Effect law and mechanism of ceramic tile powder on compressive strength of ultra high performance concrete

-

摘要: 超高性能混凝土极低的水胶比和较高的水泥用量,使其在广泛应用中面临着水泥基体高自收缩和高成本等问题,而使用工业副产品或废弃物取代部分水泥是有效的解决方法之一。废品瓷砖已成为一种大宗工业废弃物,应用瓷砖粉在超高性能混凝土中可有效地解决水泥的高消耗和废弃瓷砖的堆积问题。因此,使用瓷砖粉取代水泥质量的10wt%、15wt%、20wt%和25wt%来制备新型绿色低碳超高性能混凝土,主要研究了瓷砖粉对超高性能混凝土抗压强度的影响规律,并采用修正Andreasen堆积模型、XRD分析、TG/DTG、SEM观察探讨了瓷砖粉对超高性能混凝土的改性机制,同时对瓷砖粉超高性能混凝土的环境足迹和成本进行了分析。研究结果表明,瓷砖粉的掺入对超高性能混凝土各龄期抗压影响在±10%以内,但对7~28天和28~60天的抗压强度发展影响显著,在25wt%掺量时抗压强度增长率分别达到了104.6%和51.8%。这主要是由于瓷砖粉的掺入提高了超高性能混凝土的堆积密实度,发生二次水化反应并生成了低钙硅比的水化硅酸钙凝胶,提高了水泥的水化程度,降低了界面过渡区的宽度。并且由环境影响和成本计算可知,瓷砖粉可有效降低超高性能混凝土的能耗、CO2排放量和成本。Abstract: Ultra high performance concrete (UHPC) is faced with the problems of high cost and high self-shrinkage of cement matrix due to its extremely low water-binder ratio and high cement content in its wide application. One of the effective solutions is to replace part of cement with industrial by-products or wastes. As the waste ceramic tile has become a large amount of industrial waste, the application of ceramic tile powder in UHPC can effectively solve the problems of high consumption of cement and accumulation of waste ceramic tile. Therefore, ceramic tile powder was used to replace 10wt%, 15wt%, 20wt% and 25wt% by mass of cement to prepare a new type of green low-carbon UHPC. The effect law of ceramic tile powder on the compressive strength of UHPC was studied, and the modified Andreasen accumulation model, XRD analyses, TG/DTG, SEM observation were used to investigate the modification mechanisms, and the environmental footprint and the cost of ceramic tile powder on UHPC were also analyzed. The results show that the effect of the addition of ceramic tile powder on the compressive strength of UHPC is within ±10% at all age. Interestingly, ceramic tile powder has a significant influence on the development of compressive strength at 7-28 days and 28-60 days, and the increase rates of compressive strength of UHPC with 25wt% ceramic tile powder can reach 104.6% and 51.8%, respectively. This is mainly because that the addition of ceramic tile powder improves the packing compactness of UHPC, produces secondary hydration reaction and calcium silicate hydrate gel with low calcium-silicon ratio, improves the hydration degree of cement, and reduces the width of interface transition zone. According to environmental impact and cost calculation, ceramic tile powder can effectively reduce energy consumption, CO2 emission and cost of UHPC.

-

超高性能混凝土具有超高强、高韧性、高耐久性的特点,在工程实践中具有广泛的应用前景[1-5]。同时,由于水泥用量大,使得超高性能混凝土中的水泥基体早期的自收缩和内外温差增大,提高了水泥基体早期开裂风险。目前,在超高性能混凝土中引入纤维和利用工业副产品或废弃物取代部分水泥是比较有效的方法。其中后者不仅可改善混凝土的性能、降低能耗和成本,也可解决废弃物的堆积问题,实现废弃物资源化利用[6-9]。

瓷砖作为常用的建筑装饰材料,全球年产量约为130亿平方米,且生产过程中会有3%~7%的废品率,即每年全球约有3.9~9.1亿平方米的瓷砖废弃堆积[10-11]。而瓷砖的主要成分为SiO2和Al2O3,因此磨细后的瓷砖粉可能具有一定的火山灰活性,可以替代部分水泥制备胶凝复合材料[12-15],解决废弃瓷砖的资源化利用问题。

近年来,研究者们进行了许多瓷砖粉替代水泥对水泥基复合材料力学性能的影响研究。Babria等[16]研究了瓷砖粉替代水泥对普通混凝土抗压强度的影响,研究结果表明20%瓷砖粉替代水泥的混凝土7天和28天抗压强度分别达到24 MPa和31.84 MPa,比不用瓷砖粉替代水泥的普通混凝土分别高出54.24%和20.49%。Li等[13]发现瓷砖粉替代10%水泥的砂浆28天抗压强度达到86 MPa,比不用瓷砖粉替代水泥的普通砂浆高出约7%。Bhargav等[17]研究了用5%~20%瓷砖粉替代水泥对普通混凝土抗折强度的影响,研究结果表明随着瓷砖粉掺量的增加,普通混凝土抗折强度从7.14 MPa增加到7.76 MPa,当瓷砖粉替代率为15%时,普通混凝土抗折强度达到8.21 MPa,其抗折强度最大提高14.99%。Li等[18]研究了不同水灰比下瓷砖粉掺量对水泥砂浆抗压强度的影响,其研究结果表明瓷砖粉的掺入可增加水泥砂浆的抗压强度。当水灰比为0.40时,掺20%瓷砖粉的水泥砂浆的7天抗压强度从37.1 MPa增加到了72.4 MPa,增长率可达95.15%;当水灰比为0.55时,掺20%瓷砖粉的水泥砂浆7天抗压强度从23.9 MPa增加到了48.6 MPa,增长率为103.35%。除此之外,Mohit等[19]的研究表明随着瓷砖粉掺量的增大,水泥砂浆的7天抗压强度从39.88 MPa下降到31.97 MPa,最大下降19.83%,56天抗压强度由49.95 MPa下降到44.96 MPa。Kumar等[20]也研究了不同瓷砖粉掺量对普通混凝土抗折强度的影响,其研究结果表明0%~30%瓷砖粉的掺入均会导致普通混凝土抗折强度降低。

综上可知,现有研究主要集中在瓷砖粉对砂浆和普通混凝土力学性能的影响,同时瓷砖粉对水泥基复合材料的影响机制尚不明晰。因此,本研究使用瓷砖粉替代10%~25%的水泥制备绿色低碳超高性能混凝土。研究了瓷砖粉对超高性能混凝土抗压强度的影响规律。并从堆积密实度、物相分析、Ca(OH)2含量、水化程度、界面过渡区和钙硅比等方面分析了瓷砖粉对超高性能混凝土力学性能的改性机制。为了评估瓷砖粉超高性能混凝土的环境效益,计算了瓷砖粉超高性能混凝土的材料可持续性指标(Material sustainability indicators,MSIs)和成本。本研究旨在利用瓷砖废料制备超高性能混凝土,以达到降低超高性能混凝土能耗与成本的同时,解决废弃瓷砖堆积对土地的占用和环境的污染。

1. 原材料和试验设计

1.1 原材料

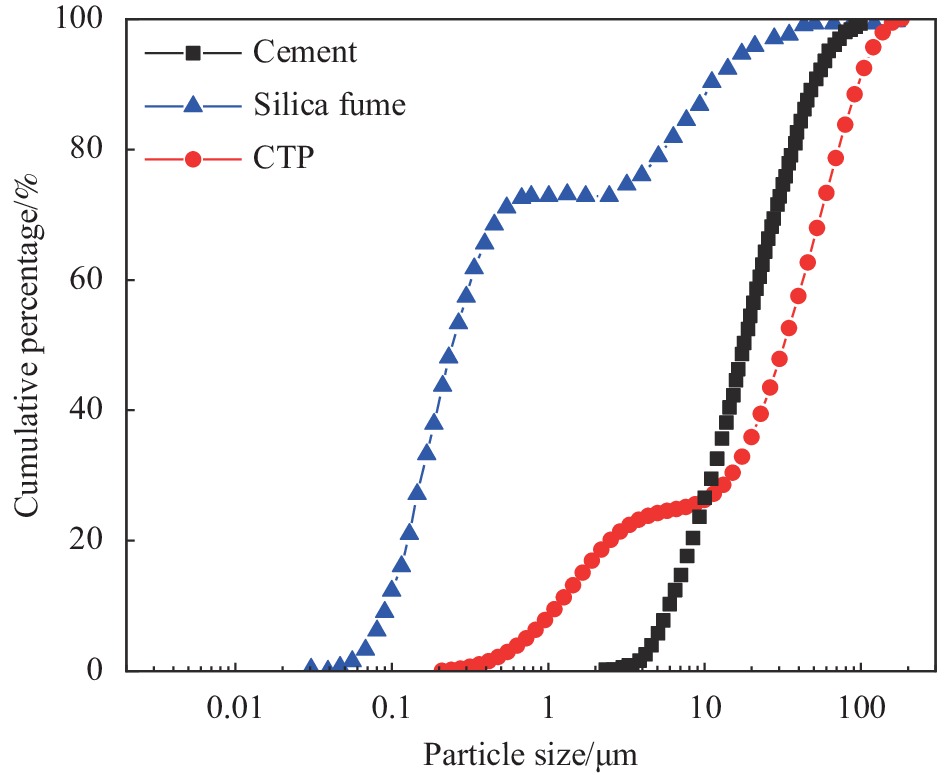

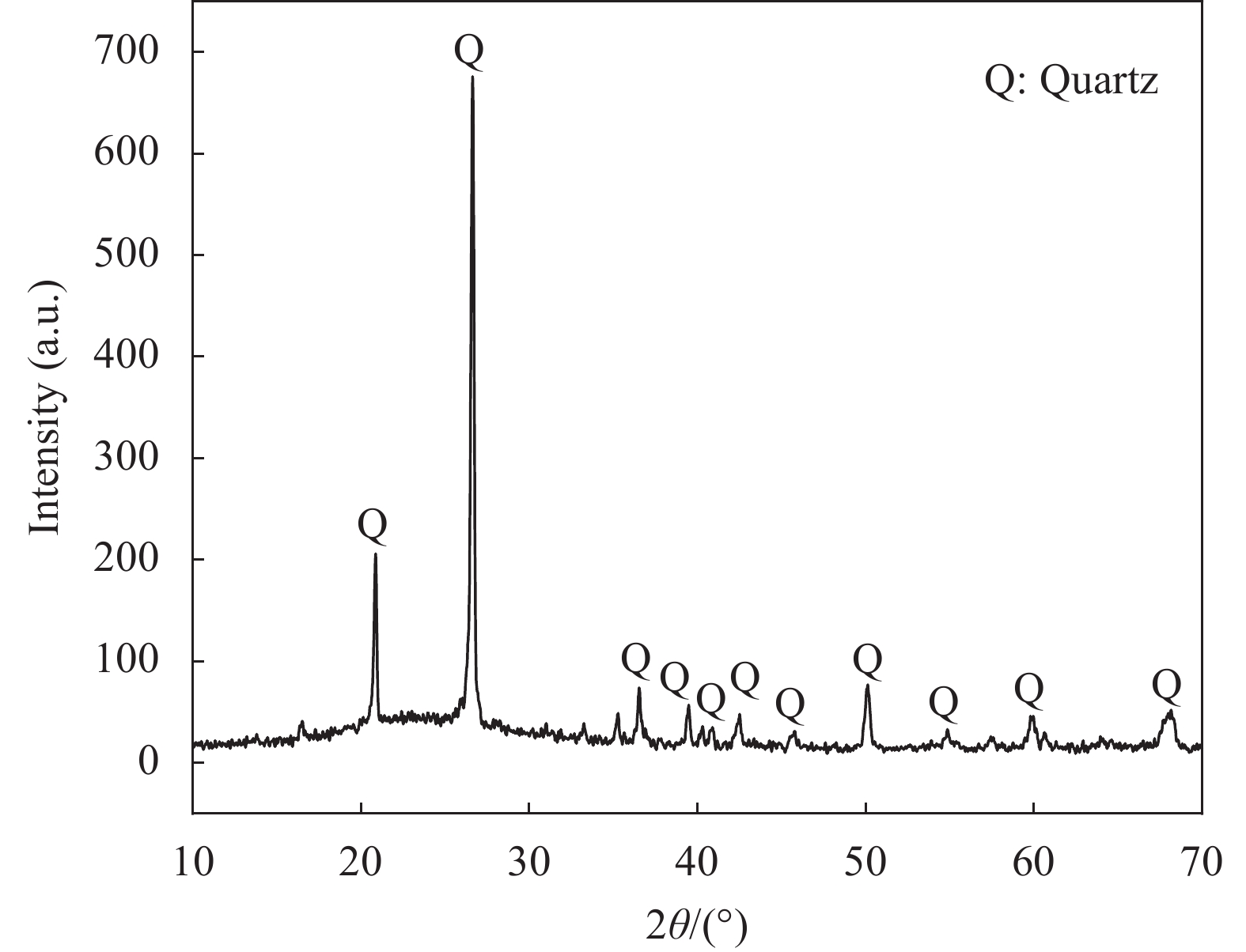

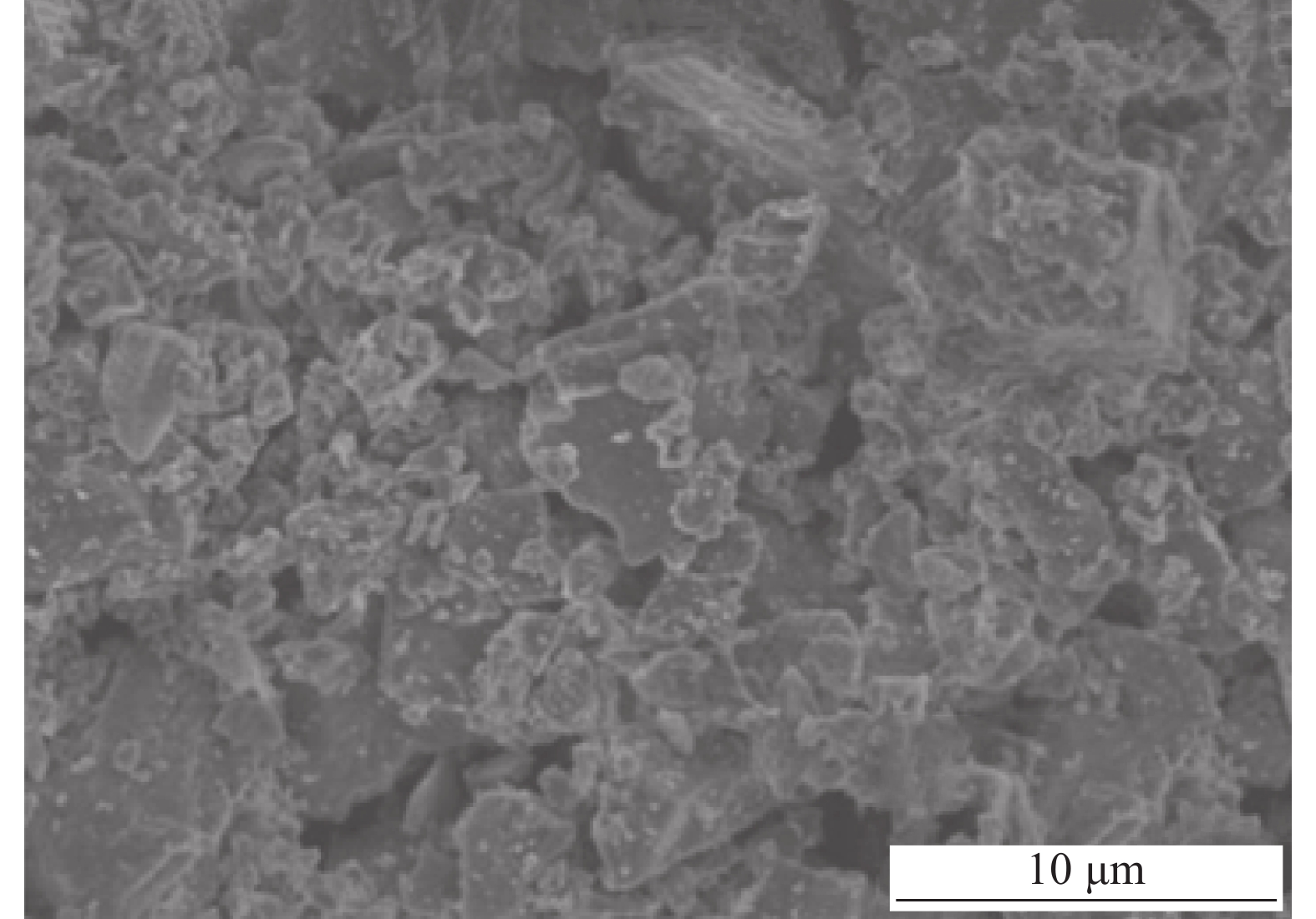

试验用到的材料主要有水泥、瓷砖粉、硅灰、石英砂、钢纤维、减水剂和水。使用的水泥为P·O52.5普通硅酸盐水泥,比表面积和平均粒径分别为408 m2/kg和20 μm,化学成分和粒径分布分别见表1和图1。瓷砖粉是由废弃瓷砖在球磨机(长沙米淇仪器设备有限公司,YXQM-4L)中粉磨2 h获得,XRD图谱和化学成分分别如图2和表1所示,瓷砖粉的主要化学成分是SiO2且为多菱角不规则颗粒(如图3所示),平均粒径在30 μm左右,小于水泥粒径的颗粒占比20%左右(如图1所示)。硅灰的化学组成和粒径分布分别如表1和图1所示。石英砂的SiO2的含量大于99%,密度为2.65 g/cm3,莫氏硬度为7,选用粗细两种粒径按1∶1比例混合使用。粗细石英砂的粒径范围分别为0.6~2.6 mm和5~240 μm。钢纤维直径为0.2 mm,长度为13 mm,抗拉强度≥2700 MPa。试验采用的减水剂为聚羧酸高效减水剂,固含量为45%,减水率≥60%。

表 1 水泥、瓷砖粉(CTP)和硅灰的化学组成Table 1. Chemical compositions of cement, ceramic tile powder (CTP) and silica fumeChemical composition Cement/wt% CTP/wt% Silica fume/wt% SiO2 22.35 78.3 95.7 Al2O3 6.30 15.9 − CaO 55.73 0.9 − Fe2O3 4.91 − − Na2O 0.07 1.9 0.11 K2O 0.68 2.1 0.45 MgO 2.84 0.8 − SO3 2.47 − − R2O − − 0.39 Cl− − − 0.02 LOI 1.15 − 2.95 Note: LOI—Limit oxygen index. 1.2 试样制备与养护

1.2.1 配合比设计

超高性能混凝土的水胶比一般在0.14~0.20[21-22],本文水胶比固定为0.18。通过总结前期有关制备超高性能混凝土的试验研究[23-24],确定超高性能混凝土的胶砂比为1∶1。胶凝材料由水泥、硅灰和CTP组成,其中硅灰的掺量固定为胶凝材料质量的10wt%,而瓷砖粉的掺量为CTP占胶凝材料的质量分数,分别为10wt%、15wt%、20wt%和25wt%。减水剂掺量为胶凝材料质量的1.5%,钢纤维掺量为单位混凝土体积的2%。具体的配合比如表2所示。

表 2 不同CTP掺量超高性能混凝土(UHPC)的配合比Table 2. Mix proportions of ultra high performance concretes (UHPC) with different contents of CTP(kg·m−3) Specimen code Binder Water Sand Steel fiber SP Cement Silica fume CTP UHPC(0wt%CTP) 1026.0 114.0 0.0 205.2 1140.0 156.0 17.1 UHPC(10wt%CTP) 912.0 114.0 114.0 205.2 1140.0 156.0 17.1 UHPC(15wt%CTP) 855.0 114.0 171.0 205.2 1140.0 156.0 17.1 UHPC(20wt%CTP) 798.0 114.0 228.0 205.2 1140.0 156.0 17.1 UHCP(25wt%CTP) 741.0 114.0 285.0 205.2 1140.0 156.0 17.1 Note: SP—Superplasticizer. 1.2.2 试样制备

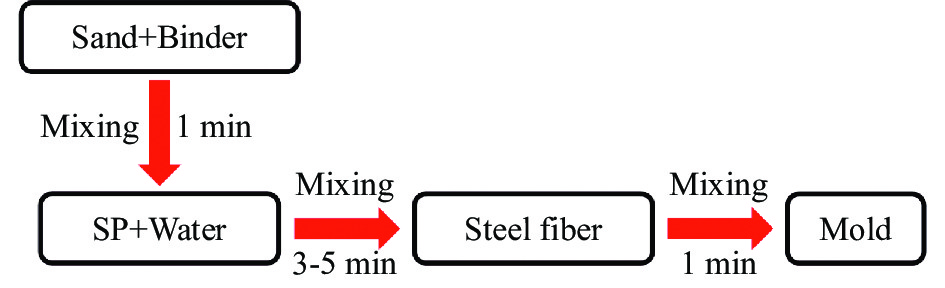

将石英砂、瓷砖粉、水泥、硅灰按顺序投入混凝土搅拌机中,搅拌1 min,之后将减水剂加入搅拌均匀的干混料中,接着将所有水加入搅拌机中搅拌3~5 min,加入钢纤维,继续搅拌1 min,然后装入模具,并振捣。具体步骤如图4所示。

1.2.3 试样养护

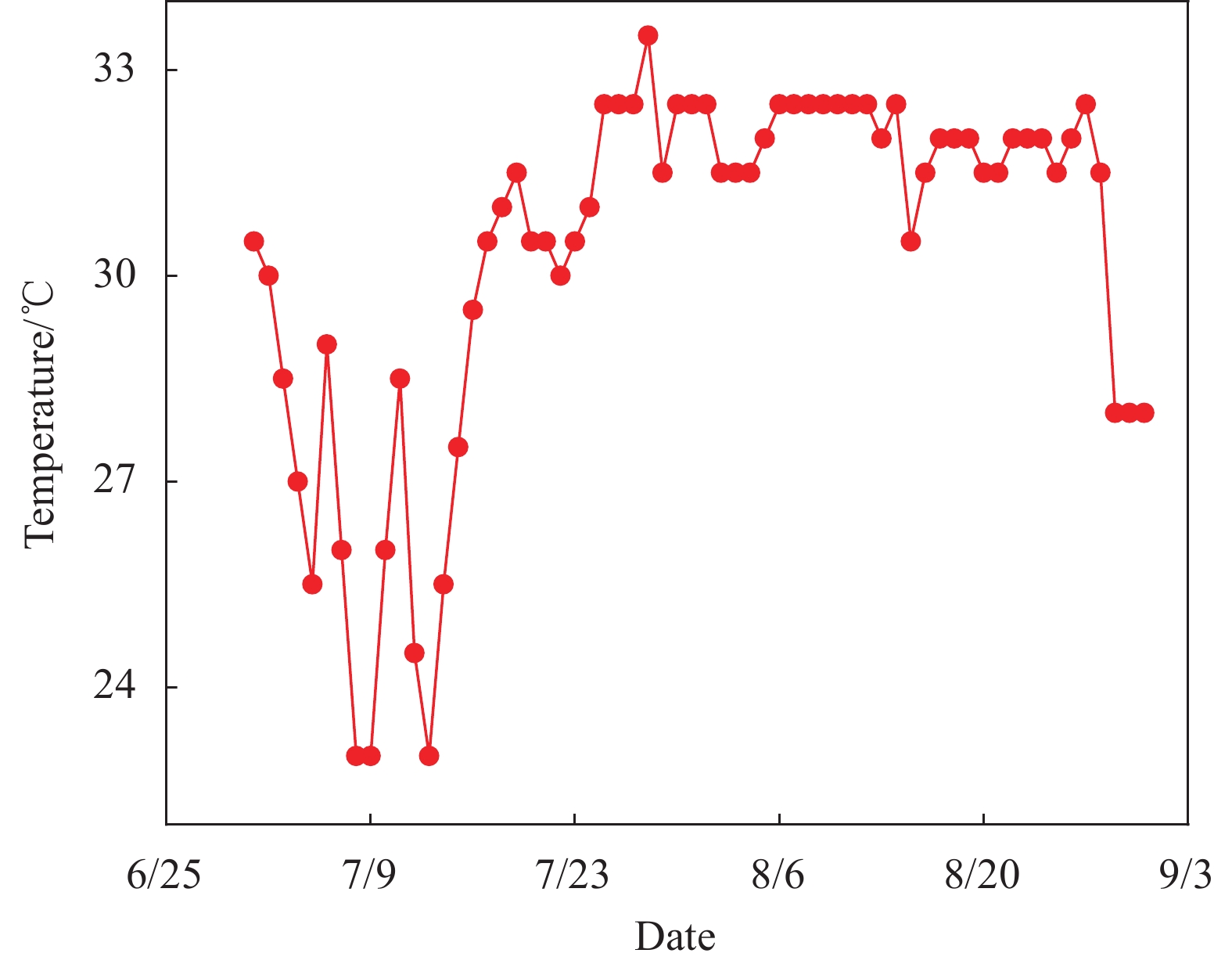

为了更符合混凝土的实际服役环境,本文采用室外环境中覆盖湿毛毡布的方法对超高性能混凝土进行养护。试验所在地点为江西省南昌市,试验进行时间为6~9月,其平均温度分布如图5所示。

1.3 试验测试方法

1.3.1 抗压性能试验

使用WHY-2000型200 t液压伺服压力试验机测试超高性能混凝土3天、7天、28天和60天龄期的抗压强度。试验方法参照《普通混凝土力学性能试验方法标准》(GB/T 50081—2002[25])进行。

1.3.2 堆积密实度计算

根据修正的Andreasen模型公式[26],并使用颗粒优化软件Emma计算得到5组配合比的堆积模型曲线。各配比计算曲线与理论模型曲线的接近程度通过残差平方和评价。残差平方和越小,表示超高性能混凝土堆积密实度越大,计算公式如下:

SRSS=n∑i=1(Pmix(Di)−Ptar(Di))2 (1) 式中:SRSS 表示残差平方和; Pmix(Di)表示各配比计算曲线中粒径小于直径Di的颗粒累积百分比;Ptar(Di)表示理论模型曲线中粒径小于直径Di的颗粒累积百分比。

1.3.3 X射线衍射试验

对用于物相分析的试样进行破碎取样,随后用无水乙醇浸泡终止水化,测试前将样品放入50℃的烘箱(上海一恒科学仪器有限公司,DZF-6024)内烘干,并将样品研磨至小于45 μm,用日本岛津公司生产的型号为XRD-6100 X射线衍射仪对7天和28天龄期不同瓷砖粉掺量超高性能混凝土的水化产物进行物相分析。

1.3.4 热重分析试验

对用于热重分析(TG/DTG)的试样进行破碎取样,随后用无水乙醇浸泡终止水化,测试前将样品放入50℃的烘箱内烘干,并将样品研磨至小于45 μm,用美国PE公司生产的TGA 4000型热重分析仪器对7天和28天龄期样品进行TG分析。样品在氮气环境中以10℃/min的升温速率从30℃加热到1000℃。根据TG/DTG曲线可以确定Ca(OH)2分解的温度范围,再根据下式计算得出Ca(OH)2含量[27]:

NCH=MCHMHΔmCH (2) 式中:NCH表示Ca(OH)2含量;MCH和MH分别为Ca(OH)2和水的摩尔质量; ΔmCH为由Ca(OH)2分解而造成的质量损失(%)。

然后根据TG/DTG曲线和参考文献[28]提供的公式计算出样品7天和28天的水化程度,计算公式如下:

βt=M105−M1000−MCaCO3MWater−Full (3) 式中:βt表示水化程度;t为水化时间;M105 表示105℃热处理2 h后的超高性能混凝土净浆的质量(g);M1000表示1000℃热处理2 h后的超高性能混凝土净浆的质量(g);MCaCO3 表示超高性能混凝土净浆在加热过程中因CaCO3分解引起的质量变化(g);MWater-Full表示1 g水泥充分水化所需用水量(g),根据参考文献[29]的调查结果,本文采用的MWater-Full值为0.256。

1.3.5 扫描电子显微镜试验

对用于扫描电子显微镜(SEM,日立分析仪器有限公司。SU8010型)的试样采用切割机(江苏东成电动工具有限公司,09-100S)切取薄片状试样,用无水乙醇浸泡3天终止水化,将样品放入50℃的烘箱内烘干,测试前,用砂纸将样品磨平,以保证其观察面和底面平整。

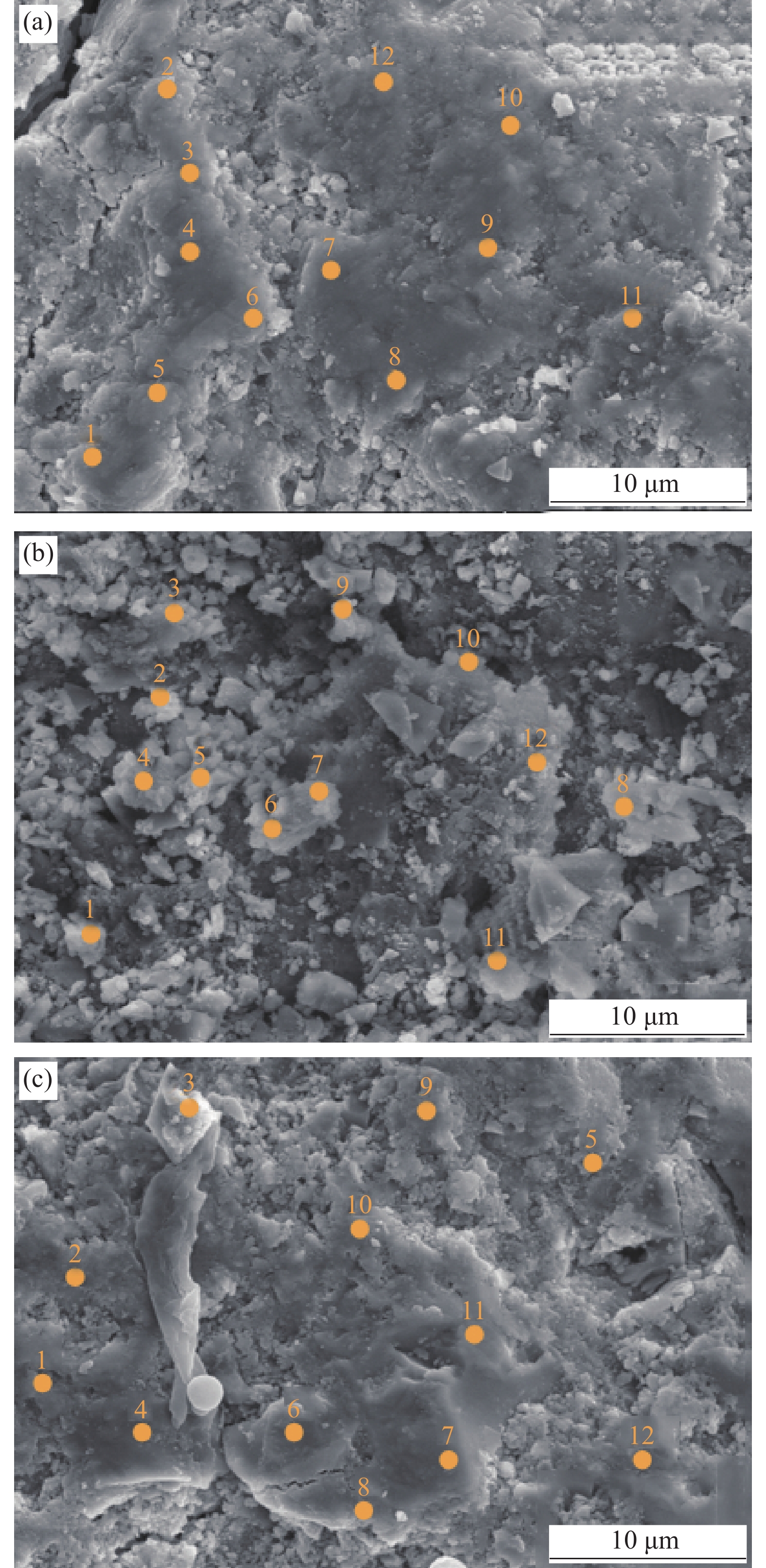

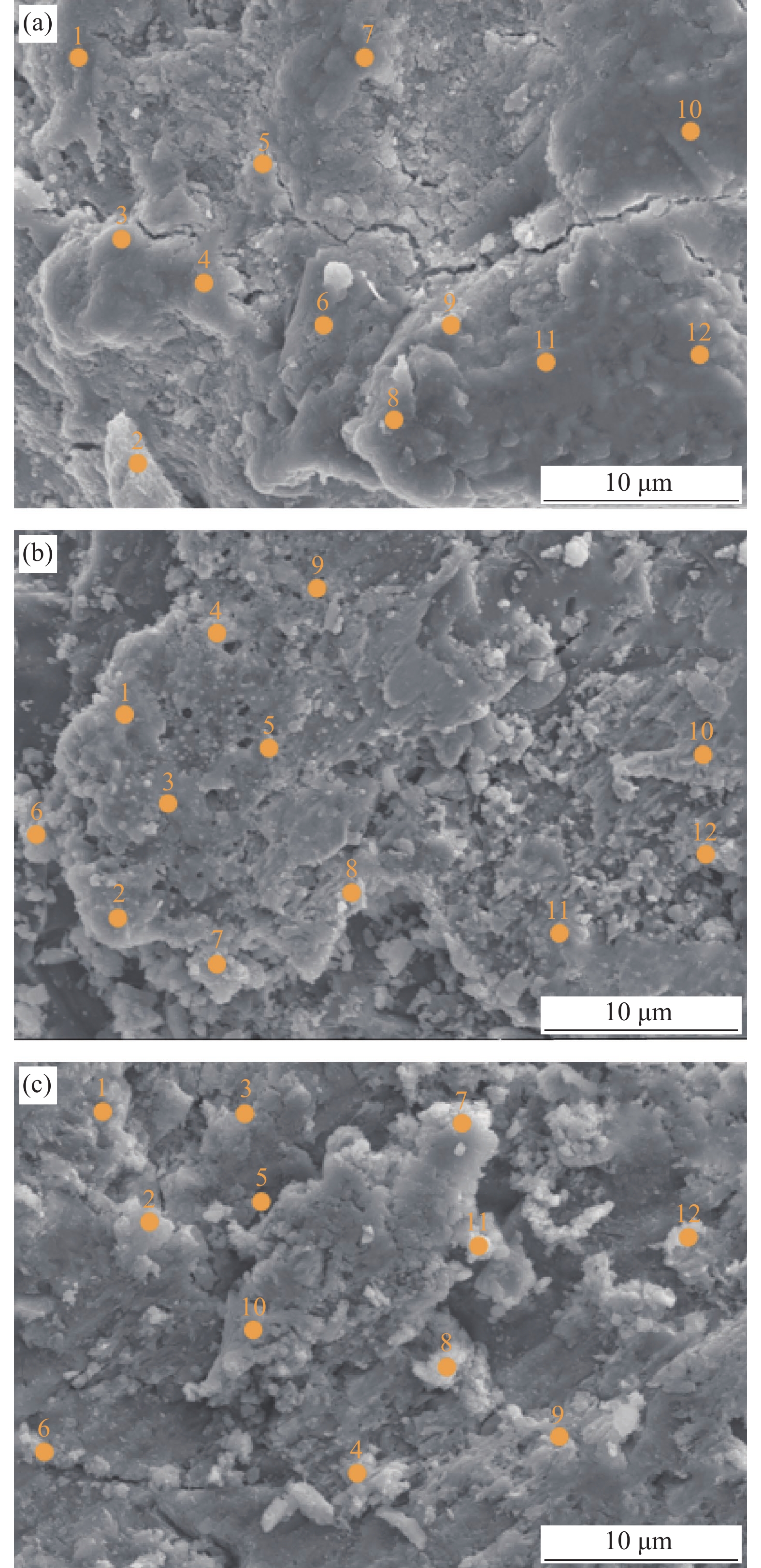

界面过渡区试验是在HITACHI SU8010型ESEM仪器的5 kV加速电压下进行的。根据参考文献[30-33],界面过渡区试验使用了二次电子成像模式,二次电子成像模式分辨率高,能够更好地表现超高性能混凝土试样的表面细节,适合于分析超高性能混凝土样品断裂面和早期水化产物等。随后采用图像处理软件Image J对图像进行条形分割,并计算出每个条形像素的灰度值,最后取20个条形像素灰度值的平均值用以表征整个区域的灰度值变化,通过像素灰度值的变化计算出超高性能混凝土中界面过渡区的宽度;在15 kV加速电压下,使用二次电子成像模式,进行能谱分析(EDS),测试水化硅酸钙凝胶的钙硅比,测试时每个试样选择10个视场,每个视场选择12个水化产物点,一共120个数据点,最后其平均值来表征某个特定配合比下的钙硅比。

2. 结果与分析

2.1 瓷砖粉超高性能混凝土力学性能

2.1.1 瓷砖粉超高性能混凝土抗压强度

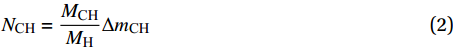

不同瓷砖粉掺量超高性能混凝土3天、7天、28天和60天的抗压强度及其增长率如图6所示。可知,同一瓷砖粉掺量的超高性能混凝土,其抗压强度随着龄期的增长而增加;同一龄期的材料,其抗压强度随着瓷砖粉掺量的增加大体上呈现先增后减的趋势。其中,10wt%掺量的瓷砖粉对抗压强度的增幅最大,3天、7天、28天和60天龄期的增长率分别为8.1%、4.7%、10.1%和9.5%;瓷砖粉掺量为20wt%时,对抗压强度的增幅最小,各龄期的增长率分别为−1.2%、−7.3%、2.8%和3.1%,但其在3天和7天龄期的抗压强度仍达到了113.3 MPa和121.1 MPa。整体上看,在瓷砖粉掺量范围内,瓷砖粉对超高性能混凝土各个龄期的抗压强度的影响基本都在±10%以内,则瓷砖粉对超高性能混凝土的抗压强度影响不大。

2.1.2 瓷砖粉超高性能混凝土抗压强度增长

图7为不同瓷砖粉掺量超高性能混凝土0~3天、3~7天、7~28天和28~60天抗压强度的增长值和增长率。可知,0~3天的抗压强度增长,在瓷砖粉掺量为10wt%时最大达到123.9 MPa,且随着瓷砖粉掺量的增加而下降,但在25wt%掺量时仍达到了114.0 MPa,与不用瓷砖粉替代水泥的普通超高性能混凝土相比仅仅下降了0.6%,说明瓷砖粉的掺入对0~3天抗压强度的发展影响不大。7~28天和28~60天的抗压强度增长随着瓷砖粉掺量的增加而增加,在25wt%掺量时增长的相对值分别达到了104.6%和51.8%,说明瓷砖粉的掺入对7~28天和28~60天超高性能混凝土抗压强度的发展有显著的积极作用。

2.2 瓷砖粉超高性能混凝土机制分析

2.2.1 瓷砖粉超高性能混凝土堆积密实度

不同CTP掺量超高性能混凝土堆积模型曲线和残差平方和SRSS计算结果分别如图8和图9所示。由图8可知,5组不同CTP掺量超高性能混凝土堆积模型曲线在0.2~110 μm之间存在差异,与瓷砖粉的粒径范围相同,且随着CTP掺量的增加,不同CTP掺量超高性能混凝土粒径分布曲线越靠近理论曲线。由图9可知,不同CTP掺量超高性能混凝土的残差平方和SRSS随着CTP掺量的增加而下降,与不用CTP替代水泥的普通超高性能混凝土相比,25wt%CTP掺量超高性能混凝土的残差平方和SRSS下降了22.5%。因此,CTP的掺入提高了超高性能混凝土体系的堆积密实度。

2.2.2 瓷砖粉超高性能混凝土物相分析

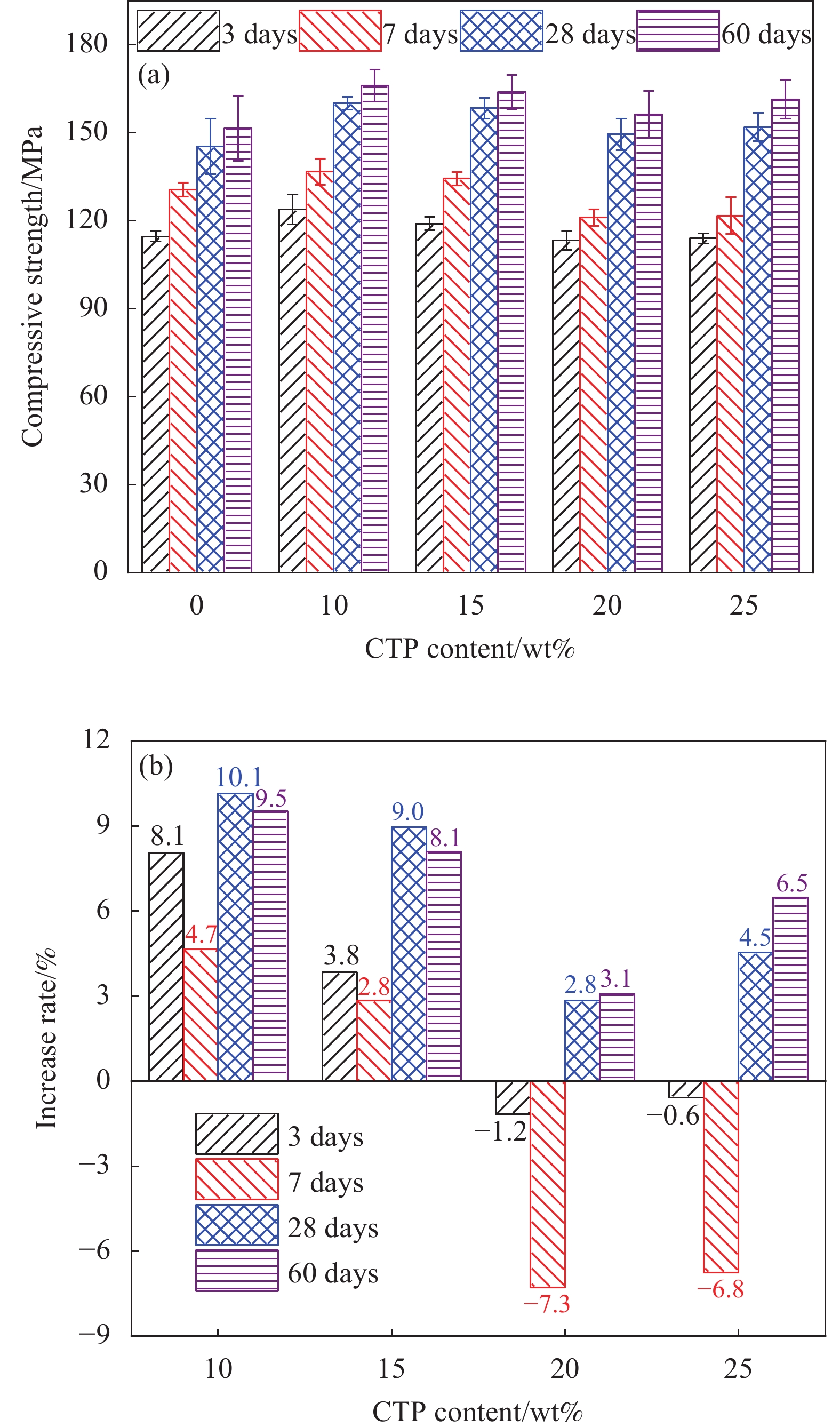

不同CTP掺量超高性能混凝土7天和28天的XRD图谱如图10所示。可知,不同CTP掺量超高性能混凝土的水化产物组成在7天和28天时基本相同。钙矾石、Ca(OH)2、硅酸二钙和石英是XRD图谱中最明显的结晶相。随着CTP掺量的增加,Ca(OH)2的峰值强度逐渐降低,表明瓷砖粉具有火山灰活性,可以消耗Ca(OH)2生成更多的水化产物。除此之外,加入CTP后,钙矾石的峰值强度逐渐降低。而在早期水化过程中,随着CTP掺量的增加,钙矾石的峰值强度略有增加,表明CTP超高性能混凝土在早期水化过程中能够形成大量的钙矾石,导致CTP超高性能混凝土的早期抗压强度降低。

2.2.3 瓷砖粉超高性能混凝土Ca(OH)2含量

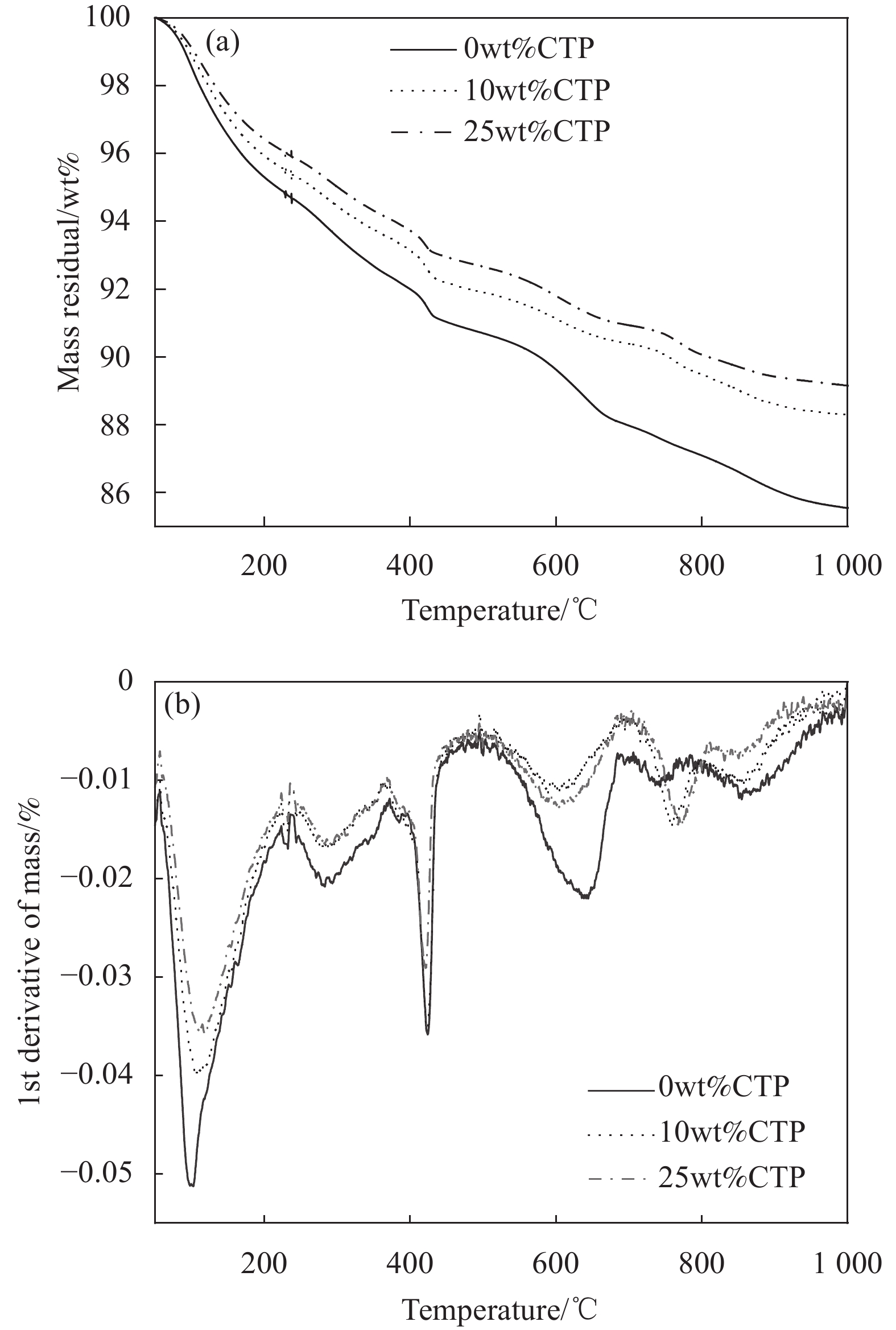

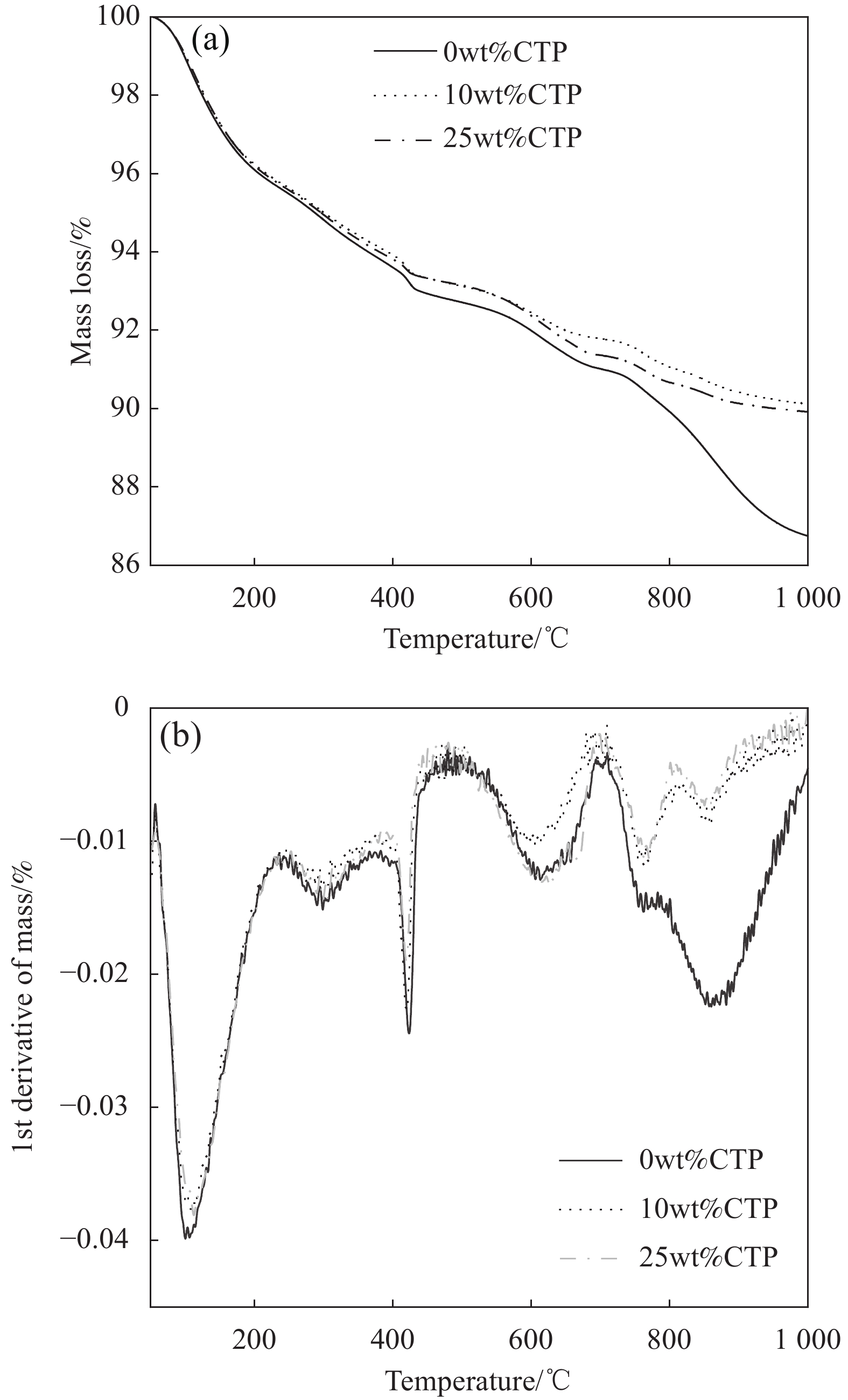

不同瓷砖粉掺量超高性能混凝土7天和28天的TG-DTG曲线及Ca(OH)2含量的计算结果分别如图11~13所示。由图13可知,7天和28天龄期表现出相同的规律,同一龄期时,Ca(OH)2含量随着瓷砖粉掺量的增加而下降。瓷砖粉掺量为25wt%时,Ca(OH)2含量最小,7天和28天龄期时分别为5.9%和4.0%,与不用瓷砖粉替代水泥的普通超高性能混凝土相比分别降低了16.0%和21.6%。同一瓷砖粉掺量时,Ca(OH)2含量随着龄期的增长而降低,瓷砖粉掺量为10wt%和25wt%时,7~28天的Ca(OH)2含量分别降低了2.2%和1.9%,下降率分别达到32.8%和32.3%,均大于不用瓷砖粉替代水泥的普通超高性能混凝土。这表明除硅灰发生火山灰反应消耗Ca(OH)2以外,瓷砖粉的掺入,进一步降低了Ca(OH)2含量,说明瓷砖粉可以和Ca(OH)2发生二次水化反应生成水化硅酸钙凝胶,具备火山灰活性。

2.2.4 瓷砖粉超高性能混凝土水化程度

图14为不同 CTP掺量超高性能混凝土的水化程度及其增长率。可知,在同一龄期时,超高性能混凝土的水化程度随着CTP掺量的增加呈现先减后增的趋势,其中掺25wt%CTP的超高性能混凝土7天和28天的水化程度分别达到55.8%和49.4%,与不用CTP替代水泥的普通超高性能混凝土相比分别提升了7.3%和降低了7.5%,这表明CTP的掺入提高了超高性能混凝土中水泥的早期水化程度,对水泥的水化有一定的促进作用。水化程度的提高主要有两方面原因:(1) CTP中粒径小于水泥的颗粒起到晶核作用,促进了水泥熟料的水化[34-35];(2) CTP与Ca(OH)2发生二次水化反应生成水化硅酸钙凝胶[36]。与10wt%掺量组相比,25wt%CTP掺量超高性能混凝土的水化程度更高,但是对应的抗压强度却更低,这可能是由于水泥含量的下降,使超高性能混凝土中水化硅酸钙凝胶的绝对含量降低。

2.2.5 瓷砖粉超高性能混凝土界面过渡区宽度

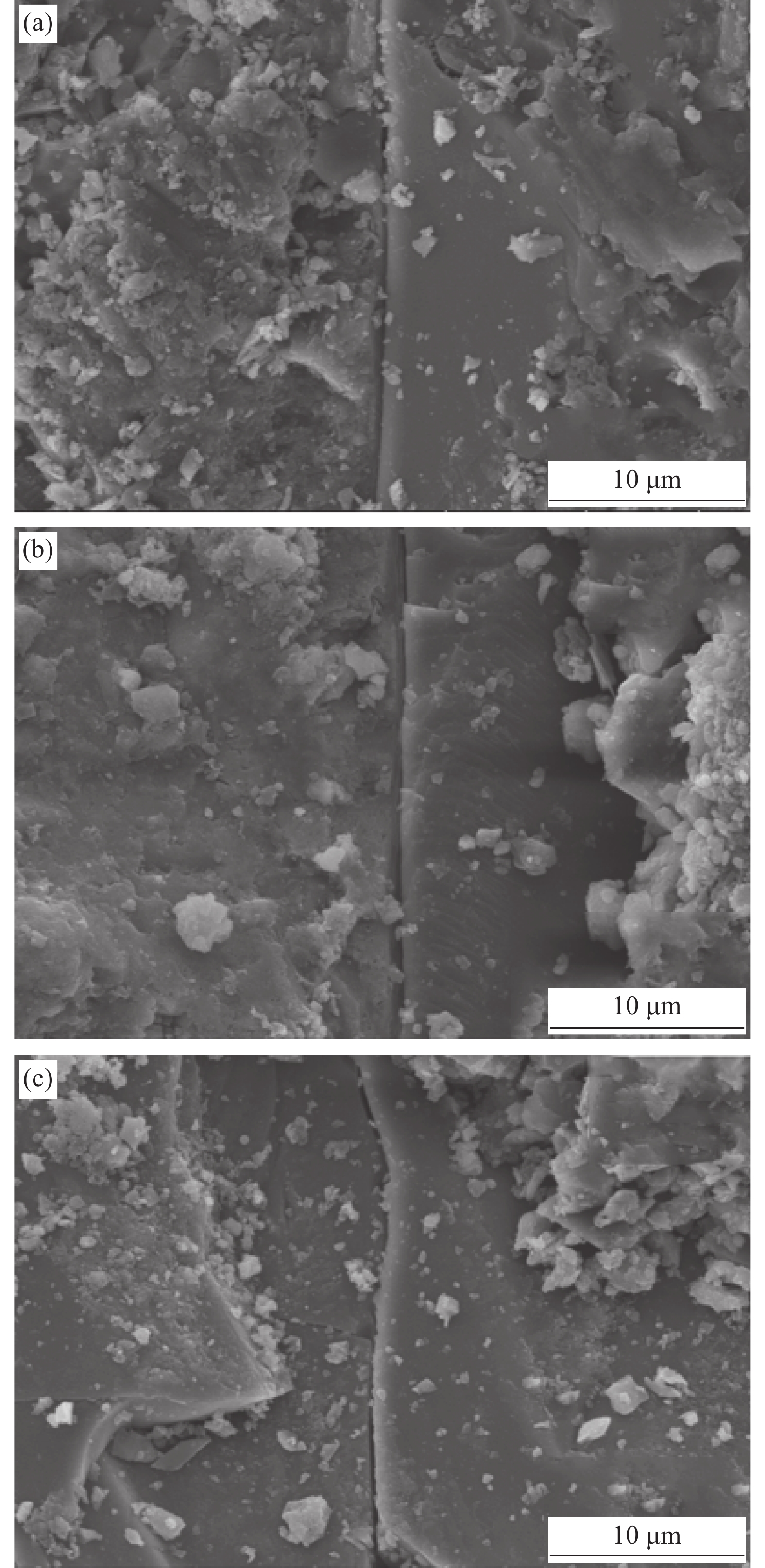

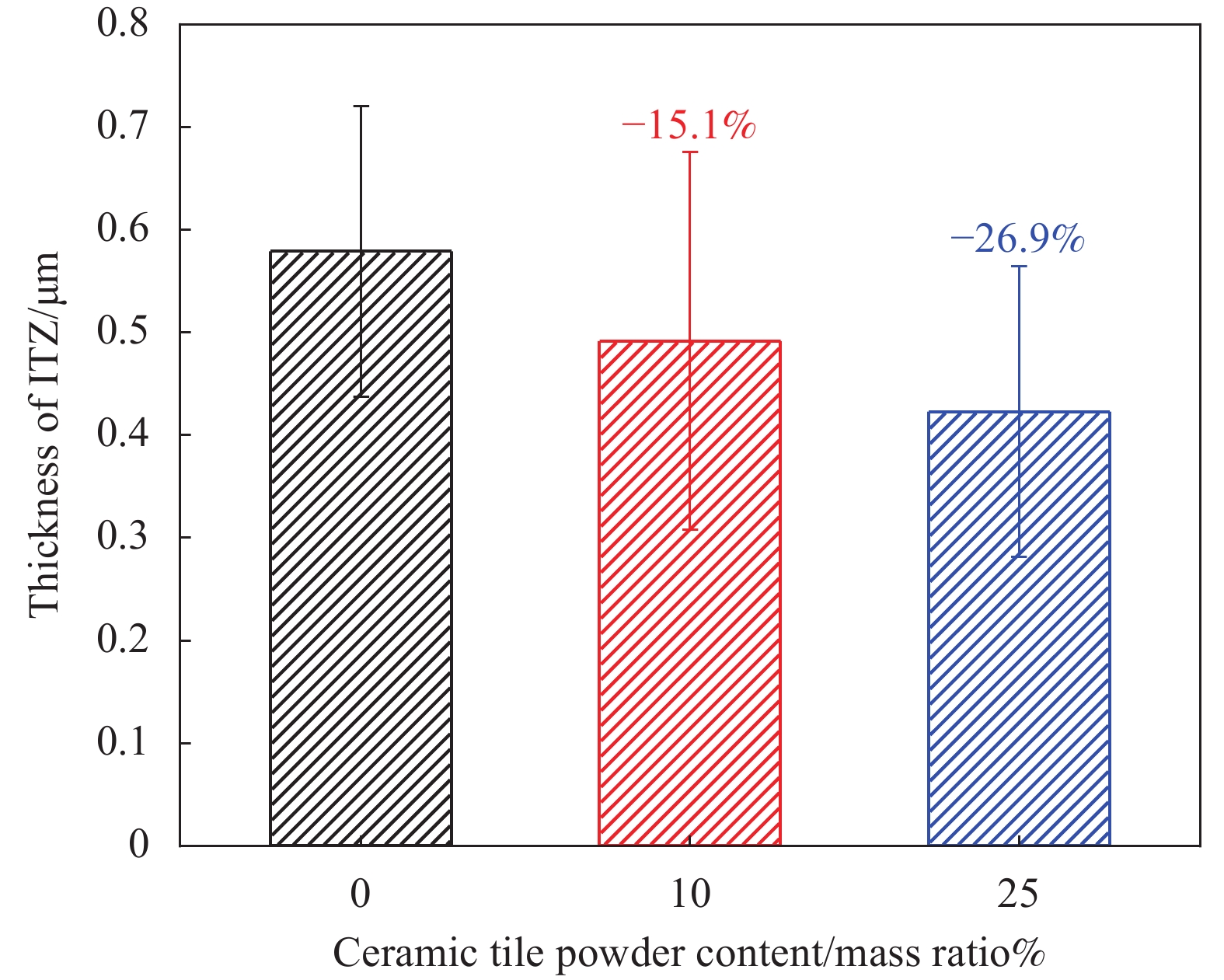

图15和图16分别为7天龄期时不同CTP掺量超高性能混凝土的界面过渡区SEM图像及其界面过渡区宽度计算结果。由图16可知,7天龄期时,CTP的掺入显著降低了界面过渡区宽度,且界面过渡区宽度随着CTP掺量的增加而减小。与不用CTP替代水泥的普通超高性能混凝土相比,10wt%和25wt%CTP掺量的超高性能混凝土的界面过渡区宽度分别降低了15.1%和26.9%。界面过渡区宽度的降低可能是由于CTP的火山灰活性,掺入的CTP能够促进水泥进一步水化,提高水泥基材料的水化程度。

2.2.6 瓷砖粉超高性能混凝土钙硅比

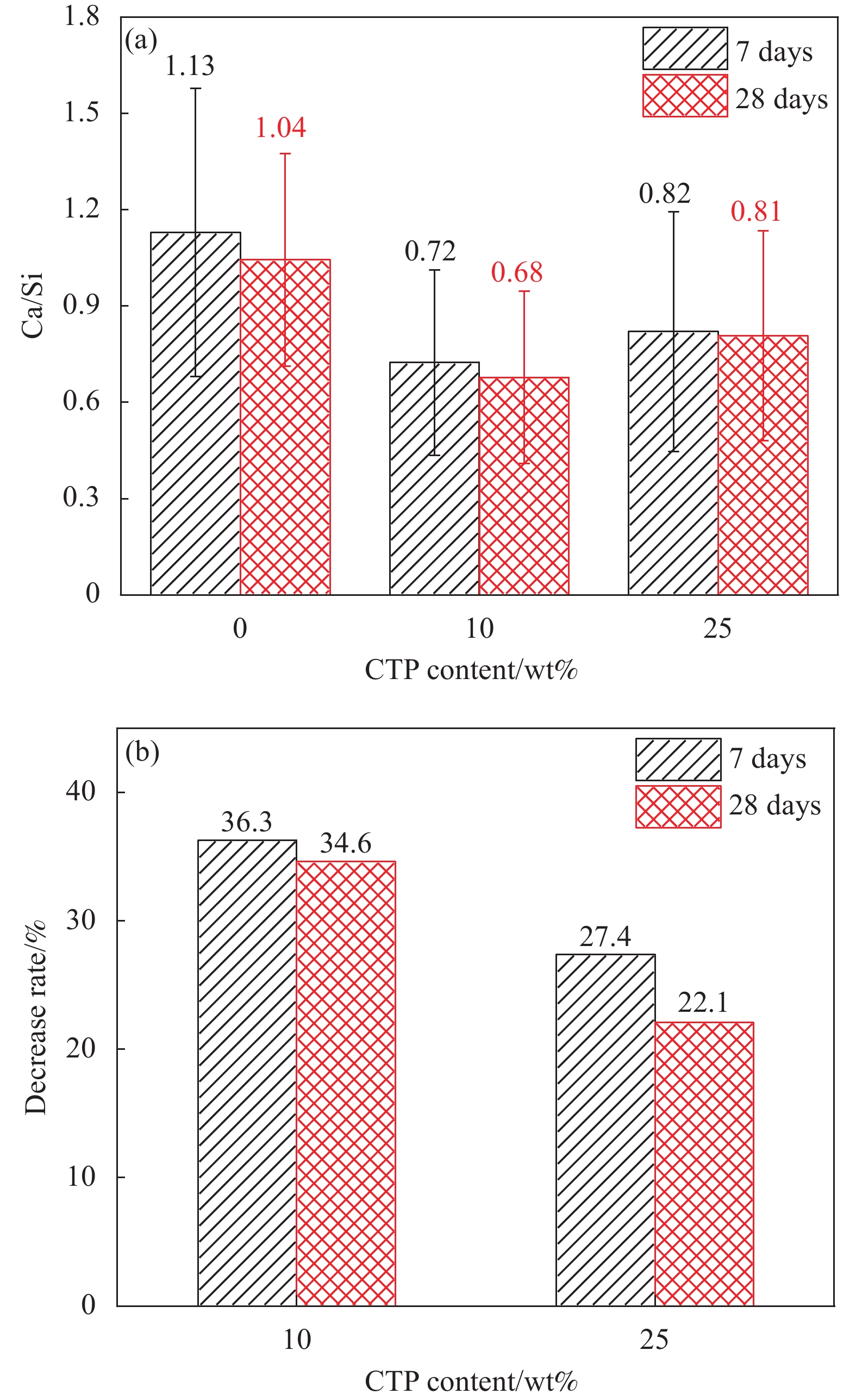

图17、图18和图19分别为不同CTP掺量超高性能混凝土的7天和28天的SEM-EDS图像及其钙硅比计算结果。由图19可知,在7天龄期,CTP的掺入能够显著降低钙硅比,和不用CTP替代水泥的普通超高性能混凝土的1.13相比,10wt%和25wt%CTP掺量的钙硅比分别降低了36.3%和27.4%。结合图13中Ca(OH)2含量在7天龄期时,随着CTP掺量的增加而下降,说明CTP在7天龄期之前已经表现出活性并发生了二次水化反应。在同一龄期时,钙硅比随着CTP掺量的增加先减小后增加,CTP掺量为10wt%时钙硅比最小,在7天和28天时分别为0.72和0.68,这与抗压强度的规律是一致的,各龄期中10wt%CTP掺量的抗压强度最高,且随着CTP掺量的继续增加,抗压强度开始下降。

2.3 瓷砖粉超高性能混凝土环境影响与成本

为了定量分析瓷砖粉超高性能混凝土的环境影响,通过材料可持续性指标(MSIs)进行研究。MSIs是根据制造过程中的材料和能量流动确定的,它们由能耗、废弃物和污染物的排放量来表示[37-39]。因此,本研究采用能耗和CO2排放量来表示瓷砖粉超高性能混凝土的MSIs。

表3列出了水泥、硅灰和CTP的能耗,CO2排放量和单价。CTP是由废弃瓷砖研磨而成,其能耗和CO2排放量分别计算了粉磨1 kg CTP时的能耗和CO2排放量,单价包含实验室加工费用和回收材料费用。瓷砖粉超高性能混凝土的MSIs和成本计算结果如表4所示。可知,随着CTP掺量的增加,MSIs和成本逐渐降低。CTP掺量为25wt%时,超高性能混凝土的能耗、CO2排放量和成本比不用CTP替代水泥的超高性能混凝土即普通超高性能混凝土分别降低了22%、16.7%和9.3%。结合抗压强度,掺25wt%CTP超高性能混凝土的抗压强度在3天、7天、28天和60天时,增减幅度都在6.8%以内,这说明用25wt%的CTP替代水泥制备超高性能混凝土,具有良好的环境效益和经济效益。

表 3 材料能耗、CO2排放量和成本Table 3. Energy intensity, CO2 emission, and cost of materialsMaterial Energy intensity/

(MJ·kg−1)CO2 emission/

kgCost/

(RMB·ton−1)Cement 5.5 0.930 680 Silica fume 0.1 0.008 2500 CTP 1.4 0.370 360 表 4 不同CTP掺量UHPC的材料可持续性指标(MSIs)和成本比较Table 4. Material sustainability indicators (MSIs) and cost comparison of UHPC with different contents of CTPMaterial Energy intensity/

(MJ·kg−1)Decrease of energy intensity/% CO2 emission/kg Decrease of

CO2 emission/%Cost/

(RMB·ton−1)Decrease of cost/% 90wt%Cement+10wt%Silica fume 5.0 0.0 0.84 0.0 862 0.0 80wt%Cement+10wt%Silica fume+10wt%CTP 4.6 8.0 0.78 7.1 830 3.7 75wt%Cement+10wt% Silica fume+15wt%CTP 4.3 14.0 0.75 10.7 814 5.6 70wt%Cement+10wt%Silica fume+20wt%CTP 4.1 18.0 0.73 13.1 798 7.4 65wt%Cement+10wt%Silica fume+25wt%CTP 3.9 22.0 0.70 16.7 782 9.3 3. 结 论

通过抗压强度试验、XRD、TG/DTG、SEM等研究了瓷砖粉超高性能混凝土的抗压强度、Ca(OH)2含量、水化程度、界面过渡区宽度及钙硅比,分析了瓷砖粉对超高性能混凝土强度的影响规律及作用机制。最后,对瓷砖粉超高性能混凝土的成本与可持续性进行了分析。主要结论如下:

(1) 随着瓷砖粉掺量的增加,超高性能混凝土的抗压强度呈现先升高后降低的趋势。其中,10wt%掺量的瓷砖粉对超高性能混凝土抗压强度增幅最大为10.1%,其他掺量对超高性能混凝土各龄期抗压强度的增减幅度在9.0%以内。瓷砖粉对0~3天抗压强度的发展影响较小;但是对7~60天的抗压强度的发展有显著的促进作用;

(2) 瓷砖粉主要通过增加堆积密实度、火山灰反应、提高水泥水化程度和降低界面过渡区宽度改善超高性能混凝土性能。掺入CTP后超高性能混凝土的粒径分布曲线更接近理论模型曲线,表明CTP的掺入改善了超高性能混凝土材料的颗粒集配并提高了其堆积密度。由于火山灰活性,CTP的加入可以促进水泥水化并加速钙矾石的形成,除此之外,还可以与Ca(OH)2发生二次水化反应、消耗Ca(OH)2含量并生成更多的水化硅酸钙。超高性能混凝土的Ca(OH)2含量随着CTP掺量的增加而降低,CTP掺量为25wt%时,超高性能混凝土的Ca(OH)2含量在7天和28天分别降低了16.0%和21.6%。超高性能混凝土中水泥的水化程度随着瓷砖粉掺量的增加而增大,其中25%掺量的瓷砖粉使超高性能混凝土7天和28天水化程度分别提高了7.3%和降低了7.5%。此外,瓷砖粉的掺入使超高性能混凝土的界面过渡区宽度和钙硅比显著降低,与不用瓷砖粉替代水泥的普通超高性能混凝土相比, 10wt%掺量的瓷砖粉使7天龄期界面过渡区宽度和钙硅比分别降低了15.1%和36.3%;

(3) 瓷砖粉替代部分水泥制备超高性能混凝土可以降低环境影响和成本。在对各龄期抗压强度增减幅度6.8%以内的基础上,与不用瓷砖粉替代水泥的超高性能混凝土即普通超高性能混凝土相比,25wt%的瓷砖粉替代水泥后能耗、CO2排放量和成本分别降低了22.0%、16.7%和9.3%。因此,瓷砖粉替代部分水泥制备超高性能混凝土具有显著的环境效益和经济效益。

-

表 1 水泥、瓷砖粉(CTP)和硅灰的化学组成

Table 1 Chemical compositions of cement, ceramic tile powder (CTP) and silica fume

Chemical composition Cement/wt% CTP/wt% Silica fume/wt% SiO2 22.35 78.3 95.7 Al2O3 6.30 15.9 − CaO 55.73 0.9 − Fe2O3 4.91 − − Na2O 0.07 1.9 0.11 K2O 0.68 2.1 0.45 MgO 2.84 0.8 − SO3 2.47 − − R2O − − 0.39 Cl− − − 0.02 LOI 1.15 − 2.95 Note: LOI—Limit oxygen index. 表 2 不同CTP掺量超高性能混凝土(UHPC)的配合比

Table 2 Mix proportions of ultra high performance concretes (UHPC) with different contents of CTP

(kg·m−3) Specimen code Binder Water Sand Steel fiber SP Cement Silica fume CTP UHPC(0wt%CTP) 1026.0 114.0 0.0 205.2 1140.0 156.0 17.1 UHPC(10wt%CTP) 912.0 114.0 114.0 205.2 1140.0 156.0 17.1 UHPC(15wt%CTP) 855.0 114.0 171.0 205.2 1140.0 156.0 17.1 UHPC(20wt%CTP) 798.0 114.0 228.0 205.2 1140.0 156.0 17.1 UHCP(25wt%CTP) 741.0 114.0 285.0 205.2 1140.0 156.0 17.1 Note: SP—Superplasticizer. 表 3 材料能耗、CO2排放量和成本

Table 3 Energy intensity, CO2 emission, and cost of materials

Material Energy intensity/

(MJ·kg−1)CO2 emission/

kgCost/

(RMB·ton−1)Cement 5.5 0.930 680 Silica fume 0.1 0.008 2500 CTP 1.4 0.370 360 表 4 不同CTP掺量UHPC的材料可持续性指标(MSIs)和成本比较

Table 4 Material sustainability indicators (MSIs) and cost comparison of UHPC with different contents of CTP

Material Energy intensity/

(MJ·kg−1)Decrease of energy intensity/% CO2 emission/kg Decrease of

CO2 emission/%Cost/

(RMB·ton−1)Decrease of cost/% 90wt%Cement+10wt%Silica fume 5.0 0.0 0.84 0.0 862 0.0 80wt%Cement+10wt%Silica fume+10wt%CTP 4.6 8.0 0.78 7.1 830 3.7 75wt%Cement+10wt% Silica fume+15wt%CTP 4.3 14.0 0.75 10.7 814 5.6 70wt%Cement+10wt%Silica fume+20wt%CTP 4.1 18.0 0.73 13.1 798 7.4 65wt%Cement+10wt%Silica fume+25wt%CTP 3.9 22.0 0.70 16.7 782 9.3 -

[1] 杨娟, 朋改非, 税国双. 再生钢纤维增韧超高性能混凝土的力学性能[J]. 复合材料学报, 2019, 36(8):1949-1956. YANG Juan, PENG Gaifei, SHUI Guoshuang. Mechanical properties of recycled steel fiber reinforced ultra-high-performance concrete[J]. Acta Materiae Compositae Sinica,2019,36(8):1949-1956(in Chinese).

[2] 姜海波, 冯家辉, 肖杰, 等. 体外预应力无腹筋超高性能混凝土梁的抗剪性能试验探索[J]. 复合材料学报, 2022, 39(2):707-717. JIANG Haibo, FENG Jiahui, XIAO Jie, et al. Experimental study on shear behavior of externally prestressed ultra-high performance concrete beams without stirrups[J]. Acta Materiae Compositae Sinica,2022,39(2):707-717(in Chinese).

[3] 杨娟, 朋改非. 纤维对超高性能混凝土残余强度及高温爆裂性能的影响[J]. 复合材料学报, 2016, 33(12):2931-2940. YANG Juan, PENG Gaifei. Effect of fiber on residual strength and explosive spalling behavior of ultra-high-performance concrete exposed to high temperature[J]. Acta Materiae Compositae Sinica,2016,33(12):2931-2940(in Chinese).

[4] 过震文, 刘小方, 段昕智, 等. 超高性能混凝土在环境温度变化下的力学性能试验研究[J]. 复合材料学报, 2021, 38(10):3495-3503. GUO Zhenwen, LIU Xiaofang, DUAN Xinzhi, et al. Experiment study on mechanical properties of ultra-high performance concrete under ambient temperature change[J]. Acta Materiae Compositae Sinica,2021,38(10):3495-3503(in Chinese).

[5] QIU L S, DONG S F, YU X, et al. Self-sensing ultra-high performance concrete for in-sit monitoring[J]. Sensors and Actuators A: Physical,2021,331:113049. DOI: 10.1016/j.sna.2021.113049

[6] 许开成, 谢国强, 陈梦成, 等. 锂云母渣作为混凝土掺合料的制备工艺研究[J]. 混凝土, 2016(11):130-132. DOI: 10.3969/j.issn.1002-3550.2016.11.035 XU Kaicheng, XIE Guoqiang, CHEN Mengcheng, et al. Research on processing technology of lepidolite slag as admixture of concrete[J]. Concrete,2016(11):130-132(in Chinese). DOI: 10.3969/j.issn.1002-3550.2016.11.035

[7] 许开成, 毕丽苹, 陈梦成. 锂渣混凝土的配合比设计研究[J]. 混凝土, 2017(1):125-129. DOI: 10.3969/j.issn.1002-3550.2017.01.031 XU Kaicheng, BI Liping, CHEN Mengcheng. Study on mixproportion design of lithium slag concrete[J]. Concrete,2017(1):125-129(in Chinese). DOI: 10.3969/j.issn.1002-3550.2017.01.031

[8] 魏慧男, 刘铁军, 邹笃建, 等. 含废弃玻璃的绿色超高性能混凝土制备及性能[J]. 建筑材料学报, 2021, 24(3):492-498. DOI: 10.3969/j.issn.1007-9629.2021.03.007 WEI Huinan, LIU Tiejun, ZOU Dujian, et al. Preparation and properties of green ultra-high performance concrete containing waste glass[J]. Journal of Building Materials,2021,24(3):492-498(in Chinese). DOI: 10.3969/j.issn.1007-9629.2021.03.007

[9] 陈梦成, 袁明胜, 刘宇翔. 陶瓷粉混凝土正交设计试验研究[J]. 混凝土, 2018(4):102-106. DOI: 10.3969/j.issn.1002-3550.2018.04.026 CHEN Mengcheng, YUAN Mingsheng, LIU Yuxiang. Experimental study on orthogonal design of ceramic poowder concrete[J]. Concrete,2018(4):102-106(in Chinese). DOI: 10.3969/j.issn.1002-3550.2018.04.026

[10] HEIDARI A, TAVAKOLI S, TAVAKOLI D. Reusing waste ceramic and waste sanitary ware in concrete as pozzolans with nano-silica and metakaolin[J]. International Journal of Sustainable Construction Engineering and Technology, 2019, 10(1): 55-67.

[11] MEYER C. The greening of the concrete industry[J]. Cement and Concrete Composites,2009,31(8):601-605. DOI: 10.1016/j.cemconcomp.2008.12.010

[12] SUBASI S, ÖZTÜRK H, EMIROGLU M. Utilizing of waste ceramic powders as filler material in self-consolidating concrete[J]. Construction and Building Materials,2017,149:567-574. DOI: 10.1016/j.conbuildmat.2017.05.180

[13] LI L, LIU W F, YOU Q X, et al. Waste ceramic powder as a pozzolanic supplementary filler of cement for developing sustainable building materials[J]. Journal of Cleaner Production,2020,259:120853. DOI: 10.1016/j.jclepro.2020.120853

[14] ATTAELMANAN M, KAMBAL M E M, MANSOUR M I. A study the effect of using ceramic waste powder as partial replacement for cement on concrete properties[J]. Journal of Karary University for Engineering and Science, 2021, 1(1): 1-7.

[15] EL-DIEB A S, KANAAN D M. Ceramic waste powder an alternative cement replacement—Characterization and evaluation[J]. Sustainable Materials and Technologies,2018,17:e63.

[16] BABRIA J P, PITRODA J R, VAGHELA K B. Effective use of ceramic waste powder as partial replacement of cement in establishing sustainable concrete[J]. Journal of Emerging Technologies and Innovative Research, 2019, 6(4): 337-348.

[17] BHARGAV M, KANSAL R. Experimental investigation to substitute of cement with ceramic tiles powder in concrete[J]. International Journal for Research in Applied Science and Engineering Technology, 2020, 8(IX): 45-98.

[18] LI L G, ZHUO Z Y, ZHU J, et al. Reutilizing ceramic polishing waste as powder filler in mortar to reduce cement content by 33% and increase strength by 85%[J]. Powder Technology,2019,355:119-126. DOI: 10.1016/j.powtec.2019.07.043

[19] MOHIT M, SHARIFI Y. Ceramic waste powder as alternative mortar-based cementitious material[J]. ACI Materials Journal,2019,116(6):107-116.

[20] KUMAR V P, REDDY K C. Durability aspects of concrete by partial replacement of cement by ceramic waste[J]. International Journal of Civil Engineering,2017,8:22-30.

[21] SCHRÖFL C, GRUBER M, PLANK J. Preferential adsorption of polycarboxylate superplasticizers on cement and silica fume in ultra-high performance concrete (UHPC)[J]. Cement and Concrete Research,2012,42(11):1401-1408. DOI: 10.1016/j.cemconres.2012.08.013

[22] 龚建清. 超高性能混凝土的级配效应研究[D]. 长沙: 湖南大学, 2008. GONG Jianqing. Study on gradation effect of ultra high performance concrete[D]. Changsha: Hunan University, 2008(in Chinese).

[23] 苏艺凡. 高流态超高性能混凝土的制备及性能研究[J]. 混凝土世界, 2022(1):61-64. DOI: 10.3969/j.issn.1674-7011.2022.01.013 SU Yifan. Study on preparation and properties of high flow ultra-high performance concrete[J]. China Concrete,2022(1):61-64(in Chinese). DOI: 10.3969/j.issn.1674-7011.2022.01.013

[24] 陈飞翔, 陈尚雷, 张国志, 等. 珊瑚礁砂制备超高性能混凝土的可行性研究[J]. 混凝土, 2020(7):65-69. DOI: 10.3969/j.issn.1002-3550.2020.07.015 CHEN Feixiang, CHEN Shanglei, ZHANG Guozhi, et al. Feasibility study on preparation of ultra high performance concrete with coral reef sand[J]. Concrete,2020(7):65-69(in Chinese). DOI: 10.3969/j.issn.1002-3550.2020.07.015

[25] 中华人民共和国建设部. 普通混凝土力学性能试验方法标准: GB/T 50081—2002[S]. 北京: 中国建筑工业出版社, 2003. Ministry of Construction of the People's Republic of China. Standard for test method of mechanical properties on ordinary concrete: GB/T 50081—2002[S]. Beijing: China Building Industry Press, 2003(in Chinese).

[26] BORGES P H, FONSECA L F, NUNES V A, et al. Andreasen particle packing method on the development of geopolymer concrete for civil engineering[J]. Journal of Materials in Civil Engineering,2014,26(4):692-697. DOI: 10.1061/(ASCE)MT.1943-5533.0000838

[27] HMED T, ELCHALAKANI M, KARRECH A, et al. Development of ECO-UHPC with very-low-C3A cement and ground granulated blast-furnace slag[J]. Construction and Building Materials,2021,284:122787. DOI: 10.1016/j.conbuildmat.2021.122787

[28] YU R, SPIESZ P, BROUWERS H. Effect of nano-silica on the hydration and microstructure development of ultra-high performance concrete (UHPC) with a low binder amount[J]. Construction and Building Materials,2014,65:140-150. DOI: 10.1016/j.conbuildmat.2014.04.063

[29] PANE I, HANSEN W. Investigation of blended cement hydration by isothermal calorimetry and thermal analysis[J]. Cement and Concrete Research,2005,35(6):1155-1164. DOI: 10.1016/j.cemconres.2004.10.027

[30] GOLEWSKI G L. The beneficial effect of the addition of fly ash on reduction of the size of microcracks in the ITZ of concrete composites under dynamic loading[J]. Energies,2021,14(3):668. DOI: 10.3390/en14030668

[31] 朱星曈, 耿欧, 朱思远. 废轮胎橡胶混凝土界面过渡区特征试验研究[J]. 硅酸盐通报, 2021, 40(2):573-578. ZHU Xingtong, GENG Ou, ZHU Siyuan. Characteristics of interface transition zone of waste tire rubber concrete[J]. Bulletin of the Chinese Ceramic Society,2021,40(2):573-578(in Chinese).

[32] 郝晓玉, 王卓. 粉煤灰对再生混凝土抗硫酸盐侵蚀及界面过渡区微观性能影响研究[J]. 混凝土, 2021(12):94-96. DOI: 10.3969/j.issn.1002-3550.2021.12.020 HAN Xiaoyu, WANG Zhuo. Effect of fly ash on sulfate erosion resistance of recycled concrete and microscopic properties of interface transition zone[J]. Concrete,2021(12):94-96(in Chinese). DOI: 10.3969/j.issn.1002-3550.2021.12.020

[33] 徐礼华, 余红芸, 池寅, 等. 钢纤维-水泥基界面过渡区纳米力学性能[J]. 硅酸盐学报, 2016, 44(8):1134-1146. XU Lihua, YU Hongyun, CHI Yin, et al. Nano-indentation character of interfacial transition zone between steel fiber and cement paste[J]. Journal of the Chinese Ceramic Society,2016,44(8):1134-1146(in Chinese).

[34] HAN B G, ZHANG L Q, ZENG S Z, et al. Nano-core effect in nano-engineered cementitious composites[J]. Compo-sites Part A: Applied Science and Manufacturing,2017,95:100-109. DOI: 10.1016/j.compositesa.2017.01.008

[35] GARCIA D C, WANG K, FIGUEIREDO R B. The influences of quartz content and water-to-binder ratio on the microstructure and hardness of autoclaved Portland cement pastes[J]. Cement and Concrete Composites,2018,91:138-147. DOI: 10.1016/j.cemconcomp.2018.05.010

[36] LASSEUGUETTE E, BURNS S, SIMMONS D, et al. Chemical, microstructural and mechanical properties of ceramic waste blended cementitious systems[J]. Journal of Cleaner Production,2019,211:1228-1238. DOI: 10.1016/j.jclepro.2018.11.240

[37] YU J, LU C, LEUNG C K, et al. Mechanical properties of green structural concrete with ultrahigh-volume fly ash[J]. Construction and Building Materials,2017,147:510-518. DOI: 10.1016/j.conbuildmat.2017.04.188

[38] WU M, ZHANG Y S, JI Y S, et al. Reducing environmental impacts and carbon emissions: Study of effects of superfine cement particles on blended cement containing high volume mineral admixtures[J]. Journal of Cleaner Production,2018,196:358-369. DOI: 10.1016/j.jclepro.2018.06.079

[39] ZHAO Y S, GAO J M, LIU C B, et al. The particle-size effect of waste clay brick powder on its pozzolanic activity and properties of blended cement[J]. Journal of Cleaner Production,2020,242:118521. DOI: 10.1016/j.jclepro.2019.118521

-

期刊类型引用(8)

1. 张立卿,刘秋萍,潘延念,熊信福,熊进刚,许开成. 含水率对镀铜钢纤维超高性能混凝土自感知性能的影响. 功能材料. 2025(02): 2186-2194 .  百度学术

百度学术

2. 张立卿,边明强,郭绵珍,潘延念,许开成,王云洋. 不同破坏荷载下镀铜钢纤维增强废弃陶瓷超高性能混凝土的压敏性. 复合材料学报. 2024(04): 1997-2013 .  本站查看

本站查看

3. 张立卿,肖振荣,刘莎,王云洋,许开成,韩宝国. 废弃陶瓷对水泥基复合材料力学性能影响与机制的研究综述. 复合材料学报. 2024(06): 2829-2844 .  本站查看

本站查看

4. 刘超群,朱泽文,代力,陈磊伟,吴福全,李亮华. 粉煤灰基超高性能混凝土配合比优化研究. 粉煤灰综合利用. 2024(03): 11-15 .  百度学术

百度学术

5. 管佳男,刘少静,贺梦佳,程博,李绍达,刘晓,李时雨. 聚羧酸减水剂和钢纤维耦合作用对UHPC性能的影响. 混凝土. 2024(08): 44-47 .  百度学术

百度学术

6. 张立卿,郭绵珍,李洪艳,韩宝国. 3D打印混凝土的流变性能及其影响因素研究综述. 复合材料学报. 2024(11): 5754-5782 .  本站查看

本站查看

7. 薛善彬,荆蜂杰,王丹,张鹏,高小建. UHPC与混凝土基体间界面剪切强度的影响因素. 复合材料学报. 2024(12): 6639-6648 .  本站查看

本站查看

8. 张祺涵. 高温后废弃陶瓷高性能混凝土力学性能研究. 江西建材. 2024(12): 76-78+82 .  百度学术

百度学术

其他类型引用(6)

-

下载:

下载: