Mechanical properties experiment of steel-concrete composite beams reinforced with BFRP bars after high temperature

-

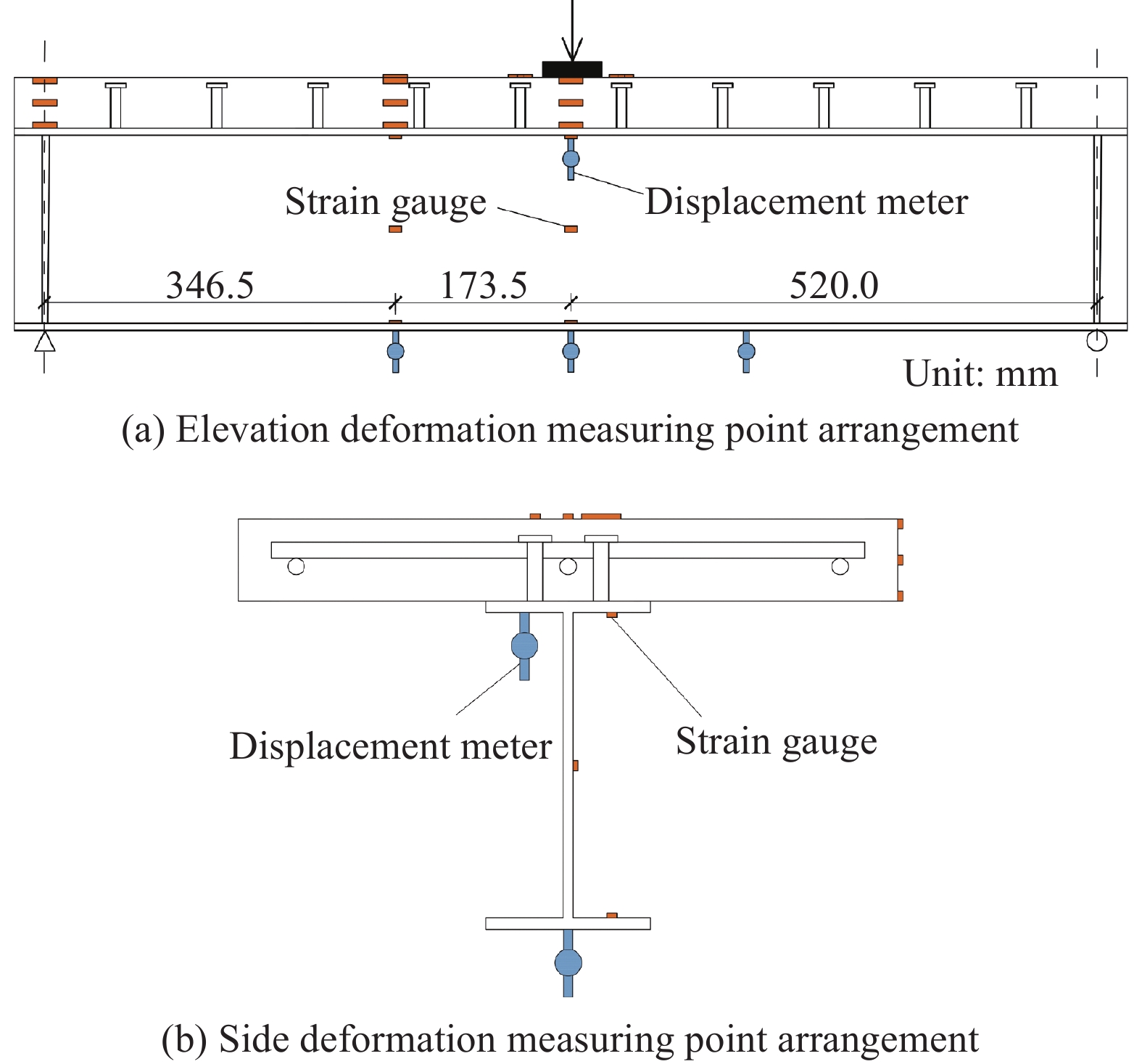

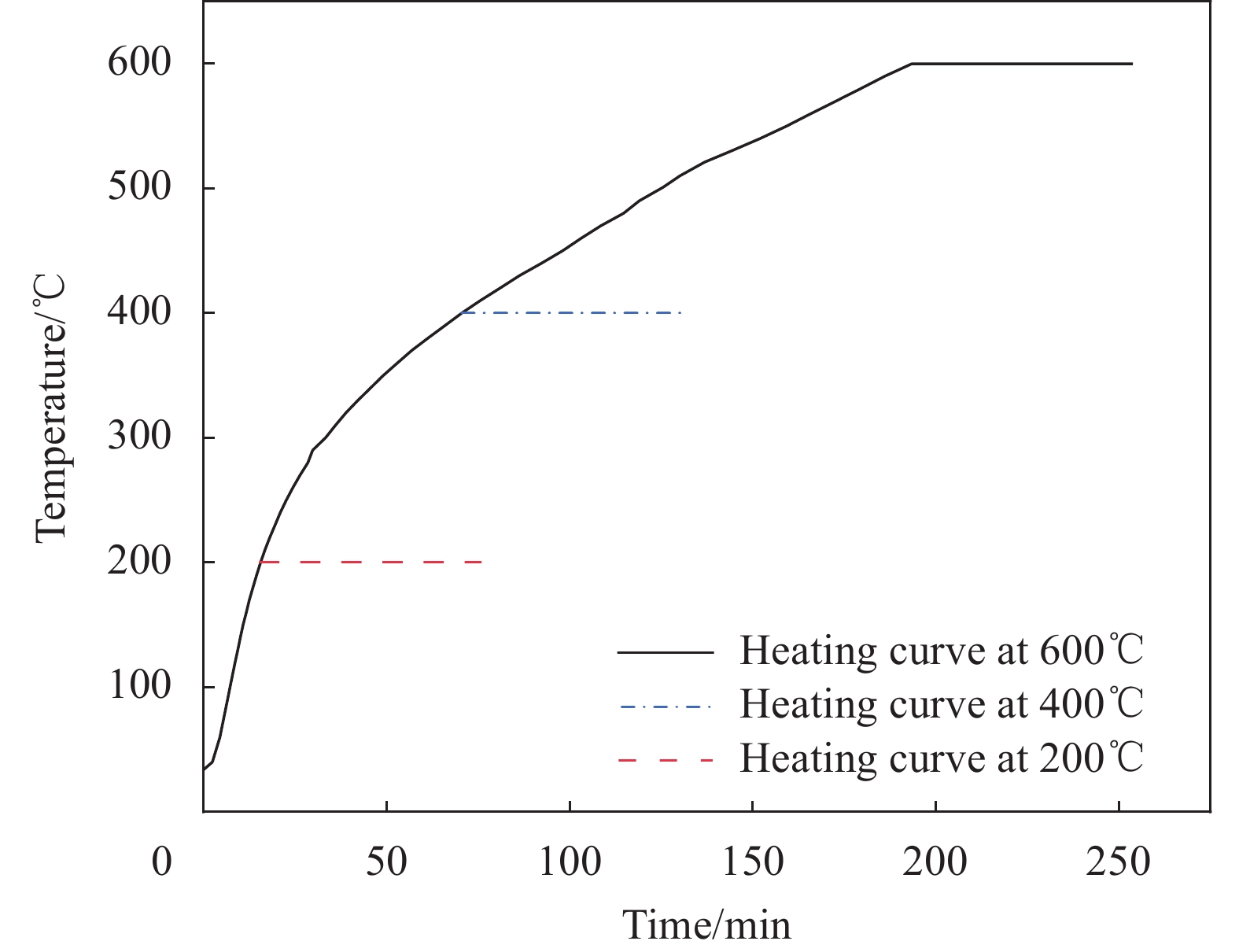

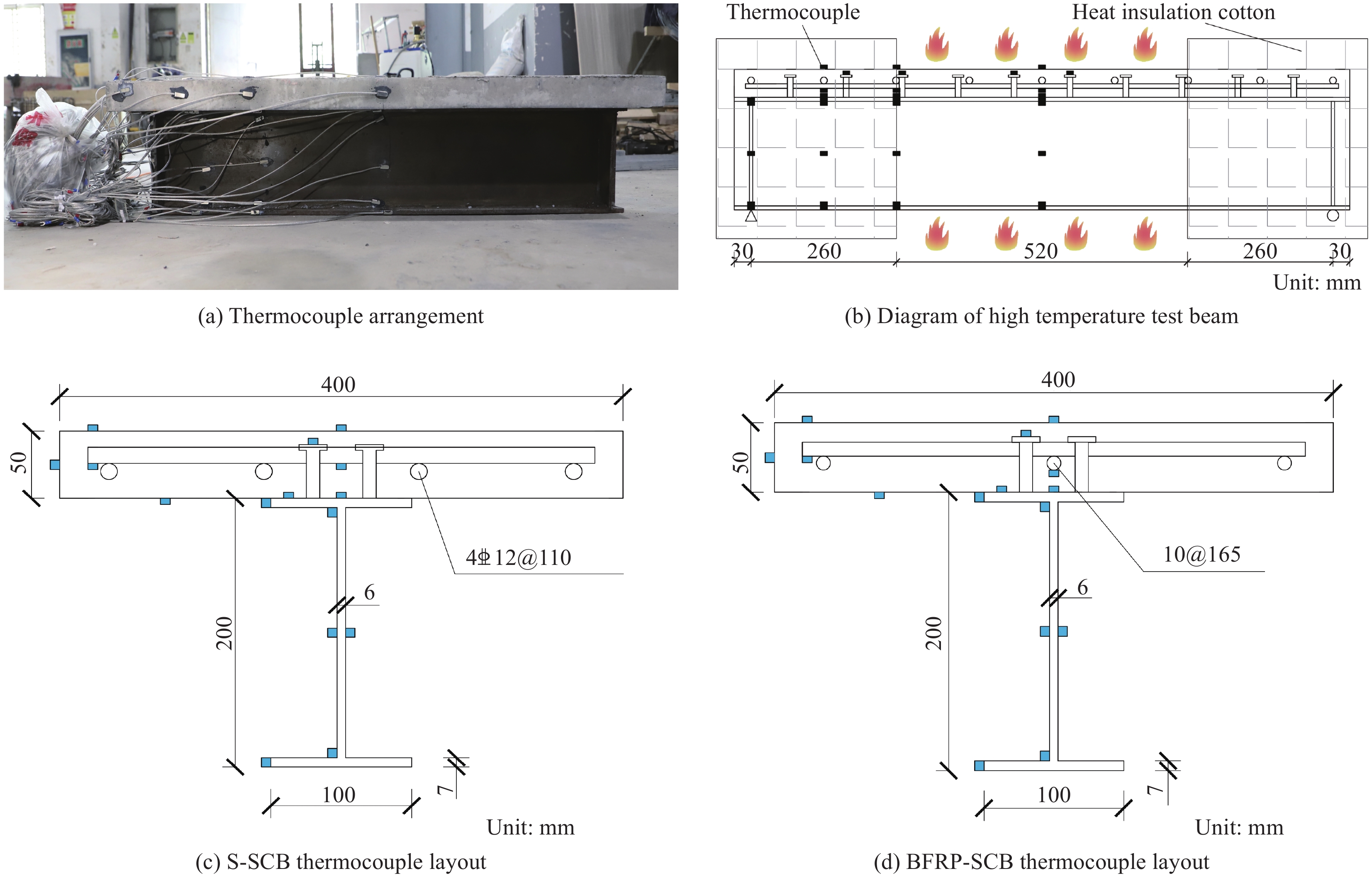

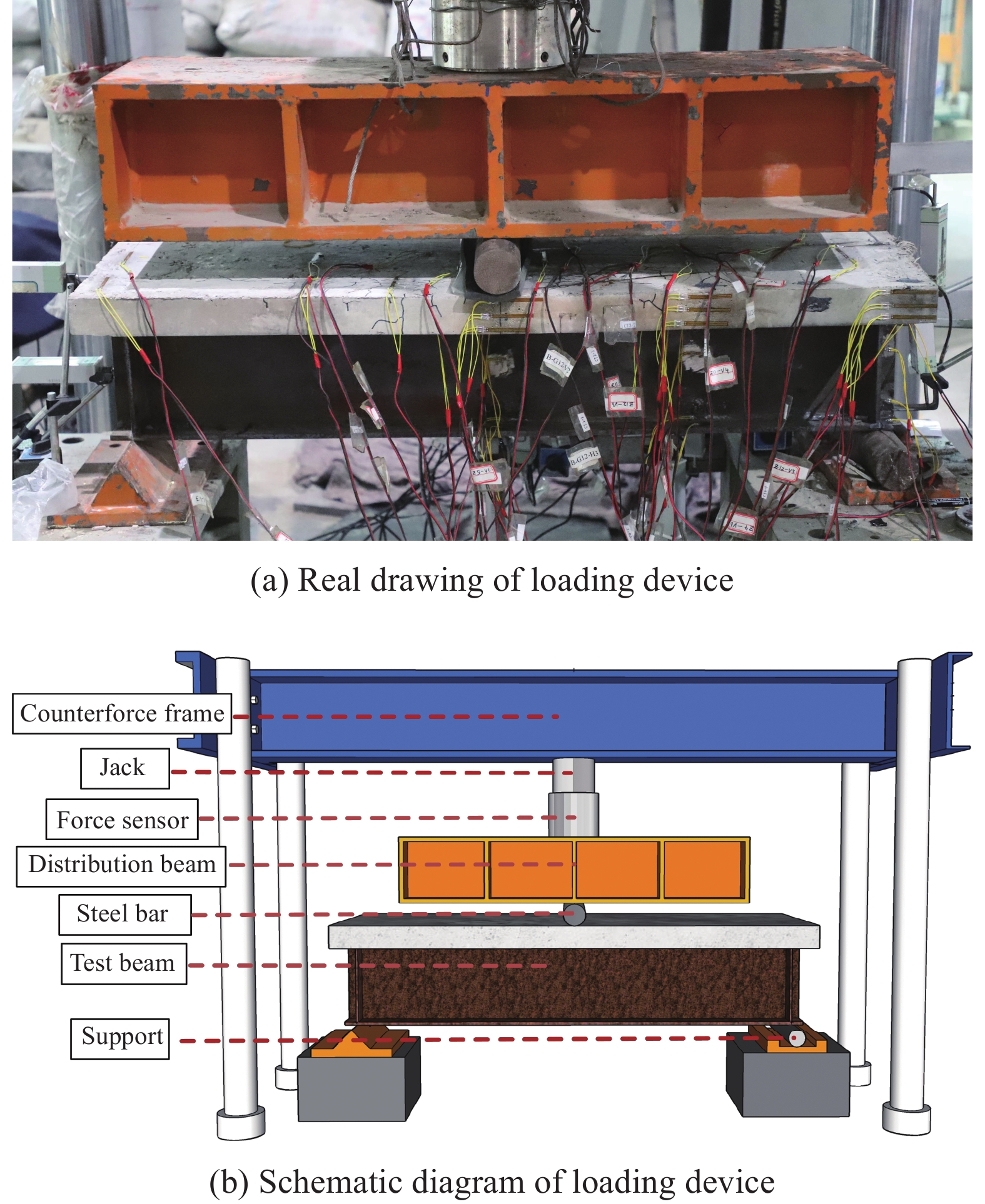

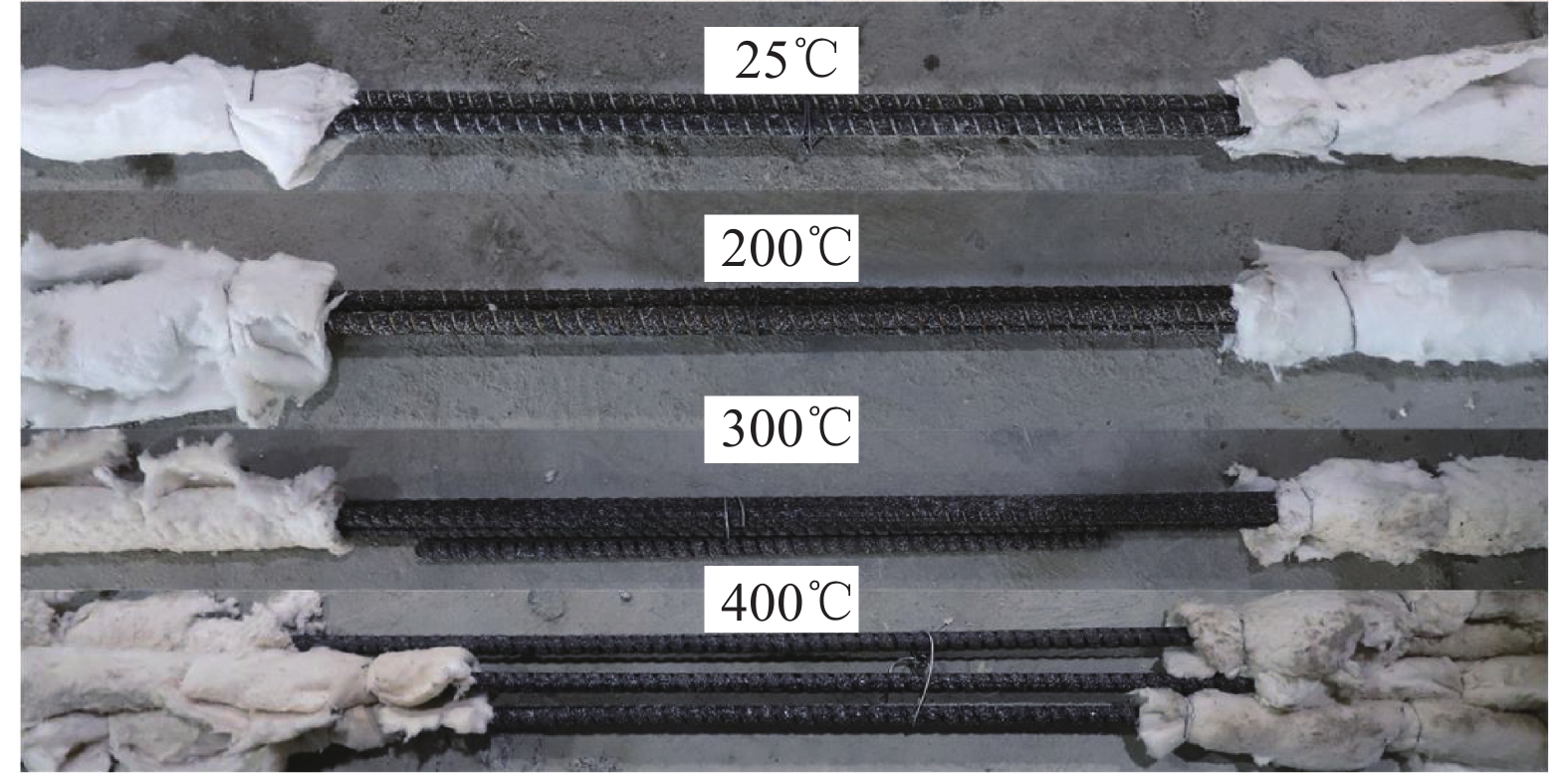

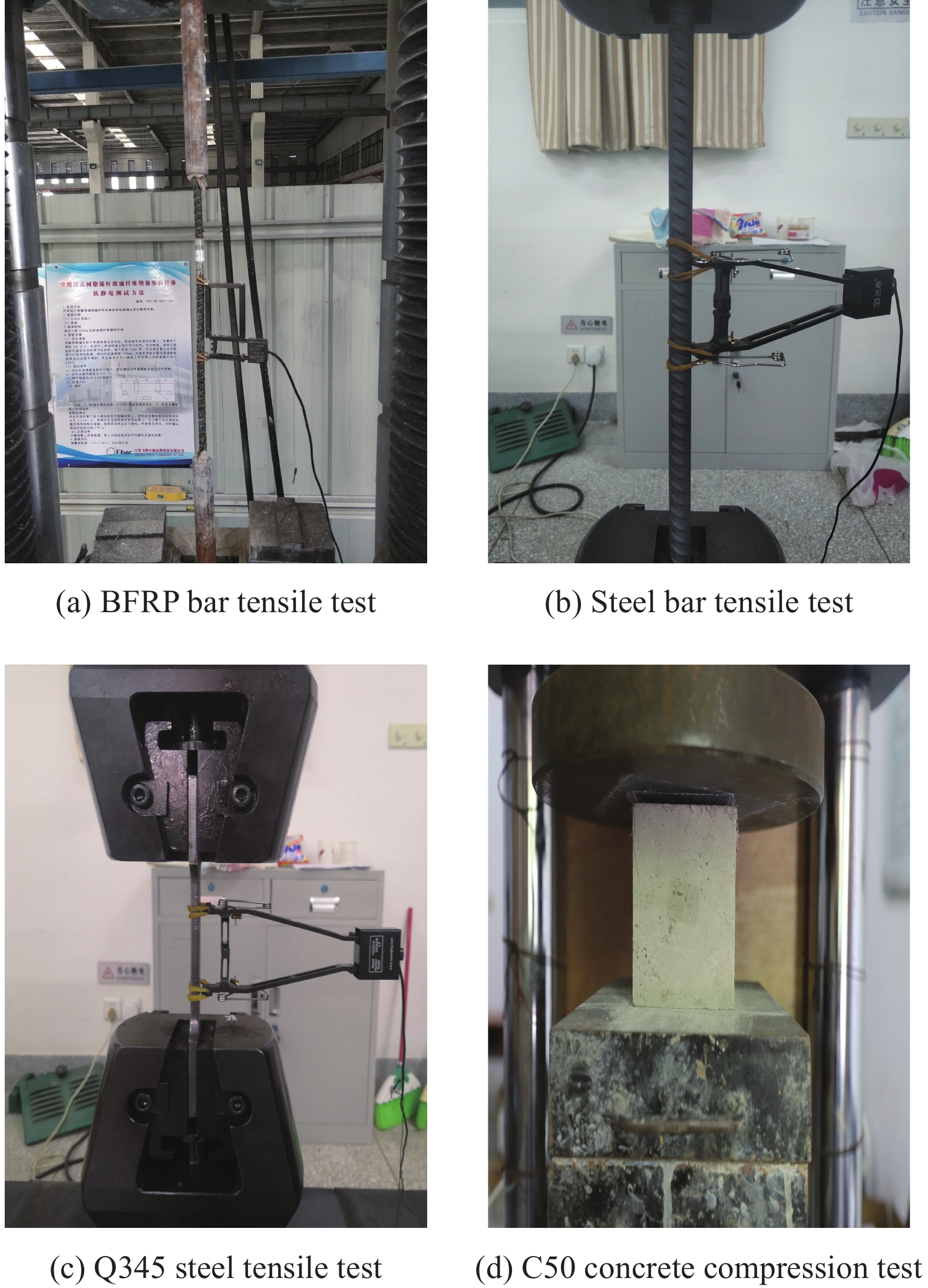

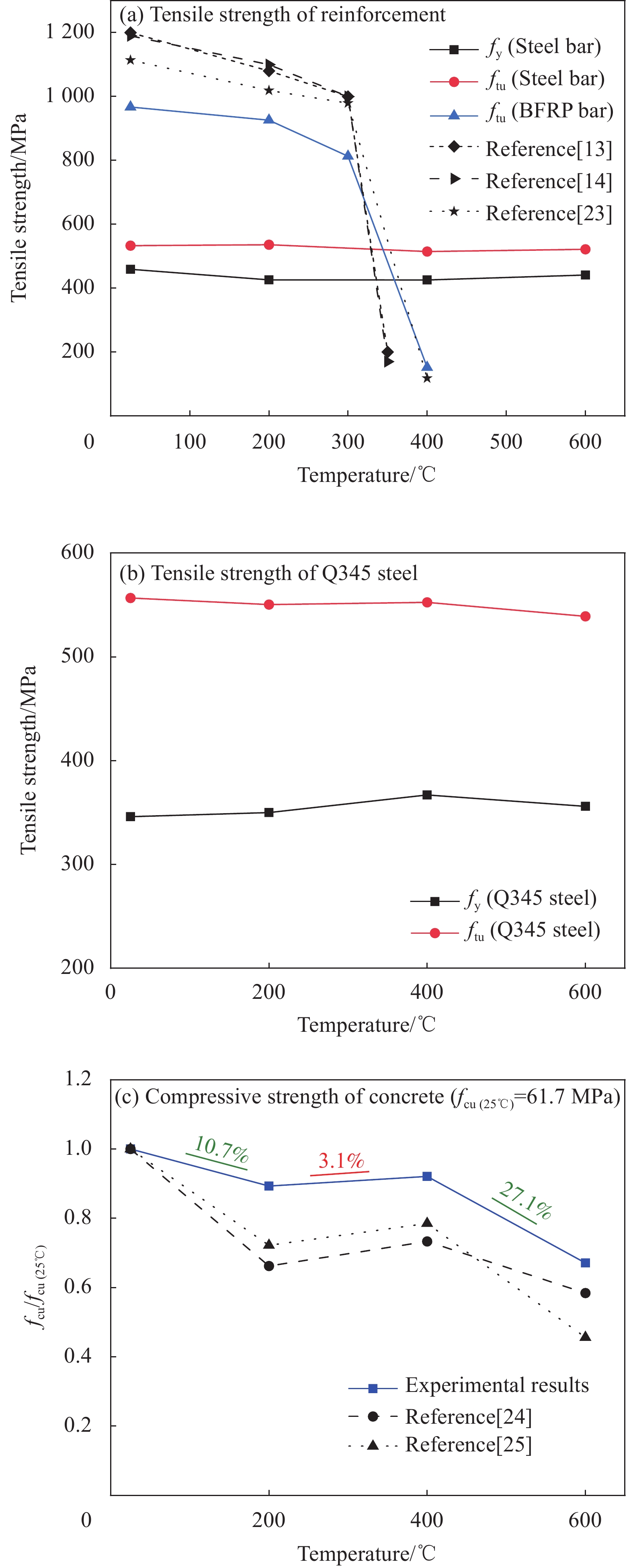

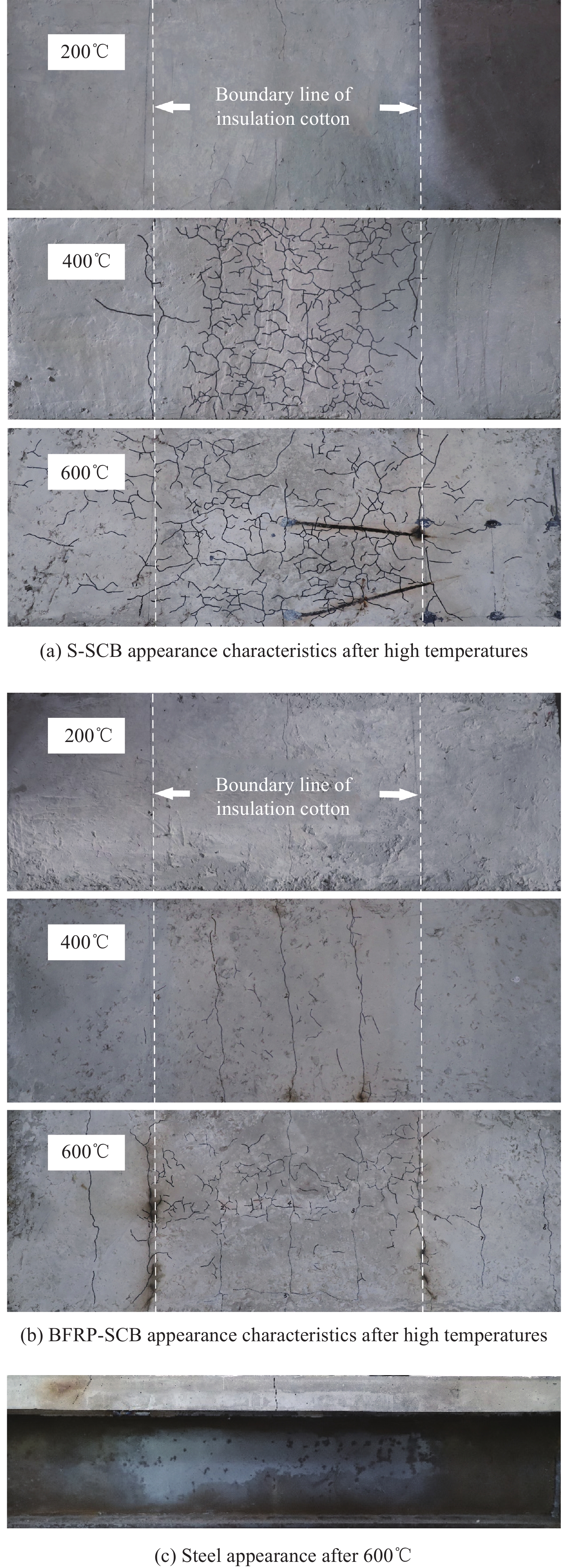

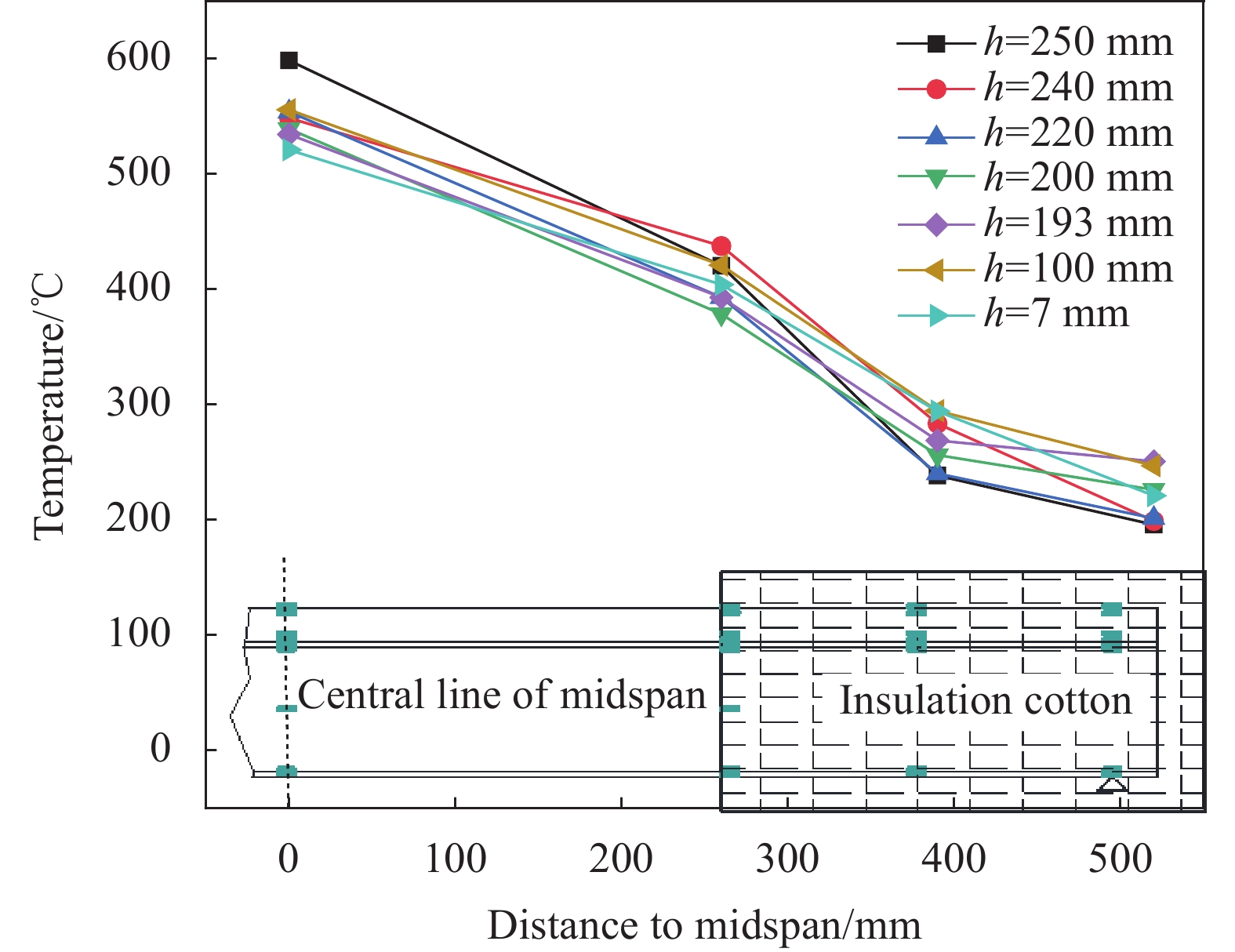

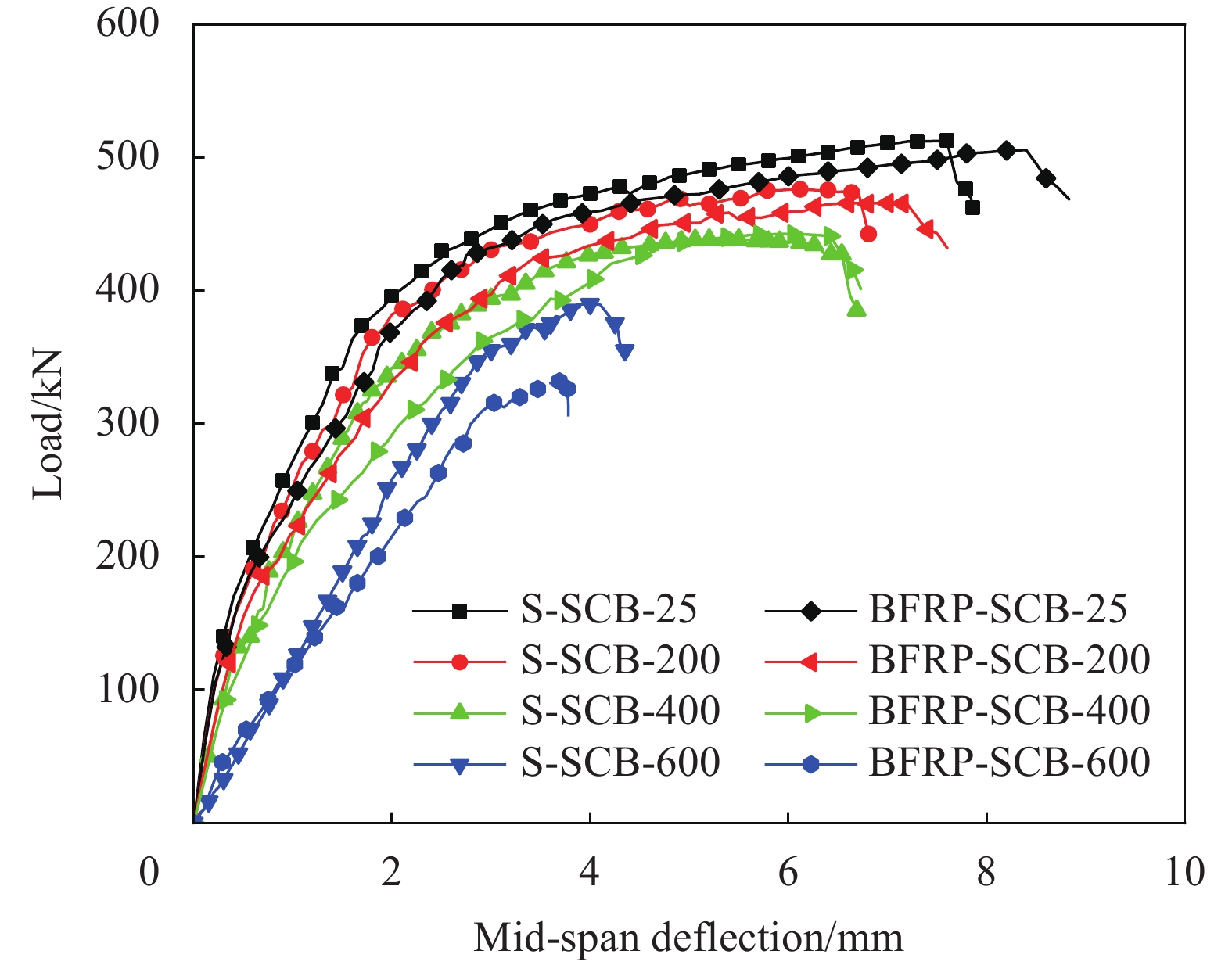

摘要: 设计了常温(25℃)、200℃、400℃和600℃四个工况,通过模型试验方法探究了玄武岩纤维增强树脂复合材料(Basalt fiber reinforced polymer,BFRP)筋钢-混组合梁高温后的破坏形态和力学性能。通过分析试验梁裂缝开展、挠度变形、温度场和破坏过程规律,研究BFRP筋和普通钢筋钢-混组合梁的破坏模式和承载能力。结果表明:经历400℃高温后,BFRP筋劣化导致力学性能大幅降低;筋体膨胀导致混凝土板开裂,其裂缝开展与普通钢筋钢-混组合梁显著不同,主裂缝沿横向筋材规律开展,且裂缝较宽。温度低于400℃时,由于混凝土的包裹,BFRP筋未达到劣化温度,两种钢-混组合梁承载能力和外观差别较小;600℃后,BFRP筋劣化,削弱了混凝土板刚度和强度,导致BFRP筋钢-混组合梁承载能力比普通钢筋钢-混组合梁降低更多;BFRP筋钢-混组合梁因整体刚度较小,加载后变形更大。高温后两种钢-混组合梁破坏模式相似,均为剪切破坏,有明显弹性、弹塑性和破坏阶段;600℃时,两种钢-混组合梁延性大幅降低,塑性变形减少,破坏较为突然。研究成果可为BFRP筋在钢-混组合梁中的应用提供参考。Abstract: Four working conditions of room temperature (25℃), 200℃, 400℃ and 600℃ were designed. The failure modes and mechanical properties of steel-concrete composite beams reinforced with basalt fiber reinforced polymer (BFRP) bars after high temperature were studied by the model experiment method. The failure modes and bearing capacity of steel-concrete composite beams reinforced with BFRP bars and steel bars were studied by analyzing the test beam’s crack development, deflection deformation, temperature field and failure process. The results show that the mechanical properties of BFRP bars are significantly reduced after a high temperature of 400℃. The mechanical properties of composite beams are significantly reduced after the high temperature of 400℃ due to the deterioration of BFRP bars. The expansion of BFRP bars leads to the cracking of concrete slab, and the crack development is obviously different from that of steel-concrete composite beams reinforced with steel bars. The main cracks regularly develop along with the transverse reinforcements, and the cracks are wider. When the temperature is lower than 400℃, BFRP bars do not reach the deterioration temperature due to the wrapping of concrete, and the bearing capacity and appearance of the two steel-concrete composite beams have little difference. After 600℃, the deterioration of BFRP bars weakens the stiffness and strength of concrete slabs, resulting in a decrease in the bearing capacity of steel-concrete composite beams reinforced with BFRP bars more than steel bars. The steel-concrete composite beams reinforced with BFRP bars have larger deformation after loading due to the small overall stiffness. After high temperature, the failure modes of the two steel-concrete composite beams are similar, which are shear failure with evident elastic, elastoplastic and failure stages. At 600℃, the ductility of the two steel-concrete composite beams is significantly reduced, the plastic deformation is reduced, and the failure is more sudden. The research results can provide a reference for applying BFRP bars in steel-concrete composite beams.

-

Keywords:

- steel-concrete composite beam /

- model test /

- high temperature /

- BFRP bars /

- mechanical properties

-

泡沫混凝土作为多孔结构的轻质混凝土,因其保温隔热性好、节能、缓冲、利废等优点,符合国家绿色发展需求,在寒区保温防护领域应用前景广阔[1-3]。泡沫混凝土的抗压强度相较普通混凝土差异较大,其力学特性一直是研究重点,目前已有多位学者开展了单轴压缩试验[4-8],结果表明,泡沫混凝土在单轴压缩状态下应力-应变曲线呈现明显的阶段效应,其抗压强度受密度、孔结构、龄期及尺寸效应的影响,龄期长、密度大、尺寸小的试块孔结构更均匀,抗压强度也越高。

当泡沫混凝土用于寒区保温防护时,受冻融环境的影响,内部孔隙水结冰膨胀产生的压力作用会导致泡沫混凝土物理力学性能发生显著变化[9]。多位学者在常温所得研究成果基础上,进一步探索了冻融环境下的相关研究。Bayraktar 等[10]通过UPV法对冻融条件下不同水泥和泡沫含量的泡沫混凝土7 d/28 d抗折、抗压强度做出评估,总结得到冻融循环下水泥含量为500 kg/m3、泡沫含量为20 kg/m3的泡沫混凝土表现出最佳的抗冻性能。高志涵等[11]借助X-CT设备对冻融后不同密度泡沫混凝土进行孔结构扫描检测,从微观角度得出冻融循环会增大孔隙率,分散孔径,进而引起力学性能下降的结论。叶林杰等[12]对冻融循环和疲劳荷载共同作用下的泡沫混凝土进行SEM 切片扫描处理,研究发现冻融会使其内部孔隙产生裂缝,且随循环荷载次数的增加微裂缝数量逐渐增加。然而,现有研究主要集中在冻融前后的力学性能和孔结构等方面,对冻融条件下泡沫混凝土的单轴压缩开裂破坏过程研究较少,其冻融损伤演化规律尚未明确。若要优化泡沫混凝土的结构设计和提高其在寒区环境下的应用性能,仅从抗压强度这单一角度考虑是不够全面的,必须进一步对冻融环境下泡沫混凝土压缩破坏全过程进行动态监测,分析其变形破坏机制。而如何观测冻融后泡沫混凝土的压缩破坏过程,测量多点开裂和裂缝发展情况是目前亟待解决的关键问题。

针对上述问题,许多新兴的无损监测方法已被应用于混凝土材料破坏试验研究中。声发射(AE)技术通过采集混凝土材料压缩过程中内部开裂产生的弹性波信号,可对其内部损伤演化过程进行动态分析[13]。数字图像相关(DIC)技术可以记录混凝土材料表面的位移场和应变场,从而对试件的裂缝萌生及扩展过程进行实时量化[14-16]。两种方法的结合可以有效克服单一测试方法的局限性,更能全面地反映泡沫混凝土材料受压过程中损伤演化规律。然而目前结合两种方法对冻融循环后泡沫混凝土压缩破坏全过程进行无损监测的研究较少。

因此,本文采用AE和DIC两种监测技术,测试了不同冻融次数下泡沫混凝土的抗压强度,利用 DIC 技术得到的应变场探讨了冻融环境下泡沫混凝土的破裂形式和裂缝的发展情况,并分析了AE信号累计计数、RA-AF值和b值多个参数与冻融后泡沫混凝土损伤演化过程之间的关系。DIC与AE监测结果互为补充和验证,将宏观力学性能与微观裂缝开展相结合,分析冻融条件下泡沫混凝土单轴压缩破坏演变过程,研究结果有助于进一步了解冻融循环后泡沫混凝土的变形模式和损伤演化规律,为泡沫混凝土性能评估和寒区应用提供一定的参考。

1. 试验材料制备与方法

1.1 试验材料制备

采用的原材料为水泥、发泡剂和水。水泥选用安徽省芜湖市生产的海螺牌硅酸盐水泥P·O 42.5;发泡剂为杭州舒之城生产的高性能蛋白类发泡剂,稀释倍数为1∶30[17];水为自来水,水灰比是0.5。制备密度为800 kg/m3泡沫混凝土试样,记为A08试样,配合比为:水泥540 kg/m3、水270 kg/m3、发泡剂0.52 kg/m3、泡沫含量为24.6 kg/m3。浇筑若干边长100 mm的立方体分别进行20、40、60和80次冻融循环。

1.2 试验方法

泡沫混凝土冻融循环试验依据《水工混凝土试验规程》[18]中规定的方法进行,试验机型为CABR-HDK型快速冻融试验机,温度范围为–20~20℃,设定冻融循环次数为20、40、60和80。试验前将试样放置在(20±5)℃水中浸泡2 d使其充分吸水饱和,在开始冻融循环前测定各试样的初始质量,每隔20次循环从各组中取出5块试样,充分干燥后进行单轴压缩试验。

采用WAW-1000电液伺服万能试验机进行泡沫混凝土单轴压缩试验,通过荷载控制的加载方式,设置加载速率为50 N/s,测试试件尺寸为100 mm×100 mm×100 mm立方体,每种试验工况重复3次。在泡沫混凝土单轴压缩过程中,同时通过声发射(AE)和数字图像(DIC)技术进行辅助监测。单轴压缩-AE-DIC联合测试试验装置及声发射探头布置如图1(a)和图1(b)所示。

声发射监测设备是由美国PAC公司设计制造的Sensor Highway Ⅲ型全天候结构健康监测系统,在试件侧面共布置3个用于采集声发射数据的探头,型号为PK6 I。涂抹凡士林作为声发射探头与试件表面的耦合剂,以确保采集声发射信号的有效性,信号采集门槛值为40 dB。

DIC监测系统采用美国Correlated Solutions公司VIC-3D系统,同时使用两个工业摄像机捕捉图像。根据DIC软件系统的测量需求,在试件正表面100 mm×100 mm区域内喷涂随机散斑,试件表面散斑喷涂的质量对试验结果至关重要,散斑制备流程如下:首先用砂纸将泡沫混凝土试件表面打磨光滑,然后先在试件表面喷涂一层白色底漆,最后用黑色哑光喷漆喷涂分布均匀的散斑。本文中的散斑直径大约为0.5 mm,对应大小约为7个像素。

2. 不同冻融循环下泡沫混凝土单轴压缩破坏过程

A08泡沫混凝土试件经历不同冻融循环次数单轴压缩应力-应变曲线图及破坏后的表面形态见图2,同时选取曲线上具有代表性的加载时刻点进行分析(点①为0.3Pmax应力时刻,点②为0.8Pmax应力时刻,点③为Pmax应力时刻,点④为峰后阶段某时刻,其中Pmax为峰值应力)。通过DIC获得泡沫混凝土试件在不同加载时刻纵向(单轴受压方向)应变云图如图3~图7所示。

通过对图2中泡沫混凝土破坏后表面形态分析可知,随冻融循环次数的增加,试件表面裂缝由单一的垂直型裂缝向倾斜的剪切型多裂缝发展,这种剪切型的多裂缝在A08-80试件中尤为显著。

从A08-0试件各时刻应变云图可以看出,在加载初期(0.3Pmax)泡沫混凝土应变场整体处于压缩状态,应变集中区域主要出现在试件一侧,这主要是由于泡沫混凝土是一种非均质多孔水泥基材料,在浇筑及养护过程中由于操作不当可能会出现一些初始微裂纹,在这些区域容易发生应变集中现象;随着荷载进一步增加(0.8Pmax),试件原有呈点状出现的应变集中区域不断聚合贯通,在左侧形成明显的应变集中带,同时其他区域应变进一步增加;在应力峰值时刻(Pmax),应变集中带面积发展达到最大,表明此时裂缝正在迅速发展并贯穿试件,试件内部开始出现局部失稳状况;在峰后阶段,由于主裂缝的形成,试件内部应变沿着裂缝逐渐释放,此前形成的应变集中带已不复存在,整体应变场也较均匀,冻融次数为20的试件在不同加载时刻也大致呈现上述规律。

在冻融循环40、60和80次时,应变集中区域多发生于中间,并且随着泡沫混凝土冻融循环次数的增加,在各试件应力峰值时刻,应变集中带的面积呈现递增的趋势,同时应变场均值在逐渐下降,该现象也表明冻融损伤破坏了泡沫混凝土内部完整性,增大了试件可能发生破裂的区域。这主要是由于冻融循环次数越多,试件内部产生的微裂缝也就越多,由能耗最小原则可知,在受载过程中,主裂缝会沿着试件的“薄弱区域”发展,而因冻融产生的内部微裂缝正好充当了上述的“薄弱区域”,随着荷载的不断增加,主裂缝在发展过程中不断与冻融产生的微裂缝汇聚贯通,因此冻融循环次数越多的试件,可能发生破裂的区域就越大,从而形成的应变集中带的面积也就越大。

上述结果表明,冻融损伤使泡沫混凝土试件的破坏模式发生了变化,冻融循环次数越多,泡沫混凝土表现出的延性破坏特征越明显,破坏由贯穿型裂缝逐渐转变为缓慢发展的分散性裂缝。

3. 不同冻融循环下声发射特征分析

3.1 声发射振铃计数分析

声发射振铃计数是指单位时间内振铃脉冲越过声发射系统门槛值的次数,是混凝土内部结构声发射信号强弱程度的表征,它的变化规律能够反映混凝土试件破坏过程中的实时形态[19-21]。本文以A08试件经历不同冻融循环次数试验结果为例,对受压破坏过程中声发射特征参数进行分析说明,其余密度泡沫混凝土试件声发射规律均类似。

图8为A08泡沫混凝土试件受压过程中AE计数、荷载与时间的关系曲线,由图可知,不同冻融循环次数下泡沫混凝土试件声发射振铃计数呈现出试验初期增长较快,随后增长速率减缓,因此,可将不同冻融循环次数下泡沫混凝土试件受压破坏过程大致分为如下3个阶段:

(1)接触段。接触阶段主要发生在受压过程的初期,各试块声发射振铃计数小幅增长。这主要是由于在受压阶段初期,泡沫混凝土内部分孔隙被压密,产生初始裂纹,造成短期内声学信号增强,振铃计数增加较快;

(2)平静段。平静阶段内声发射信号主要来自泡沫混凝土内部孔隙的挤压闭合及新生裂纹的二次扩展,由于裂纹的二次扩展需要一定能量,因此导致此阶段内声发射活动较平稳,振铃计数值保持在较低水平,且持续时间较长;

(3)陡增段。经历平静阶段之后,泡沫混凝土试件积累的能量越来越多,在达到峰值应力前裂隙迅速发展,声发射信号显著增强,振铃计数快速增长并达到峰值,这是损伤加剧的重要标志。当接近峰值荷载时,试件破坏,内部裂隙迅速扩展至表面。

此外,从图8还可以看出,经历0、20、40、60和80次冻融循环的泡沫混凝土试件总累计振铃计数值分别为

17572 、16635 、14874 、9762 和9403 ,总累计振铃计数随冻融循环次数的增加而逐渐减小。这主要是由于泡沫混凝土经历的冻融循环次数越多,其内部产生的微裂隙也就越多,导致微裂隙汇聚、贯通所需的能量就越少,因而在受压过程中声发射传感器捕捉到的振铃计数信号就越少[22-23]。表1为不同冻融循环次数下平静阶段-陡增阶段分界点特征参数。通过分析可知,经历0、20、40、60和80次冻融循环的泡沫混凝土试件相对峰值荷载分别为0.95、0.90、0.88、0.84和0.75,随着冻融循环次数的增加,相对峰值荷载逐渐下降,该现象也表明平静阶段-陡增阶段分界点随冻融循环次数增加在时间域上发生前移。

表 1 不同冻融循环次数下A08试样平静段-陡增段分界点特征参数Table 1. Characteristic parameters of the boundary between the quiet stage and the steep increase stage of A08 specimen under different freeze-thaw cyclesFreeze-thaw cycle Breakpoint load/kN Peak load/kN Relative peak load 0 29.88 31.33 0.95 20 21.82 24.24 0.90 40 17.81 20.24 0.88 60 12.15 14.47 0.84 80 7.16 9.30 0.75 Note: Relative peak load = Breakpoint load/Peak load. 3.2 声发射RA-AF值分析

声发射上升角(RA)值与平均频率(AF)值可反映混凝土试件的破裂模式。RA值越小,AF值越大,表明声发射信号波形梯度大,信号频率高,对应拉伸破坏裂纹特征;RA值越大,AF值越小,表明声发射信号波形梯度小,信号频率低,对应剪切破坏裂纹特征[24]。

图9为不同冻融循环次数下泡沫混凝土RA-AF值分布图。可知,不同冻融循环次数下声发射RA和AF值在不同阶段内均有不同程度的占比,表明泡沫混凝土试件受压破坏并非由单一类型裂缝模式控制,而是由拉伸裂缝与剪切裂缝之间交替转化决定的,从而最终导致主裂缝形成,使试件发生受压破坏[25-26]。冻融循环次数为0时,泡沫混凝土试件接触阶段、平静阶段和陡增阶段剪切裂缝所占比例分别为20.4%、36.7%和52.5%,随着受压过程的进行,剪切裂缝所占比例逐渐升高,该现象也表明泡沫混凝土破裂模式正逐步由张拉破坏向剪切破坏转变,且越接近极限荷载,剪切破裂现象越显著。

冻融为0、20、40、60和80次的泡沫混凝土试件最终破坏时剪切裂缝所占比例分别为52.5%、57.8%、59.2%、65.3%和69.2%,随着冻融循环次数的增加,泡沫混凝土压缩破坏过程中内部裂缝主要表现为张拉裂缝逐渐减少,剪切裂缝逐渐增多,表明冻融环境能够加速泡沫混凝土由张拉破坏向剪切破坏的转变。这主要是由于在冻融条件下,由于静水压力作用导致泡沫混凝土内部发生冻融损伤,使其在受载之前就产生大量拉伸裂缝,并且随着冻融循环次数的增多,拉伸裂缝所占比例也越高,泡沫混凝土受载时,其内部所积累的应变能也主要以剪切裂缝的形式耗散,与DIC所测得的试验规律一致。

3.3 声发射b值分析

声发射b值是表征声发射事件震级-频度分布尺度的参数,可有效反映混凝土受压破坏时内部损伤演化过程。b值增大,混凝土内部小事件数量占比增加,小尺度破裂增多;反之,大尺度破裂增多[27]。声发射b值传统计算方法主要包括最小二乘法和最大似然法,但上述两种方法均需先确定一个声发射幅值范围,然后再确定声发射事件数,这导致计算结果随机性较大且划分时间长短不一。因此,本文通过改进的b值计算方法分析不同冻融循环次数下泡沫混凝土试件的声发射信号分布特征,计算公式如下[28]:

b=lgN(μ−α1σ)−lgN(μ+α2σ)(α1+α2)σ (1) 式中:N为声发射事件数,本文取20;α1、α2为经验常数,一般取1;μ为N次声发射事件平均振幅(dB);σ为N次声发射事件振幅标准方差;N(μ-α1σ)为振幅高于(μ-α1σ)的累积声发射撞击数;N(μ+α2σ)为振幅高于(μ+α2σ)的累积声发射撞击数。

图10为不同冻融循环次数下泡沫混凝土声发射b值分布图。可知,声发射b值随加载进程的增加呈波动变化,大致可分为Ⅰ、Ⅱ和Ⅲ3个阶段,反映了裂隙的萌生扩展及贯通过程。Ⅰ为上升阶段,该阶段主要表现为声发射b值逐渐上升,表明此时混凝土试件内部微裂纹开始形成和扩展,小尺度破裂数量增多;Ⅱ为波动阶段,表现为声发射b值在一定阈值范围内波动,表明该阶段内小尺度与大尺度的裂纹扩展交替占据主导地位,混凝土内部裂纹处于一种渐进式稳定扩展演化过程,且能量发生阶段性的累积;Ⅲ为下降阶段,此阶段内声发射b值逐渐下降,但声发射信号密度显著增加,声发射活跃度上升,该阶段内混凝土内部微裂纹聚集贯通形成大尺度破裂面,宏观裂纹扩展较剧烈,并释放大量应变能。

声发射b值下降阶段的出现标志着混凝土内部破裂现象由小尺度向大尺度进行转变,其变化趋势是混凝土破裂失稳的重要指示[29]。通过对声发射b值下降阶段分界点进行分析可知,0、20、40、60和80次冻融循环的声发射b值下降阶段分别出现在加载进程的92.3%、89.1%、88.5%、76.5%和72.3%,随冻融循环次数的增加,b值下降阶段分界点在时间域上发生前移,表明冻融环境能够加剧泡沫混凝土内部损伤,迫使其内部提前发生大尺度破裂现象,这也与前述振铃计数变化规律一致。

4. 结 论

(1)冻融条件下泡沫混凝土的压缩破坏过程曲线呈现明显的阶段效应,且试件经历的冻融循环次数越多,延性破坏特征越明显,内部缺陷发展越迅速。

(2)泡沫混凝土压缩破坏过程的数字图像相关(DIC)特征表明,随冻融循环次数的增加,试件应变集中带的面积呈现递增的趋势,应变场均值在逐渐下降,表面裂缝由垂直的贯穿型单一裂缝向倾斜的剪切型多裂缝发展。

(3)冻融环境下泡沫混凝土压缩破坏过程的声发射振铃计数呈现接触阶段、平静阶段、陡增阶段三阶段变化规律;冻融为0、20、40、60和80次的泡沫混凝土试件相对峰值荷载分别为0.95、0.90、0.88、0.84和0.75,最终破坏时剪切裂缝所占比例分别为52.5%、57.8%、59.2%、65.3%和69.2%,声发射b值下降阶段分别出现在加载进程的92.3%、89.1%、88.5%、76.5%和72.3%;声发射上升角(RA)-平均频率(AF)值和b值的分布规律表明,冻融环境能够加速泡沫混凝土由张拉破坏向剪切破坏的转变,迫使材料内部提前发生大尺度破裂现象。

(4) DIC技术在泡沫混凝土试件破坏过程中的微裂纹演化分析方面发挥了重要作用。此外,声发射(AE)和DIC的结果相辅相成,它们的结合有助于全面了解冻融环境下泡沫混凝土微裂缝的发展规律和损伤破坏机制。

-

表 1 C50混凝土配合比

Table 1 C50 concrete mix proportion

kg/m3 Cement Mineral fines Sand Crushed stone Water Water reducer 335.2 83.2 655 1116 170 8.1 表 2 钢-混组合梁设计参数

Table 2 Design parameters of steel-concrete composite beams

Number Material composition Test temperature/℃ S-SCB-25 C50+HRB400 25 S-SCB-200 C50+HRB400 200 S-SCB-400 C50+HRB400 400 S-SCB-600 C50+HRB400 600 BFRP-SCB-25 C50+BFRP bars 25 BFRP-SCB-200 C50+BFRP bars 200 BFRP-SCB-400 C50+BFRP bars 400 BFRP-SCB-600 C50+BFRP bars 600 Notes: S, BFRP—Type of reinforcement; SCB—Steel-concrete composite beam; Figure—Test temperature; such as BFRP-SCB-200—Steel-concrete composite beam with BFRP bars at 200℃. 表 3 钢-混组合梁残余承载能力

Table 3 Residual bearing capacity of steel-concrete composite beams

Test beam Pu (25℃)/kN Pu (200℃)/kN Pu (400℃)/kN Pu (600℃)/kN S-SCB 512.8 476.2 439.1 390.0 BFRP-SCB 506.3 465.9 441.1 332.7 Note: Pu—Ultimate bearing capacity. -

[1] 卫星, 肖林, 温宗意, 等. 钢混组合结构桥梁2020年度研究进展[J]. 土木与环境工程学报, 2021, 43(S1):107-119. WEI Xing, XIAO Lin, WEN Zongyi, et al. State-of-the-art review of steel-concrete composite bridges in 2020[J]. Journal of Civil and Environmental Engineering,2021,43(S1):107-119(in Chinese).

[2] 《中国公路学报》编辑部. 中国桥梁工程学术研究综述·2021[J]. 中国公路学报, 2021, 34(2):1-97. DOI: 10.3969/j.issn.1001-7372.2021.02.002 Editorial Department of China Journal of Highway and Transport. Review on China's bridge engineering research: 2021[J]. China Journal of Highway and Transport,2021,34(2):1-97(in Chinese). DOI: 10.3969/j.issn.1001-7372.2021.02.002

[3] 王言磊, 孙会杰, 曹明敏. 环境侵蚀下钢-混凝土组合梁耐久性使用寿命分析[J]. 建筑结构学报, 2015, 36(S1):355-359. DOI: 10.14006/j.jzjgxb.2015.S1.054 WANG Yanlei, SUN Huijie, CAO Mingmin. Analysis of durability service life for steel-concrete composite beams under[J]. Journal of Building Structures,2015,36(S1):355-359(in Chinese). DOI: 10.14006/j.jzjgxb.2015.S1.054

[4] ABED F, ALHAFIZ A R. Effect of basalt fibers on the flexural behavior of concrete beams reinforced with BFRP bars[J]. Composite Structures,2019,215:23-34. DOI: 10.1016/j.compstruct.2019.02.050

[5] AHMED M O, WADDAH A H, MOHAMMAD K. Durability and mechanical properties of concrete reinforced with basalt fiber-reinforced polymer (BFRP) bars: Towards sustainable infrastructure[J]. Polymers,2021,13(9):1402. DOI: 10.3390/polym13091402

[6] GARBACZ A, URBAŃSKI M, ŁAPKO A. BFRP bars as an alternative reinforcement of concrete structures–Compatibi-lity and adhesion issues[J]. Advanced Materials Research,2015,3903(1129):233-241.

[7] HOU W, LI Z Q, GAO W Y, et al. Flexural behavior of RC beams strengthened with BFRP bars-reinforced ECC matrix[J]. Composite Structures, 2020, 241: 112092.

[8] DUIC J, KENNO S, DAS S. Performance of concrete beams reinforced with basalt fibre composite rebar[J]. Construction and Building Materials,2018,176:470-481. DOI: 10.1016/j.conbuildmat.2018.04.208

[9] 霍宝荣, 张向东. BFRP筋的力学性能试验[J]. 沈阳建筑大学学报(自然科学版), 2011, 27(4):626-630. HUO Baorong, ZHANG Xiangdong. Experimental study of mechanical properties of the BFRP bar in different diameters[J]. Journal of Shenyang Jianzhu University (Natural Science),2011,27(4):626-630(in Chinese).

[10] 吴智深, 汪昕, 史健喆. 玄武岩纤维复合材料性能提升及其新型结构[J]. 工程力学, 2020, 37(5):1-14. WU Zhishen, WANG Xin, SHI Jianzhe. Advancement of basalt fiber-reinforced polymers (BFRPs) and the novel structures reinforced with BFRPs[J]. Engineering Mecha-nics,2020,37(5):1-14(in Chinese).

[11] 姚伟发, 黄侨, 张娟秀. 火灾环境下钢-混凝土组合梁力学性能试验研究[J]. 工程力学, 2016, 33(8):58 -65. DOI: 10.6052/j.issn.1000-4750.2014.11.1000 YAO Weifa, HUANG Qiao, ZHANG Juanxiu. Experimental study on mechanical performance of steel-concrete girders under fire loading[J]. Engineering Mechanics,2016,33(8):58 -65(in Chinese). DOI: 10.6052/j.issn.1000-4750.2014.11.1000

[12] 李光辉. 高温后FRP筋混凝土梁静力与疲劳受弯性能试验研究[D]. 郑州: 郑州大学, 2019. LI Guanghui. Flexural behavior of fiber reinforced polymer (FRP) bars reinforced concrete beams under static and fatigue loads after elevated temperature exposure[D]. Zhengzhou: Zhengzhou University, 2019(in Chinese).

[13] 李趁趁, 王英来, 赵军, 等. 高温后FRP筋纵向拉伸性能[J]. 建筑材料学报, 2014, 17(6):1076-1081. DOI: 10.3969/j.issn.1007-9629.2014.06.024 LI Chenchen, WANG Yinglai, ZHAO Jun, et al. Longitudi-nal tensile properties of FRP bars after high temperature[J]. Journal of Building Materials,2014,17(6):1076-1081(in Chinese). DOI: 10.3969/j.issn.1007-9629.2014.06.024

[14] 唐利, 张春涛, 李彪, 等. 高温作用下BFRP筋力学性能试验研究[J]. 建筑科学, 2017, 33(1):36-40. DOI: 10.13614/j.cnki.11-1962/tu.2017.01.007 TANG Li, ZHANG Chuntao, LI Biao, et al. Experimental research on the mechanical properties of BFRP under high temperature[J]. Building Science,2017,33(1):36-40(in Chinese). DOI: 10.13614/j.cnki.11-1962/tu.2017.01.007

[15] HU Y J, JIANG C, LIU W, et al. Degradation of the in-plane shear modulus of structural BFRP laminates due to high temperature[J]. Sensors,2018,18(10):3361. DOI: 10.3390/s18103361

[16] 姚伟发, 黄侨, 张娟秀. 钢-混组合梁的火灾试验及剩余承载力[J]. 东南大学学报(自然科学版), 2016, 46(2):347-352. DOI: 10.3969/j.issn.1001-0505.2016.02.019 YAO Weifa, HUANG Qiao, ZHANG Juanxiu. Fire experiment and residual strength of steel-concrete composite girders[J]. Journal of Southeast University (Natural Science Edition),2016,46(2):347-352(in Chinese). DOI: 10.3969/j.issn.1001-0505.2016.02.019

[17] 张岗, 宋超杰, 李徐阳, 等. 燃油火灾下预应力混凝土梁耐火试验[J]. 中国公路学报, 2022, 35(1):210-221. DOI: 10.3969/j.issn.1001-7372.2022.01.019 ZHANG Gang, SONG Chaojie, LI Xuyang, et al. Experimental study on fire resistance of prestressed concrete girders under fuel fire exposure[J]. China Journal of Highway and Transport,2022,35(1):210-221(in Chinese). DOI: 10.3969/j.issn.1001-7372.2022.01.019

[18] 张岗, 宗如欢, 施颖, 等. 钢-混组合简支箱梁耐火性能研究[J]. 桥梁建设, 2017, 47(3):41-46. DOI: 10.3969/j.issn.1003-4722.2017.03.008 ZHANG Gang, ZONG Ruhuan, SHI Ying, et al. Study of fire resistance performance of simply-supported steel and concrete composite box girder[J]. Bridge Construction,2017,47(3):41-46(in Chinese). DOI: 10.3969/j.issn.1003-4722.2017.03.008

[19] HAKEM A, HAYA M, NOOR T, et al. Serviceability and flexural behavior of concrete beams reinforced with basalt fiber-reinforced polymer (BFRP) bars exposed to harsh conditions[J]. Polymers,2020,12(9):2110. DOI: 10.3390/polym12092110

[20] 刘静雅, 霍静思, 刘艳芝. CFRP约束高温后混凝土力学性能试验研究[J]. 工程力学, 2017, 34(9):158-166. DOI: 10.6052/j.issn.1000-4750.2016.05.0348 LIU Jingya, HUO Jingsi, LIU Yanzhi. Experimental study on the mechanical performance of post-fire concrete confined by CFRP sheets[J]. Engineering Mechanics,2017,34(9):158-166(in Chinese). DOI: 10.6052/j.issn.1000-4750.2016.05.0348

[21] AHMED H, FOUAD K, HEND E, et al. Behaviour of concrete beams reinforced using basalt and steel bars under fire exposure[J]. Engineering Structures,2021,238:112251. DOI: 10.1016/j.engstruct.2021.112251

[22] 上海市城市建设设计研究总院. 钢-混凝土组合桥梁设计规范: GB/T 50917—2013[S]. 北京: 中国计划出版社, 2013. Shanghai Urban Design Research Institute. Code for design of steel and concrete composite bridges: GB/T 50917—2013[S]. Beijing: China Planning Press, 2013(in Chinese).

[23] ZHU B, LIU H, LIU G, et al. Bond behavior between BFRP bars and hybrid fiber recycled aggregate concrete after high temperature[J]. Journal of Renewable Materials,2021,9(3):507-521. DOI: 10.32604/jrm.2021.013580

[24] 陆燕青, 周星宇, 周济, 等. 火灾高温后混凝土的轴心抗压强度及评估方法[J]. 混凝土, 2021(7):22-27. DOI: 10.3969/j.issn.1002-3550.2021.07.005 LU Yanqing, ZHOU Xingyu, ZHOU Ji, et al. Axial compres-sive strength and assessment of concrete after fire temperature[J]. Concrete,2021(7):22-27(in Chinese). DOI: 10.3969/j.issn.1002-3550.2021.07.005

[25] HAGER I. Behaviour of cement concrete at high tempera-ture[J]. Bulletin of the Polish Academy of Sciences-Technical Sciences,2013,61(1):145-154. DOI: 10.2478/bpasts-2013-0013

-

下载:

下载: