Effect of water absorption on the flame retardancy and mechanical properties of flax fiber reinforced phenolic composites grafted with dimethyl methylphosphate

-

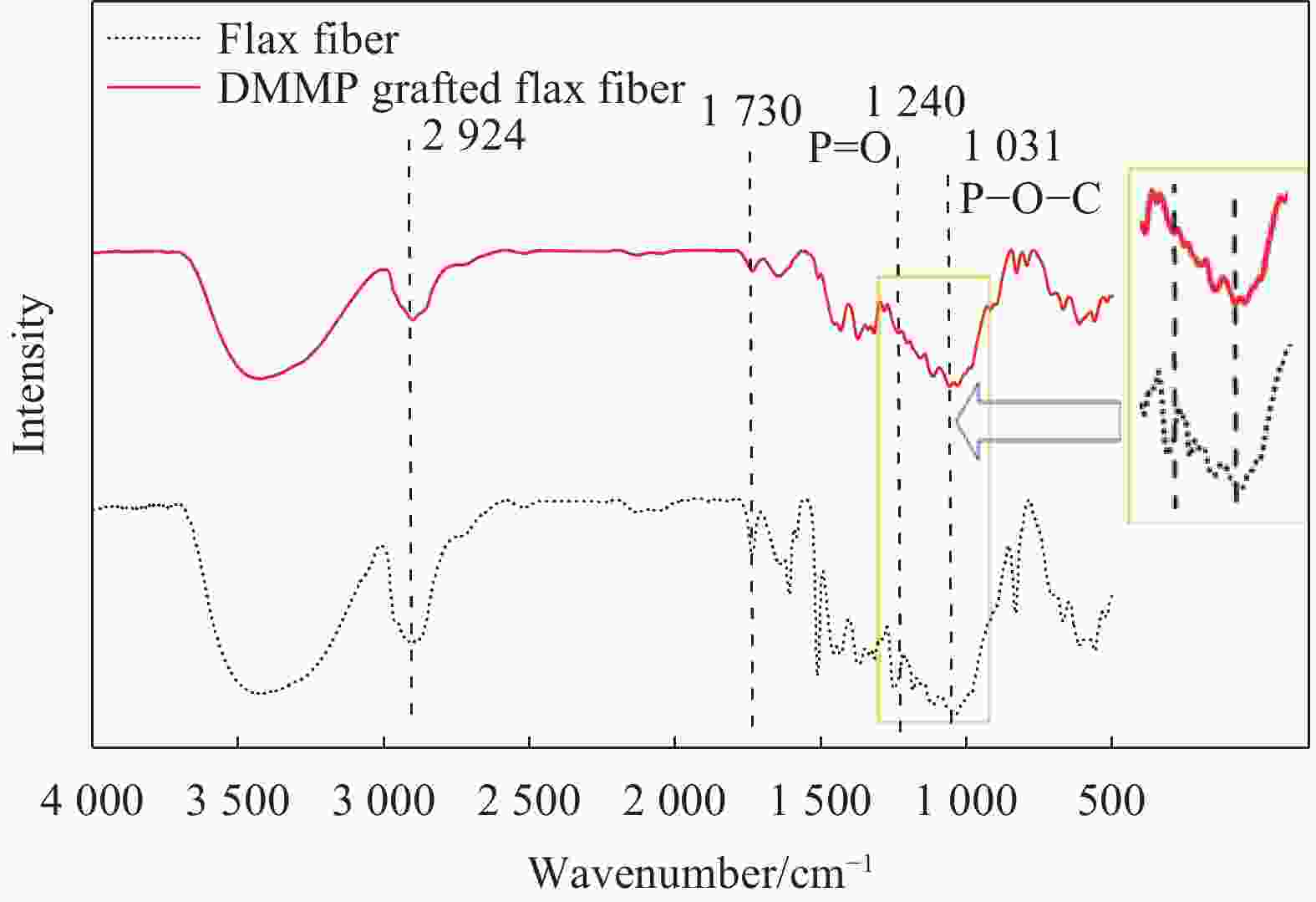

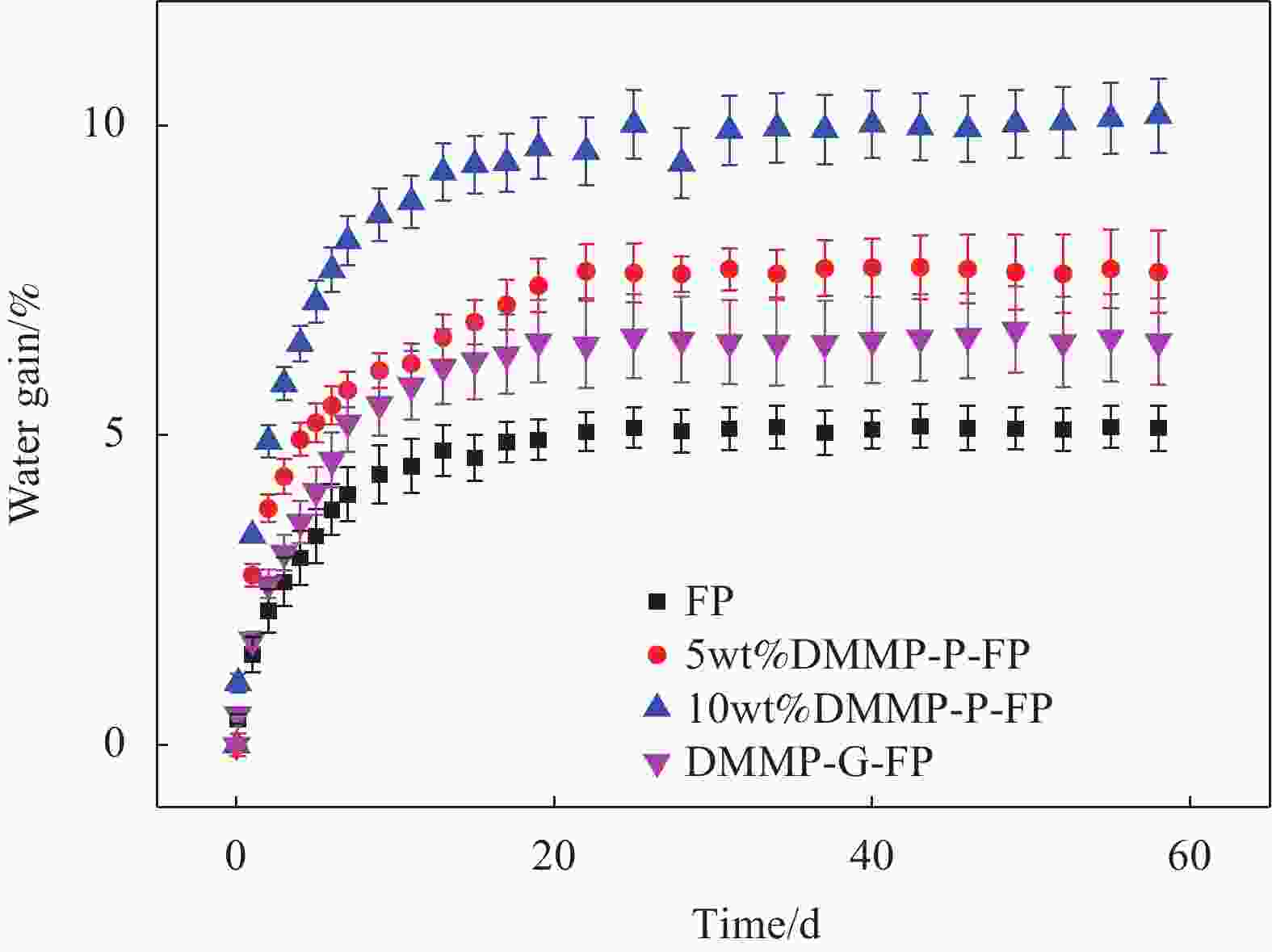

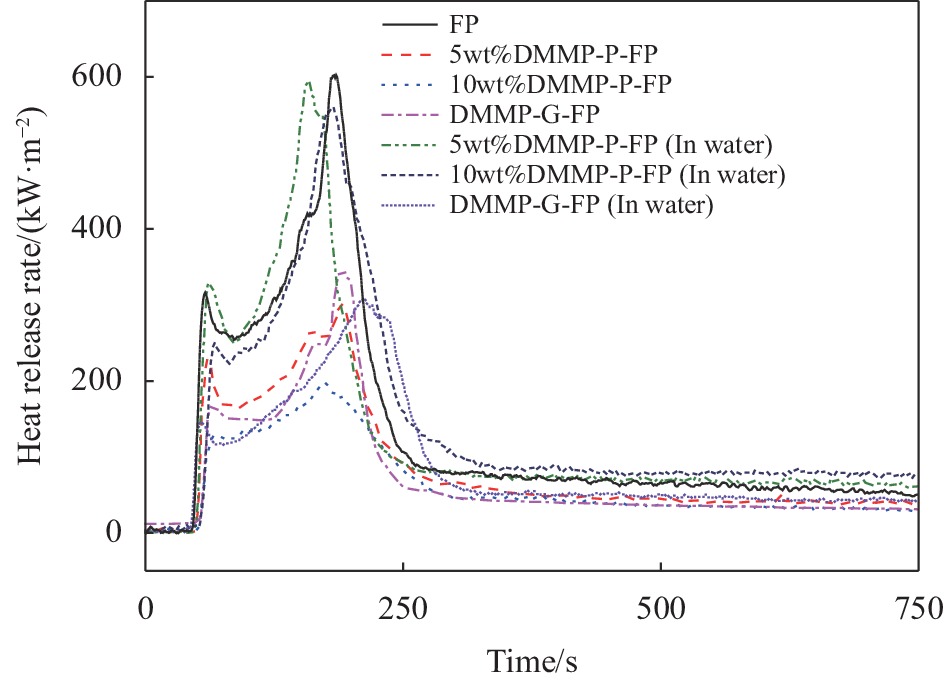

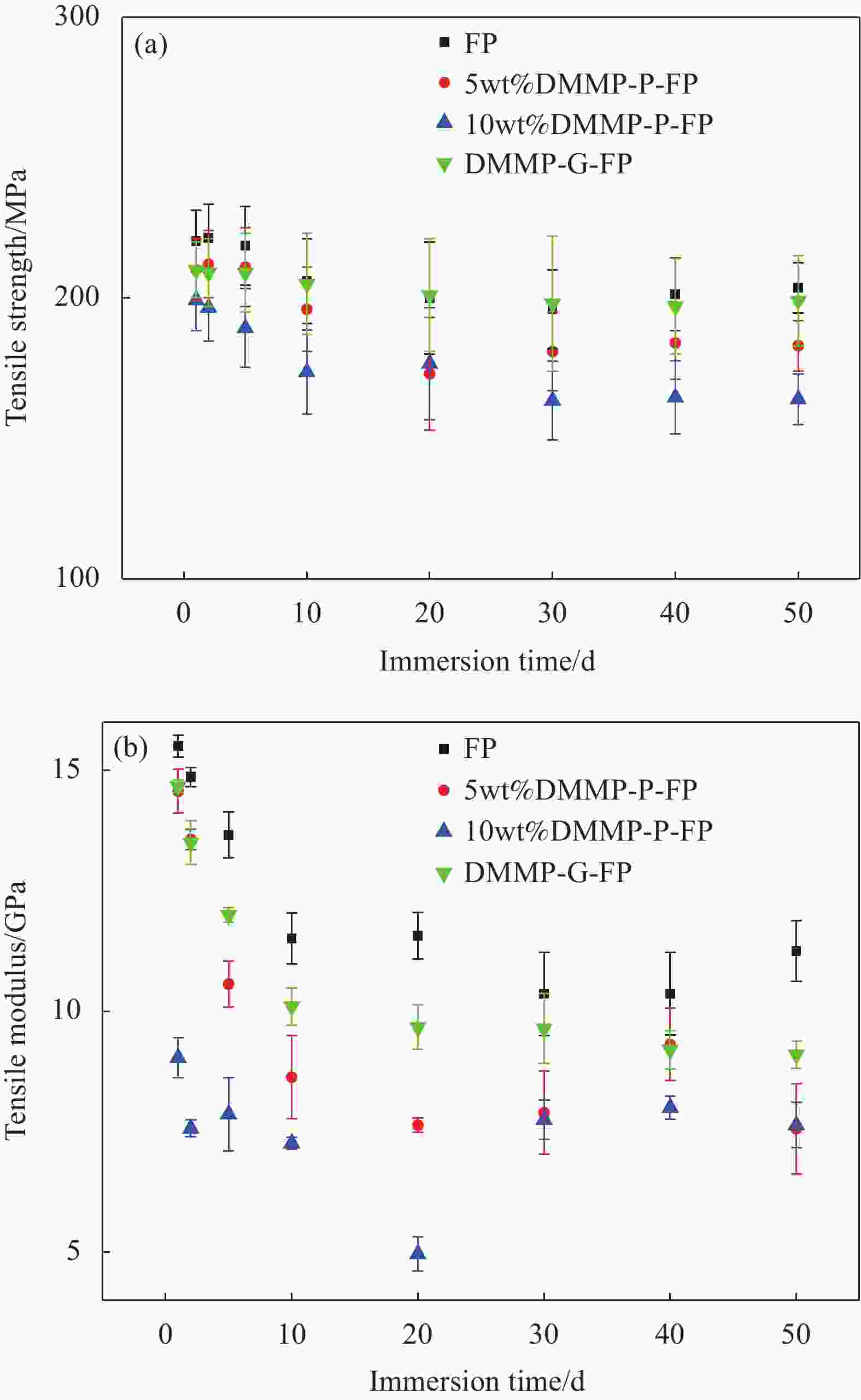

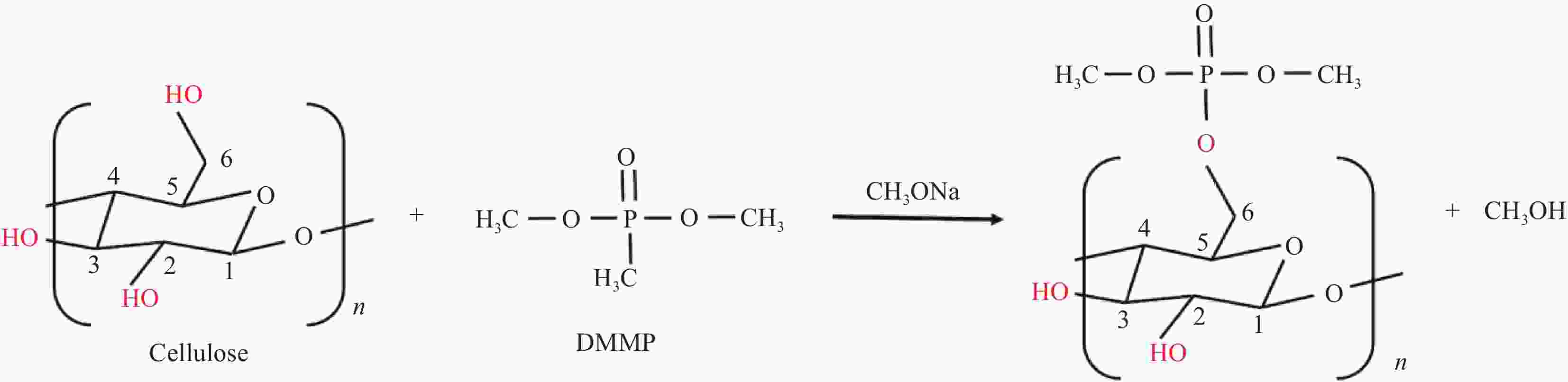

摘要: 近年来,植物纤维增强复合材料因具有绿色环保、高比模量和低成本等优点被国内外广泛关注,改善其易燃和易吸水特性成为这些年的研究热点。为研究阻燃植物纤维增强复合材料的吸水特性,以亚麻纤维增强酚醛复合材料(Flax/Phenolic,FP)为研究对象,利用甲基膦酸二甲酯(Dimethyl methylphosphonate,DMMP)接枝的方法对亚麻纤维进行阻燃处理,探索最佳处理工艺。研究DMMP接枝阻燃复合材料的吸水性及吸水对于复合材料阻燃性能和拉伸性能的影响,并与物理浸渍法进行对比。结果表明:DMMP接枝法具有更高的阻燃效率和更好的抗吸水性能。相较于DMMP物理浸渍,由DMMP接枝亚麻纤维所形成的化学键难以被水分子所破坏,吸水30天后,DMMP接枝的复合材料的极限氧指数(LOI)、垂直燃烧性能、放热和烟雾释放相较于吸水前并未发生明显改变,吸水后阻燃性能保持良好。另一方面,接枝法对于吸水后复合材料的拉伸性能的负面影响也低于物理浸渍法。Abstract: In recent years, plant fiber reinforced composites have been widely concerned because of their advantages of environmental protection, high specific modulus and low cost. In order to study the water absorption characteristics of flame retardant treated plant fiber reinforced composites, flax fiber reinforced phenolic composites (Flax/Phenolic, FP) were used as the research object. The flame retardant treatment of flax fiber was carried out by grafting dimethyl methylphosphonate (DMMP), and the optimal treatment process was explored. The water absorption of DMMP grafted composites and its influence on the flame retardancy and tensile properties of the composites were studied, compared with the physical impregnation method. The results show that DMMP grafting method has higher flame retardant efficiency and better water absorption resistance. Compared with physical impregnation method, the chemical bond formed by DMMP grafting is difficult to be destroyed by water molecules. After 30 days of water absorption, the limiting oxygen index (LOI), vertical combustion, heat release and smoke release of DMMP grafted composites have not changed significantly compared with those before water absorption, and the flame retardancy of DMMP grafted composites is well maintained after water absorption. On the other hand, the negative effect of grafting on the tensile properties of composites after water absorption is also lower than that of physical impregnation.

-

表 1 不同试样的铺层与尺寸

Table 1. Layer and dimension of different sample

Test Number of layer Dimension/mm3 Vertical combustion 16 305×75×4 LOI 16 80×10×4 Cone calorimeter 16 100×100×4 Tensile 8 250×15×2 Water absorption 20 35×35×5 Note: LOI—Limit oxygen index. 表 2 不同复合材料的描述与简写

Table 2. Description and abbreviations of different samples

Sample Description FP Untreated flax/phenolic DMMP-G-FP DMMP-grafted flax/phenolic 5wt%DMMP-P-FP 5wt%DMMP physical impregnation

treated flax/phenolic10wt%DMMP-P-FP 10wt%DMMP physical impregnation

treated flax/phenolic表 3 DMMP接枝亚麻纤维织物后垂直燃烧碳化长度与磷含量

Table 3. Vertical combustion carbonization length and phosphorus content of DMMP grafted treated flax fiber fabric

Condition 3 h 4 h 5 h 80℃ – – – 90℃ – – – 100℃ – – 44.8 mm(0.86%) 110℃ – 41.6 mm(0.92%) 38.7 mm(1.06%) 120℃ 46.4 mm(1.17%) 35.6 mm(1.18%) 35.1 mm(1.25%) Notes: "–" indicates that the specimens cannot extinguish after being moved away from the fire; The values in the parentheses are the phosphorus content on the treated flax fabric. 表 4 DMMP阻燃改性前后复合材料的24 h吸水率

Table 4. Water absorption of composites before and after DMMP flame retardant modification at 24 h

Sample 24 h water absorption/% FP 1.46 5wt%DMMP-P-FP 2.73 10wt%DMMP-P-FP 3.38 DMMP-G-FP 1.73 表 5 阻燃改性前后亚麻纤维增强酚醛复合材料垂直燃烧、LOI和老化液中磷含量(括号中为吸水30天后的垂直燃烧、LOI和老化液中磷含量)

Table 5. Vertical combustion, LOI and phosphorus content in aging solution of flax fiber reinforced phenolic composites before and after flame retardant modification (Vertical combustion, LOI and phosphorus content in the aging solution after 30 days of water absorption are in parentheses)

Sample Self-extinguishing time/s Carbonization length/mm LOI/% Phosphorus content/wt% FP –(–) –(–) 29.2(28.8) –(–) 5wt%DMMP-P-FP –(–) –(–) 32.6(30.9) –(0.48) 10wt%DMMP-P-FP 9(18) 19.9(49.7) 39.6(35.6) –(0.67) DMMP-G-FP 0(0) 18.7(33.8) 44.3(40.5) –(0.12) 表 6 复合材料阻燃改性前后锥形量热测试主要数据

Table 6. Main data of cone calorimetry test before and after flame retardant modification of composites

Sample TTI/s PHRR/(kW·m−2) THR/(MJ·m−2) TSP/m2 FP 41±2.2 602.36±5.1 161.33±6.3 7.43±0.2 5wt%DMMP-P-FP 53±1.9 306.47±21.4 90.12±15.9 4.12±0.4 10wt%DMMP-P-FP 56±0.7 296.90±31.2 86.54±15.6 3.73±0.7 DMMP-G-FP 57±0.7 325.74±41.7 88.65±2.6 3.25±0.2 5wt%DMMP-P-FP(In water) 46±0.3 593.78±23.8 150.36±14.7 7.03±1.4 10wt%DMMP-P-FP (In water) 51±3.4 560.64±15.5 140.70±6.7 6.87±0.9 DMMP-G-FP (In water) 53±1.7 333.71±30.6 93.61±3.7 3.62±0.3 Notes: TTI—Time to ignition; PHRR—Peak heat release rate; THR—Total heat release; TSP—Total smoke production. -

[1] WILLIAMS G I, WOOL R P. Composites from natural fibers and soy oil resins[J]. Applied Composite Materials,2000,7(5-6):421-432. [2] BLEDZKI A K, REIHMANE S, GASSAN J. Properties and modification methods for vegetable fibers for natural fiber composites[J]. Journal of Applied Polymer Science,1996,59(8):1329-1336. doi: 10.1002/(SICI)1097-4628(19960222)59:8<1329::AID-APP17>3.0.CO;2-0 [3] DAS O, SARMAH A K. Mechanism of waste biomass pyrolysis: Effect of physical and chemical pre-treatments[J]. Science of the Total Environment,2015,537:323-334. doi: 10.1016/j.scitotenv.2015.07.076 [4] KIM N K, DUTTA S, BHATTACHARYYA D. A review of flammability of natural fibre reinforced polymeric compo-sites[J]. Composites Science and Technology,2018,162(4):64-78. [5] MAITY S, GON D P, PAUL P. A review of flax nonwovens: Manufacturing, properties, and applications[J]. Journal of Natural Fibers,2014,11(4):365-390. doi: 10.1080/15440478.2013.861781 [6] 贾云龙, BODO F. 吸湿对单向亚麻纤维复合材料力学性能的影响[J]. 复合材料学报, 2022, 39(2):608-616.JIA Yunlong, BODO F. Influence of moisture absorption on the mechanical properties of unidirectional flax fibre composites[J]. Acta Materiae Compositae Sinica,2022,39(2):608-616(in Chinese). [7] DUNNE R, DESAI D, SADIKU R, et al. A review of natural fibres, their sustainability and automotive applications[J]. Journal of Reinforced Plastics and Composites,2016,35(13):1041-1050. doi: 10.1177/0731684416633898 [8] YAN L, KASAL B, HUANG L. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering[J]. Composites Part B: Engineering,2016,92(9):94-132. [9] 李承高, 郭瑞, 王俊琦, 等. GFRP混杂复合材料杆体在水浸泡环境下的性能演化[J]. 复合材料学报, 2021, 38(10):3290-3301.LI Chenggao, GUO Rui, WANG Junqi, et al. Property evolution of GFRP hybrid composite rod exposed in the distilled water[J]. Acta Materiae Compositae Sinica,2021,38(10):3290-3301(in Chinese). [10] AZWA Z N, YOUSIF B F, MANALO A C, et al. A review on the degradability of polymeric composites based on natural fibres[J]. Materials and Design,2013,47(9):424-442. [11] DITTENBER D B, GANGARAO H V S. Critical review of recent publications on use of natural composites in infrastructure[J]. Composites Part A: Applied Science and Manufacturing,2012,43(8):1419-1429. doi: 10.1016/j.compositesa.2011.11.019 [12] CHEOUR K, ASSARAR M, SCIDA D, et al. Effect of water ageing on the mechanical and damping properties of flax-fibre reinforced composite materials[J]. Composite Structures,2016,152(9):259-266. [13] LAOUTID F, BONNAUD L, ALEXANDRE M, et al. New prospects in flame retardant polymer materials: From fundamentals to nanocomposites[J]. Materials Science and Engineering, 2009, 63(3): 100-125. [14] JUNG D, BHATTACHARYYA D. Combined effect of silicate coating and phosphate loading on the performance improvement of a keratinous fiber-based flame retardant[J]. Chemical Engineering Journal,2021,424:130484. [15] ZERDA A S, LESSER A J. Organophosphorous additive for fortification, processibility, and flameretardance of epoxy resins[J]. Journal of Applied Polymer Science,2002,84(2):302-309. doi: 10.1002/app.10329 [16] LIU W, TANG Y, LI F, et al. TG-FTIR characterization of flame retardant polyurethane foams materials[C]//IOP Conference Series: Materials Science and Engineering. Bristol: IOP Publishing Ltd., 2016, 137: 012033. [17] WANG Z, GAO S J, CHE X X, et al. Synthesis and characterization of a flame retardant dimethylmethyl phosphonate (DMMP) and its application in FRP[C]//2013 International Conference on Intelligent Materials and Measurement (ICIMM). Durnten-Zurich: Trans Tech Publications Ltd., 2013: 29-35. [18] CHOW C P L, XING X S, LI R K Y. Moisture absorption studies of sisal fibre reinforced polypropylene composites[J]. Composites Science and Technology,2007,67(2):306-313. doi: 10.1016/j.compscitech.2006.08.005 [19] SREEKALA M S, KUMARAN M G, THOMAS S. Water sorption in oil palm fiber reinforced phenol formaldehyde composites[J]. Composites Part A: Applied Science and Manufacturing,2002,33(6):763-777. doi: 10.1016/S1359-835X(02)00032-5 [20] GARCÍA M, HIDALGO J, GARMENDIA I, et al. Wood-plastics composites with better fire retardancy and durabi-lity performance[J]. Composites Part A: Applied Science and Manufacturing,2009,40(11):1772-1776. doi: 10.1016/j.compositesa.2009.08.010 [21] MOLABA T P, CHAPPLE S, JOHN M J. Flame retardant treated flax fibre reinforced phenolic composites: Ageing and thermal characteristics[J]. Fire and Materials,2018,42(1):50-58. doi: 10.1002/fam.2456 [22] 吴长波, 张永, 易新, 等. 低熔点玻璃协效二乙基次膦酸铝阻燃PA66/GF复合材料研究[J]. 塑料工业, 2019, 47(6):4-8. doi: 10.3969/j.issn.1005-5770.2019.06.024WU Changbo, ZHANG Yong, YI Xin, et al. Research on low melting point glass synergistic aluminum diethylphosphinate flame retardant PA66/GF composites[J]. Plastics Industry,2019,47(6):4-8(in Chinese). doi: 10.3969/j.issn.1005-5770.2019.06.024 [23] American Society of Testing Materials. Standard test method for moisture absorption properties and equilibrium conditioning of polymer matrix composite materials: ASTM D5229[S]. West Conshohocken: ASTM, 2010. [24] American Society of Testing Materials. Standard test method for measuring the minimum oxygen concentration to support candle-like combustion of plastics (oxygen index): ASTM D2863[S]. West Conshohocken: ASTM, 2006. [25] American Society of Testing Materials. Standard test method for flame resistance of textiles: ASTM D6413[S]. West Conshohocken: ASTM, 2008. [26] American Society of Testing Materials. Standard test method for heat and smoke release rates for materials and products using an oxygen consumption calorimeter: ASTM E1354[S]. West Conshohocken: ASTM, 2004. [27] American Society of Testing Materials. Standard test method for tensile properties of polymer matrix composite materials: ASTM D3039[S]. West Conshohocken: ASTM, 2017. [28] American Society of Testing Materials. Standard test method for tensile strength and young’s modulus for high-modulus single-filament Materials: ASTM D3379[S]. West Conshohocken: ASTM, 1998. [29] 孙才英, 姜大伟, 徐庆玲, 等. Na+阻燃改性亚麻纤维及其对纤维性能的影响[J]. 精细化工, 2019, 36(9):1810-1814.SUN Caiying, JIANG Dawei, XU Qingling, et al. Na+ flame retardant modified flax fiber and its effect on fiber properties[J]. Fine Chemicals,2019,36(9):1810-1814(in Chinese). [30] 马豪, 李岩, 王迪, 等. 固化温度对亚麻纤维及其增强复合材料力学性能的影响[J]. 材料工程, 2015, 43(10):14-19. doi: 10.11868/j.issn.1001-4381.2015.10.003MA Hao, LI Yan, WANG Di, et al. Effect of curing tempera-ture on mechanical properties of flax fiber and its reinforced composites[J]. Materials Engineering,2015,43(10):14-19(in Chinese). doi: 10.11868/j.issn.1001-4381.2015.10.003 [31] BOURMAUD A, MORVAN C, BOUALI A, et al. Relationships between micro-fibrillar angle, mechanical properties and biochemical composition of flax fibers[J]. Industrial Crops and Products,2013,44:343-351. doi: 10.1016/j.indcrop.2012.11.031 -

下载:

下载: