Chemical modification of waterborne polyurethane with double DOPO pendant flame retardant

-

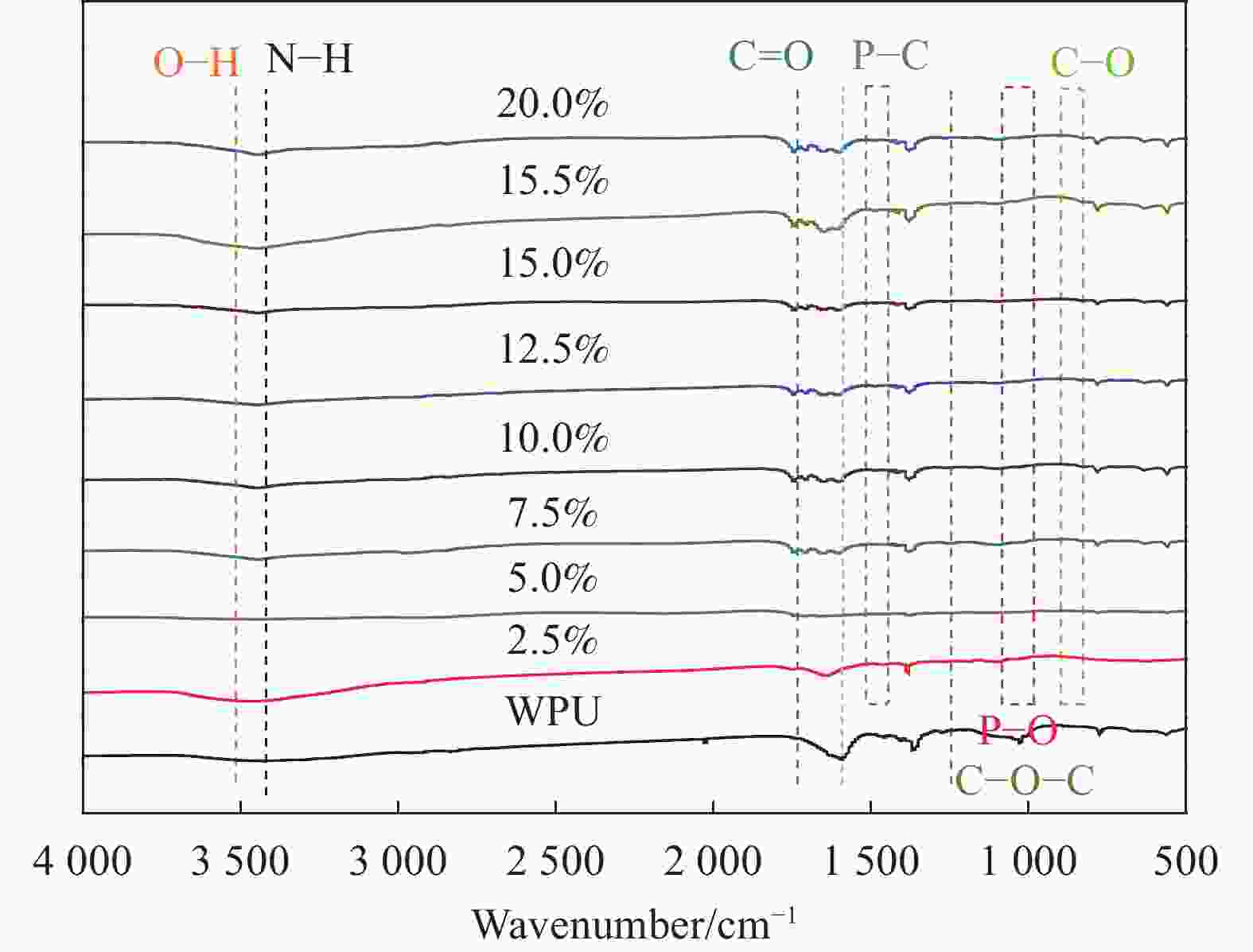

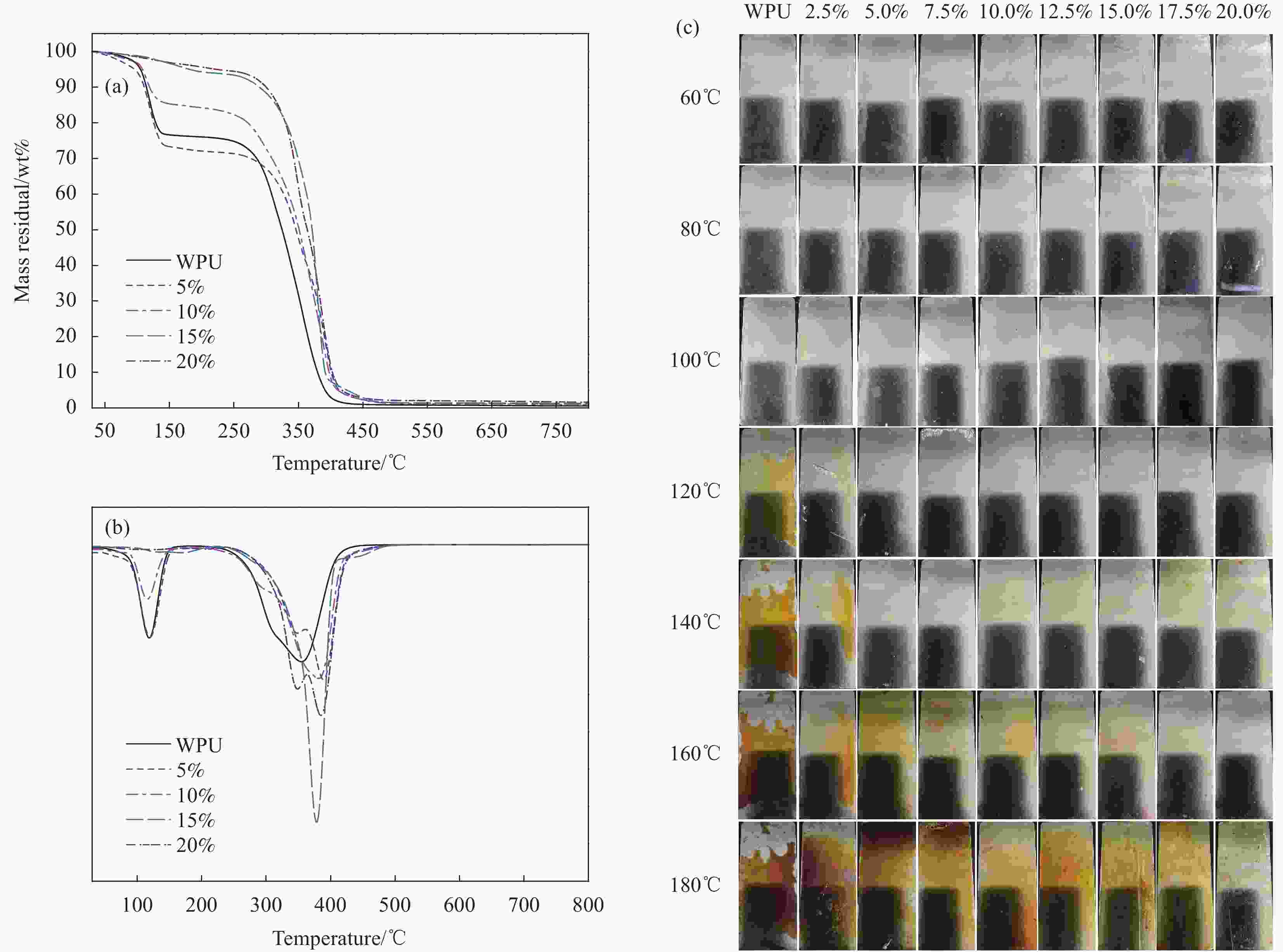

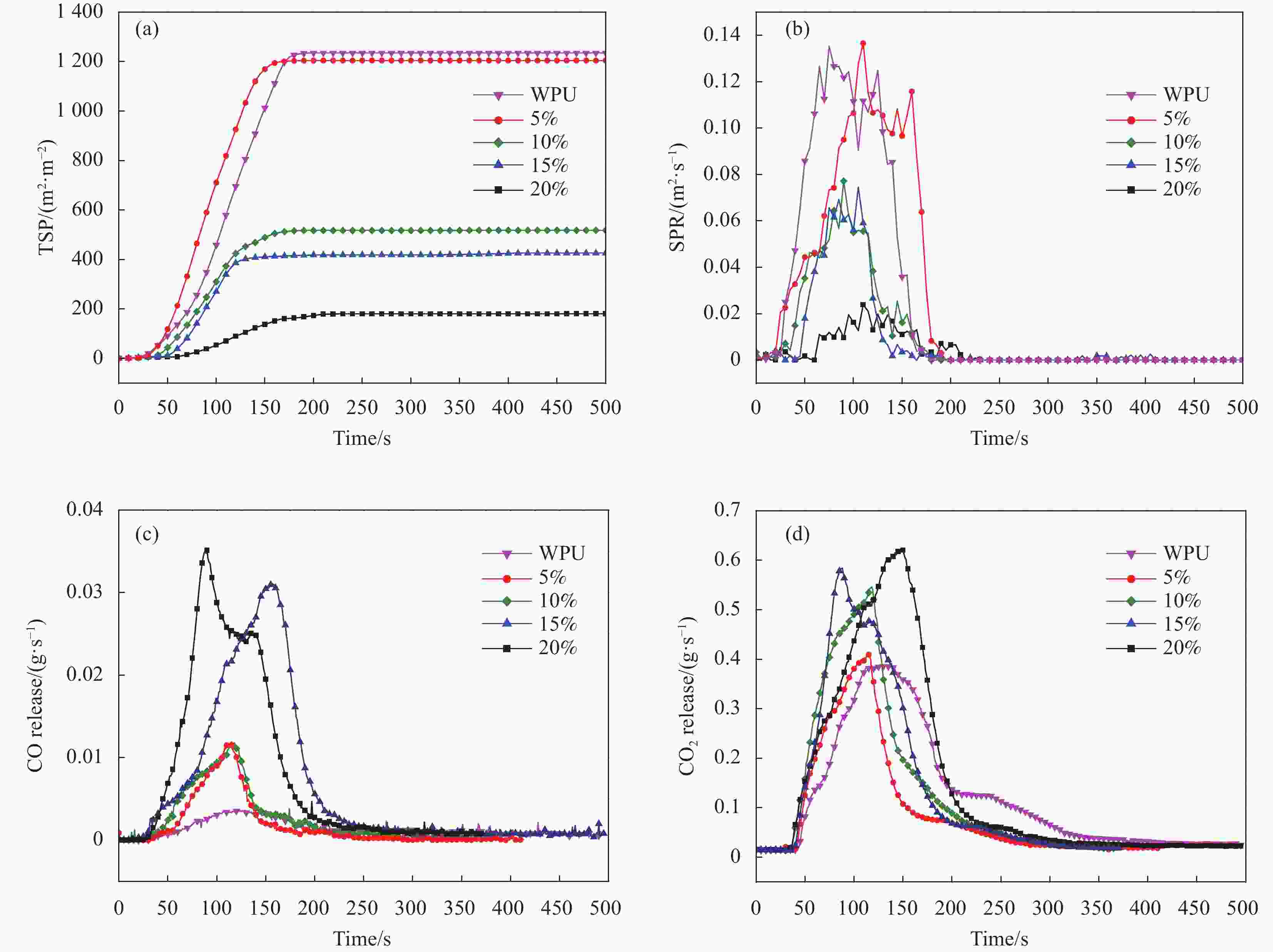

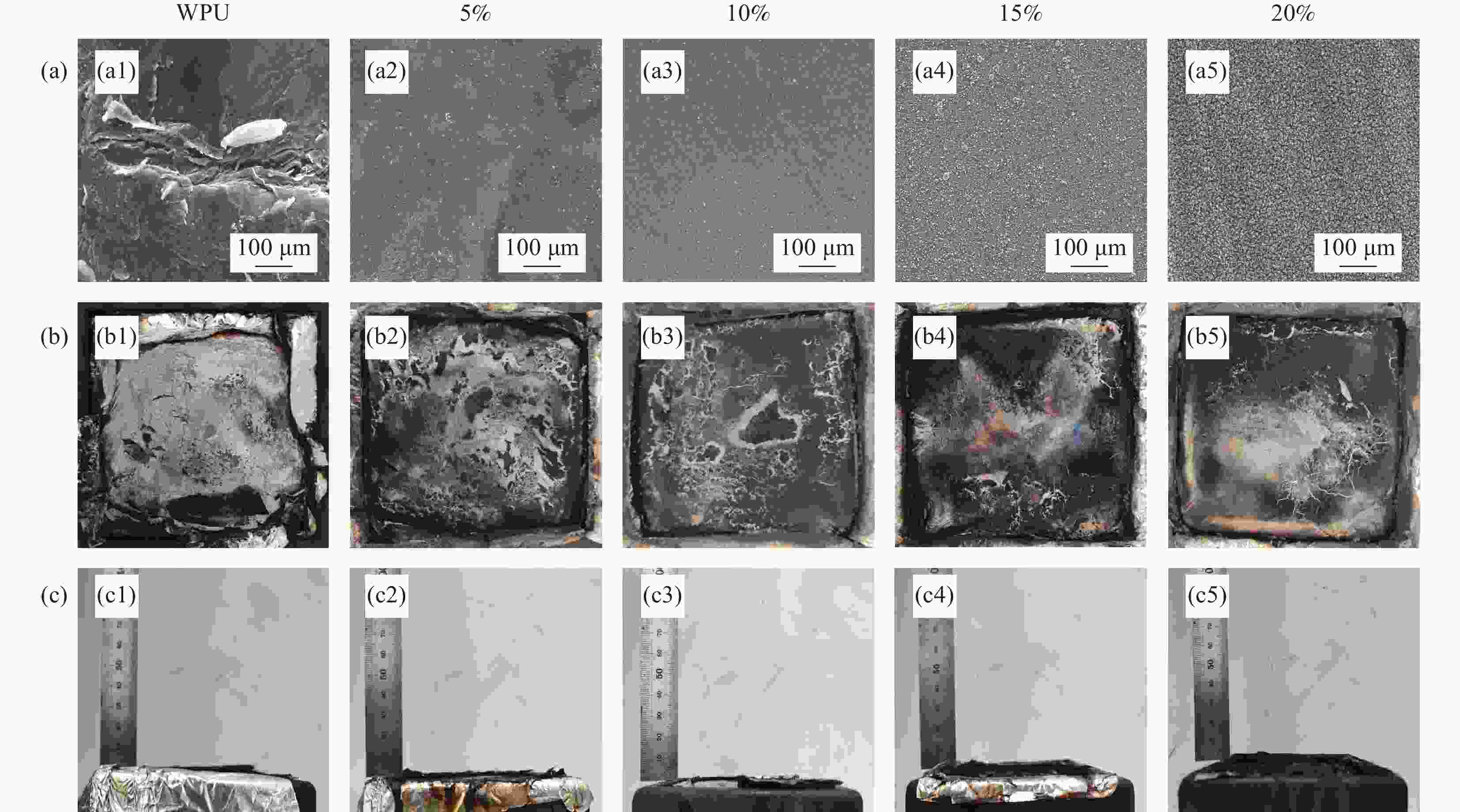

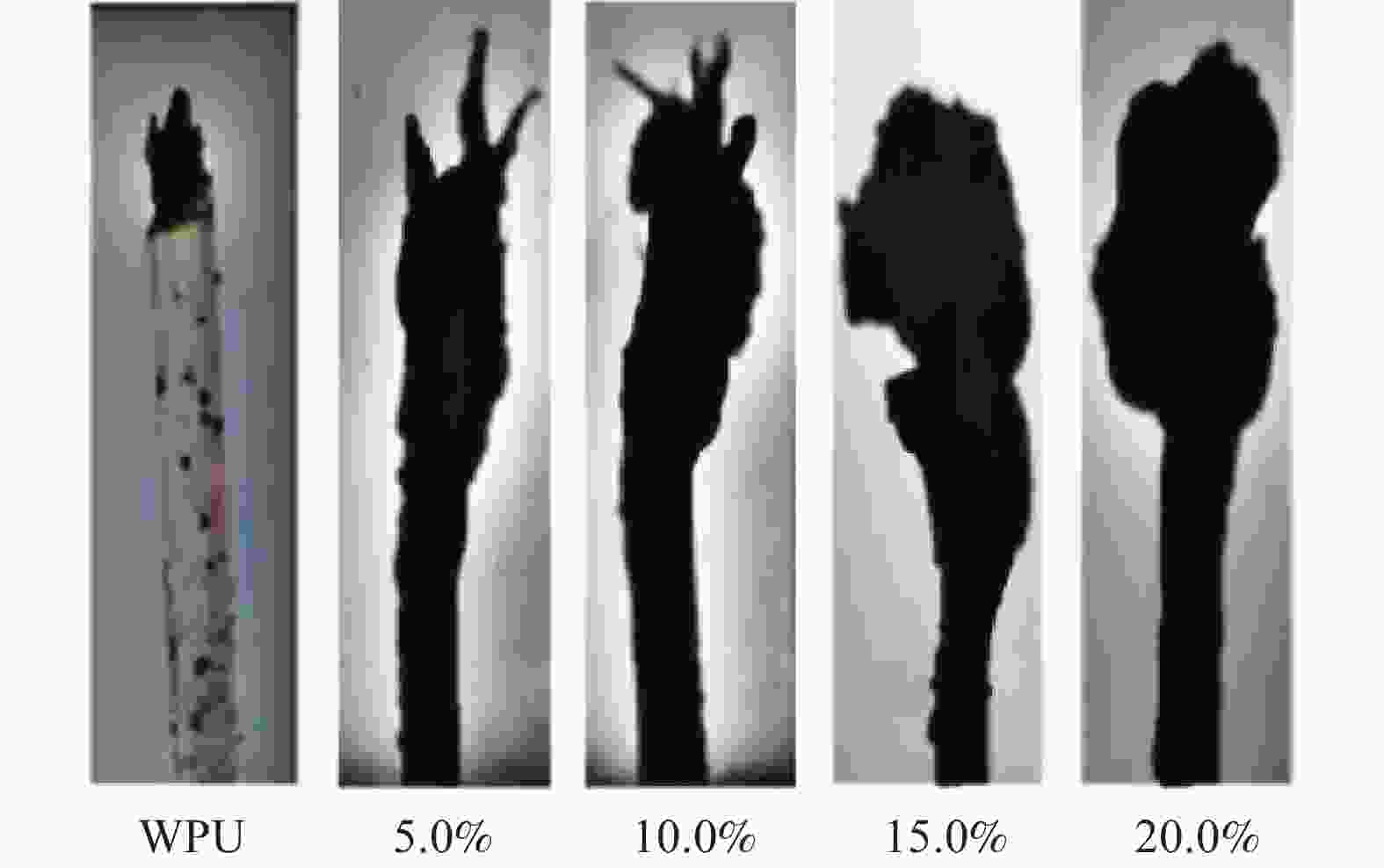

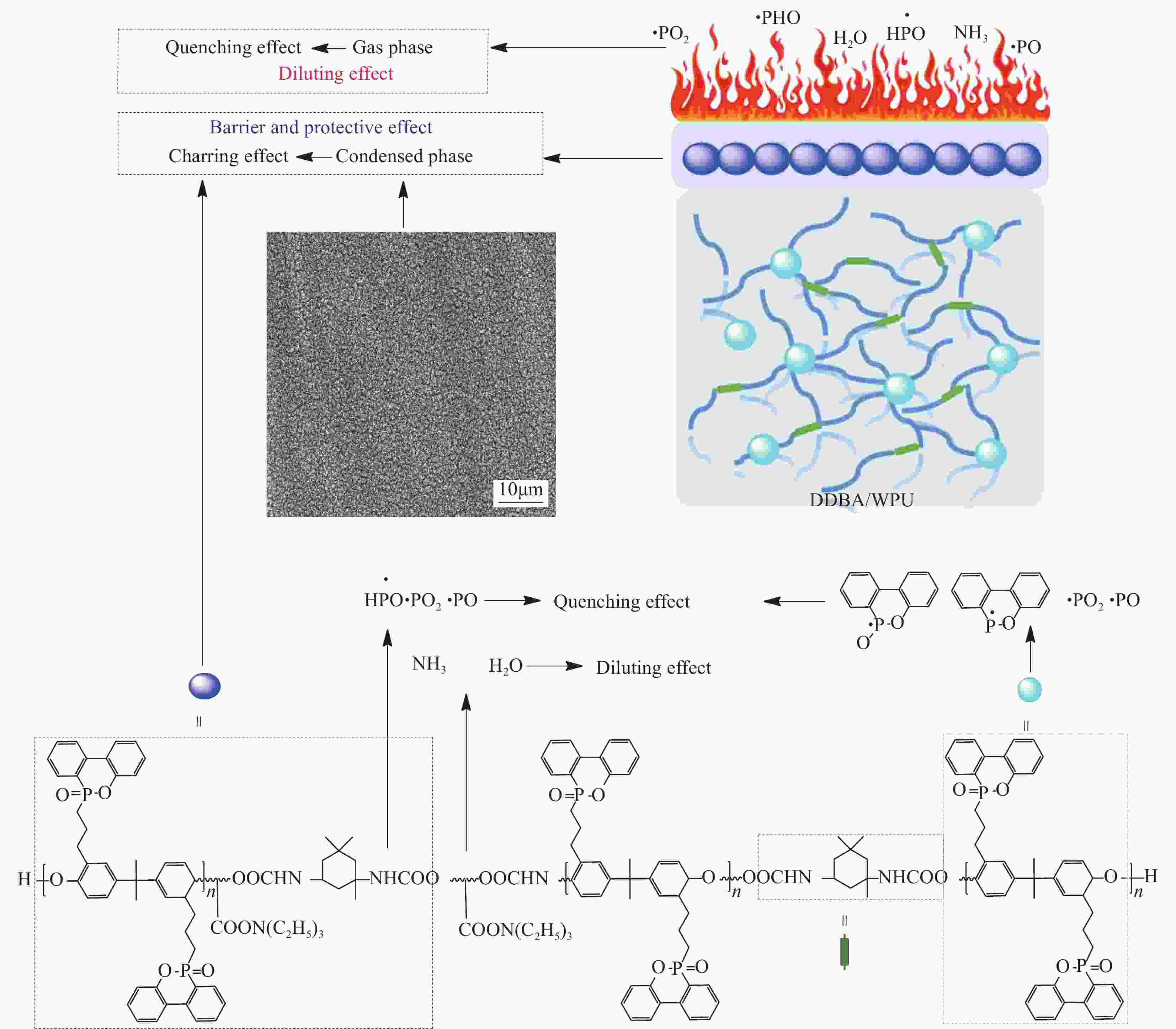

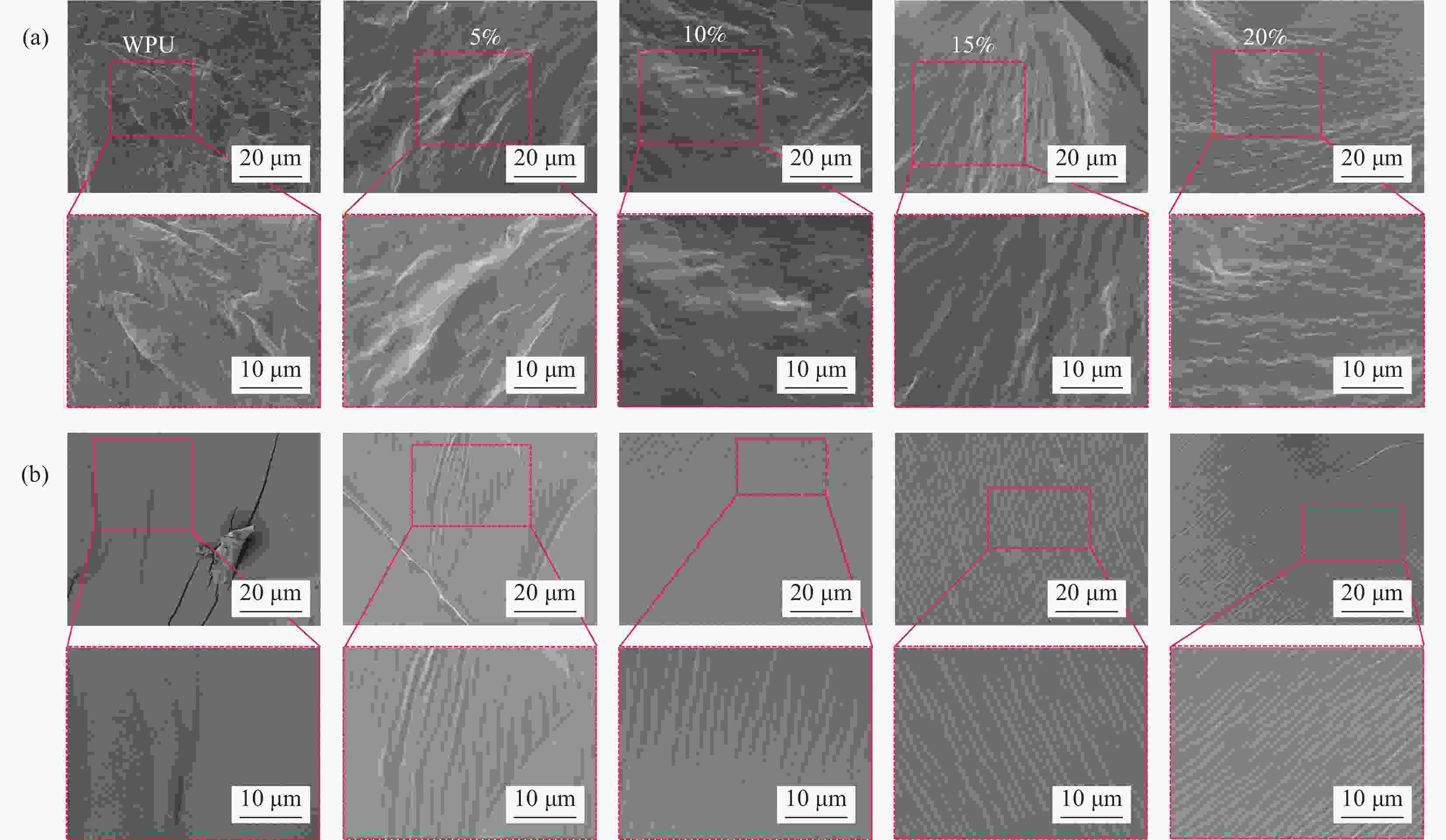

摘要: 为提高普通水性聚氨酯(WPU)耐热性、阻燃性和力学性能等,本文以9, 10-二氢-9-氧-10-磷菲-10氧化物(DOPO)和2, 2′-二烯丙基双酚A(DABA)为原料,通过“一步法”化学合成了双DOPO悬垂型阻燃剂DDBA,采用红外光谱(FTIR)和核磁共振(NMR)表征了其化学结构,并用其化学修饰WPU制备新型水性聚氨酯(DDBA/WPU)。研究了DDBA对DDBA/WPU胶膜材料耐水性、耐热性、阻燃性及力学性能的影响。通过水接触角、吸水率、热失重(TG)、锥形量热(CONE)、电镜扫描(SEM)、氧指数(LOI)、垂直燃烧(UL-94)、万能试验机等评价胶膜的相关性能。研究结果表明:随着DDBA添加量的增大,胶膜的耐水性、耐热性、阻燃性及力学性能不断提升,当DDBA的添加质量比为20%时,水接触角可达134.56°,提高了106.06%,吸水率降低了33.29%。耐受温度提高了60℃,LOI值为35.9%,烟气释放总量(TSP)和平均有效燃烧热(AEHC)分别减小了85.42%和55.76%,最大热释放速率(pHRR)、总释放热(THR)、CO2的释放量分别下降了35.40%、51.20%、58.49%,点燃时间延长了15 s,CO释放量提高了163.46%,拉伸强度可达25.7 MPa,约为改性前WPU的9.51倍。Abstract: In order to improve the heat resistance, flame retardancy and mechanical properties of traditional water-based polyurethane (WPU), in this study 9,10-dihydro-9-oxo-10-phosphenanthrene-10 oxide (DOPO) and 2,2’-diallylbisphenol A (DABA) were used as starting materials, and the chemical synthesized double DOPO pendant flame retardant DDBA, the chemical structure was characterized by infrared spectroscopy (FTIR) and nuclear magnetic resonance (NMR), and a new waterborne polyurethane (DDBA/WPU) was prepared by chemically modifying waterborne polyurethane (WPU). The effects of DDBA on water resistance, heat resistance, flame retardancy and mechanical properties of DDBA/WPU film were studied. Evaluation of the films by water contact angle, water absorption, thermal weight loss (TG), cone calorimetry (CONE), scanning electron microscope (SEM), oxygen index (LOI), vertical combustion (UL-94), universal testing machine related performance. The research results show that with the increase of DDBA addition, the water resistance, heat resistance, flame retardancy and mechanical properties of the film continue to improve. When the addition mass ratio of DDBA is 20%, the water contact angle can reach 134.56°, an increase of 106.06%, and the water absorption rate is reduced by 33.29%, the temperature resistance is increased by 60°C. Its LOI value is 35.9%, the total flue gas release (TSP) and average effective heat of combustion (AEHC) decreased by 85.42% and 55.76%. The maximum heat release rate (pHRR), total heat release (THR) and CO2 release decreased by 35.40%, 51.20%, 58.49%, ignition time is prolonged by 15 s, CO release increased by 163.46%. The tensile strength can reach 25.7 MPa, which is about 9.51 times than that of WPU before modification.

-

Key words:

- DDBA /

- waterborne polyurethane /

- water resistance /

- heat resistance /

- flame retardancy /

- mechanical propert

-

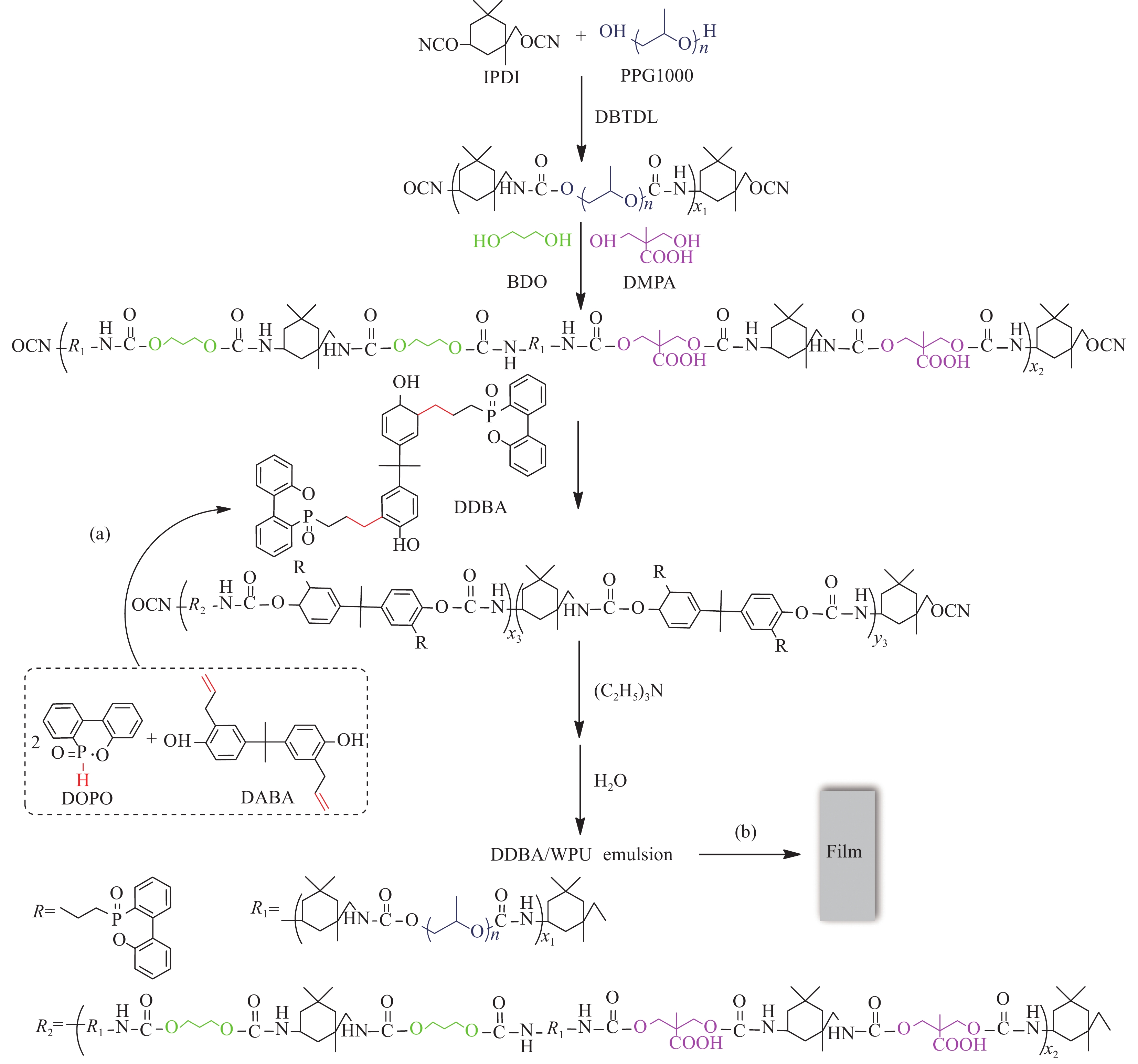

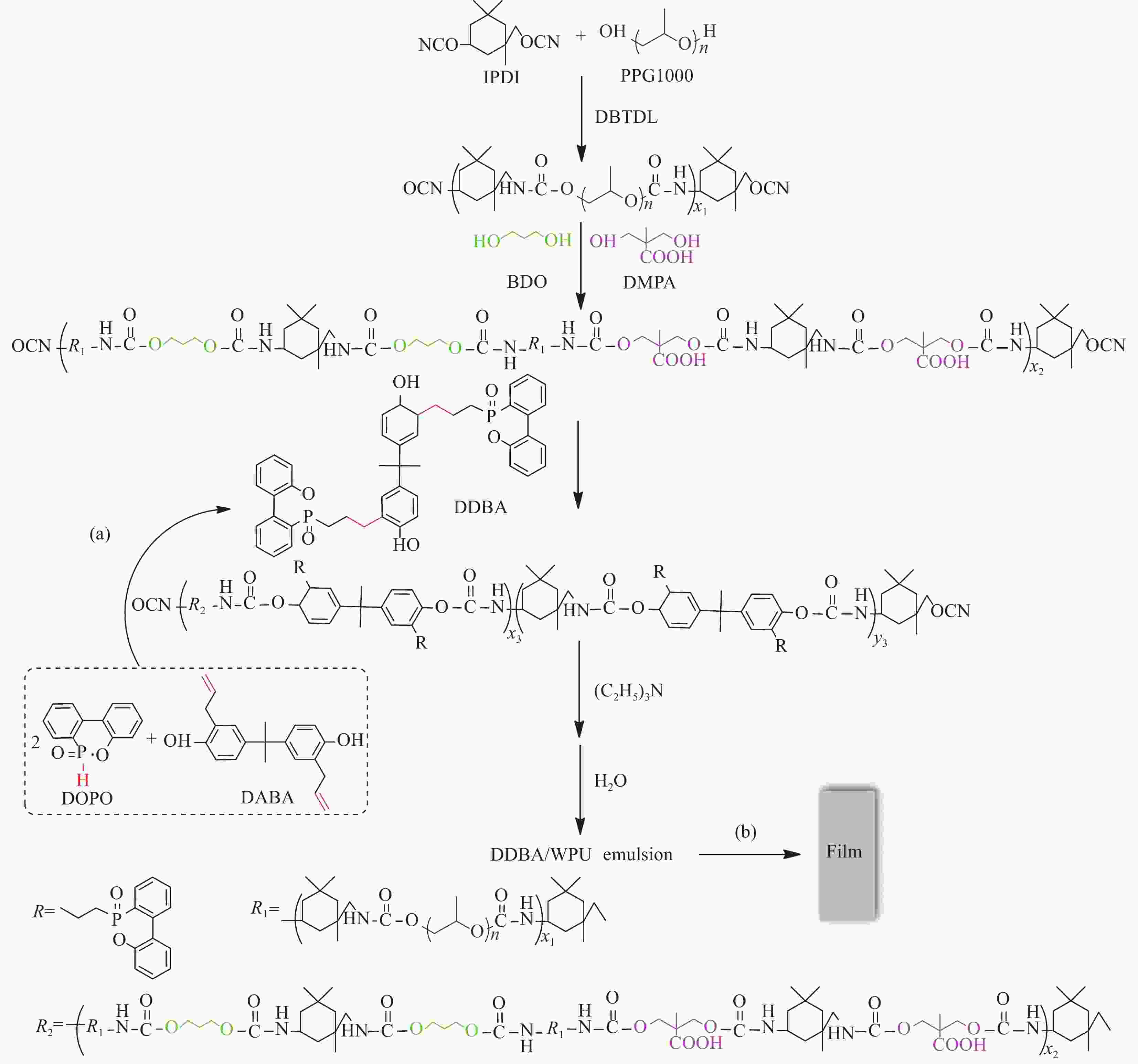

图 1 新型水性聚氨酯(DDBA/WPU)乳液合成路线

Figure 1. New waterborne polyurethane (DDBA/WPU) emulsion synthesis route

IPDI—Isophorone diisocyanate; PPG1000—Polypropylene glycol 1000; DBTDL—Dibutyltin dilaurate; BDO—1, 4-butanediol; DMPA—Dimethylolpropionic acid; DOPO—9, 10-dihydro-9-oxygen-10-phosphophene-10 oxide; DABA—2, 2'-diallyl bisphenol A

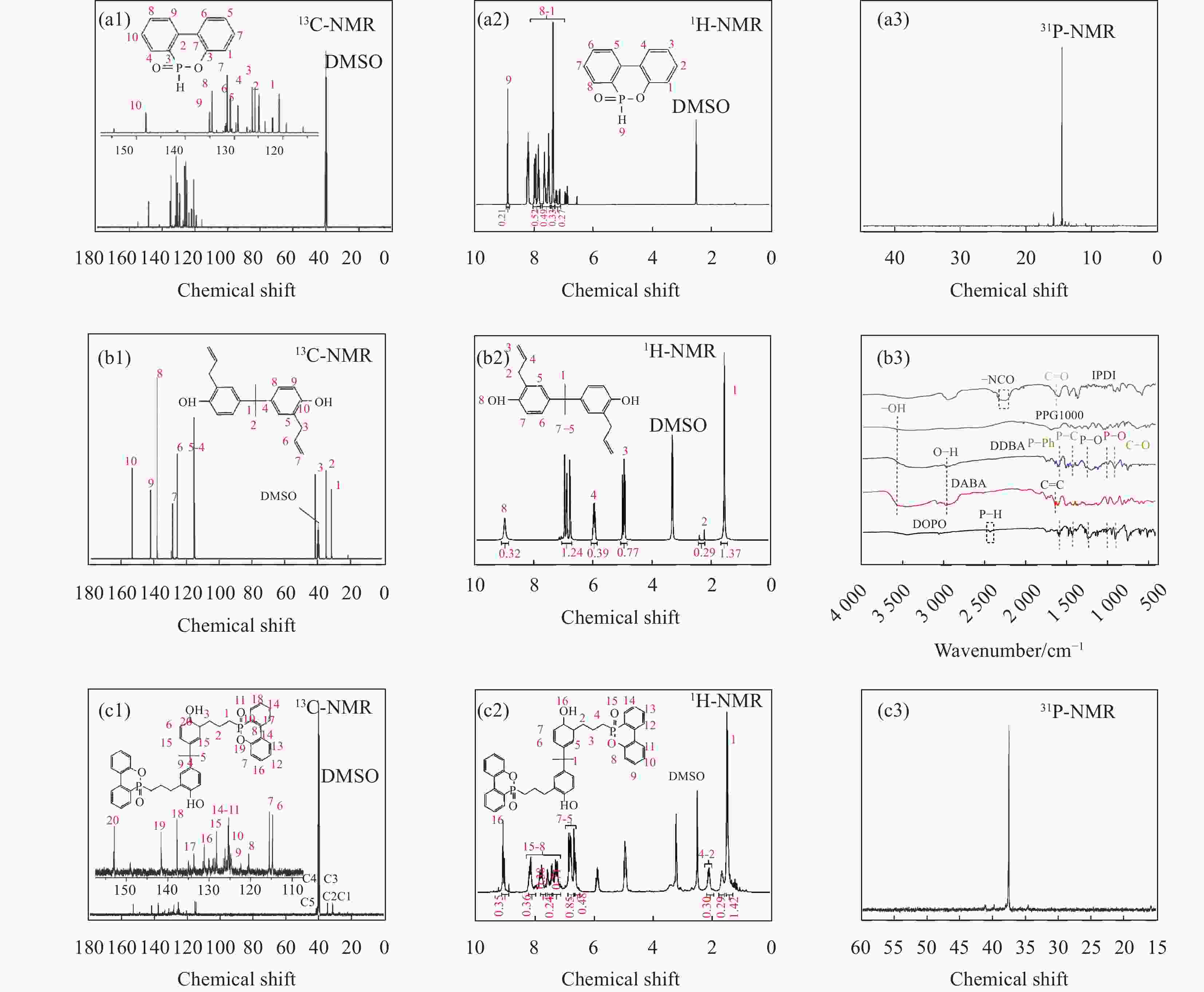

图 2 ((a1), (a2), (a3)) DOPO的13C-NMR、 1H-NMR、31P-NMR;((b1), (b2)) DABA的13C-NMR、1H-NMR;(b3)主要原料的FTIR;((c1), (c2), (c3)) DDBA的13C-NMR、1H-NMR、31P-NMR

Figure 2. ((a1), (a2), (a3)) 13C-NMR, 1H-NMR, 31P-NMR of DOPO; ((b1), (b2)) 13C-NMR, 1H-NMR of DABA; (b3) FTIR of main raw material; ((c1), (c2), (c3)) 13C-NMR, 1H-NMR, 31P-NMR of DDBA

表 1 DDBA含量对WPU乳液性能的影响

Table 1. Effect of DDBA content on the properties of WPU emulsion

n(DDBA)/% Performance Exterior Particle size/nm PDI Viscosity/(MPa·s) Stability WPU Pan blue light 57.62 0.119 22.7 * 2.5 Pan blue light 63.84 0.057 25.5 * 5 Yellowish 74.00 0.097 26.8 * 7.5 Yellowish 78.02 0.108 28.7 * 10 Pale yellow 87.74 0.046 31.3 * 12.5 Pale yellow 99.09 0.025 32.8 * 15 Pale yellow 110.60 0.019 33.2 * 17.5 Milky white 128.20 0.035 34.9 * 20 Milky white 147.50 0.139 36.3 * Notes: * indicates stable (>6 months); n(DDBA)—Mass fraction based on the total mass of IPDI and PPG1000; PDI—Polymer dispersibility index. 表 2 WPU和DDBA/WPU热分解数据

Table 2. Thermal decomposition data of WPU and DDBA/WPU

n(DDBA)/% T10%/℃ TmaxI/℃ TmaxII/℃ TmaxIII/℃ TmaxIV/℃ Char yield/% WPU 118.4 110.0 272.8 317.3 357.4 0.9 5 120.1 115.7 275.3 343.6 389.5 1.1 10 123.5 113.5 282.5 345.7 382.8 1.2 15 284.8 168.4 293.4 342.5 378.2 1.9 20 291.7 196.2 298.9 350.0 390.3 2.3 Note: T10%(℃), TmaxI(℃), TmaxII(℃), TmaxIII(℃), TmaxIV(℃)—Temperature of 10% weight loss, the maximum weight loss temperature of the first, second, third and fourth stages. 表 3 DDBA/WPU胶膜的锥形量热数据

Table 3. Cone calorimetry data of the DDBA/WPU films

n(DDBA)/% TTI/s pHRR/(kW·m2) THR/(MJ·m2) ACOY/(kg·kg−1) ACO2Y/(kg·kg−1) CO/CO2 AEHC/(MJ·kg−1) TSP/(m2·m−2) WPU 9 1214.93 134.41 0.052 4.65 0.011 35.53 1235.02 5 17 1190.58 104.82 0.054 3.13 0.017 23.04 1204.53 10 20 1017.85 104.53 0.063 3.05 0.021 20.36 518.29 15 22 792.08 97.64 0.087 2.70 0.032 18.08 425.63 20 24 784.87 65.06 0.137 1.93 0.071 15.72 180.80 Note: TTI, pHRR, THR, ACOY, ACO2Y, CO/CO2, AEHC, TSP—Ignition time, maximum heat release rate, total heat release, average CO generation, average CO2 generation, and ratio of CO to CO2 generation, the average effective heat of combustion, the total amount of flue gas released. 表 4 DDBA/WPU的氧指数(LOI)和垂直燃烧 (UL-94)等级

Table 4. Oxygen index (LOI) value and vertical combustion (UL-94) rating of DDBA/WPU

n(DDBA)/% Vertical burning test After-flame time LOI/% ${\bar {t_1}}/{\rm{s}} $ ${\bar {t_2}}/{\rm{s}} $ UL-94 rating Dripping WPU 21.9 76.0 78.2 Unrated Yes 5 26.8 11.3 10.7 V-1 No 10 29.3 8.7 7.5 V-1 No 15 32.4 4.9 5.4 V-1 No 20 35.9 2.9 1.6 V-0 No Notes: The after-flame of specimen burned to the clamp in the first flame application; ${\bar {t_1}} $, ${\bar {t_2}} $—Reignition time; V-0 for each individual sample combustion duration ${\bar {t_1}} $ or ${\bar {t_2}} $≤10 s, burning particles or drips does not ignite skim cotton; V-1 for each individual sample combustion duration ${\bar {t_1}} $ or ${\bar {t_2}} $≤30 s, burning particles or drips does not ignite skim cotton. -

[1] DU W N, GE X G, HUANG H, et al. Fabrication of high transparent mechanical strong and flame retardant waterborne polyurethane composites by incorporating phosphorus-silicon functionalized cellulose nanocrystals[J]. Journal of Applied Polymer Science,2021,125(3):139-145. [2] LUO Y F, WANG H L, WANG H J, et al. Preparation and performance of waterborne polyurethane coatings based on the synergistic flame retardant of ferrocene phosphorus and nitrogen[J]. Journal of Applied Polymer Science,2021,138(45):138-147. [3] CUI M J, LI J, CHEN X D, et al. A halogen-free flame retardant waterborne polyurethane coating based on the synergistic effect of phosphorus and silicon[J]. Progress in Organic Coatings,2021,66(32):158-164. [4] CUI J G, LIU S J, LI Q X, et al. A novel intrinsic flame-retardant waterborne poly(urethane) copolymers containing phosphorus-nitrogen[J]. Fire and Materials,2021,123(2):246-257. [5] VELENCOSO M M, BATTIG A, MARKWART J C. Molecular fire fighting—How modern phosphorus chemistry can help solve the challenge of flame retardancy[J]. Angewandte Chemie International Edition,2018,33(11):57-63. [6] HUI W, SHUANG W, XIAO S D, et al. A novel DOPO-containing HTBN endowing waterborne polyurethane with excellent flame retardance and mechanical properties[J]. Journal of Applied Polymer Science,2020,44(6):137-144. [7] 吴景, 曾威, 邝美霞, 等. 细菌纤维素-ZnO/水性聚氨酯复合薄膜的制备与性能[J]. 复合材料学报, 2020, 37(12):3026-3034. doi: 10.13801/j.cnki.fhclxb.20200407.001WU Jing, ZENG Wei, KUANG Meixia, et al. Preparation and properties of bacterial cellulose-ZnO/waterborne polyurethane composite films[J]. Acta Materiae Compositae Sinica,2020,37(12):3026-3034(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200407.001 [8] FU L A, ZHONG L A, YI L. A Synthesis of waterborne polyurethane by inserting polydimethylsiloxane and constructing dual crosslinking for obtaining the superior performance of waterborne coatings[J]. Composites Part B: Engi-neering,2022,72(18):242-251. [9] 中国国家技术监督局. 胶粘剂粘度的测定: GB/T 2794—1995[S]. 北京: 中华人民共和国化学工业部, 1995.China National Bureau of Technical Supervision. Determination of adhesive viscosity: GB/T 2794—1995[S]. Beijing: Ministry of Chemical Industry of the People's Republic of China, 1995(in Chinese). [10] 中国国家标准局. 涂料贮存稳定性试验方法: GB/T 6753.3—1986[S]. 北京: 中华人民共和国化学工业部, 1986.National Bureau of Standards of China. Test method for storage stability of coatings: GB/T 6753.3—1986[S]. Beijing: Ministry of Chemical Industry of the People's Republic of China, 1986(in Chinese). [11] ASTM. Test method for measuring the minimum oxygen concentration to support candle-like combustion of plastics: ASTM D2863-00[S]. Philadelphia: American Society of Testing Materials, 1997. [12] ASTM. Standard test method for measuring the compara-tive burning characteristics of solid plastics in a vertical position: ASTM D3801/UL-94[S]. Philadelphia: American Society of Testing Materials, 2001. [13] ZHAO L H, WANG X, WANG W. PEG/IPDI copolymerization modification to prepare new waterborne polyurethane materials[J]. Plastic Technology, 2021, 49(23): 66-70. [14] LI M, HAN L, GUO X, et al. Preparation and antifouling properties of silicone-modified waterborne polyurethane coatings[J]. Journal of Functional Polymers,2021,34(18):379-386. [15] SHUANG W, ZONG L D, XU C, et al. Synthesis of a phosphorus and nitrogen-containing flame retardant and evaluation of its application in waterborne polyurethane[J]. Journal of Applied Polymer Science,2018,16(3):135-142. [16] QIAN Y, DONG F, GUO L. Two-component waterborne polyurethane modified with terpene derivative-based polysiloxane for coatings via a thiolene click reaction[J]. Industrial Crops and Products,2021,171(45):113903. [17] DU X, WANG C, WU G, et al. The rapid and large-scale production of carbon quantum dots and their integration with polymers[J]. Angewandte Chemie International Edition,2021,60(19):8585-8595. [18] CHEN W, YUAN Y, CHEN Y. Visualized bond scission in mechano chemiluminescent polymethyl acrylate/cellulose nanocrystals composites[J]. ACS Macro Letters,2020,56(9):438-442. [19] ZHONG Y, LI P, WANG X, et al. Amoeba-inspired reengi-neering of polymer networks[J]. Green Chemistry,2021,23(7):2496-2506. [20] WEN Q, LIU B W, JI Y D. Study on the hydroxyl-terminated polydimethyl hydroxy silicone oil modified epoxy resins[J]. Thermosetting Resin,2020,35(13):25-28. [21] YURIY T, ROMAN V, OLEKSANDR M, et al. Regularities in the washing out of water soluble phosphorus-ammonium salts from the fire-protective coatings of timber through a polyurethane shell[J]. Eastern-European Journal of Enterprise Technologies,2021,62(2):10-17. [22] WANG C S, ZHANG J, WANG H, et al. Simultaneously improving the fracture toughness and flame retardancy of soybean oil-based waterborne polyurethane coatings by phosphorus-nitrogen chain extender[J]. Industrial Crops & Products,2021,163(95):187-194. [23] ZHU M H, MA Z W, LIU L, et al. Recent advances in fire-retardant rigid polyurethane foam[J]. Journal of Materials Science & Technology,2022,112:315-328. doi: 10.1016/j.jmst.2021.09.062 [24] SHUANG W, XIAO S D, XI H F, et al. Highly effective flame-retarded polyester diol with synergistic effects for waterborne polyurethane application[J]. Journal of Applied Polymer Science,2020,135(10):37-45. [25] JUN Z, JIE L, WEN Y C, et al. Synthesis and application of a phosphorus-containing waterborne polyurethane based polymeric dye with excellent flame retardancy[J]. Progress in Organic Coatings,2020,72(16):140-146. [26] YOU T W, SHAO G W, JI H W, et al. Graphene oxide-loaded zinc phosphate as an anticorrosive reinforcement in waterborne polyurethane resin[J]. International Journal of Electrochemical Science,2019,66(6):14-25. [27] FARZANE T, MANOUCHEHR K, MORTEZA E, et al. Synthesis and comprehensive study on industrially relevant flame retardant waterborne polyurethanes based on phosphorus chemistry[J]. Progress in Organic Coatings,2019,131(75):371-379. [28] WANG H, WANG S, DU X, et al. A novel DOPO-containing HTBN endowing waterborne polyurethane with excellent flame retardance and mechanical properties[J]. Journal of Applied Polymer Science,2020,137(44):49368. doi: 10.1002/app.49368 [29] ZHANG M, LUO Z Y, ZHANG J W, et al. Effects of a novel phosphorus-nitrogen flame retardant on rosin-based rigid polyurethane foams[J]. Polymer Degradation and Stability,2015,120(47):427-434. [30] LIU S M, CHEN J B, ZHAO J Q, et al. Phosphaphenanthrene-containing borate ester as a latent hardener and flame retardant for epoxy resin[J]. Polymer International,2015,64(9):1182-1190. doi: 10.1002/pi.4890 [31] 郑春森, 赵海平, 姚伯龙, 等. 功能石墨烯改性水性聚氨酯及其性能[J]. 复合材料学报, 2017, 34(12):2643-2652. doi: 10.13801/j.cnki.fhclxb.20170327.003ZHENG Chunsen, ZHAO Haiping, YAO Bolong, et al. Functional graphene-modified waterborne polyurethane and its properties[J]. Acta Materiae Compositae Sinica,2017,34(12):2643-2652(in Chinese). doi: 10.13801/j.cnki.fhclxb.20170327.003 [32] JIN Y X, HUANG G B, HAN D M, et al. Functionalizing graphene decorated with phosphorus-nitrogen containing dendrimer for high-performance polymer nanocompo-sites[J]. Composites Part A: Applied Science and Manufacturing,2016,86:9-18. doi: 10.1016/j.compositesa.2016.03.030 [33] LIU B W, ZHAO H B, WANG Y Z. Advanced flame-retardant methods for polymeric materials[J]. Advanced Materials,2021,27(7):682-691. -

下载:

下载: