Experimental study on the degradation of interlaminar shear performance of FRP bars in different corrosive environments

-

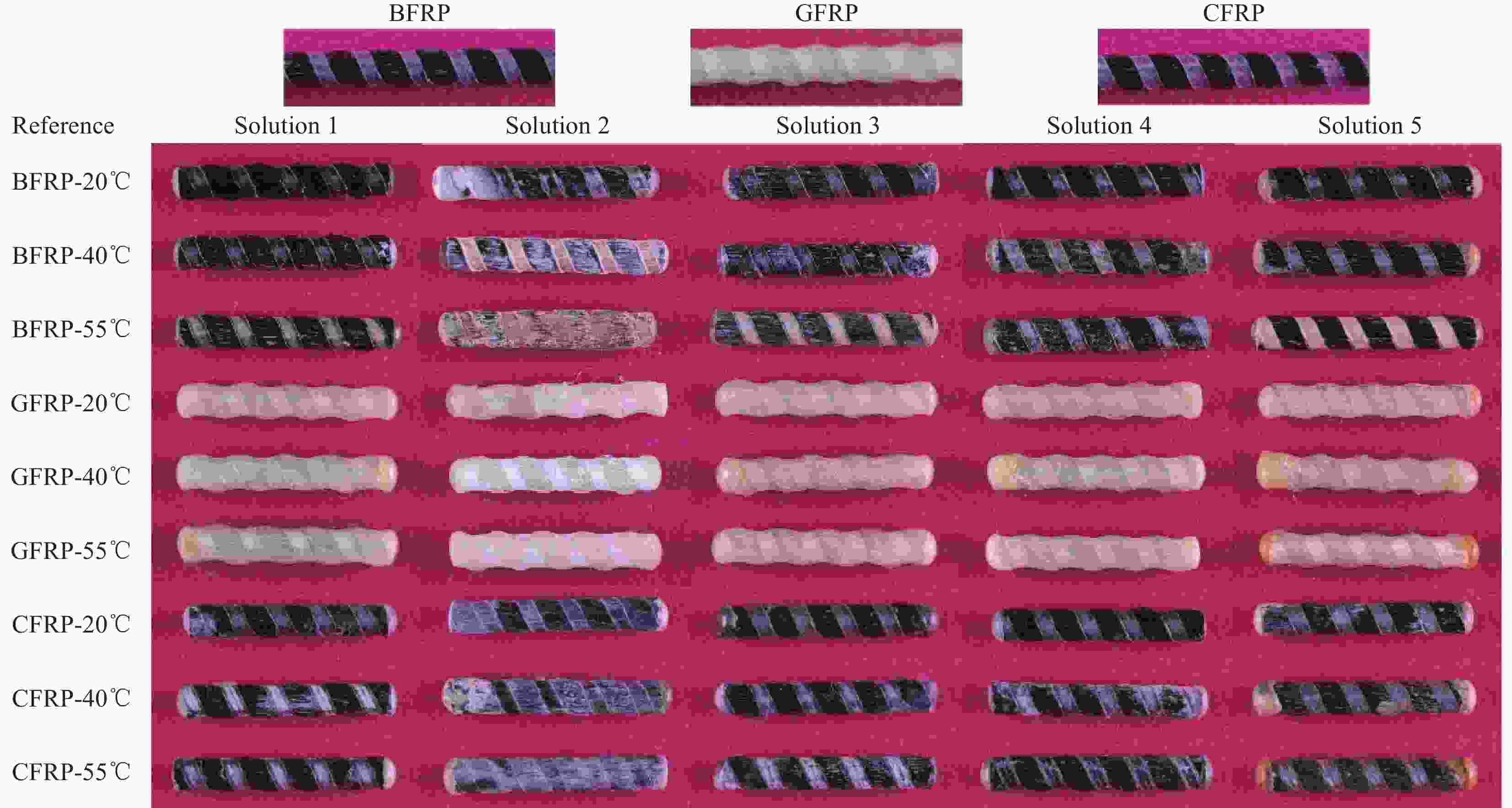

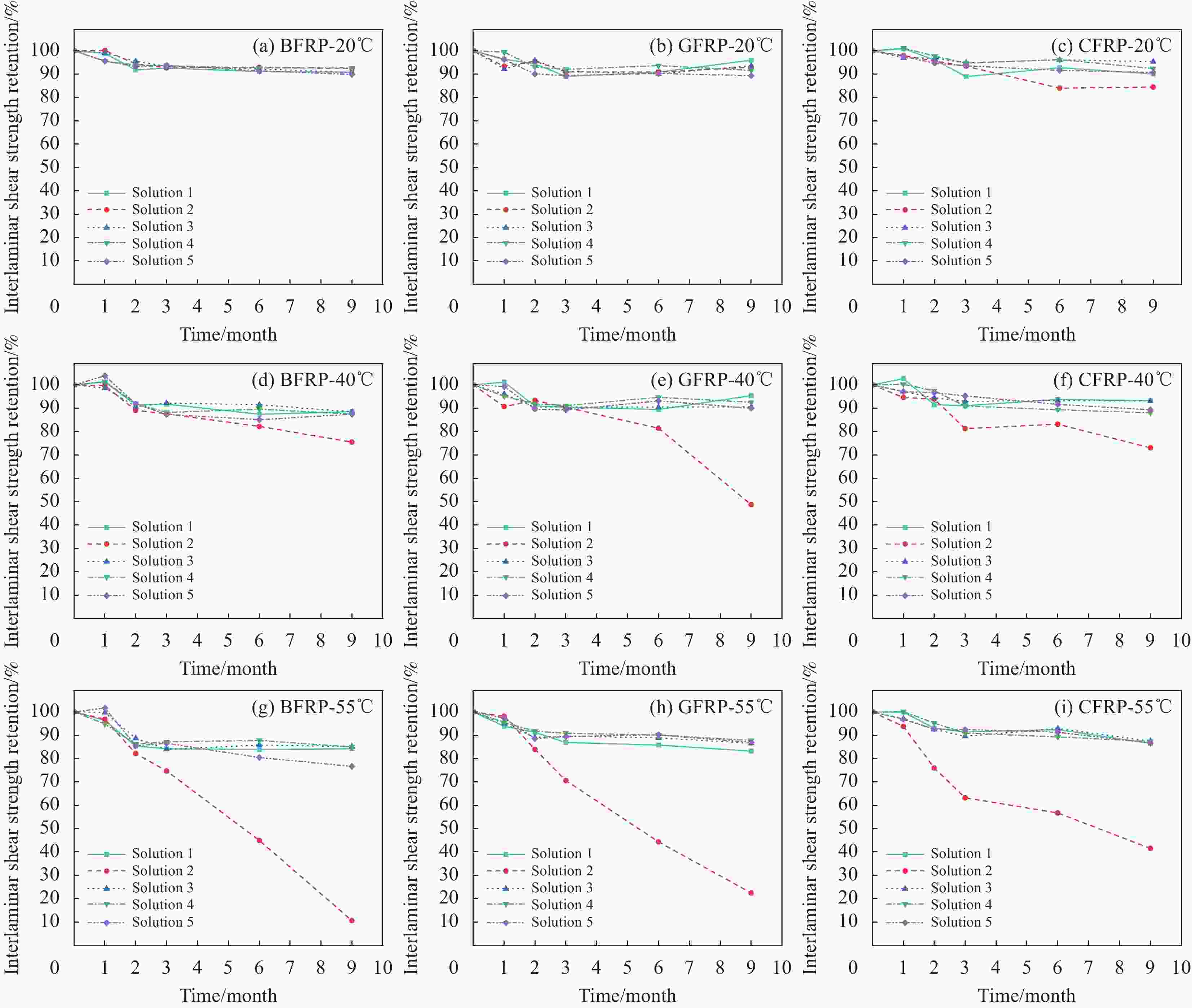

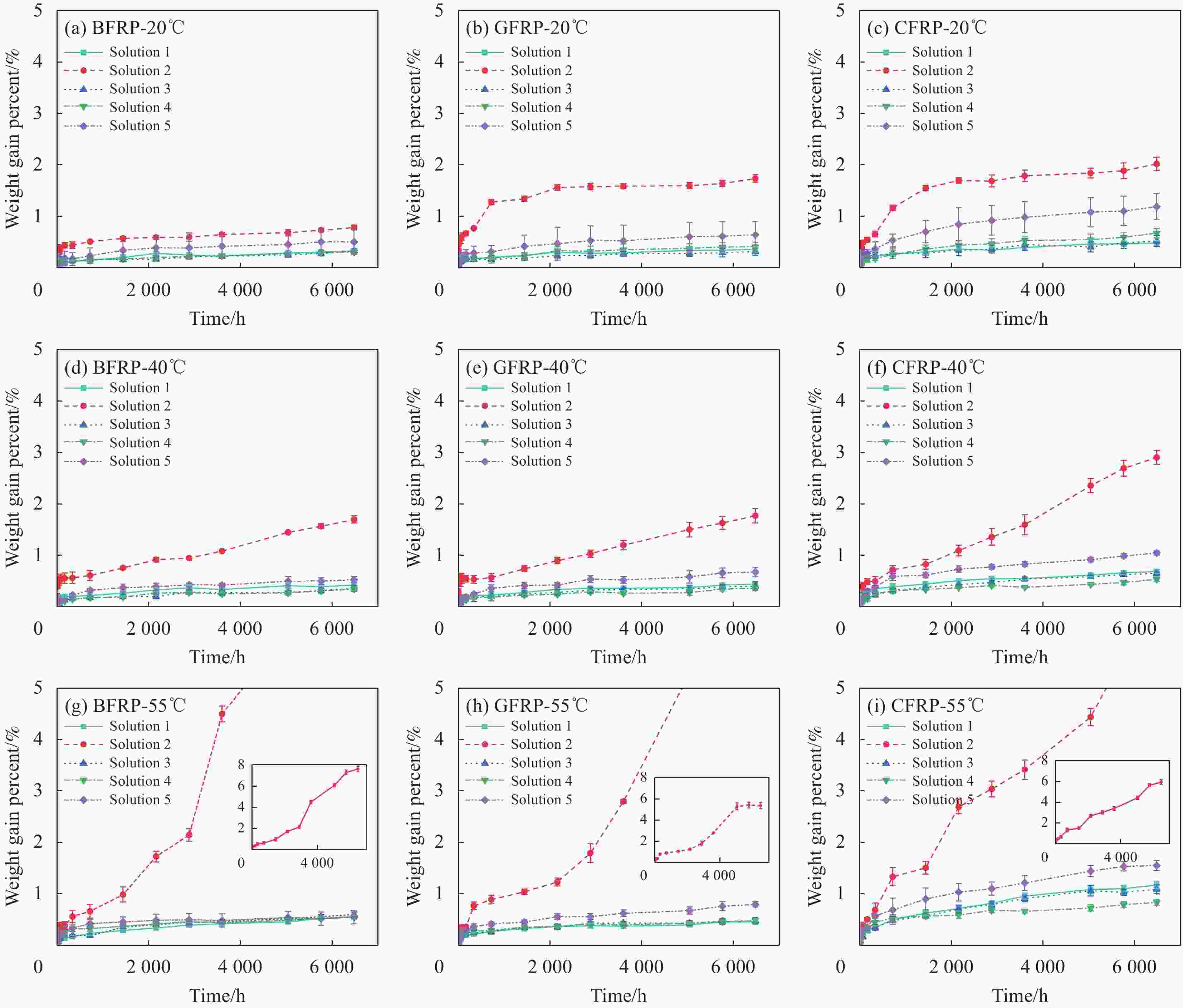

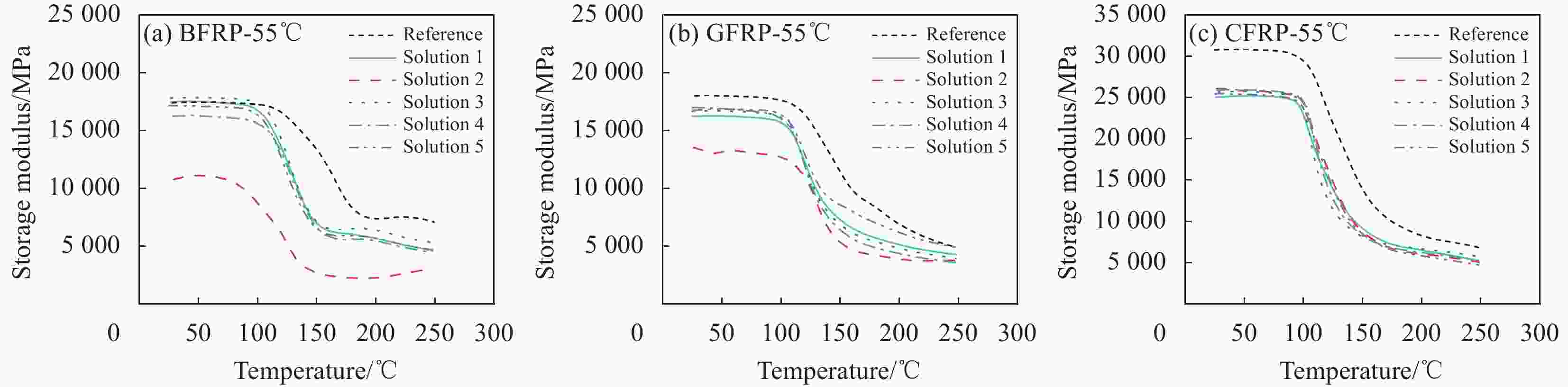

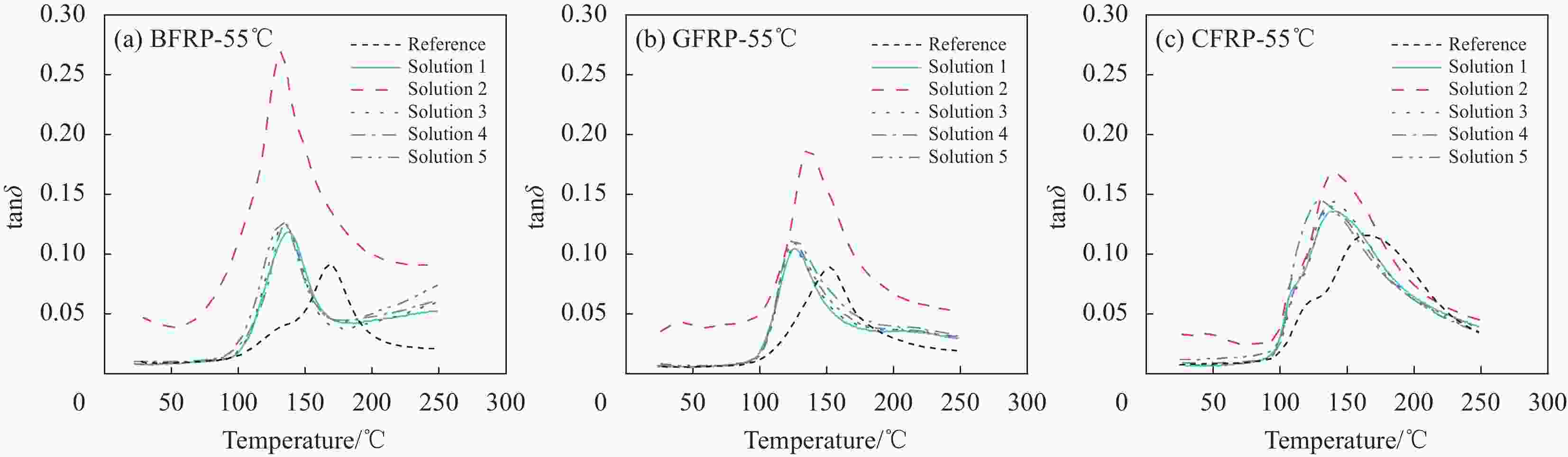

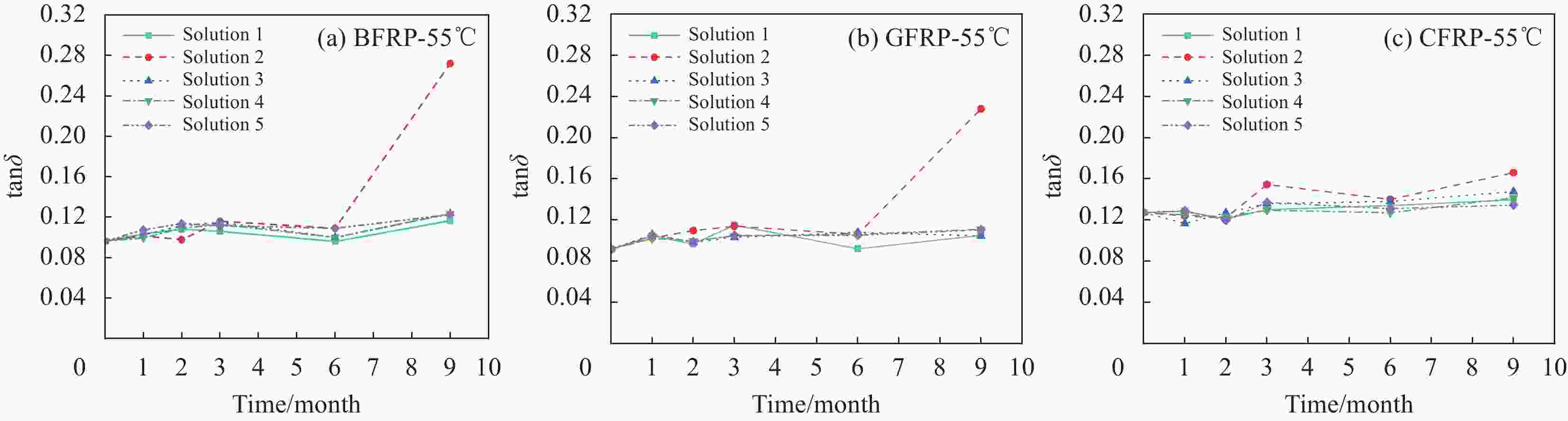

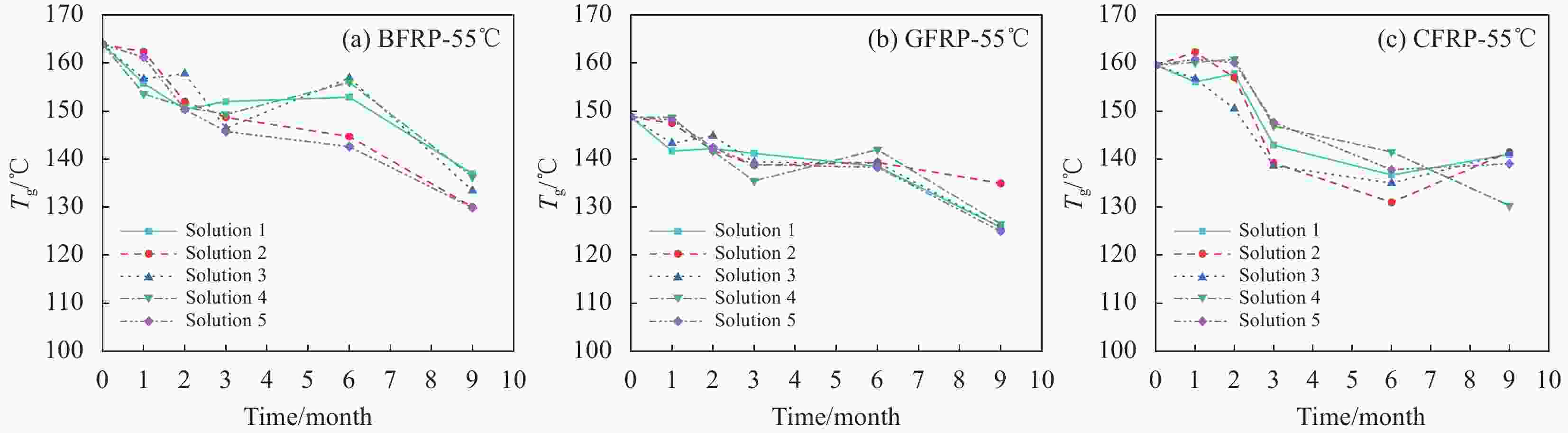

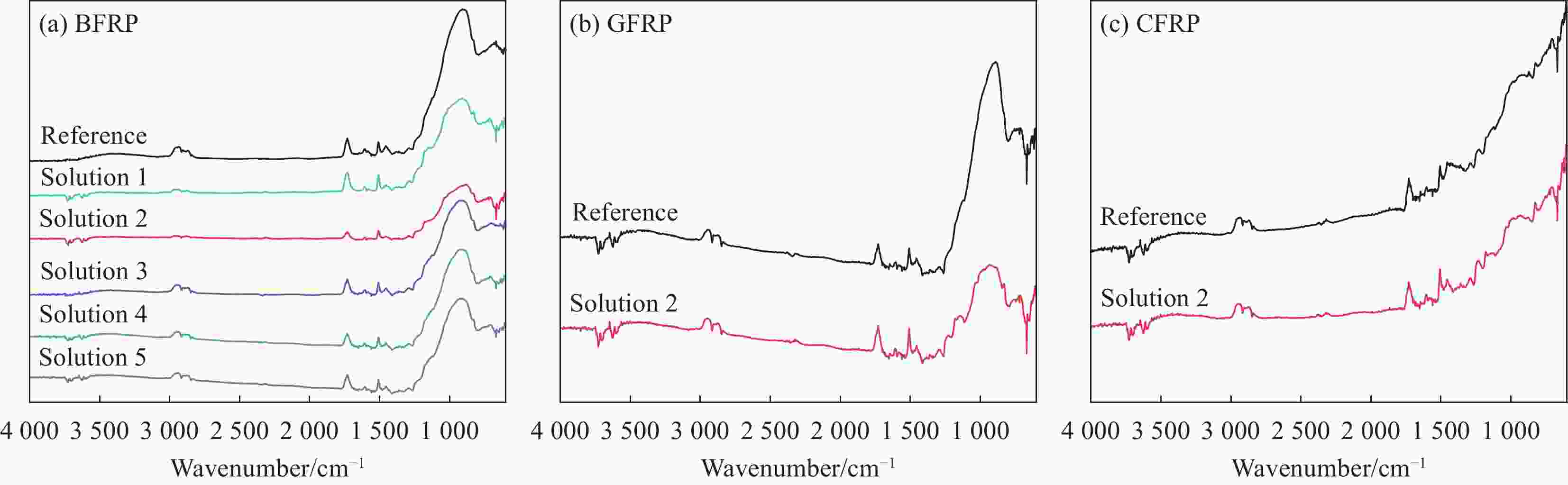

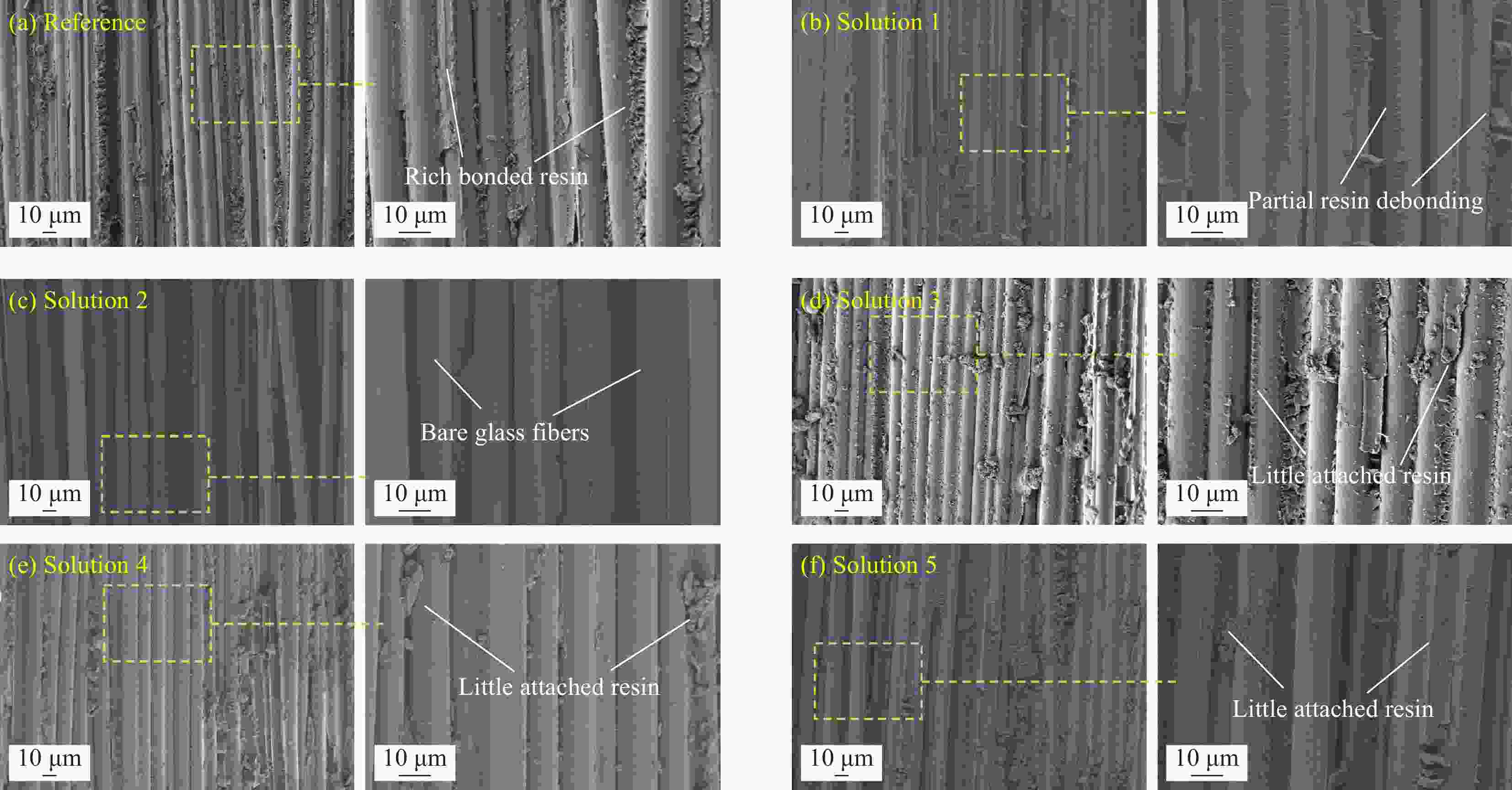

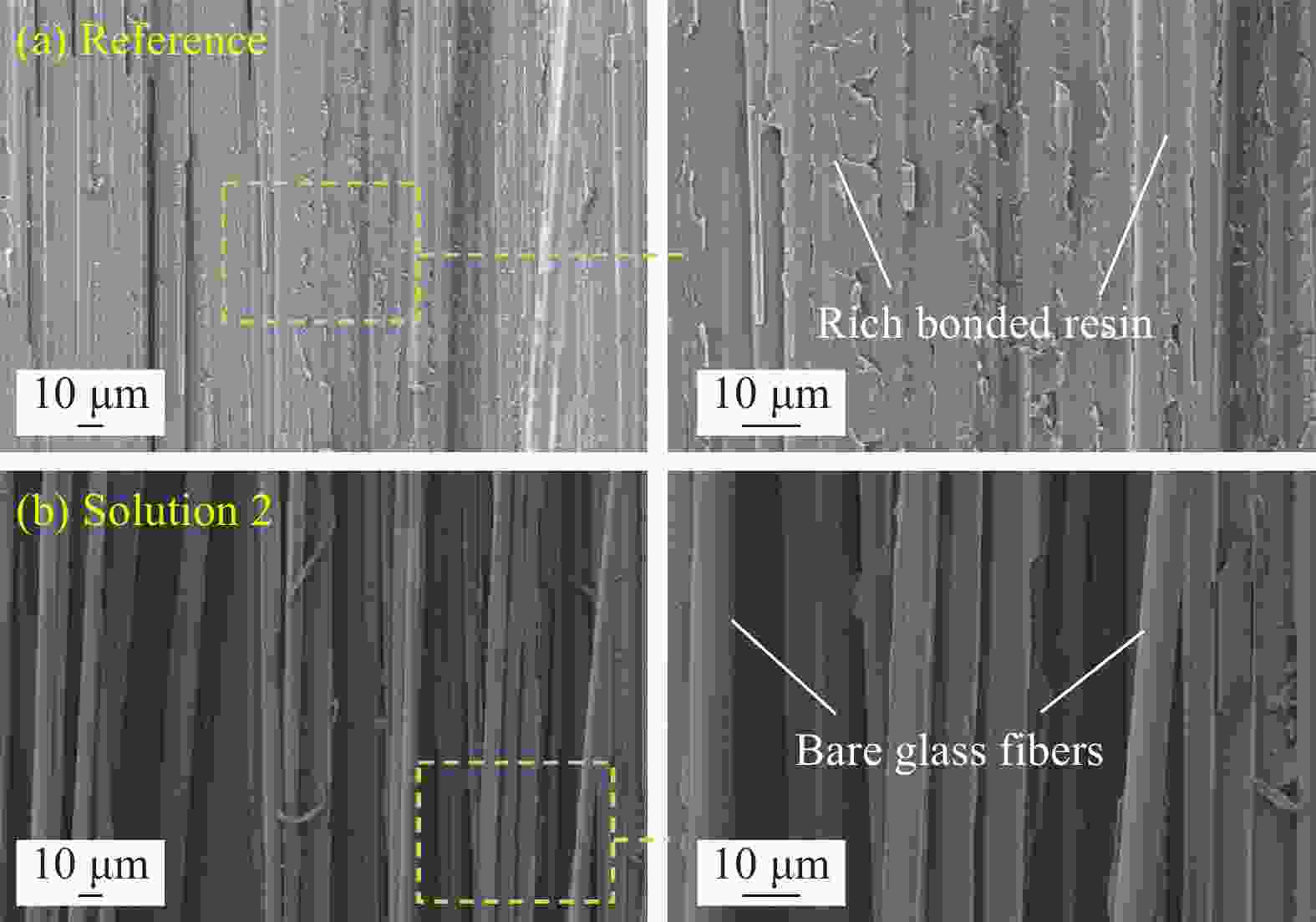

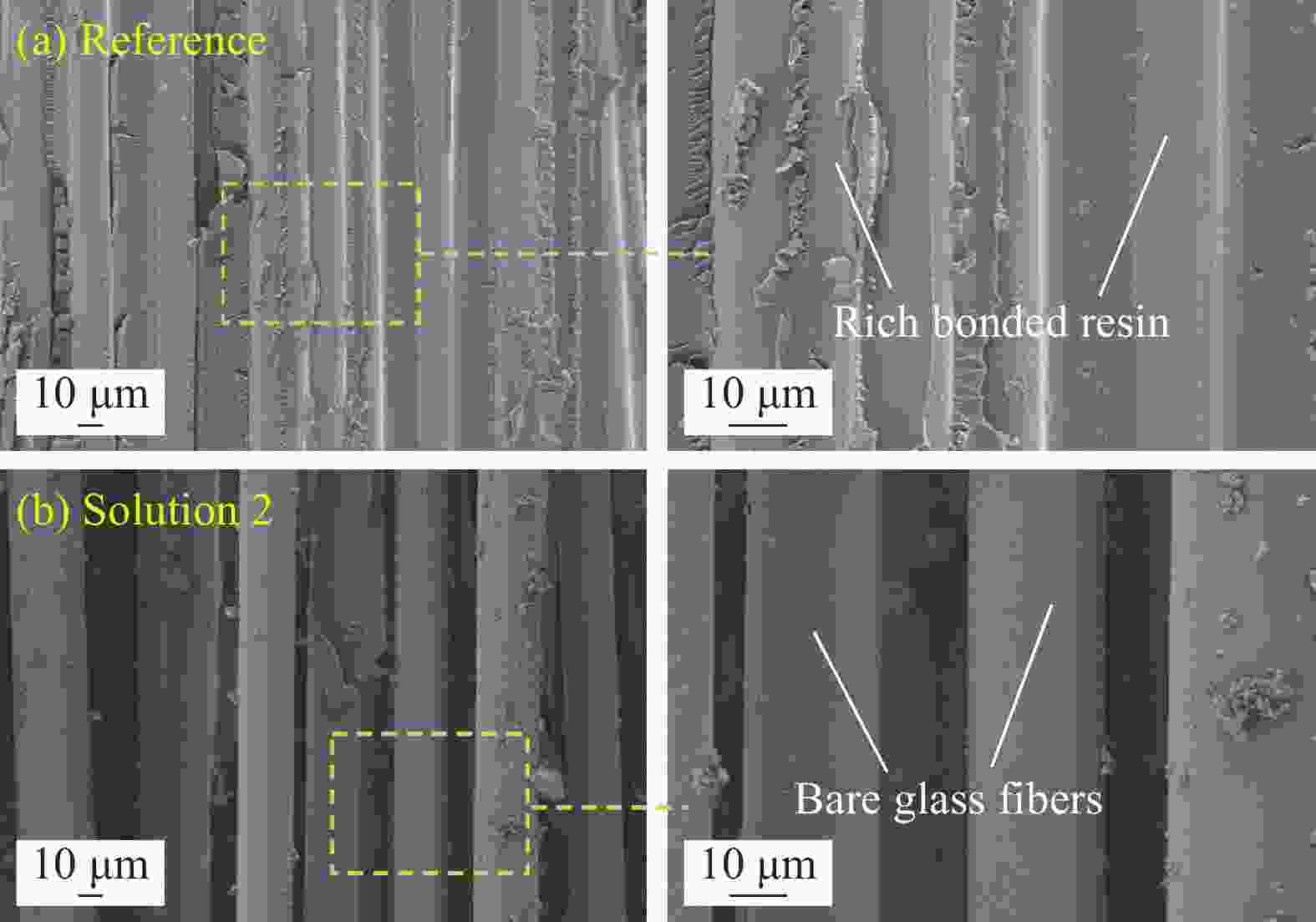

摘要: 本文研究了玄武岩纤维、玻璃纤维及碳纤维增强聚合物(BFRP、GFRP和CFRP)筋在水、强碱溶液(pH=12.8)、弱碱溶液(pH=11)、模拟海水及酸溶液(pH=1.5)这5种腐蚀溶液环境下的性能劣化情况。通过层间剪切强度测试、水吸收试验、DMA、FTIR和SEM探究了不同老化温度(20、40和55℃)与腐蚀时间(1、2、3、6和9月)下FRP筋的纤维-树脂界面粘结性能、微观结构及化学成分等的劣化规律。试验结果表明:FRP筋的层间剪切强度受腐蚀环境的影响显著,在强碱溶液中的劣化速率远高于其他溶液,其原因是高浓度的OH−离子加速了FRP筋的水解和刻蚀反应,导致大量纤维与树脂发生脱粘,最终导致层间剪切强度降低;与BFRP筋和GFRP筋相比,CFRP筋的耐久性相对优异,在相同老化条件下具有更高的层间剪切强度保留率。Abstract: In this paper, the performance deterioration of basalt-, glass- and carbon-fiber reinforced polymer (BFRP, GFRP and CFRP) bars in five kinds of corrosive solution environments, i.e., water, strong alkali solution (pH=12.8), weak alkali solution (pH=11), simulated seawater and acid solution (pH=1.5), was investigated. The deterioration patterns of fiber-resin interfacial bonding properties, microstructure and chemical composition of FRP bars at different aging temperatures (20, 40 and 55℃) and corrosion periods (1, 2, 3, 6 and 9 months) were investigated by interlaminar shear strength, water absorption, DMA, FTIR and SEM tests. The test results show that the interlaminar shear strength of FRP bars is significantly affected by the corrosive environment, and the deterioration rate of FRP specimen in the strong alkali solution is much higher than the other four solutions. The reason is that the high concentration of OH− ions accelerates the hydrolysis and etching reaction of FRP bars, causing a large number of fibers and resin debonding, which eventually leads to the reduction of interlaminar shear strength. Compared with BFRP bars and GFRP bars, CFRP bars have relatively excellent durability and higher interlaminar shear strength retention ratio under the same aging conditions.

-

Key words:

- FRP bar /

- corrosion environment /

- interlaminar shear strength /

- moisture uptake /

- FTIR /

- DMA

-

表 1 4种溶液的化学成分组成

Table 1. Chemical composition of four kinds of solutions

Composition Solution 2

concentration/(g·L−1)Solution 3

concentration/(g·L−1)Solution 4

concentration/(g·L−1)Solution 5

concentration/(g·L−1)NaOH 0.9 0.012 — — KOH 4.2 0.028 — — Ca(OH)2 118.5 0.00074 — — H2SO4 — — — 1.58 NaCl — — 24.53 — MgCl2 — — 5.20 — Na2SO4 — — 4.09 — CaCl2 — — 1.16 — KCl — — 0.695 — NaHCO3 — — 0.201 — KBr — — 0.101 — H3BO3 — — 0.027 — SrCl2 — — 0.025 — NaF — — 0.003 — Note: "—" represents "not available". 表 2 老化后BFRP筋的层间剪切强度

Table 2. Interlaminar shear strength of BFRP bars after aging

Temperature/℃ Time/

monthSolution 1 Solution 2 Solution 3 Solution 4 Solution 5 Mean/MPa COV/% Mean/MPa COV/% Mean/MPa COV/% Mean/MPa COV/% Mean/MPa COV/% 20 1 45.30 3.35 45.84 4.26 45.39 3.29 43.73 4.35 43.78 5.02 2 42.02 3.02 43.21 5.99 43.74 1.72 43.01 3.93 42.68 1.70 3 42.41 2.72 42.46 2.68 42.74 1.20 42.84 2.66 42.94 4.68 6 41.72 1.59 42.54 0.27 42.19 2.37 42.39 1.53 41.84 1.15 9 41.59 0.11 42.28 3.62 41.52 0.42 42.41 3.04 41.16 6.11 40 1 46.38 3.02 45.64 3.62 45.17 1.20 46.45 3.52 47.58 1.15 2 41.88 2.34 40.80 4.65 41.54 3.46 42.12 4.14 42.08 3.96 3 42.01 3.47 40.10 2.94 42.23 4.02 40.39 4.22 40.00 2.59 6 40.04 8.13 37.65 4.95 41.90 6.65 41.02 4.54 38.97 1.47 9 40.55 1.49 34.57 6.43 40.51 4.16 40.08 2.55 40.03 1.64 55 1 44.14 2.16 44.33 2.87 45.67 0.95 43.41 1.59 46.55 3.86 2 39.10 4.05 37.63 4.80 40.63 4.84 39.49 1.72 39.16 1.23 3 38.56 1.00 34.20 4.91 38.46 2.67 39.93 2.68 39.65 3.57 6 38.43 2.60 20.59 1.32 39.29 7.61 40.19 0.12 36.85 4.64 9 38.56 7.21 4.87 5.02 39.00 1.12 38.93 4.99 35.11 3.80 Note: COV—Coefficient of variation. 表 3 老化后GFRP筋的层间剪切强度

Table 3. Interlaminar shear strength of GFRP bars after aging

Temperature/℃ Time/

monthSolution 1 Solution 2 Solution 3 Solution 4 Solution 5 Mean/MPa COV/% Mean/MPa COV/% Mean/MPa COV/% Mean/MPa COV/% Mean/MPa COV/% 20 1 43.25 4.54 41.87 5.49 41.36 4.32 44.61 4.22 43.18 2.21 2 42.32 4.60 42.84 1.58 42.96 4.75 41.71 3.97 40.39 4.62 3 39.92 3.72 40.80 6.17 40.92 3.45 41.29 4.58 40.09 1.46 6 40.75 5.77 40.77 4.56 40.43 2.35 42.00 8.20 40.49 3.33 9 43.04 1.03 41.72 0.67 41.96 7.10 41.08 2.88 40.06 7.35 40 1 45.38 3.80 40.70 4.16 43.07 1.97 42.68 3.36 44.53 3.87 2 40.80 1.23 41.87 3.80 40.55 2.82 41.20 3.48 40.17 2.72 3 40.57 3.72 40.54 5.28 40.60 4.50 40.90 2.76 40.03 3.20 6 40.12 4.15 36.53 6.12 40.57 0.80 42.47 8.06 41.79 1.46 9 42.79 1.31 21.86 3.48 40.63 2.93 41.51 1.79 40.38 2.49 55 1 42.11 4.54 44.02 1.75 42.61 6.67 42.86 1.57 43.67 0.94 2 40.92 6.34 37.67 9.62 39.93 2.88 41.16 3.18 39.72 4.51 3 38.99 5.55 31.68 13.99 40.19 1.77 40.75 1.47 40.13 1.91 6 38.49 4.84 19.90 12.58 39.87 6.02 40.41 4.57 40.45 4.17 9 37.33 1.54 10.09 14.82 38.81 7.07 39.37 1.07 38.98 1.54 表 4 老化后CFRP筋的层间剪切强度

Table 4. Interlaminar shear strength of CFRP bars after aging

Temperature/℃ Time/

monthSolution 1 Solution 2 Solution 3 Solution 4 Solution 5 Mean/MPa COV/% Mean/MPa COV/% Mean/MPa COV/% Mean/MPa COV/% Mean/MPa COV/% 20 1 49.31 1.89 47.88 3.89 47.40 1.41 49.41 3.49 47.71 3.33 2 46.93 3.57 46.72 2.66 47.33 1.37 47.75 0.85 46.27 5.53 3 43.48 1.72 45.64 4.22 46.37 5.96 46.30 1.76 45.73 4.14 6 45.34 2.55 41.06 10.04 46.97 2.80 47.04 3.69 44.77 0.54 9 44.04 1.16 41.28 9.22 46.60 2.33 45.17 3.07 44.34 3.30 40 1 50.22 2.01 46.24 1.81 47.50 3.70 49.01 1.29 47.45 2.55 2 44.72 4.53 45.90 8.89 46.17 3.26 47.65 3.63 47.27 3.27 3 44.52 2.41 39.74 5.03 45.43 7.31 44.47 5.01 46.57 2.17 6 45.85 3.51 40.66 1.55 45.60 1.76 43.67 5.35 44.80 2.37 9 45.56 1.35 35.70 8.23 45.50 2.50 43.05 5.02 43.68 1.37 55 1 48.85 4.70 45.87 1.46 47.48 4.70 48.94 5.85 47.37 2.39 2 45.46 1.89 37.14 8.67 45.24 1.90 46.56 3.17 45.24 2.49 3 44.71 5.04 30.91 5.62 43.77 3.65 44.48 3.45 45.19 6.92 6 45.17 2.11 27.72 8.64 45.41 4.67 43.64 3.38 44.61 2.49 9 42.32 4.08 20.32 15.87 42.78 1.71 42.71 3.38 42.36 3.11 -

[1] JAFARZADEH H, NEMATZADEH M. Evaluation of post-heating flexural behavior of steel fiber-reinforced high-strength concrete beams reinforced with FRP bars: Experimental and analytical results[J]. Engineering Structures,2020,225:111292. [2] WANG Y L, WANG Y S, WAN B L, et al. Properties and mechanisms of self-sensing carbon nanofibers/epoxy composites for structural health monitoring[J]. Composite Structures,2018,200:669-678. doi: 10.1016/j.compstruct.2018.05.151 [3] 滕锦光. 新材料组合结构[J]. 土木工程学报, 2018, 51(12):1-11.TENG Jinguang. New-material hybrid structures[J]. China Civil Engineering Journal,2018,51(12):1-11(in Chinese). [4] 郝庆多, 王勃, 欧进萍. 纤维增强塑料筋在土木工程中的应用[J]. 混凝土, 2006(9):38-40.HAO Qingduo, WANG Bo, OU Jinping. Fiber reinforced polymer rebar's application to civil engineering[J]. Concrete,2006(9):38-40(in Chinese). [5] 董志强, 吴刚. FRP筋增强混凝土结构耐久性能研究进展[J]. 土木工程学报, 2019, 52(10):1-19, 29.DONG Zhiqiang, WU Gang. Research progress on durability of FRP bars reinforced concrete structures[J]. China Civil Engineering Journal,2019,52(10):1-19, 29(in Chinese). [6] 尹世平, 华云涛, 徐世烺. FRP配筋混凝土结构研究进展及其应用[J]. 建筑结构学报, 2021, 42(1):134-150.YIN Shiping, HUA Yuntao, XU Shilang. A review on research progress and application of concrete structures internally reinforced with FRP bars[J]. Journal of Building Structures,2021,42(1):134-150(in Chinese). [7] CHEN Y, DAVALOS J F, RAY I, et al. Accelerated aging tests for evaluations of durability performance of FRP reinforcing bars for concrete structures[J]. Composite Structures,2007,78(1):101-111. doi: 10.1016/j.compstruct.2005.08.015 [8] LU Z Y, SU L Z, TAN S R, et al. Long-term shear performance of bare and cement mortar-coated BFRP bars in corrosive environments[J]. Construction and Building Materials,2020,237:117658. doi: 10.1016/j.conbuildmat.2019.117658 [9] LU C H, NI M Z, CHU T S, et al. Comparative investigation on tensile performance of FRP bars after exposure to water seawater, and alkaline solutions[J]. Journal of Materials in Civil Engineering,2020,32(7):4020170. doi: 10.1061/(ASCE)MT.1943-5533.0003243 [10] WU G, DONG Z Q, WANG X, et al. Prediction of long-term performance and durability of BFRP bars under the combined effect of sustained load and corrosive solutions[J]. Journal of Composites for Construction,2015,19(3):4014058. doi: 10.1061/(ASCE)CC.1943-5614.0000517 [11] 邓宗才, 高伟男, 沈锋. 碱、盐环境下不同应力水平FRP筋抗压强度试验与理论研究[J]. 复合材料学报, 2017, 34(10):2220-2231.DENG Zongcai, GAO Weinan, SHEN Feng. Experimental and theoretical study on compressive strength of FRP rebars under different stress levels in alkali and salt solution[J]. Acta Materiae Compositae Sinica,2017,34(10):2220-2231(in Chinese). [12] 张新越, 欧进萍. FRP筋酸碱盐介质腐蚀与冻融耐久性试验研究[J]. 武汉理工大学学报, 2007, 29(1):33-36, 54.ZHANG Xinyue, OU Jinping. Durability experimental research on resistance of acidic, alkali, salt solutions and freeze-thaw properties of FRP bar[J]. Journal of Wuhan University of Technology,2007,29(1):33-36, 54(in Chinese). [13] WANG Z K, ZHAO X L, XIAN G J, et al. Durability study on interlaminar shear behaviour of basalt-, glass- and carbon-fibre reinforced polymer (B/G/CFRP) bars in seawater sea sand concrete environment[J]. Construction and Building Materials,2017,156:985-1004. doi: 10.1016/j.conbuildmat.2017.09.045 [14] BENMOKRANE B, ELGABBAS F, AHMED E A, et al. Characterization and comparative durability study of glass/vinylester, basalt/vinylester, and basalt/epoxy FRP bars[J]. Journal of Composites for Construction,2015,19(6):4015008. doi: 10.1061/(ASCE)CC.1943-5614.0000564 [15] AHMED A, GUO S C, ZHANG Z H, et al. A review on durability of fiber reinforced polymer (FRP) bars reinforced seawater sea sand concrete[J]. Construction and Building Materials,2020,256:119484. doi: 10.1016/j.conbuildmat.2020.119484 [16] ACI. Guide test methods for fiber reinforced polymers (FRPs) for reinforcing or strengthening concrete structures: ACI 440.3R—2012[S]. Michigan: American Concrete Institute, 2012. [17] ASTM. Standard practice for the preparation of substitute ocean water: ASTM D1141—98(2013)[S]. West Conshohocken: ASTM, 2013. [18] ASTM. Standard test method for apparent horizontal shear strength of pultruded reinforced plastic rods by the short-beam method: ASTM D4475—02(2016)[S]. West Conshohocken: ASTM, 2016. [19] ASTM. Standard test method for moisture absorption properties and equilibrium conditioning of polymer matrix composite materials: ASTM D5229/D5229M—20[S]. West Conshohocken: ASTM, 2020. [20] 霍文静, 张佐光, 王明超, 等. 复合材料用玄武岩纤维耐酸碱性实验研究[J]. 复合材料学报, 2007, 24(6):77-82.HUO Wenjing, ZHANG Zuoguang, WANG Mingchao, et al. Experimental study on acid and alkali resistance of basalt fiber used for composites[J]. Acta Materiae Compositae Sinica,2007,24(6):77-82(in Chinese). [21] YI Y, GUO S C, LI S, et al. Effect of alkalinity on the shear performance degradation of basalt fiber-reinforced polymer bars in simulated seawater sea sand concrete environment[J]. Construction and Building Materials,2021,299:123957. doi: 10.1016/j.conbuildmat.2021.123957 [22] XIAN G J, KARBHARI V M. Segmental relaxation of water-aged ambient cured epoxy[J]. Polymer Degradation and Stability,2007,92(9):1650-1659. doi: 10.1016/j.polymdegradstab.2007.06.015 [23] XIE J H, LI Y C, LU Z Y, et al. Effects of immersion in water, alkaline solution, and seawater on the shear performance of basalt FRP bars in seawater-sea sand concrete[J]. Journal of Composites for Construction,2022,26(2):4021071. doi: 10.1061/(ASCE)CC.1943-5614.0001184 [24] NGONO Y, MARÉCHAL Y, MERMILLIOD N. Epoxy-amine reticulates observed by infrared spectrometry. I: Hydration process and interaction configurations of embedded H2O molecules[J]. The Journal of Physical Chemistry B,1999,103(24):4979-4985. doi: 10.1021/jp984809y [25] 王自柯. FRP筋在模拟海水-海砂混凝土孔溶液浸泡下的耐久性研究[D]. 哈尔滨: 哈尔滨工业大学, 2018.WANG Zike. Study on the durability performances of fiber reinforced polymer (FRP) bars exposed to simulated seawater and sea sand concerte pore solution[D]. Harbin: Harbin Institute of Technology, 2018(in Chinese). [26] ZHAO Q, ZHANG D X, ZHAO X L, et al. Modelling damage evolution of carbon fiber-reinforced epoxy polymer composites in seawater sea sand concrete environment[J]. Composites Science and Technology,2021,215:108961. doi: 10.1016/j.compscitech.2021.108961 -

下载:

下载: