Effect of SMA laying configuration in GFRP patch on thermal vibration characteristics of repair laminate

-

摘要: 在复合材料中加入形状记忆合金(SMA)制成的纤维增强材料具有高强度、高阻尼与良好的自修复性等优点,可明显提高修理结构刚度及抗剥离性。为了探究热环境下玻璃纤维补片内嵌不同铺设数量与方式的SMA修理板的振动特性,基于Liang-Rogers的SMA本构模型编制用户自定义材料子程序(UMAT),实现有限元精确求解。对比传统修理板与本文制备的SMA修理板的振型、固有频率及阻尼比变化情况,探究不同温度下SMA铺设构型对双面贴补修理玻璃纤维层合板振动特性的影响。实验与仿真结果表明:相较于单线型(D)与垂直交叉型(C),斜铺交叉型(X) SMA修理板前三阶振型更接近传统修理板(Q0),且振型与嵌入的SMA数量无关。SMA相变时,内嵌SMA使修理板前二阶固有频率上升且上升率与SMA数量呈正相关,与SMA铺设方式关系如下:C型>D型>X型。内嵌SMA使修理板耗能能力及阻尼性优于Q0板,与SMA数量呈正相关,与SMA铺设方式关系如下:X型>C型>D型。本文研究的铺设构型中,X24型修理效果最优,其一、二阶固有频率最高可恢复至Q0板的108.47%与112.26%,阻尼比相较于Q0板增大了5.19倍。该工作可以为现有传统复合材料修理向智能复合材料修理技术转变提供参考。

-

关键词:

- SMA /

- 编织玻璃纤维复合材料 /

- 振动特性 /

- 双面贴补修理 /

- 智能材料

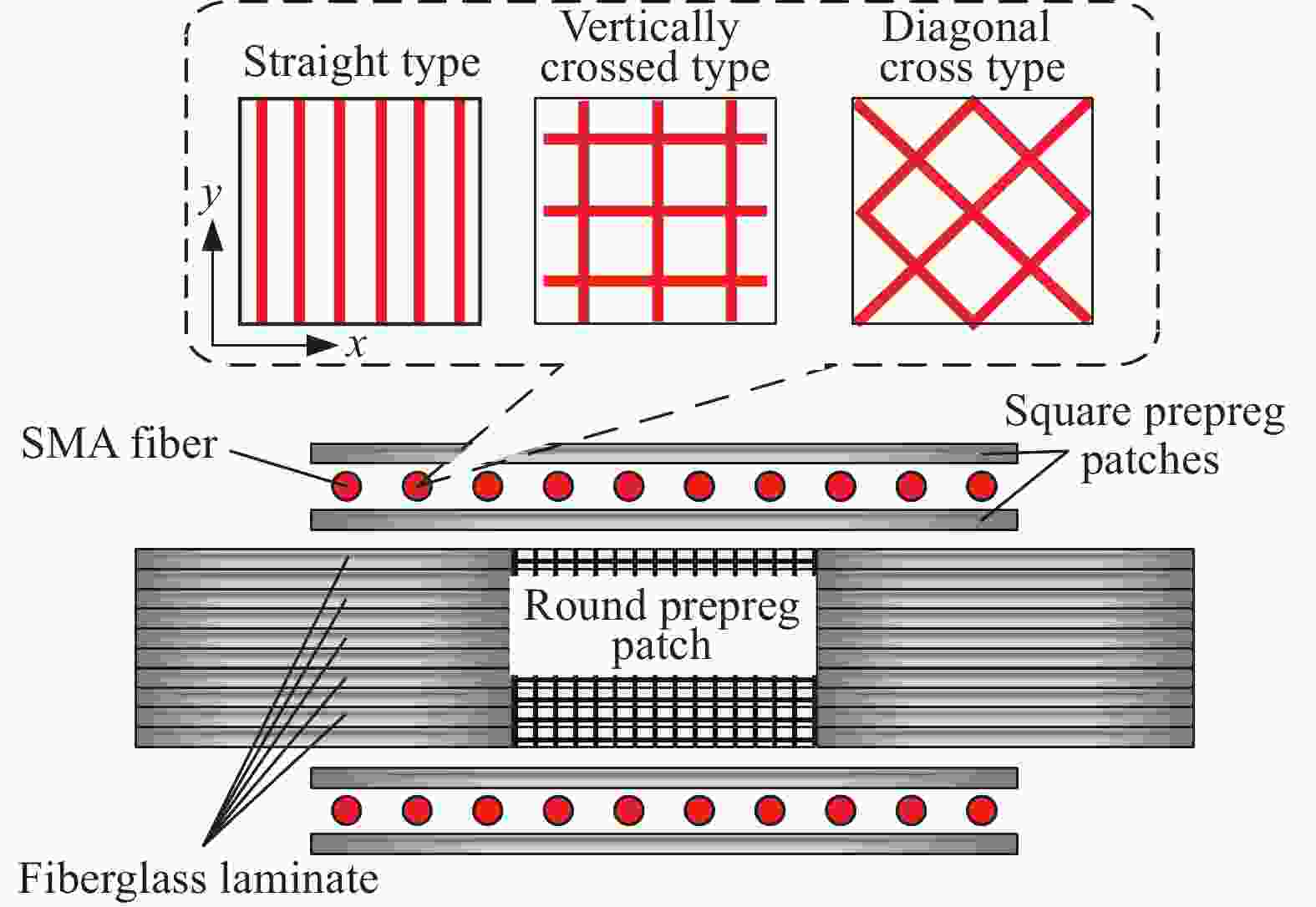

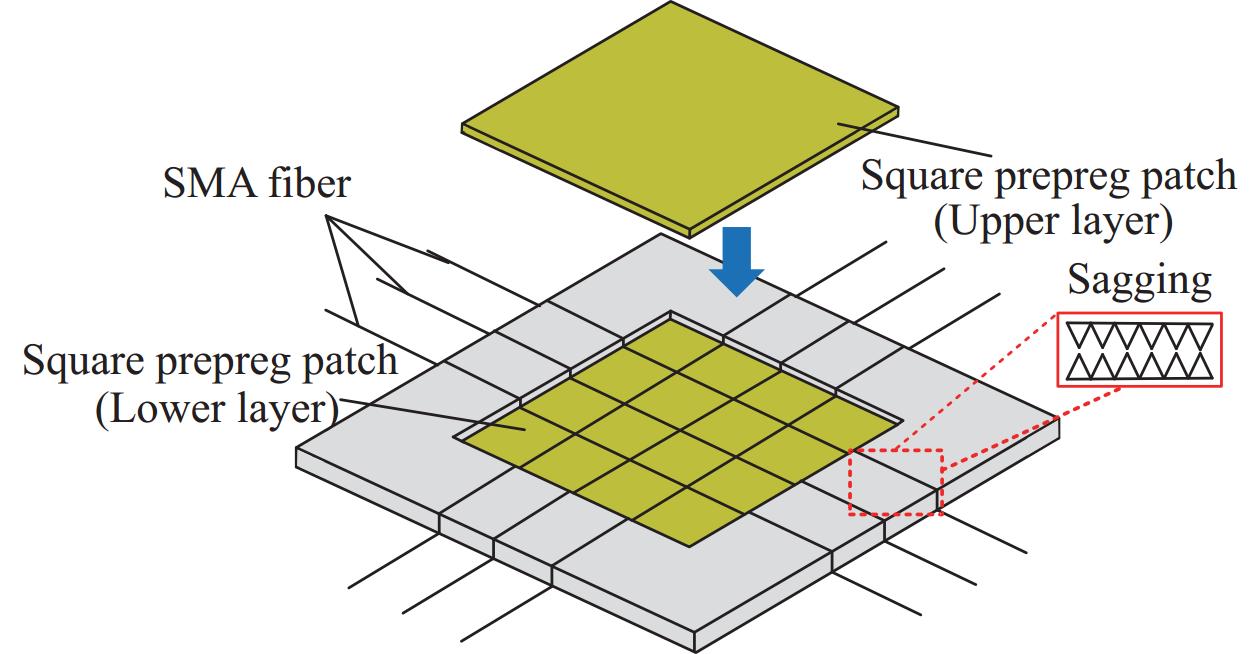

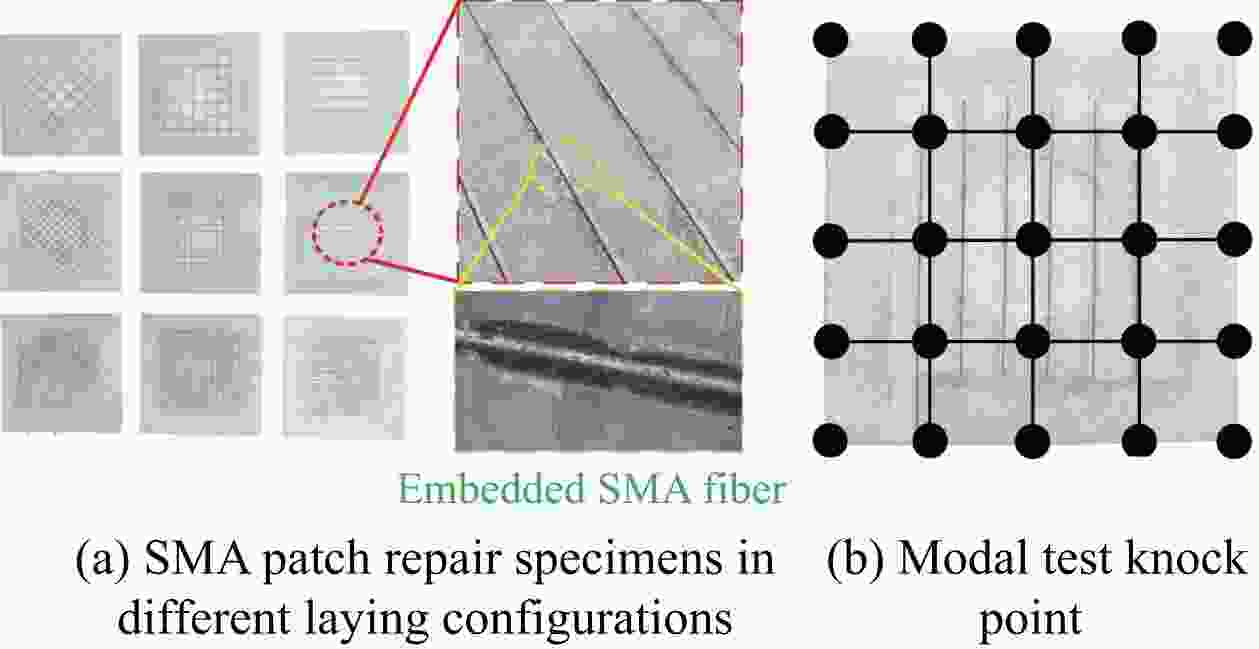

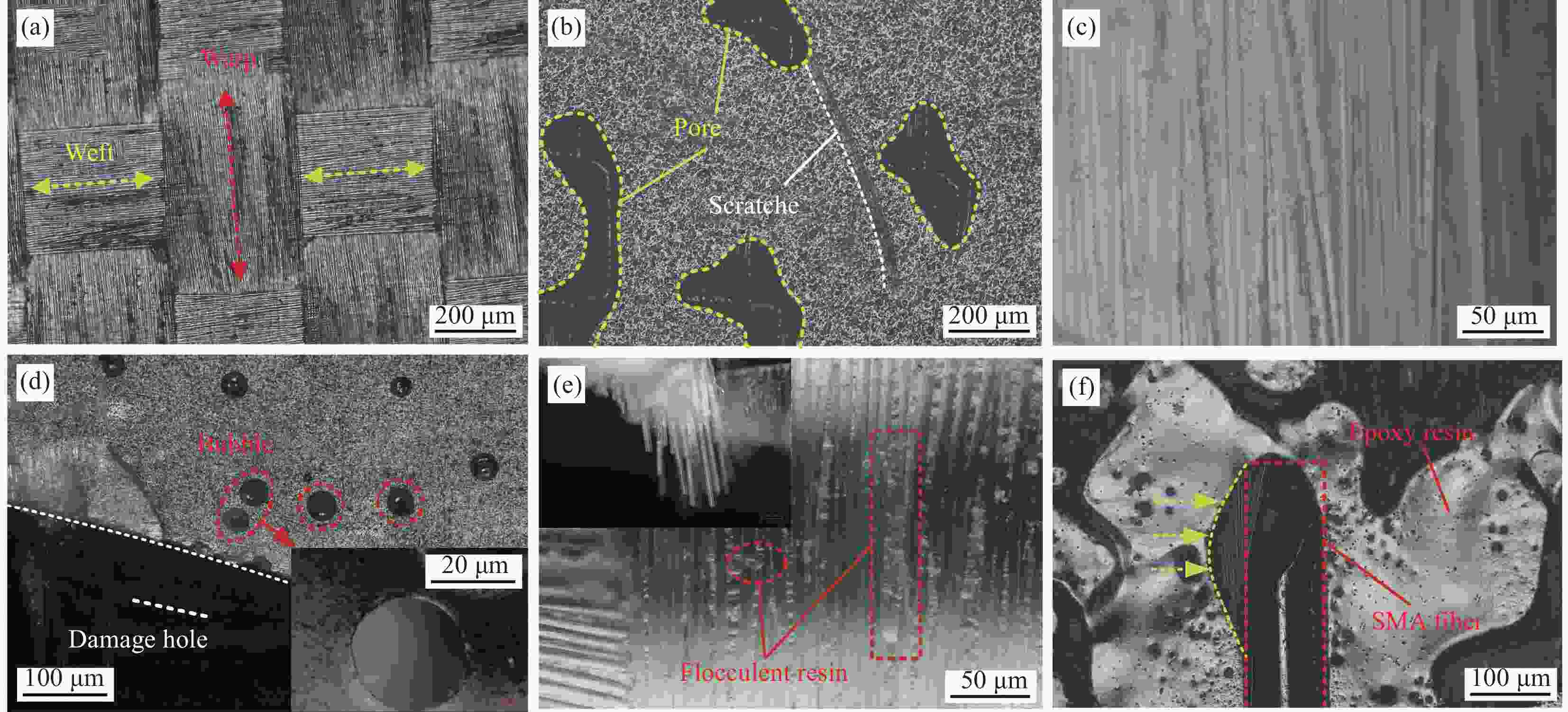

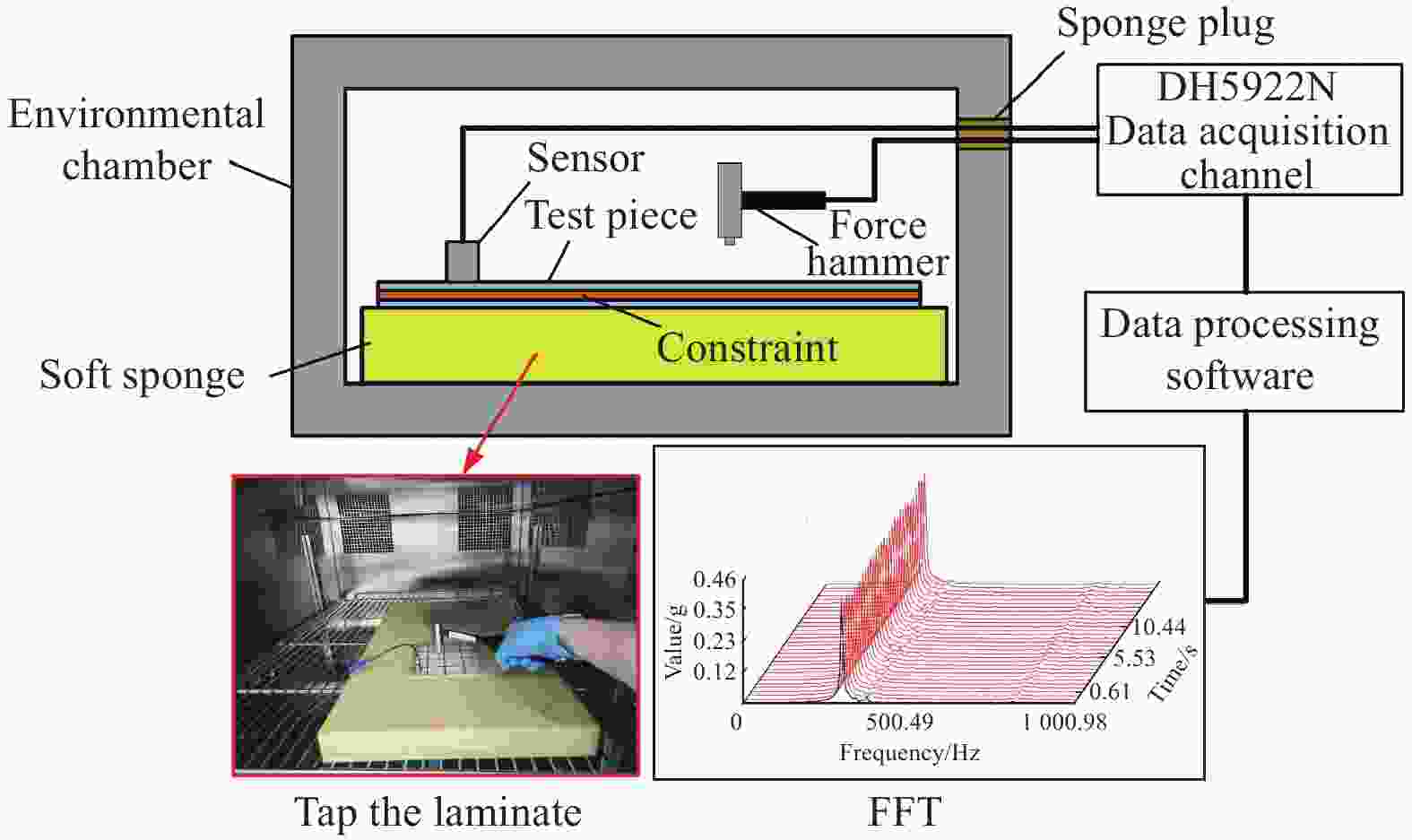

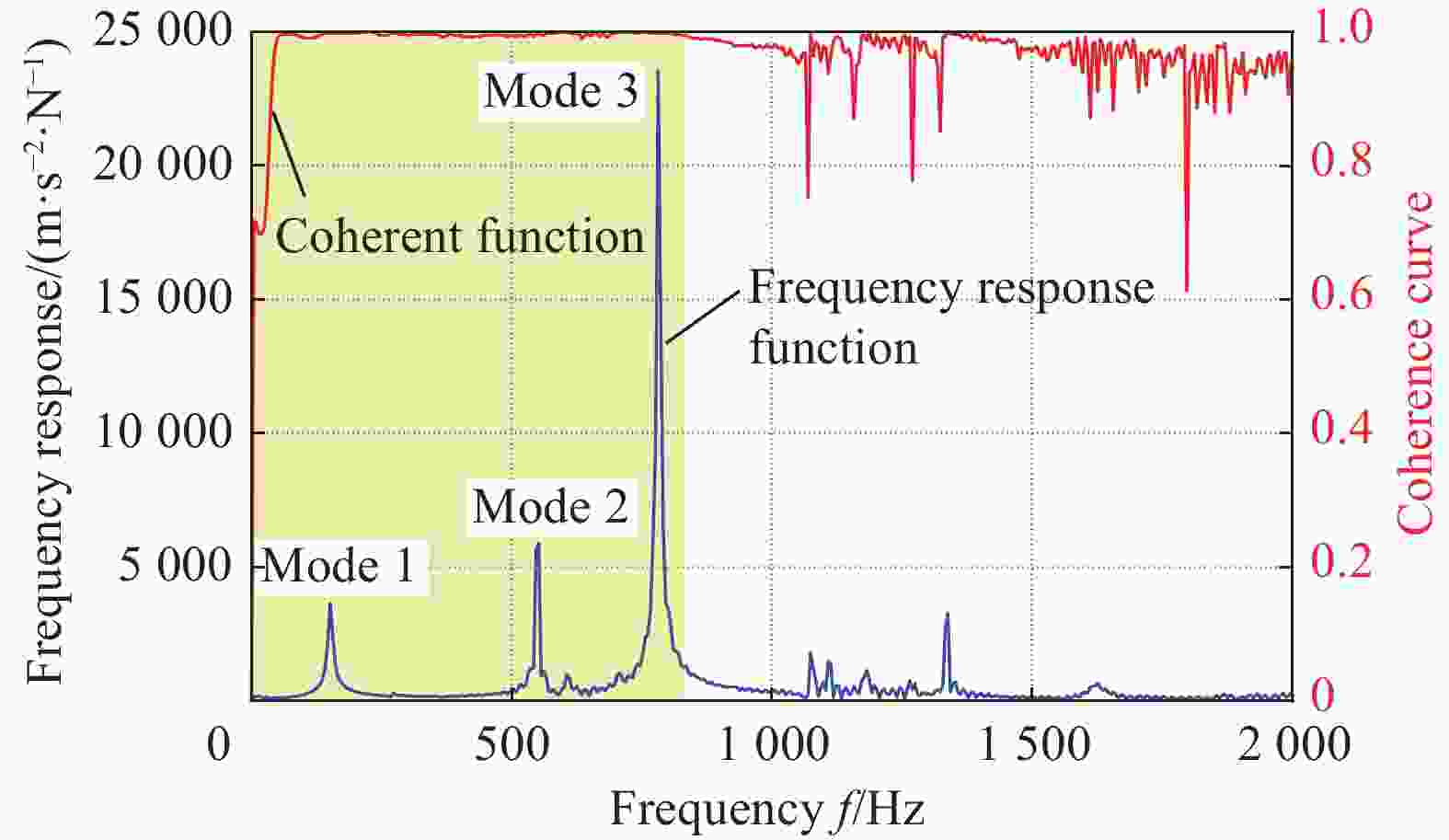

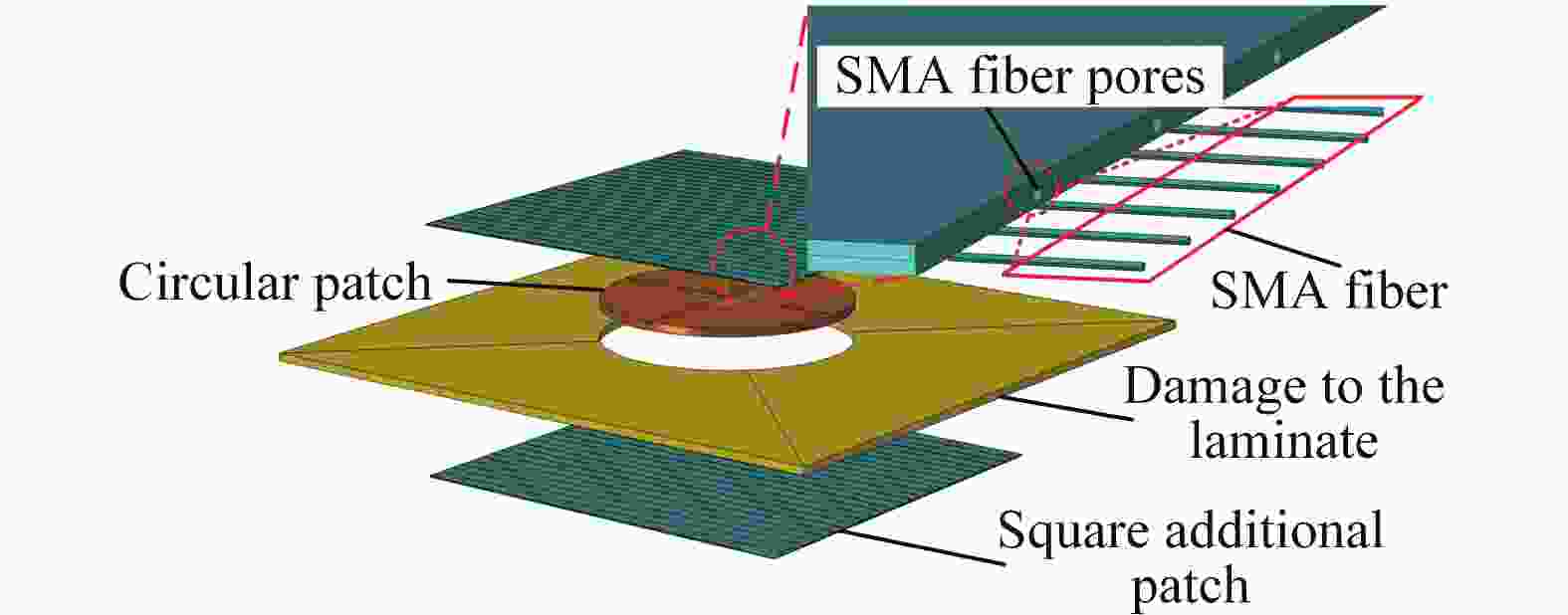

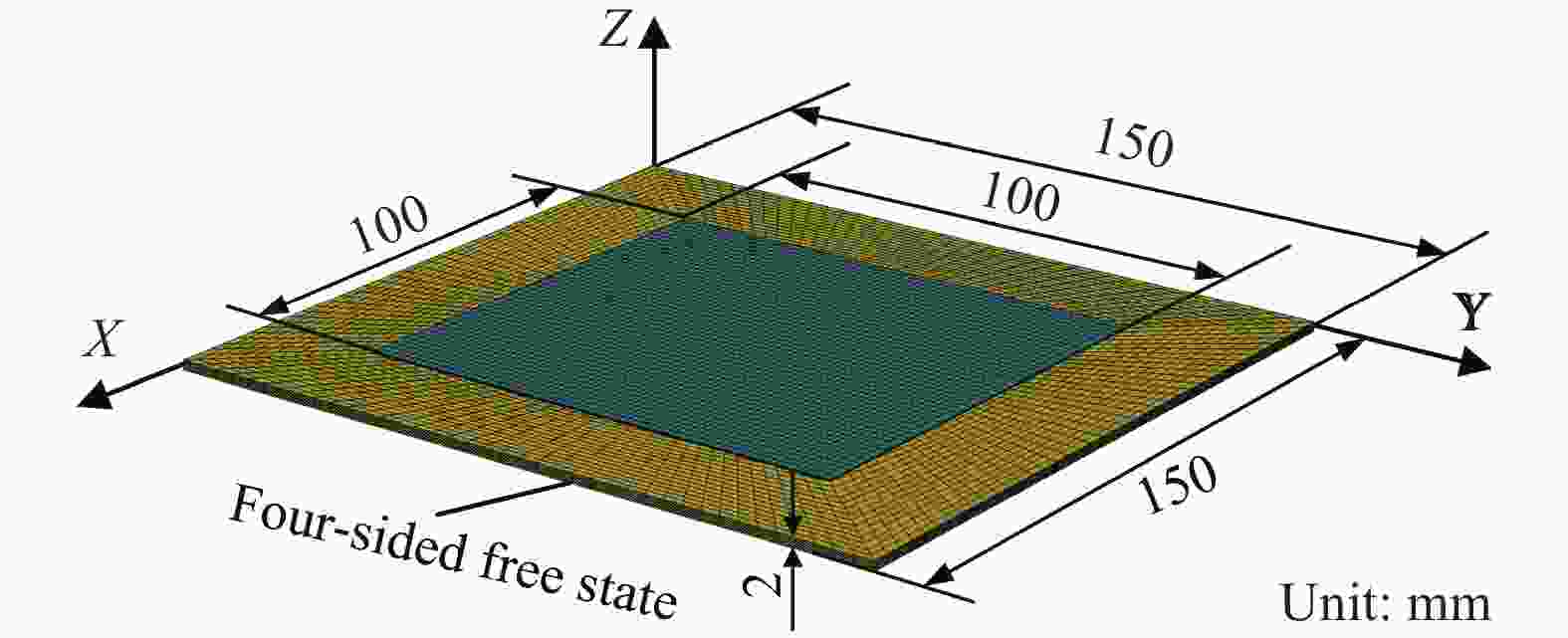

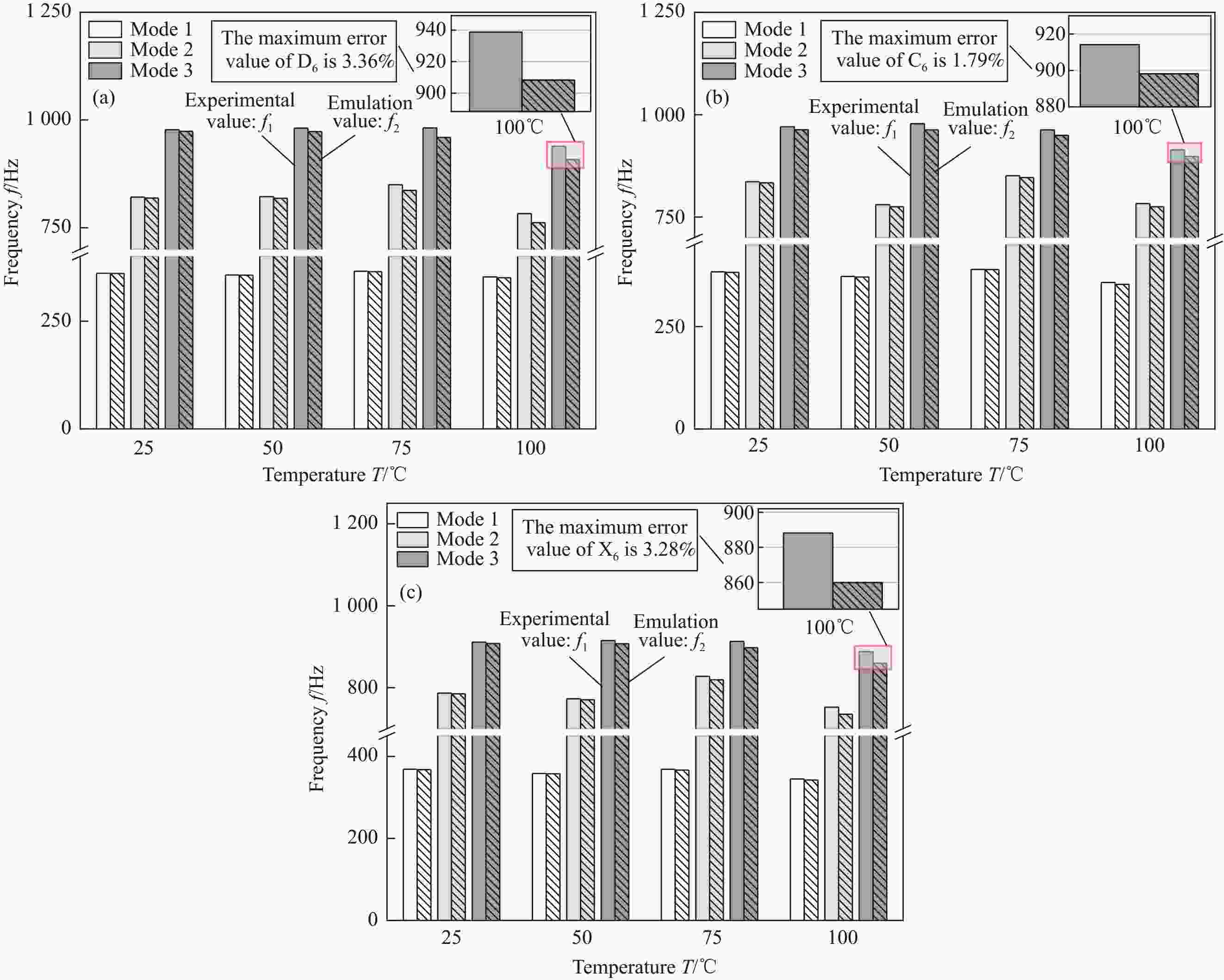

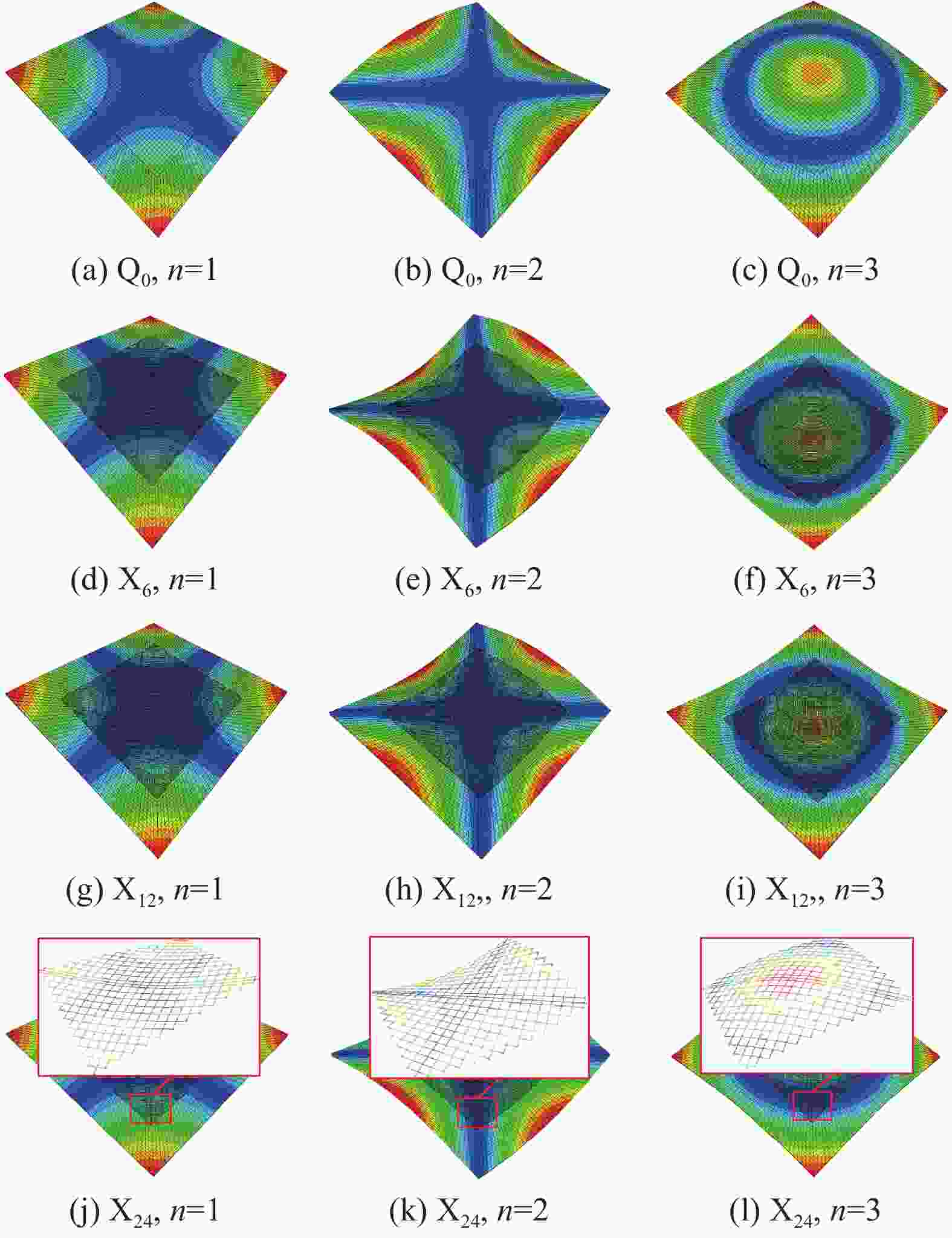

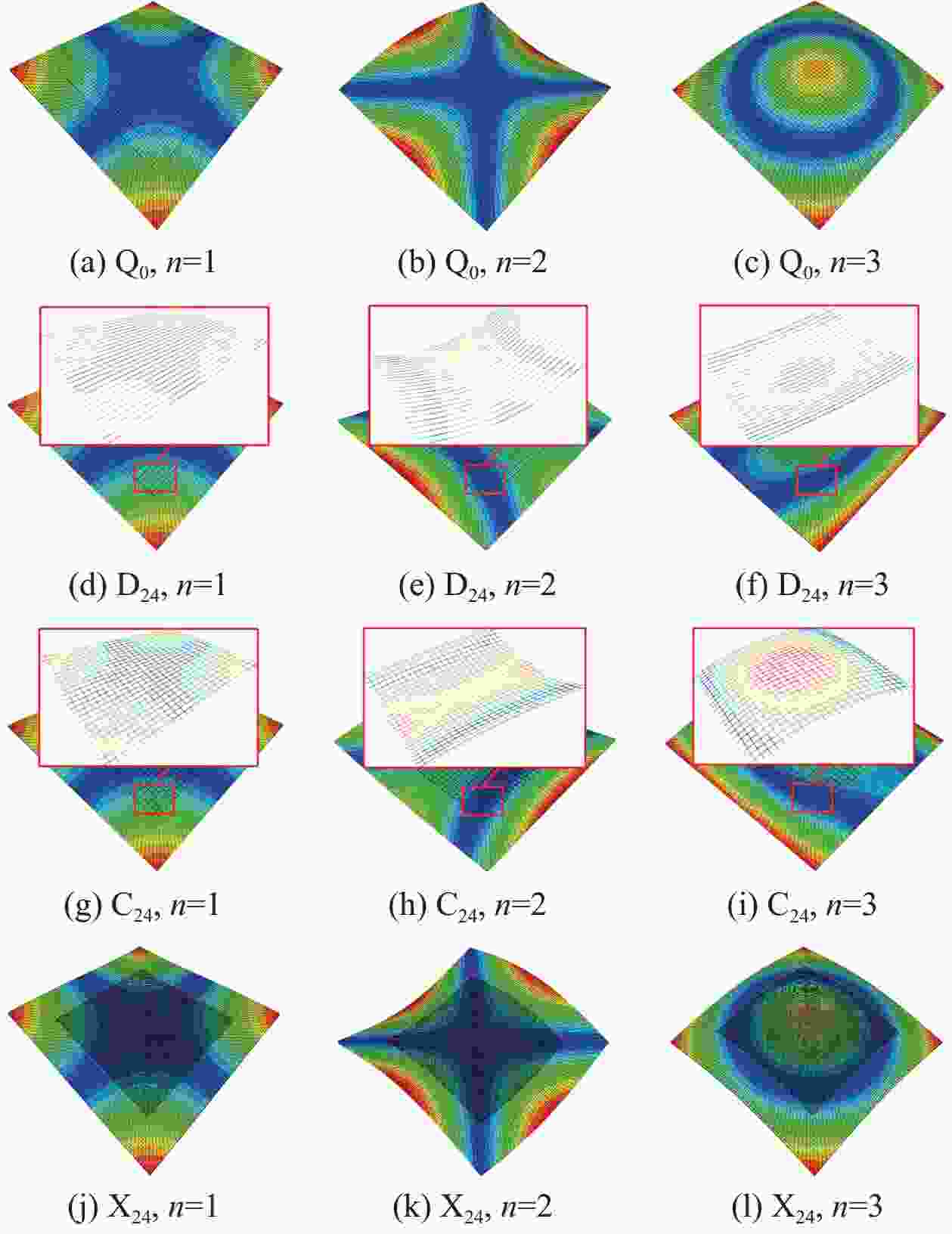

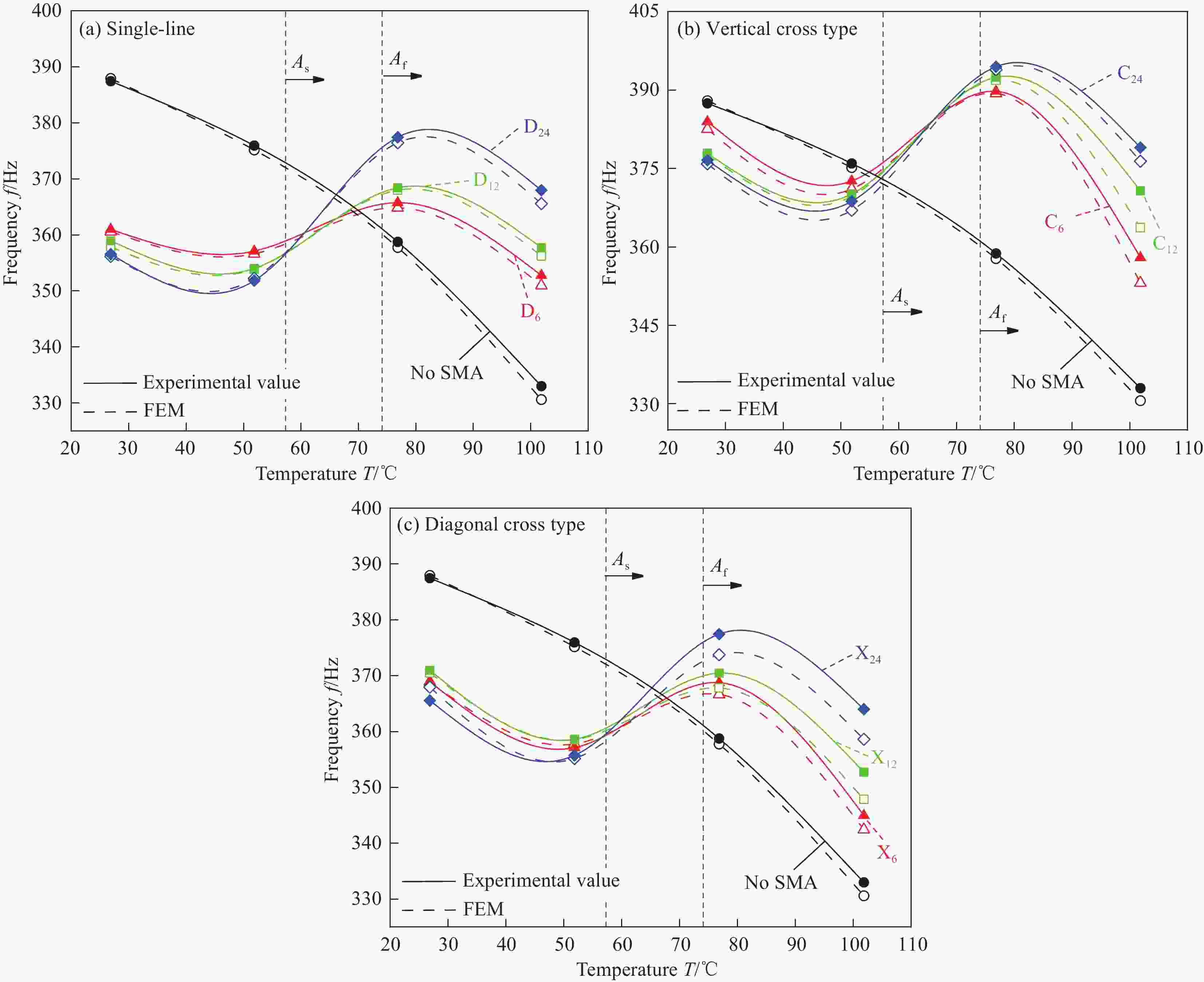

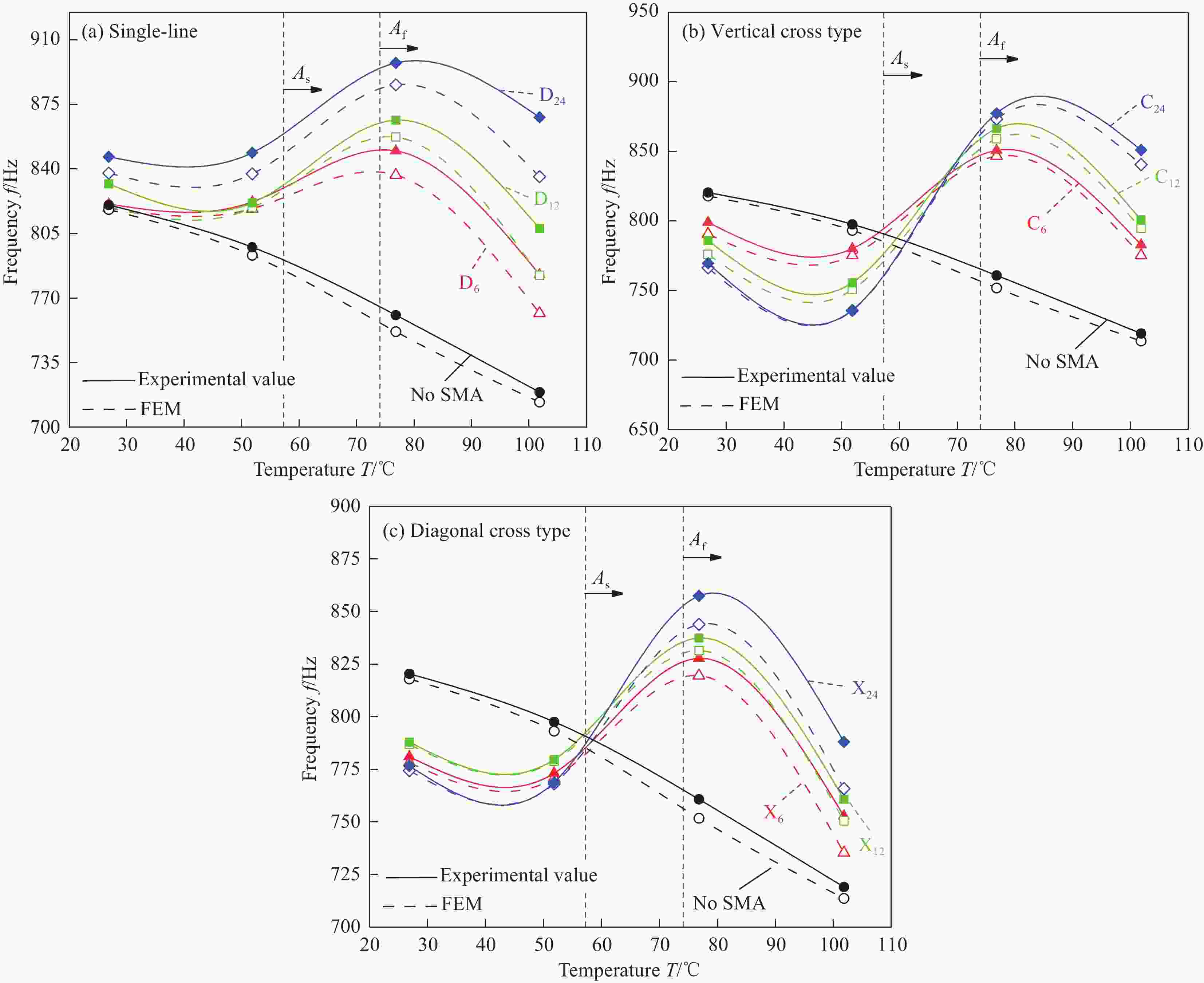

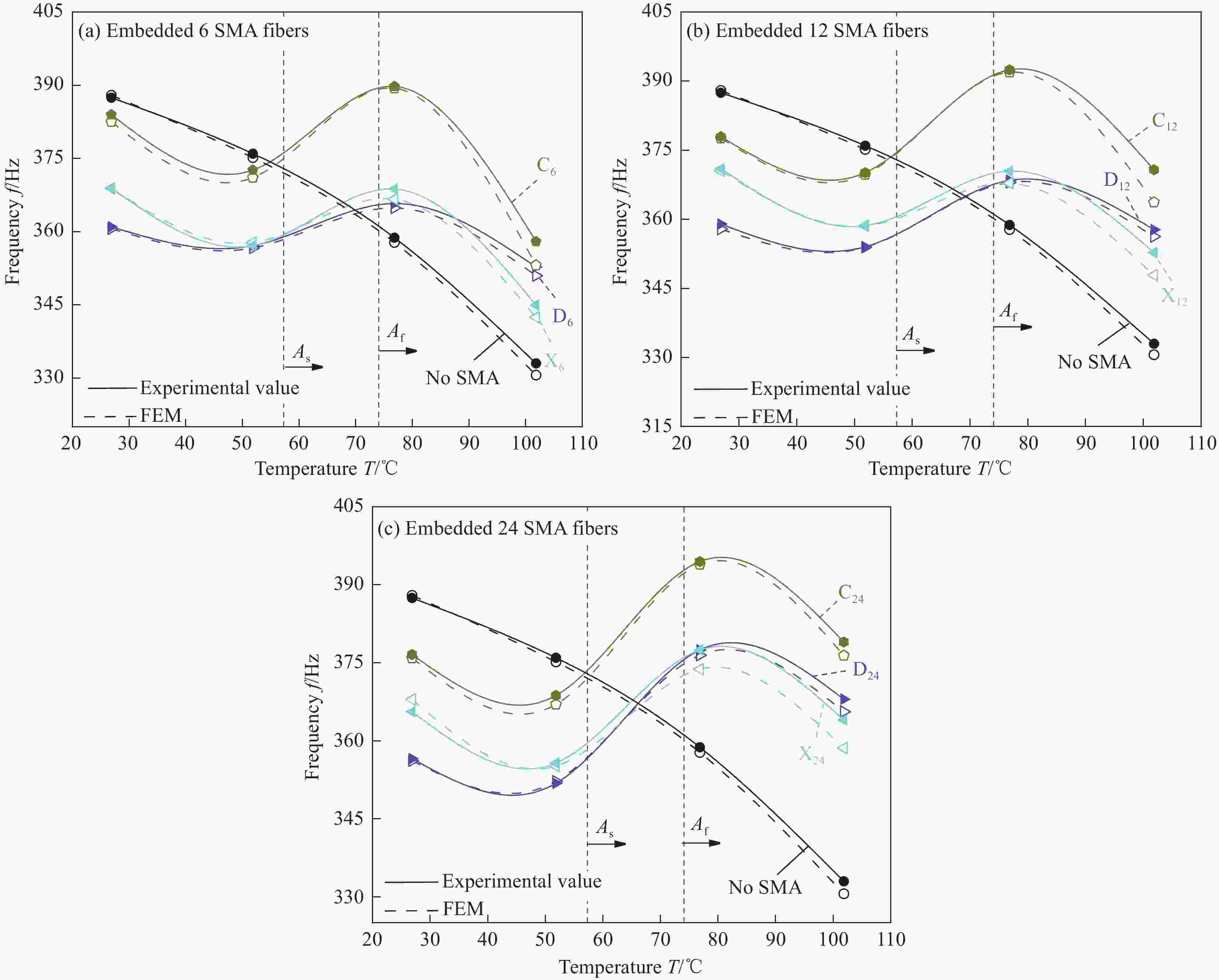

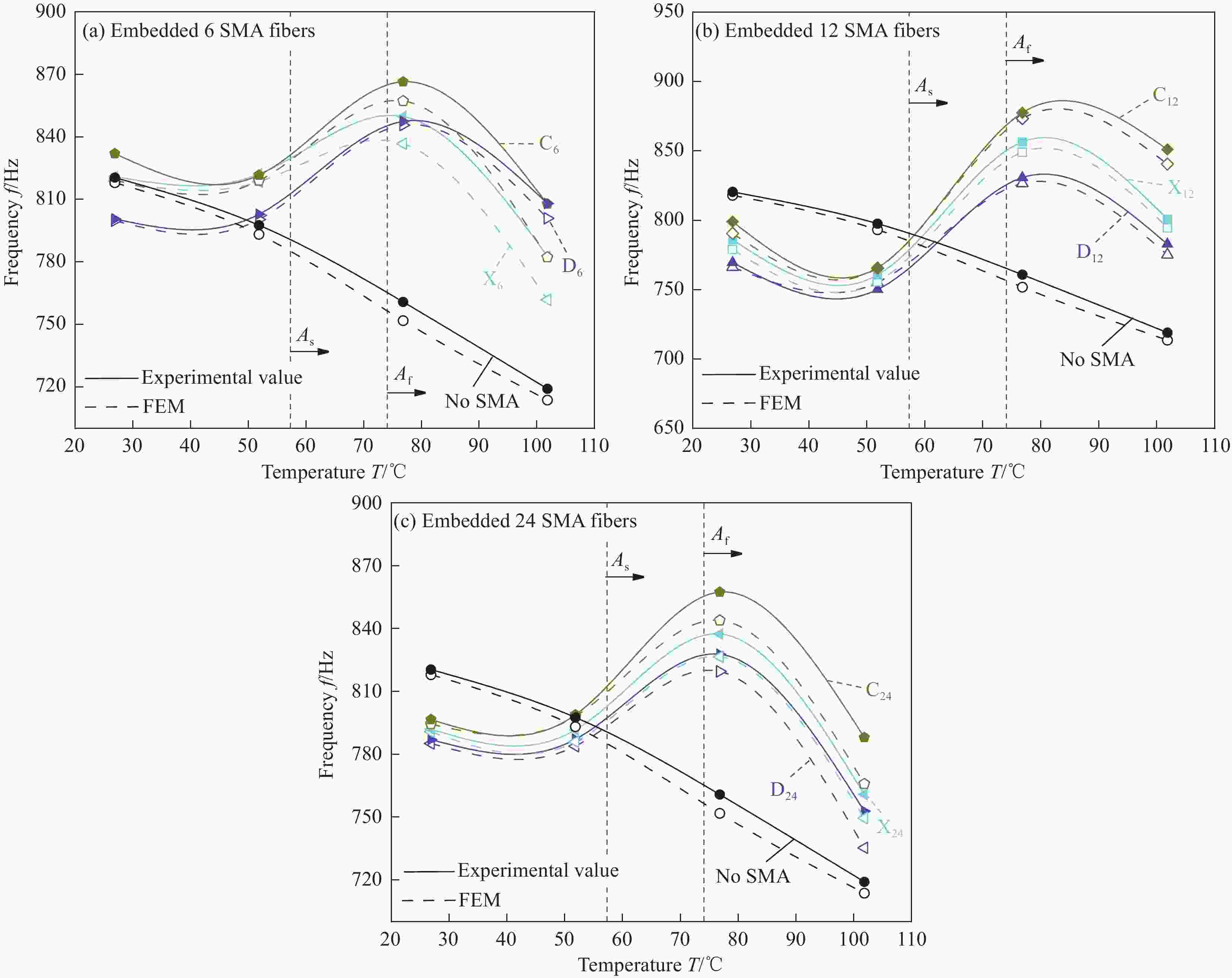

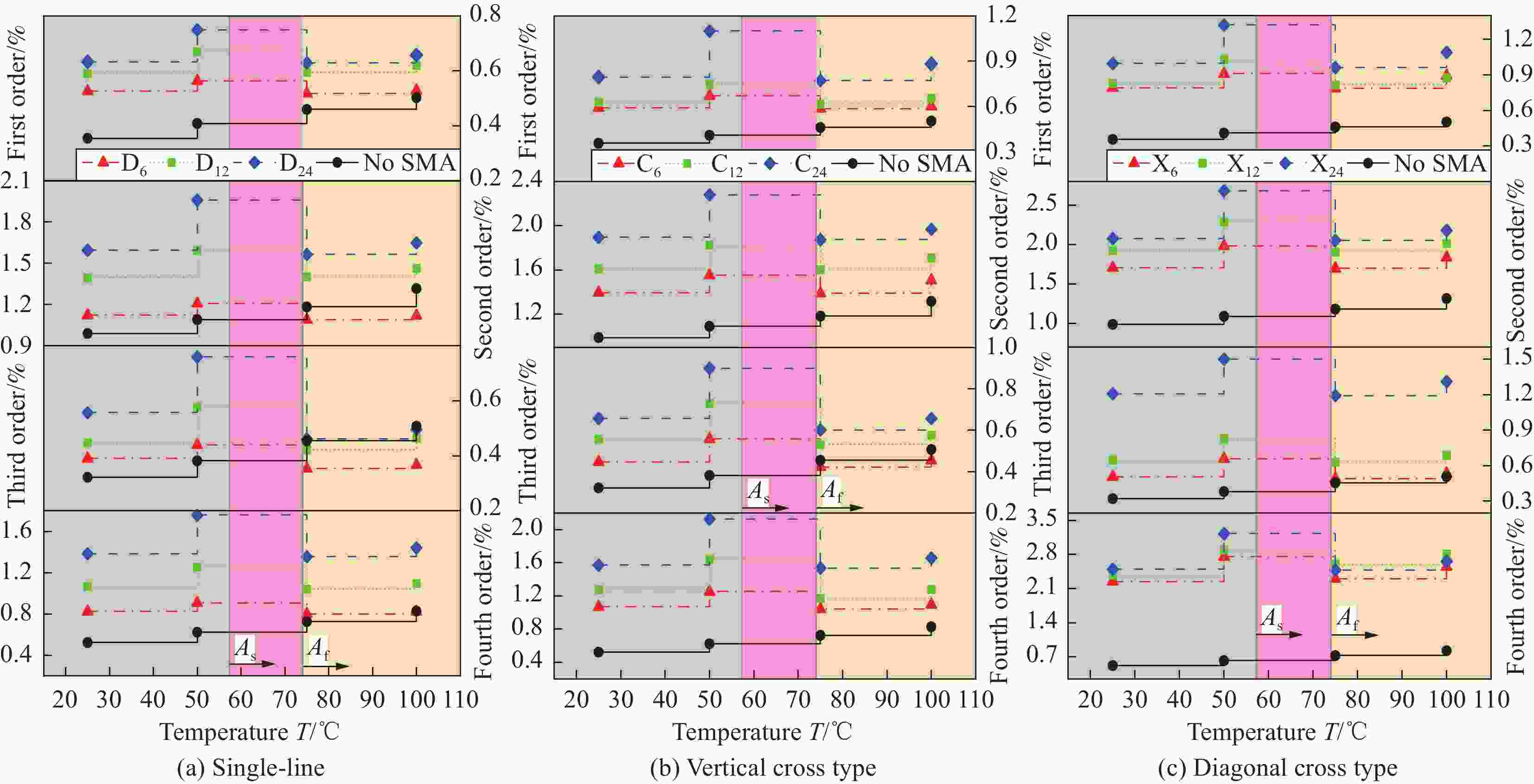

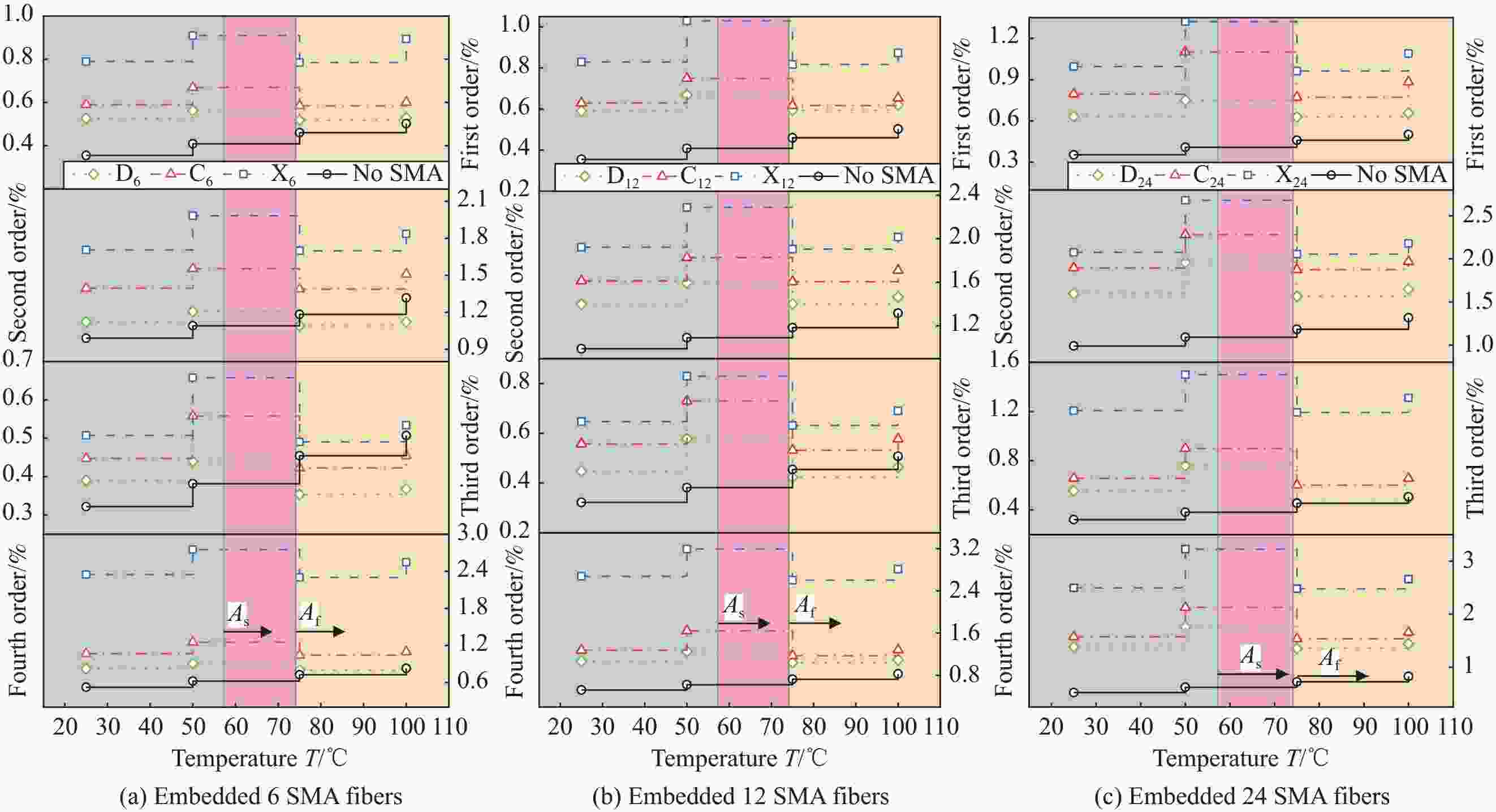

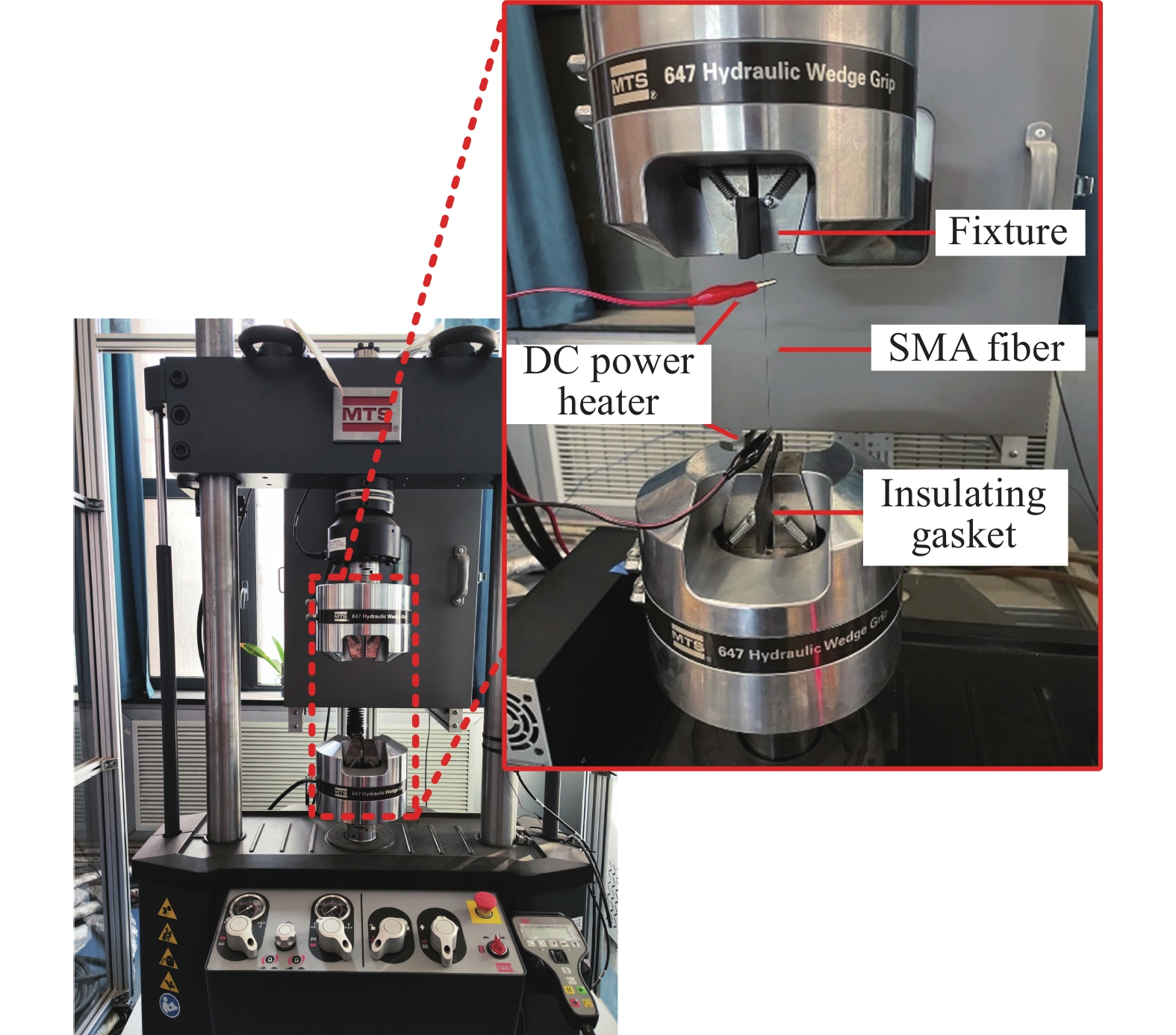

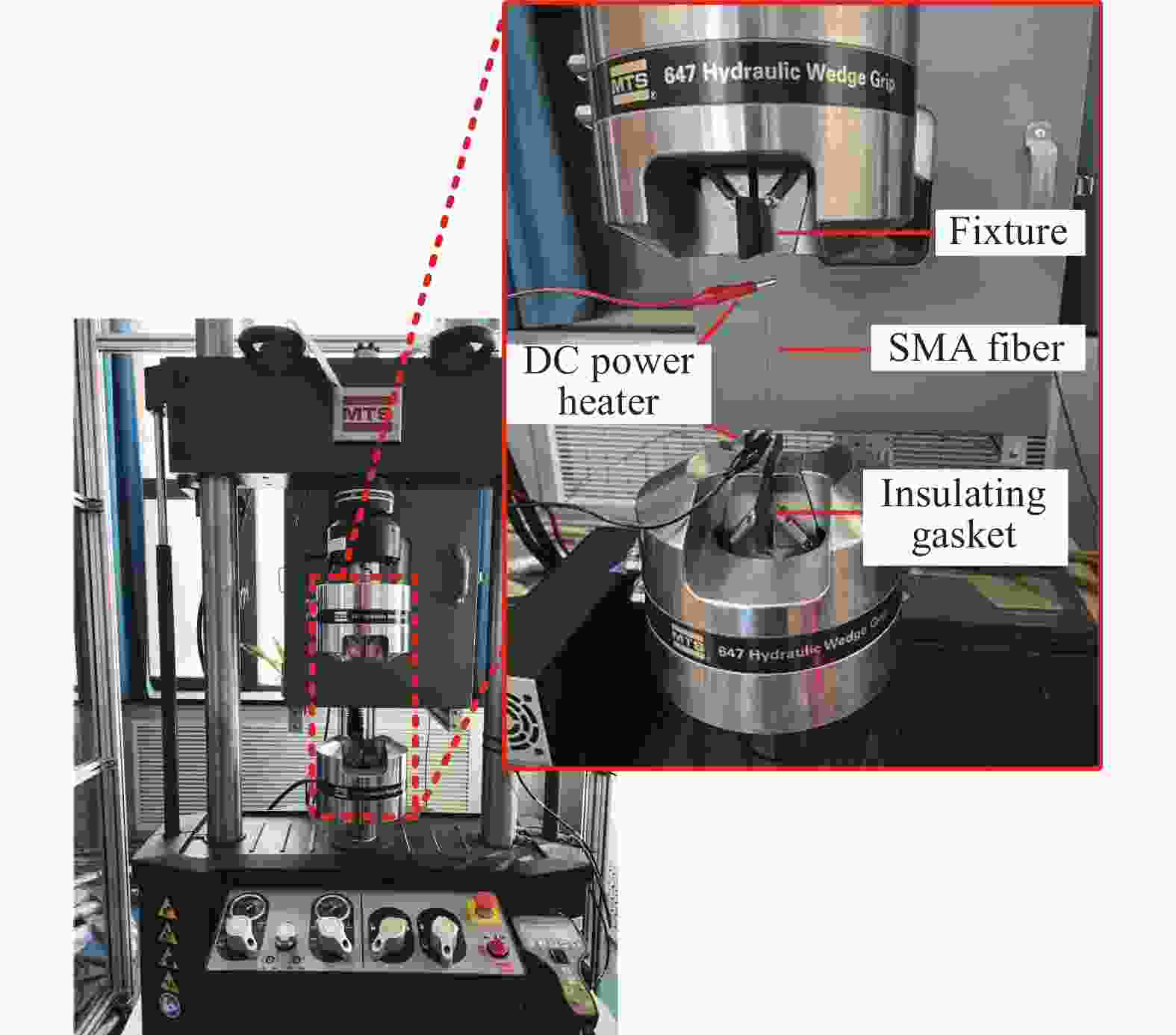

Abstract: Fiber reinforced materials made by adding shape memory alloy (SMA) to composite materials have the advantages of high strength, high damping and good self-repair, which can significantly improve the rigidity and peel resistance of repair structures. In order to explore the vibration characteristics of SMA repair plates with different laying quantities and methods embedded in glass fiber patches under thermal environment, a user-defined material subprogram (UMAT) was developed based on Liang-Rogers' SMA constitutive model to achieve accurate finite element solving. The changes of mode shape, natural frequency and damping ratio of traditional repair plate and SMA repair plate prepared in this paper were compared, and the influence of SMA laying configuration on the vibration characteristics of double-sided patch repair fiberglass laminate was explored at different temperatures. Experimental and simulation results show that compared with single-line (D) and vertical cross (C), the first three-order mode shape of the diagonal cross (X) SMA repair plate is closer to the traditional repair plate (Q0), and the mode shape is independent of the number of embedded SMAs. When the SMA phase changes, the embedded SMA increases the natural frequency of the first second order of the repair plate, and the rise rate is positively correlated with the number of SMA, which is related to the SMA laying mode as follows: C-type> D-type> X-type. The embedded SMA makes the energy dissipation capacity and damping of the repair board better than that of the Q0 board, which is positively correlated with the number of SMA, and the relationship with the SMA laying method is as follows: X-type> C-type> D-type. In the laying configuration studied in this paper, the X24 type has the best repair effect, and its natural frequency of the first and second orders can be restored to 108.47% and 112.26% of the Q0 plate, and the damping ratio is 5.19 times higher than that of the Q0 plate. This work can provide a reference for the technical transformation of existing traditional composite repair to intelligent composite material repair. -

表 1 SMA纤维性能参数

Table 1. SMA fiber performance parameters

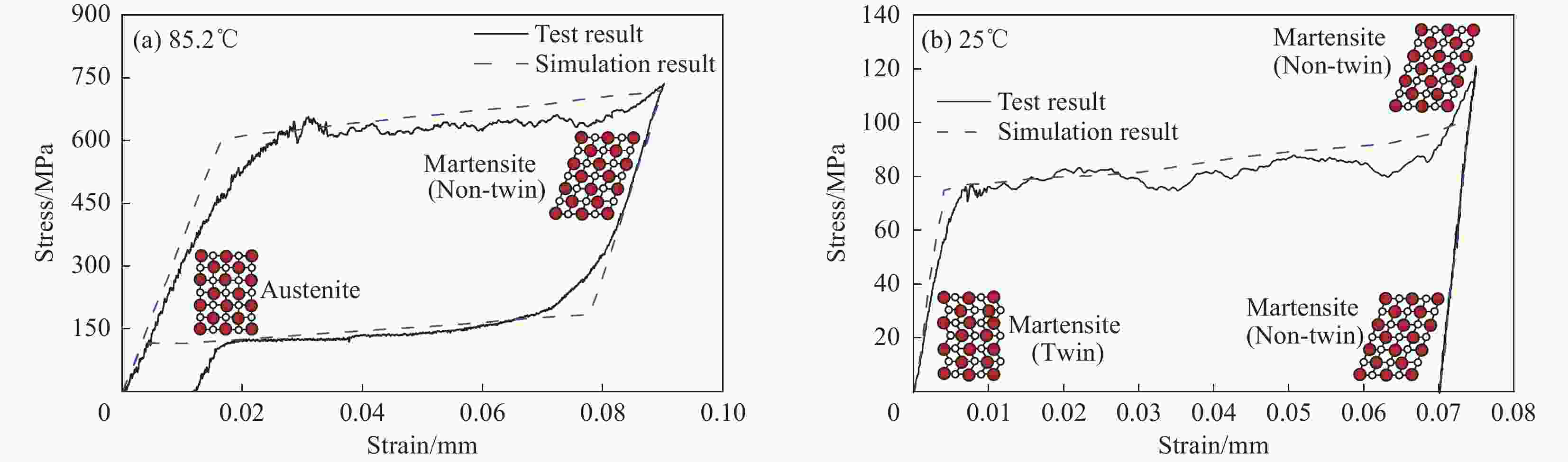

Property Value Modulus of elasticity of martensite EM/GPa 21.36 Modulus of elasticity of austenitic EA/GPa 38.47 Modulus of martensite thermoelasticity ΘM/(MPa·℃−1) 0.102 Austenitic thermoelastic modulus ΘA/(MPa·℃−1) 0.567 Martensitic phase transition start temperature Ms/℃ 34.3 Martensite phase transition end temperature Mf/℃ 26.1 Austenite phase transition start temperature As/℃ 57.3 Austenite phase transition end temperature Af/℃ 74.1 Martensite critical phase change stress coefficient $ C\mathrm{_M} $/(MPa·℃−1) 10.81 Austenite critical phase change stress coefficient $ C\mathrm{_A} $/(MPa·℃−1) 6.228 Critical phase transition begins stress $ \sigma_{\mathrm{s}}^{\text{cr}} $/MPa 73.21 Critical phase transition end stress $ \sigma_{\mathrm{f}}^{\text{cr}} $/MPa 87.63 Coefficient of thermal expansion of austenite $ \alpha\mathrm{_A} $/(10−6 ℃−1)[5] 10.26 Coefficient of thermal expansion of martensite $ \alpha_{\mathrm{M}} $/(10−6 ℃−1)[5] 6.60 Poisson's ratio $ \upsilon\mathrm{_S} $[5] 0.33 Density ρ/(kg·m−3)[5] 6450 Maximum residual strain $ \varepsilon\mathrm{\mathrm{\mathrm{\mathrm{_L}}}} $/% 7.0 Note:Data are from reference [5] and manufacturer. 表 2 Hansort 8313预浸料的性能参数

Table 2. Performance parameters of Hansort 8313 prepreg

Elastic modulus

E12, E23, E31/GPaShear modulus

G12, G23, G31/GPaPoisson's ratio

μ12, μ23, μ31Density

ρ/(kg·m−3)Coefficient of thermal Humidity expansion α1 α2 β1 β2 15.4 4.47 0.43 1660 −0.3×10−6 28.1×10−6 0 0.44 表 3 SMA纤维铺设参数及修理板分组编号

Table 3. SMA fiber laying parameters and repair plate group number

No. SMA fiber laying method Number of SMA fibers laid/root Fiber spacing/mm D6 Single-lined (D) 6 16.67 D12 12 8.33 D24 24 4.17 C6 Vertically crossed type (C) 6 23.57 C12 12 11.79 C24 24 5.89 X6 Diagonal cross type (X) 6 23.57 X12 12 11.79 X24 24 5.89 Q0 Traditional patching 0 — -

[1] 孔方昀, 常孟周, 王振清, 等. 形状记忆合金-玻璃纤维/环氧树脂复合材料在振动边界条件下的低速冲击数值模拟[J]. 复合材料学报, 2019, 36(10): 2316-2329. doi: 10.13801/j.cnki.fhclxb.20181119.006KONG Fangyun, CHANG Mengzhou, WANG Zhenqing, et al. Numerical simulation of low-velocity shock of shape memory alloy-glass fiber/epoxy resin composites under vibration boundary conditions[J]. Acta Materiae Compositae Sinica, 2019, 36(10): 2316-2329(in Chinese). doi: 10.13801/j.cnki.fhclxb.20181119.006 [2] 陈邵杰. 复合材料结构修理指南[M]. 北京: 航空工业出版社, 2001: 42-43.CHEN Shaojie. Repair guide of composite structure[M]. Beijing: Aviation Industry Press, 2001: 42-43(in Chinese). [3] ZHOU W, JI X, YANG S, et al. Review on the performance improvements and non-destructive testing of patches repaired composites[J]. Composite Structures, 2021, 263: 113659. doi: 10.1016/j.compstruct.2021.113659 [4] 刘兵飞, 刘亚冬, 张亚楠. 形状记忆合金在复合材料损伤修复中的应用[J]. 复合材料学报, 2022, 39(4): 1834-1846. doi: 10.13801/j.cnki.fhclxb.20210608.004LIU Bingfei, LIU Yadong, ZHANG Yanan. Application of shape memory alloy in damage repair of composite materials[J]. Acta Materiae Compositae Sinica, 2022, 39(4): 1834-1846(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210608.004 [5] NASSHO Y, SANADA K. Microstructure optimizations for improving interlaminar shear strength and self-healing efficiency of spread carbon fiber/epoxy laminates containing microcapsules[J]. Journal of Composite Materials, 2021, 55(1): 27-38. doi: 10.1177/0021998320943941 [6] KAMARIAN S, SONG J. A comparative study on the effect of SMAs and CNTs on the vibration of composite plates exposed to thermal environments[J]. Case Studies in Thermal Engineering, 2022, 36: 102121. doi: 10.1016/j.csite.2022.102121 [7] NEKOUEI M, RAGHEBI M, MOHAMMADI M. Free vibration analysis of hybrid laminated composite cylindrical shells reinforced with shape memory alloy fibers[J]. Journal of Vibration and Control, 2020, 26(7-8): 610-626. doi: 10.1177/1077546319889857 [8] VERMA L, ANDREW J J, SIVAKUMAR S M, et al. Compression after high-velocity impact behavior of pseudo-elastic shape memory alloy embedded glass/epoxy composite laminates[J]. Composite Structures, 2021, 259: 113519. doi: 10.1016/j.compstruct.2020.113519 [9] ROGERS C, LIANG C, JIA J. Behavior of shape memory alloy reinforced composite plates. I-Model formulations and control concepts[C]//30th Structures, Structural Dynamics and Materials Conference. Alabama, 1989: 1389. [10] PARHI A, SINGH B N. Nonlinear free vibration analysis of shape memory alloy embedded laminated composite shell panel[J]. Mechanics of Advanced Materials and Structures, 2017, 24(9): 713-724. doi: 10.1080/15376494.2016.1196777 [11] SHIAU L C, KUO S Y, CHANG S Y. Free vibration of buckled SMA reinforced composite laminates[J]. Composite Structures, 2011, 93(11): 2678-2684. doi: 10.1016/j.compstruct.2011.06.008 [12] NEKOUEI M, RAGHEBI M, MOHAMMADI M. Free vibration analysis of laminated composite conical shells reinforced with shape memory alloy fibers[J]. Acta Mechanica, 2019, 230: 4235-4255. doi: 10.1007/s00707-019-02501-z [13] MALEKZADEH K, MOZAFARI A, GHASEMI F A. Free vibration response of a multilayer smart hybrid composite plate with embedded SMA wires[J]. Latin American Journal of Solids and Structures, 2014, 11: 279-298. doi: 10.1590/S1679-78252014000200008 [14] MAHABADI R K, SHAKERI M, PAZHOOH M D. Free vibration of laminated composite plate with shape memory alloy fibers[J]. Latin American Journal of Solids and Structures, 2016, 13: 314-330. doi: 10.1590/1679-78252162 [15] KARIMIASL M, EBRAHIMI F, AKGOZ B. Buckling and post-buckling responses of smart doubly curved composite shallow shells embedded in SMA fiber under hygro-thermal loading[J]. Composite Structures, 2019, 223: 110988. doi: 10.1016/j.compstruct.2019.110988 [16] LI W, STACHIV I. Computational modeling and parametric analysis of SMA hybrid composite plates under thermal environment[J]. Sensors, 2023, 23(3): 1344. doi: 10.3390/s23031344 [17] TANAKA K. Thermomechanical sketch of shape memory effect: One-dimensional tensile behavior[J]. Res Mechanica, 1986, 18(3): 251-263.TANAKA K. Thermomechanical sketch of shape memory effect: One-dimensional tensile behavior[J]. Res Mechanica, 1986, 18(3): 251-263. [18] LIANG C, ROGERS C A. One-dimensional thermomechanical constitutive relations for shape memory materials[J]. Journal of Intelligent Material Systems and Structures, 1990, 1(2): 207-234. [19] American Society for Testing and Materials. Standard test method for tension testing of nickel-titanium superelastic materials: ASTM F2516-07e2[S]. West Conshohocken: ASTM International, 2007. [20] KIM Y J, JEONG J W, LIM J H, et al. An enhanced Brinson model with modified kinetics for martensite transformation[J]. Journal of Mechanical Science and Technology, 2017, 31: 1157-1167. doi: 10.1007/s12206-017-0214-1 [21] SONG J J, CHEN Q, NAGUIB H E. Constitutive modeling and experimental validation of the thermo-mechanical response of a shape memory composite containing shape memory alloy fibers and shape memory polymer matrix[J]. Journal of Intelligent Material Systems and Structures, 2016, 27(5): 625-641. doi: 10.1177/1045389X15575086 [22] KARIMI M R, DANESH P M, SHAKERI M. On the free vibration and design optimization of a shape memory alloy hybrid laminated composite plate[J]. Acta Mechanica, 2021, 232: 323-343. doi: 10.1007/s00707-020-02824-2 [23] American Society for Testing and Materials. Standard test method for moisture absorption properties and equilibrium conditioning of polymer matrix composite materials: ASTM D5229/D5229M—20[S]. West Conshohocken: ASTM International, 2020. [24] 谢军伟, 刘维国, 詹国宁. 复合材料开孔层合板有限元网格划分方法研究[J]. 机械设计与制造, 2020, 49(4): 228-231. doi: 10.19356/j.cnki.1001-3997.2013.04.072XIE Junwei, LIU Weiguo, ZHAN Guoning. Study on finite element meshing method of composite open-cell laminate[J]. Mechanical Design and Manufacturing, 2020, 49(4): 228-231(in Chinese). doi: 10.19356/j.cnki.1001-3997.2013.04.072 [25] 万小朋, 李小聪, 鲍凯, 等. 利用振型变化进行结构损伤诊断的研究[J]. 航空学报, 2003, 24(5): 422-426.WAN Xiaopeng, LI Xiaocong, BAO Kai, et al. Research on structural damage diagnosis using mode shape change[J]. Journal of Aeronautics, 2003, 24(5): 422-426(in Chinese). [26] 胡成宝, 王云岗, 凌道盛. 瑞利阻尼物理本质及参数对动力响应的影响[J]. 浙江大学学报, 2017, 51(7): 1284-1290.HU Chengbao, WANG Yungang, LING Daosheng. Influence of physical nature and parameters of Rayleigh damping on dynamic response[J]. Journal of Zhejiang University, 2017, 51(7): 1284-1290(in Chinese). [27] 张景业. 超弹性形状记忆合金混杂复合材料振动特性研究[D]. 哈尔滨: 哈尔滨工业大学, 2016.ZHANG Jingye. Study on vibration characteristics of superelastic shape memory alloy hybrid composites[D]. Harbin: Harbin Institute of Technology, 2016(in Chinese). [28] 杨海如. 基于材料与结构阻尼的CFRP筏架阻尼性能研究[D]. 武汉: 武汉理工大学, 2021.YANG Hairu. Study on damping performance of CFRP raft frame based on material and structural damping[D]. Wuhan: Wuhan University of Technology, 2021(in Chinese). -

下载:

下载: