In-plane compression properties of negative Poisson's ratio structure of rotating thin-walled multi-cell square tubes with foam concrete filler

-

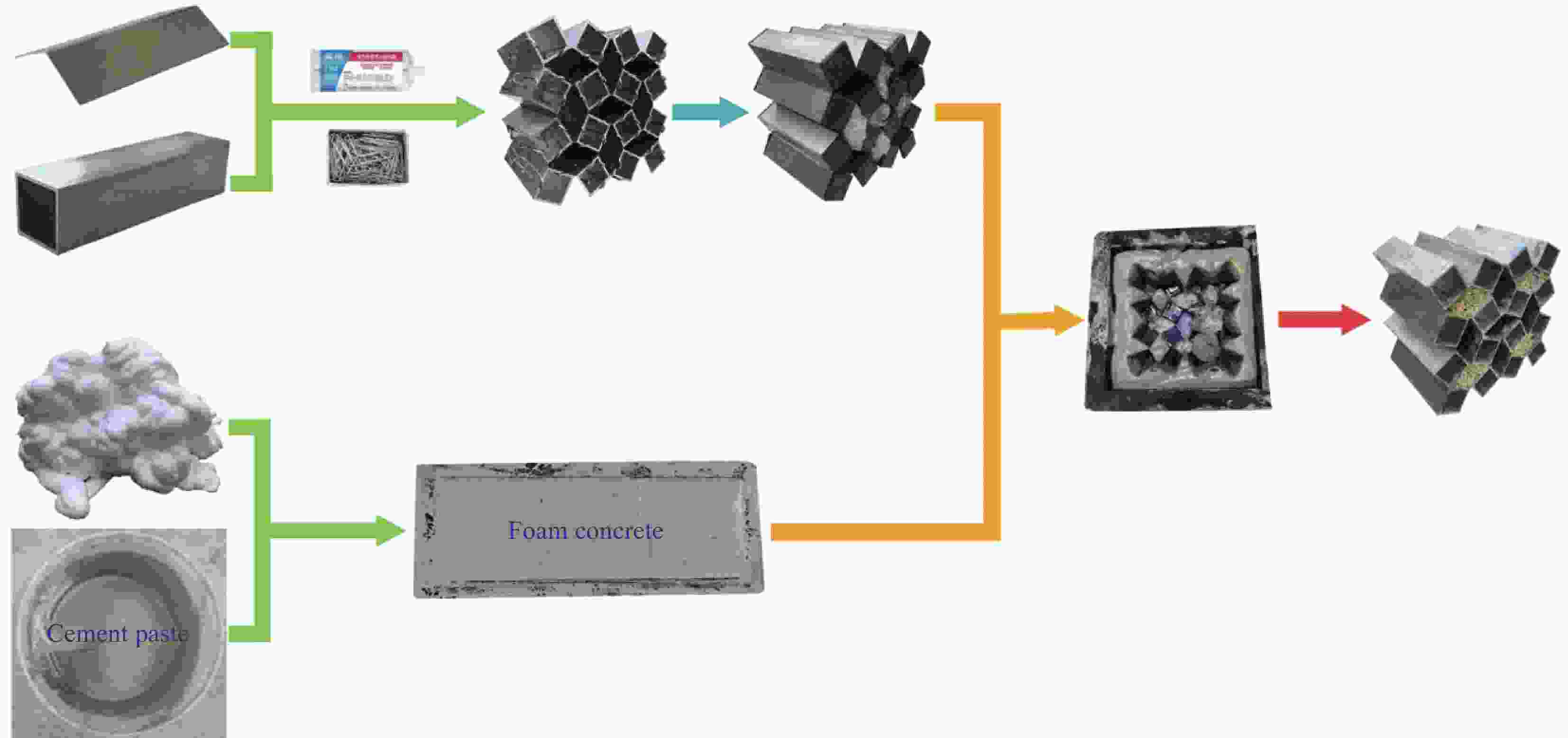

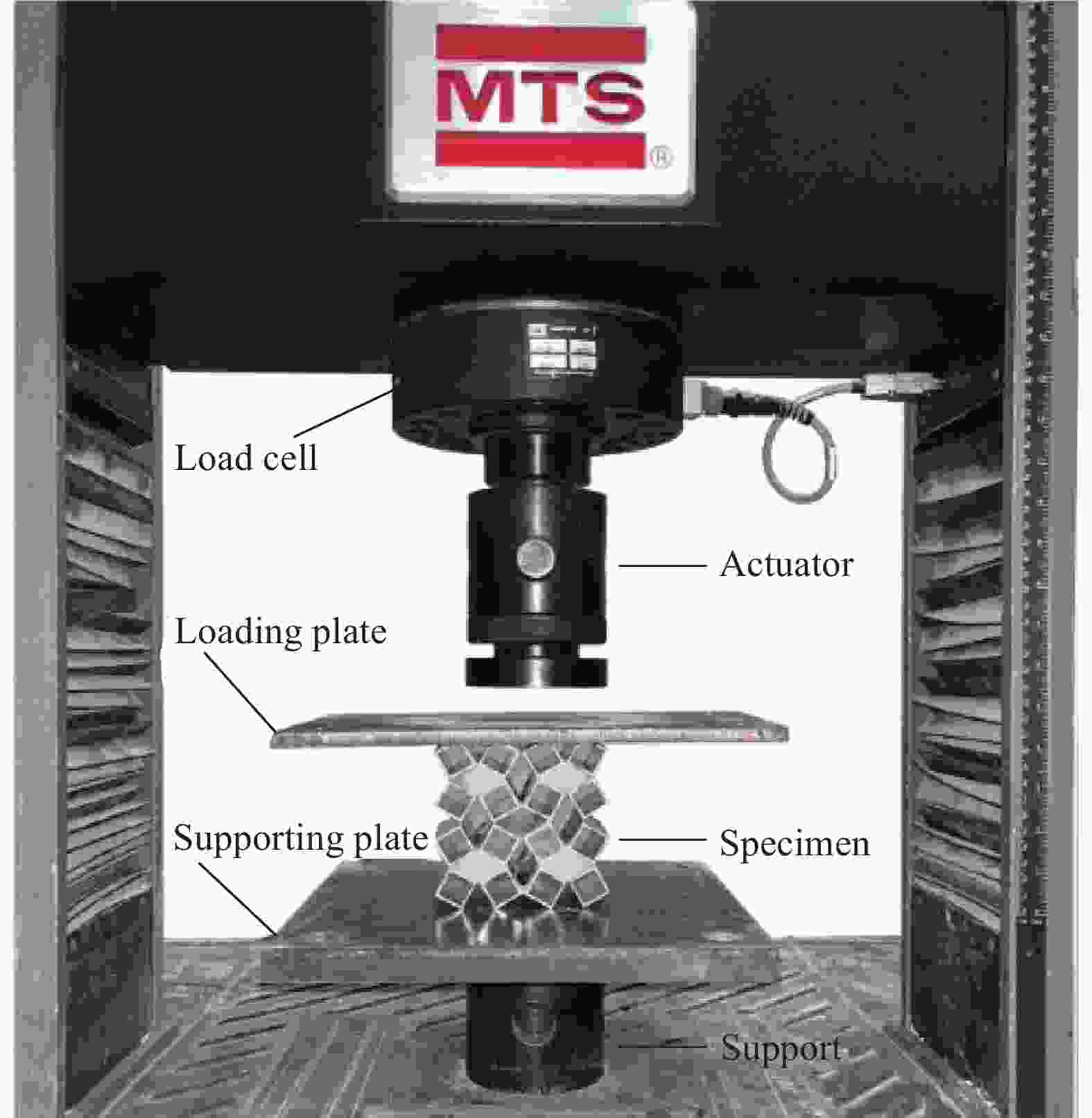

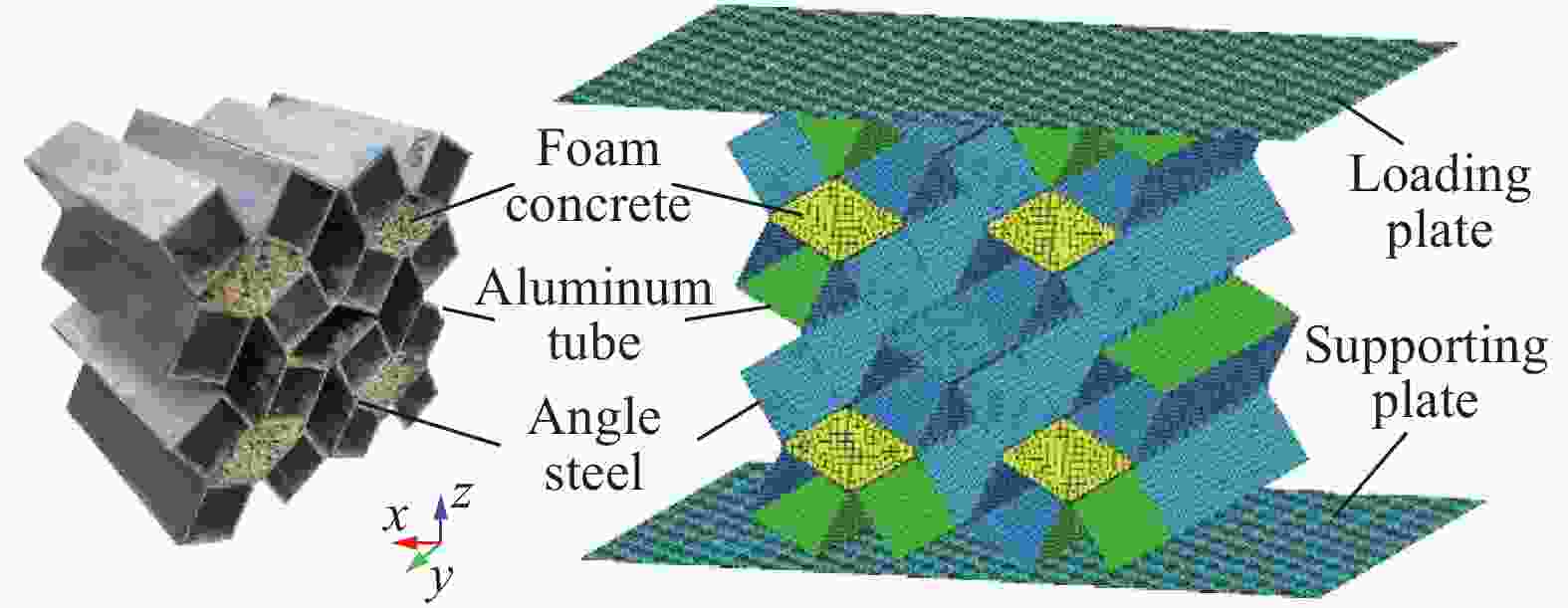

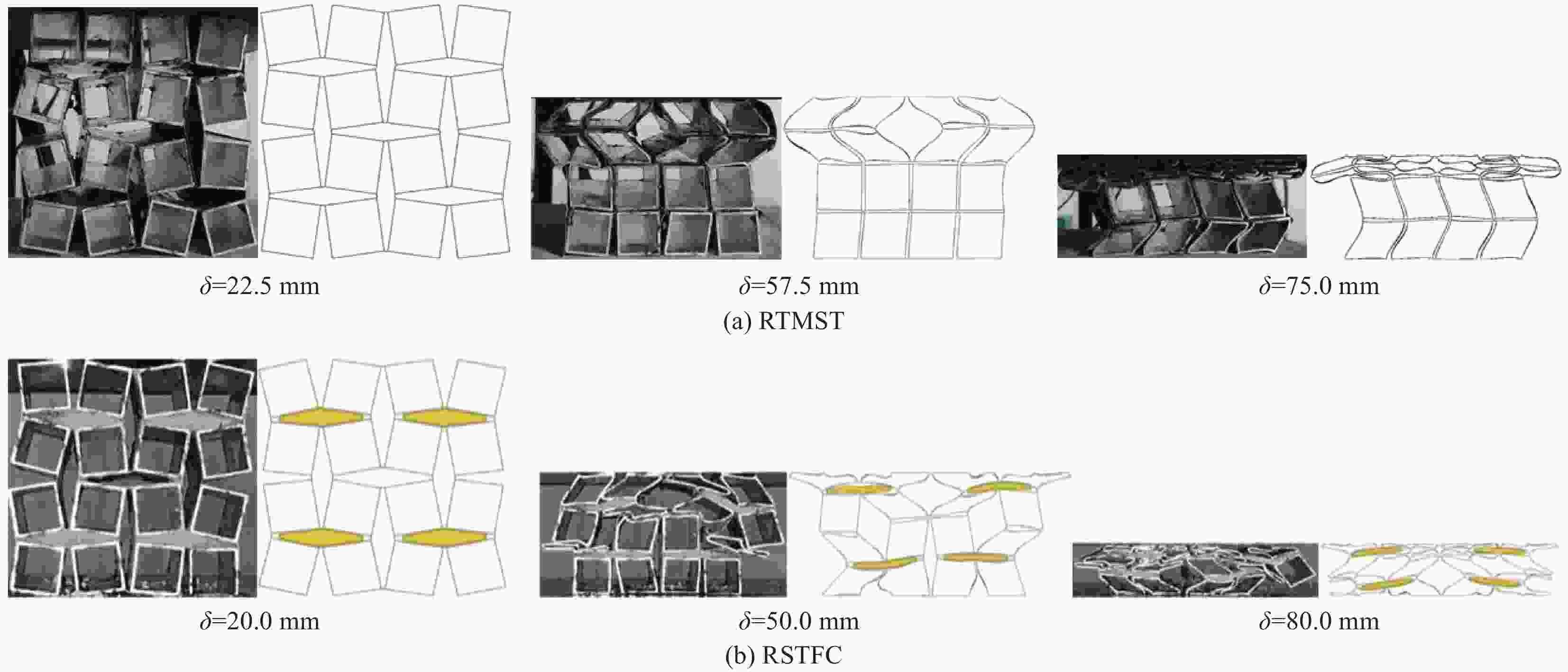

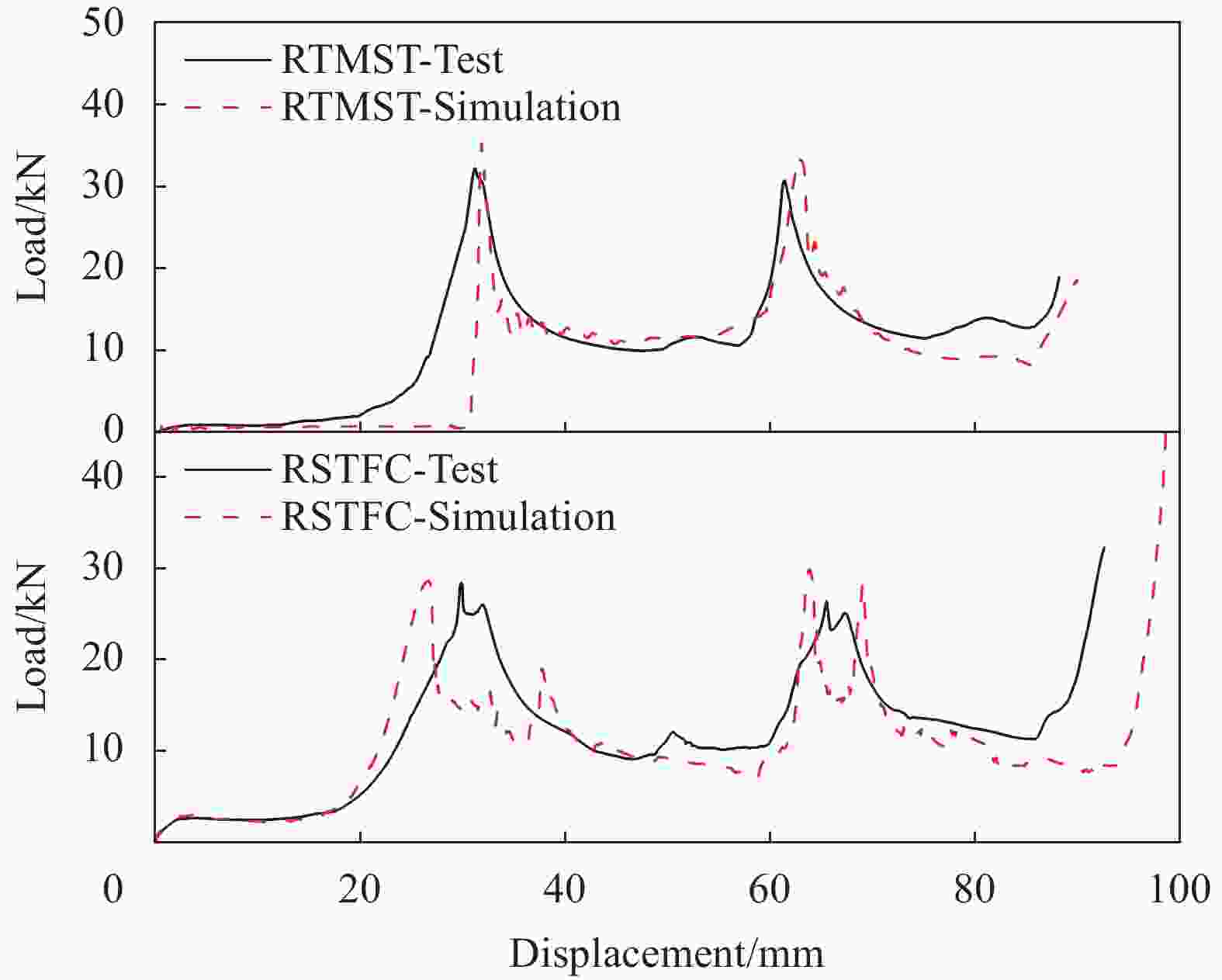

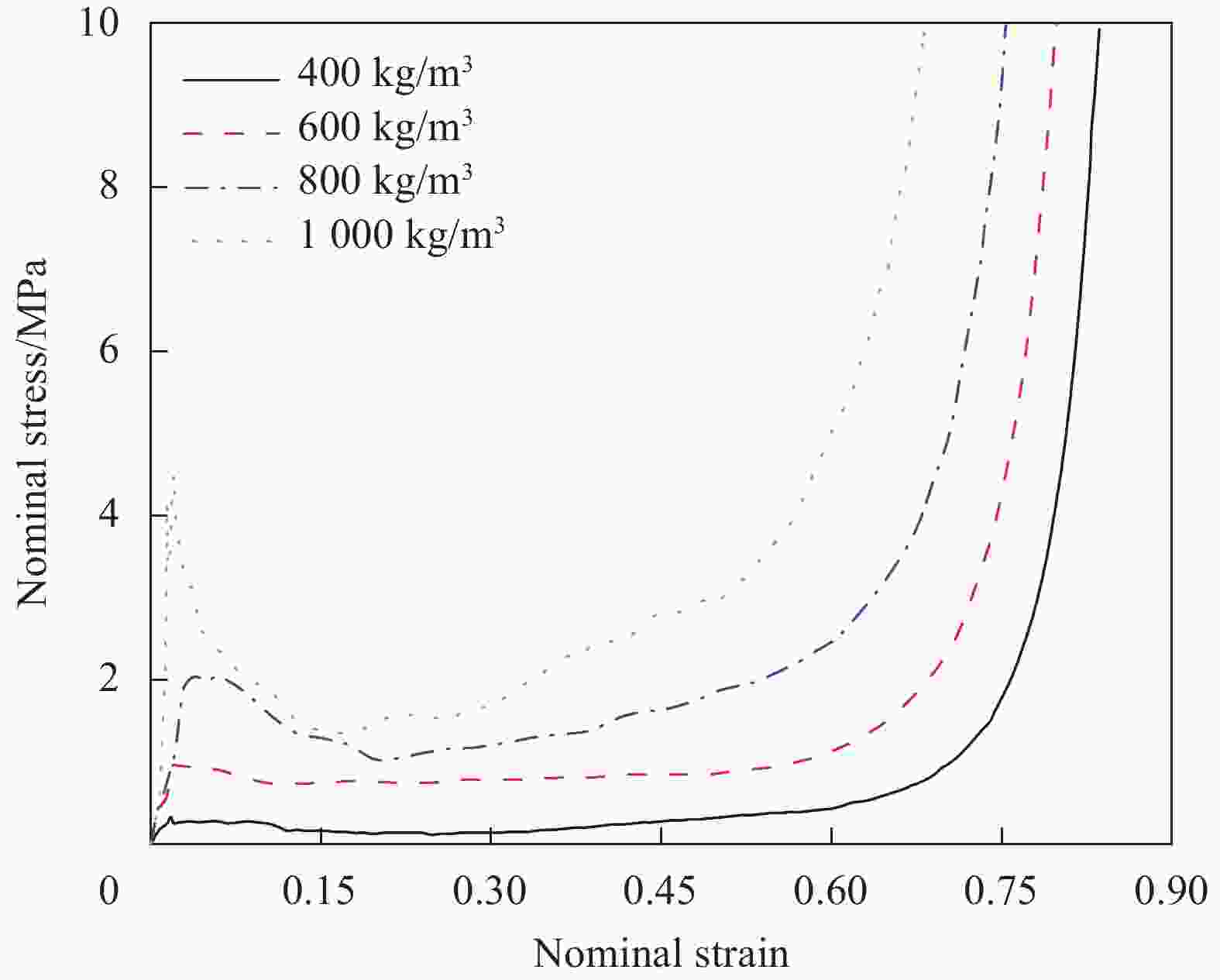

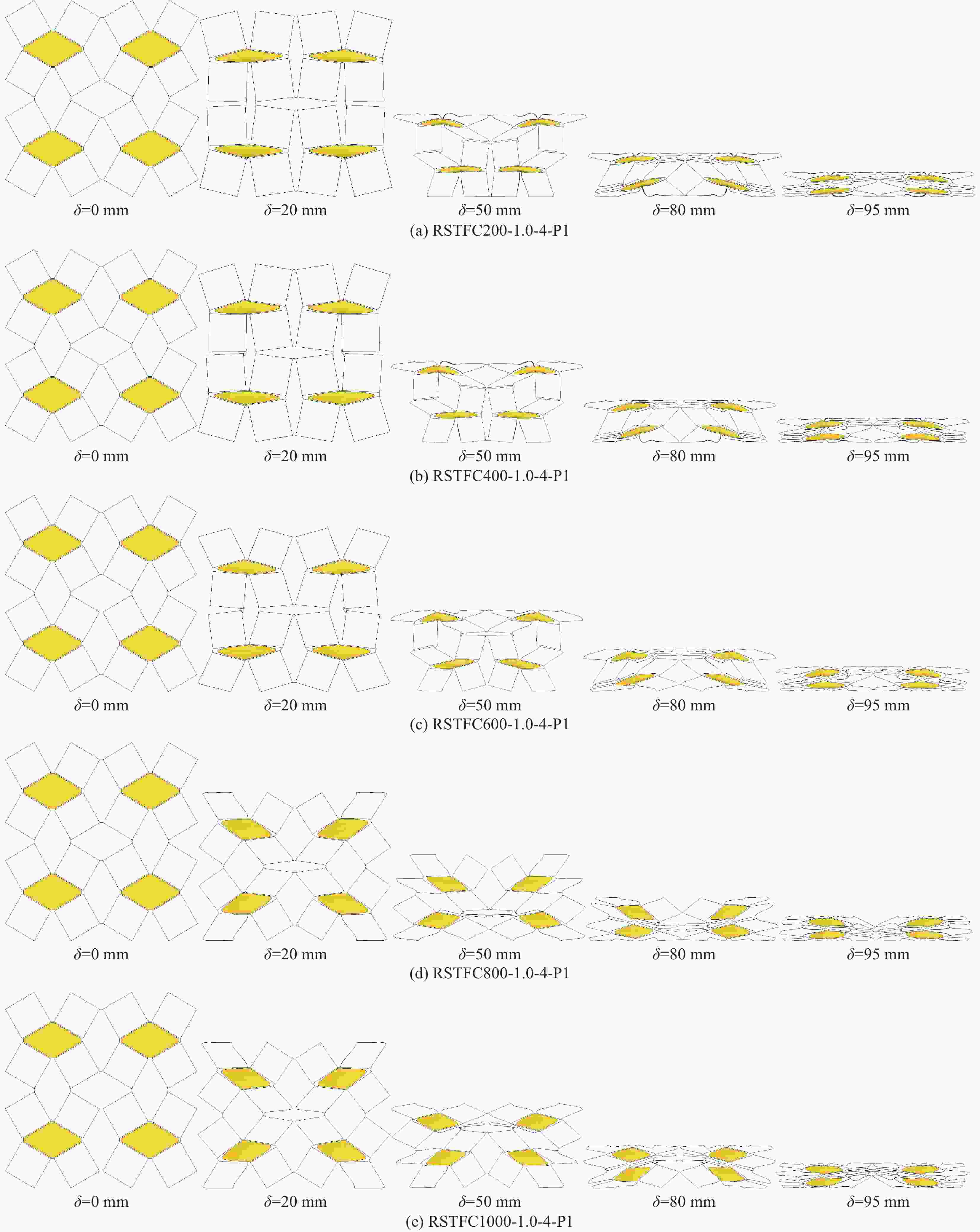

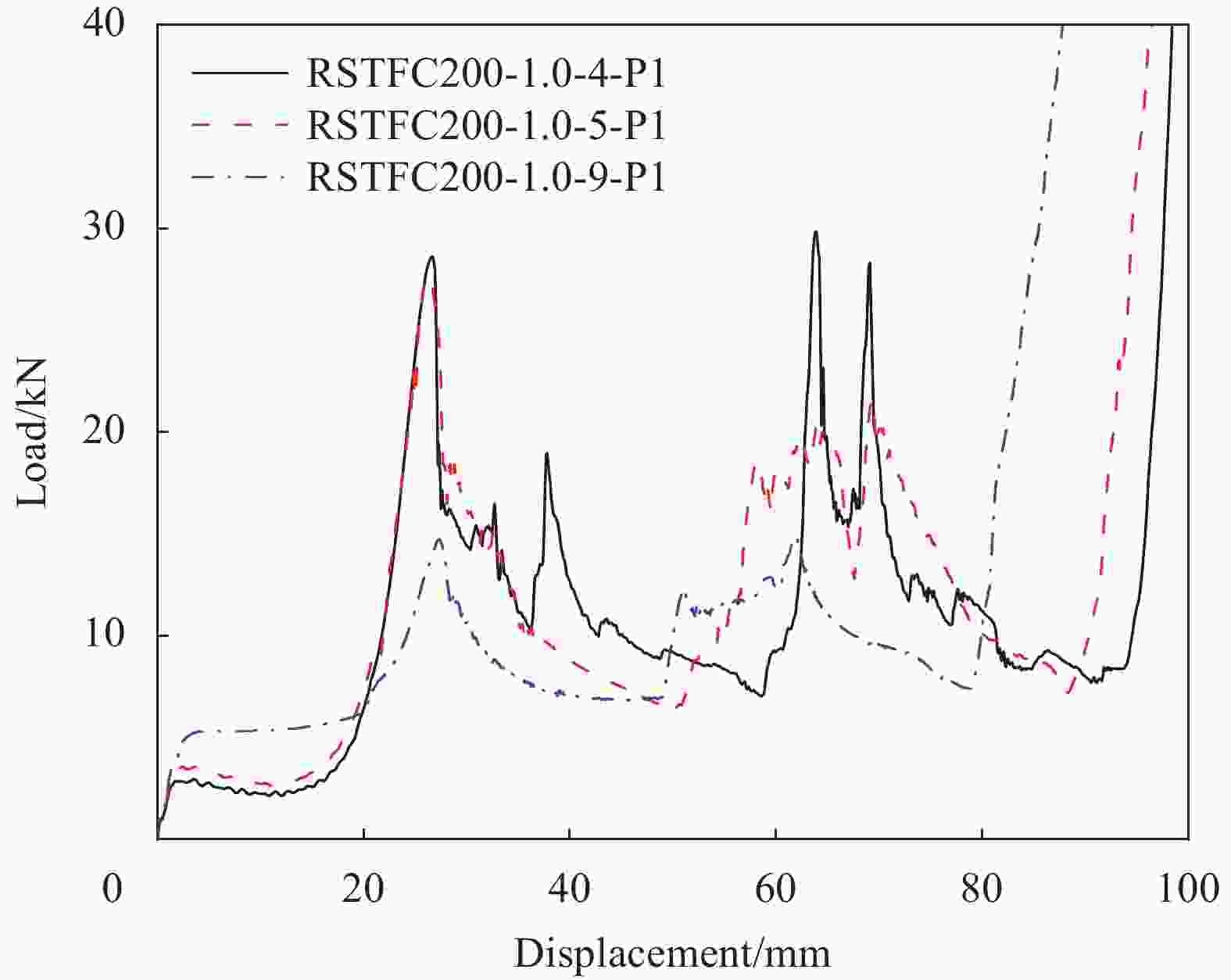

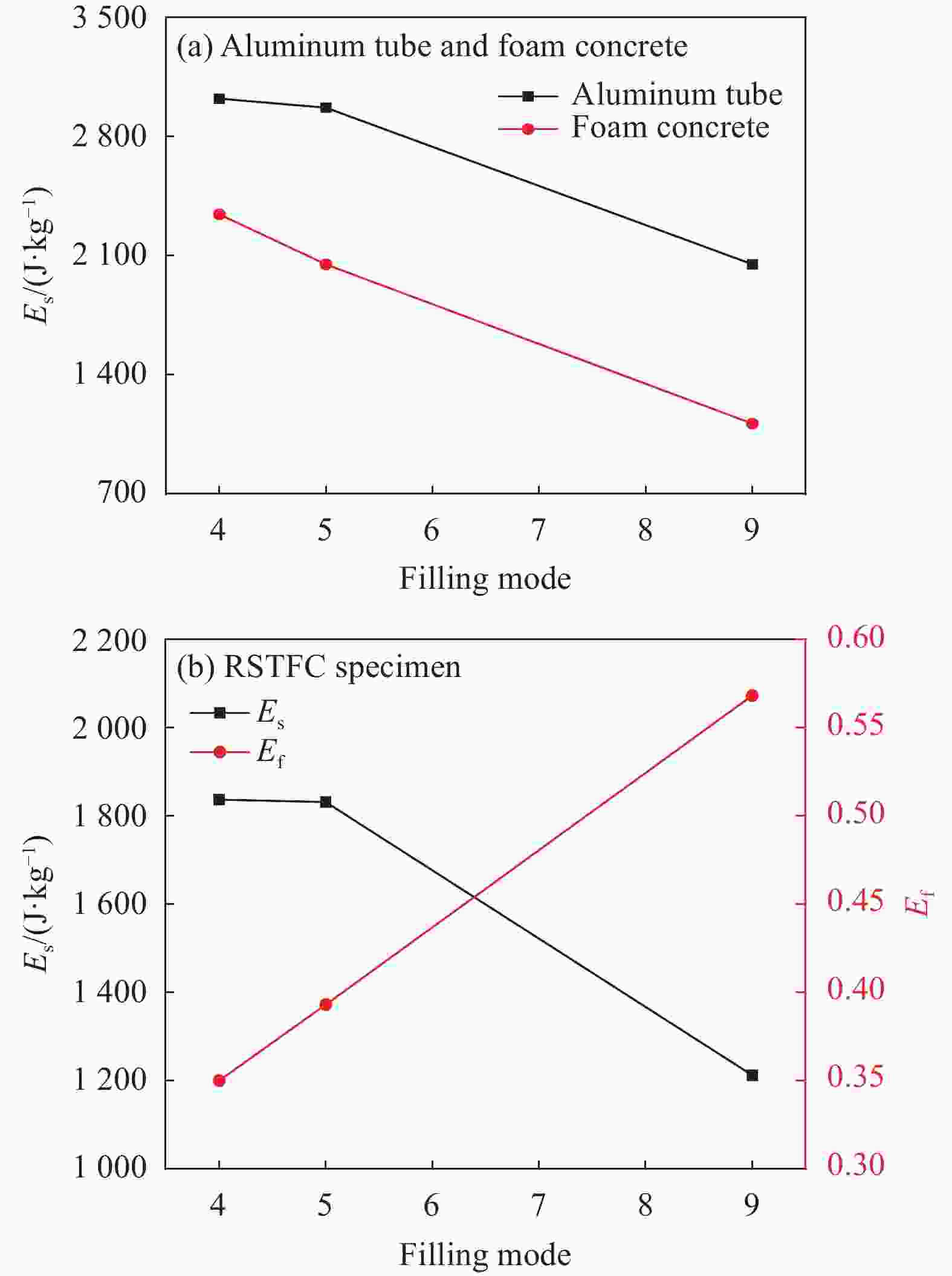

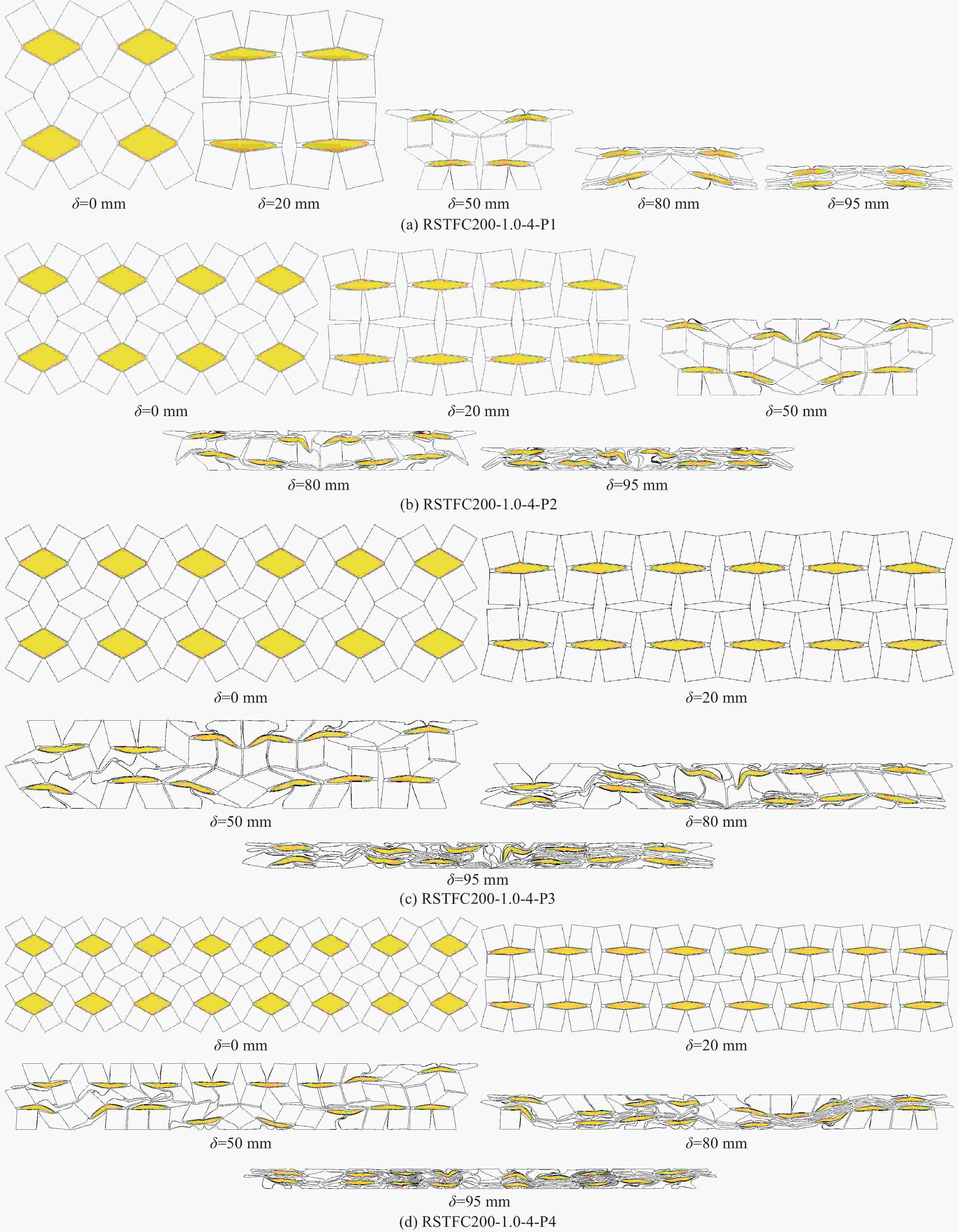

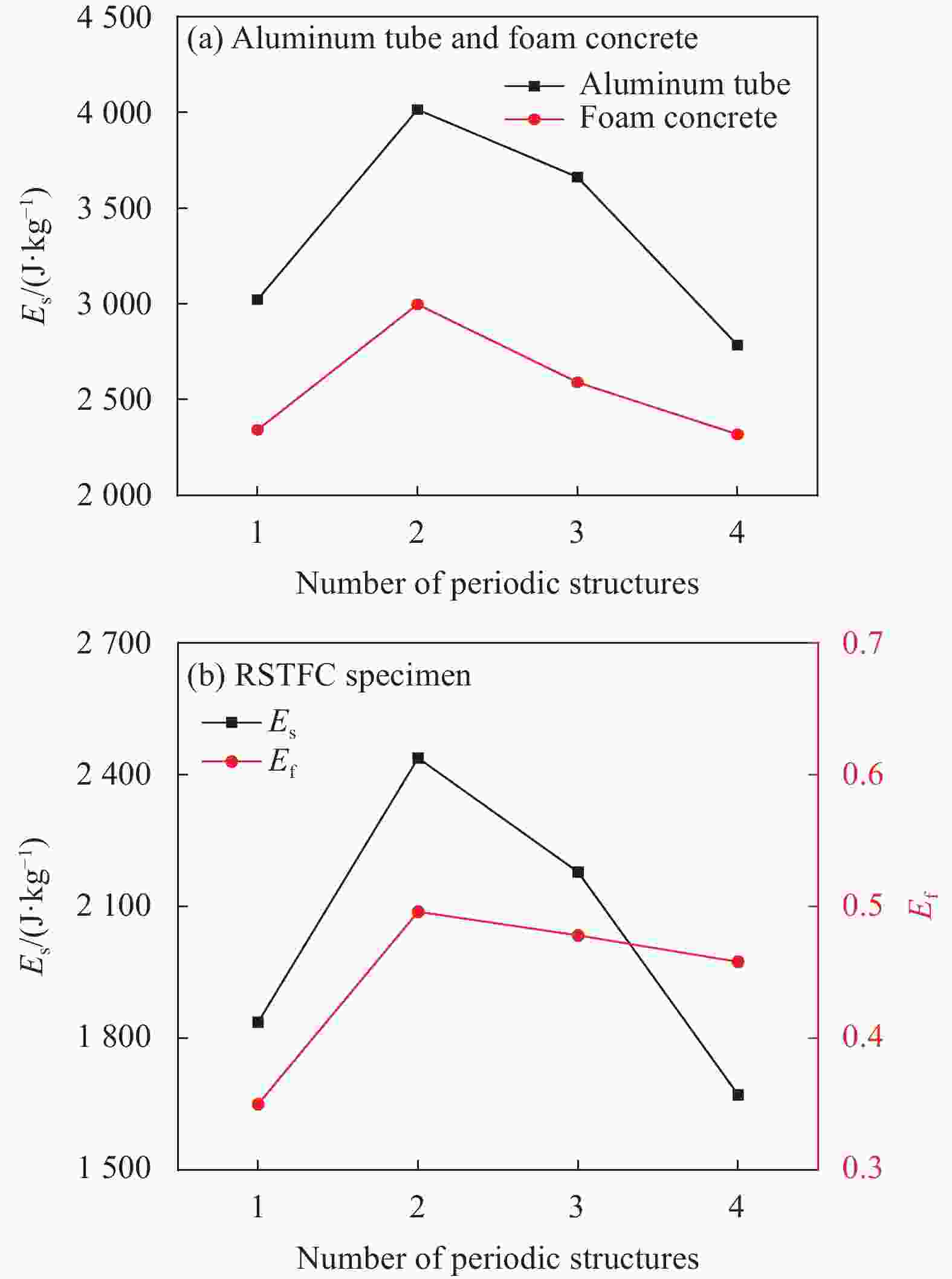

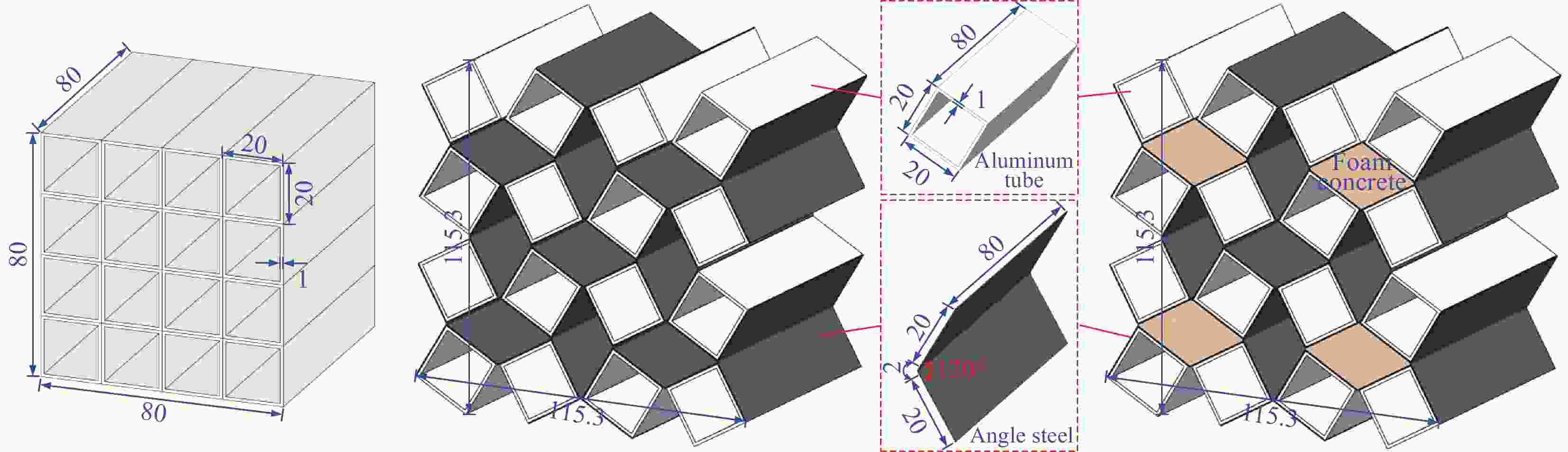

摘要: 为改善薄壁金属管件的力学及吸能性能,提出了一种泡沫混凝土填充旋转薄壁多胞方管负泊松比结构(RSTFC)。对薄壁多胞方管(TMST)、旋转薄壁多胞方管(RTMST)和RSTFC试件进行准静态面内压缩试验,研究了3类不同试件的变形模式、载荷-位移曲线和吸能性能。试验结果表明:TMST、RTMST和RSTFC试件均表现为压缩破坏;对比于TMST试件,RTMST试件因发生旋转变形可有效降低载荷峰值,同时吸收更多能量,压溃力效率和能量吸收分别增大了73.2%和33.6%;泡沫混凝土的存在促使铝管在试件旋转过程中发生了一定程度的变形及泡沫混凝土不断压缩变形,因此填充有200 kg/m3泡沫混凝土RSTFC试件的压溃力效率和能量吸收较RTMST试件分别增大了22.5%和8.9%。基于试验验证的数值结果表明:铝管和泡沫混凝土之间承载能力的相互匹配决定了RSTFC试件的力学及吸能性能,可通过调整泡沫混凝土密度、铝管壁厚和泡沫混凝土填充方式等实现对RSTFC试件变形模式、载荷传递与吸能性能的调控。因两个周期性结构试件具有相对更高的比吸能和压溃力效率,建议在实际工程中应用。Abstract: To improve the mechanical and energy absorption properties of thin-walled metal tubular structures, a type of negative Poisson's ratio structure of rotating thin-walled multi-cell square tubes with foam concrete filler (RSTFC) was proposed. Firstly, quasi-static compressive test on the thin-walled multi-cell square tubes (TMST), rotating thin-walled multi-cell square tubes (RTMST), and RSTFC specimens were carried out, and their deformation mode, load-displacement curve, and energy absorption performance were experimentally investigated. The test results show that the TMST, RTMST, and RSTFC specimens all exhibit compressive failure. Furthermore, it is found that the rotational deformation of the RTMST specimen can effectively reduce its peak load and improve the energy absorption by 73.2% and 33.6% in comparison to the TMST specimen. Moreover, due to the presence of foam concrete, the aluminum tubes undergo a certain degree of deformation during the rotational process, accompanied by continuous compression deformation of the foam concrete. As a result, the crushing force efficiency and energy absorption of the RSTFC specimen filled with 200 kg/m3 foam concrete increase by 22.5% and 8.9% respectively compared to those of the RTMST specimen. Based on the validated numerical model by test data, it is observed that the matching of bearing capacity between aluminum tube and foam concrete significantly influence the mechanical properties and energy absorption of the RSTFC specimen. Therefore, the deformation mode, load transfer, and energy absorption performance of the RSTFC specimen could be regulated by adjusting the density of foam concrete, the wall thickness of the aluminum tube, and the filling mode of foam concrete. It was recommended to apply RSTFC with two periodic structures in practical engineering due to their relatively higher specific energy absorption and crushing force efficiency.

-

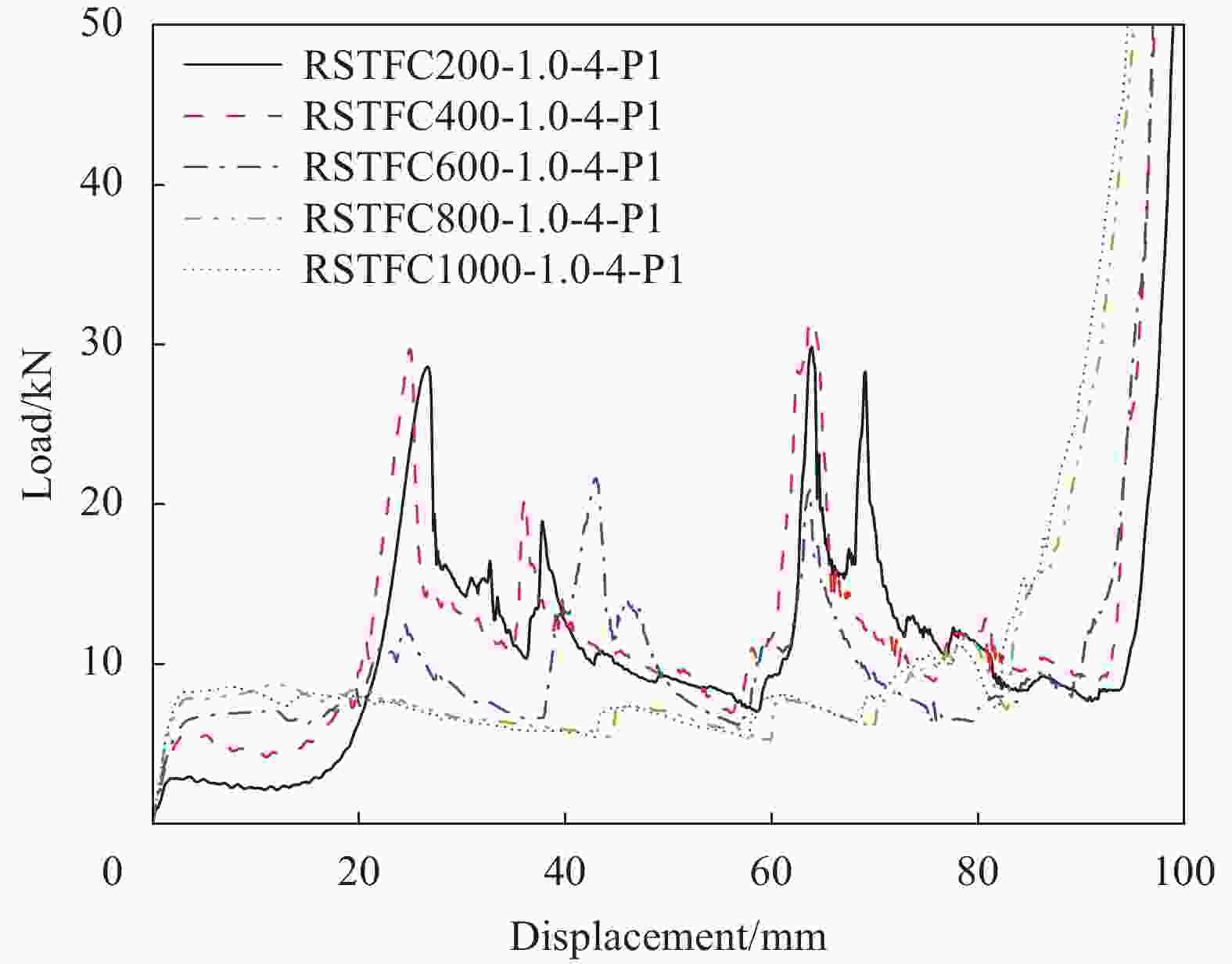

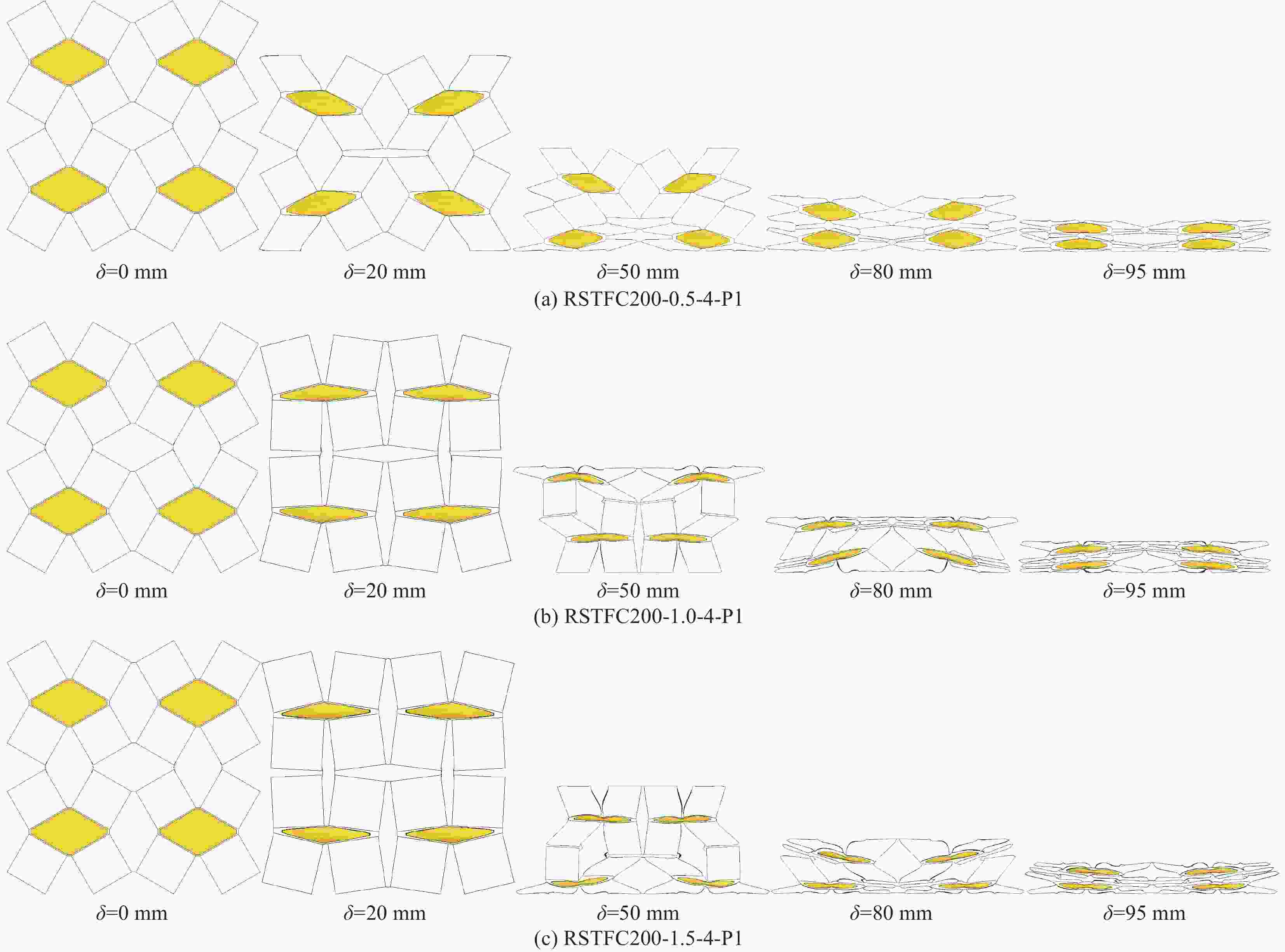

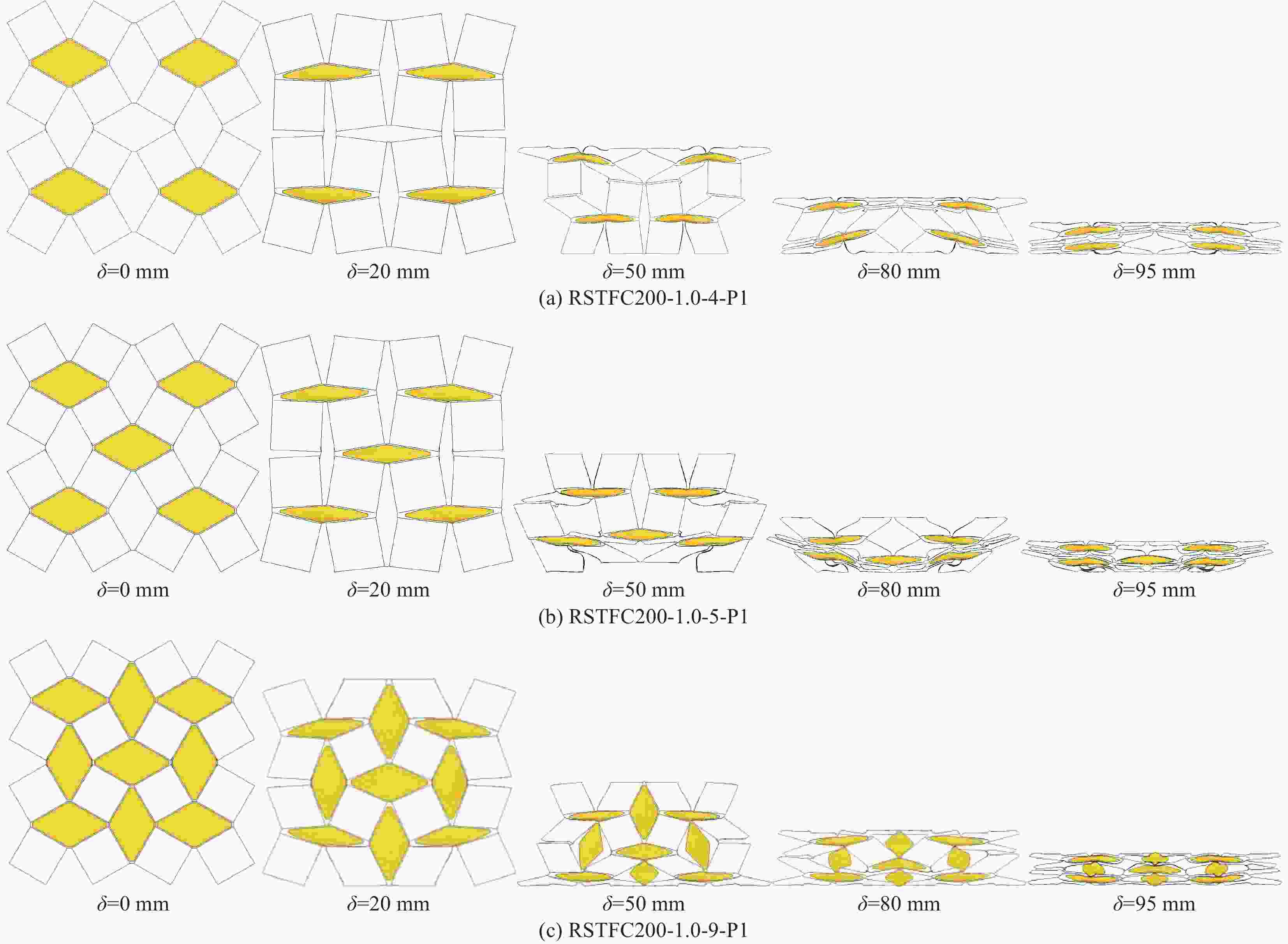

图 13 填充不同密度泡沫混凝土RSTFC试件的变形模式

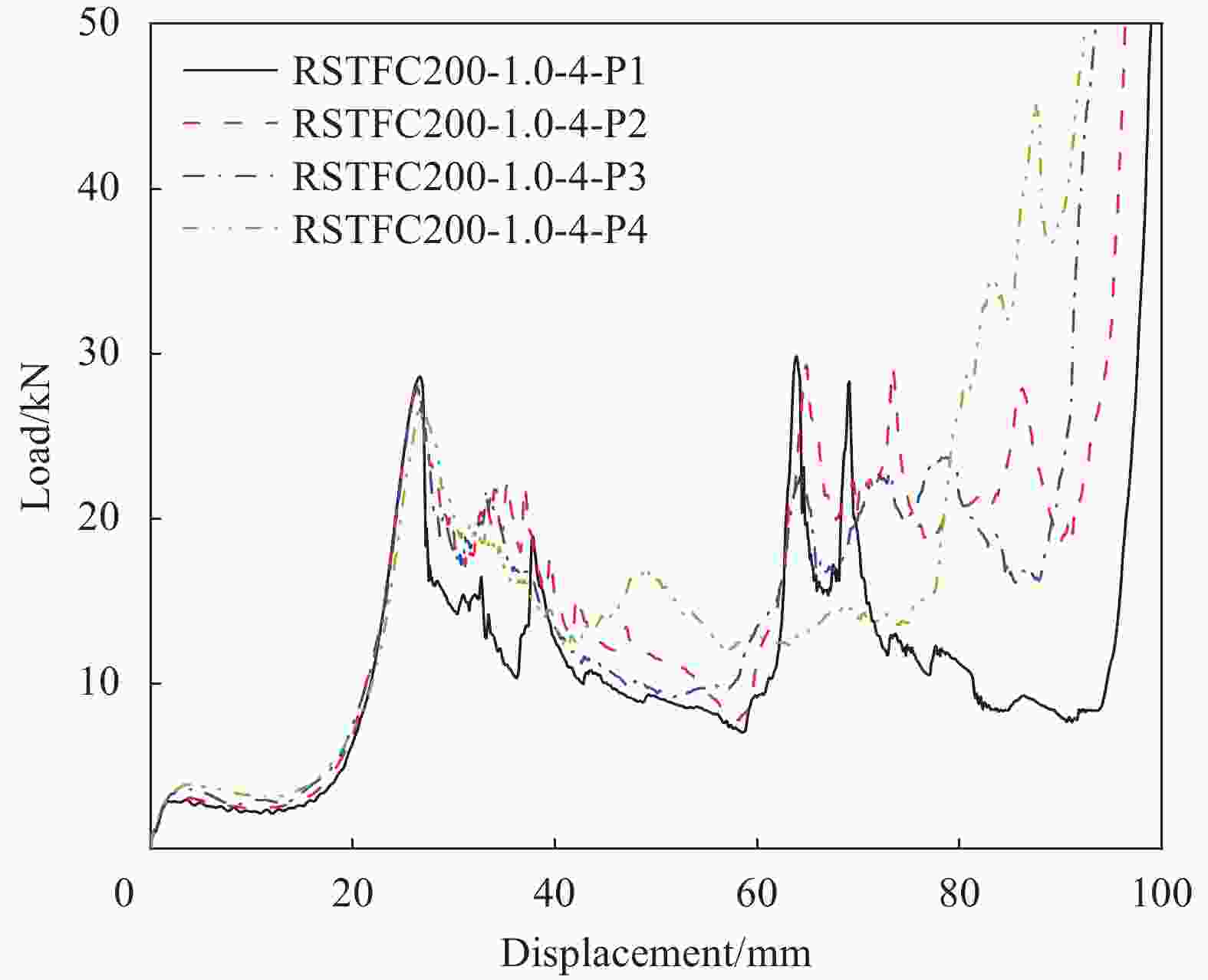

The numbers following RSTFC indicate the density of foam concrete, the thickness of aluminum tube, and the filling mode of foam concrete, respectively; P1 means the number of periodic structures is 1

Figure 13. Deformation mode of RSTFC specimens with different densities of foam concrete filler

表 1 试件质量和几何参数

Table 1. Mass and geometry parameters of specimens

Specimen Mass

/kgHeight

/mmBottom area

/mm2Density of foam

concrete/(kg·m−3)TMST 0.280 81 6521 — RTMST 0.490 119 9543 — RSTFC 0.518 120 9616 193.5 Notes: TMST—Thin-walled multi-cell square tubes; RTMST—Rotating thin-walled multi-cell square tubes. 表 2 铝、钢和泡沫混凝土的力学性能

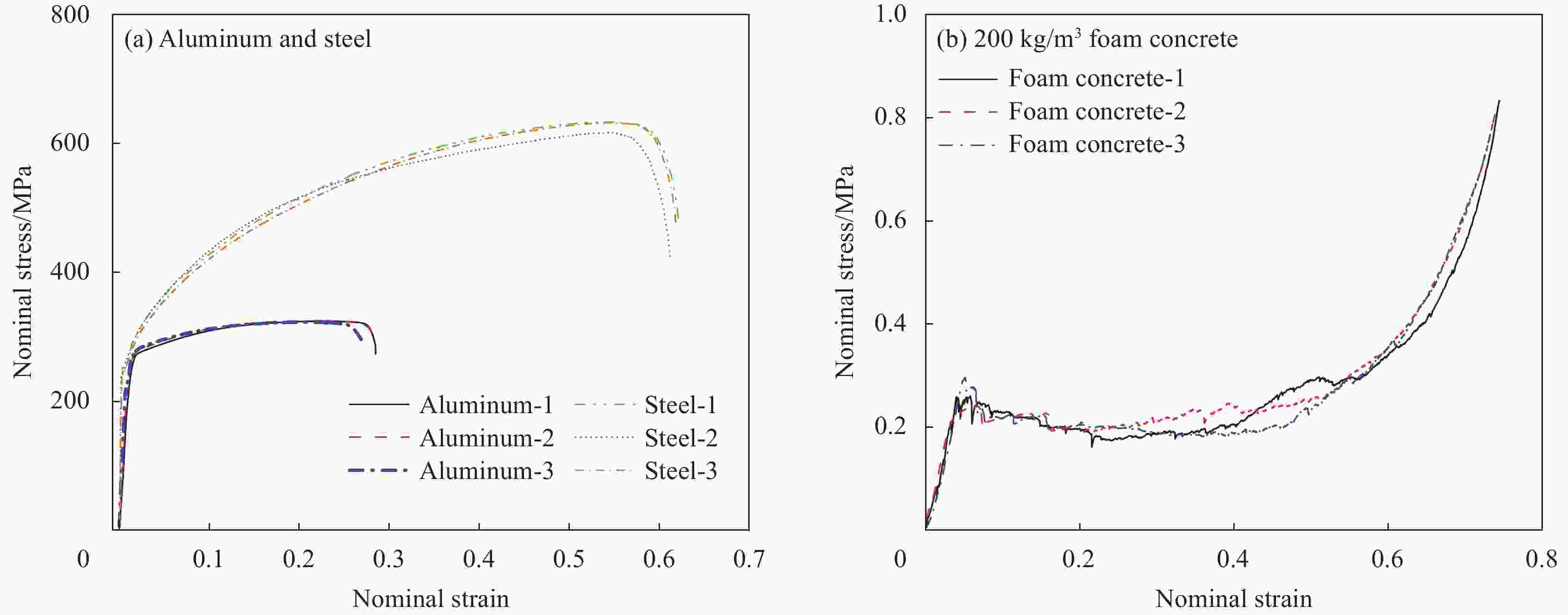

Table 2. Mechanical properties of aluminum, steel and foam concrete

Material $\rho $/(kg·m–3) $ E $/GPa ${\sigma _{\text{y}}}$/MPa ${\sigma _{\text{u}}}$/MPa ${\sigma _{\text{p}}}$/MPa Aluminum 2710 69.9 276.7 324.4 — Steel 7930 242.3 246.3 627.6 — Foam concrete 193.5 0.3 — — 0.2 Notes: $\rho $—Density; $ E $—Young's modulus; ${\sigma _{\text{y}}}$ and ${\sigma _{\text{u}}}$—Yield and ultimate strength, respectively; ${\sigma _{\text{p}}}$—Plateau stress of foam concrete. 表 3 试件的吸能性能参数

Table 3. Energy absorption performance parameters of specimens

Specimen δD

/mmEa

/JEs

/(J·kg–1)Fp

/kNFm

/kNEf TMST 47.0 675.6 2412.9 75.9 14.4 0.190 RTMST 85.1 902.4 1841.6 32.2 10.6 0.329 RSTFC 85.9 982.5 1896.7 28.4 11.4 0.403 Notes: Ea—Energy absorption; Es—Specific energy absorption; Fp—Peak crushing force; Fm—Mean crushing force; Ef—Crushing force efficiency. 表 4 填充不同密度泡沫混凝土RSTFC试件的数值结果汇总

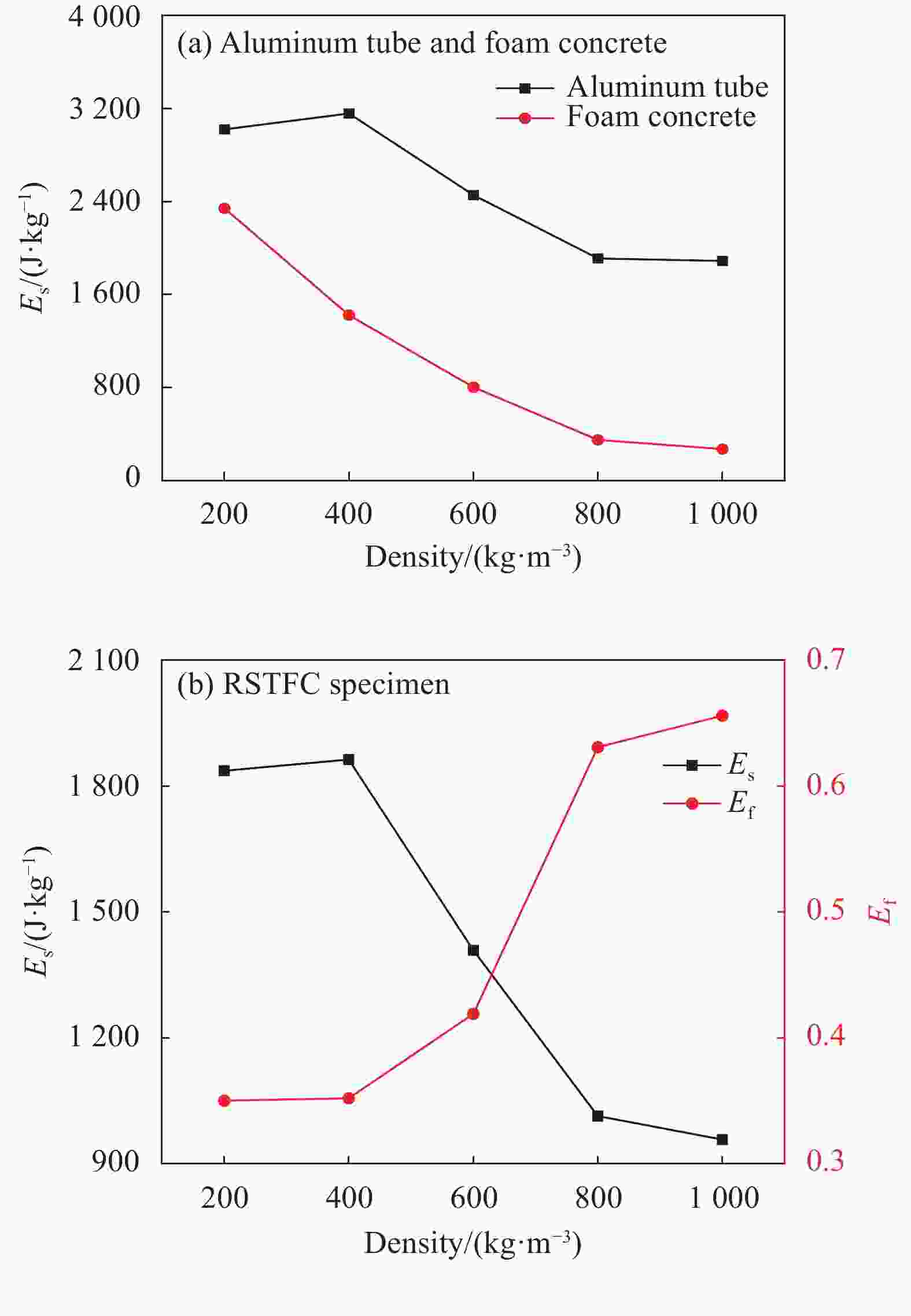

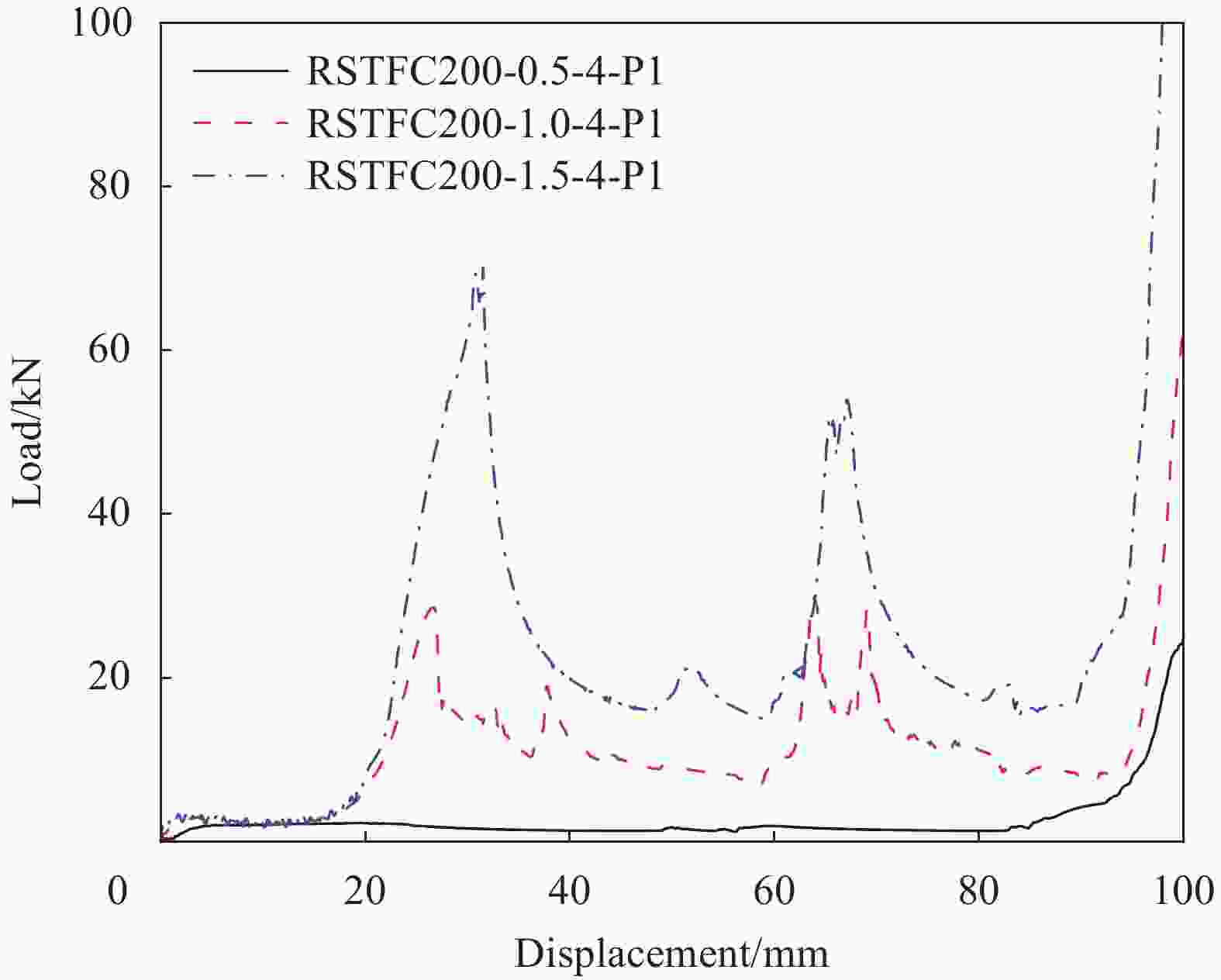

Table 4. Summary of numerical results of RSTFC specimens with different densities of foam concrete filler

Specimen Fp/kN δD/mm Ea/J Es/(J·kg–1) Fm/kN Ef RSTFC200-1.0-4-P1 29.9 91.1 951.3 1836.4 10.4 0.350 RSTFC400-1.0-4-P1 31.5 91.6 1017.4 1863.3 11.1 0.352 RSTFC600-1.0-4-P1 21.6 89.1 808.5 1408.6 9.1 0.419 RSTFC800-1.0-4-P1 11.7 82.8 610.0 1013.4 7.4 0.631 RSTFC1000-1.0-4-P1 11.2 81.8 603.1 957.3 7.4 0.656 RSTFC200-0.5-4-P1 2.3 81.2 133.8 347.9 1.6 0.720 RSTFC200-1.5-4-P1 70.1 88.7 1830.5 2839.4 20.6 0.295 RSTFC200-1.0-5-P1 27.7 88.3 961.2 1830.9 10.9 0.393 RSTFC200-1.0-9-P1 15.0 78.9 670.3 1212.1 8.5 0.568 RSTFC200-1.0-4-P2 29.3 89.9 1306.6 2437.7 14.5 0.496 RSTFC200-1.0-4-P3 28.1 87.9 1180.6 2178.3 13.4 0.478 RSTFC200-1.0-4-P4 26.5 75.0 910.8 1671.2 12.1 0.458 Notes: The letter P in the specimen index represent single periodic structure in different numbers of periodic structures; The number of periodic structures is also specified following the letter P. -

[1] BAROUTAJI A, SAJJIA M, OLABI A G. On the crashworthiness performance of thin-walled energy absorbers: Recent advances and future developments[J]. Thin-Walled Structures,2017,118:137-163. doi: 10.1016/j.tws.2017.05.018 [2] LU G X, YU T X. Energy absorption of structures and materials[M]. Cambridge: Woodhead Publishing LTD., 2003. [3] GAO Z P, ZHANG H, ZHAO J, et al. The axial crushing performance of bio-inspired hierarchical multi-cell hexagonal tubes[J]. International Journal of Mechanical Sciences,2023,239:107880. doi: 10.1016/j.ijmecsci.2022.107880 [4] HA N S, PHAM T M, CHEN W S, et al. Crashworthiness analysis of bio-inspired fractal tree-like multi-cell circular tubes under axial crushing[J]. Thin-Walled Structures,2021,169:108315. doi: 10.1016/j.tws.2021.108315 [5] XIONG J, ZHANG Y, SU L, et al. Experimental and numerical study on mechanical behavior of hybrid multi-cell structures under multi-crushing loads[J]. Thin-Walled Structures,2022,170:108588. doi: 10.1016/j.tws.2021.108588 [6] ZHANG H, GAO Z P, RUAN D. Square tubes with graded wall thickness under oblique crushing[J]. Thin-Walled Structures,2023,183:110429. doi: 10.1016/j.tws.2022.110429 [7] LUO Y H, FAN H L. Investigation of lateral crushing behaviors of hierarchical quadrangular thin-walled tubular structures[J]. Thin-Walled Structures,2018,125:100-106. doi: 10.1016/j.tws.2018.01.016 [8] TRAN T N, TON T N T. Lateral crushing behaviour and theoretical prediction of thin-walled rectangular and square tubes[J]. Composite Structures,2016,154:374-384. doi: 10.1016/j.compstruct.2016.07.068 [9] TRAN T N. Crushing analysis of multi-cell thin-walled rectangular and square tubes under lateral loading[J]. Composite Structures,2017,160:734-747. doi: 10.1016/j.compstruct.2016.10.106 [10] WU F, CHEN Y T, ZHAO S Q, et al. Mechanical properties and energy absorption of composite bio-inspired multi-cell tubes[J]. Thin-Walled Structures,2023,184:110451. doi: 10.1016/j.tws.2022.110451 [11] CHAHARDOLI S, NIA A A, ASADI M. A parametric study of the mechanical behavior of nested multi tube structures under quasi-static loading[J]. Archives of Civil and Mechanical Engineering,2019,19(4):943-957. doi: 10.1016/j.acme.2019.03.006 [12] TRAN T N. A study on nested two-tube structures subjected to lateral crushing[J]. Thin-Walled Structures,2018,129:418-428. doi: 10.1016/j.tws.2018.04.022 [13] YAO S G, TIAN Y X, LI Z X, et al. Crushing characteristic of polygonal tubes with hierarchical triangular cells[J]. Thin-Walled Structures,2020,157:107031. doi: 10.1016/j.tws.2020.107031 [14] REN X, DAS R, TRAN P, et al. Auxetic metamaterials and structures: A review[J]. Smart Materials and Structures,2018,27(2):023001. doi: 10.1088/1361-665X/aaa61c [15] 于靖军, 谢岩, 裴旭. 负泊松比超材料研究进展[J]. 机械工程学报, 2018, 54(13):1-14. doi: 10.3901/JME.2018.13.001YU Jingjun, XIE Yan, PEI Xu. State-of-art of metamaterials with negative Poisson's ratio[J]. Journal of Mechanical Engineering,2018,54(13):1-14(in Chinese). doi: 10.3901/JME.2018.13.001 [16] 任鑫, 张相玉, 谢亿民. 负泊松比材料和结构的研究进展[J]. 力学学报, 2019, 51(3):656-687. doi: 10.6052/0459-1879-18-381REN Xin, ZHANG Xiangyu, XIE Yimin. Research progress in auxetic materials and structures[J]. Chinese Journal of Theoretical and Applied Mechanics,2019,51(3):656-687(in Chinese). doi: 10.6052/0459-1879-18-381 [17] 尤泽华, 肖俊华, 王美芬. 弧边内凹蜂窝负泊松比结构的力学性能[J]. 复合材料学报, 2022, 39(7):3570-3580.YOU Zehua, XIAO Junhua, WANG Meifen. Mechanical properties of arc concave honeycomb structure with negative Poisson's ratio[J]. Acta Materiae Compositae Sinica,2022,39(7):3570-3580(in Chinese). [18] ZHOU H Y, JIA K C, WANG X J, et al. Experimental and numerical investigation of low velocity impact response of foam concrete filled auxetic honeycombs[J]. Thin-Walled Structures,2020,154:106898. doi: 10.1016/j.tws.2020.106898 [19] 王雪松, 刘卫东, 刘典. 新型反四手性蜂窝结构的面内拉伸弹性[J]. 复合材料学报, 2023, 40(8):4849-4861.WANG Xuesong, LIU Weidong, LIU Dian. In-plane tensile elasticity of a novel anti-tetrachiral cellular structure[J]. Acta Materiae Compositae Sinica,2023,40(8):4849-4861(in Chinese). [20] JIAO C X, YAN G. Design and elastic mechanical response of a novel 3D-printed hexachiral helical structure with negative Poisson's ratio[J]. Materials & Design,2021,212:110219. [21] 卢子兴, 王欢, 杨振宇, 等. 星型-箭头蜂窝结构的面内动态压溃行为[J]. 复合材料学报, 2019, 36(8):1893-1900. doi: 10.13801/j.cnki.fhclxb.20180908.001LU Zixing, WANG Huan, YANG Zhenyu, et al. In-plane dynamic crushing of star-arrowhead honeycomb structure[J]. Acta Materiae Compositae Sinica,2019,36(8):1893-1900(in Chinese). doi: 10.13801/j.cnki.fhclxb.20180908.001 [22] 杨泽水, 薛玉祥, 刘爱荣. 三维负泊松比星型结构冲击动力学研究[J]. 工程力学, 2022, 39(S1):356-363.YANG Zeshui, XUE Yuxiang, LIU Airong. Study on the impact dynamics of three-dimensional starshaped structure with negative Poisson's ratio[J]. Engineering Mechanics,2022,39(S1):356-363(in Chinese). [23] 刘彦佐, 李振羽, 杨金水. 碳纤维复合材料双箭头波纹拉胀结构的振动行为及减振性能[J]. 复合材料学报, 2022, 39(8):4117-4128.LIU Yanzuo, LI Zhenyu, YANG Jinshui. Vibration behavior and damping performance of carbon fiber composite double-arrow corrugated auxetic structures[J]. Acta Materiae Compositae Sinica,2022,39(8):4117-4128(in Chinese). [24] GUO M F, YANG H, ZHOU Y M, et al. Mechanical properties of 3D hybrid double arrow-head structure with tunable Poisson's ratio[J]. Aerospace Science and Technology,2021,119:107177. doi: 10.1016/j.ast.2021.107177 [25] GALEA R, FARRUGIA P S, DUDEK K K, et al. A novel design method to produce 3D auxetic metamaterials with continuous pores exemplified through 3D rotating auxetic systems[J]. Materials & Design,2023,226:111596. [26] 孙龙, 任鑫, 张毅, 等. 一种刚度可调控的负泊松比管状结构[J]. 复合材料学报, 2022, 39(4):1813-1823.SUN Long, REN Xin, ZHANG Yi, et al. An auxetic tubular structure with tuneable stiffness[J]. Acta Materiae Compositae Sinica,2022,39(4):1813-1823(in Chinese). [27] 周宏元, 贾昆程, 王小娟, 等. 负泊松比三明治结构填充泡沫混凝土的面内压缩性能[J]. 复合材料学报, 2020, 37(8):2005-2014. doi: 10.13801/j.cnki.fhclxb.20191207.001ZHOU Hongyuan, JIA Kuncheng, WANG Xiaojuan, et al. In-plane compression properties of negative Poisson's ratio sandwich structure filled with foam concrete[J]. Acta Materiae Compositae Sinica,2020,37(8):2005-2014(in Chinese). doi: 10.13801/j.cnki.fhclxb.20191207.001 [28] 刘彦, 王百川, 闫俊伯, 等. 侵彻作用下负泊松比蜂窝夹芯结构动态响应研究[J]. 兵工学报, 2023, 44(7): 1938-1953..LIU Yan, WANG Baichuan, YAN Junbo, et al. Study on dynamic response of honeycomb sandwich plate with negative Poisson's ratio under penetration[J]. Acta Armentarii, 2023, 44(7): 1938-1953(in Chinese). [29] REN X, ZHANG Y, HAN C Z, et al. Mechanical properties of foam-filled auxetic circular tubes: Experimental and numerical study[J]. Thin-Walled Structures,2022,170:108584. doi: 10.1016/j.tws.2021.108584 [30] 宋强, 张鹏, 鲍玖文, 等. 泡沫混凝土的研究进展与应用[J]. 硅酸盐学报, 2021, 49(2):398-410. doi: 10.14062/j.issn.0454-5648.20200316SONG Qiang, ZHANG Peng, BAO Jiuwen, et al. Research progress and application of foam concrete[J]. Journal of the Chinese Ceramic Society,2021,49(2):398-410(in Chinese). doi: 10.14062/j.issn.0454-5648.20200316 [31] 周宏元, 樊家乐, 王小娟, 等. 填充泡沫混凝土铝管组合挂板的吸能性能[J]. 复合材料学报, 2023, 40(5):2860-2871.ZHOU Hongyuan, FAN Jiale, WANG Xiaojuan, et al. Energy absorption of foam concrete filled aluminum tube composite cladding[J]. Acta Materiae Compositae Sinica,2023,40(5):2860-2871(in Chinese). [32] WANG Y H, ZHANG B Y, LU J Y, et al. Quasi-static crushing behaviour of the energy absorbing connector with polyurethane foam and multiple pleated plates[J]. Engineering Structures,2020,211:110404. doi: 10.1016/j.engstruct.2020.110404 [33] 应文剑, 王永辉, 翟希梅. 冲击荷载作用下内嵌泡沫铝耗能节点试验[J]. 哈尔滨工业大学学报, 2018, 50(12):171-177. doi: 10.11918/j.issn.0367-6234.201802056YING Wenjian, WANG Yonghui, ZHAI Ximei. Experimental study of aluminum foam filled energy absorption connectors under impact loading[J]. Journal of Harbin Institute of Technology,2018,50(12):171-177(in Chinese). doi: 10.11918/j.issn.0367-6234.201802056 [34] 杨姝, 陈鹏宇, 江峰, 等. 内凹弧形蜂窝夹芯板低速弹道冲击试验与数值仿真[J]. 振动与冲击, 2023, 42(6):255-262, 297.YANG Shu, CHEN Pengyu, JIANG Feng, et al. Low-speed ballistic impact test and numerical simulation on re-entrant circular honeycomb sandwich panels[J]. Journal of Vibration and Shock,2023,42(6):255-262, 297(in Chinese). [35] WANG B, CHEN Y S, FAN H L, et al. Investigation of low-velocity impact behaviors of foamed concrete material[J]. Composites Part B: Engineering,2019,162:491-499. doi: 10.1016/j.compositesb.2019.01.021 -

下载:

下载: