Lap-spliced behavior of CFRP-steel composite bars in coral sea-sand seawater concrete

-

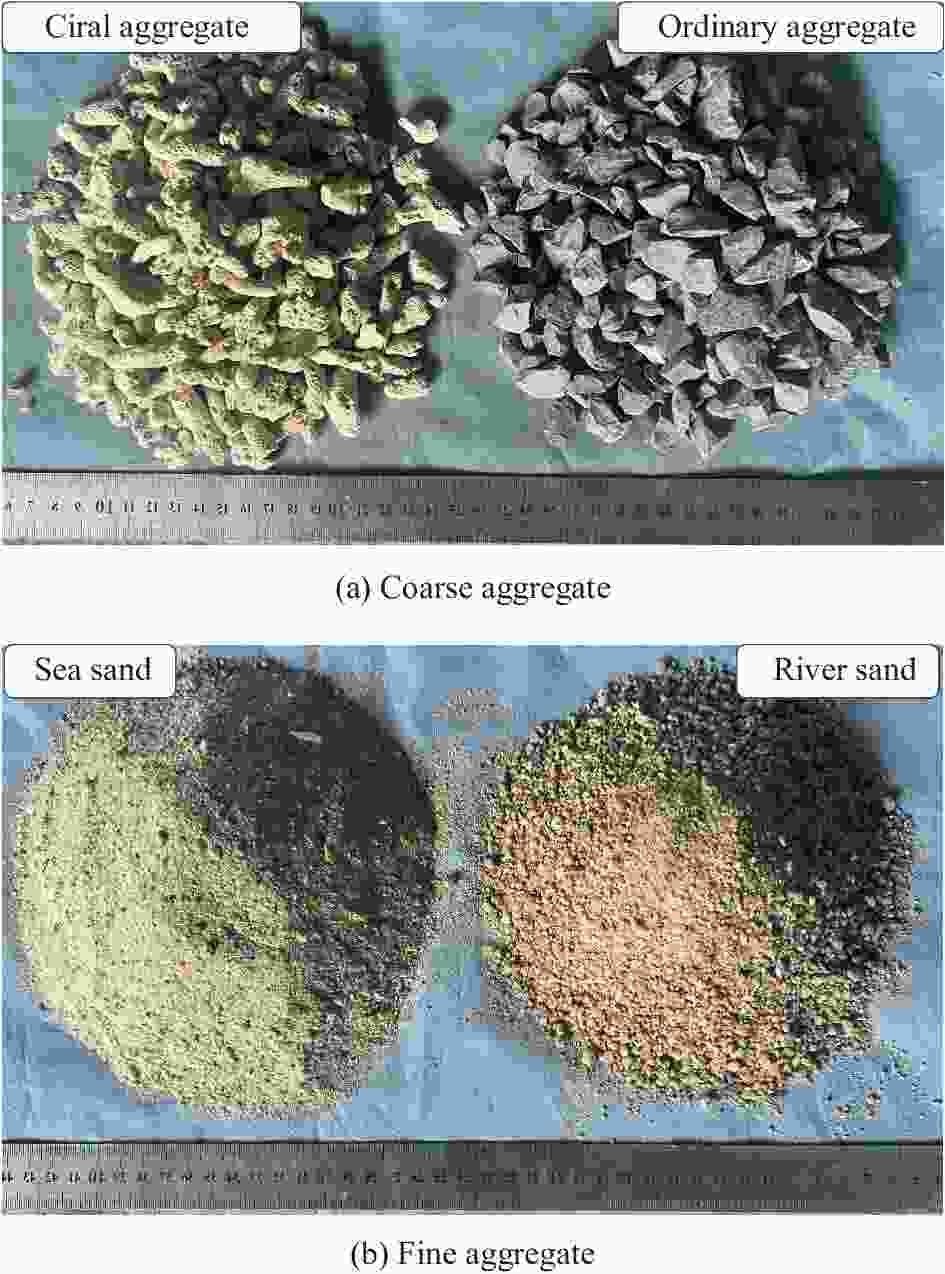

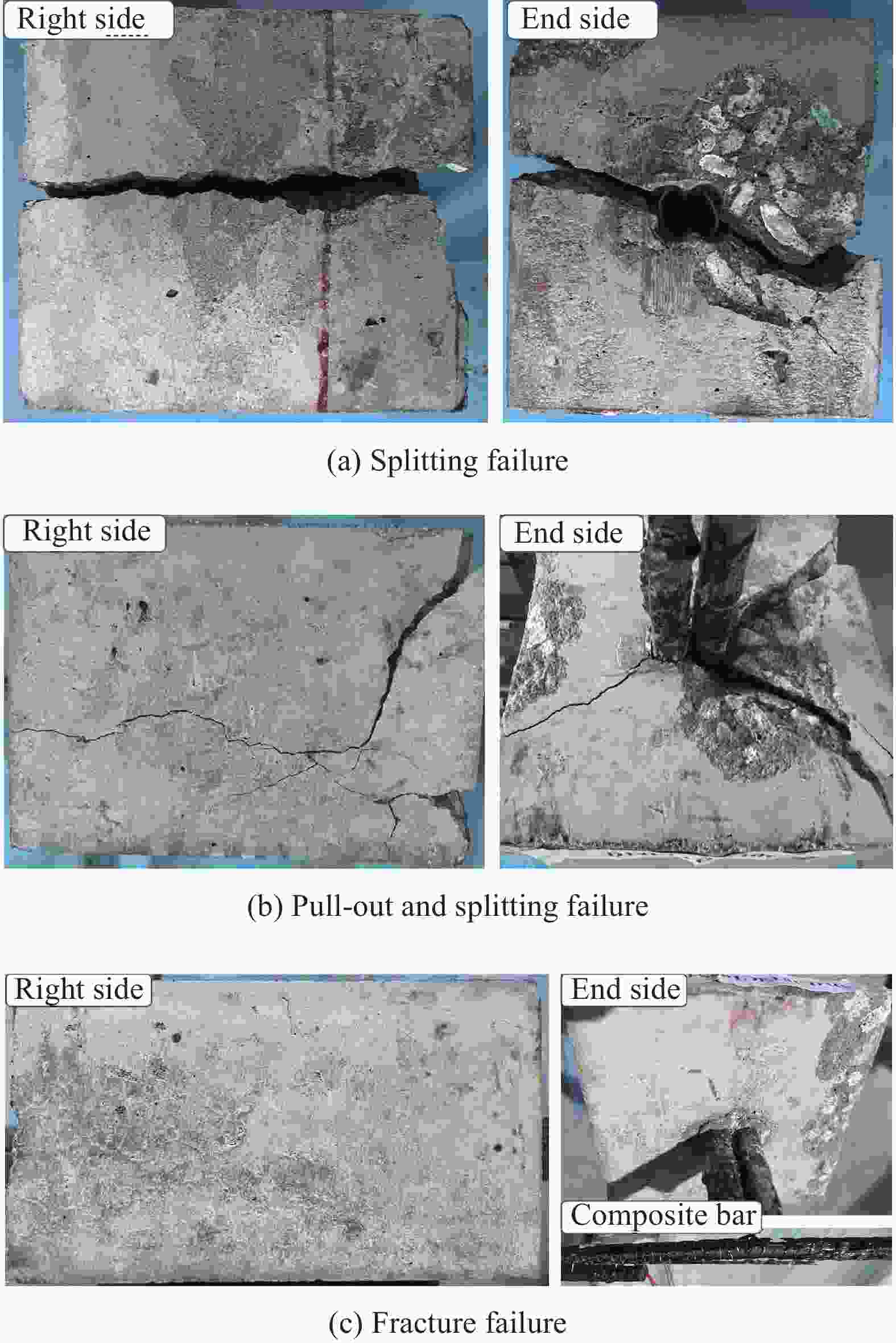

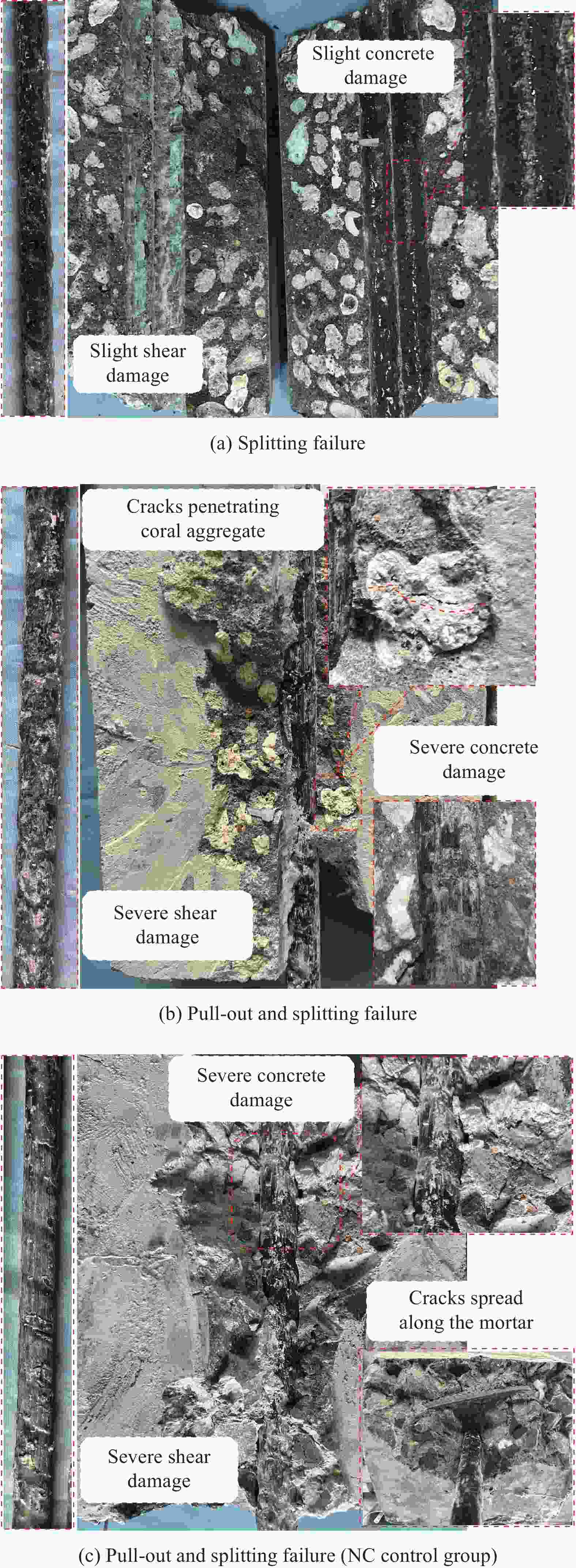

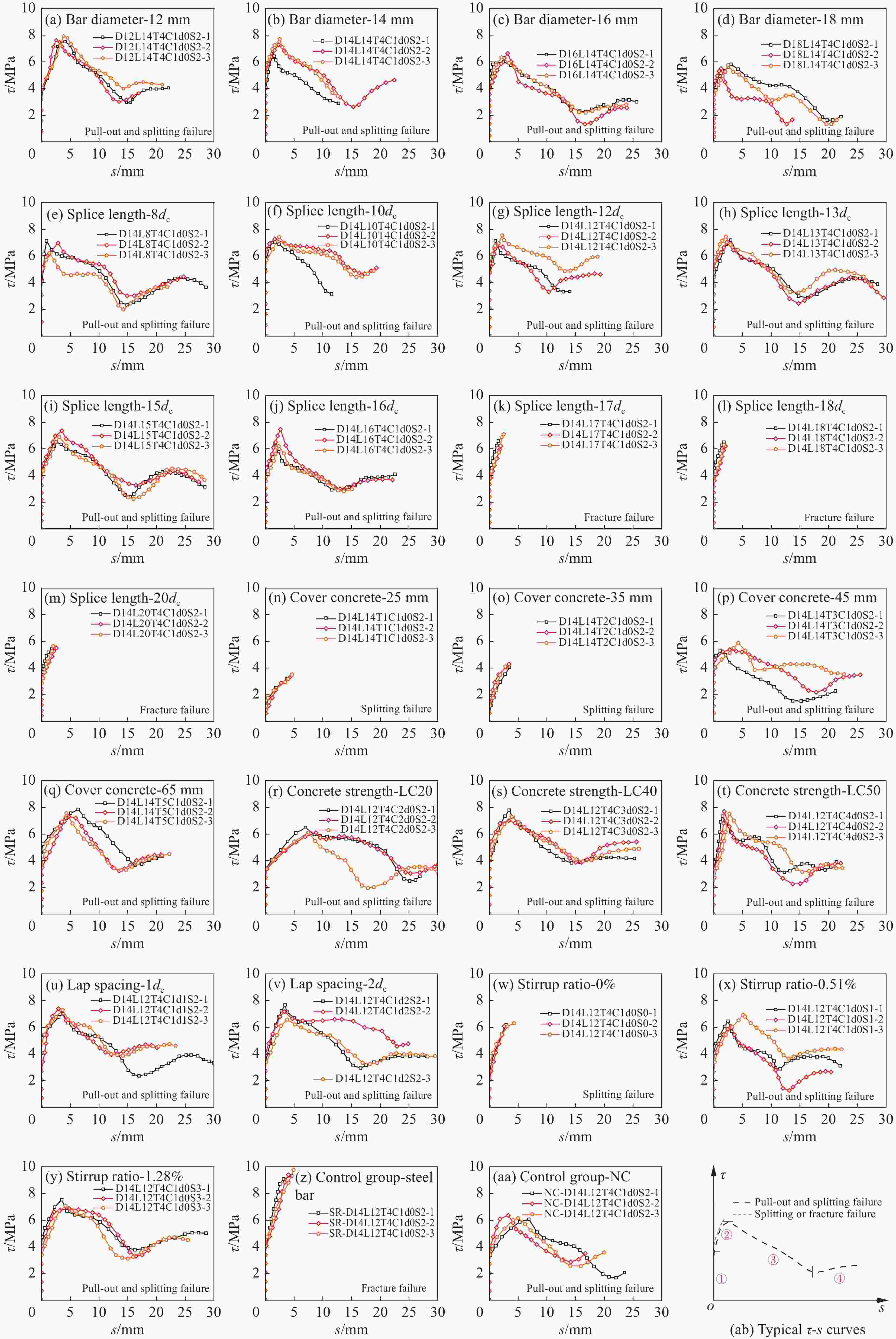

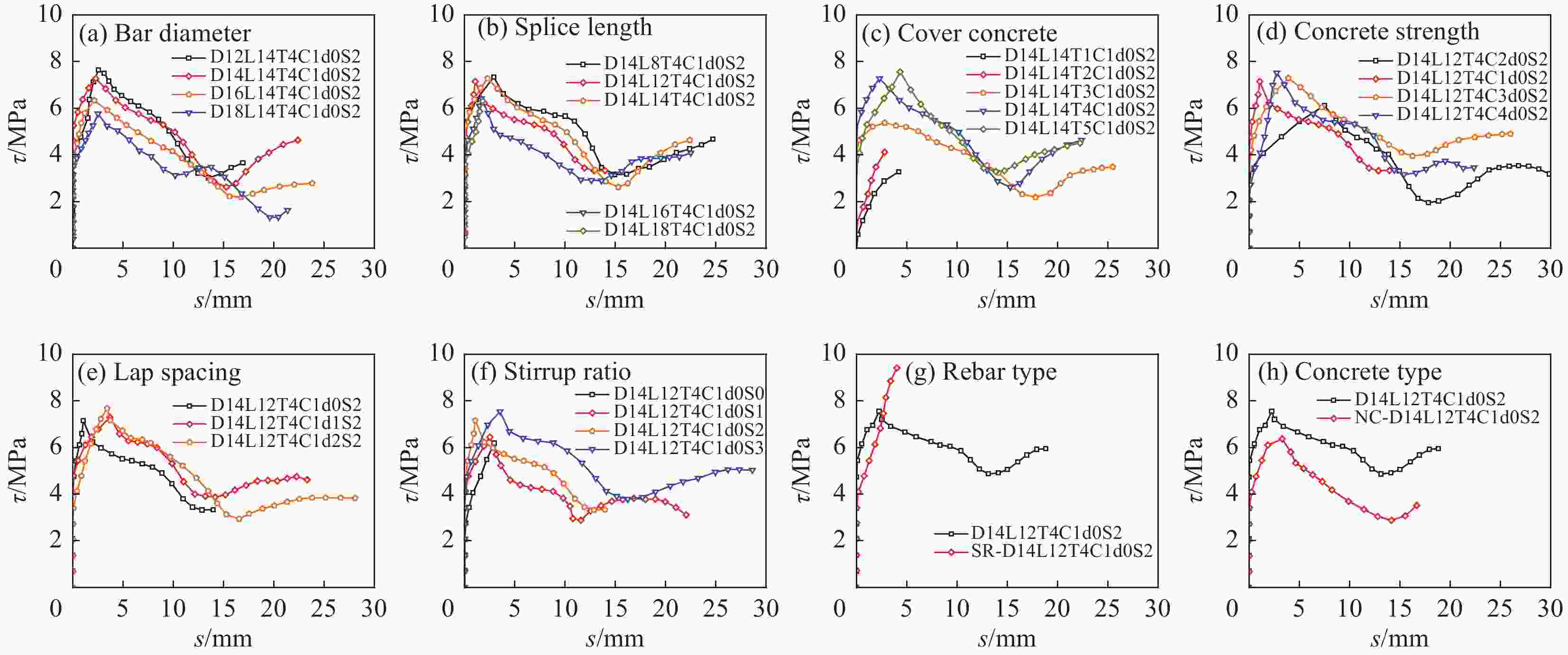

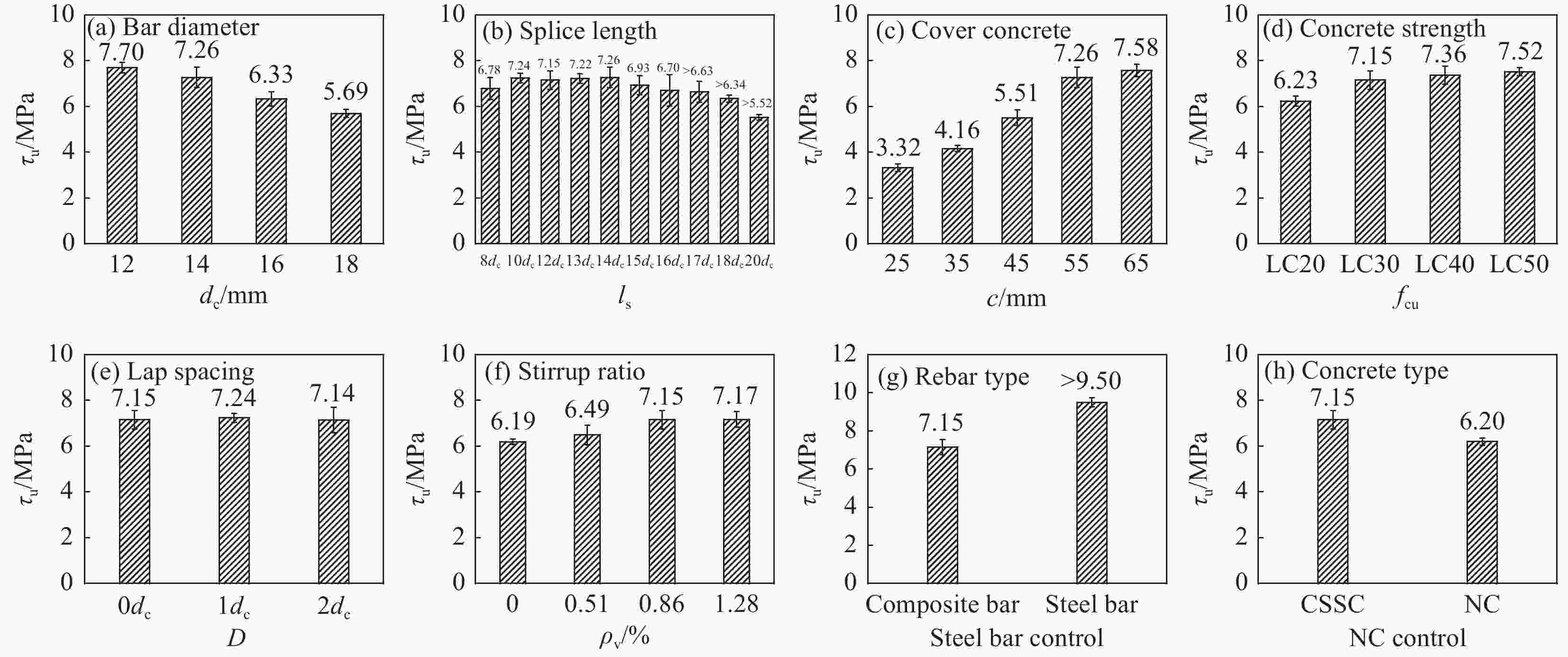

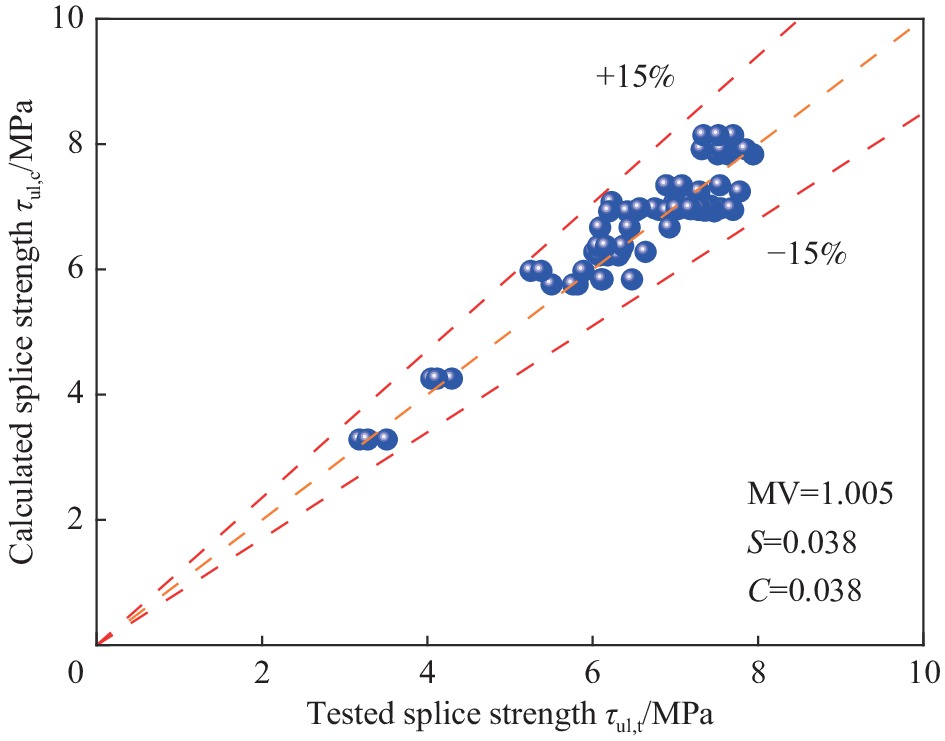

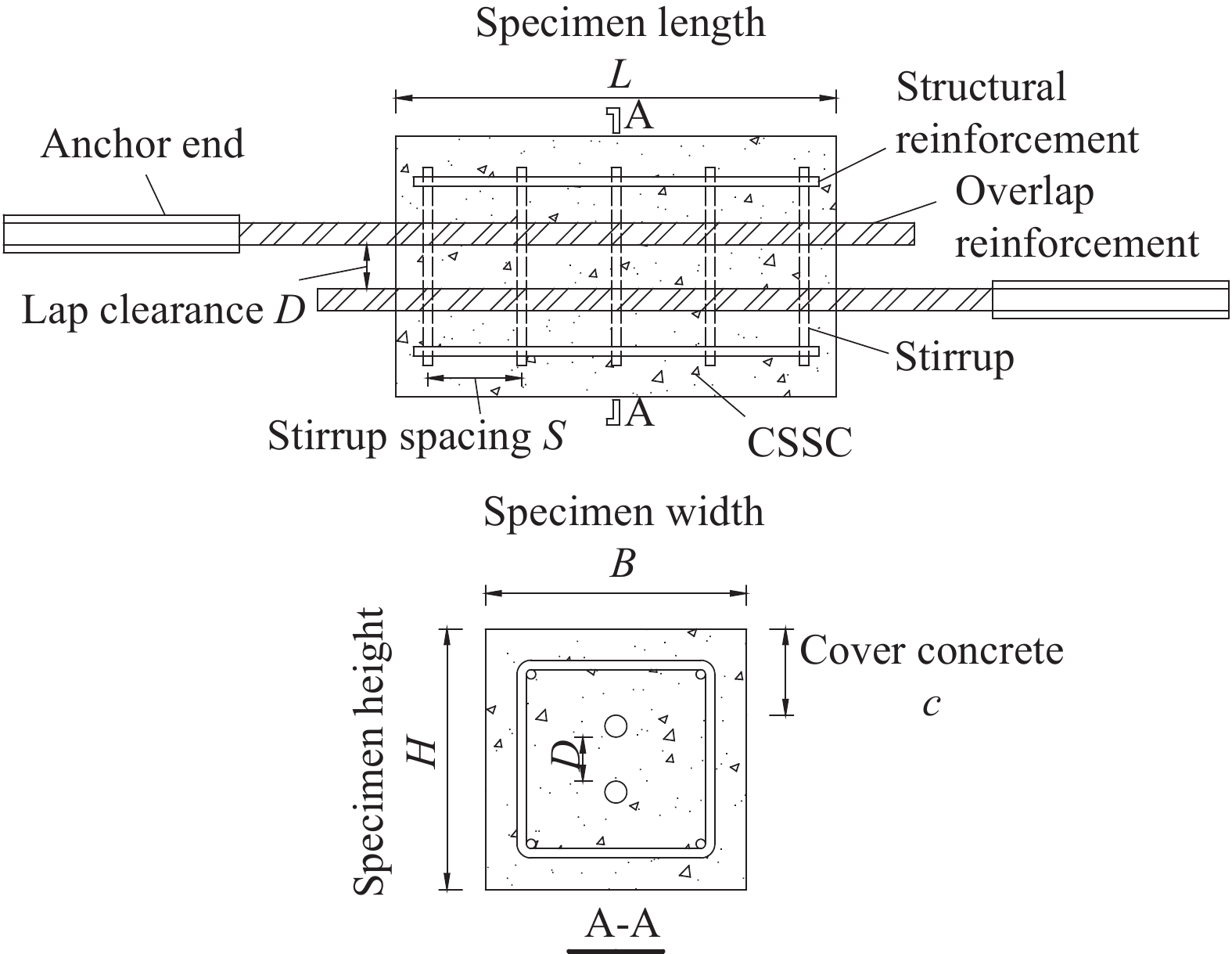

摘要: 为研究珊瑚海砂海水混凝土(CSSC)中碳纤维增强复合材料(CFRP)-钢复合筋(简称“复合筋”)搭接连接受力性能,合理确定CSSC中复合筋的搭接长度,以复合筋直径、搭接长度、保护层厚度、混凝土强度、搭接净距、配箍率、混凝土及筋材种类为试验参数,对27组共81个搭接连接试件进行了对拉试验,获得了各试验参数对CSSC中复合筋搭接连接性能的影响规律。结果表明:当搭接长度小于17倍复合筋直径(dc)时,试件发生拔出-劈裂破坏,反之则发生拉断破坏。发生拔出-劈裂破坏时,复合筋表面出现严重的剪切损伤;当搭接长度小于14dc时,试件的搭接强度约为7.2 MPa,当搭接长度大于14dc时,试件的搭接强度随搭接长度的增大逐渐减小;保护层厚度大于4dc或CSSC轴心抗压强度大于30 MPa后,试件搭接强度的变化基本上可以忽略;增大配箍率,搭接强度逐渐增大,且劈裂裂缝的宽度显著减小;与钢筋试件相比,复合筋试件搭接强度的降幅超过25%。基于试验结果,建立了CSSC中复合筋搭接强度及搭接长度计算公式,计算结果与试验结果相符,并参考《混凝土结构设计规范》简化了搭接长度的计算公式。Abstract: In order to study the mechanical behavior of lap-spliced carbon fiber reinforced polymer (CFRP)-steel composite bars (referred to as "composite bars") in coral sea-sand seawater concrete (CSSC) and determine the splice length of composite bars reasonably, tensile tests were conducted on 27 sets of 81 lap-spliced specimens and test variables included the composite bar diameter, splice length, cover thickness, concrete strength, clear space between the lap-spliced bars, stirrup ratio, concrete type, and reinforcement type. The influence of various test variables on the behavior of lap-spliced composite bars in CSSC was obtained. The results indicate that pull-out failure accompanied by concrete splitting is found for specimens with a splice length less than 17 times the diameter of the composite bar (dc), while tensile fracture failure is found for specimens with a splice length greater than 17dc. After the specimen undergoing pull-out failure, severe shear damage is formed on the surface of the composite bars. When the splice length is less than 14dc, the splice strength of the specimen is about 7.2 MPa. When the splice length is greater than 14dc, the splice strength of the specimen gradually decreases with the increase of the splice length. After the cover thickness is greater than 4dc or the axial compressive strength of CSSC is greater than 30 MPa, the change in the splice strength of the specimen can be basically ignored. Increasing the stirrup ratio gradually increases the splice strength and significantly reduces the width of the splitting crack. Compared with the lap-spliced specimens of steel bars, the decrease in splice strength of the lap-spliced specimens of composite bars exceeds 25%. Based on the experimental results, the equations for calculating the splice strength and splice length of composite bars in CSSC were established, and the calculation results are consistent with the experimental results. Then, referring to the "Code for Design of Concrete Structures", the equation for calculating the splice length was simplified.

-

表 1 试件参数及试验结果

Table 1. Test variables of specimens and test results

Specimen B×H×L/

mm3dc/

mmls/

mmc/

mmfcu D/

mmρv/

%Pu/

kNτu/

MPaτr/

MPaτul/

MPalsy/

mmlsu/

mmM w/

mmD12L14T4C1d0S2 134×134×168 12 14dc 55 LC30 0dc 0.86 48.7 7.70 3.33 7.84 142.6 263.3 PSFY 0.30 D14L14T4C1d0S2 138×138×196 14 14dc 55 LC30 0dc 0.86 62.6 7.26 2.62 6.95 172.2 281.1 PSFY 0.31 D16L14T4C1d0S2 142×142×224 16 14dc 55 LC30 0dc 0.86 71.2 6.33 1.93 6.28 224.0 335.2 PSFY 0.53 D18L14T4C1d0S2 146×146×252 18 14dc 55 LC30 0dc 0.86 81.2 5.70 1.43 5.76 281.5 389.7 PSF 0.74 D14L8T4C1d0S2 138×138×112 14 8dc 55 LC30 0dc 0.86 33.4 6.78 2.45 7.08 172.2 281.1 PSF 0.33 D14L10T4C1d0S2 138×138×140 14 10dc 55 LC30 0dc 0.86 44.6 7.24 4.55 7.02 172.2 281.1 PSF 0.30 D14L12T4C1d0S2 138×138×168 14 12dc 55 LC30 0dc 0.86 52.8 7.15 3.83 6.98 172.2 281.1 PSFY 0.39 D14L13T4C1d0S2 138×138×182 14 13dc 55 LC30 0dc 0.86 57.8 7.22 2.86 6.96 172.2 281.1 PSFY 0.37 D14L15T4C1d0S2 138×138×210 14 15dc 55 LC30 0d 0.86 64.0 6.93 2.65 6.93 172.2 281.1 PSFY 0.37 D14L16T4C1d0S2 138×138×224 14 16dc 55 LC30 0dc 0.86 66.0 6.70 2.91 6.92 172.2 281.1 PSFY 0.32 D14L17T4C1d0S2 138×138×238 14 17dc 55 LC30 0dc 0.86 >69.4 >6.63 — — 172.2 281.1 FF — D14L18T4C1d0S2 138×138×252 14 18dc 55 LC30 0dc 0.86 >70.2 >6.34 — — 172.2 281.1 FF — D14L20T4C1d0S2 138×138×280 14 20dc 55 LC30 0dc 0.86 >67.9 >5.52 — — 172.2 281.1 FF — D14L14T1C1d0S0 78×78×196 14 14dc 25 LC30 0dc 0 28.6 3.32 — 3.28 370.0 600.4 SF — D14L14T2C1d0S0 98×98×196 14 14dc 35 LC30 0dc 0 35.8 4.16 — 4.25 284.4 462.2 SF — D14L14T3C1d0S2 118×118×196 14 14dc 45 LC30 0dc 0.86 47.5 5.51 1.86 5.98 201.0 327.6 PSF 0.33 D14L14T5C1d0S2 158×158×196 14 14dc 65 LC30 0dc 0.86 65.2 7.57 3.39 7.92 150.5 246.0 PSFY 0.29 D14L12T4C2d0S2 138×138×168 14 12dc 55 LC20 0dc 0.86 46.0 6.23 2.50 5.84 206.6 336.7 PSF 0.32 D14L12T4C3d0S2 138×138×168 14 12dc 55 LC40 0dc 0.86 54.4 7.36 3.89 7.24 165.7 270.6 PSFY 0.27 D14L12T4C4d0S2 138×138×168 14 12dc 55 LC50 0dc 0.86 55.5 7.52 2.84 8.14 146.8 240.1 PSFY 0.31 D14L12T4C1d1S2 152×152×168 14 12dc 55 LC30 1dc 0.86 53.5 7.24 3.40 6.98 154.5 281.1 PSFY 0.35 D14L12T4C1d2S2 166×166×168 14 12dc 55 LC30 2dc 0.86 52.7 7.14 3.58 6.98 154.5 281.1 PSFY 0.28 D14L12T4C1d0S0 138×138×168 14 12dc 55 LC30 0dc 0 45.7 6.19 — 6.22 193.6 315.7 PSF 0.67 D14L12T4C1d0S1 138×138×168 14 12dc 55 LC30 0dc 0.51 47.9 6.49 2.60 6.67 180.3 294.3 PSF 0.42 D14L12T4C1d0S3 138×138×168 14 12dc 55 LC30 0dc 1.28 53.0 7.17 3.40 7.34 163.3 266.8 PSFY 0.18 SR-D14L12T4C1d0S2 138×138×168 14 12dc 55 LC30 0dc 0.86 >70.2 >9.50 — — — — FF — NC-D14L12T4C1d0S2 138×138×168 14 12dc 55 LC30 0dc 0.86 45.8 6.20 2.38 6.37 188.9 308.1 PSF 0.41 Notes: For the specimen number, D—Bar diameter; L—Splice length; T—Cover thickness; C—Concrete strength; d—Splice spacing; S—Stirrup ratio; 'SR-'—Steel rebar-control specimen; 'NC-'—Natural concrete-control specimen; B, H, L—Width, height, and length of the specimen respectively; dc—Diameter of the composite bar; ls—Splice length; c—Thickness of the cover concrete; fcu—Axial compressive strength of the cube; D—Spacing between overlapping bars; ρv—Reinforcement ratio of the stirrup, ρv=πdsv2/(4cssv), where dsv is the diameter of stirrup, ssv is the stirrup spacing; Pu—Ultimate load of the specimen; τu—Ultimate splice strength; τr—Residual splice strength, taken as the inflection point at which the lap stress-slip curve rises again; τul—Ultimate splice strength calculated according to Eq.(7); lsy—Critical yield splice length calculated according to Eq.(10); lsu—Critical limit splice length calculated according to Eq.(11); M—Failure mode of the overlapped specimen; PSFY—Pull-out and splitting failure of the composite bar after yielding; PSF—Pull-out and splitting failure; SF—Splitting failure; FF—Fracture failure of the embedded bar; w—Width of the splitting crack. 表 2 混凝土配合比及性能指标

Table 2. Mix proportion and performance index of concrete

Concrete

typeSG CA/

(kg·m−3)FA/

(kg·m−3)Cement/

(kg·m−3)Water/

(kg·m−3)W/C Total W/C Sand

ratePCA/

(kg·m−3)Slump/

mmfcu/

MPaf'c/

MPaft/

MPaCSSC LC20 700 784 450 193 0.40 0.43 0.45 6.75 113 39.6 25.9 1.75 LC30 672 753 530 194 0.34 0.36 6.89 69 46.5 29.7 2.09 LC40 637 714 630 193 0.29 0.31 10.08 60 48.9 34.4 2.17 LC50 596 667 750 192 0.24 0.26 13.50 48 54.3 37.6 2.44 NC C30 1209 543 453 195 — 0.43 0.31 — 115 41.3 26.6 1.91 Notes: SG—Concrete grade; CA—Coarse aggregate; FA—Fine aggregate; W/C—Mass ratio of water to cement; PCA—Water reducing agent; f'c—Axial compressive strength of the cylinder; ft—Splitting tensile strength of the cube; NC—Ordinary concrete. 表 3 CFRP-钢复合筋力学性能指标

Table 3. Mechanical properties of CFRP-steel composite bars

dc/mm Group fcfy/MPa MV/MPa fcfu/MPa MV/MPa fcfr/MPa MV/MPa 12 1 378.8 373.7 692.9 680.6 476.2 466.4 2 378.5 657.6 453.0 3 363.8 691.4 469.8 14 1 345.2 342.4 570.1 552.8 355.9 359.9 2 345.9 548.3 367.2 3 336.0 540.1 356.4 16 1 351.7 351.0 535.8 521.0 392.8 400.5 2 352.4 512.7 404.8 3 348.8 514.7 403.9 18 1 358.8 358.8 493.3 493.6 404.3 405.8 2 358.1 494.4 405.3 3 359.5 493.1 408.0 Notes: fcfy, fcfu, fcfr—Yield strength, ultimate strength, and residual strength of the composite rebar respectively; MV—Mean value. 表 4 混凝土中纤维增强复合材料(FRP)筋搭接长度计算公式

Table 4. Equations for splice length of fiber-reinforced polymer (FRP) bars in concrete

Ref. Equations Number Hui[17] ${\tau _{ {\text{ul} } } } = \dfrac{ { {f_{ {\text{fu} } } } } }{ {0.48{ { {f_{ {\text{fu} } } } } }/{ { {f_{ {\text{ts} } } } } } - 32.5} } ,{l_{\text{s} } } = \left( {0.12\dfrac{ { {f_{ {\text{fu} } } } } }{ { {f_{ {\text{ts} } } } } } - 8.125} \right)d$ (2) GB/T 50608—2020[18] $ {l_{\text{d}}} = \dfrac{{{f_{{\text{fu}}}}}}{{8{f_{{\text{ts}}}}}}d , {l_{\text{s}}} = {\zeta _{\text{l}}}{l_{\text{d}}} \geqslant 300 $ (3) ACI 440.1R—15[19] ${\tau _{ {\text{ul} } } } = \left( {0.33 + 0.025\dfrac{c}{d} + 8.3\dfrac{d}{l} } \right)\sqrt { f_{\text{c} } ^\prime },$ (4) ${l_{\text{d} } } = \dfrac{ {\alpha { { {f_{ {\text{fu } } } } } }/{ {0.083\sqrt { f_{\text{c} } ^\prime } } } - 340} }{ {13.6 + {c}/{d} } }d, {l_{\text{s} } } = 1.3{l_{\text{d} } }$ CAN/CSA S806—12[20] ${l_{\text{d} } } = 1.15 \dfrac{ { {k_1}{k_2}{k_3}{k_4}{k_5} } }{ { {d_{ {\text{cs} } } } } } \dfrac{ { {f_{ {\text{fu} } } } } }{ {\sqrt {f_{\text{c} }^\prime } } } {A_{\text{b} } } \geqslant 300, {l_{\text{s}}} = 1.3{l_{\text{d}}} $ (5) JSCE 97[21] $ {l_{\text{d}}} = {\alpha _1}\dfrac{{{f_{{\text{fu}}}}}}{{4{f_{{\text{bod}}}}}}d > 20 d ,{f_{{\text{bod }}}} = 0.22{\alpha _2}f_{\text{c}}^{2/3} ,$ (6) $ {k_{\text{c}}} = \dfrac{c}{d} + \dfrac{{15{A_{{\text{sv}}}}}}{{sd}}\dfrac{{{E_{{\text{sv}}}}}}{{{E_{\text{f}}}}}, {l_{\text{s}}} = \left( {1.0{l_{\text{d}}},1.3{l_{\text{d}}},1.7{l_{\text{d}}}} \right) $ Notes: τul—Splice strength; d—Bar diameter; ld—Anchorage length; ζl—Coefficient for lap splice ratio; ffu—Tensile strength of FRP bar; fts—Tensile strength of concrete; l—Bond length; c—Lesser of the cover to the centre of the bar or one-half of the centre-on-centre spacing of the bars; α—FRP bar location factor; k1—FRP bar location factor; k2—Concrete density factor; k3—FRP bar size factor; k4—Factor related to FRP bar type; k5—Factor related to FRP bar surface profile; Ab—Area of individual rebar; dcs—Lesser of the concrete surface to the center of the bar or two-thirds of the center-to-center spacing of bars being developed; α1=1.0 for kc≤1.0, 0.9 for 1.0<kc≤1.5, 0.8 for 1.5<kc≤2.0, 0.7 for 2.0<kc≤2.5, 0.6 for kc greater than 2.5; kc—Undetermined coefficient calculated according to Eq.(6); α1—Factor related to kc; fbod—Design bond strength of concrete; α2—Modification factor for bond strength of FRP bar; Asv—Cross-sectional area of stirrup; Esv—Elastic modulus of stirrup; s—Spacing between stirrups; Ef—Elastic modulus of FRP bar. 表 5 CSSC中CFRP-钢复合筋搭接试件相关公式计算结果和实测结果对比

Table 5. Comparison between calculated results of relevant formulas and measured results for specimens with CFRP-steel composite bar overlapped in CSSC

Specimen τu/MPa τu1/MPa ${ { {\tau _{ {\text{u} }1} } } }/{ { {\tau _{\text{u} } } } }$ τu2/MPa ${ { {\tau _{ {\text{u2} } } } } }/{ { {\tau _{\text{u} } } } }$ ls1

/mmls2

/mmls3

/mmls4

/mmls5

/mmD12L14T4C1d0S2 7.70 5.50 0.71 5.65 0.73 371 635 999 1477 1025 D14L14T4C1d0S2 7.26 5.85 0.81 5.56 0.77 331 602 916 1400 971 D16L14T4C1d0S2 6.33 5.98 0.94 5.50 0.87 349 648 991 1508 1046 D18L14T4C1d0S2 5.70 6.10 1.07 5.45 0.96 364 691 1055 1607 1239 D14L8T4C1d0S2 6.78 5.85 0.86 7.99 1.18 331 602 916 1400 971 D14L10T4C1d0S2 7.24 5.85 0.81 6.86 0.95 331 602 916 1400 971 D14L12T4C1d0S2 7.15 5.85 0.82 6.10 0.85 331 602 916 1400 971 D14L13T4C1d0S2 7.22 5.85 0.81 5.81 0.81 331 602 916 1400 971 D14L15T4C1d0S2 6.93 5.85 0.84 5.35 0.77 331 602 916 1400 971 D14L16T4C1d0S2 6.70 5.85 0.87 5.16 0.77 331 602 916 1400 971 D14L17T4C1d0S2 6.63 5.85 0.88 4.99 0.75 331 602 916 1400 971 D14L18T4C1d0S2 6.34 5.85 0.92 4.85 0.76 331 602 916 1400 971 D14L20T4C1d0S2 5.52 5.85 1.06 4.60 0.83 331 602 916 1400 971 D14L14T1C1d0S0 3.32 5.85 1.76 5.27 1.59 331 602 1043 1400 1079 D14L14T2C1d0S0 4.16 5.85 1.41 5.37 1.29 331 602 997 1400 1079 D14L14T3C1d0S2 5.51 5.85 1.06 5.47 0.99 331 602 955 1400 971 D14L14T5C1d0S2 7.57 5.85 0.77 5.66 0.75 331 602 880 1400 971 D14L12T4C2d0S2 6.23 4.64 0.74 5.70 0.91 417 719 1006 1499 1064 D14L12T4C3d0S2 7.36 6.16 0.84 6.57 0.89 314 580 826 1301 880 D14L12T4C4d0S2 7.52 7.25 0.96 6.87 0.91 267 515 775 1244 830 D14L12T4C1d1S2 7.24 5.85 0.81 6.10 0.84 331 602 916 700 863 D14L12T4C1d2S2 7.14 5.85 0.82 6.10 0.85 331 602 916 560 755 D14L12T4C1d0S0 6.19 5.85 0.95 6.10 0.99 331 602 916 1400 1079 D14L12T4C1d0S1 6.49 5.85 0.90 6.10 0.94 331 602 916 1400 1079 D14L12T4C1d0S3 7.17 5.85 0.82 6.10 0.85 331 602 916 1400 971 NC-D14L12T4C1d0S2 6.20 5.19 0.84 5.78 0.93 372 658 988 1479 1045 Mean value 0.93 0.91 Standard deviation 0.22 0.18 Notes: τu1—Splice strength calculated by Eq.(2); τu2—Splice strength calculated by Eq.(4); ls1—Splice length calculated by Eq.(2); ls2—Splice length calculated by Eq.(3); ls3—Splice length calculated by Eq.(4); ls4—Splice length calculated by Eq.(5); ls5—Splice length calculated by Eq.(6). -

[1] 蔡新光, 赵青, 陈惠苏. 珊瑚混凝土研究现状[J]. 硅酸盐学报, 2021, 49(8):1753-1764.CAI Xinguang, ZHAO Qing, CHEN Huisu. Research progress in coral concrete[J]. Journal of the Chinese Ceramic Society,2021,49(8):1753-1764(in Chinese). [2] 施养杭, 王丹芳, 吴泽进. 海砂混凝土及其耐久性保护[J]. 工程力学, 2010, 27(S2):212-216.SHI Yanghang, WANG Danfang, WU Zejin. Durability protection of sand concrete[J]. Engineering Mechanics,2010,27(S2):212-216(in Chinese). [3] 苏晨, 麻海燕, 余红发, 等. 不同珊瑚骨料对珊瑚混凝土力学性能的影响[J]. 硅酸盐学报, 2020, 48(11):1771-1780.SU Chen, MA Haiyan, YU Hongfa, et al. Effect of different coral aggregates on mechanical properties of coral concrete[J]. Journal of the Chinese Ceramic Society,2020,48(11):1771-1780(in Chinese). [4] ANGST U, ELSENER B, LARSEN C K, et al. Critical chloride content in reinforced concrete—A review[J]. Cement and Concrete Research,2009,39(12):1122-1138. doi: 10.1016/j.cemconres.2009.08.006 [5] ZHANG L, NIU D T, WEN B, et al. Corrosion behavior of low alloy steel bars containing Cr and Al in coral concrete for ocean construction[J]. Construction and Building Materials,2020,258:119564. doi: 10.1016/j.conbuildmat.2020.119564 [6] 朱虹, 董志强, 吴刚, 等. FRP筋混凝土梁的刚度试验研究和理论计算[J]. 土木工程学报, 2015, 48(11):44-53. doi: 10.15951/j.tmgcxb.2015.11.007ZHU Hong, DONG Zhiqiang, WU Gang, et al. Experimental study and theoretical calculation on the flexural stiffness of concrete beams reinforced with FRP bars[J]. China Civil Engineering Journal,2015,48(11):44-53(in Chinese). doi: 10.15951/j.tmgcxb.2015.11.007 [7] 郑百林, 李伟, 张伟伟, 等. 增强混凝土中FRP包覆筋研究(I): 微结构设计[J]. 复合材料学报, 2004, 22(1):33-37. doi: 10.3321/j.issn:1000-3851.2004.01.007ZHENG Bailin, LI Wei, ZHANG Weiwei, et al. Mechanics behavior of FRP wrapped rebar reinforced concrete (I): Microstructure design and analyses[J]. Acta Materiae Compositae Sinica,2004,22(1):33-37(in Chinese). doi: 10.3321/j.issn:1000-3851.2004.01.007 [8] 郝庆多, 王言磊, 欧进萍. GFRP/钢绞线复合筋粘结锚固试验研究及设计建议[J]. 土木工程学报, 2008, 41(4):40-48. doi: 10.3321/j.issn:1000-131X.2008.04.006HAO Qingduo, WANG Yanlei, OU Jinping. Experimental study and design recommendation on the bond between GFRP/steel wire composite rebars and concrete[J]. China Civil Engineering Journal,2008,41(4):40-48(in Chinese). doi: 10.3321/j.issn:1000-131X.2008.04.006 [9] 吴刚, 罗云标, 吴智深, 等. 钢-连续纤维复合筋(SFCB)力学性能试验研究与理论分析[J]. 土木工程学报, 2010, 43(3):53-61. doi: 10.15951/j.tmgcxb.2010.03.010WU Gang, LUO Yunbiao, WU Zhishen, et al. Experimental and theoretical studies on the mechanical properties of steel-FRP composite bars[J]. China Civil Engineering Journal,2010,43(3):53-61(in Chinese). doi: 10.15951/j.tmgcxb.2010.03.010 [10] ZHOU Y W, ZHENG Y W, PAN J, et al. Experimental investigations on corrosion resistance of innovative steel-FRP composite bars using X-ray microcomputed tomography[J]. Composites Part B: Engineering,2019,161:272-284. doi: 10.1016/j.compositesb.2018.10.069 [11] 中国工程建设标准化协会. 珊瑚骨料混凝土应用技术规程: T/CECS 694—2020[S]. 北京: 中国计划出版社, 2020.China Engineering Construction Standardization Association. Technical specification for coral aggregate concrete: T/CECS 694—2020[S]. Beijing: China Planning Press, 2020(in Chinese). [12] 罗云标, 吴刚, 吴智深, 等. 钢-连续纤维复合筋(SFCB)的生产制备研究[J]. 工程抗震与加固改造, 2009, 31(1):28-34. doi: 10.16226/j.issn.1002-8412.2009.01.018LUO Yunbiao, WU Gang, WU Zhishen, et al. Study on fabrication technique of steel fiber composite bar (SFCB)[J]. Earthquake Resistant Engineering and Retrofitting,2009,31(1):28-34(in Chinese). doi: 10.16226/j.issn.1002-8412.2009.01.018 [13] 马福栋, 邓明科, 孙宏哲, 等. 变形钢筋/超高性能混凝土搭接粘结性能[J]. 复合材料学报, 2021, 38(11):3912-3924. doi: 10.13801/j.cnki.fhclxb.20201229.006MA Fudong, DENG Mingke, SUN Hongzhe, et al. Bond behavior of deformed steel bars lap-splice in ultra high performance concrete[J]. Acta Materiae Compositae Sinica,2021,38(11):3912-3924(in Chinese). doi: 10.13801/j.cnki.fhclxb.20201229.006 [14] 方志, 陈潇, 张门哲, 等. 活性粉末混凝土中带肋钢筋搭接性能试验研究[J]. 土木工程学报, 2019, 52(3):20-28, 49.FANG Zhi, CHEN Xiao, ZHANG Menzhe, et al. Experimental study on performance of lap-spliced ribbed steel bars in reactive powder concrete[J]. China Civil Engineering Journal,2019,52(3):20-28, 49(in Chinese). [15] 陈宗平, 周济, 陈宇良, 等. 珊瑚粗骨料海水混凝土力学性能试验研究[J]. 应用力学学报, 2020, 37(5):1999-2006. doi: 10.11776/cjam.37.05.B090CHEN Zongping, ZHOU Ji, CHEN Yuliang, et al. Experimental study on mechanical properties of coral coarse aggregate seawater concrete[J]. Chinese Journal of Applied Mechanics,2020,37(5):1999-2006(in Chinese). doi: 10.11776/cjam.37.05.B090 [16] MA F D, DENG M K, FAN H K, et al. Study on the lap-splice behavior of post-yield deformed steel bars in ultra high performance concrete[J]. Construction and Building Materials,2020,262:120611. doi: 10.1016/j.conbuildmat.2020.120611 [17] 惠慧. 玻璃纤维增强聚合物(GFRP)筋搭接性能试验研究[D]. 郑州: 郑州大学, 2014.HUI Hui. Experimental study on the lap performance of tensile glass fiber reinforced polymer (GFRP) bars[D]. Zhengzhou: Zhengzhou University, 2014(in Chinese). [18] 中华人民共和国住房和城乡建设部. 纤维增强复合材料工程应用技术标准: GB/T 50608—2020[S]. 北京: 中国标准出版社, 2020.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Technical standard for fiber reinforced polymer (FRP) in construction: GB/T 50608—2020[S]. Beijing: Standards Press of China, 2020(in Chinese). [19] Committee of the American Concrete Institute. Guide for the design and construction of structural concrete reinforced with fiber-reinforced polymer (FRP) bars: ACI 440.1R—15[S]. Farmington Hills: American Concrete Institute, 2015. [20] Canadian Standards Association. Design and construction of building structures with fibre-reinforced polymers: CAN/CSA S806—12[S]. Toronto: Canadian Standards Association International, 2012. [21] UOMOTO T. Recommendation for design and construction of concrete structures using continuous fiber reinforcing materials[M]. Tokyo: Japan Society of Civil Engineers, 1997: 47-49. [22] 中华人民共和国住房和城乡建设部. 混凝土结构设计规范: GB/T 50010—2010[S]. 北京: 中国标准出版社, 2010.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Code for design of concrete structures: GB/T 50010—2010[S]. Beijing: Standards Press of China, 2010(in Chinese). -

下载:

下载: