Uniaxial constitutive relation of ultra-high performance fiber reinforced concrete and the effect of steel fiber reinforcement on it

-

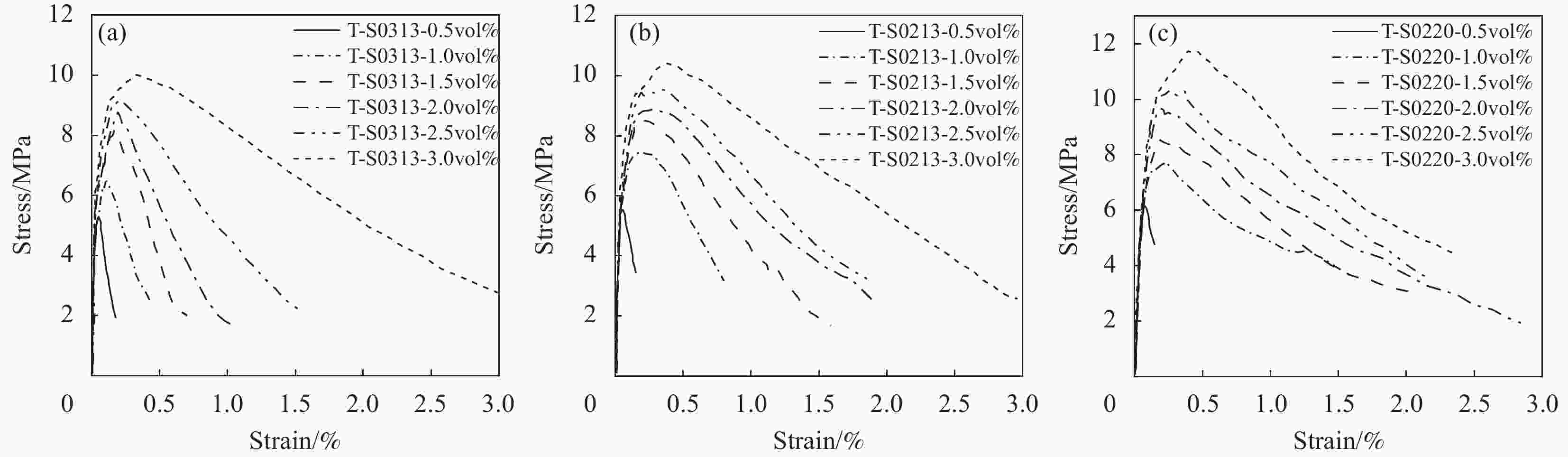

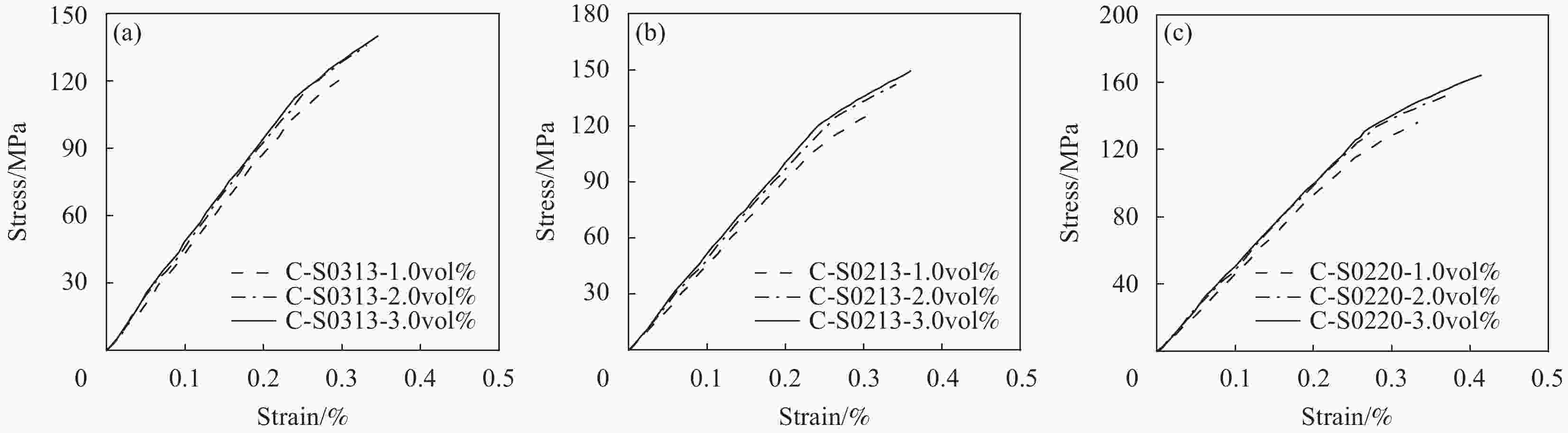

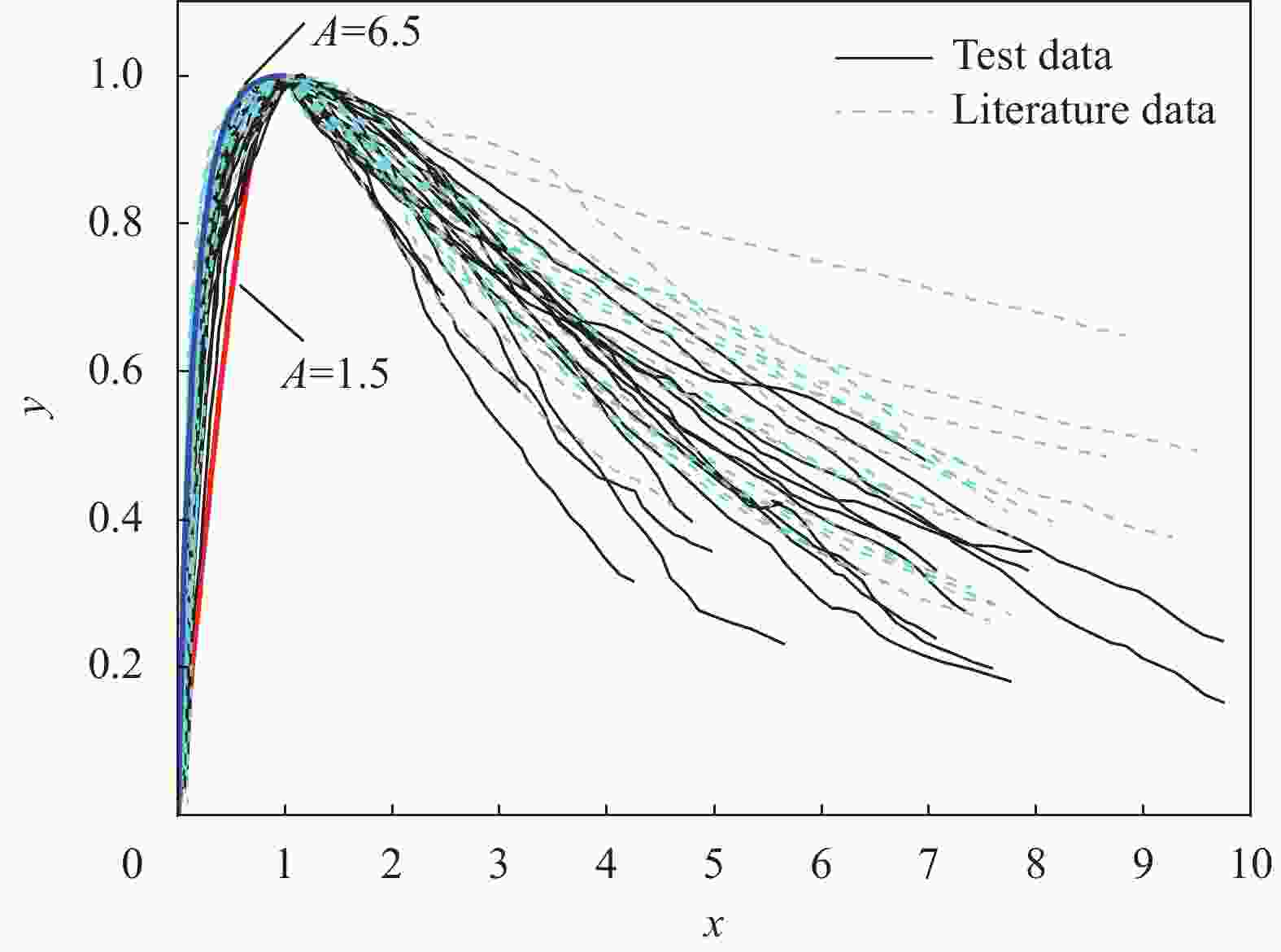

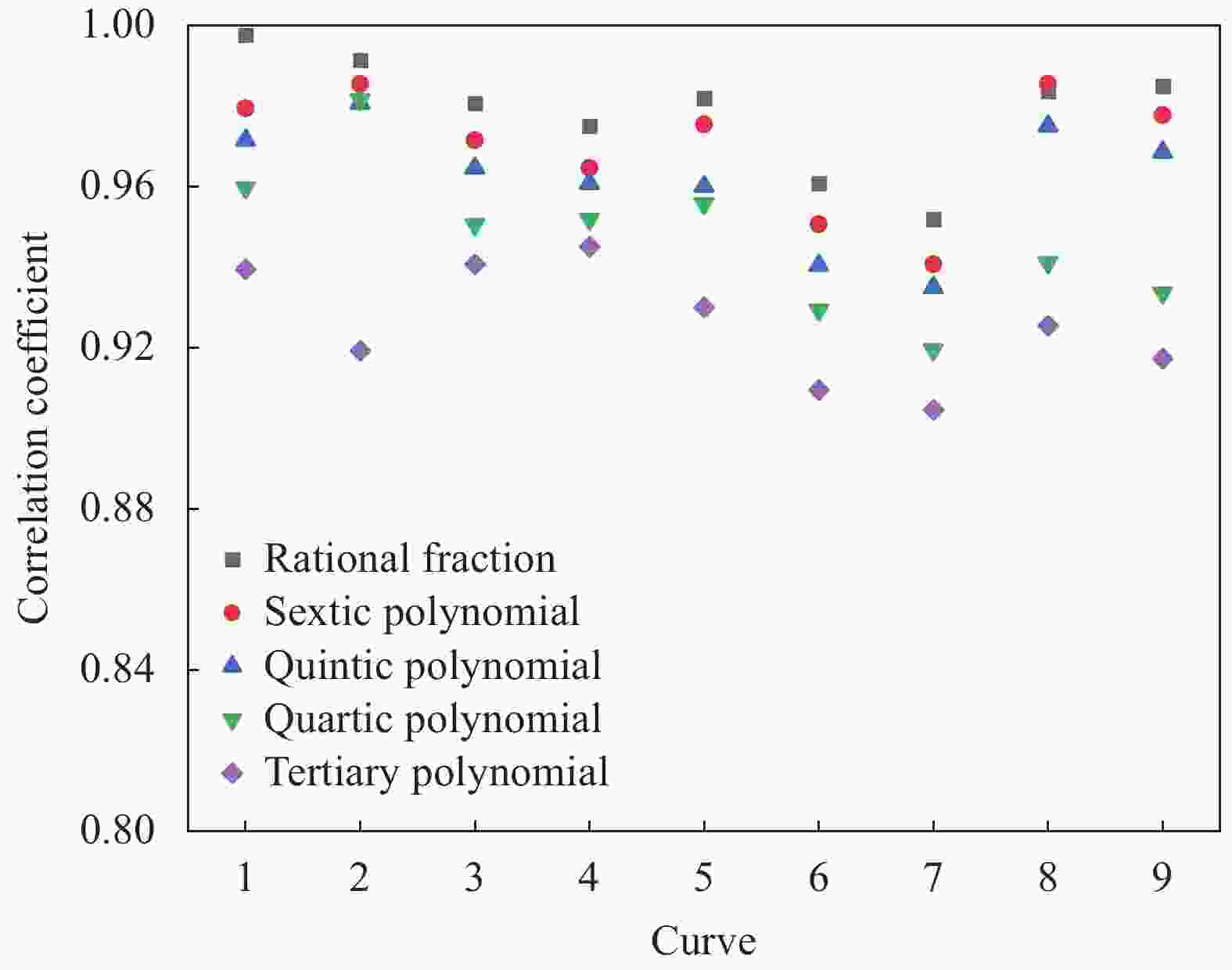

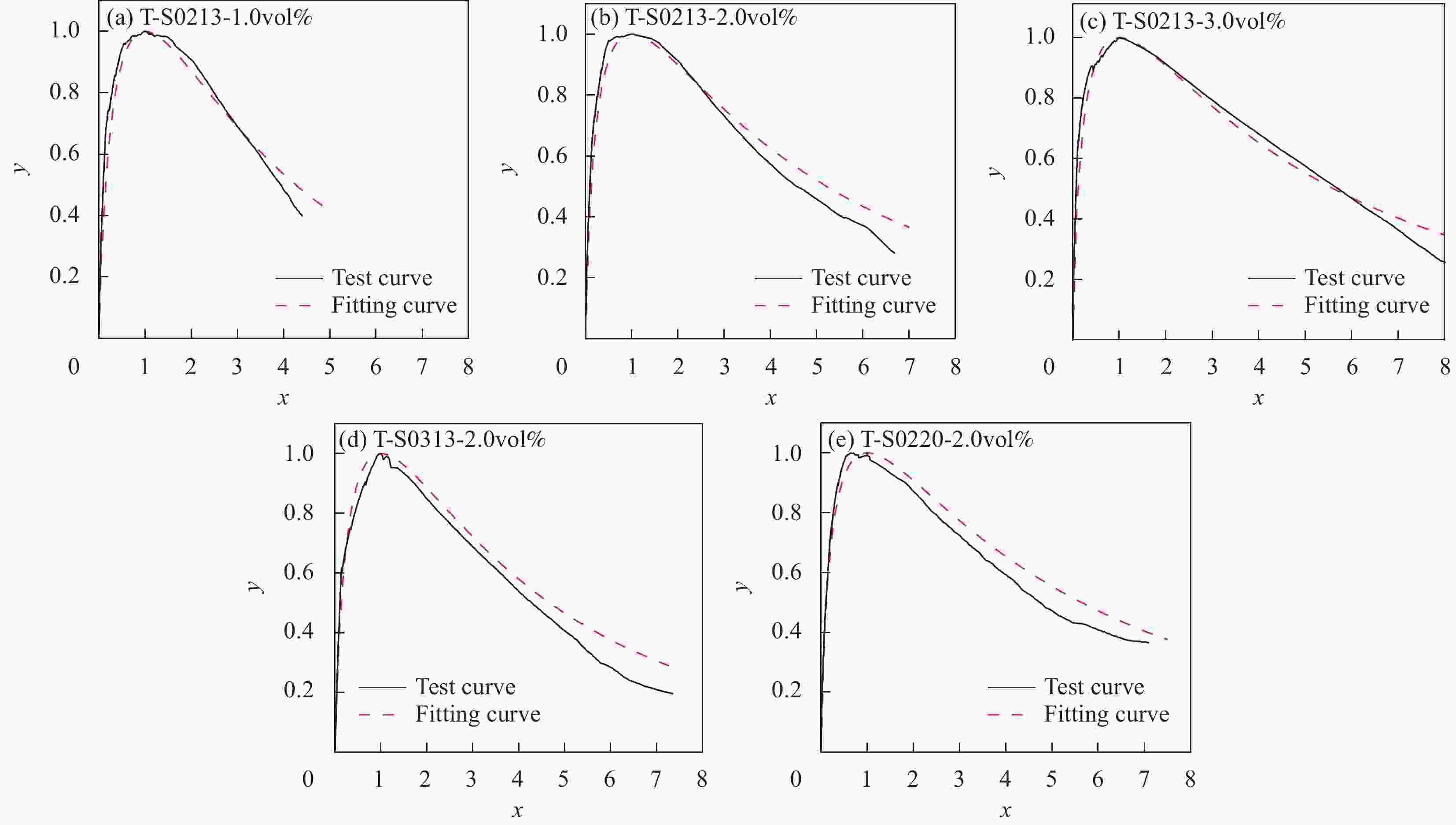

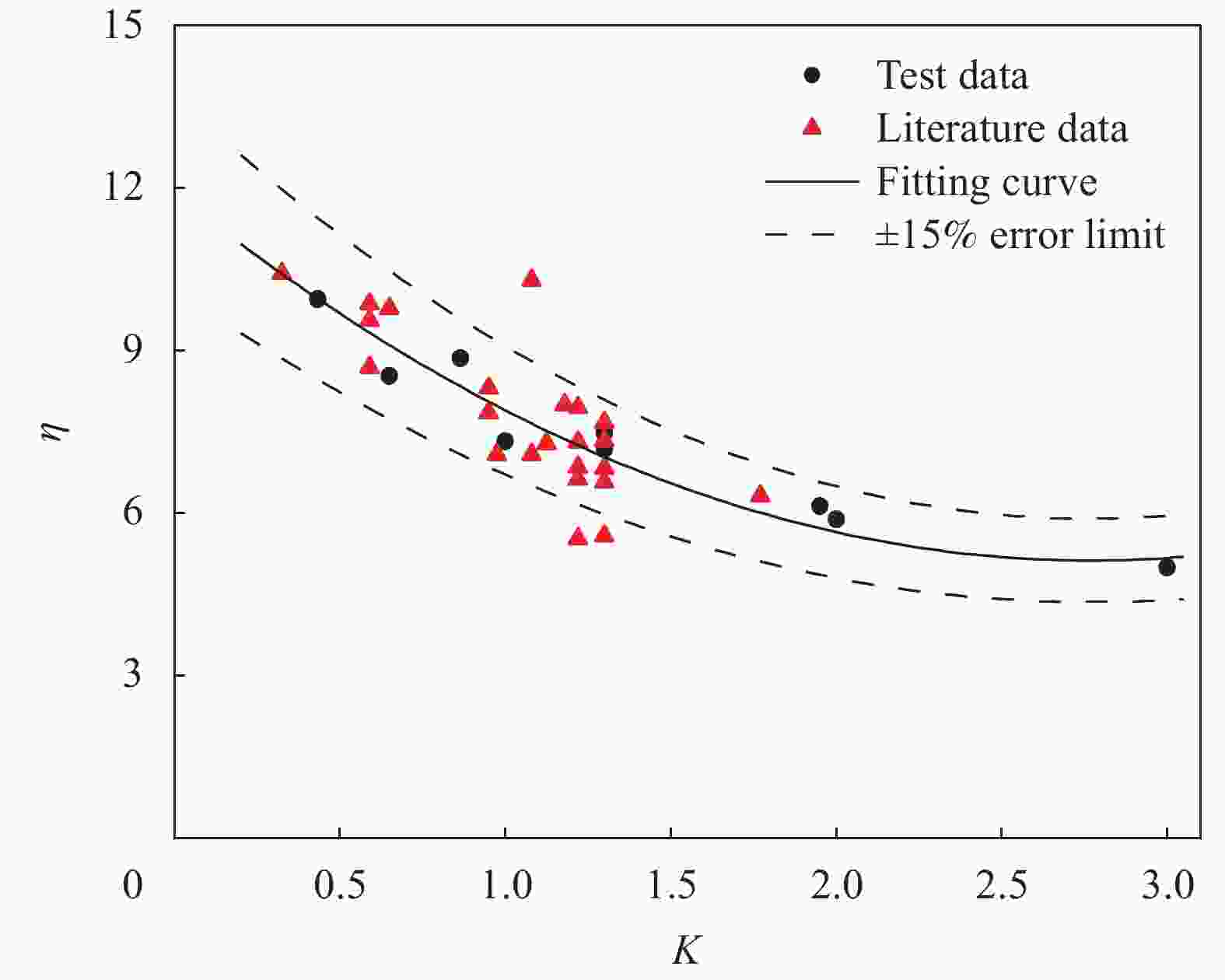

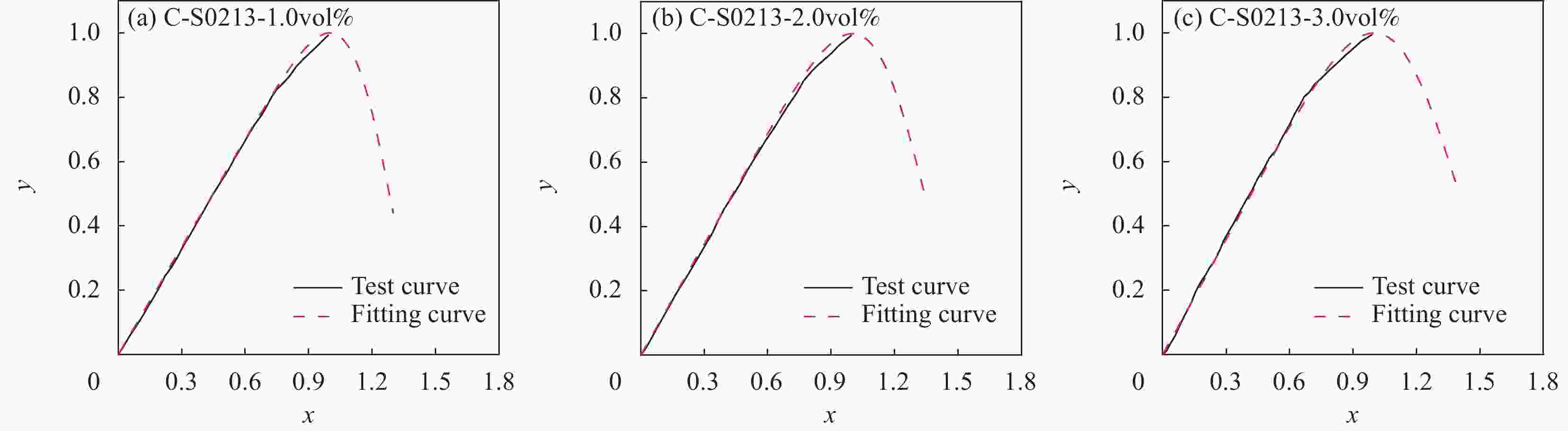

摘要: 超高性能纤维增强混凝土的单轴本构关系是认识其材料特性和非线性结构设计的基础。本文从本构方程函数模型建立的角度梳理了现有超高性能纤维增强混凝土单轴本构关系的相关研究;发现本构关系经验模型适用于结构设计计算,其中轴拉和轴压本构方程式均宜采用有理分式;本构关系简化模型适用于简化受力分析和数值模拟,其中轴拉宜采用三折线模型,轴压宜采用双折线模型;本构关系损伤模型适用于材料特性研究,其损伤演化函数较多采用Weibull分布。此外,还发现现有各种研究所得的本构方程中均不包含纤维相关参数,不能充分体现钢纤维的重要影响。因此,针对3种长径比、6种体积率的超高性能纤维增强混凝土进行轴拉和轴压试验,分析纤维对本构关系的影响。结果表明:超高性能纤维增强混凝土的轴拉和轴压本构关系经验模型均采用有理分式更适合,结合试验与收集的文献数据分析了纤维对经验模型本构方程系数的影响,提出了单轴本构关系经验模型的方程式;还探究了钢纤维参数对单轴损伤本构关系的影响,试验结果表明,钢纤维增强因子与损伤模型的控制系数间存在较强相关性,以试验数据为基础,数值分析得到钢纤维参数与本构方程控制系数间的关系式,进而提出包含钢纤维参数的轴拉和轴压损伤本构方程;并收集文献数据进行验证和修正,结果表明本文提出的本构方程与试验结果更吻合。Abstract: The uniaxial constitutive relation of ultra-high performance fiber reinforced concrete (UHPFRC) is the basis for under-standing its material properties and nonlinear structural design. From the perspective of the constitutive equation function model, this paper reviews the existing research on the uniaxial constitutive relationship of UHPFRC. It was found that the empirical model of constitutive relation is suitable for structural design calculation, and the constitutive equations of uniaxial tension and compression should adopt rational fractions. The simplified model of constitutive relation is suitable for simplified force analysis and numerical simulation. The three-fold line model is suitable for uniaxial tension, and the double-fold line model is suitable for uniaxial compression. The damage model of constitutive relation is suitable for the study of material properties, and the damage evolution function is mostly Weibull distribution. In addition, it is found that the constitutive equations obtained by various existing studies do not contain fiber parameters, which cannot fully reflect the influence of steel fibers. Therefore, uniaxial tension and compression tests were carried out on UHPFRC with three aspect ratios and six volume fractions to analyze the influence of fibers on the constitutive relationship. The results show that the rational fraction is more suitable for the empirical model function of the uniaxial tension and compression constitutive model of UHPFRC. Combined with the test and the collected literature data, the influence of fiber on the coefficient of the empirical model equation was analyzed, and the equation of the empirical model of the uniaxial constitutive relationship was proposed. The influence of steel fiber parameters on the uniaxial damage constitutive relation was also explored. The experimental results show that there is a strong correlation between the steel fiber enhancement factor and the control coefficient of the damage model. Based on the experimental data, the relationship between the parameters of steel fiber and the control coefficient of constitutive equation is obtained by numerical analysis, and then the damage constitutive equations of uniaxial tension and compression including steel fiber variables are proposed. The literature data are collected for verification and correction, indicating that the constitutive relation proposed in this paper is in better agreement with the experimental results.

-

表 1 超高性能纤维增强混凝土(UHPFRC)配合比(质量比)

Table 1. Mix proportion of ultra-high performance fiber reinforced concrete (UHPFRC)(Mass ratio)

Aggregate Binding material Superplasticizer 0.212-0.428 mm 0.428-0.850 mm 0.850-1.700 mm 0.038 mm Cement Silica fume 0.14 0.41 0.53 0.09 1 0.3 0.025 表 2 A组和B组试验方案

Table 2. Test scheme of group A and group B

Test

groupSpecimen Steel fiber volume fraction/vol% Steel fiber aspect ratio Test

groupSpecimen Steel fiber volume

fraction/vol%Steel fiber aspect ratio A C-S0313-1.0vol% 1.0 43 B T-S0313-3.0vol% 3.0 43 C-S0313-2.0vol% 2.0 43 T-S0213-0.5vol% 0.5 65 C-S0313-3.0vol% 3.0 43 T-S0213-1.0vol% 1.0 65 C-S0213-1.0vol% 1.0 65 T-S0213-1.5vol% 1.5 65 C-S0213-2.0vol% 2.0 65 T-S0213-2.0vol% 2.0 65 C-S0213-3.0vol% 3.0 65 T-S0213-2.5vol% 2.5 65 C-S0220-1.0vol% 1.0 100 T-S0213-3.0vol% 3.0 65 C-S0220-2.0vol% 2.0 100 T-S0220-0.5vol% 0.5 100 C-S0220-3.0vol% 3.0 100 T-S0220-1.0vol% 1.0 100 B T-S0313-0.5vol% 0.5 43 T-S0220-1.5vol% 1.5 100 T-S0313-1.0vol% 1.0 43 T-S0220-2.0vol% 2.0 100 T-S0313-1.5vol% 1.5 43 T-S0220-2.5vol% 2.5 100 T-S0313-2.0vol% 2.0 43 T-S0220-3.0vol% 3.0 100 T-S0313-2.5vol% 2.5 43 Notes: C—Uniaxial compression test; T—Uniaxial tension test; S0313—Diameter of steel fiber is 0.30 mm and the length is 13 mm; S0213—Diameter of steel fiber is 0.20 mm and the length is 13 mm; S0220—Diameter of steel fiber is 0.20 mm and the length is 20 mm. 表 3 A值($ A = {E_0}/{E_{\text{c}}} $)的取值范围

Table 3. Value range of A ($ A = {E_0}/{E_{\text{c}}} $)

-

[1] 陈宝春, 季韬, 黄卿维, 等. 超高性能混凝土研究综述[J]. 建筑科学与工程学报, 2014, 31(3):1-24.CHEN Baochun, JI Tao, HUANG Qingwei, et al. Research summary of ultra-high performance concrete[J]. Journal of Architecture and Civil Engineering,2014,31(3):1-24(in Chinese). [2] Societé Suisse Des Ingénieurs et Des Architectes. Betons fibres ultra-peformant: Materiaux, dimensionnement et execution (UHPFRC: Construction material, dimensioning and application)[S]. Switzerland: SIA Zurich, 2016. [3] YANG J, CHEN B, SU J, et al. Effects of fibers on the mechanical properties of UHPC: A review[J]. Journal of Traffic and Transportation Engineering (English Edition), 2022, 9(3): 363-387. [4] 陈宝春, 韦建刚, 苏家战, 等. 超高性能混凝土应用进展[J]. 建筑科学与工程学报, 2019, 36(2):10-20.CHEN Baochun, WEI Jiangang, SU Jiazhan, et al. State-of-the-art progress on application of ultra-high performance concrete[J]. Journal of Architecture and Civil Engineering,2019,36(2):10-20(in Chinese). [5] ZHOU M, LU W, SONG J, et al. Application of ultra-high performance concrete in bridge engineering[J]. Construction and Building Materials,2018,186:1256-1267. doi: 10.1016/j.conbuildmat.2018.08.036 [6] 管品武, 涂雅筝, 张普, 等. 超高性能混凝土单轴拉压本构关系研究[J]. 复合材料学报, 2019, 36(5):1295-1305.GUAN Pinwu, TU Yazheng, ZHANG Pu, et al. A review on constitutive relationship of ultra-high-performance concrete under uniaxial compression and tension[J]. Acta Materiae Compositae Sinica,2019,36(5):1295-1305(in Chinese). [7] 鞠彦忠, 徐力斌, 王德弘, 等. 混杂纤维RPC轴压应力-应变曲线试验研究[J]. 混凝土, 2019(2):23-26. doi: 10.3969/j.issn.1002-3550.2019.02.004JU Yanzhong, XU Libin, WANG Dehong, et al. Experimental study the stress-strain curve of hybrid fiber RPC under axial compression[J]. Concrete,2019(2):23-26(in Chinese). doi: 10.3969/j.issn.1002-3550.2019.02.004 [8] 时金娜, 赵燕茹, 郝松, 等. DIC技术分析玄武岩纤维混凝土单轴受压应力应变曲线研究[J]. 硅酸盐通报, 2019, 38(6):1668-1673, 1680. doi: 10.16552/j.cnki.issn1001-1625.2019.06.005SHI Jinna, ZHAO Yanru, HAO Song, et al. Analysis of uniaxial compressive stress-strain curves of basalt fiber reinforced concrete by DIC technique[J]. Bulletin of the Chinese Ceramic Society,2019,38(6):1668-1673, 1680(in Chinese). doi: 10.16552/j.cnki.issn1001-1625.2019.06.005 [9] 郭晓宇, 亢景付, 朱劲松. 超高性能混凝土单轴受压本构关系[J]. 东南大学学报(自然科学版), 2017, 47(2):369-376. doi: 10.3969/j.issn.1001-0505.2017.02.028GUO Xiaoyu, KANG Jingfu, ZHU Jingsong. Constitutive relationship of ultrahigh performance concrete under uni-axial compression[J]. Journal of Southeast University (Natural Science Edition),2017,47(2):369-376(in Chinese). doi: 10.3969/j.issn.1001-0505.2017.02.028 [10] OUYANG X, WU Z, SHAN B, et al. A critical review on compressive behavior and empirical constitutive models of concrete[J]. Construction and Building Materials,2022,323:126572. doi: 10.1016/j.conbuildmat.2022.126572 [11] 过镇海, 时旭东. 钢筋混凝土原理和分析[M]. 北京: 清华大学出版社, 2003: 464.GUO Zhenhai, SHI Xudong. Principle and analysis of reinforced concrete[M]. Beijing: TsingHua University Press, 2003: 464. [12] 郑文忠, 李莉, 卢姗姗. 钢筋活性粉末混凝土简支梁正截面受力性能试验研究[J]. 建筑结构学报, 2011, 32(6):125-134.ZHENG Wenzhong, LI Li, LU Shanshan. Experimental research on mechanical performance of normal section of reinforced reactive powder concrete beam[J]. Journal of Building Structures,2011,32(6):125-134(in Chinese). [13] 安明喆, 杨志慧, 余自若, 等. 活性粉末混凝土抗拉性能研究[J]. 铁道学报, 2010, 32(1):54-58. doi: 10.3969/j.issn.1001-8360.2010.01.010AN Mingzhe, YANG Zhihui, XU Ziruo, et al. Experimental study on the tensile performance of reactive powder concrete[J]. Journal of the China Railway Society,2010,32(1):54-58(in Chinese). doi: 10.3969/j.issn.1001-8360.2010.01.010 [14] 杨志慧. 不同钢纤维掺量活性粉末混凝土的抗拉力学特性研究[D]. 北京: 北京交通大学, 2006.YANG Zhihui. Study on tension mechanical performance of reactive powder concrete in different steel fiber volume fractions[D]. Beijing: Beijing Jiaotong University, 2006(in Chinese). [15] 刘沐宇, 吕昕睿, 曹玉贵, 等. 轻质超高性能混凝土单轴拉压应力-应变关系[J]. 武汉理工大学学报, 2019, 41(10):60-65, 93.LIU Muyu, LYU Xinrui, CAO Yugui, et al. Experimental study on stress-strain relationship of lightweight ultra-high performance concrete[J]. Journal of Wuhan University of Technology,2019,41(10):60-65, 93(in Chinese). [16] 胡翱翔, 梁兴文, 于婧, 等. 超高性能混凝土轴心受拉力学性能试验研究[J]. 湖南大学学报(自然科学版), 2018, 45(9):30-37. doi: 10.16339/j.cnki.hdxbzkb.2018.09.004HU Aoxiang, LIANG Xingwen, YU Jing, et al. Experimental study of uniaxial tensile characteristics of ultra-high performance concrete[J]. Journal of Hunan University (Natural Sciences),2018,45(9):30-37(in Chinese). doi: 10.16339/j.cnki.hdxbzkb.2018.09.004 [17] ZHENG W, LUO B, WANG Y. Stress-strain relationship of steel-fibre reinforced reactive powder concrete at elevated temperatures[J]. Materials and Structures,2015,48(7):2299-2314. doi: 10.1617/s11527-014-0312-9 [18] 黄政宇, 谭彬. 活性粉末钢纤维混凝土受压应力-应变全曲线的研究[J]. 三峡大学学报(自然科学版), 2007(5):415-420.HUANG Zhengyu, TAN Bin. Research on stress-strain curves of reactive powder concrete with steel-fiber under uniaxial compression[J]. Journal of China Three Gorges University (Natural Sciences),2007(5):415-420(in Chinese). [19] 高丹盈. 钢纤维混凝土轴压应力-应变全曲线的研究[J]. 水利学报, 1991(10): 43-48.GAO Danying. Study on complete stress-strain curve of steel fiber reinforced concrete under axial compression[J]. Journal of Hydraulic Engineering, 1991(10): 43-48(in Chinese). [20] 尹俊红, 周继阳, 赫中营. 碳纤维混凝土单轴循环受压应力应变曲线试验研究[J]. 建筑科学, 2021, 37(5):113-121. doi: 10.13614/j.cnki.11-1962/tu.2021.05.016YIN Junhong, ZHOU Jiyang, HE Zhongying. Study on the stress-strain curve of carbon fiber concrete under uniaxial cyclic compression[J]. Building Science,2021,37(5):113-121(in Chinese). doi: 10.13614/j.cnki.11-1962/tu.2021.05.016 [21] 池寅, 尹从儒, 徐礼华, 等. 钢-聚丙烯混杂纤维增强超高性能混凝土单轴循环受压力学性能[J]. 硅酸盐学报, 2021, 49(11):2331-2345. doi: 10.14062/j.issn.0454-5648.20210233CHI Yin, YIN Congru, XU Lihua, et al. Compressive mechanical properties of steel-polypropylene hybrid fiber reinforced ultrahigh-perfromance concrete under cyclic compression[J]. Journal of the Chinese Ceramic Society,2021,49(11):2331-2345(in Chinese). doi: 10.14062/j.issn.0454-5648.20210233 [22] 金凌志, 李月霞, 付强. 不同掺合料掺量的活性粉末混凝土抗压强度试验[J]. 河南科技大学学报(自然科学版), 2014, 35(5):55-62, 110-111. doi: 10.15926/j.cnki.issn1672-6871.2014.05.014JIN Lingzhi, LI Yuexia, FU Qiang. Compressive strength test on reactive powder concrete with different admixtures[J]. Journal of Henan University of Science & Technology (Natural Science),2014,35(5):55-62, 110-111(in Chinese). doi: 10.15926/j.cnki.issn1672-6871.2014.05.014 [23] 徐强, 杜进生, 张劲泉. 活性粉末混凝土受压力学性能试验[J]. 公路交通科技, 2011, 28(7):8-13. doi: 10.3969/j.issn.1002-0268.2011.07.002XU Qiang, DU Jinsheng, ZHANG Jinquan. Experiment of mechanical properties of reactive powder concrete in compression[J]. Journal of Highway and Transportation Research and Development,2011,28(7):8-13(in Chinese). doi: 10.3969/j.issn.1002-0268.2011.07.002 [24] 鞠彦忠, 王德弘, 康孟新. 不同钢纤维掺量活性粉末混凝土力学性能的试验研究[J]. 应用基础与工程科学学报, 2013, 21(2):299-306. doi: 10.3969/j.issn.1005-0930.2013.02.011JU Yanzhong, WANG Dehong, KANG Mengxin. Mechanical properties of RPC with different steel fiber contents[J]. Journal of Basic Science and Engineering,2013,21(2):299-306(in Chinese). doi: 10.3969/j.issn.1005-0930.2013.02.011 [25] 鞠彦忠, 王德弘, 李秋晨, 等. 钢纤维掺量对活性粉末混凝土力学性能的影响[J]. 实验力学, 2011, 26(3):254-260.JU Yanzhong, WANG Dehong, LI Qiuchen, et al. On the influence of steel fiber volume fraction on mechanical properties of reactive powder concrete[J]. Journal of Experimental Mechanics,2011,26(3):254-260(in Chinese). [26] 安明喆, 宋子辉, 李宇, 等. 不同钢纤维含量RPC材料受压力学性能研究[J]. 中国铁道科学, 2009, 30(5):34-38. doi: 10.3321/j.issn:1001-4632.2009.05.006AN Mingzhe, SONG Zihui, LI Yu, et al. Study on mechanical performance of reactive powder concrete with different steel fiber contents under uniaxial compression[J]. China Railway Science,2009,30(5):34-38(in Chinese). doi: 10.3321/j.issn:1001-4632.2009.05.006 [27] ZHENG W, LI H, WANG Y. Compressive stress-strain relationship of steel fiber-reinforced reactive powder concrete after exposure to elevated temperatures[J]. Construction and Building Materials,2012,35:931-940. doi: 10.1016/j.conbuildmat.2012.05.031 [28] LI L, WEN Z Z, LI S S. Experimental study on mechanical properties of reactive powder concrete[J]. Journal of Harbin Institute of Technology,2010,17(6):795-800. [29] 沈涛. 活性粉末混凝土单轴受压本构关系及结构设计参数研究[D]. 哈尔滨: 哈尔滨工业大学, 2014.SHEN Tao. Constitutive relationship of reactive power concrete under uni-axial compression and research on parameter of structural design[D]. Harbin: Harbin Institute of Technology, 2014(in Chinese). [30] 单波. 活性粉末混凝土基本力学性能的试验与研究[D]. 长沙: 湖南大学, 2002.SHAN Bo. Experiment and research on basic mechanical properties of reactive powder concrete[D]. Changsha: Hunan University, 2002(in Chinese). [31] HE J, CHEN W, ZHANG B, et al. The mechanical properties and damage evolution of UHPC reinforced with glass fibers and high-performance polypropylene fibers[J]. Materials,2021,14(9):2455. doi: 10.3390/ma14092455 [32] International Federation for Structural Concrete. International federation for structural concrete: Model code 2010[S]. France: MCS, 2012. [33] CARREIRA D J, CHU K H. Stress-strain relationship for plain concrete in compression[J]. Journal Proceedings,1985,82(6):797-804. [34] WU Z, SHI C, HE W, et al. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete[J]. Construction and Building Materials,2016,103:8-14. doi: 10.1016/j.conbuildmat.2015.11.028 [35] 杨剑, 方志. 超高性能混凝土单轴受压应力-应变关系研究[J]. 混凝土, 2008(7):11-15. doi: 10.3969/j.issn.1002-3550.2008.07.004YANG Jian, FANG Zhi. Research on stress-strain relation of ultra high performance concrete[J]. Concrete,2008(7):11-15(in Chinese). doi: 10.3969/j.issn.1002-3550.2008.07.004 [36] WU Z, SHI C, HE W, et al. Uniaxial compression behavior of ultra-high performance concrete with hybrid steel fiber[J]. Journal of Materials in Civil Engineering,2016,28(12):06016017. doi: 10.1061/(ASCE)MT.1943-5533.0001684 [37] WANG S, XU L, YIN C, et al. Experimental investigation on the damage behavior of ultra-high performance concrete subjected to cyclic compression[J]. Composite Structures,2021,267:113855. doi: 10.1016/j.compstruct.2021.113855 [38] LEMAITRE J. How to use damage mechanics[J]. Nuclear Engineering and Design,1984,80(2):233-245. doi: 10.1016/0029-5493(84)90169-9 [39] DENG F, CHI Y, XU L, et al. Constitutive behavior of hybrid fiber reinforced concrete subject to uniaxial cyclic tension: Experimental study and analytical modeling[J]. Construction and Building Materials,2021,295:123650. doi: 10.1016/j.conbuildmat.2021.123650 [40] SIMA J F, ROCA P, MOLINS C. Cyclic constitutive model for concrete[J]. Engineering Structures,2008,30(3):695-706. doi: 10.1016/j.engstruct.2007.05.005 [41] WANG S, XU L, YIN C, et al. Constitutive behavior of ultra-high-performance steel fiber reinforced concrete under monotonic and cyclic tension [J]. Journal of Building Engineering, 2023, 68: 105991. [42] DENG M, PAN J, LIANG X. Uniaxial compressive test of high ductile fiber-reinforced concrete and damage constitutive model[J]. Advances in Civil Engineering,2018,4:1-12. [43] LI B, CHI Y, XU L, et al. Cyclic tensile behavior of SFRC: Experimental research and analytical model[J]. Construction and Building Materials,2018,190:1236-1250. doi: 10.1016/j.conbuildmat.2018.09.140 [44] YUE J G, WANG Y N, BESKOS D E. Uniaxial tension damage mechanics of steel fiber reinforced concrete using acoustic emission and machine learning crack mode classification[J]. Cement and Concrete Composites,2021,123:104205. doi: 10.1016/j.cemconcomp.2021.104205 [45] XU L, HUANG L, CHI Y, et al. Tensile behavior of steel-polypropylene hybrid fiber-reinforced concrete[J]. ACI Structural Journal,2016,113(2):219-229. [46] CHI Y, YU M, HUANG L, et al. Finite element modeling of steel-polypropylene hybrid fiber reinforced concrete using modified concrete damaged plasticity[J]. Engineering Structures,2017,148:23-35. doi: 10.1016/j.engstruct.2017.06.039 [47] KRAHL P A, CARRAZEDO R, EL DEBS M K. Mechanical damage evolution in UHPFRC: Experimental and numerical investigation[J]. Engineering Structures,2018,170:63-77. doi: 10.1016/j.engstruct.2018.05.064 [48] 宁喜亮, 丁一宁. 钢纤维对混凝土单轴受压损伤本构模型的影响[J]. 建筑材料学报, 2015, 18(2):214-220. doi: 10.3969/j.issn.1007-9629.2015.02.006NING Xiliang, DING Yining. Effect of steel fiber on the damage constitutive model of concrete under uniaxial compression[J]. Journal of Building Materials,2015,18(2):214-220(in Chinese). doi: 10.3969/j.issn.1007-9629.2015.02.006 [49] 王春来, 徐必根, 李庶林, 等. 单轴受压状态下钢纤维混凝土损伤本构模型研究[J]. 岩土力学, 2006(1):151-154. doi: 10.3969/j.issn.1000-7598.2006.01.030WANG Chunlai, XU Bigen, LI Shulin, et al. Study on a constitutive model of damage of SFRC under uniaxial compression[J]. Rock and Soil Mechanics,2006(1):151-154(in Chinese). doi: 10.3969/j.issn.1000-7598.2006.01.030 [50] 程臻赟. 活性粉末混凝土单轴受压本构模型研究[J]. 中国水运(下半月), 2012, 12(12):87-88, 90.CHENG Zhenyun. Study on constitutive model of reactive powder concrete under uniaxial compression[J]. China Water Transport,2012,12(12):87-88, 90(in Chinese). [51] 薛云亮, 李庶林, 林峰, 等. 考虑损伤阀值影响的钢纤维混凝土损伤本构模型研究[J]. 岩土力学, 2009, 30(7): 1987-1992, 1999.XUE Yunliang, LI Shulin, LIN Feng, et al. Study on damage constitutive model of steel fiber reinforced concrete considering the influence of damage threshold[J]. Rock and Soil Mechanics, 2009, 30(7): 1987-1992, 1999(in Chinese). [52] 徐礼华, 黄彪, 李彪, 等. 循环荷载作用下聚丙烯纤维混凝土受压应力-应变关系研究[J]. 土木工程学报, 2019, 52(4):1-12. doi: 10.15951/j.tmgcxb.2019.04.001XU Lihua, HUANG Biao, LI Biao, et al. Study on the stress-strain relation of polypropylene fiber reinforced concrete under cyclic compression[J]. China Civil Engineering Journal,2019,52(4):1-12(in Chinese). doi: 10.15951/j.tmgcxb.2019.04.001 [53] 徐礼华, 李长宁, 李彪, 等. 循环受压状态下钢纤维混凝土一维弹塑性损伤本构模型研究[J]. 土木工程学报, 2018, 51(11):77-87. doi: 10.15951/j.tmgcxb.2018.11.006XU Lihua, LI Changning, LI Biao, et al. Study on one-dimensional elastoplastic damage constitutive model of steel fiber reinforced concrete under cyclic compression[J]. China Civil Engineering Journal,2018,51(11):77-87(in Chinese). doi: 10.15951/j.tmgcxb.2018.11.006 [54] 徐海宾, 邓宗才. 新型UHPC应力-应变关系研究[J]. 混凝土, 2015(6):66-68, 79.XU Haibin, DENG Zongcai. Stress-strain constitutive law of a new kind of UHPC[J]. Concrete,2015(6):66-68, 79(in Chinese). [55] LIAO W C, CHAO S H, PARK S Y, at el. Self-consolidating high performance fiber reinforced concrete: SCHPFRC[R]. Ann Arbor: University of Michigan, 2006. [56] ISA M N, PILAKOUTAS K, GUADAGNINI M. Determination of tensile characteristics and design of eco-efficient UHPC[J]. Structures,2021,32:2174-2194. doi: 10.1016/j.istruc.2021.03.114 [57] MOBASHER B, LI A, YAO Y, et al. Characterization of toughening mechanisms in UHPC through image correlation and inverse analysis of flexural results[J]. Cement and Concrete Composites,2021,122:104157. doi: 10.1016/j.cemconcomp.2021.104157 [58] 刘欣益, 张清华, 程震宇, 等. UHPC构件受拉性能的细观力学解析方法[J]. 中国公路学报, 2021, 34(8): 45-54.LIU Xinyi, ZHANG Qinghua, CHENG Zhenyu, et al. Micro-mechanics research on tensile mechanical behavior of UHPC specimen[J]. China Journal of Highway and Transport, 2021, 34(8): 45-54(in Chinese). [59] 赵继之, 辛公锋, 陶慕轩, 等. 超高性能混凝土单轴拉、压循环作用下力学性能及其本构模型研究[J/OL]. 工程力学: 1-13[2024-01-03].ZHAO Jizhi, XIN Gongfeng, TAO Muxuan, et al. Mechanical properties and constitutive model of ultra-high performance concrete material under uniaxial tension and compression cycles[J/OL]. Engineering Mechanics: 1-13[2024-01-03](in Chinese). [60] 张哲, 邵旭东, 李文光, 等. 超高性能混凝土轴拉性能试验[J]. 中国公路学报, 2016, 49(2):77-86. doi: 10.19721/j.cnki.1001-7372.2015.08.007ZHANG Zhe, SHAO Xudong, LI Wenguang, et al. Twice inverse analysis method based on four-point bending test results for UHPC tensile behavior characterization[J]. China Civil Engineering Journal,2016,49(2):77-86(in Chinese). doi: 10.19721/j.cnki.1001-7372.2015.08.007 [61] FANG H, GU M, ZHANG S, et al. Effects of steel fiber and specimen geometric dimensions on the mechanical pro-perties of ultra-high-performance concrete[J]. Materials,2022,15(9):3027. doi: 10.3390/ma15093027 [62] STANG H, LI V C, KRENCHEL H. Design and structural applications of stress-crack width relations in fibre reinforced concrete[J]. Materials and Structures,1995,28(4):210-219. doi: 10.1007/BF02473251 [63] KANG S T, LEE Y, PARK Y D, et al. Tensile fracture properties of an ultra high performance fiber reinforced concrete (UHPFRC) with steel fiber[J]. Composite Structures,2010,92(1):61-71. doi: 10.1016/j.compstruct.2009.06.012 [64] FUJIKAKE K, SENGA T, UEDA N, et al. Effects of strain rate on tensile behavior of reactive powder concrete[J]. Jour-nal of Advanced Concrete Technology,2006,4(1):79-84. doi: 10.3151/jact.4.79 [65] SHI Z, SU Q, KAVOURA F, et al. Uniaxial tensile response and tensile constitutive model of ultra-high performance concrete containing coarse aggregate (CA-UHPC)[J]. Cement and Concrete Composites,2023,136:104878. doi: 10.1016/j.cemconcomp.2022.104878 [66] Japan Society of Civil Engineers (JSCE). Recommendations for design and construction of ultra high strength fiber reinforced concrete structures[S]. Tokyo: Maruzen, 2006. [67] Association Française de Génie Civil. French interim recommendations of ultra high performance fibre reinforced concrete (UHPFRC): French association of civil engineering (2002) [S]. French: French Association of Civil Engineering, 2002. [68] 中华人民共和国住房和城乡建设部. 活性粉末混凝土: GB/T 31387—2015[S]. 北京: 中国标准出版社, 2015.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Reactive powder concrete: GB/T 31387—2015[S]. Beijing: Standards Press of China, 2015(in Chinese). [69] 河北省市场监督管理局. 超高性能混凝土制备与工程应用技术规程: DB13/T 2946—2019[S]. 北京: 中国标准出版社, 2019.Hebei Provincial Market Supervision and Administration Bureau. Technical specification for preparation and engi-neering application of ultra-high performance concrete: DB13/T 2946—2019[S]. Beijing: Standards Press of China, 2019(in Chinese). [70] YANG J, CHEN B, WU X, et al. Quantitative analysis of steel fibers on UHPFRC uniaxial tensile behavior using X-CT and UTT[J]. Construction and Building Materials,2023,368:130349. doi: 10.1016/j.conbuildmat.2023.130349 [71] WILLW K, EI-TAWIL S, NAAMAN A E. Properties of strain hardening ultra high performance fiber reinforced concrete (UHP-FRC) under direct tensile loading[J]. Cement & Concrete Composites,2014,48:53-66. [72] KANAKUBO T. Tensile characteristics evaluation method for ductile fiber-reinforced cementitious composites[J]. Journal of Advanced Concrete Technology,2006,4(1):3-17. doi: 10.3151/jact.4.3 [73] BIAN C, WANG J Y, GUO J Y. Damage mechanism of ultra-high performance fibre reinforced concrete at different stages of direct tensile test based on acoustic emission analysis[J]. Construction and Building Materials,2021,267:120927. doi: 10.1016/j.conbuildmat.2020.120927 [74] SHEN X, BRUHWILER E. Influence of local fiber distribution on tensile behavior of strain hardening UHPFRC using NDT and DIC[J]. Cement and Concrete Research,2020,132:106042. doi: 10.1016/j.cemconres.2020.106042 [75] AN L H, EKKEHARD F. Influence of steel fiber content and aspect ratio on the uniaxial tensile and compressive behavior of ultra high performance concrete[J]. Construction and Building Materials,2017,153:790-806. doi: 10.1016/j.conbuildmat.2017.07.130 [76] YOO D Y, KIM M J. High energy absorbent ultra-high-performance concrete with hybrid steel and polyethylene fibers[J]. Construction and Building Materials,2019,209:354-363. doi: 10.1016/j.conbuildmat.2019.03.096 [77] WILLE K, KIM D J, NAAMAN A E. Strain-hardening UHP-FRC with low fiber contents[J]. Materials and Structures,2011,44(3):583-598. doi: 10.1617/s11527-010-9650-4 [78] SAVINO V, LANZOAI L, TARANTINO A M, et al. Tensile constitutive behavior of high and ultra-high performance fibre-reinforced-concretes[J]. Construction and Building Materials,2018,186:525-536. doi: 10.1016/j.conbuildmat.2018.07.099 [79] ZHOU Z D, QIAO P Z. Tensile behavior of ultra-high performance concrete: Analytical model and experimental validation[J]. Construction and Building Materials,2019,201:842-851. doi: 10.1016/j.conbuildmat.2018.12.137 [80] ZHOU Z, QIAO P. Direct tension test for characterization of tensile behavior of ultra-high performance concrete[J]. Journal of Testing and Evaluation,2020,48(4):20170644. doi: 10.1520/JTE20170644 [81] ZHOU Z D, QIAO P Z. Direct tension test for characterization of tensile behavior of ultra-high performance concrete[J]. Journal of Testing and Evaluation,2018,48(4):2730-2749. [82] YOO D Y, SOHN H K, BORGES P H R, et al. Enhancing the tensile performance of ultra-high-performance concrete through strategic use of novel half-hooked steel fibers[J]. Journal of Materials Research and Technology,2020,9(3):2914-2925. [83] PRABHA S L, DATTATREYA J K, NEELAMEGAM M. Stress strain behaviour of ultra high performance concrete under uniaxial compression[J]. International Journal of Civil Engineering and Technology,2014,5(3):187-194. [84] 宋子辉. 不同钢纤维掺量活性粉末混凝土单轴受压力学特性及损伤分析[D]. 北京: 北京交通大学, 2008.SONG Zihui. Study on mechanical performance and damage of reactive powder concrete in different steel fiber volume fractions under uni-axial compression [D]. Beijing: Beijing Jiaotong University, 2008(in Chinese). [85] 吴有明. 活性粉末混凝土(RPC)受压应力-应变全曲线研究[D]. 广州: 广州大学, 2012.WU Youming. Study of the reactive powder concrete (RPC) about compressive stress-strain curve [D]. Guangzhou: Guangzhou University, 2012(in Chinese). [86] MA K, MA Y, XING G, et al. Behavior of ultra-high-performance concrete columns subjected to axial compressive load[J]. Advances in Structural Engineering,2021,24(16):3792-3808. doi: 10.1177/13694332211038440 [87] MOHAMED A H H, ISMAIL K W, SALIM D L. Proposed model for uniaxial compression behavior of reactive powder concrete[J]. Engineering Sciences,2015,23:591-606. [88] 马亚峰. 活性粉末混凝土(RPC200)单轴受压本构关系研究[D]. 北京: 北京交通大学, 2006.MA Yafeng. Study on constitutive relationship of 200 MPa reactive powder concrete under uni-axial compression [D]. Beijing: Beijing Jiaotong University, 2006(in Chinese). [89] HASSAN A M T, JONES S W, MAHMUD G D. Experimental test methods to determine the uniaxial tensile and compressive behaviour of ultra high performance fibre reinforced concrete (UHPFRC)[J]. Construction and Building Materials,2012,37:874-882. doi: 10.1016/j.conbuildmat.2012.04.030 [90] 李莉. 活性粉末混凝土梁受力性能及设计方法研究[D]. 哈尔滨: 哈尔滨工业大学, 2010.LI Li. Mechanical behavior and design method for reactive powder concrete beams[D]. Harbin: Harbin Institute of Technology, 2010(in Chinese). [91] PRABHA S L, DATTATREYA J K, NEELAMEGAM M, et al. Study on stress-strain properties of reactive powder concrete under uniaxial compression[J]. International Journal of Engineering Science and Technology,2010,2(11):6408-6416. [92] 李海艳. 活性粉末混凝土高温爆裂及高温后力学性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2012.LI Haiyan. Experimental study on spalling behaviour and mechanical properties of reactive powder concrete after elevated temperatures[D]. Harbin: Harbin Institute of Technology, 2012(in Chinese). [93] OLIVEIRA J L Á D, BORGES V E S, DANIN A R, et al. Stress-strain curves for steel fiber-reinforced concrete in compression[J]. Revista Matéria,2010,15(2):293-299. [94] BENCARDINO F, RIZZUTI L, SPADEA G, et al. Stress-strain behavior of steel fiber-reinforced concrete in compression[J]. Journal of Materials in Civil Engineering,2008,20(3):255-263. doi: 10.1061/(ASCE)0899-1561(2008)20:3(255) [95] NATARAJA M C, DHANG N, GUPTA A P. Stress-strain curves for steel-fiber reinforced concrete under compression[J]. Cement and Concrete Composites,1999,21(5):383-390. -

下载:

下载: