Research status and analysis of ultra-high molecular weight polyethylene fiber and its composites

-

摘要: 超高分子量聚乙烯(UHMWPE)纤维与碳纤维和芳纶纤维并称当今三大高性能纤维,具备低密度、高抗冲击性能、高断裂强度和模量的特性,同时拥有优异化学稳定性。本文综述了UHMWPE纤维及其复合材料的研究现状和最新进展,包括UHMWPE纤维和其他几种高性能纤维的性能对比,UHMWPE纤维的典型生产工艺及其对纤维性能的影响,与UHMWPE纤维匹配的树脂基体种类,提高纤维表面粘结性能、耐热性能和抗蠕变性能的改性方法,纤维织造与复合工艺及UHMWPE纤维及其复合材料的应用;最后分析了UHMWPE纤维及其复合材料当前存在的主要问题,探讨了未来可能的发展方向。

-

关键词:

- 超高分子量聚乙烯纤维 /

- 复合材料 /

- 力学性能 /

- 改性 /

- 应用

Abstract: Ultra high molecular weight polyethylene (UHMWPE) fiber, together with carbon fiber and aramid fiber, is one of the three high-performance fibers. It has the characteristics of low density, high impact resistance, high breaking strength and modulus, and excellent chemical stability. This paper reviews the current research status and recent progress of UHMWPE fiber and its composites, including the performance comparison between UHMWPE fiber and other high-performance fibers, the typical production process of UHMWPE fiber and its influence on fiber performance, the types of resin matrix matched with UHMWPE fiber, the modification methods to improve fiber surface adhesion, thermal stability and creep resistance, weaving and composite processes, and the application of UHMWPE fibers and their composite applications. Finally, the main problems existing in UHMWPE fiber and its composite materials are analyzed, and the possible development direction in the future is discussed. -

表 1 超高分子量聚乙烯(UHMWPE)纤维与对位芳纶纤维(PPTA)、碳纤维和玻璃纤维的单丝性能对比

Table 1. Comparison of monofilament performance between ultra high molecular weight polyethylene (UHMWPE) fiber with para aramid fiber (PPTA), carbon fiber and glass fiber

UHMWPE fiber PPTA Carbon fiber Glass fiber Density/(g·cm−3) 0.97 1.44 1.80 2.55 Tensile strength/GPa 3.1 2.7 3.5 2.0 Tensile modulus/GPa 100 58 230 73 Elongation/% 3.5 3.7 1.5 2.0 Specific tensile strength/(GPa·(g·cm−3)−1) 3.20 1.88 1.94 1.38 Specific tensile modulus/(GPa·(g·cm−3)−1) 103.09 10.28 127.78 28.35 Static friction coefficient 0.187 0.385 0.470 — Dynamic friction coefficient 0.199 0.319 0.305 — Energy absorbed by specific impact/J 36.0 13.8 20.0 10.0 Hydrochloric acid resistance retention rate/% 100 40 — — Sulfuric acid resistance retention rate/% 100 70 — — Decomposition temperature/℃ 125 427 2800 550 表 2 常见的与UHMWPE纤维复合用树脂的优劣及应用领域

Table 2. Strength, limitation and application fields of common resin for composite with UHMWPE fiber

Resin Strength Limitation Application EP Mild and changeable curing conditions

High hardnessPoor adhesion with UHMWPE fiber

Inadequate toughnessStructrual composites VER Common advantages of EP

Good adhesion with UHMWPE fiberSlightly worse mechanical properties TPU Good impact resistance

Good energy absorption capacity

Environment friendlyPoor adhesion with UHMWPE fiber Military protection PE Good shock absorption effect Hard to process Plates and structural composites PCH Good shock absorption effect

Easy to process— Additives for other resins Notes: EP—Epoxy resin; VER—Vinyl ester resin; TPU—Thermoplastic polyurethane; PE—Poly ethylen; PCH—Hydrocarbon resin. 表 3 不同表面改性方法的比较

Table 3. Comparison of different surface modification approaches

Surface modification method Strength Limitation Plasma treatment No loss of fiber mechanical properties Complex process, inconspicuous effect

Difficult to realize industrial continuous productionCorona discharge — Liquid oxidation Simple process, obvious effect Damage to the fiber mechanical properties,

environmental pollutionSurface coating No loss of fiber mechanical properties,

simple process, obvious effectHigh cost Adding coupling agent during

blending or extractionSimple process, obvious effect Damage to the fiber mechanical properties,

modified before UHMWPE fiber formingUV radiation grafting Simple process, obvious effect

Easy to realize industrial continuous productionLong modification time Chemical reagent grafting -

[1] 张清华. 高性能化学纤维生产及应用[M]. 2018版. 北京: 中国纺织出版社, 2018: 1-2.ZHANG Q H. Production and application of high perfor-mance chemical fiber[M]. 2018 edition. Beijing: China Textile & Apparel Press, 2018: 1-2(in Chinese). [2] CROUCH I G. Body armour-New materials, new systems[J]. Defence Technology,2019,15(3):241-253. doi: 10.1016/j.dt.2019.02.002 [3] PULUNGAN M A, SUTIKNO, SANI M S M. Analysis of bulletproof vest made from fiber carbon composite and hollow glass microsphere (HGM) in absorbing energy due to projectile impact[J]. IOP Conference Series: Materials Science and Engineering,2019,506(1):12001. doi: 10.1088/1757-899X/506/1/012001 [4] QIN F, LEI Z, MA Y, et al. Stress transfer of single yarn drawing in soft fabric studied by micro Raman spectroscopy[J]. Composites Part A: Applied Science and Manufacturing,2018,112:134-141. doi: 10.1016/j.compositesa.2018.06.002 [5] WU X, ZHAN L, HUANG M, et al. Corrosion damage evolution and mechanical properties of carbon fiber reinforced aluminum laminate[J]. Journal of Central South University,2021,28(3):657-668. doi: 10.1007/s11771-021-4635-8 [6] CRAMER K E, NAGUIB H E. Current and future needs and research for composite materials NDE[C]// Behavior and Mechanics of Multifunctional Materials and Composites XII. US: San Diego, 2018: 1059603. [7] AFROUGHSABET V, BIOLZI L, OZBAKKALOGLU T. High-performance fiber-reinforced concrete: A review[J]. Journal of Materials Science,2016,51(14):6517-6551. doi: 10.1007/s10853-016-9917-4 [8] RAO Y, FARRIS R J. A modeling and experimental study of the influence of twist on the mechanical properties of high-performance fiber yarns[J]. Journal of Applied Polymer Science,2000,77(9):1938-1949. doi: 10.1002/1097-4628(20000829)77:9<1938::AID-APP9>3.0.CO;2-D [9] 肇研, 刘寒松. 连续纤维增强高性能热塑性树脂基复合材料的制备与应用[J]. 材料工程, 2020, 48(8):49-61. doi: 10.11868/j.issn.1001-4381.2019.000209ZHAO Y, LIU H S. Preparation and application of continuous fiber reinforced high-performance thermoplastic composites[J]. Journal of Materials Engineering,2020,48(8):49-61(in Chinese). doi: 10.11868/j.issn.1001-4381.2019.000209 [10] HIREMATH N, YOUNG S, GHOSSEIN H, et al. Low cost textile-grade carbon-fiber epoxy composites for automotive and wind energy applications[J]. Composites Part B: Engineering,2020,198:108156. doi: 10.1016/j.compositesb.2020.108156 [11] 白琼琼. 高性能纤维的发展现状及展望[J]. 毛纺科技, 2021, 49(6):91-94. doi: 10.19333/j.mfkj.20210301504BAI Q Q. Review on the development of high perfor-mance fiber[J]. Wool Textile Journal,2021,49(6):91-94(in Chinese). doi: 10.19333/j.mfkj.20210301504 [12] 陈成泗. 超高分子量聚乙烯纤维及其复合材料的现状和发展[J]. 国外塑料, 2008, 26(2):56-60. doi: 10.3969/j.issn.1002-5219.2008.02.010CHEN C S. Present situation and development of ultra high molecular weight polyethylene fiber and its compo-sites[J]. World Plastics,2008,26(2):56-60(in Chinese). doi: 10.3969/j.issn.1002-5219.2008.02.010 [13] 赵刚, 赵莉, 谢雄军. 超高分子量聚乙烯纤维的技术与市场发展[J]. 纤维复合材料, 2011, 28(1):50-56. doi: 10.3969/j.issn.1003-6423.2011.01.014ZHAO G, ZHAO L, XIE X J. Ultra high molecular weight polyethylene fiber material technology and market de-velopment prospect[J]. Fiber Composites,2011,28(1):50-56(in Chinese). doi: 10.3969/j.issn.1003-6423.2011.01.014 [14] 刘晓艳, 陈美玉. 高性能纤维的摩擦系数测试与分析[J]. 四川纺织科技, 2002(1):15-17. doi: 10.3969/j.issn.1673-0356.2002.01.003LIU X Y, CHEN M Y. Testing and analysis of friction coefficient of high performance fiber[J]. Sichuan Textile Technology,2002(1):15-17(in Chinese). doi: 10.3969/j.issn.1673-0356.2002.01.003 [15] LEMSTRA P J. Chapter 1: High-performance polyethylene fibers[J]. Advanced Industrial and Engineering Polymer Research,2022,5(2):49-59. doi: 10.1016/j.aiepr.2022.03.001 [16] 王萍, 王新威, 张玉梅, 等. 干法与湿法凝胶纺丝UHMWPE纤维的结构与性能[J]. 合成纤维工业, 2014, 37(4):67-70. doi: 10.3969/j.issn.1001-0041.2014.04.018WANG P, WANG X W, ZHANG Y M, et al. Structure and properties of UHMWPE fibers prepared by dry and wet gel spinning processes[J]. China Synthetic Fiber Industry,2014,37(4):67-70(in Chinese). doi: 10.3969/j.issn.1001-0041.2014.04.018 [17] WAQAR R A, BILAL Z, HAFSA J, et al. Application of Taguchi method to investigate the effect of temperature, heating time, concentration and particle size on improved gel spinning process of UHMWPE[J]. Industria Textila, 2018, 69(5): 347-351. [18] 陈建军. 干法纺丝用UHMWPE的性能剖析[J]. 合成纤维工业, 2014, 37(4):71-73. doi: 10.3969/j.issn.1001-0041.2014.04.019CHEN J J. Performance analysis of UHMWPE for dry spinning[J]. China Synthetic Fiber Industry,2014,37(4):71-73(in Chinese). doi: 10.3969/j.issn.1001-0041.2014.04.019 [19] XIAO M, YU J, ZHU J, et al. Effect of UHMWPE concentration on the extracting, drawing, and crystallizing properties of gel fibers[J]. Journal of Materials Science,2011,46(17):5690-5697. doi: 10.1007/s10853-011-5520-x [20] WANG H, QUAN J, WANG X, et al. The effect of shrinkage on the structure and properties of ultra-high molecular weight polyethylene fibers with different concentration[J]. Journal of Applied Polymer Science,2021,138(15):50198. doi: 10.1002/app.50198 [21] CAO T, CHEN X, LIN Y, et al. Structural evolution of UHMWPE fibers during prestretching far and near melting temperature: An in situ synchrotron radiation small- and wide-angle X-ray scattering study[J]. Macromolecular Materials and Engineering,2018,303(2):1700493. doi: 10.1002/mame.201700493 [22] YU L, BAO J, WANG G, et al. Structure and properties of gel-spun ultra-high molecular weight polyethylene fibers obtained from industrial production line[J]. Journal of Applied Polymer Science,2021,138(44):51317. doi: 10.1002/app.51317 [23] WANG X, ZHENG H, SUN Y. Study on structures and properties of ultra-hot drawing UHMWPE fibers fabricated via dry spinning method[J]. Journal of Polymer Engineering,2018,38(9):863-870. doi: 10.1515/polyeng-2017-0400 [24] 于俊荣, 张燕静, 刘兆峰. UHMWPE冻胶纤维超倍拉伸性能研究[J]. 东华大学学报(自然科学版), 2003, 29(2):17-20. doi: 10.3969/j.issn.1671-0444.2003.02.004YU J R, ZHANG Y J, LIU Z F. Study on the ultra-drawing behavior of UHMWPE gel spun fiber[J]. Journal of Donghua University (Natural Science),2003,29(2):17-20(in Chinese). doi: 10.3969/j.issn.1671-0444.2003.02.004 [25] YEH J, WANG C, YU W, et al. Ultradrawing and ultimate tensile properties of ultrahigh molecular weight polyethylene composite fibers filled with functionalized nanoalumina fillers[J]. Polymer Engineering & Science,2015,55(10):2205-2214. doi: 10.1002/pen.24105 [26] FAN W, WANG C, TSAI C, et al. Ultradrawing properties of ultrahigh molecular weight polyethylenes/functionalized activated nanocarbon as-prepared fibers[J]. RSC Advances,2016,6(4):3165-3175. doi: 10.1039/c5ra20982j [27] FAN W, DING Y, TU Z, et al. Enhancement on ultimate tensile properties of ultrahigh molecular weight polyethylene composite fibers filled with activated nanocarbon particles with varying specific surface areas[J]. Polymer Engineering & Science,2018,58(6):980-990. doi: 10.1002/pen.24655 [28] ZHANG T, MA T, ZHANG J C, et al. Preparation and characterization of MWCNT/ultrahigh-molecular-weight polyethylene composite fiber[J]. Advanced Materials Research,2012,627:761-764. doi: 10.4028/www.scientific.net/AMR.627.761 [29] HAO X, CHIEN A, HUA X, et al. Dispersion of pristine CNT in UHMWPE solution to prepare CNT/UHMWPE compo-site fiber[J]. Polymers & Polymer Composites,2014,22(5):123-125. doi: 10.1179/1432891713Z.000000000201 [30] AN M, XU H, LV Y, et al. Ultra-strong gel-spun ultra-high molecular weight polyethylene fibers filled with chitin nanocrystals[J]. RSC Advances,2016,6(25):2629-2636. doi: 10.1039/c5ra25786g [31] WANG H, QUAN J, YU J, et al. Enhanced wear resistance of ultra-high molecular weight polyethylene fibers by modified-graphite oxide[J]. Journal of Applied Polymer Science,2021,138(29):50696. doi: 10.1002/app.50696 [32] WANG Y, FU J, YU J, et al. Dissolving of ultra-high molecular weight polyethylene assisted through supercritical carbon dioxide to enhance the mechanical properties of fibers[J]. Advanced Fiber Materials,2022,4(2):280-292. doi: 10.1007/s42765-021-00107-6 [33] FANG X, WYATT T, HONG Y, et al. Gel spinning of UHMWPE fibers with polybutene as a new spin solvent[J]. Polymer Engineering & Science,2016,56(6):697-706. doi: 10.1002/pen.24296 [34] FANG X, SHI J, WYATT T, et al. Twist-film gel spinning of large-diameter high-performance ultra-high molecular weight polyethylene monofilaments[J]. Textile Research Journal,2017,87(19):2323-2336. doi: 10.1177/0040517516669079 [35] CHAGAS N P D S, FRAGA G L D S, MARQUES M D F V. Fibers of ultra-high molecular weight polyethylene obtained by gel spinning with polyalphaolefin oil[J]. Macromolecular Research,2020,28(12):1082-1090. doi: 10.1007/s13233-020-8147-4 [36] CHAGAS N P D S, MARQUES M D F V. Effect of polyalphaolefin oils as a solvent in gel-spinning of ultra-high molecular weight polyethylene fibers[J]. Journal of Applied Polymer Science,2021,138(46):51372. doi: 10.1002/app.51372 [37] YAN R, ZHANG Q, SHI B, et al. Investigation on low-velocity impact and interfacial bonding properties of weft-knitted UHMWPE reinforced composites[J]. Journal of Industrial Textiles,2022,51(3S):5370-5388. doi: 10.1177/1528083720931474 [38] TADA N, JIN M, UEMORI T, et al. Prediction of fracture location in tensile test of short-fiber-self-reinforced polyethylene composite plates[C]// ASME Pressure Vessels Piping Conference. US: San Antonio, 2019. [39] 曹海建, 田鹭新, 黄晓梅, 等. 一种UHMWPE纤维增强树脂基软质防弹材料: 中国, CN111267429A[P]. 2020-06-12.CAO H J, TIAN L X, HUANG X M, et al. The utility model relates to UHMWPE fiber reinforced resin based soft bulletproof material: China, CN111267429A[P]. 2020-06-12(in Chinese). [40] ZHU D, WANG Y, ZHANG X, et al. Interfacial bond pro-perty of UHMWPE composite[J]. Polymer Bulletin,2010,65(1):35-44. doi: 10.1007/s00289-009-0232-y [41] ZHANG X, WANG Y, LU C, et al. Interfacial adhesion study on UHMWPE fiber-reinforced composites[J]. Polymer Bulletin,2011,67(3):527-540. doi: 10.1007/s00289-011-0491-2 [42] ZHANG X, WANG Y, CHENG S. Properties of UHMWPE fiber-reinforced composites[J]. Polymer Bulletin,2013,70(3):821-835. doi: 10.1007/s00289-012-0873-0 [43] CHHETRI S, BOUGHERARA H. A comprehensive review on surface modification of UHMWPE fiber and interfacial properties[J]. Composites Part A: Applied Science and Manufacturing,2020,140:106146. doi: 10.1016/j.compositesa.2020.106146 [44] MENG C, CHEN Y, XIE M, et al. Surface modification of ultrahigh molecular weight polyethylene by plasma-inducedin-situgrafting with vinyl triethoxysilane[J]. Journal of Biomedical Materials Research Part A,2018,106(2):321-332. doi: 10.1002/jbm.a.36241 [45] WU M, JIA L, LU S, et al. Interfacial performance of high-performance fiber-reinforced composites improved by cold plasma treatment: A review[J]. Surfaces and Interfaces,2021,24:101077. doi: 10.1016/j.surfin.2021.101077 [46] 贾彩霞, 王乾, 任荣, 等. 超高分子量聚乙烯(UHMWPE)纤维表面处理对UHMWPE/环氧树脂复合材料界面性能的影响机制[J]. 复合材料学报, 2020, 37(3):573-580. doi: 10.13801/j.cnki.fhclxb.20190705.001JIA C X, WANG Q, REN R, et al. Influence mechanism of ultra high molecular weight polyethylene (UHMWPE) fiber surface modification on interfacial performance of UHMWPE/epoxy composites[J]. Acta Materiae Compo-sitae Sinica,2020,37(3):573-580(in Chinese). doi: 10.13801/j.cnki.fhclxb.20190705.001 [47] JIN X, WANG W, XIAO C, et al. Improvement of coating durability, interfacial adhesion and compressive strength of UHMWPE fiber/epoxy composites through plasma pre-treatment and polypyrrole coating[J]. Composites Science and Technology,2016,128:169-175. doi: 10.1016/j.compscitech.2016.03.026 [48] 吴金丹, 汪维海, 陈宏, 等. 一种提高超高分子量聚乙烯纤维与基体树脂结合性的表面改性方法: 中国, CN114059347A[P]. 2022-02-18.WU J D, WANG W H, CHEN H, et al. A surface modification method for improving the bond between UHMWPE fiber and matrix resin: China, CN114059347A[P]. 2022-02-18(in Chinese). [49] LIU X, WANG K. Interfacial microstructure and properties between epoxy resin and novel organic hybrid graphene oxide modification ultra high molecular weight polyethylene fiber[J]. Polymer,2020,197:122472. doi: 10.1016/j.polymer.2020.122472 [50] BAHRAMIAN N, ATAI M, NAIMI-JAMAL M R. Ultra-high-molecular-weight polyethylene fiber reinforced dental composites: Effect of fiber surface treatment on mechani-cal properties of the composites[J]. Dental Materials,2015,31(9):1022-1029. doi: 10.1016/j.dental.2015.05.011 [51] MENG L, LI W, MA R, et al. Mechanical properties of rigid polyurethane composites reinforced with surface treated ultrahigh molecular weight polyethylene fibers[J]. Polymers for Advanced Technologies,2018,29(2):843-851. doi: 10.1002/pat.4193 [52] LI W, LI R, LI C, et al. Mechanical properties of surface-modified ultra-high molecular weight polyethylene fiber reinforced natural rubber composites[J]. Polymer Composites,2015,38(6):1215-1220. doi: 10.1002/pc.23685 [53] MENG L, LI W, MA R, et al. Long UHMWPE fibers reinforced rigid polyurethane composites: An investigation in mechanical properties[J]. European Polymer Journal,2018(105):55-60. doi: 10.1016/j.eurpolymj.2018.05.021 [54] LI W, FENG M, LIU X, et al. Ultra-high molecular weight polyethylene fibers/epoxy composites: Effect of fiber treatment on properties[J]. Fibers and Polymers,2019,20(2):421-427. doi: 10.1007/s12221-019-8704-7 [55] BELGACEMI R, DERRADJI M, TRACHE D, et al. Advanced hybrid materials from epoxy, oxidized UHMWPE fibers and silane surface modified silicon nitride nanoparticles[J]. High Performance Polymers,2021,33(4):440-450. doi: 10.1177/0954008320964547 [56] LI W, HUANG M, MA R. Improved mechanical properties of epoxy composites reinforced with surface-treated UHMWPE fibers[J]. Polymers for Advanced Technologies,2018,29(4):1287-1293. doi: 10.1002/pat.4240 [57] LI W, MA R, HUANG M, et al. Surface treatment of ultra-high molecular weight polyethylene fibers using potassium permanganate and mechanical properties of its composites[J]. Surface and Interface Analysis,2018,50(1):65-72. doi: 10.1002/sia.6336 [58] BELGACEMI R, DERRADJI M, MOULOUD A, et al. On the mechanical and morphological properties of highly performant composite laminates based on epoxy resin and oxidized ultrahigh-molecular-weight polyethylene fibers[J]. High Performance Polymers,2020,32(9):992-1000. doi: 10.1177/0954008320923385 [59] LI C, WANG G, JIA J, et al. The mechanical properties of UHMWPE fiber-knitted composites[J]. Journal of Engi-neered Fibers and Fabrics,2018,13(2):7-14. doi: 10.1177/155892501801300202 [60] KHAN M M R, HOSSAIN M E, JAYARAMAN R. Effect of fiber surface treatments on the strength of bonding between dyneema® fiber and HDPE matrix[J]. Composite Interfaces,2020,27(12):1061-1083. doi: 10.1080/09276440.2020.1726136 [61] LI Z, ZHANG W, WANG X, et al. Surface modification of ultra high molecular weight polyethylene fibers via the sequential photoinduced graft polymerization[J]. Applied Surface Science,2011,257(17):7600-7608. doi: 10.1016/j.apsusc.2011.03.134 [62] WANG L, GAO S, WANG J, et al. Surface modification of UHMWPE fibers by ozone treatment and UV grafting for adhesion improvement[J]. The Journal of Adhesion,2018,94(1):30-45. doi: 10.1080/00218464.2016.1229603 [63] 李志, 张炜, 吴向阳, 等. 超高分子量聚乙烯纤维表面紫外接枝聚合改性研究[J]. 化工新型材料, 2011, 39(11):46-49. doi: 10.3969/j.issn.1006-3536.2011.11.016LI Z, ZHANG W, WU X Y, et al. Surface modification of ultra high molecular weight polyethylene fibers via the UV-induced graft polymerization[J]. New Chemical Mater-ials,2011,39(11):46-49(in Chinese). doi: 10.3969/j.issn.1006-3536.2011.11.016 [64] WANG J, LIANG G, ZHAO W, et al. Studies on surface modification of UHMWPE fibers via UV initiated grafting[J]. Applied Surface Science,2006,253(2):668-673. doi: 10.1016/j.apsusc.2005.12.165 [65] ZHAO J, GUO Z, LIANG G, et al. Enzyme-mediated grafting of acrylamide to ultrahigh molecular weight polyethylene fiber: A novel radical initiation system[J]. Journal of Applied Polymer Science,2005,96(4):1011-1016. doi: 10.1002/app.21250 [66] TIAN Y L, GUO L M. Surface modification of UHMWPE fibers by means of polyethylene wax grafted maleic anhydride treatment[J]. Journal of Applied Polymer Science,2018,135(31):46555. doi: 10.1002/app.46555 [67] ZHANG Z, JIANG G, WU Y, et al. Surface functional modification of ultrahigh molecular weight polyethylene fiber by atom transfer radical polymerization[J]. Applied Surface Science,2017,427:410-415. doi: 10.1016/j.apsusc.2017.08.159 [68] AHMADI M, MASOOMI M, SAFI S. Mechanical property characterization of carbon nanofiber/epoxy nanocompo-sites reinforced by GMA-grafted UHMWPE fibers[J]. Composites Part B: Engineering,2015,83:43-49. doi: 10.1016/j.compositesb.2015.08.006 [69] AHMADI M, ZABIHI O, MASOOMI M, et al. Synergistic effect of MWCNTs functionalization on interfacial and mechanical properties of multi-scale UHMWPE fibre reinforced epoxy composites[J]. Composites Science and Technology,2016(134):1-11. doi: 10.1016/j.compscitech.2016.07.026 [70] JIAN Y, MING L. Improving the interfacial strength of PMMA resin composites by chemically grafting graphene oxide on UHMWPE fiber[J]. Composite Interfaces,2018,25(11):949-958. doi: 10.1080/09276440.2018.1439646 [71] ZHU M, REN H, LU Q, et al. An in situ surface modification method of ultra-high molecular weight polyethylene fiber on the basis of dry gel-spinning technique[J]. Polymer Testing,2021,93:106951. doi: 10.1016/j.polymertesting.2020.106951 [72] 杨燕宁, 孟家光, 程燕婷, 等. 硅烷偶联剂表面改性UHMWPE纤维的工艺优化[J]. 合成纤维工业, 2018, 41(1):31-34. doi: 10.3969/j.issn.1001-0041.2018.01.008YANG Y N, MENG J G, CHEN Y T, et al. Optimization of surface modification process of UHMWPE fiber with silane coupling agent[J]. China Synthetic Fiber Industry,2018,41(1):31-34(in Chinese). doi: 10.3969/j.issn.1001-0041.2018.01.008 [73] 冯霞, 胡俊成, 阿拉东. 多巴胺仿生修饰及聚乙烯亚胺二次功能化表面改性超高分子量聚乙烯纤维[J]. 天津工业大学学报, 2016, 35(6):14-19. doi: 10.3969/j.issn.1671-024x.2016.06.003FENG X, HU J C, A L D, et al. Surface modification of UHMWPE fibers by bio-dopamine and polyethylene imine second functionalization[J]. Journal of Tianjin Polytechnic University,2016,35(6):14-19(in Chinese). doi: 10.3969/j.issn.1671-024x.2016.06.003 [74] 冯霞, 胡俊成, 陈莉, 等. 一种超高分子量聚乙烯纤维表面处理的方法: 中国, CN 105220503 A[P]. 2016-01-06.FENG X, HU J C, CHEN L, et al. A method for surface treatment of ultra high molecular weight polyethylene fiber: China, CN105220503 A[P]. 2016-01-06(in Chinese). [75] CHHETRI S, SARWAR A, STEER J, et al. Design of a bi-layer coating configuration on ultra-high molecular weight polyethylene (UHMWPE) fiber surface to derive synergis-tic response on interfacial bond strength[J]. Composites Part A: Applied Science and Manufacturing,2022,152:106678. doi: 10.1016/j.compositesa.2021.106678 [76] HU J, FENG X, LIU Z, et al. Surface amine-functionalization of UHMWPE fiber by bio-inspired polydopamine and grafted hexamethylene diamine[J]. Surface and Interface Analysis,2017,49(7):640-646. doi: 10.1002/sia.6203 [77] ZHANG Y, CAO S, ZHOU X, et al. High-performance fiber-reinforced composites with a polydopamine/epoxy silane hydrolysis-condensate bilayer on surface of ultra-high molecular weight polyethylene fiber[J]. Journal of Applied Polymer Science,2022,139(18):52062. doi: 10.1002/app.52062 [78] SHANMUGAM L, KAZEMI M E, RAO Z, et al. Enhanced mode I fracture toughness of UHMWPE fabric/thermoplastic laminates with combined surface treatments of polydopamine and functionalized carbon nanotubes[J]. Composites Part B: Engineering,2019,178:107450. doi: 10.1016/j.compositesb.2019.107450 [79] FANG Z, TU Q, SHEN X, et al. Biomimetic surface modification of UHMWPE fibers to enhance interfacial adhesion with rubber matrix via constructing polydopamine functionalization platform and then depositing zinc oxide nanoparticles[J]. Surfaces and Interfaces,2022,29:101728. doi: 10.1016/j.surfin.2022.101728 [80] 赵晗, 尚晴, 杨萌, 等. 邻苯二酚-四乙烯五胺改性超高分子量聚乙烯纤维[J]. 高分子学报, 2020, 51(3):287-294. doi: 10.11777/j.issn1000-3304.2019.19172ZHAO H, SHANG Q, YANG M, et al. Surface modification of ultra-high molecular weight polyethylene fiber by catechol-tetraethylenepentamine[J]. Acta Polymerica Sinica,2020,51(3):287-294(in Chinese). doi: 10.11777/j.issn1000-3304.2019.19172 [81] WANG S, MA J, FENG X, et al. An effective surface modification of UHMWPE fiber for improving the interfacial adhesion of epoxy resin composites[J]. Polymer Compo-sites,2020,41(4):1614-1623. doi: 10.1002/pc.25483 [82] 李翠玉, 苏瑞, 李晓雨, 等. 复合涂层对UHMWPE纤维复合材料界面性能的影响[J]. 化工新型材料, 2021, 49(11):99-103. doi: 10.19817/j.cnki.issn1006-3536.2021.11.021LI C Y, SU R, LI X Y, et al. Influence of multicoating on interfacial property of UHMWPE fiber composite[J]. New Chemical Materials,2021,49(11):99-103(in Chinese). doi: 10.19817/j.cnki.issn1006-3536.2021.11.021 [83] 赵晗, 尚晴, 杨萌, 等. ZnO纳米棒改性超高分子量聚乙烯纤维及其性能研究[J]. 高分子学报, 2020, 51(6):649-655. doi: 10.11777/j.issn1000-3304.2019.19208ZHAO H, SHANG Q, YANG M, et al. Surface modification and properties of UHMWPE fibers by ZnO nanorods[J]. Acta Polymerica Sinica,2020,51(6):649-655(in Chinese). doi: 10.11777/j.issn1000-3304.2019.19208 [84] YU J, CHEN H, HUANG H, et al. Protein-induced decoration of applying MXene directly to UHMWPE fibers and fabrics for improved adhesion properties and electronic textiles[J]. Composites Science and Technology,2022,218:109158. doi: 10.1016/j.compscitech.2021.109158 [85] 邝金艳, 于俊荣, 肖明明, 等. EVA共混改性UHMWPE纤维的表面性能[J]. 合成纤维工业, 2011, 34(5):1-4. doi: 10.3969/j.issn.1001-0041.2011.05.001KUANG J Y, YU J R, XIAO M M, et al. Surface properties of UHMWPE fiber blending modified with EVA[J]. China Synthetic Fiber Industry,2011,34(5):1-4(in Chinese). doi: 10.3969/j.issn.1001-0041.2011.05.001 [86] KHAN M R, ABSAR S, MAHFUZ H, et al. Morphological characteristics of solution spun nanocomposite fibers synthesized from ultra high molecular weight polyethylene, nylon 6 and carbon nanotubes, compatibilized with polyethylene graft maleic anhydride[J]. Polymer Science,2015,57(6):863-873. doi: 10.1134/S0965545X15060115 [87] ZHAO X, DU J, YANG H, et al. Surface modification of ultra-high molecular weight polyethylene fiber by different kinds of SiO2 nanoparticles[J]. Polymer Composites,2017,38(9):1928-1936. doi: 10.1002/pc.23763 [88] ZHANG Y, YU J, CHEN L, et al. Surface modification of ultrahigh-molecular-weight polyethylene fibers with coupling agent during extraction process[J]. Journal of Macromolecular Science Physics,2009,48(2):391-404. doi: 10.1080/00222340802682817 [89] ZHANG Y, YU J, ZHOU C, et al. Preparation, morphology, and adhesive and mechanical properties of ultrahigh-molecular-weight polyethylene/SiO2 nanocomposite fibers[J]. Polymer Composites, 2010, 31(4): 684-690. [90] 于俊荣, 栾秀娜, 胡祖明, 等. 纳米SiO2改性超高分子量聚乙烯纤维的制备及其结构性能研究[J]. 高分子学报, 2005(5):764-768. doi: 10.3321/j.issn:1000-3304.2005.05.024YU J R, LUAN X N, HU Z M, et al. Preparation and studies on the structure and properties of ultrahigh molecular weight polyethylene/nano-SiO2 composite fibers[J]. Acta Polymerica Sinica,2005(5):764-768(in Chinese). doi: 10.3321/j.issn:1000-3304.2005.05.024 [91] 周文博, 余雯雯, 石建高. 渔用超高分子量聚乙烯/石墨烯纳米复合纤维的结构与蠕变性能[J]. 水产学报, 2019, 43(3):697-705. doi: 10.11964/jfc.20171111041ZHOU W B, YU W W, SHI J G. Structure and creep properties of UHMWPE/GR fishing nanocomposite fibers[J]. Journal of Fisheries of China,2019,43(3):697-705(in Chinese). doi: 10.11964/jfc.20171111041 [92] 郎彦庆, 王耀先, 程树军. 超高分子量聚乙漏纤维的硅烷交联改性[J]. 合成纤维, 2004, 33(4):1-3. doi: 10.3969/j.issn.1001-7054.2004.04.001LANG Y Q, WANG Y X, CHEN S J. Study on UHMWPE fibers with silane treatment[J]. Synthetic Fiber in China,2004,33(4):1-3(in Chinese). doi: 10.3969/j.issn.1001-7054.2004.04.001 [93] 张秀雨, 于俊荣, 彭宏, 等. 硅烷交联改性对UHMWPE纤维蠕变性能的影响[J]. 东华大学学报(自然科学版), 2015, 41(1):1-5, 27. doi: 10.3969/j.issn.1671-0444.2015.01.001ZHANG X Y, YU J R, PENG H, et al. Effect of silane crosslinking on the creep behavior of UHMWPE fibers[J]. Journal of Donghua University (Natural Science),2015,41(1):1-5, 27(in Chinese). doi: 10.3969/j.issn.1671-0444.2015.01.001 [94] 徐明忠, 赵国樑. UHMWPE纤维的表面交联改性[J]. 高分子材料科学与工程, 2012, 28(10):59-62. doi: 10.16865/j.cnki.1000-7555.2012.10.01XU M Z, ZHAO G L. Surface crosslinking modification of UHMWPE fibers[J]. Polymer Materials Science & Engi-neering,2012,28(10):59-62(in Chinese). doi: 10.16865/j.cnki.1000-7555.2012.10.01 [95] 马华菁, 时娟娟, 沈文东, 等. UHMWPE纤维UD布的制备及拉伸性能研究[J]. 化工新型材料, 2022(4): 87-89, 94.MA H J, SHI J J, SHEN W D, et al. Fabrication and tensile property of UD cloth using UHMWPE fiber[J]. New Che-mical Materials, 2022(4): 87-89, 94(in Chinese). [96] KANG Y, OH S, PARK J S. Properties of UHMWPE fabric reinforced epoxy composite prepared by vacuum-assisted resin transfer molding[J]. Fibers and Polymers,2015,16(6):1343-1348. doi: 10.1007/s12221-015-1343-8 [97] 徐海燕. 捻度对超高分子质量聚乙烯纱线可编织性的影响[J]. 纺织学报, 2013, 34(11):44-48. doi: 10.3969/j.issn.0253-9721.2013.11.010XU H Y. Effect of twist on knittability of ultra-high molecular weight polyethylene yarn[J]. Journal of Textile Research,2013,34(11):44-48(in Chinese). doi: 10.3969/j.issn.0253-9721.2013.11.010 [98] 贾静艳. 改性UHMWPE纤维纬平针织复合材料的力学性能研究[D]. 天津: 天津工业大学, 2017.JIA J Y. Study on mechanical properties of modified UHMWPE fiber weft flat knitting composites[D]. Tianjin: Tianjin Polytechnic University, 2017(in Chinese). [99] 邹画眉, 刘新金, 谢春萍. 组织结构对UHMWPE短纤纱织物防刺性能的影响[J]. 丝绸, 2020, 57(5):11-15. doi: 10.3969/j.issn.1001-7003.2020.05.003ZOU H M, LIU X J, XIE C P, et al. Effect of weave structure on stabbing resistance of UHMWPE staple fiber yarn fabric[J]. Journal of Silk,2020,57(5):11-15(in Chinese). doi: 10.3969/j.issn.1001-7003.2020.05.003 [100] 李翠玉, 贾静艳, 罗岳文. 不同结构UHMWPE纤维纬编针织复合材料压缩性能[J]. 复合材料学报, 2016, 33(12):2789-2796. doi: 10.13801/j.cnki.fhclxb.20160323.002LI C Y, JIA J Y, LUO Y W. Compression properties of different structures UHMWPE fiber weft knitted compo-sites[J]. Acta Materiae Compositae Sinica,2016,33(12):2789-2796(in Chinese). doi: 10.13801/j.cnki.fhclxb.20160323.002 [101] 王景景. 不同结构三维UHMWPE纤维复合材料的性能研究[J]. 现代纺织技术, 2021, 29(4):12-17. doi: 10.19398/j.att.202003024WANG J J. Research on the properties of three-dimensional UHMWPE fiber composites with different structures[J]. Advanced Textile Technology,2021,29(4):12-17(in Chinese). doi: 10.19398/j.att.202003024 [102] ANWER A A W, DONG T, NAGUIB H E. Fiber tortuosity and its effects on shock transfer characteristics of ultra high molecular weight polyethylene (UHMWPE) fibers embedded in a polyurethane composite structure[J]. Composites Science and Technology,2020,192:108112. doi: 10.1016/j.compscitech.2020.108112 [103] LI A, YUEN A C Y, WANG W, et al. A review on lithium-ion battery separators towards enhanced safety perfor-mances and modelling approaches[J]. Molecules,2021,26(2):478. doi: 10.3390/molecules26020478 [104] LI R, GAO P. Nanoporous UHMWPE membrane separa-tors for safer and high-power-density rechargeable batteries[J]. Global Challenges,2017,1(4):1700020. doi: 10.1002/gch2.201700020 [105] ZHAO C, HE J, LI J, et al. Preparation and properties of UHMWPE microporous membrane for lithium ion battery diaphragm[J]. IOP Conference Series: Materials Science and Engineering,2018,324(1):12089. doi: 10.1088/1757-899X/324/1/012089 [106] BABIKER D M D, WAN C, MANSOOR B, et al. Superior lithium battery separator with extraordinary electroche-mical performance and thermal stability based on hybrid UHMWPE/SiO2 nanocomposites via the scalable biaxial stretching process[J]. Composites Part B: Engineering,2021,211:108658. doi: 10.1016/j.compositesb.2021.108658 [107] 杨勇, 汪圣光, 杨光, 等. 一种基于高强度复合材料的雷达天线罩: 中国, CN 108258411 A[P]. 2018-07-06.YANG Y, WANG S G, YANG G, et al. A radar radome based on high strength composite material: China, CN 108258411 A[P]. 2018-07-06(in Chinese). [108] LEE D, CHOI I, LEE D G. Development of a damage tolerant structure for nano-composite radar absorbing structures[J]. Composite Structures,2015,119:107-114. doi: 10.1016/j.compstruct.2014.08.001 [109] PATIL N A, NJUGUNA J, KANDASUBRAMANIAN B. UHMWPE for biomedical applications: Performance and functionalization[J]. European Polymer Journal,2020,125:109529. doi: 10.1016/j.eurpolymj.2020.109529 [110] SHARMA V, CHOWDHURY S, KESHAVAN N, et al. Six decades of UHMWPE in reconstructive surgery[J/OL]. International Materials Reviews, 2022: 1-36. [2022-06-13]. DOI: 10.1080/09506608.2022.2047419. [111] HUSSAIN M, NAQVI R A, ABBAS N, et al. Ultra-high-molecular-weight-polyethylene (UHMWPE) as a promising polymer material for biomedical applications: A concise review[J]. Polymers,2020,12(2):323. doi: 10.3390/polym12020323 [112] ABDUL S M. Recent advances in UHMWPE/UHMWPE nanocomposite/UHMWPE hybrid nanocomposite polymer coatings for tribological applications: A comprehen-sive review[J]. Polymers,2021,13(4):608. doi: 10.3390/polym13040608 [113] BISTOLFI A, GIUSTRA F, BOSCO F, et al. Ultra-high molecular weight polyethylene (UHMWPE) for hip and knee arthroplasty: The present and the future[J]. Journal of Orthopaedics,2021,25:98-106. doi: 10.1016/j.jor.2021.04.004 [114] ZHU W, LIU H, YAN W, et al. The fabrication of superhydrophobic PTFE/UHMWPE composite surface by hot-pressing and texturing process[J]. Colloid and Polymer Science,2017,295(5):759-766. doi: 10.1007/s00396-017-4057-1 [115] WANG N, XIONG D, PAN S, et al. Robust superhydrophobic coating and the anti-icing study of its lubricants-infused-composited surface under condensing condition[J]. New Journal of Chemistry,2017,41(4):18-46. doi: 10.1039/C6NJ02824A [116] 吕生华, 王结良, 何洋. 高强度聚乙烯纤维绳索的制备研究[J]. 合成纤维工业, 2003, 26(5):26-28. doi: 10.3969/j.issn.1001-0041.2003.05.009LV S H, WANG J L, HE Y. Study on preparation of high-strength-polyethylene fiber rope[J]. China Synthetic Fiber Industry,2003,26(5):26-28(in Chinese). doi: 10.3969/j.issn.1001-0041.2003.05.009 [117] 中国国家标准化管理委员会. 渔用绳索通用技术条件: GB/T 18674—2018[S]. 北京: 中国标准出版社, 2018.Standardization Administration of China. General specification for fishing ropes: GB/T 18674—2018[S]. Beijing: Standards Press of China, 2018(in Chinese). [118] 石建高, 王鲁民. 渔用超高分子量聚乙烯纤维绳索的研究[J]. 上海水产大学学报, 2003, 12(4):371-375. doi: 10.3969/j.issn.1004-7271.2003.04.017SHI J G, WANG L M. Studies on ultra-high molecular weight polyethylene fiber ropes for fishing gear[J]. Jour-nal of Shanghai Fisheries University,2003,12(4):371-375(in Chinese). doi: 10.3969/j.issn.1004-7271.2003.04.017 [119] 杨正国. 超高分子量聚乙烯纤维防切割手套应用与市场分析[J]. 合成技术及应用, 2015, 30(2):17-19. doi: 10.3969/j.issn.1006-334X.2015.02.009YANG Z G. The development of cut resistant gloves with ultra high molecular weight polyethylene[J]. Synthetic Technology & Application,2015,30(2):17-19(in Chinese). doi: 10.3969/j.issn.1006-334X.2015.02.009 [120] 余黎明. 我国超高分子量聚乙烯行业发展现状及前景[J]. 化学工业, 2012, 30(9):1-5, 15. doi: 10.3969/j.issn.1673-9647.2012.09.001YU L M. Development status and prospect of UHMWPE industry in China[J]. Chemical Industry,2012,30(9):1-5, 15(in Chinese). doi: 10.3969/j.issn.1673-9647.2012.09.001 [121] 张艳. 超高分子量聚乙烯纤维在防弹和防刺材料方面的应用[J]. 产业用纺织品, 2010, 28(10):9-39. doi: 10.3969/j.issn.1004-7093.2010.10.008ZHANG Y. The application of ultra high molecular weight polyethylene fiber on bulletproof and stab-resistant materials[J]. Technical Textiles,2010,28(10):9-39(in Chinese). doi: 10.3969/j.issn.1004-7093.2010.10.008 [122] GOLOVIN K, PHOENIX S L. Effects of extreme transverse deformation on the strength of UHMWPE single filaments for ballistic applications[J]. Journal of Materials Science,2016,51(17):8075-8086. doi: 10.1007/s10853-016-0077-3 [123] WANG H, HAZELL P J, SHANKAR K, et al. Impact behaviour of Dyneema® fabric-reinforced composites with different resin matrices[J]. Polymer Testing,2017,61:17-26. doi: 10.1016/j.polymertesting.2017.04.026 [124] 刘春美, 马琼, 石凌飞. 警用廨头盔警用防粧料技术预测[J]. 警察技术, 2020(3):48-53. doi: CNKI:SUN:JCJS.0.2020-03-015LIU C M, MA Q, SHI L F. Analysis and development trend forecast of protective technology for police bulletproof equipment[J]. Police Technology,2020(3):48-53(in Chinese). doi: CNKI:SUN:JCJS.0.2020-03-015 [125] 袁子舜, 陆振乾, 许玥, 等. 超高分子量聚乙烯纤维平纹织物-单向布混合堆叠板的防弹机制[J]. 复合材料学报, 2022, 39(6):2682-2690. doi: 10.13801/j.cnki.fhclxb.20200000.000000YUAN Z S, LU Z Q, XU Y, et al. Ballistic mechanism of the hybrid panels with UHMWPE woven fabrics and UD la-minates[J]. Acta Materiae Compositae Sinica,2022,39(6):2682-2690(in Chinese). doi: 10.13801/j.cnki.fhclxb.20200000.000000 [126] 肖文莹, 李想, 郭万涛. Kevlar/UHMWPE混杂纤维复合材料抗弹性能[J]. 玻璃钢/复合材料, 2019(9):79-84. doi: CNKI:SUN:BLGF.0.2019-09-014XIAO W Y, LI X, GUO W T, et al. Resistance performance of Kevlar/UHMWPE fiber hybrid composites[J]. Fiber Reinforced Plastics/Composites,2019(9):79-84(in Chinese). doi: CNKI:SUN:BLGF.0.2019-09-014 [127] ZHANG Q, LIU Z, QIN Z, et al. Characterization of macroscopic impact-resistant behavior of shear thickening fluid impregnated ultra-high molecular weight polyethylene fiber flexible composites[J]. Composites Communications,2021,25:100756. doi: 10.1016/j.coco.2021.100756 [128] 田明月, 王蕊宁, 孙润军, 等. UHMWPE织物/剪切增稠液防刺复合材料的制备及性能[J]. 高分子材料科学与工程, 2020, 36(11):109-116. doi: 10.16865/j.cnki.1000-7555.2020.0261TIAN M Y, WANG R N, SUN R J, et al. Preparation and properties of UHMWPE fabric/shear thickening fluid stab-resistant composite materials[J]. Polymer Materials Science & Engineering,2020,36(11):109-116(in Chinese). doi: 10.16865/j.cnki.1000-7555.2020.0261 [129] 徐素鹏, 郑伟, 张玉芳. 剪切增稠液体增强织物防刺性能的机理研究[J]. 天津工业大学学报, 2012, 31(3):15-19. doi: 10.3969/j.issn.1671-024X.2012.03.004XU S P, ZHENG W, ZHANG Y F. Study on mechanism of sheer thickening fluiding enhancing stab-risistant performance of fabric[J]. Journal of Tianjin Polytechnic University,2012,31(3):15-19(in Chinese). doi: 10.3969/j.issn.1671-024X.2012.03.004 [130] AHMAD M, HASSIM N, AHMAD W Y W, et al. Preliminary investigation on the ballistic limit of ultra high molecular weight polyethylene unidirectional coated fabric system[J]. Fibres and Textiles in Eastern Europe,2013,99(3):89-94. [131] FIROUZI D, FOUCHER D A, BOUGHERARA H. Nylon-coated ultra high molecular weight polyethylene fabric for enhanced penetration resistance[J]. Journal of Applied Polymer Science,2014,131(11):169-172. doi: 10.1002/app.40350 [132] CHEN Z, XU Y, LI M, et al. Investigation on residual strength and failure mechanism of the ceramic/UHMWPE armors after ballistic tests[J]. Materials,2022,15(3):901. doi: 10.3390/ma15030901 [133] 刘胜, 吕攀珂, 张燕. 防弹陶瓷插板的应用性能研究[J]. 中国个体防护装备, 2010(6):10-12. doi: 10.3969/j.issn.1671-0312.2010.06.002LIU S, LV P K, ZHANG Y. Research on application performance of bulletproof ceramic plate[J]. China Personal Protective Equipment,2010(6):10-12(in Chinese). doi: 10.3969/j.issn.1671-0312.2010.06.002 [134] 欧阳科峰, 姚新, 杨阳. Al2O3陶瓷与超高分子量聚乙烯复合结构抗穿甲燃烧弹侵彻性能试验研究[J]. 防护工程, 2021, 43(3):13-18. doi: 10.3969/j.issn.1674-1854.2021.03.002OUYANG K F, YAO X, YANG Y, et al. Experimental study on anti-penetration performance of armor-piercing incendiary ammunition against composite structures of Al2O3 and UHMWPE[J]. Protective Engineering,2021,43(3):13-18(in Chinese). doi: 10.3969/j.issn.1674-1854.2021.03.002 [135] 刘迪, 肖依, 江旭伟. SiC/UHMWPE复合装甲板抗侵彻性能的试验与数值模拟[J]. 上海大学学报(自然科学版), 2020, 26(2):234-243. doi: CNKI:SUN:SDXZ.0.2020-02-008LIU D, XIAO Y, JIANG X W. Anti-penetration capability of SiC/UHMWPE composite armour plates through experimental and numerical simulation[J]. Journal of Shanghai University (Natural Science Edition),2020,26(2):234-243(in Chinese). doi: CNKI:SUN:SDXZ.0.2020-02-008 [136] 贾楠, 焦亚男, 周庆, 等. 碳化硅-超高分子量聚乙烯纤维增强树脂基复合材料复合装甲板的抗穿甲弹侵彻性能及其损伤机制[J/OL]. 复合材料学报, 2022, 39(10): 1-10. [2022-06-13]. DOI: 10.13801/j.cnki.fhclxb.20210928.002.JIA N, JIAO Y N, ZHOU Q, et al. Anti-penetration perfor-mance and damage mechanism of silicon carbor-ultra high molecular weight polyethylene fiber reinforced resin matrix composite deck[J]. Acta Materiae Compo-sitae Sinica, 2022, 39(10): 1-10. [2022-06-13]. DOI: 10.13801/j.cnki.fhclxb.20210928.002. [137] 张佐光, 仲伟虹, 孙志杰, 等. 一种先进复合材料防弹板: 中国, CN 2406216 Y[P]. 2000-11-15.ZHANG Z G, ZHONG W H, SUN Z J, et al. An advanced composite bulletproof plate: China, CN 2406216 Y[P]. 2000-11-15. [138] 秦溶蔓, 朱波, 乔琨, 等. 复合结构碳纤维防弹板的防弹性能仿真[J]. 工程科学学报, 2021, 43(10):1346-1354. doi: 10.13374/j.issn2095-9389.2021.04.21.001QIN R M, ZHU B, QIAO K, et al. Simulation study of the protective performance of composite structure carbon fiber bulletproof board[J]. Chinese Journal of Engineering,2021,43(10):1346-1354(in Chinese). doi: 10.13374/j.issn2095-9389.2021.04.21.001 [139] 秦溶蔓, 朱波, 乔琨, 等. 陶瓷/纤维复合材料层间混杂结构对装甲板抗侵彻性能的影响[J]. 材料导报, 2020, 34(18):18183-18187. doi: 10.11896/cldb.20030208QIN R M, ZHU B, QIAO K, et al. Effect of hybrid structure of ceramic/fiber composite material on penetration resis-tance of armor plate[J]. Materials Reports,2020,34(18):18183-18187(in Chinese). doi: 10.11896/cldb.20030208 [140] 何芳, 王玉林, 万怡灶, 等. 三维编织超高分子量聚乙烯纤维/碳纤维/环氧树脂混杂复合材料力学行为及混杂效应[J]. 复合材料学报, 2008, 25(6):52-58. doi: 10.3321/j.issn:1000-3851.2008.06.010HE F, WANG Y L, WAN Y Z, et al. Mechanical properties and hybrid effect of 3D braided UHMWPE fiber/carbon fiber/epoxy resin hybrid composites[J]. Acta Materiae Compositae Sinica,2008,25(6):52-58(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.06.010 [141] 仲越, 徐铭涛, 王萍, 等. 碳纤维-超高分子量聚乙烯纤维混杂增强环氧树脂复合材料低速冲击性能及失效机制[J]. 复合材料学报, 2022, 39(7):3202-3211. doi: 10.13801/j.cnki.fhclxb.20210909.008ZHONG Y, XU M T, WANG P, et al. Low-velocity impact properties and failure mechanism of carbon fiber-UHMWPE fiber hybrid reinforced epoxy resin composites[J]. Acta Materiae Compositae Sinica,2022,39(7):3202-3211(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210909.008 [142] HU Y, SHI Y, LIU D, et al. Damage tolerance of 2-dimentional UHMWPE/CF hybrid woven laminates subjected to low-velocity impact[J]. Materials & Design,2020,191:108604. doi: 10.1016/j.matdes.2020.108604 [143] 吕生华, 周志威, 李芳, 等. UHMWPE纤维/碳纤维混杂复合材料性能研究[J]. 材料导报, 2006, 20(7):135-137. doi: 10.3321/j.issn:1005-023X.2006.07.038LV S H, ZHOU Z W, LI F, et al. Study on properties of UHMWPE fiber/carbon fiber hybrid composites[J]. Mate-rials Review,2006,20(7):135-137(in Chinese). doi: 10.3321/j.issn:1005-023X.2006.07.038 [144] 何洋, 梁国正, 杨洁颖, 等. 超高分子量聚乙烯纤维/碳纤维混杂复合材料研究[J]. 航空学报, 2004, 25(5):504-507. doi: 10.3321/j.issn:1000-6893.2004.05.017HE Y, LIANG G Z, YANG J Y, et al. Study of UHMWPE fiber/carbon fiber hybrid composite[J]. Acta Aeronau-tica et Astronautica Sinica,2004,25(5):504-507(in Chinese). doi: 10.3321/j.issn:1000-6893.2004.05.017 -

下载:

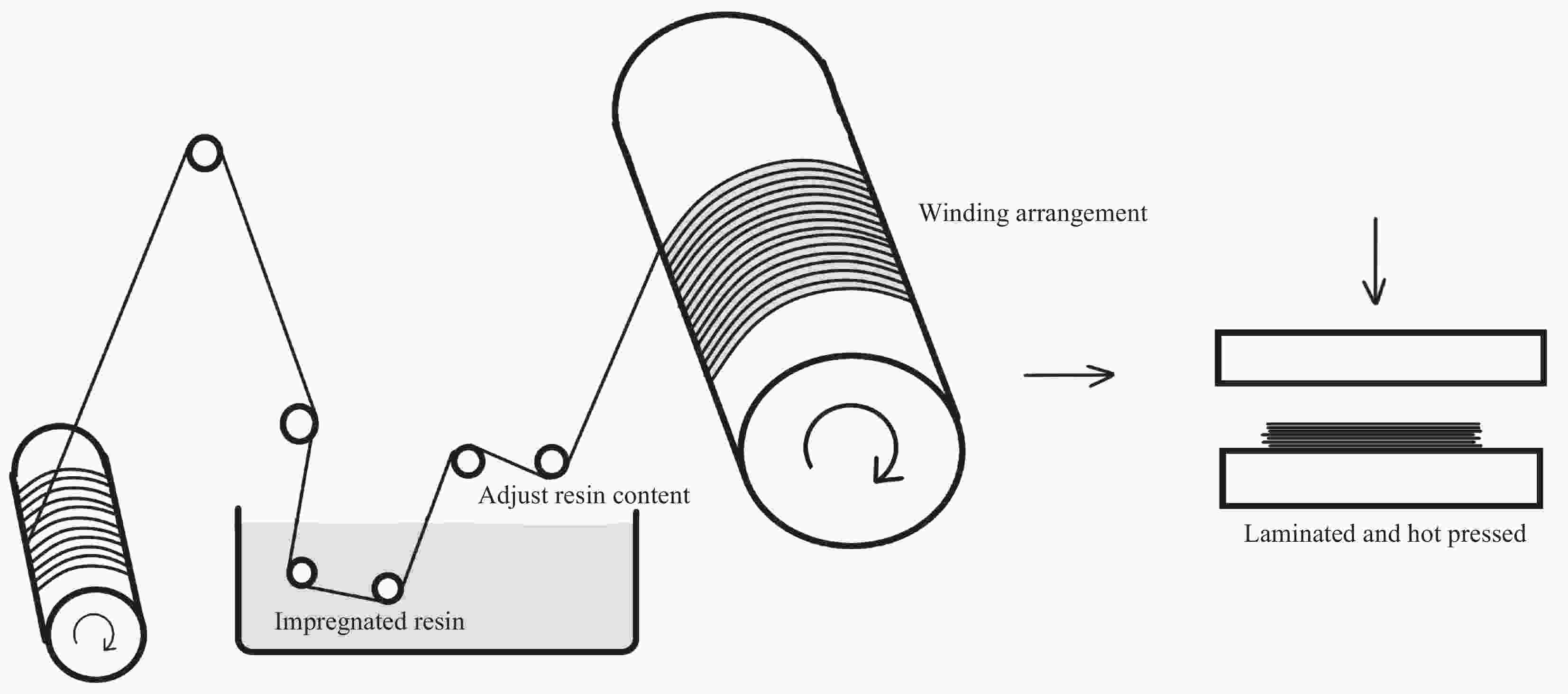

下载: