Ultimate strength of imperfect moderate thick composite cylindrical pressure shell under hydrostatic pressure

-

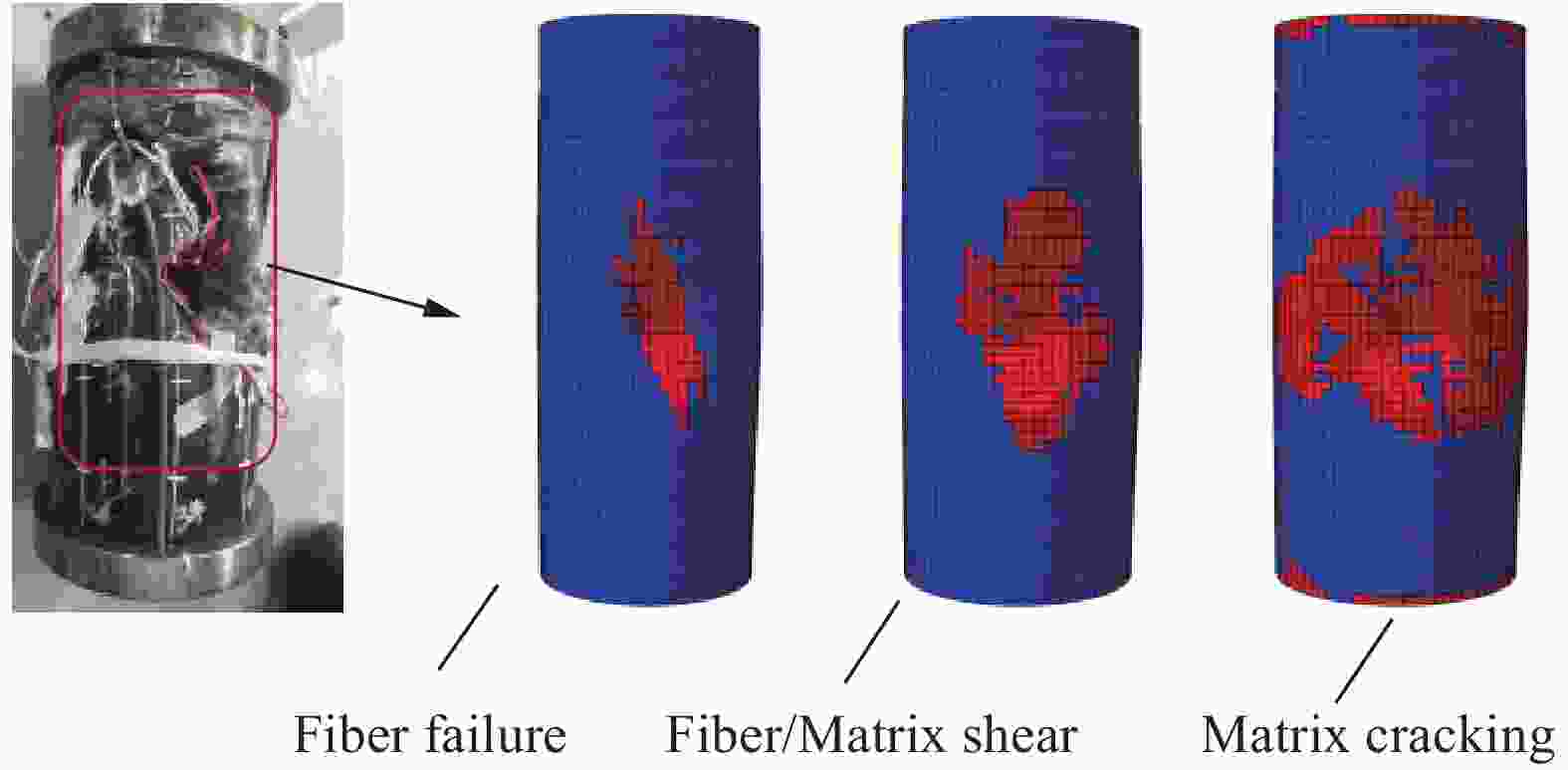

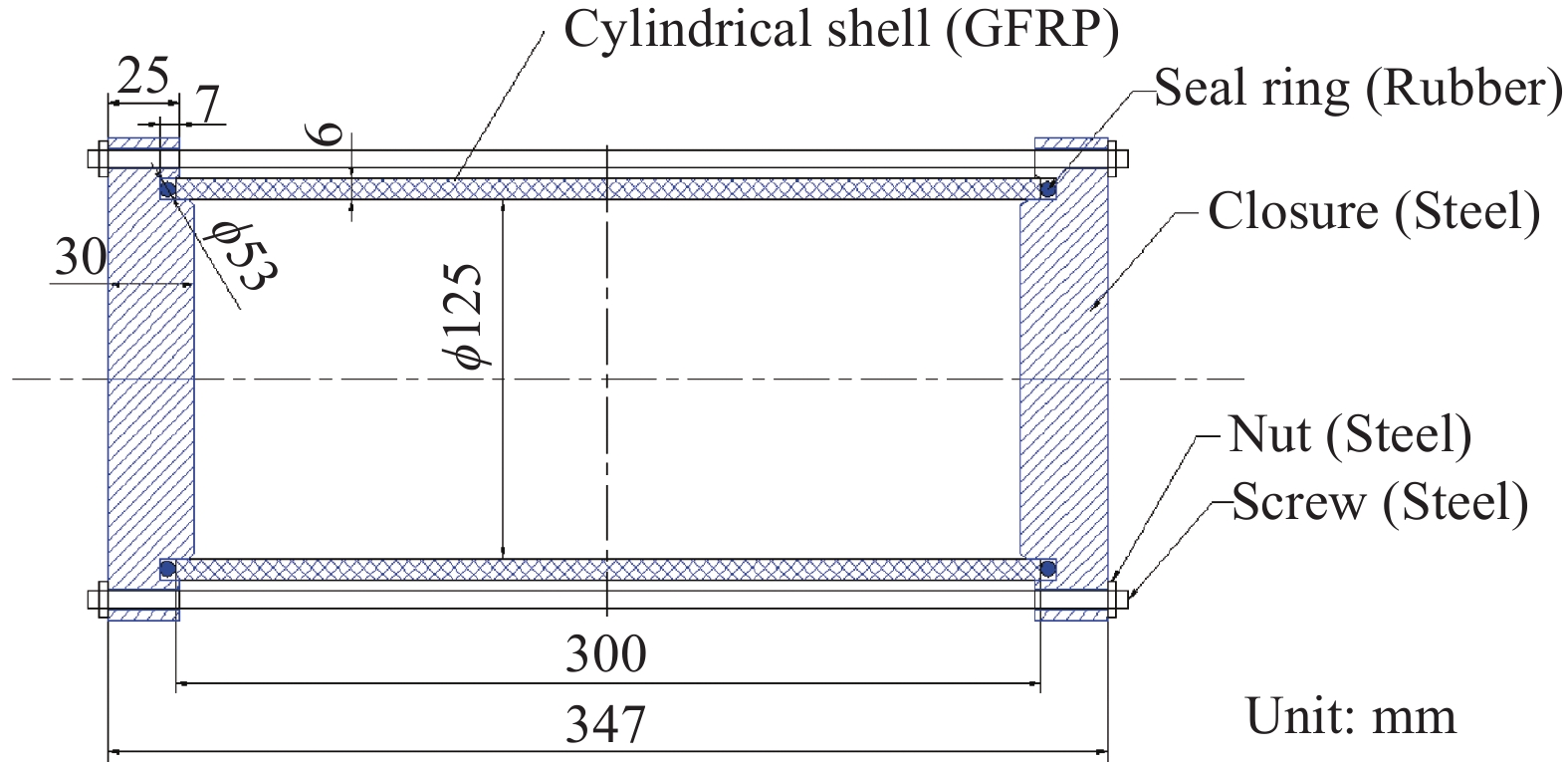

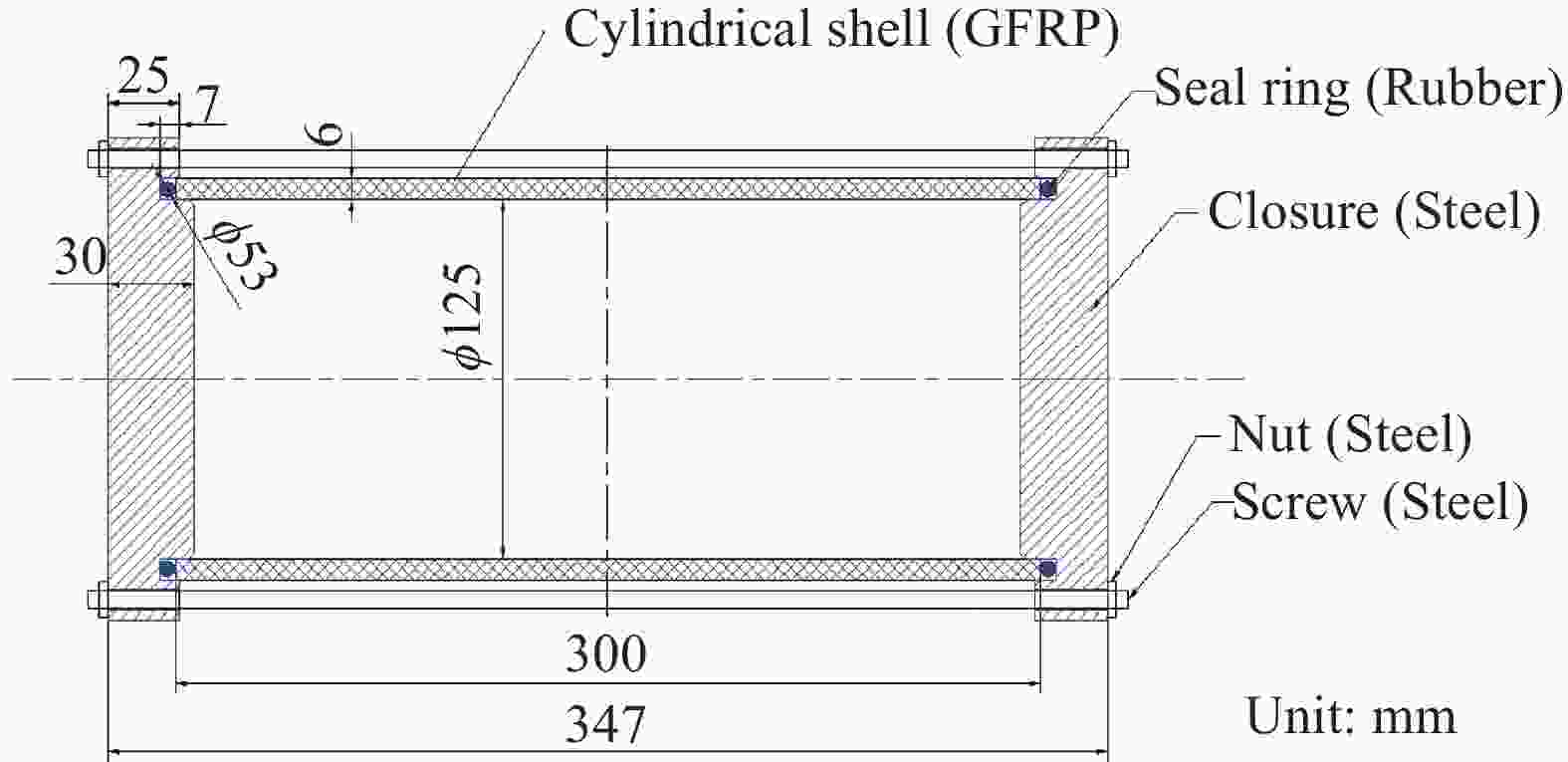

摘要: 为探究静水压下含缺陷中厚复合材料圆柱耐压壳的极限强度,以湿法缠绕工艺制备中厚玻璃纤维增强树脂基复合材料(GFRP)圆柱耐压壳结构模型,对其初挠度进行测试,并开展静水压破坏试验,分析了结构的极限承载能力、应变响应和破坏模式。基于实测初挠度及破坏模式,建立含缺陷复合材料圆柱壳的非线性分析有限元模型,同时考虑壳体几何缺陷及承压过程中的复合材料面内损伤,编制ABAQUS接口子程序USDFLD,对模型的损伤过程进行数值模拟,获得静水压下含缺陷中厚复合材料圆柱壳的渐进失效过程,并与试验结果对比验证。研究表明:在静水压下中厚GFRP圆柱壳结构在破坏前载荷几乎呈线性增加,最终破坏模式为材料的压缩破坏,整体屈曲破坏模式不明显。考虑结构的几何缺陷和材料损伤演化后,采用非线性有限元模拟得到的壳体极限强度与试验结果吻合良好,可以作为预测含缺陷中厚复合材料圆柱壳极限强度的方法。采用该方法对影响中厚复合材料圆柱耐压壳极限强度的关键参数进行了研究,为深海复合材料耐压壳的研究设计提供参考。Abstract: In order to investigate the ultimate strength of imperfect composite cylindrical shell under hydrostatic pressure, a moderate thick filament wounded glass fiber-reinforced polymer (GFRP) composite cylindrical model was fabricated, and its initial deflection was measured before hydrostatic external pressure test. Then the compo-site cylinder model was tested up to failure under hydrostatic external pressure, the ultimate bearing capacity, strain response and failure mode were analyzed comprehensively. Based on the measured initial deflection and failure mode, a nonlinear finite element model was established, which the initial geometric defects and in-plane damage of composites during the loading procedure were simultaneously considered in the numerical model. Through programming interface subroutine with ABAQUS software, the failure process and mechanism of moderate thick GFRP cylinder model were obtained, and numerical result were compared and comparative verified with the experimental results. The results show that the ultimate load of moderate thick GFRP cylinder model is almost increasing before model collapse, and the final failure mode is the compression failure of the composite material, while the global buckling failure mode is not obvious. After considering the geometrical defects and damage evolution of composites, the ultimate strength of the moderate thick composite cylindrical shell is agreed well with the experimental result. It can be used as a method to predict the ultimate strength of medium thickness composite cylindrical shells with defects. On this basis, the key parameters affecting the ultimate strength of medium thickness composite cylindrical shells were studied, which can provide reference for the design of deep-sea composite pressure shells.

-

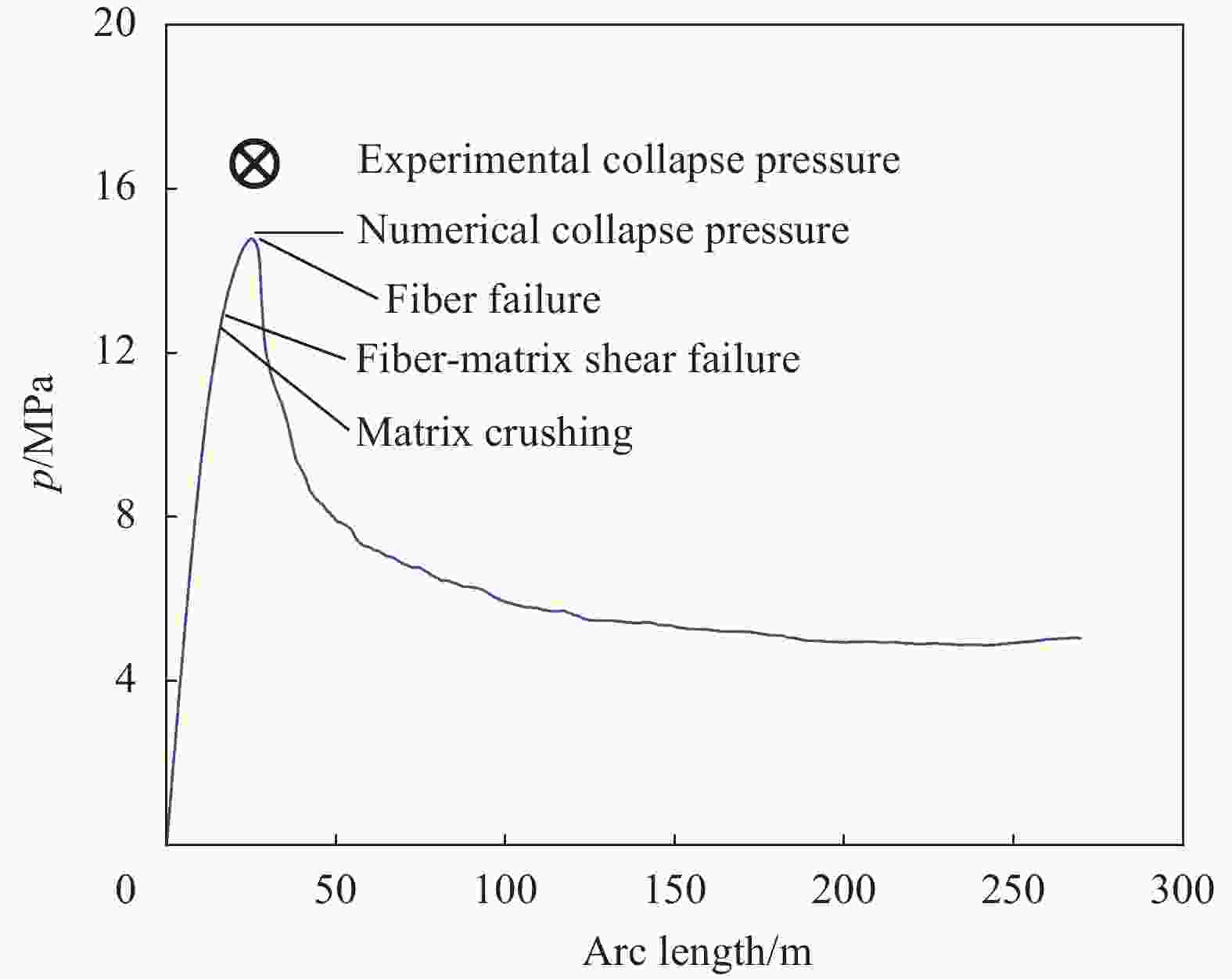

图 15 不同几何缺陷下GFRP圆柱壳静水压力与弧长p的关系

Im_0.1%R, Im_0.3%R, Im_0.5%R, Im_0.8%R, Im_1.0%R—Geometric defects of size 0.1%R, 0.3%R, 0.5%R, 1%R; R—Radius of the cylindrical shell

Figure 15. Relationship between hydrostatic pressure and arc length p of GFRP cylindrical shell under different magnitude of geometrical defects

表 1 应变测点位置信息

Table 1. Location information of strain measuring points

Axial number Location-angle Circumferential number Location-angle E5 L/6-90o E6 L/6-90o E7 L/3-90o E8 L/6-90o E9 L/2-180o E10 L/2-180o E11 L/2-180o E12 L/2-180o E13 L/2-225o E14 L/2-225o E15 L/2-247.5o E16 L/2-247.5o E17 0-270o E18 0-270o 表 2 GFRP力学参数

Table 2. Material properties of GFRP

Engineering constant Value Strength constant Value E1/GPa 41 Xt/MPa 1140 E2/GPa 10.4 Xc/MPa 620 G12/GPa 4.3 Yt/MPa 39 G23/GPa 3.5 Yc/MPa 128 v12 0.28 Sxy/MPa 89 Notes: E1, E2—Elastic modulus in fiber direction, in-plane transverse modulus; G12, G23—Shear modulus in fiber direction and in-plane transverse direction, in-plane transverse direction and out-of-plane transverse direction, respectively; v12—Poisson's ratio of fiber direction and in-plane transverse direction; Xt, Xc, Yt, Yc—Tension strength and compression strength in fiber direction and in-plane transverse direction, respectively; Sxy—Shear strength of fiber direction and in-plane transverse direction. 表 3 基于单点扰动载荷法(SPLA)的GFRP圆柱壳屈曲压力和载荷下降系数(KDF)

Table 3. Buckling load and load drop factor (KDF) of GFRP cylindrical shell based on single point disturbance loading method (SPLA)

Point Perfect model/MPa Buckling load/MPa KDF 1 18.55 15.88 0.856 2 18.55 15.75 0.849 3 18.55 15.70 0.846 4 18.55 15.75 0.849 5 18.55 15.88 0.856 表 4 基于失效模式的GFRP复合材料面内性能退化方法

Table 4. In-plane property degradation of GFRP composites based on the failure mode

Failure mode Field variable Property degradation (In-plane) FV1 FV2 FV3 → E1 E2 v12 G12 No failure 0 0 0 → E1 E2 v12 G12 Matrix cracking 1 0 0 → E1 (5%-10%)E2 0 G12 Fiber-matrix shear 0 1 0 → E1 (5%-10%)E2 0 (5%-10%)G12 Fiber failure 0 0 1 → 0.14E1 (5%-10%)E2 0 (5%-10%)G12 Notes: FV1—Field variable 1, represents matrix cracking failure if it equals to 1; FV2—Field variable 2, represents fiber-matrix shear failure if it equals to 1; FV3—Field variable 3, represents fiber failure if it equals to 1. -

[1] SMITH C S. Design of submersible pressure hulls in composite materials[J]. Marine Structures,1991,4(2):141-182. [2] CRAVEN R, GRAHAM D, DALZEL-JOB J. Conceptual design of a composite pressure hull[J]. Ocean Engineer- ing,2016,128:153-162. doi: 10.1016/j.oceaneng.2016.10.031 [3] HOM K. Composite materials for pressure hull structures[J]. Ocean Engineering,1969,1(3):315-322. [4] DAVIES P, CHOQUESUE D, BIGOURDAN B, et al. Compo-site cylinders for deep sea applications: An overview[J]. Journal of Pressure Vessel Technology Transportation, 2016, 138: 060904. [5] 谭智铎. 7000米级深海滑翔机复合材料耐压舱结构设计研究[D]. 沈阳: 东北大学, 2015.TAN Zhiduo. Research on structure design of composite pressure hulls for 7000 depth glider[D]. Shenyang: Northeastern University, 2015(in Chinese). [6] SIMITSES G J. Buckling of moderately thick laminated cylindrical shells: A review[J]. Composites Part B: Engineering,1996,27B:581-587. [7] SIMITSES G J, KARDOMATES G A. Imperfection sensitivity of moderately thick composite cylindrical shells[J]. Composites Science & Technology,2000,22(4):259-276. [8] MESSAGER T. Buckling of imperfect laminated cylinders under hydrostatic pressure[J]. Composite Structures,2001,53:301-307. doi: 10.1016/S0263-8223(01)00014-9 [9] TSOUVALIS N G, ZAFEIRATOU A A, PAPAZO-GLOU V J. The effect of geometric imperfections on the buckling behaviour of composite laminated cylinders under external hydrostatic pressure[J]. Composites Part B: Engineering,2003,34(3):217-226. [10] LI Z, SHEN K C, ZHANG X H, et al. Buckling of composite cylindrical shells with ovality and thickness variation subjected to hydrostatic pressure[J]. Defense Technology,2022(5):862-875. [11] 孙宇. 外压载荷下复合材料圆柱壳的缺陷敏感性研究[D]. 大连: 大连理工大学, 2017.SUN Yu. Imperfection sensitivity of composite cylindrical shell under external pressure[D]. Dalian: Dalian University of Technology, 2017(in Chinese). [12] CARVELLI V, PANZERI N, POGGI C. Buckling strength of GFRP under-water vehicles[J]. Composite Part B: Engi-neering,2001,32:89-101. doi: 10.1016/S1359-8368(00)00063-9 [13] HUR S H, SON H J, KWEON J H, et al. Postbuckling of composite cylinders under external hydrostatic pressure[J]. Composite Structures,2008,86:114-124. doi: 10.1016/j.compstruct.2008.03.028 [14] HAN J Y, JUNG H Y, CHO J R, et al. Buckling analysis and test of composite shells under hydrostatic pressure[J]. Journal of Materials Processing Technology,2008,201:742-745. doi: 10.1016/j.jmatprotec.2007.11.228 [15] 沈克纯, 潘光, 施瑶, 等. 静水压力下碳纤维缠绕复合材料圆柱壳体应变特性及承载能力研究[J]. 西北工业大学学报, 2020, 38(5):937-943. doi: 10.3969/j.issn.1000-2758.2020.05.003SHEN Kechun, PAN Guang, SHI Yao, et al. Exploring strain characteristics and bearing capacity of a carbon filament-wound composite cylindrical shell under hydrostaic pressure[J]. Journal of Northwestern Polytechnical University,2020,38(5):937-943(in Chinese). doi: 10.3969/j.issn.1000-2758.2020.05.003 [16] CAI B P, LIU Y H, LIU Z K, et al. Reliability-based load and resistance factor design of composite pressure vessel under external hydrostatic pressure[J]. Composite Structures,2011,93(11):2844-2852. doi: 10.1016/j.compstruct.2011.05.020 [17] DVORAK G J, PROCHAZKA P. Thick-walled composite cylinders with optimal fiber prestress[J]. Composites Part B: Engineering,1996,27(6):643-649. doi: 10.1016/S1359-8368(96)00001-7 [18] National Aeronautics and Space Administration. Buckling of thin-walled circular cylinders: NASA SP-8007[S]. Washington: NASA Special Publication, 1965. [19] SINGER J. Buckling experiments: Experimental methods in buckling of thin-walled structures[J]. Applied Mechanics Reviews,2002,56(1):1215-1220. [20] CHO Y S, OH D H, PAIK J K. An empirical formula for predicting the collapse strength of composite cylindrical-shell structures under external pressure loads[J]. Ocean Engineering,2019,172(15):191-198. [21] 周承倜. 弹性稳定理论[M]. 成都: 四川人民出版社, 1981: 119-124.ZHOU Chengti. Theory of elastic stability[M]. Chengdu: Sichuan Pepole's Publishing House, 1981: 119-124(in Chinese). [22] 张建, 周通, 王纬波, 等. 模态缺陷条件下复合材料柱形壳屈曲特性[J]. 复合材料学报, 2017, 34(3):588-596. doi: 10.13801/j.cnki.fhclxb.20160523.004ZHANG Jian, ZHOU Tong, WANG Weibo, et al. Buckling of a composite cylindrical shell considering mode imperfections[J]. Acta Materiae Compositae Sinica,2017,34(3):588-596(in Chinese). doi: 10.13801/j.cnki.fhclxb.20160523.004 [23] European Committee for Standardization. Strength and stability of shell structures: EN 1993-1-6[S]. BSI: EN Special Publication, 2007. [24] HÜHNE C, ROLFES R, BREITBACH E, et al. Robust design of composite cylindrical shells under axial compression—Simulation and validation[J]. Thin-Walled Structures,2008,46(7):947-962. [25] 王博, 田阔, 郝鹏, 等. 多级加筋板结构承载性能与缺陷敏感度研究[J]. 固体火箭技术, 2014, 37(3): 408-412.WANG Bo, TIAN Kuo, HAO Peng, et al. Load-carrying capacity and imperfection-sensitivity analysis of hierarchical stiffened panels[J]. Journal of Solid Rocket Technology, 2014, 37(3): 408-412(in Chinese). [26] WANG B, DU K F, HAO P, et al. Numerically and experimentally predicted knockdown factors for stiffened shells under axial compression[J]. Thin-Walled Structures,2016,109:13-24. doi: 10.1016/j.tws.2016.09.008 [27] WAGNER H N R, HÜHNE C, NIEMANN S. Robust knockdown factors for the design of axially loaded cylindrical and conical composite shells–Development and validation[J]. Compo-site Structures,2017,173:281-303. [28] WAGNER H N R, HÜHNE C, NIEMANN S, et al. Robust design criterion for axially loaded cylindrical shells-simulation and validation[J]. Thin-Walled Structures,2017,115:154-162. doi: 10.1016/j.tws.2016.12.017 [29] WANG B, DU K F, HAO P, et al. Experimental validation of cylindrical shells under axial compression for improved knockdown factors[J]. International Journal of Solids and Structures,2019,164:37-51. doi: 10.1016/j.ijsolstr.2019.01.001 [30] 张晓军, 刘文婷, 范士锋. 纤维缠绕复合材料结构渐进失效分析与可靠性评估[M]. 西安: 西北工业大学出版社, 2018.ZHANG Xiaojun, LIU Wenting, FAN Shifeng. Progressive failure analysis and reliability evaluation of filament wounded composite structures[M]. Xi'an: Nortwestern Polytechnical University Press, 2018(in Chinese). [31] HASHIN Z. Failure criteria for unidirectional fiber compo-sites[J]. Journal of Applied Mechanics,1980,47(2):329-334. doi: 10.1115/1.3153664 [32] HASHIN Z, ROTEM A. A fatigue failure criteria for fiber reinforced materials[J]. Journal of Composite Materials,1973(7):448-464. [33] CHANG F K, CHANG K Y. A progressive damage model for laminated composites containing stress concentrations[J]. Journal of Applied Mechanics,1987,21(9):834-855. [34] 卫宇璇, 张明, 刘佳, 等. 基于模态缺陷的变刚度复合材料圆柱壳屈曲特性[J]. 吉林大学学报(工学版), 2022, 52(1):91-100. doi: 10.13229/j.cnki.jdxbgxb20200715WEI Yuxuan, ZHANG Ming, LIU Jia, et al. Buckling performance of variable stiffness composite cylindrical shells based on mode imperfections[J]. Journal of Jilin University (Engineering and Technology Edition),2022,52(1):91-100(in Chinese). doi: 10.13229/j.cnki.jdxbgxb20200715 [35] 中国船级社. 潜水系统和潜水器入级规范[S]. 北京: 人民交通出版社, 2018.CCS. Classification specification for submersible systems and submersibles[S]. Beijing: China Communications Press, 2018. [36] QATU M S, SULLIVAN R W, WANG W. Recent research advances on the dynamic analysis of composite shells: 2000-2009[J]. Composite Structures,2010,93(1):14-31. doi: 10.1016/j.compstruct.2010.05.014 [37] LEE G C, KWEON J H, CHOI J H. Optimization of compo-site sandwich cylinders for underwater vehicle application[J]. Composite Structures,2013,96(4):691-697. [38] 李彬, 庞永杰, 程妍雪, 等. 基于铺层参数的复合材料耐压壳协同优化设计[J]. 上海交通大学学报, 2017, 51(3):308-315. doi: 10.16183/j.cnki.jsjtu.2017.03.010LI Bin, PANG Yongjie, CHENG Yanxue, et al. Collaborative optimization for composite material pressure hull based on lamination parameters[J]. Journal of Shanghai Jiaotong University,2017,51(3):308-315(in Chinese). doi: 10.16183/j.cnki.jsjtu.2017.03.010 [39] IMRAN M, SHI D Y, TONG L L, et al. Design optimization of egg-shaped composite submersible pressure hull for minimum buoyancy factor[J]. Defence Technology,2021,17(6):1817-1832. doi: 10.1016/j.dt.2020.11.002 -

下载:

下载: