Research progress of medical magnesium alloy properties and its alloying improvement path

-

摘要: 医用镁合金耐腐蚀性能和强度相较于传统医用金属材料较差,严重限制了其在医疗器械领域中的应用。研究表明,合金化可以显著改善医用镁合金的性能,但是由于不同合金元素的加入对镁合金力学性能、耐腐蚀性能和生物相容性的影响不同,并且元素对合金的改善效果也存在差异。因此,研究不同元素的添加对医用镁合金性能影响具有重要的意义。本文首先综述了近年来对镁基合金力学性能、腐蚀降解性能及其生物相容性的综合研究,其次分析了镁基合金在添加了不同合金元素下的性能差异,并针对合金化后医用镁基合金材料的局限性,提出了未来发展建议,期望为今后的临床应用提供宝贵经验。Abstract: The corrosion resistance and strength of magnesium alloys are poor compared to traditional medical metal materials, which seriously limits their application in the field of medical devices. Studies have shown that alloying can significantly improve the properties of medical magnesium alloys, but due to the different effects of the addition of different alloying elements on the mechanical properties, corrosion resistance and biocompatibility of magnesium alloys, and there are differences in the improvement effect of the elements on the alloys. Therefore, it is of great significance to study the effects of the addition of different elements on the properties of medical magnesium alloys. This paper firstly reviews the comprehensive studies on the mechanical properties, corrosion degradation properties and their biocompatibility of magnesium-based alloys in recent years, and secondly analyses the differences in the properties of magnesium-based alloys with the addition of different alloying elements, and puts forward suggestions for the future development of medical magnesium-based alloy materials in view of the limitations of alloying and expects to provide valuable experience for future clinical applications.

-

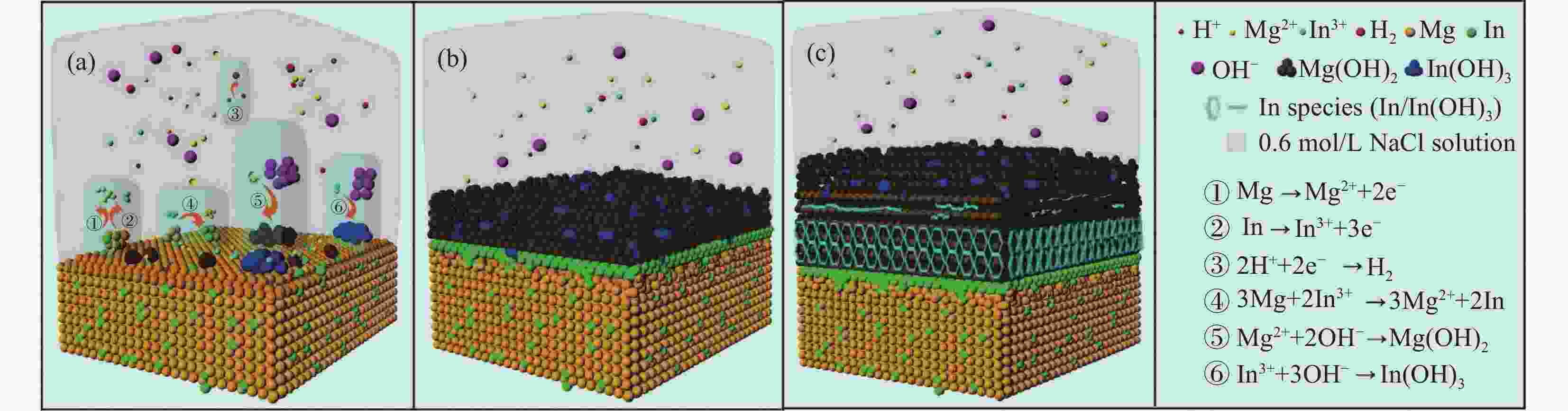

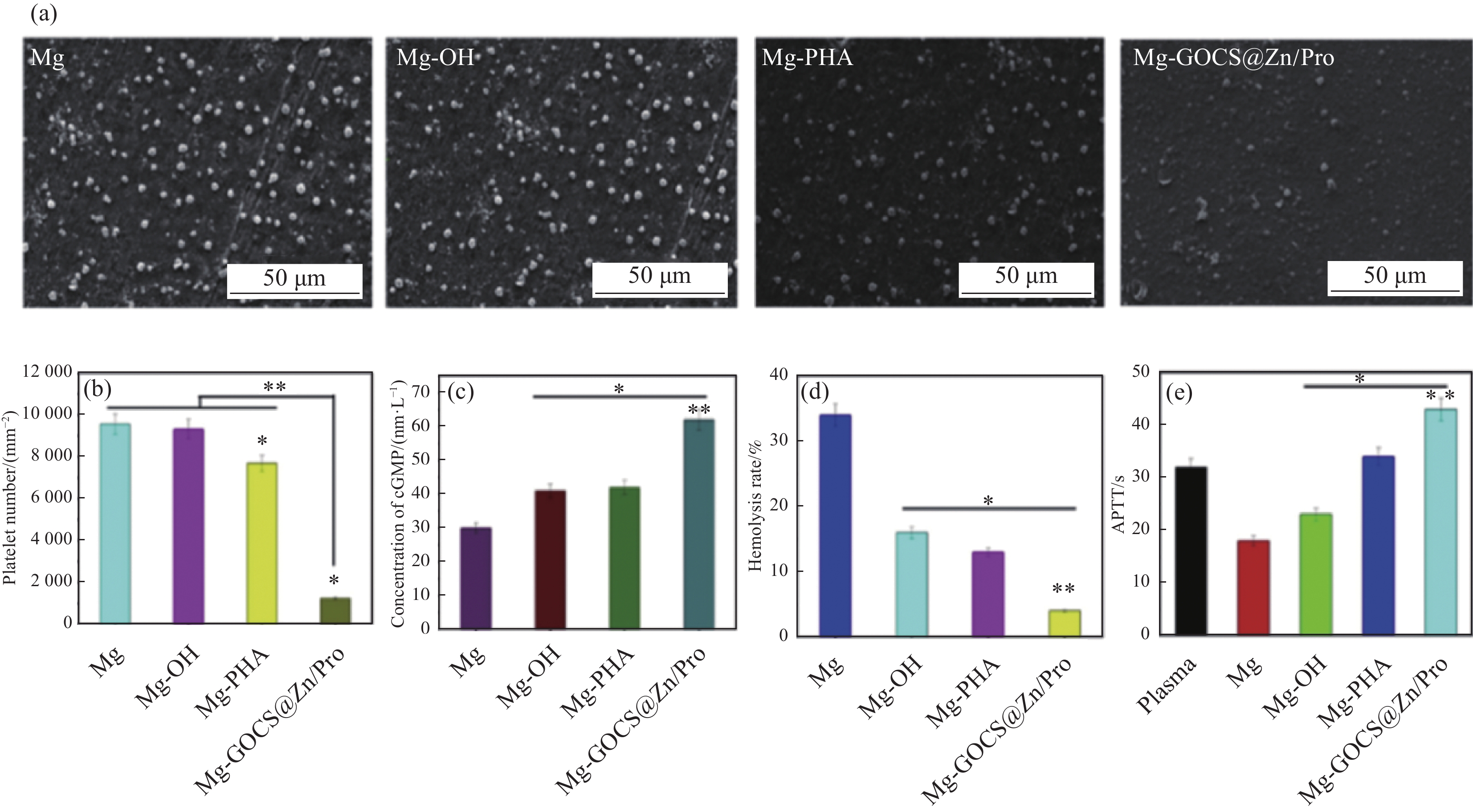

图 1 ((a), (b)) 附着在不同表面上的血小板的SEM图像和数量;(c) 不同样品上血小板的环鸟苷单磷酸(cGMP)表达;((d), (e)) 不同样品的溶血率和活化部分凝血活酶时间(APTT)[36]

Significance level *P<0.05 indicates statistical differences compared to Mg; **P<0.05 indicates statistical differences compared to all other groups; PHA—Calcium hydroxyapatite; GOCS—Graphene oxide cholesterol sulfate; Pro—Protein; cGMP—Cyclic guanosine monophosphate; APTT—Activated partial thromboplastin time

Figure 1. ((a), (b)) SEM images and number of platelets attached to different surfaces; (c) cGMP expression of platelets on different samples; ((d), (e)) Haemolysis rate and APTT of different samples[36]

图 2 镁离子通过促进增殖和分化来增强成骨示意图:(a) Mg2+通过Mitogen-Activated Protein Kinase/Extracellular Signal-Regulated Kinase途径(控制干细胞成骨分化的信号通路之一)促进干细胞分化为成骨细胞;(b) Mg2+通过改善成骨分化促进新骨形成;(c) Mg2+通过上调骨髓间充质干细胞中的愈合骨骼中的细胞外基质成分(COL10 A1)和血管内皮生长因子(VEGF)的表达来增强骨再生;(d) Mg2+激活Wingless/Integrated信号通路(在细胞间进行通信和调控的机制)以上调β-连环蛋白及其下游基因(LEF1、DKK1)的表达[37]

MagT1—Magnesium transporter 1; MAPK/ERK—Mitogen-activated protein kinase/extracellular signal-regulated kinase; NFAT—Nuclear factor of activated T-cells; PGC-1α—Peroxisome proliferator-activated receptor gamma coactivator 1-alpha; ERRα—Estrogen-related receptor alpha; VEGF—Vascular endothelial growth factor; hBMSCs—Bone marrow stromal cells; DRG—Dorsal root ganglion; MAGT1—Magnesium transporter 1; TRPM7—Transient receptor potential melastatin 7; CGRP—Calcitonin gene-related peptide; CALCRL-RAMP1—Calcitonin receptor-like receptor-receptor activity-modifying protein 1; PDSC—Periosteum-derived stem cells; cAMP—Cyclic adenosine monophosphate; P—Phosphate; CREM1—cAMP responsive element modulator 1; CTNNB1—Catenin beta 1; LEF1—Lymphoid enhancer-binding factor 1; DKK1—Dickkopf-1; Wnt—Wingless/Integrated

Figure 2. Schematic diagram of magnesium ions enhancing osteogenesis by promoting proliferation and differentiation: (a) Mg2+ promotes differentiation of stem cells into osteoblasts via Mitogen-Activated Protein Kinase/Extracellular Signal-Regulated Kinase pathway (one of the signaling pathways controlling osteogenic differentiation of stem cells); (b) Mg2+ promotes new bone formation by improving osteogenic differentiation; (c) Mg2+ enhances bone regeneration by upregulating extracellular matrix components in healing bone (COL10 A1) and vascular endothelial growth factor (VEGF) expression in bone marrow mesenchymal stem cells; (d) Mg2+ activates Wingless/Integrated signaling pathway (mechanisms for communication and regulation between cells) upregulates the expression of β-linked protein and its down-stream genes (LEF1, DKK1)[37]

图 4 Mg-4Zn-0.5Ca-xMn合金在Hank'溶液中30天的腐蚀速率及其飞行时间二次离子质谱法(ToF-SIMS)对氯离子、MnO和MnO2薄膜进行2D成像分析:(a) Mg-4Zn-0.5Ca;(b) Mg-4Zn-0.5Ca-0.4Mn;(c) 4 h后Hank'溶液中的Mg-0Zn-5.0Ca-8.2Mn合金[69]

Figure 4. Depicts the corrosion rate of Mg-4Zn-0.5Ca-xMn alloy in the Hank's solution for 30 days, along with the 2D imaging analysis of chloride ions, MnO, and MnO2 thin films using time-of-flight secondary ion mass spectrometry (ToF-SIMS): (a) Mg-4Zn-0.5Ca; (b) Mg-4Zn-0.5Ca-0.4Mn;(c) Mg-0Zn-5.0Ca-8.2Mn alloy after 4 h in Hank's solution[69]

图 5 植入前后肝肾功能的主要血清生化指标水平:(a) 丙氨酸氨基转移酶;(b) 天冬氨酸氨基转移酶;(c) 肌酐;(d) 血尿素氮;(e)血清镁[75]

Figure 5. Levels of the main serum biochemical indicators of liver and kidney function before and after implantation: (a) Alanine aminotransferase; (b) Aspartate aminotransferase; (c) Creatinine; (d) Blood urea nitrogen; (e) Serum magnesium[75]

ALT—Alanine aminotransferase

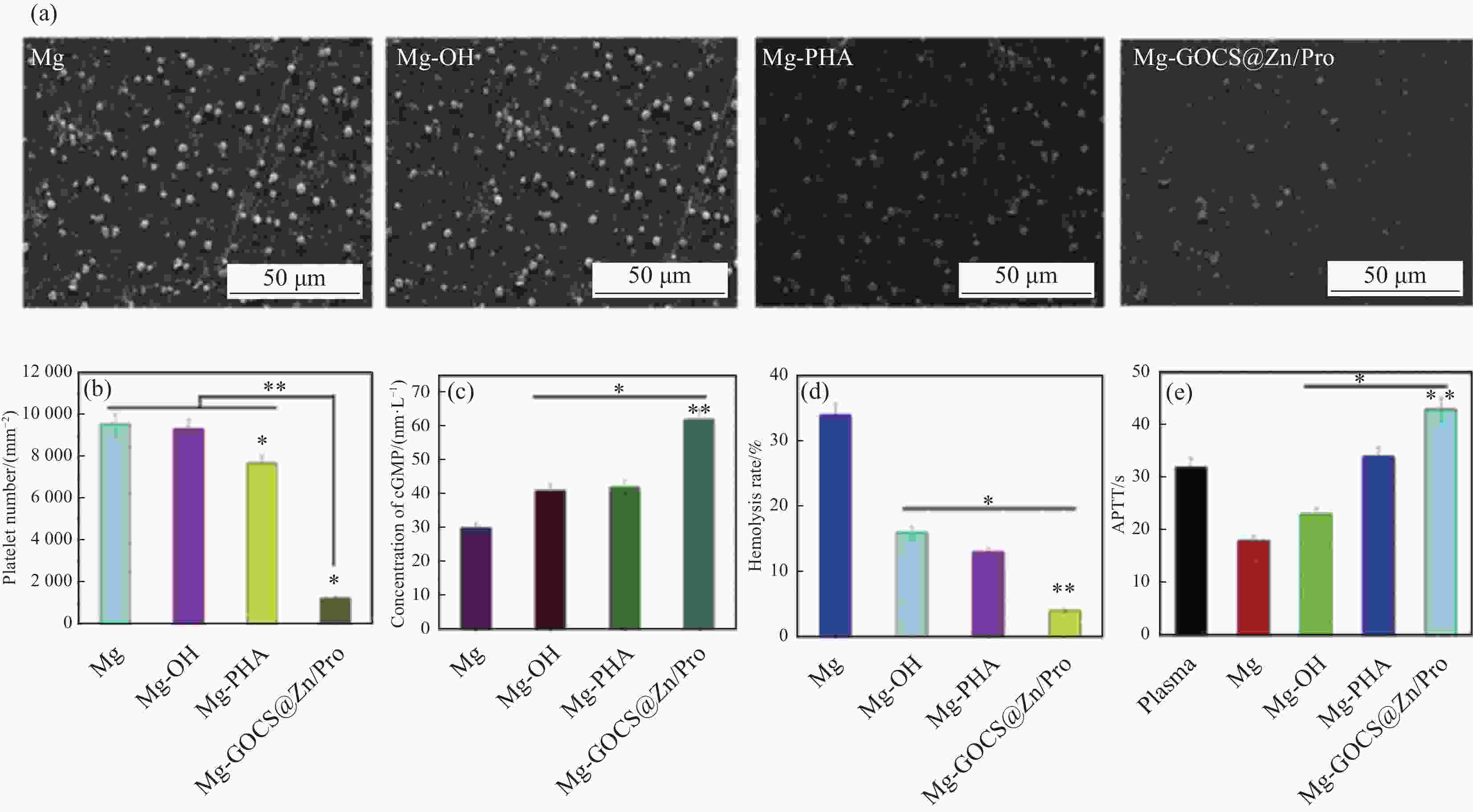

图 6 镁铟合金腐蚀过程中电化学置换反应的横截面机制示意图:(a)铟离子在镁表面的吸附和置换反应等腐蚀过程;(b) 短时间(25天)浸泡后形成的腐蚀层;(c)长期(200天)浸泡后形成的腐蚀层[79]

Figure 6. Cross-sectional mechanism of electrochemical replacement reactions during corrosion of magnesium-indium alloys: (a) Corrosion processes such as adsorption of indium ions on the magnesium surface and replacement reactions; (b) Corrosion layer formed after a short period of time (25 days) of immersion; (c) Corrosion layer formed after a long period of time (200 days) of immersion[79]

表 1 不同医用植入材料的力学性能对比[20]

Table 1. Comparison of mechanical properties of different medical implant materials[20]

Performance indicators Density/(g·cm−3) Elasticity modulus/GPa Yield strength/MPa Fracture toughness/MPa Natural bone 1.8-2.1 3-20 130-180 3-6 Mg 1.74-2.0 41-45 65-100 15-40 Ti alloy 4.4-4.5 110-117 758-1117 55-115 Co-Cr alloy 8.3-9.2 230 450-1000 N/A Stainless steel 7.9-8.1 189-205 170-310 50-200 Hydroxyapatite 3.1 73-117 600 0.7 D, L-polylactic acid 1.26 1.9-2.4 Not available Not available β-calcium phosphate 3.07 33-90 140-154 Not available Note: N/A—Not available. 表 2 医用镁合金器材植入标准

Table 2. Criteria for implantation of medical magnesium alloy devices

Medical use Yield strength/MPa Tensile strength/MPa Compression strength/MPa Modulus of elasticity/GPa Corrosion rate/ (mm·year−1) Biodegradation rate/month Ref. Vascular stents 100-300 200-500 200-500 5-20 Less than 0.5 Based on specific clinical needs [42-44] Splint 150-300 200-400 250-500 45-60 Less than 0.2 4-12 [45-46] Bone screw 50-200 100-300 150-300 40-60 Less than 0.2 Based on specific clinical needs [47-49] 表 3 Mg-Zn合金的力学性能与腐蚀速率

Table 3. Mechanical properties and corrosion rate of Mg-Zn alloy

Alloy/wt% Fabrication method Yield strength/MPa Ultimate tensile strength/MPa Elongation/% Corrosion rate/ (mm·year−1) Immersion test solution Ref. Mg-1Zn As-Cast 110 211 [82] Mg-1Zn-0.5Sn 115 239 Mg-4Zn As-extruded 118 223 15.4 1.87 Phosphate buffered saline (PBS) [83] Mg-4Zn-1Sn 133 234 18 0.62 Mg-4Zn-1.5Sn 142 238 20.9 0.45 Mg-4Zn-2Sn 147 250 19.8 0.77 Mg-4Zn-0.5Ni As-cast 17 0.32 3.5wt%KCl solution [84] Mg-4Zn-1Ni 22.1 1.72 Mg-4Zn-2Ni 20.3 62.08 Mg-4Zn-4Ni 20.1 76.27 Mg-0.5Zn-0.2Ca As-extruded 119 224 25 0.22 0.5wt%NaCl solution [85] Mg-0.5Zn-0.2Ge 171 249 10 0.21 Mg-6Zn-0.5Ce As-extruded 183 286 18.16 [86] Mg-3Zn-0.2Ca As-extruded 298.17 15.75 [87] Mg-0.5Zn-0.5Nd As-cast 126 213 32.2 [88] Mg-2Zn-0.5Ca As-extruded 326 25.1 15.02 Simulated body fluid (72 h) [74] Mg-8Li-2Al As-extruded 115 12.8 19.43 [89] 表 4 Mg-RE合金的力学性能与腐蚀速率

Table 4. Mechanical properties and corrosion rate of Mg-RE alloy

Alloy/wt% Fabrication method Yield strength/MPa Ultimate tensile strength/MPa Elongation/% Corrosion rate/ (mm·year−1) Immersion test solution Ref. Mg-7Y-0.5Nd As-Cast 151 257 14 36.75 3.5wt% NaCl solution (72 h) [90] Mg-7Y-1Nd 157 269 13 25.51 Mg-7Y-1.5Nd 165 285 10 19.69 Mg-1Y As-extruded 72 174 48 2.153 3.5wt% NaCl solution (168 h) [91] Mg-1Y-0.3Gd 84 188 59 1.985 Mg-1Y-0.6Gd 86 188 52 0.575 Mg-2Gd As-extruded 115 189 49 — — [92] Mg-2Gd-0.5Mn 84 172 51 — — Mg-2Gd-1.3Mn 132 206 45 — — Mg-2Gd-1.5Mn 154 219 42 — — Mg-2Gd-2Mn 189 243 33 — — Mg-0.3Sc As-extruded 50 162 16 — — [93] Mg-0.3Sc-1Zn 111 228 19 — — Mg-0.3Sc-3Zn 113 250 21 — — Mg-0.3Sc-6Zn 117 260 25 — — Mg-2Gd As-extruded 111 191 23.1 — — [94] Mg-2Gd-0.1Ni 142 212 20.8 — — Mg-2Gd-0.2Ni 168 239 19.1 — — Mg-2Gd-0.3Ni 234 287 18.1 — — 表 5 镁基四元合金的力学性能与腐蚀速率

Table 5. Mechanical properties and corrosion rate of magnesium-based tetrameric alloys

Alloy/wt% Fabrication method Yield strength/MPa Ultimate tensile strength/MPa Elongation/% Corrosion rate/(mm·year−1) Immersion test solution Ref. Mg-6Zn-0.5Ce-1Mn As-extruded 232 304 14.7 — — [86] Mg-3Zn-0.2Ca-0.1Ag As-extruded — 300.45 15.72 — — [87] Mg-3Zn-0.2Ca-0.3Ag — 305.33 16.47 — — Mg-3Zn-0.2Ca-0.5Ag — 282.64 14.93 — — Mg-3Zn-0.2Ca-0.7Ag — 293.25 16.06 — — Mg-0.5Zn-0.5Nd-3Sc As-Cast 82 174 17.1 — — [88] Mg-0.5Zn-0.5Nd-6Sc 101 180 14.4 — — Mg-0.5Zn-0.5Nd-3Sc As-extruded 110 207 29.8 — — Mg-0.5Zn-0.5Nd-6Sc 153 223 21.7 — — Mg-2Zn-0.5Ca-0.5Sr As-extruded — 340 19 14.26 — [74] Mg-2Zn-0.5Ca-1.0Sr — 334 20.4 17.9 — Mg-8Li-2Al-1.5Sn As-extruded — 136 10.4 10.49 — [89] Mg-8Li-2Al-1.5Nd — 129 10 41 — Mg-8Li-2Al-1.5Ca — 125 8 14.88 — Mg-0.6Zr-0.5Sr-0.5Sc As-Cast 63 73 — 32.9 Hank's balanced salt solution

(2 h)[95] Mg-0.6Zr-0.5Sr-1Sc 54 72 — 22.4 Mg-0.6Zr-0.5Sr-2Sc 77 81 — 18.1 Mg-0.6Zr-0.5Sr-3Sc 74 95 — 14.5 Mg-8.5Gd-5Y-0.2Al As-extruded 263 376 12.82 3.8 3.5wt% NaCl solution [96] Mg-8.5Gd-5Y-0.5Al 264 363 7.71 8.11 Mg-8.5Gd-5Y-0.8Al 276 377 5.29 18.61 Mg-8.5Gd-5Y-1.1Al 289 390 3.05 33.84 -

[1] HEDAYATI R, AHMADI S M, MIETAERT K, et al. Fatigue and quasistatic mechanical behavior of bio-degradable porous biomaterials based on magnesium alloys[J]. Journal of Biomedical Materials Research Part A, 2018, 106(7): 1798-1811. doi: 10.1002/jbm.a.36380 [2] SU Y C, FU J Y, ZHOU J C, et al. Blending with transition metals improves bioresorbable zinc as better medical implants[J]. Bioactive Materials, 2023, 20: 243-258. doi: 10.1016/j.bioactmat.2022.05.033 [3] UPPAL G, THAKUR A, CHAUHAN A, et al. Magnesium based implants for functional bone tissue regeneration—A review[J]. Journal of Magnesium and Alloys, 2022, 10(2): 356-386. doi: 10.1016/j.jma.2021.08.017 [4] CHATTERJEE S, SAXENA M, PADMANABHAN D, et al. Futuristic medical implants using bioresorbable materials and devices[J]. Biosensors and Bioelectronics, 2019, 142: 111489. doi: 10.1016/j.bios.2019.111489 [5] GAO X Z, DAI C Y, JIA Q, et al. In vivo corrosion behavior of biodegradable magnesium alloy by MAF treatment[J]. Scanning, 2021, 2021: 1-9. [6] SU Y C, LIN J X, SU Y C, et al. Investigation on composition, mechanical properties, and corrosion resistance of Mg-0.5Ca-X (Sr, Zr, Sn) biological alloy[J]. Scanning, 2018, 2018: 6519310. [7] DAROONPARVAR M, KHAN M F, SAADEH Y, et al.Enhanced corrosion resistance and surface bioactivity of AZ31B Mg alloy by high pressure cold sprayed monolayer Ti and bilayer Ta/Ti coatings in simulated body fluid[J]. Materials Chemistry and Physics, 2020, 256: 123627. doi: 10.1016/j.matchemphys.2020.123627 [8] SONG G, LI T T, CHEN L. The mechanical properties and interface bonding mechanism of immiscible Mg/steel by laser-tungsten inert gas welding with filler wire[J]. Materials Science and Engineering: A, 2018, 736: 306-315. doi: 10.1016/j.msea.2018.08.078 [9] SONG M S, ZENG R C, DING Y F, et al. Recent advances in biodegradation controls over Mg alloys for bone fracture management: A review[J]. Journal of Materials Science & Technology, 2019, 35(4): 535-544. [10] ZHAO D W, WITTE F, LU F Q, et al. Current status on clinical applications of magnesium-based orthopaedic implants: A review from clinical translational perspective[J]. Biomaterials, 2017, 112: 287-302. doi: 10.1016/j.biomaterials.2016.10.017 [11] LIN D, CHAI Y J, MA Y F, et al. Rapid initiation of guided bone regeneration driven by spatiotemporal delivery of IL-8 and BMP-2 from hierarchical MBG-based scaffold[J]. Biomaterials, 2019, 196: 122-137. doi: 10.1016/j.biomaterials.2017.11.011 [12] BAIRAGI D, MANDAL S. A comprehensive review on biocompatible Mg-based alloys as temporary orthopaedic implants: Current status, challenges, and future prospects[J]. Journal of Magnesium and Alloys, 2022, 10(3): 627-669. doi: 10.1016/j.jma.2021.09.005 [13] LIU Y X, CURIONI M, DONG S Y, et al. Understanding the effects of excimer laser treatment on corrosion behavior of biodegradable Mg-1Ca alloy in simulated body fluid[J]. Journal of Magnesium and Alloys, 2022, 10(4): 1004-1023. doi: 10.1016/j.jma.2021.11.011 [14] WINDHAGEN H, RADTKE K, WEIZBAUER A, et al. Biodegradable to titanium screw in hallux valgus surgery: Short term results of the first prospective, randomized, controlled clinical pilot study[J]. Biomedical Engineering Online, 2013, 12: 1-10. doi: 10.1186/1475-925X-12-1 [15] WAN Y C, XU S Y, LIU C M, et al. Enhanced strength and corrosion resistance of Mg-Gd-Y-Zr alloy with ultrafine grains[J]. Materials Letters, 2018, 213: 274-277. doi: 10.1016/j.matlet.2017.11.096 [16] SHARMA R C, DABRA V, SINGH G, et al. Multi-response optimization while machining of stainless steel 316L using intelligent approach of grey theory and grey-TLBO[J]. World Journal of Engineering, 2022, 19(3): 329-339. doi: 10.1108/WJE-06-2020-0226 [17] ALI M, HUSSEIN M A, AL-AQEELI N. Magnesium-based composites and alloys for medical applications: A review of mechanical and corrosion properties[J]. Journal of Alloys and Compounds, 2019, 792: 1162-1190. doi: 10.1016/j.jallcom.2019.04.080 [18] JOOST W J, KRAJEWSKI P E. Towards magnesium alloys for high-volume automotive applications[J]. Scripta Materialia, 2017, 128: 107-112. doi: 10.1016/j.scriptamat.2016.07.035 [19] TSAKIRIS V, TARDEI C, CLICINSCHI F M. Biodegradable Mg alloys for orthopedic implants—A review[J]. Journal of Magnesium and Alloys, 2021, 9(6): 1884-1905. doi: 10.1016/j.jma.2021.06.024 [20] KUMAR R, KATYAL P. Effects of alloying elements on performance of biodegradable magnesium alloy[J]. Materials Today: Proceedings, 2022, 56: 2443-2450. doi: 10.1016/j.matpr.2021.08.233 [21] ZENG R, DIETZEL W, WITTE F, et al. Progress and challenge for magnesium alloys as biomaterials[J]. Advanced Engineering Materials, 2008, 10(8): B3-B14. doi: 10.1002/adem.200800035 [22] ZENG R, ZHANG J, HUANG W, et al. Review of studies on corrosion of magnesium alloys[J]. Transactions of Nonferrous Metals Society of China, 2006, 16: s763-s771. doi: 10.1016/S1003-6326(06)60297-5 [23] GHALI E. Corrosion resistance of aluminum and magnesium alloys: Understanding, performance, and testing[M]. Hoboken: John Wiley & Sons, 2010: 169-172. [24] SONG G, ATRENS A. Understanding magnesium corrosion—A framework for improved alloy performance[J]. Advanced Engineering Materials, 2003, 5(12): 837-858. doi: 10.1002/adem.200310405 [25] LIU L J, SCHLESINGER M. Corrosion of magnesium and its alloys[J]. Corrosion Science, 2009, 51(8): 1733-1737. doi: 10.1016/j.corsci.2009.04.025 [26] POINERN G E J, BRUNDAVANAM S, FAWCETT D. Biomedical magnesium alloys: A review of material properties, surface modifications and potential as a biodegradable orthopaedic implant[J]. American Journal of Biomedical Engineering, 2012, 2(6): 218-240. [27] LIU Y, ZHENG Y F, CHEN X H, et al. Fundamental theory of biodegradable metals-definition, criteria, and design[J]. Advanced Functional Materials, 2019, 29(18): 1805402. doi: 10.1002/adfm.201805402 [28] 任伊宾, 黄晶晶, 杨柯, 等. 纯镁的生物腐蚀研究[J]. 金属学报, 2005, 41(11): 1228-1232. doi: 10.3321/j.issn:0412-1961.2005.11.018REN Yibin, HUANG Jingjing, YANG Ke, et al. Study on biological corrosion of pure magnesium[J]. Acta Metallurgica Sinica, 2005, 41(11): 1228-1232(in Chinese). doi: 10.3321/j.issn:0412-1961.2005.11.018 [29] LIANG M J, WU C, MA Y, et al. Influences of aggressive ions in human plasma on the corrosion behavior of AZ80 magnesium alloy[J]. Materials Science and Engineering: C, 2021, 119: 111521. doi: 10.1016/j.msec.2020.111521 [30] XIN Y C, HU T, CHU P K. Influence of test solutions on in vitro studies of biomedical magnesium alloys[J]. Journal of the Electrochemical Society, 2010, 157(7): C238. doi: 10.1149/1.3421651 [31] POKHAREL D B, WU L P, DONG J H, et al. Effect of glycine addition on the in-vitro corrosion behavior of AZ31 magnesium alloy in Hank’s solution[J]. Journal of Materials Science & Technology, 2021, 81: 97-107. [32] LIU S Y, WANG B. Electrochemical corrosion behavior of a magnesium calcium alloy in simulated body fluids with different glucose concentrations[J]. Journal of Materials Research and Technology, 2020, 9(3): 6612-6619. doi: 10.1016/j.jmrt.2020.04.052 [33] 张文毓. 生物医用金属材料研究现状与应用进展[J]. 金属世界, 2020 (1): 21-27. doi: 10.3969/j.issn.1000-6826.2020.01.007ZHANG Wenyu. Research status and application progress of biomedical metal materials[J]. Metal World, 2020 (1): 21-27(in Chinese). doi: 10.3969/j.issn.1000-6826.2020.01.007 [34] PENG H Z, FAN K, ZAN R, et al. Degradable magnesium implants inhibit gallbladder cancer[J]. Acta Biomaterialia, 2021, 128: 514-522. doi: 10.1016/j.actbio.2021.04.051 [35] 陈宝林, 王东安. 用于心血管医疗装置的聚合物表面构建与生物相容性研究Ⅲ-聚合物生物材料表面的凝血及抗凝血涂层改性[J]. 中国组织工程研究, 2015 (8): 1277-1283. doi: 10.3969/j.issn.2095-4344.2015.08.024CHEN Baolin, WANG Dongan. Study on polymer surface construction and biocompatibility of cardiovascular medical devices III-Coagulation and anticoagulation coating modification on the surface of polymer biomaterials[J]. Chinese Journal of Tissue Engineering Research, 2015 (8): 1277-1283(in Chinese). doi: 10.3969/j.issn.2095-4344.2015.08.024 [36] PAN C J, ZHAO Y J, YANG Y, et al. Immobilization of bioactive complex on the surface of magnesium alloy stent material to simultaneously improve anticorrosion, hemocompatibility and antibacterial activities[J]. Colloids and Surfaces B: Biointerfaces, 2021, 199: 111541. doi: 10.1016/j.colsurfb.2020.111541 [37] ZHOU H, LIANG B, JIANG H T, et al. Magnesium-based biomaterials as emerging agents for bone repair and regeneration: From mechanism to application[J]. Journal of Magnesium and Alloys, 2021, 9(3): 779-804. doi: 10.1016/j.jma.2021.03.004 [38] ZHANG Y F, XU J K, RUAN Y C, et al. Implant-derived magnesium induces local neuronal production of CGRP to improve bone-fracture healing in rats[J]. Nature Medicine, 2016, 22(10): 1160-1169. doi: 10.1038/nm.4162 [39] 杨婷婷. 生物可降解镁合金的制备、表征及体外生物活性评价[D]. 长春: 吉林大学, 2014.YANG Tingting. Preparation, characterization, and in vitro bioactivity evaluation of biodegradable magnesium alloys[D]. Changchun: Jilin University, 2014(in Chinese). [40] LIU C, FU X K, PAN H B, et al. Biodegradable Mg-Cu alloys with enhanced osteogenesis, angiogenesis, and long-lasting antibacterial effects[J]. Scientific Reports, 2016, 6: 27374. doi: 10.1038/srep27374 [41] 王健, 马翔宇, 冯亚非, 等. 镁离子对成骨细胞活力和分化的促进作用及其机制研究[J]. 现代生物医学进展, 2015, 15(15): 2836-2839. doi: 10.13241/j.cnki.pmb.2015.15.009WANG Jian, MA Xiangyu, FENG Yafei, et al. Study on the promoting effect and mechanism of magnesium ions on the viability and differentiation of osteoblasts[J]. Progress in Modern Biomedicine, 2015, 15(15): 2836-2839(in Chinese). doi: 10.13241/j.cnki.pmb.2015.15.009 [42] 陈亚楠. 生物可吸收冠脉支架的弹塑性变形及动力学行为研究[D]. 北京: 北京科技大学, 2023.CHEN Yanan. Elastic-plastic deformation and dynamic behaviour of bioresorbable coronary scaffolds[D]. Beijing: University of Science and Technology Beijing, 2023(in Chinese). [43] GAO Y M, WANG L Z, GU X N, et al. A quantitative study on magnesium alloy stent biodegradation[J]. Journal of Biomechanics, 2018, 74: 98-105. doi: 10.1016/j.jbiomech.2018.04.027 [44] 陈晨忻. 可降解镁合金血管支架的结构优化设计和实验验证研究[D]. 上海: 上海交通大学, 2023.CHEN Chenxin. Structural optimisation design and experimental validation of degradable magnesium alloy vascular scaffolds[D]. Shanghai: Shanghai Jiao Tong University, 2023(in Chinese). [45] 梁文强. 新型镁合金对成骨细胞黏附及增殖的影响及作用机制研究[D]. 兰州: 兰州大学, 2023.LIANG Wenqiang. Study on the effect and mechanism of action of new magnesium alloy on osteoblast adhesion and proliferation[D]. Lanzhou: Lanzhou University, 2023(in Chinese). [46] SHIRURKAR A, TAMBOLI A, JAGTAP P N, et al. Mechanical behavior of ZM21 magnesium alloy locking plates—An experimental and finite element study[J]. Materials Today: Proceedings, 2017, 4(6): 6728-6736. doi: 10.1016/j.matpr.2017.06.448 [47] 孟晓丽, 吕萍, 崔旭东, 等. 生物可降解锌合金用于骨植入物的研究进展[J]. 表面技术, 2022, 51(10): 66-75. doi: 10.16490/j.cnki.issn.1001-3660.2022.10.008MENG Xiaoli, LYU Ping, CUI Xudong, et al. Research progress on biodegradable zinc alloys for bone implants[J]. Surface Technology, 2022, 51(10): 66-75(in Chinese). doi: 10.16490/j.cnki.issn.1001-3660.2022.10.008 [48] WOLFF M, SCHAPER J G, SUCKERT M R, et al. Magnesium powder injection molding (MIM) of orthopedic implants for biomedical applications[J]. JOM, 2016, 68: 1191-1197. doi: 10.1007/s11837-016-1837-x [49] 李敬瑶. 医用镁合金表面涂层制备及其体外降解特性和细胞相容性研究[D]. 广州: 暨南大学, 2022.LI Jingyao. Preparation of medical magnesium alloy surface coating and its in vitro degradation characteristics and cytocompatibility[D]. Guangzhou: Jinan University, 2022(in Chinese). [50] DUAN Y N, GAO Q F, ZHANG Z J, et al. Chemical ordering induced strengthening in lightweight Mg alloys[J]. Nanomaterials, 2022, 12(19): 3488. doi: 10.3390/nano12193488 [51] ZHOU H Y, HOU R Q, YANG J J, et al. Influence of zirconium (Zr) on the microstructure, mechanical properties and corrosion behavior of biodegradable zinc-magnesium alloys[J]. Journal of Alloys and Compounds, 2020, 840: 155792. doi: 10.1016/j.jallcom.2020.155792 [52] SUN J P, XU B Q, YANG Z Q, et al. Mediating the strength, ductility and corrosion resistance of high aluminum containing magnesium alloy by engineering hierarchical precipitates[J]. Journal of Alloys and Compounds, 2021, 857: 158277. doi: 10.1016/j.jallcom.2020.158277 [53] ESMAILY M, SVENSSON J E, FAJARDO S, et al. Fundamentals and advances in magnesium alloy corrosion[J]. Progress in Materials Science, 2017, 89: 92-193. doi: 10.1016/j.pmatsci.2017.04.011 [54] CORMICK G, BELIZÁN M J. Calcium intake and health[J]. Nutrients, 2019, 11(7): 1606. doi: 10.3390/nu11071606 [55] 王昌, 崔亚军, 刘汉源, 等. 可生物降解医用镁合金的合金化研究进展[J]. 材料导报, 2015, 29(11): 55-60.WANG Chang, CUI Yajun, LIU Hanyuan, et al. Research progress on alloying of biodegradable medical magnesium alloys[J]. Materials Reports, 2015, 29(11): 55-60(in Chinese). [56] MA D, LUAN S, JIN P, et al. The effects of Ca on the microstructure, mechanical and corrosion properties of extruded Mg-2Zn-0.5Mn alloy[J]. Journal of Materials Research and Technology, 2023, 25: 2880-2889. doi: 10.1016/j.jmrt.2023.06.075 [57] ZHANG Y, LI J X, LI J Y. Effects of calcium addition on phase characteristics and corrosion behaviors of Mg-2Zn-0.2Mn-xCa in simulated body fluid[J]. Journal of Alloys and Compounds, 2017, 728: 37-46. doi: 10.1016/j.jallcom.2017.08.264 [58] MOHAMED A, El-AZIZ A M, BREITINGER H G. Study of the degradation behavior and the biocompatibility of Mg-0.8Ca alloy for orthopedic implant applications[J]. Journal of Magnesium and Alloys, 2019, 7(2): 249-257. doi: 10.1016/j.jma.2019.02.007 [59] KIM S Y, KIM Y K, KWANG-KYUN Y, et al. Determination of ideal Mg-35Zn-xCa alloy depending on Ca concentration for biomaterials[J]. Journal of Alloys and Compounds, 2018, 766: 994-1002. doi: 10.1016/j.jallcom.2018.06.088 [60] RADHA R, SREEKANTH D. Insight of magnesium alloys and composites for orthopedic implant applications—A review[J]. Journal of Magnesium and Alloys, 2017, 5(3): 286-312. doi: 10.1016/j.jma.2017.08.003 [61] 申广鑫, 张代东, 张晓茹, 等. 锌对稀土镁合金组织与力学性能的影响[J]. 中国稀土学报, 2019, 37(6): 739-745.SHEN Guangxin, ZHANG Daidong, ZHANG Xiaoru, et al. The influence of zinc on the microstructure and mechanical properties of rare earth magnesium alloys[J]. Journal of the Chinese Society of Rare Earths, 2019, 37(6): 739-745(in Chinese). [62] CAI S, LEI T, LI N, et al. Effects of Zn on microstructure, mechanical properties and corrosion behavior of Mg-Zn alloys[J]. Materials Science and Engineering: C, 2012, 32(8): 2570-2577. doi: 10.1016/j.msec.2012.07.042 [63] WEI L Y, LI J Y, ZHANG Y, et al. Effects of Zn content on microstructure, mechanical and degradation behaviors of Mg-xZn-0.2Ca-0.1 Mn alloys[J]. Materials Chemistry and Physics, 2020, 241: 122441. doi: 10.1016/j.matchemphys.2019.122441 [64] HE Y H, TAO H R, ZHANG Y, et al. Biocompatibility of bio-Mg-Zn alloy within bone with heart, liver, kidney and spleen[J]. Chinese Science Bulletin, 2009, 54(3): 484-491. doi: 10.1007/s11434-009-0080-z [65] CAO X, LI C, WU B, et al. Research of dynamic corrosion behavior, microstructure, and biocompatibility of Mg-Zn-Ca-Zr alloys in simulated body fluid solution induced by Zn element addition[J]. Advanced Engineering Materials, 2023, 25(8): 2201402. doi: 10.1002/adem.202201402 [66] MIAH M R, IJOMONE O M, OKOH C O A, et al. The effects of manganese overexposure on brain health[J]. Neurochemistry International, 2020, 135: 104688. doi: 10.1016/j.neuint.2020.104688 [67] ABDIYAN F, MAHMUDI R, GHASEMI H M. Effect of Mn addition on the microstructure, mechanical properties and corrosion resistance of a biodegradable Mg-Gd-Zn alloy[J]. Materials Chemistry and Physics, 2021, 271: 124878. doi: 10.1016/j.matchemphys.2021.124878 [68] LIU Y, CHENG W, GU X, et al. Tailoring the microstructural characteristic and improving the corrosion resistance of extruded dilute Mg-0.5Bi-0.5Sn alloy by microalloying with Mn[J]. Journal of Magnesium and Alloys, 2021, 9(5): 1656-1668. doi: 10.1016/j.jma.2020.07.010 [69] 赵德华, 李斌伟, 朴建英, 等. Mn添加对可生物降解Mg-4Zn-0.5Ca-xMn合金腐蚀性能的影响[J]. 合金与化合物学报, 2017, 695: 1166-1174. doi: 10.1016/j.jallcom.2016.10.244ZHAO Dehua, LI Binwei, PIAO Jianying, et al. Influence of Mn addition on the corrosion behavior of biodegradable Mg-4Zn-0.5Ca-xMn alloys[J]. Journal of Alloys and Compounds, 2017, 695: 1166-1174(in Chinese). doi: 10.1016/j.jallcom.2016.10.244 [70] SHI L, YAN Y, SHAO C, et al. The influence of yttrium and manganese additions on the degradation and biocompatibility of magnesium-zinc-based alloys: In vitro and in vivo studies[J]. Journal of Magnesium and Alloys, 2022. [71] MARTINS JR A C, MORCILLO P, IJOMONE O M, et al. New insights on the role of manganese in Alzheimer’s disease and Parkinson’s disease[J]. International Journal of Environmental Research and Public Health, 2019, 16(19): 3546. doi: 10.3390/ijerph16193546 [72] DING D, ROTH J, SALVI R. Manganese is toxic to spiral ganglion neurons and hair cells in vitro[J]. Neurotoxicology, 2011, 32(2): 233-241. doi: 10.1016/j.neuro.2010.12.003 [73] DING Y, WEN C, HODGSON P, et al. Effects of alloying elements on the corrosion behavior and biocompatibility of biodegradable magnesium alloys: A review[J]. Journal of Materials Chemistry B, 2014, 2(14): 1912-1933. doi: 10.1039/C3TB21746A [74] QIN J, CHANG L, SU X. Influence of Sr on microstructure evolution, mechanical and corrosion properties of extruded Mg-2Zn-0.5Ca alloy[J]. Journal of Magnesium and Alloys, 2023. [75] WEN Y F, LIU Q S, WANG J F, et al. Improving in vitro and in vivo corrosion resistance and biocompatibility of Mg-1Zn-1Sn alloys by microalloying with Sr[J]. Bioactive Materials, 2021, 6(12): 4654-4669. doi: 10.1016/j.bioactmat.2021.04.043 [76] 杨淼, 邢砾云, 刘晓波, 等. 稀土Gd改性镁合金在溶液中的应力腐蚀行为研究[J/OL]. 中国稀土学报:1-15[2023-11-29].YANG Miao, XING Liyun, LIU Xiaobo, et al. Stress corrosion behaviour of rare earth Gd-modified magnesium alloys in solution[J/OL]. Chinese Journal of Rare Earths: 1-15[2023-11-29](in Chinese). [77] ZHAO L, MA G J, JIN P P, et al. Role of Y on the microstructure, texture and mechanical properties of Mg-Zn-Zr alloys by powder metallurgy[J]. Journal of Alloys and Compounds, 2019, 810: 151843. doi: 10.1016/j.jallcom.2019.151843 [78] LIU J N, BIAN D, ZHENG Y F, et al. Comparative in vitro study on binary Mg-RE (Sc, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu) alloy systems[J]. Acta Biomaterialia, 2020, 102: 508-528. doi: 10.1016/j.actbio.2019.11.013 [79] YIN M, HOU L F, WANG Z W, et al. Self-generating construction of applicable corrosion-resistant surface structure of magnesium alloy[J]. Corrosion Science, 2021, 184: 109378. doi: 10.1016/j.corsci.2021.109378 [80] XING F J, GUO F, SU J, et al. The existing forms of Zr in Mg-Zn-Zr magnesium alloys and its grain refinement mechanism[J]. Materials Research Express, 2021, 8(6): 066516. doi: 10.1088/2053-1591/ac083c [81] WAN D Q, WANG H B, YE S T, et al. The damping and mechanical properties of magnesium alloys balanced by aluminum addition[J]. Journal of Alloys and Compounds, 2019, 782: 421-426. doi: 10.1016/j.jallcom.2018.11.393 [82] ZHAO W K, WANG J F, JIANG W Y, et al. A novel biodegradable Mg-1Zn-0.5 Sn alloy: Mechanical properties, corrosion behavior, biocompatibility, and antibacterial activity[J]. Journal of Magnesium and Alloys, 2020, 8(2): 374-386. doi: 10.1016/j.jma.2020.02.008 [83] JIANG W Y, WANG J F, ZHAO W K, et al. Effect of Sn addition on the mechanical properties and bio-corrosion behavior of cytocompatible Mg-4Zn based alloys[J]. Journal of Magnesium and Alloys, 2019, 7(1): 15-26. doi: 10.1016/j.jma.2019.02.002 [84] NIU H Y, DENG K K, NIE K B, et al. Microstructure, mechanical properties and corrosion properties of Mg-4Zn-xNi alloys for degradable fracturing ball applications[J]. Journal of Alloys and Compounds, 2019, 787: 1290-1300. doi: 10.1016/j.jallcom.2019.02.089 [85] JIANG P L, BLAWERT C, HOU R Q, et al. A comprehensive comparison of the corrosion performance, fatigue behavior and mechanical properties of micro-alloyed MgZnCa and MgZnGe alloys[J]. Materials & Design, 2020, 185: 108285. [86] HOU C H, CAO H S, QI F G, et al. Investigation on microstructures and mechanical properties of Mg-6Zn-0.5Ce- xMn ( x= 0 and 1) wrought magnesium alloys[J]. Journal of Magnesium and Alloys, 2022, 10(4): 993-1003. doi: 10.1016/j.jma.2020.09.019 [87] YU L T, ZHAO Z H, TANG C K, et al. The mechanical and corrosion resistance of Mg-Zn-Ca-Ag alloys: The influence of Ag content[J]. Journal of Materials Research and Technology, 2020, 9(5): 10863-10875. doi: 10.1016/j.jmrt.2020.07.088 [88] XIN L N, ZHOU J Q, MEI D, et al. Effects of Sc on microstructure, mechanical properties and corrosion behavior of Mg-0.5Zn-0.5Nd-xSc alloys[J]. Journal of Alloys and Compounds, 2023, 934: 168044. doi: 10.1016/j.jallcom.2022.168044 [89] ACIKGOZ S, KURNAZ S C. The effects of individual addition of Sn, Nd, and Ca on the microstructure, mechanical properties, and corrosion behavior of the Mg-Li-Al alloy[J]. International Journal of Metalcasting, 2023, 17(3): 1580-1595. doi: 10.1007/s40962-022-00869-8 [90] JIANG Q T, LYU X Z, LU D Z, et al. The corrosion behavior and mechanical property of the Mg-7Y-xNd ternary alloys[J]. Journal of Magnesium and Alloys, 2018, 6(4): 346-355. doi: 10.1016/j.jma.2018.09.002 [91] CI W J, DENG L L, CHEN X H, et al. Effect of minor Gd addition on micro-structure, mechanical performance, and corrosion behavior of Mg-Y-Gd alloys[J]. Journal of Materials Research and Technology, 2023, 26: 4107-4120. doi: 10.1016/j.jmrt.2023.08.166 [92] ZHAO T S, HU Y B, HE B, et al. Effect of manganese on microstructure and properties of Mg-2Gd magnesium alloy[J]. Materials Science and Engineering: A, 2019, 765: 138292. doi: 10.1016/j.msea.2019.138292 [93] CI W J, CHEN X H, SUN Y, et al. Effect of Zn on mechanical and corrosion properties of Mg-Sc-Zn alloys[J]. Journal of Materials Science & Technology, 2023, 158: 31-42. [94] WANG Y Q, ZHANG D F, ZHONG S Y, et al. Effect of minor Ni addition on the microstructure, mechanical properties and corrosion behavior of Mg-2Gd alloy[J]. Journal of Materials Research and Technology, 2022, 20: 3735-3749. doi: 10.1016/j.jmrt.2022.08.051 [95] MUNIR K, LIN J X, WEN C E, et al. Mechanical, corrosion, and biocompatibility properties of Mg-Zr-Sr-Sc alloys for biodegradable implant applications[J]. Acta Biomaterialia, 2020, 102: 493-507. doi: 10.1016/j.actbio.2019.12.001 [96] SU C, WANG J F, HU H, et al. Enhanced strength and corrosion resistant of Mg-Gd-Y-Al alloys by LPSO phases with different Al content[J]. Journal of Alloys and Compounds, 2021, 885: 160557. doi: 10.1016/j.jallcom.2021.160557 -

下载:

下载: