Research on microstructure and site preference of NiTi alloy coating on 316L by laser cladding

-

摘要: 60 NiTi (60wt%Ni-40wt%Ti)合金具有高硬度、高弹性模量及优异的耐磨和耐腐蚀性能,在许多领域有潜在的应用价值。本文对激光熔覆方法在316L不锈钢表面制备NiTi涂层的微观组织结构和物相组成进行了分析。结果表明:基材中主要成分Fe和Cr扩散到熔覆涂层中并显著地影响了镍钛涂层的组织结构和性能。熔覆涂层主要组成相为NiTi和Ni3Ti,提高Ni含量可抑制NiTi2析出。第一性原理计算结果显示,Fe和Cr元素易于固溶在B2结构的NiTi相中,并且都倾向于置换晶胞中的Ni原子。Ni3Ti晶胞结构中的Ni和Ti原子各有2个不同的晶位,Fe原子倾向于置换晶胞中Ni-1晶位的Ni原子,而Cr原子倾向于置换晶胞中Ni-2晶位的Ni原子。根据涂层的成分分析结合模拟可知,镍钛合金涂层中NiTi和Ni3Ti相的化学式分别为Ni5Ti8Fe2Cr和Ni9Ti4Fe2Cr。Abstract: 60 NiTi (60wt%Ni-40wt%Ti) alloy presents higher hardness, high elastic modulus, good abrasion performance and excellent corrosion resistance, making it suitable for various applications in different fields. This paper investigated the microstructure and phase composition of NiTi alloy coating on 316L stainless steel prepared by laser cladding. It shows that the main alloying elements Fe and Cr in the substrate are significantly doped into the cladding coating, which obviously affect the microstructure and properties of Ni-Ti coating. The main phases in the coating are NiTi and Ni3Ti phases. Increase the content of Ni can inhibit the precipitation of NiTi2. First-principles calculation based on density functional theory was used to study the phase preference and site preference occupations of the alloying elements Fe and Cr from substrate in NiTi and Ni3Ti phases. The microstructure and phase composition of the coatings were investigated as well. The results show that, NiTi and Ni3Ti are the major phases in the coating. Both Fe and Cr atoms prefer to substitute Ni atom in the NiTi (B2) crystal structure. However, in the Ni3Ti crystal structure, each Ni and Ti atom has two different crystal positions, Fe atom prefers to substitute position Ni-1 and Cr atom prefers to substitute position Ni-2 instead. Combined the experiment and calculation results, the major phases in the coatings after element doping are supposed to be Ni5Ti8Fe2Cr and Ni9Ti4Fe2Cr.

-

Keywords:

- laser cladding /

- NiTi alloy /

- first-principles calculation /

- alloy doping /

- site preference /

- surface modification

-

尽管镍钛记忆合金(55 NiTi)独特的形状记忆功能及超弹性得到广泛应用,但组织结构稳定性欠佳、硬度不高、刚性不足等因素限制了其在精密机械中承载构件的应用[1]。Ni含量为60wt%的镍钛合金(60 NiTi合金)类似于金属间化合物,具有高硬度和良好的韧性及突出的耐磨性、抗腐蚀性、无磁性和轻量化特性,在精密轴承和航空航天等领域被视为理想的材料而得到广泛关注[2-4]。NiTi合金直接加工零部件不仅成本高而且难以加工成型复杂结构[5-6]。近年来,激光选区熔化(Selective laser melting,SLM) 3D打印成型技术发展迅速,特别是利用激光熔覆技术进行表面改性,在金属基体材料表面制备合金涂层,涂层与基材界面可形成良好的冶金结合,大大提高了基材的表面性能。该技术因加工速度快、灵活性高、成本低等优势而得到广泛关注[7-9]。

研究表明,在镍钛合金涂层激光熔覆过程中,涂层中会熔入大量的基体合金元素,因此研究镍钛合金涂层中元素掺杂及其对涂层组织结构和性能的影响成为关注的问题之一[10-11]。有人利用基于密度泛函理论(Density functional theory,DFT)的第一性原理方法模拟计算了掺杂合金元素的相择优和点位择优[12-14]。如席蒙等[15]运用第一性原理研究了过渡族元素在NiTi (B2)相中的占位倾向,结果表明V、Cr、Mn、Fe、Co等掺杂元素倾向于占据Ni位。Yin等[16]对NiTiX (X = Cu、Fe)合金进行了研究,在B2结构的NiTi相中,Cu和Fe原子都倾向于占据晶体结构中Ni的位置,同时认为Fe原子对Ni原子的置换能够显著提高NiTi相的结构稳定性。由Ni-Ti二元合金相图[17]可知,室温下能够稳定存在的镍钛合金相除了NiTi相外,还有Ni3Ti、NiTi2两个相。目前大部分对于镍钛合金相中元素掺杂的研究都聚焦在B2结构的NiTi相,少有对于其他两相的研究。

本文通过在316L不锈钢表面制备不同组分的镍钛合金熔覆涂层,对其微观组织结构和相组成进行了分析,同时运用第一性原理研究了基材主要成分Fe和Cr元素在NiTi和Ni3Ti相中的分配和占位情况,并结合实验分析模拟了固溶Fe和Cr元素的镍钛合金相结构。

1. 试验材料与方法

1.1 样品的制备与表征

试验中采用的基底材料是尺寸为10 cm×10 cm×1 cm的316L不锈钢板,其化学成分如表1所示。用于激光熔覆的粉末为球形Ni单质粉末和等原子比的55 NiTi合金粉末,其化学成分见表2。按照镍钛元素质量比为3∶2配制55 NiTi+5 Ni的混合粉末用于60 NiTi合金涂层制备。另外,利用纯55 NiTi合金粉末制备55 NiTi涂层进行对比研究,理解镍含量对合金涂层组织结构的影响。

表 1 基体材料316L不锈钢的化学成分Table 1. Chemical composition of 316L stainless steel substrateElement Fe Cr Ni Mo Mn Si P C S Mass fraction/wt% Balance 16.320 10.120 2.040 0.920 0.340 0.026 0.016 0.015 表 2 Ni粉末和55 NiTi合金粉末的化学成分Table 2. Chemical composition of Ni and 55 NiTi powdersElement Ni Ti Fe Nb Co C Si O Mass fraction of

Ni powder/wt%Balance — 0.003 — 0.020 0.020 0.003 0.006 Mass fraction of 55 NiTi powder/wt% 56.460 Balance 0.005 0.010 0.005 0.005 — 0.037 图1是用来制备样品的激光熔覆设备及原理示意图。试验中使用美国IPG Photonics公司生产的YLS-10000型光纤激光器,制备过程参数见表3。激光器的运动由日本FANUC公司生产的 R-30 iA六轴联动机械手臂来实现,熔覆过程中采用99.9%纯度的氩气作为保护气体和送粉气体。为防止基板因热应力导致开裂,316L基板在熔覆前预热至200℃。

对制备好的激光熔覆涂层试件,沿着垂直于激光扫描方向线切割金相试样,用于物相分析和微观结构观察。样品经镶嵌、打磨和抛光后,用体积配比为HF∶HNO3∶H2O = 1∶4∶5的溶剂进行表面腐蚀,采用OLYMPUS GX51显微镜观察涂层形貌。利用配备OXFORD Ultim Extreme能谱仪的扫描电子显微镜(COXEM EM-30)对涂层的微观组织结构和元素分布进行表征分析,并使用德国Bruker D8型X射线衍射仪(Cu靶,Kα射线,电压为40 kV,电流为40 mA)对涂层进行物相分析。

表 3 激光熔覆工艺参数Table 3. Process parameters for laser claddingParameter Value Laser power/kW 2.0 Scan speed/(mm·s–1) 2.0 Laser beam spot diameter/mm 7.2 Working distance/mm 10 Overlap ratio/% 55 Powder feed rate/(r·min–1) 50 Carrier gas flow rate/(L·min–1) 8 Shielding gas flow rate/(L·min–1) 5 1.2 计算方法

采用基于密度泛函理论第一性原理的软件包VASP (Vienna ab-initio simulation package)研究基材中的Fe和Cr原子在NiTi和Ni3Ti结构中的占位情况。在计算离子与价电子间的相互作用时使用平面波赝势法(Projector augmented-wave,PAW)来描述,电子与电子之间的交换能和关联能的表述采用广义梯度近似(Generalized gradient approximation,GGA)下的Perdew-Burke-Ernzerhof (PBE)方程,截断能取500 eV。对布里渊区K点取样时采用Monkhorst-Pack法,其中对NiTi相采用8×8×8网格法,对Ni3Ti相采用11 × 11 × 6网格法。为保证计算结果的准确性和可靠性,对所涉及的晶体结构都进行了充分的结构优化,结构优化时能量收敛精度为10−5 eV,力的收敛精度为0.2 eV/nm。研究Fe和Cr原子在Ni3Ti晶体结构中的占位倾向时,首先对1个Fe原子和1个Cr原子取代晶胞中的1个Ni原子和1个Ti原子的形成能进行计算,计算公式为

EF=116(ET−xENi−yETi−EFe/Cr) (1) 其中:EF为单个Fe或者Cr原子置换后的结合能;ET为晶胞的总能量;ENi、ETi、EFe/Cr分别指Ni、Ti、Fe或Cr单个原子的能量;x和y指晶胞中Ni和Ti原子的数量。16是指Ni3Ti超胞中含有的原子总数量。需要指出的是,本文研究过程中未考虑周期性边界条件下的镜像力对计算结果的影响。

2. 试验结果与分析讨论

2.1 镍钛合金熔覆涂层物相构成及微观组织

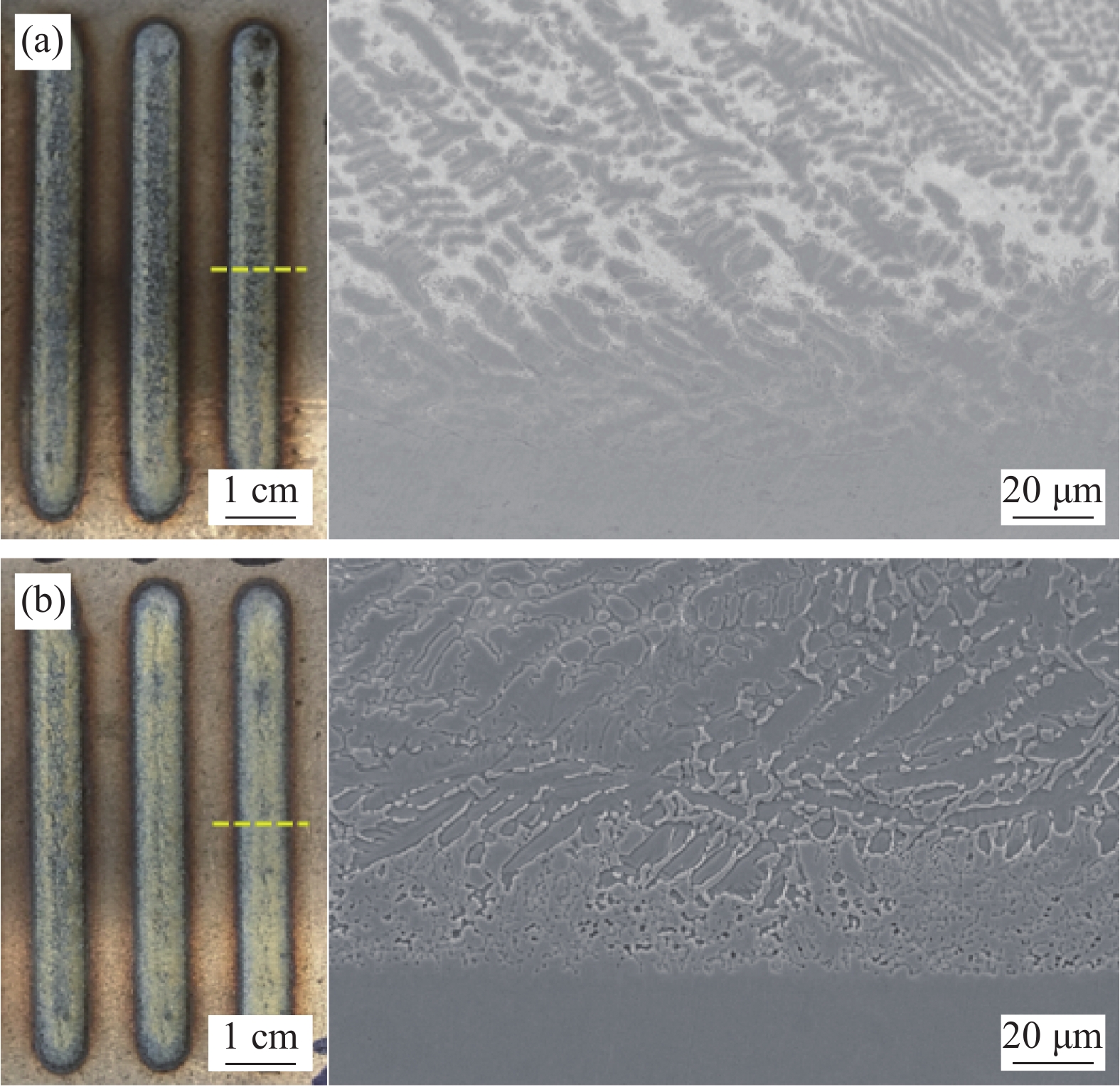

图2是激光熔覆制备的两种镍钛合金涂层样品的外观形貌和涂层截面的金相组织。显示出熔覆轨迹清晰且表面无裂纹,截面金相组织中未发现显著的气孔或夹杂物等结构缺陷。熔覆层与基材的界面熔合线连续可见,显示熔覆层与基材之间形成了良好的冶金结合。熔合区主要是大尺寸的平面晶,上层的涂层主要为树枝晶结构。

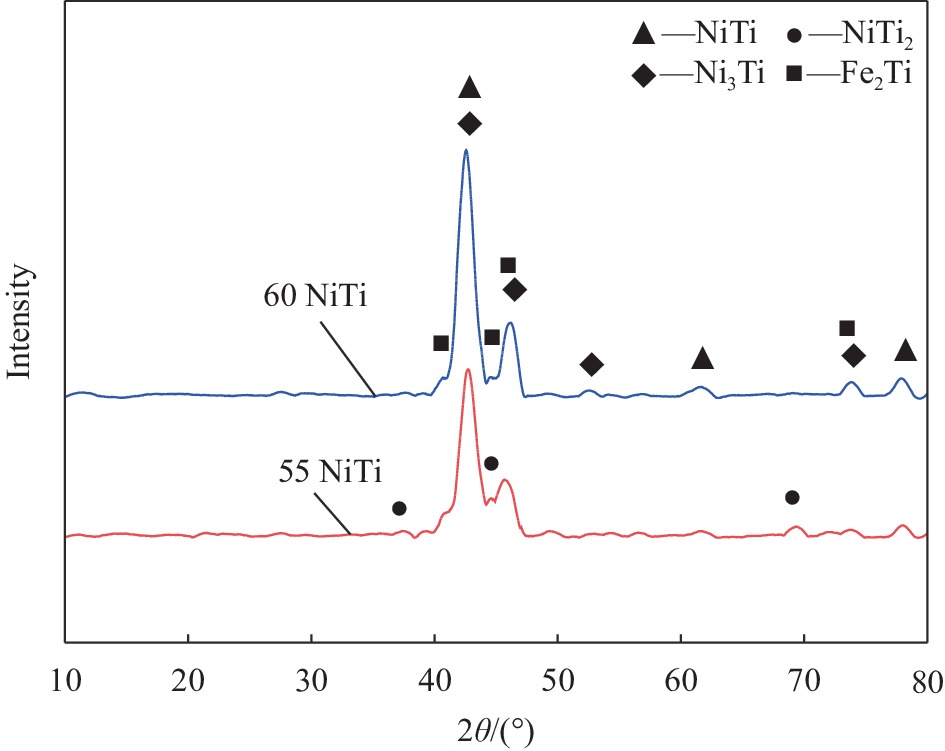

图3是两种熔覆涂层的XRD图谱,两种涂层中最强的特征峰衍射角度相近。对比PDF卡片可知,两种涂层主要由B2结构的NiTi相和密排六方结构的Ni3Ti相组成,此外涂层中都有少量Fe2Ti相。由Fe-Ti-Ni三元相图可知,当温度达到1000℃以上,Fe原子与涂层中的Ti原子结合,可形成Fe2Ti相,并且在快速冷却条件下能够在室温下稳定存在[18]。需要注意的是,XRD结果显示NiTi2相只存在于55 NiTi涂层中,在60 NiTi涂层中未发现其特征峰的存在。这是由于NiTi2相的形成需要富钛环境,在提高涂层中Ni含量后,涂层中绝大部分区域都是富镍环境,即使生成少量NiTi2相,也会与Ni进一步反应,最终以NiTi相或Ni3Ti相的形式存在,这表明提高Ni含量可抑制NiTi2析出。

图4是涂层中部区域的微观组织形貌。对该视场中不同形貌区域进行EDS点扫描,表4给出了这些特征点位EDS扫描分析结果。点1和点4镍钛原子比接近1,结合XRD分析结果可判断这两个位置是B2结构的NiTi相,具有树枝晶形貌。同时可以看出,NiTi相中含有一定量Fe元素和少量的Cr元素。树枝晶之间的片层状组织为典型的共晶组织,根据表4中点3和点6的EDS分析结果可判断共晶组织中浅色片层状组织为NiTi相;结合点2和点5的EDS分析结果可判断共晶组织中片状结构间的深色组织为Ni3Ti相。

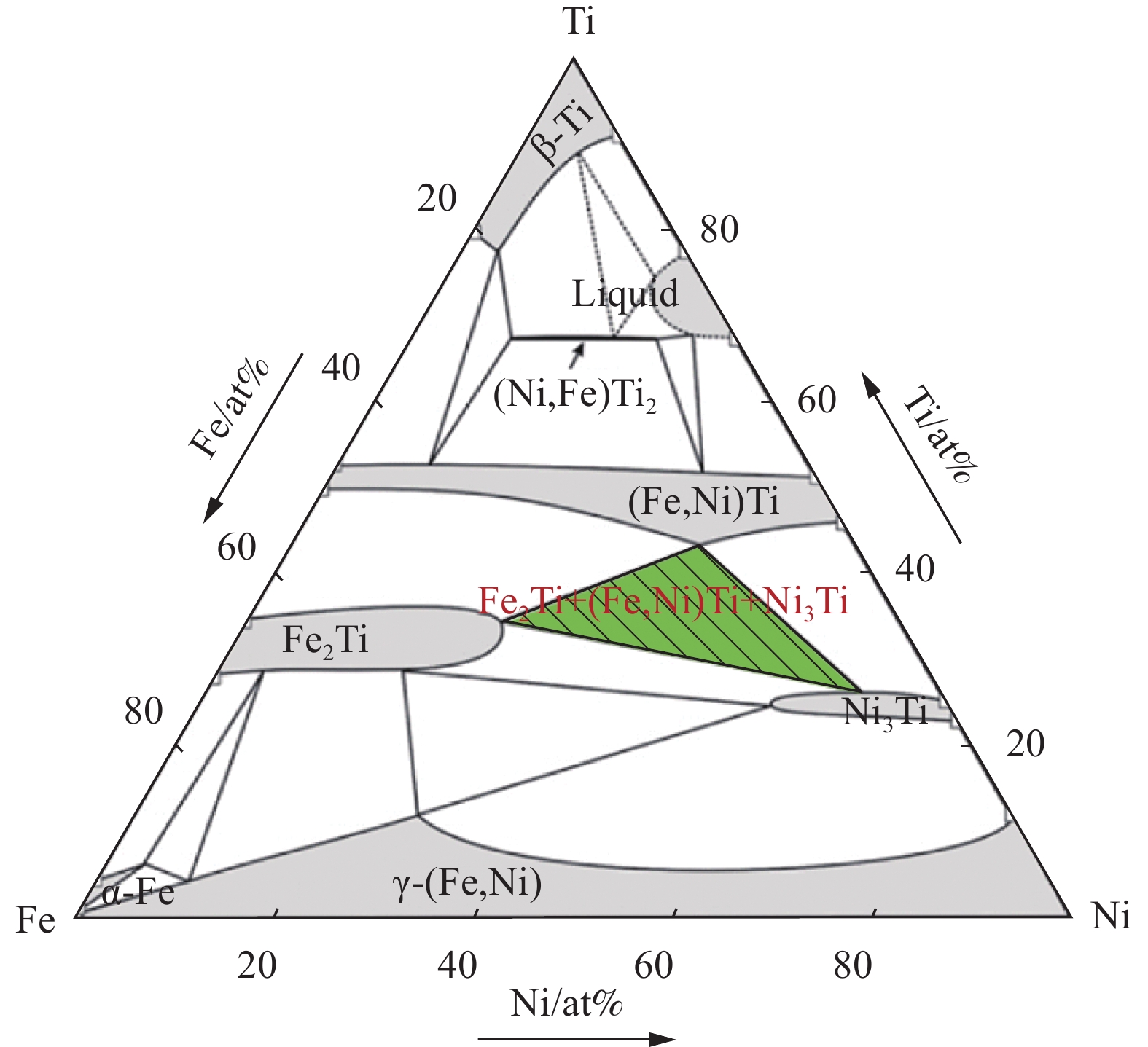

Coating Position Ni/at% Ti/at% Fe/at% Cr/at% Major phase 55 NiTi 1 35.34 41.28 15.63 7.75 NiTi 2 59.59 25.74 10.32 4.35 Ni3Ti 3 45.10 34.77 14.52 5.61 Ni3Ti + NiTi 60 NiTi 4 38.48 42.89 13.42 5.21 NiTi 5 61.63 23.27 9.26 5.84 Ni3Ti 6 50.08 30.34 16.33 3.25 Ni3Ti + NiTi 由表4给出的成分分析结果可以看出,基材中的Fe和Cr元素已经扩散到涂层中部,并固溶于涂层中NiTi相及Ni3Ti相结构中。鉴于Cr元素含量相对较低,先讨论Ni、Ti、Fe这3种元素的相对含量对涂层相组成的影响。由于激光熔覆过程中涂层会在极短的时间内冷却下来,在高温下形成的固溶体在涂层组织得以留存下来。参考铁镍钛三元合金系在1000℃时的等温截面相图[18],如图5所示,可以看出在镍钛含量近等原子比情况下,主要以(Ni, Fe)Ti相的形式存在,随着Ni含量的提高,Ni3Ti相析出,因此可以判断60 NiTi涂层中Ni3Ti相的含量高于55 NiTi涂层。另外,Fe元素在镍钛含量近等原子比条件下,会优先固溶到NiTi相中形成(Ni, Fe)Ti固溶体。图5中斜杠阴影三角形标出的区域是本文所制备的熔覆涂层成分范围,结合XRD分析可知,55 NiTi涂层位于斜杠阴影三角形偏上顶点的位置,而60 NiTi涂层占据相图中斜杠阴影三角形里偏右下顶点位置。

2.2 Fe和Cr原子在NiTi和Ni3Ti相中的固溶

表4显示55 NiTi和60 NiTi涂层中都含有Fe元素和Cr元素。根据Fe-Ni-Ti三元相图,Fe元素在镍钛合金中只有当其含量超过40wt%且在富钛的条件才会形成Fe2Ti相。EDS分析结果表明,Fe元素在镍钛合金涂层中含量较低(10wt%~20wt%之间),因此Fe元素在熔覆涂层中主要以固溶的形式存在于NiTi和Ni3Ti相中,在靠近基板的Fe富集区有可能形成少量Fe2Ti相。

图6是55 NiTi和60 NiTi涂层中NiTi和Ni3Ti相中Ni、Ti、Fe和Cr元素含量柱状图。可以看出,Fe元素在B2结构的NiTi相中的平均原子占比为14.5%,在密排六方结构的Ni3Ti相中的平均原子占比仅为9.8%。表明Fe元素在NiTi相中的固溶度要高于Ni3Ti相中的固溶度。而Cr元素在NiTi相和Ni3Ti相中的原子含量占比接近,说明Cr在两相中有着相近的固溶度。

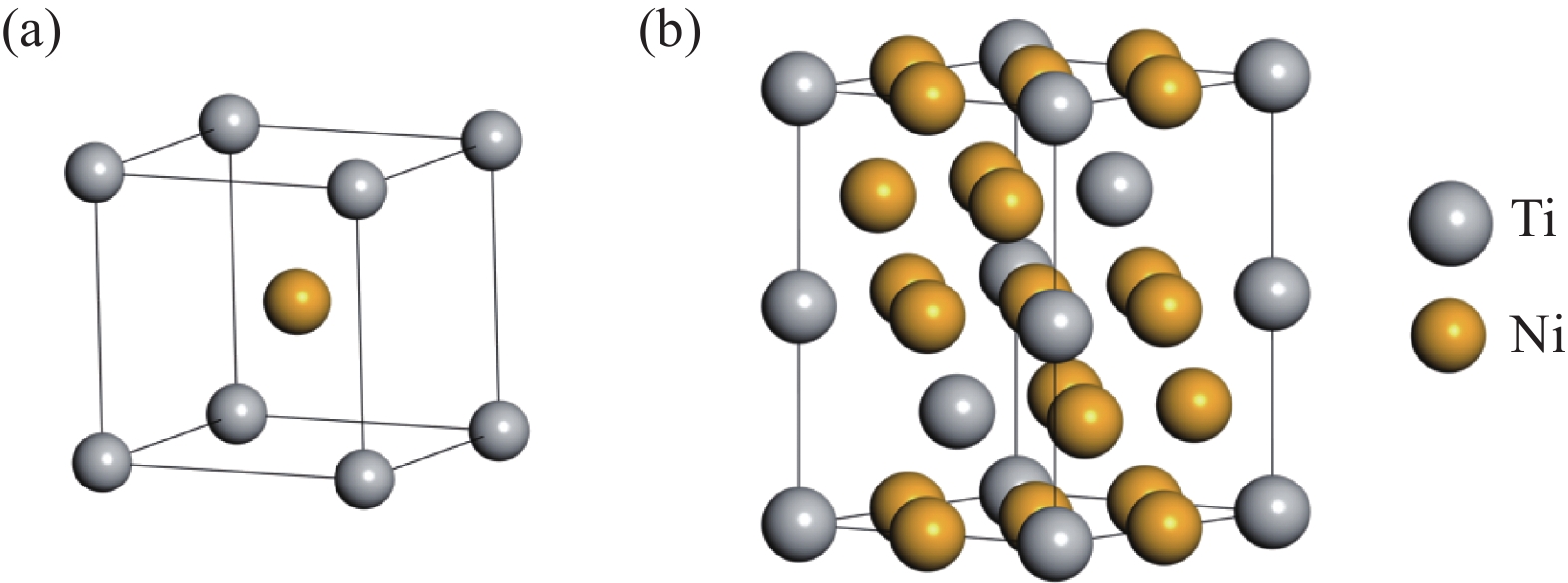

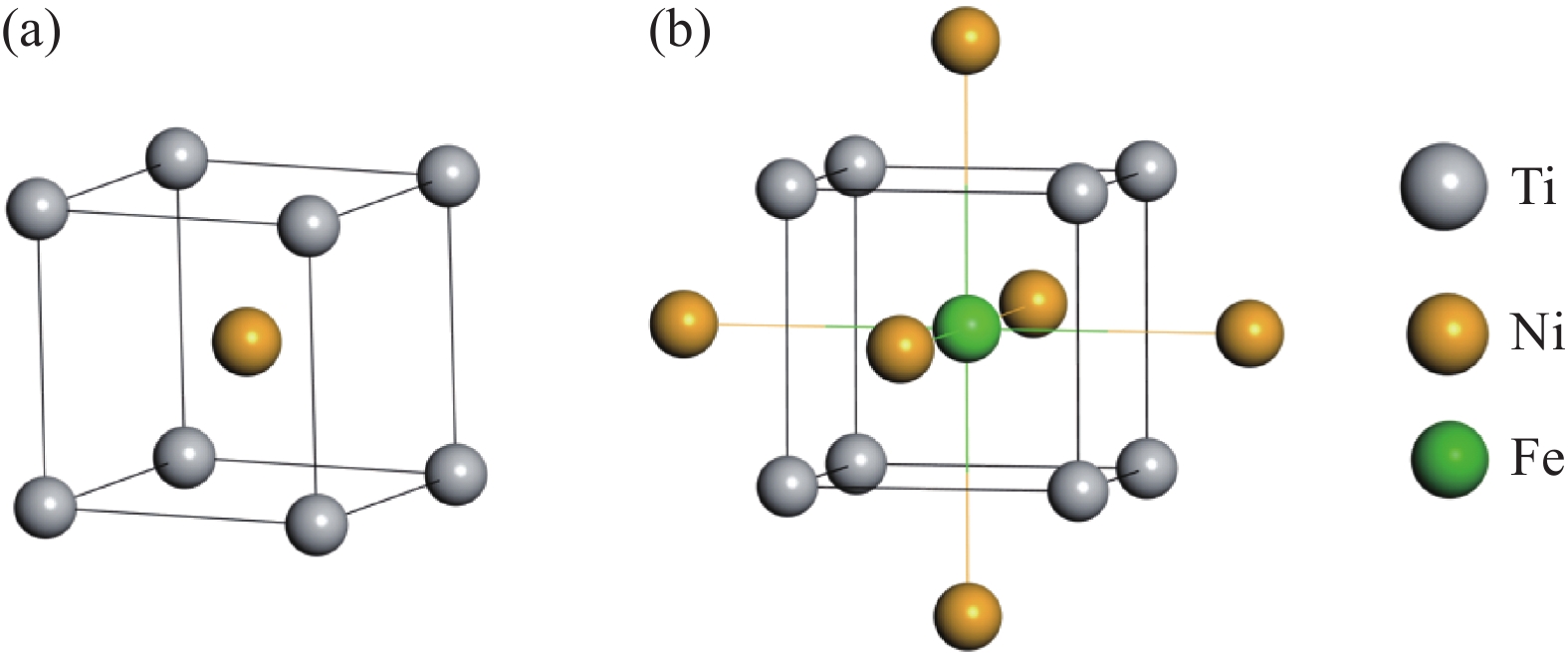

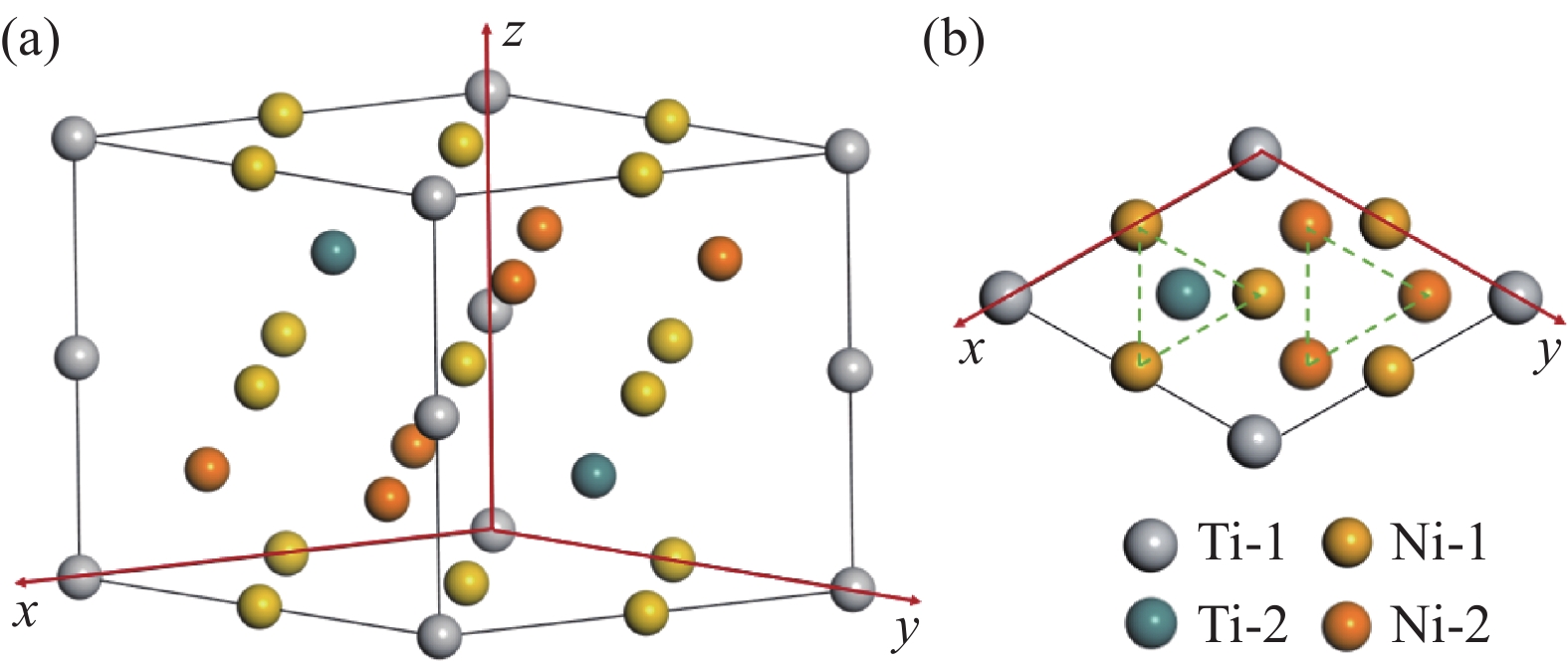

Fe和Cr原子在NiTi和Ni3Ti相中固溶度的差异和两相的不同晶体结构相关。表5列出了两相晶胞的晶格常数及晶胞中Ni原子和Ti原子的位置。根据各相的空间点阵及其对应原子位置,利用Materials Studio 8.0软件建立晶胞结构,以方便直观地研究元素占位情况。如图7(a)所示,室温下NiTi (B2)晶胞是CsCl型复杂立方结构,每个晶胞含有1个Ti原子和1个Ni原子。Ni3Ti晶胞是密排六方结构,每个晶胞包含4个Ti原子和12个Ni原子,其晶体结构如图7(b)所示。另外,表6中列出了Ni、Ti、Fe和Cr这4种元素的原子半径和电负性[19],根据表中数据可知,Fe或Cr原子固溶在NiTi (B2)和Ni3Ti相中都是以置换固溶的形式存在,由于溶质原子(Fe和Cr)与溶剂原子(Ni和Ti)有相近的原子半径和电负性。

表 5 NiTi相和Ni3Ti相的晶胞结构和原子位置Table 5. Crystal structure and atom position of the NiTi and Ni3Ti phaseCompound Lattice category Lattice parameter Atom Position NiTi SP No.221 a=b=c=0.3005 nm Ni 1a α=β=γ=90° Ti 1b Ni3Ti SP No.194 a=b=0.5096 nm Ni-1 6g c=0.8304 nm Ni-2 6h α=β=90° Ti-1 2a γ=120° Ti-2 2c 表 6 Ni、Ti、Fe和Cr的原子半径及其电负性Table 6. Atom radius and its electronegativity of Ni, Ti, Fe and Cr atomElement Atomic radius/nm Atomic electronegativity/eV Ni 0.125 1.91 Ti 0.145 1.54 Fe 0.124 1.83 Cr 0.125 1.66 2.3 Fe和Cr原子在NiTi (B2)相中的占位

现有文献对Fe和Cr原子在NiTi (B2)相中的占位研究表明[15],Fe和Cr原子都会优先占据晶胞中Ni原子的位置,图8是Fe原子置换了晶胞中的Ni原子后的晶体结构示意图。这首先是基于相近原子半径和电负性的原子优先置换的原则,这样置换后引起的晶格畸变相对较小,同时固溶体中Fe原子周围的Ti原子有返回它们原来位置的作用力,由此引起的原子弛豫使形成的(Ni, Fe)Ti固溶体能够稳定存在[20]。

除此之外,Bozzolo等[21]从置换后结合能变化的角度研究了Fe原子在NiTi (B2)中的占位情况,也得出了相同的结论。如表5所示,NiTi (B2)体心立方结构相对简单,Ni原子和Ti原子在晶胞中都只有一种晶位,其位置分别是1a和1b,每个Fe原子替换1个Ni原子会造成原晶胞结合能的变化为−1.2497 eV,而替换1个Ti原子则会带来+3.8254 eV的变化,结合能越低的晶体结构越稳定,因此Fe原子优先置换出晶胞中的Ni原子[21-22]。同时研究表明[21],NiTi (B2)结构中的Ni原子被Fe原子取代后还会造成反位缺陷,替换过程损失的能量会通过形成Ni3Ti相来平衡,因此Fe原子置换后形成(Ni, Fe)Ti相的同时,还会进一步提高Ni3Ti相在涂层中的比例。

2.4 Fe和Cr原子在Ni3Ti相中的占位

现有研究大部分聚焦于Fe和Cr原子在NiTi相中的占位情况,但是对Fe和Cr原子在Ni3Ti相中占位情况的研究相对较少。在NiTi (B2)体心立方结构中Ni和Ti原子都只有1个晶位,然而在Ni3Ti密排六方结构中的Ni原子和Ti原子各有2个不同的晶位,其在晶胞中的坐标位置如表7所示。图9是根据其原子坐标把不同晶位的Ni原子和Ti原子用不同颜色做了区分,不同的晶位对应着不同的杂阶,说明同一种原子在晶体结构中所处的化学环境不同,对应着不同的价电子结构。

表8中列出的是通过VASP软件计算出的Fe和Cr原子置换Ni3Ti晶胞中不同晶位的Ni和Ti原子后的晶格常数。从表中可以看出,当置换不同晶位的同一种原子时(如Fe原子取代Ni-1晶位和Ni-2晶位的Ni原子),其晶格常数变化不大,但是同种元素取代Ti原子后的晶格常数总是比其取代Ni原子后要小,这是Ti的原子半径(0.145 nm)比Ni的原子半径(0.125 nm)大导致的。

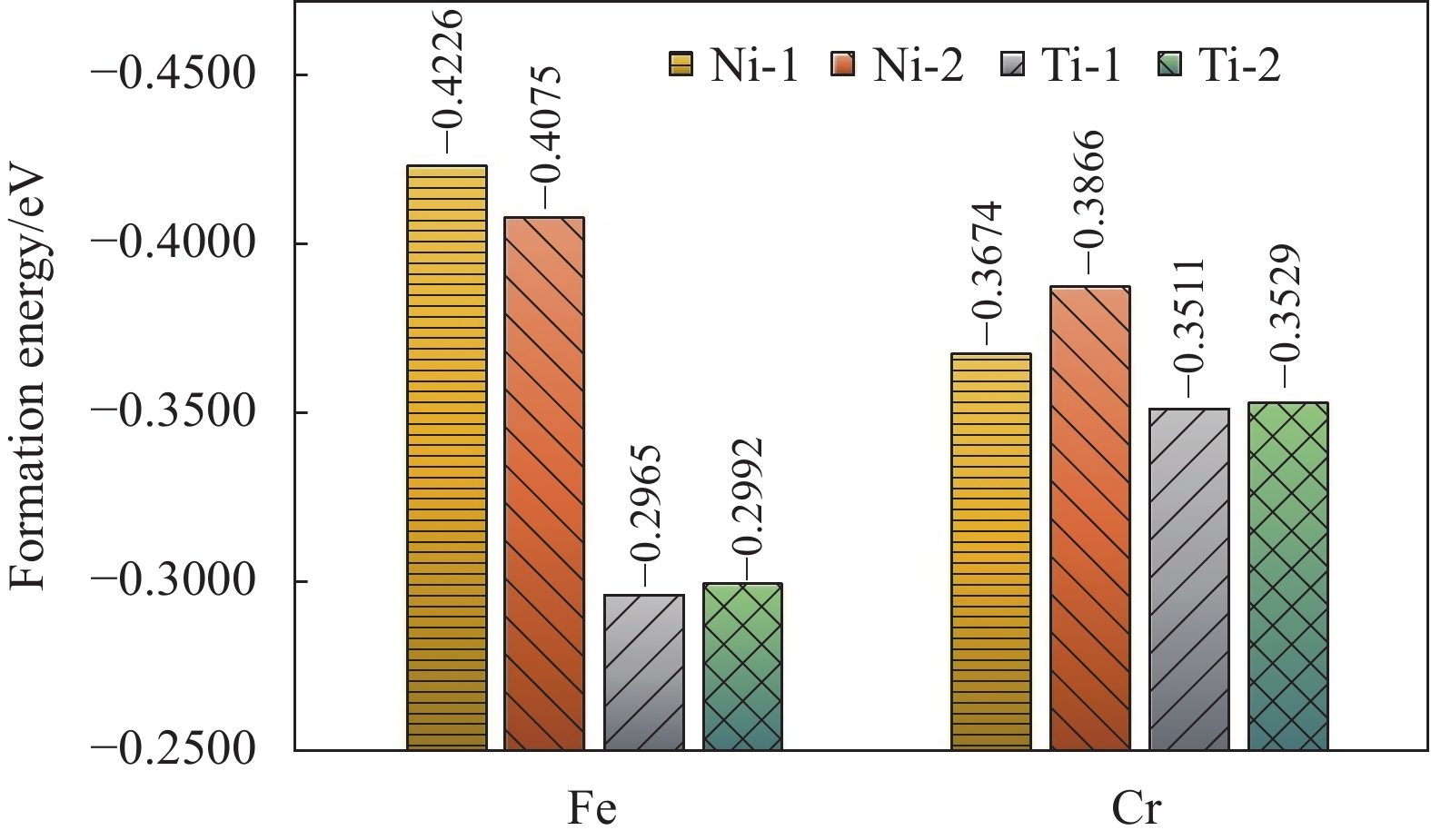

表 7 Ni3Ti相晶胞中原子坐标Table 7. Atom coordinates in Ni3Ti crystal structureCompound Atom x y z Ni3Ti Ni-1 0.5 0 0 Ni-2 0.8333 0.6667 0.25 Ti-1 0 0 0 Ti-2 0.3333 0.6667 0.25 表 8 Fe和Cr原子置换后Ni3Ti晶胞的晶格常数Table 8. Lattice parameters of Ni3Ti crystal after substitution of Fe and Cr atomAtom Replaced position Composition a/nm b/nm c/nm Fe Ni-1 Ni11Ti4Fe 0.5118 0.4418 0.8316 Ni-2 Ni11Ti4Fe 0.5116 0.4419 0.8317 Ti-1 Ni12Ti3Fe 0.5068 0.4388 0.8286 Ti-2 Ni12Ti3Fe 0.5060 0.4385 0.8281 Cr Ni-1 Ni11Ti4Cr 0.5122 0.4434 0.8357 Ni-2 Ni11Ti4Cr 0.5129 0.4443 0.8377 Ti-1 Ni12Ti3Cr 0.5088 0.4407 0.8293 Ti-2 Ni12Ti3Cr 0.5085 0.4404 0.8293 图10是根据式(1)通过VASP计算出的单个Fe原子或Cr原子占据Ni3Ti结构中不同晶位的Ni和Ti原子所对应的结合能。首先置换后的形成能都小于0,说明Fe原子和Cr原子置换Ni3Ti晶格中任意晶位的Ni原子或者Ti原子都可能形成稳定结构;其次同种元素取代Ni原子和Ti原子时的形成能不同,表明其置换后的结构稳定性存在差异。通常情况下形成能越负,说明置换后的结构稳定性越好[21]。取代不同原子的形成能相差越大,则表明替换原子的占位倾向性越明显。从图10中可以看出Fe原子和Cr原子在Ni3Ti中都倾向于置换Ni原子,区别在于Fe原子优先置换位于Ni-1晶位的Ni原子,而Cr原子优先置换位于Ni-2晶位的Ni原子。

2.5 Fe和Cr元素固溶对涂层相结构的影响

结合2.4节中计算得出的Fe和Cr原子在Ni3Ti晶体结构中的占位倾向和图6中列出的Fe和Cr在55 NiTi和60 NiTi涂层中的EDS扫描结果,可以计算出Fe原子及Cr原子分别在NiTi (B2)和Ni3Ti相中的固溶度,如表9所示。

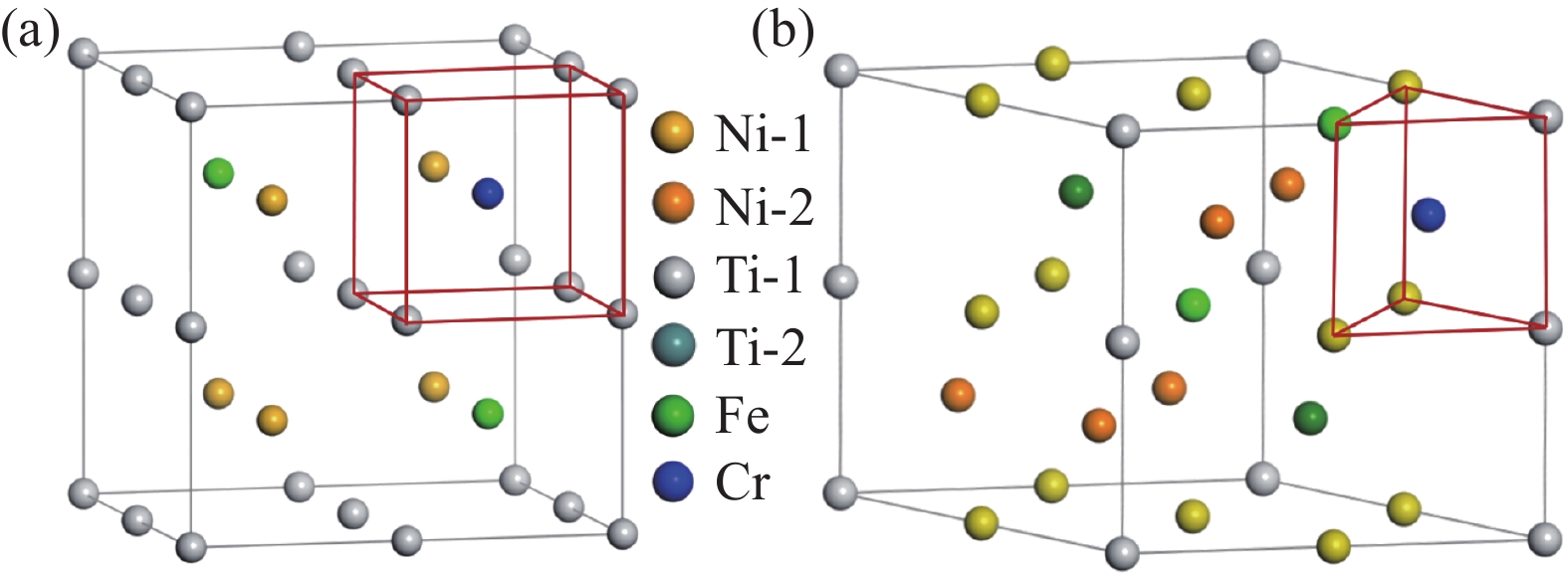

表 9 Fe和Cr原子在NiTi和Ni3Ti结构中的原子占比Table 9. Atomic proportion of Fe and Cr atom in NiTi and Ni3Ti crystal structure after substitutionPhase Composition after substitution Ni/at% Ti/at% Fe/at% Cr/at% NiTi (B2) Ni5Ti8Fe2Cr 31.25 50.00 12.50 6.25 Ni3Ti Ni9Ti4Fe2Cr 56.25 25.00 12.50 6.25 在B2结构的NiTi相晶胞中,2个Fe原子和1个Cr原子都替换了原晶胞中的Ni原子,固溶后的化学式为Ni5Ti8Fe2Cr。在Ni3Ti结构中,2个Fe原子替换Ni-1晶位的Ni原子,1个Cr原子替换Ni-2晶位的Ni原子,固溶后化学式为Ni9Ti4Fe2Cr。所有计算都是在相同的结构优化条件下进行的,收敛计算后得出的形成能和晶格常数列在表10中。计算得出固溶后NiTi晶胞和Ni3Ti晶胞的形成能分别为−0.3286 eV和−0.3050 eV,形成能均为负,从理论层面佐证了所制备的镍钛熔覆涂层有较稳定的结构。但是与单个原子固溶置换后的形成能相比,随着固溶原子数量的增加,其形成能也显著提高了,说明Fe和Cr固溶后原晶体结构的稳定性下降。此外,固溶后晶胞的晶格常数也变大了。图11是按照涂层中的固溶度构建的NiTi和Ni3Ti晶胞结构示意图。

表 10 Fe和Cr原子置换后的形成能及晶格常数Table 10. Formation energy and lattice parameters after substitution of Fe and Cr atomsCrystal Composition Formation

energy/eVa/nm b/nm c/nm NiTi (B2) Ni5Ti8Fe2Cr −0.3286 0.5962 0.5962 0.6007 Ni3Ti Ni9Ti4Fe2Cr −0.3050 0.5128 0.4432 0.8362 3. 结 论

在316L不锈钢表面通过激光熔覆的方式制备了不同组分的镍钛合金涂层,进行了涂层的微观组织观察和相分析,并通过第一性原理技术探讨了Fe和Cr原子在涂层中的固溶现象,结果表明:

(1) 涂层主要由NiTi相和Ni3Ti相构成,60 NiTi合金中没有发现NiTi2相,表明提高Ni含量可抑制NiTi2相析出;

(2) 由于B2结构的NiTi主要体现为金属键属性,原子间的键合力比密排六方结构的Ni3Ti晶胞弱,Fe和Cr元素倾向于固溶在NiTi相中,且都倾向于置换NiTi晶胞中的Ni原子形成固溶体;

(3) 在Ni3Ti晶胞中,Ni原子和Ti原子都有2个不同的晶位。模拟结果表明,Fe原子倾向于替换Ni3Ti晶胞中Ni-1晶位的Ni原子,而Cr原子倾向于替换Ni3Ti晶胞中Ni-2晶位的Ni原子;

(4) 结合涂层元素分析,模拟计算出了涂层中NiTi相和Ni3Ti两相的晶体结构常数,并得出经过Fe和Cr元素固溶置换后,这两相的化学式分别为Ni5Ti8Fe2Cr和Ni9Ti4Fe2Cr。

-

表 1 基体材料316L不锈钢的化学成分

Table 1 Chemical composition of 316L stainless steel substrate

Element Fe Cr Ni Mo Mn Si P C S Mass fraction/wt% Balance 16.320 10.120 2.040 0.920 0.340 0.026 0.016 0.015 表 2 Ni粉末和55 NiTi合金粉末的化学成分

Table 2 Chemical composition of Ni and 55 NiTi powders

Element Ni Ti Fe Nb Co C Si O Mass fraction of

Ni powder/wt%Balance — 0.003 — 0.020 0.020 0.003 0.006 Mass fraction of 55 NiTi powder/wt% 56.460 Balance 0.005 0.010 0.005 0.005 — 0.037 表 3 激光熔覆工艺参数

Table 3 Process parameters for laser cladding

Parameter Value Laser power/kW 2.0 Scan speed/(mm·s–1) 2.0 Laser beam spot diameter/mm 7.2 Working distance/mm 10 Overlap ratio/% 55 Powder feed rate/(r·min–1) 50 Carrier gas flow rate/(L·min–1) 8 Shielding gas flow rate/(L·min–1) 5 Coating Position Ni/at% Ti/at% Fe/at% Cr/at% Major phase 55 NiTi 1 35.34 41.28 15.63 7.75 NiTi 2 59.59 25.74 10.32 4.35 Ni3Ti 3 45.10 34.77 14.52 5.61 Ni3Ti + NiTi 60 NiTi 4 38.48 42.89 13.42 5.21 NiTi 5 61.63 23.27 9.26 5.84 Ni3Ti 6 50.08 30.34 16.33 3.25 Ni3Ti + NiTi 表 5 NiTi相和Ni3Ti相的晶胞结构和原子位置

Table 5 Crystal structure and atom position of the NiTi and Ni3Ti phase

Compound Lattice category Lattice parameter Atom Position NiTi SP No.221 a=b=c=0.3005 nm Ni 1a α=β=γ=90° Ti 1b Ni3Ti SP No.194 a=b=0.5096 nm Ni-1 6g c=0.8304 nm Ni-2 6h α=β=90° Ti-1 2a γ=120° Ti-2 2c 表 6 Ni、Ti、Fe和Cr的原子半径及其电负性

Table 6 Atom radius and its electronegativity of Ni, Ti, Fe and Cr atom

Element Atomic radius/nm Atomic electronegativity/eV Ni 0.125 1.91 Ti 0.145 1.54 Fe 0.124 1.83 Cr 0.125 1.66 表 7 Ni3Ti相晶胞中原子坐标

Table 7 Atom coordinates in Ni3Ti crystal structure

Compound Atom x y z Ni3Ti Ni-1 0.5 0 0 Ni-2 0.8333 0.6667 0.25 Ti-1 0 0 0 Ti-2 0.3333 0.6667 0.25 表 8 Fe和Cr原子置换后Ni3Ti晶胞的晶格常数

Table 8 Lattice parameters of Ni3Ti crystal after substitution of Fe and Cr atom

Atom Replaced position Composition a/nm b/nm c/nm Fe Ni-1 Ni11Ti4Fe 0.5118 0.4418 0.8316 Ni-2 Ni11Ti4Fe 0.5116 0.4419 0.8317 Ti-1 Ni12Ti3Fe 0.5068 0.4388 0.8286 Ti-2 Ni12Ti3Fe 0.5060 0.4385 0.8281 Cr Ni-1 Ni11Ti4Cr 0.5122 0.4434 0.8357 Ni-2 Ni11Ti4Cr 0.5129 0.4443 0.8377 Ti-1 Ni12Ti3Cr 0.5088 0.4407 0.8293 Ti-2 Ni12Ti3Cr 0.5085 0.4404 0.8293 表 9 Fe和Cr原子在NiTi和Ni3Ti结构中的原子占比

Table 9 Atomic proportion of Fe and Cr atom in NiTi and Ni3Ti crystal structure after substitution

Phase Composition after substitution Ni/at% Ti/at% Fe/at% Cr/at% NiTi (B2) Ni5Ti8Fe2Cr 31.25 50.00 12.50 6.25 Ni3Ti Ni9Ti4Fe2Cr 56.25 25.00 12.50 6.25 表 10 Fe和Cr原子置换后的形成能及晶格常数

Table 10 Formation energy and lattice parameters after substitution of Fe and Cr atoms

Crystal Composition Formation

energy/eVa/nm b/nm c/nm NiTi (B2) Ni5Ti8Fe2Cr −0.3286 0.5962 0.5962 0.6007 Ni3Ti Ni9Ti4Fe2Cr −0.3050 0.5128 0.4432 0.8362 -

[1] HASSAN M, MEHRPOUYA M, DAWOOD S. Review of the machining difficulties of nickel-titanium based shape memory alloys[J]. Advances in Mechanical and Manufacturing Engineering, 2014 , 564 : 533-537.

[2] VELMURUGAN C, SENTHILKUMAR V, DINESH S, et al. Review on phase transformation behavior of NiTi shape memory alloys[J]. Materials Today: Proceedings,2018,5(6):14597-14606. DOI: 10.1016/j.matpr.2018.03.051

[3] WANG X, KUSTOV S, VAN HUMBEECK J. A short review on the microstructure, transformation behavior and functional properties of NiTi shape memory alloys fabricated by selective laser melting[J]. Materials (Basel),2018,11(9):1683. DOI: 10.3390/ma11091683

[4] 王本力. 镍钛形状记忆合金的研究及其应用进展[J]. 新材料产业, 2021, 4(4):28-31. WANG Benli. Research and application progress of NiTi shape memory alloys[J]. Advanced Materials Industry,2021,4(4):28-31(in Chinese).

[5] 杨建楠, 黄彬, 谷小军, 等. 形状记忆合金力学行为与应用综述[J]. 固体力学学报, 2021, 42(4):345-375. YANG Jiannan, HUANG Bin, GU Xiaojun, et al. A review of shape memory alloys: Mechanical behaviour and application[J]. Chinese Journal of Solid Mechanics,2021,42(4):345-375(in Chinese).

[6] SABURI T, YOSHIDA M, NENNO S. Deformation behavior of shape memory TiNi alloy crystals[J]. Scripta Metallurgica,1984,18(4):363-366. DOI: 10.1016/0036-9748(84)90453-8

[7] ELAHINIA M, SHAYESTEH MOGHADDAM N, TAHERI ANDANI M, et al. Fabrication of NiTi through additive manufacturing: A review[J]. Progress in Materials Science,2016,83:630-663. DOI: 10.1016/j.pmatsci.2016.08.001

[8] 任虔弘, 陈超越, 卢战军, 等. 激光选区熔化制备镍钛合金的研究进展[J]. 材料研究与应用, 2021, 15(3):276-286. DOI: 10.3969/j.issn.1673-9981.2021.03.013 REN Qianhong, CHEN Chaoyue, LU Zhanjun, et al. Progress in the preparation of NiTi alloy by selective laser melting[J]. Materials Research and Application,2021,15(3):276-286(in Chinese). DOI: 10.3969/j.issn.1673-9981.2021.03.013

[9] 郭绍庆, 刘伟, 黄帅, 等. 金属激光增材制造技术发展研究[J]. 中国工程科学, 2020, 22(3):56-62. GUO Shaoqing, LIU Wei, HUANG Shuai, et al. Development of laser additive manufacturing technology for metals[J]. Strategic Study of Chinese Academy of Engi-neering,2020,22(3):56-62(in Chinese).

[10] FENG Y, DU Z, HU Z. Study on the effect of Ni addition on the microstructure and properties of NiTi alloy coating on AISI 316L prepared by laser cladding[J]. Materials,2021,14(16):4373. DOI: 10.3390/ma14164373

[11] DU Z, HU Z, FENG Y, et al. The effect of powder composition on the microstructure and corrosion resistance of laser cladding 60 NiTi alloy coatings on SS 316L[J]. Metals,2021,11(7):1104. DOI: 10.3390/met11071104

[12] 肖斌, 吴雨沁, 刘轶. 基于第一性原理计算的镍基单晶高温合金掺杂的机器学习研究[J]. 上海金属, 2020, 42(3):97-104, 110. XIAO Bin, WU Yuqin, LIU Yi. Machine learning on doping of nickel-base single crystal superalloy based on first-principles calculation[J]. Shanghai Metals,2020,42(3):97-104, 110(in Chinese).

[13] OHNO K, TSUCHIYA M, KUWAHARA R, et al. Study on Ni-Ti alloys around equiatomic composition by the first-principles phase field method [J]. Computational Materials Science, 2021, 191: 110284.

[14] 孙浚晞, 杜婉, 肖斌, 等. 镍基单晶高温合金多组元置换的第一性原理研究[J]. 上海金属, 2021, 43(6):92-102. SUN Junxi, DU Wan, XIAO Bin, et al. First-principles study of multiple component subsititution in nickel-based single crystal superalloy[J]. Shanghai Metals,2021,43(6):92-102(in Chinese).

[15] 席蒙, 尚家香. 过渡元素掺杂NiTi合金的第一性原理研究[J]. 稀有金属材料与工程, 2016, 45(8):2041-2045. XI Meng, SHANG Jiaxiang. First principle study on NiTi alloyed with transition elements[J]. Rare Metal Materials and Engineering,2016,45(8):2041-2045(in Chinese).

[16] YIN J Y, LI G F, SI Y L, et al. Micromechanism of Cu and Fe alloying process on the martensitic phase transformation of NiTi-based alloys: First-principles calculation[J]. Jour-nal of Structural Chemistry,2016,56(6):1051-1057.

[17] OKAMOTO H, OKAMOTO H. Phase diagrams for binary alloys[M]. Ohio: ASM International Materials Park, 2000.

[18] DUARTE L I, KLOTZ U E, LEINENBACH C, et al. Experimental study of the Fe-Ni-Ti system[J]. Intermetallics,2010,18(3):374-384. DOI: 10.1016/j.intermet.2009.08.008

[19] 李梦龙. 化学数据速查手册[Z]. 北京: 化学工业出版社. 2003. LI Menglong. Concise handbook of chemical China[Z]. Beijing: Chemical Industry Press, 2003(in Chinese).

[20] 陈志伟, 敬云兵, 甘春雷, 等. Fe含量对等原子比NiTi形状记忆合金微观组织、相变行为和显微硬度的影响[J]. 材料研究与应用, 2021, 15(2):118-124. DOI: 10.3969/j.issn.1673-9981.2021.02.006 CHEN Zhiwei, JING Yunbing, GAN Chunlei, et al. Effect of Fe content on microstructure, phase transformation bevaviour and microhardness of the equiatomic NiTi shape memory alloy[J]. Materials Research and Application,2021,15(2):118-124(in Chinese). DOI: 10.3969/j.issn.1673-9981.2021.02.006

[21] BOZZOLO G, NOEBE R D, MOSCA H O. Site preference of ternary alloying additions to NiTi: Fe, Pt, Pd, Au, Al, Cu, Zr and Hf[J]. Journal of Alloys and Compounds,2005,389(1-2):80-94. DOI: 10.1016/j.jallcom.2004.07.051

[22] 张磊, 李世春. Ni-Ti系金属间化合物的电子结构与结合能计算[J]. 材料导报, 2011, 25(10):126-130. ZHANG Lei, LI Shichun. Calculations of valence electron structure and cohesive energy for intermetallic compounds in Ni-Ti alloys[J]. Materials Reports,2011,25(10):126-130(in Chinese).

-

期刊类型引用(1)

1. 齐广浩,王训伟,雷保珍,王青云,罗子洪,邱耀弘. 基于Moldex 3D与GA-BP的MIM微小齿轮工艺参数优化. 粉末冶金工业. 2024(05): 49-56 .  百度学术

百度学术

其他类型引用(0)

-

下载:

下载: