Preparation of glass microspheres/aluminum matrix syntactic foam and its quasi-static compressive characteristic and energy absorption

-

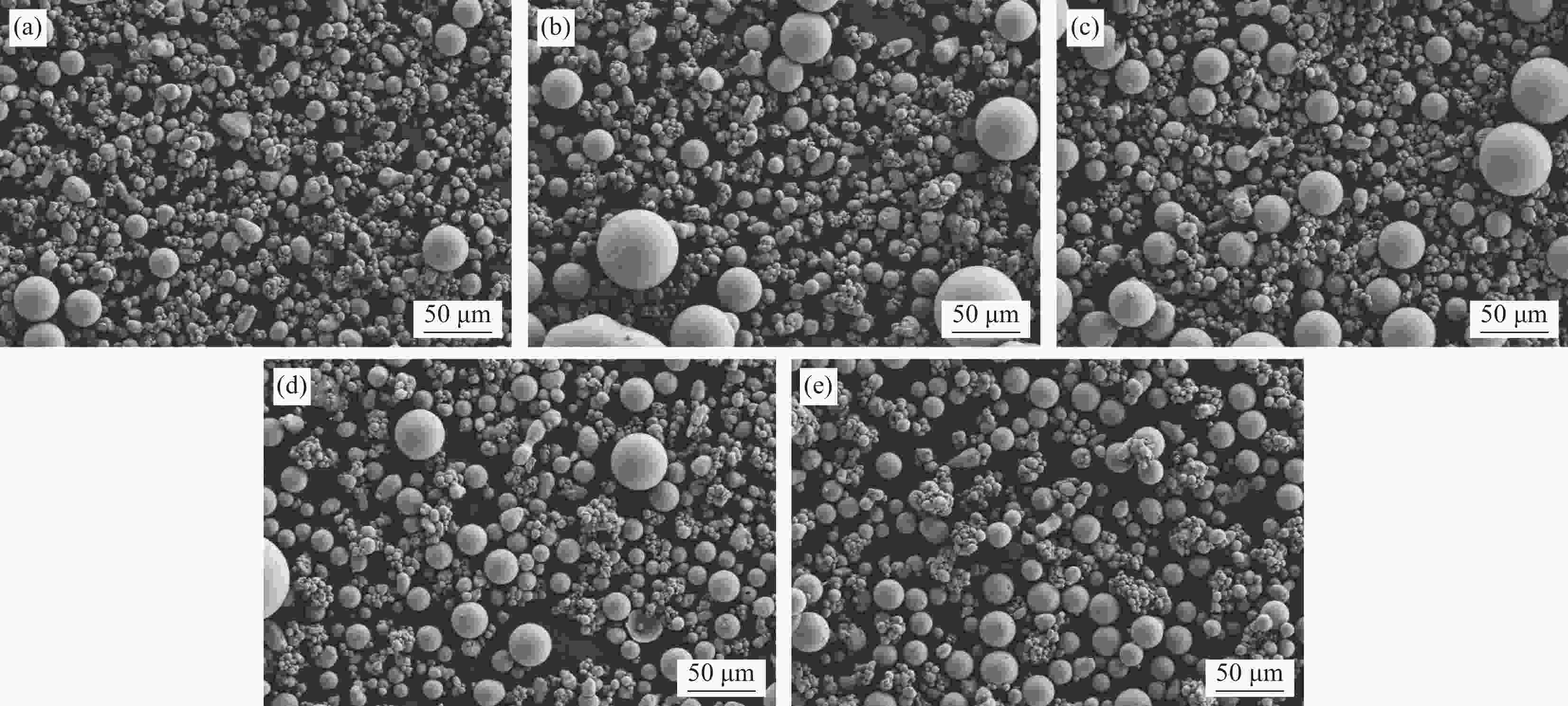

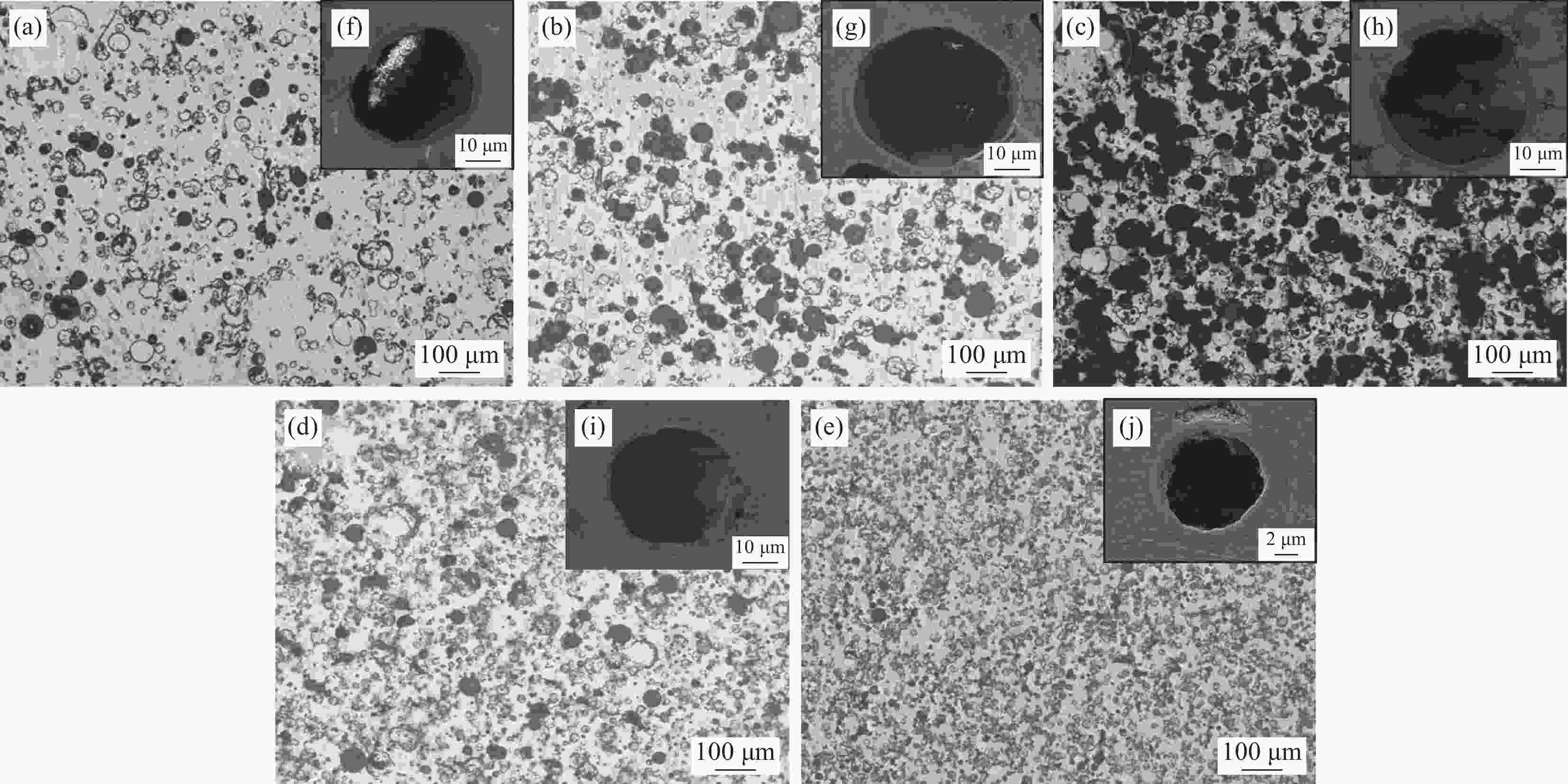

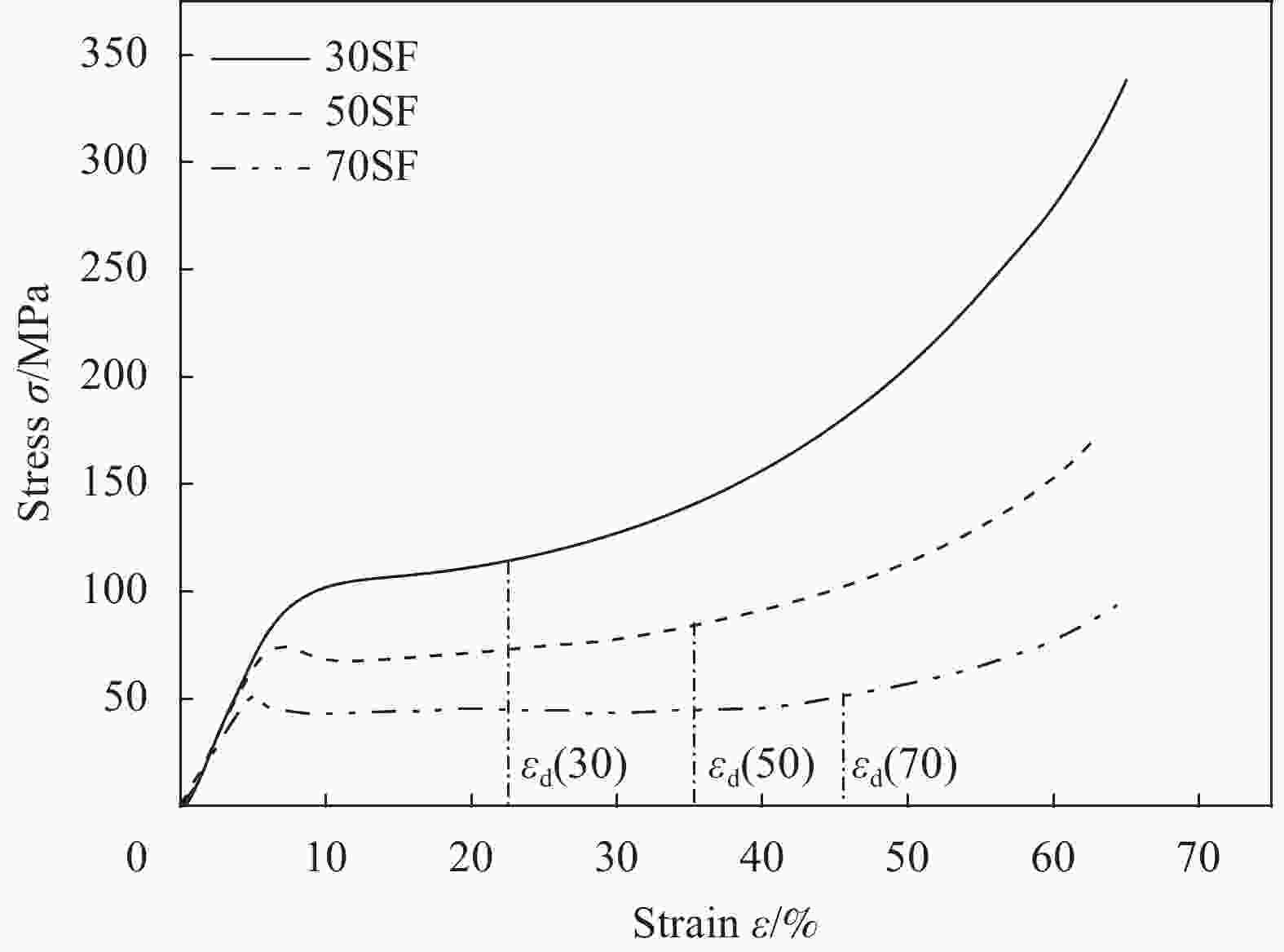

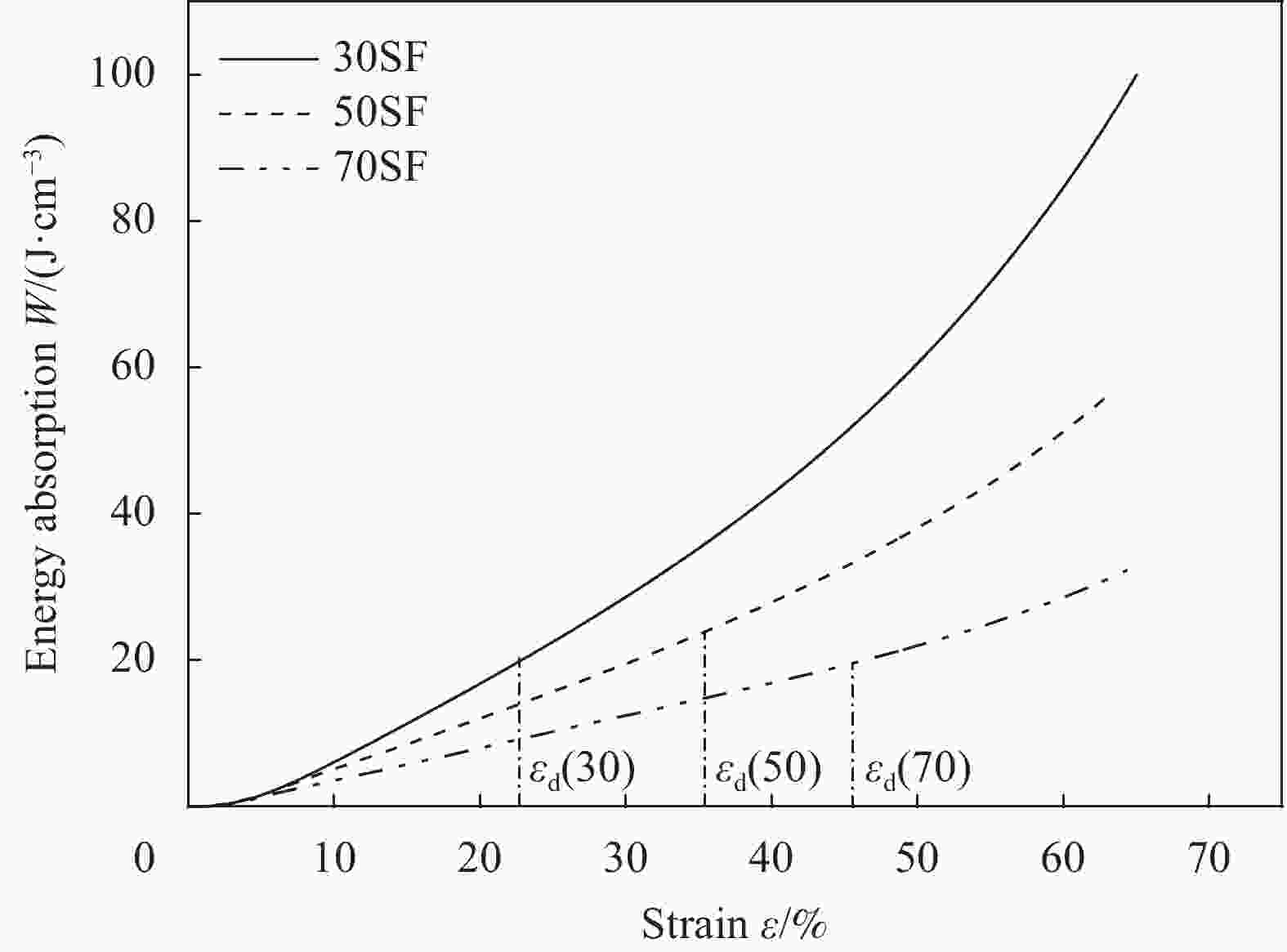

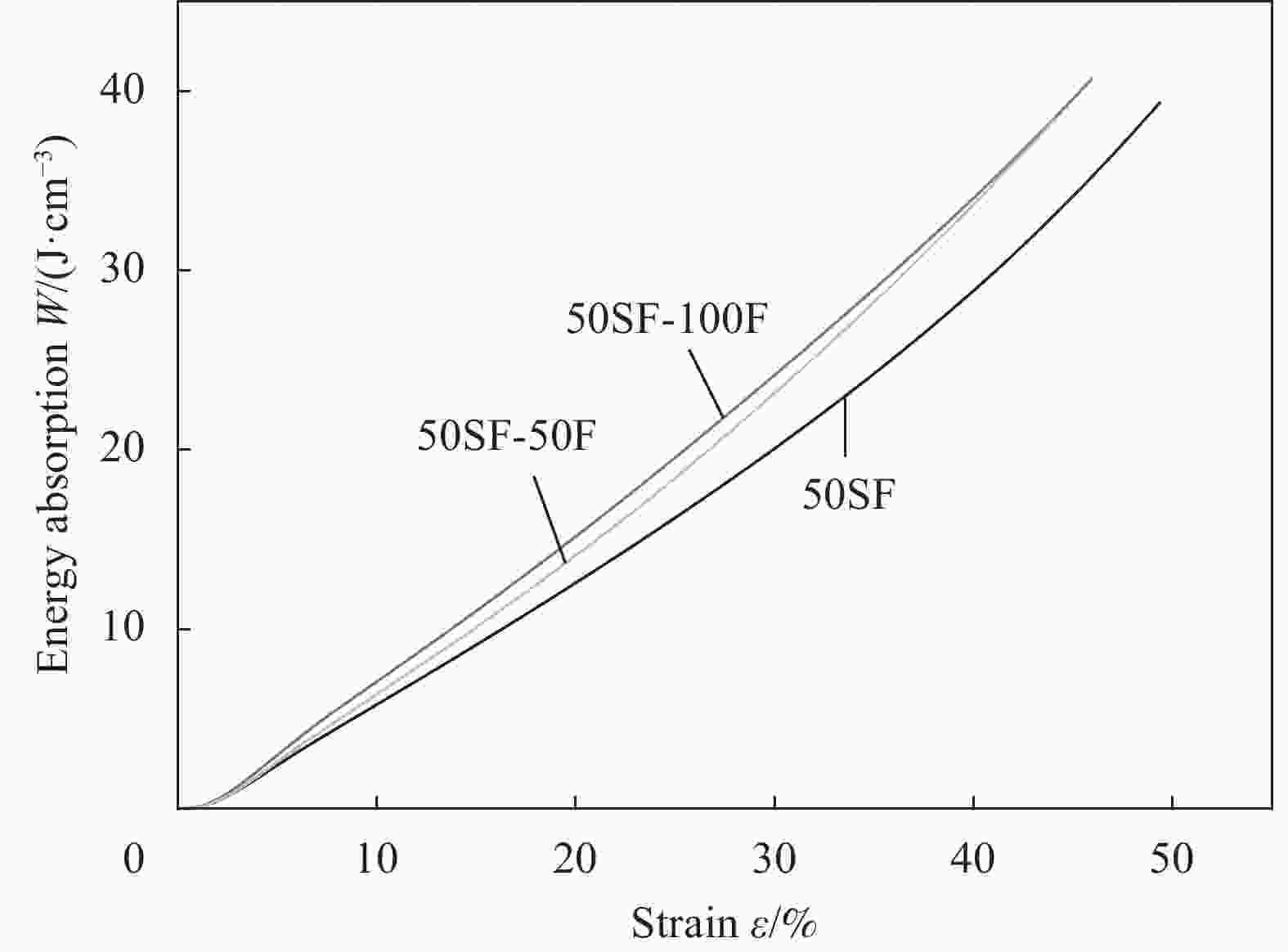

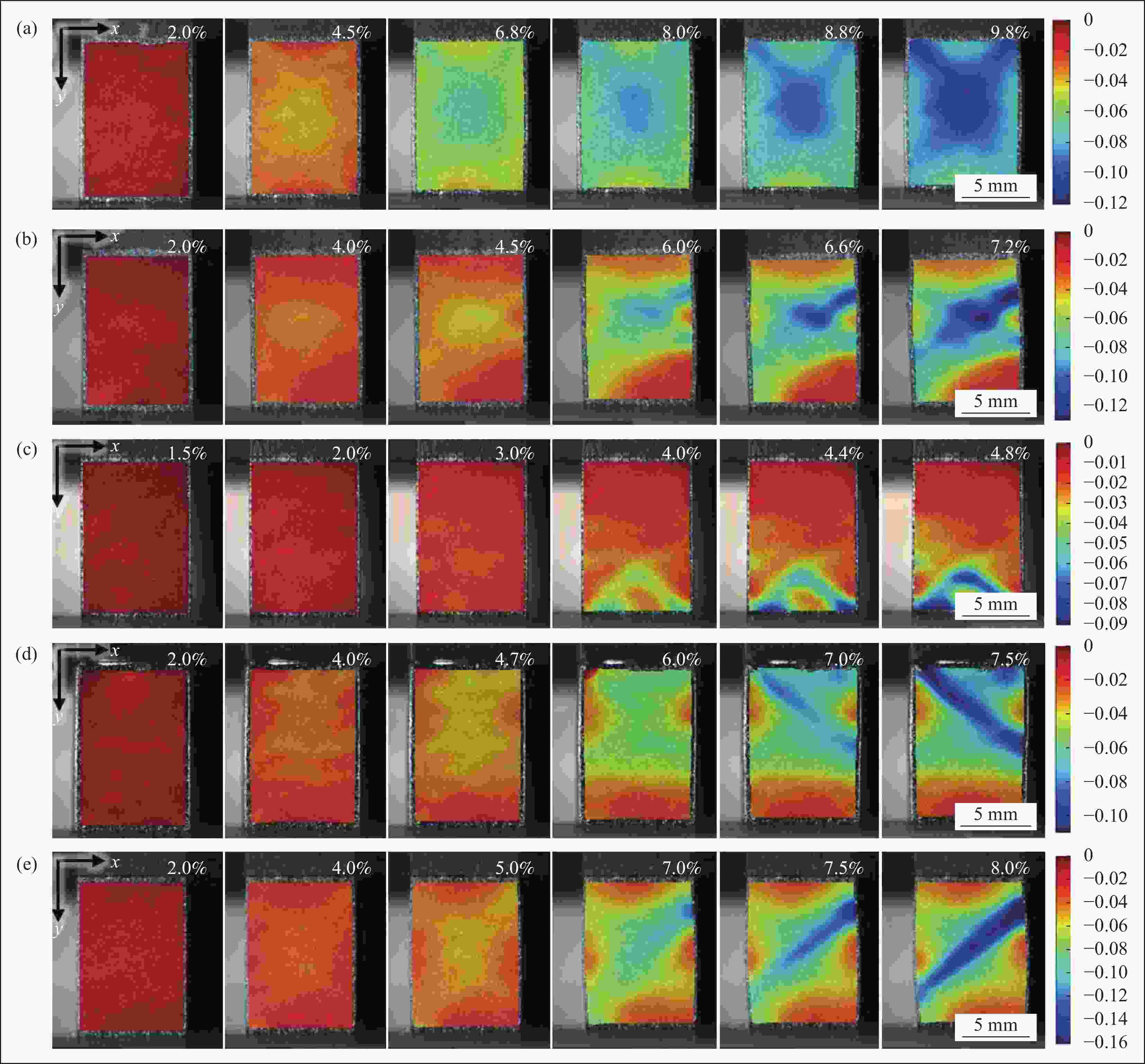

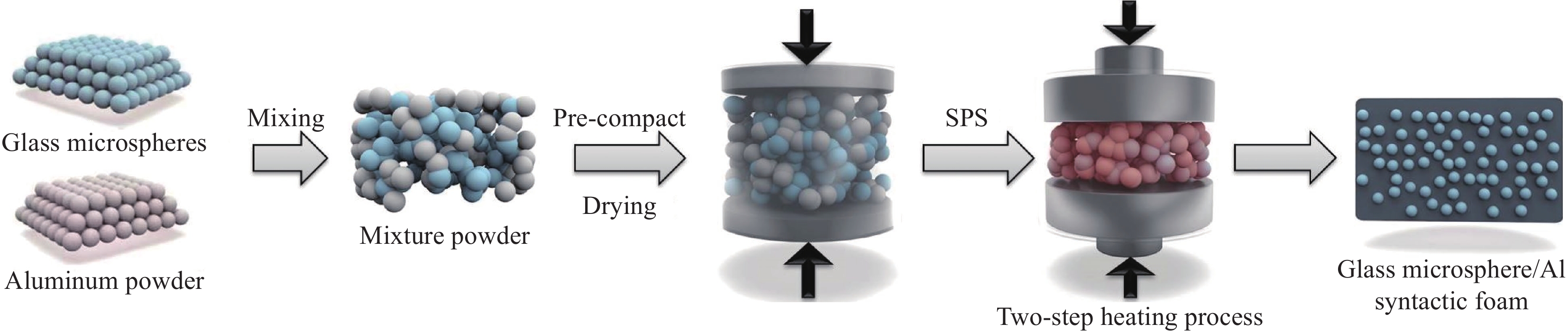

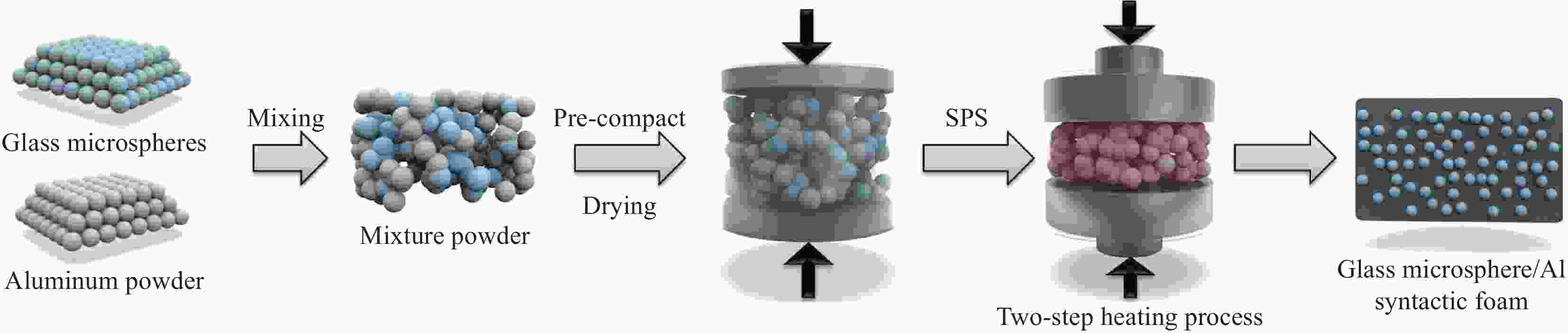

摘要: 铝基多孔复合材料由铝基体和空心微球复合而成,兼具轻质与吸能特性。本文采用放电等离子烧结 (SPS)方法制备玻璃空心微球/铝基多孔复合材料,通过光学显微镜、SEM、准静态压缩原位观察和数字图像相关技术表征,分析了空心微球含量及尺寸对复合材料准静态压缩变形行为和吸能性能的影响。结果表明:两步升温SPS烧结制备所得的铝基多孔复合材料,其微球弥散均匀嵌于铝基体中,铝基体熔合致密。随空心微球含量增加,复合材料压缩应力整体降低,屈服平台区扩大但由平滑转变为锯齿状,压缩变形行为从较均匀的鼓状形变逐渐发展为脆性剪切,微球体积分数为50vol%的多孔复合材料吸能能力为23.6 J·cm−3,高于体积分数为30vol%和70vol%的多孔复合材料,复合材料吸能能力与微球含量间存在最优对应关系。小尺寸微球具有更好的抗压能力,随小尺寸微球占比的提高,复合材料微观上可承受更高的应力-应变集中,宏观上剪切形变的压缩应变增大,本文中小尺寸微球多孔复合材料的峰值应力和吸能能力分别为89.4 MPa和29.0 J·cm−3,与大尺寸微球多孔复合材料相比分别提高23.5%和22.9%。Abstract: Aluminum matrix syntactic foams are a novel class of cellular materials synthesized by hollow particles and aluminum matrix, which exhibit lightweight and high energy-absorbing capacity. In this study, the glass microspheres/aluminum matrix syntactic foams were prepared by the spark plasma sintering (SPS) method. The effects of the content and size of microspheres on the quasi-static compressive deformation behavior and energy absorption properties of the syntactic foams were analyzed by optical microscope (OM), SEM, quasi-static compression in situ observation, and digital image correlation (DIC) characterization. The results show that the microspheres of aluminum matrix syntactic foams prepared by two-step heating SPS sintering are uniformly embedded in the aluminum matrix, while the aluminum matrix is completely fused with high densification. With the increase of the microsphere content, the compressive stress of the syntactic foam decreases as a whole, meanwhile, the yield plateau expands and changes from smooth to zigzag. In addition, the compressive deformation behavior gradually develops from a relatively uniform drum-shaped deformation to brittle shear. The energy absorption capacity of the syntactic foam with the volume fraction of 50vol% is 23.6 J·cm−3, which is higher than that with the volume fraction of 30vol% and 70vol%. There is an optimal correspondence between the energy absorption capacity and the microsphere content of the syntactic foam. Small-sized microspheres have better compressive resistance. With the increase of the small-sized microsphere proportion, the syntactic foams can withstand higher stress and strain concentration on the microscopic level, as a result, the compressive strain of shear deformation increases on the macro level. In this study, the peak stress and energy absorption capacity of the syntactic foam with small-sized microspheres are 89.4 MPa and 29.0 J·cm−3, which are 23.5% and 22.9% higher than those of the syntactic foam with large-sized microsphere, respectively.

-

图 3 玻璃空心微球/铝基多孔复合材料显微形貌:((a), (f)) 30SF;((b), (g)) 50SF;((c), (h)) 70SF;((d), (i)) 50SF-50F;((e), (j)) 50SF-100F

Figure 3. Optical micrographs and SEM images of the glass microspheres/aluminum matrix syntactic foams: ((a), (f)) 30SF; ((b), (g)) 50SF; ((c), (h)) 70SF; ((d), (i)) 50SF-50F; ((e), (j)) 50SF-100F

表 1 玻璃空心微球的材料特性

Table 1. Properties of glass microspheres

Type Particle size/μm True density/

(g·cm−3)Porosity

P0/%10th 50th 90th Top size K46 15 40 70 80 0.46 81.89 IM16K 12 20 30 40 表 2 空心微球-铝粉复合粉体组成

Table 2. Constitute of the cenospheres-Al mixture powder

Type Vcenosphere/vol% VK46/% VIM16K/% 30SF 30 100 0 50SF 50 100 0 70SF 70 100 0 50SF-50F 50 50 50 50SF-100F 50 0 100 Notes: Vcenosphere—Volume fraction of cenospheres in mixture powder; VK46—Volume fraction of K46 in fixed cenospheres; VIM16K—Volume fraction of IM16K in fixed cenospheres; SF—Syntactic foam; F—Fine. 表 3 玻璃空心微球/铝基多孔复合材料密度及孔隙率

Table 3. Density and porosity of glass microsphere/aluminum matrix syntactic foams

Type ρsf/(g·cm−3) Vs/% Vp/% 30SF 2.14 25.1 20.5 50SF 1.67 46.0 37.6 70SF 1.34 60.7 49.7 50SF-50F 1.66 46.4 38.0 50SF-100F 1.64 47.1 38.6 Notes: ρsf—Average density of syntactic foam; Vs—Volume fraction of microspheres in syntactic foam; Vp—Porosity of syntactic foam. 表 4 玻璃空心微球/铝基多孔复合材料准静态压缩特征参量

Table 4. Summary of quasi-static compression data for glass microsphere/aluminum matrix syntactic foams

Type σp/MPa σpl/MPa εd/% W/(J·cm−3) 30SF 94.8±2.3 105.7±0.5 22.8±1.6 20.0 50SF 72.4±1.2 70.1±2.6 35.4±0.4 23.6 70SF 51.6±0.5 44.5±2.0 45.7±0.4 19.7 50SF-50F 81.5±2.0 80.3±0.6 31.6±0.4 25.7 50SF-100F 89.4±4.7 86.0±3.1 35.1±0.4 29.0 Notes: σp—Peak stress; σpl—Plateau stress; W—Energy absorption. -

[1] SHIL'KO S V, CHERNOUS D A, ZHANG Q, et al. Uniaxial compression model for a metal-matrix/hollow-microsphere composite synthesized by pressure infiltration[J]. Mechanics of Materials,2020,144:103349. doi: 10.1016/j.mechmat.2020.103349 [2] KATONA B, SZLANCSIK A, TÁBI T, et al. Compressive characteristics and low frequency damping of aluminium matrix syntactic foams[J]. Materials Science and Engineering: A,2019,739:140-148. doi: 10.1016/j.msea.2018.10.014 [3] LIN Y, ZHANG Q, CHANG J, et al. Microstructural characterization and compression mechanical response of glass hollow spheres/Al syntactic foams with different Mg additions[J]. Materials Science and Engineering: A,2019,766:138338. doi: 10.1016/j.msea.2019.138338 [4] MOVAHEDI N, MURCH G E, BELOVA I V, et al. Functionally graded metal syntactic foam: Fabrication and mechanical properties[J]. Materials & Design,2019,168:107652. [5] 张博一, 高金涛, 王理, 等. 粉煤灰空心球/Al复合泡沫材料准静态力学性能及本构模型[J]. 复合材料学报, 2021, 38(8):2655-2665. doi: 10.13801/j.cnki.fhclxb.20201116.003ZHANG Boyi, GAO Jintao, WANG Li, et al. Quasi-static mechanical properties and constitutive model of fly ash cenosphere/aluminum syntactic foam[J]. Acta Materiae Compositae Sinica,2021,38(8):2655-2665(in Chinese). doi: 10.13801/j.cnki.fhclxb.20201116.003 [6] ZHANG B, LIN Y F, LI S, et al. Quasi-static and high strain rates compressive behavior of aluminum matrix syntactic foams[J]. Composites Part B: Engineering,2016,98:288-296. doi: 10.1016/j.compositesb.2016.05.034 [7] ZHANG Q, LIN Y F, CHI H T, et al. Quasi-static and dynamic compression behavior of glass cenospheres/5A03 syntactic foam and its sandwich structure[J]. Composite Structures,2018,183:499-509. doi: 10.1016/j.compstruct.2017.05.024 [8] MOVAHEDI N, CONWAY S, BELOVA I V, et al. Influence of particle arrangement on the compression of functionally graded metal syntactic foams[J]. Materials Science and Engineering: A,2019,764:138242. doi: 10.1016/j.msea.2019.138242 [9] BIRLA S, MONDAL D P, DAS S, et al. Effect of cenosphere content on the compressive deformation behaviour of aluminum-cenosphere hybrid foam[J]. Materials Science and Engineering: A,2017,685:213-226. doi: 10.1016/j.msea.2016.12.131 [10] 朱烨飞, 孙雨果. 单轴压缩载荷下闭孔泡沫铝的变形机制[J]. 复合材料学报, 2017, 34(8):1810-1816. doi: 10.13801/j.cnki.fhclxb.20161116.002ZHU Yefei, SUN Yuguo. Deformation mechanism of closed-cell aluminum foam under uniaxial compression[J]. Acta Materiae Compositae Sinica,2017,34(8):1810-1816(in Chinese). doi: 10.13801/j.cnki.fhclxb.20161116.002 [11] MYERS K, KATONA B, CORTES P, et al. Quasi-static and high strain rate response of aluminum matrix syntactic foams under compression[J]. Composites Part A: Applied Science and Manufacturing,2015,79:82-91. doi: 10.1016/j.compositesa.2015.09.018 [12] GOEL M D, MONDAL D P, YADAV M S, et al. Effect of strain rate and relative density on compressive deformation behavior of aluminum cenosphere syntactic foam[J]. Materials Science and Engineering: A,2014,590:406-415. doi: 10.1016/j.msea.2013.10.048 [13] COX J, LUONG D, SHUNMUGASAMY V, et al. Dynamic and thermal properties of aluminum alloy A356/silicon carbide hollow particle syntactic foams[J]. Metals,2014,4(4):530-548. doi: 10.3390/met4040530 [14] LUONG D D, STRBIK O M, HAMMOND V H, et al. Development of high performance lightweight aluminum alloy/SiC hollow sphere syntactic foams and compressive characterization at quasi-static and high strain rates[J]. Journal of Alloys and Compounds,2013,550:412-422. doi: 10.1016/j.jallcom.2012.10.171 [15] MATTHEW L, VASANTH C S, OLIVER M S, et al. Compressive and thermal characterization of syntactic foams containing hollow silicon carbide particles with porous shell[J]. Journal of Applied Polymer Science,2014,131(17):1-5. [16] ORBULOV I N, MÁJLINGER K. Description of the compressive response of metal matrix syntactic foams[J]. Materials & Design,2013,49:1-9. [17] ROHATGI P K, KIM J K, GUPTA N, et al. Compressive characteristics of A356/fly ash cenosphere composites synthesized by pressure infiltration technique[J]. Composites Part A: Applied Science and Manufacturing,2006,37(3):430-437. doi: 10.1016/j.compositesa.2005.05.047 [18] TAO X F, ZHAO Y Y. Compressive behavior of Al matrix syntactic foams toughened with Al particles[J]. Scripta Materialia,2009,61:461-464. doi: 10.1016/j.scriptamat.2009.04.045 [19] SANTA MARIA J A, SCHULTZ B F, FERGUSON J B, et al. Al-Al2O3 syntactic foams—Part I: Effect of matrix strength and hollow sphere size on the quasi-static properties of Al-A206/Al2O3 syntactic foams[J]. Materials Science and Engineering: A,2013,582:415-422. doi: 10.1016/j.msea.2013.05.081 [20] SANTA MARIA J A, SCHULTZ B F, FERGUSON J B, et al. Effect of hollow sphere size and size distribution on the quasi-static and high strain rate compressive properties of Al-A380-Al2O3 syntactic foams[J]. Journal of Materials Science,2013,49(3):1267-1278. doi: 10.1007/s10853-013-7810-y [21] TAO X F, ZHANG L P, ZHAO Y Y. Al matrix syntactic foam fabricated with bimodal ceramic microspheres[J]. Materials & Design,2009,30(7):2732-2736. [22] AL-SAHLANI K, BROXTERMANN S, LELL D, et al. Effects of particle size on the microstructure and mechanical properties of expanded glass-metal syntactic foams[J]. Materials Science and Engineering: A,2018,728:80-87. doi: 10.1016/j.msea.2018.04.103 [23] GHOSH D, WIEST A, CONNER R D. Uniaxial quasistatic and dynamic compressive response of foams made from hollow glass microspheres[J]. Journal of the European Ceramic Society,2016,36(3):781-789. doi: 10.1016/j.jeurceramsoc.2015.10.018 [24] NEVILLE B P, RABIEI A. Composite metal foams processed through powder metallurgy[J]. Materials & Design,2008,29(2):388-396. [25] 中国国家标准化管理委员会. 金属材料 延性试验 多孔状和蜂窝状金属压缩试验方法: GB/T 31930—2015[S]. 北京: 中国标准出版社, 2015.Standardization Administration of the People's Republic of China. Metallic meterials—Ductility testing—Compression test for porous and cellular metals: GB/T 31930—2015[S]. Beijing: China Standards Press, 2005(in Chinese). [26] BLABER J, ADAIR B, ANTONIOU A. Ncorr: Open-source 2D digital image correlation matlab software[J]. Experimental Mechanics,2015,55(6):1105-1122. doi: 10.1007/s11340-015-0009-1 [27] 曹磊. 粉末冶金铝及铝合金颗粒界面结构及其对力学性能的影响研究[D]. 上海: 上海交通大学, 2020.CAO Lei. The study on microstructures of interparticle boundaries in Al and Al alloys prepared by power metallurgy and their effects on the mechanical properties[D]. Shanghai: Shanghai Jiao Tong University, 2020(in Chinese). [28] 孙愈琦. 放电等离子烧结制备铝合金复合材料及其性能研究[D]. 郑州: 郑州大学, 2020.SUN Yuqi. Preparation and properties of aluminum alloy composites by spark plasma sintering[D]. Zhengzhou: Zhengzhou University, 2020(in Chinese). [29] ORBULOV I N. Compressive properties of aluminium matrix syntactic foams[J]. Materials Science and Engineering: A,2012,555:52-56. doi: 10.1016/j.msea.2012.06.032 [30] LIN Y F, ZHANG Q, MA X Y, et al. Mechanical behavior of pure Al and Al-Mg syntactic foam composites containing glass cenospheres[J]. Composites Part A: Applied Science and Manufacturing,2016,87:194-202. doi: 10.1016/j.compositesa.2016.05.001 -

下载:

下载: