coated porous carbon composite materials[J]. Journal of Alloys and Compounds, 2021, 856: 158194. doi: 10.1016/j.jallcom.2020.158194 [29] TANG X H, TANG Y, WANG Y, et al. Interfacial metallization in segregated poly(lactic acid)/poly(ε-caprolactone)/multi-walled carbon nanotubes composites for enhancing electromagnetic interference shielding[J]. Composites Part A: Applied Science and Manufacturing, 2020, 139: 106116. doi: 10.1016/j.compositesa.2020.106116 [30] YANG Y, HUANG Q, PAYNE G F, et al. A highly conductive, pliable and foldable Cu/cellulose paper electrode enabled by controlled deposition of copper nanoparticles[J]. Nanoscale, 2019, 11(2): 725-732. doi: 10.1039/C8NR07123C [31] QIN M, ZHANG L, WU H. Dielectric loss mechanism in electromagnetic wave absorbing materials[J]. Advanced Science, 2022, 9(10): 2105553. doi: 10.1002/advs.202105553 [32] YANG Z, YAO Y, DUAN L, et al. Synthesis of effective microwave absorber C/ZnS/Cu composites via molten salt route[J]. Materials Letters, 2023, 333: 133640. doi: 10.1016/j.matlet.2022.133640 [33] WANG B, WU Q, FU Y, et al. A review on carbon/magnetic metal composites for microwave absorption[J]. Journal of Materials Science & Technology, 2021, 86: 91-109. [34] CHENG J, ZHANG H, XIONG Y, et al. Construction of multiple interfaces and dielectric/magnetic heterostructures in electromagnetic wave absorbers with enhanced absorption performance: A review[J]. Journal of Materiomics, 2021, 7(6): 1233-1263. doi: 10.1016/j.jmat.2021.02.017 [35] YANG W, JIANG B, LIU Z, et al. Magnetic coupling engineered porous dielectric carbon within ultralow filler loading toward tunable and high-performance microwave absorption[J]. Journal of Materials Science & Technology, 2021, 70: 214-223. [36] SHI S, MOU P, WANG D, et al. Co/carbon nanofiber with adjustable size and content of Co nanoparticles for tunable microwave absorption and thermal conductivity[J]. Journal of Materiomics, 2024, 10(1): 124-133. [37] WANG Y L, WANG G S, ZHANG X J, et al. Porous carbon polyhedrons coupled with bimetallic CoNi alloys for frequency selective wave absorption at ultralow filler loading[J]. Journal of Materials Science & Technology, 2022, 103: 34-41. [38] WANG H Y, SUN X B, XIN Y, et al. Ultrathin self-assembly MXene/Co-based bimetallic oxide heterostructures as superior and modulated microwave absorber[J]. Journal of Materials Science & Technology, 2023, 134: 132-141. [39] SUN L, ZHU Q, JIA Z, et al. CrN attached multi-component carbon nanotube composites with superior electromagnetic wave absorption performance[J]. Carbon, 2023, 208: 1-9. doi: 10.1016/j.carbon.2023.03.021 [40] SUN M, XIONG Z, ZHANG Z, et al. One-dimensional Ag@NC-Co@NC composites with multiphase core-shell hetero-interfaces for boosting microwave absorption[J]. Composites Science and Technology, 2022, 228: 109663. doi: 10.1016/j.compscitech.2022.109663 [41] ZHANG S, LI Z, YAO Y, et al. Heat transfer characteristics and compatibility of molten salt/ceramic porous composite phase change material[J]. Nano Energy, 2022, 100: 107476. doi: 10.1016/j.nanoen.2022.107476 [42] YOON H, MATTEINI P, HWANG B. Review on three-dimensional ceramic filler networking composites for thermal conductive applications[J]. Journal of Non-Crystalline Solids, 2022, 576: 121272. doi: 10.1016/j.jnoncrysol.2021.121272 [43] LI W, YU Z, WEN Q, et al. Ceramic-based electromagnetic wave absorbing materials and concepts towards lightweight, flexibility and thermal resistance[J]. International Materials Reviews, 2023, 68(5): 487-520. doi: 10.1080/09506608.2022.2077028 [44] YIN X, KONG L, ZHANG L, et al. Electromagnetic properties of Si-C-N based ceramics and composites[J]. International Materials Reviews, 2014, 59(6): 326-355. doi: 10.1179/1743280414Y.0000000037 [45] ZHAO S, MA H, SHAO T, et al. High temperature metamaterial enhanced electromagnetic absorbing coating prepared with alumina ceramic[J]. Journal of Alloys and Compounds, 2021, 874: 159822. doi: 10.1016/j.jallcom.2021.159822 [46] XING H, CHEN W, LIU C, et al. Construction of core-shell-structured Al2O3@PPy composites with high-performance electromagnetic wave absorption performance[J]. Journal of Materials Science: Materials in Electronics, 2022, 33(29): 23196-23211. doi: 10.1007/s10854-022-09084-x [47] HONG Z, YU X, XING Y, et al. Tunable head-conducting microwave-absorbing multifunctional composites with excellent microwave absorption, thermal conductivity and mechanical properties[J]. Journal of Composites Science, 2023, 7(1): 15. doi: 10.3390/jcs7010015 [48] SHAO T, MA H, WANG J, et al. High temperature absorbing coatings with excellent performance combined Al2O3 and TiC material[J]. Journal of the European Ceramic Society, 2020, 40(5): 2013-2019. doi: 10.1016/j.jeurceramsoc.2020.01.036 [49] MU Y, ZHOU W, HU Y, et al. Temperature-dependent dielectric and microwave absorption properties of SiCf/SiC-Al2O3 composites modified by thermal cross-linking procedure[J]. Journal of the European Ceramic Society, 2015, 35(11): 2991-3003. doi: 10.1016/j.jeurceramsoc.2015.04.016 [50] XIANG Z, WANG Y, YIN X, et al. Microwave absorption performance of porous heterogeneous SiC/SiO2 microspheres[J]. Chemical Engineering Journal, 2023, 451: 138742. doi: 10.1016/j.cej.2022.138742 [51] ZHANG H, LIU H, WU H, et al. Microwave absorbing property of gelcasting SiC-Si3N4 ceramics with hierarchical pore structures[J]. Journal of the European Ceramic Society, 2022, 42(4): 1249-1257. doi: 10.1016/j.jeurceramsoc.2021.12.011 [52] ZHOU W, YIN R, LONG L, et al. Enhanced high-temperature dielectric properties and microwave absorption of SiC nanofibers modified Si3N4 ceramics within the gigahertz range[J]. Ceramics International, 2018, 44(11): 12301-12307. doi: 10.1016/j.ceramint.2018.04.017 [53] ZANG X, LI H, LU Y, et al. Dielectric properties and thermal conductivity of Si3N4-SiC composite ceramics[J]. Journal of the Korean Ceramic Society, 2022, 59(6): 903-908. doi: 10.1007/s43207-022-00232-x [54] XU J, SHU R W, WAN Z L, et al. Construction of three-dimensional hierarchical porous nitrogen-doped reduced graphene oxide/hollow cobalt ferrite composite aerogels toward highly efficient electromagnetic wave absorption[J]. Journal of Materials Science & Technology, 2023, 132: 193-200. [55] PAN D, YANG G, ABO-DIEF H M, et al. Vertically aligned silicon carbide nanowires/boron nitride cellulose aerogel networks enhanced thermal conductivity and electromagnetic absorbing of epoxy composites[J]. Nano-Micro Letters, 2022, 14(1): 118. doi: 10.1007/s40820-022-00863-z [56] BAI Y, LIU R, WANG L, et al. Microwave absorption and thermal conductivity properties of HO-BNNS@Fe3O4 composites[J]. Journal of Alloys and Compounds, 2020, 837: 155574. doi: 10.1016/j.jallcom.2020.155574 [57] ZHANG Y, HEO Y J, SON Y R, et al. Recent advanced thermal interfacial materials: A review of conducting mechanisms and parameters of carbon materials[J]. Carbon, 2019, 142: 445-460. doi: 10.1016/j.carbon.2018.10.077 [58] BALANDIN A A. Thermal properties of graphene and nanostructured carbon materials[J]. Nature Materials, 2011, 10(8): 569-581. doi: 10.1038/nmat3064 [59] BAO W, LIU Y, ZHAO X. Recent research progress of carbon-based and their composites for electromagnetic waves absorption[J]. Textile Research Journal, 2023, 93(7-8): 1889-1912. doi: 10.1177/00405175221136290 [60] LI Q, ZHANG Z, QI L, et al. Toward the application of high frequency electromagnetic wave absorption by carbon nanostructures[J]. Advanced Science, 2019, 6(8): 1801057. doi: 10.1002/advs.201801057 [61] FAN B X, XING L, YANG K X, et al. Salt-templated graphene nanosheet foams filled in silicon rubber toward prominent EMI shielding effectiveness and high thermal conductivity[J]. Carbon, 2023, 207: 317-327. doi: 10.1016/j.carbon.2023.03.022 [62] JIANG B, QI C, YANG H, et al. Recent advances of carbon-based electromagnetic wave absorption materials facing the actual situations[J]. Carbon, 2023, 208: 390-409. doi: 10.1016/j.carbon.2023.04.002 [63] WANG H Y, SUN X, WANG G S. A MXene-modulated 3D crosslinking network of hierarchical flower-like MOF derivatives towards ultra-efficient microwave absorption properties[J]. Journal of Materials Chemistry A, 2021, 9(43): 24571-24581. doi: 10.1039/D1TA06505J [64] WANG H Y, SUN X B, YANG S H, et al. 3D ultralight hollow NiCo compound@MXene composites for tunable and high-efficient microwave absorption[J]. Nano-Micro Letters, 2021, 13: 1-15. doi: 10.1007/s40820-020-00525-y [65] HE L, LI X, DAI R, et al. Compositional and morphological design of hierarchical Co2Y@MnO2@CNTs core-shell microflowers for broadband microwave absorption application[J]. Journal of Alloys and Compounds, 2021, 869: 159270. doi: 10.1016/j.jallcom.2021.159270 [66] HUANG X, LIU X, JIA Z, et al. Synthesis of 3D cerium oxide/porous carbon for enhanced electromagnetic wave absorption performance[J]. Advanced Composites and Hybrid Materials, 2021, 4(4): 1398-1412. doi: 10.1007/s42114-021-00304-2 [67] XU W, WANG G S, YIN P G. Designed fabrication of reduced graphene oxides/Ni hybrids for effective electromagnetic absorption and shielding[J]. Carbon, 2018, 139: 759-767. doi: 10.1016/j.carbon.2018.07.044 [68] ZHAO P Y, WANG H Y, CAI B, et al. Electrospinning fabrication and ultra-wideband electromagnetic wave absorption properties of CeO2/N-doped carbon nanofibers[J]. Nano Research, 2022, 15(9): 7788-7796. doi: 10.1007/s12274-022-4675-x [69] YANG Y, CHENG J, PAN F, et al. Phragmites-derived magnetic carbon fiber with hollow assembly architecture toward full-covered effective bandwidth at Ku band[J]. Carbon, 2023, 213: 118228. doi: 10.1016/j.carbon.2023.118228 [70] QIU Y, YANG H, CHRNG Y, et al. MOFs derived flower-like nickel and carbon composites with controllable structure toward efficient microwave absorption[J]. Composites Part A: Applied Science and Manufacturing, 2022, 154: 106772. doi: 10.1016/j.compositesa.2021.106772 [71] 邹海仲, 万炜涛, 杨名华, 等. 复合粉体制备导热吸波材料及其表征[J]. 高分子材料科学与工程, 2019, 35(2): 136-140. doi: 10.16865/j.cnki.1000-7555.2019.0053ZOU Haizhong, WAN Weitao, YANG Minghua, et al. Preparation and characterization of composite powder for thermally conductive and absorbing materials[J]. Journal of Polymer Materials Science and Engineering, 2019, 35(2): 136-140(in Chinese). doi: 10.16865/j.cnki.1000-7555.2019.0053 [72] WANG X X, YOU F F, WU L S, et al. Enhanced heat conductance and microwave absorption of 2D laminated Ti3C2T x MXene microflakes via steering surface, defects, and interlayer spacing[J]. Journal of Alloys and Compounds, 2022, 918: 165740. doi: 10.1016/j.jallcom.2022.165740 [73] WANG X, YOU F, YAO Q, et al. Synchronously boosting microwave-absorbing and heat-conducting capabilities in CeO2/Ce(OH)3 core-shell nanorods/nanofibers via Fe-doping amount control[J]. Materials Horizons, 2023, 10(7): 2677-2690. doi: 10.1039/D3MH00061C [74] XING L, XIA H X, SHEN K J, et al. Co-manipulation of defects and porosity for enhancing the electrical insulation, microwave absorbing/shielding, and thermal properties of filter-paper-derived 2D interlinked carbon fiber networks[J]. Carbon, 2023, 215: 118433. doi: 10.1016/j.carbon.2023.118433 [75] JI R, XING L, YANG K X, et al. Defect and interface co-steering ultra-wide microwave absorption and superior thermal conductance of TiO2/Fe/C nanocomposites[J]. Applied Surface Science, 2023, 608: 155207. doi: 10.1016/j.apsusc.2022.155207 [76] FU K, LIU X Y, YANG Y J, et al. Synchronously enhanced electromagnetic wave absorption and heat conductance capabilities of flower-like porous γ-Al2O3@Ni@C composites[J]. Chemical Engineering Journal, 2023, 457: 141318. doi: 10.1016/j.cej.2023.141318 [77] YOU F F, LIU X Y, YING M W, et al. In situ generated gas bubble-directed self-assembly of multifunctional MgO-based hybrid foams for highly efficient thermal conduction, microwave absorption, and self-cleaning[J]. Materials Horizons, 2023, 10(10): 4609-4625. doi: 10.1039/D3MH01040F [78] GUO Y, RUAN K, WANG G, et al. Advances and mechanisms in polymer composites toward thermal conduction and electromagnetic wave absorption[J]. Science Bulletin, 2023, 68(11): 195-212. [79] HUANG C, QIAN X, YANG R. Thermal conductivity of polymers and polymer nanocomposites[J]. Materials Science and Engineering: Reports, 2018, 132: 1-22. doi: 10.1016/j.mser.2018.06.002 [80] XIAO M, DU B X. Review of high thermal conductivity polymer dielectrics for electrical insulation[J]. High Voltage, 2016, 1(1): 34-42. doi: 10.1049/hve.2016.0008 [81] LI Y, LI C, ZHANG L, et al. Effect of microscopic-ordered structures on intrinsic thermal conductivity of liquid-crystalline polysiloxane[J]. Journal of Materials Science: Materials in Electronics, 2019, 30: 8329-8338. doi: 10.1007/s10854-019-01150-1 [82] YANG X, ZHONG X, ZHANG J, et al. Intrinsic high thermal conductive liquid crystal epoxy film simultaneously combining with excellent intrinsic self-healing performance[J]. Journal of Materials Science & Technology, 2021, 68: 209-215. [83] LI Y, GONG C, LI C, et al. Liquid crystalline texture and hydrogen bond on the thermal conductivities of intrinsic thermal conductive polymer films[J]. Journal of Materials Science & Technology, 2021, 82: 250-256. [84] ZHANG F, FENG Y, FENG W. Three-dimensional interconnected networks for thermally conductive polymer composites: Design, preparation, properties, and mechanisms[J]. Materials Science and Engineering: R: Reports, 2020, 142: 100580. [85] XING L, CHEN Y, YANG Y, et al. Incorporation of FexOy nanoparticles into 3D interlinked porous carbon nanofiber networks to synergistically enhance the electrical insulation, electromagnetic wave absorbing/shielding performance and thermal conductivity[J]. Chemical Engineering Journal, 2023, 469: 143952. doi: 10.1016/j.cej.2023.143952 [86] JIANG Y, SHI X, FENG Y, et al. Enhanced thermal conductivity and ideal dielectric properties of epoxy composites containing polymer modified hexagonal boron nitride[J]. Composites Part A: Applied Science and Manufacturing, 2018, 107: 657-664. doi: 10.1016/j.compositesa.2018.02.016 [87] OHAYON-LAVI A, BUZAGLO M, LIGATI S, et al. Compression-enhanced thermal conductivity of carbon loaded polymer composites[J]. Carbon, 2020, 163: 333-340. doi: 10.1016/j.carbon.2020.03.026 [88] QIAN Y, TAO Y, LI Y, et al. High performance epoxy resin with efficient electromagnetic wave absorption and heat dissipation properties for electron packaging by modification of 3D MDCF@h-BN[J]. Chemical Engineering Journal, 2022, 441: 136033. doi: 10.1016/j.cej.2022.136033 [89] XU Y, WANG X, HAO Q. A mini review on thermally conductive polymers and polymer-based composites[J]. Composites Communications, 2021, 24: 100617. doi: 10.1016/j.coco.2020.100617 [90] WANG J, SUN Q, LI J, et al. Polymer-based nanocompoites: Role of interface for effective microwave absorption[J]. Materials Today Physics, 2023, 31: 100981. doi: 10.1016/j.mtphys.2023.100981 [91] LAN D, GAO Z, ZHAO Z, et al. Application progress of conductive conjugated polymers in electromagnetic wave absorbing composites[J]. Composites Communications, 2021, 26: 100767. doi: 10.1016/j.coco.2021.100767 [92] CUI W G, ZHOU X, ZHAO B, et al. 3D porous PVDF foam anchored with ultra-low content of graphene and Ni nanochains towards wideband electromagnetic waves absorption[J]. Carbon, 2023, 210: 118070. doi: 10.1016/j.carbon.2023.118070 [93] WU Z, TAN D, TIAN K, et al. Facile preparation of core-shell Fe3O4@polypyrrole composites with superior electromagnetic wave absorption properties[J]. The Journal of Physical Chemistry C, 2017, 121(29): 15784-15792. doi: 10.1021/acs.jpcc.7b04230 [94] FAN B, XING L, YANG K, et al. Synergistically enhanced heat conductivity-microwave absorption capabilities of g-C3N4@Fe@C hollow micro-polyhedra via interface and composition modulation[J]. Chemical Engineering Journal, 2023, 451: 138492. doi: 10.1016/j.cej.2022.138492 [95] YANG X, FU K, WU L, et al. Synergistic enhancement of thermal conduction and microwave absorption of silica films based on graphene/chiral PPy/Al2O3 ternary aerogels[J]. Carbon, 2022, 199: 1-12. -

下载:

下载: