Research progress of biomimetic biomass-based adhesives

-

摘要: 目前以石油化工产物为主要原料的工业用合成树脂胶黏剂占市场主导地位,不可持续发展,并且在其合成和使用过程中释放有机挥发物,带来环境污染问题。利用可再生生物质资源开发环保胶黏剂具有重大研究意义和发展前景。但生物质胶黏剂普遍存在黏度大、施胶性能差、耐水性差、产品稳定性差等缺点制约其实际应用。对此,广大研究者采用物理化学手段进行改性研究,以提高胶黏剂胶接和使用性能,其中受自然界启发,利用仿生手段改性胶黏剂是研究热点之一。本文综述了仿生改性在大豆蛋白胶黏剂、木质素胶黏剂、单宁胶黏剂、糖基胶黏剂的研究进展,探讨了生物质胶黏剂仿生改性研究前景,并对其应用进行展望,以期对生物质胶黏剂改性和性能提高提供研究思路和方法,推动生物质胶黏剂的规模化应用。Abstract: Currently, industrial synthetic resin adhesives, which mainly use petroleum-based chemicals as raw materials, dominate the market. However, their unsustainable development and the release of volatile organic compounds during synthesis and application lead to environmental pollution. Therefore, it is of significant research significance and development prospects to develop environmentally friendly adhesives using renewable biomass resources. However, biomass-based adhesives generally suffer from high viscosity, poor adhesive performance, low water resistance, and poor product stability, which limit their practical application. To address these issues, researchers have used physical and chemical methods to modify these adhesives, aiming to improve their bonding and usage performance. Inspired by nature, the use of biomimetic approaches to modify adhesives is one of the hotspots in research. This article reviews the research progress on biomimetic modification of soy protein adhesives, lignin adhesives, tannin adhesives, and polysaccharide adhesives, discusses the research prospects of biomimetic modification of biomass-based adhesives, and provides an outlook on their applications. These efforts aim to provide new ideas and methods for the modification and performance improvement of biomass-based adhesives and promote their large-scale application.

-

图 3 纸纤维(PF) (a)、羧基纸纤维(CPF) (b) 和 UiO66-NH2@CPF (c)的SEM图像; (d) UiO66-NH2@CPF宏观形态;(e) Zr元素分布图;(f) UiO66-NH2的SEM图像[41]

Figure 3. SEM images of paper fiber (PF) (a), carboxyl paper fibers (CPF) (b) and UiO66-NH2@CPF (c); (d) Macromorphology of UiO66-NH2@CPF;(e) Element mapping of Zr; (f) SEM image of UiO66-NH2[41]

-

[1] 王伟, 李小梦, 汪任山. 我国人造板产业发展现状研究[J]. 品牌与标准化, 2023, 379(2): 181-183. doi: 10.3969/j.issn.1674-4977.2023.02.058WANG Wei, LI Xiaomeng, WANG Renshan. Research on the development status of China's wood-based panel industry[J]. Brand and Standardization, 2023, 379(2): 181-183 (in Chinese). doi: 10.3969/j.issn.1674-4977.2023.02.058 [2] 何明明, 王雅慧, 刘真, 等. 我国生物质人造板产业资源利用与发展前景[J]. 林产工业, 2023, 60(3): 84-87.HE Mingming, WANG Yahui, LIU Zhen, et al. Resource utilization and development prospect of biomass wood-based panel industry in China[J]. China Forest Products Industry, 2023, 60(3): 84-87 (in Chinese). [3] 黄春雷, 韦毅, 文志朋, 等. 人造板工业用胶黏剂应用现状及市场分析[J]. 大众科技, 2022, 24(12): 43-48. doi: 10.3969/j.issn.1008-1151.2022.12.011HUANG Chunlei, WEI Yi, WEN Zhipeng, et al. Application status and market analysis of adhesives for wood-based panel industry[J]. Popular Science and Technology, 2022, 24(12): 43-48 (in Chinese). doi: 10.3969/j.issn.1008-1151.2022.12.011 [4] 高伟. 木材胶黏剂和涂料市场新趋势[J]. 中国人造板, 2022, 29(10): 43-44.GAO Wei. New trends in wood adhesives and coatings market[J]. China Wood-based Panels, 2022, 29(10): 43-44 (in Chinese). [5] 邓雪, 梁坚坤, 李利芬, 等. 油料饼粕基木材胶黏剂研究应用进展[J]. 西北林学院学报, 2023, 38(1): 212-217. doi: 10.3969/j.issn.1001-7461.2023.01.29DENG Xue, LIANG Jiankun, LI Lifen, et al. Progress in the research and application of oilseed cake meal-based wood adhesives[J]. Journal of Northwest Forestry University, 2023, 38(1): 212-217 (in Chinese). doi: 10.3969/j.issn.1001-7461.2023.01.29 [6] 赵西坡, 李炫康, 李俊成, 等. 环境友好型胶黏剂的现状与发展[J]. 塑料, 2022, 51(5): 147-155.ZHAO Xipo, LI Xuankang, LI Juncheng, et al. Current status and development of environmentally friendly adhesives[J]. Plastics, 2022, 51(5): 147-155 (in Chinese). [7] 杨香香, 张挺, 李新兵. 浅议人造板及其制品的除醛方法[J]. 中国人造板, 2022, 29(3): 23-26. doi: 10.3969/j.issn.1673-5064.2022.03.006YANG Xiangxiang, ZHANG Ting, LI Xinbing. Deformalization of wood-based panels and their products[J]. China Wood-based Panels, 2022, 29(3): 23-26 (in Chinese). doi: 10.3969/j.issn.1673-5064.2022.03.006 [8] 沈仁杰, 胡睿, 陈之善. 我国无醛胶黏剂技术及无醛添加人造板的发展思考[J]. 当代化工研究, 2022, 17(2): 6-9. doi: 10.3969/j.issn.1672-8114.2022.17.003SHEN Renjie, HU Rui, CHEN Zhishan. Development of formaldehyde-free adhesive technology and formaldehyde-free wood-based panel in China[J]. Modern Chemical Research, 2022, 17(2): 6-9 (in Chinese). doi: 10.3969/j.issn.1672-8114.2022.17.003 [9] KUMAR C, LEGGATE W. An overview of bio-adhesives for engineered wood products[J]. International Journal of Adhesion and Adhesives, 2022, 118(2): 103187. [10] 赵思齐, 王含章, 王浏浏, 等. 大豆蛋白胶黏剂低黏化改性研究进展[J]. 高分子材料科学与工程, 2023, 39(3): 163-171. doi: 10.16865/j.cnki.1000-7555.2023.0052ZHAO Siqi, WANG Hanzhang, WANG Liuliu, et al. Progress of low viscosity modification of soy protein adhesives[J]. Polymer Materials Science and Engineering, 2023, 39(3): 163-171 (in Chinese). doi: 10.16865/j.cnki.1000-7555.2023.0052 [11] 田启民. 环保高性能胶黏剂的制备方法与研究进展[J]. 中华纸业, 2023, 44(4): 15-19. doi: 10.3969/j.issn.1007-9211.2023.04.005TIAN Qimin. Preparation method and research progress of environmentally friendly high-performance adhesives[J]. China Pulp & Paper Industry, 2023, 44(4): 15-19 (in Chinese). doi: 10.3969/j.issn.1007-9211.2023.04.005 [12] 劳万里, 段新芳, 李晓玲, 等. 人造板工业生命周期评价研究进展[J]. 西北林学院学报, 2023, 38(1): 205-211. doi: 10.3969/j.issn.1001-7461.2023.01.28LAO Wanli, DUAN Xinfang, LI Xiaoling, et al. Progress of life cycle assessment in wood-based panel industry[J]. Journal of Northwest Forestry University, 2023, 38(1): 205-211 (in Chinese). doi: 10.3969/j.issn.1001-7461.2023.01.28 [13] HUSSIN M, ABD LATIF N, HAMIDON T, et al. Latest advancements in high-performance bio-based wood adhesives: A critical review[J]. Journal of Materials Research and Technology, 2022, 21: 3909-3946. doi: 10.1016/j.jmrt.2022.10.156 [14] 何金蓉, 屈伟, 冯云, 等. 抗菌人造板的研究进展及展望[J]. 林产工业, 2023, 60(4): 75-80.HE Jinrong, QU Wei, FENG Yun, et al. Research progress and prospect of antimicrobial artificial boards[J]. Forest Industry, 2023, 60(4): 75-80 (in Chinese). [15] 任天航, 刘明, 吴义强, 等. 废弃人造板回收利用研究进展[J]. 林产工业, 2022, 59(1): 34-40. doi: 10.19531/j.issn1001-5299.202201006REN Tianhang, LIU Ming, WU Yiqiang, et al. Research progress on recycling of waste wood-based panel[J]. China Forest Products Industry, 2022, 59(1): 34-40 (in Chinese). doi: 10.19531/j.issn1001-5299.202201006 [16] 姜鑫, 李泽, 杜官本, 等. 乙二醛在木材胶黏剂领域的应用研究[J]. 林产工业, 2022, 59(10): 41-45.JIANG Xin, LI Ze, DU Guanben, et al. Application of glyoxal in wood adhesives[J]. China Forest Products Industry, 2022, 59(10): 41-45 (in Chinese). [17] 孙博, 阚雨菲, 高振华. HN-PAE树脂对大豆蛋白胶黏剂的共交联改性研究[J]. 木材科学与技术, 2022, 36(2): 54-59.SUN Bo, KAN Yufei, GAO Zhenhua. Co-crosslinking modification of soybean protein adhesive by HN-PAE resin[J]. Chinese Journal of Wood Science and Technology, 2022, 36(2): 54-59 (in Chinese). [18] 赵艳, 张泽宇, 赵晨程, 等. 环氧树脂改性大豆蛋白胶黏剂的研究[J]. 包装工程, 2021, 42(5): 95-99. doi: 10.19554/j.cnki.1001-3563.2021.05.012ZHAO Yan, ZHANG Zeyu, ZHAO Chencheng, et al. Research on epoxy resin modified soy protein adhesive[J]. Packaging Engineering, 2021, 42(5): 95-99 (in Chinese). doi: 10.19554/j.cnki.1001-3563.2021.05.012 [19] 陈明松, 杨杨芳, 卜立新, 等. 常温固化大豆蛋白胶黏剂制备非结构集成材研究[J]. 中国人造板, 2021, 28(3): 10-16. doi: 10.3969/j.issn.1673-5064.2021.03.003CHEN Mingsong, YANG Yangfang, BU Lixin, et al. Study on the preparation of non-structural composite materials by room temperature curing soy protein adhesive[J]. China Wood-based Panels, 2021, 28(3): 10-16 (in Chinese). doi: 10.3969/j.issn.1673-5064.2021.03.003 [20] 张二兵, 涂伊静, 叶曼玉, 等. 单宁和纳米SiO2改性大豆基胶黏剂的制备及其性能[J]. 林产化学与工业, 2022, 42(1): 36-42. doi: 10.3969/j.issn.0253-2417.2022.01.005ZHANG Erbing, TU Yijing, YE Manyu, et al. Preparation and properties of soybean-based adhesives modified with tannins and nano-SiO2[J]. Chemistry and Industry of Forest Products, 2022, 42(1): 36-42 (in Chinese). doi: 10.3969/j.issn.0253-2417.2022.01.005 [21] BACIGALUPE A, ESCOBAR M. Soy protein adhesives for particleboard production: A review[J]. Journal of Polymers and the Environment, 2021, 29(7): 2033-2045. doi: 10.1007/s10924-020-02036-8 [22] 阚浩峰, 阚雨菲, 何文诚, 等. 主剂pH对聚酰胺树脂型API胶黏剂性能的作用机制[J]. 林业工程学报, 2023, 8(2): 87-94.KAN Haofeng, KAN Yufei, HE Wencheng, et al. Mechanism of pH of main agent on properties of polyamide resin API adhesives[J]. Journal of Forestry Engineering, 2023, 8(2): 87-94 (in Chinese). [23] 严晨亮, 孙丰文, 魏信义, 等. 碳酸钙微晶改性玉米芯粉制备脲醛树脂胶黏剂填料的研究[J]. 木材科学与技术, 2022, 36(4): 45-50.YAN Chenliang, SUN Fengwen, WEI Xinyi, et al. Preparation of urea-formaldehyde resin adhesive filler from calcium carbonate microcrystalline-modified corncob powder[J]. Chinese Journal of Wood Science and Technology, 2022, 36(4): 45-50 (in Chinese). [24] WU Q, DENG L, WANG Y, et al. Preparation and characterization of soy protein-based adhesive modified by microcrystalline cellulose[J]. Materials Express, 2022, 12(3): 457-463. doi: 10.1166/mex.2022.2170 [25] 陈欢, 汪宗涛, 陈仕清, 等. 木质素环氧化接枝物及其制备大豆蛋白胶黏剂研究[J]. 材料导报, 2021, 35(20): 20190-20194.CHEN Huan, WANG Zongtao, CHEN Shiqing, et al. Study on lignin epoxidation grafts and their preparation of soy protein adhesives[J]. Materials Reports, 2021, 35(20): 20190-20194 (in Chinese). [26] 高振华, 李锦, 张冰寒, 等. 碱热活化改性高温豆粕制备大豆蛋白胶黏剂[J]. 生物质化学工程, 2022, 56(3): 1-8.GAO Zhenhua, LI Jin, ZHANG Binghan, et al. Preparation of soy protein adhesive from high-temperature soybean meal modified by alkali heat activation[J]. Biomass Chemical Engineering, 2022, 56(3): 1-8 (in Chinese). [27] 徐艳涛, 刘晴, 韩宇飞, 等. 低黏度大豆蛋白胶黏剂制备及其在刨花板应用[J]. 木材科学与技术, 2022, 36(3): 33-39.XU Yantao, LIU Qing, HAN Yufei, et al. Preparation of low viscosity soy protein adhesive and its application to particleboard[J]. Chinese Journal of Wood Science and Technology, 2022, 36(3): 33-39 (in Chinese). [28] ZHAO S, WANG Z, PANG H, et al. Designing biomimetic microphase-separated motifs to construct mechanically robust plant protein resin with improved water-resistant performance[J]. Macromolecular Materials and Engineering, 2020, 305(2): 1900462. doi: 10.1002/mame.201900462 [29] HUANG X X, CHEN Y, LI J, et al. Development of a strong soy protein-based adhesive with excellent antibacterial and antimildew properties via biomineralized silver nanoparticles[J]. Industrial Crops and Products, 2022, 188: 115567. doi: 10.1016/j.indcrop.2022.115567 [30] CHENG H, KILGORE K, FORD C, et al. Adhesive performance of cotton seed protein modified by catechol-containing compounds[J]. Journal of Adhesion Science and Technology, 2022, 36(16): 1781-1793. doi: 10.1080/01694243.2021.1984713 [31] WILKER J. The iron-fortified adhesive system of marine mussels[J]. Angewandte Chemie-International Edition, 2010, 49(44): 8076-8078. doi: 10.1002/anie.201003171 [32] CHANG H, ADIBNIA V, LI C S, et al. Short-sequence superadhesive peptides with topologically enhanced cation-π interactions[J]. Chemistry of Materials, 2021, 33(13): 5168-5176. doi: 10.1021/acs.chemmater.1c01171 [33] PANG H, MA C, ZHANG S. Conversion of soybean oil extraction wastes into high-performance wood adhesives based on mussel-inspired cation-pi interactions[J]. International Journal of Biological Macromolecules, 2022, 209: 83-92. doi: 10.1016/j.ijbiomac.2022.03.152 [34] 孙成祥, 李阳, 徐迟, 等. 碳纳米管阵列仿生黏附受静电作用影响的研究进展[J]. 材料导报, 2020, 34(19): 19050-19060.SUN Chengxiang, LI Yang, XU Chi, et al. Progress of carbon nanotube array biomimetic adhesion affected by electrostatic interaction[J]. Materials Reports, 2020, 34(19): 19050-19060 (in Chinese). [35] 周晨, 吴俊涛. 仿生微纳米纤维黏附材料[J]. 化学进展, 2018, 30(12): 1863-1873.ZHOU Chen, WU Juntao. Biomimetic micro- and nanofiber adhesive materials[J]. Progress in Chemistry, 2018, 30(12): 1863-1873 (in Chinese). [36] 汪中原, 陆晓波, 刘琦, 等. 仿壁虎机器人脚掌的黏附性能研究及模拟微重力下黏脱附轨迹设计[J]. 科学通报, 2017, 62(19): 2149-2156.WANG Zhongyuan, LU Xiaobo, LIU Qi, et al. Adhesion performance study of gecko-mimicking robotic paws and design of adhesion and detachment trajectories under simulated microgravity[J]. Chinese Science Bulletin, 2017, 62(19): 2149-2156 (in Chinese). [37] PANG H, ZHAO S, MO L, et al. Mussel-inspired bio-based water-resistant soy adhesives with low-cost dopamine analogue-modified silkworm silk fiber[J]. Journal of Applied Polymer Science, 2020, 137(23): 31-39. [38] WANG Z, ZHAO S, ZHANG W, et al. Bio-inspired cellulose nanofiber-reinforced soy protein resin adhesives with dopamine-induced codeposition of "water-resistant" interphases[J]. APSS, 2019, 478: 441-450. [39] GU W, LIU X Y, GAO Q, et al. Bio-inspired co-deposition strategy of aramid fibers to improve performance of soy protein isolate-based adhesive[J]. Industrial Crops and Products, 2020, 150: 131120. [40] ZHANG J, LONG C, ZHANG X, et al. An easy-coating, versatile, and strong soy flour adhesive via a biomineralized structure combined with a biomimetic brush-like polymer[J]. Chemical Engineering Journal , 2022, 450: 138387. doi: 10.1016/j.cej.2022.138387 [41] ZHOU Y, WU T, ZENG G, et al. A tough, anti-mildew and anti-counterfeiting soybean protein adhesive enhanced by gecko-inspired functional fiber and bio-based epoxide[J]. Journal of Cleaner Production, 2021, 323: 131120. [42] LI K, JIN S, ZENG G, et al. Biomimetic development of a strong, mildew-resistant soy protein adhesive via mineral-organic system and phenol-amine synergy[J]. Industrial Crops and Products, 2022, 187: 112013. [43] ZHANG Y, LIU Z, XU Y, et al. High performance and multifunctional protein-based adhesive produced via phenol-amine chemistry and mineral reinforcement strategy inspired by arthropod cuticles[J]. Chemical Engineering Journal, 2021, 426: 11890. [44] 邓竣骞, 陈玲, 连海兰. 木质素基聚氨酯胶黏剂的研究进展[J]. 林产化学与工业, 2023, 43(3): 160-172. doi: 10.3969/j.issn.0253-2417.2023.03.019DENG Junqian, CHEN Ling, LIAN Hailan. Research progress of lignin-based polyurethane adhesives[J]. Chemistry and Industry of Forest Products, 2023, 43(3): 160-172 (in Chinese). doi: 10.3969/j.issn.0253-2417.2023.03.019 [45] 赵保成, 姜志华, 王素鹏, 等. 木质素无醛胶黏剂在实木复合地板生产中研究与应用[J]. 中国人造板, 2021, 28(1): 3-6. doi: 10.3969/j.issn.1673-5064.2021.01.002ZHAO Baocheng, JIANG Zhihua, WANG Supeng, et al. Research and application of lignin aldehyde-free adhesives in the production of solid wood composite flooring[J]. China Wood-based Panels, 2021, 28(1): 3-6 (in Chinese). doi: 10.3969/j.issn.1673-5064.2021.01.002 [46] 周妤莲, 廖晶晶, 龙思宇, 等. 碱液化处理木质素基酚醛树脂的制备及性能研究[J]. 塑料科技, 2022, 50(12): 1-5. doi: 10.15925/j.cnki.issn1005-3360.2022.12.001ZHOU Yulian, LIAO Jingjing, LONG Siyu, et al. Preparation and properties of lignin-based phenolic resin by alkaline liquefaction treatment[J]. Plastics Science and Technology, 2022, 50(12): 1-5 (in Chinese). doi: 10.15925/j.cnki.issn1005-3360.2022.12.001 [47] 李澜鹏, 李秀峥, 白富栋. 木质素基酚醛树脂胶黏剂研究进展[J]. 当代化工研究, 2021, 50(7): 1711-1715.LI Lanpeng, LI Xiuzheng, BAI Fudong. Progress of lignin-based phenolic resin adhesive[J]. Modern Chemical Research, 2021, 50(7): 1711-1715 (in Chinese). [48] 李斐红, 黄江, 陈林, 等. 用木质素无醛胶黏剂制造刨花板的探索与实践[J]. 轻纺工业与技术, 2021, 50(3): 7-8. doi: 10.3969/j.issn.2095-0101.2021.03.003LI Feihong, HUANG Jiang, CHEN Lin, et al. Exploration and practice of particleboard manufacturing with lignin-based aldehyde-free adhesive[J]. Light and Textile Industry and Technology, 2021, 50(3): 7-8 (in Chinese). doi: 10.3969/j.issn.2095-0101.2021.03.003 [49] 王丽, 陈秀兰, 王俊伟, 等. 木质素胶黏剂在无醛纤维板中的应用[J]. 中国人造板, 2021, 28(1): 17-20.WANG Li, CHEN Xiulan, WANG Junwei, et al. Application of lignin adhesive in formaldehyde-free fiberboard[J]. China Wood-based Panels, 2021, 28(1): 17-20 (in Chinese). [50] 孙楠, 邸明伟. 木质素在聚合物材料中应用的研究进展[J]. 高分子材料科学与工程, 2021, 37(5): 141-148. doi: 10.16865/j.cnki.1000-7555.2021.0132SUN Nan, DI Mingwei. Research progress of lignin application in polymer materials[J]. Polymeric Materials Science and Engineering, 2021, 37(5): 141-148 (in Chinese). doi: 10.16865/j.cnki.1000-7555.2021.0132 [51] WANG Z, BO J, XIA W. Synthesis of wood lignin-urea-formaldehyde resin adhesive[J]. Advanced Materials Research, 2012, 560: 242-246. [52] GAO S, LIU Y, WANG C, et al. Synthesis of lignin-based polyacid catalyst and its utilization to improve water resistance of urea–formaldehyde resins[J]. Polymers, 2020, 12(1): 175. [53] YOUNESI-KORDKHEILI H, PIZZI A. A comparison among lignin modification methods on the properties of lignin-phenol-formaldehyde resin as wood adhesive[J]. Polymers, 2021, 13(20): 15678. [54] AI X, FENG S, SHUI T, et al. Effects of alcell lignin methylolation and lignin adding stage on lignin-based phenolic adhesives[J]. Molecules, 2021, 26(22): 6762. doi: 10.3390/molecules26226762 [55] PEI W, SHANG W, LIANG C, et al. Using lignin as the precursor to synthesize Fe3O4@lignin composite for preparing electromagnetic wave absorbing lignin-phenol-formaldehyde adhesive[J]. Industrial Crops and Products, 2020, 154: 19870. [56] HUSSIN M, AZIZ A, IQBAL A, et al. Development and characterization novel bio-adhesive for wood using kenaf core (Hibiscus cannabinus) lignin and glyoxal[J]. International Journal of Biological Macromolecules, 2019, 122: 713-722. doi: 10.1016/j.ijbiomac.2018.11.009 [57] AZIZ N, LATIP A, PENG L, et al. Reinforced lignin-phenol-glyoxal (LPG) wood adhesives from coconut husk[J]. International Journal of Biological Macromolecules, 2019, 141: 185-196. doi: 10.1016/j.ijbiomac.2019.08.255 [58] GONG X, LIU T, YU S, et al. The preparation and performance of a novel lignin-based adhesive without formaldehyde[J]. Industrial Crops and Products, 2020, 153: 12090. [59] SINGH S, OSTENDORF K, EURING M, et al. Environmentally sustainable, high-performance lignin-derived universal adhesive[J]. Green Chemistry, 2022, 24(6): 2624-2635. doi: 10.1039/D2GC00014H [60] ZHANG J, WANG W, ZHOU X, et al. Lignin-based adhesive crosslinked by furfuryl alcohol-glyoxal and epoxy resins[J]. Nordic Pulp & Paper Research Journal, 2019, 34(2): 228-238. [61] WANG W, LI Y, ZHANG H, et al. Double-interpenetrating-network lignin-based epoxy resin adhesives for resistance to extreme environment[J]. Biomacromolecules, 2022, 23(3): 779-788. doi: 10.1021/acs.biomac.1c01204 [62] KALAMI S, CHEN N, BORAZJANI H, et al. Comparative analysis of different lignins as phenol replacement in phenolic adhesive formulations[J]. Industrial Crops and Products, 2018, 125: 520-528. doi: 10.1016/j.indcrop.2018.09.037 [63] WEI C, ZHU X, PENG H, et al. Facile preparation of lignin-based underwater adhesives with improved performances[J]. ACS Sustainable Chemistry & Engineering, 2019, 7(4): 4508-4514. [64] 郭鑫珠, 李泽珩, 万正威, 等. 天然胶黏剂的研究进展[J]. 高校化学工程学报, 2021, 35(4): 579-588.GUO Xinzhu, LI Zeheng, WAN Zhengwei, et al. Research progress of natural adhesives[J]. Journal of Chemical Engineering of Chinese Universities, 2021, 35(4): 579-588 (in Chinese). [65] 夏芹, 周润之, 洪锐彬, 等. 国内外刨花板原材料的研究进展[J]. 广州化工, 2022, 50(2): 21-23.XIA Qin, ZHOU Runzhi, HONG Ruibin, et al. Research progress of particleboard raw materials at home and abroad[J]. Guangzhou Chemical Industry, 2022, 50(2): 21-23 (in Chinese). [66] 王浏浏, 张伟, 陈松武. 缩合单宁-PEI改性大豆蛋白胶黏剂制备及性能研究[J]. 林产工业, 2023, 60(4): 8-13. doi: 10.19531/j.issn1001-5299.202304002WANG Liuliu, ZHANG Wei, CHEN Songwu. Preparation and properties of condensed tannin-PEI modified soy protein adhesive[J]. China Forest Products Industry, 2023, 60(4): 8-13 (in Chinese). doi: 10.19531/j.issn1001-5299.202304002 [67] 彭晋达, 邓霜琪, 廖岽森, 等. UF树脂与杨梅单宁胶黏剂共混特性研究[J]. 西南林业大学学报(自然科学), 2022, 42(6): 140-150.PENG Jinda, DANG Shuangqi, LIAO Dongsen, et al. Characterization of UF resin blended with prune tannin adhesive[J]. Journal of Southwest Forestry College (Natural Science), 2022, 42(6): 140-150 (in Chinese). [68] LI K, GENG X, SIMONSEN J, et al. Novel wood adhesives from condensed tannins and polyethylenimine[J]. International Journal of Adhesion and Adhesives, 2004, 24(4): 327-333. doi: 10.1016/j.ijadhadh.2003.11.004 [69] LI J, ZHU W, ZHANG S, et al. Depolymerization and characterization of Acacia mangium tannin for the preparation of mussel-inspired fast-curing tannin-based phenolic resins[J]. Chemical Engineering Journal, 2019, 370: 420-431. doi: 10.1016/j.cej.2019.03.211 [70] ARIAS A, GONZALEZ GARCIA S, FEIJOO G, et al. Tannin-based bio-adhesives for the wood panel industry as sustainable alternatives to petrochemical resins[J]. Journal of Industrial Ecology, 2022, 26(2): 627-642. doi: 10.1111/jiec.13210 [71] LIU C, ZHANG Y, LI X, et al. "Green" bio-thermoset resins derived from soy protein isolate and condensed tannins[J]. Industrial Crops and Products, 2017, 108: 363-370. doi: 10.1016/j.indcrop.2017.06.057 [72] PANG H, YAN Q, MA C, et al. Polyphenol-metal ion redox-induced gelation system for constructing plant protein adhesives with excellent fluidity and cold-pressing adhesion[J]. ACS Applied Materials & Interfaces, 2021, 13(49): 59527-59537. doi: 10.1021/acsami.1c18401 [73] CHEN Y, YU Y, YUAN X, et al. A biomimetic adhesive with high adhesion strength and toughness comprising soybean meal, chitosan, and condensed tannin-functionalized boron nitride nanosheets[J]. International Journal of Biological Macromolecules, 2022, 219: 611-625. doi: 10.1016/j.ijbiomac.2022.08.028 [74] GHAHRI S, PIZZI A. Improving soy-based adhesives for wood particleboard by tannins addition[J]. Wood Science and Technology, 2018, 52(1): 261-279. doi: 10.1007/s00226-017-0957-y [75] BENHAMOU A, BOUSSETTA A, KASSAB Z, et al. Elaboration of carboxylated cellulose nanocrystals filled starch-based adhesives for the manufacturing of eco-friendly particleboards[J]. Construction and Building Materials, 2022, 348: 19530. [76] ZIDANES U, DIAS M, LORENCO M, et al. Preparation and characterization of tannin-based adhesives reinforced with cellulose nanofibrils for wood bonding[J]. Holzforschung, 2021, 75(2): 159-167. doi: 10.1515/hf-2020-0033 [77] 李娜. 高性能淀粉基胶黏剂的制备与研究 [D]. 无锡: 江南大学, 2022.LI Na. Preparation and research of high performance starch-based adhesives [D]. Wuxi: Jiangnan University, 2022 (in Chinese). [78] 陈磊. 淀粉基木材胶黏剂的制备、改性及其分子模拟研究 [D]. 武汉: 华中农业大学, 2020.CHEN Lei. Preparation, modification and molecular modeling of starch-based wood adhesives [D]. Wuhan: Huazhong Agricultural University, 2020(in Chinese). [79] 毛杰. 魔芋多糖木材胶黏剂的研究[D]. 福州: 福建农林大学, 2009.MAO Jie. Research on wood adhesive with konjac polysaccharide[D]. Fuzhou: Fujian Agriculture and Forestry University, 2009(in Chinese). [80] LI K, ZUO Y, ZHENG L, et al. Preparation of high-strength, water-resistant starch adhesive and its bonding mechanism to cotton stalk[J]. Industrial Crops and Products, 2023, 194: 116344. doi: 10.1016/j.indcrop.2023.116344 [81] YIN H, ZHENG P, ZHANG E, et al. Improved wet shear strength in eco-friendly starch-cellulosic adhesives for woody composites[J]. Carbohydrate Polymers, 2020, 250(8): 789-791. [82] IMRE B, VILAPLANA F. Organocatalytic esterification of corn starches towards enhanced thermal stability and moisture resistance[J]. Green Chemistry, 2020, 22(15): 5017-5031. doi: 10.1039/D0GC00681E [83] ZHANG Y, DING L, GU J, et al. Preparation and properties of a starch-based wood adhesive with high bonding strength and water resistance[J]. Carbohydrate Polymers, 2015, 115(2): 32-37. [84] CUI R, CHEN F, ZHAO Y, et al. A novel injectable starch-based tissue adhesive for hemostasis[J]. Journal of Materials Chemistry B, 2020, 8(36): 8282-8293. doi: 10.1039/D0TB01562H [85] WANG Z, ZHU H, HUANG J, et al. Improvement of the bonding properties of cassava starch-based wood adhesives by using different types of acrylic ester[J]. International Journal of Biological Macromolecules, 2019, 126: 603-611. doi: 10.1016/j.ijbiomac.2018.12.113 [86] LU D, WANG H, WANG X, et al. Biomimetic chitosan-graft-polypeptides for improved adhesion in tissue and metal[J]. Carbohydrate Polymers, 2019, 215: 20-28. doi: 10.1016/j.carbpol.2019.03.065 [87] OSMAN A, LIN E, HWANG D. A sticky carbohydrate meets a mussel adhesive: Catechol-conjugated levan for hemostatic and wound healing applications[J]. Carbohydrate Polymers, 2023, 299: 120172. doi: 10.1016/j.carbpol.2022.120172 [88] CHEN L, DIN Z, YANG D, et al. Functional nanoparticle reinforced starch-based adhesive emulsion: Toward robust stability and high bonding performance[J]. Carbohydrate Polymers, 2021, 269: 15123. [89] CHEN L, LI J, DIN Z H, et al. Sustainable bio-based wood adhesive incorporated different functionalized nanoparticles: A performance comparison study[J]. Starch-Starke, 2021, 73: 7-12. [90] ZHANG Y, CUNNINGHAM M, SMEETS N, et al. Starch nanoparticle incorporation in latex-based adhesives[J]. European Polymer Journal, 2018, 106: 128-138. doi: 10.1016/j.eurpolymj.2018.07.014 -

下载:

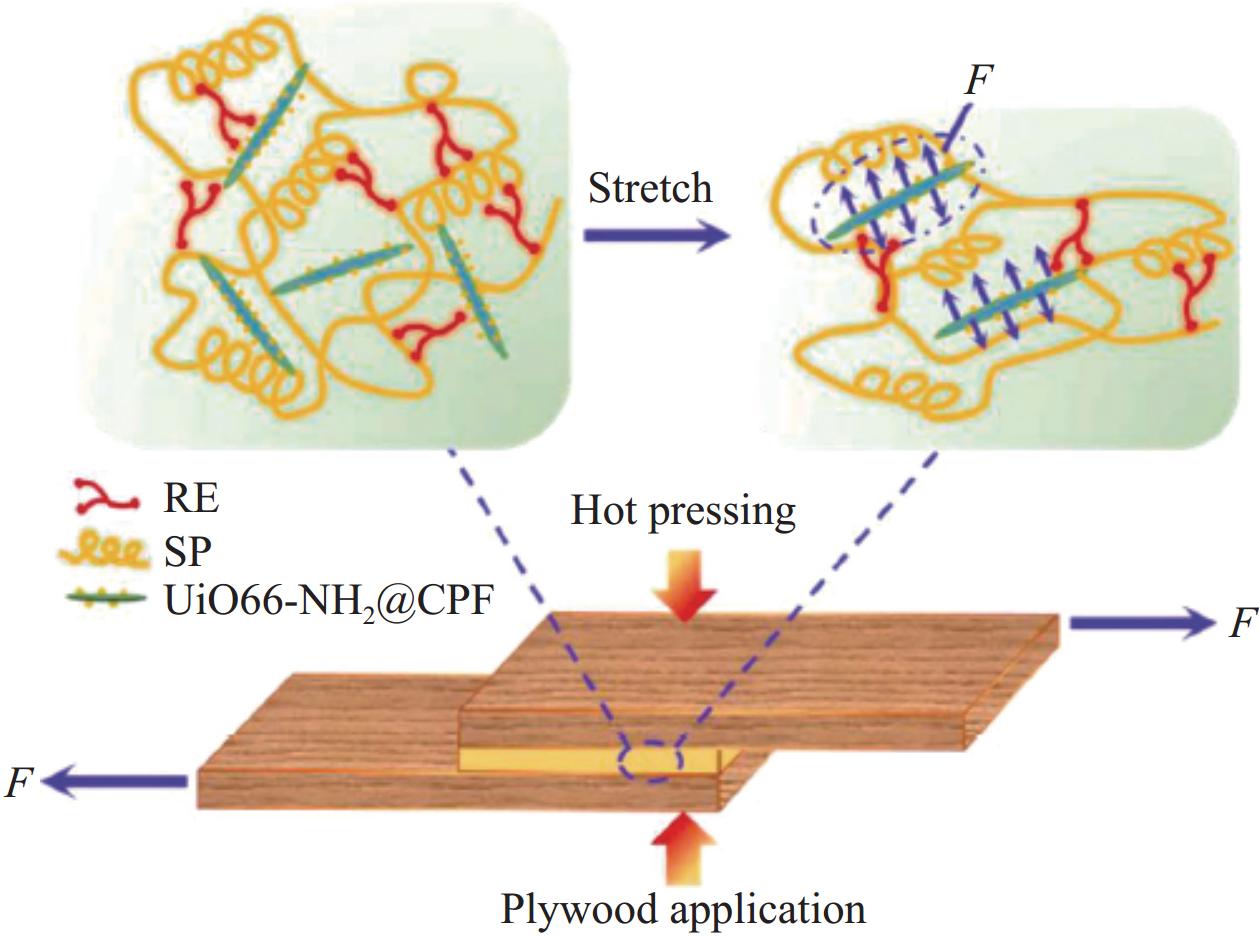

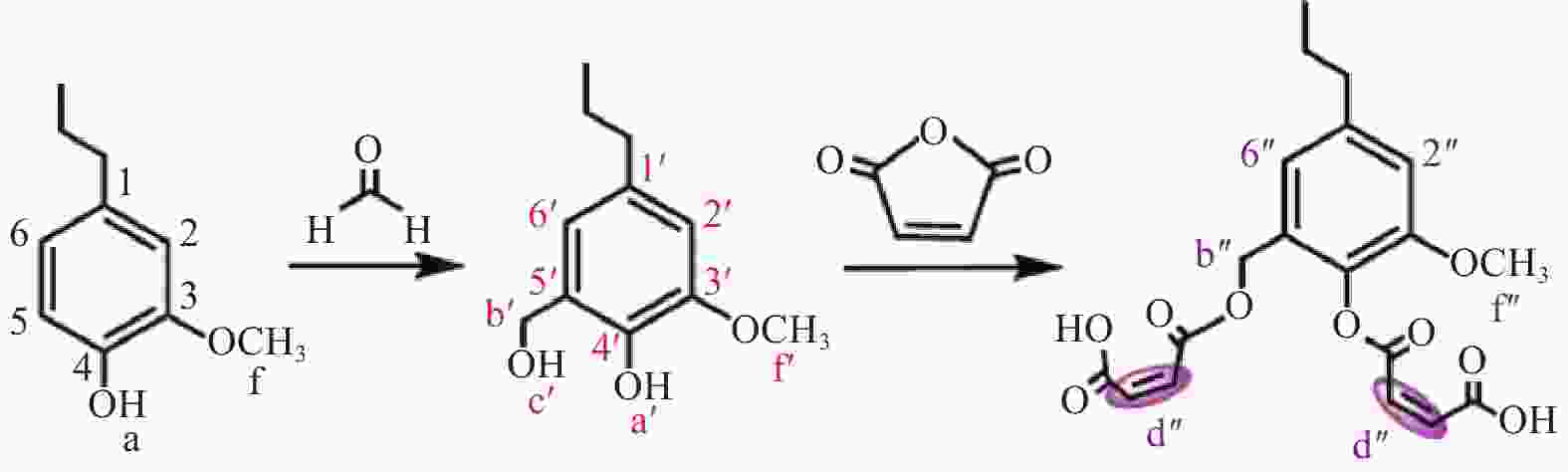

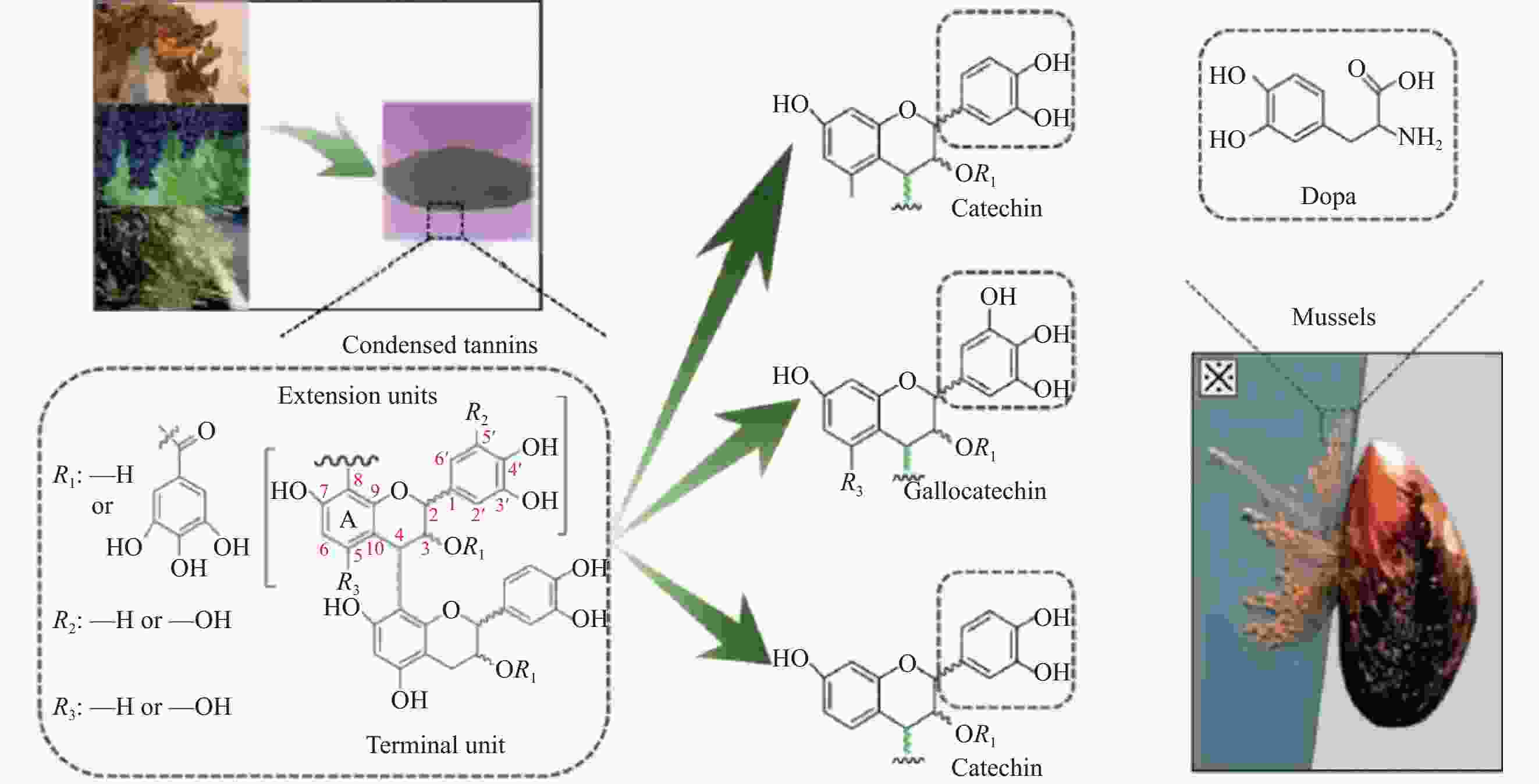

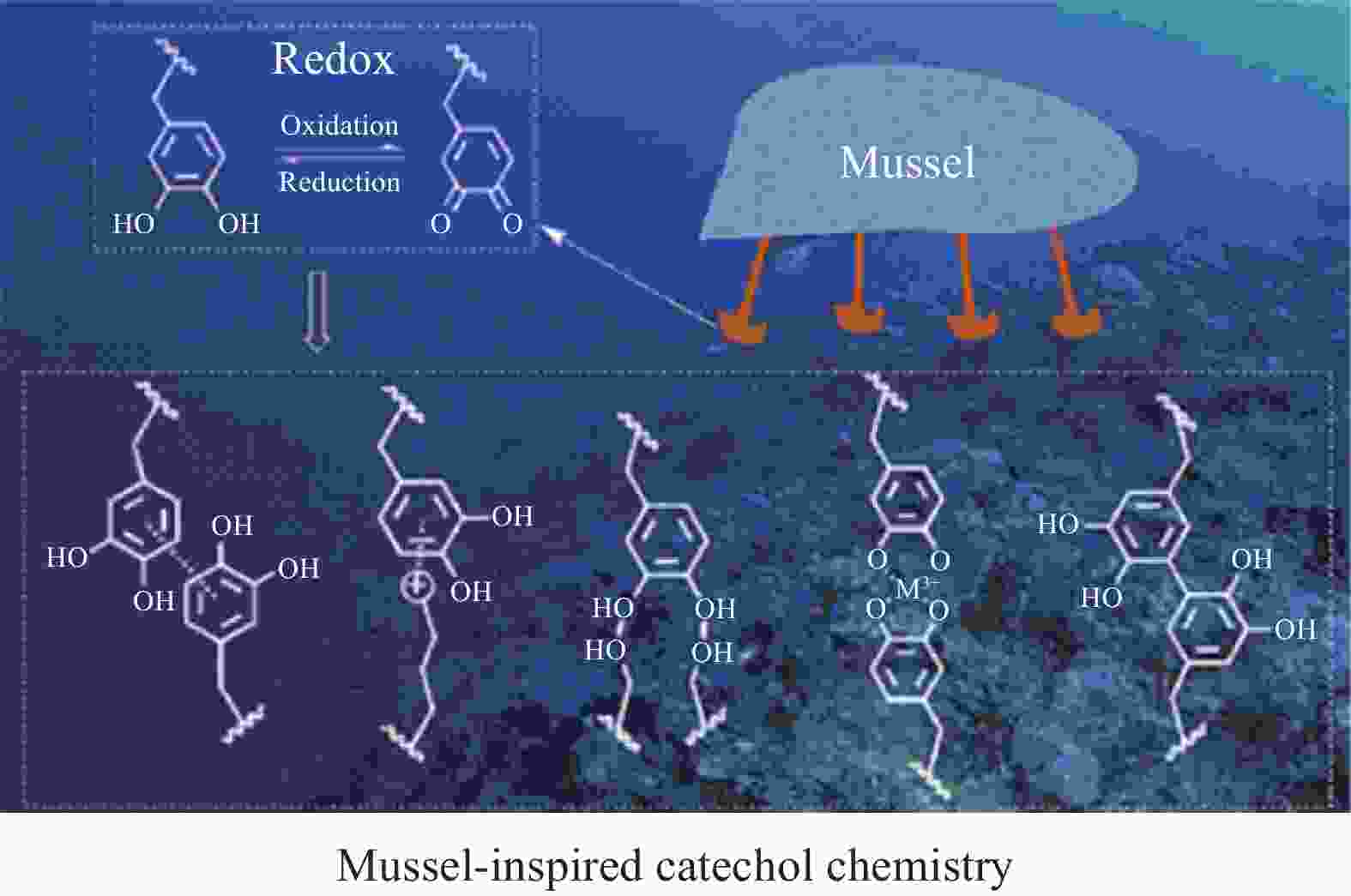

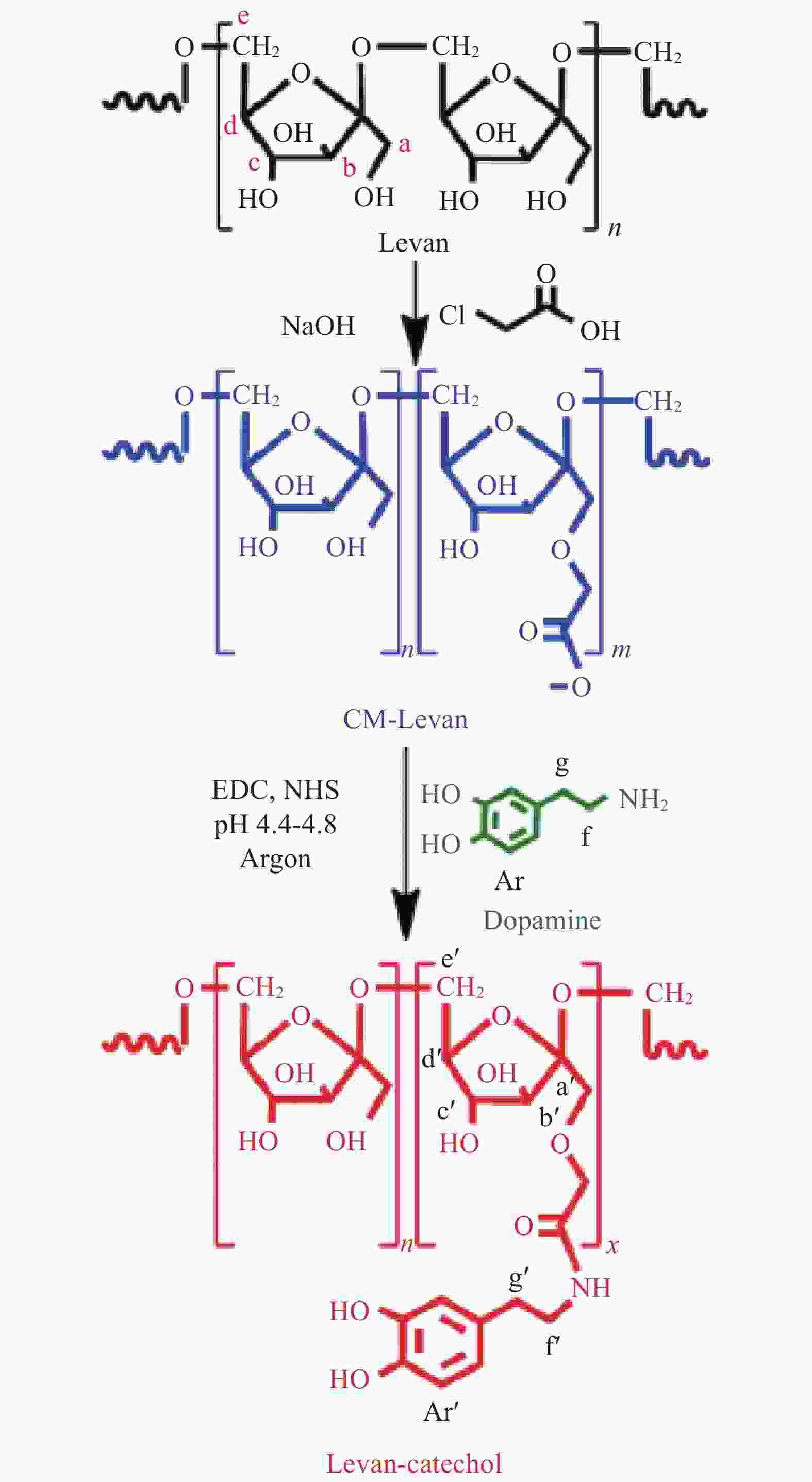

下载: