Accelerated creep testing of tensile properties of glued laminated bamboo

-

摘要: 通过短期(500 h)拉伸蠕变试验,研究了不同应力水平下集成竹顺纹拉伸蠕变行为及变化规律,采用了Findley蠕变模型对蠕变曲线进行模拟;通过阶梯等温法加速蠕变试验,对集成竹顺纹拉伸长期蠕变行为进行了加速表征,构建了跨度50年的蠕变主曲线。结果表明:不同应力水平下,集成竹拉伸蠕变曲线具有初始蠕变和稳态蠕变两个阶段;集成竹拉伸蠕变行为符合线性黏弹性,在任意时刻,其蠕变变形基本与应力水平成正比;根据蠕变主曲线,在60%极限荷载下,集成竹约在104天发生蠕变断裂,呈现脆性破坏形态;Findley蠕变模型不仅能较好地模拟集成竹短期拉伸蠕变行为,其外推结果与加速蠕变试验所得主曲线吻合良好。基于上述试验结果与分析,建立了考虑材料蠕变效应的等时应力-应变曲线,进一步讨论了针对不同设计使用年限的集成竹弹性模量调整系数,并与GB/T 50005—2017《木结构设计标准》建议值进行了对比。

-

关键词:

- 集成竹 /

- 拉伸蠕变 /

- 加速蠕变试验 /

- 蠕变曲线 /

- Findley蠕变模型

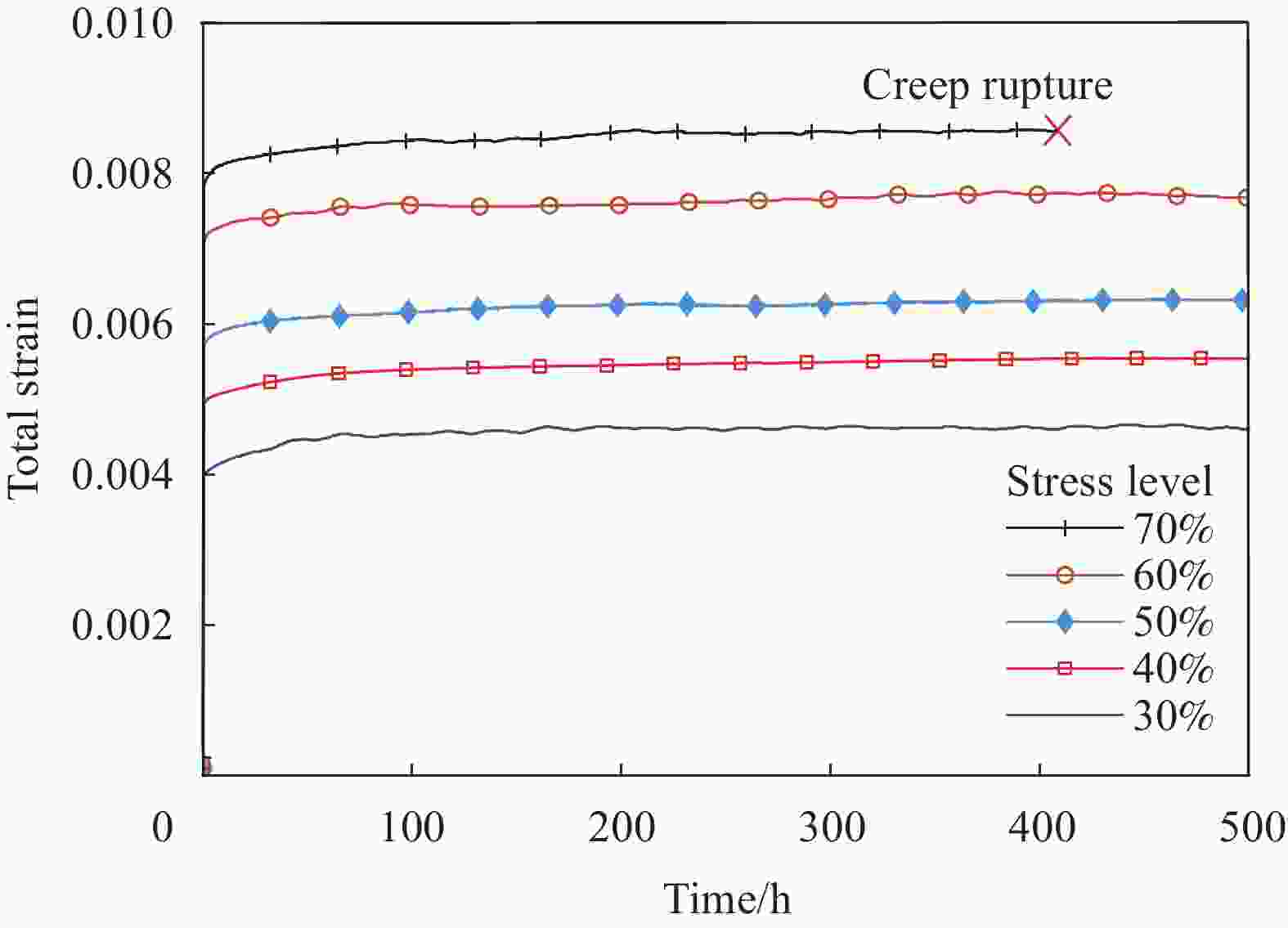

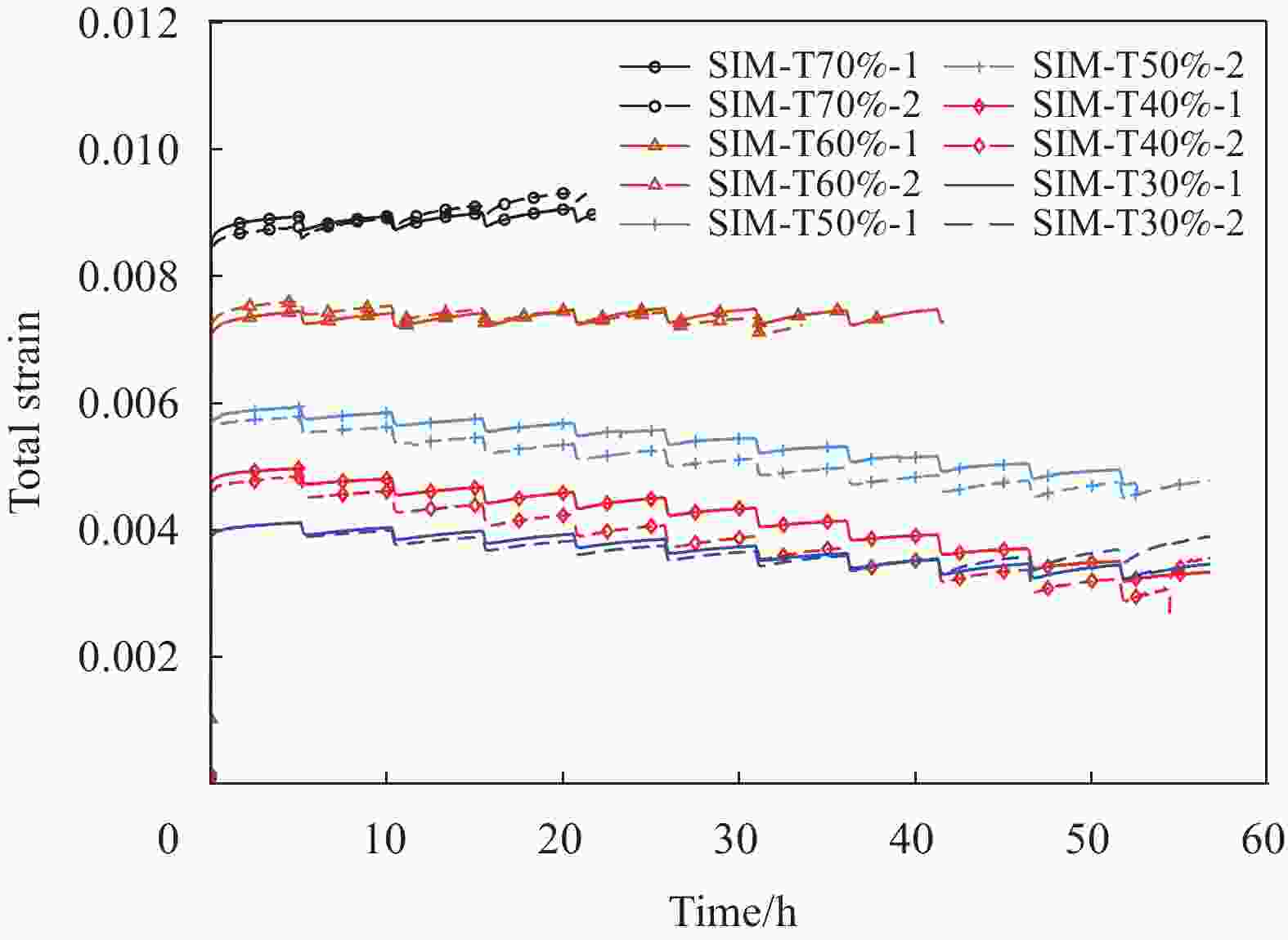

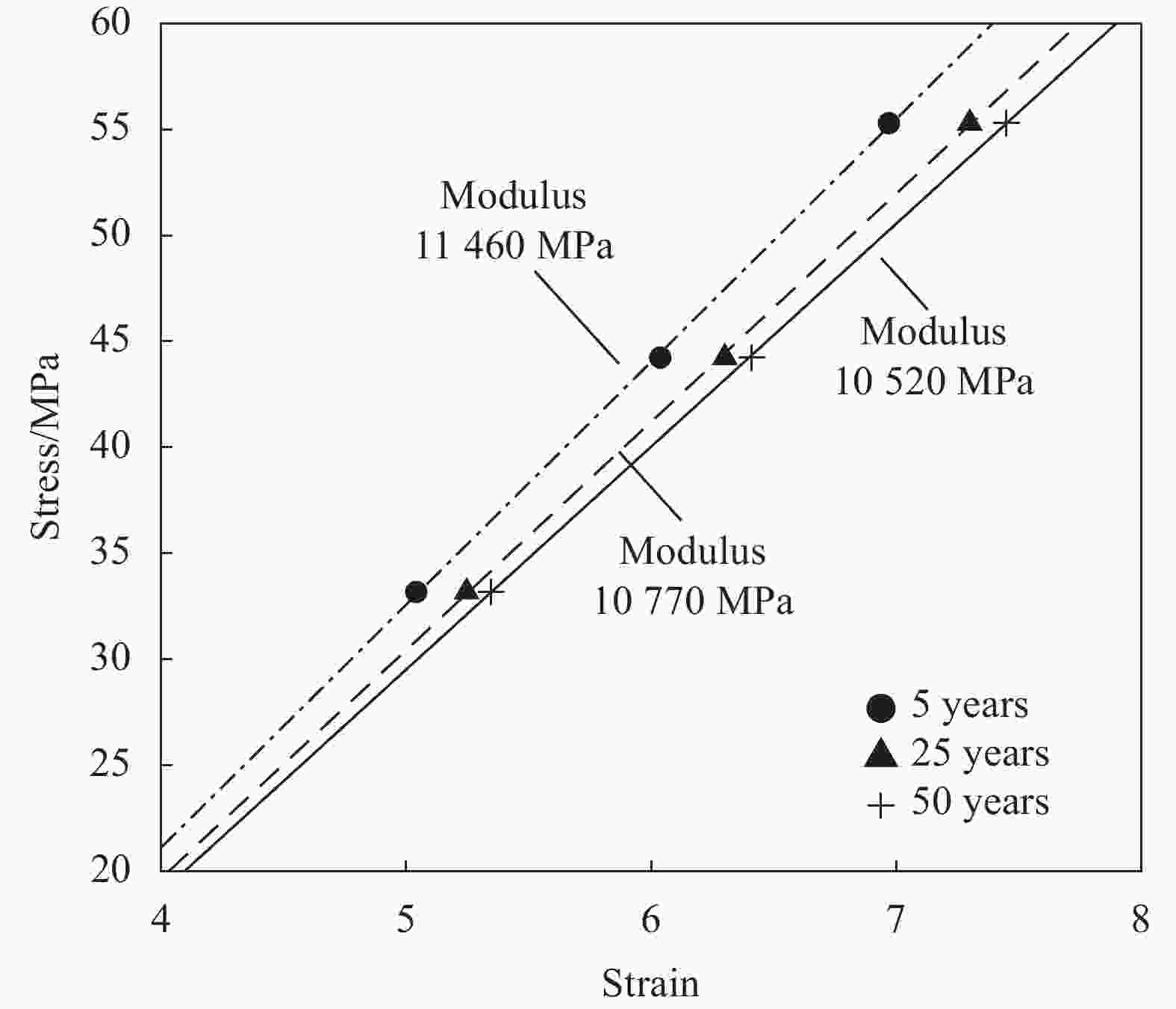

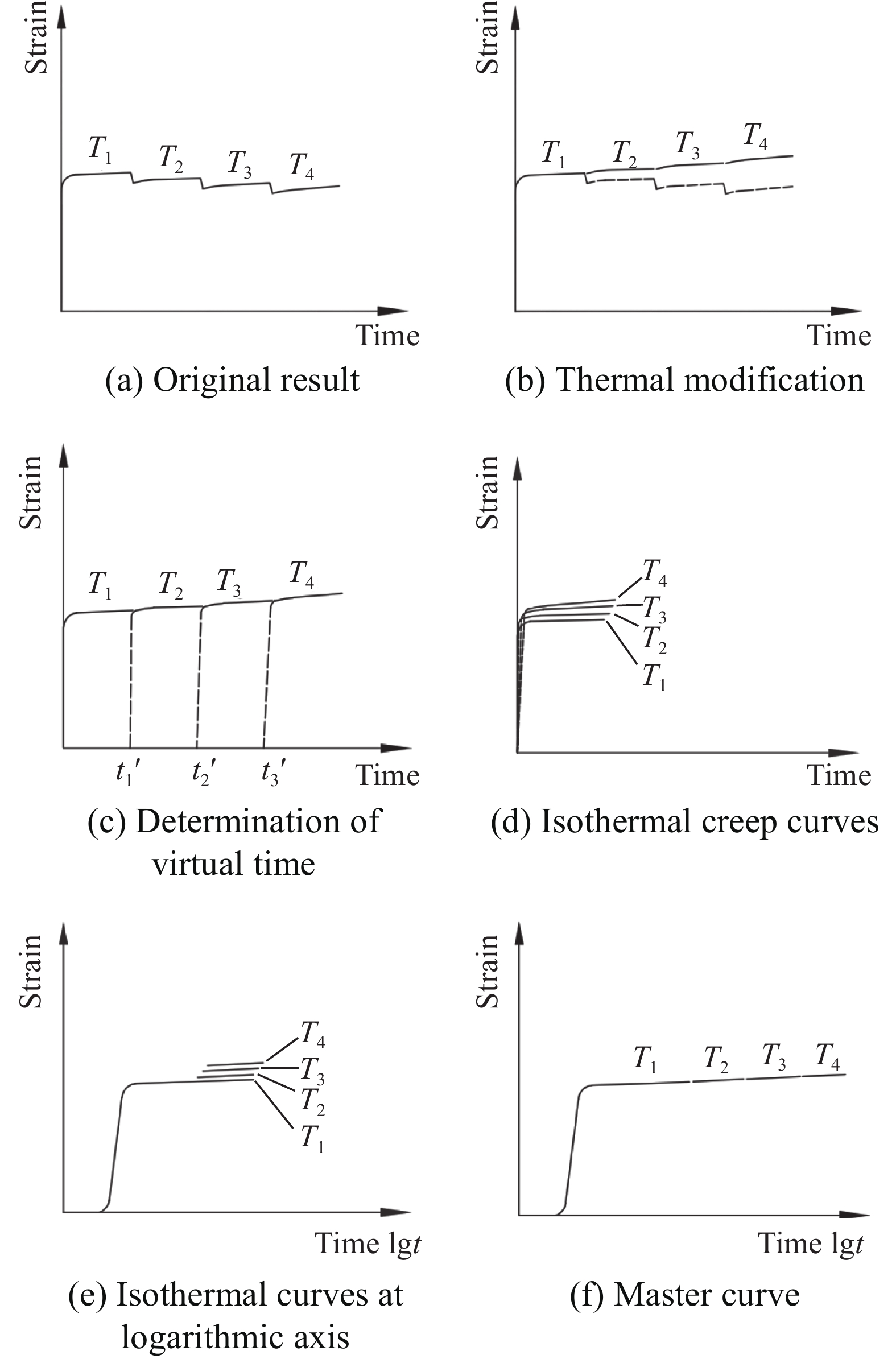

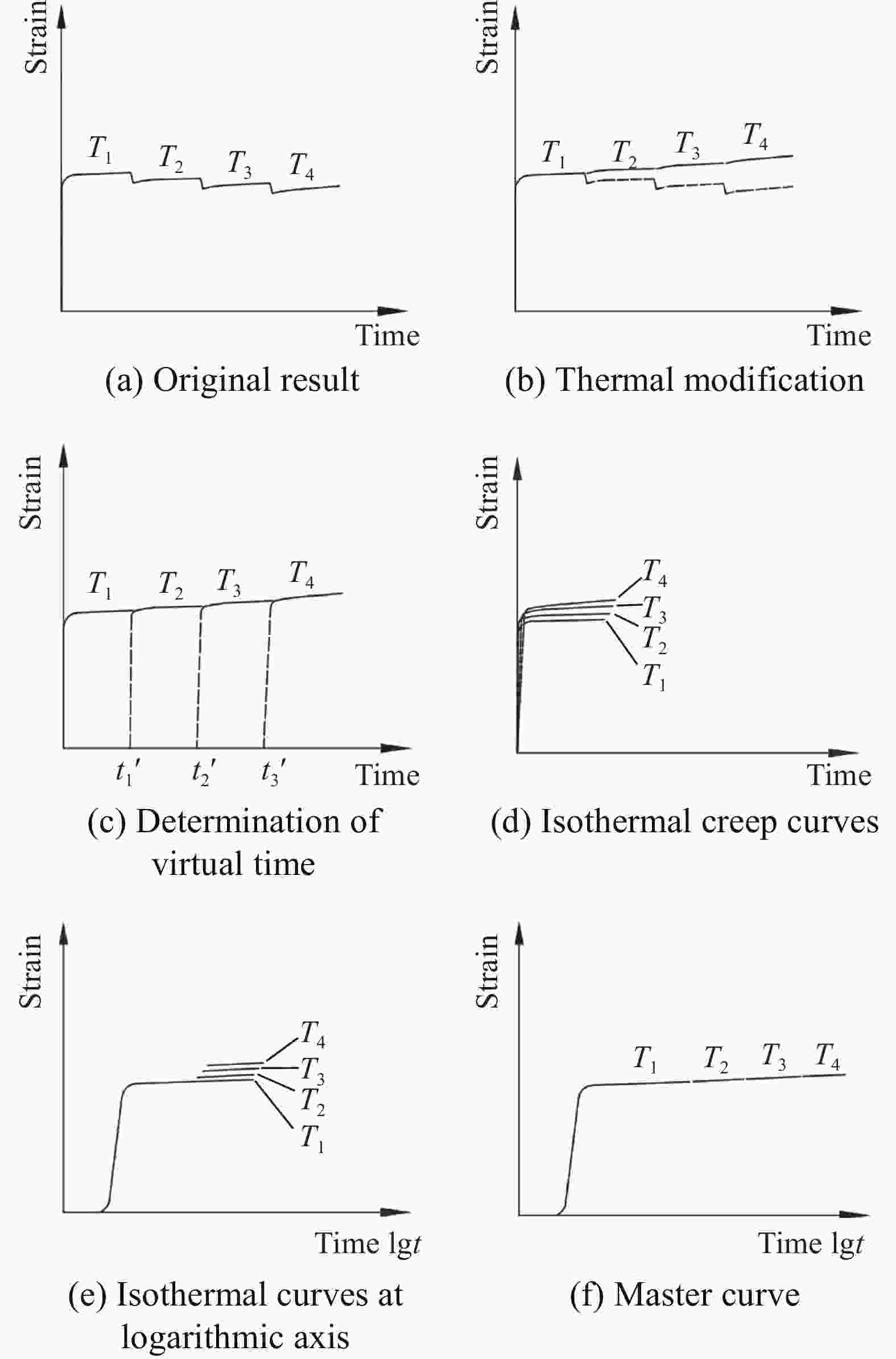

Abstract: The tensile creep behavior of glued laminated bamboo was experimentally studied by the conventional creep test with a time duration of 500 h. The Findley creep model was used to fit the creep curves. The accelerated test using the stepped isothermal method (SIM) was applied to characterize the long-term tensile behavior of glued laminated bamboo. The SIM master curves display the creep characteristics of several decades beyond the test duration. The results show that the tensile creep curve of glued laminated bamboo has two stages under different stress levels: The primary and the secondary creep stages. The tensile creep behavior of glued laminated bamboo conforms to linear viscoelasticity, and its creep deformation is proportional to the stress level at any time. When the stress level is high (reaching 60% of the ultimate strength), the glued laminated bamboo undergoes creep fracture, presenting a brittle failure mode. The Findley creep model can well fit the short-term tensile creep behavior of glued laminated bamboo, and its extrapolation agrees well with the SIM creep master curve. Based on the test results and analysis, the isochronous stress-strain curves were established. The coefficient of elastic modulus of laminated bamboo for different design service life was further discussed and compared with the recommended values in GB/T 50005—2017 standard for design of timber structures.-

Key words:

- glued laminated bamboo /

- tensile creep /

- accelerated creep testing /

- creep curve /

- Findley creep model

-

表 1 阶梯等温法(SIM)加速蠕变试验加载方案

Table 1. Loading scheme of the accelerated creep test using the stepped isothermal method (SIM)

Loading condition Number of specimen Stress

levelStepped temperature/℃ SIM-T0% 2 0% 23, 30, 37, 44, 51, 58, 65, 72, 79, 86 SIM-T30% 2 30% SIM-T40% 2 40% SIM-T50% 2 50% SIM-T60% 2 60% SIM-T70% 2 70% Note: T—Tensile loading. 表 2 Findley蠕变模型拟合参数

Table 2. Fitting parameters of Findley creep model

Stress level $ {\varepsilon _0} $ $ a $ $ n $ $ {R^2} $ 30% $ 3.58 \times {10^{ - 3}} $ $ 6.01 \times {10^{ - 4}} $ 0.09 0.74 40% $ 4.39 \times {10^{ - 3}} $ $ 6.61 \times {10^{ - 4}} $ 0.11 0.98 50% $ 5.17 \times {10^{ - 3}} $ $ 6.53 \times {10^{ - 4}} $ 0.09 0.95 60% $ 6.46 \times {10^{ - 3}} $ $ 6.97 \times {10^{ - 4}} $ 0.10 0.92 70% $ 7.22 \times {10^{ - 3}} $ $ 7.25 \times {10^{ - 4}} $ 0.11 0.96 Notes: $ {\varepsilon _0} $—Instantaneous elastic strain; $ a $ and $ n $—Parameters of Findley model; $ {R^2} $—Goodness of fit. 表 3 不同设计使用年限集成竹弹性模量调整系数

Table 3. Coefficient of elastic modulus of glued laminated bamboo for different design service life

-

[1] 中国工程建设标准化协会. 工程竹材: T/CECS 10138—2021[S]. 北京: 中国标准出版社, 2021.China Association for Engineering Construction Standardization. Engineered bamboo: T/CECS 10138—2021[S]. Beijing: Standards Press of China, 2021(in Chinese). [2] 陈国, 王振国, 吴新涛, 等. 竹集成材钉节点抗剪性能试验研究[J]. 湖南大学学报(自然科学版), 2023, 50(1):119-127.CHEN Guo, WANG Zhenguo, WU Xintao, et al. Experimental study on shear performance of laminated bamboo lumber nailed connections[J]. Journal of Hunan University (Natural Sciences),2023,50(1):119-127(in Chinese). [3] SUN X F, HE M J, LI Z. Novel engineered wood and bamboo composites for structural applications: State-of-art of manufacturing technology and mechanical performance evaluation[J]. Constructions and Building Materials,2020,249:118751. doi: 10.1016/j.conbuildmat.2020.118751 [4] 张家亮, 茅鸣, 俞斌武, 等. 钢-竹组合工字形柱轴压性能试验研究[J]. 建筑结构学报, 2022, 43(2):105-115.ZHANG Jialiang, MAO Ming, YU Binwu, et al. Experimental study on axial compressive behavior of steel-bamboo I-section composite columns[J]. Journal of Building Structures,2022,43(2):105-115(in Chinese). [5] 刘燕燕, 黄东升, 盛宝璐. 集成竹I型层间断裂特性试验研究与数值分析[J]. 建筑结构学报, 2023, 44(1):280-288.LIU Yanyan, HUANG Dongsheng, SHENG Baolu. Experimental study and numerical simulation on mode-I interlaminar fracture behavior of laminated bamboo[J]. Journal of Building Structures,2023,44(1):280-288(in Chinese). [6] 肖岩, 陈国, 单波, 等. 竹结构轻型框架房屋的研究与应用[J]. 建筑结构学报, 2010, 31(6):195-203.XIAO Yan, CHEN Guo, SHAN Bo, et al. Research and application of lightweight glue-laminated bamboo frame structure[J]. Journal of Building Structures,2010,31(6):195-203(in Chinese). [7] XIAO Y, ZHOU Q J, SHAN B. Design and construction of modern bamboo bridges[J]. Journal of Bridge Engineering (ASCE),2010,15:533-541. doi: 10.1061/(ASCE)BE.1943-5592.0000089 [8] 肖岩, 单波. 现代竹结构 [M]. 北京: 中国建筑工业出版社, 2013: 1-18.XIAO Yan, SHAN Bo. Glubam structures[M]. Beijing: China Architecture & Building Press, 2013: 1-18(in Chinese). [9] 谢桥军, 肖岩. 大跨度胶合竹结构屋架受力性能研究[J]. 建筑结构学报, 2016, 37(4):47-53.XIE Qiaojun, XIAO Yan. Experimental study on large-span glubam roof trusses[J]. Journal of Building Structures,2016,37(4):47-53(in Chinese). [10] 蒋为安, 刘可为, 张鑫, 等. 中国竹建筑工程2035发展趋势与路径研究[J]. 土木工程学报, 2021, 54(10):125-132.JIANG Weian, LIU Kewei, ZHANG Xin, et al. Trends and path for development of bamboo structural engineering towards 2035 in China[J]. China Civil Engineering Journal,2021,54(10):125-132(in Chinese). [11] TSUBAKI T, NAKANO T. Creep behavior of bamboo under various desorption conditions[J]. Holzforschung,2010,64:489-493. [12] GOTTRON J, HARRIES K A, XU Q. Creep behavior of bamboo[J]. Construction and Building Materials,2014,66:79-88. doi: 10.1016/j.conbuildmat.2014.05.024 [13] BROKANS A, OZOLA L. Behaviour of creep of timber beams under natural environmental conditions[J]. WIT Transactions on the Built Environment,2014,137:479-489. [14] NUR YAZDANI P E, JOHNSON E, DUWADI S. Creep effect in structural composite lumber for bridge application[J]. Journal of Bridge Engineering,2004,9(1):87-94. doi: 10.1061/(ASCE)1084-0702(2004)9:1(87) [15] XIAO Y, LI Z, YANG R. Long-term loading behavior of a full-scale glubam bridge model[J]. Journal of Bridge Engineering,2014,19(9):04014027. doi: 10.1061/(ASCE)BE.1943-5592.0000600 [16] 李磊. 现代新型胶竹材料蠕变性能及组合结构蠕变研究[D]. 长沙: 湖南大学, 2012: 24-29.LI Lei. Research on creep property of glubam and modern bamboo composite structure[D]. Changsha: Hunan University, 2012: 24-29(in Chinese). [17] 陈思, 魏洋, 赵鲲鹏, 等. 重组竹顺纹受压蠕变性能及预测模型[J]. 复合材料学报, 2021, 38(3): 944-952.CHEN Si, WEI Yang, ZHAO Kunpeng, et al. Creep performance and prediction model of bamboo scrimber under compression[J]. Acta Materiae Compositae Sinica, 2021, 38(3): 944-952(in Chinese). [18] 李玉顺, 张秀华, 吴培增, 等. 重组竹在长期荷载作用下的蠕变行为[J]. 建筑材料学报, 2019, 22(1):65-71.LI Yushun, ZHANG Xiuhua, WU Peizeng, et al. Creep behavior of bamboo scrimber under long-term load[J]. Journal of Building Materials,2019,22(1):65-71(in Chinese). [19] MA X X, SHI S Q, WANG G, et al. Long creep-recovery behavior of bamboo-based products[J]. Journal of Wood Science,2017,64(2):119-125. [20] 马欣欣. 结构用竹质工程材料的蠕变特性研究[D]. 北京: 中国林业科学研究院, 2015: 74-81.MA Xinxin. Creep properties of bamboo-based engineering composite material applied in structure[D]. Beijing: Chinese Academy of Forestry, 2015: 74-81(in Chinese). [21] ZHAO K, WEI Y, CHEN S, et al. Experimental investigation of the long-term behavior of reconstituted bamboo beams with various loading levels[J]. Journal of Building Engi-neering,2021,36:102107. doi: 10.1016/j.jobe.2020.102107 [22] PLAZEK D J. Temperature dependence of the viscoelastic behavior of polystyrene[J]. Journal of Physical Chemistry,1965,69(10):3480-3487. doi: 10.1021/j100894a039 [23] LEADERMAN H. Elastic and creep properties of filamentous materials and other high polymers[J]. The Journal of Physical and Colloid Chemistry,2002,51(3):886. [24] HUNG K, WU T, CHEN Y, et al. Assessing the effect of wood acetylation on mechanical properties and extended creep behavior of wood/recycled-polypropylene composites[J]. Construction and Building Materials,2016,108:139-145. doi: 10.1016/j.conbuildmat.2016.01.039 [25] 欧荣贤, 姚开泰, 孙理超, 等. 木塑复合材料蠕变特性及预测方法的研究进展[J]. 复合材料学报, 2021, 38(6):1734-1753.OU Rongxian, YAO Kaitai, SUN Lichao, et al. State-of-the-art of the creep characteristics of wood-plastic composite and its prediction methods[J]. Acta Materiae Compositae Sinica,2021,38(6):1734-1753(in Chinese). [26] PENG H, JIANG J, ZHAN T, et al. Flexural creep behavior of hierarchical bamboo structure using time-temperature-stress superposition principle[J]. Industrial Crops and Products,2022,190:115906. doi: 10.1016/j.indcrop.2022.115906 [27] THORNTON J S, PAULSON J N, SANDRI D. Conventional and stepped isothermal methods for characterizing long term creep strength of polyester geogrids[C]//ROWE R K. Proceedings of the 6th International Conference on Geosynthetics. Atlanta: Industrial Fabrics Assciation International, 1998: 691-698. [28] ALWIS K G N C, BURGOYNE C J. Accelerated creep testing for aramid fibres using the stepped isothermal method[J]. Journal of Materials Science,2008,43(14):4789-4800. doi: 10.1007/s10853-008-2676-0 [29] ZHAO Y, LU Z, YAO H, et al. A fast and precise methodology of creep master curve construction for geosynthetics based on stepped isothermal method (SIM)[J]. Geotextiles and Geomembranes,2021,49:952-962. doi: 10.1016/j.geotexmem.2021.01.005 [30] American Society of Testing Materials. Standard test method for accelerated tensile creep and creep-rupture of geosynthetic materials based on time-temperature superposition using the stepped isothermal method: ASTM D6992—16[S]. West Conshohocken: ASTM Committee, 2016. [31] American Society of Testing Materials. Standard test method for accelerated compressive creep of geosynthetic materials based on time-temperature superposition using the stepped isothermal method: ASTM D7361—07[S]. West Conshohocken: ASTM Committee, 2007. [32] BOLTZMANN L. Zur theorie der elastischen nachwirkung[C]//KAISERL. Sitzungsberichte der Kaiserlichen Akademie der Wissenhaften Mathematische Naturwissenhaft. Wien: Gerold's Sohn Press, 1874: 275-305. [33] American Society of Testing Materials. Standard test methods for small clear specimens of timber: ASTM D143—14[S]. West Conshohocken: ASTM Committee, 2014. [34] American Society of Testing Materials. Standard test methods for tensile, compressive, and flexural creep and creep-rupture of plastics: ASTM D2990—17[S]. West Conshohocken: ASTM Committee, 2017. [35] FINDLEY W N, LAI J S, ONARN K. Creep and relaxation of nonlinear viscoelastic materials[M]. New York: North-Holland Publishing Company, 1976: 8-10. [36] 中华人民共和国住房和城乡建设部. 木结构设计规范: GB/T 50005—2017[S]. 北京: 中国建筑工业出版社, 2017.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for design of timber structures: GB/T 50005—2017[S]. Beijing: China Architecture & Building Press, 2017(in Chinese). -

下载:

下载: