Preparation and properties of BaSO4/TPU nanocomposites

-

摘要: 食品行业用输送带在运转过程中,可能会出现面层塑料颗粒脱落黏附在食品上,造成食品质量不合格,对人体健康产生负面影响。因此,开展可X射线探测的面层材料改性研究十分重要。本文通过熔融共混法制备了BaSO4/热塑性聚氨酯弹性体(TPU)纳米复合材料。通过扫描电子显微镜(SEM)、傅里叶变换红外光谱(FTIR)、热失重分析(TGA)、硬度和拉伸试验等系统地进行BaSO4/TPU纳米复合材料的结构、热稳定性能和力学性能的表征。特别地,通过X射线透视测试表征复合材料的X射线显影性能。SEM表明BaSO4以纳米尺寸均匀分散在TPU基体中。力学性能测试结果表明,BaSO4对TPU有增强作用,BaSO4添加量为10wt%时,BaSO4/TPU纳米复合材料的综合力学性能最佳,拉伸强度、断裂伸长率和断裂功较未改性TPU提高了10.19%、30.09%和31.92%。TGA测试结果表明BaSO4/TPU复合材料的高温热稳定性有所提高。此外,通过添加纳米BaSO4,复合材料的X射线显影性能也得到了改善,从而实现在输送带面层中的应用。Abstract: During the operation of the conveyor belt used in the food industry, the plastic particles on the surface layer may fall off and adhere to the food, resulting in unqualified food quality and a negative impact on human health. Therefore, it is of great importance to research the modification of surface layer materials that can be detected by X-rays. In this study, BaSO4/thermoplastic polyurethane (TPU) nanocomposites were prepared by the melt blending method. The phase morphology, thermal stability, and tensile property of BaSO4/TPU nanocomposites were systematically characterized by scanning electron microscopy (SEM), Fourier transform infrared spectroscopy (FTIR), thermal gravimetric analysis (TGA), hardness, and tensile property tests. In particular, the X ray developing properties of the composites were characterized by X ray fluoroscopy tests. SEM shows that BaSO4/TPU nanocomposites are the best. The tensile strength, elongation at break and work of fracture improve by 10.19%, 30.09% and 31.92% compared to unmodified TPU. The TGA test results show that the high-temperature thermal stability of BaSO4/TPU nanocomposites is improved. In addition, by adding BaSO4, the X ray developing properties of the composites are also improved, thus realizing the application in the surface layer of conveyor belts.

-

Key words:

- thermoplastic polyurethane /

- BaSO4 /

- nanocomposites /

- X ray developing properties /

- tensile property

-

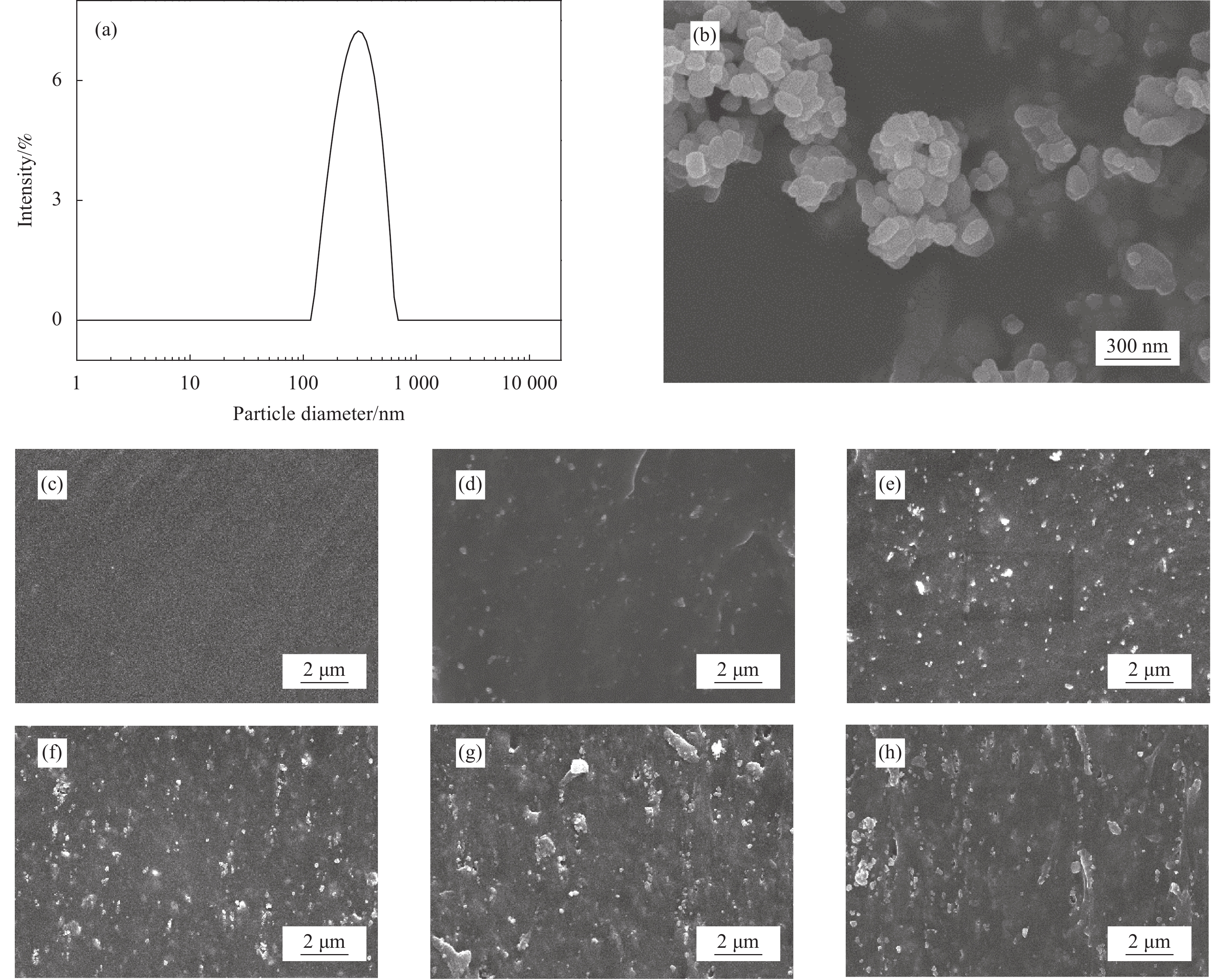

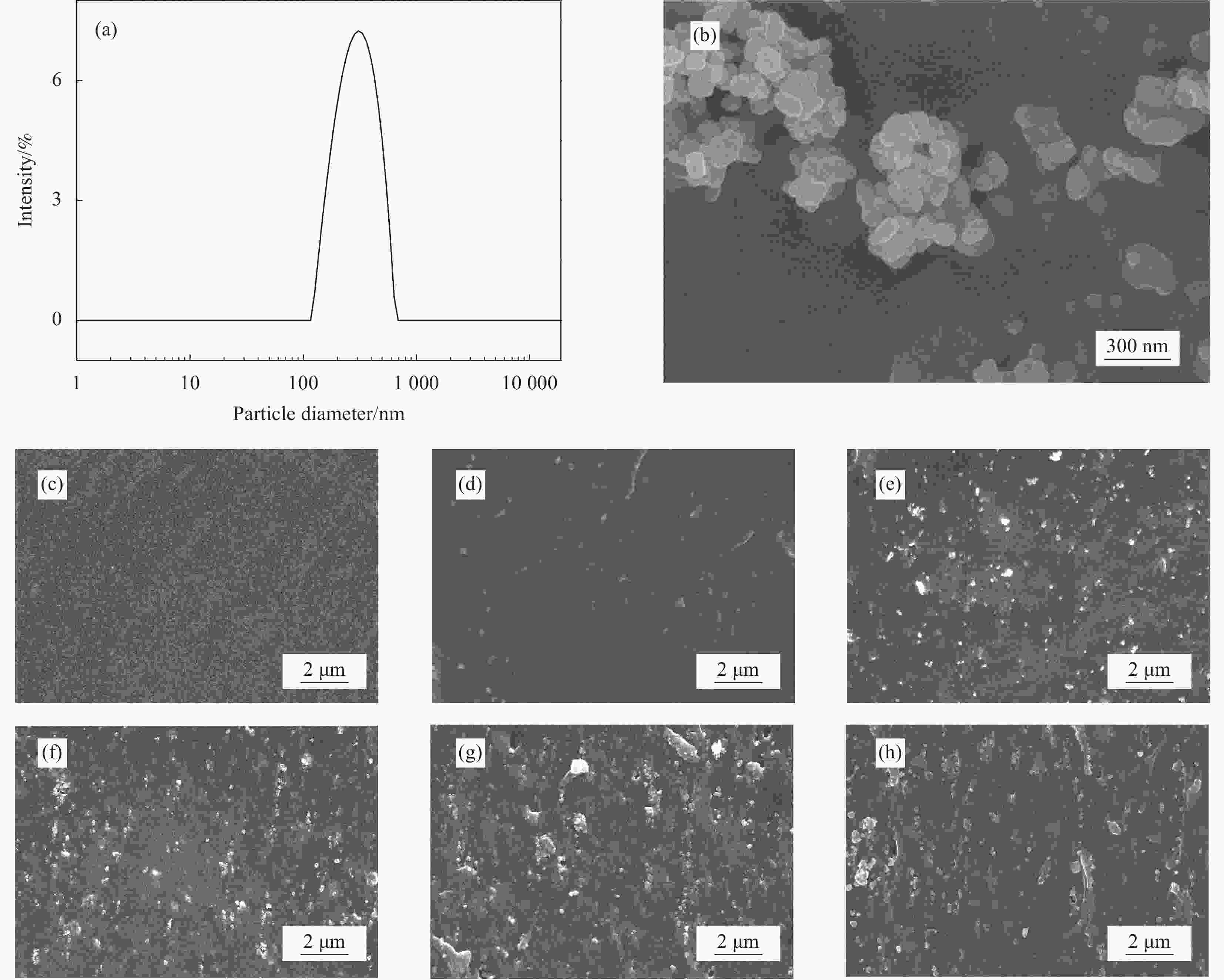

图 1 (a) BaSO4粒径分布;BaSO4/热塑性聚氨酯弹性体(TPU)复合材料断面的SEM图像:(b) BaSO4;(c) TPU;(d) BaSO4/TPU-5;(e) BaSO4/TPU-10;(f) BaSO4/TPU-12.5;(g) BaSO4/TPU-15;(h) BaSO4/TPU-20

Figure 1. (a) BaSO4 particle size distribution; SEM images of the cross section for BaSO4/thermoplastic polyurethane (TPU) composites: (b) BaSO4; (c) TPU; (d) BaSO4/TPU-5; (e) BaSO4/TPU-10; (f) BaSO4/TPU-12.5; (g) BaSO4/TPU-15; (h) BaSO4/TPU-20

表 1 BaSO4/热塑性聚氨酯弹性体 (TPU)纳米复合材料的组成

Table 1. Composition of BaSO4/thermoplastic polyurethane (TPU) nanocomposites

Sample Mass percentage of each component in nanocomposites/wt% TPU BaSO4 KH-570 TPU 100.0 0 0.0 BaSO4/TPU-5 94.6 5 0.4 BaSO4/TPU-10 89.2 10 0.8 BaSO4/TPU-12.5 86.5 12.5 1.0 BaSO4/TPU-15 83.8 15 1.2 BaSO4/TPU-20 78.4 20 1.6 表 2 TPU与BaSO4/TPU纳米复合材料的热失重数据

Table 2. Date from TG and DTG curves of TPU and BaSO4/TPU nanocomposites

Sample Tonset/℃ T50%/℃ T1 max/℃ T2 max/℃ C.R.600℃/% TPU 302.5 361.6 348.5 407.7 2.91 BaSO4/TPU-5 283.7 362.6 332.6 414.1 7.04 BaSO4/TPU-10 279.5 375.4 340.0 414.8 12.02 BaSO4/TPU-12.5 271.4 378.5 340.0 414.7 14.33 BaSO4/TPU-15 272.7 391.8 342.8 415.9 17.72 BaSO4/TPU-20 266.2 398.6 340.2 416.2 21.14 Notes: Tonset—Onset degradation temperature (temperature at 5.0% mass loss); T50%—Temperature at 50.0% mass loss; T1 max and T2 max—Maximum decomposition temperature in the first and second stage; C.R.600℃—Yield of char residue at 600℃. 表 3 TPU与BaSO4/TPU纳米复合材料的灰度值数据

Table 3. Date of grayscale value of TPU and BaSO4/TPU nanocomposites

Sample Grayscale value TPU 31.57 BaSO4/TPU-5 28.35 BaSO4/TPU-10 23.16 BaSO4/TPU-12.5 19.23 BaSO4/TPU-15 15.97 BaSO4/TPU-20 11.77 -

[1] KANBUR Y, TAYFUN U. Investigating mechanical, thermal, and flammability properties of thermoplastic polyurethane/carbon nanotube composites[J]. Journal of Thermoplastic Composite Materials,2018,31(12):1661-1675. doi: 10.1177/0892705717743292 [2] WANG W, LIAO X, HE Y, et al. Thermoplastic polyurethane/polytetrafluoroethylene composite foams with enhanced mechanical properties and anti-shrinkage capability fabricated with supercritical carbon dioxide[J]. The Journal of Supercritical Fluids,2020,163:104861. doi: 10.1016/j.supflu.2020.104861 [3] KAUSAR A. Polyurethane composite foams in high-performance applications: A review[J]. Polymer-Plastics Technology and Engineering,2018,57(4):346-369. doi: 10.1080/03602559.2017.1329433 [4] BASHIR A, MAQBOOL M, LV R, et al. Surface modified boron nitride towards enhanced thermal and mechanical performance of thermoplastic polyurethane composite[J]. Composites Part B: Engineering,2021,218:108871. doi: 10.1016/j.compositesb.2021.108871 [5] HUANG A, PENG X, TURNG L S. In-situ fibrillated polytetrafluoroethylene (PTFE) in thermoplastic polyurethane (TPU) via melt blending: Effect on rheological behavior, mechanical properties, and microcellular foamability[J]. Polymer,2018,134:263-274. doi: 10.1016/j.polymer.2017.11.053 [6] JUN Y, HABIBPOUR S, HAMIDINEJAD M, et al. Enhanced electrical and mechanical properties of graphene nano-ribbon/thermoplastic polyurethane composites[J]. Carbon,2021,174:305-316. doi: 10.1016/j.carbon.2020.12.023 [7] BALA H, FU W, GUO Y, et al. In situ preparation and surface modification of barium sulfate nanoparticles[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2006, 274(1-3): 71-76. [8] 颜志勇, 袁孟红, 黄素萍, 等. X光显影纤维的研究[J]. 合成纤维工业, 2002(2):32-34. doi: 10.3969/j.issn.1001-0041.2002.02.010YAN Zhiyong, YUAN Menghong, HUANG Suping, et al. Study on X-ray developing fiber[J]. China Synthetic Fiber Industry,2002(2):32-34(in Chinese). doi: 10.3969/j.issn.1001-0041.2002.02.010 [9] LUO C, CHEN G, ZHU K, et al. Preparation of X-ray developable LDPE/SA-BaSO4 composites and their thermal and mechanical properties[J]. Polymer Composites,2016,37(5):1396-1406. doi: 10.1002/pc.23308 [10] ROMERO-IBARRA I C, BONILLA-BLANCAS E, SÁNCHEZ-SOLÍS A, et al. Influence of X-ray opaque BaSO4 nanoparticles on the mechanical, thermal and rheological pro-perties of polyoxymethylene nanocomposites[J]. Journal of Polymer Engineering, 2012, 32(4-5): 319-326. [11] WANG K, WU J, ZENG H. Microstructure and fracture behavior of polypropylene/barium sulfate composites[J]. Journal of Applied Polymer Science,2006,99(3):1207-1213. doi: 10.1002/app.22596 [12] GAO W, ZHOU B, MA X, et al. Preparation and characterization of BaSO4/poly(ethylene terephthalate) nanocomposites[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2011,385(1-3):181-187. [13] CAO X, ZHANG H, CHEN M, et al. Preparation, characterization, and properties of modified barium sulfate nanoparticles/polyethylene nanocomposites as T-shaped copper intrauterine devices[J]. Journal of Applied Polymer Science,2014,131(12):1-7. [14] 中国国家标准化管理委员会. 塑料 拉伸性能的测定 第2部分: 模塑和挤塑塑料的试验条件: GB/T 1040.2—2006[S]. 北京: 中国标准出版社, 2006.Standardization Administration of the People's Republic of China. Plastics—Determination of tensile properties—Part 2: Test conditions for moulding and extrusion plastics: GB/T 1040.2—2006[S]. Beijing: China Standards Press, 2006(in Chinese). [15] 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶 压入硬度试验方法 第1部分: 邵氏硬度计法(邵尔硬度): GB/T 531.1—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People's Republic of China. Rubber, vulcanized or thermmoplastic—Determination of indentation hardness—Part 1: Duromerer method (Shore hardness): GB/T 531.1—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [16] CHEN X, WANG L, SHI J, et al. Effect of barium sulfate nanoparticles on mechanical properties and crystallization behaviour of HDPE[J]. Polymers and Polymer Composites,2010,18(3):145-152. doi: 10.1177/096739111001800304 [17] TANG Q, GAO K. Structure analysis of polyether-based thermoplastic polyurethane elastomers by FTIR, 1H NMR and 13C NMR[J]. International Journal of Polymer Analysis and Characterization,2017,22(7):569-574. doi: 10.1080/1023666X.2017.1312754 [18] NAGARAJA B M, ABIMANYU H, JUNG K D, et al. Preparation of mesostructured barium sulfate with high surface area by dispersion method and its characterization[J]. Journal of Colloid and Interface Science,2007,316(2):645-651. doi: 10.1016/j.jcis.2007.09.004 [19] ZUIDERDUIN W C J, WESTZAAN C, HUÉTINK J, et al. Toughening of polypropylene with calcium carbonate particles[J]. Polymer,2003,44(1):261-275. doi: 10.1016/S0032-3861(02)00769-3 [20] YANG J, XU Y, NIE S, et al. Morphological structure, impact toughness, thermal property and kinetic analysis on the cold crystallization of poly(lactic acid) biocomposites toughened by precipitated barium sulfate[J]. Polymer Degradation and Stability,2018,158:176-189. doi: 10.1016/j.polymdegradstab.2018.11.008 [21] SHAHZAMANI M, REZAEIAN I, LOGHMANI M S, et al. Effects of BaSO4, CaCO3, kaolin and quartz fillers on mechanical, chemical and morphological properties of cast polyurethane[J]. Plastics, Rubber and Composites,2012,41(6):263-269. doi: 10.1179/1743289811Y.0000000035 [22] YANG J, WANG C, SHAO K, et al. Morphologies, mechanical properties and thermal stability of poly(lactic acid) toughened by precipitated barium sulfate[J]. Russian Journal of Physical Chemistry A,2015,89(11):2092-2096. doi: 10.1134/S0036024415110242 -

下载:

下载: