Performance optimization and deterioration mechanism of fiber reinforced epoxy/vinyl resin composite materials: A review

-

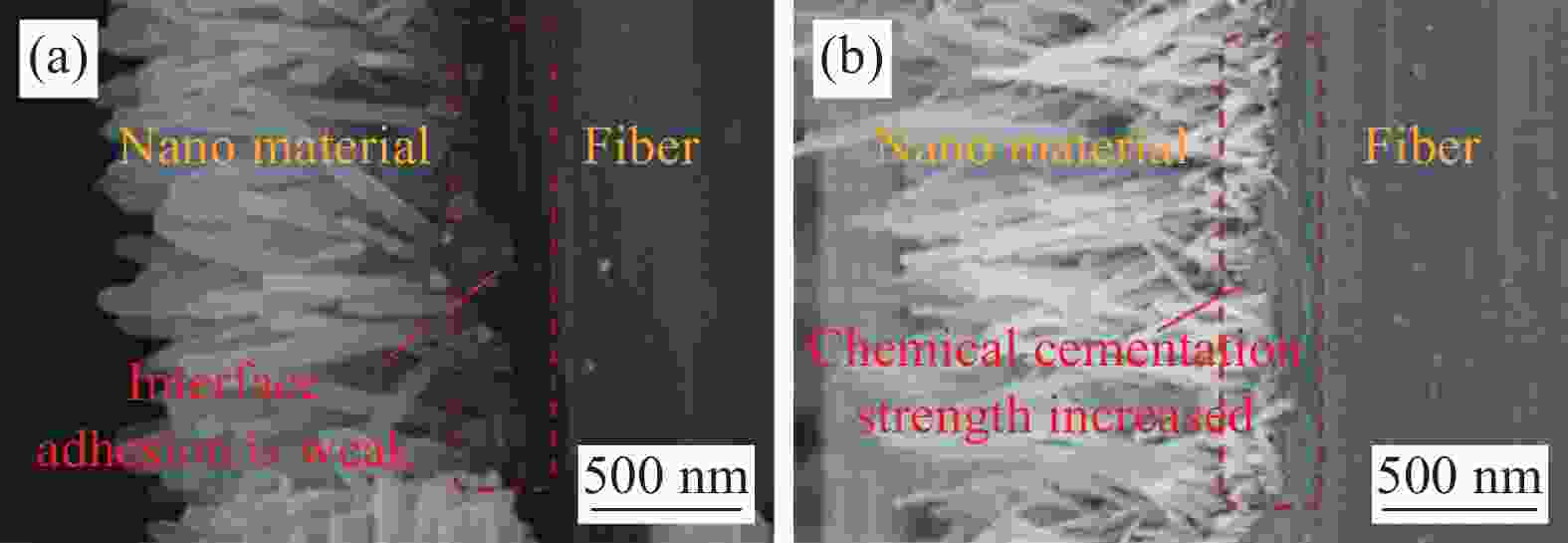

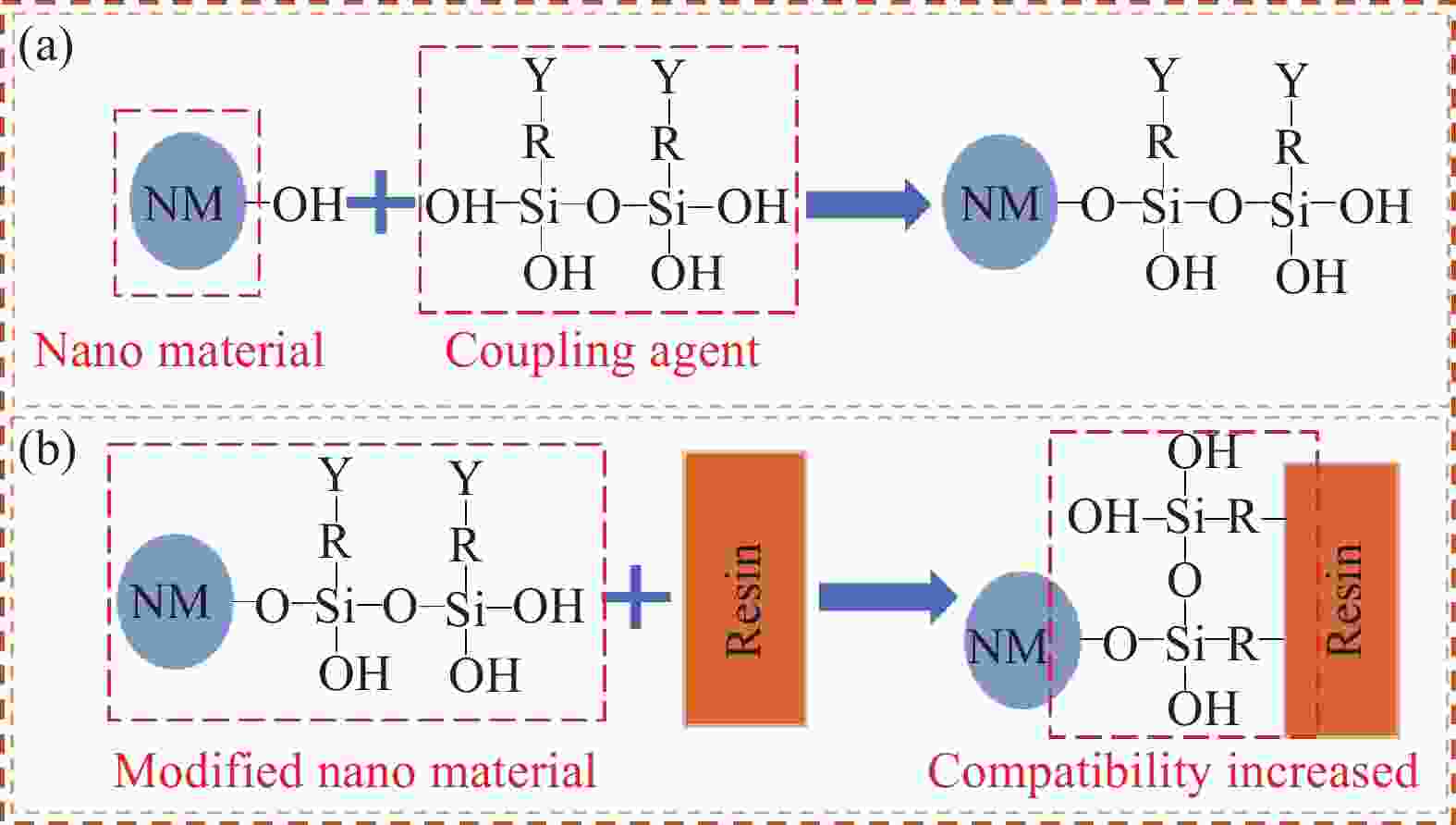

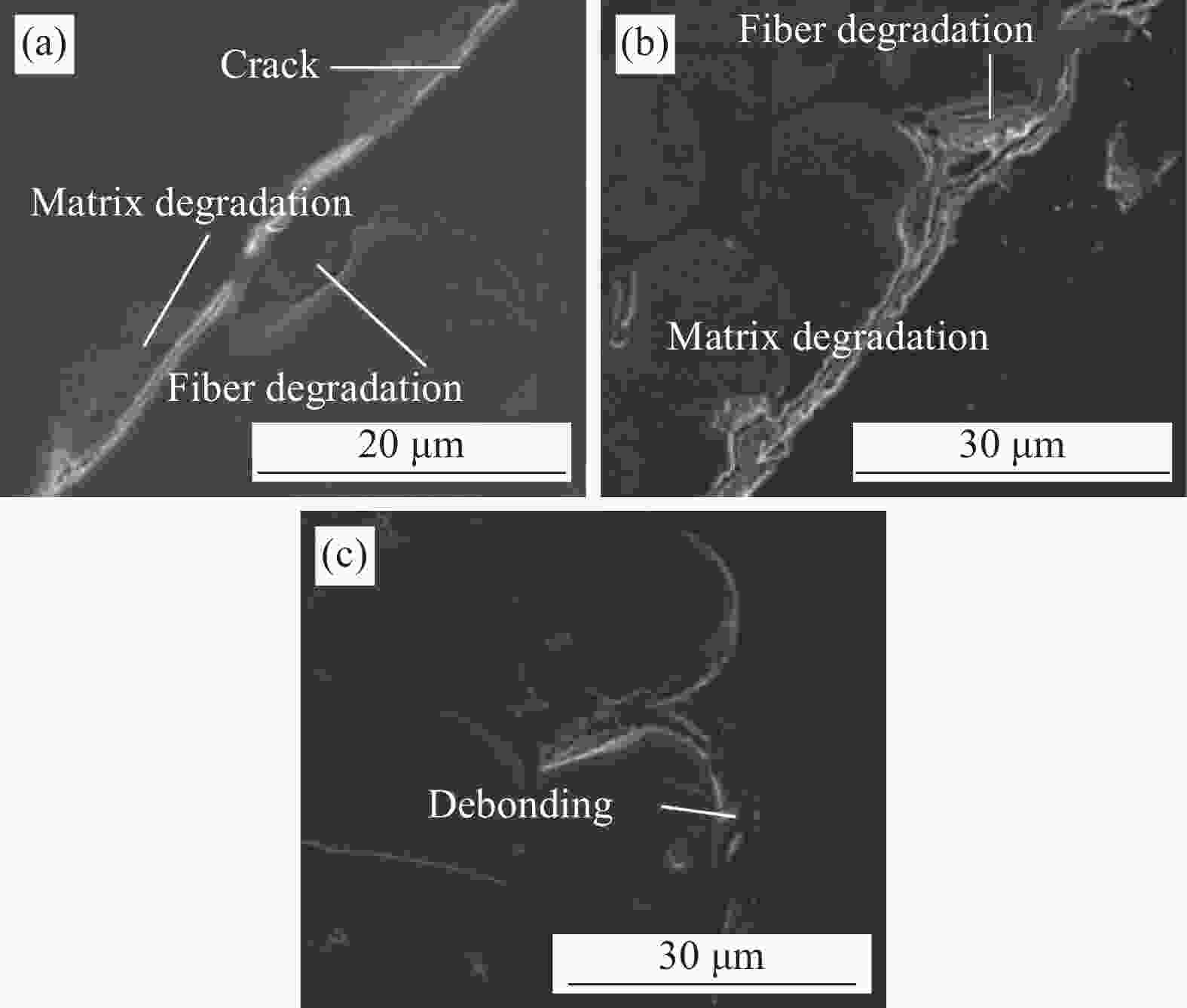

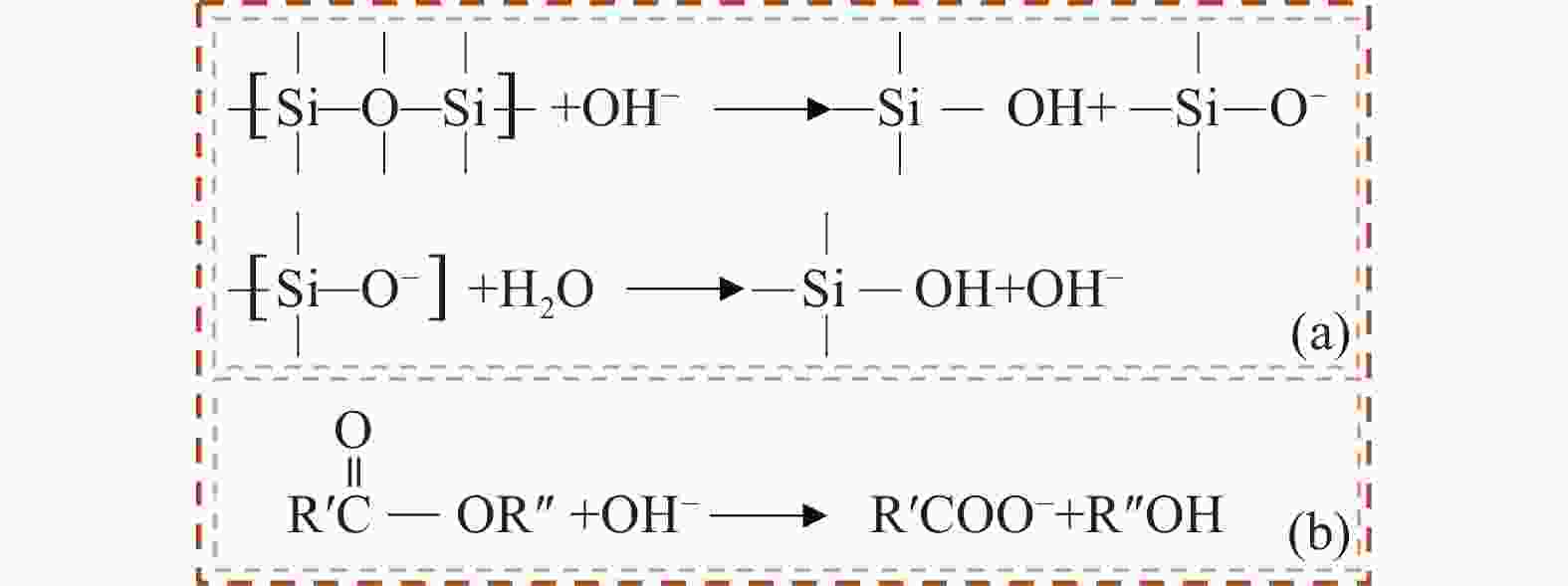

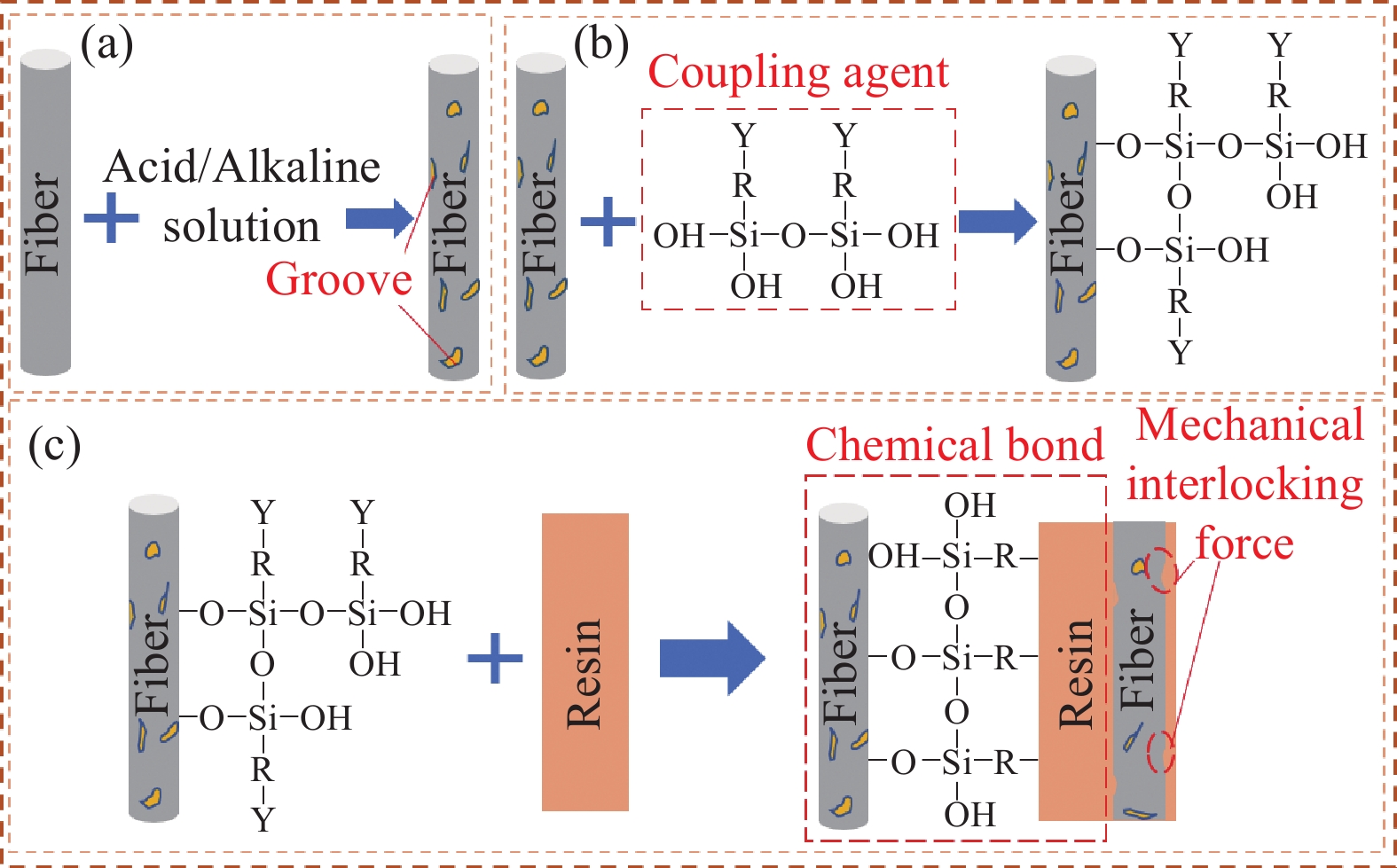

摘要: 纤维增强聚合物(FRP)复合材料具有轻质高强、耐腐蚀、经济效益高的优势,在基础建设施设中表现出巨大潜力,但在复杂环境下长期服役后,FRP复合材料的力学性能下降超过50%,限制了其在工程中的应用。基于此,针对FRP复合材料各组分优化设计方法进行了总结,并分析了热氧、紫外线、腐蚀介质环境中FRP复合材料的长期性能演化规律;根据化学结构及微观形貌分析,阐述了FRP复合材料在复杂环境中的劣化机制,进一步归纳了其在复杂环境下的长期性能预测模型,可为保证FRP复合材料在复杂环境中的长期使用性能提供理论依据,促进其在实际工程中的应用。Abstract: Fiber reinforced polymer (FRP) composite has great potential in infrastructure construction due to the advantages of light weight and high strength, corrosion resistance and high economic benefit. However, the performance of FRP composite will decrease by more than 50% after long-term service in complex environment, which limits its application in engineering. In the paper, the enhancement methods of different FRP composites components are reviewed. The evolution law of FRP composites on long-term properties under thermal oxygen, ultraviolet and corrosive media environment are revealed, and the deterioration mechanism of FRP composites in complex environment is elucidated by the analysis of chemical structure and microstructure. In addition, the long-term performance prediction model of FRP composites under complex environments is summarized, which can provide theoretical basis for ensuring the long-term performance of FRP composites in complex environment and promote its application in practical engineering.

-

表 1 FRP复合材料力学性能特征预测模型

Table 1. Features of mechanical properties prediction models of FRP composites

Number Document Predicting value Prediction model Annotation 1 [63] Porosity of composites, $ {{P}}_{\text{s}} $ $ \alpha=\dfrac{29.92}{t+13}+\dfrac{0.75}{t+0.48}P_{\mathrm{s}}+0.12P_{\mathrm{s}}^2 $ $ \alpha $ is the ultrasonic attenuation coefficient; $ {t} $ is the thickness of the FRP composite. 2 [64] Strength of the composite at porosity $v $, $ {\sigma }_{{\mathrm{pre}}\left(v\right)} $ $ \sigma_{\rm{pre}} (v)=\sigma_{0(0)} \mathrm{e}^{-a_2 v}$ $ {\sigma }_{\text{0(0)}} $ is the strength of the composites when the porosity is 0; v is the porosity; b, a1, a2 are the coefficients, respectively. 3 [65] $ \sigma_{\text {pre }(v)}=\sigma_{0(0)}-\dfrac{1}{1-a_1+a_1 \mathrm{e}^{b v}} $ 4 [66] Tensile strength of the composite, $ {\sigma }_{\text{cu}} $ $ \sigma_{{\mathrm{c u}}}=C_{{\mathrm{o s}}} \eta_{{\mathrm{1 s}}} \varPhi_{\mathrm{f}} \sigma_{{\mathrm{fu}}}+\sigma_{{{\mathrm{mu}}}}\left(1-\varPhi_{\mathrm{f}}\right) $ $ {{C}}_{\text{os}} $ is the fiber orientation coefficient; $ {\eta }_{\text{1}\text{s}} $ is the fiber length effective factor; $ {\sigma}_{\text{mu}} $ is the tensile strength of resin matrix; $ {\varPhi}_{\text{f}} $ is the fiber volume fraction; σfu is the tensile strength of fibers. 5 [68] Elasticity modulus of FRP composites, $ {{E}}_{\text{a}} $ $ \dfrac{E_{\rm {a}}}{E_{\rm {m}}}=\dfrac{1+V_{\rm{f}}}{1-1.25 V_{\rm{f}}+4.3\left(E_{\rm{m}}/ E_{\rm{f}}\right) V_{\rm{f}}} $

$ \sigma_{\mathrm{c}}=\left(1-d_{\mathrm{c}}\right) E_{\mathrm{a}} \varepsilon_0$$ {{E}}_{\text{m}} $ is the elasticity modulus of resin matrix; $ {{E}}_{\text{f}} $ is the elasticity modulus of fibers; $ {{V}}_{\text{f}} $ is the volume fraction of fibers; $ \sigma_{\mathrm{c}} $ is the strength of composites; $ {d}_{{\mathrm{c}}} $ is the damage factor; $ {\varepsilon }_{0} $ is the strain of composites. 表 2 FRP复合材料长期性能预测模型

Table 2. Features of long-term performance prediction models of FRP composites

Number Document Predicting value Prediction model Annotation 1 [72] Tensile strength retention rate, $ \mathit{{Y}} $ $ Y =100\left(1-\dfrac{\sqrt{2 D_0 C_t}}{r_0}\right)^2 $

$ \dfrac{M_t}{M_{\infty}} =1-\exp \left[7.3\left(\dfrac{D_0 t}{h^2}\right)^{0.75}\right]$$ {D}_{0} $ is the diffusion coefficient; $ {{C}}_{{t}} $ is the ion concentration of solution; $ {{r}}_{\text{0}} $ is the radius of the composites; $ {{M}}_{{t}} $ is the hygroscopicity of the FRP composites at time t; $ {{M}}_{\text{∞}} $is the saturated hygroscopicity; $ {h} $ is the thickness of material. 2 [74] Alculated diffusion coefficients after long-term aging, $ {D}_{{\mathrm{{\mathrm{c}}}}} $ $ {D}_{{\mathrm{c}}}={D}_{0}{{\mathrm{e}}}^{-\dfrac{{E}_{{\mathrm{a}}}}{RT}} $ $ {{E}}_{\text{a}} $ is the activation energy; $ {R} $ is the universal gas constant; $ {T} $ is the absolute temperature. 3 [75] Deterioration rate, K $K = A{\rm{exp}}\left( {\dfrac{{ - {E_{\rm{a}}}}}{{RT}}} \right) $ A is a constant. 4 [76] Temperature time-shift factor, $ \mathrm{TSF} $ $ \mathrm{TSF}=\exp\left[\dfrac{E_{\mathrm{a}}}{R}\left(\dfrac{1}{T_0}-\dfrac{1}{T_1}\right)\right] $ $ {{T}}_{\text{0}} $, $ {{T}}_{\text{1}} $ are the ambient temperature, respectively. 5 [77] Temperature-corrected time-shift factor, η $\eta=\dfrac{12}{\sum_1^{12} \exp \left[{E_{\mathrm{a}}}/{{R}}\left({1}/{T_{{\mathrm{A T}}}}-{1}/{T_{{\mathrm{M T}}}}\right)\right]}$ $ {{T}}_{\text{AT}} $ is the average annual temperature; $ {{T}}_{\text{MT}} $ is the average monthly temperature. 6 [76] Design value of tensile strength, $ {f}_{{\rm{ftd}}} $ $ {\mathrm{E R F}}=1-\beta\left[\varDelta_1-\rho \lg \left(\dfrac{{\mathrm{D L}}}{\alpha \cdot {\mathrm{T S F}} \cdot \eta}\right)\right]$

$ {{f}}_{\text{ftd}}\text{=}{{f}}_{\text{ftd}}\text{}{{\mathrm{ERF}}} $$ {{\mathrm{ERF}}} $ is the environmental factor; $ \beta $ is the correction factor of FRP composites; $ \alpha $is the correction factor of normal FRP composite; $ \varDelta _{\text{1}} $the strength decay rate of composites after one year exposure; $ \rho $is the slope of the linear regression of Arrhenius' formula; DL is design life in years. 7 [78] Strength retention rate, Yt ${Y_t} = (100 - {Y_\infty }){\rm{exp}}\left( {\dfrac{{ - t}}{\tau }} \right) + Y $ t is the exposure time; $ \tau $ is the fitting parameter; Y∞ is the strength retention of the composite when the exposure time is infinity. -

[1] HOLLAWAY L C. A review of the present and future utilisation of FRP composites in the civil infrastructure with re-ference to their important in-service properties[J]. Construction and Building Materials, 2010, 24(12): 2419-2445. [2] 朱海堂, 方高干, 孙丽萍. 纤维增强聚合物(FRP)耐久性能研究进展[J]. 玻璃钢/复合材料, 2009(2): 78-81, 86.ZHU Haitang, FANG Gaogan, SUN Liping. Progress of studies on durability of fiber reinforced polymer[J]. Composites Science and Engineering, 2009(2): 78-81, 86(in Chinese). [3] SALUDUNG A, OGAWA Y, KAWAI K. Microstructure and mechanical properties of epoxy resin-reinforced geopolymer exposed to high temperatures[J]. Materials Letters, 2023, 331: 133473. doi: 10.1016/j.matlet.2022.133473 [4] PRASAD M M, KISHORE R, BHARATHY G N, et al. Investi-gation on mechanical, microstructural and thermal properties of coconut peduncle fibre epoxy resin[J]. Materials Today: Proceedings, 2022, 69: 1478-1484. doi: 10.1016/j.matpr.2022.10.092 [5] 陈广立, 耿浩然, 陈俊华, 等. 不同处理方法对碳纤维表面形态及Cf/C复合材料强度的影响[J]. 材料工程, 2006(S1): 160-164.CHEN Guangli, GENG Haoran, CHEN Junhua, et al. Effect of carbon fibers surface and strength of Cf/C composite by different treatment methods[J]. Journal of Materials Engineering, 2006(S1): 160-164(in Chinese). [6] JIAO L, ZHAO X, GUO Z, et al. Effect of γ irradiation on the properties of functionalized carbon-doped boron nitride reinforced epoxy resin composite[J]. Polymer Degradation and Stability, 2022, 206: 110167. doi: 10.1016/j.polymdegradstab.2022.110167 [7] 李静, 申士杰, 袁卉, 等. 表面处理对玄武岩纤维增强酚醛树脂复合材料界面结合强度的影响[J]. 材料导报, 2013, 27(20): 71-73, 94.LI Jing, SHEN Shijie, YUAN Hui, et al. Influence of surface treatment on the interface bonding strength of basalt fiber reinforced phenolic resin composite[J]. Materials Reports, 2013, 27(20): 71-73, 94(in Chinese). [8] 李静, 申士杰, 李伟娜, 等. 酸刻蚀对玄武岩纤维表面偶联剂吸附量及纤维/环氧树脂复合材料力学性能的影响[J]. 复合材料学报, 2014, 31(4): 888-894.LI Jing, SHEN Shijie, LI Weina, et al. Effect of acid modification on coupling agent amount of basalt fiber surface and mechanical property of BF/expoxy composites[J]. Acta Materiae Compositae Sinica, 2014, 31(4): 888-894(in Chinese). [9] WU G, MA L, LIU L, et al. Interfacially reinforced methylphenylsilicone resin composites by chemically grafting multiwall carbon nanotubes onto carbon fibers[J]. Composites Part B: Engineering, 2015, 82: 50-58. doi: 10.1016/j.compositesb.2015.08.012 [10] QIN J, WAN C, YAO Z, et al. Growing carbon nanotubes on continuous carbon fibers to produce composites with improved interfacial properties: A step towards commercial production and application[J]. Composites Science and Technology, 2021, 211: 10887. [11] MA L X, ZHANG J W, TENG C Q. Covalent functionalization of aramid fibers with zinc oxide nano-interphase for improved UV resistance and interfacial strength in composites[J]. Composites Science and Technology, 2020, 188: 107996. doi: 10.1016/j.compscitech.2020.107996 [12] ZHANG J W, TENG C Q. Nondestructive growing nano-ZnO on aramid fibers to improve UV resistance and enhance interfacial strength in composites[J]. Materials & Design, 2020, 192: 108774. [13] 敖玉辉, 陈丽岩, 孙阳阳, 等. 乙烯基酯树脂固化条件及其复合材料的研究[J]. 高科技纤维与应用, 2010, 35(6): 46-50. doi: 10.3969/j.issn.1007-9815.2010.06.010AO Yuhui, CHEN Liyan, SUN Yangyang, et al. Investigation on the curing technology and composite of epoxy vinyl ester resin[J]. Hi-Tech Fiber and Application, 2010, 35(6): 46-50(in Chinese). doi: 10.3969/j.issn.1007-9815.2010.06.010 [14] 闫兴艳, 彭阳峰, 童天中, 等. 潮湿表面用环氧树脂固化剂的合成及其性能[J]. 热固性树脂, 2022, 37(5): 1-6.YAN Xingyan, PENG Yangfeng, TONG Tianzhong, et al. Synthesis and properties of epoxy resin curing agent for wet surface[J]. Thermosetting Resin, 2022, 37(5): 1-6(in Chinese). [15] 李伟捷, 光善仪, 徐洪耀. 不同固化剂复配的耐高温环氧树脂体系性能[J]. 高分子材料科学与工程, 2022, 38(5): 69-80.LI Weijie, GUANG Shanyi, XU Hongyao. Properties of high temperature resistant epoxy resin cured by different mixed curing agents[J]. Polymer Materials Science & Engineering, 2022, 38(5): 69-80(in Chinese). [16] 谢卫刚, 赵东林, 景磊, 等. 石墨烯/环氧树脂复合材料的制备与力学性能[J]. 高分子材料科学与工程, 2012, 28(9): 129-132.XIE Weigang, ZHAO Donglin, JING Lei, et al. Preparation and mechanical properties of graphene/epoxy composites by in situ reduction of graphene oxide[J]. Polymer Materials Science & Engineering, 2012, 28(9): 129-132(in Chinese). [17] ZHANG D, HUANG Y, CHIA L. Effects of carbon nanotube (CNT) geometries on the dispersion characterizations and adhesion properties of CNT reinforced epoxy composites[J]. Composite Structures, 2022, 296: 115942. doi: 10.1016/j.compstruct.2022.115942 [18] SU Z, SCHADLER L S, DUNCAN R, et al. Mechanisms leading to improved mechanical performance in nanoscale alumina filled epoxy[J]. Composites Science and Technology, 2008, 68: 2965-2975. doi: 10.1016/j.compscitech.2008.01.009 [19] ZHOU Y, WHITE E, HOSUR M, et al. Effect of particle size and weight fraction on the flexural strength and failure mode of TiO2 particles reinforced epoxy[J]. Materials Letters, 2010, 64: 806-809. doi: 10.1016/j.matlet.2010.01.016 [20] LI H, ZHANG Z, MA X, et al. Synthesis and characterization of epoxy resin modified with nano-SiO2 and γ-glycidoxypropyltrimethoxy silane[J]. Surface and Coatings Technology, 2007, 201(9-11): 5269-5272. doi: 10.1016/j.surfcoat.2006.07.143 [21] ZHAO R, LUO W. Fracture surface analysis on nano-SiO2/epoxy composite[J]. Materials Science and Engineering: A, 2008(483-484): 313-315. [22] 史孝群, 肖久梅, 马文江, 等. 硅烷偶联剂在聚合物基复合材料增容改性中的应用[J]. 工程塑料应用, 2002(7): 54-56.SHI Xiaoqun, XIAO Jiumei, MA Wenjiang, et al. Application of silane coupling agents in the improving compatibility and modification of polymer composites[J]. Engineering Plastics Application, 2002(7): 54-56(in Chinese). [23] TSAI Y, BOSZE E, BARJASTEH E, et al. Influence of hygrothermal environment on thermal and mechanical properties of carbon fiber/fiber glass hybrid composites[J]. Composites Science and Technology, 2009, 69(3-4): 432-437. doi: 10.1016/j.compscitech.2008.11.012 [24] MANSOURI L, DJEBBAR A, KHATIR S, et al. Effect of hygrothermal aging in distilled and saline water on the mechani-cal behaviour of mixed short fibre/woven composites[J]. Composite structures, 2019, 207: 816-825. doi: 10.1016/j.compstruct.2018.09.067 [25] ELLYIN F, MASER R. Environmental effects on the mecha-nical properties of glass-fiber epoxy composite tubular specimens[J]. Composites Science and Technology, 2004, 64(12): 1863-1874. doi: 10.1016/j.compscitech.2004.01.017 [26] 樊威, 李嘉禄. 热氧老化对碳纤维织物增强聚合物基复合材料弯曲性能的影响[J]. 复合材料学报, 2015, 32(5): 1260-1270.FAN Wei, LI Jialu. Effect of thermo-oxidative aging on flexural properties of carbon fiber fabric reinforced polymer matrix composites[J]. Acta Materiae Compositae Sinica, 2015, 32(5): 1260-1270(in Chinese). [27] SHAUN C, LUNGU C. Influence of temperature on styrene emission from a vinyl ester resin thermoset composite material[J]. Science of the Total Environment, 2011, 409(18): 3403-3408. doi: 10.1016/j.scitotenv.2011.05.042 [28] 贾耀雄, 许良, 敖清阳, 等. 不同热氧环境对T800碳纤维/环氧树脂复合材料力学性能的影响[J]. 材料工程, 2022, 50(4): 156-161. doi: 10.11868/j.issn.1001-4381.2021.000678JIA Yaoxiong, XU Liang, AO Qingyang, et al. Effect of dif-ferent thermal-oxidative environments on mechanical properties of T800 carbon fiber/epoxy resin composites[J]. Journal of Materials Engineering, 2022, 50(4): 156-161(in Chinese). doi: 10.11868/j.issn.1001-4381.2021.000678 [29] 李习习, 王涛, 侯锐钢. 玻璃纤维/乙烯基酯树脂复合材料的热老化机理[J]. 热固性树脂, 2020, 35(1): 49-53.LI Xixi, WANG Tao, HOU Ruigang. Thermal aging mecha-nism of glass fiber/vinyl ester resin composites[J]. Ther-mosetting Resin, 2020, 35(1): 49-53(in Chinese). [30] 王国建, 孙耀宁, 蒋万乐, 等. 玻璃纤维增强环氧乙烯基酯树脂基复合材料的热老化性能[J]. 工程塑料应用, 2017, 45(10): 87-91, 107. doi: 10.3969/j.issn.1001-3539.2017.10.016WANG Guojian, SUN Yaoning, JIANG Wanle, et al. Thermal aging properties of GF reinforced epoxy vinyl ester resin matrix composites[J]. Engineering Plastics Application, 2017, 45(10): 87-91, 107(in Chinese). doi: 10.3969/j.issn.1001-3539.2017.10.016 [31] 曹诺, 符永高, 王玲, 等. 废PCB粉料/环氧树脂再生复合材料的抗热氧老化改性研究[J]. 塑料科技, 2016, 44(12): 43-46. doi: 10.15925/j.cnki.issn1005-3360.2016.12.005CAO Nuo, FU Yonggao, WANG Ling, et al. Study on thermo-oxidation aging resistance of waste PCB non-metallic powder/epoxy resin recycled composites[J]. Plastics Science and Technology, 2016, 44(12): 43-46(in Chinese). doi: 10.15925/j.cnki.issn1005-3360.2016.12.005 [32] 刘虹邑, 范东阳, 李愿杰, 等. 环氧树脂复合材料的耐热氧老化改性[J]. 高分子材料科学与工程, 2021, 37(8): 102-109. doi: 10.16865/j.cnki.1000-7555.2021.0204LIU Hongyi, FAN Dongyang, LI Yuanjie, et al. Modification of epoxy resin composites with thermo-oxidative aging properties[J]. Polymer Materials Science & Engineering, 2021, 37(8): 102-109(in Chinese). doi: 10.16865/j.cnki.1000-7555.2021.0204 [33] 岳清瑞, 杨勇新. 纤维增强复合材料加固结构耐久性研究综述[J]. 建筑结构学报, 2009, 30(6): 8-15.YUE Qingrui, YANG Yongxin. Introduction to durability of concrete strengthened with fiber reinforced polymers[J]. Journal of Building Structures, 2009, 30(6): 8-15(in Chinese). [34] TANKS J, NAITO K. UV durability assessment of a thermoplastic epoxy-based hybrid composite rod for structural reinforcement and retrofitting[J]. Journal of Building Engineering, 2022, 48: 103922. doi: 10.1016/j.jobe.2021.103922 [35] JOSEPH P V, RABELLO M S, MATTOSO L H C, et al. Environ-mental effects on the degradation behaviour of sisal fiber reinforced polypropylene composites[J]. Composites Science and Technology, 2002, 62: 1357-1372. doi: 10.1016/S0266-3538(02)00080-5 [36] NAKADA M, MIYANO Y, KINOSHITA M, et al. Time-temperature dependence of tensile strength of unidirectional CFRP[J]. Journal of Composite Materials, 2002, 36(22): 2567-2581. doi: 10.1177/002199802761405295 [37] FELIPE R C T S, FELIPE R N B, BATISTA A C M C, et al. Influence of environmental aging in two polymer-reinforced composites using different hybridization methods: Glass/Kevlar fiber hybrid strands and in the weft and warp alternating Kevlar and glass fiber strands[J]. Composites Part B: Engineering, 2019, 174: 106994. doi: 10.1016/j.compositesb.2019.106994 [38] 王国建, 孙耀宁, 蒋万乐, 等. 紫外线对玻纤环氧乙烯基酯树脂基复合材料性能的影响[J]. 材料科学与工艺, 2017, 25(3): 46-51.WANG Guojian, SUN Yaoning, JIANG Wanle, et al. Effect of UV on the properties of glass epoxy vinyl resin-based composites[J]. Materials Science and Technology, 2017, 25(3): 46-51(in Chinese). [39] SEVIM C, VARLIKLI C. Solar and environmental degradation effect on tensile strength and glass transition temperature of glass fibre reinforced plastic laminates[J]. Polymers & Polymer Composites, 2010, 18(6): 283-287. [40] RAMESHKUMARR C, ANDERSON A, RAVICHANDRAN S. UV, FIRT and surface properties of fiber reinforced low-density polyethylene laminated composites[J]. Materials Today: Proceedings, 2021, 45: 6216-6223. doi: 10.1016/j.matpr.2020.10.565 [41] SHINY L, SHUBHAM, RAJESH K P, et al. Effect of ultravio-let radiations on interlaminar shear strength and thermal properties of glass fiber/epoxy composites[J]. Materials Today: Proceedings, 2021, 43: 524-529. doi: 10.1016/j.matpr.2020.12.028 [42] ZHAI Z, FENG L, LI G, et al. The anti-ultraviolet light (UV) aging property of aluminium particles/epoxy composite[J]. Progress in Organic Coatings, 2016, 101: 305-308. doi: 10.1016/j.porgcoat.2016.09.006 [43] TENNENT N H. Clear and pigmented epoxy resins for stained glass conservation: Light ageing studies[J]. Studies in Conservation, 1979, 24(4): 153-164. [44] CABRAL FONSECA S, CORREIA J, RODRIGUES M, et al. Artificial accelerated ageing of GFRP pultruded profiles made of polyester and vinylester resins: Characterisation of phy-sical-chemical and mechanical damage[J]. Strain, 2012, 48: 162-173. doi: 10.1111/j.1475-1305.2011.00810.x [45] ROSU D, ROSU L, CASCAVAL C N. Effect of ultraviolet ra-diation on vinyl ester network based on bisphenol A[J]. Journal of Photochemistry and Photobiology A: Chemistry, 2008, 194(2-3): 275-282. doi: 10.1016/j.jphotochem.2007.08.025 [46] WU C, MENG B C, TAM L, et al. Yellowing mechanisms of epoxy and vinyl ester resins under thermal, UV and na-tural aging conditions and protection methods[J]. Polymer Testing, 2022, 114: 107708. [47] 别依诺, 朱四荣, 贺攀, 等. 纳米SiO2-硅烷协同改性对玄武岩纤维/环氧树脂复合材料力学性能及蠕变性能的影响[J]. 复合材料学报, 2022, 39(8): 3723-3732.BIE Yinuo, ZHU Sirong, HE Pan, et al. Effect of nano-SiO2 particles-silane synergistic modification on mechanical properties and creep properties of basalt fiber/epoxy composites[J]. Acta Materiae Compositae Sinica, 2022, 39(8): 3723-3732. [48] KHOTBEHSARA M M, MANALO A, ARAVINTHAN T, et al. Effects of ultraviolet solar radiation on the properties of particulate-filled epoxy based polymer coating[J]. Polymer Degradation and Stability, 2020, 181: 109352. doi: 10.1016/j.polymdegradstab.2020.109352 [49] QI Y L, XIANG B, ZHANG J. Effect of titanium dioxide (TiO2) with different crystal forms and surface modifications on cooling property and surface wettability of cool roofing materials[J]. Solar Energy Materials and Solar Cells, 2017, 172: 34-43. doi: 10.1016/j.solmat.2017.07.017 [50] WANG S, ZHANG J, LIU L, et al. Evaluation of cooling pro-perty of high density polyethylene (HDPE)/titanium dio-xide (TiO2) composites after accelerated ultraviolet (UV) irradiation[J]. Solar Energy Materials and Solar Cells, 2015, 143: 120-127. doi: 10.1016/j.solmat.2015.06.032 [51] FAN H Z, ZHAO J M, ZHANG J F, et al. TiO2/SiO2/kaolinite hybrid filler to improve the flame retardancy, smoke suppression and anti-aging characteristics of epoxy resin[J]. Materials Chemistry and Physics, 2022, 277: 125576. doi: 10.1016/j.matchemphys.2021.125576 [52] WONG T, LAU K, TAM W, et al. UV resistibility of a nano-ZnO/glass fibre reinforced epoxy composite[J]. Materials & Design, 2014, 56: 254-257. [53] XIAN G, LI H, SU X. Water absorption and hygrothermal ageing of ultraviolet cured glass-fiber reinforced acrylate composites[J]. Polymer Composites, 2012, 33(7): 1120-1128. [54] CHEN Y, DAVALOS J F, RAY I. Durability prediction for GFRP reinforcing bars using short-term data of accele-rated aging tests[J]. Journal of Composites for Construction, 2006, 10(4): 279-286. doi: 10.1061/(ASCE)1090-0268(2006)10:4(279) [55] MANALO A, MARANAN G, BENMOKRANE B, et al. Comparative durability of GFRP composite reinforcing bars in concrete and in simulated concrete environments[J]. Cement and Concrete Composites, 2020, 109: 103564. doi: 10.1016/j.cemconcomp.2020.103564 [56] XIN H, LIU Y, MOSALLAM A, et al. Hygrothermal aging effects on flexural behavior of pultruded glass fiber reinforced polymer laminates in bridge applications[J]. Construction and Building Materials, 2016, 127: 237-247. doi: 10.1016/j.conbuildmat.2016.09.151 [57] BAZLI M, LI Y, ZHAO X, et al. Durability of seawater and sea sand concrete filled filament wound FRP tubes under seawater environments[J]. Composites Part B: Engineering, 2020, 202: 108409. doi: 10.1016/j.compositesb.2020.108409 [58] AFSHAR A, LIAO H T, CHIANG F P, et al. Time-dependent changes in mechanical properties of carbon fiber vinyl ester composites exposed to marine environments[J]. Composite Structures, 2016, 144: 80-85. doi: 10.1016/j.compstruct.2016.02.053 [59] HADIGHEH S A, GRAVINA R J, SMITH S T. Effect of acid attack on FRP-to-concrete bonded interfaces[J]. Constructure and Building Materials, 2017, 152: 285-303. doi: 10.1016/j.conbuildmat.2017.06.140 [60] SURESHA B, RAMESH B N, SUBBAYA K M, et al. Mechani-cal and three-body abrasive wear behavior of carbon-epoxy composite with and without graphite filler[J]. Jour-nal of Composite Materials, 2010, 44(21): 2509-2519. doi: 10.1177/0021998310369589 [61] CHEN Y, DAVALOS J F, RAY I, et al. Accelerated aging tests for evaluations of durability performance of FRP reinforcing bars for concrete structures[J]. Composite Structures, 2007, 78(1): 101-111. doi: 10.1016/j.compstruct.2005.08.015 [62] FERGANI H, DI B, MATTEO M, et al. Durability and degradation mechanisms of GFRP reinforcement subjected to severe environments and sustained stress[J]. Constructure and Building Materials, 2018, 170: 637-648. doi: 10.1016/j.conbuildmat.2018.03.092 [63] 朱洪艳. 孔隙对碳/环氧复合材料层压板性能的影响与评价研究[D]. 哈尔滨: 哈尔滨工业大学, 2010.ZHU Hongyan. Research on effect and evaluation of voids on properties of carbon/epoxy composite laminates[D]. Harbin: Harbin Institute of Technology, 2010. [64] 李果, 王继辉, 倪爱清, 等. 不同厚度碳纤维布/环氧树脂复合材料孔隙率超声衰减模型[J]. 复合材料学报, 2020, 37(4): 877-885.LI Guo, WANG Jihui, NI Aiqing, et al. Ultrasonic attenua-tion model of porosity of carbon fiber cloth/epoxy resin composites with different thicknesses[J]. Acta Materiae Compositae Sinica, 2020, 37(4): 877-885(in Chinese). [65] GÜRDAL Z, TOMASINO A P, BIGGERS S B. Effects of processing induced defects on laminate response-interlami-nar tensile strength[J]. SAMPE Journal, 1991, 27(4): 39-49. [66] 杨鹏飞, 樊俊铃, 宁宁, 等. 不同孔隙率碳纤维增强环氧树脂复合材料板的压缩强度及其预测模型[J]. 机械工程材料, 2021, 45(6): 52-56.YANG Pengfei, FAN Junling, NING Ning, et al. Compres-sive strength and its prediction model of carbon fiber reinforced epoxy resin composite plates with different porosi-ties[J]. Materials for Mechanical Engineering, 2021, 45(6): 52-56(in Chinese). [67] 吴昊, 花军, 刘诚, 等. 亚麻纤维增强环氧树脂基复合材料拉伸强度的预测模型[J]. 机械工程材料, 2015, 39(7): 113-116.WU Hao, HUA Jun, LIU Cheng, et al. Tensile strength prediction model of flax fiber reinforced epoxy resin matrix composite[J]. Materials for Mechanical Engineering, 2015, 39(7): 113-116(in Chinese). [68] 朱文墨, 李刚, 杨小平, 等. 连续纤维增强树脂复合材料纵向压缩强度预测模型的发展及其影响因素[J]. 复合材料学报, 2020, 37(1): 1-15.ZHU Wenmo, LI Gang, YANG Xiaoping, et al. Development of prediction model and influencing factors of longitudinal compressive strength for continuous fiber reinforced polymer composites[J]. Acta Materiae Compositae Sinica, 2020, 37(1): 1-15(in Chinese). [69] 李艳茹, 程忠庆, 姜海波. 利用外方内圆模型预测单向连续纤维增强树脂基复合材料的横向弹性模量[J]. 复合材料学报, 2018, 35(8): 2110-2115. doi: 10.13801/j.cnki.fhclxb.20170920.003LI Yanru, CHENG Zhongqing, JIANG Haibo. Prediction of transverse elastic modulus of unidirectional continuous fiber reinforced resin composites using the model of circle-in-square[J]. Acta Materiae Compositae Sinica, 2018, 35(8): 2110-2115(in Chinese). doi: 10.13801/j.cnki.fhclxb.20170920.003 [70] YAO L, SHAO X, FENG Q. Predicting the mechanical pro-perties of unidirectional fiber reinforced plastics from fiber and resin properties using data mining[J]. Computational Materials Science, 2020, 185: 109986. doi: 10.1016/j.commatsci.2020.109986 [71] LIU B, LIU Y. Corrosion life prediction of glass fiber reinforced plastics by optimized BP neural network[J]. Inorganic Chemistry Communications, 2022, 144: 109846. doi: 10.1016/j.inoche.2022.109846 [72] TANNOUS F E, SAADATMANESH H. Environmental effects on the mechanical properties of E-glass FRP rebars[J]. ACI Materials Journal, 1998, 95: 87-100. [73] DONG S, ZHOU P, GUO R, et al. Durability study of glass fiber reinforced polypropylene sheet under simulated seawater sea sand concrete environment[J]. Journal of Materials Research and Technology, 2022, 20: 1079-1092. doi: 10.1016/j.jmrt.2022.07.097 [74] YU Y, LIU S, PAN Y, et al. Durability of glass fiber-reinforced polymer bars in water and simulated concrete pore solution[J]. Construction and Building Materials, 2021, 299: 123995. doi: 10.1016/j.conbuildmat.2021.123995 [75] PAN Y, YAN D. Study on the durability of GFRP bars and carbon/glass hybrid fiber reinforced polymer (HFRP) bars aged in alkaline solution[J]. Composite Structures, 2021, 261: 113285. doi: 10.1016/j.compstruct.2020.113285 [76] HUANG J W, ABOUTAHA R A F, HUANG J, et al. Environmental reduction factors for GFRP bars used as concrete reinforcement: New scientific approach[J]. Journal of Composites for Constructure, 2010, 14(5): 479-486. doi: 10.1061/(ASCE)CC.1943-5614.0000122 [77] FENG G, ZHU D, GUO S, et al. A review on mechanical properties and deterioration mechanisms of FRP bars under severe environmental and loading conditions[J]. Cement and Concrete Composites, 2022, 134: 104758. doi: 10.1016/j.cemconcomp.2022.104758 [78] GUO R, LI C, XIAN G. Water absorption and long-term thermal and mechanical properties of carbon/glass hybrid rod for bridge cable[J]. Engineering Structures, 2023, 274: 115176. doi: 10.1016/j.engstruct.2022.115176 -

下载:

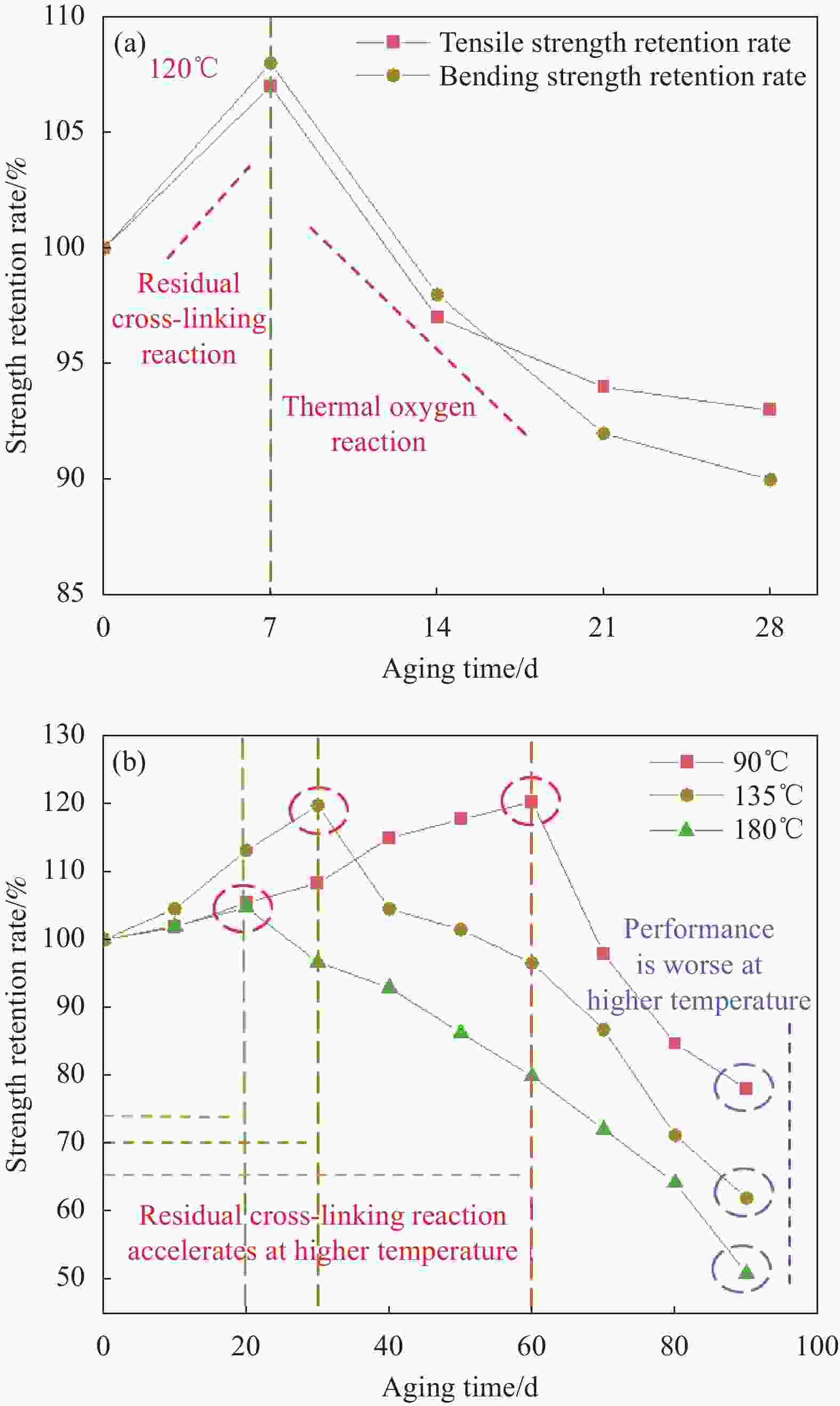

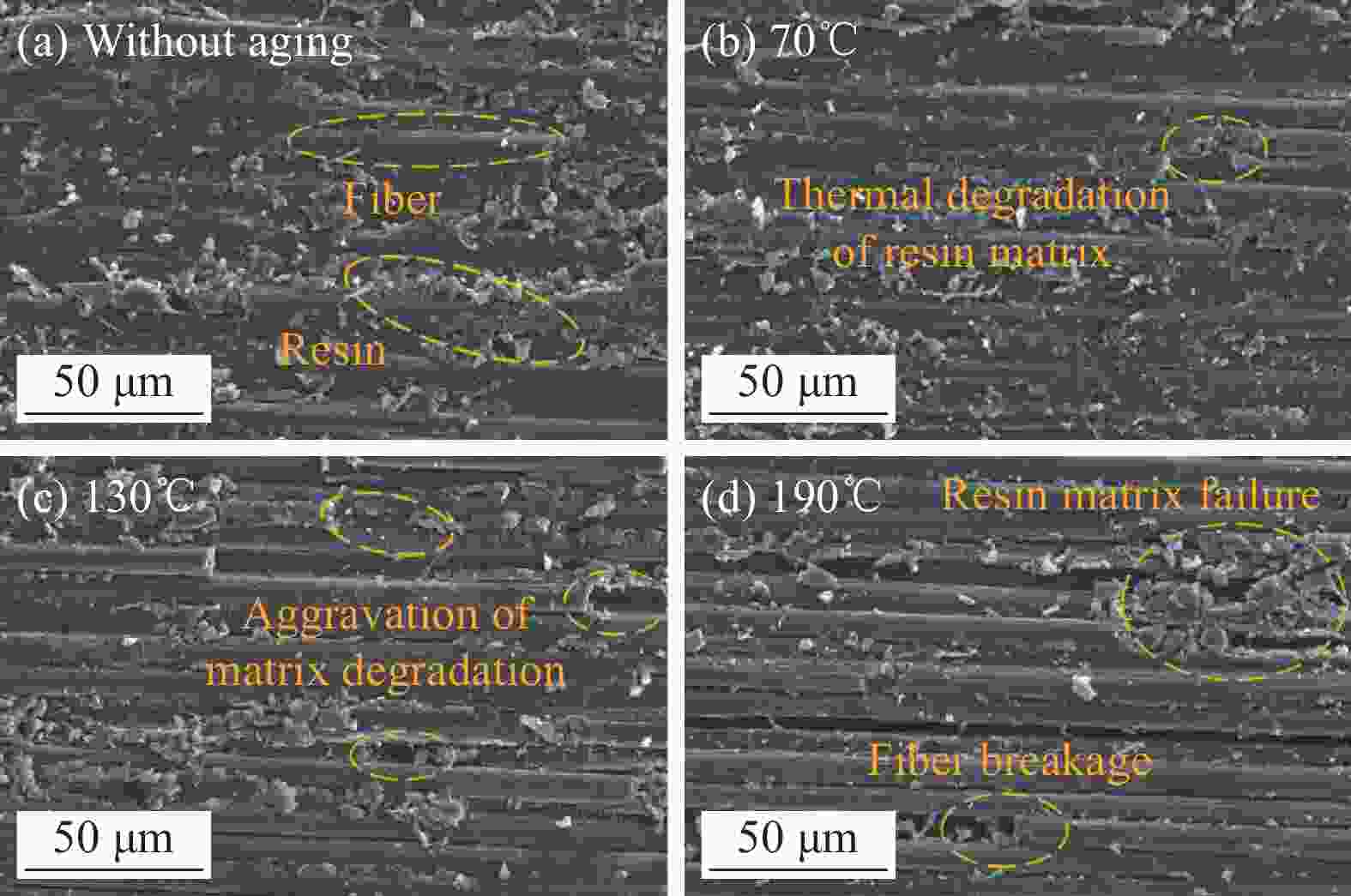

下载: