Piezoresistivity of copper-plated steel fibers reinforced ultra high performance concrete with ceramic waste powder under different failure load types

-

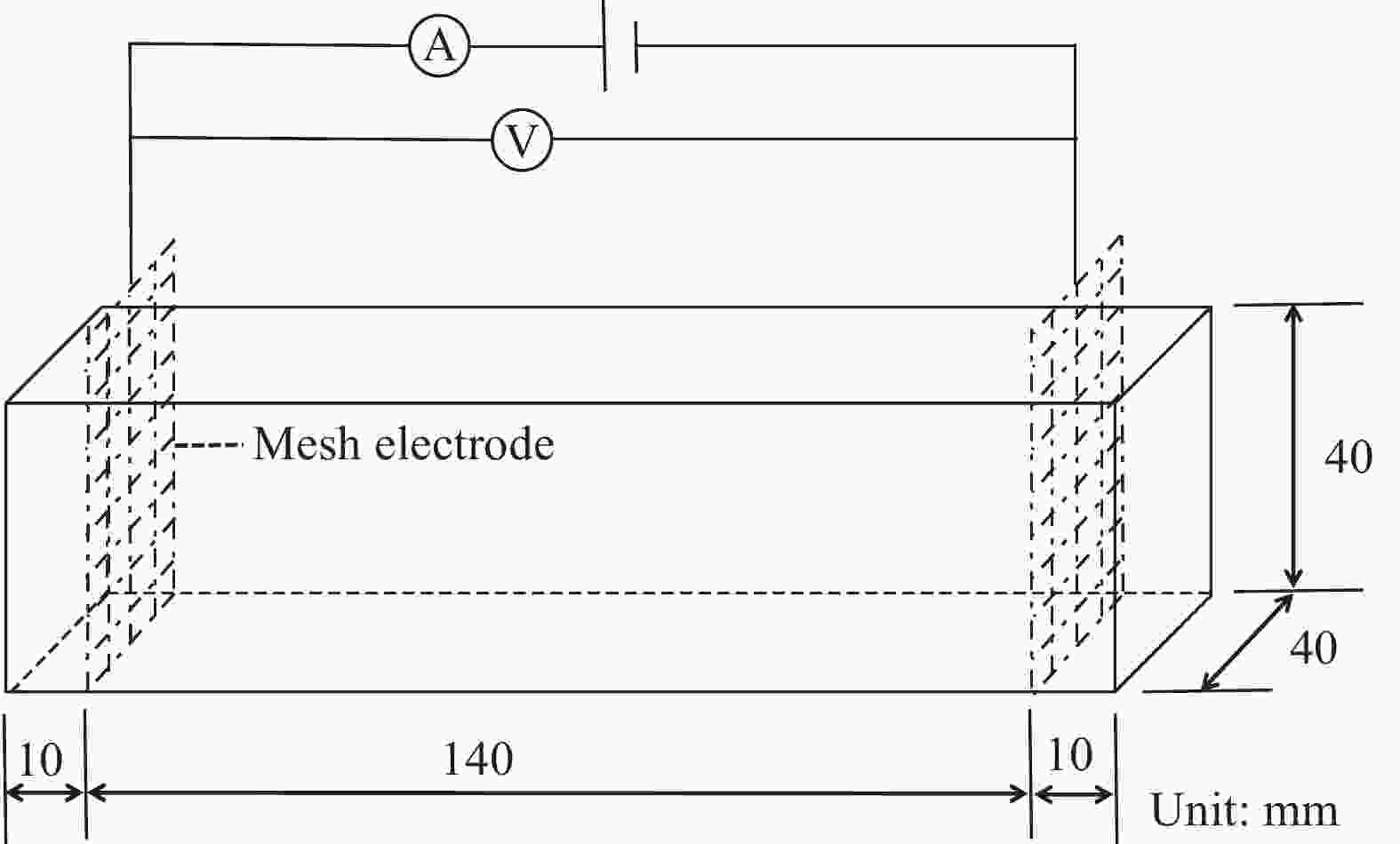

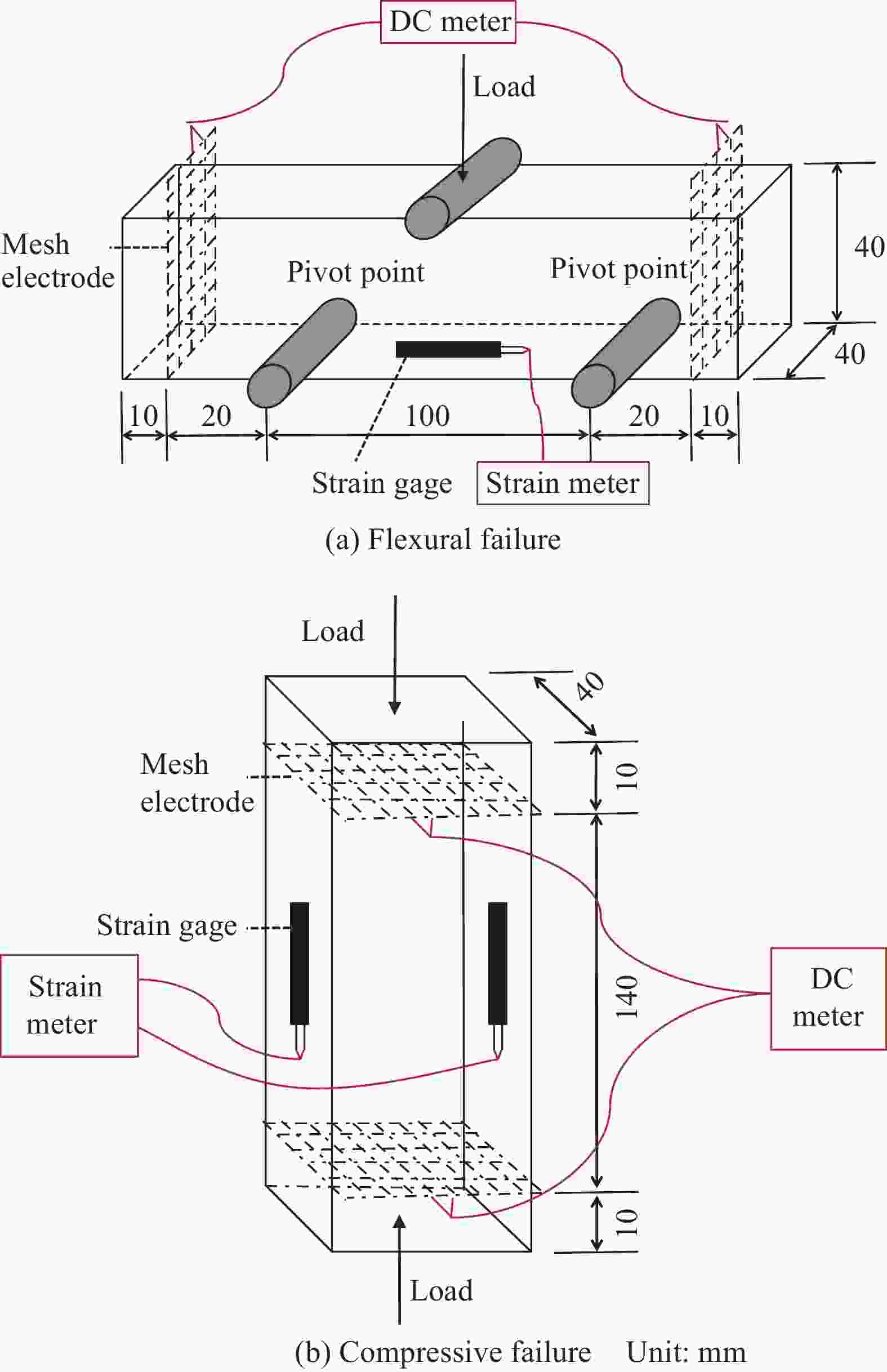

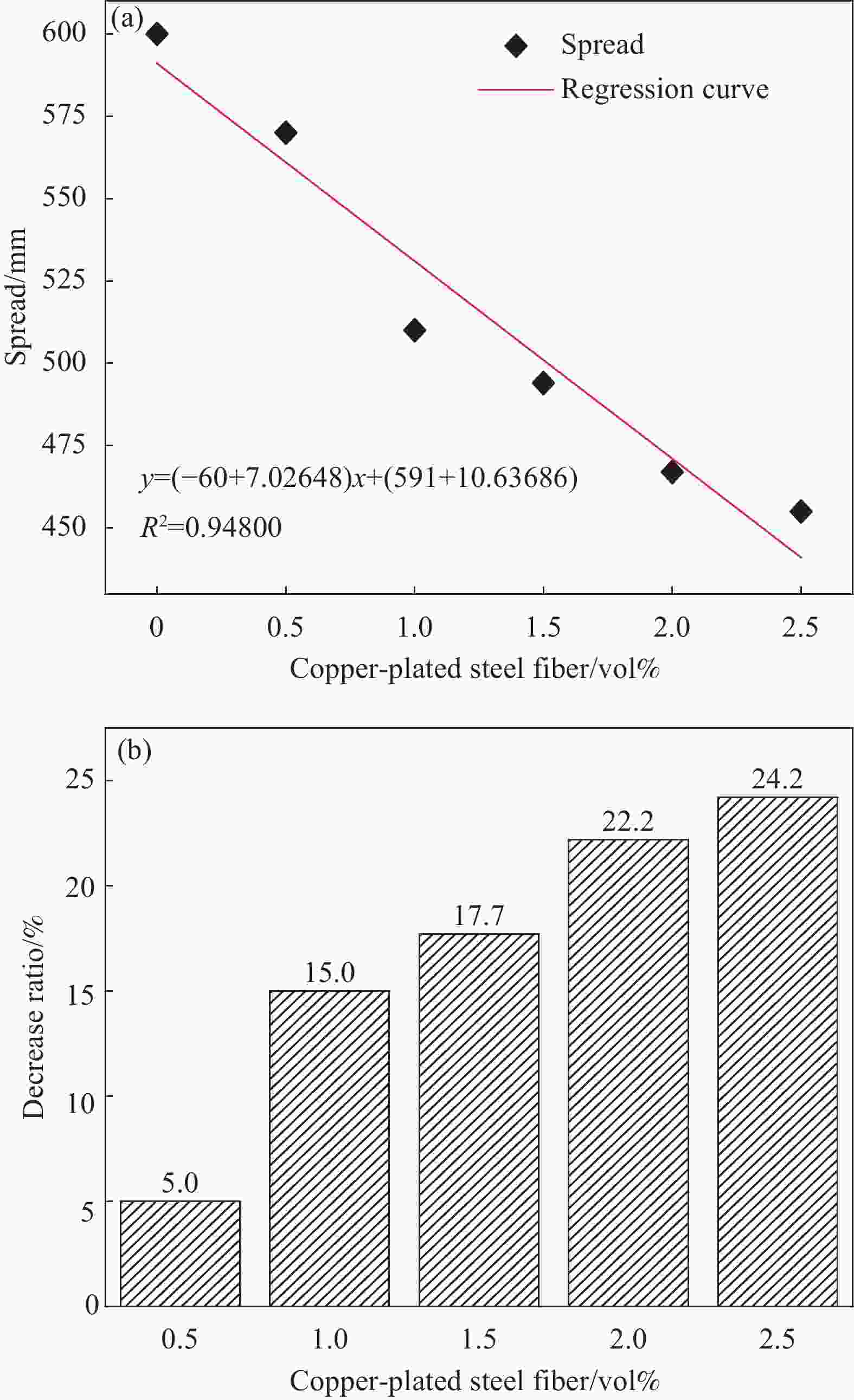

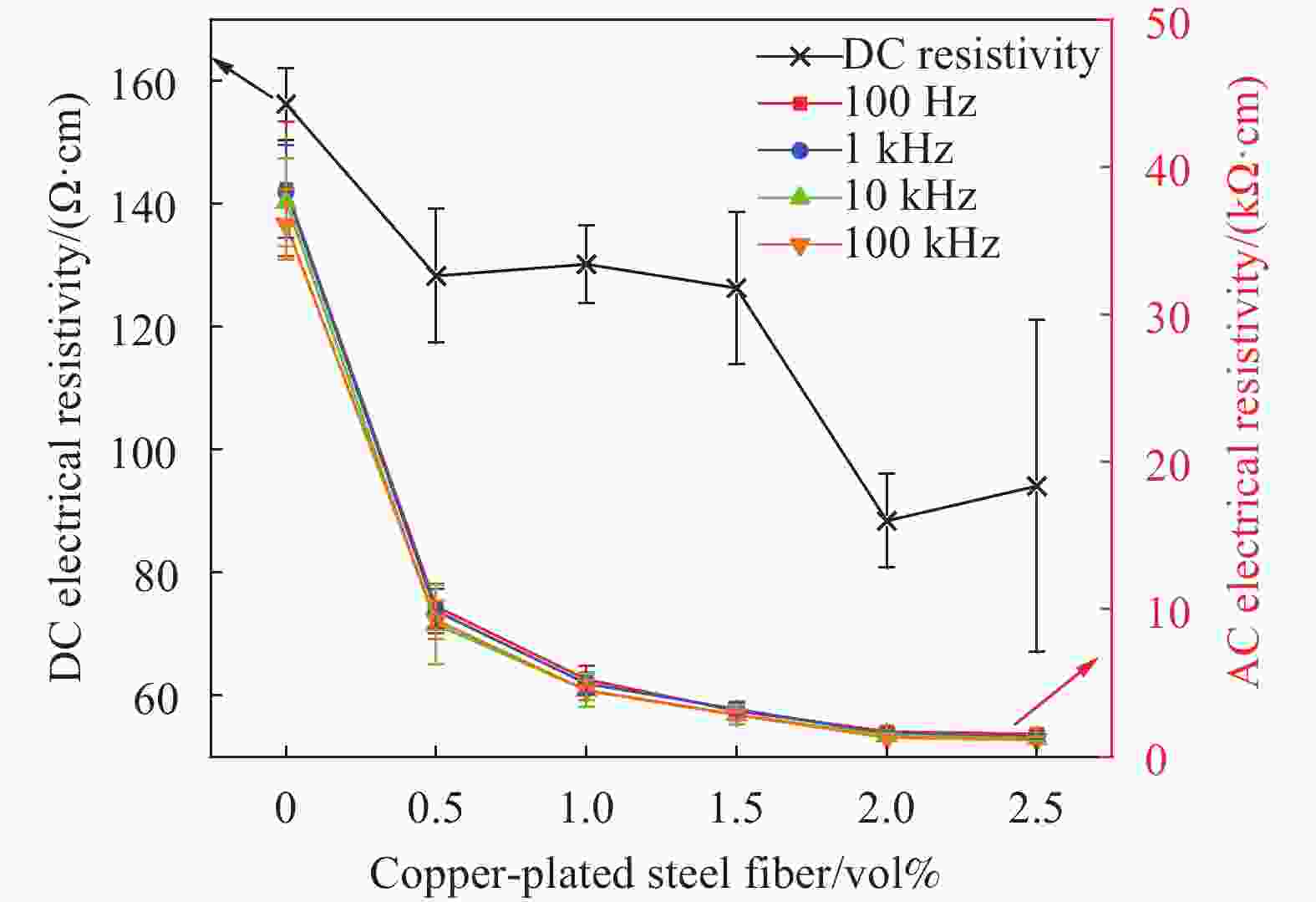

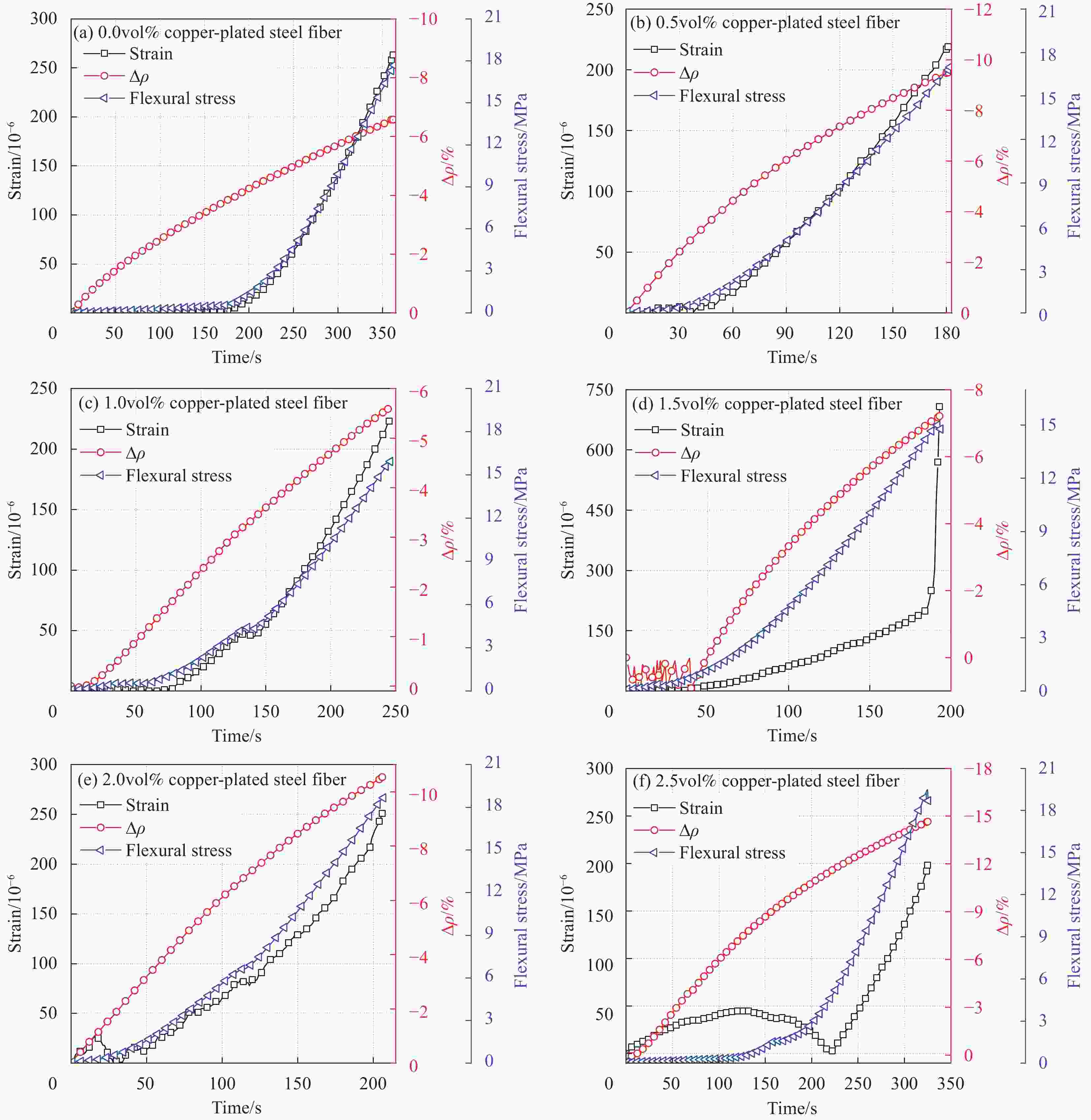

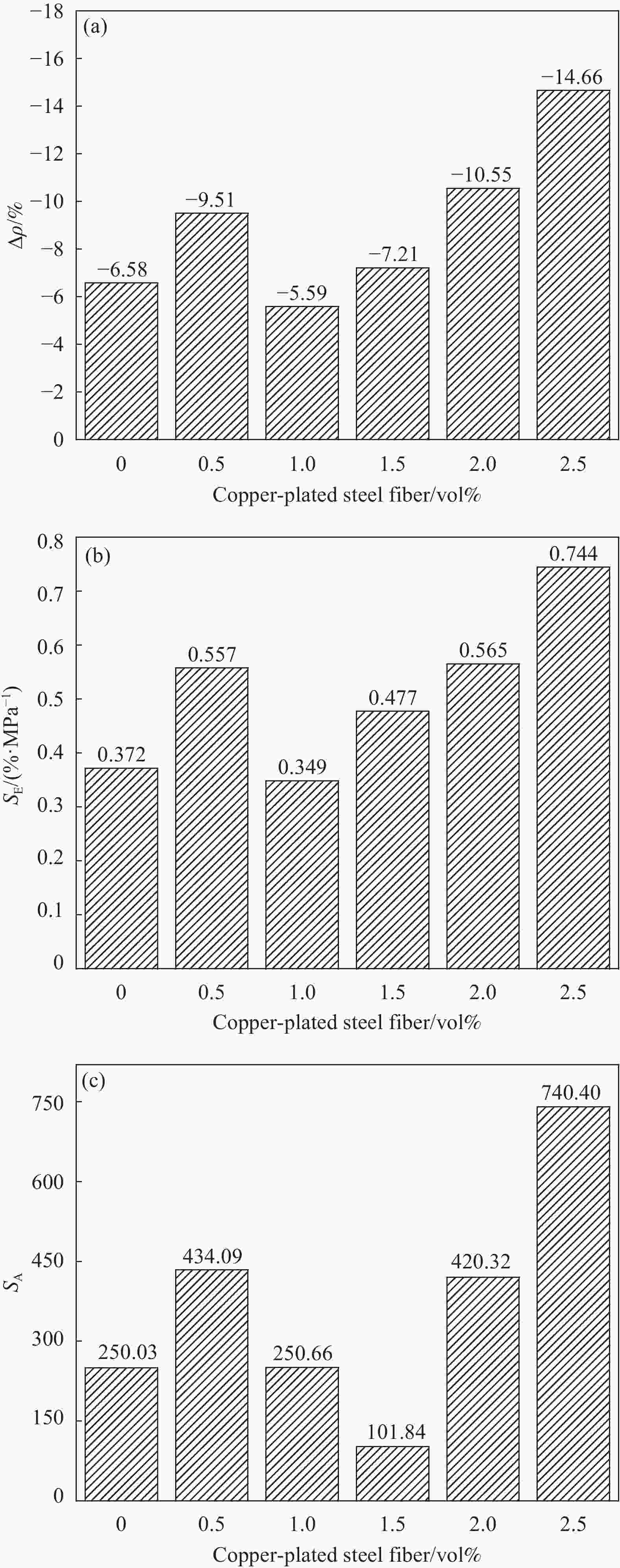

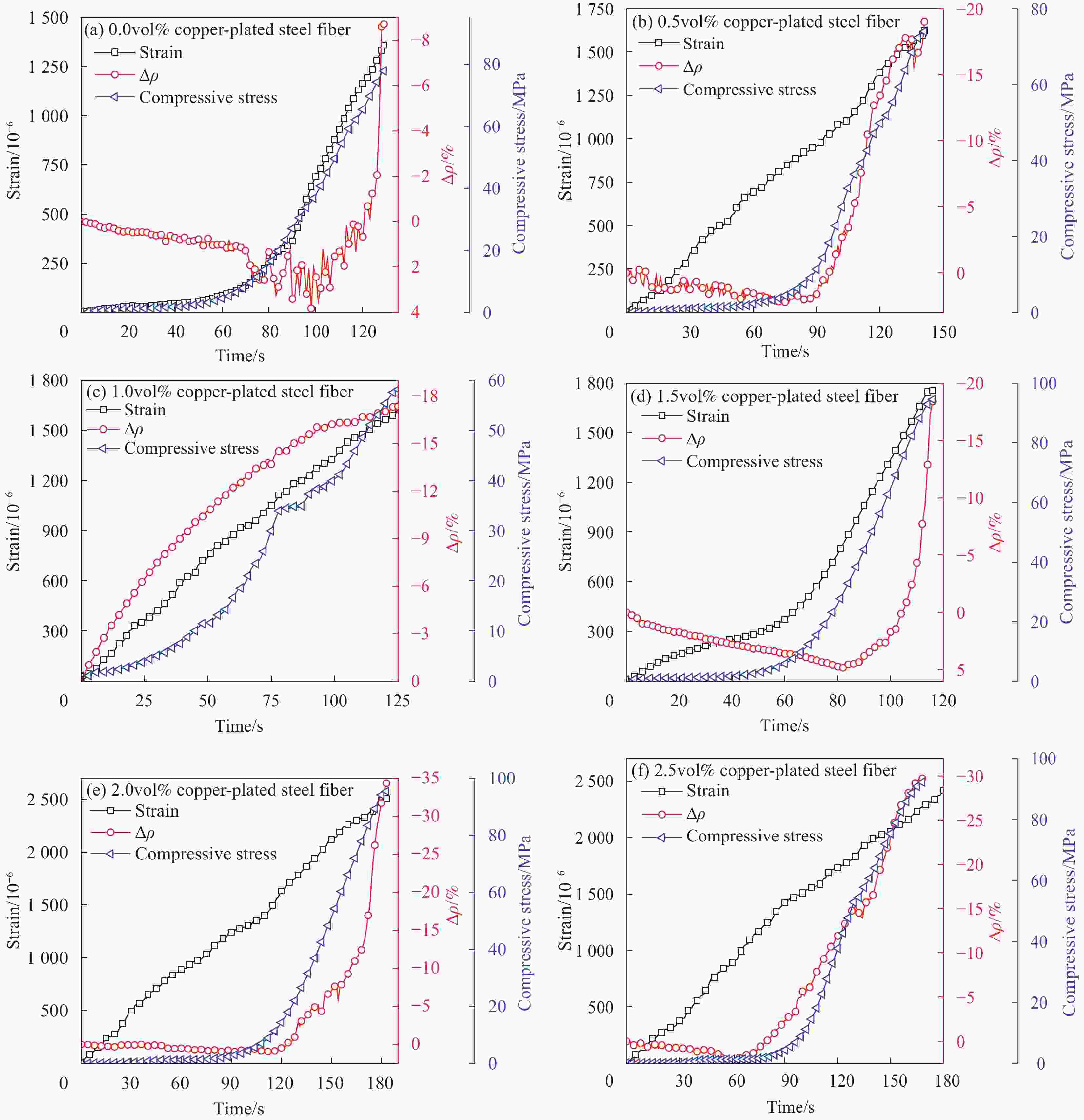

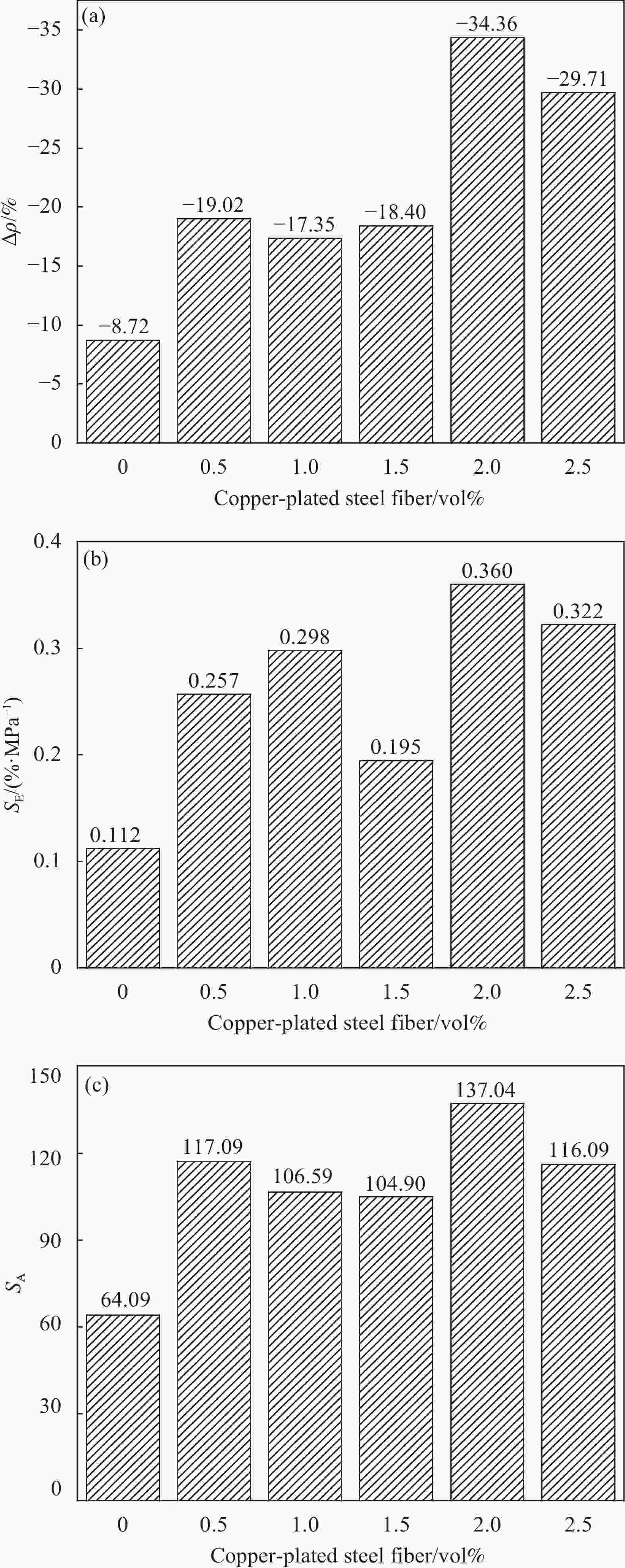

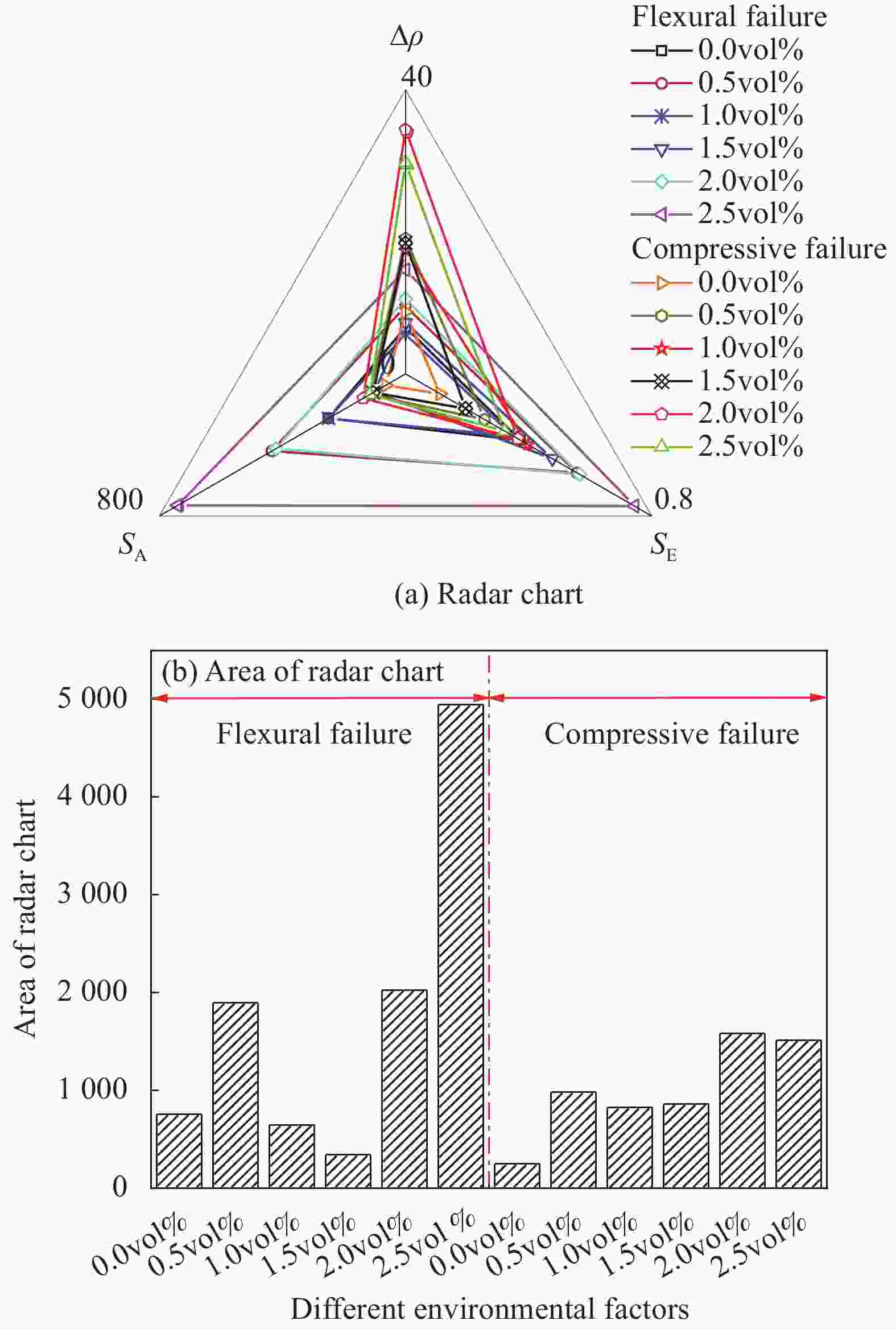

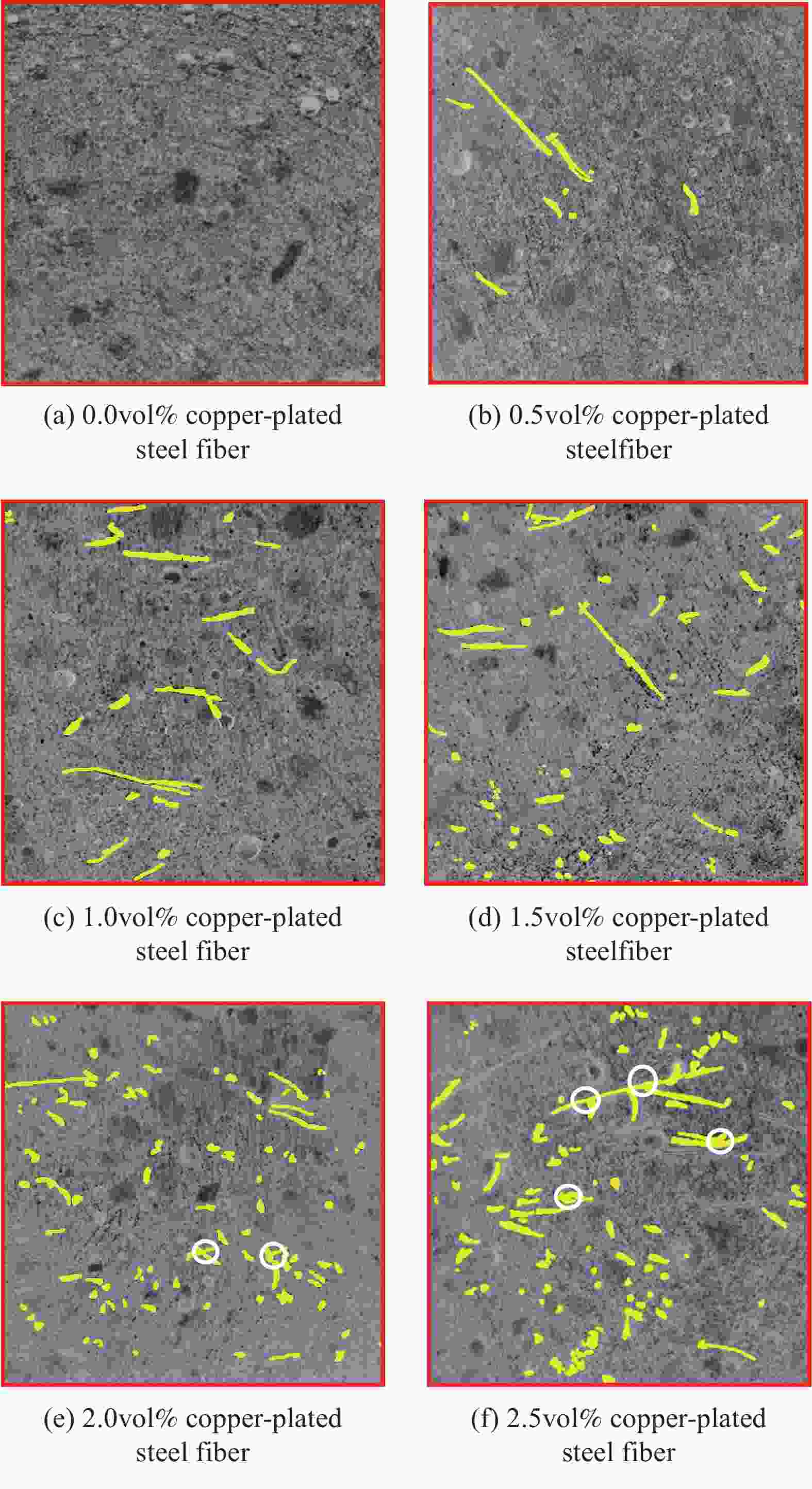

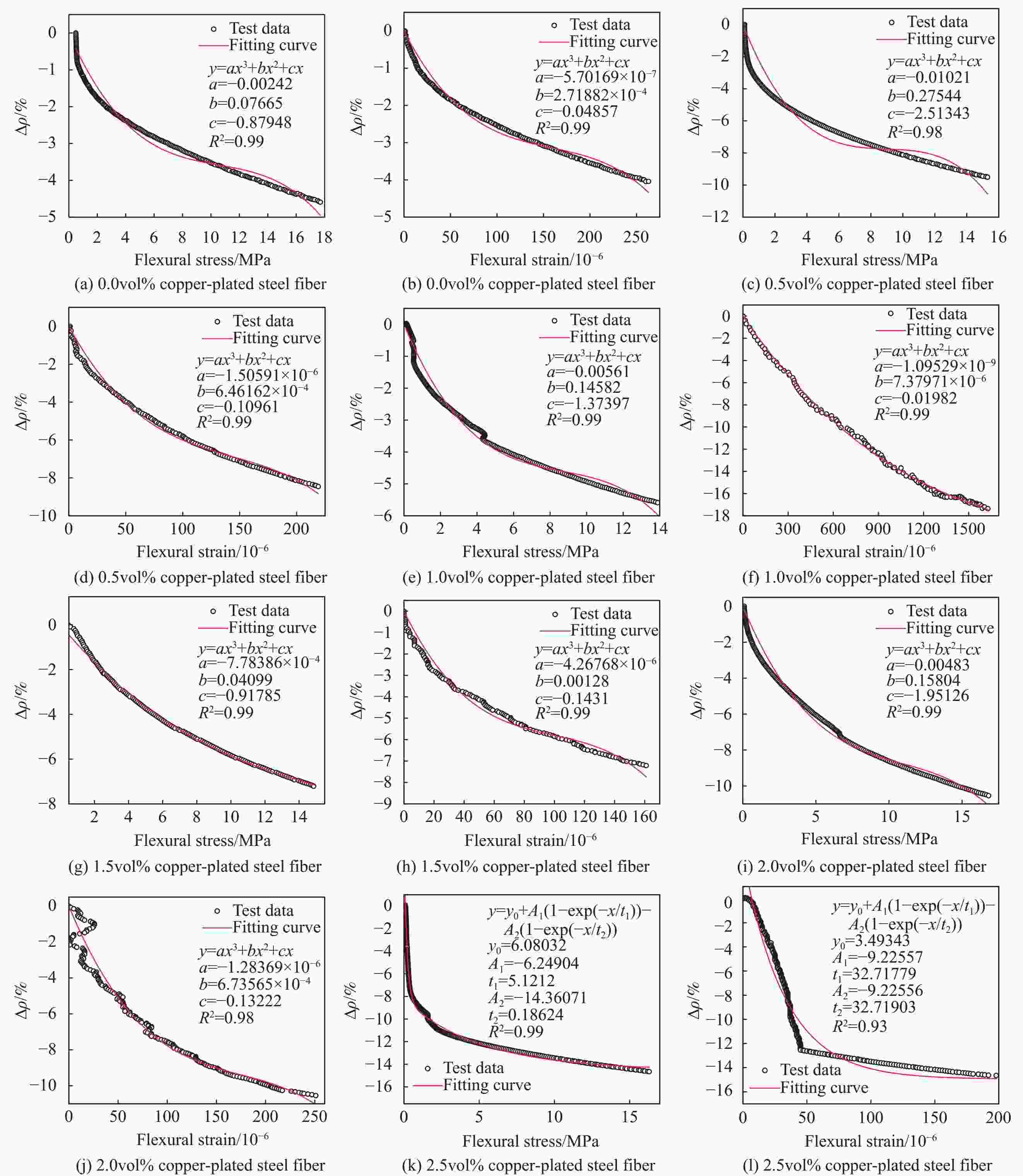

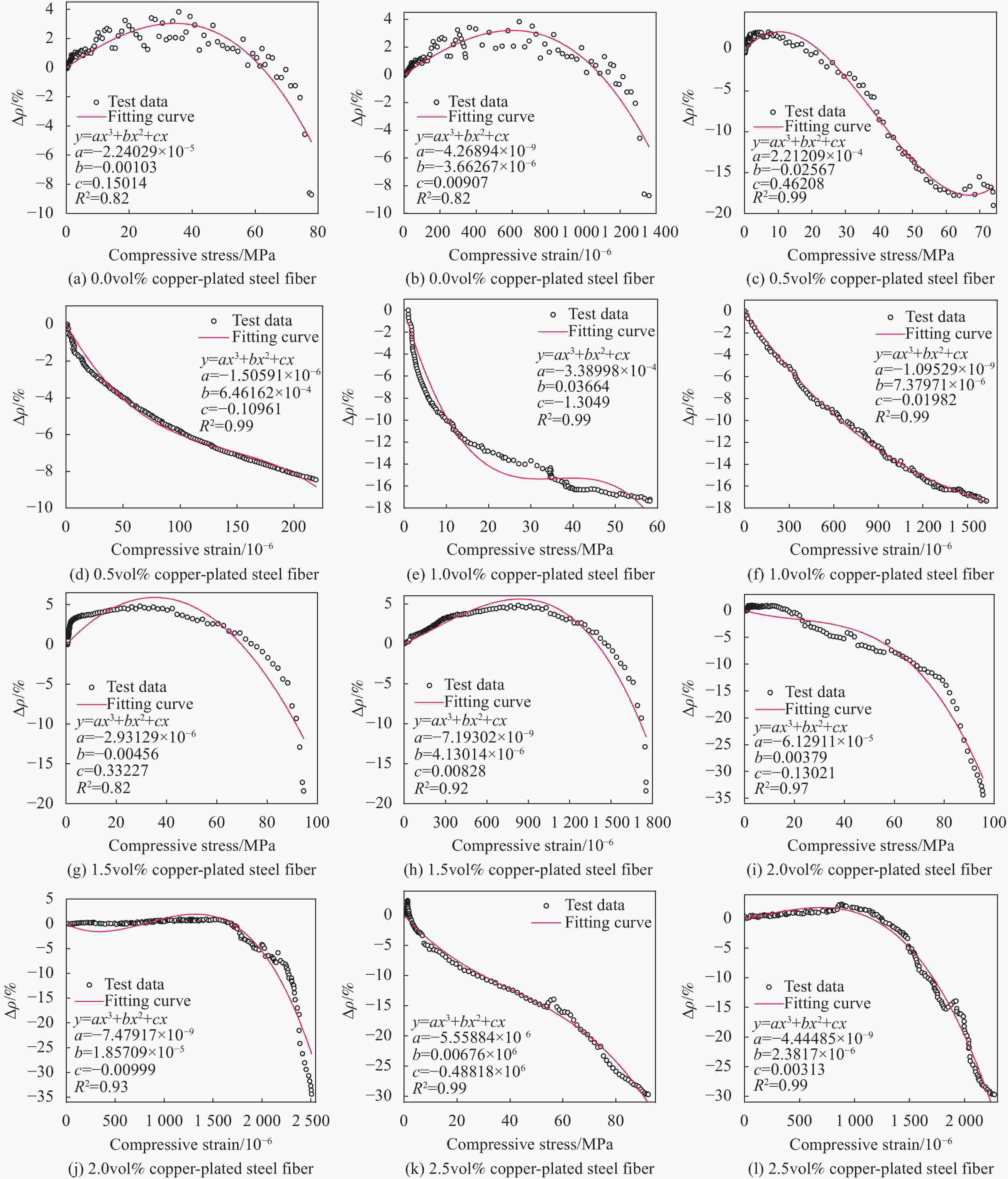

摘要: 镀铜钢纤维具有良好的导电性、耐腐蚀性和力学性能,而废弃陶瓷粉较水泥具有低电阻率、低碳性、火山灰活性和内养护作用。则镀铜钢纤维和废弃陶瓷粉的协同作用有望赋予混凝土良好且稳定的压敏性能和宽的应力/应变监测范围。因此,本文制备了低碳智能镀铜钢纤维增强废弃陶瓷超高性能混凝土,并研究了镀铜钢纤维掺量对废弃陶瓷超高性能混凝土流动性能、电学性能和不同荷载类型下的废弃陶瓷超高性能混凝土压敏性能的影响规律,并建立了力-电本构模型。研究结果表明:扩展度随镀铜钢纤维的掺入而降低,但均能达到自流平效果;镀铜钢纤维可显著降低废弃陶瓷超高性能混凝土的直流和交流电阻率;镀铜钢纤维大幅度提高废弃陶瓷超高性能混凝土在极限抗折和抗压荷载下的电阻率变化率和应力/应变灵敏度,且在抗折破坏荷载工况下的压敏性更好。通过力-电本构模型可知,其电阻率变化率和应力/应变曲线基本遵从三次多项式函数关系。因此,可通过测试镀铜钢纤维增强废弃陶瓷超高性能混凝土的电阻率实现混凝土结构的应力/应变监测。Abstract: The copper-plated steel fiber has excellent electrical conductivity, corrosion resistance and good mechanical properties. Compared with cement, the ceramic waste powder has low electrical resistivity, low carbon property, pozzolanic activity and internal curing. The synergy between copper-plated steel fiber and waste ceramic powder is expected to endow concrete with excellent and stable piezoresistivity and a wide stress/strain monitoring range. Therefore, low-carbon and smart copper-plated steel fiber reinforced ultra high performance concrete with ceramic waste was prepared. Then, the effects of copper-plated steel fibers content on the slump, electrical and piezoresistivity properties under different failure load types of the ultra high performance concrete with ceramic waste were analyzed, and the stress-electricity constitutive model was established. The results show that the spread of ultra high performance concrete with waste ceramic powder reduces with increasing copper-plated steel fiber content, but still has self-leveling compacting characteristics. The copper-plated steel fiber can significantly reduce the direct current and alternating current resistivity of the ultra high performance concrete with ceramic waste. The copper-plated steel fiber greatly improves the fractional change in resistivity and stress/strain sensitivity of the ultra high performance concrete with ceramic waste under ultimate flexural and compressive loads, and the piezoresistivity properties are better under the fracture failure condition. According to the stress-electricity constitutive model, both the fractional change in resistivity and stress/strain curves basically follow the cubic polynomial function relationship. Therefore, the copper-plated steel fiber reinforced ultra high performance concrete with ceramic waste can be used to monitor the stress/strain of concrete structures through testing resistivity.

-

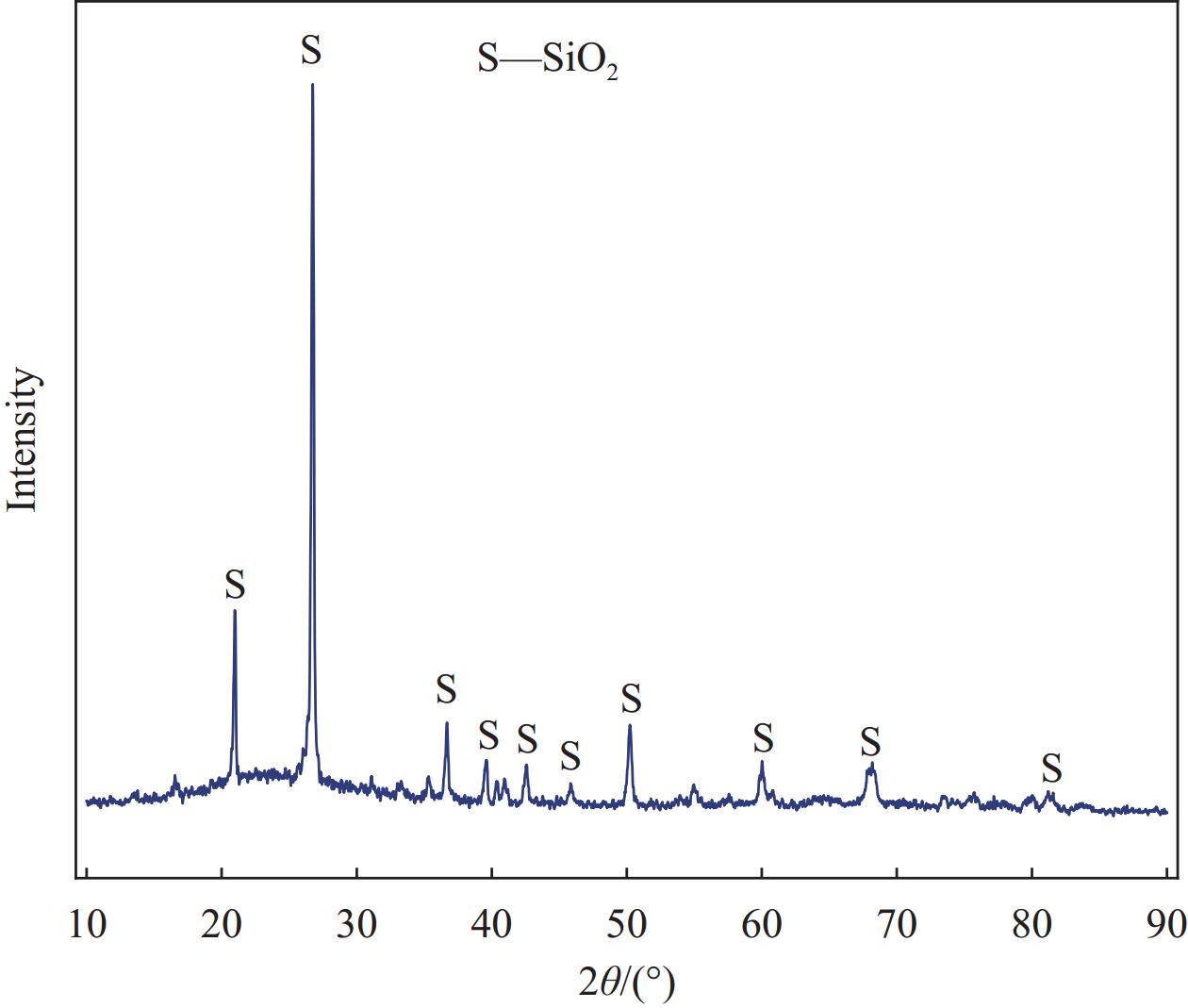

表 1 水泥和废弃陶瓷粉化学成分

Table 1. Chemical composition of cement and ceramic waste powder

Chemical

compositionCement/wt% Ceramic waste

powder/wt%CaO 62.769 1.704 SiO2 20.654 68.170 Al2O3 5.333 17.180 SO3 4.007 0.031 Fe2O3 3.189 1.114 MgO 2.557 0.722 K2O 0.768 6.104 TiO2 0.237 0.127 Na2O 0.191 0.031 P2O5 0.052 0.120 MnO 0.042 0.043 SrO 0.034 0.026 表 2 镀铜钢纤维增强废弃陶瓷超高性能混凝土的配合比

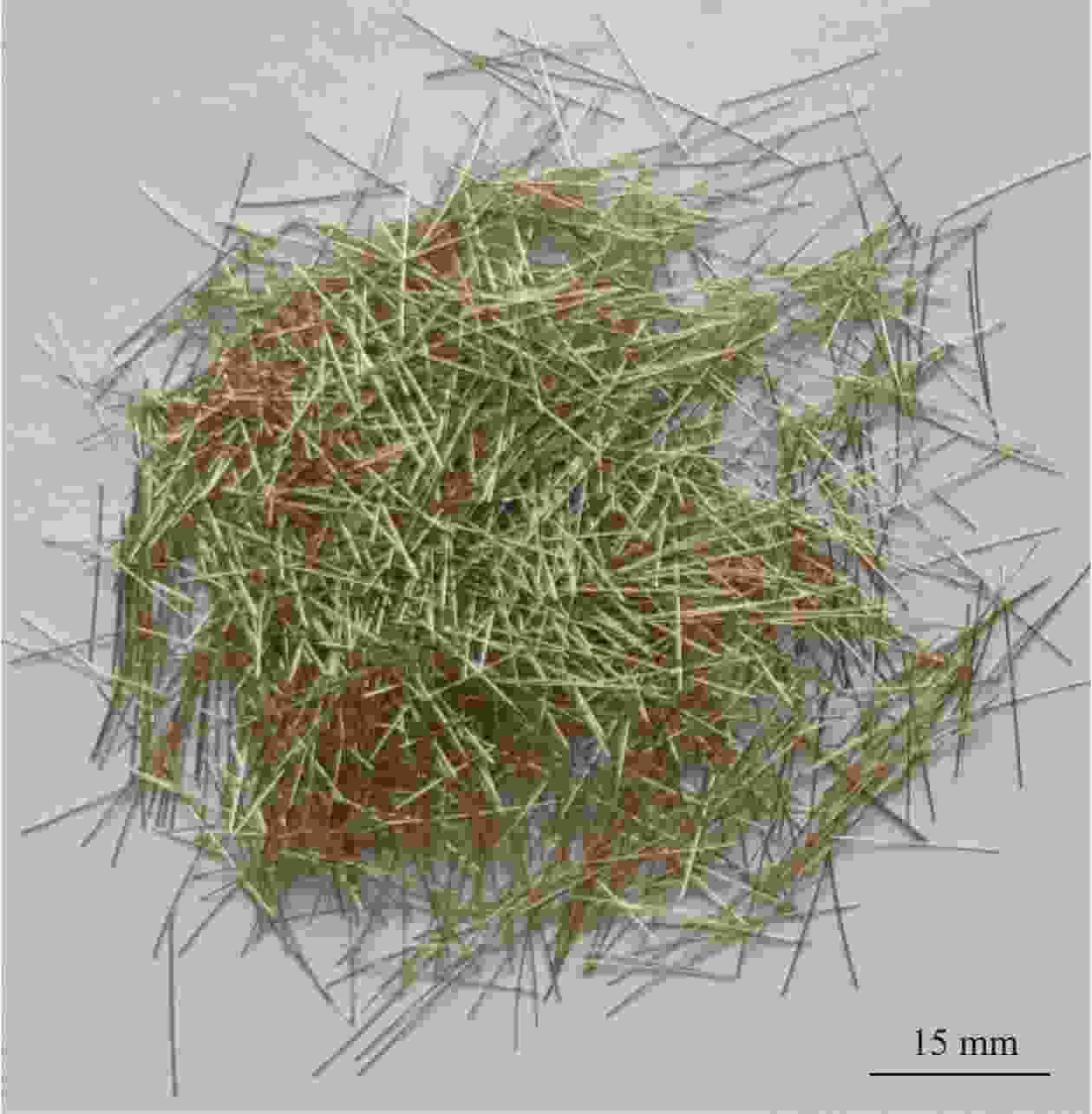

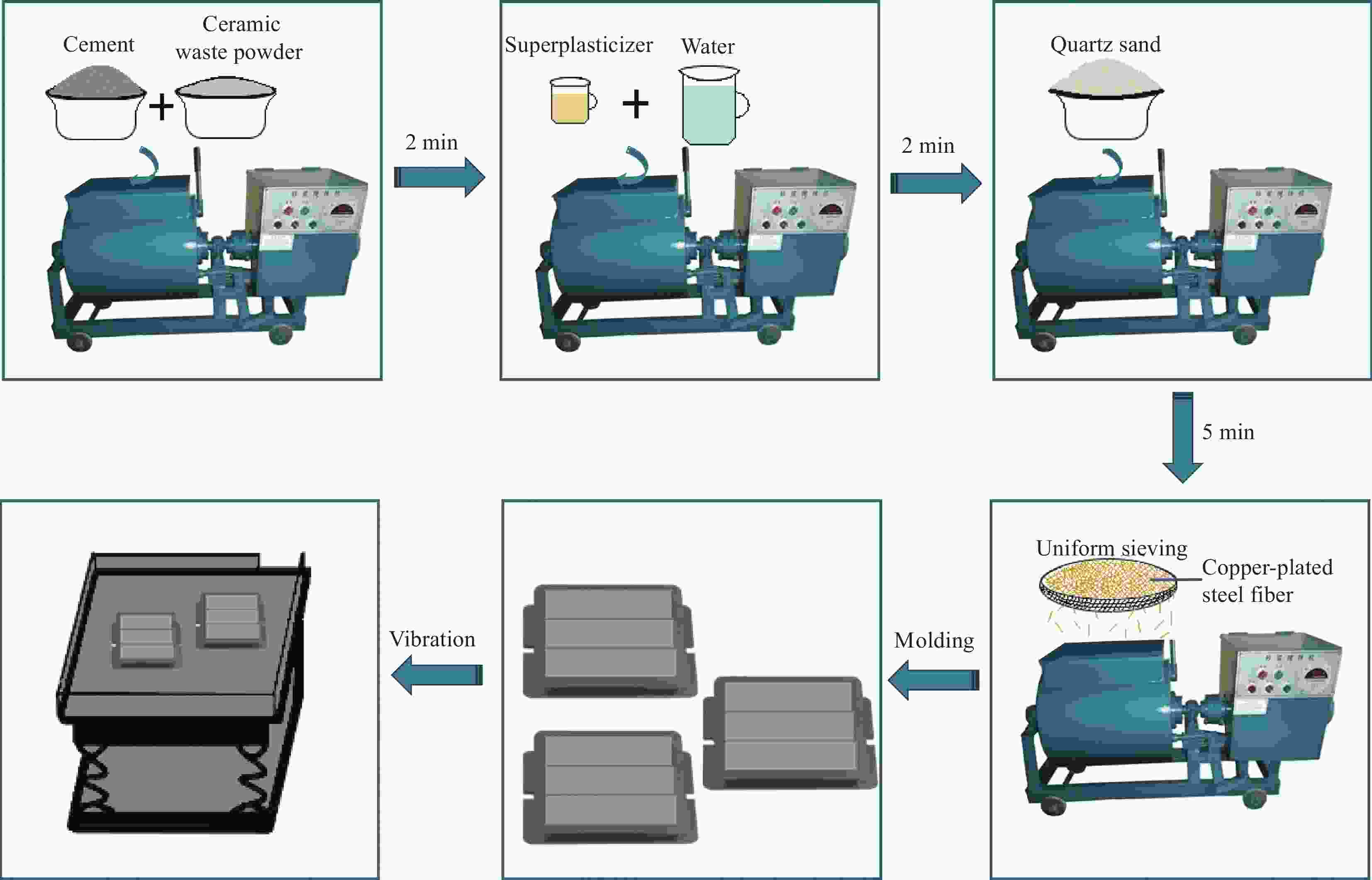

Table 2. Mix proportions copper-plated steel fiber reinforced ultra high performance concrete with ceramic waste powder

Specimen code Cement/% Ceramic waste

powder/%Quartz sand/% Water/% Copper-plated

steel fiber/vol%Superplasticizer/wt% 0.0vol% copper-plated steel fiber 75 25 100 18 0.00 1.50 0.5vol% copper-plated steel fiber 75 25 100 18 0.50 1.50 1.0vol% copper-plated steel fiber 75 25 100 18 1.00 1.50 1.5vol% copper-plated steel fiber 75 25 100 18 1.50 1.50 2.0vol% copper-plated steel fiber 75 25 100 18 2.00 1.50 2.5vol% copper-plated steel fiber 75 25 100 18 2.50 1.50 表 3 镀铜钢纤维间的平均间距

Table 3. Average distances of copper-plated steel fibers

Copper-plated steel fiber/vol% Average distance/mm 0.50 39.03 1.00 27.60 1.50 22.54 2.00 19.52 2.50 17.46 表 4 纯水泥和25%废弃陶瓷粉替代率水泥净浆的孔溶液离子浓度

Table 4. Pore solution ion contents of pure cement paste and cement paste with 25% ceramic waste powder

Main ion Ion content/(μg·mL−1) 100% cement 75% cement+25%

ceramic waste powderCa2+ 205.00 226.70 K+ 29.13 40.89 Na+ 7.53 9.23 Al3+ 0.51 0.35 Si4+ 0.49 0.35 Sr+ 0.38 0.38 Ba2+ 0.05 0.07 Mo2+ 0.01 0.06 Total content 243.10 278.03 表 5 纯水泥和25%废弃陶瓷粉替代率水泥净浆在全烘干状态下的电阻率和孔溶液电阻率

Table 5. Resistivity and pore solution resistivity of pure cement paste and cement paste with 25% ceramic waste powder in full drying condition

Specimen DC electrical

resistivity/

(Ω·cm)AC electrical

resistivity/

(Ω·cm)Pore solution

resistivity/

(Ω·cm)100% cement 168438.43 984026.19 292.22 75% cement+25% ceramic waste powder 56814.16 205888.52 264.55 -

[1] FAN L, MENG W N, TENG L, et al. Effect of steel fibers with galvanized coatings on corrosion of steel bars embedded in UHPC[J]. Composites Part B: Engineering, 2019, 177: 107445. doi: 10.1016/j.compositesb.2019.107445 [2] DEMIRCILIOGLU E, TEOMETE E, OZBULUT O E. Strain sensitivity of steel-fiber-reinforced industrial smart concrete[J]. Journal of Intelligent Material Systems and Structures, 2020, 31(1): 127-136. doi: 10.1177/1045389X19888722 [3] TUAN C Y. Electrical resistance heating of conductive concrete containing steel fibers and shavings[J]. ACI Materials Journal, 2004, 101(1): 65-71. [4] DONG S F, WANG X Y, ASHOUR A, et al. Enhancement and underlying mechanisms of stainless steel wires to fatigue properties of concrete under flexure[J]. Cement and Concrete Composites, 2022, 126: 104372. doi: 10.1016/j.cemconcomp.2021.104372 [5] DONG S F, HAN B G, OU J P, et al. Electrically conductive behaviors and mechanisms of short-cut super-fine stainless wire reinforced reactive powder concrete[J]. Cement and Concrete Composites, 2016, 72: 48-65. [6] DONG S F, WANG Y L, ASHOUR A, et al. Uniaxial compressive fatigue behavior of ultra-high performance concrete reinforced with super-fine stainless wires[J]. International Journal of Fatigue, 2021, 142: 105959. [7] SANTILLÁN N, SPERANZA S, TORRENTS J M, et al. Evaluation of conductive concrete made with steel slag aggregates[J]. Construction and Building Materials, 2022, 360: 129515. doi: 10.1016/j.conbuildmat.2022.129515 [8] DING Y, YANG Y, LIU R G, et al. Study on pressure sensitivity of smart polymer concrete based on steel slag[J]. Measurement, 2019, 140: 14-21. doi: 10.1016/j.measurement.2019.03.040 [9] 王云洋, 薛常喜, 丁思齐, 等. 埋入混凝土的自感知水泥基传感器受力分析[J]. 建筑材料学报, 2015, 18(4): 546-552, 558 .WANG Yunyang, XUE Changxi, DING Siqi, et al. Force analysis of self-sensing cement-based sensors embedded in concrete[J]. Journal of Building Materials, 2015, 18(4): 546-558(in Chinese). [10] HAN B G, WANG Y Y, SUN S W, et al. Nanotip-induced ultrahigh pressure-sensitive composites: Principles, properties and applications[J]. Composites Part A: Applied Science and Manufacturing, 2014, 59: 105-114. doi: 10.1016/j.compositesa.2014.01.005 [11] SONG F C, CHEN Q, JIANG Z W, et al. Piezoresistive properties of ultra-high-performance fiber-reinforced concrete incorporating few-layer graphene[J]. Construction and Building Materials, 2021, 305: 124362. doi: 10.1016/j.conbuildmat.2021.124362 [12] WANG Y Y, ZHANG L Q. Development of self-sensing cementitious composite incorporating hybrid graphene nanoplates and carbon nanotubes for structural health monitoring[J]. Sensors and Actuators A: Physical, 2022, 336: 113367. doi: 10.1016/j.sna.2022.113367 [13] LUO B F, DONG J. Optimizing piezoresistivity of alkali-activated mortar using carboxylated multi-walled carbon nanotubes/basalt fibers[J]. Materials Letters, 2022, 329: 133151. doi: 10.1016/j.matlet.2022.133151 [14] LIU L Y, XU J X, YIN T J, et al. Improving electrical and piezoresistive properties of cement-based composites by combined addition of nano carbon black and nickel nanofiber[J]. Journal of Building Engineering, 2022, 51: 104312. doi: 10.1016/j.jobe.2022.104312 [15] LU D, WANG D Y, ZHONG J. Highly conductive and sensitive piezoresistive cement mortar with graphene coated aggregates and carbon fiber[J]. Cement and Concrete Composites, 2022, 134: 104731. doi: 10.1016/j.cemconcomp.2022.104731 [16] 张立卿, 占小静, 韩宝国, 等. 静电自组装碳纳米管/二氧化钛水泥基复合材料的自感知性能[J]. 复合材料学报, 2023, 40(9): 5225-5240.ZHANG Liqing, ZHAN Xiaojing, HAN Baoguo, et al. Self-sensing performance of cementitious composites with electrostatic self-assembly carbon nanotube/titanium dioxide[J]. Acta Materiae Compositae Sinica , 2023, 40(9): 5225-5240(in Chinese). [17] RAM KUMAR D, THIRUMURUGAN V, SATYANARAYANAN K S. Experimental study on optimization of smart mortar with the addition of brass fibres[J]. Materials Today: Proceedings, 2022, 50: 388-393. doi: 10.1016/j.matpr.2021.11.371 [18] HAN J J, MIAO Z, WANG J L, et al. Investigation of the corrosion-induced damage mechanism of steel fibers in ultra-high-performance steel fiber-reinforced concrete using X-ray computed tomography[J]. Construction and Building Materials, 2023, 368: 130429. doi: 10.1016/j.conbuildmat.2023.130429 [19] FARHAN N A, SHEIKH M N, HADI M N S. Experimental investigation on the effect of corrosion on the bond between reinforcing steel bars and fibre reinforced geopolymer concrete[J]. Structures, 2018, 14: 251-261. doi: 10.1016/j.istruc.2018.03.013 [20] SU N Y, FAN X C. Experimental study on flexural toughness of steel-polyvinyl alcohol hybrid fiber reinforced concrete[J]. IOP Conference Series: Earth and Environmental Science, 2021, 719(2): 022080. doi: 10.1088/1755-1315/719/2/022080 [21] ASHKEZARI G D, FOTOUHI F, RAZMARA M. Experimental relationships between steel fiber volume fraction and mechanical properties of ultra-high performance fiber-reinforced concrete[J]. Journal of Building Engineering, 2020, 32: 101613. doi: 10.1016/j.jobe.2020.101613 [22] 周天舒, 孙亚飞, 彭月月. 复掺功能填料机敏混凝土的压阻响应[J]. 材料科学与工程学报, 2021, 39(5): 763-767. doi: 10.14136/j.cnki.issn.1673-2812.2021.05.009ZHOU Tianshu, SUN Yafei, PENG Yueyue. Piezoresistive response of smart concrete with compounding functional filler[J]. Journal of Materials Science and Engineering, 2021, 39(5): 763-767(in Chinese). doi: 10.14136/j.cnki.issn.1673-2812.2021.05.009 [23] 张立卿, 潘延念, 胡文兵, 等. 废弃瓷砖粉对超高性能混凝土的抗压强度影响规律与机制[J]. 复合材料学报, 2023, 40(3): 1611-1623. doi: 10.13801/j.cnki.fhclxb.20220630.002ZHANG Liqing, PAN Yannian, HU Wenbing, et al. Effect law and mechanism of ceramic tile powder on compressive strength of ultra high performance concrete[J]. Acta Materiae Compositae Sinica, 2023, 40(3): 1611-1623(in Chinese). doi: 10.13801/j.cnki.fhclxb.20220630.002 [24] ZHANG L Q, SHEN H, XU K C, et al. Effect of ceramic waste tile as a fine aggregate on the mechanical properties of low-carbon ultrahigh performance concrete[J]. Construction and Building Materials, 2023, 370: 130595. [25] ABUSHANAB A, ALNAHHAL W, SOHAIL M G, et al. Mechanical and durability properties of ultra-high performance steel FRC made with discarded materials[J]. Journal of Building Engineering, 2021, 44: 103264. doi: 10.1016/j.jobe.2021.103264 [26] 田晓鹤. 混杂纤维增强混凝土压敏性试验研究[J]. 湖南交通科技, 2017, 43(2): 116-119.TIAN Xiaohe. Experimental study on piezoresistive of hybrid fiber reinforced concrete[J]. Hunan Communication Science and Technology, 2017, 43(2): 116-119(in Chinese). [27] 王林飞, 杜红秀, 刘晓仙. 混杂纤维对活性粉末混凝土压敏性的影响[J]. 混凝土, 2021(1): 66-69. doi: 10.3969/j.issn.1002-3550.2021.01.016WANG Linfei, DU Hongxiu, LIU Xiaoxian. Effect of pressure sensitivity on hybrid fiber of reactive concrete[J]. Concrete, 2021(1): 66-69(in Chinese). doi: 10.3969/j.issn.1002-3550.2021.01.016 [28] LEE S H, KIM S, YOO D Y. Hybrid effects of steel fiber and carbon nanotube on self-sensing capability of ultra-high-performance concrete[J]. Construction and Building Materials, 2018, 185: 530-544. doi: 10.1016/j.conbuildmat.2018.07.071 [29] WANG L F, ZHANG Y F, DU H X, et al. Health monitoring of C60 smart concrete based on self-sensing[J]. Materials Today Communications, 2023, 35: 105834. doi: 10.1016/j.mtcomm.2023.105834 [30] XU K C, HUANG W Y, ZHANG L Q, et al. Mechanical properties of low-carbon ultrahigh-performance concrete with ceramic tile waste powder[J]. Construction and Building Materials, 2021, 287: 123036. doi: 10.1016/j.conbuildmat.2021.123036 [31] 中华人民共和国住房和城乡建设部. 普通混凝土拌合物性能试验方法标准: GB/T 50080—2016[S]. 北京: 中国标准出版社, 2016.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test method of performance on ordinary fresh concrete: GB/T 50080—2016[S]. Beijing: Standards Press of China, 2016(in Chinese). [32] ROMUALDI J P, MANDEL J A. Tensile strength of concrete affected by uniformly distributed and closely spaced short lengths of wire reinforcement[J]. Journal of the American Concrete Institute, 1964, 61(6): 27-37. [33] BACH T T H, COUMES C C D, POCHARD I, et al. Influence of temperature on the hydration products of low pH cements[J]. Cement and Concrete Research, 2012, 42(6): 805-817. doi: 10.1016/j.cemconres.2012.03.009 [34] ANDERSSON K, ALLARD B, BENGTSSON M, et al. Chemical composition of cement pore solutions[J]. Cement and Concrete Research, 1989, 19(3): 327-332. doi: 10.1016/0008-8846(89)90022-7 [35] ZHANG L Q, ZHENG Q F, DONG X F, et al. Tailoring sensing properties of smart cementitious composites based on excluded volume theory and electrostatic self-assembly[J]. Construction and Building Materials, 2020, 256: 119452. doi: 10.1016/j.conbuildmat.2020.119452 [36] 董素芬. 特细钢微丝复合活性粉末混凝土力学与功能性能[D]. 大连: 大连理工大学, 2018.DONG Sufen. Mechanical and functional performances of super-fine stainless wire reinforced reactive powder concrete[D]. Dalian: Dalian University of Technology, 2018(in Chinese). [37] WEN S H, CHUNG D D L. A comparative study of steel-and carbon-fibre cement as piezoresistive strain sensors[J]. Advances in Cement Research, 2003, 15(3): 119-128. doi: 10.1680/adcr.2003.15.3.119 [38] CHEN X Y, ZHANG D, CHENG S K, et al. Sustainable reuse of ceramic waste powder as a supplementary cementitious material in recycled aggregate concrete: Mechanical properties, durability and microstructure assessment[J]. Journal of Building Engineering, 2022, 52: 104418. doi: 10.1016/j.jobe.2022.104418 [39] XU F M, LIN X S, ZHOU A N, et al. Effects of recycled ceramic aggregates on internal curing of ultra high performance concrete[J]. Construction and Building Materials, 2022, 322: 126484. doi: 10.1016/j.conbuildmat.2022.126484 -

下载:

下载: