Investigation of microwave-assisted MgO-modified carbon fiber-reinforced and toughened epoxy resin composites

-

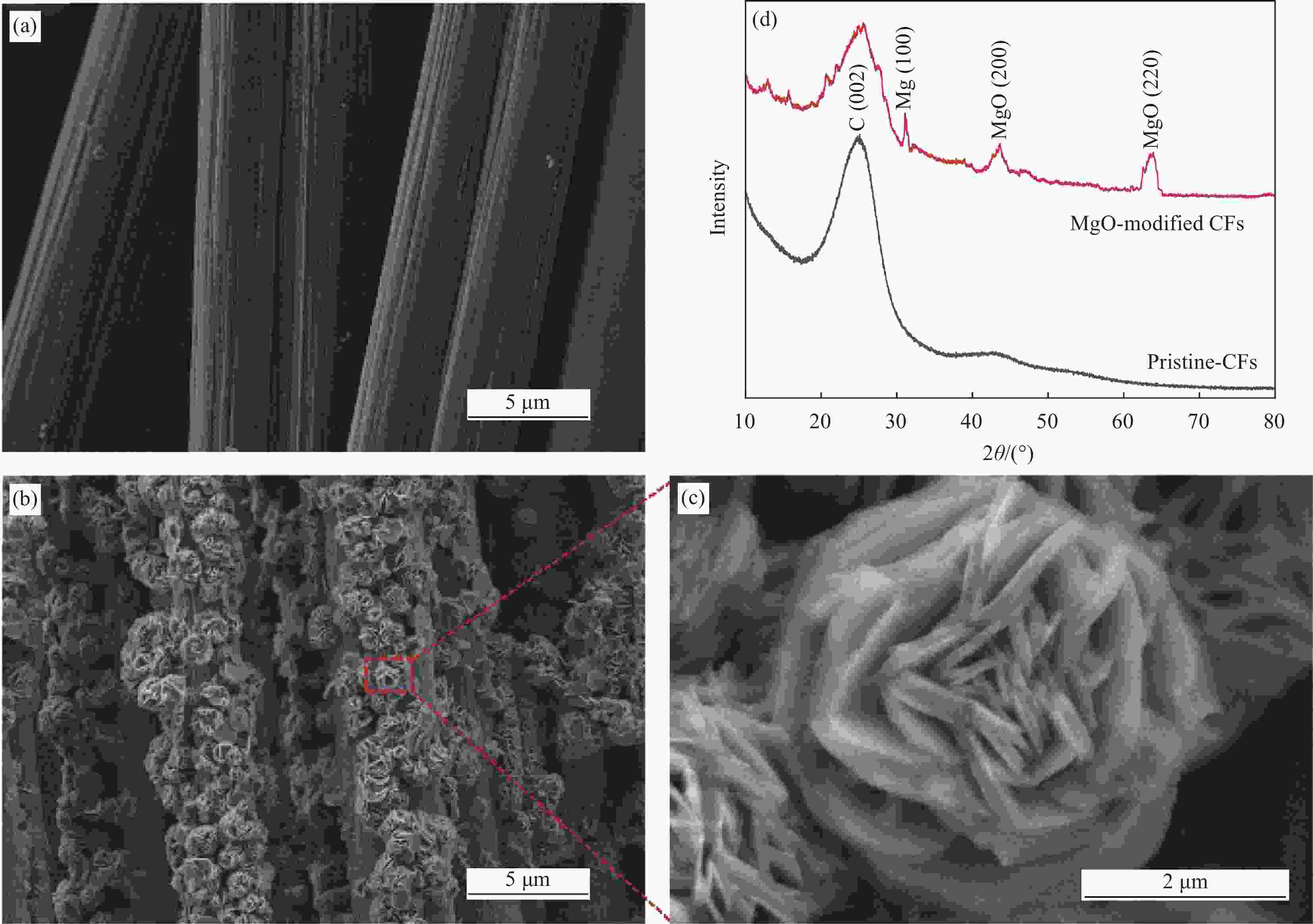

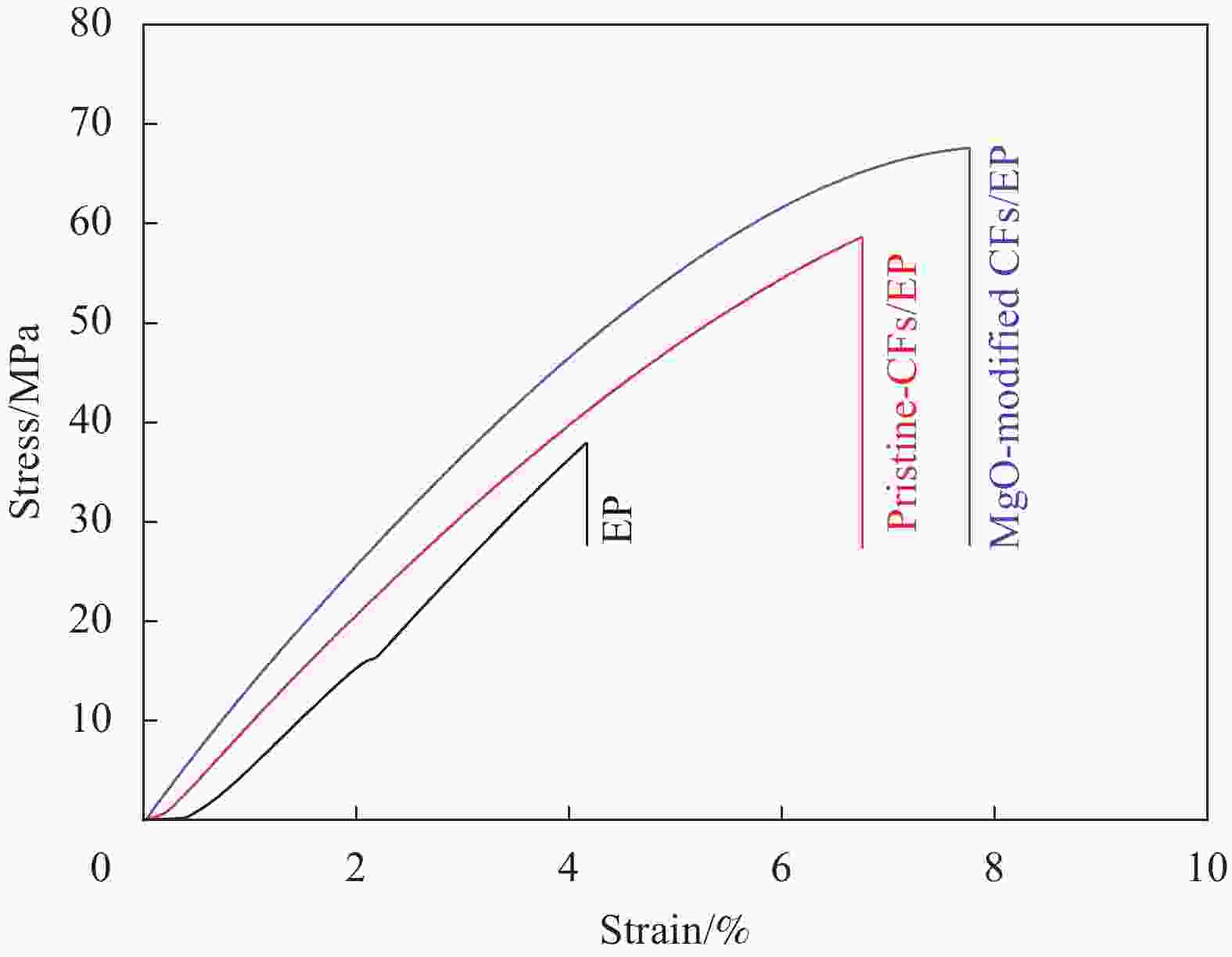

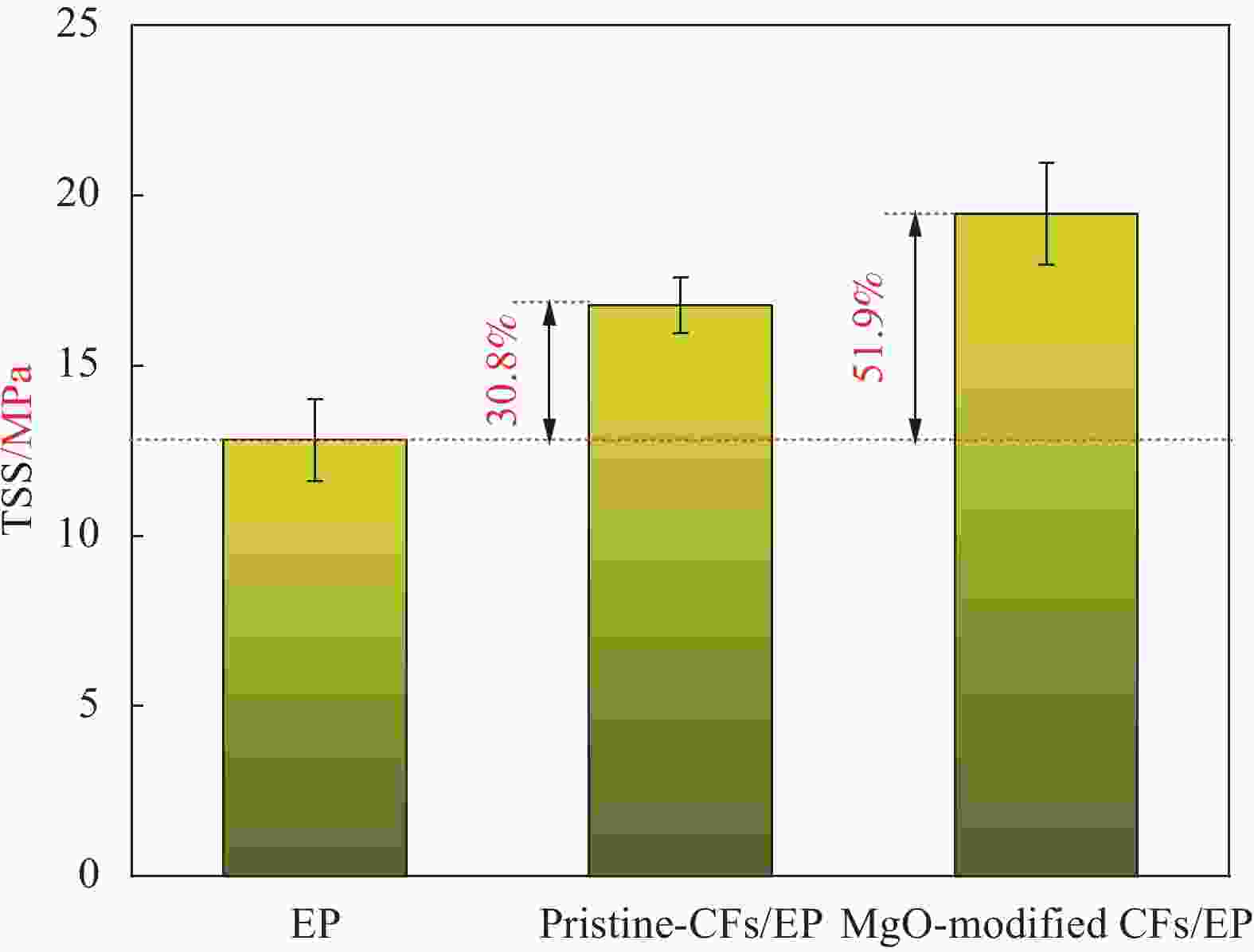

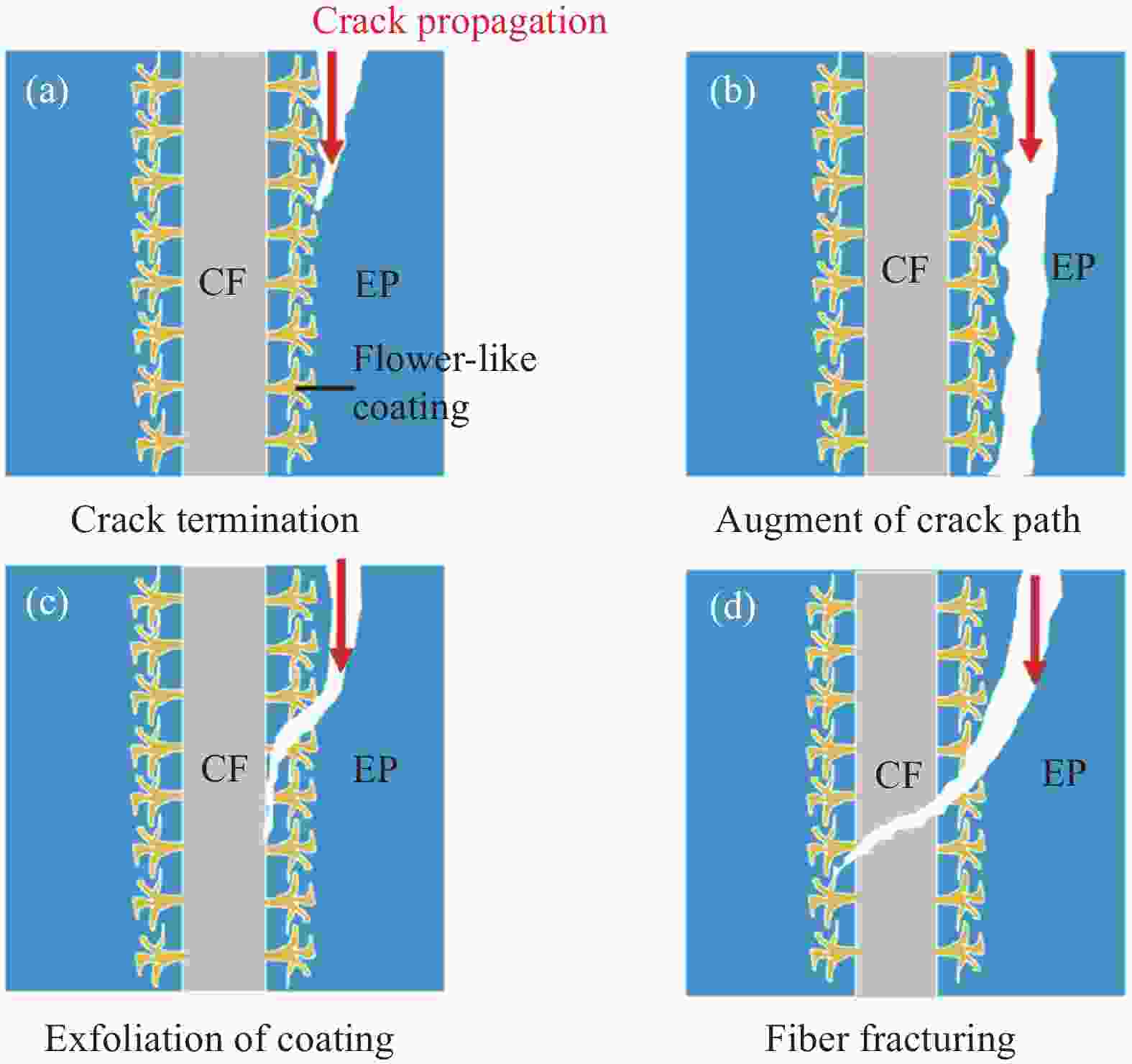

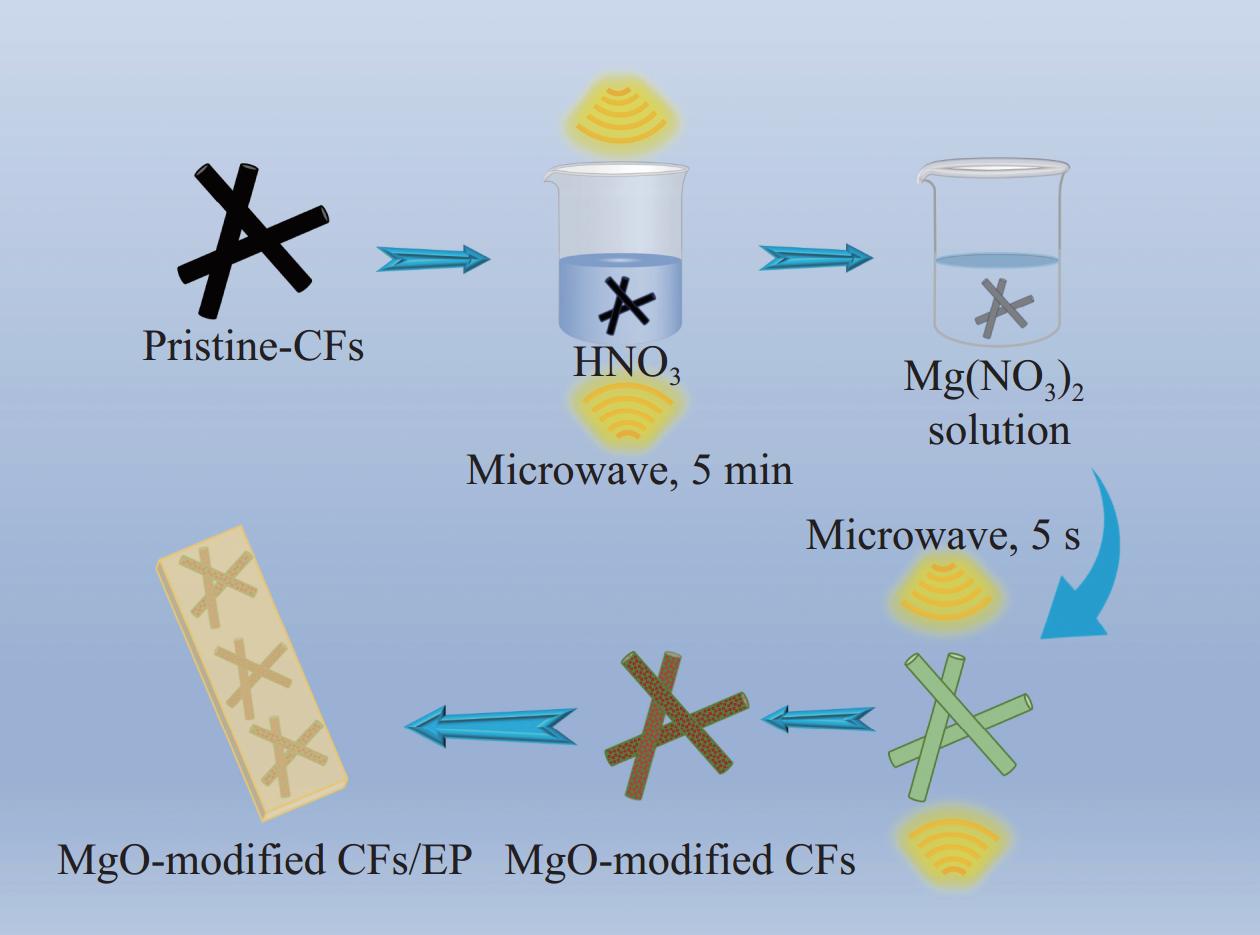

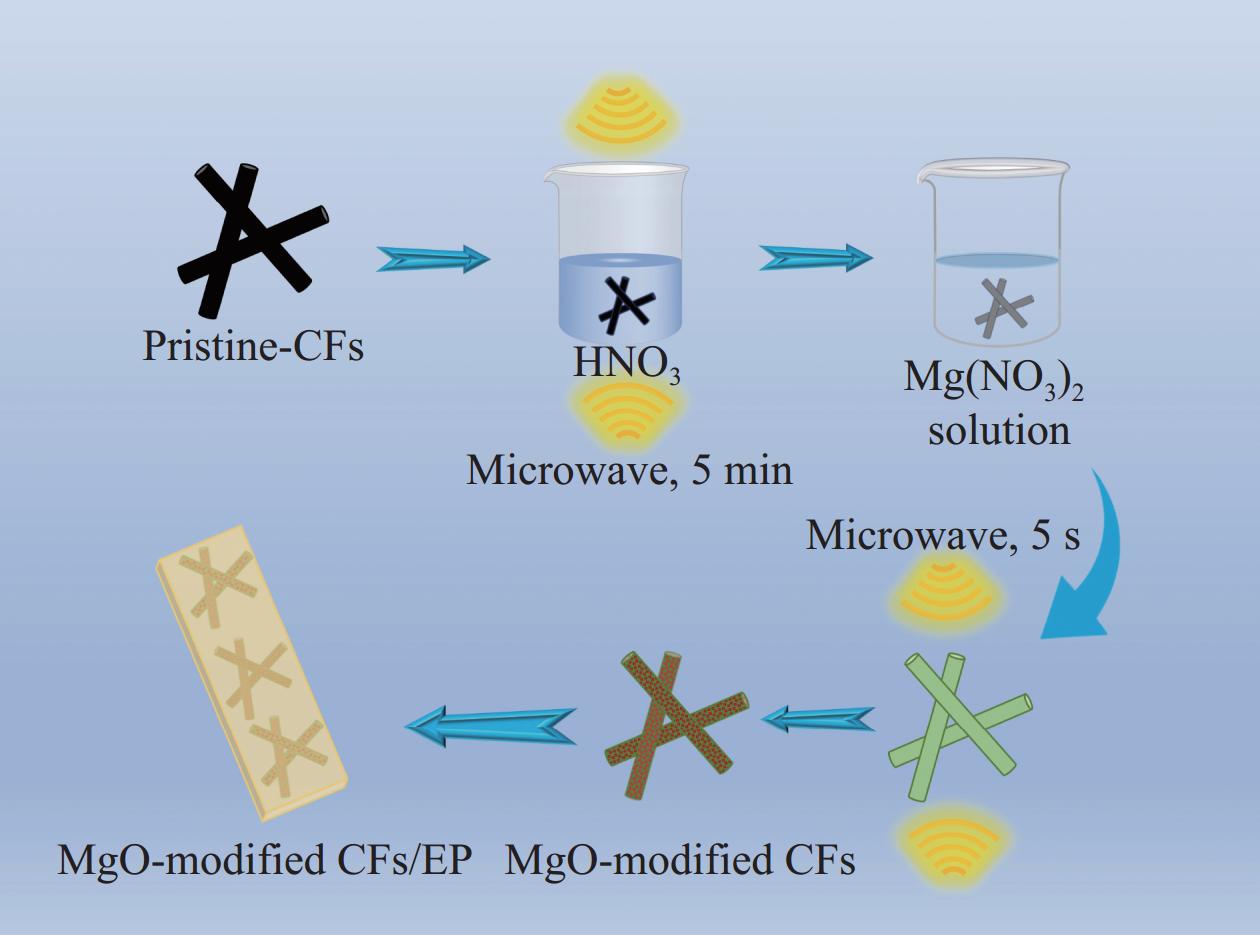

摘要: 对碳纤维表面进行改性处理是提高碳纤维/环氧树脂复合材料(CFs/EP)界面结合力的主要方法,而特殊的表面形貌结构能有效预防应力集中并提升复合材料的综合力学性能。本文采用微波辅助的方法在碳纤维表面快速高效地制备了一种花朵状MgO,考察了其对CFs/EP复合材料力学性能的影响。研究发现:花朵状MgO增加了碳纤维表面的粗糙程度,促进了碳纤维与EP基体不规则界面的形成,增强了其与EP基体的机械啮合作用。这种多尺度边界形态可以增加裂纹扩展途径,从而消耗更多的能量并有效缓解CFs/EP复合材料因应力集中而产生的破坏。花朵状MgO改性碳纤维极大地改善了复合材料的力学性能,与未改性碳纤维增强环氧树脂相比,花朵状MgO改性碳纤维/环氧树脂复合材料的拉伸强度、弯曲强度和冲击强度分别提高了15.2%、21.8%和14.3%。因此,花朵状MgO改性碳纤维同时显著提高了CFs/EP复合材料的强度和韧性。这为碳纤维在聚合物基复合材料中的广泛应用提供了技术支持,为制备更多特殊形貌纤维增强树脂基复合材料提供了更广阔的思路。Abstract: Surface modification of carbon fiber is the primary method for enhancing the interface bonding strength of carbon fiber/epoxy resin composite (CFs/EP). The unique surface morphology can effectively prevent stress concentration and enhance the comprehensive mechanical properties of the composite. A flower-shaped MgO was synthesized on the surface of carbon fibers rapidly and efficiently using a microwave-assisted method, and its impact on the mechanical properties of CFs/EP composites was investigated. It was found that the flower-like MgO increased the roughness of carbon fiber surface markedly. So irregular interface between carbon fiber and EP matrix formed. As a result, the mechanical interlocking force between carbon fiber and EP matrix was enhanced significantly. This multiscale boundary morphology could increase the crack propagation path. Thereby, more energy could be consumed and the failure of CFs/EP composites caused by stress concentration could be alleviated effectively. Compared to unmodified CFs/EP composite, MgO-modified CFs/EP composite exhibited a 15.2%, 21.8%, and 14.3% increase in tensile strength, bending strength and impact strength, respectively. Therefore, MgO-modified carbon fiber improved the strength and toughness of carbon fibers significantly. The research provides technique support for the wider application of carbon fibers in polymer composite. Meanwhile, it extends broader ideas for fibers with much more unique surface morphologies in strengthening polymer composite.

-

Key words:

- carbon fiber /

- epoxy resin /

- microwave /

- MgO /

- reinforced and toughened /

- mechanical property

-

表 1 EP和CFs/EP复合材料的拉伸性能

Table 1. Tensile properties of EP and CFs/EP composites

Specimen Tensile strength/MPa Tensile modulus/MPa Elongation at break/% Increase intensile strength/% EP 37.8±0.5 900.3±28.4 4.1±0.3 — Pristine-CFs/EP 58.6±0.4 1194.1±41.6 6.8±0.4 55.0 MgO-modified CFs/EP 67.5±0.6 1587.3±36.5 7.7±0.2 78.6 表 2 EP和CFs/EP复合材料的弯曲和冲击性能

Table 2. Bending and impact properties of EP and CFs/EP composites

Specimen Bending strength/MPa Bending modulus/MPa Impact strength/(kJ·m−2) Increase in bending strength/% EP 42.1±3.2 1.5±0.1 4.4±0.3 — Pristine-CFs/EP 58.5±3.8 2.1±0.2 5.6±0.4 39.0 MgO-modified CFs/EP 71.2±2.5 2.5±0.1 6.4±0.3 69.1 -

[1] TIAN X, HAN S, ZHUANG Q, et al. Surface modification of staple carbon fiber by dopamine to reinforce natural latex composite[J]. Polymers, 2020, 12(4): 988. doi: 10.3390/polym12040988 [2] NIE H J, SHEN X J, TANG B L, et al. Effectively enhanced interlaminar shear strength of carbon fiber fabric/epoxy composites by oxidized short carbon fibers at an extremely low content[J]. Composites Science and Technology, 2019, 183: 107803. doi: 10.1016/j.compscitech.2019.107803 [3] HIREMATH N, YOUNG S, GHOSSEIN H, et al. Low cost textile-grade carbon-fiber epoxy composites for automotive and wind energy applications[J]. Composites Part B:Engineering, 2020, 198: 108156. doi: 10.1016/j.compositesb.2020.108156 [4] 杨智勇, 张东, 顾春辉, 等. 国外空天往返飞行器用先进树脂基复合材料研究与应用进展[J]. 复合材料学报, 2022, 39(7): 3029-3043. doi: 10.13801/j.cnki.fhclxb.20220325.004YANG Zhiyong, ZHANG Dong, GU Chunhui, et al. Research and application of advanced resin matrix composites for aerospace shuttle vehicles abroad[J]. Acta Materiae Compositae Sinica, 2022, 39(7): 3029-3043 (in Chinese). doi: 10.13801/j.cnki.fhclxb.20220325.004 [5] MA R, LI W, HUANG M, et al. The reinforcing effects of dendritic short carbon fibers for rigid polyurethane composites[J]. Composites Science and Technology, 2019, 170: 128-134. doi: 10.1016/j.compscitech.2018.11.047 [6] SIRIVEDIN S, FENNER D, NATH R, et al. Matrix crack propagation criteria for model short-carbon fibre/epoxy composites[J]. Composites Science and Technology, 2000, 60(15): 2835-2847. doi: 10.1016/S0266-3538(00)00167-6 [7] REALE BATISTA M D, DRZAL L T. Carbon fiber/epoxy matrix composite interphases modified with cellulose nanocrystals[J]. Composites Science and Technology, 2018, 164: 274-281. doi: 10.1016/j.compscitech.2018.05.010 [8] YENIER Z, ALTAY L, SARIKANAT M. Effect of surface modification of carbon fiber on mechanical properties of carbon/epoxy composites[J]. Emerging Materials Research, 2020, 9(1): 1-8. [9] SUN T, ZHANG X, QIU B, et al. Controllable construction of gradient modulus intermediate layer on high strength and high modulus carbon fibers to enhance interfacial properties of epoxy composites by efficient electrochemical grafting[J]. Composites Part B: Engineering, 2022, 247: 110279. doi: 10.1016/j.compositesb.2022.110279 [10] KAYNAK C, ORGUN O, TINCER T. Matrix and interface modification of short carbon fiber-reinforced epoxy[J]. Polymer Testing, 2005, 24(4): 455-462. doi: 10.1016/j.polymertesting.2005.01.004 [11] LIU X, LI W, YANG J, et al. The effects of string-like copper plated short carbon fibers reinforced rigid polyurethane composites[J]. Journal of Applied Polymer Science, 2021, 139: e51968. [12] HUANG M, LI W, LIU X, et al. The effects of cauliflower-like short carbon fibers on the mechanical properties of rigid polyurethane matrix composites[J]. Polymer Testing, 2020, 89: 106718. doi: 10.1016/j.polymertesting.2020.106718 [13] ZHOU Y, LI W, LIU H, et al. Reinforcement of nest-like Zn layers on the surface of carbon fibers for rigid polyurethane composites[J]. Polymers for Advanced Technologies, 2022, 33(7): 2289-2299. doi: 10.1002/pat.5681 [14] ZHAO G Z, LIU J H, XU L, et al. Comparative study of conventional and microwave heating of polyacrylonitrile-based fibres[J]. Journal of Polymer Engineering, 2021, 41(3): 175-183. doi: 10.1515/polyeng-2020-0167 [15] CHING LAU C, KEMAL BAYAZIT M, REARDON P J T, et al. Microwave intensified synthesis: Batch and flow chemistry[J]. Chemical Record, 2019, 19(1): 172-187. doi: 10.1002/tcr.201800121 [16] ZHONG G, XU S, DONG Q, et al. Rapid, universal surface engineering of carbon materials via microwave-induced carbothermal shock[J]. Advanced Functional Materials, 2021, 31(18): 2010968. doi: 10.1002/adfm.202010968 [17] ANSARI A, ALI A, ASIF M, et al. Microwave-assisted MgO NP catalyzed one-pot multicomponent synthesis of polysubstituted steroidal pyridines[J]. New Journal of Chemistry, 2018, 42(1): 184-197. doi: 10.1039/C7NJ03742B [18] CHAITANYA S, CHEEDARALA R K, SONG J I. Microwave-synthesized Mg2+ doped jute fibers and their application as a reinforcement in biocomposites[J]. Composites Part B: Engineering, 2020, 197: 108154 doi: 10.1016/j.compositesb.2020.108154 [19] 中国国家标准化管理委员会. 树脂浇铸体性能试验方法: GB/T 2567—2021[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People's Republic of China. Resin casting performance test method: GB/T 2567—2021[S]. Beijing: China Standards Press, 2008(in Chinese). [20] 中国国家标准化管理委员会. 胶粘剂 拉伸剪切强度的测定(刚性材料对刚性材料): GB/T 7124—2008[S]. 北京: 中国标准出版社, 2003.Standardization Administration of the People's Republic of China. Adhesives—Determination of tensile lap-shear strength of rigid-to-rigid bonded assemblies: GB/T 7124—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [21] LIN Y, ZHANG Q, LIU T, et al. Sol-gel MgO coating on glass microspheres for inhibiting excessive interfacial reaction in Al-Mg matrix syntactic foam[J]. Journal of Alloys and Compounds, 2019, 798: 59-66. doi: 10.1016/j.jallcom.2019.05.258 [22] YANG L, CHEN Y, XU Z, et al. Effect of surface modification of carbon fiber based on magnetron sputtering technology on tensile properties[J]. Carbon, 2023, 204: 377-386. doi: 10.1016/j.carbon.2022.12.045 [23] HAN P, MA L, SONG G, et al. Strengthening and modulating interphases in carbon fiber/epoxy composites by grafting dendritic polyetheramine with different molecular weights onto carbon fiber[J]. Polymer Composites, 2018, 40: E1526-E1536. [24] NARDUCCI F, LEE K Y, PINHO S T. Interface micro-texturing for interlaminar toughness tailoring: A film-casting technique[J]. Composites Science and Technology, 2018, 156: 203-214. doi: 10.1016/j.compscitech.2017.10.016 [25] CHANG L, GUO W J, TANG Q H. Assessing the tensile shear strength and interfacial bonding mechanism of poplar plywood with high-density polyethylene films as adhesive[J]. BioResources, 2017, 12(1): 571-585. [26] DONG J, HE J, JIA C, et al. Growth of carbon black onto continuous carbon fiber to produce composites with improved mechanical and interfacial properties: A step closer to industrial production[J]. Composites Science and Technology, 2019, 173: 83-89. doi: 10.1016/j.compscitech.2019.01.024 [27] YUAN X, ZHU B, CAI X, et al. Influence of different surface treatments on the interfacial adhesion of graphene oxide/carbon fiber/epoxy composites[J]. Applied Surface Science, 2018, 458: 996-1005. doi: 10.1016/j.apsusc.2018.06.161 [28] HE Z L, XU J K, ZHANG L, et al. Dramatically enhanced tensile strength and impact toughness of polydicyclopentadiene composites by covalent bond formation between phenyl-functionalized silica and dicyclopentadiene[J]. Composites Part B: Engineering, 2019, 170: 31-40. doi: 10.1016/j.compositesb.2019.04.040 [29] ZHANG X, FAN X, YAN C, et al. Interfacial microstructure and properties of carbon fiber composites modified with graphene oxide[J]. ACS Applied Materials & Interfaces, 2012, 4(3): 1543-1552. doi: 10.1021/am201757v -

下载:

下载: