Composition and architecture design in additive manufacturing of titanium matrix composites

-

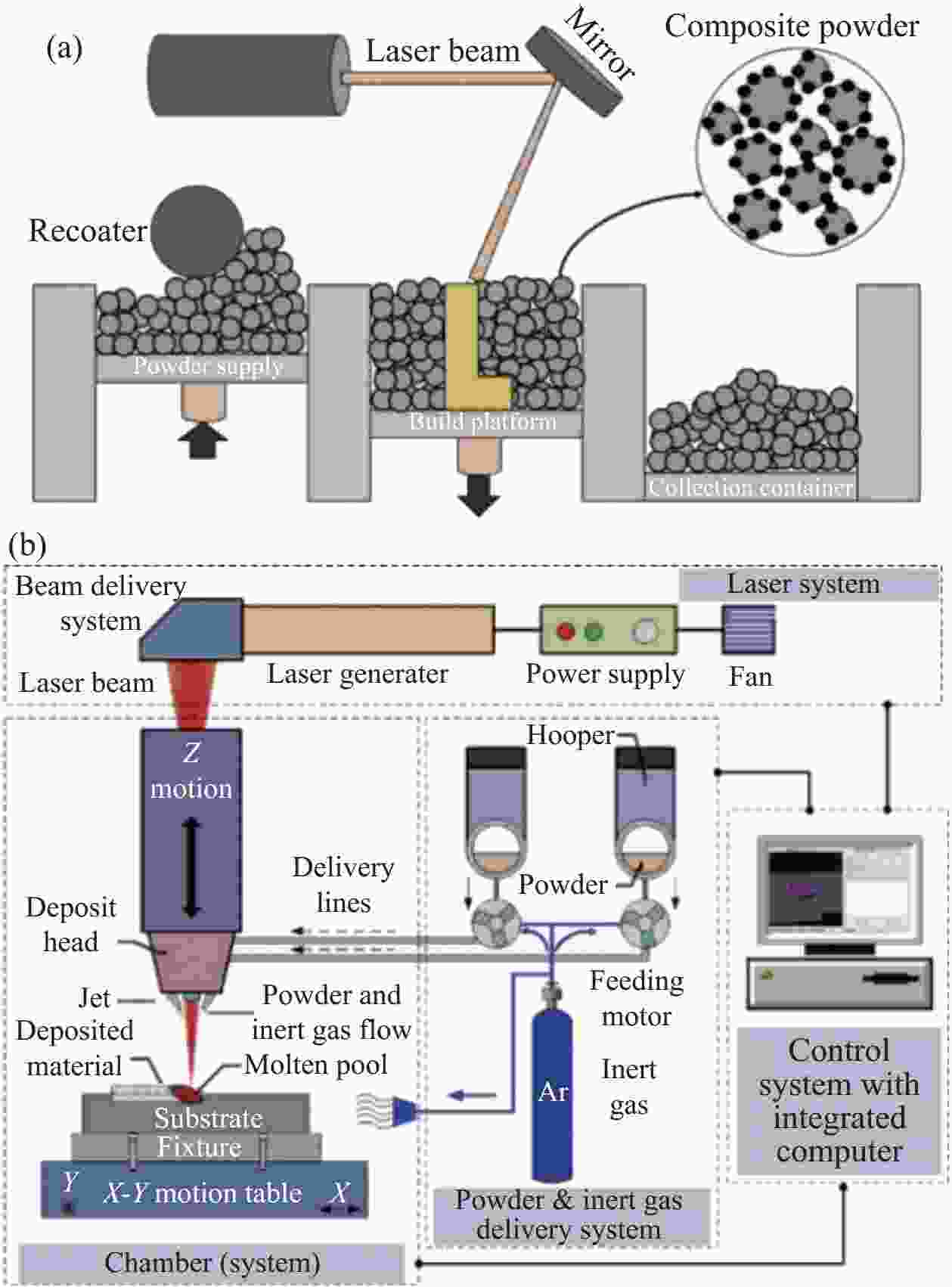

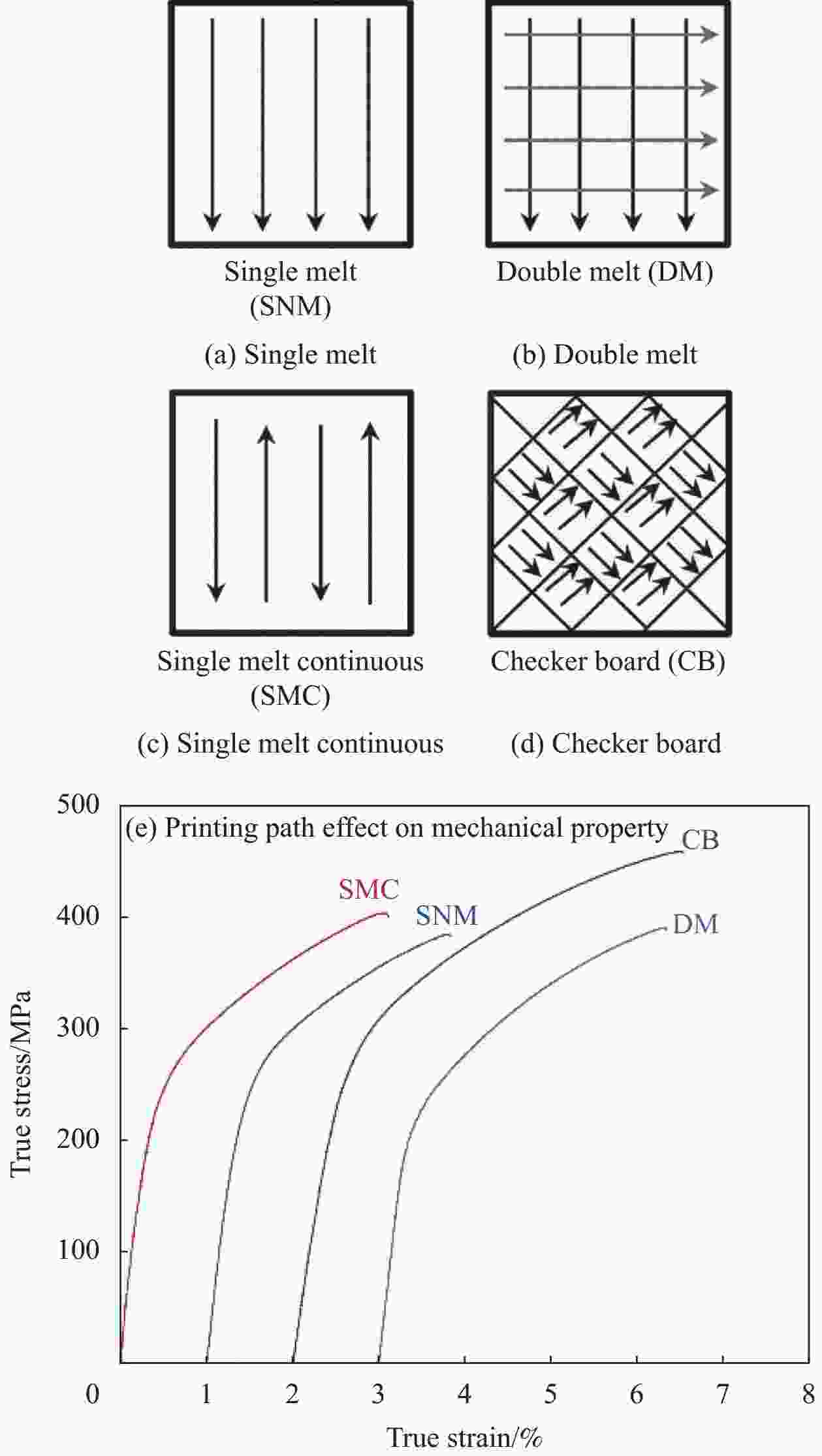

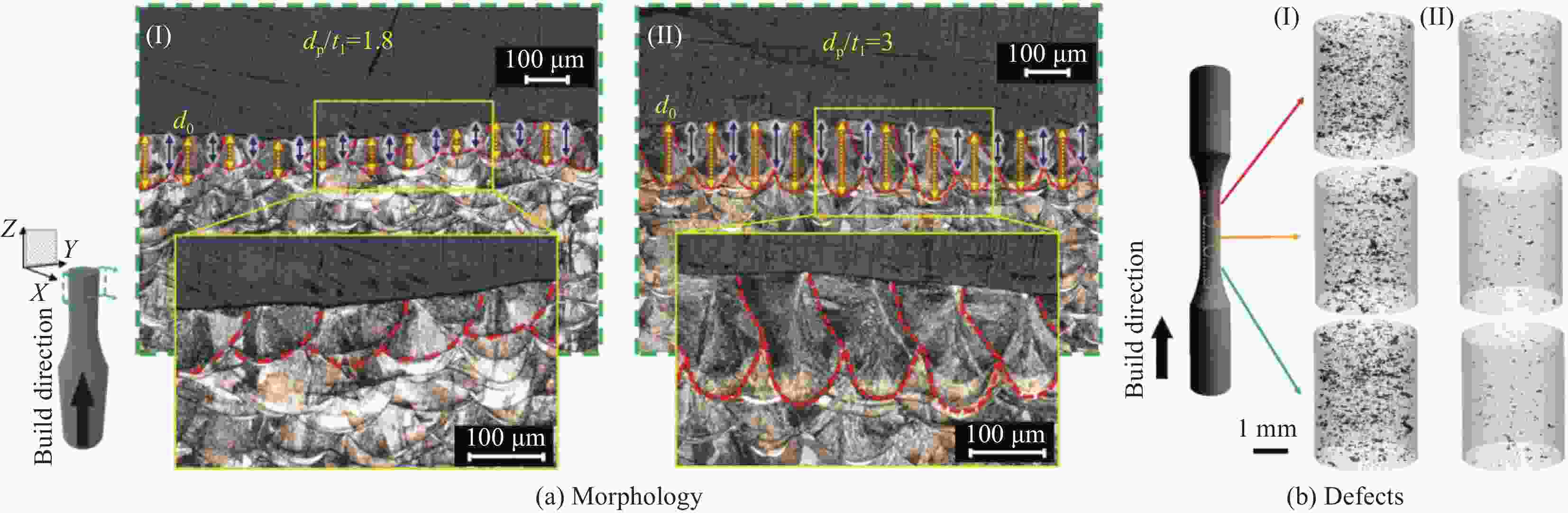

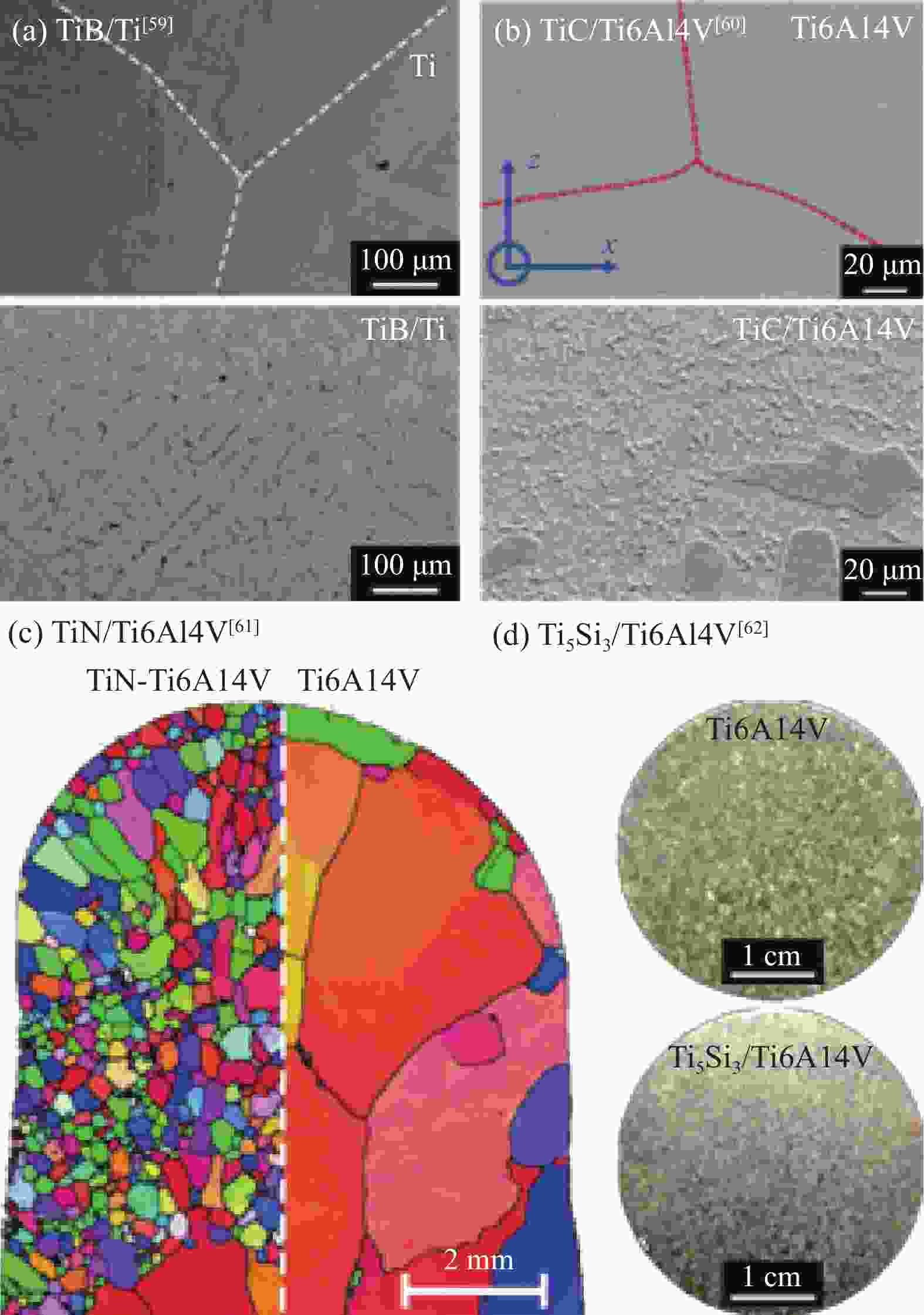

摘要: 增材制造技术作为一种样件快速成型制备技术,为基于成分调控与结构设计的高性能钛基复合材料的开发带来了机遇。本文介绍了增材制造钛基复合材料研究与应用的最新进展,分析了能量密度、打印路径及冷速控制等对材料显微组织与力学性能的影响。在此基础上,介绍了以陶瓷、金属间化合物及稀土元素为主的增材制造钛基复合材料成分调控策略。其中,以TiB、TiC为代表的陶瓷增强相及Ti-Cu体系的金属间化合物为目前钛基复合材料中广泛使用的增强体;以La、Ce和Nd为主的稀土元素则可有效解决氧偏聚问题并显著细化晶粒。进而以网状结构和层状结构为例介绍了增材制造钛基复合材料结构设计研究进展。其中,网状结构多通过Ti与B和C元素的原位反应生成增强相,并通过控制凝固过程实现对增强相非均匀分布的调控;层状结构则多通过交替打印多种粉体获得。网状、层状结构设计对钛基复合材料强韧化有着积极的作用。本文最后通过对研究现状和未来研究趋势的简要分析与展望,为增材制造高性能钛基复合材料的设计与制备提供一定参考。Abstract: Additive manufacturing is a rapid prototyping technology offering opportunities to develop high performance composites via composition regulation and architecture design. This brief review presents the latest research progress and application of additive manufactured titanium matrix composites (TMCs). Firstly, the effects of energy density, printing path and cooling rate on the microstructure and mechanical properties are systematically analyzed. Then, the composition regulation strategies pertaining to ceramic reinforcements, intermetallic compounds and rare earth elements are introduced. In general, the ceramic reinforcing phases and the intermetallic compounds play a positive role in tailoring the microstructures and thus mechanical properties of composites. The rare earth elements effectively inhibit oxygen polarization and refine the grains. Furthermore, the research on TMCs with network and laminated structures are presented. The network architecture is mostly generated by the in-situ reaction of Ti with B or C, which is controlled by the solidification process. The laminated structure is achieved via printing multiple powders alternately. Both architectures promote simultaneous strengthening and toughening. Finally, the state of the art and future outlooks are briefly presented to provide a reference for the design and preparation of high-performance TMCs via additive manufacturing.

-

图 1 增材制造(AM)在工业领域的应用:(a) 飞机舱门部件[11];(b) Space X 发动机[12];(c) 汽车整体叶盘[13];(d) 飞机推进系统热交换器[14];(e) 人造关节[15];(f) 人造牙齿[16];(g) 船舶螺旋桨[18];(h) 汽车减震部件的拓扑优化[20]

Figure 1. Additive manufacturing (AM) in industrial applications: (a) Aircraft hatch components[11]; (b) Space X engine[12]; (c) Automobile integral blisk[13]; (d) Heat exchangers for aircraft propulsion systems[14]; (e) Artificial joint[15]; (f) Artificial tooth[16]; (g) Propellers for ship[18]; (h) Topology optimization of automotive shock absorbing parts[20]

HE—Heat exchanger

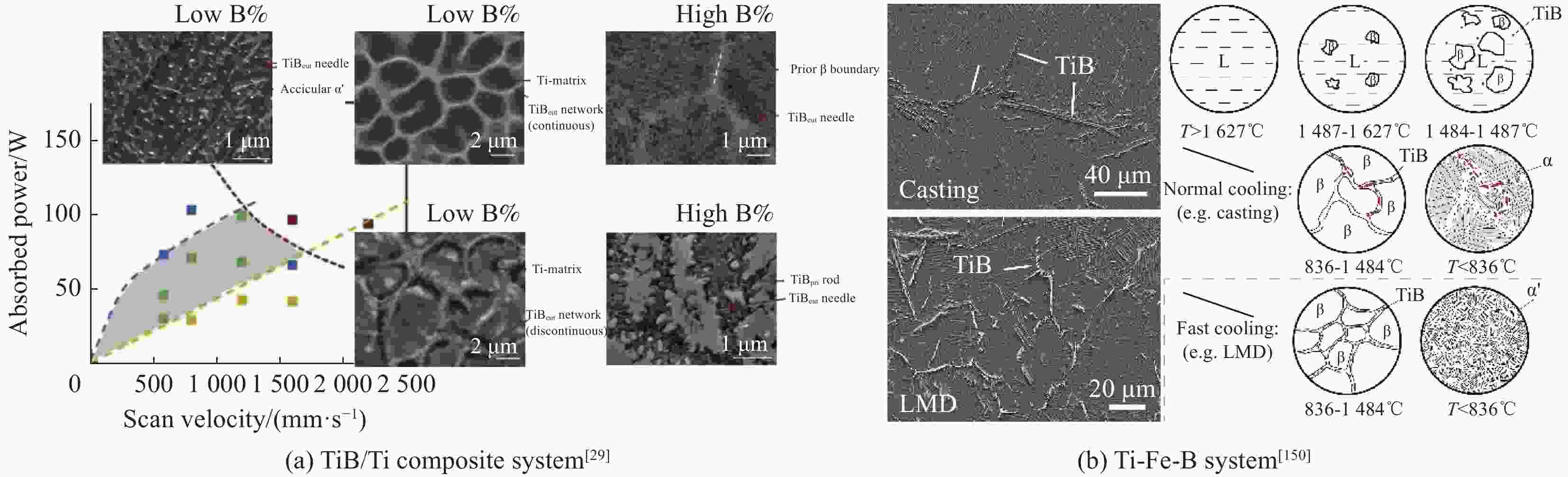

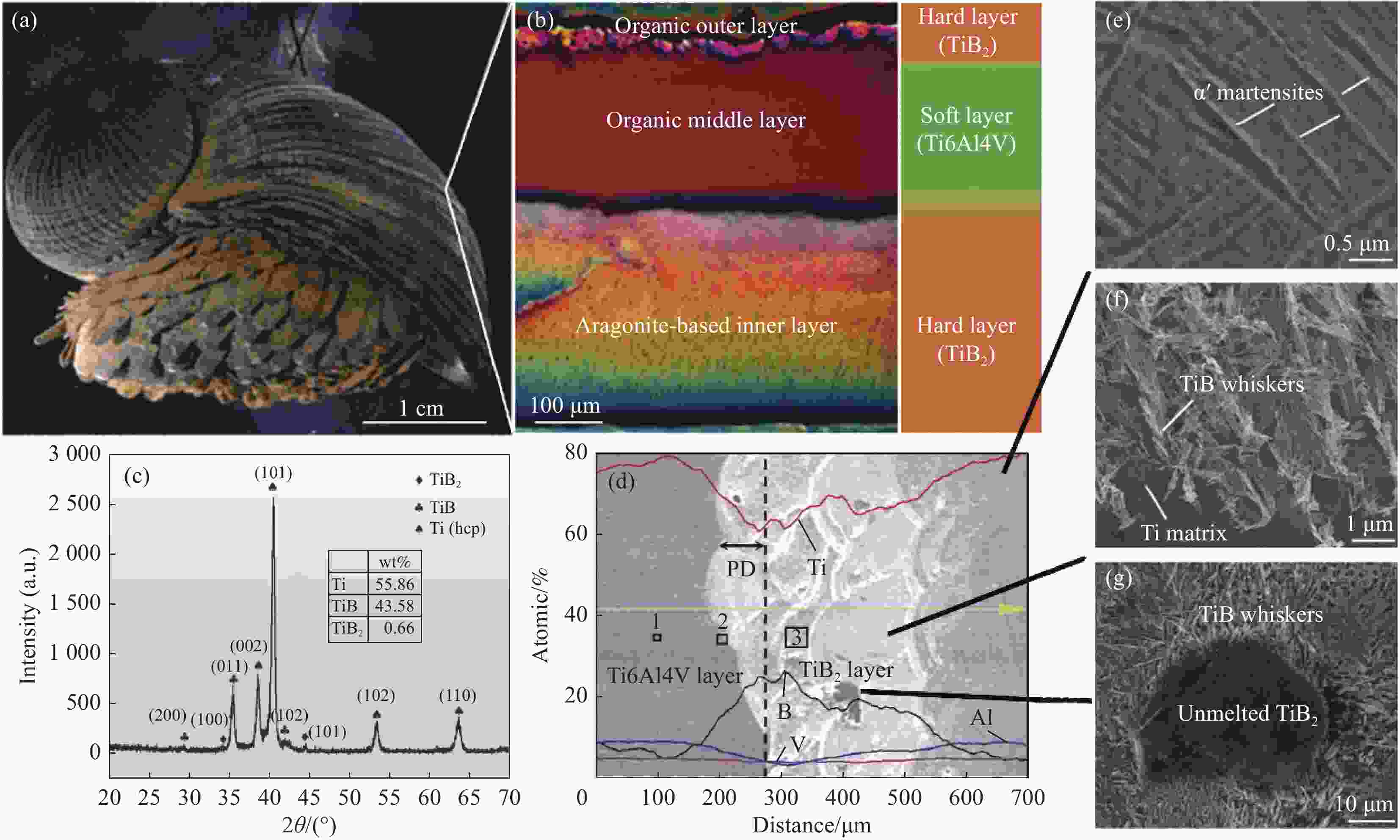

图 12 蜗牛壳启迪的仿生层状Ti-TiB2复合材料[30, 163]:(a) 蜗牛壳;(b) 蜗牛壳微观结构;(c) 层状复合材料物相;(d) 层状复合材料形貌;(e) 软相α'-Ti;(f) TiB晶须(TiBw)在硬层中;(g) 未熔TiB2颗粒

Figure 12. Snail shell bio-inspired Ti-TiB2 laminated composite[30, 163]: (a) Snail shell; (b) Micro-structure of snail shell; (c) XRD of laminated composite; (d) Morphology of the composite; (e) α'-Ti soft layer; (f) TiB whiskers (TiBw) in hard layer; (g) Unmelted TiB2

PD—Penetration depth

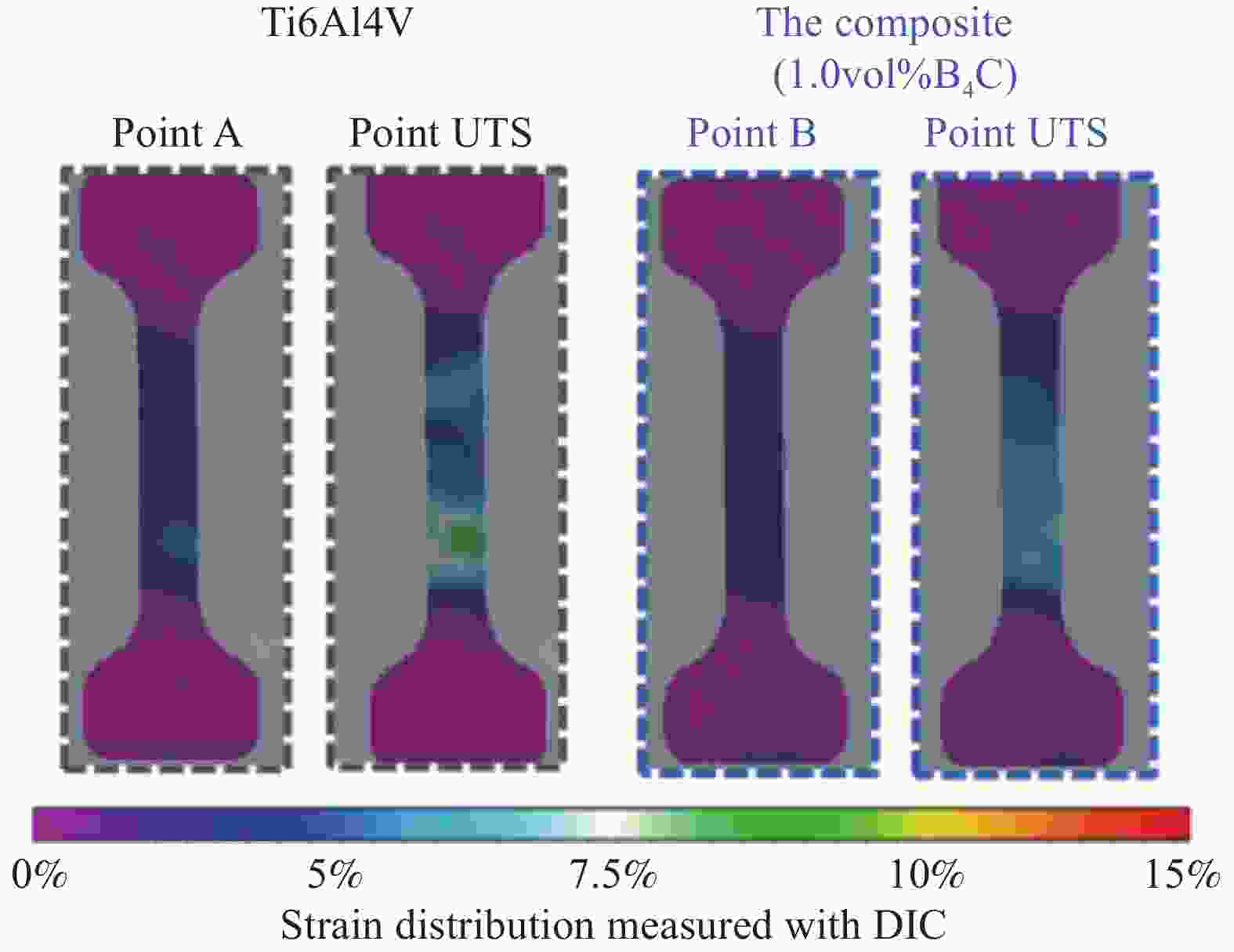

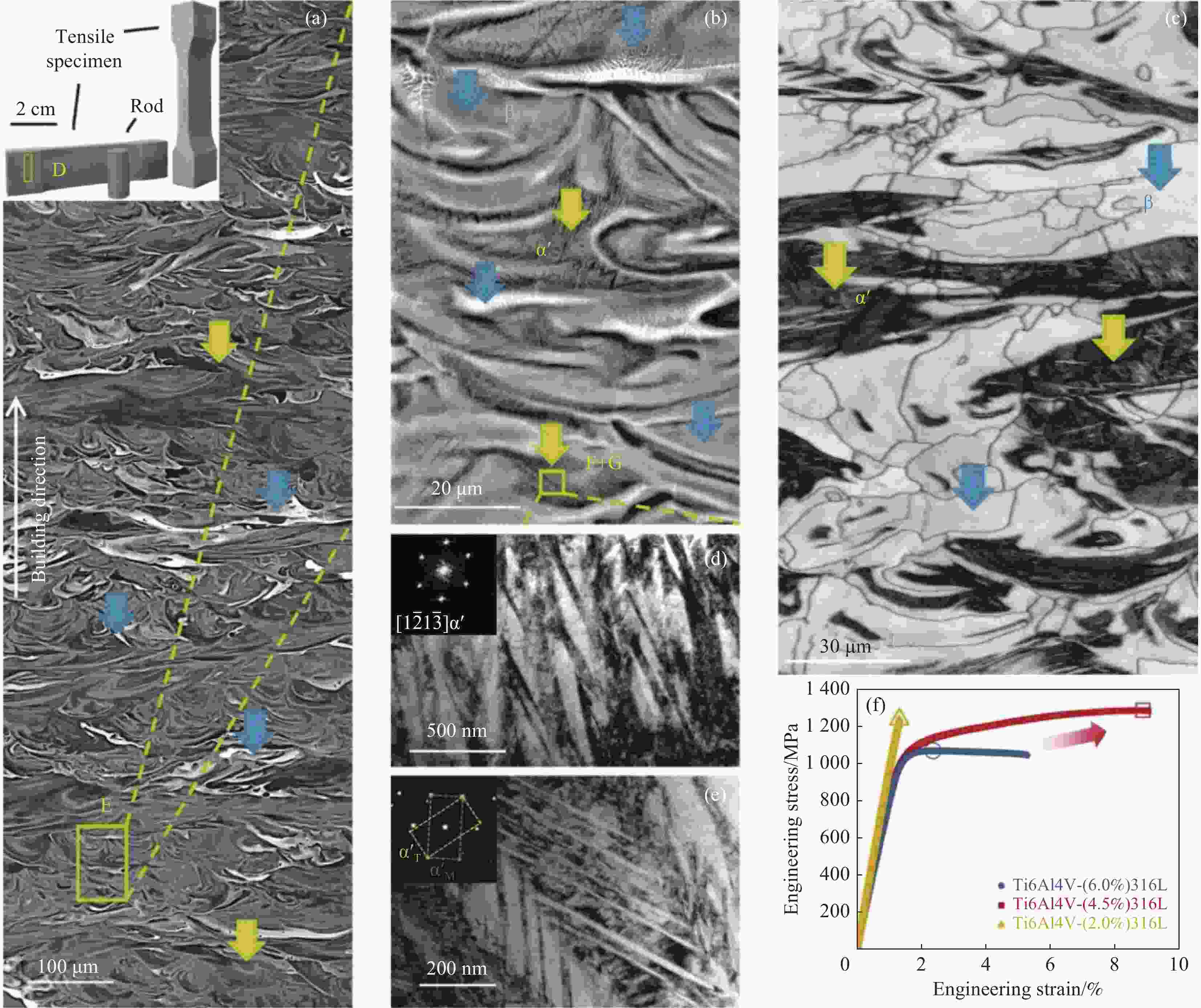

图 13 Ti6Al4V-(4.5%)316L复合体系非均匀组织及性能[103]:(a) 类层状结构;(b) 层状结构由α'及β相组成;(c) 全等轴晶形貌;(d) 细小针状α'马氏体;(e) 超细孪晶;(f) 应力-应变曲线

Figure 13. Ti6Al4V-(4.5%)316L composite system inhomogeneous structure and performance[103]: (a) Lava-like laminated microstructure; (b) Acicular α' martensite and ultrafine β grains with solidification cellular structure; (c) Ultrafine grain structure without columnar grains; (d) Fine acicular α' martensite; (e) Ultrafine twin structure; (f) Stress-strain curves

α'T—Twin of α'M

-

[1] KUMAR M B, SATHIYA P. Methods and materials for additive manufacturing: A critical review on advancements and challenges[J]. Thin-Walled Structures, 2021, 159: 107228. doi: 10.1016/j.tws.2020.107228 [2] KATZ-DEMYANETZ A, POPOV JR V V, KOVALEVSKY A, et al. Powder-bed additive manufacturing for aerospace application: Techniques, metallic and metal/ceramic composite materials and trends[J]. Manufacturing Review, 2019, 6: 5. [3] 李礼, 戴煜. 中国增材制造技术现状及发展趋势[J]. 新材料产业, 2018(8): 30-33.LI Li, DAI Yu. Current situation and development trend of additive manufacturing technology in China[J]. Advanced Materials Industry, 2018(8): 30-33(in Chinese). [4] ALFAIFY A, SALEH M, ABDULLAH F M, et al. Design for additive manufacturing: A systematic review[J]. Sustainability, 2020, 12(19): 7936. doi: 10.3390/su12197936 [5] PRAVEENA B A, LOKESH N, BURADI A, et al. A comprehensive review of emerging additive manufacturing (3D printing technology): Methods, materials, applications, challenges, trends and future potential[J]. Materials Today: Proceedings, 2022, 52: 1309-1313. doi: 10.1016/j.matpr.2021.11.059 [6] SHI J, WANG Y. Development of metal matrix composites by laser-assisted additive manufacturing technologies: A review[J]. Journal of Materials Science, 2020, 55(23): 9883-9917. doi: 10.1007/s10853-020-04730-3 [7] 姚燕生, 汪俊, 陈庆波, 等. 激光增材制造产品缺陷及其处理技术研究现状[J]. 激光与光电子学进展, 2019, 56(10): 45-56. doi: 10.3788/LOP56.100004YAO Yansheng, WANG Jun, CHEN Qingbo, et al. Research status defects and defect treatment technology for laser additive manufactured products[J]. Laser and Optoelectronics Progress, 2019, 56(10): 45-56(in Chinese). doi: 10.3788/LOP56.100004 [8] ZHUO Y, YANG C, FAN C, et al. Microstructure and mechanical properties of wire arc additive repairing Ti-5Al-2Sn-2Zr-4Mo-4Cr titanium alloy[J]. Materials Science and Technology, 2020, 36(15): 1712-1719. doi: 10.1080/02670836.2020.1822061 [9] ZHUO Y, YANG C, FAN C, et al. Effects of thermal undercooling and thermal cycles on the grain and microstructure evolution of TC17 titanium alloy repaired by wire arc additive manufacturing[J]. The International Journal of Advanced Manufacturing Technology, 2023, 124: 3161-3169. [10] 顾冬冬, 张红梅, 陈洪宇, 等. 航空航天高性能金属材料构件激光增材制造[J]. 中国激光, 2020, 47(5): 32-55. doi: 10.3788/CJL202047.0500002GU Dongdong, ZHANG Hongmei, CHEN Hongyu, et al. Laser additive manufacturing of high-performance metallic aerospace components[J]. Chinese Journal of Lasers, 2020, 47(5): 32-55(in Chinese). doi: 10.3788/CJL202047.0500002 [11] MICALLEF K. Airbus continues to innovate bionic design for future sustainable flights[EB/OL]. Redshift by Autodesk. (2019-12-3)[2024-2-28]. https://www.facebook.com/AutodeskNetfabb/posts/10156676561921629. [12] 胡美娟, 吉玲康, 马秋荣, 等. 激光增材制造技术及现状研究[J]. 石油管材与仪器, 2019, 5(5): 1-6.HU Meijuan, JI Lingkang, MA Qiurong, et al. Overview of laser additive manufacturing technology and status[J]. Petroleum Tubular Goods and Instruments, 2019, 5(5): 1-6(in Chinese). [13] GONZÁLEZ-BARRIO H, CALLEJA-OCHOA A, DE LACALLE L N L, et al. Hybrid manufacturing of complex components: Full methodology including laser metal deposition (LMD) module development, cladding geometry estimation and case study validation[J]. Mechanical Systems and Signal Processing, 2022, 179: 109337. doi: 10.1016/j.ymssp.2022.109337 [14] WROBEL R, SCHOLES B, MUSTAFFER A, et al. Design and experimental characterisation of an additively manufactured heat exchanger for the electric propulsion unit of a high-altitude solar aircraft[C]//2019 IEEE Energy Conversion Congress and Exposition (ECCE). New York: IEEE, 2019: 753-760. [15] LI H, ZONG R, REN X, et al. Effective prediction of residual stress and distortion of artificial knee joints by selective laser melting[J]. The International Journal of Advanced Manufacturing Technology, 2022, 123(1-2): 591-601. doi: 10.1007/s00170-022-10106-5 [16] REVILLA-LEÓN M, BARMAK A B, RUBENSTEIN J, et al. Wear at the implant-framework interface between titanium implant platform and the additively manufactured titanium and cobalt-chromium frameworks[J]. Journal of Prosthodontics, 2023, 33(1): 77-85. [17] ZHANG X, LIU S, LIU Y, et al. Titanium alloy fabricated by additive manufacturing for medical applications: Obtaining, characterization and application[J]. Metals, 2023, 13(3): 462. doi: 10.3390/met13030462 [18] NOTA C, RÜCKERT G, HEUZÉ J L, et al. A first feedback on manufacturing and in-service behaviour of a WAAM-made propeller for naval application[J]. Welding in the World, 2023, 67(4): 1113-1121. doi: 10.1007/s40194-023-01475-w [19] GOVINDARAJ R B, JUNGHANS E, ANDERSEN I, et al. Additive manufactured marine component-Ni Al bronze propeller[J]. Procedia Structural Integrity, 2021, 34: 20-25. doi: 10.1016/j.prostr.2021.12.039 [20] BASSOLI E, DEFANTI S, TOGNOLI E, et al. Design for additive manufacturing and for machining in the automotive field[J]. Applied Sciences, 2021, 11(16): 7559. doi: 10.3390/app11167559 [21] 祝弘滨, 刘昱. 金属3D打印技术在轨道交通装备领域的应用研究现状[J]. 现代城市轨道交通, 2019(10): 77-81.ZHU Hongbin, LIU Yu. Current research status of metal prototyping manufacturing (3D-printing) technology application in rail transit equipment[J]. Modern Urban Transit, 2019(10): 77-81(in Chinese). [22] SINGH G, RAMAMURTY U. Reprint: Boron modified titanium alloys[J]. Progress in Materials Science, 2021, 120: 100815. doi: 10.1016/j.pmatsci.2021.100815 [23] HUANG L J, GENG L, PENG H X. Microstructurally inhomogeneous composites: Is a homogeneous reinforcement distribution optimal?[J]. Progress in Materials Science, 2015, 71: 93-168. doi: 10.1016/j.pmatsci.2015.01.002 [24] HUANG L, AN Q, GENG L, et al. Multiscale architecture and superior high-temperature performance of discontinuously reinforced titanium matrix composites[J]. Advanced Materials, 2021, 33(6): 2000688. doi: 10.1002/adma.202000688 [25] BANDYOPADHYAY A, TRAXEL K D, LANG M, et al. Alloy design via additive manufacturing: Advantages, challenges, applications and perspectives[J]. Materials Today, 2022, 52: 207-224. doi: 10.1016/j.mattod.2021.11.026 [26] 高楚寒, 吴文恒, 张亮. 高温钛合金及钛基复合材料增材制造技术研究现状[J]. 粉末冶金技术, 2023, 41(1): 55-62.GAO Chuhan, WU Wenheng, ZHANG Liang. Research status of additive manufacturing technology used for high temperature titanium alloys and titanium matrix composites[J]. Powder Metallurgy Technology, 2023, 41(1): 55-62(in Chinese). [27] LIU C, JIN K H, YE J, et al. Additive manufacturing of (TiB+TiC)/Ti6Al4V composites with tailored network reinforcement architecture[J]. Composites Communications, 2023, 40: 101611. doi: 10.1016/j.coco.2023.101611 [28] ZHANG D, QIU D, GIBSON M A, et al. Additive manufacturing of ultrafine-grained high-strength titanium alloys[J]. Nature, 2019, 576(7785): 91-95. doi: 10.1038/s41586-019-1783-1 [29] HE Y, MONTGOMERY C, BEUTH J, et al. Melt pool geometry and microstructure of Ti6Al4V with B additions processed by selective laser melting additive manufacturing[J]. Materials and Design, 2019, 183: 108126. doi: 10.1016/j.matdes.2019.108126 [30] WANG R, GU D, LIN K, et al. Multi-material additive manufacturing of a bio-inspired layered ceramic/metal structure: Formation mechanisms and mechanical properties[J]. International Journal of Machine Tools and Manufacture, 2022, 175: 103872. doi: 10.1016/j.ijmachtools.2022.103872 [31] MITRA I, BOSE S, DERNELL W S, et al. 3D printing in alloy design to improve biocompatibility in metallic implants[J]. Materials Today, 2021, 45: 20-34. doi: 10.1016/j.mattod.2020.11.021 [32] 耿林, 范国华. 金属基复合材料的构型强韧化研究进展[J]. 中国材料进展, 2016, 35(9): 686-693, 701.GENG Lin, FAN Guohua. Progress on strengthening and toughening mechanism for metal matrix composites by configuration design[J]. Materials China, 2016, 35(9): 686-693, 701(in Chinese). [33] 张朝瑞, 钱波, 张立浩, 等. 金属增材制造工艺、材料及结构研究进展[J]. 机床与液压, 2023, 51(9): 180-196.ZHANG Chaorui, QIAN Bo, ZHANG Lihao, et al. Research progress of metal additive manufacturing process, materials and structure[J]. Machine Tool and Hydraulics, 2023, 51(9): 180-196(in Chinese). [34] FEREIDUNI E, GHASEMI A, ELBESTAWI M. Selective laser melting of aluminum and titanium matrix composites: Recent progress and potential applications in the aerospace industry[J]. Aerospace, 2020, 7(6): 77. doi: 10.3390/aerospace7060077 [35] HU Y, CONG W, WANG X, et al. Laser deposition-additive manufacturing of TiB-Ti composites with novel three-dimensional quasi-continuous network microstructure: Effects on strengthening and toughening[J]. Composites Part B: Engineering, 2018, 133: 91-100. doi: 10.1016/j.compositesb.2017.09.019 [36] SINGH N, UMMETHALA R, HAMEED P, et al. Competition between densification and microstructure of functional materials by selective laser melting[J]. Material Design and Processing Communications, 2020, 2(3): e146. [37] DADBAKHSH S, MERTENS R, HAO L, et al. Selective laser melting to manufacture "in situ" metal matrix composites: A review[J]. Advanced Engineering Materials, 2019, 21(3): 1801244. doi: 10.1002/adem.201801244 [38] PRASHANTH K G, SCUDINO S. Quasi crystalline composites by additive manufacturing[C]//Key Engineering Materials. Bäch: Trans Tech Publications LTD., 2019, 818: 72-76. [39] ZHANG L C, ATTAR H. Selective laser melting of titanium alloys and titanium matrix composites for biomedical applications: A review[J]. Advanced Engineering Materials, 2016, 18(4): 463-475. doi: 10.1002/adem.201500419 [40] THIJS L, VERHAEGHE F, CRAEGHS T, et al. A study of the microstructural evolution during selective laser melting of Ti-6Al-4V[J]. Acta Materialia, 2010, 58(9): 3303-3312. doi: 10.1016/j.actamat.2010.02.004 [41] DE ROJAS CANDELA C S, RIQUELME A, BONACHE V, et al. Ti6Al4V/SiC metal matrix composites additively manufactured by direct laser deposition[J]. Metals and Materials International, 2022, 28(12): 3120-3144. doi: 10.1007/s12540-022-01191-y [42] SINGH N, HAMEED P, UMMETHALA R, et al. Selective laser manufacturing of Ti-based alloys and composites: Impact of process parameters, application trends, and future prospects[J]. Materials Today Advances, 2020, 8: 100097. doi: 10.1016/j.mtadv.2020.100097 [43] PRASHANTH K G, SCUDINO S, ECKERT J. Defining the tensile properties of Al-12Si parts produced by selective laser melting[J]. Acta Materialia, 2017, 126: 25-35. doi: 10.1016/j.actamat.2016.12.044 [44] ZHANG L C, ATTAR H, CALIN M, et al. Review on manufacture by selective laser melting and properties of titanium based materials for biomedical applications[J]. Materials Technology, 2016, 31(2): 66-76. doi: 10.1179/1753555715Y.0000000076 [45] BI J, LEI Z, CHEN Y, et al. An additively manufactured Al-14.1Mg-0.47Si-0.31Sc-0.17Zr alloy with high specific strength, good thermal stability and excellent corrosion resistance[J]. Journal of Materials Science and Technology, 2021, 67: 23-35. [46] ZHANG X Y, FANG G, LEEFLANG S, et al. Effect of subtransus heat treatment on the microstructure and mechanical properties of additively manufactured Ti-6Al-4V alloy[J]. Journal of Alloys and Compounds, 2018, 735: 1562-1575. doi: 10.1016/j.jallcom.2017.11.263 [47] SUN S H, HAGIHARA K, NAKANO T. Effect of scanning strategy on texture formation in Ni-25at%Mo alloys fabricated by selective laser melting[J]. Materials and Design, 2018, 140: 307-316. doi: 10.1016/j.matdes.2017.11.060 [48] FARSHIDIANFAR M H, KHAJEPOUR A, GERLICH A. Real-time control of microstructure in laser additive manufacturing[J]. The International Journal of Advanced Manufacturing Technology, 2016, 82: 1173-1186. doi: 10.1007/s00170-015-7423-5 [49] FARSHIDIANFAR M H, KHAJEPOUR A, GERLICH A P. Effect of real-time cooling rate on microstructure in laser additive manufacturing[J]. Journal of Materials Processing Technology, 2016, 231: 468-478. doi: 10.1016/j.jmatprotec.2016.01.017 [50] LIU L, WANG G, REN K, et al. Marangoni flow patterns of molten pools in multi-pass laser cladding with added nano-CeO2[J]. Additive Manufacturing, 2022, 59(A): 103156. [51] NEZHADFAR P D, SHAMSAEI N, PHAN N. Enhancing ductility and fatigue strength of additively manufactured metallic materials by preheating the build platform[J]. Fatigue and Fracture of Engineering Materials and Structures, 2021, 44(1): 257-270. doi: 10.1111/ffe.13372 [52] ATTAR H, EHTEMAM-HAGHIGHI S, KENT D, et al. Recent developments and opportunities in additive manufacturing of titanium-based matrix composites: A review[J]. International Journal of Machine Tools and Manufacture, 2018, 133: 85-102. doi: 10.1016/j.ijmachtools.2018.06.003 [53] NIU H Z, YIN B G, ZHANG H R, et al. Multiphase polymorphic nanoparticles reinforced titanium matrix composite produced by selective electron beam melting of a prealloyed composite powder[J]. Scripta Materialia, 2021, 200: 113916. doi: 10.1016/j.scriptamat.2021.113916 [54] HOFMANN D C, KOLODZIEJSKA J, ROBERTS S, et al. Compositionally graded metals: A new frontier of additive manufacturing[J]. Journal of Materials Research, 2014, 29(17): 1899-1910. doi: 10.1557/jmr.2014.208 [55] 李浩. 放电等离子烧结TiBw/TA15复合材料组织及性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2019.LI Hao. Microstructure and properties of TiBw/TA15 composites prepared by spark plasma sintering[D]. Harbin: Harbin Institute of Technology, 2019(In Chinese [56] XIA M, LUO Q, TAN R, et al. Corrosion behavior of in situ synthesized (TiC+TiB)/Ti composites by laser powder-bed fusion: Role of scan strategy[J]. Journal of Alloys and Compounds, 2022, 929: 167255. [57] HU Z, TONG G, NIAN Q, et al. Laser sintered single layer graphene oxide reinforced titanium matrix nanocomposites[J]. Composites Part B: Engineering, 2016, 93: 352-359. doi: 10.1016/j.compositesb.2016.03.043 [58] ONG S P, CHOLIA S, JAIN A, et al. The materials application programming interface (API): A simple, flexible and efficient API for materials data based on representational state transfer (REST) principles[J]. Computational Materials Science, 2015, 97: 209-215. doi: 10.1016/j.commatsci.2014.10.037 [59] BERMINGHAM M J, MCDONALD S D, NOGITA K, et al. Effects of boron on microstructure in cast titanium alloys[J]. Scripta Materialia, 2008, 59(5): 538-541. doi: 10.1016/j.scriptamat.2008.05.002 [60] MA G, YU C, TANG K, et al. High-mass-proportion TiCp/Ti6Al4V titanium matrix composites prepared by directed energy deposition[J]. Additive Manufacturing, 2020, 35: 101323. doi: 10.1016/j.addma.2020.101323 [61] KENNEDY J R, DAVIS A E, CABALLERO A E, et al. The potential for grain refinement of wire-arc additive manufactured (WAAM) Ti-6Al-4V by ZrN and TiN inoculation[J]. Additive Manufacturing, 2021, 40: 101928. doi: 10.1016/j.addma.2021.101928 [62] LI N, CUI C, LIU S, et al. Microstructure and mechanical properties of Ti6Al4V alloy modified and reinforced by in situ Ti5Si3/Ti composite ribbon inoculants[J]. Metals, 2017, 7(7): 267. doi: 10.3390/met7070267 [63] 朱冬, 张亮, 吴文恒, 等. 钛基复合材料激光选区熔化增材制造成形技术研究进展[J]. 材料导报, 2021, 35(Z1): 347-351.ZHU Dong, ZHANG Liang, WU Wenheng, et al. Research progress of selective laser melting additive manufacturing technology of titanium matrix composites[J]. Materials Reports, 2021, 35(Z1): 347-351(in Chinese). [64] FEREIDUNI E, GHASEMI A, ELBESTAWI M. Microstructural characterization and mechanical properties of nano- scale/sub-micron TiB-reinforced titanium matrix composites fabricated by laser powder bed fusion[J]. Journal of Alloys and Compounds, 2022, 896: 163054. doi: 10.1016/j.jallcom.2021.163054 [65] JACKSON B, TORRENS R, BOLZONI L, et al. Additive manufacturing of Ti-6Al-4V with added boron: Microstructure and hardness modification[J]. Key Engineering Materials, 2018, 770: 165-173. doi: 10.4028/www.scientific.net/KEM.770.165 [66] VERMA P K, WARGHANE S, NICHUL U, et al. Effect of boron addition on microstructure, hardness and wear performance of Ti-6Al-4V alloy manufactured by laser powder bed fusion additive manufacturing[J]. Materials Characterization, 2021, 172: 110848. doi: 10.1016/j.matchar.2020.110848 [67] PATIL A S, HIWARKAR V D, VERMA P K, et al. Effect of TiB2 addition on the microstructure and wear resistance of Ti-6Al-4V alloy fabricated through direct metal laser sintering (DMLS)[J]. Journal of Alloys and Compounds, 2019, 777: 165-173. doi: 10.1016/j.jallcom.2018.10.308 [68] CHANDRASEKAR P, BALUSAMY V, CHANDRAN K S R, et al. Laser surface hardening of titanium-titanium boride (Ti-TiB) metal matrix composite[J]. Scripta Materialia, 2007, 56(7): 641-644. doi: 10.1016/j.scriptamat.2006.11.035 [69] LIN Y H, LIN Z H, CHEN Q T, et al. Laser in-situ synthesis of titanium matrix composite coating with TiB-Ti network-like structure reinforcement[J]. Transactions of Nonferrous Metals Society of China, 2019, 29(8): 1665-1676(in Chinese). [70] DICECCO L A, MEHDI M, EDRISY A, et al. Fatigue improvement of additive manufactured Ti-TiB material through shot peening[J]. Metals, 2021, 11(9): 1423. doi: 10.3390/met11091423 [71] FANG M, HAN Y, SHI Z, et al. Embedding boron into Ti powder for direct laser deposited titanium matrix composite: Microstructure evolution and the role of nano-TiB network structure[J]. Composites Part B: Engineering, 2021, 211: 108683. doi: 10.1016/j.compositesb.2021.108683 [72] LI N, WANG T, JIANG S. An innovative TiB whisker architecture of titanium matrix composite devised by scanning electron beam remodeling[J]. Journal of Alloys and Compounds, 2022, 895: 162719. doi: 10.1016/j.jallcom.2021.162719 [73] BOUDREAU D B, DICECCO L A, GALI O A, et al. Fatigue behaviour of additive manufactured Ti-TiB[J]. Materials Research Society Advances, 2018, 3(62): 3641-3653. [74] SINGH G, SATYANARAYANA D V V, PEDERSON R, et al. Enhancement in creep resistance of Ti-6Al-4V alloy due to boron addition[J]. Materials Science and Engineering A, 2014, 597: 194-203. doi: 10.1016/j.msea.2013.12.078 [75] ANIS A L, TALARI M K, BABU N K, et al. Grain refinement of Ti-15V-3Cr-3Sn-3Al metastable β titanium alloy[J]. Journal of Alloys and Compounds, 2018, 749: 320-328. doi: 10.1016/j.jallcom.2018.03.286 [76] DONG Y, LI Y, EBEL T, et al. Cost-affordable, high-performance Ti-TiB composite for selective laser melting additive manufacturing[J]. Journal of Materials Research, 2020, 35(15): 1922-1935. [77] 齐振佳, 张晓星, 王豫跃, 等. 硼对激光增材制造TC4微观组织及力学性能的影响[J]. 中国激光, 2020, 47(6): 124-130. doi: 10.3788/CJL202047.0602002QI Zhenjia, ZHANG Xiaoxing, WANG Yuyue, et al. Effect of B on microstructure and tensile properties of laser additive manufactured TC4 alloy[J]. Chinese Journal of Lasers, 2020, 47(6): 124-130(in Chinese). doi: 10.3788/CJL202047.0602002 [78] 钦兰云, 门继华, 赵朔, 等. TiB2含量对选区激光熔化TiB/Ti-6Al-4V复合材料组织及力学性能的影响[J]. 中国激光, 2021, 48(6): 55-64. doi: 10.3788/CJL202148.0602102QIN Lanyun, MEN Jihua, ZHAO Shuo, et al. Effect of TiB2 content on microstructure and mechanical properties of TiB/Ti-6Al-4V composites formed by selective laser melting[J]. Chinese Journal of Lasers, 2021, 48(6): 55-64(in Chinese). doi: 10.3788/CJL202148.0602102 [79] 李长富, 任皓显, 步佳颀, 等. 增材制造的含硼Ti-6Al-4V钛合金的组织与性能研究[J]. 中国激光, 2021, 48(18): 129-137. doi: 10.3788/CJL202148.1802014LI Changfu, REN Haoxian, BU Jiaqi, et al. Study on microstructures and properties of additive manufactured Ti-6Al-4V alloy with boron[J]. Chinese Journal of Lasers, 2021, 48(18): 129-137(in Chinese). doi: 10.3788/CJL202148.1802014 [80] RAMASOBANE P, MASHININI P M, MASINA B. In-situ synthesis of TiC/Ti-6Al-4V-ELI composite by laser[C]// MAREE K. Conference of the South African Advanced Materials Initiative. Cape Town: South African Journal of Science and Technology, 2021, 40(1): 70-74. [81] LI L, WANG J, LIN P, et al. Microstructure and mechanical properties of functionally graded TiCp/Ti6Al4V composite fabricated by laser melting deposition[J]. Ceramics International, 2017, 43(18): 16638-16651. doi: 10.1016/j.ceramint.2017.09.054 [82] LIU S, SHIN Y C. The influences of melting degree of TiC reinforcements on microstructure and mechanical properties of laser direct deposited Ti6Al4V-TiC composites[J]. Materials and Design, 2017, 136: 185-195. doi: 10.1016/j.matdes.2017.09.063 [83] HUO P, ZHAO Z, DU W, et al. Deformation and fracture mechanisms of in situ synthesized TiC reinforced TC4 matrix composites produced by selective laser melting[J]. Ceramics International, 2021, 47(14): 19546-19555. doi: 10.1016/j.ceramint.2021.03.292 [84] WEI W, ZHANG Q, WU W, et al. Agglomeration-free nanoscale TiC reinforced titanium matrix composites achieved by in-situ laser additive manufacturing[J]. Scripta Materialia, 2020, 187: 310-316. doi: 10.1016/j.scriptamat.2020.06.057 [85] LI H, YANG Z, CAI D, et al. Microstructure evolution and mechanical properties of selective laser melted bulk-form titanium matrix nanocomposites with minor B4C additions[J]. Materials and Design, 2020, 185: 108245. doi: 10.1016/j.matdes.2019.108245 [86] MENG X, MIN J, SUN Z, et al. Columnar to equiaxed grain transition of laser deposited Ti6Al4V using nano-sized B4C particles[J]. Composites Part B: Engineering, 2021, 212: 108667. doi: 10.1016/j.compositesb.2021.108667 [87] DONG Y, WANG D, LI Q, et al. Strong and ductile titanium via additive manufacturing under a reactive atmosphere[J]. Materials Today Advances, 2023, 17: 100347. doi: 10.1016/j.mtadv.2023.100347 [88] SAHASRABUDHE H, SODERLIND J, BANDYOPADHYAY A. Laser processing of in situ TiN/Ti composite coating on titanium[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2016, 53: 239-249. doi: 10.1016/j.jmbbm.2015.08.013 [89] XIA L, DING K, GU D, et al. Interfacial structure and wear properties of selective laser melted Ti/(TiC+TiN) composites with high content of reinforcements[J]. Journal of Alloys and Compounds, 2021, 870: 159436. doi: 10.1016/j.jallcom.2021.159436 [90] ZHANG Y, SAHASRABUDHE H, BANDYOPADHYAY A. Additive manufacturing of Ti-Si-N ceramic coatings on titanium[J]. Applied Surface Science, 2015, 346: 428-437. doi: 10.1016/j.apsusc.2015.03.184 [91] ZHOU S, ZHAO Y, WANG X, et al. Enhanced corrosion resistance of Ti-5wt%TiN composite compared to commercial pure Ti produced by selective laser melting in HCl solution[J]. Journal of Alloys and Compounds, 2020, 820: 153422. doi: 10.1016/j.jallcom.2019.153422 [92] ZHAO Y, WU C, ZHOU S, et al. Selective laser melting of Ti-TiN composites: Formation mechanism and corrosion behaviour in H2SO4/HCl mixed solution[J]. Journal of Alloys and Compounds, 2021, 863: 158721. doi: 10.1016/j.jallcom.2021.158721 [93] ZHANG X, LI D, ZHENG Y, et al. In-situ synthesis of Ti5Si3-reinforced titanium matrix nanocomposite by selective laser melting: Quasi-continuous reinforcement network and enhanced mechanical performance[J]. Journal of Materials Processing Technology, 2022, 309: 117752. doi: 10.1016/j.jmatprotec.2022.117752 [94] HIXSON W R, YU J, WILSON A, et al. Eutectic composition titanium metal matrix composites for laser powder bed fusion via surface remelt analyses[J]. Materials Science and Technology, 2023, 39(13): 1650-1660. [95] WANG Z, FU B, WANG Y, et al. Effect of Cu content on the precipitation behaviors, mechanical and corrosion properties of as-cast Ti-Cu alloys[J]. Materials, 2022, 15(5): 1696. [96] WANG H, SONG W, LIU M, et al. Manufacture-friendly nanostructured metals stabilized by dual-phase honeycomb shell[J]. Nature Communications, 2022, 13: 2034. doi: 10.1038/s41467-022-29782-8 [97] VILARDELL A M, YADROITSEV I, YADROITSAVA I, et al. Manufacturing and characterization of in-situ alloyed Ti6Al4V(ELI)-3at%Cu by laser powder bed fusion[J]. Additive Manufacturing, 2020, 36: 101436. doi: 10.1016/j.addma.2020.101436 [98] ZYKOVA A, VORONTSOV A, NIKOLAEVA A, et al. Structural design and performance evaluation of Ti6Al4V/5%Cu produced by electron-beam additive technology with simultaneous double-wire feeding[J]. Materials Letters, 2022, 312: 131586. doi: 10.1016/j.matlet.2021.131586 [99] WANG X, ZHANG L J, NING J, et al. Effect of Cu-induced eutectoid transformation on microstructure and mechanical properties of Ti-6Al-4V alloy by laser wire deposition[J]. Materials Science and Engineering: A, 2022, 833: 142316. doi: 10.1016/j.msea.2021.142316 [100] 梁恩泉, 黄森森, 马英杰, 等. Fe对Ti-6Al-4V ELI合金力学性能的影响[J]. 材料研究学报, 2016, 30(4): 299-306.LIANG Enquan, HUANG Sensen, MA Yingjie, et al. The influence of Fe on the mechanical properties of Ti-6Al-4V ELI alloy[J]. Chinese Journal of Material Research, 2016, 30(4): 299-306(in Chinese). [101] CHEN F, GU Y, XU G, et al. Improved fracture toughness by microalloying of Fe in Ti-6Al-4V[J]. Materials and Design, 2020, 185: 108251. doi: 10.1016/j.matdes.2019.108251 [102] LU B, ZHANG C, GUO Z, et al. High-carbon ferrochrome effects on microstructure and mechanical properties of powder metallurgy titanium alloys[J]. Journal of Materials Engineering and Performance, 2019, 28: 5361-5368. doi: 10.1007/s11665-019-04282-x [103] ZHANG T, HUANG Z, YANG T, et al. In situ design of advanced titanium alloy with concentration modulations by additive manufacturing[J]. Science, 2021, 374(6566): 478-482. doi: 10.1126/science.abj3770 [104] LIN H, LING J, CHEN W, et al. High-throughput determination of mechanical and diffusion properties of Ti-Ta-Fe alloys[J]. Transactions of Nonferrous Metals Society of China, 2022, 32(12): 3963-3972. doi: 10.1016/S1003-6326(22)66070-9 [105] GOUDA M K, GEPREEL M A H, YAMANAKA K, et al. Cold-workability and microstructure change with β-phase stability in high-strength Ti-Mn binary alloys[J]. JOM, 2019, 71: 3590-3599. doi: 10.1007/s11837-019-03690-7 [106] 蒋焓鸿, 姜中涛. 稀土元素对钛合金组织与性能的影响研究进展[J]. 粉末冶金工业, 2021, 31(5): 81-86. doi: 10.13228/j.boyuan.issn1006-6543.20200240JIANG Hanhong, JIANG Zhongtao. The effects of addition of rare earth elements on microstructure and properties of titanium alloys[J]. Powder Metallurgy Industry, 2021, 31(5): 81-86(in Chinese). doi: 10.13228/j.boyuan.issn1006-6543.20200240 [107] SVETLANA S, IVAN G, OKSANA U, et al. Effect of rare earth element addition on structure of heat-resistant Ti-6.5Al-4Zr-2.5Sn-2.4V-1Nb-0.5Mo-0.2Si titanium alloy[C]//2017 International Conference on Mechanical, Material and Aerospace Engineering. Moscow: MATEC Web of Conferences, 2017, 114: 02008. [108] 汤慧萍, 刘咏, 韦伟峰, 等. 添加稀土元素对粉末冶金Ti合金显微组织和力学性能的影响[J]. 中国有色金属学报, 2004, 14(2): 244-249. doi: 10.19476/j.ysxb.1004.0609.2004.02.017TANG Huiping, LIU Yong, WEI Weifeng, et al. Effect of rare earth element on microstructure and mechanical properties of powder metallurgy Ti alloy[J]. Transactions of Nonferrous Metals Society of China, 2004, 14(2): 244-249(in Chinese). doi: 10.19476/j.ysxb.1004.0609.2004.02.017 [109] YANG Z, LU W, ZHAO L, et al. Microstructure and mechanical property of in situ synthesized multiple-reinforced (TiB+TiC+La2O3)/Ti composites[J]. Journal of Alloys and Compounds, 2008, 455(1-2): 210-214. doi: 10.1016/j.jallcom.2007.01.087 [110] YANG Z, LU W, QIN J, et al. Microstructure and tensile properties of in situ synthesized (TiC+TiB+Nd2O3)/Ti-alloy composites at elevated temperature[J]. Materials Science and Engineering A, 2006, 425(1-2): 185-191. doi: 10.1016/j.msea.2006.03.063 [111] HE D, WANG H, HUANG W, et al. Microstructure and mechanical properties of LaB6/Ti-6Al-4V composites fabricated by selective laser melting[J]. Metals, 2023, 13(2): 264. doi: 10.3390/met13020264 [112] BERMINGHAM M J, STJOHN D H, KRYNEN J, et al. Promoting the columnar to equiaxed transition and grain refinement of titanium alloys during additive manufacturing[J]. Acta Materialia, 2019, 168: 261-274. doi: 10.1016/j.actamat.2019.02.020 [113] LIU M, LIU S, CHEN W, et al. Effect of trace lanthanum hexaboride on the phase, grain structure, and texture of electron beam melted Ti-6Al-4V[J]. Additive Manufacturing, 2019, 30: 100873. doi: 10.1016/j.addma.2019.100873 [114] BERMINGHAM M J, MCDONALD S D, DARGUSCH M S. Effect of trace lanthanum hexaboride and boron additions on microstructure, tensile properties and anisotropy of Ti-6Al-4V produced by additive manufacturing[J]. Materials Science and Engineering: A, 2018, 719: 1-11. doi: 10.1016/j.msea.2018.02.012 [115] FENG Y, FENG K, YAO C, et al. Effect of LaB6 addition on the microstructure and properties of (Ti3Al+TiB)/Ti composites by laser cladding[J]. Materials and Design, 2019, 181: 107959. doi: 10.1016/j.matdes.2019.107959 [116] WANG X, ZHANG L, NING J, et al. Effect of addition of micron-sized lanthanum oxide particles on morphologies, microstructures and properties of the wire laser additively manufactured Ti-6Al-4V alloy[J]. Materials Science and Engineering: A, 2021, 803: 140475. doi: 10.1016/j.msea.2020.140475 [117] WANG Q, ZHANG K, QIU D, et al. Additive manufacturing of high-strength commercially pure titanium through lanthanum oxide addition[J]. Materials Characterization, 2021, 176: 111074. doi: 10.1016/j.matchar.2021.111074 [118] LIU Y, JIANG W, CHEN Z, et al. Optimization of processing parameters and microstructure evolution of (TiB+La2O3)/Ti6Al4V manufactured by laser melting deposition[J]. Journal of Materials Research and Technology, 2023, 24: 8086-8097. doi: 10.1016/j.jmrt.2023.05.058 [119] LI K M, LIU Y J, LIU X C, et al. Simultaneous strength-ductility enhancement in as-cast Ti6Al4V alloy by trace Ce[J]. Materials and Design, 2022, 215: 110491. doi: 10.1016/j.matdes.2022.110491 [120] CHEN T, WU D, LIU F, et al. Effect of CeO2 on microstructure and wear resistance of TiC bioinert coatings on Ti6Al4V alloy by laser cladding[J]. Materials, 2018, 11(1): 58. [121] LIU Y, SUN R, NIU W, et al. Effects of CeO2 on microstructure and properties of TiC/Ti2Ni reinforced Ti-based laser cladding composite coatings[J]. Optics and Lasers in Engineering, 2019, 120: 84-94. doi: 10.1016/j.optlaseng.2019.03.001 [122] 黄文君, 王文焱, 张豪胤, 等. 添加Nd元素对钛合金析出行为的影响规律[J]. 稀有金属, 2017, 41(3): 245-251. doi: 10.13373/j.cnki.cjrm.xy16050022HUANG Wenjun, WANG Wenyan, ZHANG Haoyin, et al. Precipitated phase of titanium alloy with adding Nd elements[J]. Chinese Journal of Rare Metals, 2017, 41(3): 245-251(in Chinese). doi: 10.13373/j.cnki.cjrm.xy16050022 [123] YAN W, WANG H, TANG H, et al. Effect of Nd addition on microstructure and tensile properties of laser additive manufactured TC11 titanium alloy[J]. Transactions of Nonferrous Metals Society of China, 2022, 32(5): 1501-1512. doi: 10.1016/S1003-6326(22)65889-8 [124] KENNEDY J R, DAVIS A E, CABALLERO A E, et al. β grain refinement by yttrium addition in Ti-6Al-4V wire-arc additive manufacturing[J]. Journal of Alloys and Compounds, 2022, 895(2): 162735. [125] YANG J, CHEN Y, XIAO S, et al. Effect of reinforcements on β→α transformation and tensile properties of a near α titanium matrix composite[J]. Materials Science and Engineering: A, 2019, 766: 138337. doi: 10.1016/j.msea.2019.138337 [126] WANG X, ZHANG L, NING J, et al. Hierarchical grain refinement during the laser additive manufacturing of Ti-6Al-4V alloys by the addition of micron-sized refractory particles[J]. Additive Manufacturing, 2021, 45: 102045. doi: 10.1016/j.addma.2021.102045 [127] PRASAD V V B, BHAT B V R, MAHAJAN Y R, et al. Structure-property correlation in discontinuously reinforced aluminium matrix composites as a function of relative particle size ratio[J]. Materials Science and Engineering: A, 2002, 337(1-2): 179-186. doi: 10.1016/S0921-5093(02)00024-2 [128] YAMAMOTO T, OTSUKI A, ISHIHARA K, et al. Synthesis of near net shape high density TiB/Ti composite[J]. Materials Science and Engineering: A, 1997, 239-240: 647-651. [129] KUMAI S, HU J, HIGO Y, et al. Effects of dendrite cell size and particle distribution on the near-threshold fatigue crack growth behaviour of cast Al-SiCp composites[J]. Acta Materialia, 1996, 44(6): 2249-2257. doi: 10.1016/1359-6454(95)00357-6 [130] PENG H X, FAN Z, EVANS J R G. Novel MMC microstructure with tailored distribution of the reinforcing phase[J]. Journal of Microscopy, 2001, 201(2): 333-338. doi: 10.1046/j.1365-2818.2001.00780.x [131] ZHOU Z, PENG H X, FAN Z, et al. MMCs with a controlled non-uniform distribution of submicron Al2O3 particles in a 6061Al matrix[J]. Materials Science and Technology, 2000, 16(7-8): 908-912. [132] PENG H X, FAN Z, EVANS J R G. Bi-continuous metal matrix composites[J]. Materials Science and Engineering: A, 2001, 303(1-2): 37-45. doi: 10.1016/S0921-5093(00)01879-7 [133] HUANG L J, GENG L, LI A B, et al. In situ TiBw/Ti-6Al-4V composites with novel reinforcement architecture fabricated by reaction hot pressing[J]. Scripta Materialia, 2009, 60(11): 996-999. doi: 10.1016/j.scriptamat.2009.02.032 [134] HUANG L J, GENG L, PENG H X. In situ (TiBw+TiCp)/Ti6Al4V composites with a network reinforcement distribution[J]. Materials Science and Engineering: A, 2010, 527(24-25): 6723-6727. doi: 10.1016/j.msea.2010.07.025 [135] HUANG L J, GENG L, PENG H X, et al. Room temperature tensile fracture characteristics of in situ TiBw/Ti6Al4V composites with a quasi-continuous network architecture[J]. Scripta Materialia, 2011, 64(9): 844-847. doi: 10.1016/j.scriptamat.2011.01.011 [136] 高翔. 增强体网状分布对SiCp/Al复合材料力学性能影响的有限元模拟[D]. 哈尔滨: 哈尔滨工业大学, 2019.GAO Xiang. Effects of reinforcement network distribution on mechanical properties of SiCp/Al composites via finite element method[D]. Harbin: Harbin Institute of Technology, 2019(in Chinese). [137] GAO X, PENG M, ZHANG X, et al. Profound strengthening and toughening effect of reinforcement aspect ratio in composite with network architecture[J]. Journal of Alloys and Compounds, 2023, 931: 167444. doi: 10.1016/j.jallcom.2022.167444 [138] GAO X, ZHANG X, QIAN M, et al. Fracture behaviour of SiCp/Al composites with network architecture[J]. Materialia, 2020, 12: 100725. doi: 10.1016/j.mtla.2020.100725 [139] LIU G F, CHEN T J. Synthesis of heterogeneity-improved heterostructured 2024Al alloy with excellent synergy of strength and ductility via powder thixoforming[J]. Journal of Alloys and Compounds, 2023, 932: 167661. doi: 10.1016/j.jallcom.2022.167661 [140] LI S, HAN Y, WANG X, et al. Novel strategy of planting nano-TiB fibers with ultra-fine network distribution into Ti-composite powder and its thermal transition mechanism[J]. Composites Communications, 2022, 29: 101002. doi: 10.1016/j.coco.2021.101002 [141] ZHANG X, XU Y, WANG M, et al. A powder-metallurgy-based strategy toward three dimensional graphene-like network for reinforcing copper matrix composites[J]. Nature Communications, 2020, 11: 2775. doi: 10.1038/s41467-020-16490-4 [142] WANG R, GU D, HUANG G, et al. Multilayered gradient titanium-matrix composites fabricated by multi-material laser powder bed fusion using metallized ceramic: Forming characteristics, microstructure evolution, and multifunctional properties[J]. Additive Manufacturing, 2023, 62: 103407. doi: 10.1016/j.addma.2023.103407 [143] ZHONG Y, LIU L, WIKMAN S, et al. Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting[J]. Journal of Nuclear Materials, 2016, 470: 170-178. doi: 10.1016/j.jnucmat.2015.12.034 [144] LIU Q, WU H, PAUL M J, et al. Machine-learning assisted laser powder bed fusion process optimization for AlSi10Mg: New microstructure description indices and fracture mechanisms[J]. Acta Materialia, 2020, 201: 316-328. doi: 10.1016/j.actamat.2020.10.010 [145] KELLER T, LINDWALL G, GHOSH S, et al. Application of finite element, phase-field, and CALPHAD-based methods to additive manufacturing of Ni-based superalloys[J]. Acta Materialia, 2017, 139: 244-253. doi: 10.1016/j.actamat.2017.05.003 [146] YU Q, WANG C, ZHAO Z, et al. New Ni-based superalloys designed for laser additive manufacturing[J]. Journal of Alloys and Compounds, 2021, 861: 157979. doi: 10.1016/j.jallcom.2020.157979 [147] WANG Z, TANG S Y, SCUDINO S, et al. Additive manufacturing of a martensitic Co-Cr-Mo alloy: Towards circumventing the strength-ductility trade-off[J]. Additive Manufacturing, 2021, 37: 101725. doi: 10.1016/j.addma.2020.101725 [148] BO H, LU D D, CHENG R, et al. Experimental study and thermodynamic modeling of the Ti-Cu-B system[J]. Calphad, 2022, 77: 102431. doi: 10.1016/j.calphad.2022.102431 [149] TAMIRISAKANDALA S, MIRACLE D B. Microstructure engineering of titanium alloys via small boron additions[J]. International Journal of Advances in Engineering Sciences and Applied Mathematics, 2010, 2: 168-180. [150] NIU J, DAI G, GUO Y, et al. Microstructure and mechanical properties of B modified Ti-Fe alloy manufactured by casting, forging and laser melting deposition[J]. Composites Part B: Engineering, 2021, 216: 108854. doi: 10.1016/j.compositesb.2021.108854 [151] HUANG L, DUAN T, AN Q, et al. Gas tungsten arc welding of network structured titanium matrix composite[J]. Science and Technology of Welding and Joining, 2018, 23(5): 357-364. [152] 纪明. TIG重熔对网状结构TiBw/TC4复合材料组织及性能的影响[D]. 哈尔滨: 哈尔滨工业大学, 2018.JI Ming. Effects of tig remelting on microstructure and properties of TiBw/TC4 composites with network microstructure[D]. Harbin: Harbin Institute of Technology, 2018(in Chinese). [153] DAS M, BHATTACHARYA K, DITTRICK S A, et al. In situ synthesized TiB-TiN reinforced Ti6Al4V alloy composite coatings: Microstructure, tribological and in-vitro biocompatibility[J]. Mitun Journal of the Mechanical Behavior of Biomedical Materials, 2014, 29: 259-271. doi: 10.1016/j.jmbbm.2013.09.006 [154] WANG S, ZHAO Z, BAI P, et al. Effect of in situ synthesis TiC on the microstructure of graphene/Ti6Al4V composite fabricated by selective laser melting[J]. Materials Letters, 2021, 304: 130715. doi: 10.1016/j.matlet.2021.130715 [155] YU C, LIU X, LI Y, et al. Investigations of the microstructure and performance of TiCp/Ti6Al4V composites prepared by directed laser deposition[J]. International Journal of Mechanical Sciences, 2021, 205: 106595. doi: 10.1016/j.ijmecsci.2021.106595 [156] 吴昊. 钛基层状复合材料的反应合成及其室温变形机制研究[D]. 哈尔滨: 哈尔滨工业大学, 2016.WU Hao. Reaction synthesis and room temperature deformation mechanism of titanium-based laminated composites[D]. Harbin: Harbin Institute of Technology, 2016(in Chinese). [157] 黄猛. 层状Ti/Al复合材料形变与断裂行为研究[D]. 哈尔滨: 哈尔滨工业大学, 2019.HUANG Meng. Study on deformation and fracture behavior of layered Ti/Al metal composites[D]. Harbin: Harbin Institute of Technology, 2019(in Chinese). [158] HOPKINS C D, DAPINO M J, FERNANDEZ S A. Statistical characterization of ultrasonic additive manufacturing Ti/Al composites[J]. Journal of Engineering Materials and Technology, 2010, 132(4): 041006. doi: 10.1115/1.4002073 [159] ZHOU Y, WANG Z, ZHA Z, et al. Achieve high interfacial bonding strength of Ti/Al laminated composite at room temperature via electropulsing-assisted ultrasonic additive manufacturing[J]. Metallurgical and Materials Transactions A, 2023, 54: 399-404. doi: 10.1007/s11661-022-06923-8 [160] HOTZ H, ZIMMERMANN M, GRECO S, et al. Additive manufacturing of functionally graded Ti-Al structures by laser-based direct energy deposition[J]. Journal of Manufacturing Processes, 2021, 68(A): 1524-1534. [161] JING Z, LIU X, WANG W, et al. Laser additive manufacturing of TC4/AlSi12 bimetallic structure via Nb interlayer[J]. Metals, 2022, 15(24): 9071. [162] TABRIZI S G, SAJJADI S A, BABAKHANI A, et al. Analytical and experimental investigation of the effect of SPS and hot rolling on the microstructure and flexural behavior of Ti6Al4V matrix reinforced with in-situ TiB and TiC[J]. Journal of Alloys and Compounds, 2017, 692: 734-744. doi: 10.1016/j.jallcom.2016.09.026 [163] YAO H, DAO M, IMHOLT T, et al. Protection mechanisms of the iron-plated armor of a deep-sea hydrothermal vent gastropod[J]. PNAS, 2010, 107(3): 987-992. doi: 10.1073/pnas.0912988107 [164] JIAO T, JIANG T, DAI G, et al. The microstructure evolution of TC4-(TiB+TiC)/TC4 laminated composites by laser melting deposition[J]. Materials Characterization, 2023, 197: 112665. doi: 10.1016/j.matchar.2023.112665 -

下载:

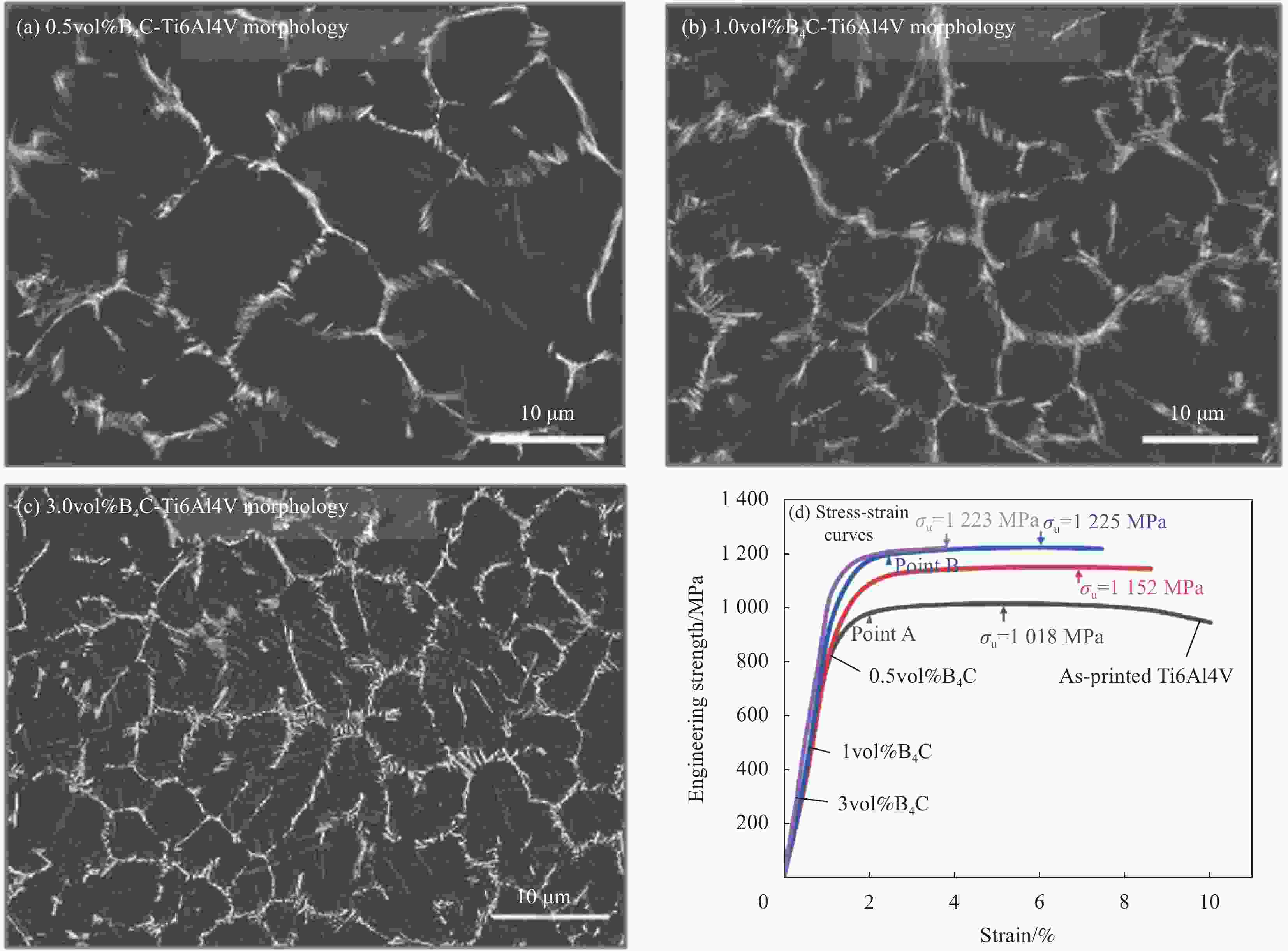

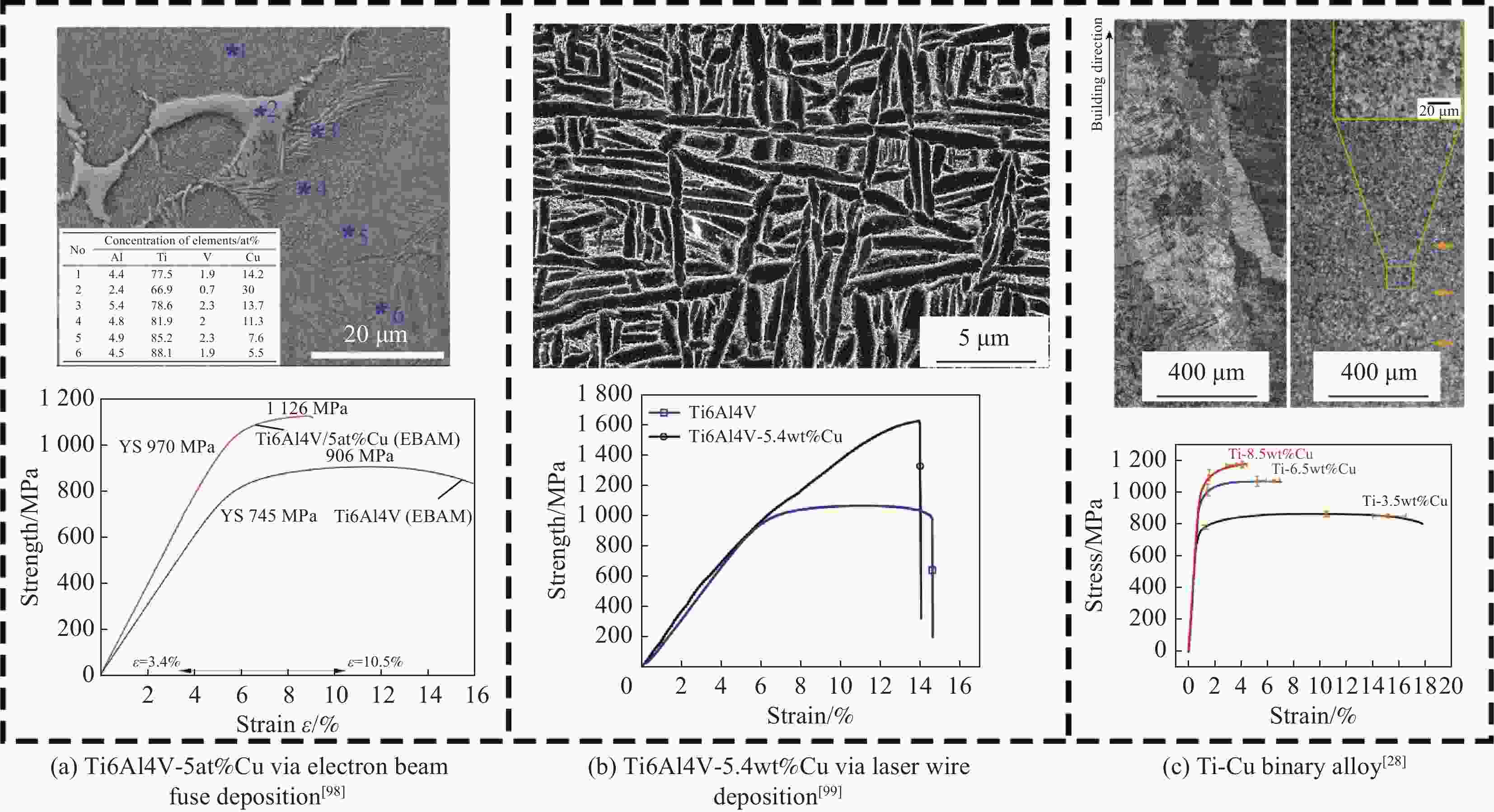

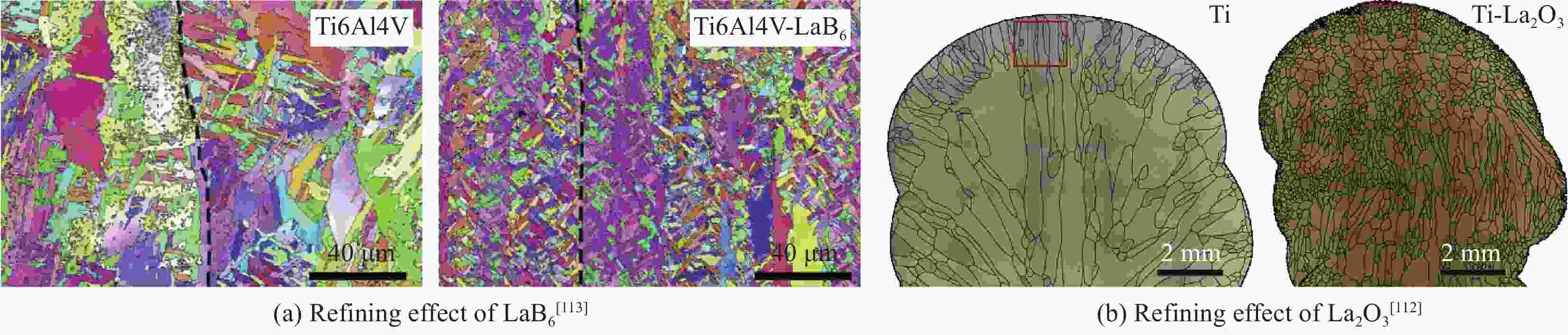

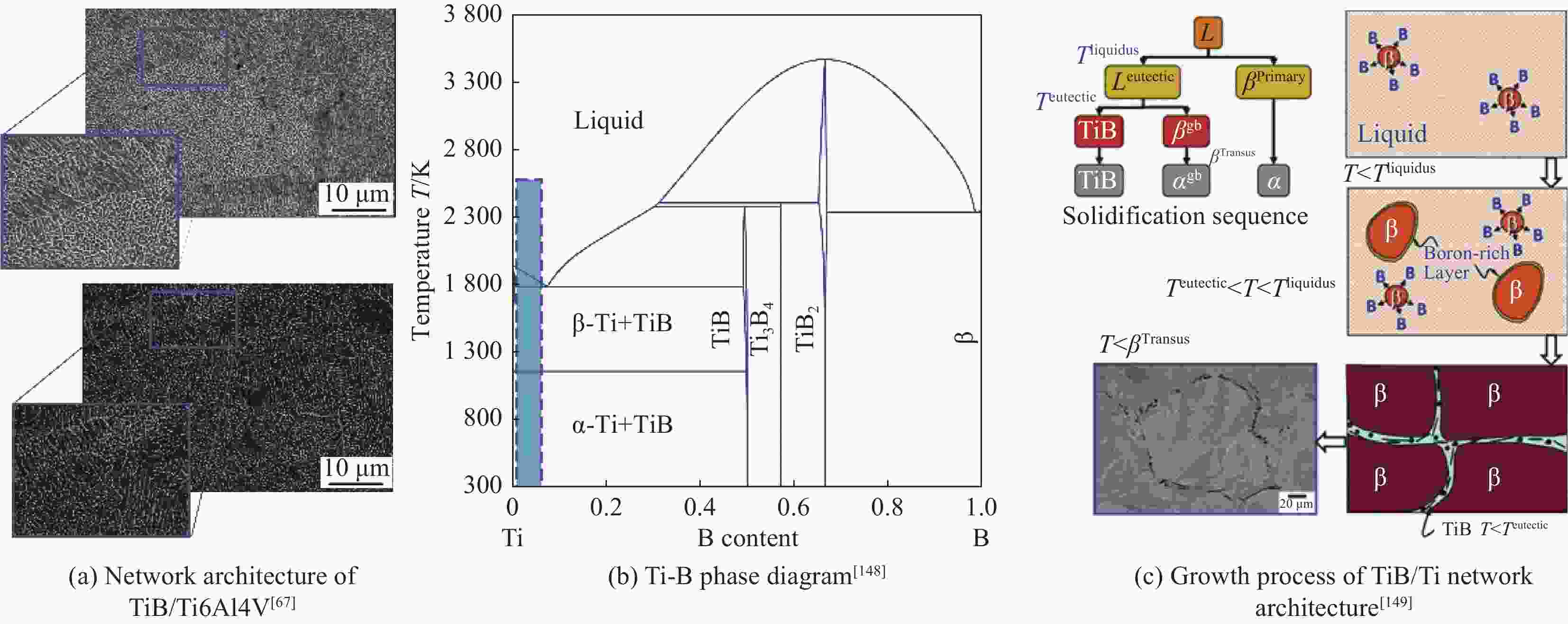

下载: