Influence of glass frit on high temperature properties and dielectric properties of Si3N4 modified boron phenolic resin composites

-

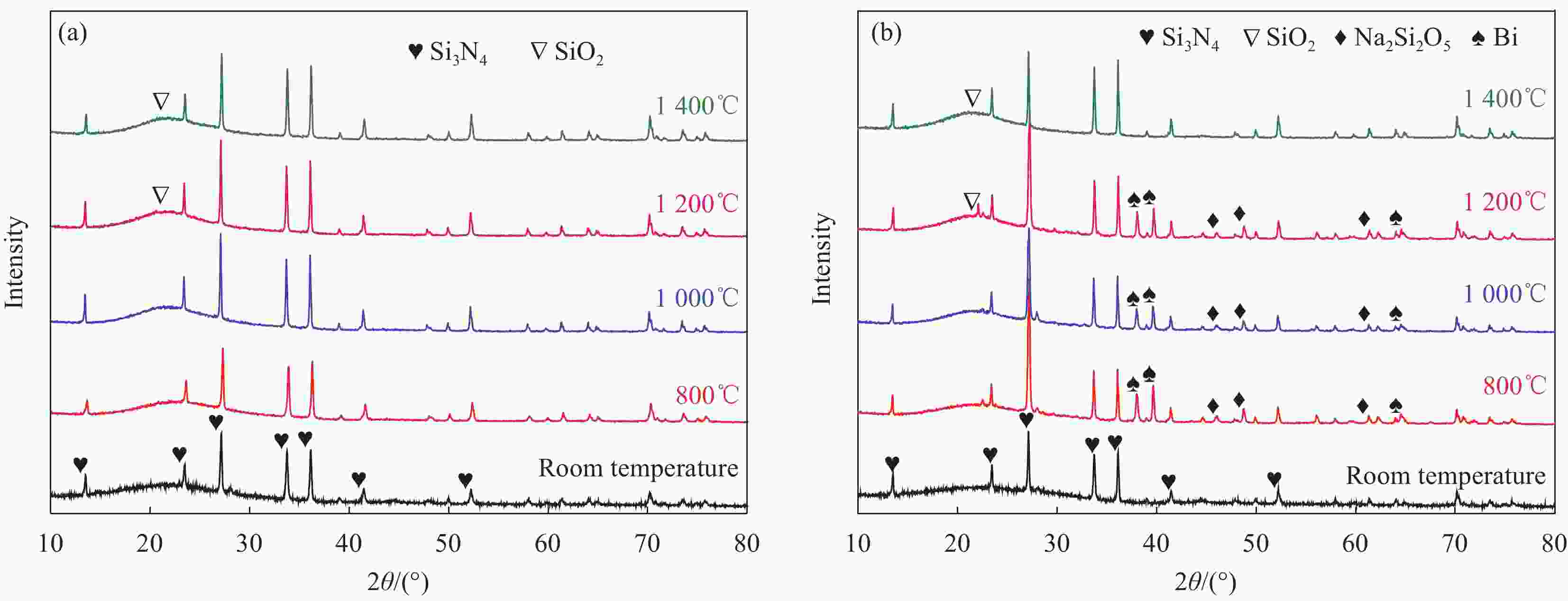

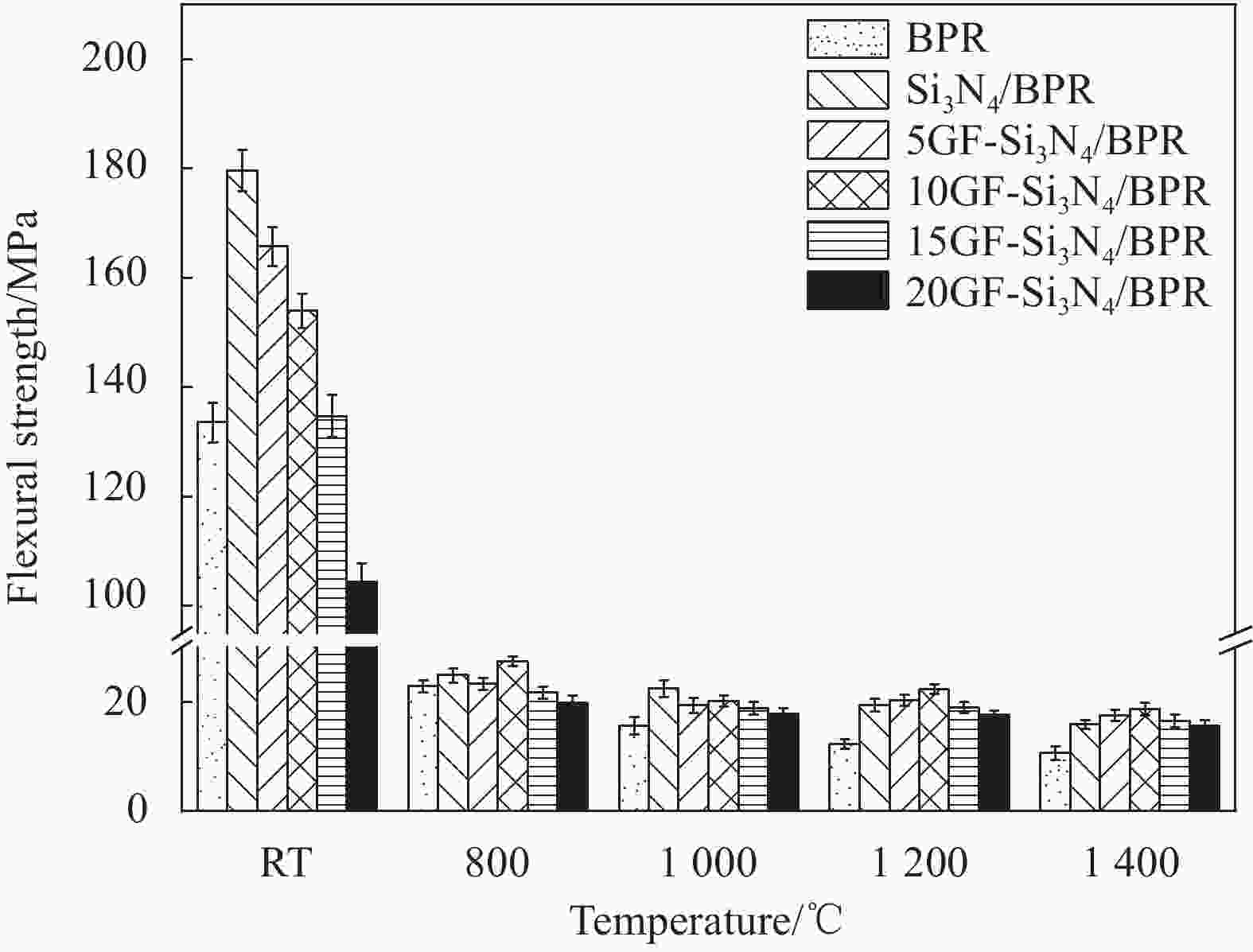

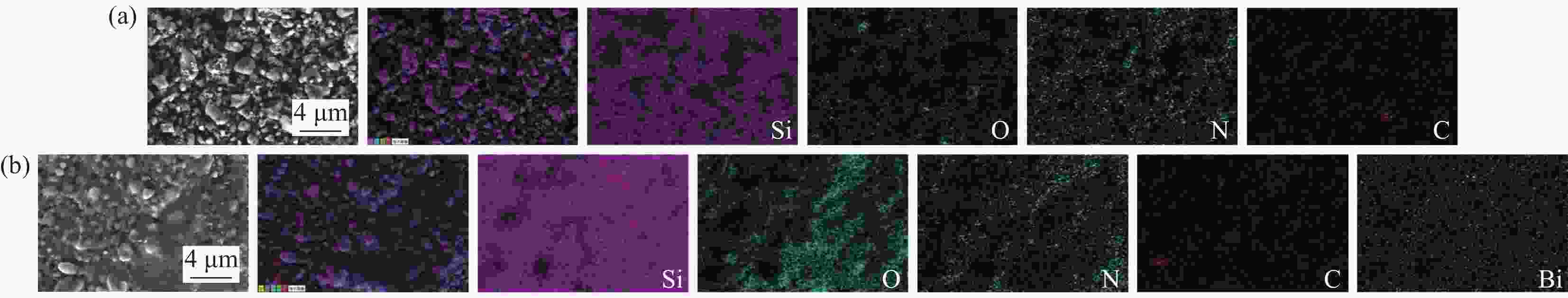

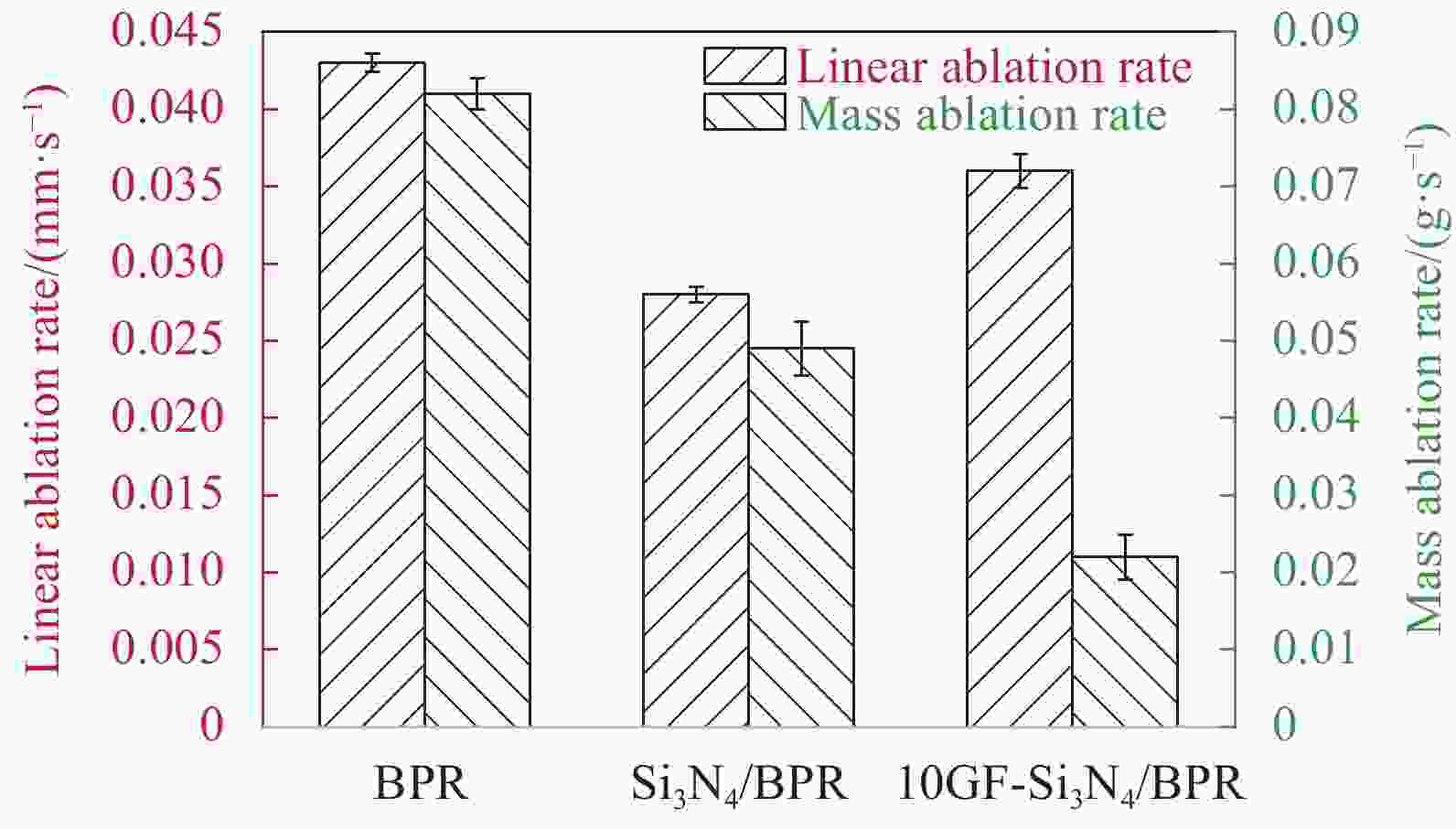

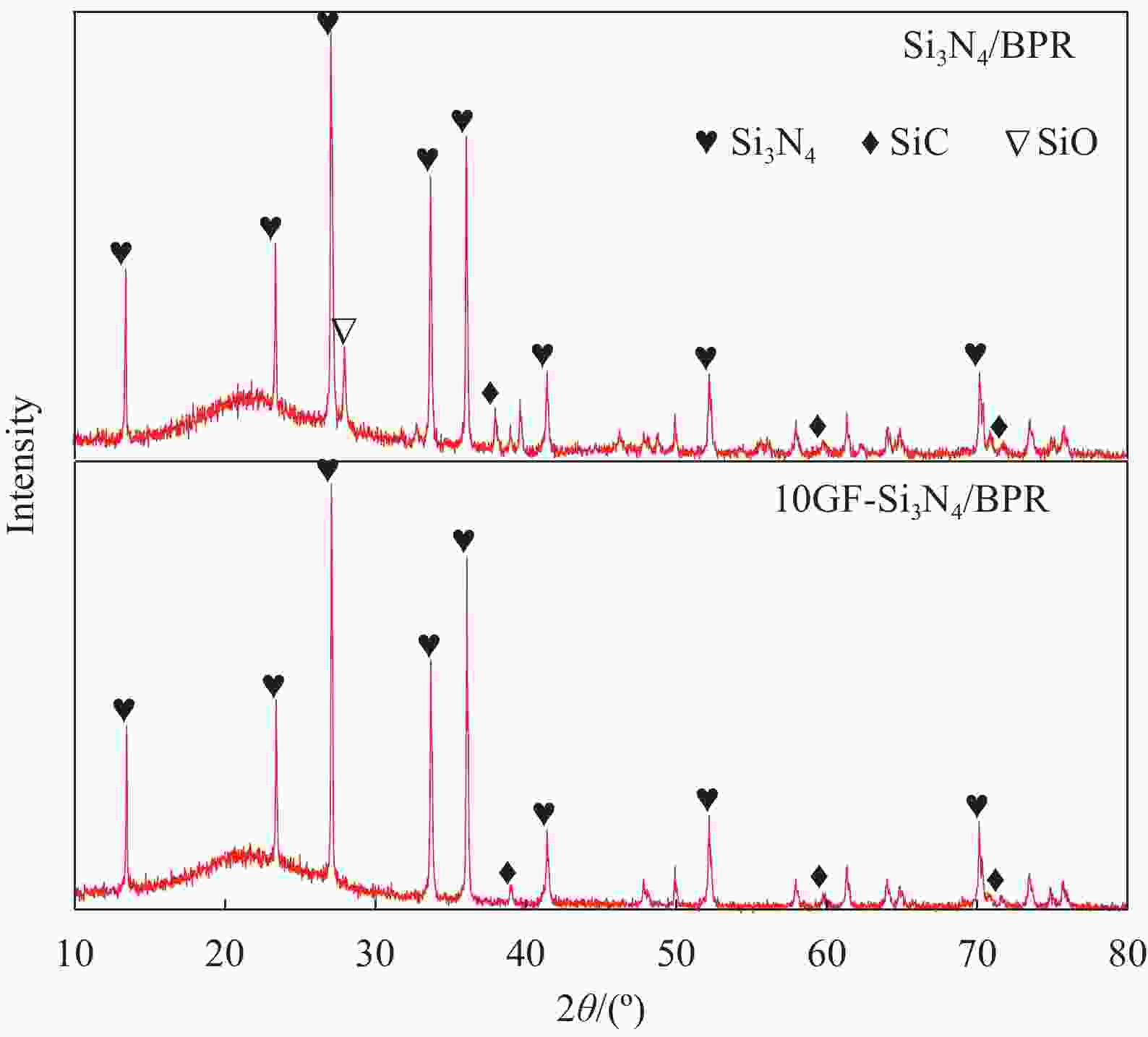

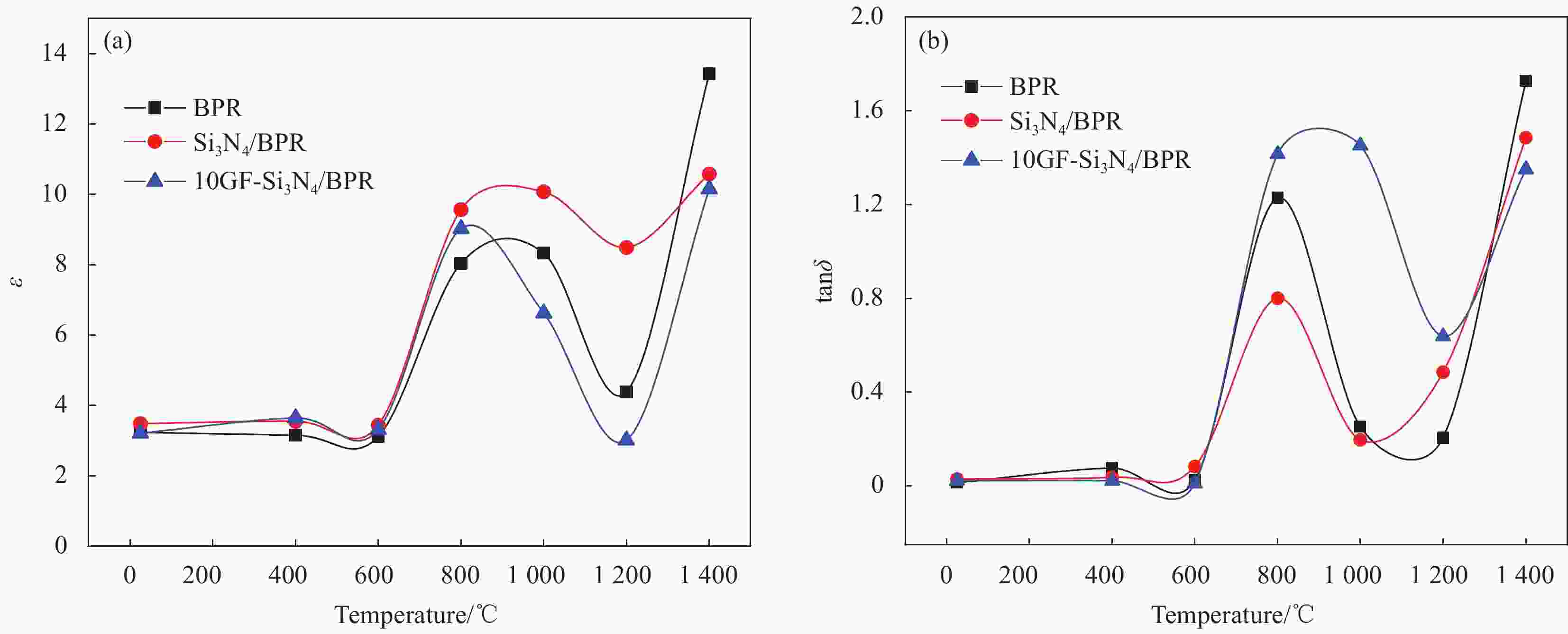

摘要: 为了探究助熔剂对树脂基复合材料高温性能及微观结构的影响,以低熔点玻璃料(GF)为助熔剂,Si3N4颗粒为耐高温陶瓷填料,采用模压工艺制备GF-Si3N4改性高硅氧玻璃纤维增强硼酚醛树脂复合材料(GF-Si3N4/BPR),研究GF对复合材料高温性能及介电性能的影响。结果表明:引入的GF促进了复合材料表面液相的形成和陶瓷层的致密化,抑制了热氧对复合材料的进一步侵蚀,复合材料高温性能明显提高。1200℃处理后,其弯曲强度与纯树脂试样(BPR)和未添加GF的试样(Si3N4/BPR)相比,分别提高了81.3%和14.9%;质量烧蚀率分别降低了73.1%和55.1%。此外,在8.2 GHz下,复合材料的介电常数(ε)和损耗角正切值(tanδ)随温度的升高逐渐增大。而在800℃以上,生成的玻璃相有效遏制了树脂裂解产生的游离碳与孔洞、裂纹对材料介电性能的不利影响。所制备的复合材料具有优良的高温性能和介电性能,有望应用在高温透波领域。Abstract: To investigate effect of flux on properties and microstructure of resin matrix composites at elevated temperature, glass frit (GF) and Si3N4 modified high silica glass fiber reinforced boron phenolic resin composites (GF-Si3N4/BPR) were prepared via a compression molding technique using low melting point GF as flux and Si3N4 particles as high temperature resistant fillers. The influence of GF on the high temperature properties and dielectric properties of composites was studied. The results show that the introduced GF promotes the formation of liquid phase on the surface of composites and the densification of the ceramic layer, inhibiting erosion of composites by oxygen at elevated temperatures and significantly improving the high temperature performance of composites. The flexural strength of GF-Si3N4/BPR treated at 1200℃ was increased by 81.3% and 14.9%, respectively, compared with high silica glass fiber reinforced boron phenolic resin composites (BPR) and Si3N4 modified high silica glass fiber reinforced boron phenolic resin composites (Si3N4/BPR), while the mass ablation rate was reduced by 73.1% and 55.1%, respectively, compared with BPR and Si3N4/BPR. Furthermore, at 8.2 GHz, the dielectric constant (ε) and loss tangent (tanδ) of the composites gradually increased with increasing temperature. At temperatures above 800°C, the resulting glass phase effectively restrains the adverse effects of free carbon, pores, and cracks generated by resin cracking on the dielectric properties of the material. The prepared composite material has excellent high temperature properties and dielectric properties, and is expected to be applied in the field of high temperature wave transmission.

-

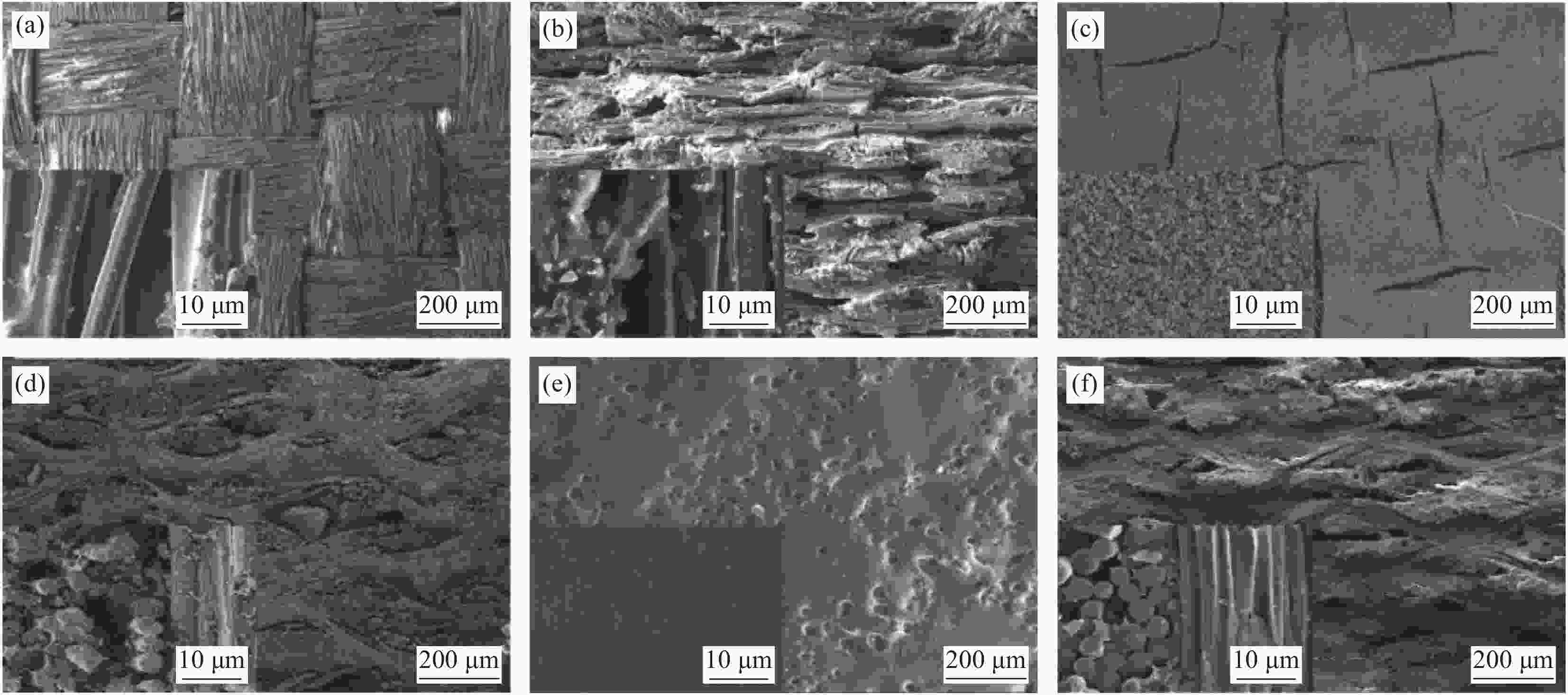

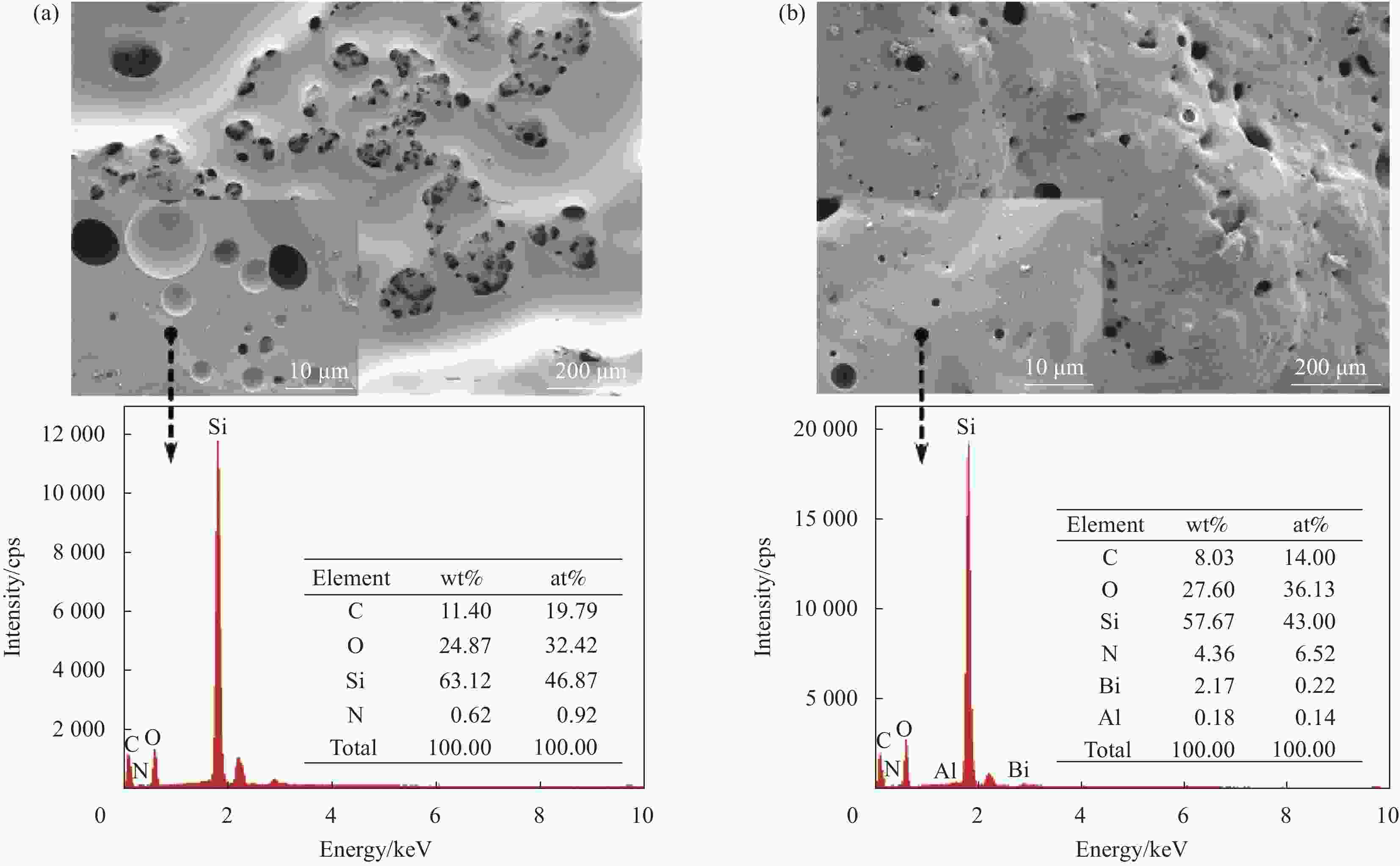

图 3 1200℃处理后GF-Si3N4/BPR复合材料表面和断面微观形貌:((a), (c), (e)) BPR、Si3N4/BPR和10GF-Si3N4/BPR的表面;((b), (d), (f)) BPR、Si3N4/BPR和10GF-Si3N4/BPR的断面

Figure 3. Surface and cross-section micro-morphologies of GF-Si3N4/BPR composites treated at 1200℃: ((a), (c), (e)) Surfaces of BPR, Si3N4/BPR and 10GF-Si3N4/BPR; ((b), (d), (f)) Cross-sections of BPR, Si3N4/BPR and 10GF-Si3N4/BPR

表 1 低熔点玻璃料(GF)主要成分及含量

Table 1. Main components and contents of low melting point glass frit (GF)

wt% SiO2 K2O Na2O ZnO Al2O3 BaO TiO2 Bi2O3 P2O5 Fe2O3 52.04 16.26 8.43 5.68 0.44 4.33 9.24 2.96 0.13 0.10 表 2 GF-Si3N4/BPR复合材料配方

Table 2. GF-Si3N4/BPR composite formulations

Sample Mass ratio BPR Si3N4 GF BPR 100 0 0 Si3N4/BPR 100 30 0 5GF-Si3N4/BPR 100 30 5 10GF-Si3N4/BPR 100 30 10 15GF-Si3N4/BPR 100 30 15 20GF-Si3N4/BPR 100 30 20 Note: BPR—Boron phenolic resin. 表 3 GF-Si3N4/BPR复合材料的热分解特性

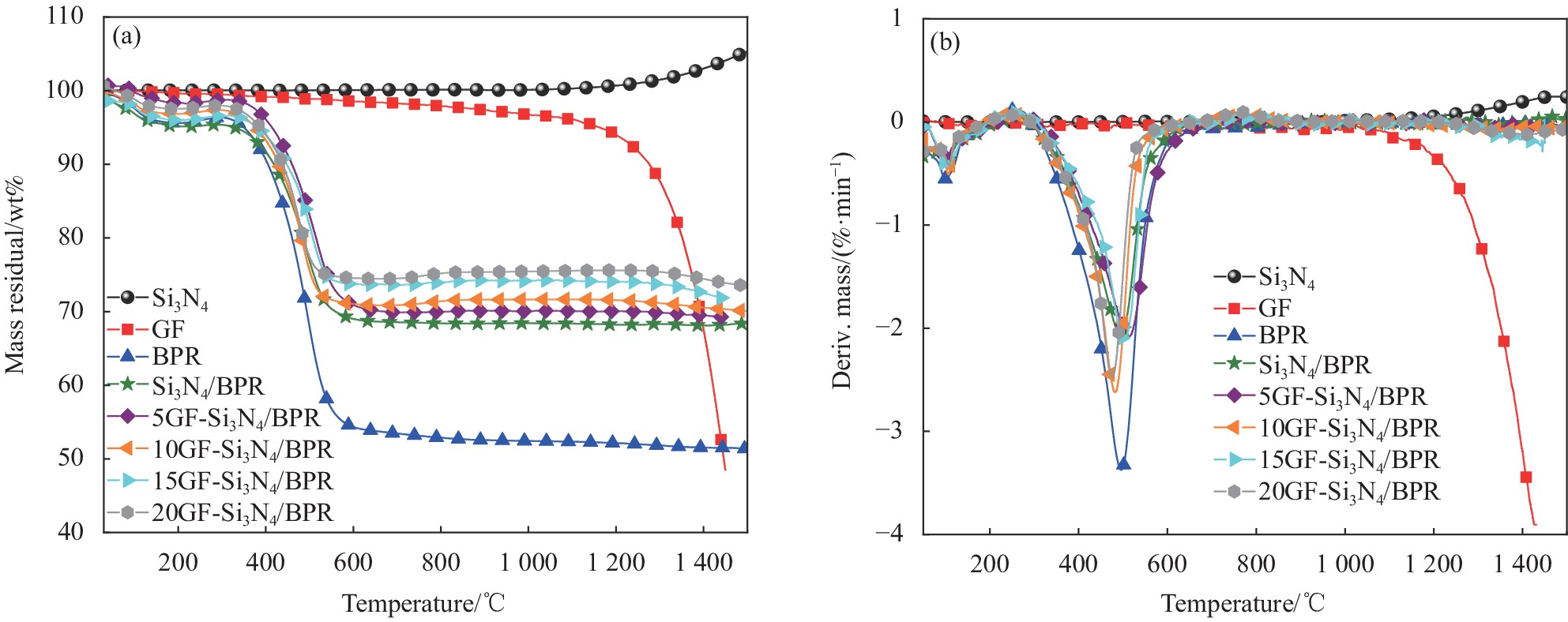

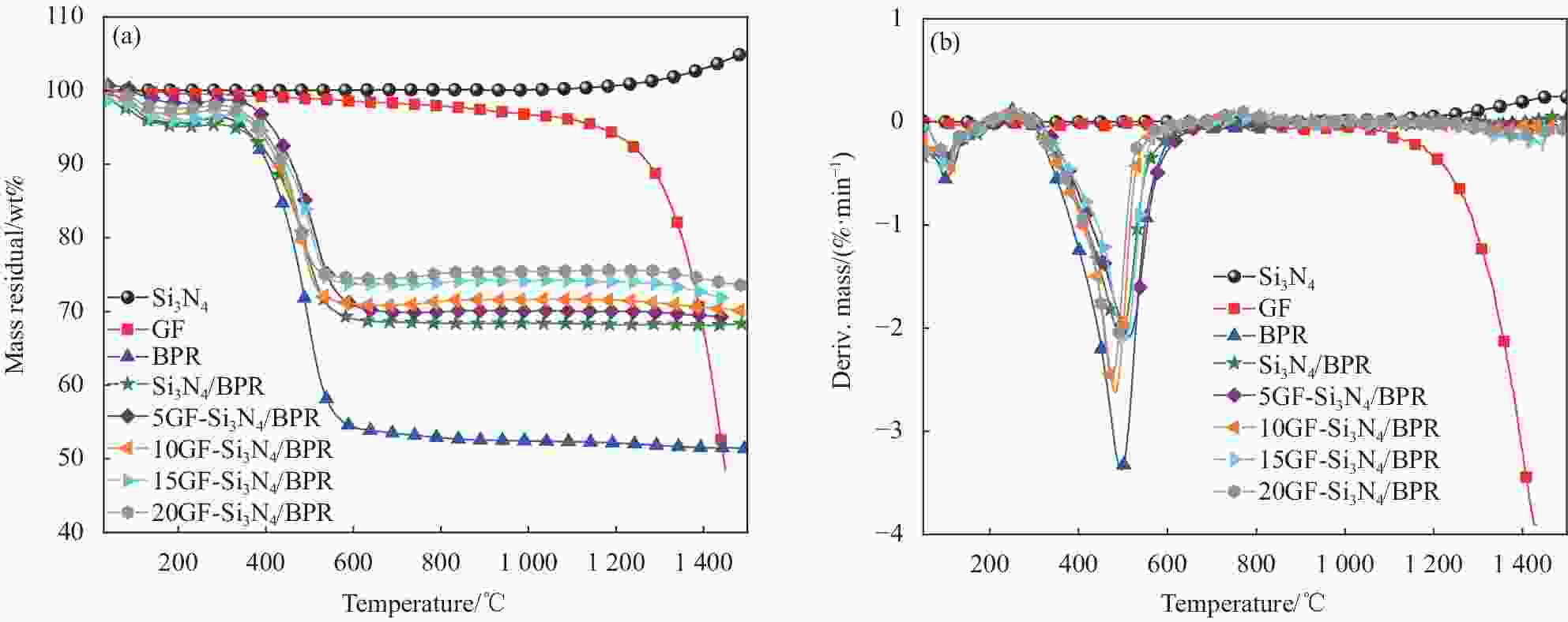

Table 3. Thermal decomposition properties of GF-Si3N4/BPR composites

Sample Tmax/℃ Residue yield/% 400℃ 600℃ 800℃ 1200℃ 1400℃ BPR 495.9 90.63 54.32 52.88 52.15 51.54 Si3N4/BPR 494.2 92.41 69.73 69.14 68.98 68.87 5GF-Si3N4/BPR 501.3 93.42 70.21 69.24 69.33 68.75 10GF-Si3N4/BPR 481.8 93.30 71.05 71.40 71.56 70.54 15GF-Si3N4/BPR 500.9 94.33 75.14 75.31 75.40 73.91 20GF-Si3N4/BPR 495.7 93.28 73.73 74.36 74.78 73.61 Note: Tmax—Temperature at which the thermal mass loss rate is the maximum. 表 4 不同温度处理后的GF-Si3N4/BPR复合材料电导率

Table 4. Conductivity of GF-Si3N4/BPR composites treated at different temperatures

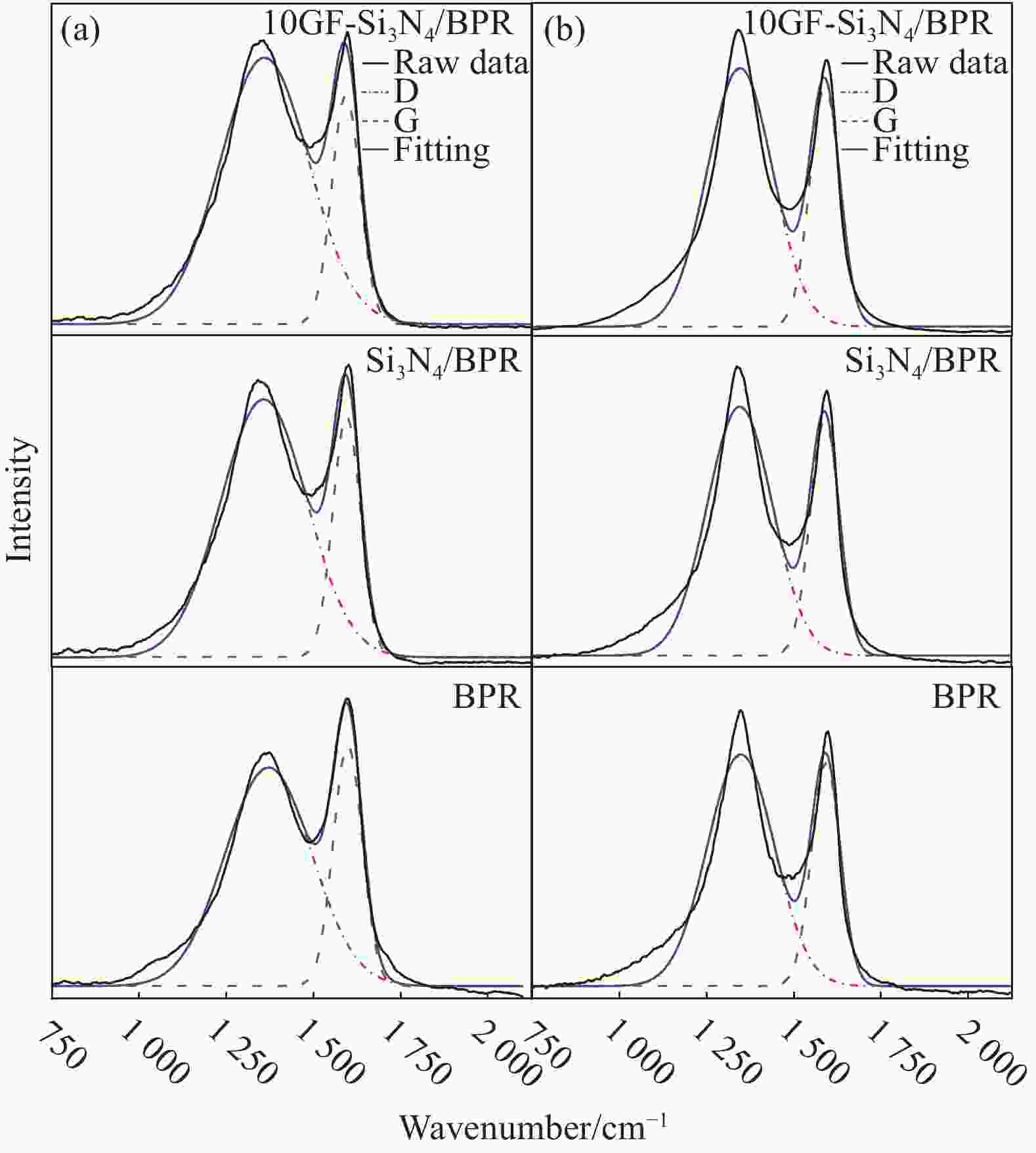

Sample Conductivity/(10−10 S·m–1) RT 800℃ 1000℃ 1200℃ 1400℃ BPR 0.222 113 93.5 162 358 Si3N4/BPR 0.125 149 142 80 188 10GF-Si3N4/BPR 0.111 87 150 65.8 128 表 5 GF-Si3N4/BPR复合材料裂解玻璃碳的ID/IG值

Table 5. ID/IG values of pyrolyzed glassy carbon of GF-Si3N4/BPR composites

Sample ID/IG 800℃ 1400℃ BPR 2.717 2.403 Si3N4/BPR 3.236 2.364 10GF-Si3N4/BPR 3.663 2.326 Note: ID/IG—Intensity ratio of the D band to the G band. -

[1] 朱召贤, 朱小飞, 黄洪勇, 等. 低密度树脂基防热材料研究进展[J]. 中国材料进展, 2019, 38(11):1086-1092. doi: 10.7502/j.issn.1674-3962.201806008ZHU Zhaoxian, ZHU Xiaofei, HUANG Hongyong, et al. Research progress of low-density resin based thermal protection materials[J]. Materials China,2019,38(11):1086-1092(in Chinese). doi: 10.7502/j.issn.1674-3962.201806008 [2] 张瑾瑜, 雷豹, 杨东生, 等. 航天飞行器典型高温透波结构热匹配性能分析[J]. 宇航总体技术, 2021, 5(3):59-64.ZHANG Jinyu, LEI Bao, YANG Dongsheng, et al. The analysis of thermal matching of a typical high temperature wave transmission structure of aero-spacecraft[J]. Astronautical Systems Engineering Technology,2021,5(3):59-64(in Chinese). [3] TRIANTOU K, PEREZ B, MARINOU A, et al. Performance of cork and ceramic matrix composite joints for reentry thermal protection structures[J]. Composites Part B: Engineering,2017,108:270-278. [4] 傅华东, 秦岩, 王辉, 等. 2.5D 石英纤维增强硼酚醛树脂可陶瓷化复合材料的制备与烧蚀性能[J]. 复合材料学报, 2020, 3(4):767-774.FU Huadong, QIN Yan, WANG Hui, et al. Preparation and ablation performance of 2.5D fiber reinforced boron-phenolic resin ceramizable composites[J]. Acta Materiae Compositae Sinica,2020,3(4):767-774(in Chinese). [5] 任粒. 聚合物基功能复合材料的设计、制备及介电和磁性能研究[D]. 北京: 北京科技大学, 2016.REN Li. Design and preparation of polymer based functional composites with dielectric and magnetic preperties[D]. Beijing: University of Science and Technology Beijing, 2016(in Chinese). [6] TANG L, ZHANG J L, TANG Y S, et al. Polymer matrix wave transparent composites: A review[J]. Journal of Materials Science & Technology,2021,75(16):225-251. [7] 宋麦丽, 傅利坤. 高性能耐高温陶瓷透波材料的研究进展[J]. 材料导报, 2012, 26(S1):226-229.SONG Maili, FU Likun. Research development of high temperature ceramic wave-transparent materials[J]. Materials Reports,2012,26(S1):226-229(in Chinese). [8] 黄良, 朱朋莉, 梁先文, 等. 无机颗粒填充聚合物复合材料的介电性能研究[J]. 材料导报, 2014, 28(19):11-20.HUANG Liang, ZHU Pengli, LIANG Xianwen, et al. Study on the dielectric properties of inorganic particles filled polymer composites[J]. Materials Reports,2014,28(19):11-20(in Chinese). [9] BADHE Y, BALASUBRAMANIAN K. Novel hybrid ablative composites of resorcinol formaldehyde as thermal protection systems for reentry vehicles[J]. RSC Advances,2014,4(55):28956-28963. [10] YANG W, XU B, QI M, et al. Improving ablation properties of ceramifiable vitreous silica fabric reinforced boron phenolic resin composites via an incurporation of MoSi2[J]. Plastics, Rubber and Composites,2020,49(10):456-469. doi: 10.1080/14658011.2020.1808758 [11] 董闯, 邓宗义, 任依林, 等. 石榴石微粉改性硼酚醛树脂的制备与耐高温性能[J]. 复合材料学报, 2022, 39(6):2673-2681. doi: 10.13801/j.cnki.fhclxb.20210628.001DONG Chuang, DENG Zongyi, REN Yilin, et al. Preparation and high temperature resistance of modified boron phenolic resin with almandine micropowder[J]. Acta Materiae Compositae Sinica,2022,39(6):2673-2681(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210628.001 [12] 石毓锬, 梁国正, 兰立文. 树脂基复合材料在导弹雷达天线罩中的应用[J]. 材料工程, 2000(5):36-39.SHI Yutan, LIANG Guozheng, LAN Liwen. Research of polymer-matrix composites for missile radomes[J]. Jour-nal of Materials Engineering,2000(5):36-39(in Chinese). [13] 宋麦丽, 崔红, 闫联生, 等. 高硅氧/有机硅透波材料介电性能实验分析[J]. 固体火箭技术, 2006(5):364-366, 371.SONG Maili, CUI Hong, YAN Liansheng, et al. Experimental analysis on dielectric properties of silica glass/silicone radome material[J]. Journal of Solid Rocket Technology,2006(5):364-366, 371(in Chinese). [14] 王思青, 张长瑞, 王圣威, 等. Si3N4基复相陶瓷天线罩材料的制备及性能[J]. 国防科技大学学报, 2006(2):44-47. doi: 10.3969/j.issn.1001-2486.2006.02.010WANG Siqing, ZHANG Changrui, WANG Shengwei, et al. Preparation and properties of Si3N4 matrix radome ceramics[J]. Journal of National University of Defense Technology,2006(2):44-47(in Chinese). doi: 10.3969/j.issn.1001-2486.2006.02.010 [15] QI G J, ZHANG C R, HU H F, et al. Preparation of three-dimensional silica fiber reinforced silicon nitride compo-sites using perhydropolysilazane as precursor[J]. Materials Letters,2005,59(26):3256-3258. doi: 10.1016/j.matlet.2005.04.057 [16] 中国国家标准化管理委员会. 纤维增强塑料弯曲性能试验方法: GB/T 1449—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Test method for bending properties of fiber reinforced plastics: GB/T 1449—2005[S]. Beijing: China Standard Press, 2005(in Chinese). [17] 国防科学技术工业委员会. 烧蚀材料烧蚀试验方法: GJB 323 A—1996[S]. 北京: 中国标准出版社, 1996.Commission of Scientific and Technical Industry on National Defence. Ablation test method for ablation materials: GJB 323 A—1996[S]. Beijing: China Standard Press, 1996(in Chinese). [18] 范珊珊, 石敏先, 孟盼, 等. 助熔剂对陶瓷化硼酚醛复合材料热行为及微观结构的影响[J]. 复合材料学报, 2017, 34(1):60-66. doi: 10.13801/j.cnki.fhclxb.20160411.004FAN Shanshan, SHI Minxian, MENG Pan, et al. Effects of fusing agent on the thermal behavior and microstructure of ceramifiable boron phenolic resin composites[J]. Acta Materiae Compositae Sinica,2017,34(1):60-66(in Chinese). doi: 10.13801/j.cnki.fhclxb.20160411.004 [19] ZHANG L, ZHANG Y, WANG L, et al. Phenolic resin modified by boron-silicon with high char yield[J]. Polymer Testing,2019,73:208-213. doi: 10.1016/j.polymertesting.2018.11.033 [20] 徐博, 丁杰, 王兵, 等. AlB2对高硅氧纤维增强可瓷化酚醛树脂基复合材料及其裂解产物力学性能的影响[J]. 复合材料学报, 2021, 38(1):129-136.XU Bo, DING Jie, WANG Bing, et al. Effects of AlB2 on mechanical properties of high silica fiber reinforced ceramicizable phenolic resin matrix composites and their pyrolysis products[J]. Acta Materiae Compositae Sinica,2021,38(1):129-136(in Chinese). [21] 邢建申, 王树彬, 张跃. 石英纤维析晶行为[J]. 复合材料学报, 2006(6): 75-79.XING Jianshen,WANG Shubin, ZHANG Yue. Crystallization of quartz fiber[J]. Acta Materiae Compositae Sinica, 2006(6): 75-79(in Chinese). [22] SHI M X, CHEN X, FAN S S, et al. Fluxing agents on ceramification of composites of MgO-Al2O3-SiO2/boron phenolic resin[J]. Journal of Wuhan University of Technology,2018,33(2):381-388. doi: 10.1007/s11595-018-1833-8 [23] 闵春英, 黄玉东, 刘丽, 等. 温度对甲基硅树脂基复合材料介电性能及力学性能的影响[J]. 固体火箭技术, 2007(4):348-352. doi: 10.3969/j.issn.1006-2793.2007.04.020MIN Chunying, HUANG Yudong, LIU Li, et al. Effect of temperature on dielectric and mechanical properties of methyl silicone resin composites[J]. Journal of Solid Rocket Technology,2007(4):348-352(in Chinese). doi: 10.3969/j.issn.1006-2793.2007.04.020 [24] 詹未荫. 聚合物基微波介质复合材料的制备与性能[D]. 武汉: 武汉理工大学, 2014.ZHAN Weiyin. Preparation and properties of microwave dielectric polymer matrix composites[D]. Wuhan: Wuhan University of Technology, 2014(in Chinese). [25] 涂建华, 张利波, 彭金辉, 等. 酚醛树脂基玻璃炭结构的显微激光拉曼光谱研究[J]. 高分子材料科学与工程, 2005(6):205-208. doi: 10.3321/j.issn:1000-7555.2005.06.052TU Jianhua, ZHANG Libo, PENG Jinhui, et al. Microscopic laser Raman spectroscopy of phenolic resinbased glass carbon structure[J]. Polymeric Materials Science and Engineering,2005(6):205-208(in Chinese). doi: 10.3321/j.issn:1000-7555.2005.06.052 [26] WANG S, YONG W, CHENG B, et al. The thermal stability and pyrolysis mechanism of boron-containing phenolic resins: The effect of phenyl borates on the char formation[J]. Applied Surface Science,2015,331:519-529. doi: 10.1016/j.apsusc.2015.01.062 -

下载:

下载: