Low-velocity impact properties of foam sandwich composites with different thicknesses prepared via thermal expansion molding process

-

摘要: 热膨胀工艺能够一体化成型各种泡沫夹芯复合材料。选择初始厚度为1 mm的可膨胀环氧泡沫预浸胶,通过控制模具型腔尺寸以控制不同成型压力制备4种不同厚度的泡沫夹芯板。以10 J和42 J冲击能量研究热膨胀工艺和芯材厚度对泡沫夹芯复合材料低速冲击性能的影响。通过ABAQUS有限元分析、超声C扫描对比试验数据分析了不同试样的损伤模式。通过冲击后压缩试验分析了不同试样的损伤容限。结果发现更高膨胀倍率的泡沫芯子,产生更低的膨胀力,泡沫夹芯板的抗冲击强度降低,但结构具有更优异的吸能效果。高能量和低强度的泡沫芯子都会导致蒙皮更高的损伤程度。试样在10 J能量冲击后的压缩强度衰减率为8.2%,而42 J能量冲击后的压缩强度衰减率达到38.2%。成型压力和芯子的厚度对泡沫夹芯板的损伤容限影响很小。研究确定了热膨胀工艺成型泡沫夹芯复合材料具有高的结构和抗冲击性能可设计性。Abstract: Thermal expansion molding process is expected to be integrated to form various foam sandwich composites. The expandable epoxy foam prepreg with an initial thickness of 1 mm was selected, and four kinds of foam sandwich panels with different thicknesses were prepared by controlling the mold cavity size and different molding pressures. The impact energies of 10 J and 42 J were used to study the effects of thermal expansion process and core thickness on the low-velocity impact properties of foam sandwich composites. The damage patterns of different specimens were investigated by ABAQUS finite element analysis, ultrasonic C-scan and the test data. Compression after impact tests were conducted to investigate the damage tolerance of different specimens. The results show that the foam core with higher expansion rate produces lower expansion force, and the impact strength of the foam sandwich board is reduced, but the structure has better energy absorption effect. Both high impact energy and low strength foam cores lead to higher damage degree of the skin. The compression strength decay rate of the sample at 10 J impact energy is 8.2%, and the compression strength decay rate of the sample at 42 J impact energy is 38.2%. The forming pressure and the thickness of the core have little effect on the damage tolerance of the foam sandwich plate. The high designability of structural and impact resistance properties of foam sandwich composites formed by thermal expansion process was determined.

-

乙烯-四氟乙烯(ETFE)薄膜凭借其良好的物理特性及力学性能,在新型建筑、能源等领域中已被广泛应用。在实际工程应用中,ETFE膜结构的撕裂破坏可归结为内部因素与外部环境因素的协同作用。膜面处膜材在制造与安装过程中,不可避免地会存在微小孔洞、细微折痕和微裂纹等初始缺陷,以及偶发的外来飞致物刺穿引起的切缝;这使膜材在预应力、极端风荷载及雨雪荷载的复合作用下,极易产生应力集中而诱发缺陷不断扩展,最终膜材撕裂损伤,严重情况下甚至会引发膜结构的整体失效,对结构安全构成重大威胁。并且当膜材在中心区域处受到集中载荷或存在制造缺陷时,极有可能会出现显著的中心撕裂行为[1, 2]。因此,除了需对ETFE薄膜的常规力学性能进行研究,也有必要对其撕裂力学行为开展深入研究。

吴明儿[3-5]、崔家春[6, 7]、胡建辉[8]、Zhang[9]、Surholt[10]和Zhao[11-13]等分别对ETFE薄膜进行了系列试验与分析,揭示了薄膜的单轴和双轴力学行为,研究了弹性模量、屈服强度、断裂强度和徐变等力学参数和规律。整体上,现有研究多集中在ETFE母材的粘-弹塑性行为及本构关系等,在撕裂性能的研究尚十分欠缺。而随着ETFE膜结构的社会需求增长,对其撕裂性能研究的欠缺势必会阻碍ETFE膜结构的进一步应用和发展。另外,国内外学者已对织物类膜材的撕裂强度及破坏规律开展了深入研究[14-20],可为ETFE薄膜撕裂力学性能的研究提供一定参考。Chen等[14, 15]对层压织物进行了系统的单轴撕裂试验,分析了切缝长度、切缝角度、偏轴角对其撕裂行为和撕裂强度的影响;Sun等[18, 19]深入研究了单轴拉伸下切缝长度和切缝角度对PTFE涂层织物撕裂性能的影响;Zhang等[20]论证了切口样式、切缝尺寸和试样尺寸对PVC涂层织物单轴中心撕裂特性的影响。

鉴于此,本文针对典型ETFE薄膜,进行单轴中心撕裂试验,研究切缝长度、切缝角度和切口样式对ETFE薄膜的破坏形态特征及撕裂力学行为的影响。另外,数字图像相关(DIC)技术具有全场测量、非接触、高分辨率等优势[21-23],可为撕裂力学行为分析提供准确可靠的数据支撑,将用于薄膜撕裂全过程薄膜位移场和应变场的测量与重构。所得结论可为ETFE薄膜材料的撕裂力学性能研究和ETFE膜结构的安全性评估提供有益参考。

1. 试验概况

1.1 试验材料及试件尺寸

试验采用ETFE #250/NJ/

1600 /NT薄膜,其厚度为250μm,密度为1.75 g·cm−3。材料由乙烯和四氟乙烯聚合生成,无色透明,具有优秀的耐化学腐蚀性能和自洁性能[24]。考虑到当前暂无专门的ETFE膜材撕裂性能检测标准,因此参照GB/T 1040.3-2006[25],以ETFE薄膜单轴拉伸试验的长条形试件的尺寸,直接作为单轴中心撕裂试验的试样尺寸,以实现测试需求。试件尺寸为150 mm×25 mm,夹持端长为25 mm,有效测试区域为100 mm×25 mm。散斑区域设置为50 mm×25 mm,散斑直径为0.5 mm。其中,切缝长度为5 mm,切缝方向角以膜材机器展开方向(MD)的垂直线为基准线,逆时针旋转θ。试件示意图如图1所示。另外,为保证试件在拉伸过程中的滑移量可控,采用在试件夹持端处使用粘结剂粘附砂纸的方法,通过增大夹具与试件接触面之间的摩擦系数,提升夹持的稳定性与可靠性。1.2 试验设备

试验选用深圳三思UTM4000型电子万能试验机和尼康D3200高像素照相机。其中,试验机位移速率范围为0.001~500.000 mm·min−1;变形测量范围为10~800 mm,±1‰变形精度;拉压力传感器量程为200 N、精度为0.2 N;尼康D3200高像素照相机拥有

2400 万像素。含中心切缝的ETFE薄膜加载过程中的夹持示意图如图2所示。试验中先对试件施加5 N的预张力,再匀速(50 mm·min−1)加载至试件破坏,并记录试件在试验过程中的变形、荷载和图像数据。1.3 试验工况及环境

试验工况设置为切缝长度、切缝角度和切口样式。其中,切缝长度以2.5 mm为梯度,选取为2.5、5.0、7.5、10.0、12.5和15.0 mm;切缝角度以MD方向为基准,逆时针每旋转15°为一个梯度,选取0°、15°、30°、45°、60°、75°和90°七个角度;切口样式则将典型试件的“一”形切缝更换为其它切口样式,且切口样式可分为开放性切缝(如“一、V、X和十”形等)和封闭性切口(如圆形、椭圆形和矩形切口等)[26];不同切缝角度和切口样式的示意图如图3所示。每个工况的有效试件为3个,以保证试验的有效性。

试验温度控制在(20±2.0)℃,相对湿度控制在(65±4.0)%。

2. 试验结果及分析

2.1 撕裂过程及破坏形态

ETFE薄膜在不同工况下典型撕裂过程如图4所示,其膜面含散斑贴膜以便于观察,三种工况下的ETFE薄膜的撕裂过程均呈现出4个特征状态:

(ⅰ)切缝初始状态:在外加5 N预张力时,因其外加荷载较小,切缝保持未张开状态。

(ⅱ)切缝张开状态:随着外加荷载不断增加,切缝逐渐张开,切缝张开形状近似呈现椭圆形;薄膜在切缝尖端上下邻域展现出显著的面外屈曲现象。

(ⅲ)极限撕裂状态:随着外加荷载进一步增大,切缝开口进一步扩大,面外屈曲现象也变得更加明显,薄膜的塑性变形显著增加;其切缝尖端处由于应力集中效应显著,会形成撕裂三角区,出现明显的颈缩现象,并且切缝开始沿着垂直于加载方向扩展。

(ⅳ)完全破坏状态:在薄膜到达极限撕裂状态以后,随着荷载的增大,切缝扩展速度加剧,薄膜的承载能力不断下降,薄膜最终达到完全破坏状态,丧失所有承载能力,并且不同切口样式导致薄膜呈现的破坏形态各异。

图5为ETFE薄膜在切缝张开状态下的切缝邻域εxy应变云图,该云图可直观的展现出薄膜面外屈曲的位置分布及其方向。据图可知,薄膜的面外屈曲的位置集中分布于切口上下邻域;εxy应变云图集中区呈现“X”型分布,其中,“X”型的中心点与切口的中心点重合。在构成“X”型的同一边上,面外屈曲的方向相同;而在构成“X”型的不同边上,面外屈曲的方向相反。随着切缝长度变化,薄膜面外屈曲的位置几乎保持不变。随着切缝角度变化,面外屈曲的位置仍处于切口上下邻域,随之发生相同角度的倾斜。随着切口样式变化,切口会沿着拉伸方向发生不同的张开变形,从而使薄膜面外屈曲的位置随之变化。

2.2 切缝长度影响

不同切缝长度的ETFE薄膜的撕裂抗力-位移曲线如图6(a)所示,撕裂曲线随切缝长度改变存在规律性衍变,但存在典型共同特征,不妨提取典型撕裂曲线对ETFE薄膜撕裂力学行为进行深入阐释(见图6(b))。

如图6(a)所示,随着切缝长度增大,撕裂抗力-位移曲线的撕裂前段的斜率不发生变化。在撕裂抗力上升阶段,曲线斜率增加的部分随切缝长度增大而逐渐消失;当切缝长度为2.5 mm、5.0 mm时,可明显观察到曲线斜率上升的趋势,而当切缝长度增大至7.5 mm后,曲线的斜率随着位移的增大而越来越小,无法观察到曲线斜率上升。在撕裂后段,当薄膜的切缝长度从2.5 mm增大到15.0 mm,薄膜有效承载截面不断减小,其极限撕裂抗力从130.74 N下降至57.94 N,下降55.68%;断裂位移由45.48 mm下降至11.05 mm,下降75.70%。

如图6(b)所示,典型撕裂曲线以4个特征点为界,可分为3个特征阶段。其中,初始点O为曲线与纵轴的交点,类屈服点A为曲线斜率首次发生变化点,峰值点B为曲线撕裂抗力最大点和破坏点C为曲线与横轴的交点;4特征点分别与典型撕裂过程的4个特征状态相对应。

(OA)撕裂前段:曲线从不为零的初始点O开始,对应着试验前施加的预张力状态;在该阶段ETFE薄膜呈现出显著的线弹性行为,薄膜的初始弹性模量较大。

(AB)撕裂抗力上升阶段:曲线到达类屈服点A后,斜率迅速减小,明显小于撕裂前段的斜率,开始出现较大的塑性变形;随着位移增大,薄膜内部结构会充分发生变化,撕裂抗力不断增加,曲线斜率明显上升;随后由于变形继续增大导致刚度下降,撕裂抗力增加的速度变缓,曲线斜率又开始下降至零。

(BC)撕裂后段:曲线到达峰值点B时,薄膜达到极限撕裂抗力,开始发生显著的撕裂扩展;随着位移增加,撕裂抗力不断下降,并且撕裂扩展的速度不断加快,撕裂抗力下降幅度逐渐变大,最终下降到破坏点C,对应着薄膜完全破坏。

2.3 切缝角度影响

不同切缝角度的ETFE薄膜撕裂抗力-位移曲线如图7所示。随着切缝角度增大,撕裂抗力-位移曲线的撕裂前段的斜率不发生变化,并且类屈服点对应的位移由1.52 mm上升至1.57 mm,撕裂前段所历经的位移仅增加1.97%,曲线几乎同时进入下一阶段。在撕裂抗力上升阶段,不同切缝角度的薄膜的曲线均会呈现出斜率增大的趋势,并且撕裂抗力上升阶段随切缝角度增加而显著变长。在撕裂后段,当切缝角度由0°增大至90°时,对应的等效切缝长度[27]由5 mm减少至0 mm,其极限撕裂抗力由107.69 N上升至134.25 N,断裂位移由24.39 mm上升至79.90 mm。

可见,随着切缝角度的增大,对应的等效切缝长度随之减小,薄膜的承载途径逐渐恢复,用来承受拉伸荷载的有效截面增大,薄膜的极限撕裂强度增强,使薄膜不易到达极限撕裂状态,使得其断裂位移也随之增大。并且当切缝长度保持为5 mm时,切缝角度由0°增大到90°,其极限撕裂抗力和断裂位移分别上升了24.66%和227.59%,断裂位移的变化率远大于极限撕裂抗力的变化率。因此,切缝角度的改变对薄膜的极限撕裂抗力影响较小,而会显著影响薄膜完全破坏时对应的断裂位移。

图8为不同切缝角度的ETFE薄膜的切缝尖端邻域的竖向应变场云图。据图可知,当预制切缝长度为5 mm的“一”形切缝时,薄膜在切缝邻域出现明显的应变集中区(红色区域),并且其应变集中区分布于切缝尖端邻域上,随切缝角度的增加而发生相应的偏转。这是由于薄膜在预制初始切缝后,在切缝尖端邻域,随着拉伸应力的增大,切缝张开导致薄膜沿着切缝方向发生横向收缩,并且在切缝上下邻域处发生面外屈曲,薄膜会向面外凸出,导致切缝尖端邻域处承受的应力远高于其它区域,从而使薄膜在该区域处的竖向应变较大而出现应变集中区。因此,随着切缝角度的增大,薄膜切缝张开所致的横向收缩效应及面外屈曲现象发生相应的变化,使薄膜的应变集中区始终分布于切缝尖端邻域,从而使得薄膜的应变集中区发生相应的偏转。

2.4 切口样式影响

图9为不同切口样式的ETFE薄膜的撕裂抗力-位移曲线。不同切口样式对薄膜撕裂曲线的撕裂后段影响显著,导致含不同切口样式的薄膜在完全破坏时,整体上表现出两种破坏模式:类脆性破坏和类延性破坏。如图9(a)和图9(f)所示,对于无切缝和含圆形切口的ETFE薄膜,撕裂曲线到达峰值点后立即发生破坏,在撕裂后段历经的位移占整个撕裂过程发生的位移比例极小;并且在试验过程中可听到轻脆的崩断声,薄膜突然发生破坏,展现出类脆性破坏特性。而对于图9其它切口样式的ETFE薄膜,则呈现类延性破坏特性。撕裂曲线到达峰值点后,薄膜虽然达到了极限撕裂强度,但并不会立即发生断裂破坏;薄膜的切缝不断扩展,有效承载截面逐渐减小,薄膜在历经较大的位移后才完全破坏,可观察到明显预兆。

图10为撕裂试样典型损伤模式示意图。可知,含切口的ETFE薄膜,在拉伸撕裂过程中,切口破坏了薄膜的完整性,使薄膜较易出现面外屈曲和颈缩,从而使薄膜在切口邻域处出现显著的大变形区。这会导致薄膜的应力分布不均匀,在大变形区出现应力集中,从而引发撕裂,使薄膜在切口尖端处出现撕裂三角区,薄膜的承载性能下降。并随着撕裂三角区的逐渐扩展,薄膜的有效承载区域不断减小,薄膜的承载性能逐渐下降为零。并且,不同切口样式会使薄膜的大变形区不同,从而使其应力集中各不相同,导致不同切口样式使薄膜承载性能的衰减程度各异。

图11为不同切口样式的ETFE薄膜对应的极限撕裂抗力。对于含开放性切缝的薄膜,相较于无切缝薄膜,含“V、X和十”形切缝的薄膜的极限撕裂抗力均约为138.13 N,下降40.58%,而含“一”形切缝的薄膜仅为107.25 N,下降53.86%。因此,当切缝的横向尺寸相同时,“一”形切缝贯穿了薄膜的主要受力方向,应力集中显著,对薄膜的极限撕裂强度的不利影响最大。对于含封闭性切口的薄膜,相较于无切缝薄膜,含圆形和椭圆形切口的薄膜的极限撕裂强度约为151.88 N,下降34.66%,含矩形-I切口的薄膜仅为115.19 N,下降50.44%。因此,当切口的横向尺寸相同时,矩形-I切口由于具有直角边缘等特性,使薄膜的应力集中程度远大于含圆形和椭圆形切口的薄膜,使薄膜承载性能的衰减程度更大。另外,含矩形-II切口的薄膜的极限撕裂强度为129.63 N,相较于无切缝薄膜的下降44.23%。可见,当切口几何外形相同时,对于横向尺寸较大的切口,其周围的应力集中区域较大,薄膜较易产生撕裂扩展,故对薄膜极限撕裂强度的不利影响更大。

3. 结 论

结合系列试验与数字图像相关(DIC)技术,深入分析了乙烯-四氟乙烯(ETFE)薄膜的单轴中心撕裂行为,主要结论如下:

(1) ETFE薄膜的典型撕裂扩展过程呈现出4个特征状态;不同切缝参数显著影响薄膜面外屈曲的位置和破坏形态,但不影响薄膜切缝扩展的方向始终为垂直于加载方向;

(2) ETFE薄膜的撕裂抗力-位移曲线随不同工况的变化而发生非线性衍变,但存在典型共同特征,可划分为3个特征阶段:撕裂前段、撕裂抗力上升阶段和撕裂后段;

(3)当切缝长度从2.5 mm增大到15.0 mm时,薄膜的有效承载截面变小,其极限撕裂强度和断裂位移分别减小了55.75%和75.70%;当切缝角度从0°增大到90°时,薄膜承载途径逐渐恢复,其极限撕裂强度增大了24.67%,而断裂位移却增大了227.59%;

(4)切口样式使薄膜在完全破坏时呈现出类脆性破坏特征或类延性破坏特征。当横向尺寸相同时,在开放性切缝中,“一”形切缝贯穿薄膜主要受力方向,应力集中显著,对薄膜极限撕裂强度的不利影响最大;在封闭性切口中,与光滑边缘切口相比,直角边缘切口使薄膜的应力集中效应更显著,使薄膜易在切口尖角处发生撕裂,造成薄膜承载性能的显著衰减。所得结论可为相关均质性膜材的撕裂力学性能研究和膜结构的安全性评估提供有益参考。

-

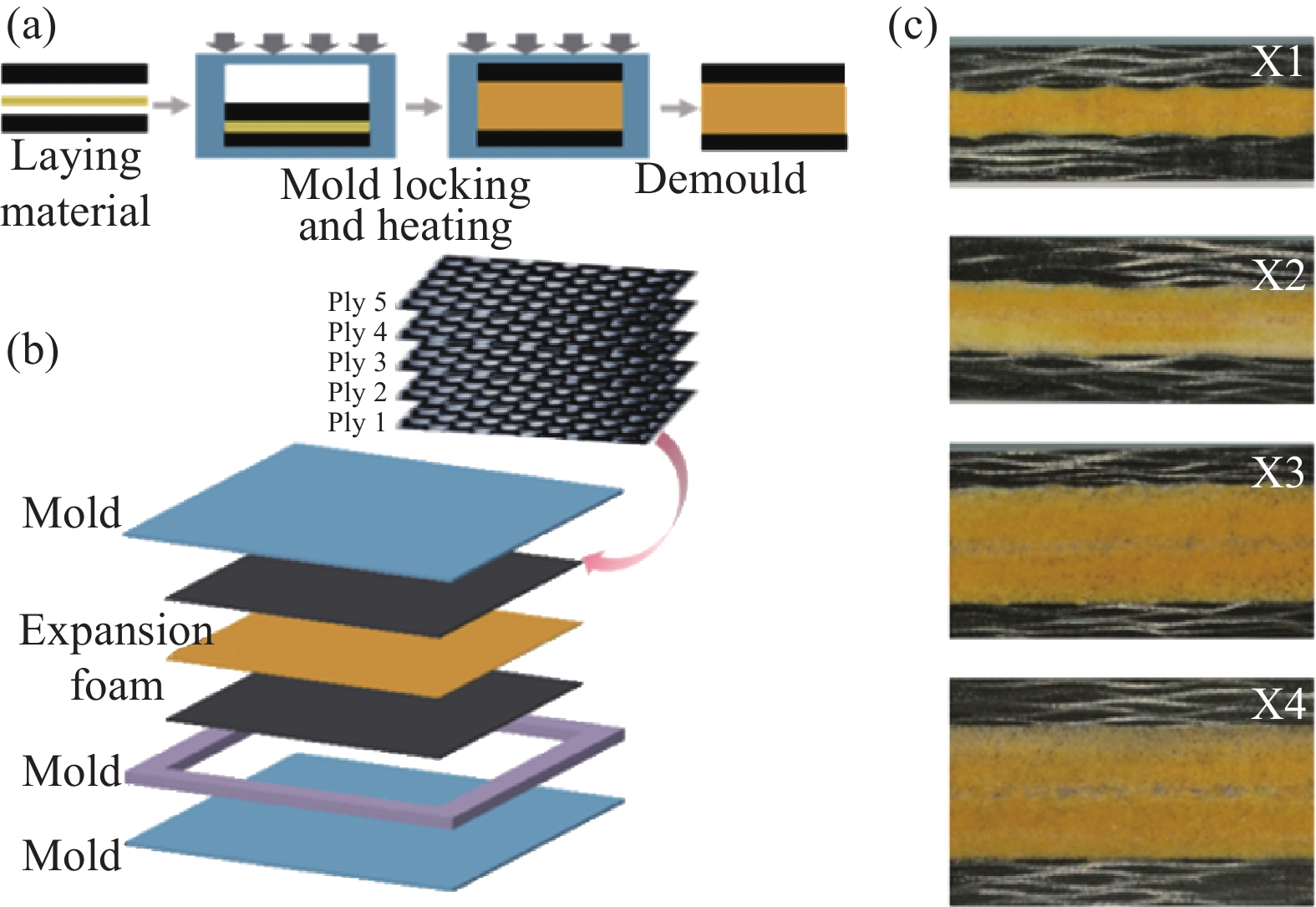

图 1 (a) 热膨胀成型工艺制备泡沫夹芯复合材料示意图;(b) 模具及试样铺层示意图;(c) 泡沫膨胀不同倍率制备的夹芯复合材料断面图

Figure 1. (a) Schematic diagram of foam sandwich composites prepared via thermal expansion molding process; (b) Schematic diagram of mold and sample lay-up; (c) Sectional diagram of sandwich composites prepared by foam expansion at different ratios

表 1 有限元分析(FEA)相关的材料参数

Table 1 Material parameters related to finite element analysis (FEA)

Materials Density/

(kg·m−3)Tensile strength/MPa Young's modulus/MPa Compressive strength/MPa Poisson's

ratio vShear strength τ/MPa Shear modulus G/MPa X1 M-1 318 7.98 395 3.47 0 3.91 62.28 X2 M-1 162 4.68 201 2.31 0 1.95 39.29 X3 M-1 109 2.23 170 1.95 0 1.64 31.26 X4 M-1 78 1.34 113 0.99 0 1.08 21.17 805 (XT) 61340 (E1) 509 (XC) 0.04 (v12) 112 (S12) 7600 (G12) CFRP 1580 805 (YT) 61340 (E2) 509 (YC) 0.30 (v13) 59 (S13) 2700 (G13) 50 (ZT) 6900 (E3) 170 (ZC) 0.30 (v23) 59 (S23) 2700 (G23) Cohesive 2000 — 1200 — 0.32 — 385 Notes: XT, YT, ZT—Tensile strength of the three directions of CFRP; E1, E2, E3—Young's modulus of the three directions of CFRP; XC, YC, ZC—Compressive strength of the three directions of CFRP; v12, v13, v23—Poisson's ratio; S12, S13, S23—Shear strength; G12, G13, G23—Shear modulus; CFRP—Carbon fber reinforced polymer; M-1—Epoxy resin based rigid foam with thermal expansion function. 表 2 冲击有限元分析模型数据

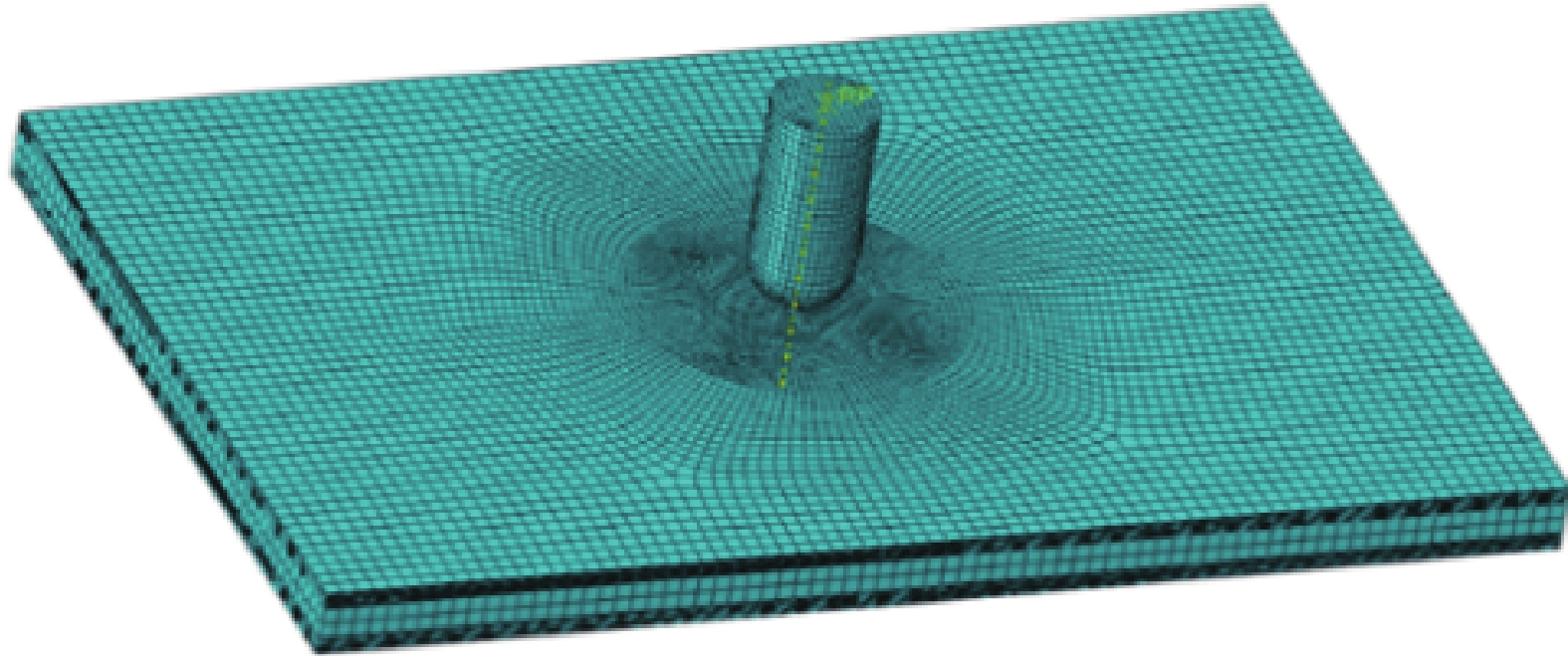

Table 2 Finite element analysis model data of impact test

Sample number Part Thickness Mesh style Mesh number X1 CFRP 2 mm+2 mm

2 mm

0SC8R 141880 Foam C3D8R 14188 Cohesive COH3D8 7094 X2 CFRP 2 mm+2 mm

4 mm

0SC8R 141880 Foam C3D8R 14188 Cohesive COH3D8 7094 X3 CFRP 2 mm+2 mm

6 mm

0SC8R 141880 Foam C3D8R 14188 Cohesive COH3D8 7094 X4 CFRP

Foam

Cohesive2 mm+2 mm

8 mm

0SC8R

C3D8R

COH3D8141880

28376

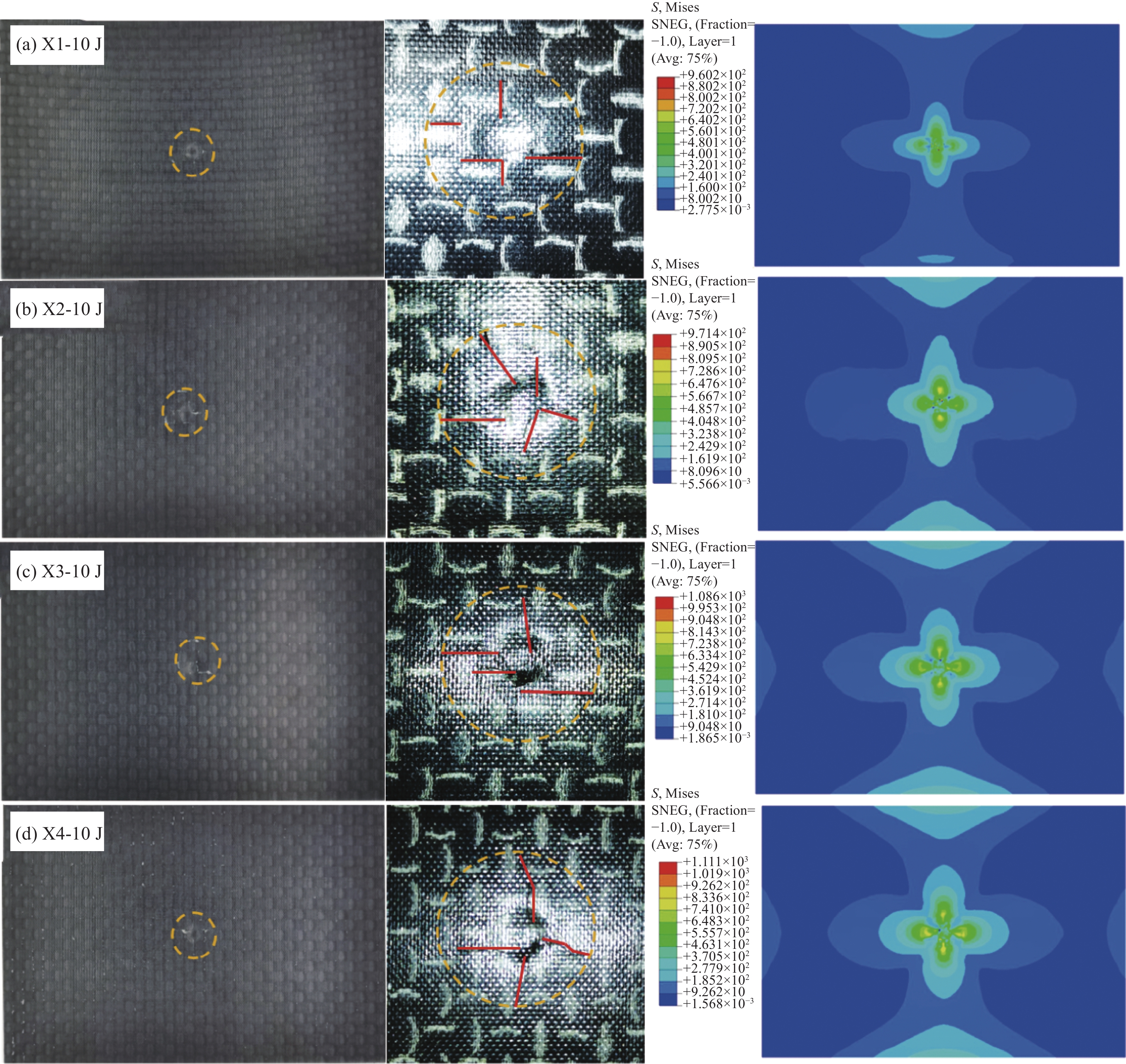

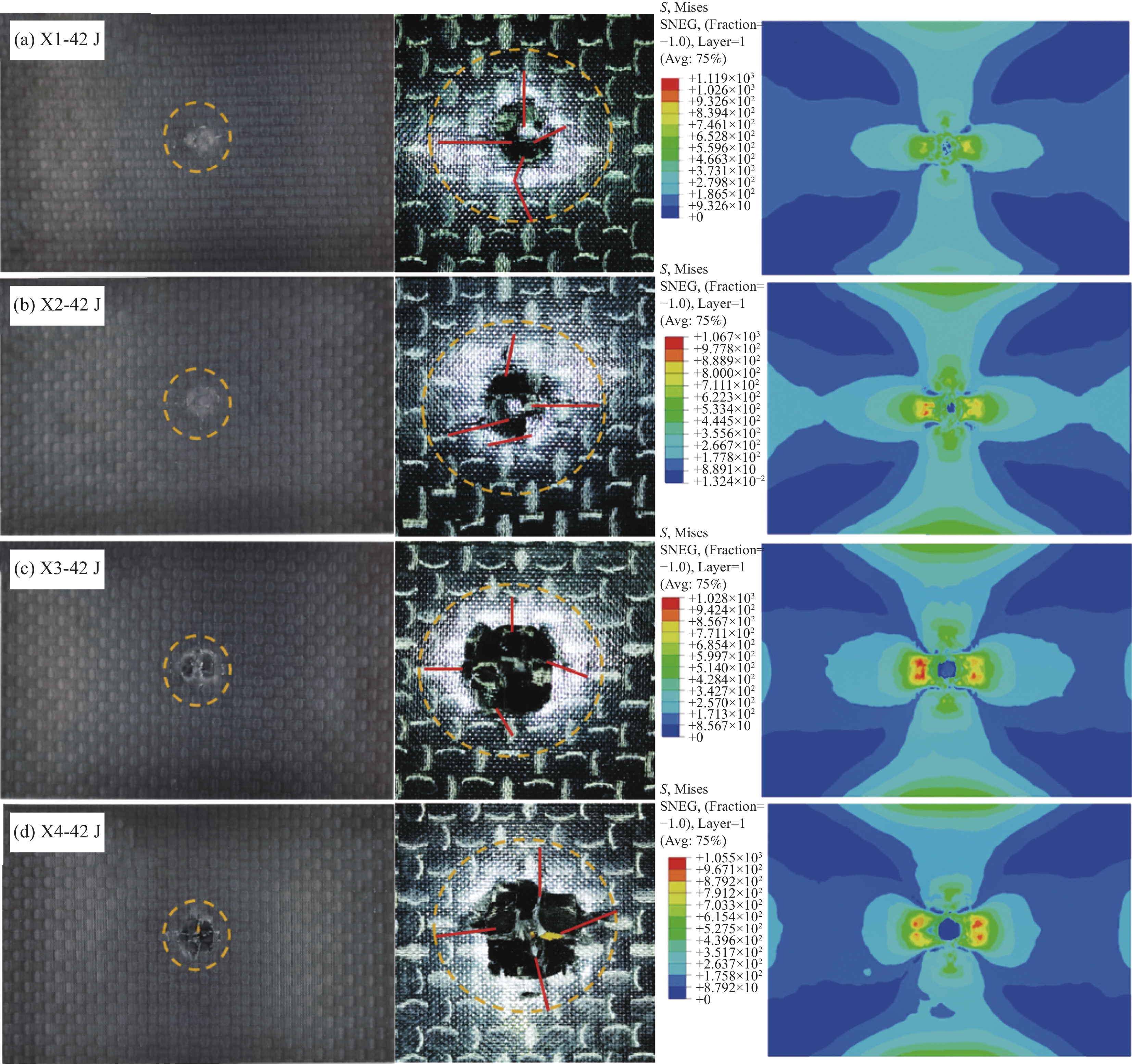

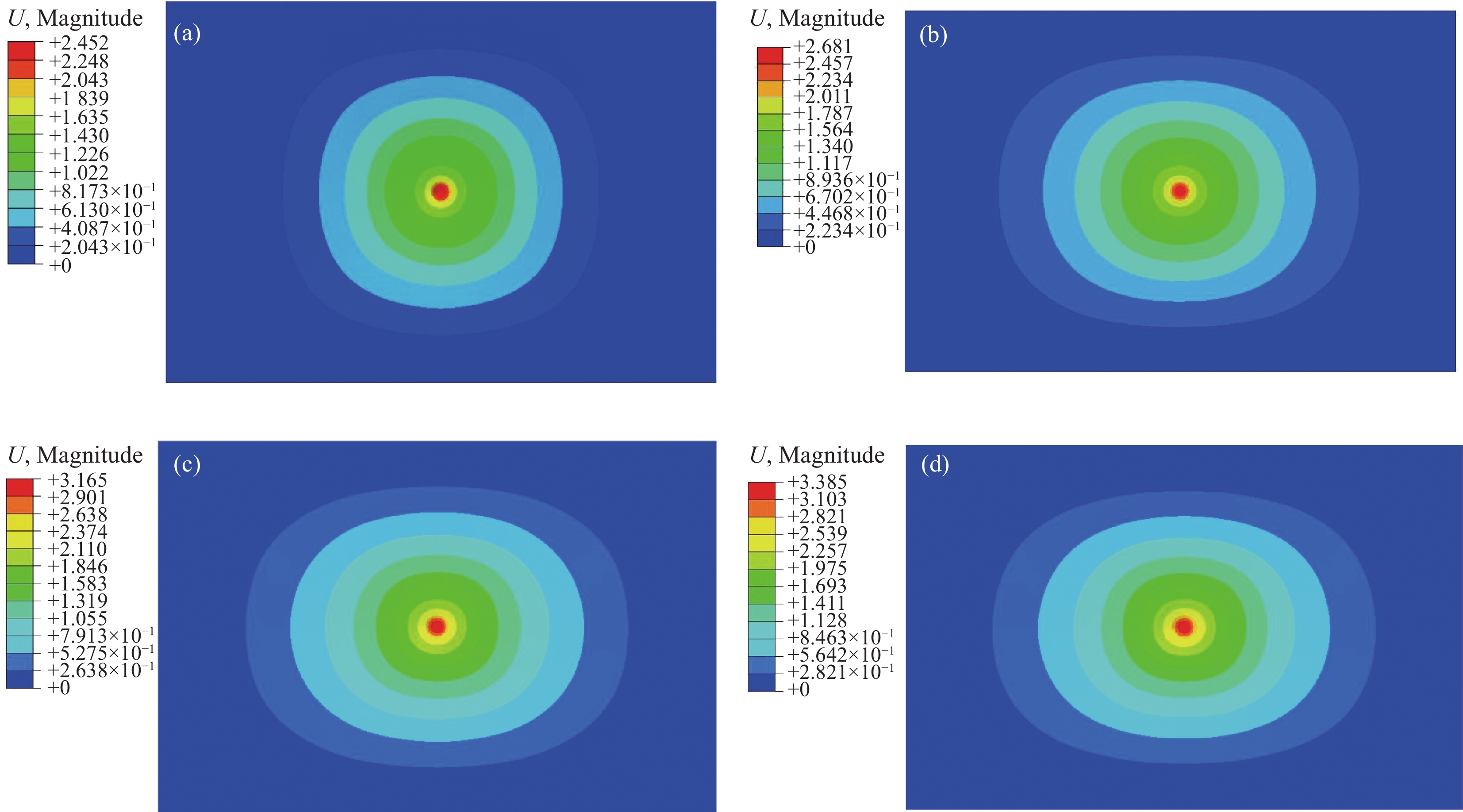

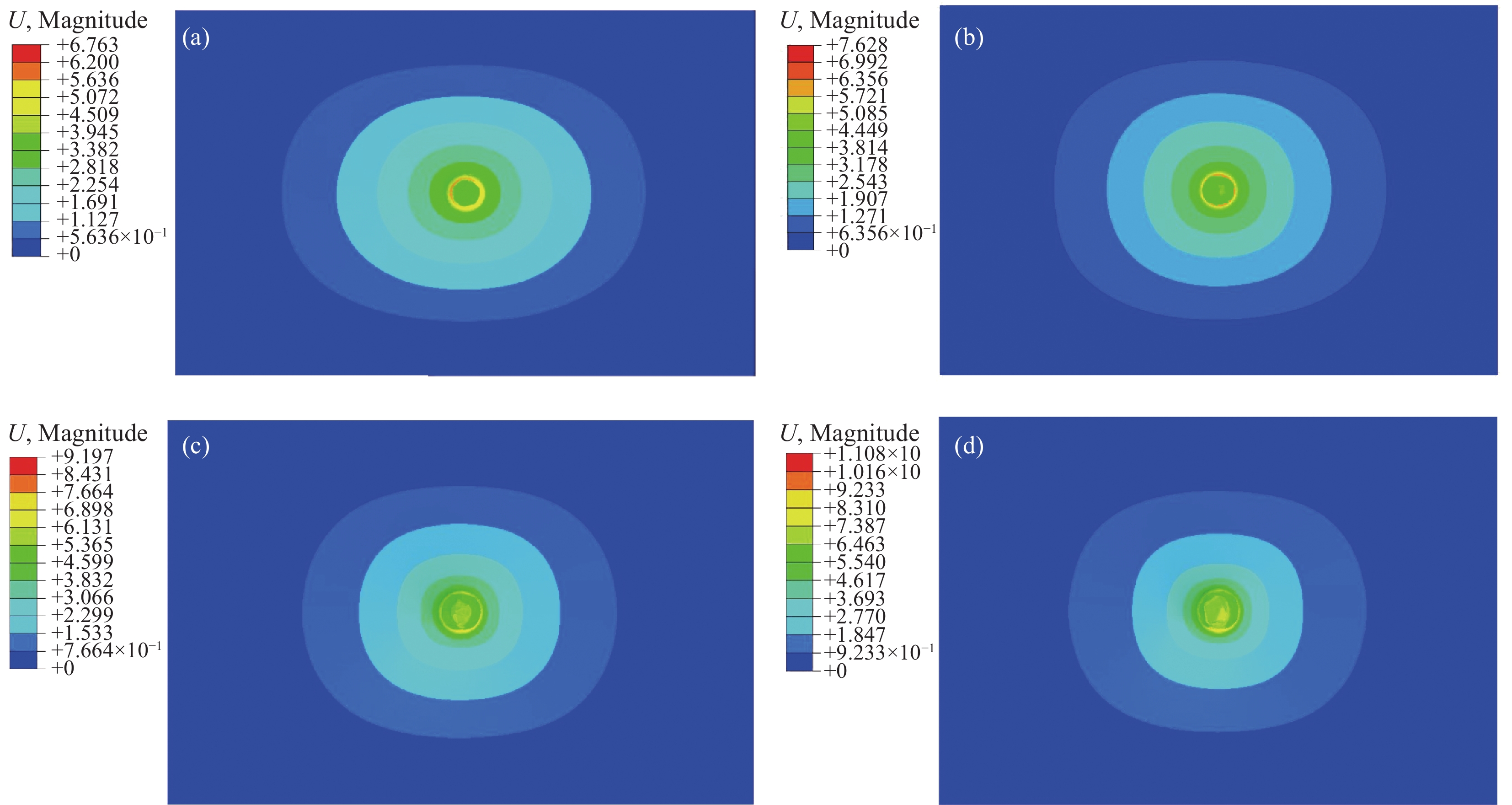

7094Notes: SC8R—8-node quadrilateral in-plane general continuous shell elements; C3D8R—Linear 3D reduced integration solid elements; COH3D8—Cohesive element. 表 3 X1~X4试样冲击试验损伤数据对比

Table 3 Comparison of impact test damage data for X1-X4 samples

Sample number Stress/MPa (FEA) Displacement/mm Area of damage/mm2 Experiment FEA Error/% Experiment FEA Error/% C-scan Error/% X1-10 J 960 2.71 2.45 9.59 39.57 45.23 14.30 44.16 11.60 X2-10 J 971 2.92 2.68 8.22 47.76 54.37 13.84 54.08 13.23 X3-10 J 1086 3.20 3.16 1.25 58.06 67.89 16.93 65.01 11.97 X4-10 J 1111 3.26 3.38 3.68 69.36 80.21 15.64 76.94 10.93 X1-42 J 1119 6.91 6.76 2.17 114.93 136.64 18.89 134.71 17.21 X2-42 J 1067 7.67 7.63 0.52 145.19 167.59 15.43 160.52 10.56 X3-42 J 1028 9.04 9.19 1.65 206.02 238.96 15.99 229.54 11.42 X4-42 J 1055 11.44 11.08 3.15 298.49 353.25 18.35 320.31 7.31 -

[1] 徐佳佳, 方海, 韩娟, 等. 格构腹板增强泡沫夹芯复合材料准静态压缩吸能特性[J]. 复合材料学报, 2022, 39(8):3965-3981. DOI: 10.13801/j.cnki.fhclxb.20211117.002 XU Jiajia, FANG Hai, HAN Juan, et al. Energy absorption behavior of foam-filled sandwich composite materials reinforced by lattice webs under quasi-static compression[J]. Acta Materiae Compositae Sinica,2022,39(8):3965-3981(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20211117.002

[2] 辛志东, 杜娟, 聂彦平, 等. 某全泡沫夹芯复合材料无人机平尾的强度分析与验证[J]. 纤维复合材料, 2022, 39(4):61-64. XIN Zhidong, DU Juan, NIE Yanping, et al. Strength analysis and verification of an all-foam sandwich composite UAV flat tail[J]. Fiber Composites,2022,39(4):61-64(in Chinese).

[3] ONDER A, ROBINSON M. Investigating the feasibility of a new testing method for GFRP/polymer foam sandwich composites used in railway passenger vehicles[J]. Composite Structures,2020,233:111576. DOI: 10.1016/j.compstruct.2019.111576

[4] DOGAN A. Low-velocity impact, bending, and compression response of carbon fiber/epoxy-based sandwich composites with different types of core materials[J]. Journal of Sandwich Structures & Materials,2021,23(6):1956-1971.

[5] KANG G H, JOUNG C, KIM H G, et al. Manufacturing, thermoforming, and recycling of glass fiber/PET/PET foam sandwich composites: DOE analysis of recycled materials[J]. Polymer Composites,2022,43(12):8807-8817. DOI: 10.1002/pc.27063

[6] 石昌, 王继辉, 朱俊, 等. 梯形格栅结构增强泡沫夹芯复合材料平压性能[J]. 复合材料学报, 2022, 39(2):590-600. DOI: 10.13801/j.cnki.fhclxb.20210506.002 SHI Chang, WANG Jihui, ZHU Jun, et al. Flatwise compression properties of trapezoidal lattice-web reinforced foam core sandwich composites[J]. Acta Materiae Compositae Sinica,2022,39(2):590-600(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20210506.002

[7] UYTTERSPROT J, DE CORTE W, INGELBINCK B. Influence of SLS design requirements on the material consumption and self-weight of web-core sandwich panel FRP composite footbridges[J]. Composite Structures,2021,262:113334. DOI: 10.1016/j.compstruct.2020.113334

[8] TAO J, LI F, ZHU R, et al. Compression properties of a novel foam-core sandwich cylinder reinforced with stiffeners[J]. Composite Structures,2018,206:499-508. DOI: 10.1016/j.compstruct.2018.08.085

[9] 曹晓明, 顾轶卓, 李超, 等. 碳纤维复合材料方管硅橡胶热膨胀成型工艺研究[J]. 玻璃钢/复合材料, 2012(6):64-68, 46. CAO Xiaoming, GU Yizhuo, LI Chao, et al. Research on thermal expansion molding process of carbon fiber composite square tube silicone rubber[J]. FRP/Composites,2012(6):64-68, 46(in Chinese).

[10] 张艳芳, 刘志杰, 胡克伟, 等. 硅橡胶热膨胀法成型复合材料制件的研究[J]. 塑料工业, 2014, 42(12):55-58. DOI: 10.3969/j.issn.1005-5770.2014.12.015 ZHANG Yanfang, LIU Zhijie, HU Kewei, et al. Research on composite parts formed by thermal expansion of silicone rubber[J]. China Plastics Industry,2014,42(12):55-58(in Chinese). DOI: 10.3969/j.issn.1005-5770.2014.12.015

[11] 杜刚, 曾竟成, 张长安, 等. 硅橡胶热膨胀模塑成型法制备碳/环氧复合材料管研究[J]. 纤维复合材料, 2003(2):26-28. DOI: 10.3969/j.issn.1003-6423.2003.02.008 DU Gang, ZENG Jingcheng, ZHANG Chang'an, et al. Preparation of carbon/epoxy composite pipe by thermal expansion molding of silicone rubber[J]. Fiber Composites,2003(2):26-28(in Chinese). DOI: 10.3969/j.issn.1003-6423.2003.02.008

[12] MIN W, TAO L, YAN Z, et al. Feasibility verification and bending property of web-reinforced foam sandwich composites prepared via thermal expansion molding process[J]. Composite Structures,2022,294:115720. DOI: 10.1016/j.compstruct.2022.115720

[13] 张钟. 热膨胀模压法成型复合材料夹层结构工艺及其性能研究[D]. 南京: 南京航空航天大学, 2007. ZHANG Zhong. Study on the process and properties of composite sandwich structure formed by thermal expansion molding[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2007(in Chinese).

[14] 施赫荣, 王继辉, 倪爱清, 等. 穿孔泡沫夹芯复合材料灌注工艺仿真与方案优选[J]. 复合材料学报, 2023, 40(2):782-793. DOI: 10.13801/j.cnki.fhclxb.20220323.001 SHI Herong, WANG Jihui, NI Aiqing, et al. Simulation and optimization of infusion process for perforated foam sandwich composite[J]. Acta Materiae Compositae Sinica,2023,40(2):782-793(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20220323.001

[15] 杨张韬, 倪爱清, 王继辉, 等. 孔槽泡沫夹芯复合材料真空辅助树脂传递工艺仿真与优化[J]. 材料导报, 2024, 38(2): 253-261. YANG Zhangtao, NI Aiqing, WANG Jihui, et al. Simulation and optimization of vacuum-assisted resin transfer process for porous foam sandwich composites[J]. Materials Reports, 38(2): 253-261(in Chinese).

[16] 袁超, 邱启艳. 复合材料泡沫夹层结构翼尖小翼成型技术研究[J]. 科技与创新, 2019(6):62-63. DOI: 10.15913/j.cnki.kjycx.2019.06.062 YUAN Chao, QIU Qiyan. Research on forming technology of composite foam sandwich structure wingtip winglet[J]. Science, Technology and Innovation,2019(6):62-63(in Chinese). DOI: 10.15913/j.cnki.kjycx.2019.06.062

[17] AL-SHAMARY A K J, KARAKUZU R, OZDEMIR O. Low-velocity impact response of sandwich composites with different foam core configurations[J]. Journal of Sandwich Structures & Materials,2016,18(6):754-768. DOI: 10.1177/109963621665326

[18] 孙子恒, 王继辉, 倪爱清, 等. 不同铺层复合材料夹芯结构低速冲击与冲击后剩余强度研究[J]. 复合材料科学与工程, 2020(11):102-110. DOI: 10.3969/j.issn.1003-0999.2020.11.017 SUN Ziheng, WANG Jihui, NI Aiqing, et al. Study on low-velocity impact and residual strength of composite sandwich structures with different lay-up layers[J]. Composite Materials Science and Engineering,2020(11):102-110(in Chinese). DOI: 10.3969/j.issn.1003-0999.2020.11.017

[19] DOGAN A, ARIKAN V. Low-velocity impact response of E-glass reinforced thermoset and thermoplastic based sandwich composites[J]. Composites Part B: Engineering,2017,127:63-69. DOI: 10.1016/j.compositesb.2017.06.027

[20] NANAYAKKARA A, FEIH S, MOURITZ A P. Experimental impact damage study of a Z-pinned foam core sandwich composite[J]. Journal of Sandwich Structures & Materials,2012,14(4):469-486.

[21] KAYA G, SELVER E. Impact resistance of Z-pin-reinforced sandwich composites[J]. Journal of Composite Materials,2019,53(26-27):3681-3699. DOI: 10.1177/0021998319845428

[22] 程树良, 吴灵杰, 孙帅, 等. X型点阵夹芯结构受局部冲击时动态力学性能试验与数值模拟[J]. 复合材料学报, 2022, 39(7):3641-3651. DOI: 10.13801/j.cnki.fhclxb.20210903.005 CHENG Shuliang, WU Lingjie, SUN Shuai, et al. Experiment and numerical simulation of dynamic mechanical properties of X-lattice sandwich structure under local impact[J]. Acta Materiae Compositae Sinica,2022,39(7):3641-3651(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20210903.005

[23] HE W, LIU J, TAO B, et al. Experimental and numerical research on the low velocity impact behavior of hybrid corrugated core sandwich structures[J]. Composite Structures,2016,158:30-43. DOI: 10.1016/j.compstruct.2016.09.009

[24] HUNT C J, MORABITO F, GRACE C, et al. A review of composite lattice structures[J]. Composite Structures, 2022, 284: 115120.

[25] 孙士勇, 秦进, 杨睿, 等. 缝纫泡沫夹芯复合材料细观纤维柱破坏行为[J]. 复合材料学报, 2020, 37(4):837-844. DOI: 10.13801/j.cnki.fhclxb.20190617.003 SUN Shiyong, QIN Jin, YANG Rui, et al. Fracture behavior of meso-fiber column in the stitched foam sandwich composites[J]. Acta Materiae Compositae Sinica,2020,37(4):837-844(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20190617.003

[26] MIN W, QI L, ZHAO X, et al. Preparation and properties of expandable epoxy foam prepreg for sandwich composites prepared via thermal expansion molding process[J]. Journal of Applied Polymer Science,2022,140(7):53469.

[27] TAO L, MIN W, QI L, et al. The hygrothermal aging process and mechanism of CFRP papered by prepreg that may be stored at room temperature[J]. Polymer Degradation and Stability,2020,182:109395. DOI: 10.1016/j.polymdegradstab.2020.109395

[28] ASTM International. Standard test method for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event: ASTM D7136/D7136M—2015[S]. West Conshohocken: ASTM, 2015.

[29] GU J, CHEN P. Some modifications of Hashin's failure criteria for unidirectional composite materials[J]. Composite Structures,2017,182:143-152. DOI: 10.1016/j.compstruct.2017.09.011

[30] DUARTE A P C, DÍAZ SÁEZ A, SILVESTRE N. Comparative study between XFEM and Hashin damage criterion applied to failure of composites[J]. Thin-Walled Structures,2017,115:277-288. DOI: 10.1016/j.tws.2017.02.020

[31] ASTM International. Standard test method for compressive residual strength properties of damaged polymer matrix composite plates: ASTM D7137/D7137M—2007[S]. West Conshohocken: ASTM, 2007.

[32] YANG B, WANG Z, ZHOU L, et al. Study on the low-velocity impact response and CAI behavior of foam-filled sandwich panels with hybrid facesheet[J]. Composite Structures,2015,132:1129-1140. DOI: 10.1016/j.compstruct.2015.07.058

-

目的

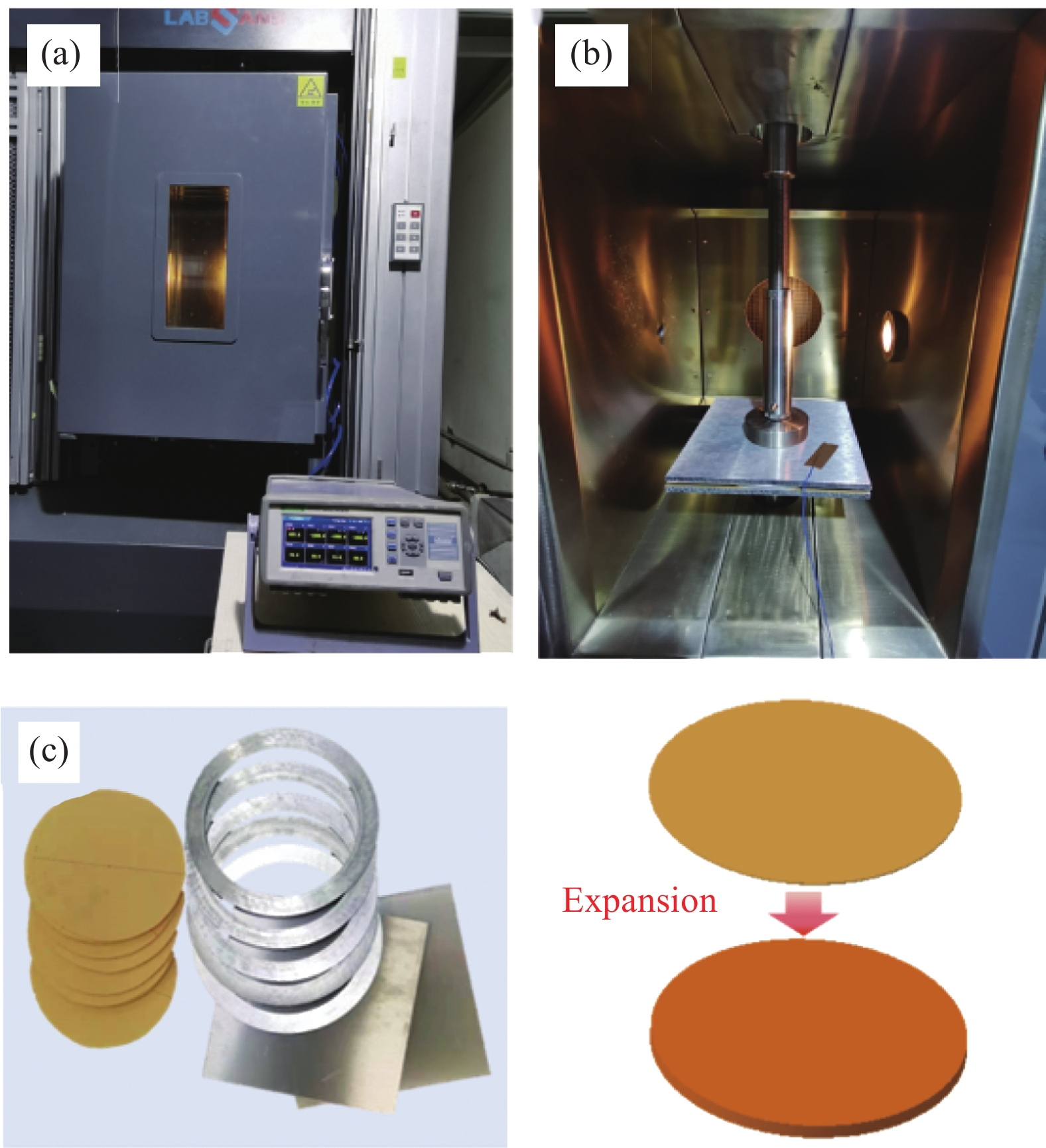

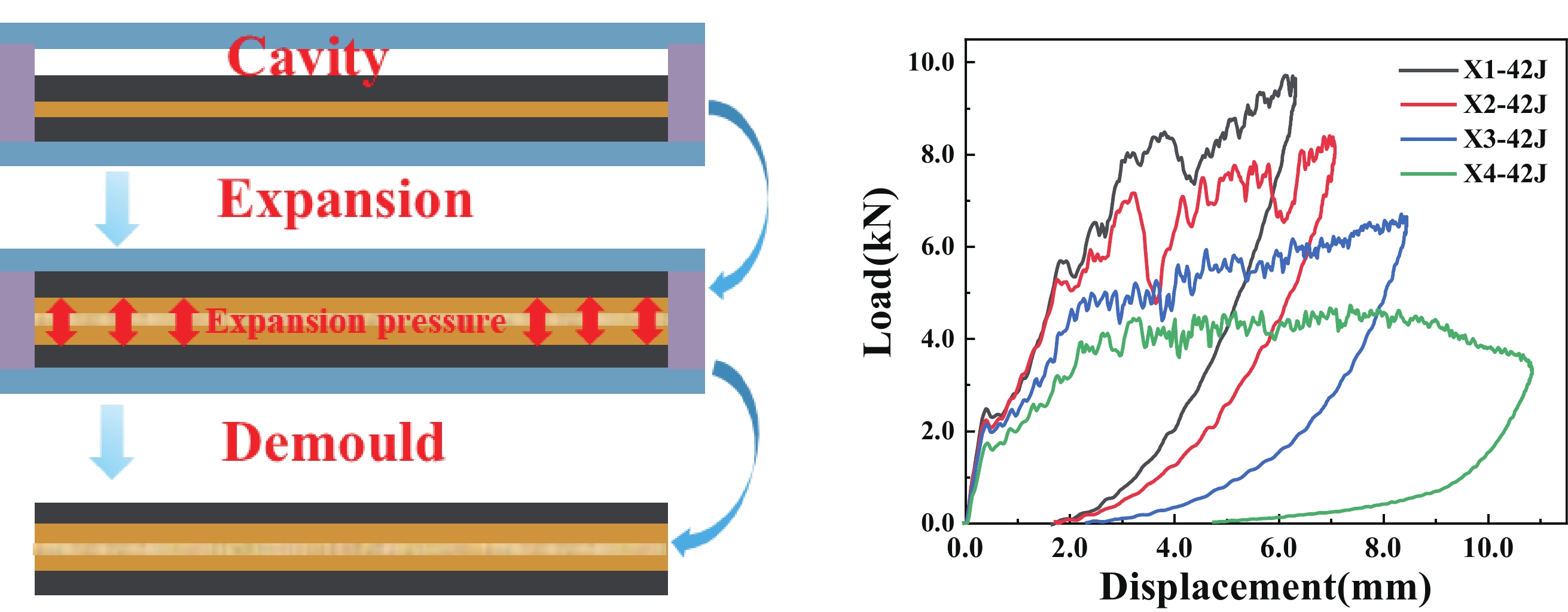

基于前期热膨胀工艺的研究基础,提出使用一种可膨胀泡沫预浸胶一体化制备不同厚度的泡沫夹芯板。分析了不同泡沫膨胀倍率产生的不同膨胀力对成型后泡沫夹芯复合材料的抗低速冲击性能影响。建立冲击仿真分析模型,为这种热膨胀工艺制备复杂加筋夹芯复合结构零部件提供分析依据。

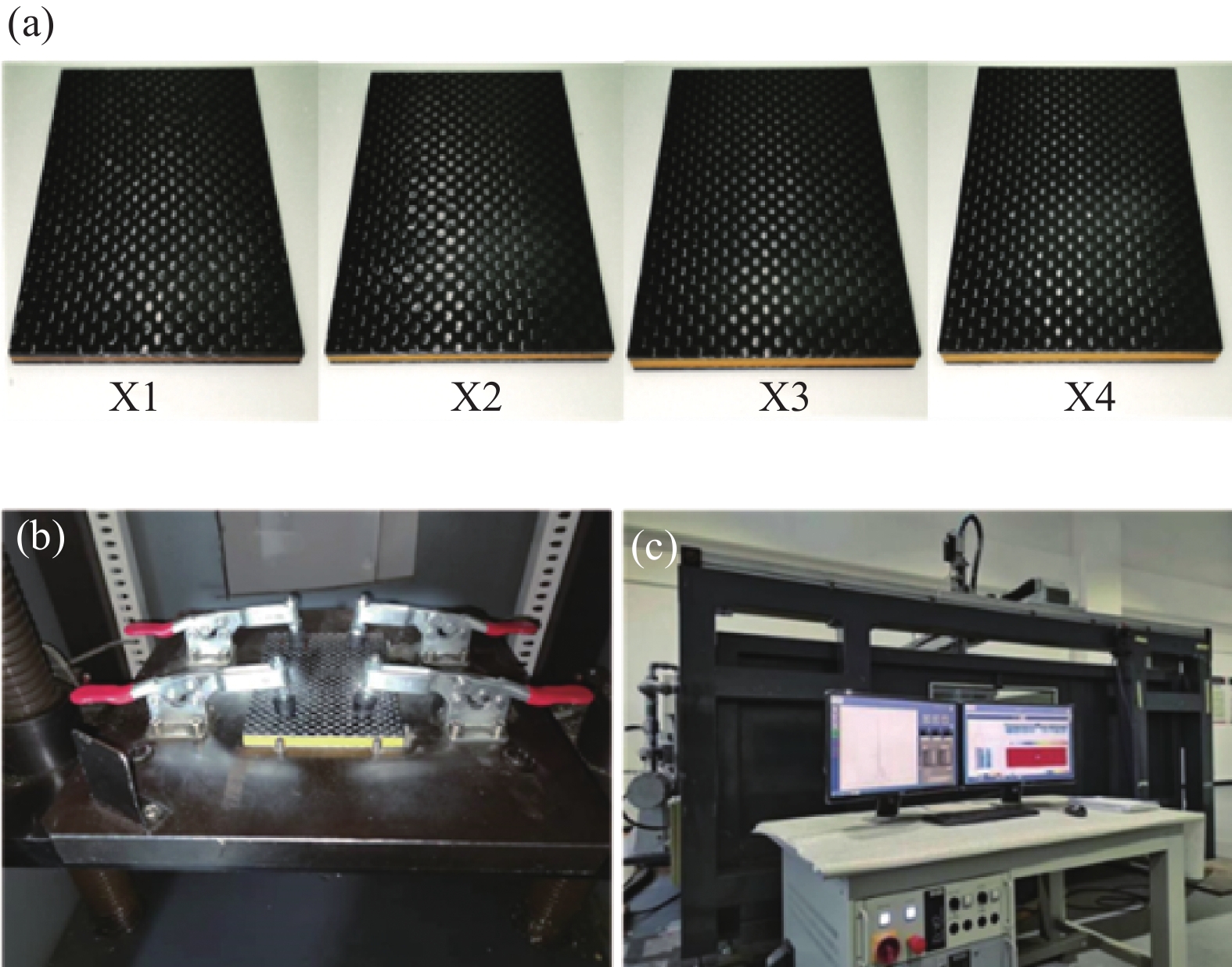

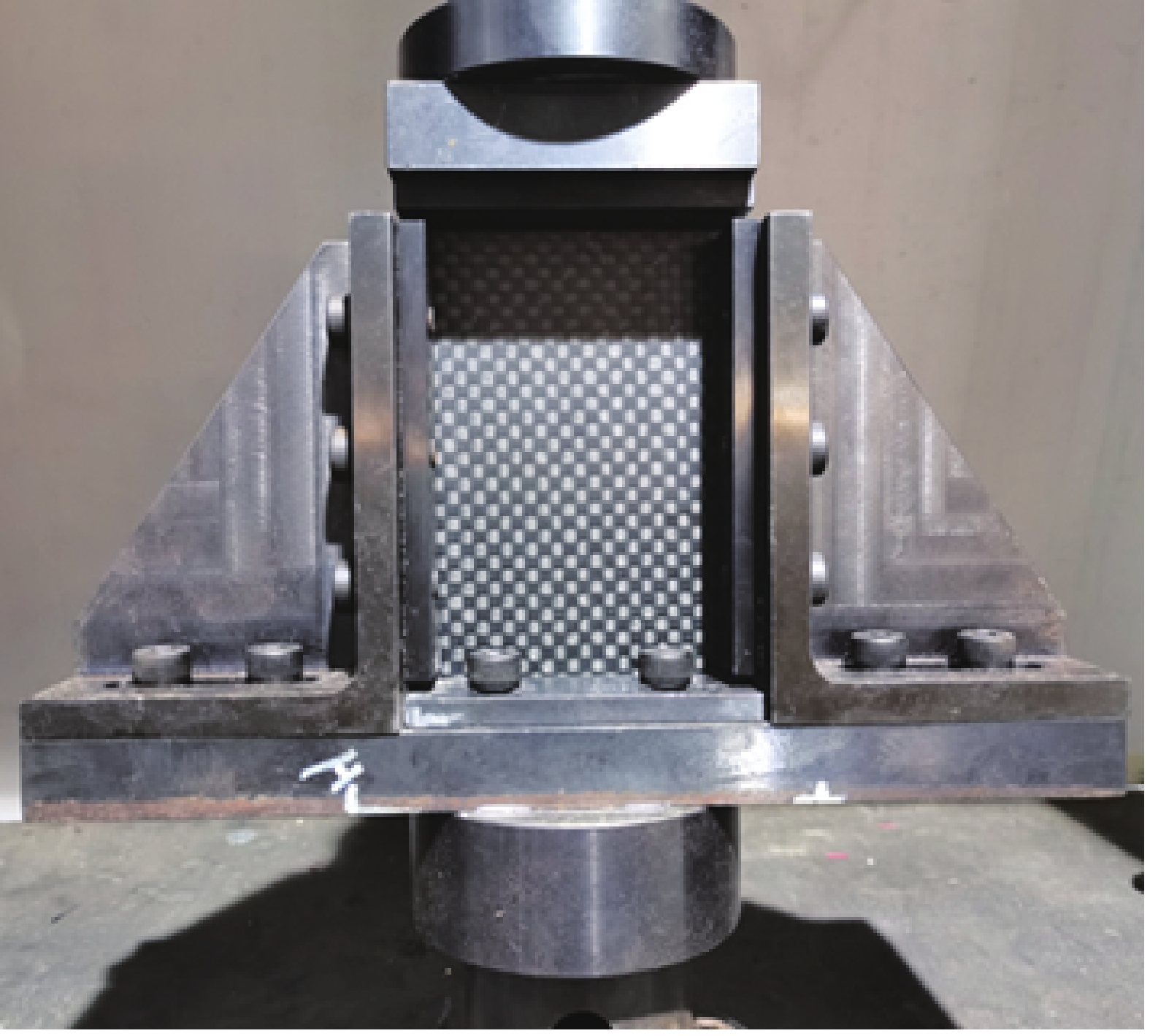

方法基于热膨胀工艺的成型特点,控制模具型腔尺寸不同制备了四种典型膨胀倍率的泡沫夹芯板。以10 J和42 J冲击能量研究热膨胀工艺和芯材厚度对泡沫夹芯复合材料低速冲击性能的影响。通过ABAQUS有限元分析、超声C扫描对比试验数据研究了不同试样的损伤模式。冲击后压缩试验研究不同试样的损伤容限。

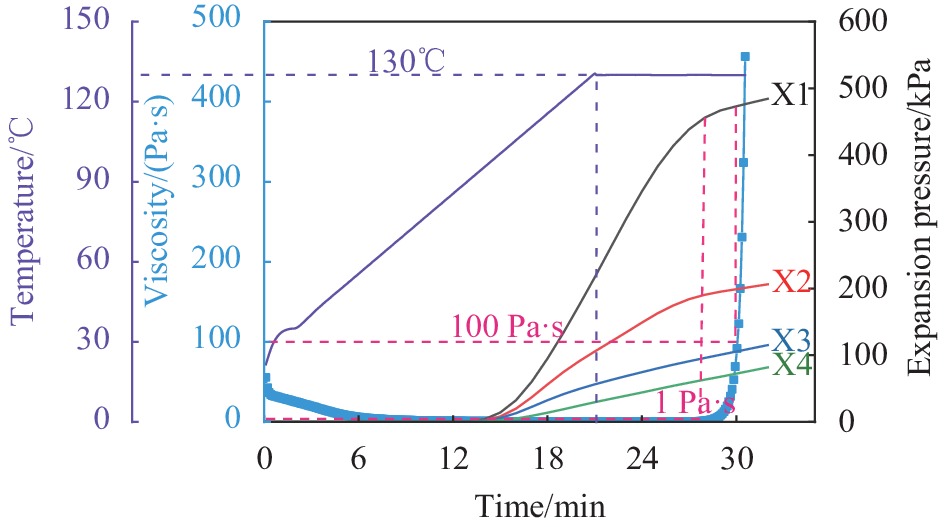

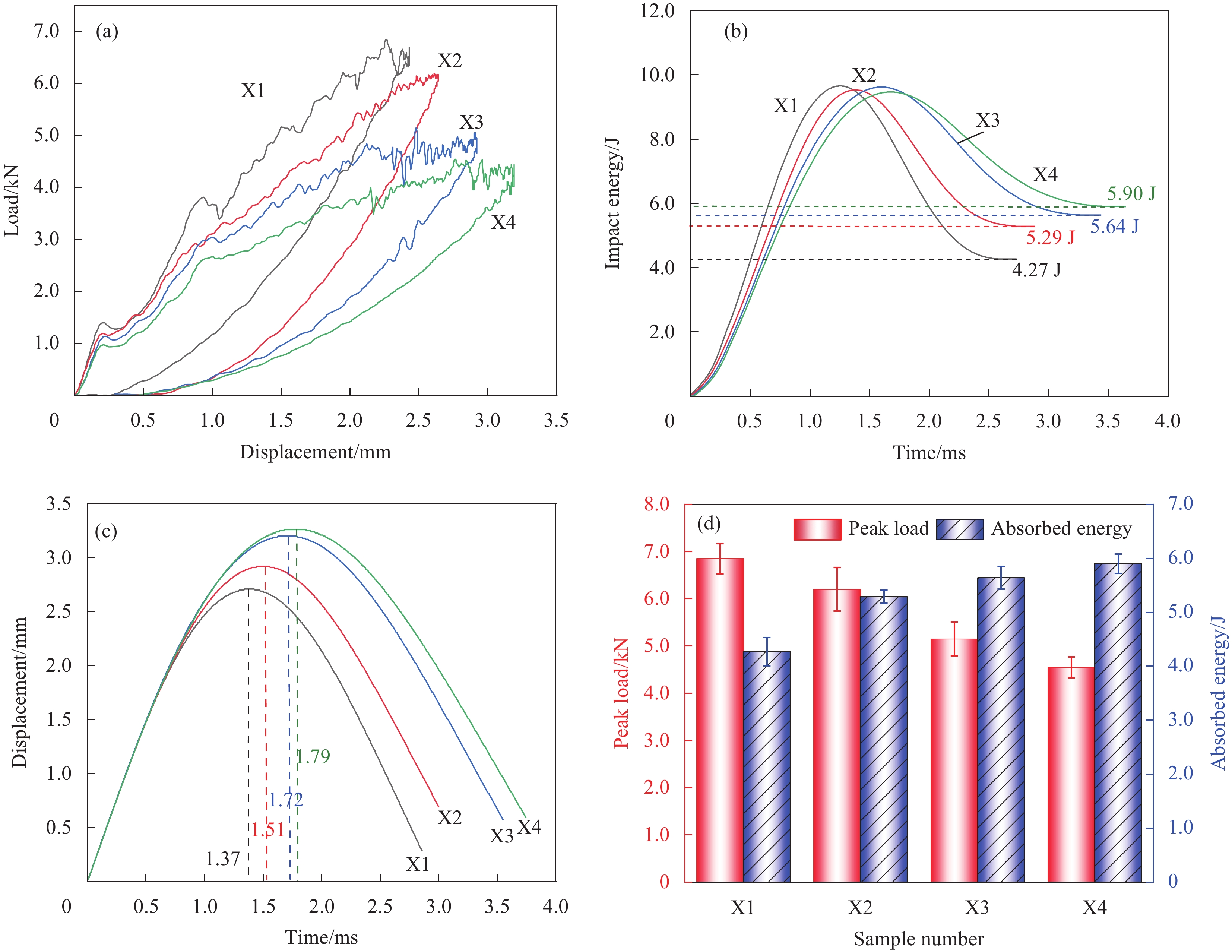

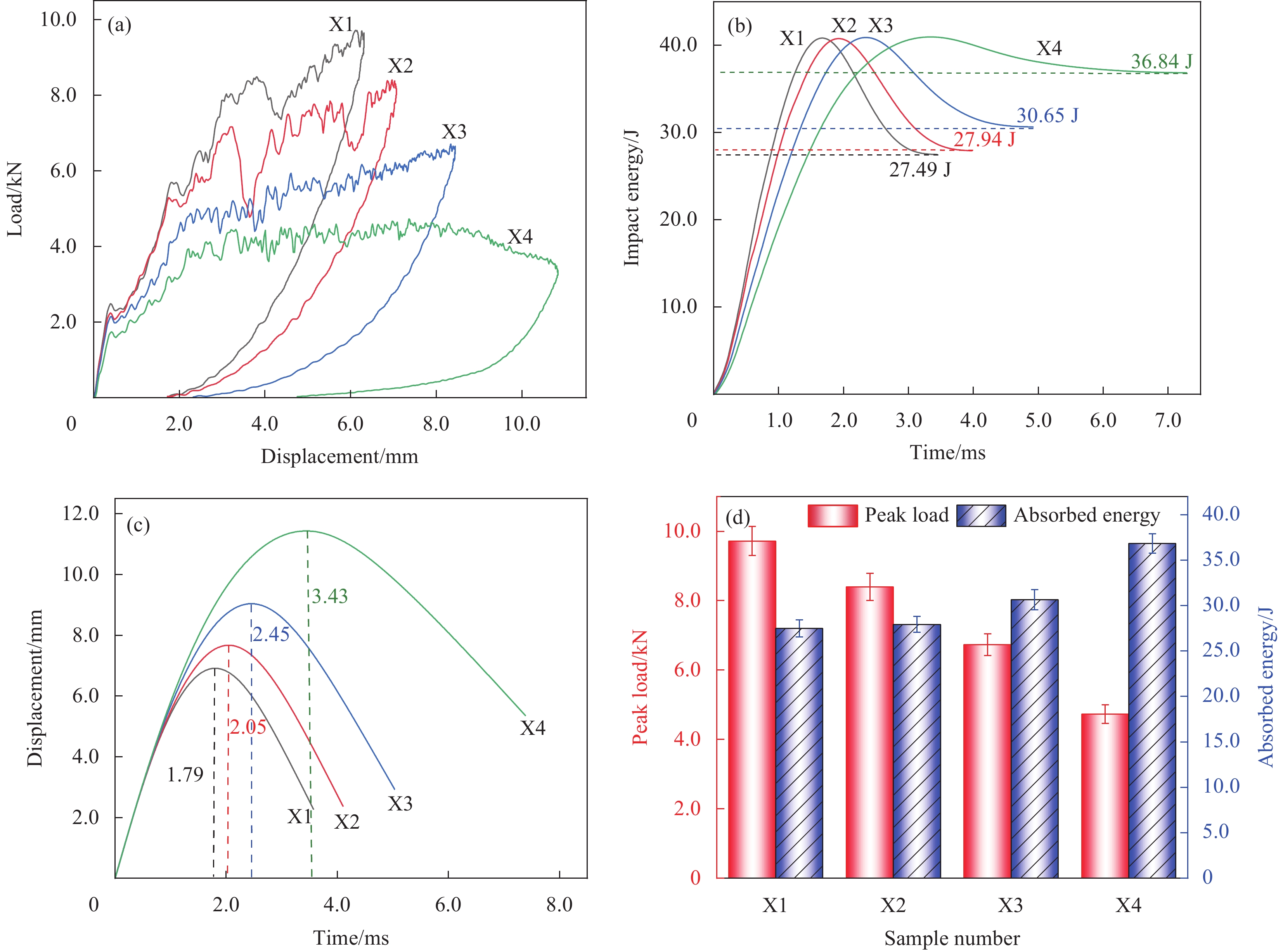

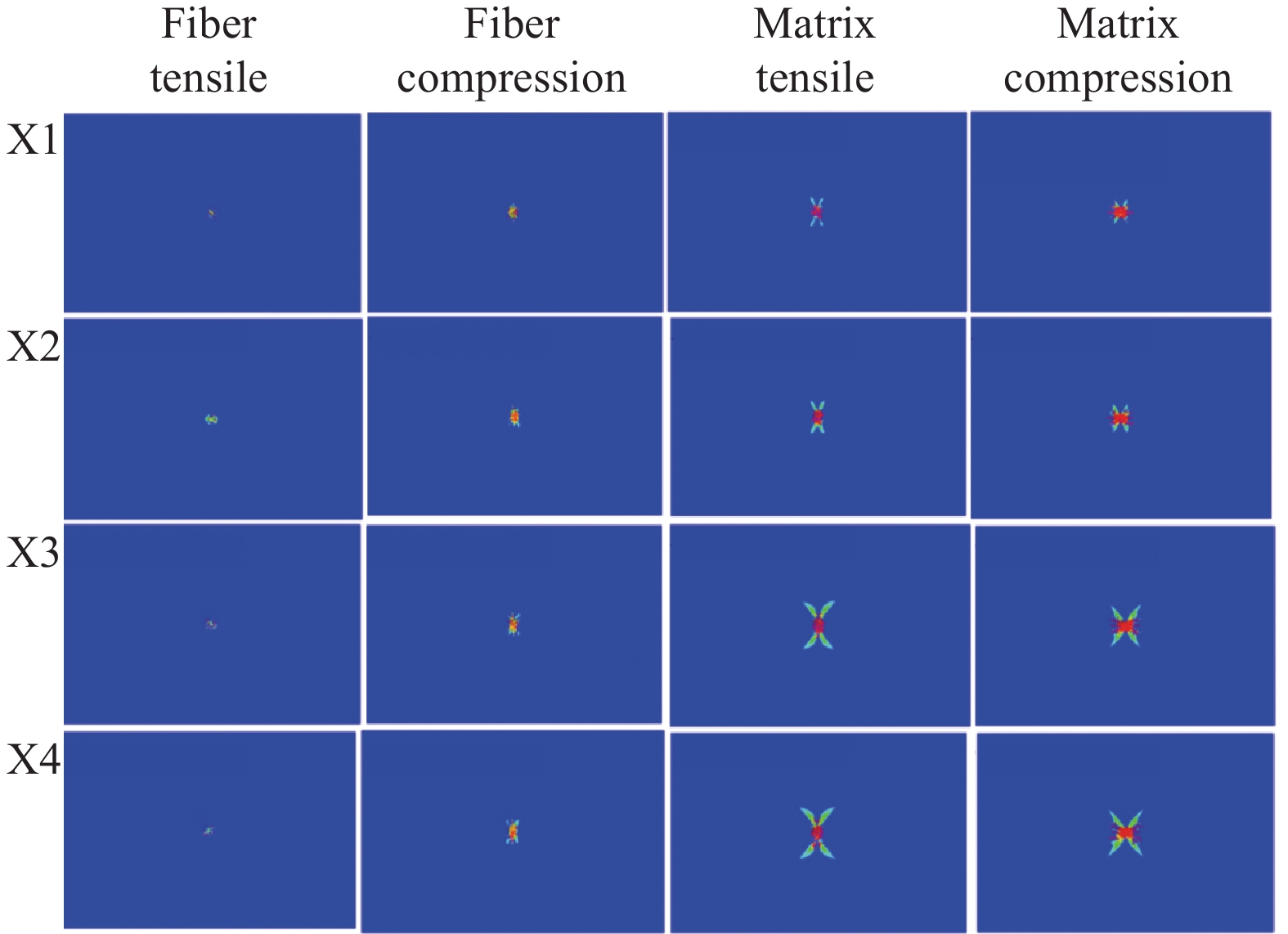

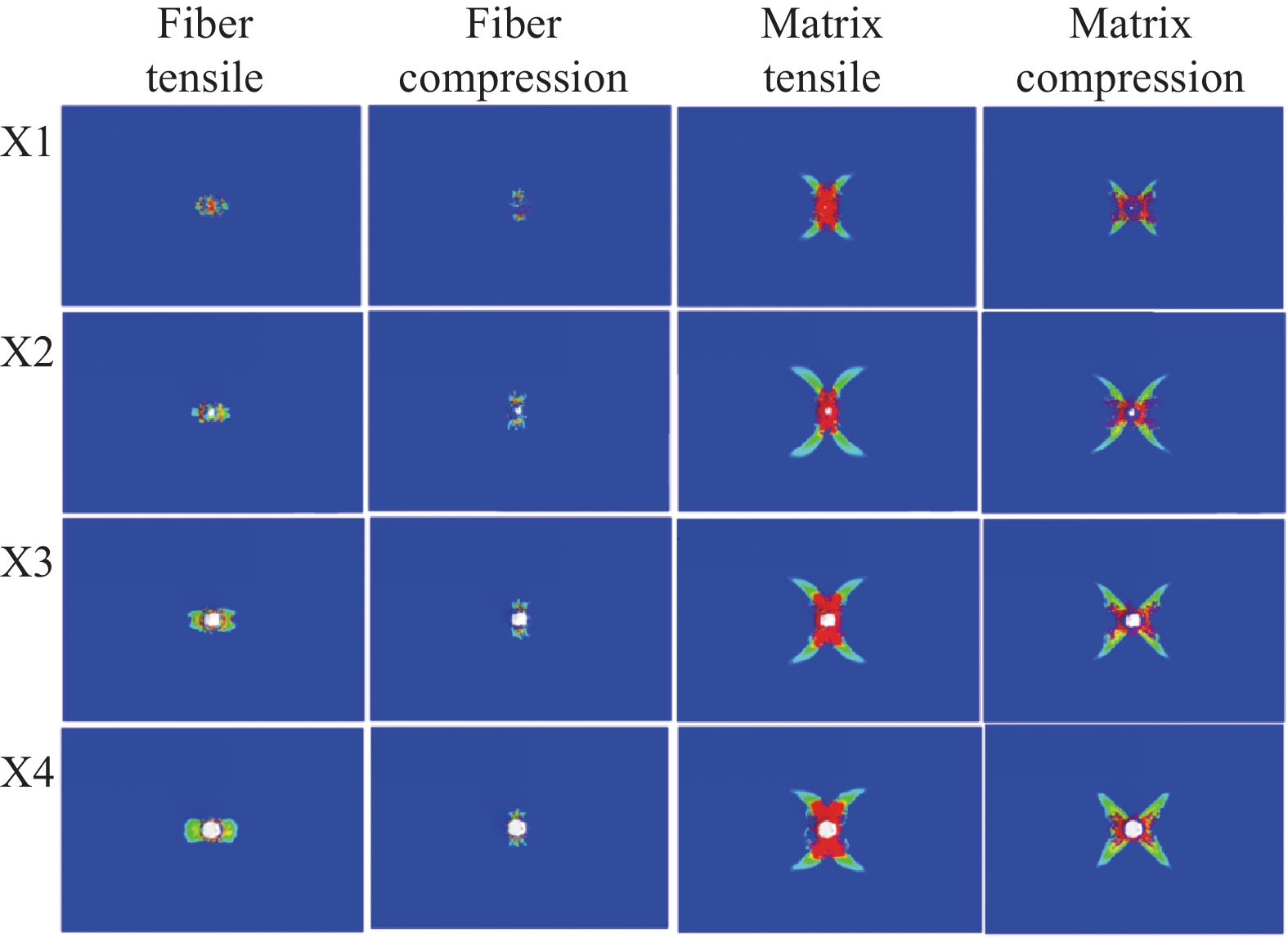

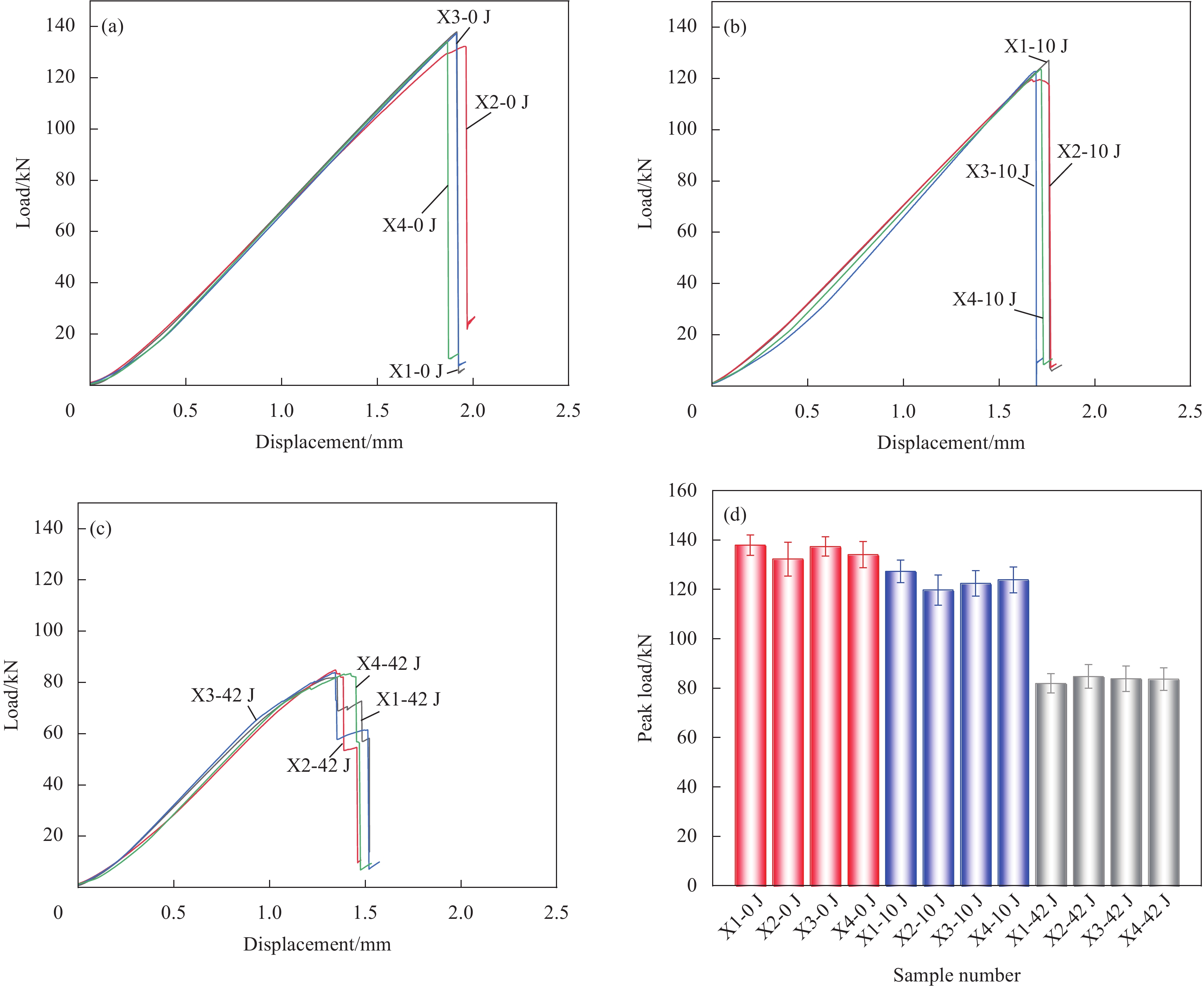

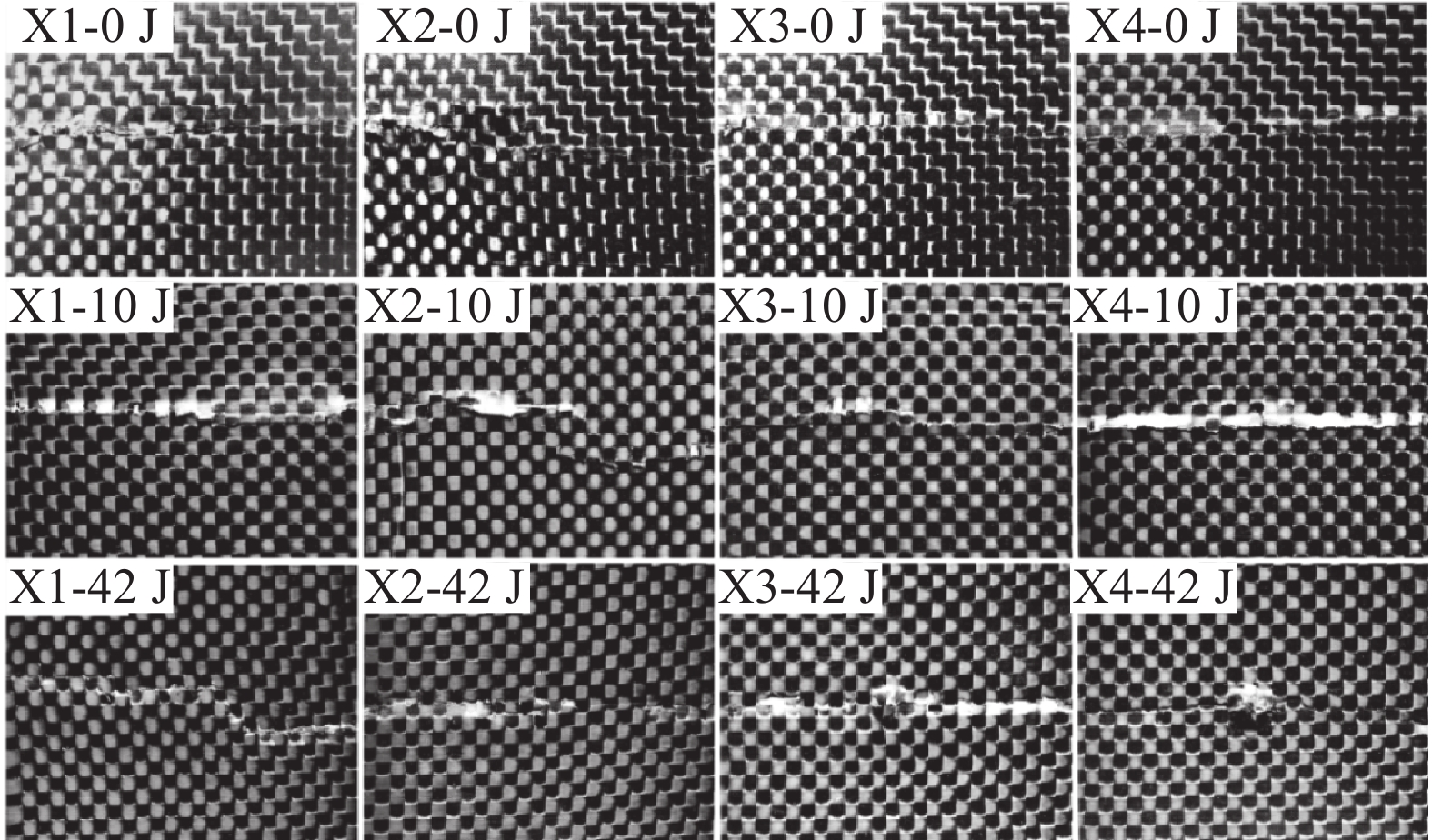

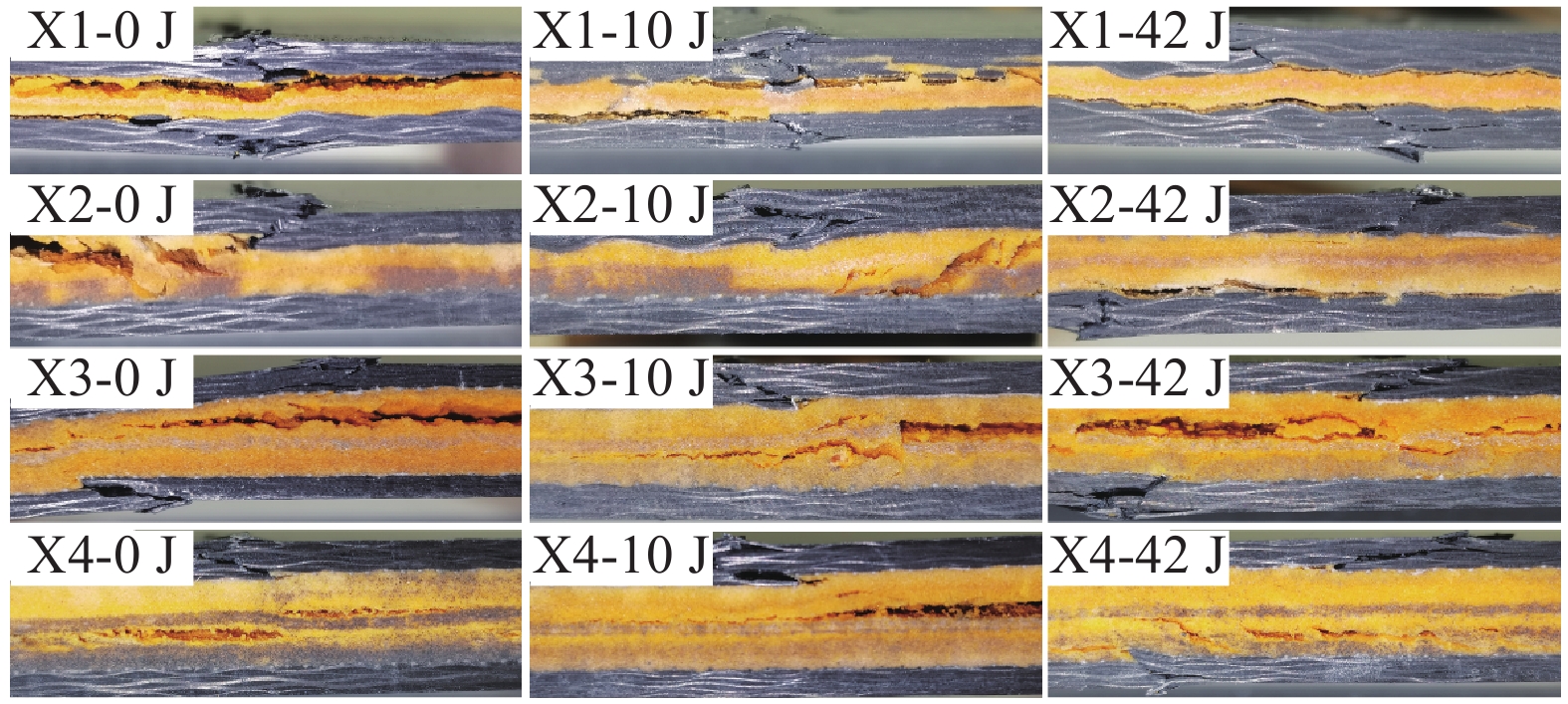

结果随着泡沫膨胀倍率增高,峰值载荷表现出逐渐降低的趋势,并且达到峰值载荷时的位移逐渐增大。从整个夹芯板结构的强度和刚度来看,都表现出随着膨胀倍率增大而降低的趋势。从试样的吸收能量来看,泡沫膨胀倍率越高,吸能效果越好。厚度更大的泡沫夹芯板在受到冲击载荷作用时,泡沫芯子受到压缩载荷作用发生塌陷,在泡沫芯子损伤的过程中会不断吸收锤头的能量,相同质量下,低密度大厚度的泡沫芯子相比较高密度低厚度的泡沫芯子更容易塌陷损伤吸收锤头能量。10 J和42 J冲击能量下X1-X4试样的凹坑深度都是逐渐增大的,并且表面的宏观损伤面积也是逐渐增大的。随着泡沫膨胀倍率增大,泡沫的厚度增大,压缩强度和密度都降低,在相同能量下,泡沫夹芯板的损伤深度就越大。对于同一种泡沫夹芯板试样,由于设置了单元删减,所以在纤维拉伸、纤维压缩、基体拉伸和基体压缩的失效云图上,在中间位置完全失效删除的白色区域,损伤形状和尺寸都完全一致。从纤维的损伤来看,在冲击载荷的作用下,除了会击破试样产生一定的凹坑,还会沿着纤维方向产生一定的裂纹扩展引起纤维的进一步损伤。试样在低速冲击损伤后,较低的冲击能量对剩余压缩强度影响较大,随着冲击能量增大,剩余压缩强度逐渐降低。在冲击后压缩实验中,当冲击能量达到一定的程度,试样的损伤程度达到较大水平,随着冲击能量进一步增大,锤头完全穿透试样,试样不再有更严重的损伤,剩余压缩强度的数值将趋于稳定。

结论热膨胀工艺能够控制不同的模具型腔尺寸一体化成型不同厚度的泡沫夹芯板,相比较传统的工艺具有更高的结构可设计性,有望进一步扩展泡沫夹芯复合材料的应用领域。泡沫的膨胀倍率越低,强度越高,导致夹芯板试样的抗冲击强度更高,结构刚度也更高。但更高膨胀倍率的泡沫芯子具有更优异的吸能效果,在10 J和42 J冲击能量下,X4试样相比较X1试样吸收能量分别提高了38.17%和34.01%。从失效模式来看,更高的冲击能量下夹芯板的损伤更严重,10 J冲击能量只有上蒙皮发生损伤,42 J冲击能量下蒙皮开始发生损伤。随着芯子的厚度增大,在相同冲击能量下,上蒙皮的凹坑深度和损伤面积更大。冲击后压缩可以确定不同厚度的泡沫芯子对夹芯板的损伤容限几乎没有影响。冲击能量为10 J时,试样的压缩强度平均衰减率为8.2%,冲击能量为42 J时,试样的压缩强度平均衰减率达到38.2%。

-

泡沫夹芯复合材料因轻质高强、耐腐蚀、结构可设计性高等优点而广泛应用于航空航天、汽车、体育、风电等领域。但传统的成型工艺复杂,芯材需要单独成型,结构“多步骤”成型的低效率问题限制了应用的发展。热膨胀成型工艺有望一体化成型各种泡沫夹芯复合材料,可膨胀泡沫芯子的使用提高了轻质夹芯复合结构的可设计性。泡沫夹芯复合材料因追求轻量化使结构对冲击损伤的抵抗能力较差,对于这种新型热膨胀工艺如何影响泡沫芯子的性能,从而影响夹芯复合材料结构的抗冲击性能有待于进一步研究。

本文基于热膨胀工艺的成型特点,控制模具型腔尺寸制备了四种典型膨胀倍率的泡沫夹芯板。以10 J和42 J冲击能量研究热膨胀工艺和芯材厚度对泡沫夹芯复合材料低速冲击性能的影响。通过ABAQUS有限元分析、超声C扫描对比试验数据研究了不同试样的损伤模式。冲击后压缩试验研究不同试样的损伤容限。结果发现更高膨胀倍率的泡沫芯子产生更低的膨胀力,泡沫夹芯板的抗冲击强度降低,但结构具有更好的吸能效果。高能量和低强度的泡沫芯子都会导致CFRP蒙皮更高的损伤程度。试样在10 J冲击能量的压缩强度衰减率为8.2%,而42 J冲击能量下试样的压缩强度衰减率达到38.2%。成型压力和芯子的厚度对泡沫夹芯板的抗冲击损伤容限影响很小。研究确定了热膨胀工艺成型泡沫夹芯复合材料具有高的结构和抗冲击性能可设计性。

热膨胀工艺成型不同厚度泡沫夹芯板的技术路线和冲击载荷—位移曲线

下载:

下载: