| [1] |

SEKKAL W, ZAOUI A. Thermal and acoustic insulation properties in nanoporous geopolymer nanocomposite[J]. Cement and Concrete Composites, 2023, 138: 104955. doi: 10.1016/j.cemconcomp.2023.104955

|

| [2] |

FERNÁNDEZ-JIMÉNEZ A, PALOMO A, CRIADO M. Microstructure development of alkali-activated fly ash cement: A descriptive model[J]. Cement and Concrete Research, 2004, 35(6): 1204-1209.

|

| [3] |

AZIZ A, FELAOUS K, ALOMAYRI T, et al. A state-of-the-art review of the structure and properties of laterite-based sustainable geopolymer cement[J]. Environmental Science and Pollution Research, 2023, 30(19): 54333-54350. doi: 10.1007/s11356-023-26495-3

|

| [4] |

LIU Q, CUI M Y, LI X C, et al. Alkali-hydrothermal activation of mine tailings to prepare one-part geopolymer: Activation mechanism, workability, strength, and hydration reaction[J]. Ceramics International, 2022, 48(20): 30407-30417. doi: 10.1016/j.ceramint.2022.06.318

|

| [5] |

BOMPA D, XU B, CORBU O C. Evaluation of one-part slag-fly-ash alkali-activated mortars incorporating waste glass powder[J]. Journal of Materials in Civil Engineering, 2022, 34(12): 05022001. doi: 10.1061/(ASCE)MT.1943-5533.0004532

|

| [6] |

SHI Y, ZHAO Q, XUE C, et al. Preparation and curing method of red mud-calcium carbide slag synergistically activated fly ash-ground granulated blast furnace slag based eco-friendly geopolymer[J]. Cement and Concrete Composites, 2023, 139: 104999. doi: 10.1016/j.cemconcomp.2023.104999

|

| [7] |

卢佳涛, 孔丽娟, 樊子瑞, 等. 铁尾矿砂-地聚物复合材料的界面与性能[J]. 建筑材料学报, 2022, 25(6): 585-590, 606. doi: 10.3969/j.issn.1007-9629.2022.06.006LU Jiatao, KONG Lijuan, FAN Zirui, et al. Interface and performance of iron tailings-geopolymer composites[J]. Journal of Building Materials, 2022, 25(6): 585-590, 606(in Chinese). doi: 10.3969/j.issn.1007-9629.2022.06.006

|

| [8] |

BRANDVOLD A S, TRINDADE A C C, KRIVEN W M. Rheological assessment of metakaolin-based geopolymer composites through squeeze flow[J]. Journal of the American Ceramic Society, 2023, 106(7): 4038-4051. doi: 10.1111/jace.18564

|

| [9] |

FAN L F, DING H, ZHONG W L, et al. A rapid approach for determining the mechanical properties of geopolymer concrete based on image processing technology (IPT)[J]. Construction and Building Materials, 2023, 378: 131165. doi: 10.1016/j.conbuildmat.2023.131165

|

| [10] |

万小梅, 刘杰, 朱亚光, 等. 粉煤灰用量和早期养护温度对EGC拉伸性能的影响[J]. 建筑材料学报, 2022, 25(4): 401-407. doi: 10.3969/j.issn.1007-9629.2022.04.011WAN Xiaomei, LIU Jie, ZHU Yaguang, et al. Influence of fly ash content and early curing temperature on tensile performance of EGC[J]. Journal of Building Materials, 2022, 25(4): 401-407(in Chinese). doi: 10.3969/j.issn.1007-9629.2022.04.011

|

| [11] |

田青, 屈孟娇, 张苗, 等. 废弃混凝土再生微粉激活方式研究进展[J]. 硅酸盐通报, 2020, 39(8): 2476-2485. doi: 10.16552/j.cnki.issn1001-1625.2020.08.015TIAN Qing, QU Mengjiao, ZHANG Miao, et al. Research progress on activation way of recycled powder of waste concrete[J]. Bulletin of the Chinese Ceramic Society, 2020, 39(8): 2476-2485(in Chinese). doi: 10.16552/j.cnki.issn1001-1625.2020.08.015

|

| [12] |

王晓钧. 粉煤灰机械研磨中物理与机械力化学现象的研究[D]. 南京: 南京工业大学, 2003.WANG Xiaojun. Study on mechanical-chemistry and physical properties of mechanically ground fly ash[D]. Nanjing: Nanjing University of Technology, 2003(in Chinese).

|

| [13] |

李娜, 徐中慧, 李萍, 等. 机械力活化粉煤灰制备地聚合物的性能及机理研究[J]. 功能材料, 2018, 49(4): 4102-4106.LI Na, XU Zhonghui, LI Ping, et al. Mechanical activation of fly ash: Effect on performance and mechanism of resulting geopolymer[J]. Journal of Functional Materials, 2018, 49(4): 4102-4106(in Chinese).

|

| [14] |

SHA D, PAN B, SUN Y. A novel raw material for geopolymers: Coal-based synthetic natural gas slag[J]. Journal of Cleaner Production, 2020, 262: 121238. doi: 10.1016/j.jclepro.2020.121238

|

| [15] |

杨南如. 机械力化学过程及效应(Ⅰ)-机械力化学效应[J]. 建筑材料学报, 2000, 3(1): 19-26. doi: 10.3969/j.issn.1007-9629.2000.01.004YANG Nanru. Processes and effects of mechanochemistry(Ⅰ)-chemical effects of mechanochemistry[J]. Journal of Building Materials, 2000, 3(1): 19-26(in Chinese). doi: 10.3969/j.issn.1007-9629.2000.01.004

|

| [16] |

刘音, 刘洋, 周煜明, 等. 机械研磨时间对粗粉煤灰基充填胶凝材料性能的影响[J]. 煤炭科学技术, 2017, 45(6): 221-225. doi: 10.13199/j.cnki.cst.2017.06.036LIU Yin, LIU Yang, ZHOU Yuming, et al. Mechanical grinding time affected to performances of reject fly ash-based backfill binding material[J]. Coal Science and Technology, 2017, 45(6): 221-225(in Chinese). doi: 10.13199/j.cnki.cst.2017.06.036

|

| [17] |

刘春琦, 马天, 李钊, 等. 天然矿物的机械力化学活化改性研究进展[J]. 金属矿山, 2021(10): 75-81. doi: 10.19614/j.cnki.jsks.202110011LIU Chunqi, MA Tian, LI Zhao, et al. Research progress in the mechanochemical activation and modification of natural minerals[J]. Metal Mine, 2021(10): 75-81(in Chinese). doi: 10.19614/j.cnki.jsks.202110011

|

| [18] |

丁浩, 邢锋, 冯乃谦. 天然沸石搅拌磨湿法细磨中机械力化学效应的研究[J]. 矿产综合利用, 2000(6): 26-31. doi: 10.3969/j.issn.1000-6532.2000.06.007DING Hao, XING Feng, FENG Naiqian. Study on mechano-chemical modification of mineral pigment and filler[J]. Multipurpose Utilization of Mineral Resources, 2000(6): 26-31(in Chinese). doi: 10.3969/j.issn.1000-6532.2000.06.007

|

| [19] |

崔孝炜, 冷欣燕, 南宁, 等. 机械力活化对钢渣粒度分布和胶凝性能的影响[J]. 硅酸盐通报, 2018, 37(12): 3821-3826. doi: 10.16552/j.cnki.issn1001-1625.2018.12.018CUI Xiaowei, LENG Xinyan, NAN Ning, et al. Mechanical activation effect on the performance of steel slag particle size distribution and cementitious properties[J]. Bulletin of the Chinese Ceramic Society, 2018, 37(12): 3821-3826(in Chinese). doi: 10.16552/j.cnki.issn1001-1625.2018.12.018

|

| [20] |

许晴. 机械力化学法活化粉煤灰固化含油钻屑技术研究[D]. 绵阳: 西南科技大学, 2016.XU Qing. Technology study on mechanochemistry activating the fly ash for solidifying the oil drilling cuttings[D]. Mianyang: Southwest University of Science and Technology, 2016(in Chinese).

|

| [21] |

李端乐. 掺超细循环流化床粉煤灰水泥的特性研究[D]. 北京: 中国矿业大学(北京), 2018.LI Duanle. Characteristics of cement with ultrafine circulating fluidized bed fly ash[D]. Beijing: China University of Mining and Technology (Beijing), 2018(in Chinese).

|

| [22] |

李萌, 周庆立, 白丽梅, 等. 机械力化学效应提高铁尾矿活性实验研究[J]. 矿产综合利用, 2021(1): 179-185. doi: 10.3969/j.issn.1000-6532.2021.01.030LI Meng, ZHOU Qingli, BAI Limei, et al. Experimental study on improving the activity of iron tailings by mechanochemical effect[J]. Multipurpose Utilization of Mineral Resources, 2021(1): 179-185(in Chinese). doi: 10.3969/j.issn.1000-6532.2021.01.030

|

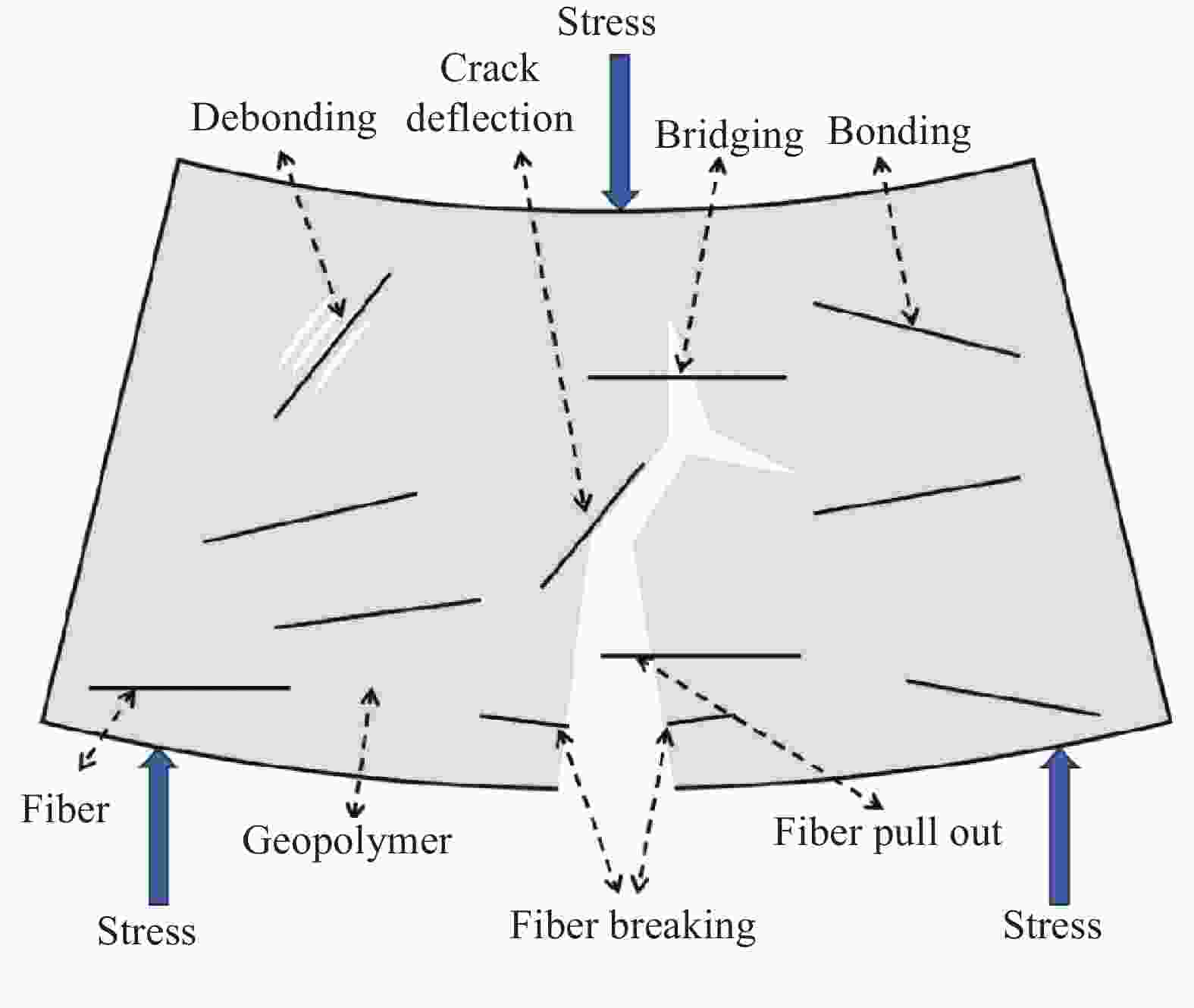

| [23] |

赵越, 王晓岩, 苑文仪, 等. 机械力化学活化煤矸石一步制备高效混凝剂[J]. 矿产保护与利用, 2020, 40(1): 16-22. doi: 10.13779/j.cnki.issn1001-0076.2020.01.003ZHAO Yue, WANG Xiaoyan, YUAN Wenyi, et al. Mechanochemical activated coal gangue one-step preparation of high-efficiency coagulant[J]. Conservation and Utilization of Mineral Resources, 2020, 40(1): 16-22(in Chinese). doi: 10.13779/j.cnki.issn1001-0076.2020.01.003

|

| [24] |

张超凡, 管学茂, 张海波, 等. 机械力化学改性钙基膨润土提高注浆材料的稳定性[J]. 材料导报, 2019, 33(20): 3408-3412. doi: 10.11896/cldb.18090282ZHANG Chaofan, GUAN Xuemao, ZHANG Haibo, et al. Mechano-chemical modified calcium bentonite improves stability of grouting materials[J]. Materials Reports, 2019, 33(20): 3408-3412(in Chinese). doi: 10.11896/cldb.18090282

|

| [25] |

KATO K, XIN Y, HITOMI T, et al. Surface modification of fly ash by mechano-chemical treatment[J]. Ceramics International, 2019, 45(1): 849-853. doi: 10.1016/j.ceramint.2018.09.254

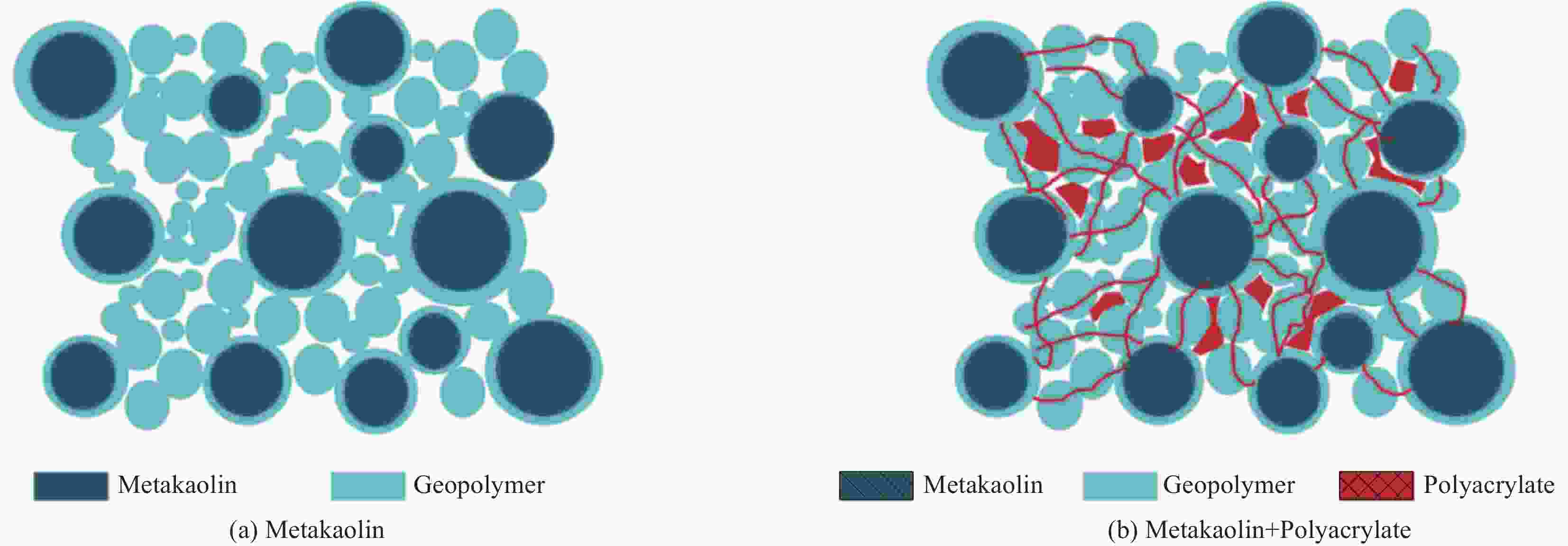

|

| [26] |

TCHAKOUTE KOUAMO H, ELIMBI A, MBEY J A, et al. The effect of adding alumina-oxide to metakaolin and volcanic ash on geopolymer products: A comparative study[J]. Construction and Building Materials, 2012, 35: 960-969. doi: 10.1016/j.conbuildmat.2012.04.023

|

| [27] |

REN X, ZHANG L, RAMEY D, et al. Utilization of aluminum sludge (AS) to enhance mine tailings-based geopolymer[J]. Journal of Materials Science, 2015, 50(3): 1370-1381. doi: 10.1007/s10853-014-8697-y

|

| [28] |

GARCÍA-LODEIRO I, CHERFA N, ZIBOUCHE F, et al. The role of aluminium in alkali-activated bentonites[J]. Materials and Structures, 2015, 48(3): 585-597. doi: 10.1617/s11527-014-0447-8

|

| [29] |

高巧玲, 范功端. 硅灰对新型地质聚合物胶凝材料力学性能影响的研究进展[J]. 武汉工程大学学报, 2020, 42(5): 540-545. doi: 10.19843/j.cnki.CN42-1779/TQ.202004008GAO Qiaoling, FAN Gongduan. Effects of silica fume on mechanical properties of novel geopolymer-based cementitious materials: A brief review[J]. Journal of Wuhan Institute of Technology, 2020, 42(5): 540-545(in Chinese). doi: 10.19843/j.cnki.CN42-1779/TQ.202004008

|

| [30] |

GHARZOUNI A, OUAMARA L, SOBRADOS I, et al. Alkali-activated materials from different aluminosilicate sources: Effect of aluminum and calcium availability[J]. Journal of Non-Crystalline Solids, 2018, 484: 14-25. doi: 10.1016/j.jnoncrysol.2018.01.014

|

| [31] |

ARBI K, PALOMO A, FERNÁNDEZ-JIMÉNEZ A. Alkali-activated blends of calcium aluminate cement and slag/diatomite[J]. Ceramics International, 2013, 39(8): 9237-9245. doi: 10.1016/j.ceramint.2013.05.031

|

| [32] |

叶家元. 活化铝土矿选尾矿制备碱激发胶凝材料及其性能变化机制[D]. 北京: 中国建筑材料科学研究总院, 2015.YE Jiayuan. A geopolymer synthesized from calcined ore-dressing tailing of bauxite and the mechanism of performance evolution[D]. Beijing: China Building Materials Academy, 2015(in Chinese).

|

| [33] |

UYSAL M, AL-MASHHADANI M M, AYGÖRMEZ Y, et al. Effect of using colemanite waste and silica fume as partial replacement on the performance of metakaolin-based geopolymer mortars[J]. Construction and Building Materials, 2018, 176: 271-282. doi: 10.1016/j.conbuildmat.2018.05.034

|

| [34] |

KIM G W, OH T, KYUN LEE S, et al. Development of Ca-rich slag-based ultra-high-performance fiber-reinforced geopolymer concrete (UHP-FRGC): Effect of sand-to-binder ratio[J]. Construction and Building Materials, 2023, 370: 130630. doi: 10.1016/j.conbuildmat.2023.130630

|

| [35] |

ZHANG S, KEULEN A, ARBI K, et al. Waste glass as partial mineral precursor in alkali-activated slag/fly ash system[J]. Cement and Concrete Research, 2017, 102: 29-40. doi: 10.1016/j.cemconres.2017.08.012

|

| [36] |

SAMARAKOON M H, RANJITH P G, DE SILVA V R S. Effect of soda-lime glass powder on alkali-activated binders: Rheology, strength and microstructure characterization[J]. Construction and Building Materials, 2020, 241: 118013. doi: 10.1016/j.conbuildmat.2020.118013

|

| [37] |

CHEAH C B, TAN L E, RAMLI M. The engineering properties and microstructure of sodium carbonate activated fly ash/slag blended mortars with silica fume[J]. Composites Part B: Engineering, 2019, 160: 558-572. doi: 10.1016/j.compositesb.2018.12.056

|

| [38] |

LIU Y, SHI C, ZHANG Z, et al. An overview on the reuse of waste glasses in alkali-activated materials[J]. Resources, Conservation and Recycling, 2019, 144: 297-309. doi: 10.1016/j.resconrec.2019.02.007

|

| [39] |

HAJIMOHAMMADI A, NGO T, KASHANI A. Glass waste versus sand as aggregates: The characteristics of the evolving geopolymer binders[J]. Journal of Cleaner Production, 2018, 193: 593-603. doi: 10.1016/j.jclepro.2018.05.086

|

| [40] |

SI R, DAI Q, GUO S, et al. Mechanical property, nanopore structure and drying shrinkage of metakaolin-based geopolymer with waste glass powder[J]. Journal of Cleaner Production, 2020, 242: 118502. doi: 10.1016/j.jclepro.2019.118502

|

| [41] |

ALANAZI H, HU J, KIM Y. Effect of slag, silica fume, and metakaolin on properties and performance of alkali-activated fly ash cured at ambient temperature[J]. Construction and Building Materials, 2019, 197: 747-756. doi: 10.1016/j.conbuildmat.2018.11.172

|

| [42] |

ALCAMAND H A, BORGES P H R, SILVA F A, et al. The effect of matrix composition and calcium content on the sulfate durability of metakaolin and metakaolin/slag alkali-activated mortars[J]. Ceramics International, 2018, 44(5): 5037-5044. doi: 10.1016/j.ceramint.2017.12.102

|

| [43] |

MEHTA A, SIDDIQUE R, OZBAKKALOGLU T, et al. Fly ash and ground granulated blast furnace slag-based alkali-activated concrete: Mechanical, transport and microstructural properties[J]. Construction and Building Materials, 2020, 257: 119548. doi: 10.1016/j.conbuildmat.2020.119548

|

| [44] |

LYU B, GUO L, FEI X, et al. Preparation and properties of green high ductility geopolymer composites incorporating recycled fine brick aggregate[J]. Cement and Concrete Composites, 2023, 139: 105054. doi: 10.1016/j.cemconcomp.2023.105054

|

| [45] |

ABDOLLAHNEJAD Z, DALVAND A, MASTALI M, et al. Effects of waste ground glass and lime on the crystallinity and strength of geopolymers[J]. Magazine of Concrete Research, 2018, 71: 1-38.

|

| [46] |

HANJITSUWAN S, PHOO-NGERNKHAM T, DAMRONGWIRIYANUPAP N. Comparative study using Portland cement and calcium carbide residue as a promoter in bottom ash geopolymer mortar[J]. Construction and Building Materials, 2017, 133: 128-134. doi: 10.1016/j.conbuildmat.2016.12.046

|

| [47] |

HUANG G, JI Y, LI J, et al. Improving strength of calcinated coal gangue geopolymer mortars via increasing calcium content[J]. Construction and Building Materials, 2018, 166: 760-768. doi: 10.1016/j.conbuildmat.2018.02.005

|

| [48] |

SONG W, ZHU Z, PU S, et al. Multi-technical characterization and correlations between properties of standard cured alkali-activated high-calcium FA binders with GGBS as additive[J]. Construction and Building Materials, 2020, 241: 117996. doi: 10.1016/j.conbuildmat.2020.117996

|

| [49] |

GARCÍA-LODEIRO I, FERNÁNDEZ-JIMÉNEZ A, PALOMO A. Variation in hybrid cements over time: Alkaline activation of fly ash-Portland cement blends[J]. Cement and Concrete Research, 2013, 52: 112-122. doi: 10.1016/j.cemconres.2013.03.022

|

| [50] |

SUWAN T, FAN M. Influence of OPC replacement and manufacturing procedures on the properties of self-cured geopolymer[J]. Construction and Building Materials, 2014, 73: 551-561. doi: 10.1016/j.conbuildmat.2014.09.065

|

| [51] |

彭 晖, 李一聪, 罗冬, 等. 碱激发偏高岭土/矿渣复合胶凝体系反应水平及影响因素分析[J]. 建筑材料学报, 2020, 23(6): 1390-1397.PENG Hui, LI Yicong, LUO Dong, et al. Analysis of reaction level and factors of alkali activated metakaolin/GGBFS[J]. Journal of Building Materials, 2020, 23(6): 1390-1397(in Chinese).

|

| [52] |

郭晓潞, 施惠生, 夏明. 不同钙源对地聚合物反应机制的影响研究[J]. 材料研究学报, 2016, 30(5): 348-354. doi: 10.11901/1005.3093.2015.558GUO Xiaolu, SHI Huisheng, XIA Ming. Effect of different calcium resouces on reaction mechanism of geopolymer[J]. Chinese Journal of Materials Research, 2016, 30(5): 348-354(in Chinese). doi: 10.11901/1005.3093.2015.558

|

| [53] |

HUANG G, JI Y, ZHANG L, et al. Influence of calcium content on structure and strength of MSWI bottom ash-based geopolymer[J]. Magazine of Concrete Research, 2019, 71(7): 362-372. doi: 10.1680/jmacr.17.00542

|

| [54] |

RAJENDRAN M, BAKTHAVATCHALAM K, LEELA BHARATHI S M. Review on the hybridized application of natural fiber in the development of geopolymer concrete[J]. Journal of Natural Fibers, 2023, 20(1): 2178578. doi: 10.1080/15440478.2023.2178578

|

| [55] |

KORNIEJENKO K, FRĄCZEK E, PYTLAK E, et al. Mechanical properties of geopolymer composites reinforced with natural fibers[J]. Procedia Engineering, 2016, 151: 388-393. doi: 10.1016/j.proeng.2016.07.395

|

| [56] |

DE AZEVEDO A R G, CRUZ A S A, MARVILA M T, et al. Natural fibers as an alternative to synthetic fibers in reinforcement of geopolymer matrices: A comparative review[J]. Polymers, 2021, 13(15): 2493. doi: 10.3390/polym13152493

|

| [57] |

TONIOLO N, BOCCACCINI A R. Fly ash-based geopolymers containing added silicate waste: A review[J]. Ceramics International, 2017, 43(17): 14545-14551. doi: 10.1016/j.ceramint.2017.07.221

|

| [58] |

ÖZ A, BAYRAK B, KAPLAN G, et al. Effect of waste colemanite and PVA fibers on GBFS-Metakaolin based high early strength geopolymer composites (HESGC): Mechanical, microstructure and carbon footprint characteristics[J]. Construction and Building Materials, 2023, 377: 131064. doi: 10.1016/j.conbuildmat.2023.131064

|

| [59] |

EL-HASSAN H, ELKHOLY S. Performance evaluation and microstructure characterization of steel fiber-reinforced alkali-activated slag concrete incorporating fly ash[J]. Journal of Materials in Civil Engineering, 2019, 31(10): 4019223. doi: 10.1061/(ASCE)MT.1943-5533.0002872

|

| [60] |

CHOI J, LEE B Y, RANADE R, et al. Ultra-high-ductile behavior of a polyethylene fiber-reinforced alkali-activated slag-based composite[J]. Cement and Concrete Composites, 2016, 70: 153-158. doi: 10.1016/j.cemconcomp.2016.04.002

|

| [61] |

XU J, KANG A, WU Z, et al. Evaluation of workability, microstructure and mechanical properties of recycled powder geopolymer reinforced by waste hydrophilic basalt fiber[J]. Journal of Cleaner Production, 2023, 396: 136514. doi: 10.1016/j.jclepro.2023.136514

|

| [62] |

郑斌义. 单向连续SiCf增强铝硅酸盐聚合物基复合材料的力学性能[D]. 哈尔滨: 哈尔滨工业大学, 2013.ZHENG Binyi. Machanical properties of unidirectional SiC fiber reinforced potassium-based geopolymer composites[D]. Harbin: Harbin Institute of Technology, 2013(in Chinese).

|

| [63] |

王亚超. 碱激发粉煤灰基地质聚合物强化增韧及耐久性能研究[D]. 西安: 西安建筑科技大学, 2014.WANG Yachao. Investigations on reinforcing, toughening and durability of alkali-activated fly ash-based geopolymer[D]. Xi'an: Xi'an University of Architecture and Technology, 2014(in Chinese).

|

| [64] |

YU T, CHEN J, GUO H, et al. Mechanical properties and microstructure of ground granulated blast furnace slag-based geopolymer reinforced with polyvinyl alcohol fibers[J]. Journal of Material Cycles and Waste Management, 2023, 25(3): 1719-1731. doi: 10.1007/s10163-023-01646-3

|

| [65] |

BASKAR P, ANNADURAI S, SEKAR K, et al. A review on fresh, hardened, and microstructural properties of fibre-reinforced geopolymer concrete[J]. Polymers, 2023, 15(6): 1484. doi: 10.3390/polym15061484

|

| [66] |

RANJBAR N, ZHANG M. Fiber-reinforced geopolymer composites: A review[J]. Cement and Concrete Composites, 2020, 107: 103498. doi: 10.1016/j.cemconcomp.2019.103498

|

| [67] |

KHAN M Z N, HAO Y, HAO H, et al. Mechanical properties of ambient cured high strength hybrid steel and synthetic fibers reinforced geopolymer composites[J]. Cement and Concrete Composites, 2018, 85: 133-152. doi: 10.1016/j.cemconcomp.2017.10.011

|

| [68] |

GU G, PEI Y, MA T, et al. Role of carbon fiber in the electrothermal behavior and geopolymerization process of carbon fiber-reinforced FA-GBFS geopolymer composite[J]. Construction and Building Materials, 2023, 369: 130597. doi: 10.1016/j.conbuildmat.2023.130597

|

| [69] |

WANG T, YANG L, RAO F, et al. Effect of chitosan on the mechanical properties and acid resistance of metakaolin-blast furnance slag-based geopolymers[J]. Environmental Science and Pollution Research, 2023, 30(16): 47025-47037. doi: 10.1007/s11356-023-25676-4

|

| [70] |

SINGLA R, SENNA M, MISHRA T, et al. High strength metakaolin/epoxy hybrid geopolymers: Synthesis, characterization and mechanical properties[J]. Applied Clay Science, 2022, 221: 106459. doi: 10.1016/j.clay.2022.106459

|

| [71] |

LU C, WANG Q, LIU Y, et al. Influence of new organic alkali activators on microstructure and strength of fly ash geopolymer[J]. Ceramics International, 2022, 48(9): 12442-12449. doi: 10.1016/j.ceramint.2022.01.109

|

| [72] |

CHEN X, ZHU G, ZHOU M, et al. Effect of organic polymers on the properties of slag-based geopolymers[J]. Construction and Building Materials, 2018, 167: 216-224. doi: 10.1016/j.conbuildmat.2018.02.031

|

| [73] |

QIN Y, CHEN X, LI B, et al. Study on the mechanical properties and microstructure of chitosan reinforced metakaolin-based geopolymer[J]. Construction and Building Materials, 2021, 271: 121522. doi: 10.1016/j.conbuildmat.2020.121522

|

| [74] |

KHATER H M, EL NAGGAR A. Combination between organic polymer and geopolymer for production of eco-friendly metakaolin composite[J]. Journal of the Australian Ceramic Society, 2020, 56(2): 599-608. doi: 10.1007/s41779-019-00371-1

|

| [75] |

CATAURO M, PAPALE F, LAMANNA G, et al. Geopolymer/peg hybrid materials synthesis and investigation of the polymer influence on microstructure and mechanical behavior[J]. Materials Research, 2015, 18(4): 698-705. doi: 10.1590/1516-1439.342814

|

| [76] |

CHEN X, ZHOU M, GE X, et al. Study on the microstructure of metakaolin-based geopolymer enhanced by polyacrylate[J]. Journal of the Ceramic Society of Japan, 2019, 127(3): 165-172. doi: 10.2109/jcersj2.18186

|

| [77] |

ROVIELLO G, RICCIOTTI L, MOLINO A J, et al. Hybrid geopolymers from fly ash and polysiloxanes[J]. Molecules, 2019, 24(19): 3510. doi: 10.3390/molecules24193510

|

| [78] |

ZHANG M, XU H, PHALÉ ZEZE A L, et al. Coating performance, durability and anti-corrosion mechanism of organic modified geopolymer composite for marine concrete protection[J]. Cement and Concrete Composites, 2022, 129: 104495. doi: 10.1016/j.cemconcomp.2022.104495

|

| [79] |

COLANGELO F, ROVIELLO G, RICCIOTTI L, et al. Preparation and characterization of new geopolymer-epoxy resin hybrid mortars[J]. Materials, 2013, 6(7): 2989-3006. doi: 10.3390/ma6072989

|

| [80] |

MIRKOVIĆ M, YILMAZ M S, KLJAJEVIĆ L, et al. Design of PEI and amine modified metakaolin-brushite hybrid polymeric composite materials for CO2 capturing[J]. Polymers, 2023, 15(7): 1669. doi: 10.3390/polym15071669

|

| [81] |

IVANOVIĆ M, KNEŽEVIĆ S, RADOVIĆ I, et al. Preparation and characterization of geopolymers based on metakaolin with the addition of organic phase PVA[J]. Sustainability, 2023, 15(5): 4441. doi: 10.3390/su15054441

|

下载:

下载: