Mechanical behavior of bamboo scrimber filled steel tube under different loading modes

-

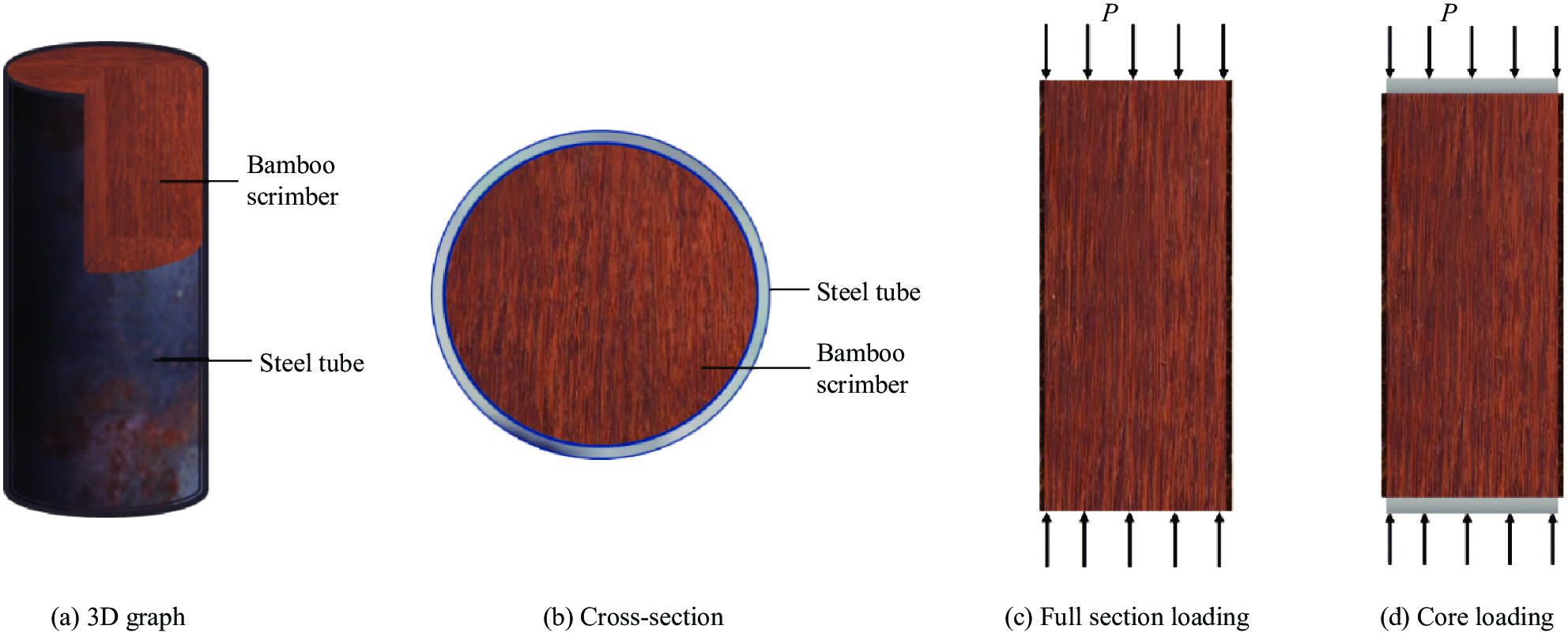

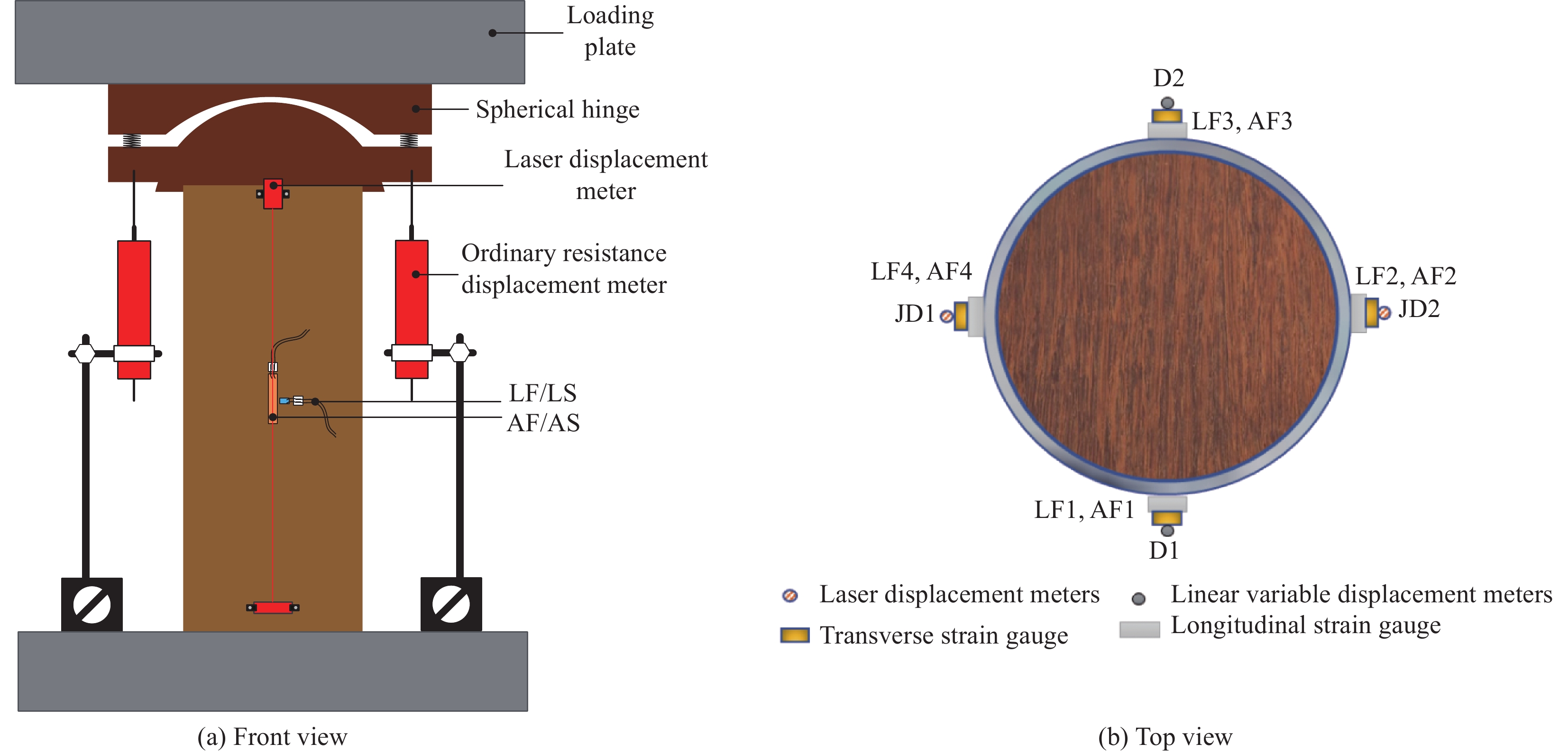

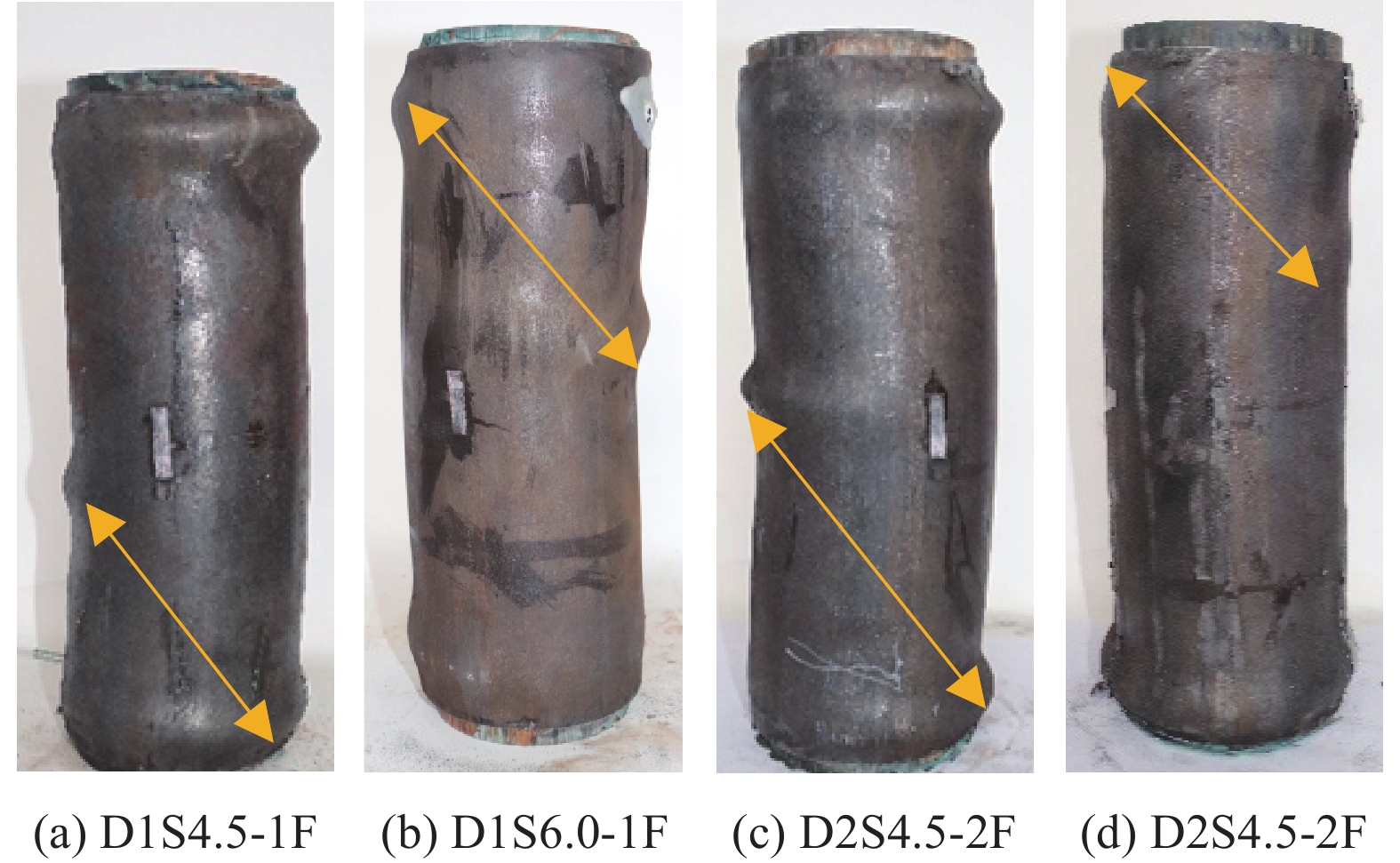

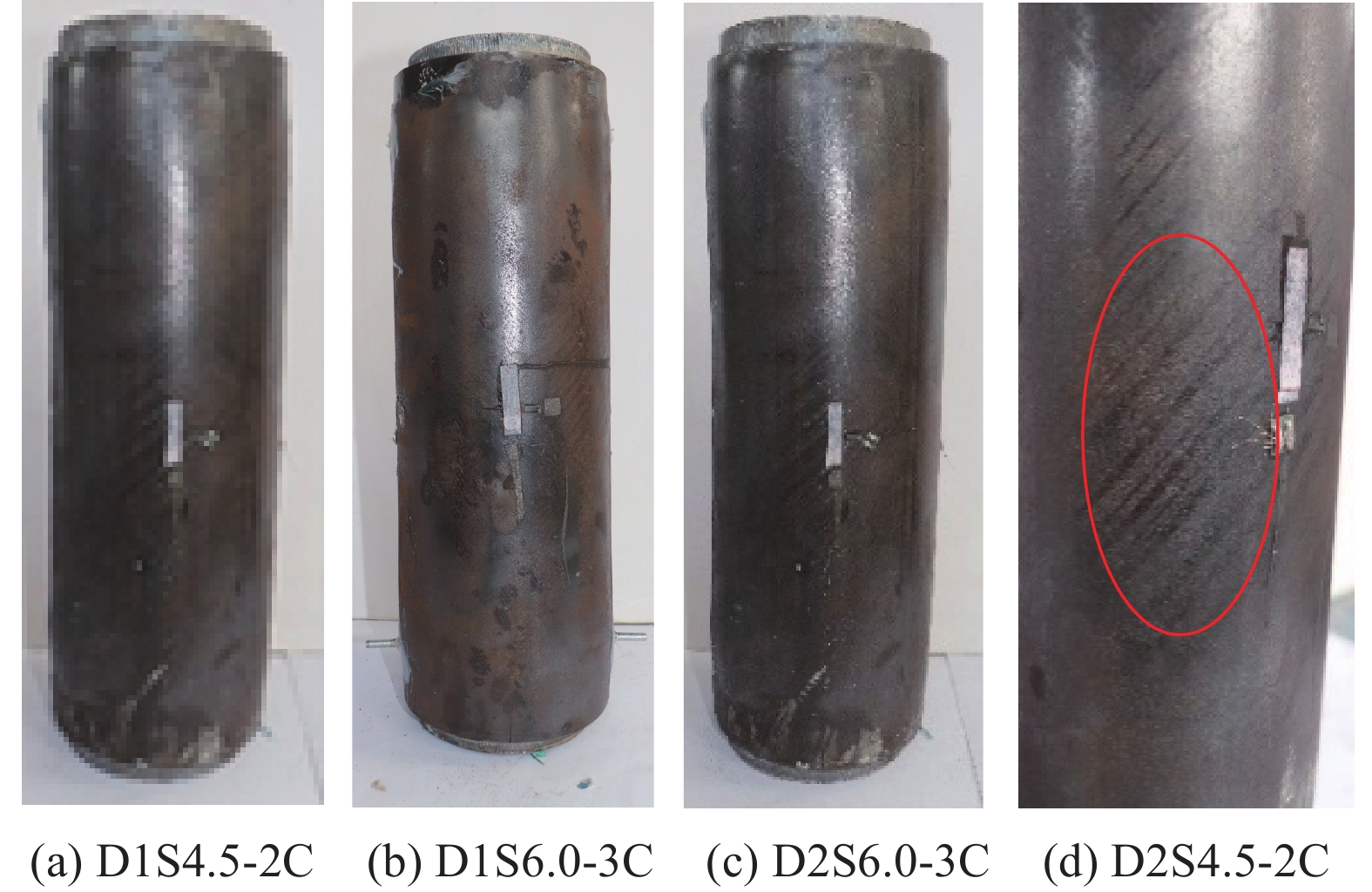

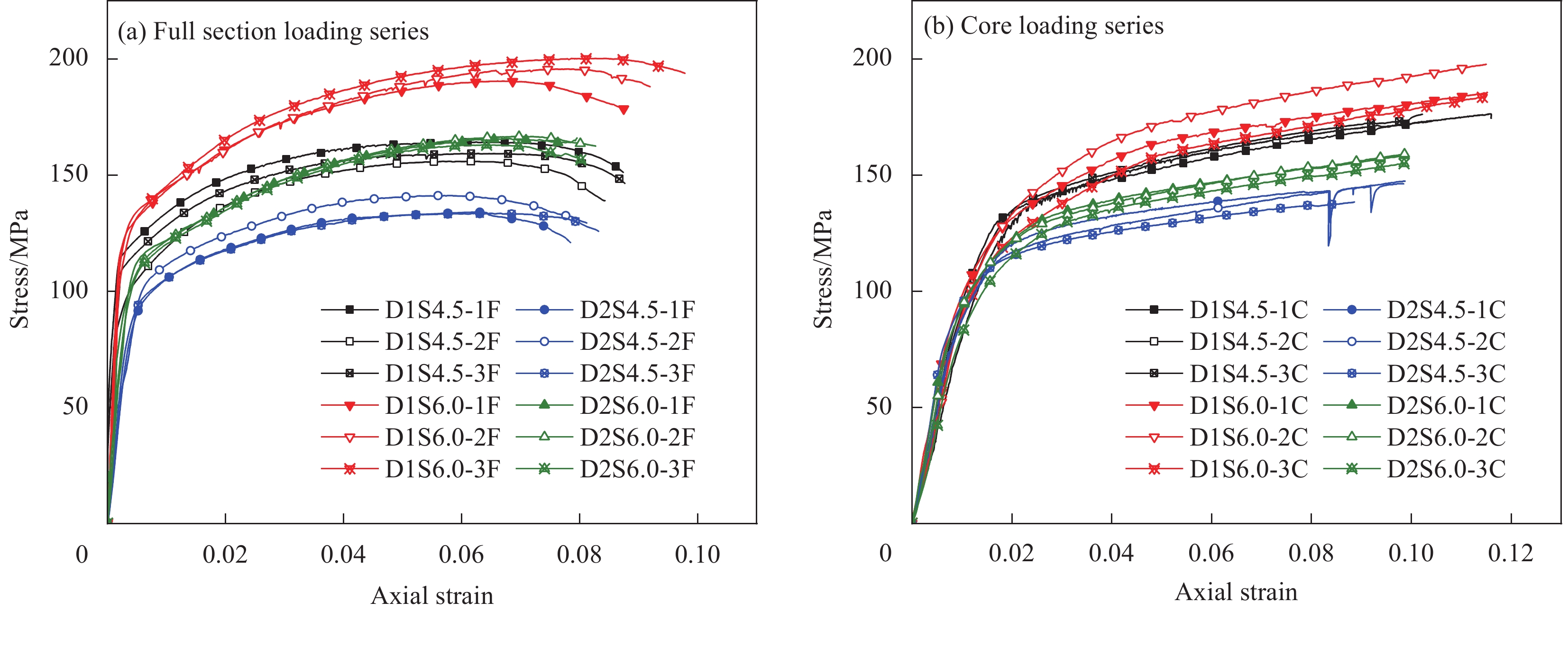

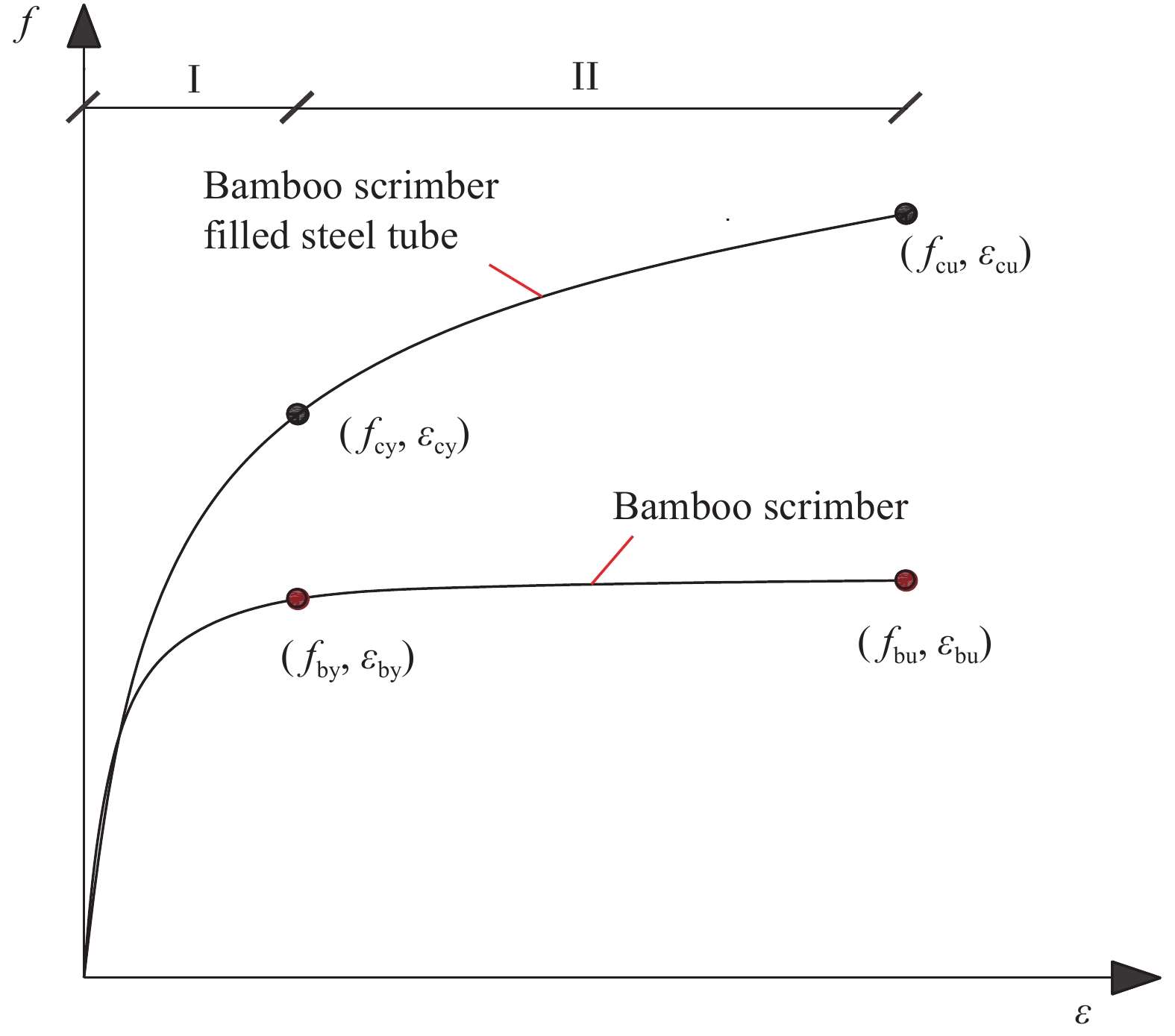

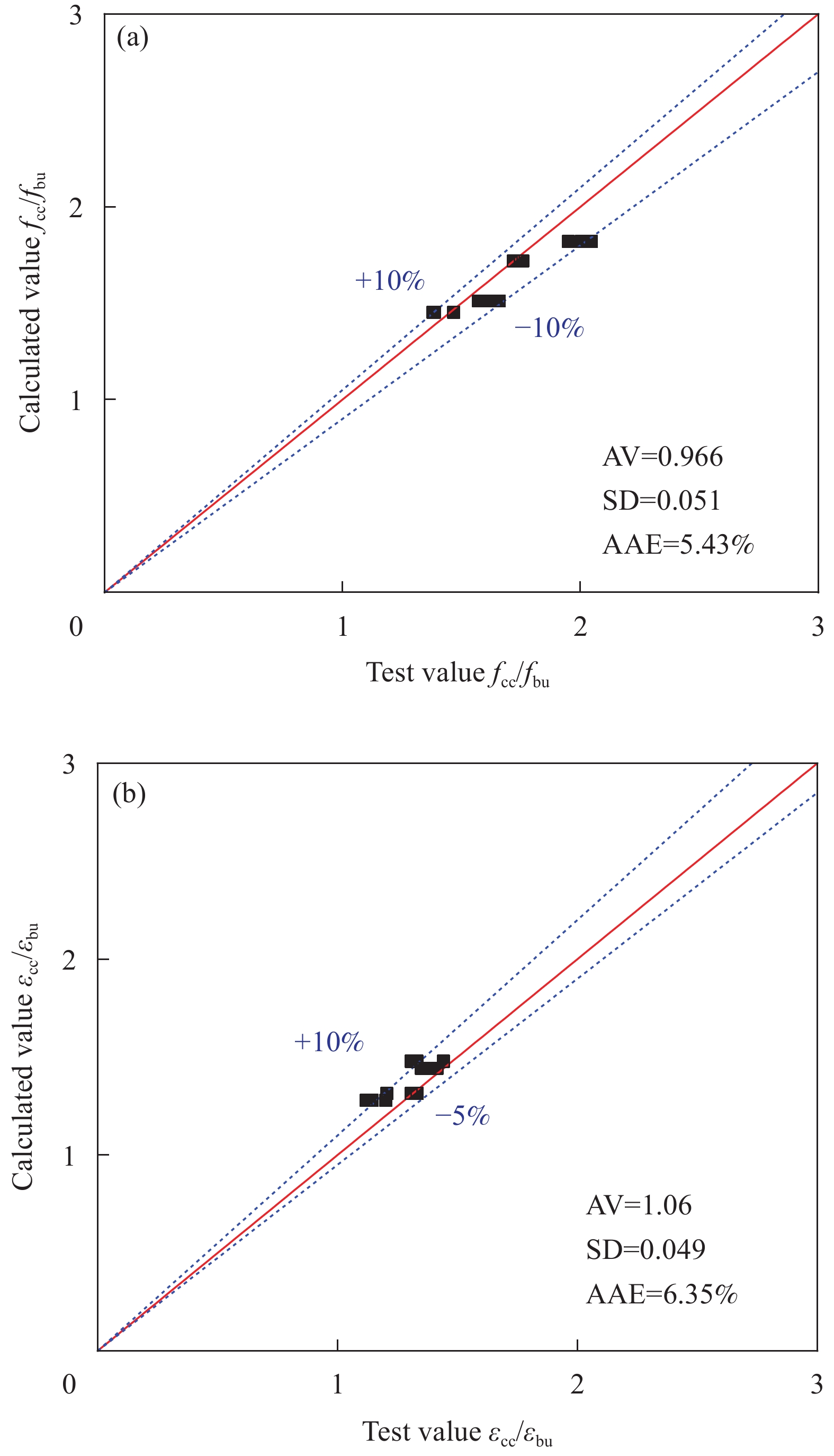

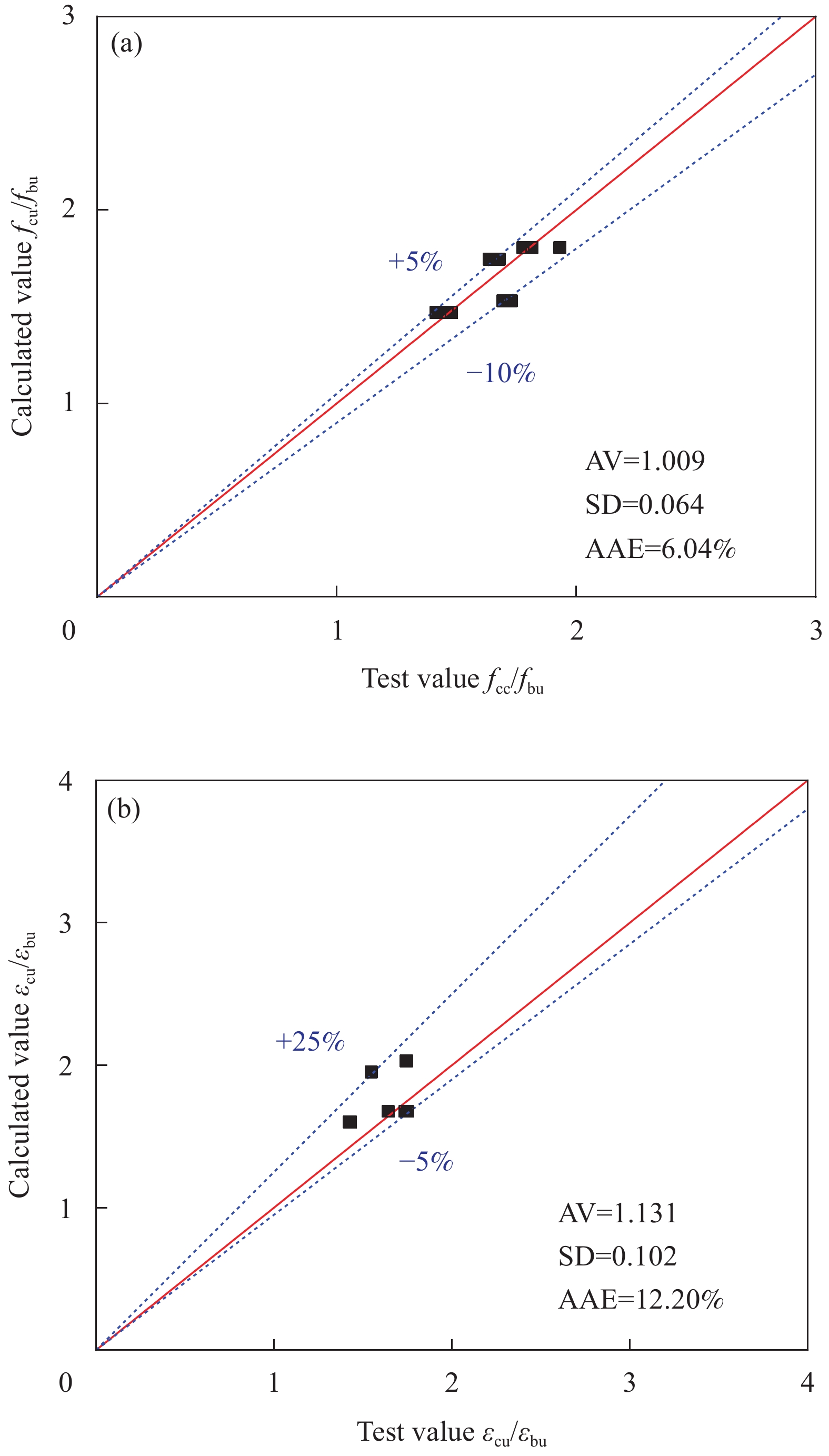

摘要: 本文将重组竹与钢管复合形成新型钢管约束重组竹。对24个新型钢管约束重组竹圆柱试件进行了轴压试验,研究了钢管厚度和加载方式(全截面与核心加载)对其轴压性能的影响。试验结果表明:外加钢管能够有效地提高结构承载力和变形能力;钢管约束重组竹圆柱主要破坏形态为剪切破坏;结构的峰值应力、峰值应变均与钢管厚度呈正相关,随着钢管厚度增加,试件的峰值应力最大增长22.4%,峰值应变最大增长6.1%;核心受压钢管重组竹较全截面受压试件展现了更好的承载潜力和变形能力。根据全截面受压和核心受压的曲线不同,考虑了钢管套箍系数,分别提出了两种加载方式下新型钢管约束重组竹的极限应力、极限应变和峰值应力、峰值应变的预测模型,应力计算模型误差均在10%以内。最后建议了应力-应变全曲线模型,预测了不同加载方式下新型钢管约束重组竹的应力-应变变化规律。Abstract: By means of structural innovation, a new type of bamboo scrimber filled steel tube was formed by composite materials of bamboo scrimber and steel tube. Axial compression tests were carried out on 24 cylindrical specimens of the new type of bamboo scrimber filled steel tube to study the effect of steel tube thickness and loading mode (full section and core loading) on its axial compression performance. The test results show that the external steel tube can effectively improve the structural bearing capacity and deformation capacity, and the main failure mode of the bamboo scrimber filled steel tube is shear failure. The peak stress and peak strain of the structure are positively correlated with the steel tube thickness. As the steel tube thickness increases, the maximum increase in peak stress of the specimens reaches 22.4%, while the maximum increase in peak strain is 6.1%. The core loading specimens exhibit better load bearing potential and deformation capacity than the full section loading specimens. Based on the different curves of full section loading and core loading, and considering the steel tube confinement factor, the prediction models of ultimate stress, ultimate strain, peak stress and peak strain of the new type of bamboo scrimber filled steel tube under different loading modes are proposed, and the error of the stress calculation model is less than 10%. Finally, the stress-strain full curve model is proposed, and the stress-strain variation of the new bamboo scrimber filled steel tube under different loading modes is predicted.

-

Janus材料因其独特的结构或组成的不对称性展现出很多特殊的功能,近年来为人们所广泛关注[1-4]。目前,Janus材料在乳化剂[5]、自驱动马达[6]、药物释放[7]、催化[8]和柔性可穿戴[9]等众多领域都展现出巨大的应用前景。自1991年被诺贝尔奖获得者De Gennes[1]首次提出以来,经过30多年的发展,已经有多种不同组成或形貌结构的Janus材料被合成出来,从组成来分类,主要有聚合物/聚合物型、无机物/无机物型及聚合物/无机物型;从形貌来区分,包括颗粒状[10]、棒状[11]、片状[12]、锥状[13]及雪人状[14]等。

不同于传统Janus材料,Janus中空球在空间结构上中心对称,其非对称性体现在内外表面的化学组成和性质上,这种独特的结构使其可以用作特殊微容器,用于分离富集、传输和受限反应等[15-19]。但是,研究发现,完整致密的壳层会限制微球和环境之间的物质传输[15]。因此,为了提高Janus微球和环境之间的物质传输速率,引入了贯穿壳层的孔道,即Janus笼。目前,已经有多种功能Janus笼被制备出来,作为高效传输的微反应容器,在水处理、催化,环境响应富集释放等方向展现出一定的应用前景[20-23]。

课题组在之前的工作中,最早提出了乳液界面溶胶凝胶法制备二氧化硅Janus中空球的方法[24]。进而在此基础上通过两种表面活性剂在乳液界面发生微相分离在中空球表面形成通孔,同时引入磁性纳米粒子并在中空球内腔接枝温敏性聚合物,得到热敏性的聚合物-无机物复合功能Janus笼[22]。但是,在之前的研究中也发现,Janus笼的表面孔径很难调控,孔径也只能限制在50 nm以下,如果想要通过增加致孔表面活性剂的量得到更大孔径的笼,不仅孔径变化不大,而且还会导致壳层局部呈不连续结构,在表面形成二氧化硅小颗粒,进而破坏球形结构,无法得到完整的中空球。

基于这些考虑,在此提出了新的研究思路,先用烷基和末端带卤素基团的硅烷偶联剂代替带活性双键的硅烷偶联剂,壳层依旧引入磁性纳米颗粒,先制备出支撑性良好、孔径大范围可调的无机Janus笼,进而利用可控自由基聚合代替自由基聚合,在更温和的反应条件下在内腔接枝pH响应性聚合物,得到支撑性好、孔径大范围可调的功能有机/无机功能复合Janus笼,并验证了其可以在改变环境pH的条件下实现对油相的可控吸收和释放,以及在磁操控下实现装载物的定向传输,有望用于药物装载和体内靶向释放等领域。

1. 实验材料及方法

1.1 原材料

无水三氯化铁(FeCl3,分析纯)、油酸钠(分析纯)、油酸(分析纯)、吐温80(Tween 80,化学纯)、十二烷基硫酸钠(SDS,化学纯)、铜粉(分析纯)和52#石蜡(熔点50~52℃)购自国药集团化学试剂有限公司;3-氨丙基三乙氧基硅烷(APTES,98%)、香豆素-6 (98%)、荧光素5-异硫氰酸酯(FITC,95%)、三乙胺(99%)、正辛基三乙氧基硅烷(98%)和2-溴-2-甲基丙酰溴(98%)购自北京百灵威科技有限公司;正硅酸乙酯(分析纯)、甲醇(分析纯)、正癸烷(分析纯)和甲苯(分析纯)购自西陇科学股份有限公司;1, 1-双十八烷基-3, 3, 3, 3-四甲基吲哚羰花青高氯酸盐(dil-C18,98%)和甲基丙烯酸二乙氨基乙酯(DEAEMA,>98.5%)购自西格玛奥德里奇(上海)贸易有限公司(Sigma-Aldrich);三[2-(二甲氨基)乙基]胺(Me6TREN,97%)购自梯希爱(上海)化成工业发展有限公司(TCI);预水解的苯乙烯马来酸酐共聚物水溶液(HSMA,10wt%)为自制。

1.2 实验方法

1.2.1 样品制备

(1) 磁性无机Janus笼的制备。取0.3 g合成的油溶性磁性Fe3O4颗粒[25]、1.1 g APTES、0.88 g正辛基三乙氧基硅烷和5.2 g正硅酸乙酯加入到25 g正癸烷中混合均匀作为油相;将15 mL 10wt%的HSMA的水溶液加入75 mL水中,用2 mol/L HCl调pH为3~4。然后再加入0.03 g Tween 80,混合均匀,作为水相。混合水油两相,用高速剪切机(Fluko FA25,德国Fluko)在12000 r/min的速度下剪切乳化3 min。将剪切所得乳液转移至三口瓶中,70℃反应12 h,得到磁性无机Janus笼。

(2) 末端Br基硅烷偶联剂的合成。将4.31 g APTES和2.55 g三乙胺(TEA)加入到20 mL甲苯中,通氮气30 min。再将5.95 g溴代异丁酰溴(BiBB)溶解于10 mL甲苯中,加入到恒压漏斗中。在冰浴条件下,缓慢的将溴代异丁酰溴甲苯溶液缓慢滴加到体系中,磁力搅拌过夜后,离心除去下层白色沉淀后,旋蒸除去甲苯,即得到末端为溴基的硅烷偶联剂。

(3) pH响应性磁性复合Janus笼的制备。将10 mg 铜粉和50 mg上述步骤(1)合成的磁性无机Janus笼分散到36 mL水中,通氮气30 min。将0.2 g DEAEMA和30 μL配体Me6TREN分散到18 mL甲醇中,通氮气30 min后和水相混合,在50℃水浴中反应12 h。磁分离,用乙醇洗涤3次,真空干燥,得到内表面接枝有PDEAEMA的磁性聚合物/无机磁性复合Janus笼。

1.2.2 复合Janus笼pH响应性吸释实验

(1) 复合Janus笼对油相的pH响应性吸释和磁分离。在0.2 g甲苯中加入少量油溶性荧光染料dil-C18染色,在样品瓶中将10 mg磁性复合Janus笼分散在5 g水中,再加入染色甲苯,调节pH至5,此时水油两相明显分层,再调节pH至9,振荡吸附,甲苯层消失,用磁铁吸附,吸附有甲苯的复合Janus笼即在磁铁一侧的瓶壁处富集,将pH调回5,振荡静置后用磁铁吸附,甲苯层重新出现;同样在0.2 g甲苯中加入少量油溶性荧光染料dil-C18染色,在样品瓶中将10 mg磁性复合Janus笼分散在5 g水中,再加入染色甲苯,调节pH至5,此时水油两相明显分层,保持pH值不变,振荡后用磁铁吸附,甲苯无法被复合Janus笼吸附。

(2) 复合Janus笼在荧光显微镜下的pH响应性吸释:将50 mg磁性复合Janus笼分散在10 g水中,加入水溶性荧光燃料FITC进行染色标记。将0.5 g加入少量香豆素-6荧光染料染色的甲苯加入到溶解有10 mg表面活性剂SDS的10 g水中,超声乳化得到水包油乳液。将FITC标记的复合Janus笼水分散液加入到乳液中,调节pH至9左右,避光搅拌,分别在磁分离复合Janus笼前后在荧光显微镜(Olympus IX83,日本Olympus)下观察;再调节pH至5左右,避光搅拌,同样分别在磁分离复合Janus笼前后在荧光显微镜下观察。

2. 结果与讨论

2.1 磁性无机Janus笼的制备、孔径调节与表征

在之前制备复合Janus笼时,课题组是将硅烷前驱体和聚合物单体同时溶解在油相中,一步得到有机/无机复合Janus多孔球[22]。但是多孔球的孔径只能在50 nm左右且难以调节,对应的致孔表面活性剂Tween 80在水相的浓度在0.22wt%以下,当Tween 80浓度继续升高时,会使多孔球外表面生成SiO2小颗粒,进而破坏球形结构。

本文用正辛基三乙氧基硅烷代替含活性双键的硅烷偶联剂作为球壳内侧接枝亲油基团的硅前驱体,同时将制备的油溶性Fe3O4纳米颗粒分散在油相中,得到外侧为氨基,内侧为烷基的磁性无机Janus笼。样品分别在扫描电子显微镜(SEM,带有元素分析 EDX的Quanta FEG 250,美国 FEI)和透射电子显微镜(TEM,JEM-1011,日本 JEOL)下进行观察,如图1所示。Janus笼的直径约为1~3 μm,孔径约为200~400 nm (图1(a)、图1(b)),同时不同于内侧接枝活性双键的无机Janus笼,即使没有聚合物的支撑,内侧为正辛基硅烷修饰的Janus笼也不会塌缩。进而对无机Janus笼进行超声粉碎,可以得到表面具有孔道的磁性Janus片(图1(c))。对得到的Janus片进行包埋切片,在TEM下观察,如图1(d)所示,可以看到磁性纳米粒子镶嵌在壳层中。

调节致孔表面活性剂Tween 80的加入量,即可对Janus笼球壳表面的通孔孔径进行调节。如图2所示,Tween 80在水相的浓度分别为0.01wt% (图2(a))、0.02wt% (图2(b))、0.04wt% (图2(c))和0.08wt% (图2(d))时,其表面孔径可从40 nm左右增加到约1 μm。

![]() 图 1 内侧修饰正辛基的磁性无机Janus笼的SEM图像 (a) 和TEM图像 (b);由磁性无机Janus笼破碎得到的Janus多孔片的SEM图像 (c) 和甲基丙烯酸甲酯(MMA)包埋切片后的TEM图像 (d)Figure 1. SEM image (a) and TEM image (b) of magnetic organic Janus cage with octyl group grafted onto interior surface; SEM image (c) of Janus porous nanosheets crushed from magnetic inorganic Janus cage and cross section TEM image (d) of slice of magnetic inorganic Janus cage after embedding in methyl methacrylate (MMA) and section

图 1 内侧修饰正辛基的磁性无机Janus笼的SEM图像 (a) 和TEM图像 (b);由磁性无机Janus笼破碎得到的Janus多孔片的SEM图像 (c) 和甲基丙烯酸甲酯(MMA)包埋切片后的TEM图像 (d)Figure 1. SEM image (a) and TEM image (b) of magnetic organic Janus cage with octyl group grafted onto interior surface; SEM image (c) of Janus porous nanosheets crushed from magnetic inorganic Janus cage and cross section TEM image (d) of slice of magnetic inorganic Janus cage after embedding in methyl methacrylate (MMA) and section在之前的工作中,即使Tween 80的含量提高近10倍,孔径的大小变化也不明显[22],相比之下,本文孔径对Tween 80的量变化更敏感。这是由于在之前工作中,由于无机/有机壳层是一锅法制备,因而在油相中加入了大量的聚合物单体,其和Tween 80相容性比烷烃溶剂要差,使Tween 80在界面的微相分区面积较小,即使浓度增加,对分区面积影响也不大,因而难以对孔径进行大范围调节,继续增加Tween 80的浓度只能破坏壳层。而本文先构建无机壳层,油相中只添加了硅前驱体,同时用烷基硅烷偶联剂代替带有活性双键的硅前驱体,使油相和Tween 80非极性部分的基团极性相近,使Tween 80微区可以在界面更加铺展,因而能够通过改变Tween 80的量来实现孔径的大范围调节。为了进一步验证,在不改变其他条件,仅仅不添加聚合物单体的情况下重复之前的制备过程,如图3所示,腔内不一步接枝聚合物时,制备的无机笼的孔径明显变大且孔径对Tween 80的含量更加敏感,但是失去聚合物的支撑,无机笼壳层本身支撑性差,呈塌缩状态。

![]() 图 3 (a) 水相中Tween 80添加量为0.22wt%制备的无机/有机复合Janus笼的SEM图像;(b) 水相中Tween 80添加量为0.04wt%制备的无机笼的SEM图像Figure 3. (a) SEM image of the polymer/inorganic composite Janus cages synthesized at 0.22wt% of Tween 80 in aqueous phase; (b) SEM image of inorganic Janus cages synthesized at 0.04wt% of Tween 80 without addition of monomer in aqueous phase

图 3 (a) 水相中Tween 80添加量为0.22wt%制备的无机/有机复合Janus笼的SEM图像;(b) 水相中Tween 80添加量为0.04wt%制备的无机笼的SEM图像Figure 3. (a) SEM image of the polymer/inorganic composite Janus cages synthesized at 0.22wt% of Tween 80 in aqueous phase; (b) SEM image of inorganic Janus cages synthesized at 0.04wt% of Tween 80 without addition of monomer in aqueous phase2.2 磁性pH响应性聚合物/无机复合Janus笼的制备

研究发现,用带烷基的硅前驱体替代带活性双键的硅前驱体能够得到支撑性良好的无机笼,但是单纯的烷基链修饰内侧使得无机笼没有活性位点去接枝功能性的聚合物,限制了Janus笼的应用。考虑到自由基聚合难以控制,本工作基于“铜媒介”可控自由基聚合法(CuCRP)代替自由基聚合,在笼内侧接枝了pH响应性聚合物[26]。

为了在无机Janus笼内表面接枝聚合物,先要在内侧修饰上卤素基团。通过氨丙基三乙氧基硅烷和溴代异丁酰溴在等物质的量的条件下进行反应,制备出末端为溴基的硅烷偶联剂。对产物进行核磁共振(1H NMR,Bruker Avance III 400 HD,德国 Bruker)表征,各个H原子峰已在图4(a)中标注,其中,化学位移在6.96×10−6的峰对应着酰胺上与N相连的H,且积分结果为1 ,证明末端为溴基的硅烷偶联剂成功合成。再以摩尔比1∶1的比例将合成的末端Br基硅烷偶联剂和正辛基三乙氧基硅烷一起加入油相作为亲油一侧的修饰基团,得到内表面接枝Br基的Janus笼。如图4(b)所示,对Janus笼进行EDX元素分析,证明Br的成功引入。

![]() 图 4 (a) 合成的末端带Br基的硅烷偶联剂的核磁共振图谱;(b) 内表面接枝Br基的磁性无机Janus笼的SEM图像及内嵌EDX图谱(方框为元素分析所选区域)Figure 4. (a) 1H NMR spectrum of synthesized silane end with Br group; (b) SEM image and inset EDX spectrum of magnetic inorganic Janus cage with Br group grafted onto the interior surface (Box is the selected area for element analysis)

图 4 (a) 合成的末端带Br基的硅烷偶联剂的核磁共振图谱;(b) 内表面接枝Br基的磁性无机Janus笼的SEM图像及内嵌EDX图谱(方框为元素分析所选区域)Figure 4. (a) 1H NMR spectrum of synthesized silane end with Br group; (b) SEM image and inset EDX spectrum of magnetic inorganic Janus cage with Br group grafted onto the interior surface (Box is the selected area for element analysis)成功在壳层内侧引入溴基以后,采用“铜媒介”可控自由基聚合法(CuCRP)制备pH响应性Janus笼[26],将磁性无机Janus笼分散在水相,pH响应性单体DEAEMA和配体分散在甲醇中,混溶后加入铜粉作为催化剂,壳层内侧的溴基引发聚合,接枝上pH响应性聚合物PDEAEMA,即得到pH响应的磁性聚合物/无机复合Janus笼。其反应体系温和简单,在水和甲醇混溶体系就可以聚合油溶性单体,更加清洁无污染,反应体系耐氧性高。在扫描电镜下观察,其形貌未有明显变化(图5(a))。将接枝功能聚合物的复合Janus笼用预聚物甲基丙烯酸甲酯(MMA)包埋,再进行切片并在TEM下观察,如图5(b)所示,发现Janus笼壳层内出现衬度较低的一层,说明PDEAEMA仅接枝在Janus笼的内表面(为了便于观察,包埋切片的Janus笼未复合磁性纳米颗粒)。将复合Janus笼超声破碎得到复合多孔片,发现内侧接枝聚合物之后变得粗糙(图5(c)),用HF刻蚀除去无机层,得到聚合物笼(图5(d))。

对复合Janus笼分别进行红外图谱(FTIR,Bruker EQUINOX 55,德国 Bruker)和热失重(TGA, Perkin-Elmer Pyris 1, 美 国 Perkin-Elmer)分析。其红外图谱如图6(a)所示,接枝聚合物后的Janus笼(曲线2)对比于无机磁性Janus笼(曲线1),在1725 cm−1出现新的特征峰,对应着聚合物PDEAEMA的酯基峰。此外,1050~1150 cm−1对应着二氧化硅Si—O—Si的非对称伸缩振动峰,1633 cm−1对应的为氨基的特征峰,595 cm−1对应着的Fe—O特征峰。通过TGA分析可测得复合Janus笼中聚合物的含量(图6(b))。图中曲线1为无机磁性Janus笼的热失重曲线,其残余63.1wt%,失重的原因主要为有机基团热解和硅前驱体进一步缩合造成。而曲线2为接枝聚合物后的复合Janus笼的曲线,其热解后残余36.8wt%,因而计算出复合Janus笼中聚合物质量含量为41.7wt%。

![]() 图 5 (a) 内表面接枝聚甲基丙烯酸二乙氨基乙酯(PDEAEMA)的磁性无机/有机复合Janus笼的SEM图像;(b) 未复合磁性纳米颗粒的内表面接枝PDEAEMA无机/有机复合Janus笼切片的TEM图像;(c) 复合Janus笼破碎后的多孔片的SEM图像;(d) 用HF酸刻蚀除去无机壳层后的有机笼的SEM图像Figure 5. (a) SEM image of magnetic composite Janus cage with polydiethylaminoethyl methacrylate (PDEAEMA) grafted onto interior surface; (b) Cross-section TEM image of composite Janus cage with PDEAEMA grafted onto interior surface (without Fe3O4 nanoparticles); (c) SEM image of Janus porous nanosheets crushed from composite Janus cage; (d) SEM image of organic cage obtained by etching inorganic shell with HF

图 5 (a) 内表面接枝聚甲基丙烯酸二乙氨基乙酯(PDEAEMA)的磁性无机/有机复合Janus笼的SEM图像;(b) 未复合磁性纳米颗粒的内表面接枝PDEAEMA无机/有机复合Janus笼切片的TEM图像;(c) 复合Janus笼破碎后的多孔片的SEM图像;(d) 用HF酸刻蚀除去无机壳层后的有机笼的SEM图像Figure 5. (a) SEM image of magnetic composite Janus cage with polydiethylaminoethyl methacrylate (PDEAEMA) grafted onto interior surface; (b) Cross-section TEM image of composite Janus cage with PDEAEMA grafted onto interior surface (without Fe3O4 nanoparticles); (c) SEM image of Janus porous nanosheets crushed from composite Janus cage; (d) SEM image of organic cage obtained by etching inorganic shell with HF![]() 图 6 (a) 磁性无机Janus笼(曲线1)和磁性有机/无机复合Janus笼(曲线2)的FTIR图谱;(b) 磁性无机Janus笼(曲线1)和磁性有机/无机复合Janus笼(曲线2)的在空气中的热失重曲线Figure 6. (a) FTIR spectra of magnetic inorganic Janus cage ( curve 1) and magnetic composite Janus cage (curve 2); (b) Thermogravimetric analysis (TGA) curves in air of magnetic inorganic Janus cage (curve 1) and magnetic composite Janus cage (curve 2)

图 6 (a) 磁性无机Janus笼(曲线1)和磁性有机/无机复合Janus笼(曲线2)的FTIR图谱;(b) 磁性无机Janus笼(曲线1)和磁性有机/无机复合Janus笼(曲线2)的在空气中的热失重曲线Figure 6. (a) FTIR spectra of magnetic inorganic Janus cage ( curve 1) and magnetic composite Janus cage (curve 2); (b) Thermogravimetric analysis (TGA) curves in air of magnetic inorganic Janus cage (curve 1) and magnetic composite Janus cage (curve 2)2.3 磁性pH响应性聚合物/无机复合Janus笼用于油水分离、传输和响应性吸释

PDEAEMA为pH响应性聚合物,pKa约为7.2,当环境pH值大于其pKa时,PDEAEMA表现为疏水,反之则为亲水。Janus笼接枝pH响应性聚合物后,可以通过调节pH值来改变Janus笼内部的亲疏水环境,实现磁操控的pH响应性油水分离,进而可用于药物在体内的靶向释放等。

首先对复合Janus笼进行磁操控pH响应性吸释和磁分离实验,如图7所示。先将油溶性荧光染料dil-C18加入到少量甲苯中以便后续观察,将甲苯加入到分散有复合Janus笼的水中并调节水相pH值为5,两者不互溶形成界限分明的两相(图7(a))。再将水相pH值调至9,振荡吸附,甲苯和水相分层消失,体系呈浑浊的均相,再用磁铁进行磁分离,发现不再出现两相分层,而是甲苯都随着复合Janus笼被吸附在瓶壁上(图7(b))。将pH调回5,振荡后静置,再用磁铁进行磁分离,发现油水分相重新出现,当环境变为酸性时,油相重新被Janus笼释放出来(图7(c))。作为对照,保持水相pH值为5不变,重复上述实验,发现油相无法在酸性条件下被复合笼吸入(图7(d)、图7(e))。由此,复合Janus笼可对环境中的油进行pH响应性的吸释并可在磁操控下定向运输。

![]() 图 7 内表面接枝PDEAEMA的磁性复合Janus笼对油相的pH响应性及磁操控分离实验:(a) 分散有复合Janus笼的水(下层)和甲苯(上层)分相照片,甲苯中加入1, 1-双十八烷基-3, 3, 3, 3-四甲基吲哚羰花青高氯酸盐 (dil-C18)染料以便于观察,水相pH值为5;(b) 调节pH至9,振荡后磁分离吸收甲苯的复合Janus笼的照片;(c) 调节pH至5,振荡静置后磁铁吸附复合Janus笼的照片;(d) 分散有复合Janus笼的水(下层)和经dil-C18染色的甲苯(上层)分相照片,水相pH值为5;(e) 保持pH为5不变,振荡静置后磁铁吸附复合Janus笼的照片Figure 7. pH-responsive absorption and release of the oil and magnetic manipulation of magnetic composite Janus cage with PDEAEMA grafted onto interior surface: (a) Immiscible mixture of toluene (top)/aqueous dispersion of composite Janus cage (bottom), oil soluble dye 1, 1'-dioctadecyl-3, 3, 3', 3'-tetramethylindodicarbocyanine perchlorate (dil-C18) is added in toluene and the pH value of aqueous dispersion is 5; (b) pH value is modulated to 9 and oil contained magnetic Janus cages are collected by magnets after vibration; (c) pH value is modulated back to 5 and magnetic Janus cages are collected by magnets after vibration with the release of dyed oil; (d) Immiscible mixture of toluene (top)/aqueous dispersion of composite Janus cage (bottom), oil soluble dye dil-C18 is added in toluene and the pH value of aqueous dispersion is 5; (e) pH value remains to be 5 and magnetic Janus cages are collected by magnets after vibration while dyed oil remains unchanged

图 7 内表面接枝PDEAEMA的磁性复合Janus笼对油相的pH响应性及磁操控分离实验:(a) 分散有复合Janus笼的水(下层)和甲苯(上层)分相照片,甲苯中加入1, 1-双十八烷基-3, 3, 3, 3-四甲基吲哚羰花青高氯酸盐 (dil-C18)染料以便于观察,水相pH值为5;(b) 调节pH至9,振荡后磁分离吸收甲苯的复合Janus笼的照片;(c) 调节pH至5,振荡静置后磁铁吸附复合Janus笼的照片;(d) 分散有复合Janus笼的水(下层)和经dil-C18染色的甲苯(上层)分相照片,水相pH值为5;(e) 保持pH为5不变,振荡静置后磁铁吸附复合Janus笼的照片Figure 7. pH-responsive absorption and release of the oil and magnetic manipulation of magnetic composite Janus cage with PDEAEMA grafted onto interior surface: (a) Immiscible mixture of toluene (top)/aqueous dispersion of composite Janus cage (bottom), oil soluble dye 1, 1'-dioctadecyl-3, 3, 3', 3'-tetramethylindodicarbocyanine perchlorate (dil-C18) is added in toluene and the pH value of aqueous dispersion is 5; (b) pH value is modulated to 9 and oil contained magnetic Janus cages are collected by magnets after vibration; (c) pH value is modulated back to 5 and magnetic Janus cages are collected by magnets after vibration with the release of dyed oil; (d) Immiscible mixture of toluene (top)/aqueous dispersion of composite Janus cage (bottom), oil soluble dye dil-C18 is added in toluene and the pH value of aqueous dispersion is 5; (e) pH value remains to be 5 and magnetic Janus cages are collected by magnets after vibration while dyed oil remains unchanged进而在荧光显微镜下观察复合Janus笼对油相pH响应性的吸释过程,如图8所示。将甲苯加入香豆素-6荧光染料标记后再用十二烷基硫酸钠(SDS)为乳化剂和水乳化得到水包油乳液,乳液液滴在荧光显微镜下呈现蓝色。将pH响应性复合Janus笼先用FITC进行荧光标记,染料可吸附在Janus笼壳层便于后续观察。再将标记后的Janus笼加入上述荧光标记的水和甲苯的乳液中,分散均匀,调节pH为9左右,避光搅拌后再置于荧光显微镜下观察,发现蓝色的甲苯液滴(圆圈内)被吸入到Janus笼腔体内(图8(a)),磁分离Janus笼后取水相置于荧光显微镜下观察,蓝色液滴消失(图8(b)),证明在pH=9的条件下,Janus笼将甲苯完全吸入腔内;把pH调至5,壳层内聚合物由疏水转变为亲水,甲苯被挤出,此时在荧光显微镜下仅仅看到Janus笼呈现绿色的光圈,腔内蓝色液滴消失(图8(c)),磁分离后对水相取样观察,出现蓝色液滴(球形),证明甲苯被Janus笼响应性释放(图8(d)),说明复合Janus笼可通过改变环境pH值可以实现可控的油水分离。

![]() 图 8 pH=9时复合Janus笼吸附荧光染色甲苯的荧光显微镜图像(a)和用磁铁分离吸附甲苯的Janus笼后,上层水样的荧光显微镜图像(b); pH=5时Janus笼释放出甲苯后的荧光显微镜图像(c)和磁铁分离Janus笼后上层水样的荧光显微镜图像(d)Figure 8. Fluorescence microscopy images of the Janus composite cage after absorption of toluene with pH of the circumstance of 9 (a) and the supernatant water after magnetic collection of the Janus cage (b); Fluorescence microscopy images of the Janus composite cage after release of toluene with pH of the circumstance of 5 (c) and the supernatant water after magnetic collection of the Janus cage (d)

图 8 pH=9时复合Janus笼吸附荧光染色甲苯的荧光显微镜图像(a)和用磁铁分离吸附甲苯的Janus笼后,上层水样的荧光显微镜图像(b); pH=5时Janus笼释放出甲苯后的荧光显微镜图像(c)和磁铁分离Janus笼后上层水样的荧光显微镜图像(d)Figure 8. Fluorescence microscopy images of the Janus composite cage after absorption of toluene with pH of the circumstance of 9 (a) and the supernatant water after magnetic collection of the Janus cage (b); Fluorescence microscopy images of the Janus composite cage after release of toluene with pH of the circumstance of 5 (c) and the supernatant water after magnetic collection of the Janus cage (d)3. 结 论

(1) 通过乳液界面溶胶凝胶和两种表面活性剂在界面微相分离先制备磁性无机Janus笼,内部修饰的烷基基团使无机笼壳层具有良好支撑性,同时可通过调节吐温80 (Tween 80)含量实现孔径在40 nm~1 μm可调,进一步利用同样修饰在内表面的卤素基团,通过“Cu媒介”的活性自由基聚合法在温和的反应条件下成功在内表面接枝pH响应性聚合物得到功能无机/有机复合Janus笼。

(2) 将复合Janus笼用于油水分离,证明了其可通过调控环境pH来实现对油相的响应性吸收和释放。这种pH敏感性的微容器且表面带有增强传质的孔道,有望用于药物的装载和体内靶向释放等领域。

-

图 7 不同钢管厚度钢管重组竹应力-应变曲线对比

Figure 7. Comparisons of stress-strain curves of bamboo scrimber filled steel tube with different steel tube thickness

fc—Peak stress of bamboo scrimber filled steel tube specimen; fc0—Ultimate stress of the bamboo scrimber; εc0—Ultimate strain of the bamboo scrimber; εc—Peak strain of bamboo scrimber filled steel tube specimen

表 1 钢管约束重组竹柱轴压试验结果

Table 1 Axial compression test result of bamboo scrimber filled steel tube

Specimen H/mm Db/mm Ds/mm Pcu/kN fce/MPa εce fcy/MPa εcy fcc/MPa εcc Ebs/GPa D1S4.5-F 345 103 114 1628.8 92.56 0.0019 — — 159.58 0.064 44.5 D1S6.0-F 345 100 114 1994.2 113.32 0.0021 — — 195.37 0.063 52.3 D2S4.5-F 400 122 133 1882.3 78.58 0.0019 — — 135.49 0.063 42.1 D2S6.0-F 400 119 133 2292.6 95.71 0.0018 — — 165.02 0.065 43.8 D1S4.5-C 345 103 114 1412.0 — — 142.78 0.033 169.46 0.086 15.8 D1S6.0-C 345 100 114 1413.2 — — 162.90 0.047 179.94 0.087 16.2 D2S4.5-C 400 122 133 1630.3 — — 122.86 0.033 139.46 0.075 16.7 D2S6.0-C 400 119 133 1674.3 — — 131.55 0.031 150.54 0.075 15.2 Notes: Specimens were numbered according to the different parameters of the specimens; D—Diameter of specimen; S—Thickness of the steel tube; F—Full section loading; C—Core loading; H—Height of all specimens; Db—Diameter of bamboo scrimber; Ds—Outer diameter of steel tube; Pcu—Peak load; fce—Proportional limit stress; εce—Proportional limit strain; fcy—Yield stress; εcy—Yield strain; fcc—Peak stress; εcc—Peak strain; Ebs—Nominal initial compressive elastic modulus. 表 2 钢管力学性能指标

Table 2 Mechanical properties of steel tube

Ds/mm ts/mm fy/MPa fu/MPa Es/GPa 114 4.5 327.4 465.9 205.2 133 4.5 336.8 502.2 206.1 114 6.0 376.0 510.2 206.4 133 6.0 381.2 499.2 205.1 Notes: ts—Thickness of steel tube; fy—Yield strength of steel tube; fu—Ultimate tensile strength of steel tube; Es—Elastic modulus of steel tube. 表 3 重组竹试件力学性能指标

Table 3 Properties of bamboo scrimber

Specimen H/mm Db/mm Pbu/kN fby/MPa εby fbu/MPa εbu Eb/GPa D103 345 103 823.8 95.41 0.029 98.87 0.050 18.6 D100 345 100 767.0 94.24 0.029 97.66 0.050 15.6 D122 400 122 1121.9 92.61 0.028 95.97 0.052 15.0 D119 400 119 1053.4 91.40 0.026 94.71 0.048 14.8 Notes: Pbu—Ultimate load; fby—Yield stress of the bamboo scrimber; εby—Yield strain of the bamboo scrimber; fbu—Ultimate stress of the bamboo scrimber; εbu—Ultimate strain of the bamboo scrimber; Eb—Initial compressive elastic modulus. -

[1] HARELIMANA V, ZHU J, YUAN J, et al. Investigating the bamboo as alternative partial replacement of steel bars in concrete reinforcement members[J]. The Structural Design of Tall and Special Buildings,2022,6:31.

[2] 陈思, 魏洋, 赵鲲鹏, 等. 重组竹顺纹受压蠕变性能及预测模型[J]. 复合材料学报, 2021, 38(3):944-952. DOI: 10.13801/j.cnki.fhclxb.20200615.002 CHEN Si, WEI Yang, ZHAO Kunpeng, et al. Creep performance and prediction model of bamboo scrimber under compression[J]. Acta Materiae Compositae Sinica,2021,38(3):944-952(in Chinese). DOI: 10.13801/j.cnki.fhclxb.20200615.002

[3] CHEN S, WEI Y, ZHU J, et al. Experimental investigation of the shear performance of bamboo scrimber beams reinforced with bamboo pins[J]. Construction and Building Materials,2023,365:130044. DOI: 10.1016/j.conbuildmat.2022.130044

[4] YU Y, LIU R, HUANG Y, et al. Preparation, physical, mechanical, and interfacial morphological properties of engineered bamboo scrimber[J]. Construction and Building Materials,2017,157:1032-1039. DOI: 10.1016/j.conbuildmat.2017.09.185

[5] 盛叶, 黄庚浪, 叶小凡, 等. 重组竹抗拉力学性能分析[J]. 林业工程学报, 2023, 8(1):46-52. SHENG Ye, HUANG Genglang, YE Xiaofan, et al. Analysis on mechanical properties of bamboo scrimber under tension stress[J]. Journal of Forestry Engineering,2023,8(1):46-52(in Chinese).

[6] 杨娜, 张亚慧. 重组竹材料技术创新与面临的关键问题[J]. 世界竹藤通讯, 2021, 19(5):64-68. YANG Na, ZHANG Yahui. Technological innovation for bamboo scrimber and its key technical problems faced[J]. World Bamboo and Rattan,2021,19(5):64-68(in Chinese).

[7] LIU W, LIU M, HUANG J, et al. Constitutive relation models of bamboo scrimber under uniaxial loading along the fibre direction[J]. European Journal of Wood and Wood Products,2021,79:811-820. DOI: 10.1007/s00107-021-01680-8

[8] 朱彦, 卞玉玲, 周爱萍, 等. 重组竹高温下单轴受压性能试验研究[J]. 建筑结构学报, 2021, 42(9):127-134. DOI: 10.14006/j.jzjgxb.2019.0866 ZHU Yan, BIAN Yuling, ZHOU Aiping, et al. Experimental study on uniaxial compressive properties of parallel strand bamboo at high temperatures[J]. Journal of Building Structures,2021,42(9):127-134(in Chinese). DOI: 10.14006/j.jzjgxb.2019.0866

[9] WEI Y, JI X, DUAN M, et al. Flexural performance of bamboo scrimber beams strengthened with fiber-reinforced polymer[J]. Construction and Building Materials,2017,142:66-82. DOI: 10.1016/j.conbuildmat.2017.03.054

[10] ZHANG J, TONG K, WU P, et al. Research status on steel-bamboo composite structure[J]. MATEC Web of Conferences,2019,275:1018. DOI: 10.1051/matecconf/201927501018

[11] LI Y S, YAO J, LI R, et al. Thermal and energy performance of a steel-bamboo composite wall structure[J]. Energy and Buildings,2017,156:225-237. DOI: 10.1016/j.enbuild.2017.09.083

[12] ZHANG X, XU J, ZHANG X, et al. Life cycle carbon emission reduction potential of a new steel-bamboo composite frame structure for residential houses[J]. Journal of Building Engineering,2021,39(4):102295.

[13] SHI D, DEMARTINO C, LI Z, et al. Axial load-deformation behavior and fracture characteristics of bolted steel to laminated timber and glubam connections[J]. Composite Structures,2023,305:116486. DOI: 10.1016/j.compstruct.2022.116486

[14] HASSANIEH A, VALIPOUR H, BRADFORD M. Load-slip behaviour of steel-cross laminated timber (CLT) composite connections[J]. Journal of Constructional Steel Research,2016,122:110-121. DOI: 10.1016/j.jcsr.2016.03.008

[15] CRISTIANO L, FRANGI A. Experimental investigation on in-plane stiffness and strength of innovative steel-timber hybrid floor diaphragms[J]. Engineering Structures,2017,138:229-244. DOI: 10.1016/j.engstruct.2017.02.032

[16] SHAN Q, ZHANG J, TONG K, et al. Study on flexural behaviour of box section bamboo-steel composite beams[J]. Advances in Civil Engineering,2020,2020:8878776.

[17] 刘战江, 王占良, 吴时旭, 等. 装配式钢-竹组合结构建筑施工工艺及工程应用[J]. 建筑技术, 2023, 54(1):45-48. LIU Zhanjiang, WANG Zhanliang, WU Shixu, et al. Research on building construction technology and engineering application of prefabricated steel-bamboo composite structure[J]. Architecture Technology,2023,54(1):45-48(in Chinese).

[18] ZHANG J, ZHANG Z, TONG K, et al. Bond performance of adhesively bonding interface of steel-bamboo composite structure[J]. Journal of Renewable Materials,2020,8(6):687-702. DOI: 10.32604/jrm.2020.09513

[19] ZHAO W, LUO Z, LI Y. Axial compression testing of bamboo-laminated encased steel tube composite columns[J]. Iranian Journal of Science and Technology Transactions of Civil Engineering,2020,44(2):645-655. DOI: 10.1007/s40996-020-00381-1

[20] GAN D, ZHANG T, ZHOU X, et al. Experimental investigation on the bamboo-concrete filled circular steel tubular stub columns[C]//Proceedings of the 12th International Conference on Advances in Steel-Concrete Composite Structures. Spain: Universitat Politècnica de València, 2018: 385-391.

[21] 中国国家标准化管理委员会. 金属材料拉伸试验: 第一部分: 室温试验方法: GB/T 228.1—2010[S]. 北京: 中国标准出版社, 2010. Standardization Administration of the People's Republic of China. Tensile test of metallic materials: Part 1: Test method at room temperature: GB/T 228.1—2010[S]. Beijing: Standards Press of China, 2010(in Chinese).

[22] ASTM. Standard test methods for small clear specimens of timber: ASTM D143—09[S]. West Conshohocken: ASTM International, 2009.

[23] 柏佳文, 魏洋, 张依睿, 等. 新型碳纤维增强复合材料-钢复合管海水海砂混凝土圆柱轴压试验[J]. 复合材料学报, 2021, 38(9):3084-3093. BAI Jiawen, WEI Yang, ZHANG Yirui, et al. Axial compression behavior of new seawater and sea sand concrete filled circular carbon fiber reinforced polymer-steel composite tube columns[J]. Acta Materiae Compositae Sinica,2021,38(9):3084-3093(in Chinese).

[24] 郭莹, 许天祥, 刘界鹏. 圆CFRP-钢复合管约束高强混凝土短柱轴压试验研究[J]. 建筑结构学报, 2019, 40(5):124-131. GUO Ying, XU Tianxiang, LIU Jiepeng. Experimental study on axial behavior of circular CFRP-steel composite tubed high-strength concrete stub columnss[J]. Journal of Building Structures,2019,40(5):124-131(in Chinese).

[25] 魏洋, 纪雪微, 端茂军, 等. 重组竹轴向应力-应变关系模型[J]. 复合材料学报, 2018, 35(3): 572-579. WEI Yang, JI Xuewei, DUAN Maojun, et a. Model for axial stress strain relationship of bamboo scrimber[J]. Acta Materiac Compositae Sinica, 2018, 35(3): 572-579(in Chinese).

[26] WEI Y, BAI J, ZHANG Y, et al. Compressive performance of high-strength seawater and sea-sand concrete-filled circular FRP-steel composite tube columns[J]. Engineering Structures,2021,240:112357. DOI: 10.1016/j.engstruct.2021.112357

[27] CHANG G, MANDER J. Seismic energy based fatigue damage analysis of bridge columns: Part I—Evaluation of seismic capacity[M]. Buffalo: National Center for Earthquake Engineering Research, 1994: 2.

[28] 张依睿, 魏洋, 柏佳文, 等. 纤维增强聚合物复合材料-钢复合圆管约束混凝土轴压性能预测模型[J]. 复合材料学报, 2019, 36(10):2478-2485. ZHANG Yirui, WEI Yang, BAI Jiawen, et al. Models for predicting axial compression behavior of fiber reinforced polymer-steel composite circular tube confined concrete[J]. Acta Materiae Compositae Sinica,2019,36(10):2478-2485(in Chinese).

-

期刊类型引用(10)

1. 翟兆阳,李欣欣,张延超,刘忠明,杜春华,张华明. 连续光纤激光切割金属薄壁材料工艺研究. 红外与激光工程. 2024(02): 33-43 .  百度学术

百度学术

2. 陶洋,李存静,逄增媛,张典堂. 展宽布/网胎针刺C/C复合材料制备及力学性能. 复合材料学报. 2024(04): 1934-1944 .  本站查看

本站查看

3. 董志刚,王中旺,冉乙川,鲍岩,康仁科. 碳纤维增强陶瓷基复合材料超声振动辅助铣削加工技术的研究进展. 机械工程学报. 2024(09): 26-56 .  百度学术

百度学术

4. 席翔,李海龙,陈友元,裴景奇,廖城坤,薛琳,储洪强,冉千平. 碳纤维增强碳基复合材料的介电性能对应力的自感知. 高分子材料科学与工程. 2024(05): 115-124 .  百度学术

百度学术

5. 钱奇伟,张昕,杨贞军,沈镇,校金友. 基于CT图像深度学习的三维编织C/C复合材料微观组分与缺陷智能识别. 复合材料学报. 2024(07): 3536-3543 .  本站查看

本站查看

6. 翟兆阳,李欣欣,张延超,刘忠明,杜春华,张华明. 基于正交试验的金属薄壁材料激光切割工艺优化. 中国机械工程. 2024(07): 1279-1289 .  百度学术

百度学术

7. 何金玲. 纤维复材浆料流变性能分析及矿混匀质量应用研究. 粘接. 2024(09): 87-90 .  百度学术

百度学术

8. 姚先龙. 碳基复合材料的应用及相关制备方法. 信息记录材料. 2023(01): 36-38 .  百度学术

百度学术

9. 石磊,罗浩,罗瑞盈. 胶层厚度对C/C复合材料剪切粘接性能的影响. 炭素技术. 2023(04): 22-26 .  百度学术

百度学术

10. 刘科众,陈舟,王泽鹏,韩保恒. C/C复合材料增密过程孔隙结构及演化研究. 机械设计与制造工程. 2022(10): 33-36 .  百度学术

百度学术

其他类型引用(10)

-

目的

随着乡村振兴及碳中和、碳达峰国家战略的不断深入推进,竹结构逐渐成为实现绿色发展的重要组成部分。重组竹不仅具有较好的韧性,而且其抗压、抗拉强度均大于普通木材,有望在工程结构中广泛应用,然而研究表明其受压时胶合处脆弱,易产生劈裂破坏。如果能够很好的解决重组竹的劈裂破坏问题,则能更好的发挥重组竹承载性能。本文将重组竹与钢材组合形成钢-竹组合结构,且使得重组竹位于钢管的核心,形成新型钢管约束重组竹。可望克服重组竹承载时过早的劈裂破坏,同时提升钢结构在稳定性和屈曲性能方面的不足,发挥多种材料共同工作的优点。重组竹替代传统混凝土,一定程度上实现了未来社会对现代工程结构提出的绿色、可持续发展要求。为了更好地在工程实际中推广钢管重组竹组合柱,本文提出了这种新型结构在轴向荷载作用下的应力-应变曲线模型。

方法本文分析了钢管重组竹组合柱在不同加载模式下的轴压作用下的典型应力-应变关系曲线,研究了加载方式和钢管厚度等因素对钢管约束重组竹轴压性能的影响规律,分析了其破坏特征和受力性能,考虑了钢管套箍系数,提出了适用于圆形新型钢管约束重组竹的极限应力、极限应变和峰值应力、峰值应变的预测模型以及应力-应变全曲线模型,并利用24个试验数据对提出的模型进行了验证,结果表明提出的模型具有较好的精确性和适用性。

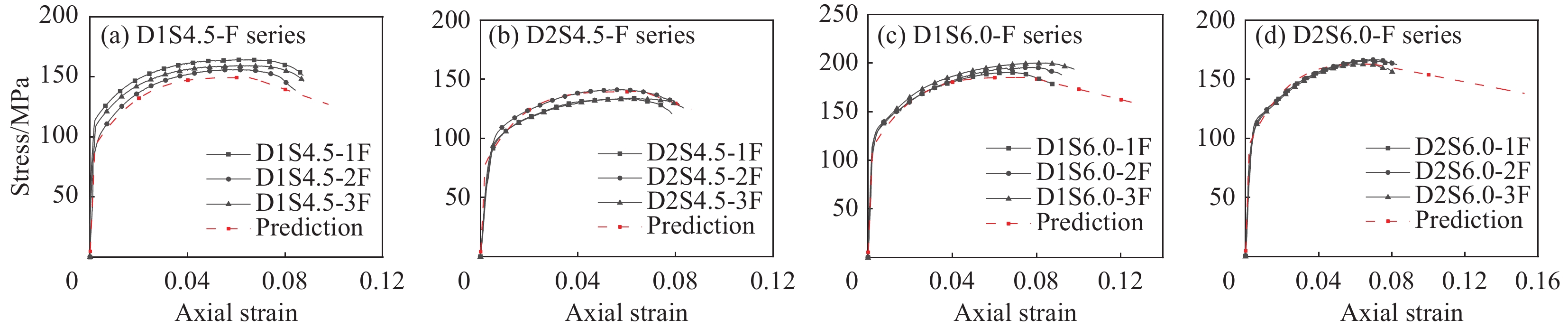

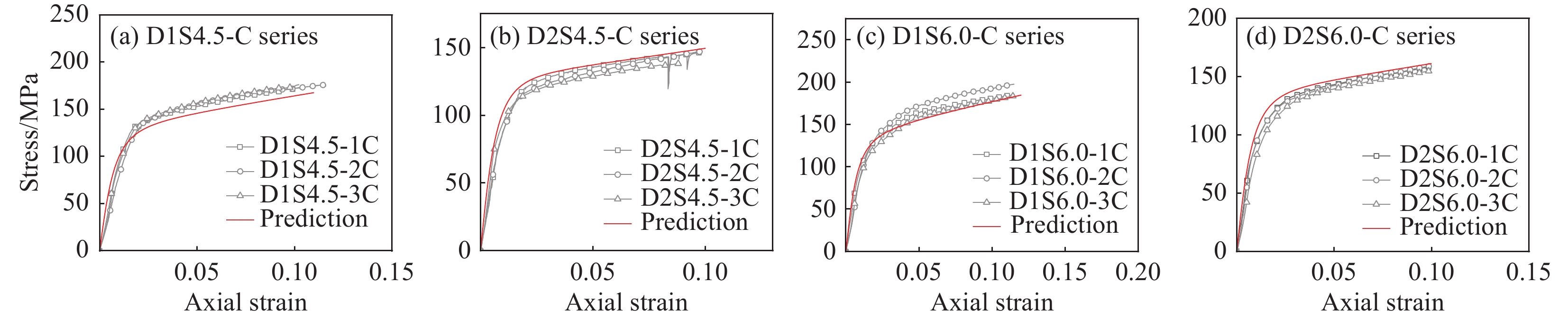

结果从对不同加载模式下钢管重组竹组合柱轴压性能、应力-应变模型验证结果的分析发现:①全截面受压钢管约束重组竹柱的应力应变关系曲线主要分为弹性阶段、弹塑性阶段、下降段;核心受压钢管约束重组竹柱的应力-应变关系曲线可分为弹性阶段和弹塑性阶段。②核心受压与全截面受压的钢管重组竹试件的峰值应力相差不大,峰值应变稍高于全截面受压的钢管重组竹试件,主要是因为核心受压中仅重组竹承受荷载,钢管能够提供更多侧向约束作用,限制重组竹的侧向膨胀,从而提高试件的抗压强度和变形能力。全截面受压试件中,钢管承受纵向压力而快速屈服,约束力不足,两者组合结构的变形较小。③对于不同试验参数的钢管重组竹组合柱,钢管厚度的增加对于试件应力-应变曲线的影响主要体现在弹塑性阶段,钢管厚度越大,弹性阶段较长,且弹塑性阶段斜率较大,试件的整体承载力明显增强,变形能力明显改善。④提出的极限应变、峰值应力和峰值应变计算模型模拟出的数据与试验数据也较为吻合;利用提出的应力-应变曲线模型计算得到的预测曲线与试验曲线较为吻合。

结论新型钢管重组竹组合柱为重组竹在工程实际中的直接利用提供了可能性,两者的组合不仅解决了重组竹劈裂破坏的问题,又有效提高了结构的承载能力和变形能力。本文提出的钢管重组竹组合柱的应力-应变曲线模型计算结果与试验结果较吻合,表明此模型适用于本文的结构。

-

重组竹不仅具有较好的韧性,而且其抗压、抗拉强度均大于普通木材,有望在工程结构中广泛应用,然而研究表明其受压时胶合处脆弱,易产生劈裂破坏。如果能够很好的解决重组竹的劈裂破坏问题,则能更好的发挥重组竹承载性能。将重组竹与钢材组合形成钢-竹组合结构,且使重组竹位于钢管的核心,可望克服重组竹承载时过早的劈裂破坏,同时提升钢结构在稳定性和屈曲性能方面的不足,发挥多种材料共同工作的优点。重组竹替代传统混凝土,一定程度上实现了未来社会对现代工程结构提出的绿色、可持续发展要求。

本文将重组竹与钢管复合形成新型钢管约束重组竹。对24个新型钢管约束重组竹圆柱试件进行了轴压试验,研究了钢管厚度和加载方式(全截面与核心加载)对其轴压性能的影响。试验结果表明,外加钢管能够有效地提高结构承载力和变形能力;钢管约束重组竹圆柱主要破坏形态为剪切破坏;结构的峰值应力、峰值应变均与钢管厚度呈正相关,随着钢管厚度增加,试件的峰值应力最大增长22.4%,峰值应变最大增长6.1%;核心受压钢管重组竹较全截面受压试件展现了更好的承载潜力和变形能力。根据全截面受压和核心受压的曲线不同,考虑了钢管套箍系数,分别提出了两种加载方式下钢管约束重组竹的极限应力、极限应变和峰值应力、峰值应变的预测模型,应力计算模型误差均在10%以内。最后建议了应力-应变全曲线模型,预测了不同加载方式下新型钢管约束重组竹的应力-应变变化规律。

钢管约束重组竹组合柱 (a)结构截面图;(b) 全截面加载全曲线模型;(c) 核心加载全曲线模型

下载:

下载: